Acrylic emulsion for PVC (Polyvinyl Chloride) water-based ink and preparation method of acrylic emulsion

A technology of acrylic emulsion and water-based ink, applied in the field of emulsion, can solve the problems of health damage of printing operators and substrate contact personnel, and achieve the effects of good transparency, improved printing gloss, and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

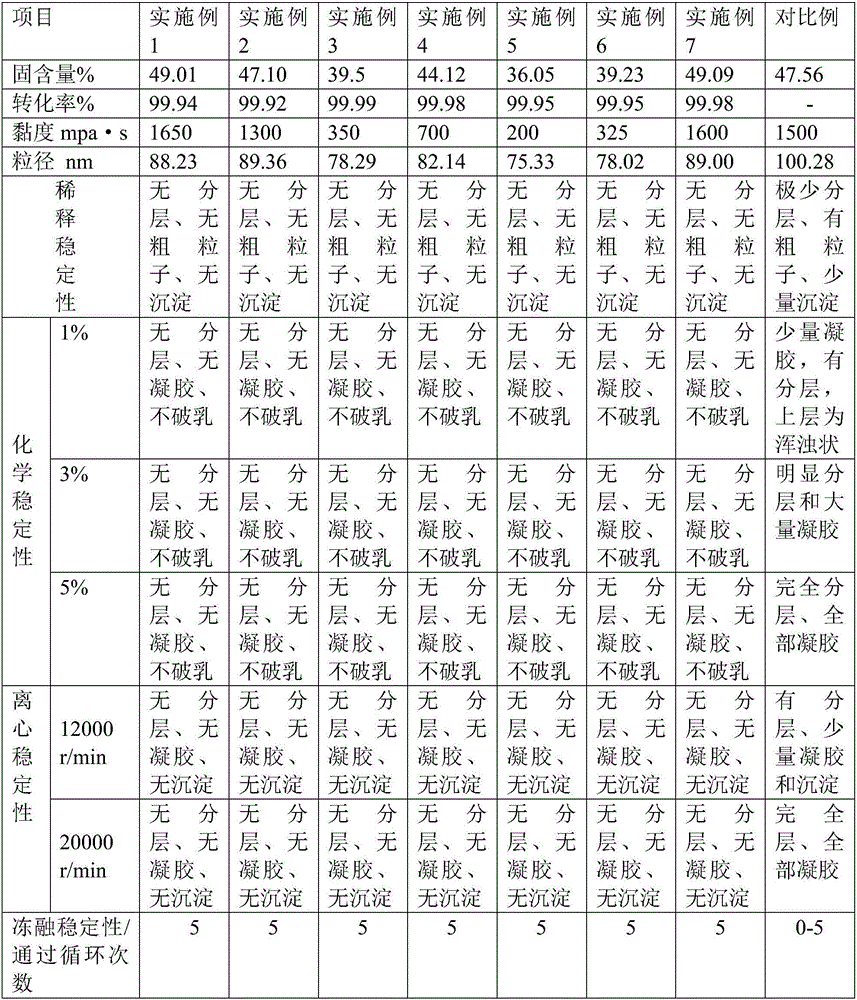

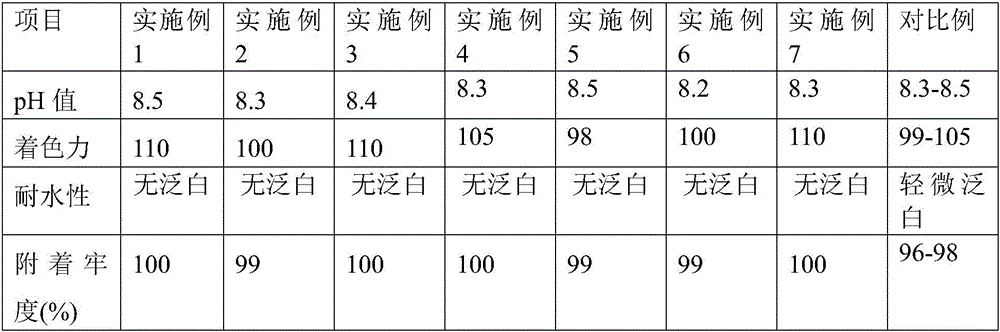

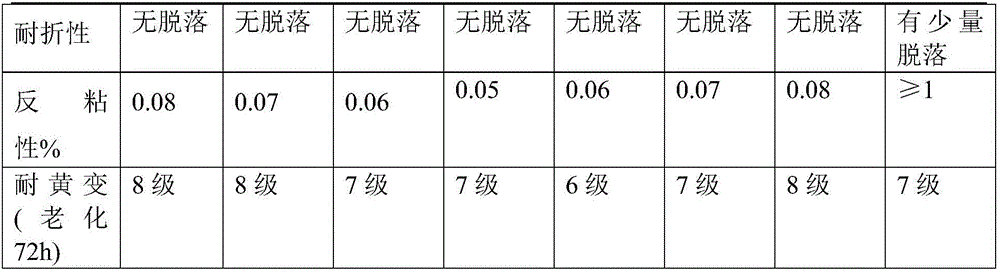

Examples

Embodiment 1

[0039] An acrylic emulsion for PVC water-based ink, comprising the following components by weight percentage, core structure monomer: 1% methyl methacrylate, 0.2% ethyl acrylate, 0.2% acrylamide, 0.2% silane coupling agent %; shell structure monomer: methyl methacrylate 11%, butyl acrylate 20%, ethyl acrylate 5%, methacrylic acid 1%, acrylic acid 1%, caprolactam 0.4%; anionic emulsifier 7.7%, reactive 0.3% emulsifier, 1.5% non-ionic emulsifier, 0.5% ammonium persulfate, 0.8% 30% ammonia water, 0.2% bactericide, 49% deionized water.

[0040] Above-mentioned emulsion can be prepared by traditional technique, and more optimal selection is to select the preparation method of the present invention for use, comprises the following steps:

[0041] (1) Preparation of core layer pre-emulsion: add 2% deionized water, 2% anionic emulsifier, methyl methacrylate, ethyl acrylate, acrylamide, silane coupling agent successively in the pre-emulsification kettle I, Thoroughly stir for 1 hour t...

Embodiment 2

