Patents

Literature

67results about How to "Thin film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength polyethylene film

InactiveUS6248831B1Close tolerance in film thicknessGood high speed extrusion bubble stabilitySolubilityAlpha-olefin

A process for production of a polyethylene blend in situ comprising contacting ethylene and at least one alpha-olefin with a magnesium / titanium based catalyst system including a partially activated precursor and a cocatalyst in each of two fluidized bed reactors connected in series, one of the provisos being that the precursor is formed by contacting an alkylaluminum halide with a solid reaction product prepared from a magnesium alkoxide, a titanium tetraalkoxide, and a solubility enhancing agent.

Owner:UNION CARBIDE CORP

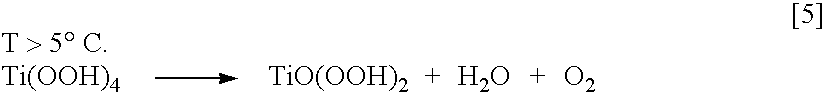

Metal peroxide films

ActiveUS20050234178A1Efficient use ofImprove wettabilityNanotechZirconium compoundsParticulatesNanoparticle

Disclosed are adhesive coating compositions containing a metal peroxide for producing clear colorless adhesive coatings on substrates, particularly micro particulate substrates. In one preferred embodiment the nanoparticle coatings are chemically active and function at a high level of efficiency due to the high total surface area of the micro particulate substrate. Also disclosed are coated substrates and compositions having nanoparticles bound to a substrate by the coating compositions.

Owner:PURETI

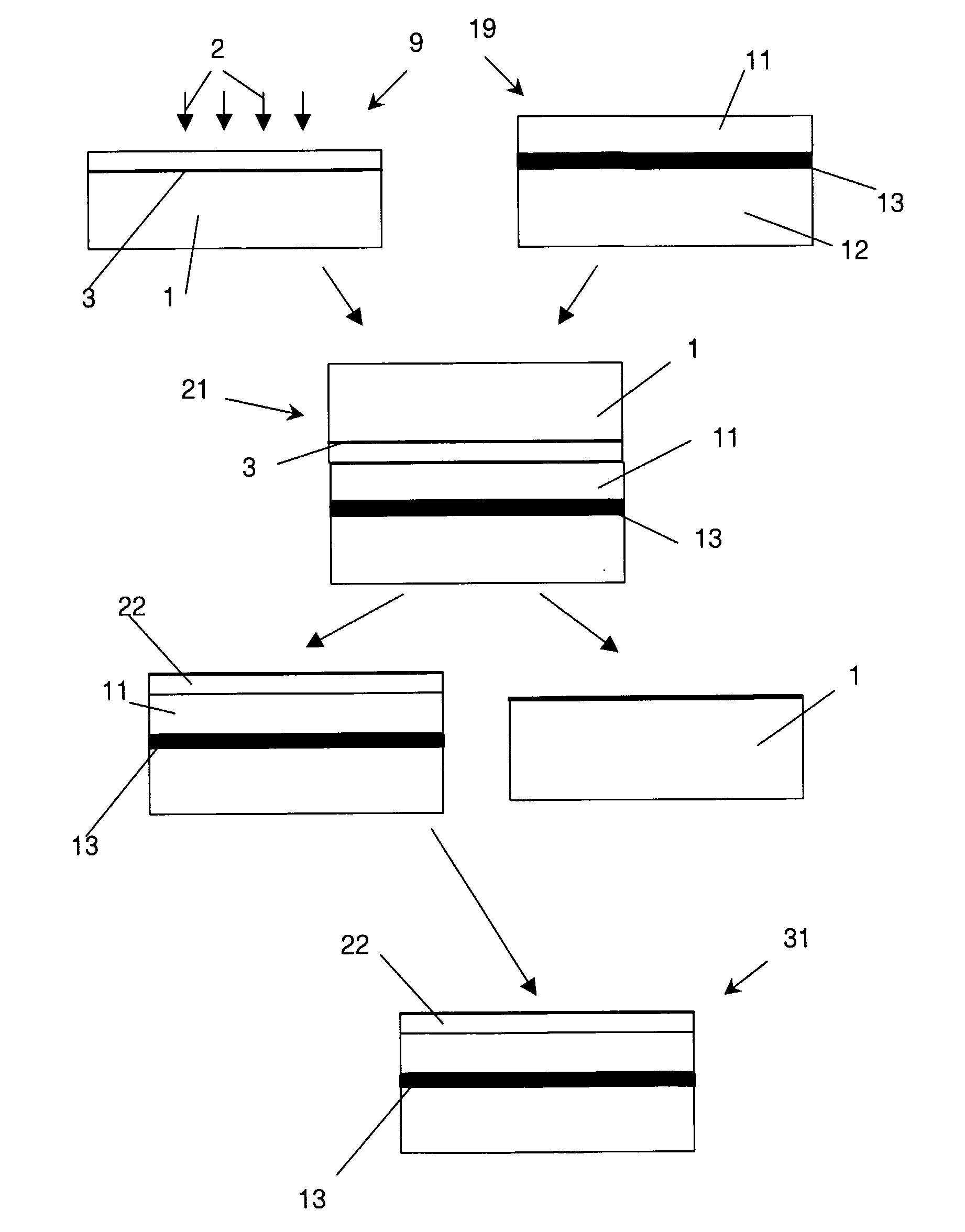

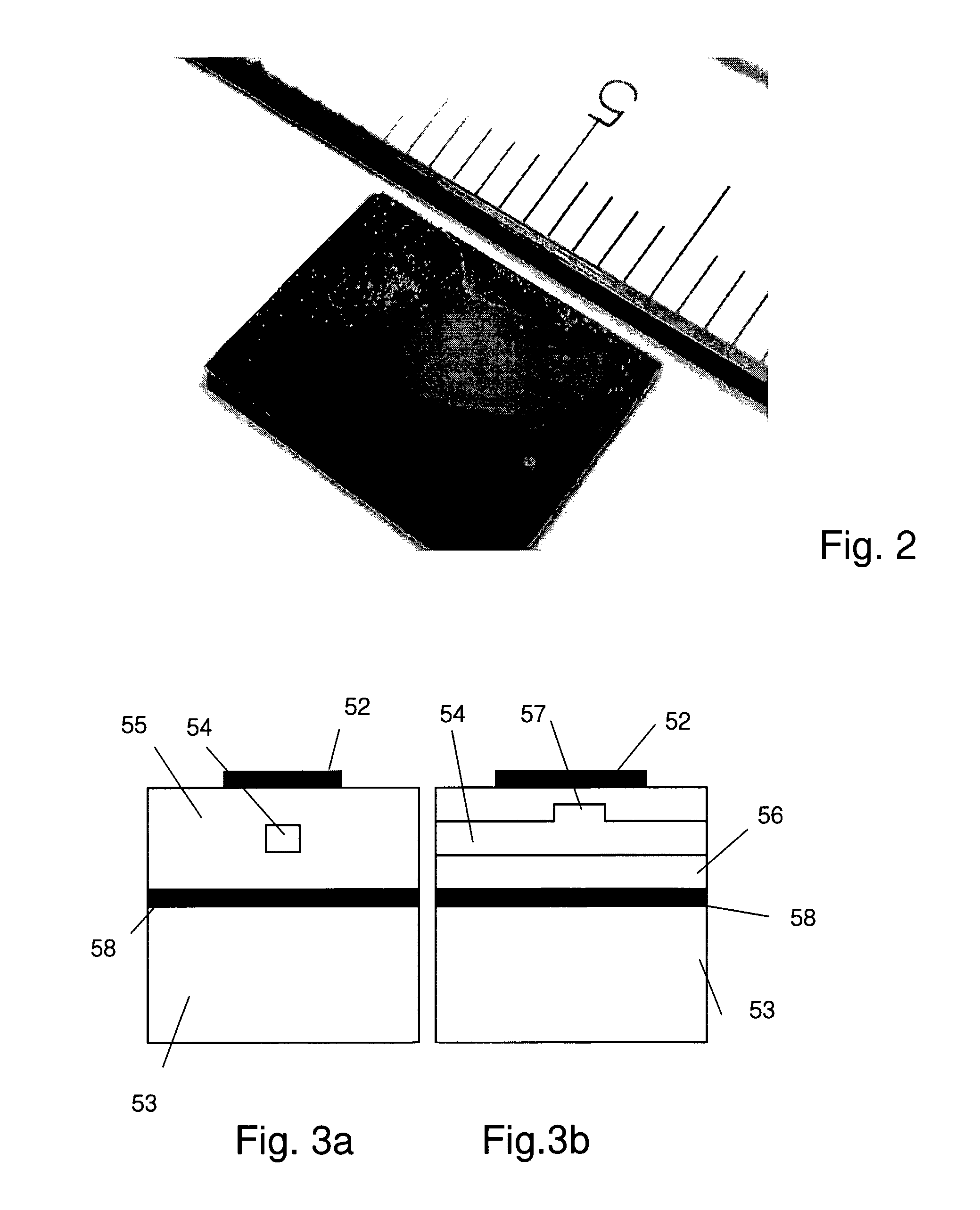

Ferroelectric Thin Films and Devices Comprising Thin Ferroelectric Films

InactiveUS20080165565A1Small sizeAddress rising pricesThermoelectric device with dielectric constant thermal changePiezoelectric/electrostrictive device manufacture/assemblyMicrometerFerroelectric thin films

A method of producing a device with a ferroelectric crystal thin film on a first substrate including the steps of providing a ferroelectric crystal, of irradiating a first surface of the ferroelectric crystal with ions so that a damaged layer is created underneath the first surface, of bonding a block of material including the first substrate to the ferroelectric crystal to create a bonded element, wherein an interface is formed between the first surface and a second surface of the block, and of heating the bonded element and separating it at the damaged layer, so that a ferroelectric crystal layer remains supported by the first substrate. By this method, very thin films—down to thicknesses of a fraction of a micrometer—of ferroelectric crystals may be fabricated without jeopardizing the monocrystalline structure.

Owner:ETH ZZURICH

Metal peroxide films

ActiveUS7205049B2Improve wettabilityEfficient use ofNanotechZirconium compoundsParticulatesNanoparticle

Disclosed are adhesive coating compositions containing a metal peroxide for producing clear colorless adhesive coatings on substrates, particularly micro particulate substrates. In one preferred embodiment the nanoparticle coatings are chemically active and function at a high level of efficiency due to the high total surface area of the micro particulate substrate. Also disclosed are coated substrates and compositions having nanoparticles bound to a substrate by the coating compositions.

Owner:PURETI

Chemical Resistant Ionomers and Protective Coverings

ActiveUS20110143620A1Low rateImprove moisture vapor transmission rateIon-exchanger regenerationSynthetic resin layered productsPolyesterPolymer science

This invention relates to novel chemical resistant, film forming, and moisture vapor permeable ionomers, including specialized polyurethane ionomers, polyurea ionomers, polyamide ionomers, polyester ionomers, or a mixture of the said ionomers, having high content of covalent-bonded ionic groups, total >100 milli-equivalents per 100 gram of ionomers. These specialized ionomers have low noxious chemical crossover rate, high moisture vapor transmission rate, hydrolytically stable in humid environment, and capable of forming thin films. These novel chemical resistant ionomers can be cationic (selected from tertiary amines and their derivatives or quaternary ammoniums), anionic (selected from aliphatic carboxylic acids and their derivatives or aliphatic sulfonic acids and their derivatives), or zwitterions (selected from ionomers or a mixture of ionomers containing both cations and anions groups), or a mixture of any combination of the above three types, preferably in a form of coating solutions or dispersions suitable for coatings to form thin films or membranes, to protect the coated surface with acceptable barrier properties at any humidity with high moisture vapor permeability. One major application is in the field of protective fabric and protective clothing, gloves, shoes, hats, tents, sleeping bags, and protective skin cream against noxious liquids and gases.

