High-barrier polyester film and preparation method thereof

A polyester film, high-barrier technology, applied in the coating and other directions, can solve the problems of complex production and processing, low light transmittance and high production cost of high-barrier polyester film, eliminating the need for pre-coating primer process and simplifying production. Process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

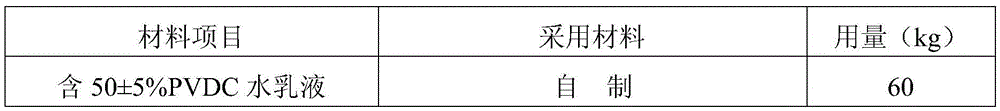

[0038] Preparation of the first part of high barrier resin coating solution

[0039] Basic process: In the container, add 50-80 parts by weight of Solvay Specialty Plastics Co., Ltd. under stirring A063 brand PVDC water emulsion or self-made PVDC water emulsion (high content can be adjusted to contain 50±5% PVDC water emulsion), the stirring speed is 120 rpm. Then take 0.8-1.6 parts by weight of surfactant, 0.1-0.8 parts by weight of leveling agent, 0.1-0.4 parts by weight of defoamer, and 22.4-38.4 parts by weight of distilled water, and add them into the PVDC water emulsion. Stir for 60 minutes, filter and discharge.

Embodiment 1

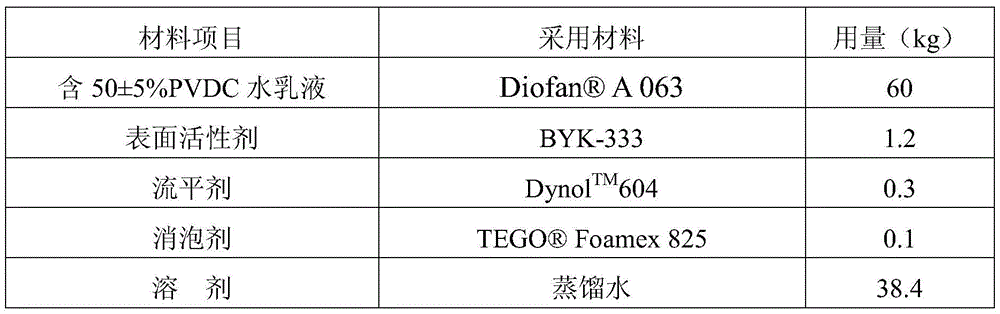

[0041] Formula 3 of the high barrier resin coating solution of the present invention (the viscosity of the 3# high barrier resin coating solution at 25°C is 60mPa·s):

[0042]

[0043]

Embodiment 2

[0045] High barrier resin coating liquid formulation 4 of the present invention (the 4# high barrier resin coating liquid has a viscosity of 63mPa·s at 25°C):

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com