[0054] An acrylic emulsion for PVC water-based ink, comprising the following components by weight percentage, core structure monomer: 0.5% methyl methacrylate, 0.5% ethyl acrylate, 0.5% acrylamide, 0.5% silane coupling agent %; shell structure monomer: methyl methacrylate 15%, butyl acrylate 15%, ethyl acrylate 4%, methacrylic acid 0.5%, acrylic acid 0.5%, caprolactam 5%; anionic emulsifier 2%, reactive type 0.4% emulsifier, 1.5% non-ionic emulsifier, 1.5% ammonium persulfate, 0.5% 30% ammonia water, 0.1% bactericide, 52% deionized water.

[0055] Above-mentioned emulsion can be prepared by traditional technique, and more optimal selection is to select the preparation method of the present invention for use, comprises the following steps:

[0056] (1) Preparation of the core layer pre-emulsion: add 5% deionized water, 0.5% anionic emulsifier, methyl methacrylate, ethyl acrylate, acrylamide, silane coupling agent successively in the pre-emulsification kettle I, Fully stir for ...

Embodiment 3

[0069] An acrylic emulsion for PVC water-based ink, comprising the following components by weight percentage, core structure monomer: 0.4% methyl methacrylate, 0.6% ethyl acrylate, 0.6% acrylamide, 0.4% silane coupling agent %; shell structure monomer: methyl methacrylate 13.2%, butyl acrylate 16.7%, caprolactam 0.1%; anionic emulsifier 3%, reactive emulsifier 0.2%, nonionic emulsifier 1%, ammonium persulfate 2%, 30% ammonia water 1%, fungicide 0.3%, deionized water 60.5%.

[0070] Above-mentioned emulsion can be prepared by traditional technique, and more optimal selection is to select the preparation method of the present invention for use, comprises the following steps:

[0071] (1) Preparation of the core layer pre-emulsion: add 4% deionized water, 0.7% anionic emulsifier, methyl methacrylate, ethyl acrylate, acrylamide, silane coupling agent successively in the pre-emulsification kettle I, Fully stir for 1.2h to obtain the core layer pre-emulsion;

[0072] (2) Preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com