Rubber and polytetrafluoroethylene bonding method

A technology of polytetrafluoroethylene and polytetrafluoroethylene film, which is applied in the bonding field of rubber and polytetrafluoroethylene, can solve the problems of affecting the service life of the product, the combination is not tight enough, and is easy to be corroded, so as to increase the service life, Good bonding effect, not easy to detach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

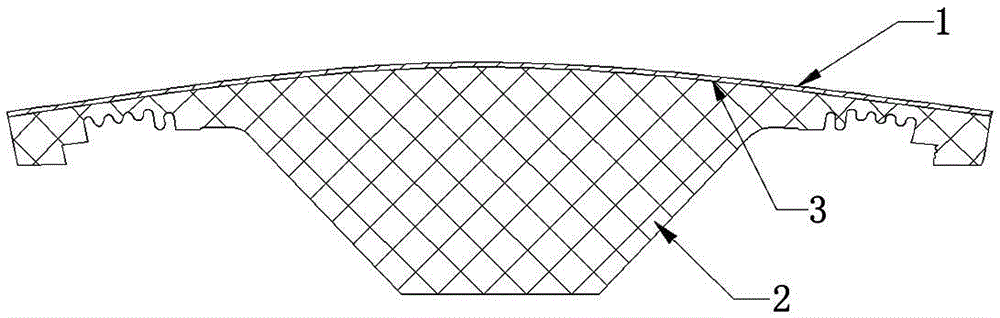

Image

Examples

Embodiment Construction

[0014] The present invention is a kind of bonding method of rubber and polytetrafluoroethylene, comprises the following steps:

[0015] 1) Treat the surface of one side of the turned PTFE membrane in sodium naphthalene treatment solution to eliminate free ions on the surface of the PTFE membrane and increase the surface roughness, so that the PTFE and rubber can fully glued together;

[0016] 2) Mix the Chemlock 205 primer with toluene or xylene at a weight ratio of 1:1 to dilute the Chemlok 205 primer, and then coat the side surface of the polytetrafluoroethylene film that has been treated with sodium sodium treatment solution. Apply the diluted Chemlock 205 primer, and dry it in a constant temperature oven at 60°C for 30 minutes after the coating is completed;

[0017] 3) Mix Chemrock 252X topcoat with toluene or xylene at a weight ratio of 1:1 to dilute the Chemlok 252X topcoat, and coat the diluted Chemlok 205 base coat after drying Locke 252X topcoat, after coating, dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com