Gold and silver powder adhesive, preparation method thereof, wallpaper and textiles

A gold and silver powder and adhesive technology, which is used in the field of wallpaper and textiles, can solve the problems of poor high temperature resistance, weak orientation ability, unstable performance of printed products, etc., and achieve excellent weather resistance and oxidation resistance, water resistance and The effect of excellent high temperature resistance, excellent brilliance and hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

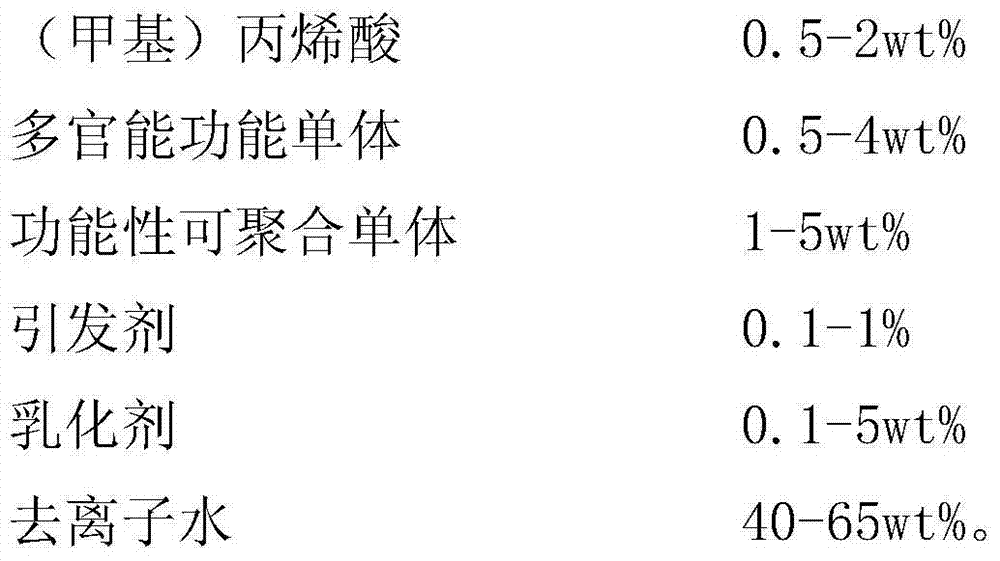

[0091] (1) Formula: ethyl acrylate: 5wt%, butyl acrylate: 15wt%, methyl methacrylate: 8wt%, 2-hydroxyethyl methacrylate: 2wt%, acrylic acid: 0.5wt%, diacetone propylene Amide: 1wt%, acrylamide: 1wt%, multifunctional functional monomer (1,6-hexanediol diacrylate): 0.8wt%, emulsifier (composed of 2-acrylamide-2-methyl-propyl Ammonium sulfonate: 1wt%, allyloxy nonylphenol ether: 0.5wt%, 2-acrylamido-2-methyl-propylsulfonic acid sodium salt: 1wt%, initiator (potassium persulfate ): 0.2wt%, PH value regulator (ammonia): 1.0wt%, antioxidant (acetophenhydrazine): 0.5wt%, buffer (sodium bicarbonate): 0.5wt%, film-forming aid (by twelve Alcohol ester: 0.5wt%, ethylene glycol: 1wt%, water-based defoamer (DC-65, Dow Corning): 0.2wt%, antifreeze agent (benzotriazole): 0.10wt%, water-based antifoam Thickener (PUR62, Germany Mingling Company): 1wt% and the balance of water.

