Patents

Literature

152results about How to "Address water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

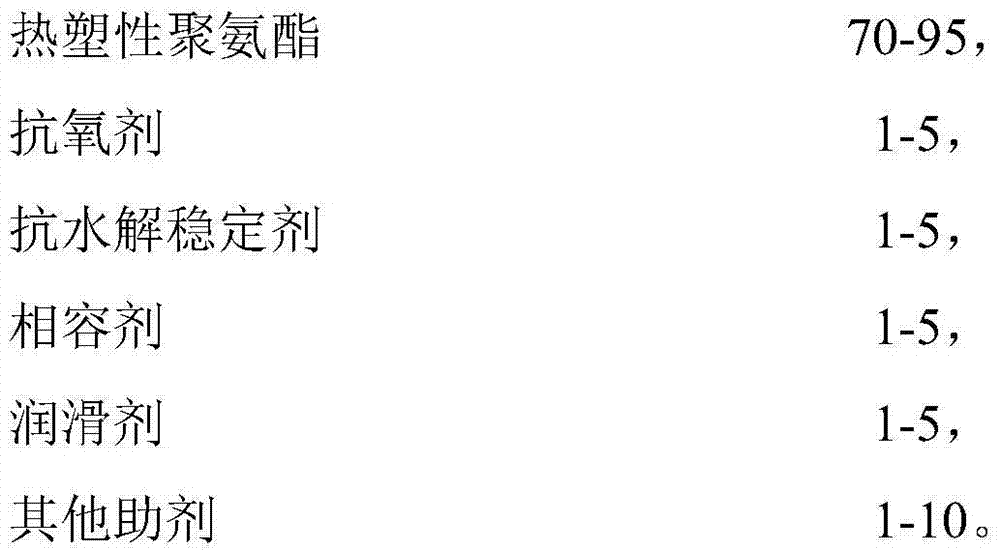

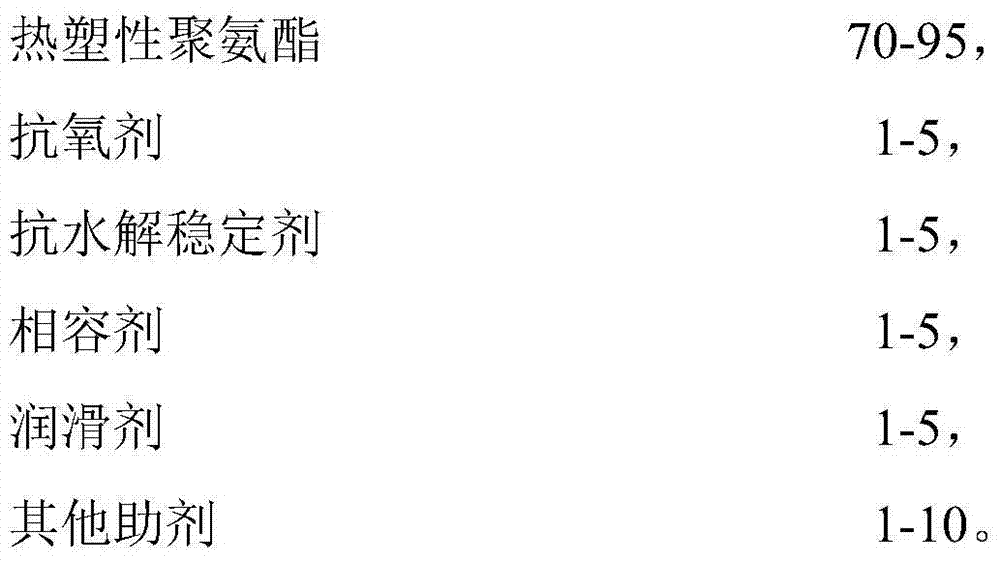

Thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and preparation method thereof

The invention relates to a thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 70-95 parts of thermoplastic polyurethane, 1-5 parts of antioxidant, 1-5 parts of hydrolysis-resistant stabilizer, 1-5 parts of compatilizer, 1-5 parts of lubricant and 1-10 parts of other assistant. Compared with the prior art, the antioxidant, hydrolysis-resistant stabilizer, lubricant and other assistants are added, so that the modified composite material has the advantages of favorable mechanical properties, high elasticity, favorable wear resistance, higher heat stability, hydrolysis resistance, higher oxidation resistance and higher processability. When being used for FDM 3D printing, the thermoplastic polyurethane modified composite material has the characteristics of smooth printing process, no odor, smooth printing product surface, beautiful appearance, stable size, low tendency to shrinkage, favorable mechanical properties, high flexibility, high heat stability, high hydrolysis resistance, high oxidation resistance and high processability.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