Owner:ZHEJIANG HYPROOF TECH CO LTD

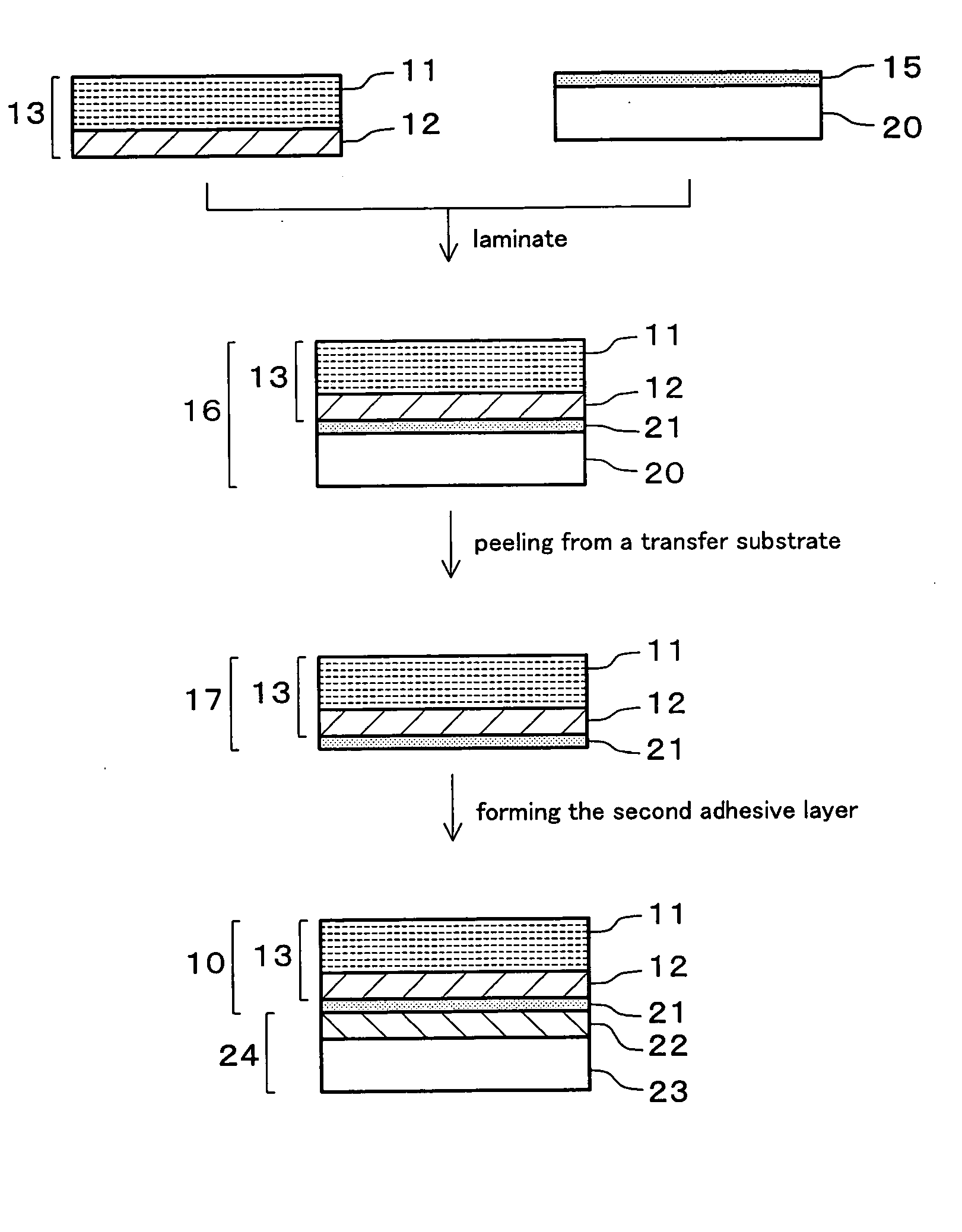

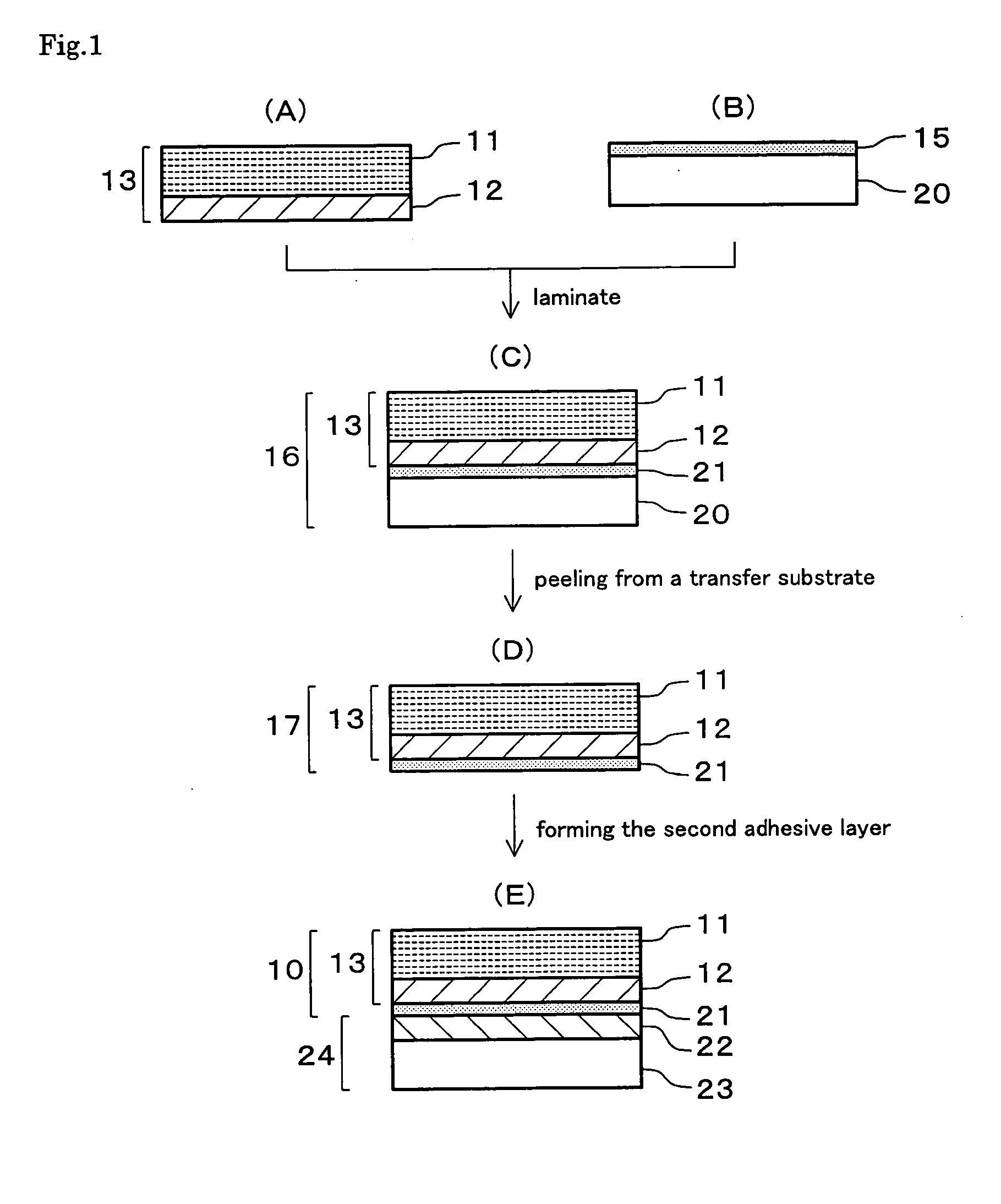

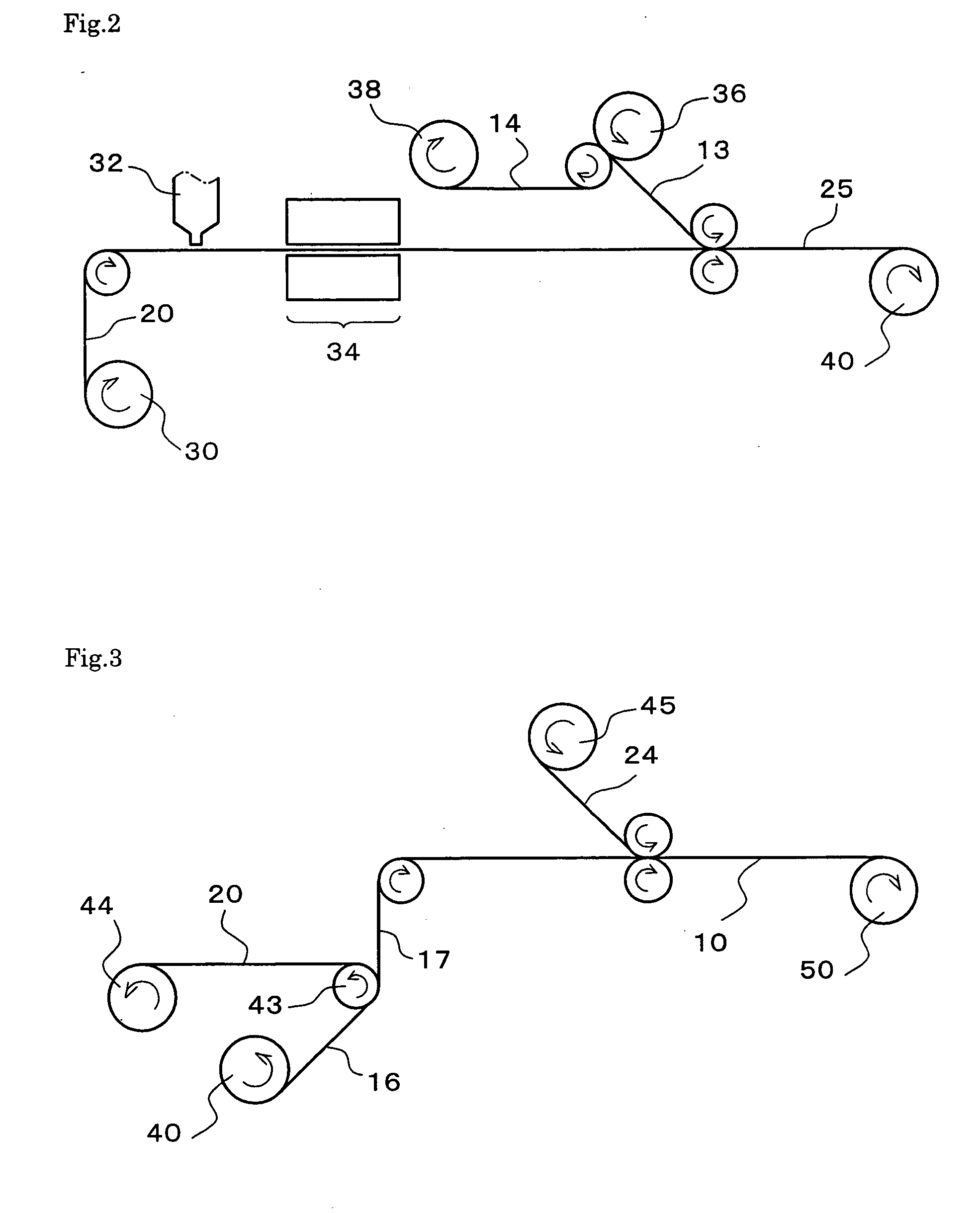

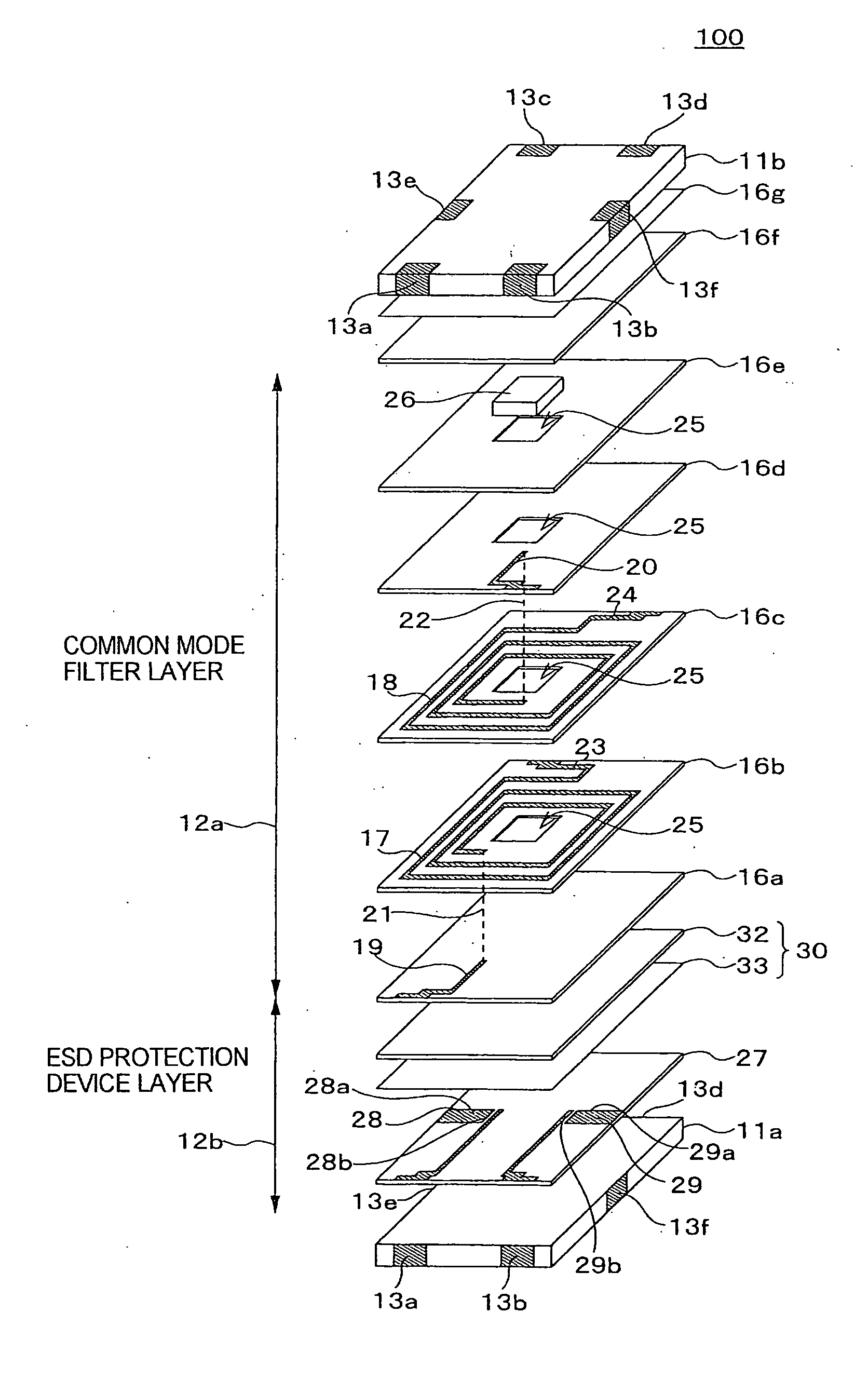

Method for producing a laminate polarizing plate and an optical member using thereof

InactiveUS20050269020A1Simple constitutionImprove viewing angleDecorative surface effectsLaminationCoated surfaceRefractive index

A method for producing a laminate polarizing plate comprising a first phase retarder film and a second phase retarder film, wherein the first phase retarder film comprises an in-plane oriented transparent resin film having an adhesive layer on its surface, the second phase retarder film has at least one coating layer with refractive index anisotropy, and the second phase retarder film is on the adhesive layer is provided. The method comprising: a first step of forming the coating layer on a transfer substrate, followed by laminating an opposite surface of the coating layer to the transfer substrate on the adhesive layer of the first phase retarder film; and a second step of peeling the transfer substrate from the coating layer along with forming a second adhesive layer on the surface of the coating layer from which the transfer substrate has been peeled.

Owner:SUMITOMO CHEM CO LTD

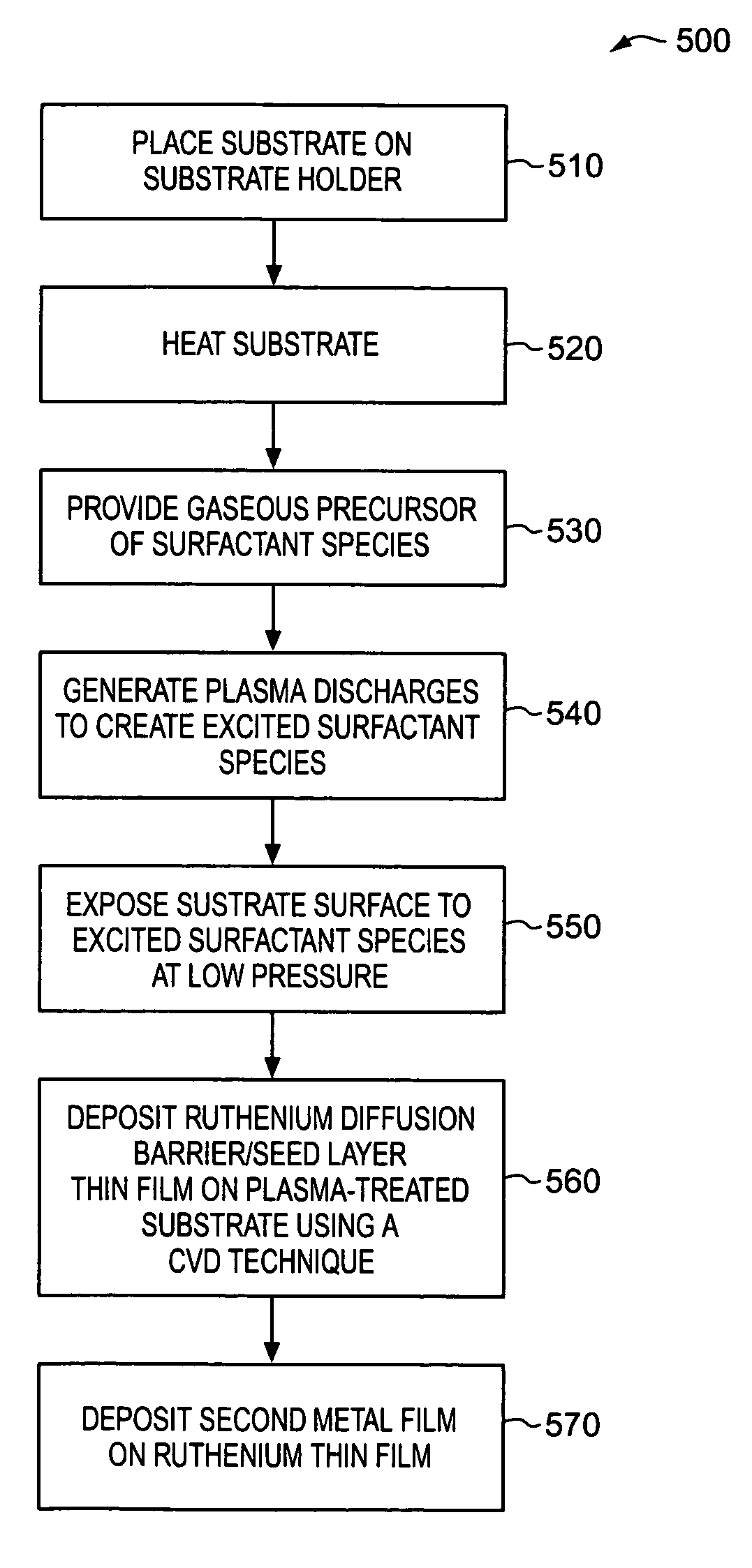

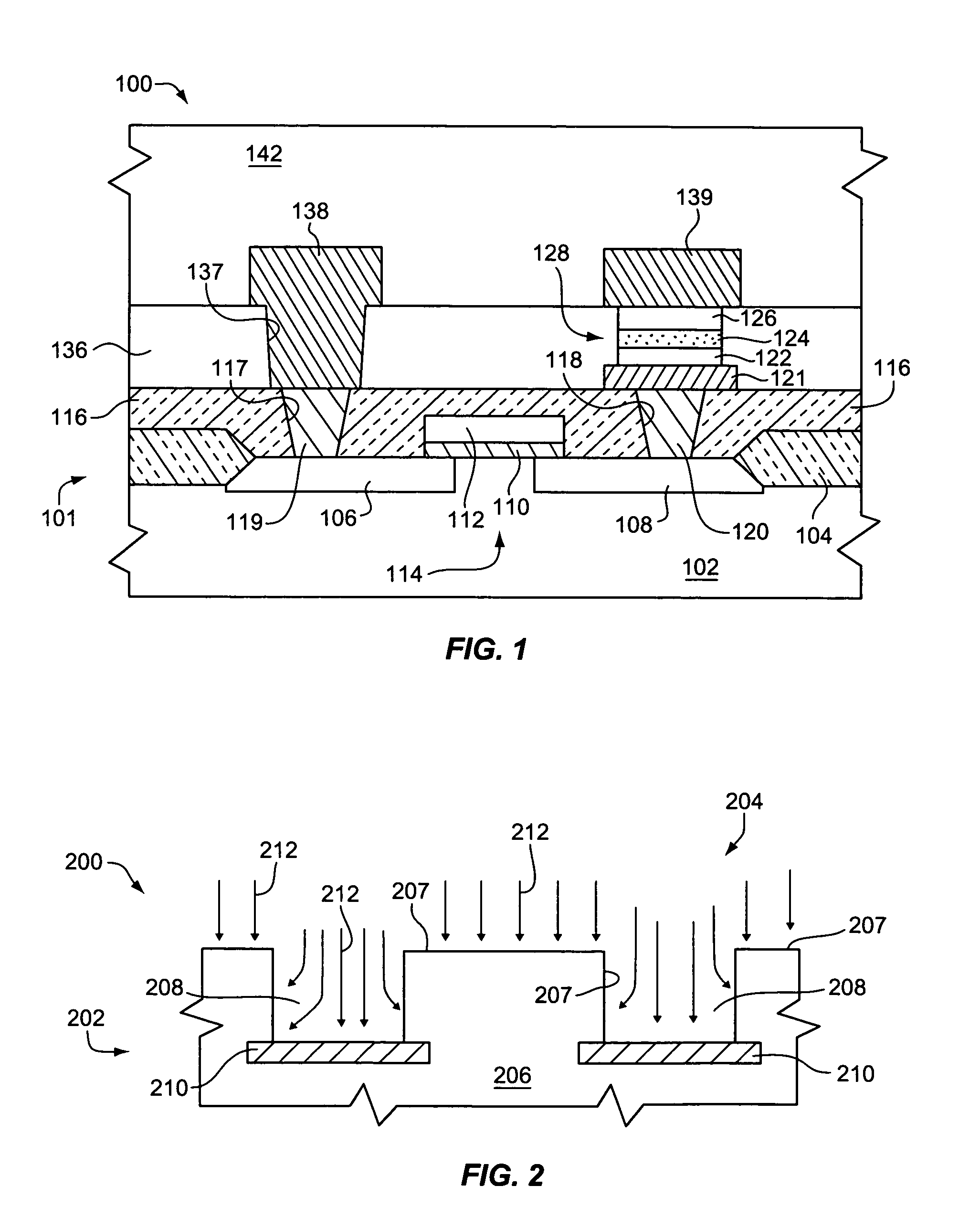

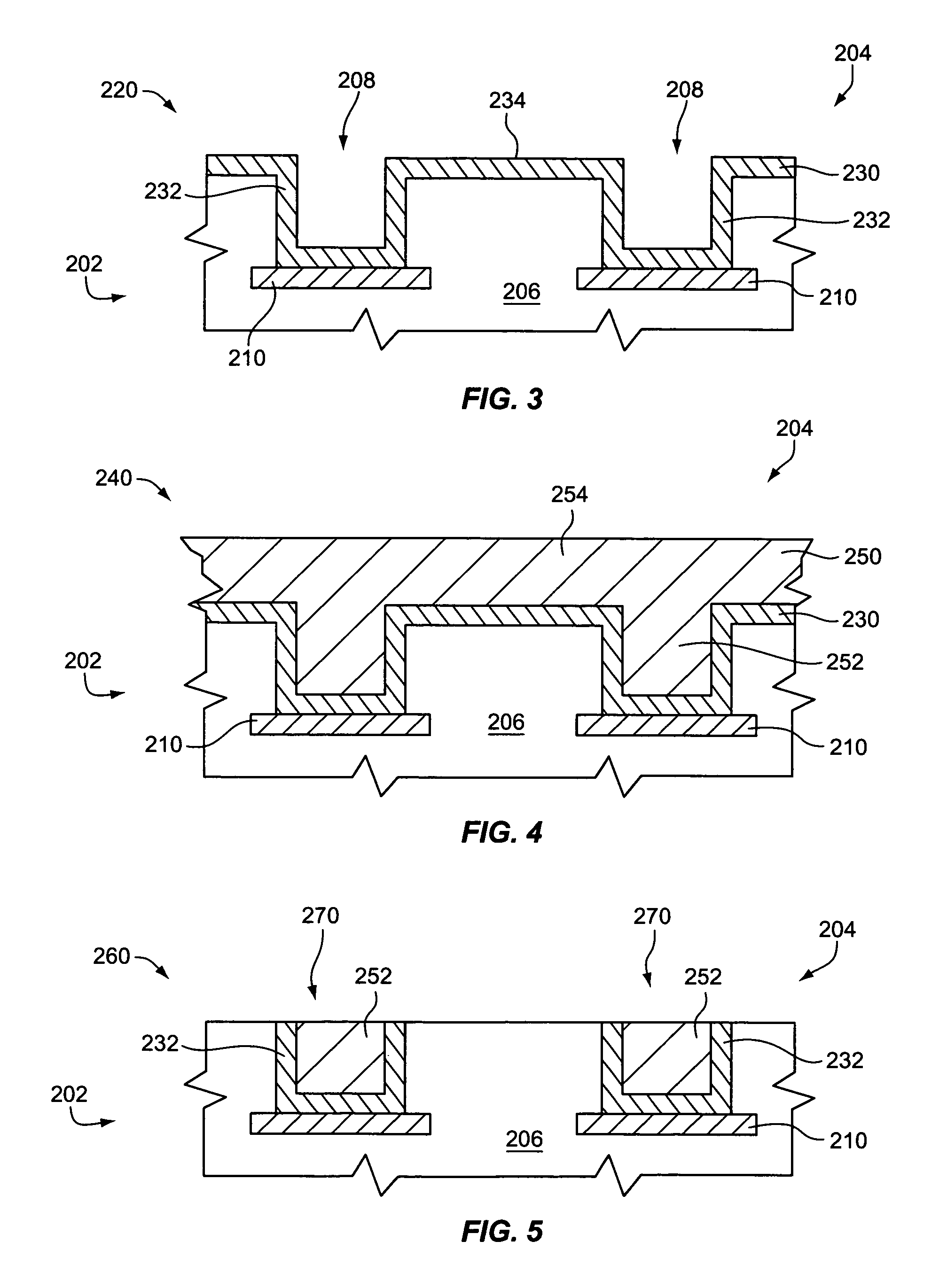

Surface treatment using iodine plasma to improve metal deposition

ActiveUS7041596B1Increase depositionShorten the timePretreated surfacesSemiconductor/solid-state device manufacturingIndiumIodine

An excited surfactant species is created by generating plasma discharge in a surfactant precursor gas. A surfactant species typically includes at least one of iodine, led, thin, gallium, and indium. A surface of an integrated circuit substrate is exposed to the excited surfactant species to form a plasma-treated surface. A ruthenium thin film is deposited on the plasma-treated surface using a CVD technique.