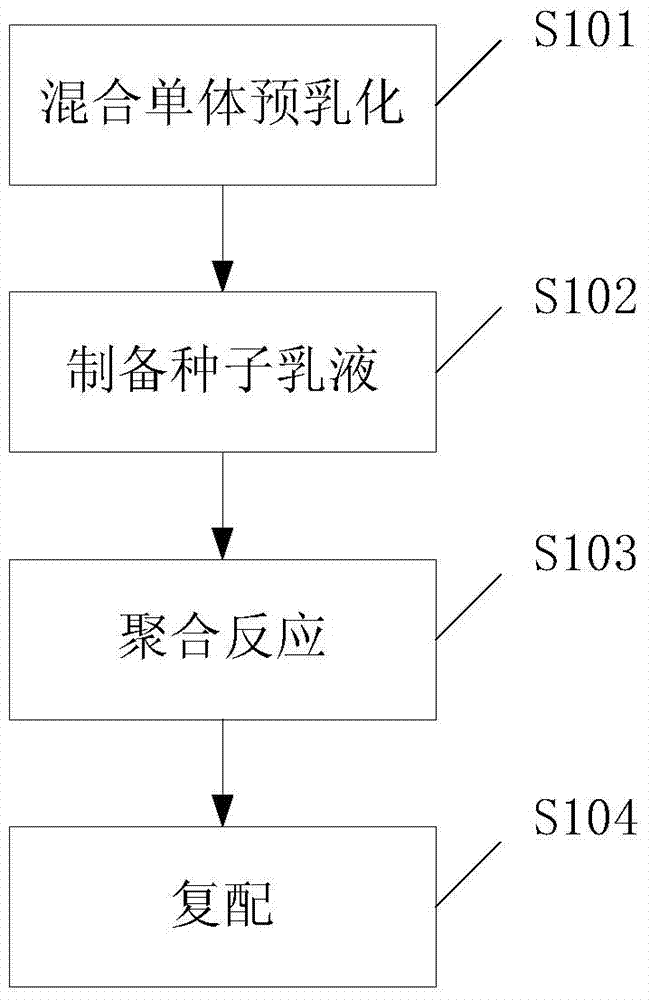

[0092] (2) Preparation method:

[0093] A. Pre-emulsification of mixed monomers: Add 65% of the total amount of e...

Embodiment 2

[0098] (1) Formula: ethyl acrylate: 8wt%, butyl acrylate: 12wt%, methyl methacrylate: 6wt%, butyl methacrylate: 2wt%, 2-hydroxyethyl methacrylate: 2wt%, Acrylic acid: 0.5wt%, diacetone acrylamide: 1wt%, acrylamide: 1wt%, multifunctional functional monomer (1,6-hexanediol diacrylate): 1wt%, emulsifier (composed of 2-acrylic acid amino group -2-Methyl-propylsulfonic acid ammonium salt: 1wt%, allyloxy nonylphenol ether: 0.5wt%, 2-acrylamido-2-methyl-propylsulfonic acid sodium salt: 1wt% composition ), initiator (potassium persulfate): 0.2wt%, pH regulator (ammonia): 1.0wt%, antioxidant (acetylphenylhydrazine): 1wt%, buffer (sodium bicarbonate): 0.5wt%, and Membrane additive (composed of lauryl alcohol ester: 0.5wt%, ethylene glycol: 1wt%), water-based defoamer (DC-65, Dow Corning): 0.2wt%, antifreeze (benzotriazole) : 0.10wt%, water-based thickener (PUR62, Germany Mingling Company): 1wt% and the rest of water.

[0099] (2) Preparation method:

[0100] A. Pre-emulsification of ...

Embodiment 3

[0105] (1) Formula: ethyl acrylate 8wt%, butyl acrylate 12wt%, methyl methacrylate: 6wt%, butyl methacrylate: 2wt%, 2-hydroxyethyl methacrylate: 5wt%, acrylic acid: 0.5wt%, diacetone acrylamide: 1wt%, acrylamide: 1wt%, multifunctional functional monomer (1,6-hexanediol diacrylate): 1wt%, emulsifier (composed of 2-acrylic acid amino-2 -Methyl-propylsulfonate ammonium salt: 1wt%, allyloxynonylphenol ether: 0.5wt%, 2-acrylamido-2-methyl-propylsulfonate sodium salt: 1wt%), Initiator (potassium persulfate) 0.2wt%, PH regulator (ammonia): 1.0wt%, antioxidant (acetophenhydrazine): 1wt%, buffer (sodium bicarbonate): 0.5wt%, film-forming aid (composed of lauryl alcohol ester: 0.5wt%, ethylene glycol: 1wt%), water-based defoamer (DC-65, Dow Corning): 0.2wt%, antifreeze agent (benzotriazole): 0.10wt %, water-based thickener (PUR62, Germany Mingling Company): 1wt% and the balance of water.

[0106] (2) Preparation method:

[0107] A. Pre-emulsification of mixed monomers: Add 65% of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com