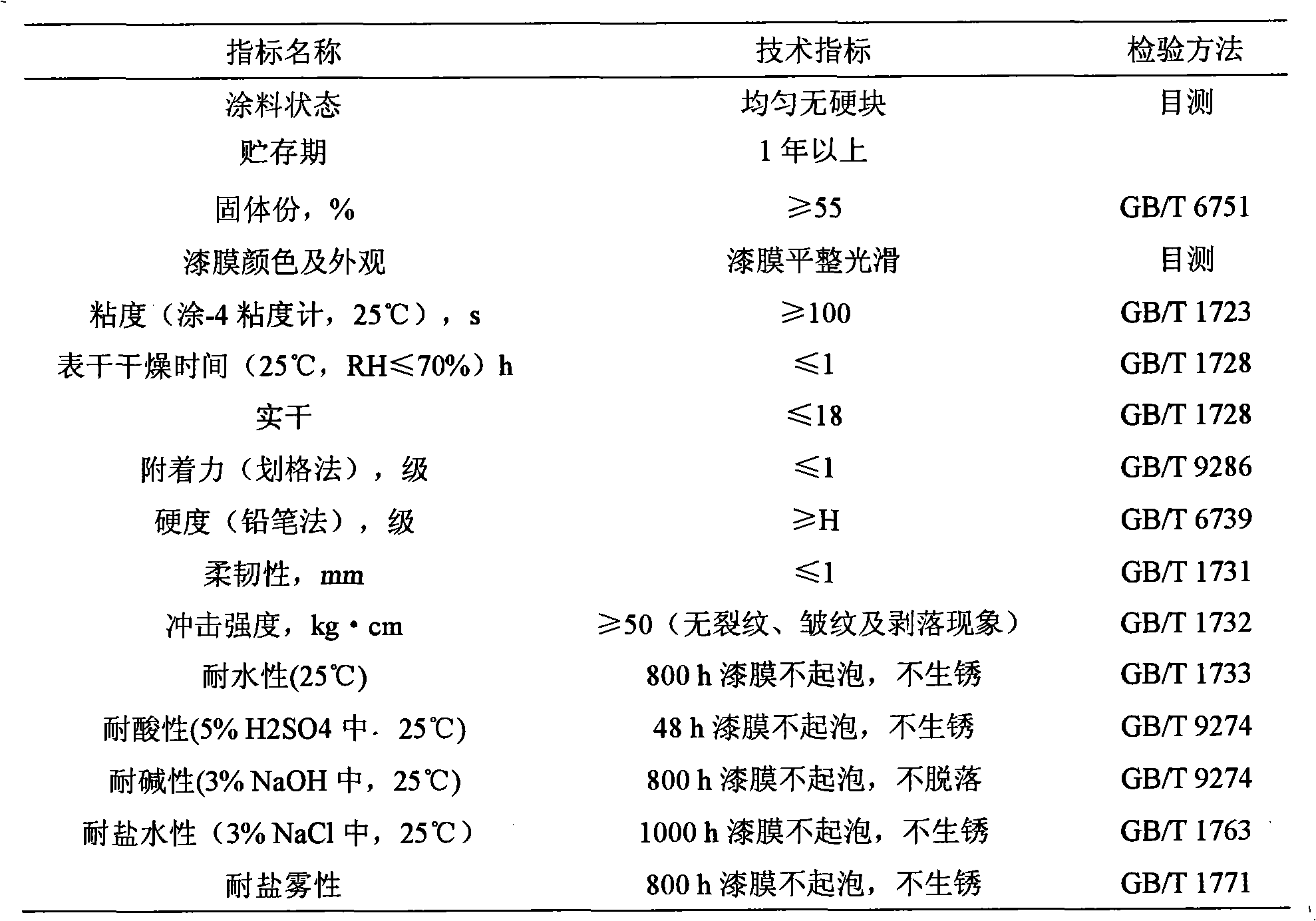

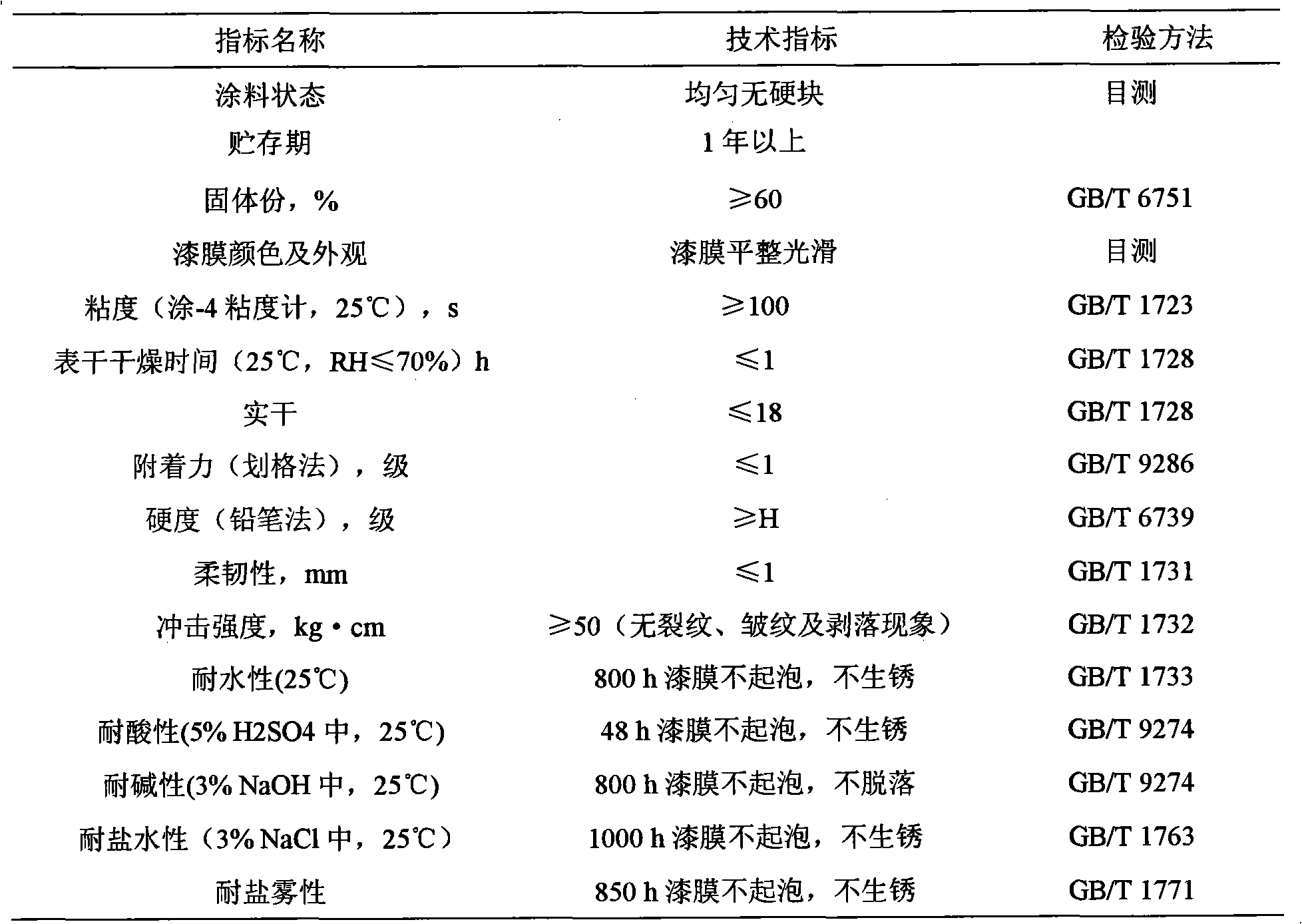

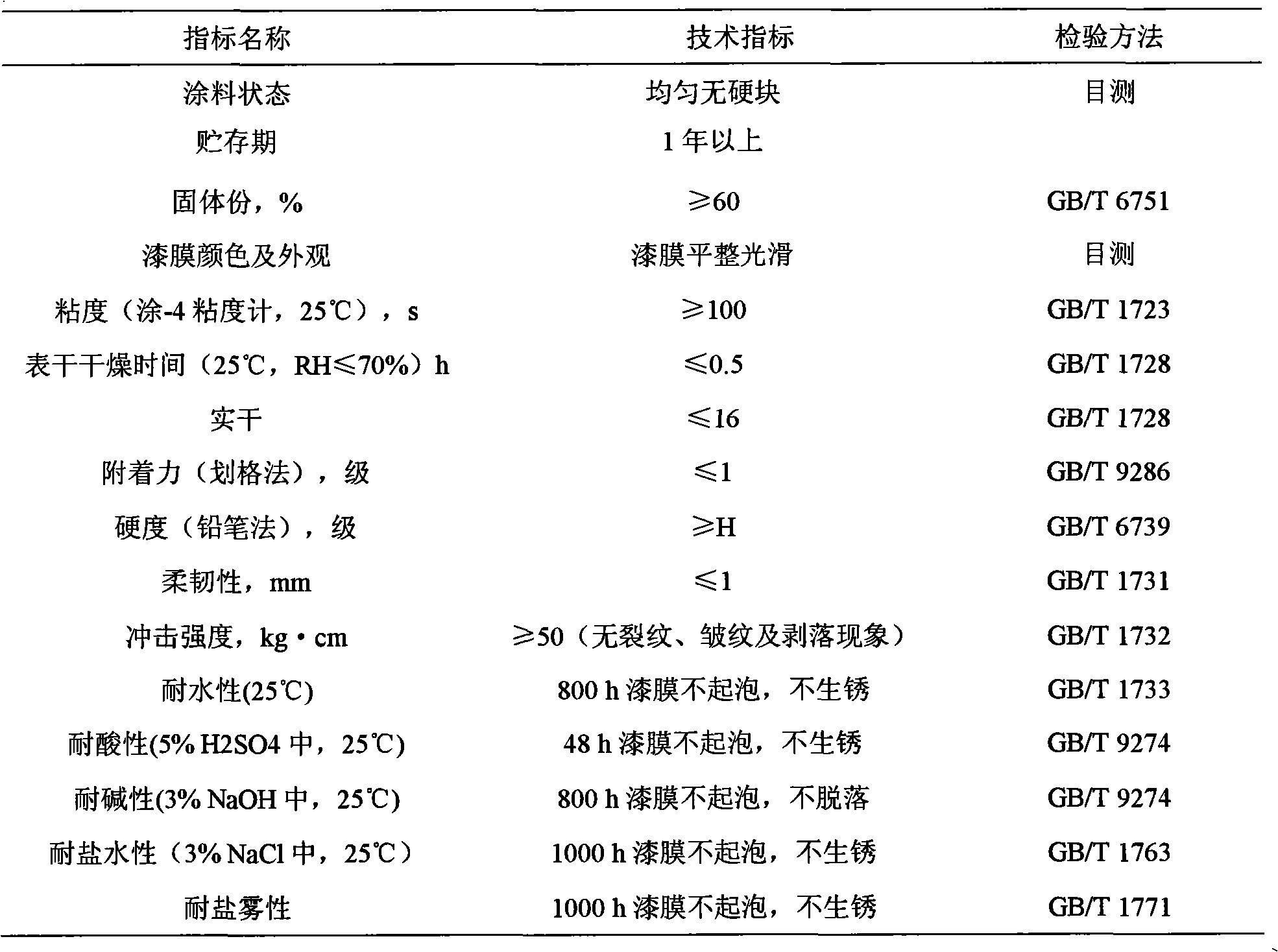

Water borne epoxy resin anticorrosive paint and preparation method thereof

InactiveCN101633814AGood value for moneyGood weather and humidity resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyHydrophilic monomer

The invention discloses a water borne epoxy resin anticorrosive paint and preparation method thereof and solves the contradiction between storage stability of water dispersion and water resistance and corrosion resistance of dispersion film in the prior art. The paint is prepared by mixing oxosilane modified water borne epoxy resin dispersion, iron oxide red, rustproofing pigment, talc powder, defoaming agent, flatting agent, flash rust proofing agent and deionized water in ratio, and the invention is characterized in that: hydrophilic monomer is introduced to epoxy resin molecular chain, so the paint has self-emulsifying characteristic; and oxosilane is applied to modifying of the water borne epoxy resin, so that the paint can be heated and self-solidified. The paint has good storage stability and good construction performance, film can be fast dried and has high rigidity after being dried, the film is bright and smooth, water proof, corrosion resistant, washing resistant, good in comprehensive performance and low in cost. The invention can meet the requirement of anticorrosive paint in the fields of storage tank, bridge and the like.

Owner:HUANGGANG NORMAL UNIV

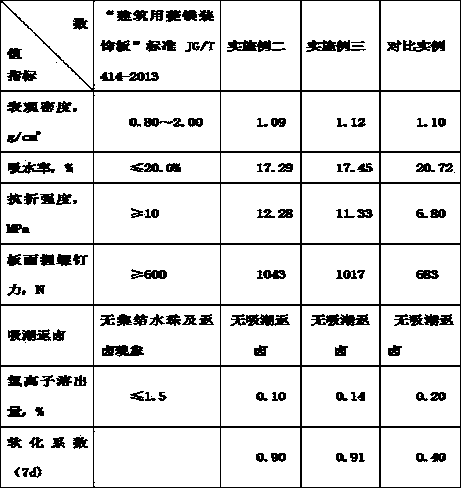

Water-resistant magnesium oxysulfate fire-proof plate and manufacturing method thereof

InactiveCN103979920AAddress water resistanceSolve the problem of moisture absorption and brine returnGlass fiberSlurry

The invention discloses a water-resistant magnesium oxysulfate fire-proof plate and a manufacturing method thereof and belongs to the field of fire-proof plate production. The fire-proof plate is prepared by adding active filler into slurry, mixing, hardening under a certain condition and demoulding, wherein modified magnesium oxysulfate is taken as a base material and medium-alkali glass fiber and non-woven fabrics and other materials are taken as a skeleton. Compared with the prior art, the fire-proof door core plate disclosed by the invention has no moisture absorption, higher durability than a conventional glass magnesium plate and smooth and beautiful appearance. The fire-proof plate can be applied to the field of building fire protection, especially fire protection engineering under a humid environment and has a good popularization and application value.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

Cured cross-linked glutinous rice flour hydrogel, preparation method and application thereof

ActiveCN101885853ARaw materials are easy to getSimple preparation processAdhesivesCross-linkControlled release

The invention relates to a cured cross-linked glutinous rice flour hydrogel, a preparation method and application thereof. The preparation method comprises the following steps: glutinous rice flour, a cross-linking agent and water are taken as raw materials, wherein, the cross-linking agent accounts for 0.01%-20% of the glutinous rice flour by mass; and in the presence of a pH regulator, the cured glutinous rice flour acts with the cross-linking agent. The glutinous rice flour is one or more mixtures of sticky rice, sticky corn, husked millet, big glutinous millet, small glutinous millet and sticky sorghum rice and starch and modified starch of the glutinous rice. The cured cross-linked glutinous rice flour hydrogel can be compatible with various matters, drugs of different types and the like, can be used for medical tablets, granules, capsules, gels, ointments, films, implanted preparations and patches as a slowly controlled release film for medicines, an auxiliary material for preparations, a water absorbing gel material and an adhesive material, and can be applied to water absorption, moisture preservation, cosmetics, tissue engineering cell culture, separation and purification, surgical operation, diaphragm and the like.

Owner:五莲县计量检测服务中心

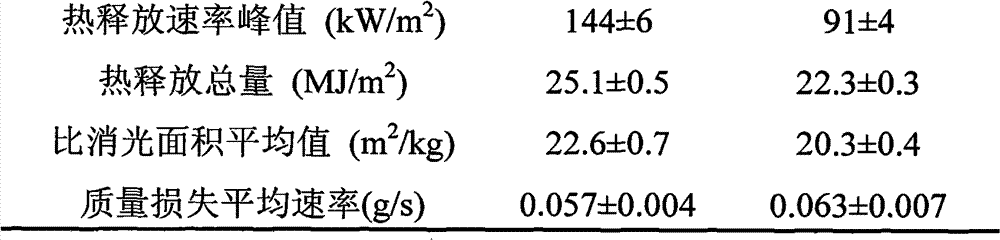

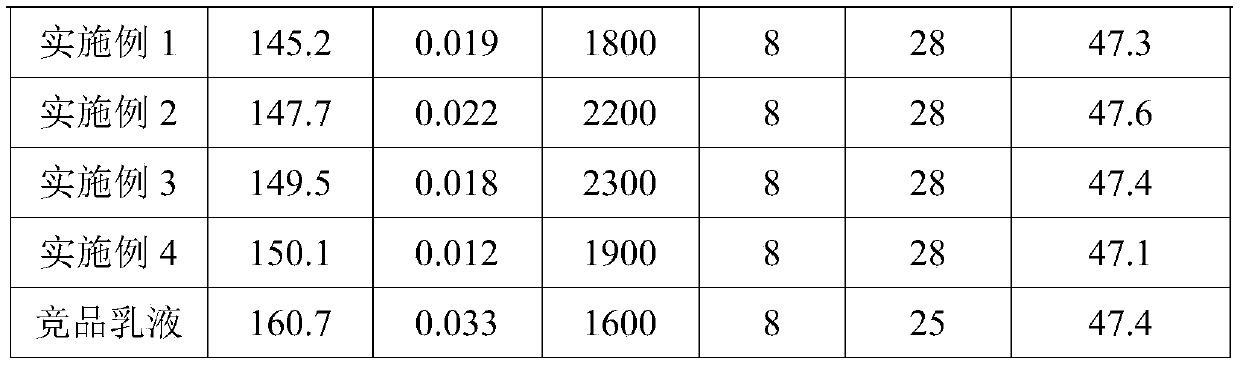

Preparation method of waterborne epoxy resin emulsion

The invention relates to a preparation method of a waterborne epoxy resin emulsion. The preparation method comprises the following steps: mixing bisphenol A epoxy resin, polyethylene glycol monomethyl ether and toluene, stirring, and performing azeotropic dehydration to get a mixed liquid; dissolving a catalyst in the toluene, then raising the temperature of the mixed liquid under magnetic stirring, reacting under the protection of nitrogen, and removing a solvent by reduced pressure evaporation when the retention rate of epoxy in the bisphenol A epoxy resin is reduced to 50%, thus getting a reactive non-ionic epoxy emulsifying agent; and dropwise adding distilled water while intensely stirring the liquid-state epoxy resin, a cosolvent and the reactive non-ionic epoxy emulsifying agent, thus getting the waterborne epoxy resin emulsion. The preparation method disclosed by the invention has the beneficial effects that the epoxy resin emulsion emulsified by the non-ionic waterborne epoxy resin emulsifying agent is good in stability, has no toxicity and zero content of organic volatile matters, is safe and environmentally-friendly, and can be used for maintaining the excellent chemical-resistant performance of the epoxy resin and simultaneously increasing the flexibility of a paint film.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

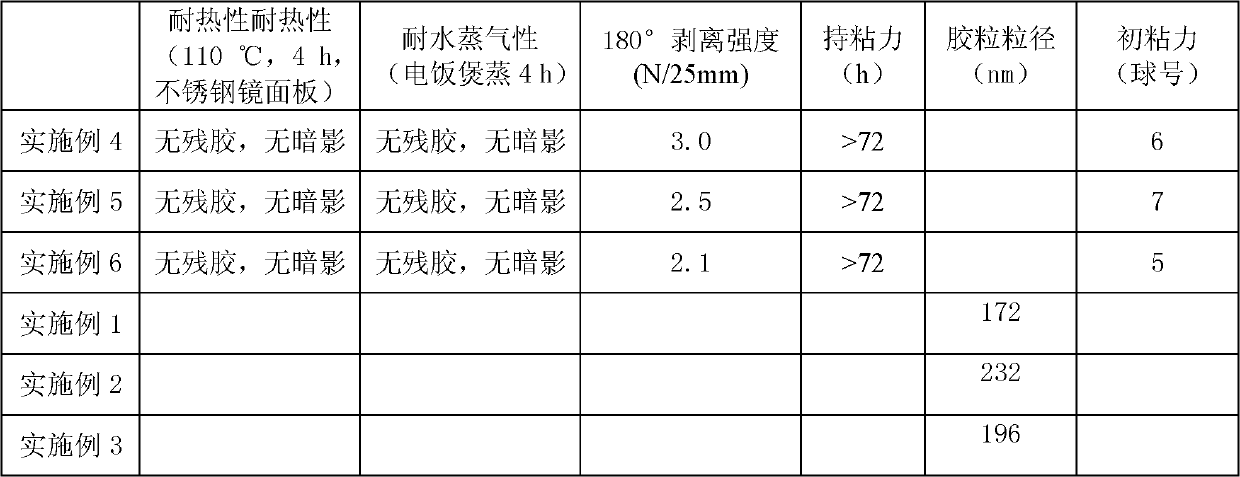

Acrylic acid emulsion and functional acrylic acid emulsion for unshadowed protective film

InactiveCN102167773AEvenly distributedReduce shadowsNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceFunctional monomer

The invention relates to acrylic acid emulsion and functional acrylic acid emulsion for an unshadowed protective film comprising the same. The acrylic acid emulsion is compounded with an external cross-linking agent to obtain the functional acrylic acid emulsion for the unshadowed protective film which can be applied to a high-finish stainless steel mirror board to form the unshadowed protective film. A preparation method of the acrylic acid emulsion comprises the following steps of: 1) performing polymerization on a functional monomer and an acrylic ester monomer by pre-emulsification and seeding polymerization processes to prepare an acrylic ester polymer, wherein a comonomer comprises the following components in percentage by weight: 5 to 20 percent of the functional monomer, 5 to 10 percent of hard acrylic ester monomer, 10 to 20 percent of medium soft acrylic ester monomer and 50 to 80 percent of soft acrylic ester monomer; Tg of the hard acrylic ester monomer is more than or equal to 36 DEG C; Tg of the medium soft acrylic ester monomer is between 35 and -25 DEG C; and Tg of the soft acrylic ester monomer is less than or equal to -24 DEG C; and 2) adjusting the pH value of the polymer emulsion prepared in the step 1) to be alkalescent to obtain the acrylic acid emulsion.