Owner:NOVELLUS SYSTEMS

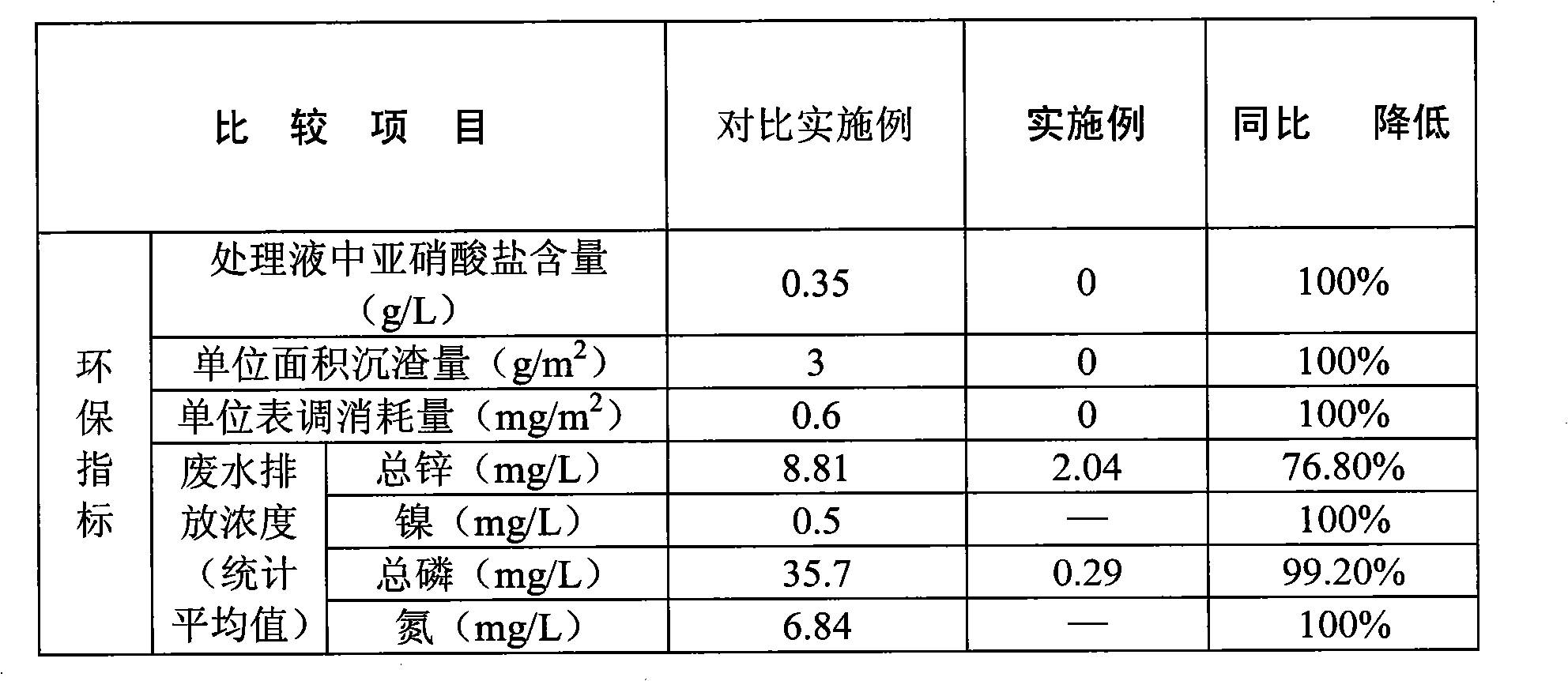

Surface pretreatment agent before metal coating and preparation method and use method thereof

InactiveCN101660153AImprove densification performanceTightly boundMetallic material coating processesWater solubleFilm-forming agent

The invention discloses a surface pretreatment agent before metal coating, consisting of components with the following weight ratio: 15-19 portions of film-forming agents; 15-19 portions of coupling agents; 18-23 portions of water-soluble F-containing complex compounds; and 85-90 portions of water. A method for preparing the surface pretreatment agent before metal coating is as follows: firstly wetting the film-forming agents sufficiently with water; and then adding the coupling agents, the F-containing complex compounds or the salts thereof, and the balance of water to be evenly mixed; the method for using the surface pretreatment agent before metal coating comprises the following steps of: firstly using water to dilute the surface pretreatment agent before metal coating until the pH value thereof is 4.5-6; spraying or infiltrating the surface of the treated metal with the treatment time of 30s-90s; and by adopting the technical scheme, the film can be tightly combined with the coating on the metal surface, forms a middle layer with very strong combination force between the metal and the coating, has very good combination force both with the metal surface and the coating, and cancompletely replace the phosphating agent.

Owner:安徽天航机电有限公司

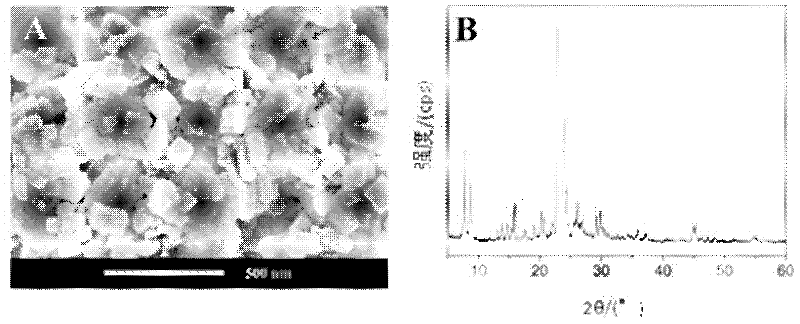

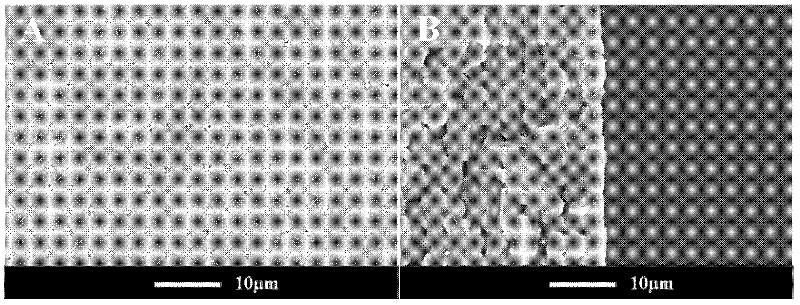

A kind of preparation method of acetic acid dehydration ZSM-5 zeolite membrane

ActiveCN102285668AThin filmContinuous and uniform film layerPentasil aluminosilicate zeoliteOrganic acidChemistry

The invention discloses a method for synthesizing zeolite socony mobil-5 (ZSM-5) zeolite membrane by dehydration by acetic acid, which comprises: directly introducing an ultrathin crystal seed layer onto a macroporous carrier by a two-step crystal process, regulating the Si to Al ratio of a crystallization mother solution by using F<-> as an inorganic structural guiding agent, and preparing a 5 to 6 micrometer thick ZSM-5 zeolite membrane, particularly a ZSM-5 zeolite membrane in which the Si to Al ratio is 10, by using a secondary growth process; therefore, the limit that the membrane can only be formed under a condition that the Si to Al ratio of the crystallization mother solution is more than 20 if an organic template agent is not used is break through, the hydrophilic property of themembrane is improved greatly, and the generation of microstructures which are not acid resistant with aluminum enriched surface and inter-crystal gap is avoided effectively. The membrane thus has high acetic acid dehydration and separation selectively and high acid resistance, the low-flux, low-selectivity and low-acid-resistance technical bottlenecks that zeolite membrane organic acid dehydration faces are broken through, and a firm foundation is laid for the industrial use of the zeolite membrane.

Owner:DALIAN UNIV OF TECH

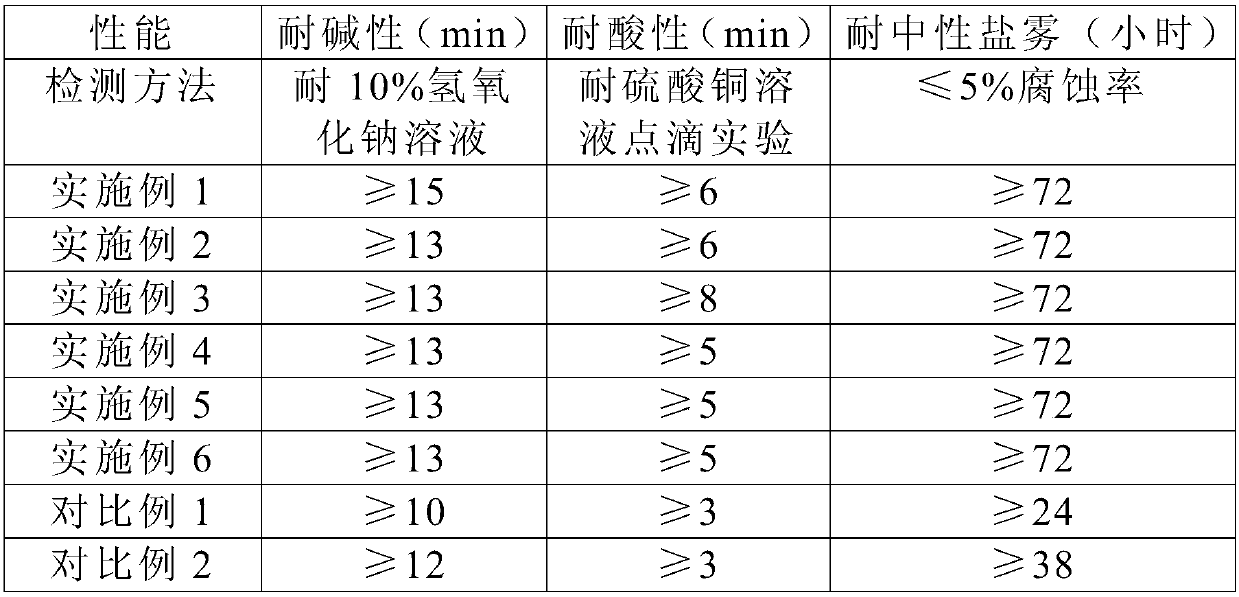

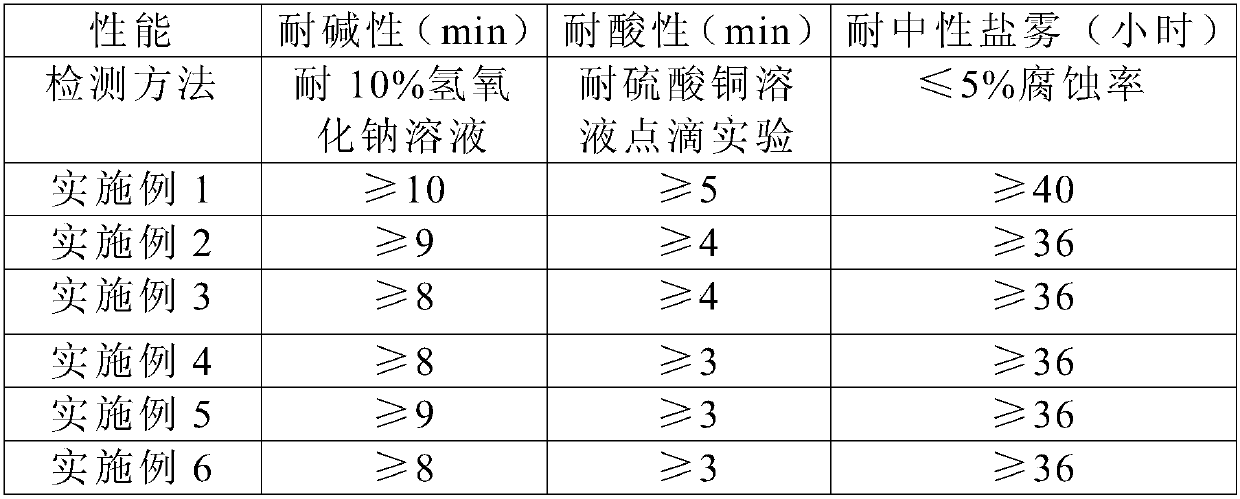

Corrosion-resistant neutral chrome-free coating agent and preparation method thereof

InactiveCN107761088AHigh hardnessIncrease salt spray timeMetallic material coating processesSilanesColor changes

The invention belongs to the technical field of chemicals, and relates to a metal surface treatment technology, in particular to a corrosion-resistant neutral chrome-free coating agent and a preparation method thereof. The corrosion-resistant neutral chrome-free coating agent comprises the following components of, by weight, 2-10 parts of water soluble resin, 2-10 parts of micromolecule solvents,10-30 parts of nano oxide sol, 0-5 parts of film-forming auxiliary agents, 1-10 silane coupling agents, 0-5 parts of pH conditioning agents and 50-70 parts of water. The corrosion-resistant neutral chrome-free coating agent is convenient to apply, and is directly in contact with aluminum, magnesium and an aluminum-magnesium alloy plate at ordinary temperature, so that the magnesium-aluminum alloyplate which is high in corrosion resistance, acid resistance and alkali resistance and reaches the hardness requirement can be produced. Aluminum and magnesium alloys using the corrosion-resistant neutral chrome-free coating agent have no color change in the surfaces, and a self-colored passive film can be obtained; and a film layer is thin, and the corrosion-resistant neutral chrome-free coatingagent has little impedance to a metal base and has no corrosion and the subsequent serviceability of the metal base is not affected.

Owner:广东锴力环保新材料有限公司

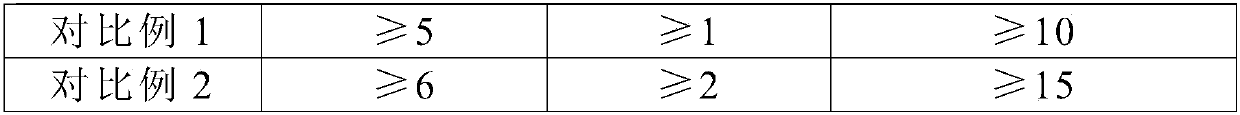

Resin wave absorption paint and preparation method thereof

ActiveCN106977986AGood solution to the dispersion problemSolve the problem of fragmentationRadiation-absorbing paintsEpoxy resin coatingsHigh intensitySolvent

The invention provides resin wave absorption paint, which is prepared from resin, graphene and ferroferric oxide compounded material, dispersing agents, anti-settling agents and solvents. The paint is characterized in that the addition mode of graphene materials in the resin wave absorption paint is creatively changed; firstly, the graphene is compounded with a hard material of ferroferric oxide in the paint to obtain the graphene and ferroferric oxide compounded material; then, the graphene and ferroferric oxide compounding material is combined with the other ingredients to obtain the resin wave absorption paint. The graphene dispersing problem can be better solved; the complete realization of the excellent performance is ensured; the problem of mixing nonuniformity of flexible graphene materials in a paint system is solved; in addition, the uniform dispersion of ferroferric oxide nanometer particles on the surface of the graphene can be realized; the performance is better achieved; more importantly, the specific ingredients are matched to be used, so that the prepared resin wave absorption paint has the advantages of thin film layer, high intensity, strong wave absorption capability, wide wave absorption frequency band and low cost; wide application prospects are realized.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

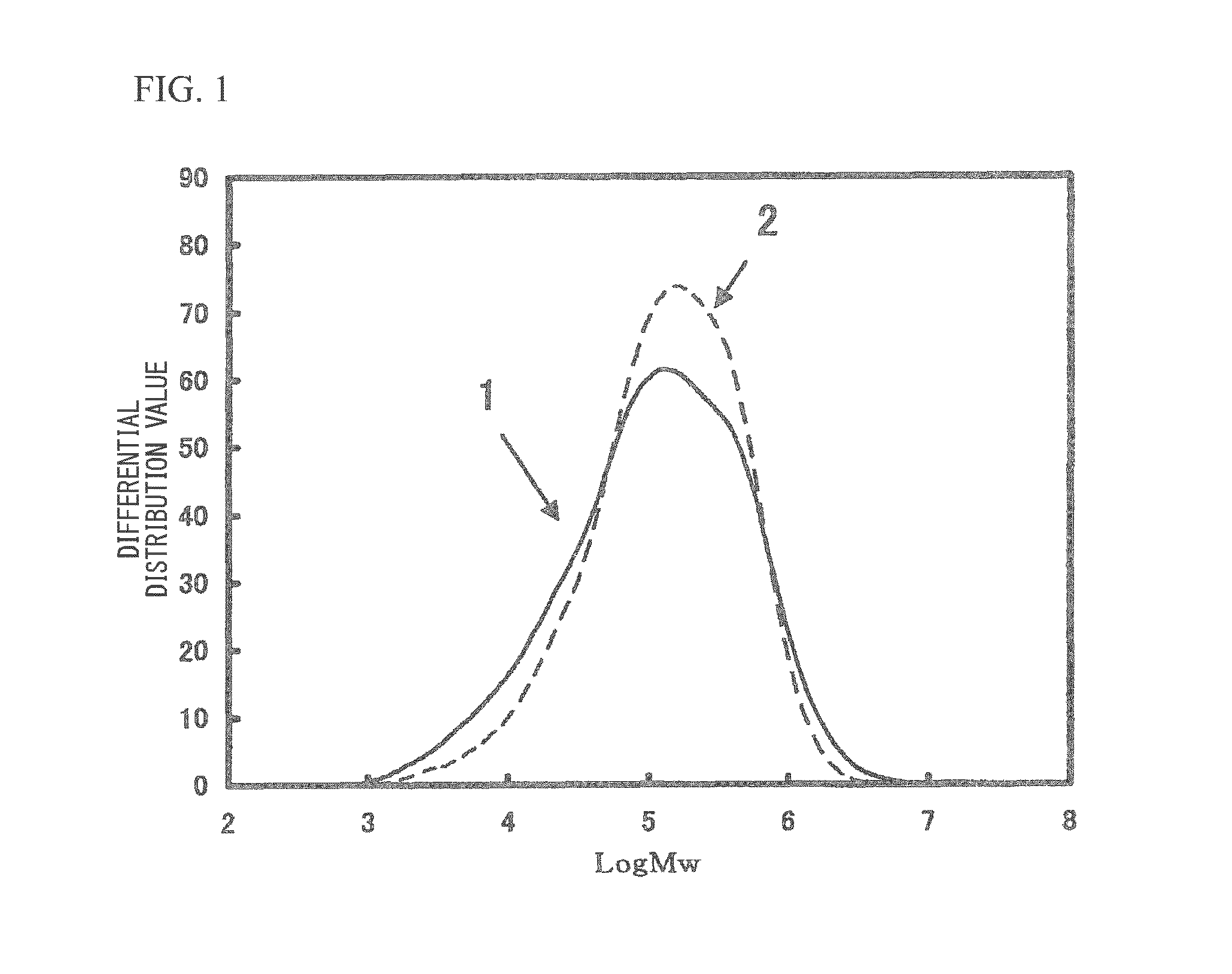

Biaxially stretched polypropylene film for capacitors

ActiveUS20150140266A1High breakdown strengthImprove toleranceFixed capacitor dielectricSynthetic resin layered productsPolymer scienceHeat resistance

A biaxially stretched polypropylene film for a capacitor containing an isotactic polypropylene. The weight average molecular weight (Mw) of the isotactic polypropylene as measured by gel permeation chromatography (GPC) is 250,000 to 450,000, the molecular weight distribution Mw / Mn is 7 to 12 and Mz / Mn is 20 to 40, and the value of a difference obtained by subtracting a differential distribution value when the logarithmic molecular weight Log(M)=6 from a differential distribution value when Log(M)=4.5 on a molecular weight distribution curve thereof is 8% to 20%. The ultrathin biaxially stretched polypropylene film for a capacitor has superior heat resistance performance and withstands voltage performance.

