Surface pretreatment agent before metal coating and preparation method and use method thereof

A pretreatment agent, front surface technology, applied in the direction of metal material coating process, etc., can solve the problems of poor corrosion resistance, difficult film formation of fluorine compounds, difficult to replace phosphating agents, etc., to achieve simple and convenient operation and improve compactness. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

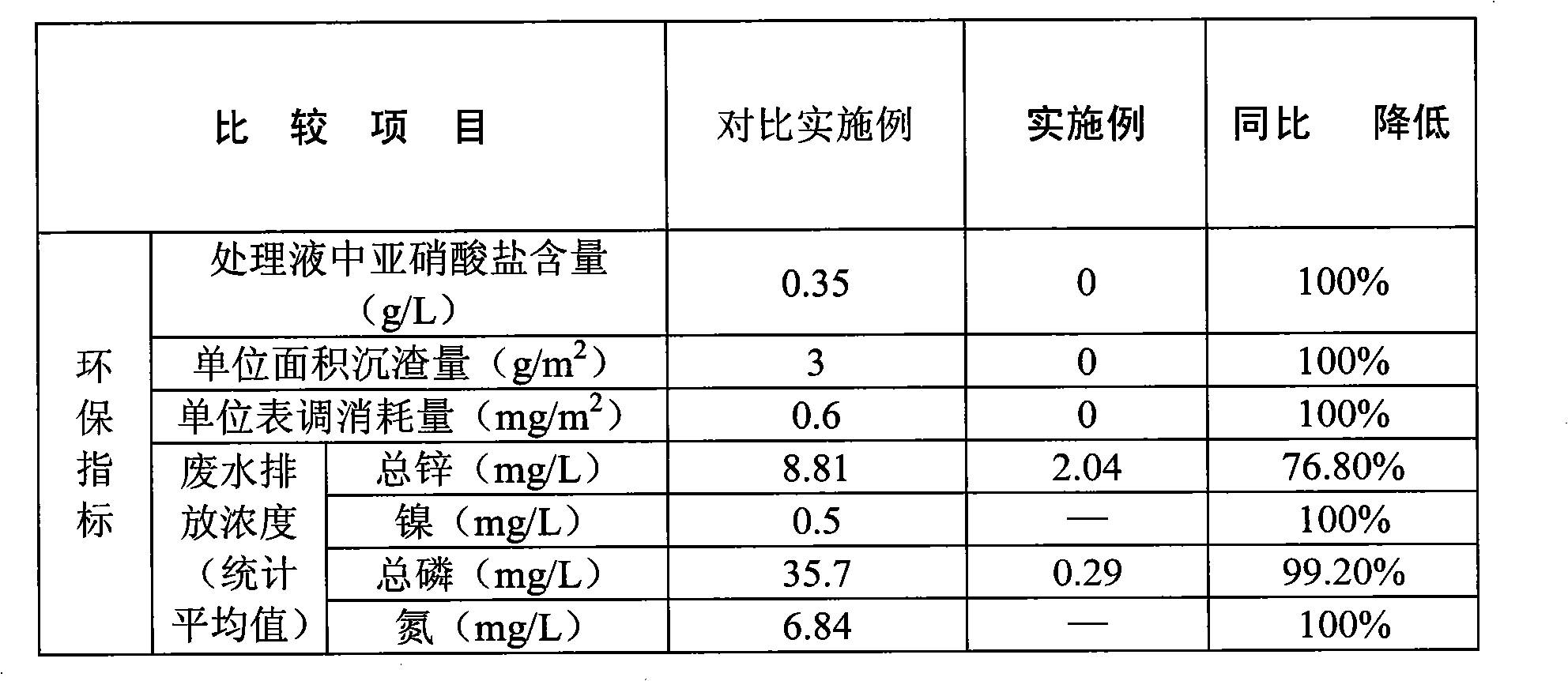

Examples

Embodiment 1

[0043] A surface pretreatment agent before metal painting:

[0044] Nanoscale SiO 2 1.5kg;

[0045] Water-soluble silane coupling agent: 1.6kg;

[0046] h 2 TiF 6 : 1.8kg;

[0047] Water: 8.5kg.

[0048] Nanoscale SiO 2 Fully wet with water, add water-soluble silane coupling agent, stir and disperse to obtain colloid, add H 2 TiF 6 , then add the rest of the water and mix well; slowly add 0.1M H 2 SO 4 Stir evenly, adjust the pH value of the treatment agent to 2.0 to prepare the surface treatment agent before metal coating.

[0049] First add clear water to the coating tank, then add the surface treatment agent before metal coating prepared above, stir for 30-45 minutes, measure the concentration and adjust the pH value to 4.5.

[0050] Take the spare GB / T1727 standard 5×10cm that has been degreased 2 5 pieces of cold-rolled steel plates were immersed in the coating tank for 30 seconds, taken out and cleaned 3 times, washed 3 times with circulating ...

Embodiment 2

[0052] A surface pretreatment agent before metal painting:

[0053] Nanoscale TiO 2 1.9kg;

[0054] Water-soluble silane coupling agent 1.8kg;

[0055] h 2 SiF 6 1.5kg;

[0056] h 2 ZrF 6 0.8kg;

[0057] 9kg of water.

[0058] The preparation method is the same as in Example 1; add 0.9kg of antiscalant polyacrylic acid to the prepared product, stir well, and slowly add 0.1M H 2 SO 4 Stir evenly, adjust the pH value of the treatment agent to 3 to prepare the surface treatment agent before metal coating.

[0059] First add clear water to the coating tank, then add the product prepared above and stir for 30-45 minutes, measure the concentration and adjust the pH value to 5.

[0060] Take the spare GB / T1727 standard 5×10cm that has been degreased 2 5 pieces of cold-rolled steel plates, evenly spray the treatment agent with a pH value of 5 on the cold-rolled steel plates, let it stand for 60 seconds, wa...

Embodiment 3

[0062] A surface pretreatment agent before metal painting:

[0063] Nanoscale SiO 2 1.1kg;

[0064] Nanoscale ZrO 2 0.9kg;

[0065] Aluminum zirconium crosslinking agent (coupling agent) 1.9kg;

[0066] h 2 Hf 6 2.1kg;

[0067] 8.8kg of water.

[0068] The preparation method is the same as in Example 1; add 0.5kg of scale inhibitor maleic acid-acrylic acid copolymer to the prepared product, stir evenly, and slowly add 0.1M H 2 SO 4 Stir evenly, adjust the pH value of the treatment agent to 2.5 to prepare the surface treatment agent before metal coating.

[0069] First add clear water to the coating tank, then add the product prepared above, stir for 30-45 minutes, measure the concentration and adjust the pH value to 6.

[0070] Take the spare 5×10cm that has been degreased 2 5 pieces of galvanized sheets were immersed in the treatment agent coating tank with a pH value of 6 for 90 seconds, taken out and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com