Owner:南京夜视丽精细化工有限责任公司

Adult giant salamander feed and preparation method thereof

InactiveCN103689283AAddress nutritional needsAddressing palatability issuesAnimal feeding stuffAnimal sciencePrawn

The invention relates to an artificial feed, and particularly relates to an adult giant salamander feed and a preparation method thereof. The feed is prepared by uniformly mixing 20-50% of powdery feed and 50-80% of minced fresh fish in percentage by weight, wherein the powdery feed comprises the following components in percentage by weight: 30-60% of defatted fish meal, 2-10% of fermented soybean meal, 1-5% of active ferment, 2-10% of krill powder, 5-15% of soybean meal, 0.5-4% of sodium alginate, 0.2-3% of calcium chloride, 0.5-5% of monocalcium phosphate, 5-25% of alpha-starch, 0.1-3% of beta-1, 3-glucan, 0.1-2% of citric acid, 1-5% of premix of vitamins and mineral substances and 0.1-0.5% of lactic acid bacteria. According to the invention, a powdery compound feed and the fresh minced fish are mixed according to a certain proportion so as to prepare a soft-granule feed; the feed is rich in nutrition, is good in viscosity, contains partial biodiasmin, and well meets the requirements of the adult giant salamander on nutrition, palatability and water resistance of the feed.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

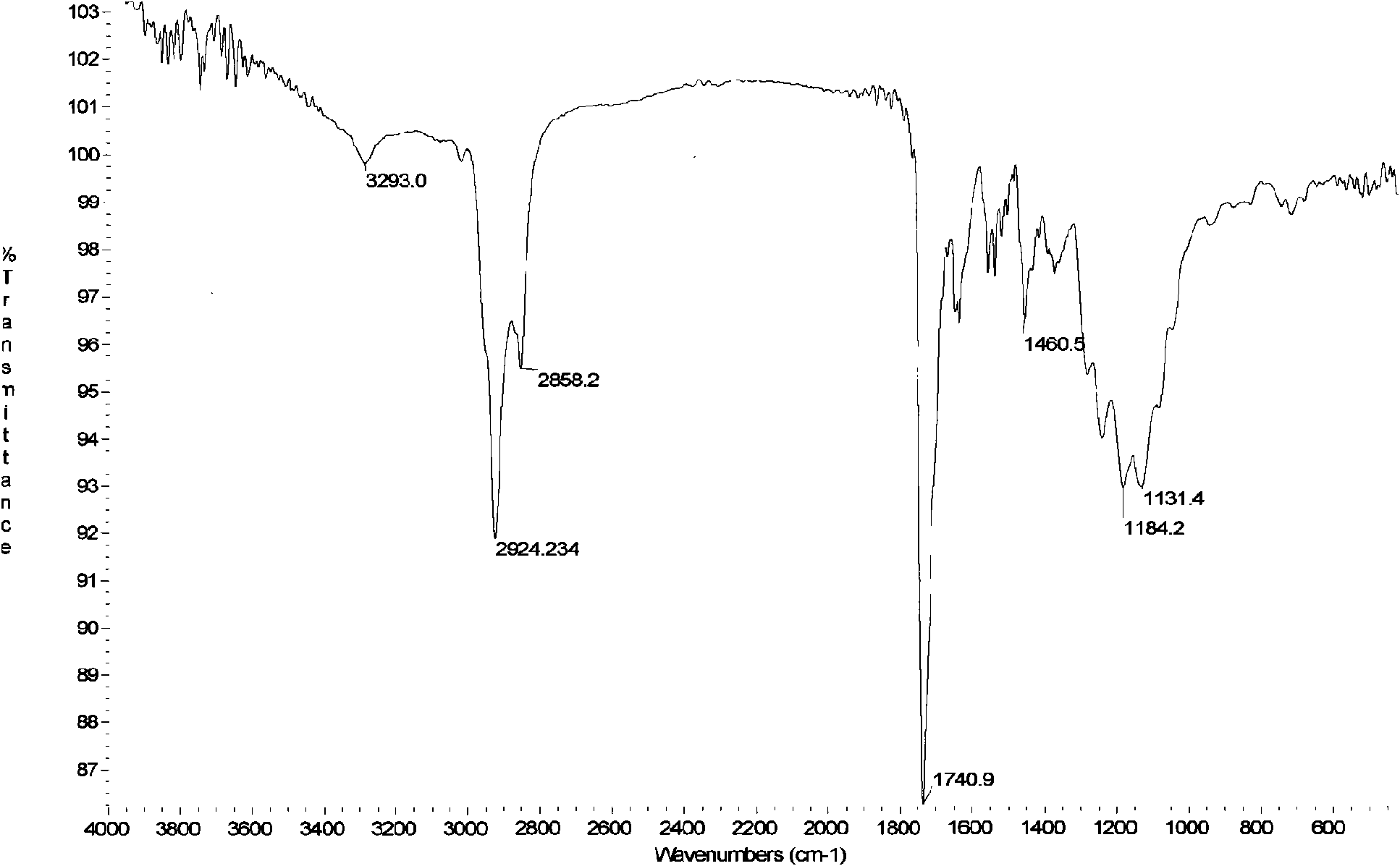

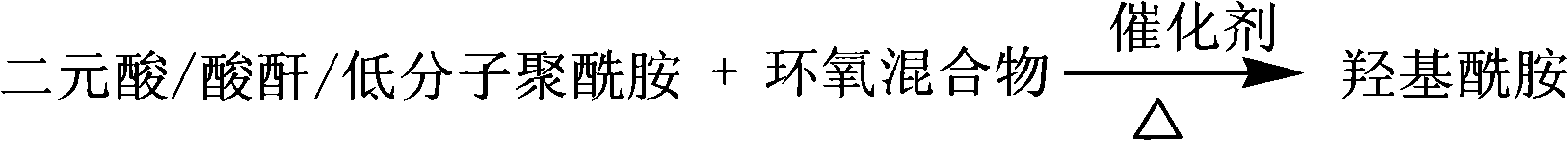

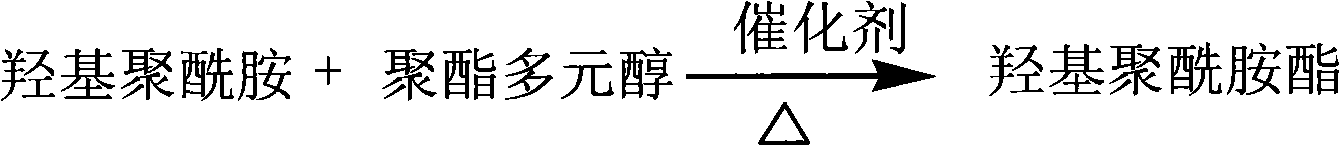

Method for preparing polyamide resin used for water color ink

The invention provides a method for preparing polyamide resin used for water color ink, which comprises the following steps: firstly, obtaining hydroxypolyamide through the ring cleavage addition reaction between 1mol eurelon with 2000-4000 molecular weight and / or dibasic acid and / or estolide containing 5-36 carbon atoms and 1-1.3 mol of epoxy compound in a nitrogen atmosphere at the temperature of 90-140 DEG C and under the catalysis of tertiary amine or quaternary ammonium salt; secondly, obtaining hydroxyl polyesteramide through the ring cleavage addition reaction between the hydroxypolyamide obtained in the first step and polyester polyol in an inert organic solvent at the temperature of 50-80 DEG C and under the catalysis of protonic acid accounting for 1-3 percent of gross mass of the hydroxypolyamide and the polyester polyol, or Lewis acid; thirdly, obtaining daiamid through esterification reaction between the hydroxyl polyesteramide obtained in the second step and estolide in an inert organic solvent at the temperature of 80-130 DEG C and under the catalysis of toluenesulfonic acid or sulphuric acid, and then obtaining the polyamide resin used for water color ink after decompressing and distilling the inert organic solvent, neutralizing with alkaline matters and adding de-ionized water. The invention contains low VOC and has simple preparation technology.

Owner:JIANGSU QIANGLIN BIO ENERGY

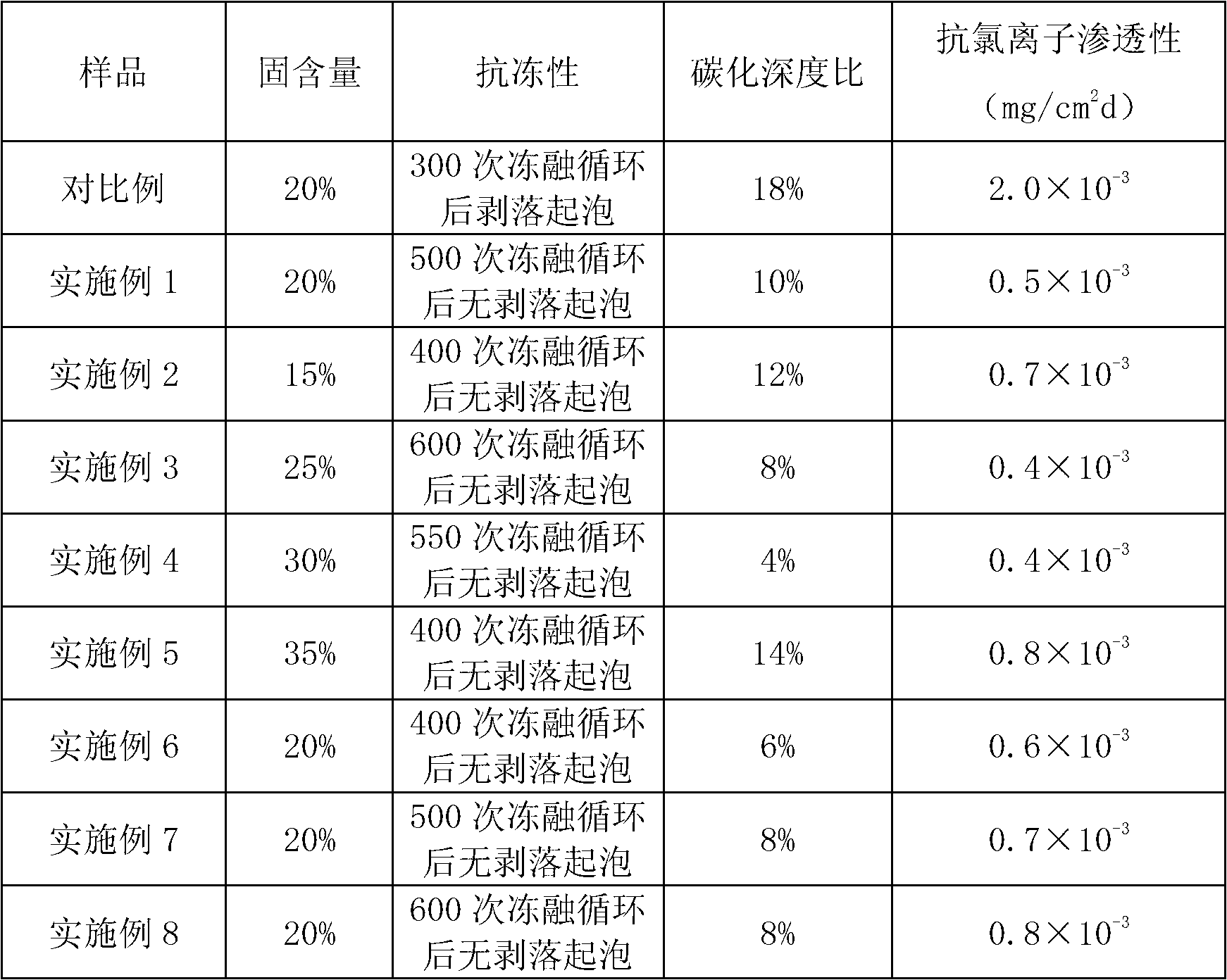

Concrete protection paint and preparation method thereof

The invention relates to a concrete protection paint which comprises the following raw materials in parts by weight: 60-96 parts of vinyl-containing monomer, 2-20 parts of carbonyl / formyl-containing vinyl monomer and 1-10 parts of diazanyl-containing monomer. The preparation method comprises the following steps: under stirring conditions, mixing and dropwisely adding vinyl monomer, carbonyl / formyl-containing vinyl monomer and a silane coupling agent into an emulsifier water solution to obtain a monomer emulsion; synchronously and dropwisely adding an initiator water solution and the monomer emulsion into a base solution at 50-90 DEG C to carry out emulsion polymerization, and adding diazanyl-containing monomer to obtain a polymer emulsion; and evenly mixing the polymer emulsion with a film-forming assistant, a plasticizer, a leveling agent, a defoaming agent and water to obtain the concrete protective paint. The invention solves the problem of lower water resistance when the traditional ambient crosslinking material is used for concrete protection, and can effectively lower the concrete carbonization and chloride ion permeability; and the film can not easily crack in a freeze-thawing environment.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