Owner:OJI HLDG CORP

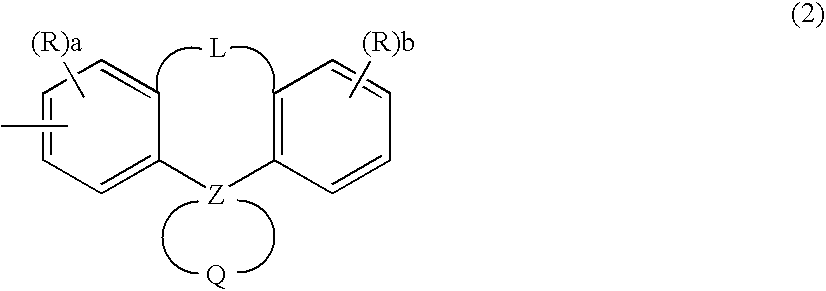

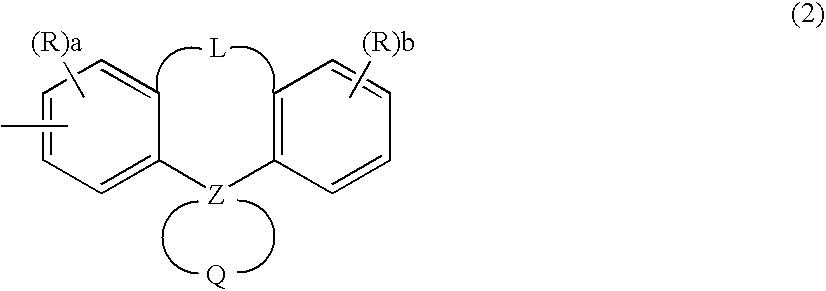

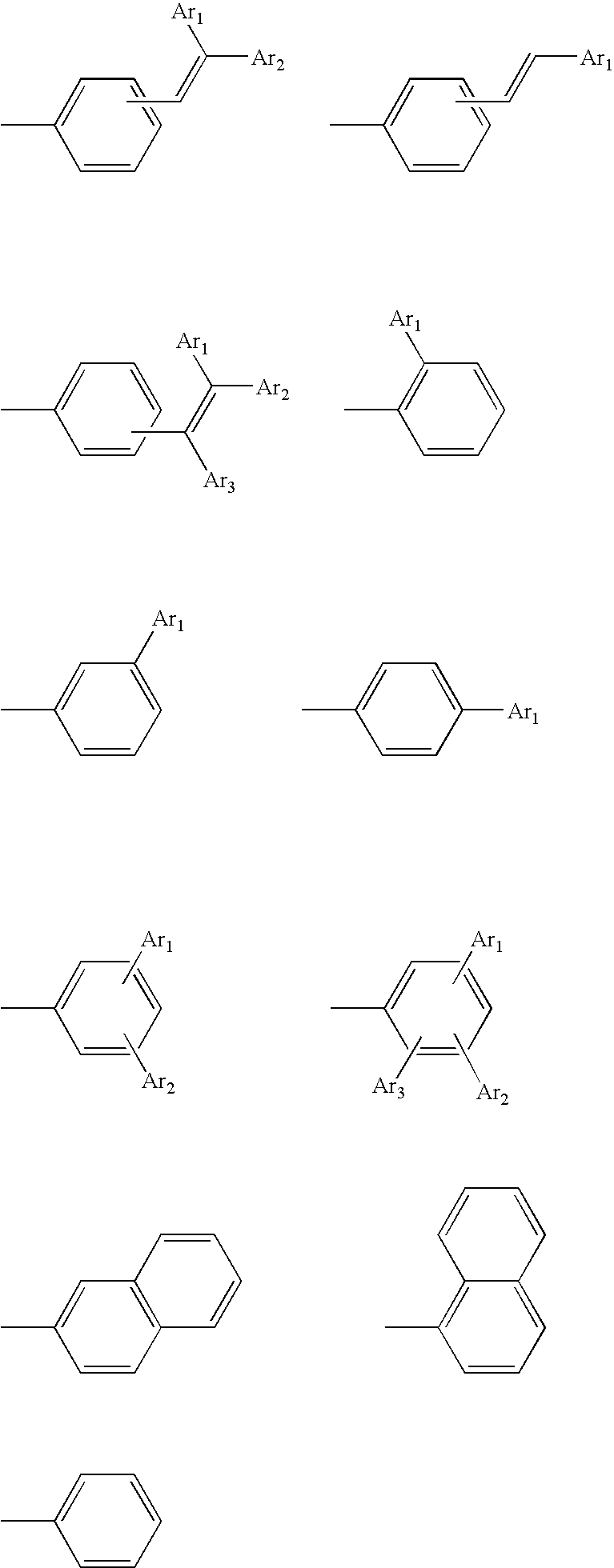

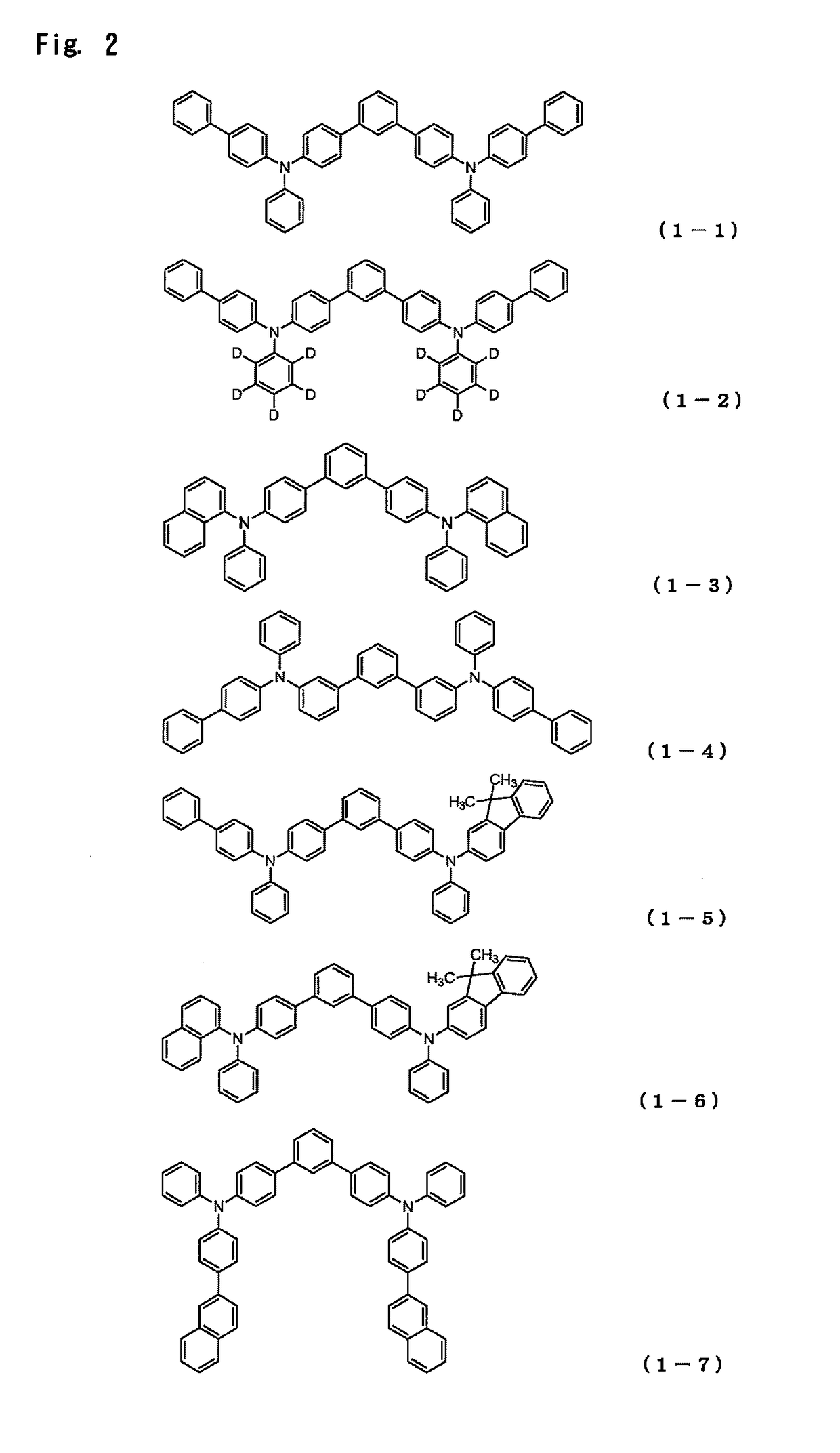

Compound having spiro bond, material for luminescent coating formation and organic electroluminescence element including the same

InactiveUS20070042220A1Improve heat resistanceImprove stabilityOrganic chemistryDischarge tube luminescnet screensHeat resistanceCompound (substance)

A novel compound having a spiro bond with a specific structure, a material for forming a luminous coated film comprising the compound having the spiro bond with the specific structure, and an organic electroluminescence device which comprises at least one organic thin film layer sandwiched between a pair of electrode consisting of an anode and a cathode, wherein the organic thin film layer comprises the compound having the spiro bond. The organic EL device employing either the compound having a spiro bond or the material for forming luminous coated film in accordance with the present invention is superior in heat resistance, has stability of the thin film composing the device, emits uniform blue light, and exhibits an excellent luminance, current efficiency even under a low driving voltage.

Owner:IDEMITSU KOSAN CO LTD

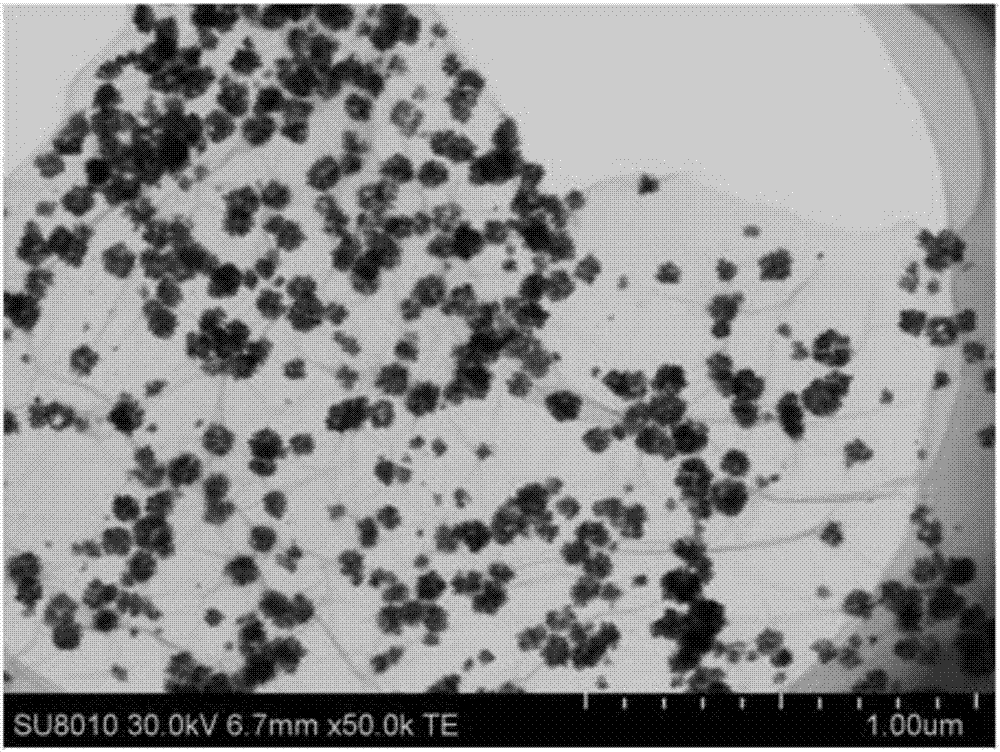

Two-component graphene heavy-duty anti-corrosive coating material and preparation method thereof

InactiveCN109749569AImprove anti-corrosion performanceImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention provides a two-component graphene heavy-duty anti-corrosive coating material, which comprises a component A and a component B, wherein the two-component graphene heavy-duty anti-corrosive coating material comprises the following components in percentage by weight based on 100% of the total weight of the component A: 0.2-2wt% of graphene; 10-30wt% of epoxy resin; 20-50wt% of zinc powder; 0.5-3wt% of a dispersant; 0.5-4wt% of an anti-settling agent; 0.2-1wt% of a defoaming agent; 0.2-2 wt% of a silane coupling agent; 0.3-2wt% of a thickener; 10-20wt% of a pigment filler; and 10-20wt% of a first solvent, wherein the zinc powder is a mixture of spherical zinc powder and flaky zinc powder; and the coating material comprises the following components in percentage by weight based on100% of the total weight of the component B: 50-75% of a curing agent; 1-5wt% of a curing accelerator; and 20-50wt% of a second solvent.

Owner:SHENZHEN GRAPHENE LAND LEGEND TECH CO LTD

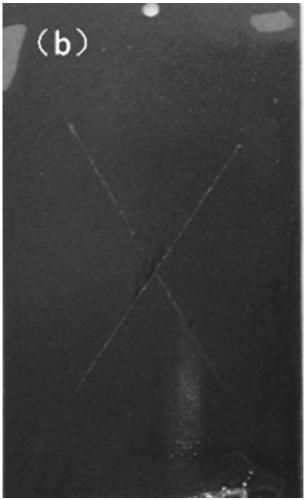

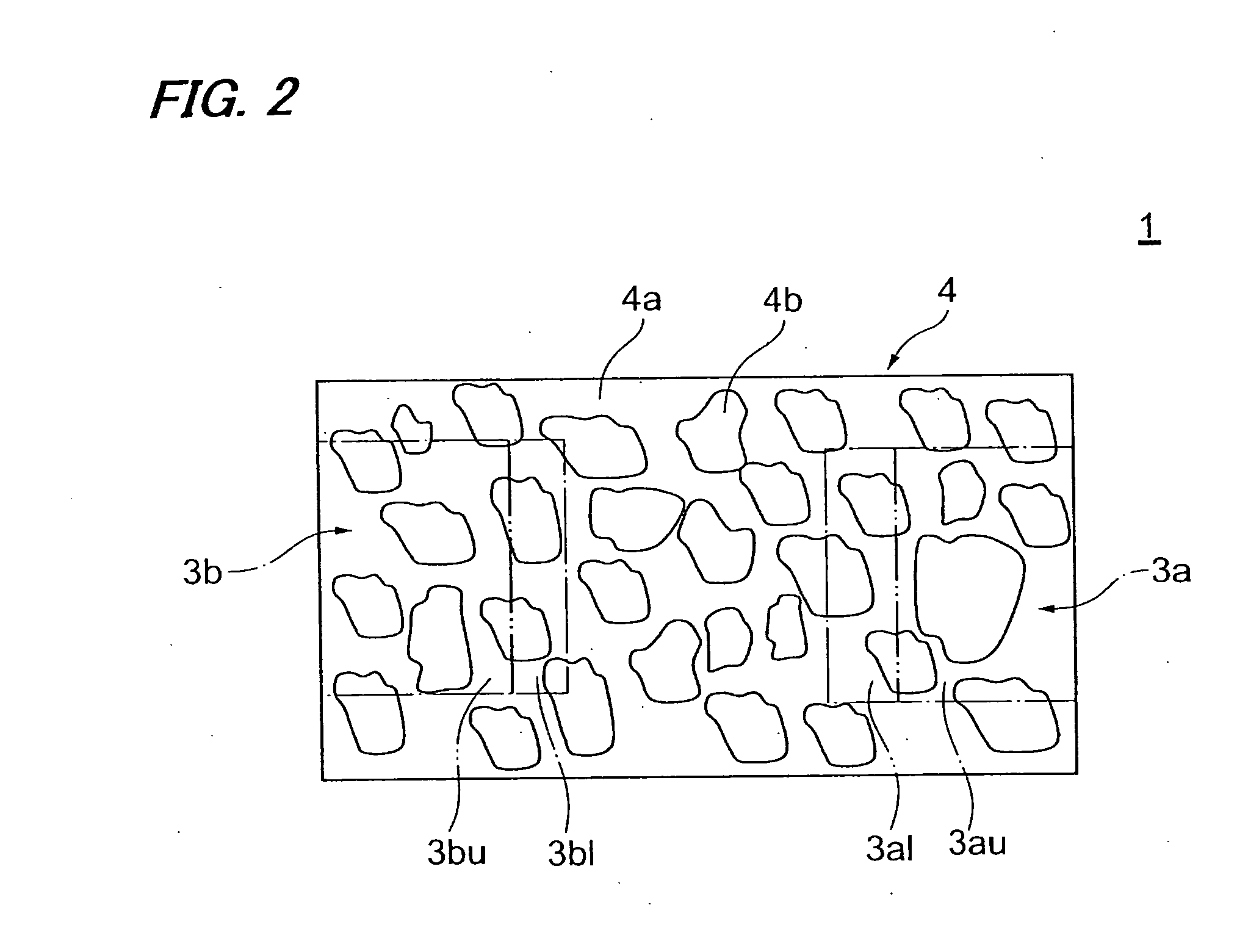

ESD protection device and composite electronic component of the same

ActiveUS20100157496A1Increased durabilityLow costEmergency protective arrangement detailsMagnetic materialsElectronic componentElectron

Owner:TDK CORPARATION

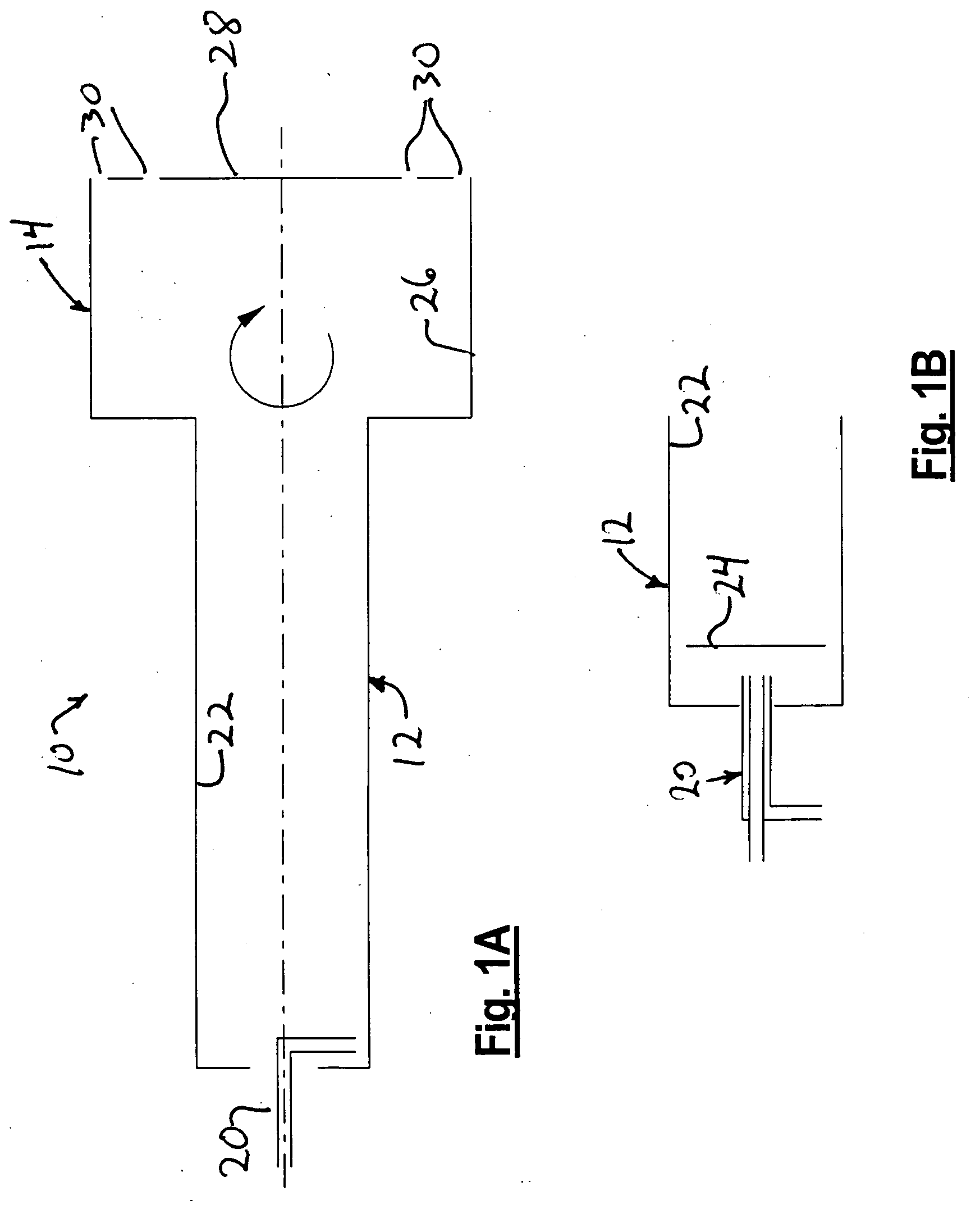

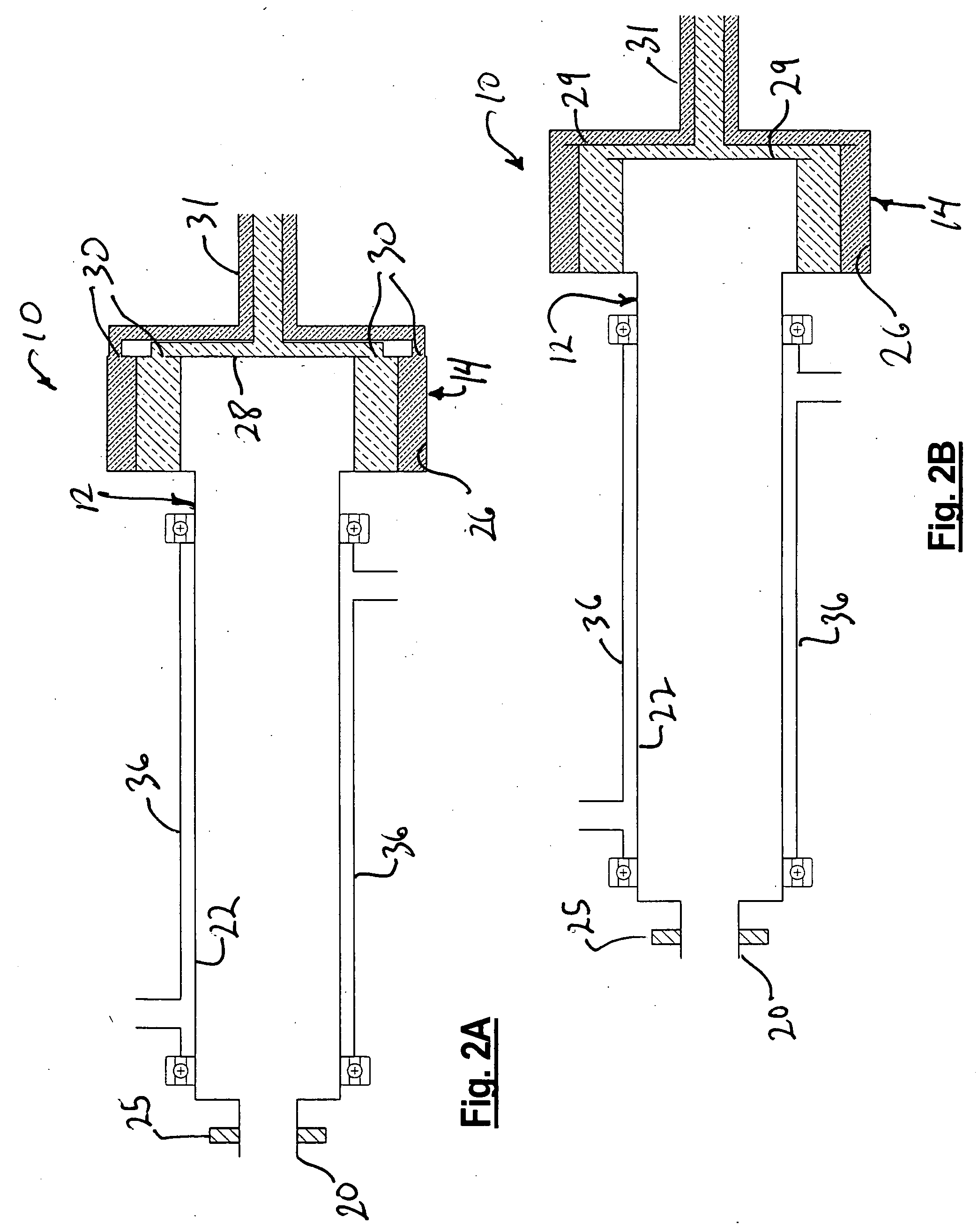

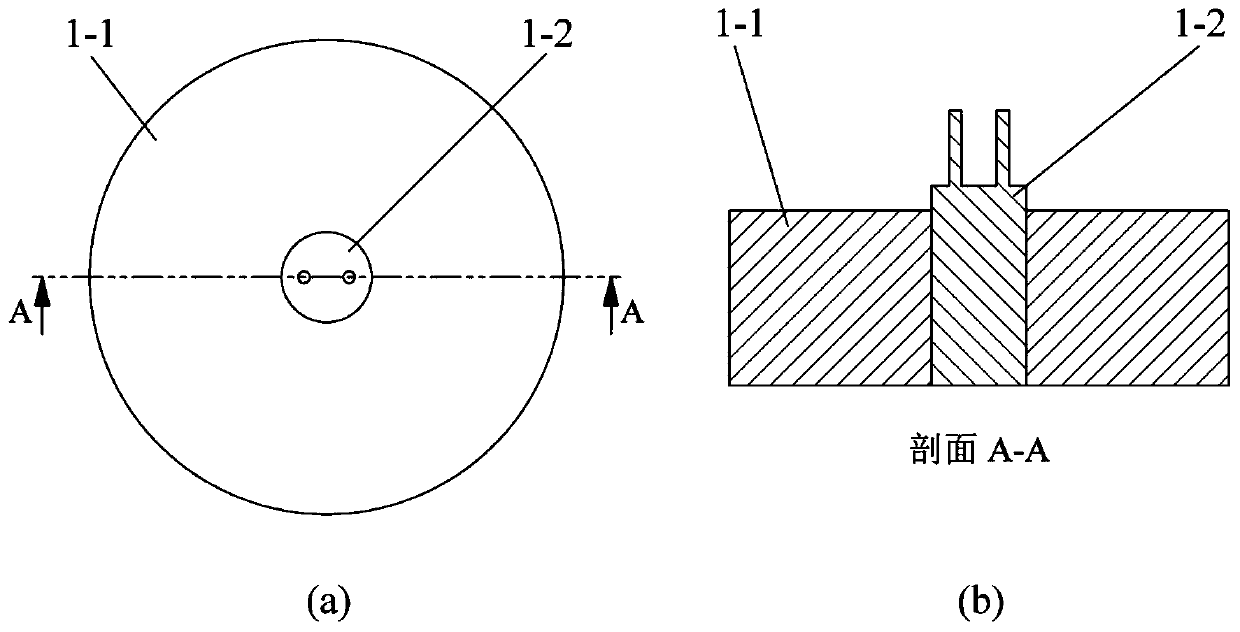

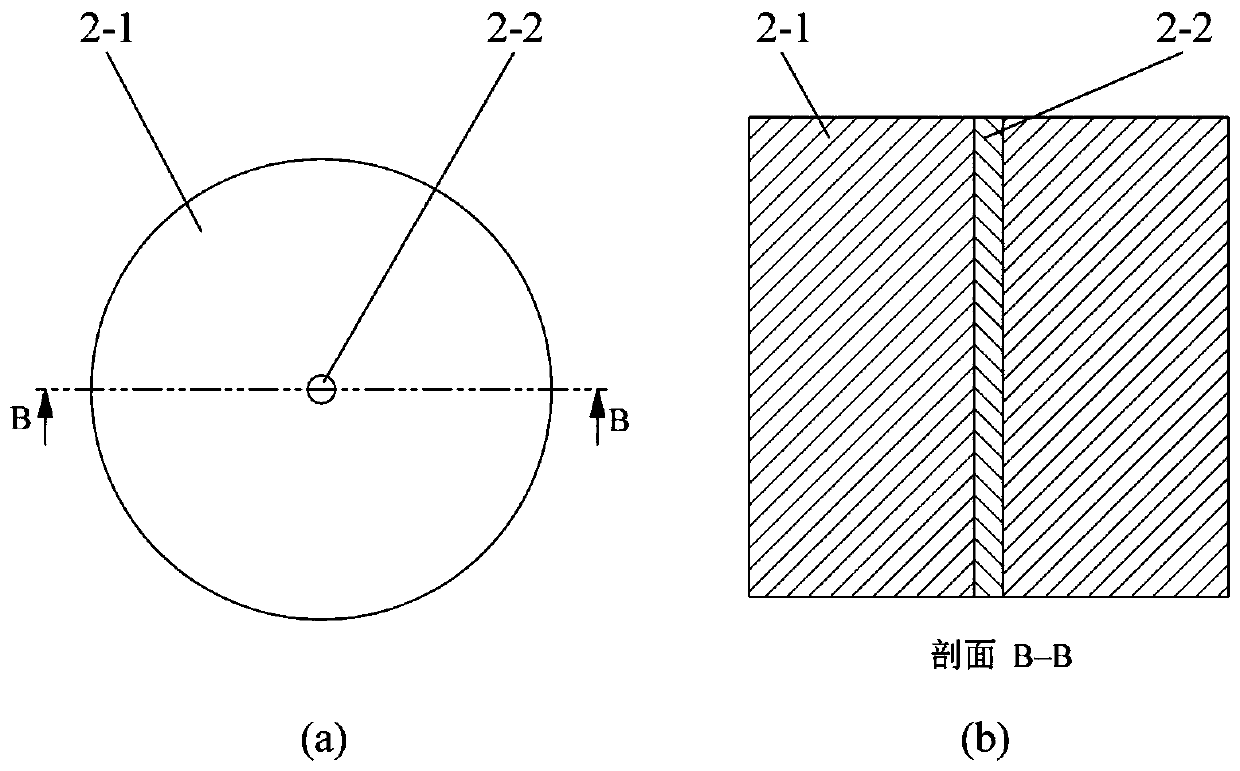

Thin film tube reactor

InactiveUS20060147357A1Minimize downstream processingReduce wasteFlow mixersTransportation and packagingThin membraneEngineering

The invention provides a thin film tube reactor, including an elongate tube that is rotatable about its longitudinal axis. A mixing plate rotatable about the tube's longitudinal axis may be positioned within the tube near the inlet. A plurality of fluid process components are fed into the tube and directed toward the mixing plate. In the absence of the mixing plate, the process components are directed toward the inner surface of the tube. Heating and cooling elements surround the tube to control the process temperature at particular points along the tube. A structured surface that is integral with or affixed to the inner surface of the tube immobilizes a catalyst slurry applied to the inner surface. A separation reservoir includes an end plate with a plurality of radially spaced outlet ports for controlling the output of the products from said separation reservoir.