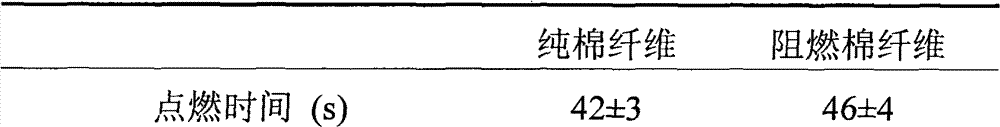

Flame-retardant cotton fiber and preparation method thereof

The invention discloses a flame-retardant cotton fiber and a preparation method thereof. An intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating contains an intumescent flame retardant, polyvinyl alcohol and montmorillonoid. The intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating is prepared by adopting the following step of: carrying out layer-by-layer self-assembly on a polyvinyl alcohol aqueous solution with the intumescent flame retardant and montmorillonoid suspension liquid dispersed in water to obtain the intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating. The flame-retardant cotton fiber is obtained by treating the intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating. According to the flame-retardant cotton fiber and the preparation method thereof, the intumescent flame-retardant modified polyvinyl alcohol / montmorillonoid composite coating is prepared by the adoption of a layer-by-layer self-assembly technology; and through the synergistic flame-retardant effect of the intumescent flame retardant and montmorillonoid, the flame retardance of cotton fibers is improved, so that the usage amount of the flame retardant for cotton fabrics is reduced, therefore the cost of flame-retardant cotton fibers is lowered.

Owner:TAIZHOU UNIV

Silane coupling agent modified resin easy-peel environment friendly water-based pressure-sensitive adhesive

InactiveCN102703003AEasy to peelLow costNon-macromolecular adhesive additivesEster polymer adhesivesEnvironmental resistanceWater based

The invention relates to silane coupling agent modified resin easy-peel environment friendly water-based pressure-sensitive adhesive. A preparation method of the silane coupling agent modified resin easy-peel environment friendly water-based pressure-sensitive adhesive comprises the following steps: (1) using water as a solvent, uniformly mixing polyvinyl alcohol, an anionic surface agent, an emulsifying agent and a pH regulating agent, heating to 50 DEG C, and adding acrylic acid monomers, a silane coupling agent, crosslinking monomers and a polymerization degree regulating agent for reacting for 1h at 60-65 DEG C to obtain a preliminary emulsion; (2) uniformly mixing 25% of the preliminary emulsion and 40% of initiator, heating to 80-85 DEG C, after the liquid becomes blue, beginning to drop the residual preliminary emulsion, adding 20% of the initiator every 1h to finish dropping within 3h, finally, replenishing the residual initiators, and refluxing for 1-1.5h at 90 DEG C; and (3) cooling the reaction liquid to 40 DEG C, adding a bridging agent, uniformly mixing, and then cooling to room temperature. The silane coupling agent modified resin easy-peel environment friendly water-based pressure-sensitive adhesive provided by the invention has the advantages of low price, simple process, high bonding strength, peelability and the like, and pollution to the environment of solvent type pressure-sensitive adhesive can be avoided.

Owner:SHANGHAI ZHONGXIN YUXIANG CHEM

Core-shell pure acrylic emulsion for exterior wall coating as well as preparation method and application thereof

The invention discloses a core-shell pure acrylic emulsion for an exterior wall coating as well as a preparation method and application thereof, and belongs to the technical field of building coatings. The core-shell pure acrylic emulsion comprises the following components in parts by mass: 5.07-30 parts of a core monomer, 5.07-30 parts of a shell monomer, 0.6-12 parts of a reactive emulsifier, 0.02-2 parts of a nonionic emulsifier, 0.02-5 parts of an initiator, 0.02-2 parts of a defoaming agent, 0.02-2 parts of a preservative, 0.02-5 parts of a pH neutralizing agent and 45-60 parts of deionized water. The core monomer is a main monomer; the shell monomer comprises 4.93-20 parts of a main monomer, 1-10 parts of a hydrophobic soft monomer, 0.02-2.55 parts of a polar monomer, 0.01-1.25 partsof a room temperature self-crosslinking monomer component A, 0.01-1.25 parts of a room temperature self-crosslinking monomer component B, and 0.02-2.5 parts of a photoinitiator crosslinking agent, wherein the main monomer comprises an acrylic soft monomer and an acrylic hard monomer; and the mass ratio of the room temperature self-crosslinking monomer component A to the room temperature self-crosslinking monomer component B is 2:1. The emulsion provided by the invention has balanced performance on the whole, and improves the comprehensive performance such as film compactness, adhesive force,water resistance, and raindrop imprint resistance on the basis of fully ensuring film formation.

Owner:安徽衡光新材料科技有限公司

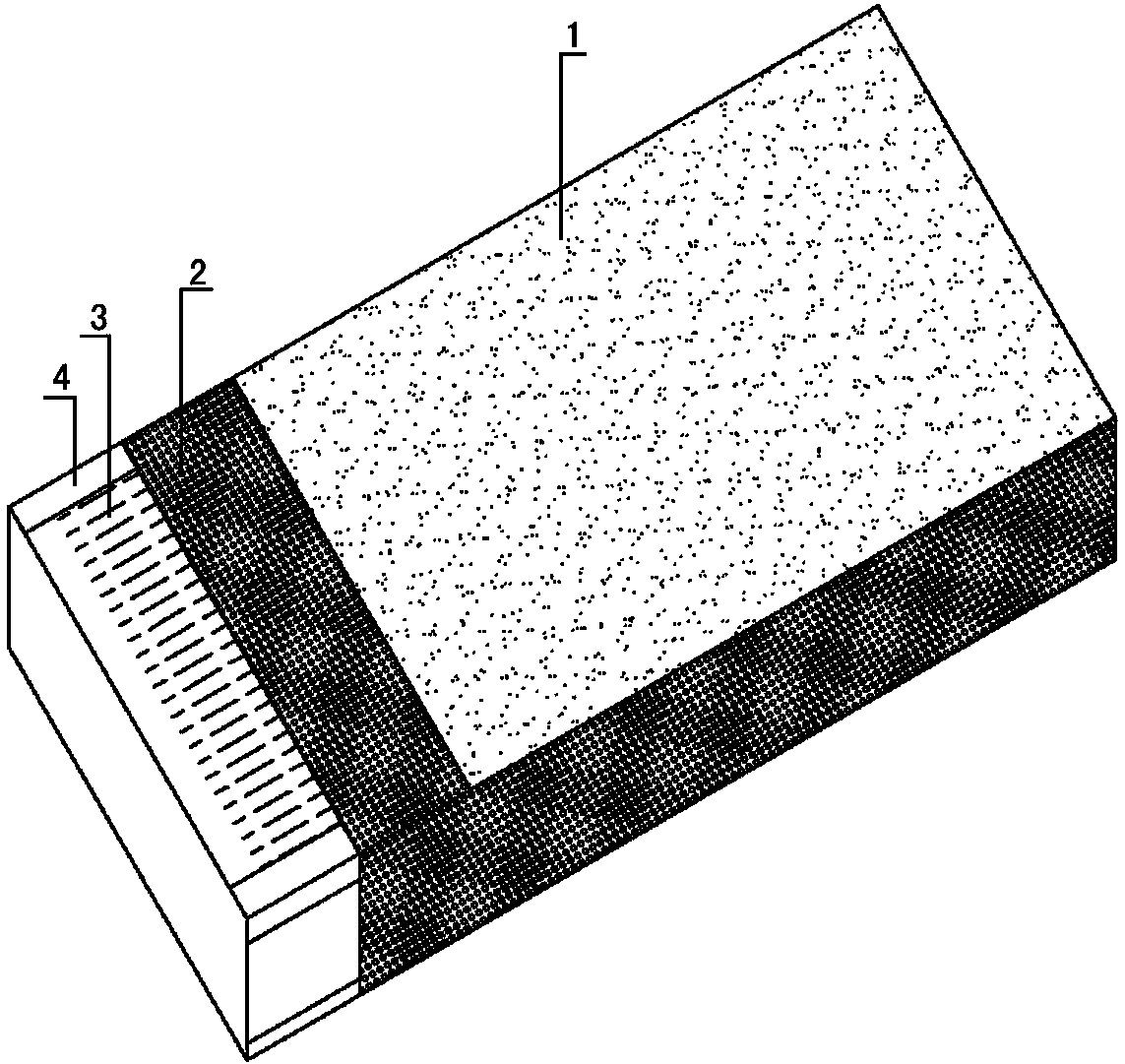

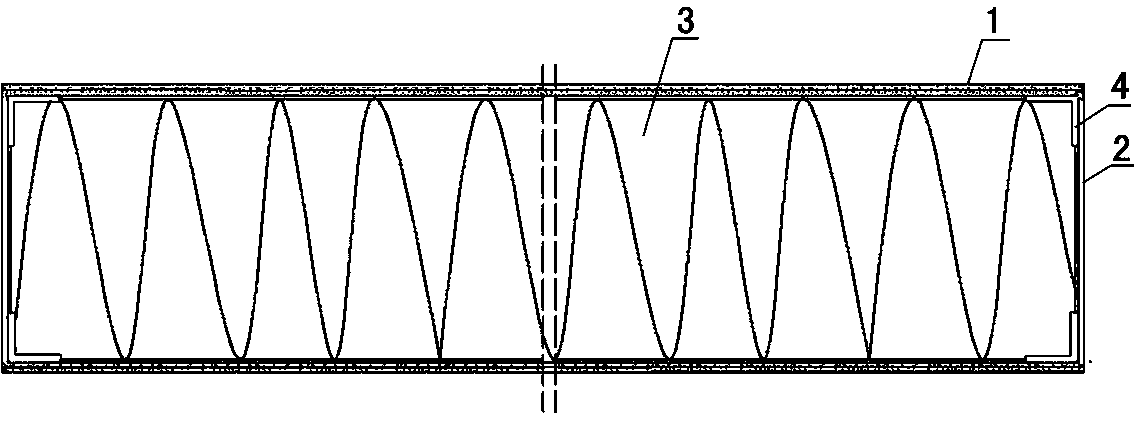

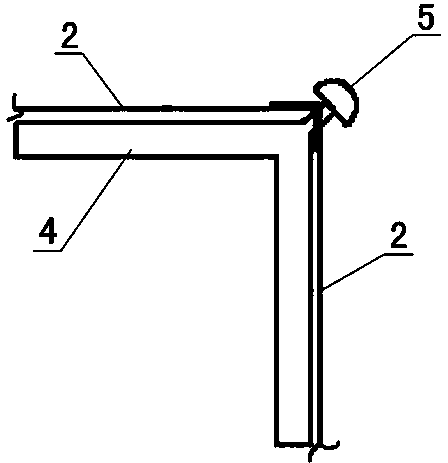

Basalt fiber gridding cloth wrapped rock wool composite heat-preserving plate and manufacturing method thereof

InactiveCN103850353AHigh strengthMeet the technical requirements of thermal insulation constructionHeat proofingFire proofingAdhesive cementPolyvinyl chloride

The invention discloses a basalt fiber gridding cloth wrapped rock wool composite heat-preserving plate and a manufacturing method thereof. The basalt fiber gridding cloth wrapped rock wool composite heat-preserving plate comprises a heat-preserving plate and gridding clothes which wrap the upper and lower surfaces and left and right surfaces of the heat-preserving plate, wherein the heat-preserving plate is formed by splicing a plurality of vertical cotton strips; the fiber direction of each vertical cotton strip is vertical to the upper and lower surfaces of the heat-preserving plate; a PVC (polyvinyl chloride) protecting corner wraps each of the four corner angles of the heat-preserving plate; a row of toothed openings corresponding to gridding cloth meshes in the gridding clothes is formed in the PVC protecting corner on one corner angle of the heat-preserving plate; the gridding clothes are basalt fiber gridding clothes; one end of each basalt fiber gridding cloth is hung to the toothed openings through the gridding cloth meshes; after wrapping around the heat-preserving plate for one circle, the other end of each basalt fiber gridding cloth is also hung to the toothed openings through the gridding cloth meshes. The four surfaces of the heat-preserving plate formed by splicing the vertical cotton strip are wrapped by the basalt fiber gridding clothes, and a hydrophobic bonding adhesive cement is coated on the upper and lower surfaces of the heat-preserving plate, so that the whole tensile strength of the rock wool composite plate is effectively improved.