Owner:NANODYNAMICS INC

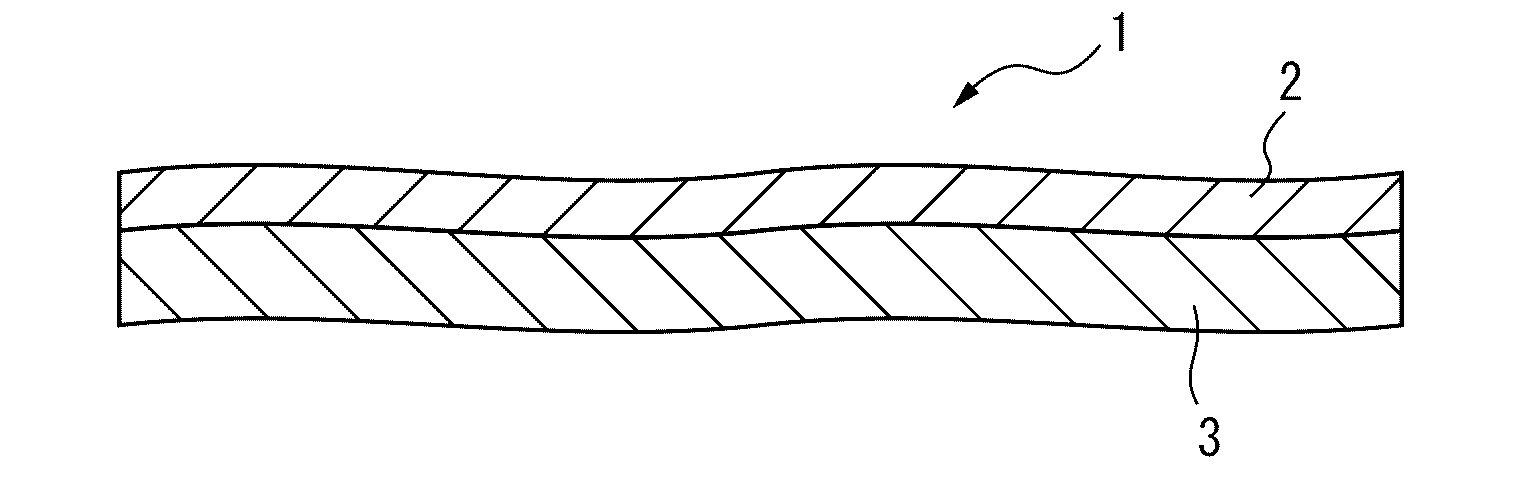

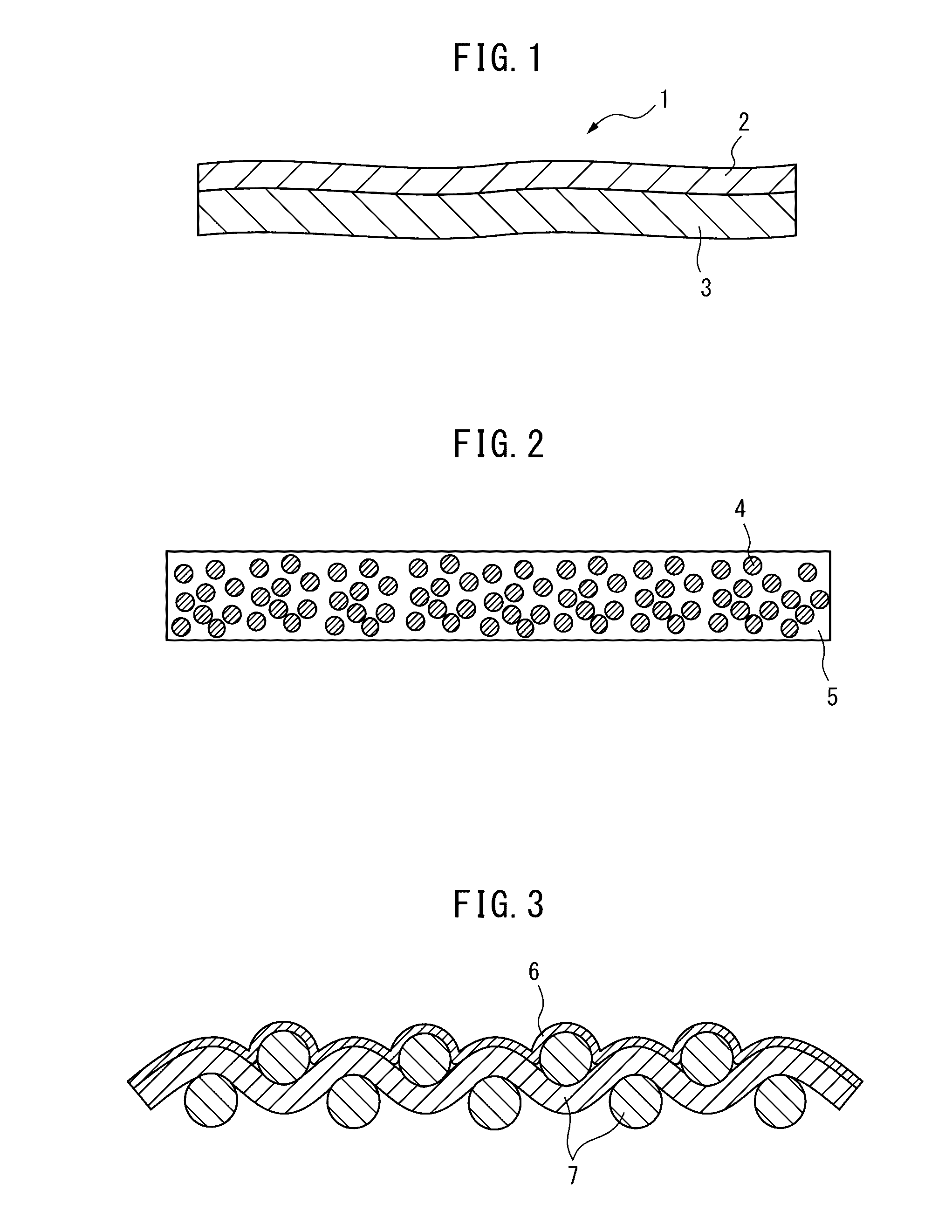

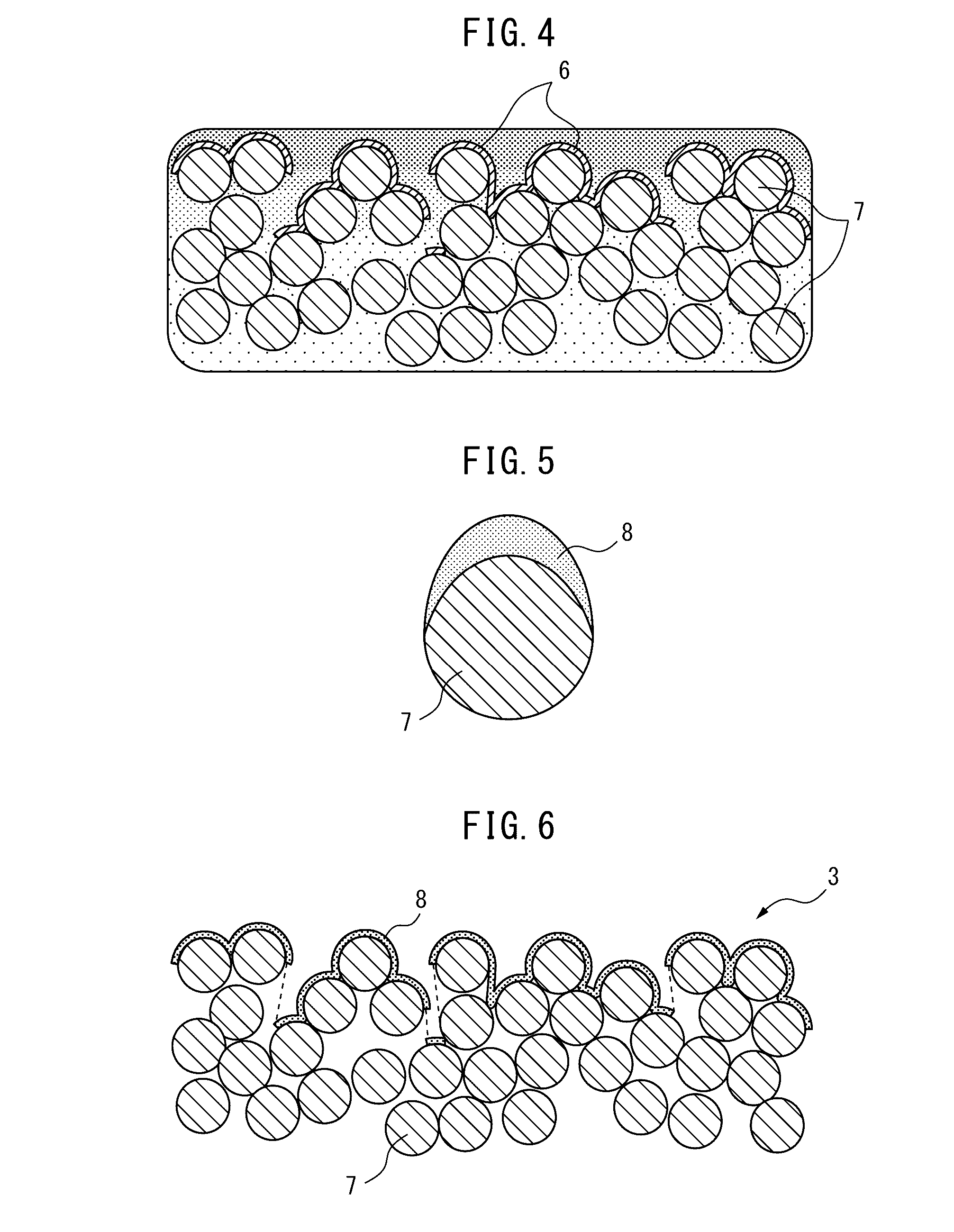

Noise-absorbing sheet

InactiveUS20170002488A1Good noise absorptionHighly effective noise absorptionShielding materialsLayered productsFiberSurface resistivity

Provided is a noise-absorbing sheet that is highly effective at absorbing noise from magnetic and / or electric fields, the noise-absorbing effect being effective in wider bandwidths. A noise-absorbing sheet upon which at least two layers are stacked, wherein the noise absorbing sheet is characterized in that a magnetic layer containing a magnetic material and a layer of a noise-absorbing fabric in which a metal is deposited on constituent fibers are layered on said sheet, and the common logarithmic value of the surface resistivity of at least one side of the noise-absorbing fabric is 0 to 6.

Owner:ASAHI KASEI KK

Preparation method of environment-friendly metal antiseptic silane modified waterborne polyurethane resin and antiseptic treatment method

InactiveCN105017500AIncrease the degree of cross-linkingImprove adhesionMetallic material coating processesPolymer scienceIce water

The invention relates to a preparation method of environment-friendly metal antiseptic silane modified waterborne polyurethane resin and an antiseptic treatment method, and belongs to the technical field of metal surface antiseptic treatment. The preparation method comprises the steps that polyhydric alcohols, polyisocyanates and a hydrophilic chain-extending agent react for 2 h and then added with a cross-linking agent, a reaction continues to be carried out for 3 h at 80 DEG C, the mixture is added with triethylamine for neutralizing after being cooled to 60 DEG C, and a waterborne polyurethane prepolymer is obtained; then the waterborne polyurethane prepolymer is cooled by ice water to room temperature and added with water under strong stirring for high-speed dispersion, a silane coupling agent is added to terminate the prepolymer, high-speed dispersion is carried out for 30 min, standing and defoaming are carried out, and therefore the metal antiseptic silane modified waterborne polyurethane resin is obtained. The invention further discloses the antiseptic treatment method for metal. The antiseptic treatment method comprises the steps that the obtained antiseptic resin is placed in a container, evenly attached to the surface of the purified metal and then driven at room temperature. By using the antiseptic resin for treating the surface of metal, the antiseptic performance is remarkably improved, the technology is simple, a coating film is thin, and the cost is low.

Owner:广东德丽雅新材料有限公司 +1

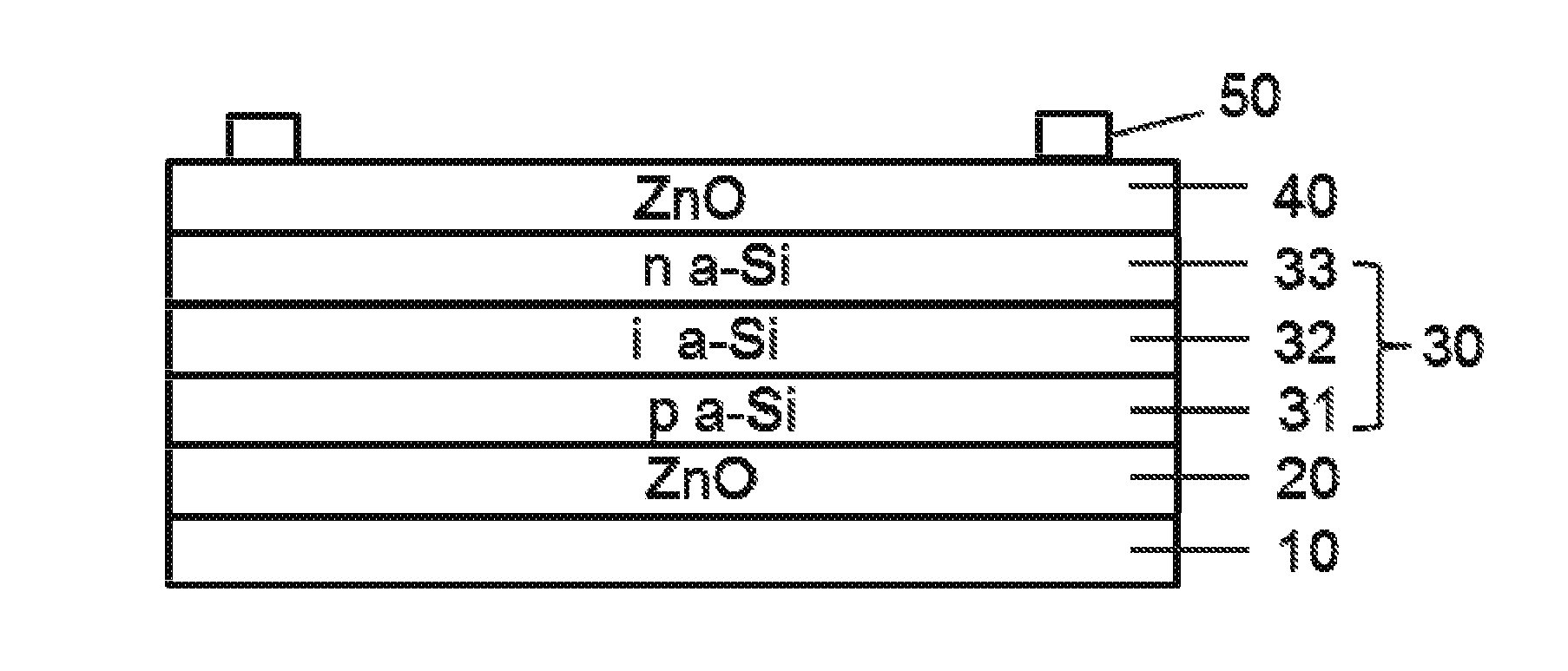

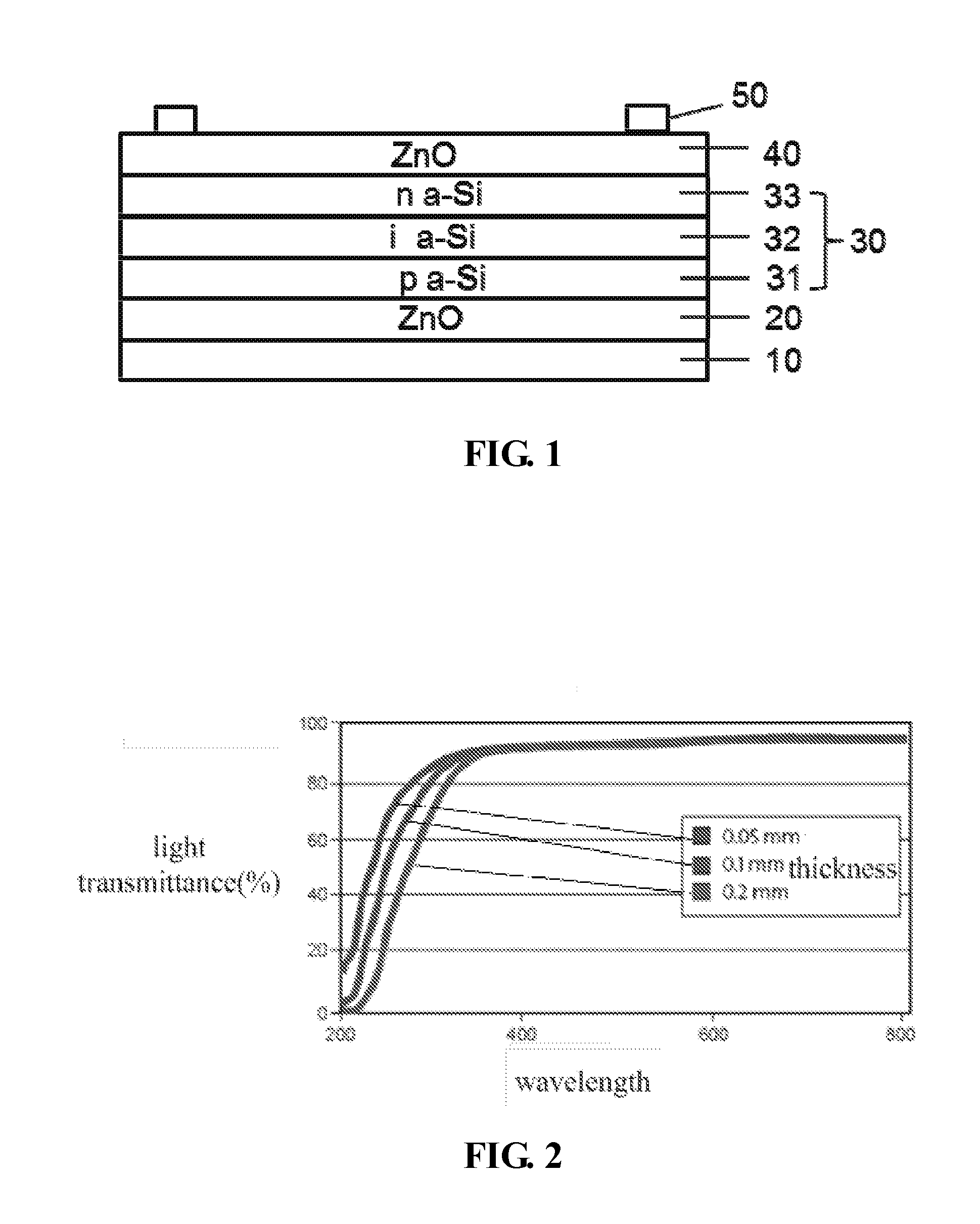

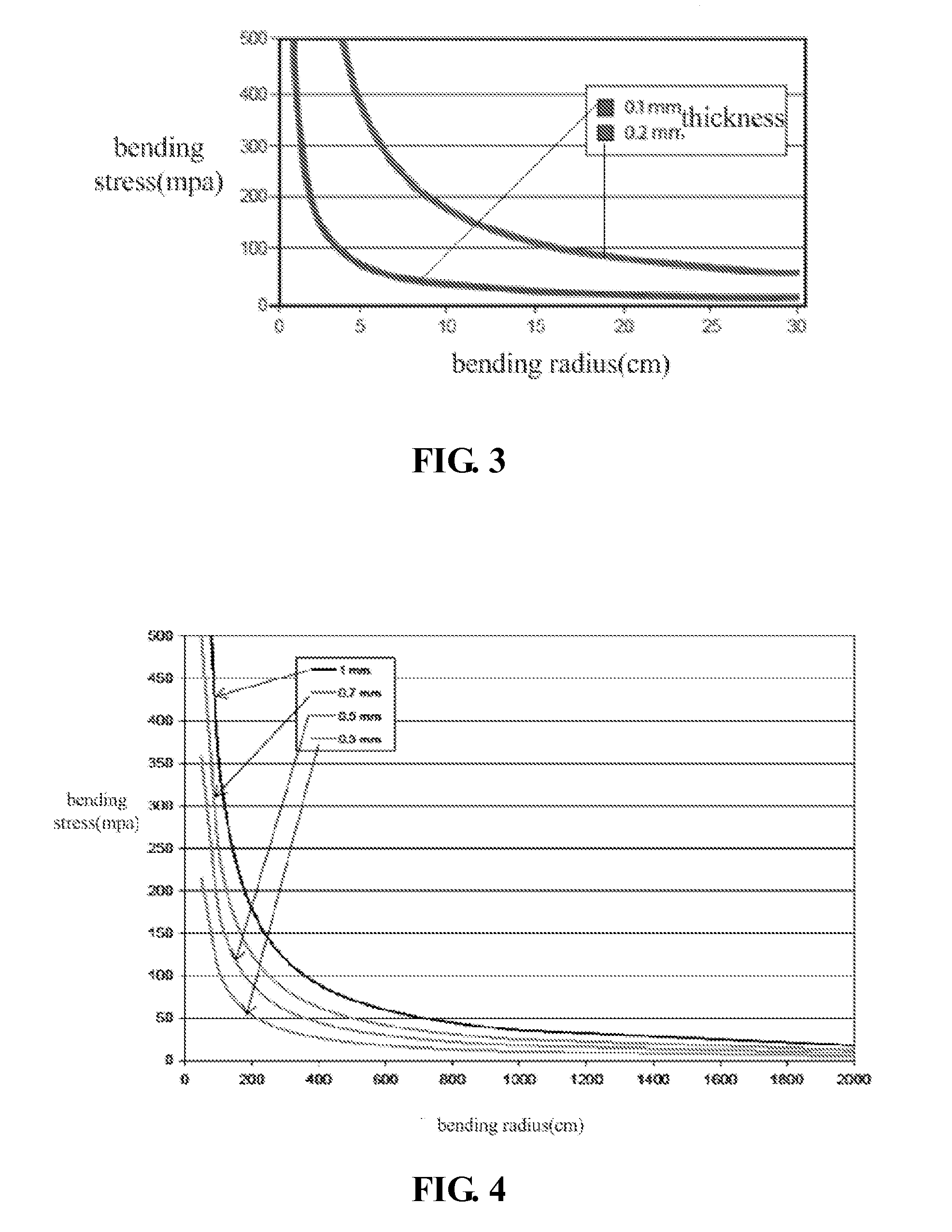

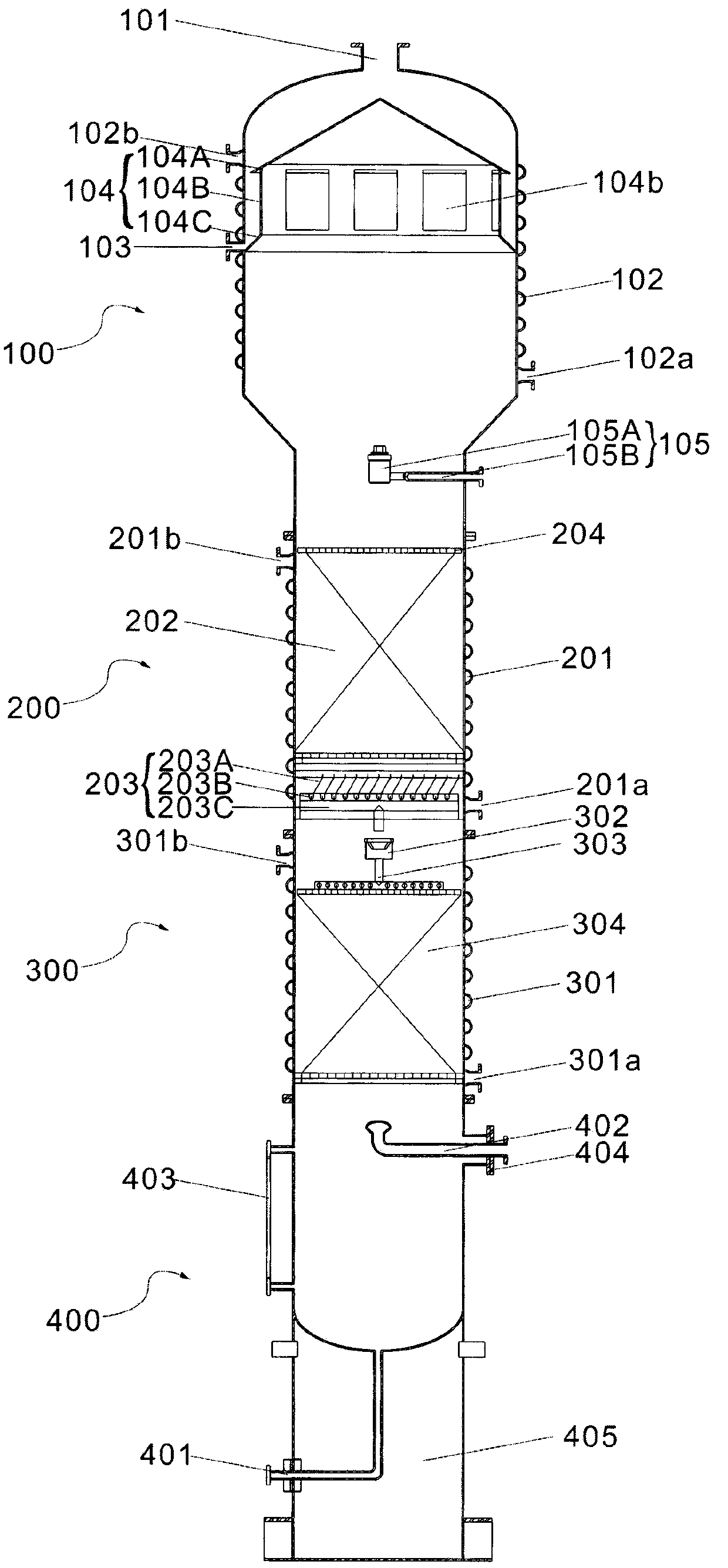

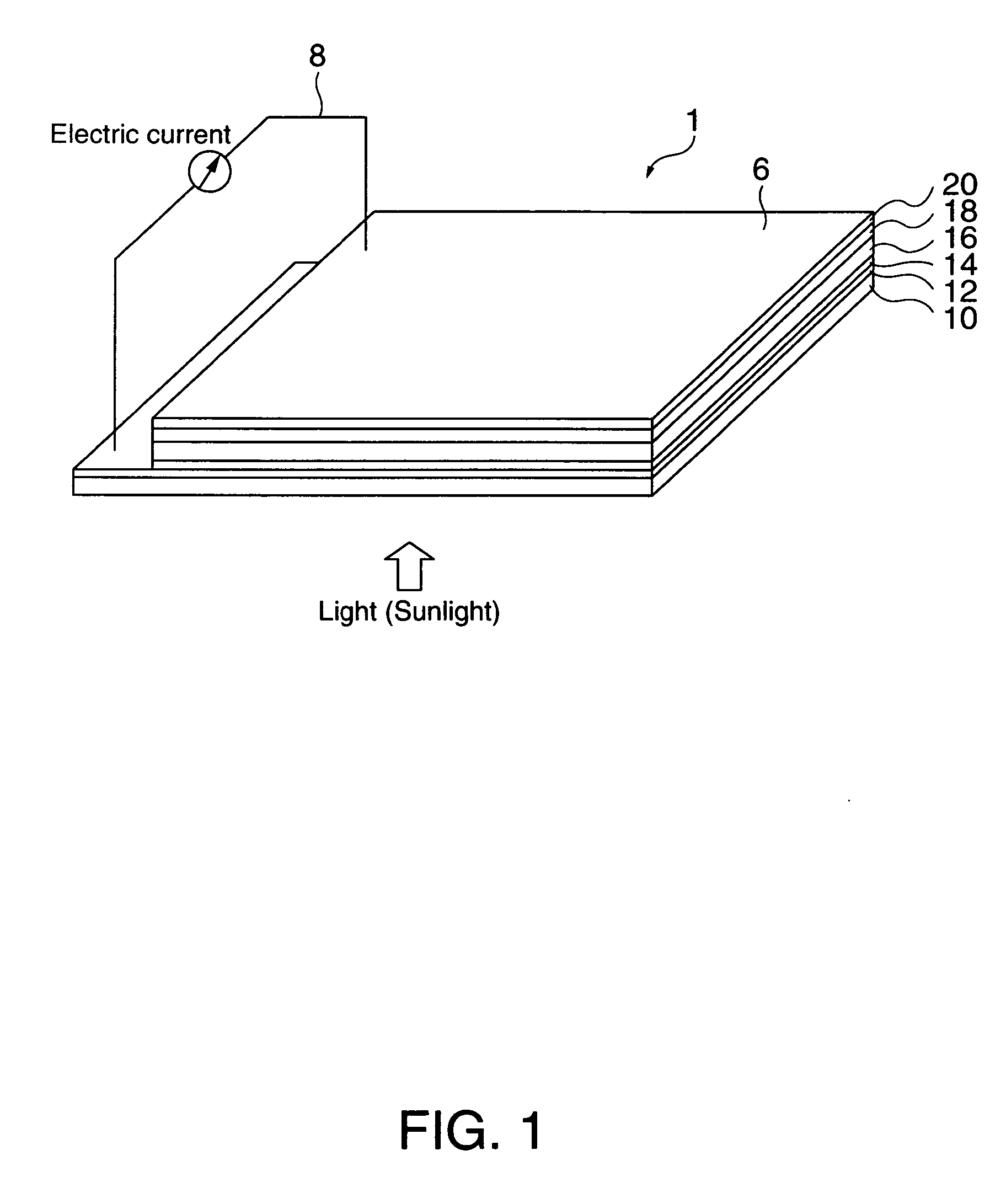

Thin film solar cell panel and manufacturing method thereof

InactiveUS20160118519A1Improve production efficiencyBeautiful appearancePhotovoltaic supportsPV power plantsOptical transmittanceEngineering

The present invention provides a thin film solar cell panel and a manufacturing method thereof. The thin film solar cell panel comprises a substrate, a first electrode disposed on the substrate. The substrate is an ultra-thin glass substrate with a thickness of 0.1-1 mm. The ultra-thin glass substrate has a bending capacity, and a minimum bending radius thereof reaches below 10 cm. The first electrode is continuously disposed on the substrate during its formation. Light transmittance of the thin film solar cell panel of the present invention is enhanced, and the thin film solar cell panel can be conveniently used to manufacture a bending solar cell component.

Owner:SHANGHAI SOLAR INVESTMENT MANAGEMENT PARTNERSHIPS S

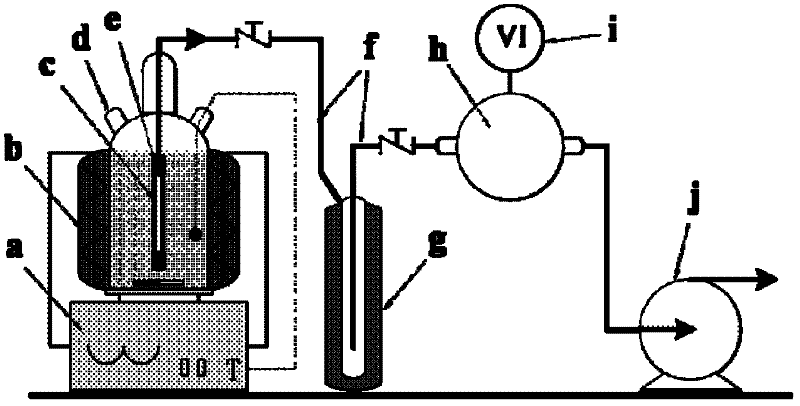

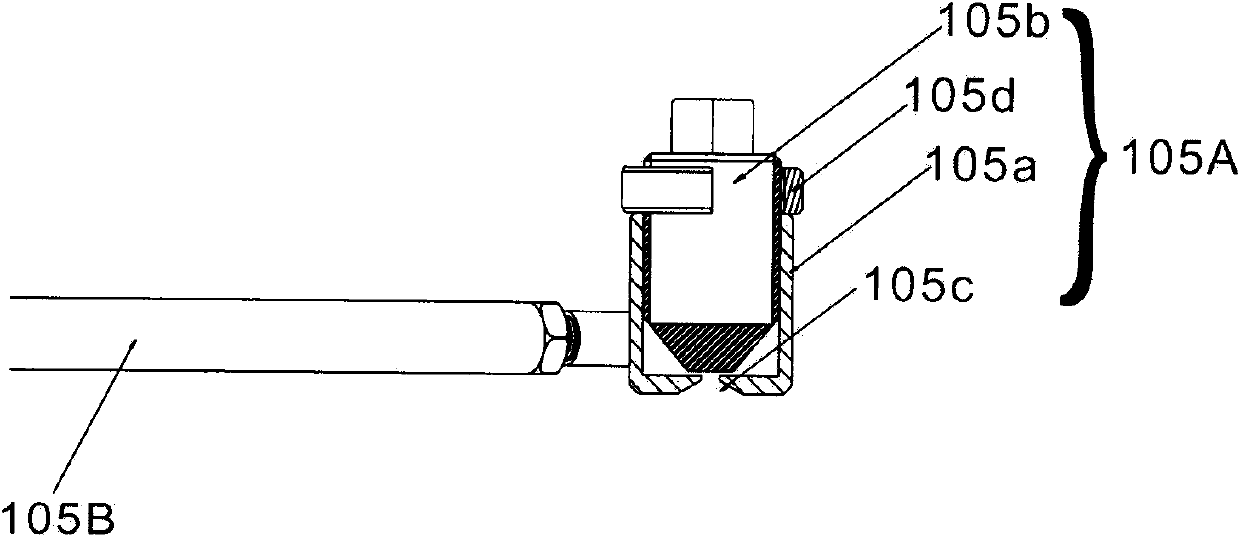

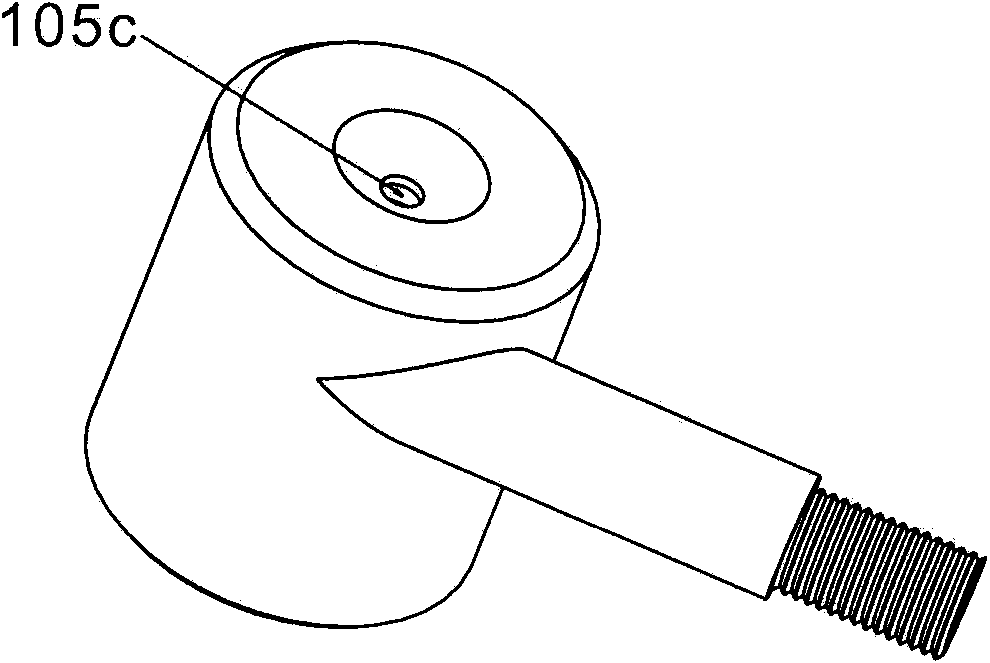

Grease deacidification equipment and deacidification method

ActiveCN103740463AEvenly dispersedGood dispersionFatty-oils/fats refiningOil and greaseSteam pressure

The invention discloses grease deacidification equipment and a deacidification method. The grease deacidification equipment sequentially comprises a first barrel body, a second barrel body, a third barrel body and a fourth barrel body from top to bottom. The deacidification method carried out by using the equipment takes de-colored grease as a raw material; a temperature range of a deacidification tower of the raw material is 170-260 DEG C; the flow of steam is 3-11kg / h and the vacuum degree is 133.3-266.6Pa. Grease is collected by a liquid collection device and the contact area between the grease and the direct steam is further enlarged; the removing efficiency of free fatty acid is sufficiently improved and an oil path is effectively prevented from being shortened out; the spraying effect is controlled by adjusting a spraying device and the de-colored grease enters a nozzle and is sprayed into the deacidification tower in a micro-droplet shape, so that the distribution of the de-colored oil at a filler section is uniform and a formed film is thin; substances with high steam pressure including ketones, aldehydes and the like, and the fatty acids, hydrocarbons and the like with high boiling points can be effectively removed; the steam use amount is less when the deacidification equipment is used and is only about 25% of the steam use amount of a common plate type deodorization tower.

Owner:陈汉卿

Non-aqueous lithium-ion battery electrolyte and lithium ion battery

InactiveCN108075188AImprove first-time efficiencyImprove normal temperature cycle performanceSecondary cells servicing/maintenanceHigh temperature storageAlkaline earth metal

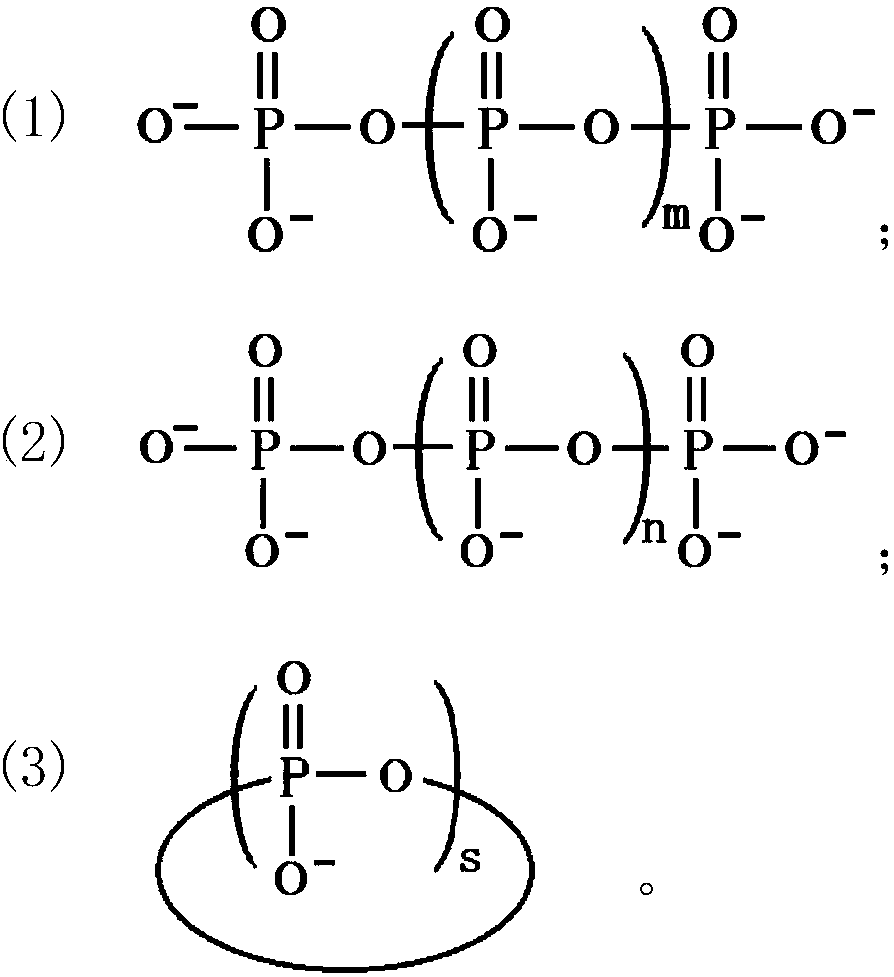

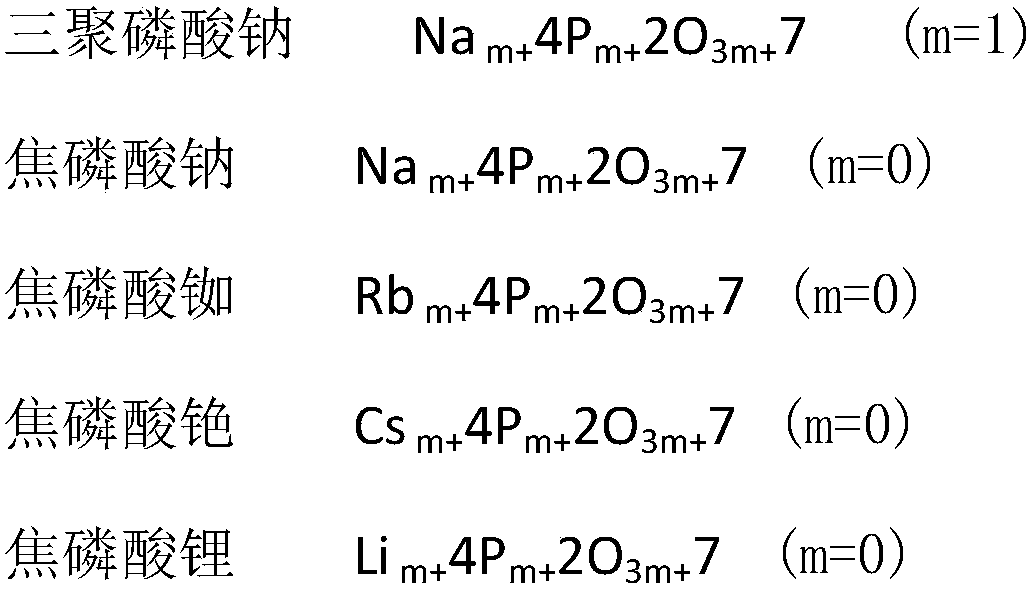

The invention discloses a non-aqueous lithium-ion battery electrolyte and a lithium ion battery. The non-aqueous lithium-ion battery electrolyte contains electrolyte salt, a non-aqueous organic solvent and a functional additive, wherein the functional additive is selected from one or combination of multiple compounds with chemical formulae of (K)(m+4)P(m+2)O(3m+7), (L)(n / 2+2)P(n+2)O(3n+7) and (K)s(PO3)s, K is an alkali metal element selected from a first main group except hydrogen; L is an alkali metal element selected from a second main group except beryllium in the periodic table of elements; (K)(m+4)P(m+2)O(3m+7) contains an anionic group P(m+2)O(3m+7)<(m+4)->, and m is 0 or a positive integer; (L)(n / 2+2)P(n+2)O(3n+7) contains an anionic group P(n+2)O(3n+7)<(n+4)->, and n is 0 or a positive even number; (K)s(PO3)s contains an anionic group (PO3)s<s->, and s is 3 or an integer larger than 3. During first formation of a battery prepared from the non-aqueous lithium-ion battery electrolyte, a dense and uniform SEI film with high lithium ion conductivity can be formed, so that first charge-discharge efficiency of the battery is improved, and normal-temperature cycling performance, rate capability, high-temperature cycling performance, high-temperature storage performance and low-temperature discharge performance of the battery are improved.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