Owner:河北东华绿源节能科技有限公司

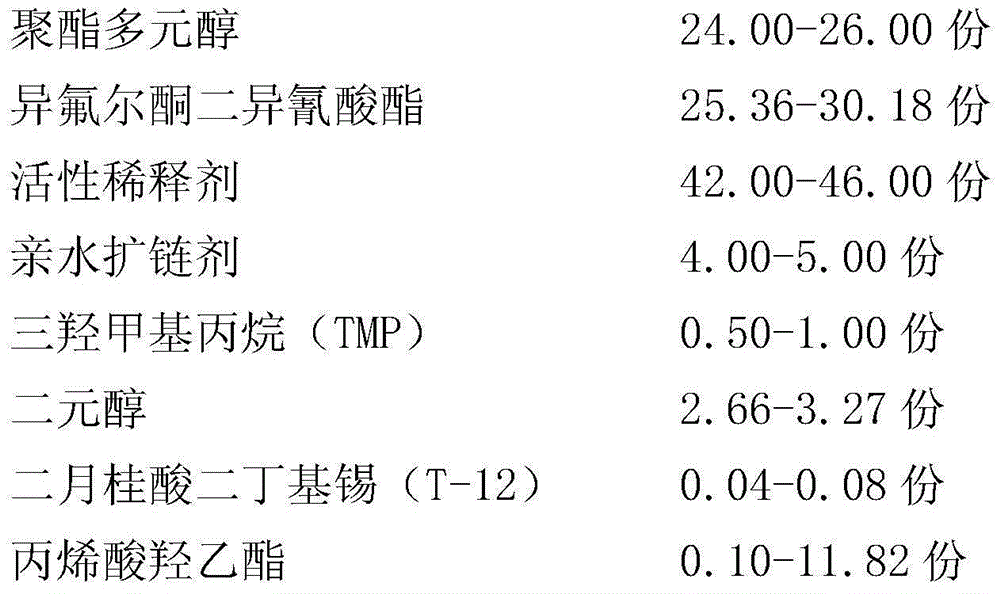

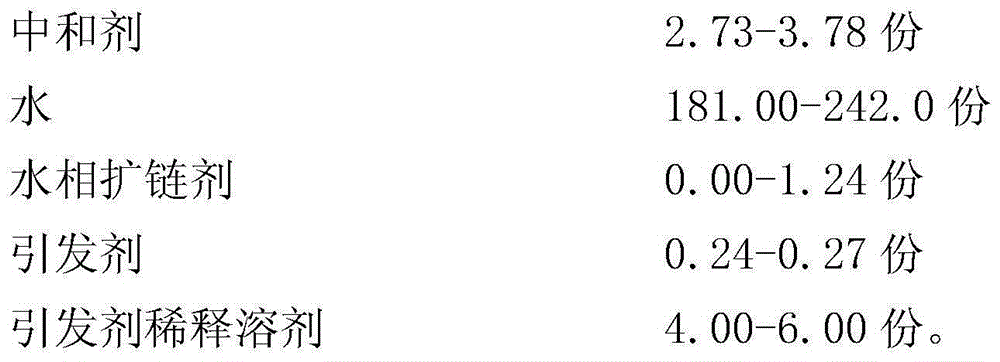

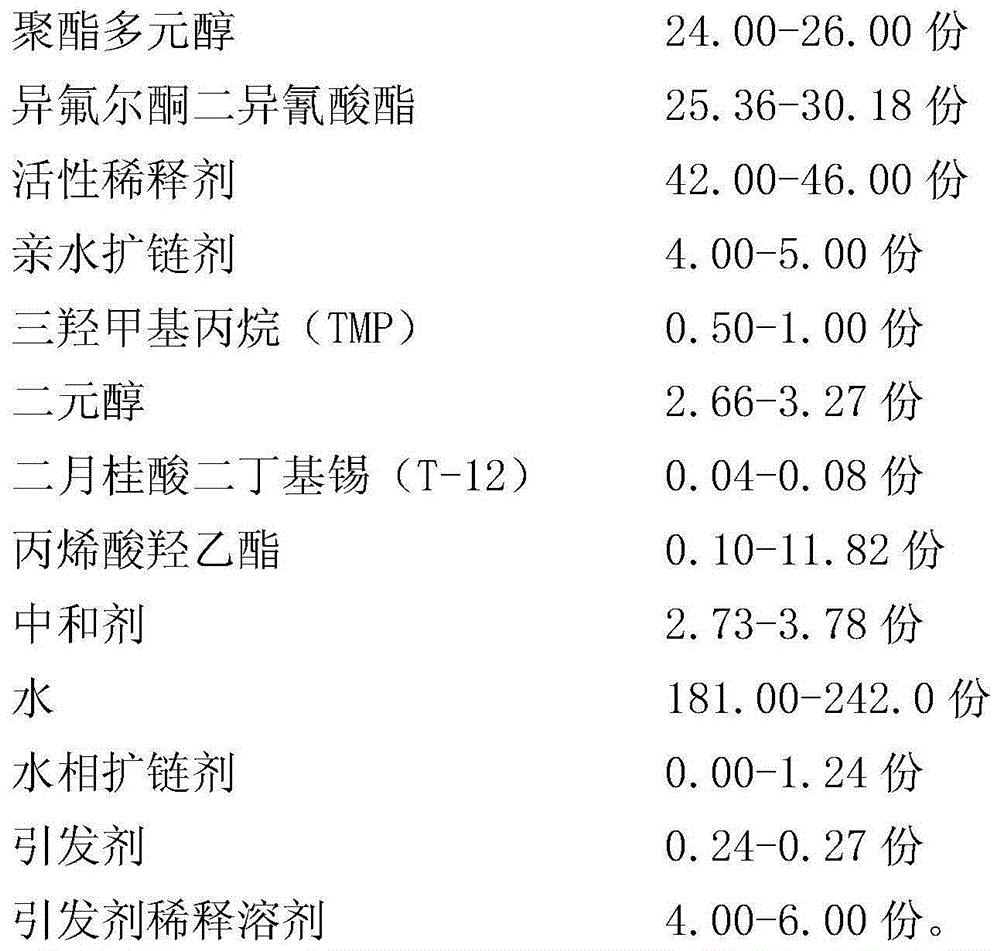

Polyurethane-acrylic ester composite emulsion of core-shell interpenetrating polymer network structure and preparation method thereof

The invention relates to polyurethane-acrylic ester composite emulsion of a core-shell interpenetrating polymer network structure and a preparation method thereof. The polyurethane-acrylic ester composite emulsion is prepared from polyester polyol, isophorone diisocyanate, reactive diluent, a hydrophilic chain-extending agent, trimethylolpropane, dihydric alcohol, dibutyltin dilaurate, hydroxyethyl acrylate, a neutralizing agent, water, an aqueous phase chain-extending agent, an initiating agent and initiating agent diluting solvent. The polyurethane-acrylic ester composite emulsion and the preparation method thereof have the following advantages that the problem that water resistance is lowered due to addition of emulsifier is solved; pollution caused by organic solvent and tediousness of the later-period organic solvent extraction technology are avoided. The emulsion is polyurethane-acrylic ester copolymer emulsion of a core-shell crosslinking interpenetrating polymer network structure.

Owner:SKSHU PAINT

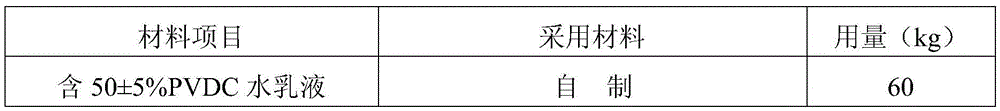

High-barrier polyester film and preparation method thereof

The invention discloses a high-barrier polyester film. The high-barrier polyester film is characterized by comprising a base film and a high-barrier resin coating applied and cured on a single surface or double surfaces of the base film, wherein the thickness of the high-barrier polyester film is 15-80 mu m; the base film is a biaxially stretched polyester film prepared from polyethylene terephthalate. The preparation method of the high-barrier resin coating comprises steps as follows: the polyethylene terephthalate chips are subjected to fusion and chip casting through an extruder and longitudinal stretching to form a thin stock chip, a single surface or double surfaces of the thin stock chip is or are coated with a high-barrier resin coating solution in an on-line coating manner, and the base film with the coating of the high-barrier resin coating solution is obtained after drying, horizontal stretching and heat setting, and the high-barrier polyester film is obtained. The oxygen transmissibility of the high-barrier polyester film is 6.0-12.3 cm<3> / m<2>*d*atm, the moisture transmissibility is 6.1-10.5 g / m<2>*d, and the high-barrier polyester film is particularly applicable to the field of package.

Owner:江苏东材新材料有限责任公司

Gold and silver powder adhesive, preparation method thereof, wallpaper and textiles

ActiveCN103756601AGood bonding effectExcellent water resistance and high temperature resistanceEster polymer adhesivesIonTemperature resistance

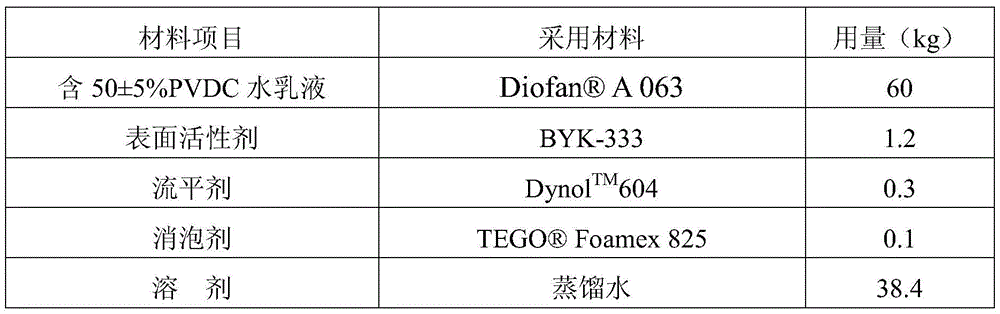

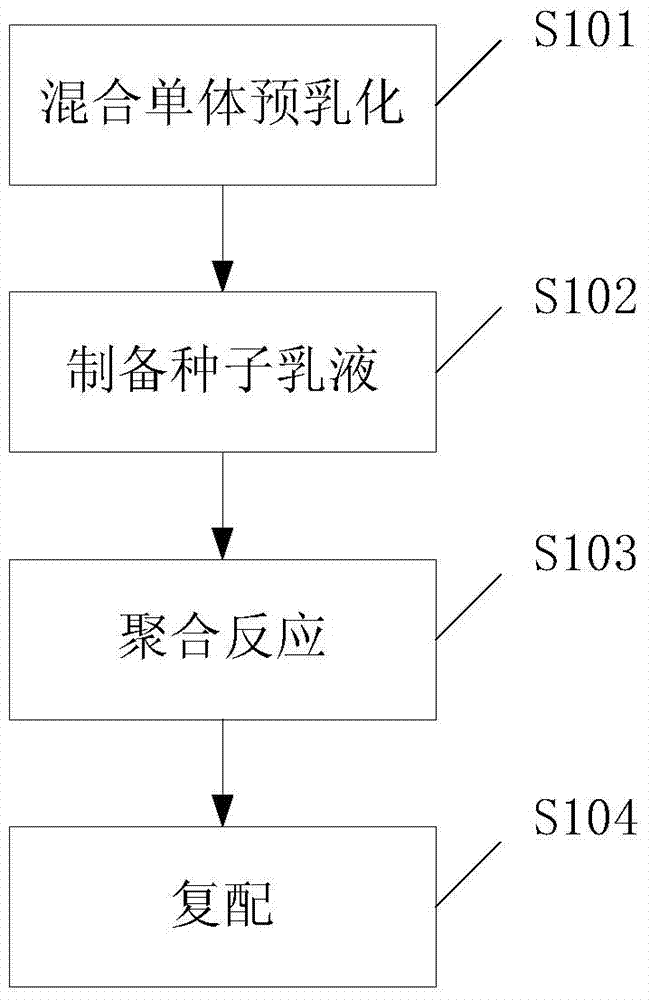

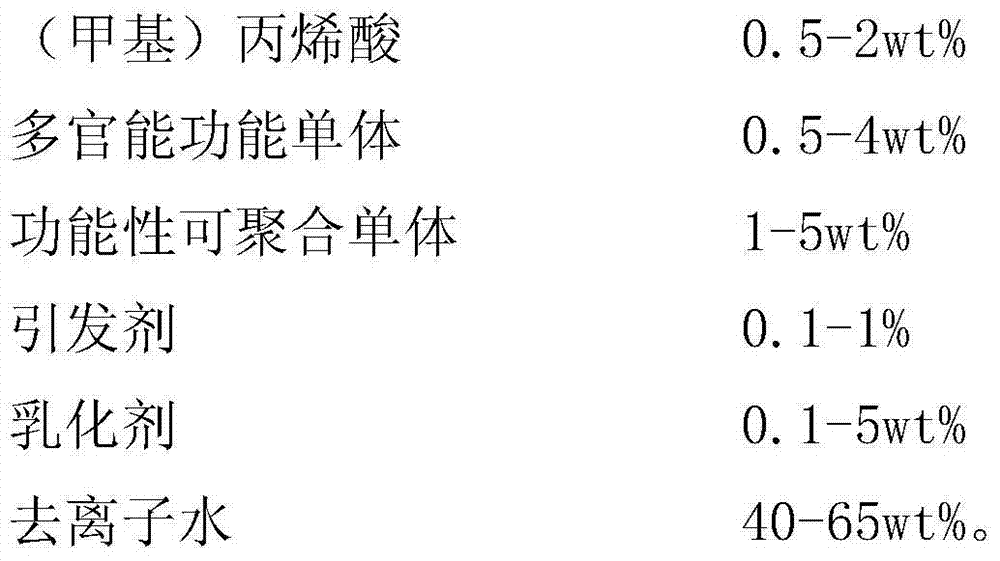

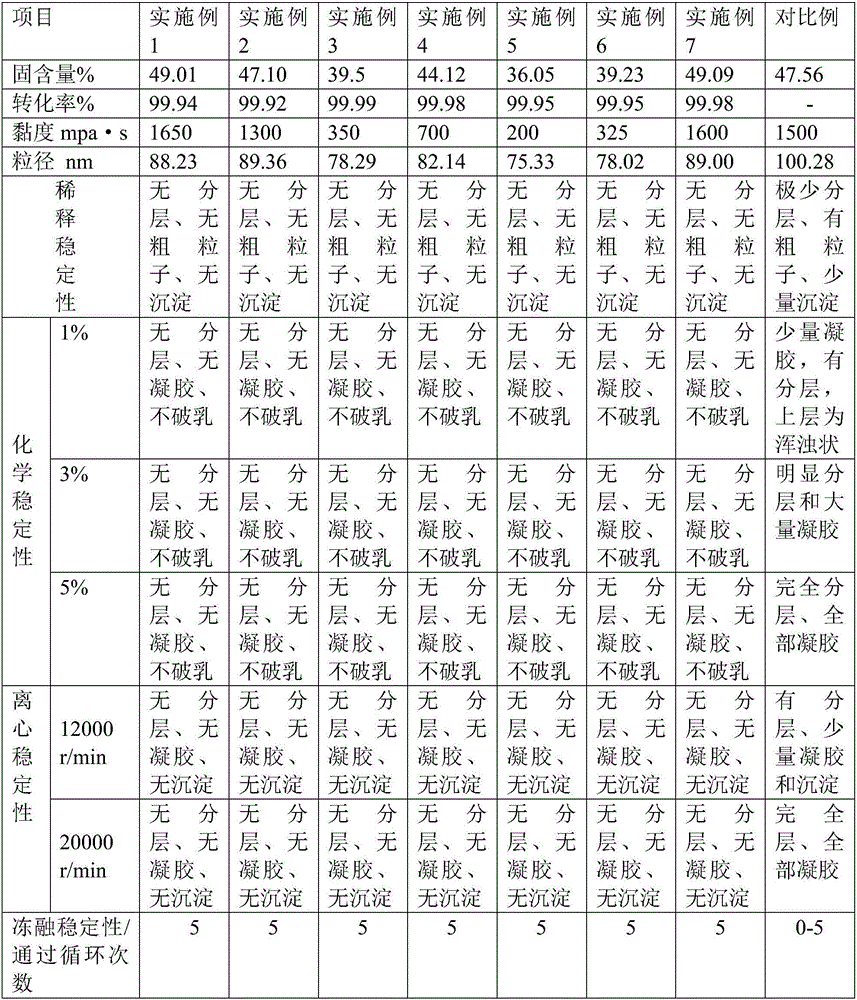

The invention discloses a gold and silver powder adhesive. The gold and silver powder adhesive is prepared by using hard monomers, soft monomers, hydroxy ester containing monomers, (methyl)acrylic acid, multifunctional monomers, functional polymerizable monomers, emulsifying agents, initiators and deionized water as main raw materials and carrying out the processes of mixed monofunctional monomer pre-emulsification, seed reaction, monofunctional and multifunctional mixed monomer polymerization reaction and compounding. The solid content of the gold and silver powder adhesive is 30-50wt% of waterborne acrylate emulsion. Accordingly, the invention also discloses a method for preparing the gold and silver powder adhesive as well as wallpaper and textiles prepared by applying the gold and silver powder adhesive. The gold and silver powder adhesive has good adhesion, good water and high temperature resistance, strong covering power and high glossiness, and has the characteristics that the gold and silver powder adhesive is resistant to oxidation for a long time and does not discolor.

Owner:佛山市三水灏诚合成树脂有限公司

Acrylic emulsion for PVC (Polyvinyl Chloride) water-based ink and preparation method of acrylic emulsion

The invention discloses an acrylic emulsion for PVC (Polyvinyl Chloride) water-based ink, and belongs to the technical field of emulsions. The acrylic emulsion is of a core-shell structure and comprises the following components in percentage by mass: 2-10% of an anionic emulsifier, 0-0.5% of a reaction type emulsifier, 0-3% of a non-ionic emulsifier, 0.05-2% of ammonium persulfate, 0.5-1.0% of 30% ammonium hydroxide, 0.1-0.3% of a bactericide, 40-70% of deionized water, a core structure monomer and a shell structure monomer, wherein the core structure monomer comprises the following components in percentage by weight: 0.1-10% of methyl methacrylate, 0-5% of ethyl acrylate, 0-5% of acrylamide and 0-5% of a silane coupling agent; the shell structure monomer comprises the following components in percentage by weight: 10-25% of methyl methacrylate, 15-25% of butyl acrylate, 0-10% of ethyl acrylate, 0-1% of methacrylic acid, 0-1% of crylic acid and 0-5% of caprolactam. The acrylic emulsion is excellent in adhesion property and good in water resistance on a PVC substrate.

Owner:GUANGDONG HENGGUANG CHEM CO LTD

Antibiosis solution used for dressing, antibiosis dressing and preparation method for antibiosis dressing

ActiveCN104248776AAddress water resistanceSolve the bactericidalBiocideFungicidesIsolated environmentBond Force

The invention discloses an antibiosis solution used for dressing, an antibiosis dressing and a preparation method for the antibiosis dressing. The antibiosis solution comprises, in parts by weight, 0.15-1 part of a biguanide antiseptic, 0.03-1 part of a quaternary-ammonium-salt antiseptic, 0.03-1 part of ethanol and 97-99.79 parts of water. The antibiosis dressing prepared from the antibiosis solution solves the disadvantages that conventional antibiosis dressings are not resistant to water washing, slow in sterilization effect, high in cost and the like. Under the same sterilization effect, the antibiosis dressing is low in antiseptic addition amount and relatively cheap in price; the antibiosis solution is good in bonding force and compatibility with a base material, is capable rapidly killing Gram-positive bacteria, Gram-negative bacteria and other multiple bacteria and fungi, and has wide-spectrum rapid bactericidal effect; and the antibiosis dressing is applicable to surgery wounds, burns, scalds and other chronic wounds, and provides a moist and bacterium-isolated environment for wounds. The antibiosis solution and the antibiosis dressing are simple in preparation technology, and large-scale industrialized production can be realized.

Owner:AOMEI MEDICAL SUPPLIES CO LTD

Nonionic and anionic mixed waterborne polyurethane curing agent and preparation method thereof

The invention discloses a nonionic and anionic mixed waterborne polyurethane curing agent and a preparation method thereof. The method comprises the following steps of: adding oligomer polyols to an HDI monomer in the presence of nitrogen, stirring and heating the oligomer polyols and the HDI monomer to 60-80 DEG C, and carrying out heat preservation and reaction for 2-3 hours to obtain an additive product; adding a trimer catalyzer to the additive product, carrying out thermal reaction at 60-80 DEG C; when the NCO content reaches a target value, removing unreacted HDI monomer under the conditions of 150-180 DEG C and 0.01-0.05Torr to obtain an HDI prepolymer; cooling the obtained HDI prepolymer to 60-70 DEG C, adding an anion modifier and carrying out thermal reaction for 2-4 hours; and adding a neutralizer, reacting for 0.5-1 hour, cooling and discharging the product to obtain the waterborne polyurethane curing agent. The preparation method disclosed by the invention is simple; the obtained waterborne polyurethane curing agent is light in color, high in effective -NCO content, yellowing-resistant and good in storage stability.

Owner:广州嘉宝莉地坪材料有限公司

Styrene modified alkyd resin, preparation method thereof and alkyd resin paint

The invention discloses styrene modified alkyd resin which comprises the following raw materials in percentage by weight: 12-30% of styrene, 8-16% of xylene, 24-35% of trimethylbenzene, 14-19% of soybean oil, 1.5-1.8% of a toughening agent, 1-5% of tung oil, 7-9% of phthalic anhydride, 1-4% of pentaerythritol, 1-3% of epoxy resin, 1-3% of benzoic acid, 1-5% of maleic anhydride, 1.5-2% of grease leftovers, 0.01-0.03% of a catalyst, and 1-3% of an initiator. The invention further discloses alkyd resin paint containing the styrene modified alkyd resin. The alkyd resin paint comprises the following components in percentage by weight: 70-99% of the styrene modified alkyd resin disclosed by the invention, 0-30% of pigment and 0.2-1.5% of an additive. The styrene modified alkyd resin disclosed by the invention is simple in preparation method, due to copolymerization reaction of styrene, unsaturated fatty acid and maleic anhydride, the modified alkyd resin has the characteristics of high hardness and rapid dryness, when the modified alkyd resin is used in alkyd resin paint, the defects that the conventional alkyd resin paint is long in construction period, low in working efficiency and poor in water resistance are overcome.

Owner:广东鲸鲨化工有限公司

Water-resistant phosphogypsum block and preparation process thereof

InactiveCN107500698AImproved to alkalineAdjust clotting timeCement mixing apparatusPolyvinyl alcoholSuperplasticizer

The invention provides a water-resistant phosphogypsum block and a preparation process thereof. The water-resistant phosphogypsum block comprises the following raw materials by weight: 70%-100% of phosphogypsum, 50%-80% of water, 3-8% of polyvinyl alcohol, 3%-6% of styrene-acrylic ester emulsion, 0.05%-0.8% of paraffin emulsion, 0.01%-1.5% of hydrosilicone oil, 0.1%-2% of a naphthalene-series superplasticizer, 0.2%-2% of white portland cement, 0.1%-5% of sulphoaluminate cement, 0.1%-10% of calcium hydroxide, 0.01%-6% of aluminum potassium sulfate dodecahydrate and 0.01% to 1% of aluminum sulfate. The preparation process comprises four specific steps of pulp preparation, molding, stripping and drying. The phosphogypsum setting time and mechanical strength can be effectively adjusted by different components in the formula. Automated production is taken into account, and meanwhile the problems of low mechanical strength and poor water resistance of pure phosphogypsum under high alkalinity conditions can be effectively solved.

Owner:南通绿洲节能环保产品有限公司

Production process of high-density nylon fabric

InactiveCN103696282ASolve the problem of high temperature yellowingSolve the poor anti-ultraviolet effectFibre typesDyeing processAcetic acidCooking & baking

The invention discloses a production process of a high-density nylon fabric. The process comprises the following steps: (1) unwinding and sewing; (2) performing desizing pretreatment; (3) presetting at 170 DEG C, namely adding 5-6g / L isopropanolamine and a 30g / L anti-yellowing agent, wherein the liquid content is 40 percent; (4) dyeing; (5) fixing color, adding a 5g / L anion color fixing agent and 4g / L acetic acid, performing color fixing treatment for 50 minutes and washing with clear water; (6) dehydrating and scutching; (7) carrying out after finishing, namely adding a 30g / L water-proofing agent, a 5g / L silicone softening agent, a 8g / L crosslinking agent and 4g / L fatty alcohol-polyoxyethylene ether, wherein the liquid detention rate is 40 percent, the drying temperature is 120 DEG C and the baking temperature is 190 DEG C; and (8) calendering. By adopting the production process, the problems of easiness in high-temperature yellowing, poor ultraviolet resistance, poor water repellency, poor oil repellency, poor water washing resistance, low color fastness, not ideal downproofness and the like due to the adoption of a non-reasonable production process in the existing production process of high-density nylon fabrics are solved.

Owner:常熟市爱博尔服饰有限公司

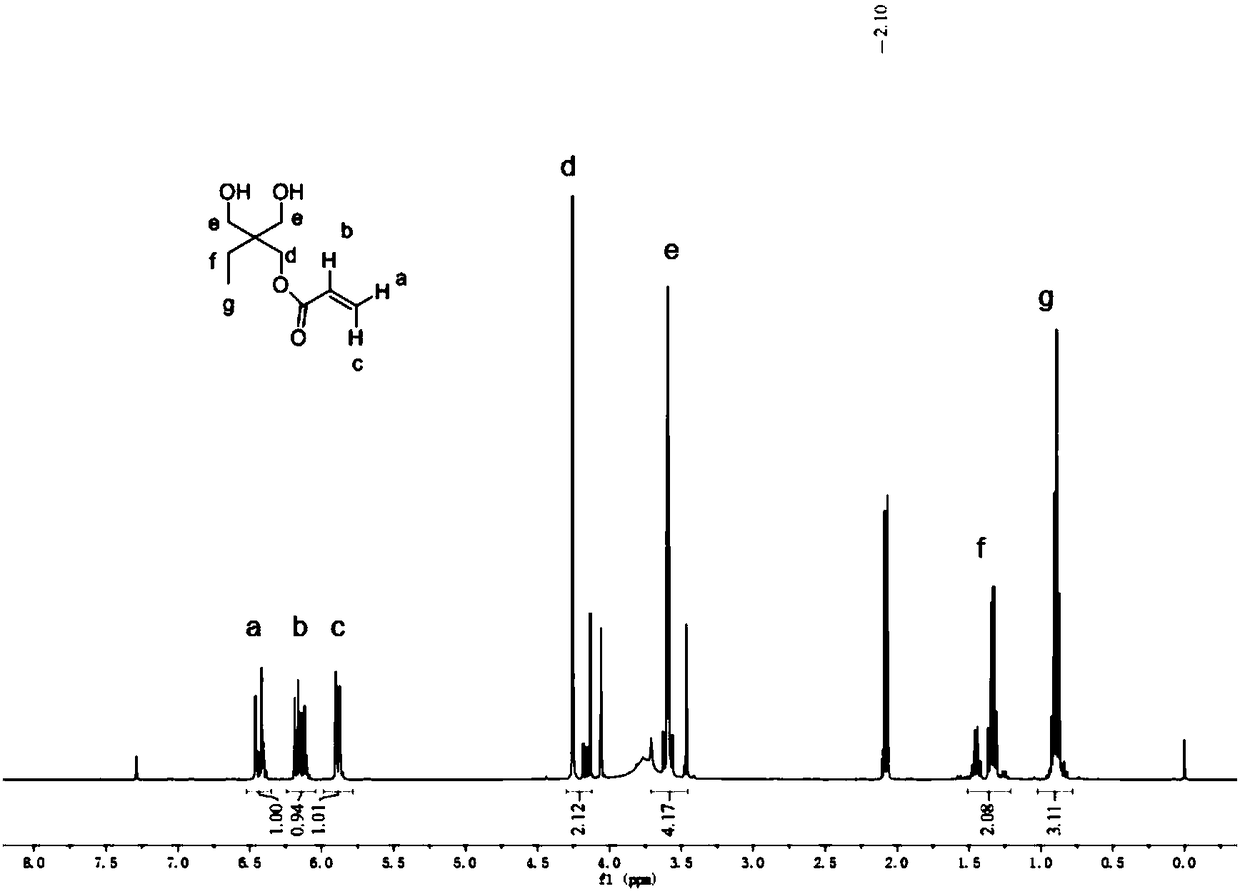

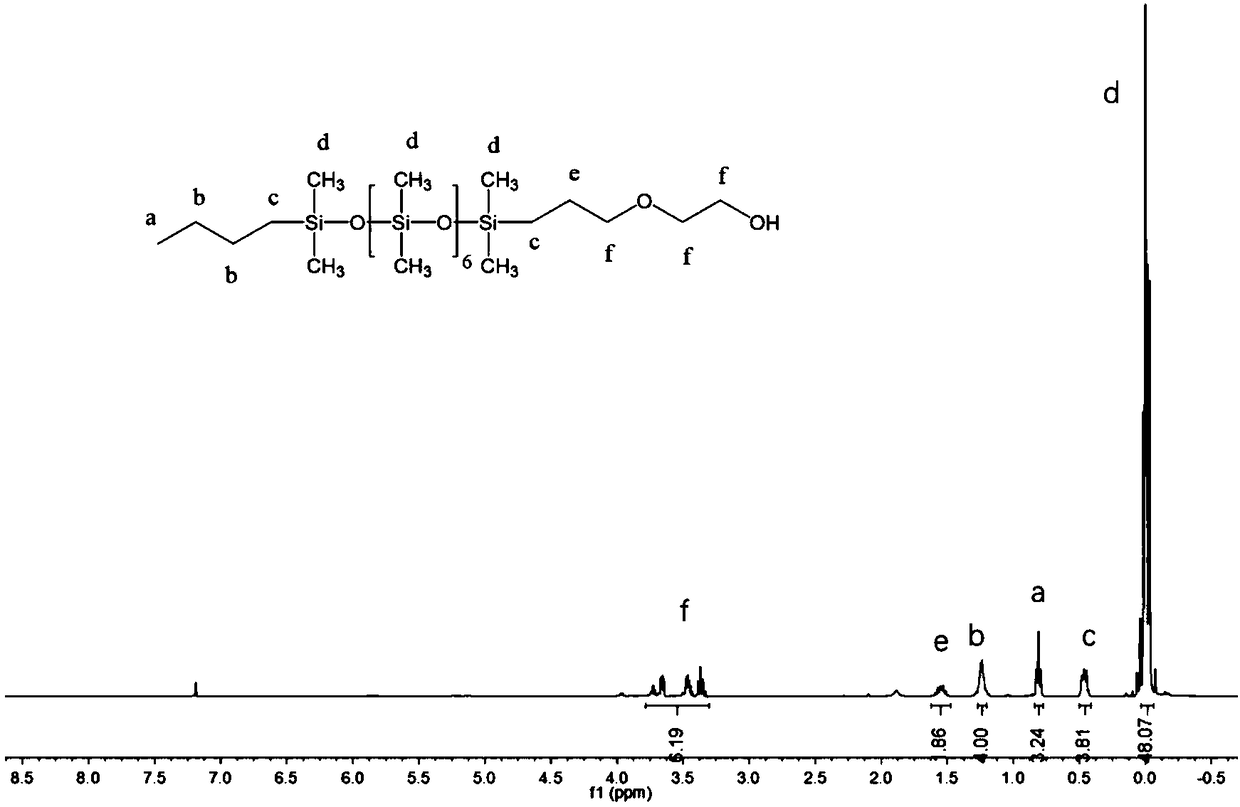

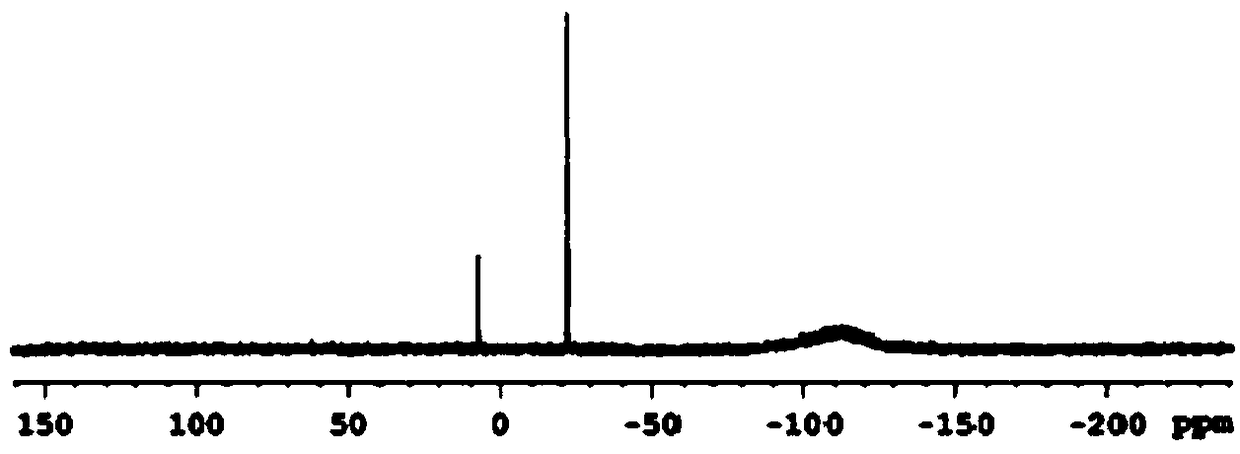

Method for preparing photopolymerizable organosilicon polyurethane acrylate aqueous oligomer and composition thereof

The invention discloses a method for preparing a photopolymerizable organosilicon polyurethane acrylate aqueous oligomer and a composition thereof. The method is based on the shortcomings of the current photopolymerizable organosilicon polyurethane acrylate aqueous oligomer, and the method comprises the following steps: synthesizing 2,2-bis(hydroxymethyl) butyl acrylate (HBA), and introducing thematerial into the oligomer molecule to make the polymer side chain is rich in unsaturated carbon-carbon double bonds; synthesizing one-terminated hydroxypolydimethylsiloxane (Si-OH), and introducing the substrate to the end of a main chain of the aqueous polyurethane acrylate oligomer so that the substrates facilitate enrichment on the surface of the material. Through the above molecular design, the problems of poor water resistance and low hardness of the aqueous photocurable material caused by the low double bond content and low crosslink density of the photocurable material are effectivelysolved, and the disadvantages that silicone chain is easily wrapped by the crosslinked network when is in the middle of the main chain so that the silicone is not enriched at the surface of the material, so that the surface hydrophobicity of the material can be effectively increased.

Owner:安庆北化大科技园有限公司

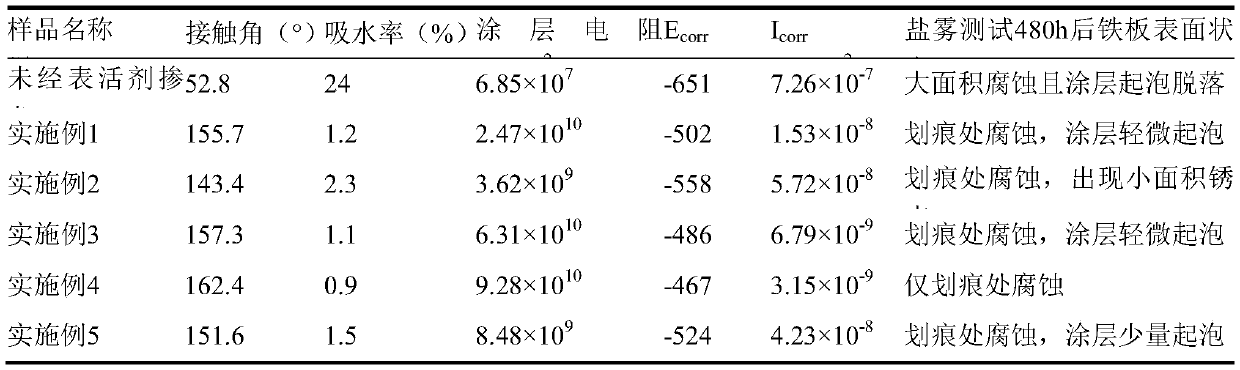

Preparation method of terpolymer doped polyaniline super-hydrophobic composite anticorrosive paint

ActiveCN110229594AExcellent superhydrophobicityGood compatibilityAnti-corrosive paintsEpoxy resin coatingsResin matrixAniline

The invention discloses a preparation method of a terpolymer doped polyaniline super-hydrophobic composite anticorrosive paint. The method includes: firstly adopting solution polymerization, stirringa hydrophilic vinyl monomer, a fluorine-containing acrylate monomer and an oil-soluble initiator in a solvent evenly and carrying out reaction for a period of time, then adding a functional acrylic monomer or long-chain acrylate monomer as a third monomer for further reaction for a period of time to obtain a fluorine-containing terpolymer surfactant; then mixing the fluorine-containing terpolymersurfactant with an aniline monomer and an oxidant evenly, and carrying out reaction for a period of time to obtain super-hydrophobic polyaniline; and finally dispersing the prepared super-hydrophobicpolyaniline evenly in a resin matrix to prepare the polyaniline super-hydrophobic composite anticorrosive paint with excellent anticorrosive performance. The terpolymer doped polyaniline super-hydrophobic composite anticorrosive paint provided by the invention solves the problems of poor waterproofness and corrosion resistance of the resin matrix itself, and can greatly improve the long-acting anti-corrosion performance of metals when used as an anticorrosive paint.

Owner:SHAANXI UNIV OF SCI & TECH

Anticorrosive moistureproof bamboo wood processing adhesive

InactiveCN105368344AWide range of raw materialsExtensive sources of raw materialsNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveFatty acid glycerol esters

The present invention discloses an anticorrosive moistureproof bamboo wood processing adhesive and relates to the technical field of adhesives, the anticorrosive moistureproof bamboo wood processing adhesive is prepared from the following materials: starch, potassium permanganate (5% solution), sodium hydroxide (10% solution), nano zinc oxide ZnO, nano zirconia (ZrO2), a tackifier, a preservative, a moistureproof agent, fatty acid glycerides, urea, deionized water and ammonia, the anticorrosive moistureproof bamboo wood processing adhesive solves the shortcomings of low bonding strength, poor water resistance and poor corrosion resistance of the traditional bamboo wood processing adhesive, and is wide in source of the raw materials, simple in production process, environmental-friendly, and non-pollution.

Owner:广德县永彬竹木工艺品厂

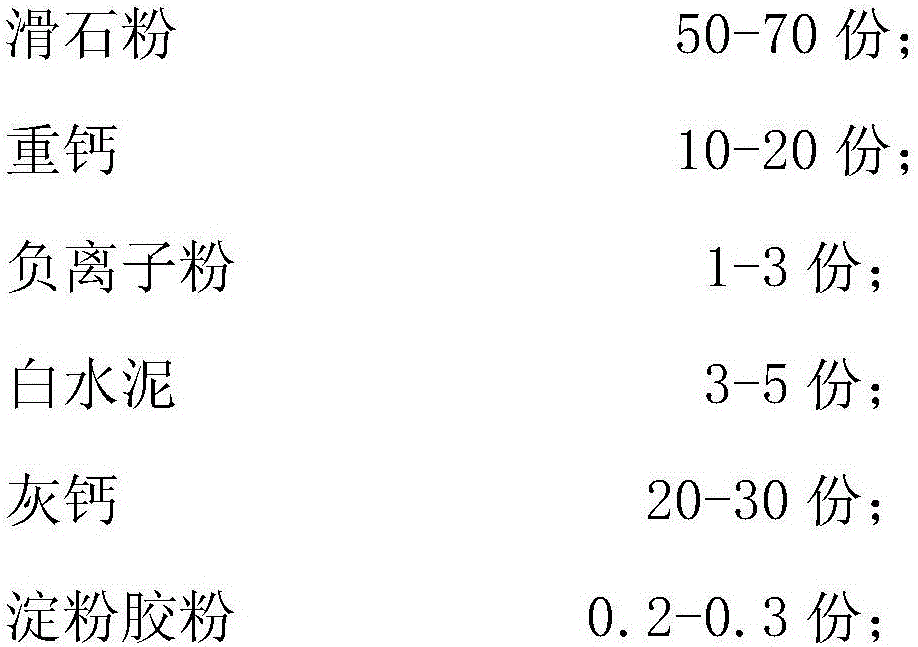

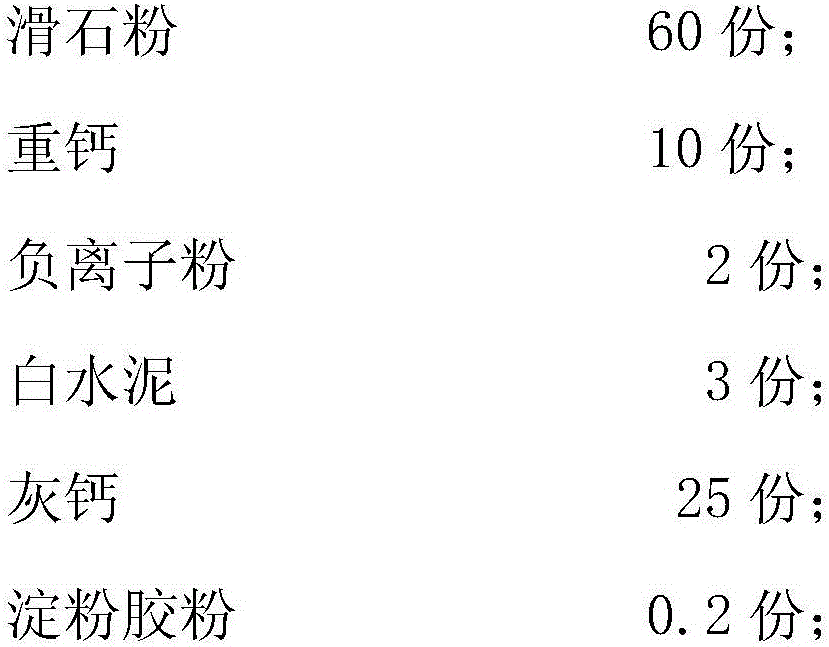

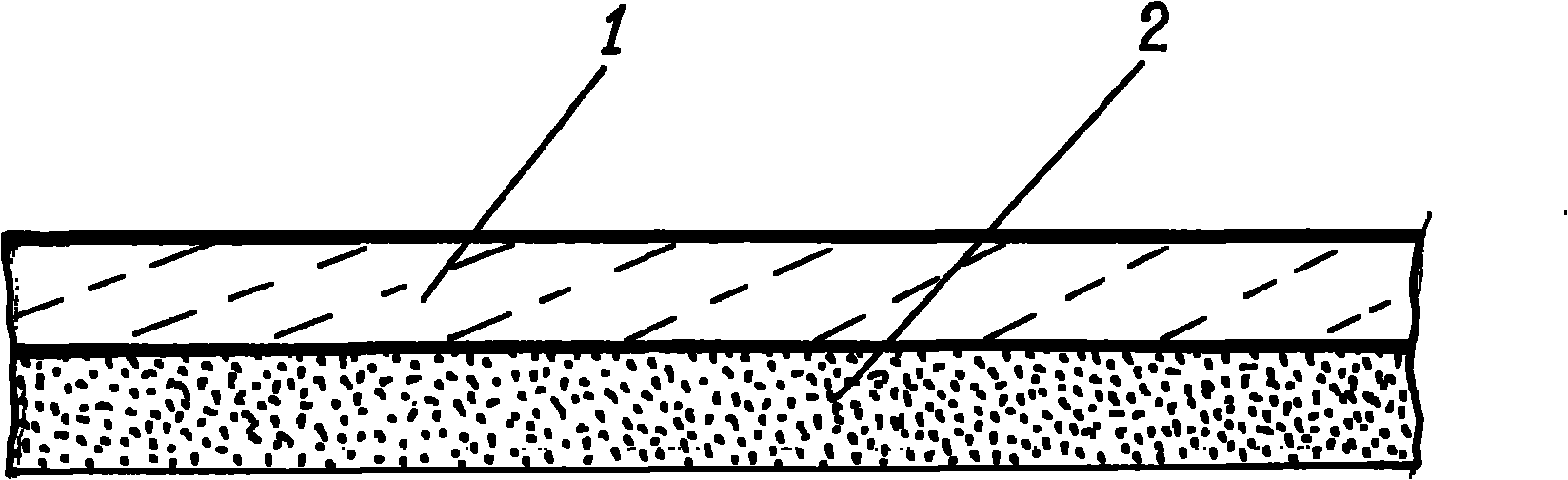

Negative ion interior-wall waterproof putty powder and preparation method thereof

InactiveCN105907154AHigh bonding strengthImprove crack resistanceFilling pastesElectrically-conductive paintsPhysical well beingLiving environment

Negative ion interior-wall waterproof putty powder and its preparation method belong to the technical field of building wall decoration materials. Raw materials comprise, by weight, 50-70 parts of talcum powder, 10-20 parts of ground calcium carbonate, 1-3 parts of negative ion power, 3-5 parts of white cement, 20-30 parts of ash-calcium and 0.2-0.3 part of starch rubber powder. The above raw materials are successively added into a horizontal or vertical mixer and stirred for 1-2h; and after discharging, the negative ion interior-wall waterproof putty powder is obtained. The invention has the following advantages: living environment is improved for people to a larger extent, and people can experience the feeling of living in the nature without going outside and health condition of people is improved. According to the invention, problems such as low bonding strength and poor water resistance and flexibility, etc. of common putty are solved; and negative ions can be effectively released to satisfy people's longing for the nature, and existing living environment is fundamentally improved. The product is of great development significance.

Owner:SHANDONG BAIER BUILDING MATERIAL CO LTD

Biodegradable mulch with compound function

InactiveCN101828495AComposite functionAddress water resistancePlant protective coveringsNutritionPlastic mulch

The invention relates to biodegradable mulch with a compound function, which takes the biodegradable mulch as a carrier. A functional preparation is sprayed on one surface of the mulch so as to form the functional biodegradable mulch; and the biodegradable mulch comprises the following components based on weight percentage: 33-68% of master batches, 30-65% of 7042 and 5-7% of 1F7B, and the functional preparation is insecticide or herbicide or nutrient solution. The biodegradable mulch has the positive effects as follows: the surface of the biodegradable mulch can be directly compounded with an oily, milky and / or humid powder functional preparation; the mulch can effectively and slowly release the insecticide, the herbicide and the nutrient solution so as to achieve better effects in killing insects, weeding and providing nutrition for crops; the mulch can adapt to different climate and soil environments, and meet the requirements of heat preservation and soil moisture conservation of different crops; after completing functional actions, the mulch can be automatically degraded without pollution; and the mulch has the advantages of convenient use and lower cost, thus obviously improving the agricultural production efficiency.

Owner:常州百利基生物材料科技有限公司

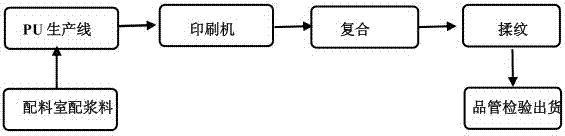

Production method of breathable leather

ActiveCN103898773AImprove hydrolysis resistanceReduce manufacturing costLaminationLamination apparatusProduction lineSurface layer

The invention relates to a production method of breathable leather. The condition that in a production method of the breathable leather, environment pollution in the production process is free and the problem of product breathability is available can be solved at present can not be splved. The production method comprises the following steps: (1) preparing a sizing agent, wherein the sizing agent consists of polyurethane resin and color chips in a weight ratio of 100:1.2, and the viscosity of the sizing agent is adjusted to be 1500cps; (2) mounting release paper onto a PU (Polyurethane) production line, firstly, drying the release paper at 100 DEG C, subsequently coating the release paper with the sizing, and furthermore, drying at 140 DEG C so as to obtain a half-finished product; (3) printing a dry method surface layer of the release paper with patterns and glossiness by using a three-edition printing machine; (4) compounding the release paper with a piece of base cloth by using a binding agent; and (5) washing in water by using a graining machine; and (6) inspecting to be qualified to obtain a breathable leather product. By adopting the production method, the product breathability can be solved.

Owner:ZHEJIANG SHENTENG COATED FABRICS

Biodegradable mulching film

ActiveCN101831097AMeet the requirements of heat preservation and moisture retention periodDoes not affect plantingClimate change adaptationPlant protective coveringsMicrocrystalline waxMaterial consumption

The invention discloses a biodegradable mulching film, which comprises the following components in percentage by weight: 33 to 68 percent of alloy master particle, 30 to 65 percent of 7042(LDPE), and 5 to 7 percent of 1F7B. The alloy master particles comprise the following components in percentage by weight: 0.01 to 0.03 percent of tert-butyl peroxide isopropyl benzene, 1.50 to 2.25 percent of fumaric acid, 4.50 to 5.60 percent of microcrystalline wax, 3.60 to 5.40 percent of polyethylene wax, 3.00 to 4.20 percent of MG70, 9.00 to 13.0 percent of N210 and 68 to 80 percent of cornstarch. The biodegradable mulching film has the advantages that: the biodegradable mulching film can adapt to different climates and soil environments in various places as well as the requirements of different crops, the mulching film is degraded in the design life without influencing the planting of the crops, and the mulching film is degraded uniformly and thoroughly; the balance problem of water resistance and hydrophily is solved, and the mulching film has higher ground adherence; and the specific gravity is small, the thickness of the mulching film is only 0.005mm, the material consumption is low and use cost is low, and the biodegradable mulching film can be popularized and applied on a large scale.

Owner:常州百利基生物材料科技有限公司

Method for manufacturing anode foil of alternating current motor capacitor

ActiveCN104078240AExcellent dielectric propertiesAvoid serious corrosionElectrolytic capacitorsPhosphoric acidAlternating current

The invention discloses a method for manufacturing anode foil of an alternating current motor capacitor. The method includes the steps of hydration processing, five-stage formation processing, high-temperature heat processing, depolarization processing, repairing formation processing, post-processing and drying processing, and is characterized in that the formation preprocessing step is additionally executed after the hydration processing step, the hydration processing step is that immersion processing is carried out with an ethanediol water solution, and the formation preprocessing step is that the corroded foil obtained after hydration processing is placed into a maleic acid solution for immersing processing. According to the method, hydration processing is carried out in the first stage of the anode oxide film forming working procedure with the ethanediol water solution, and the dielectric property of anode oxide film is improved; the corroded foil obtained after hydration processing is processed with the maleic acid to prevent the foil from being seriously corroded, and the water resisting property of the oxide film is finally achieved; formation is carried out with phosphoric acid and a saline solution of the phosphoric acid in first-stage formation processing and second-stage formation processing, and the specific volume is easily improved; meanwhile, due to the fact that phosphoric acid film is thin, the bending strength of the formed foil can be obviously improved.

Owner:南通南辉电子材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com