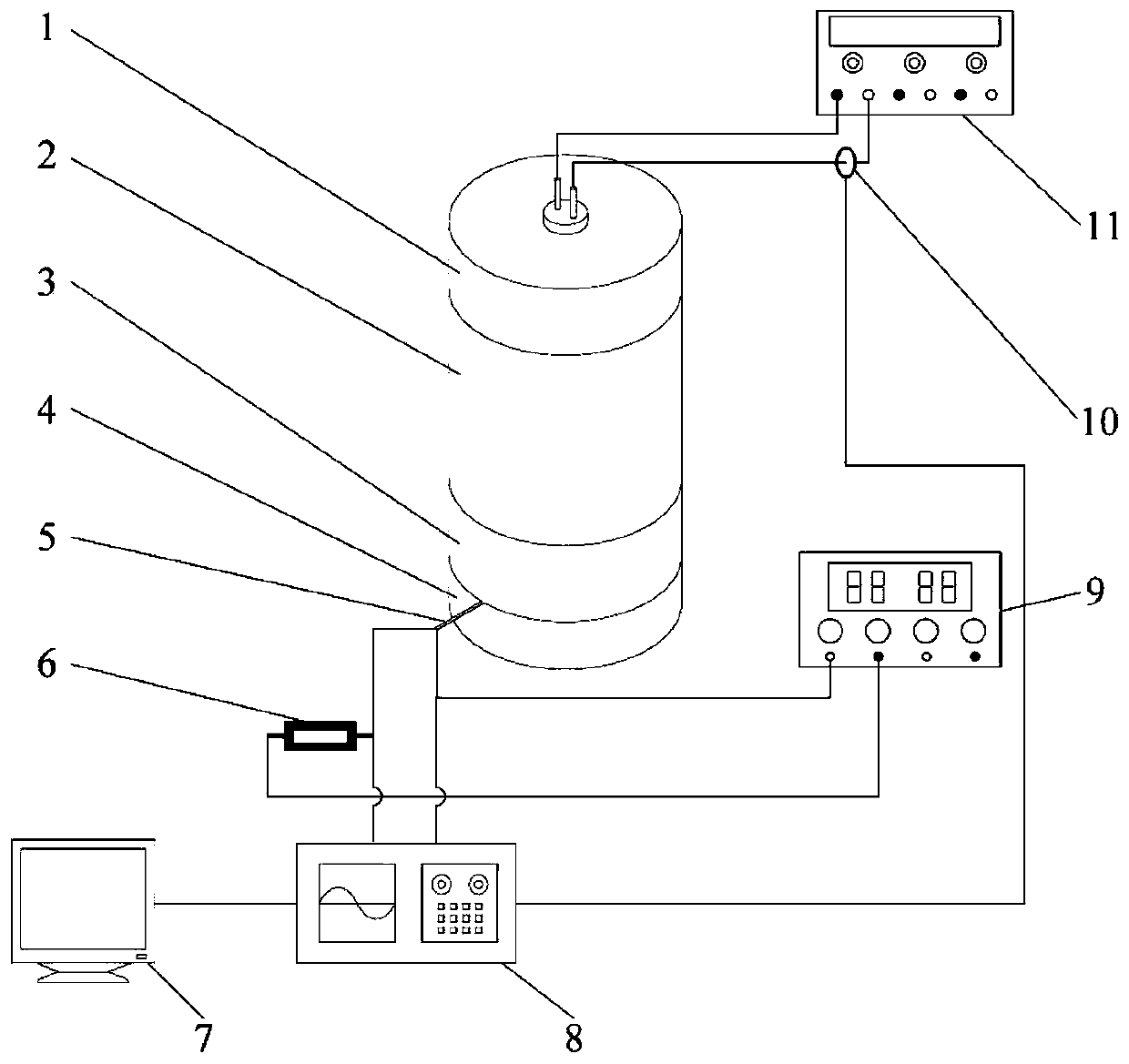

Micro-scale charge detonation pressure and detonation velocity test system based on MEMS pressure-conducted probe

ActiveCN110926281AWith miniaturizationThin filmAmmunition testingDevices using electric/magnetic meansElectrical resistance and conductanceOvercurrent

The invention relates to a micro-scale charge detonation pressure and detonation velocity test system based on a MEMS pressure-conducted probe. The system comprises an initiation device, wherein the lower end of the initiation device and the upper end of a micro-scale charge body are connected and fixed, the lower end of the micro-scale charge body is fixed to the upper end of an inert medium, andthe lower end of the inert medium is fixedly connected with a bottom plate; the edge of the micro-scale charge body and the inert medium is embedded with the MEMS pressure-conducted probe, and leadsof the MEMS pressure-conducted probes are led out from the interfaces of the inert medium and the bottom plate; the leads, a resistor and a constant voltage source of the MEMS pressure-conducted probeform a current loop; the leads of the MEMS pressure-conducted probe are connected with the input end of an oscilloscope; and the initiation device is connected with an initiator, the initiator is connected with the input end of the oscilloscope through a current ring, and the output end of the oscilloscope is connected with a computer. The MEMS pressure-conducted probe can obtain the explosive detonation velocity and the initial velocity of the medium shockwave at the same time, so that a detonation velocity growth curve and the end face output detonation pressure of the micro-scale charge are calculated and obtained. The system is suitable for measuring the output performance of micro-scale charge, and improves the measuring precision.

Owner:XI AN JIAOTONG UNIV

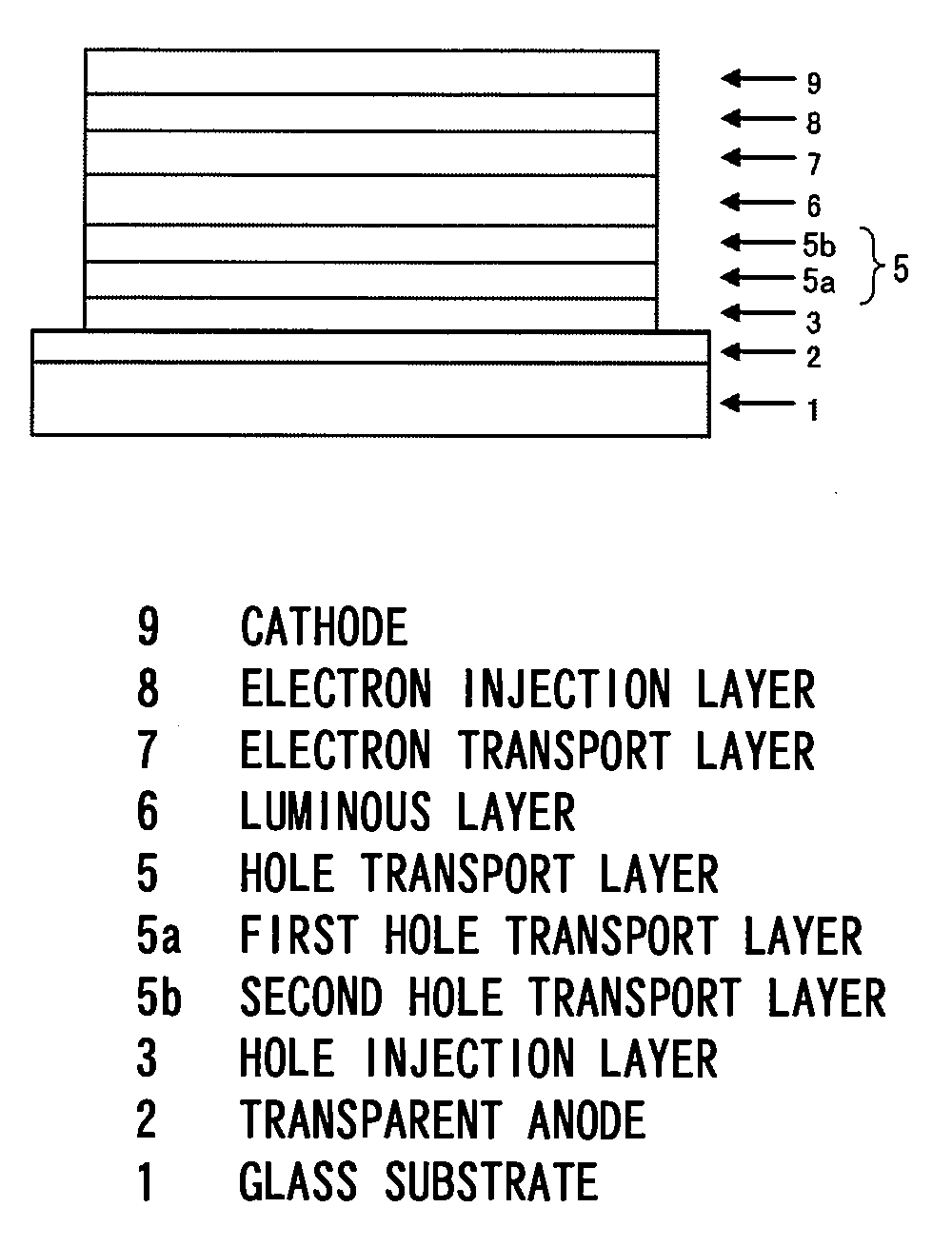

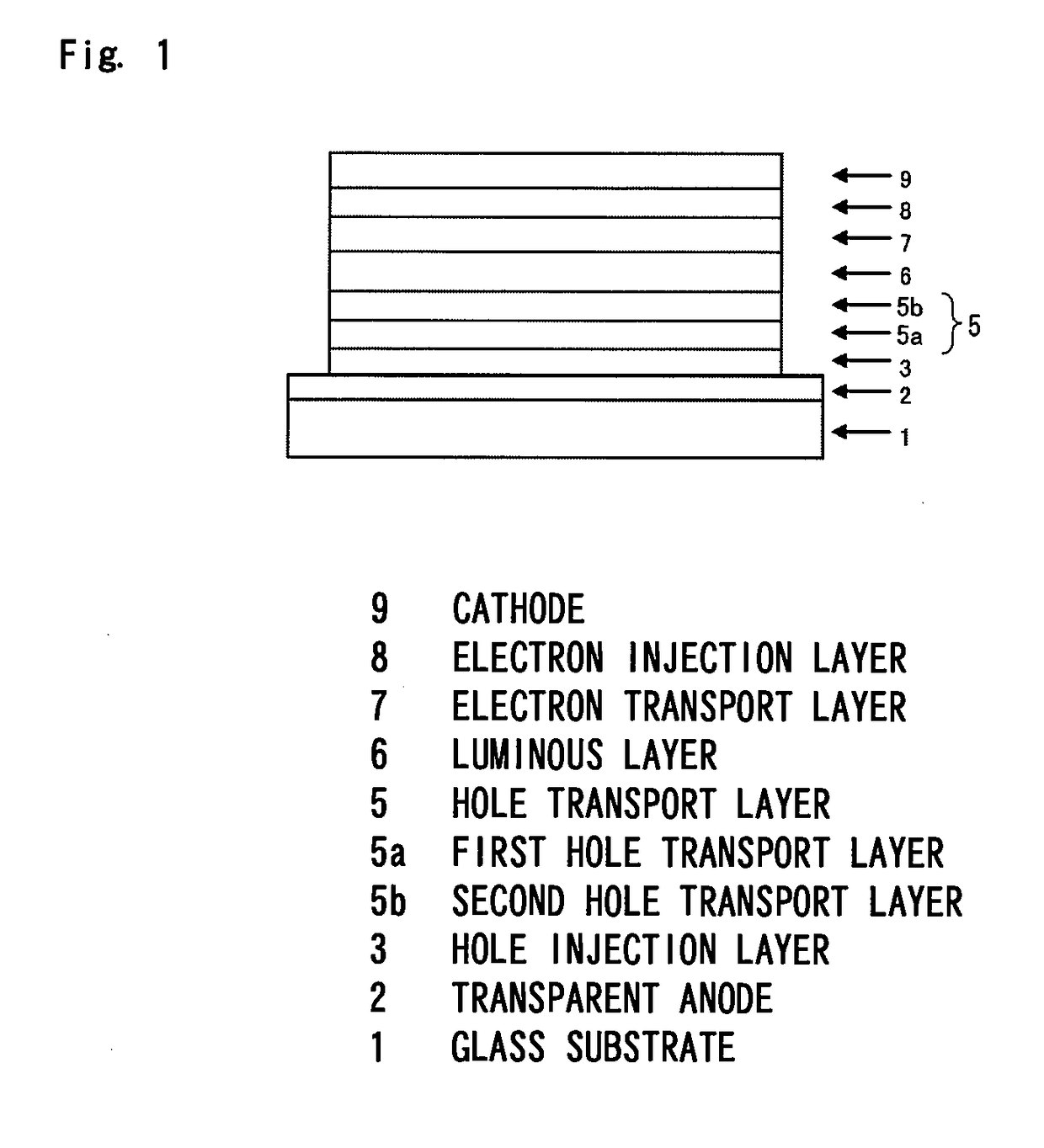

Organic electroluminescent device

ActiveUS20170358753A1Improve efficiencyReduce the driving voltageOrganic chemistrySolid-state devicesOrganic electroluminescenceHole transport layer

The present invention provides an organic electroluminescent device having at least an anode, a hole transport layer, a luminous layer, an electron transport layer, and a cathode in this order, wherein the hole transport layer contains an arylamine compound having a specific structure, and the luminous layer contains an indenoindole derivative or a carbazole derivative having a specific structure. The organic EL device of the present invention is an organic EL device improved in luminous efficiency, driving voltage and durability.

Owner:HODOGAYA KAGAKU IND +1

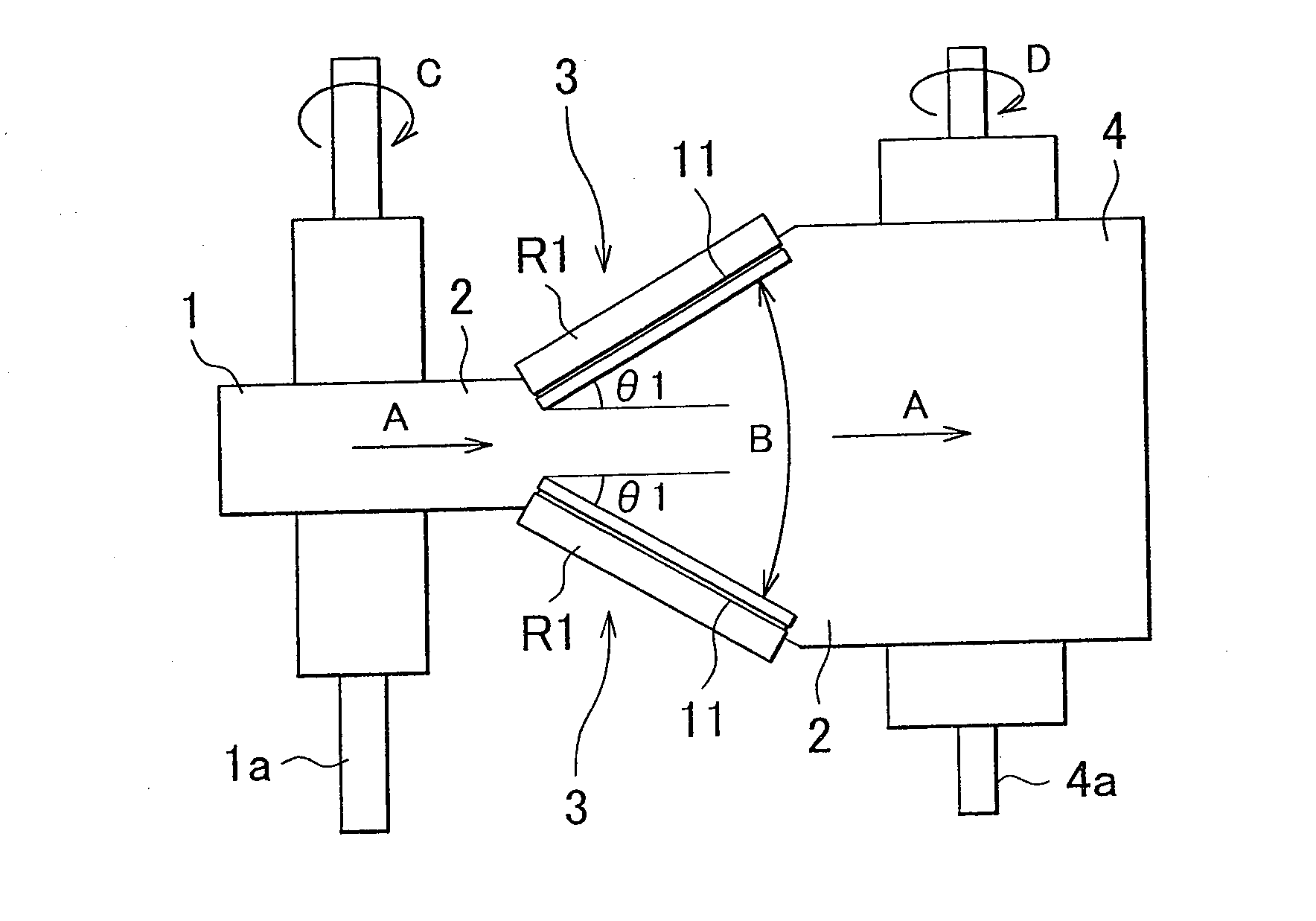

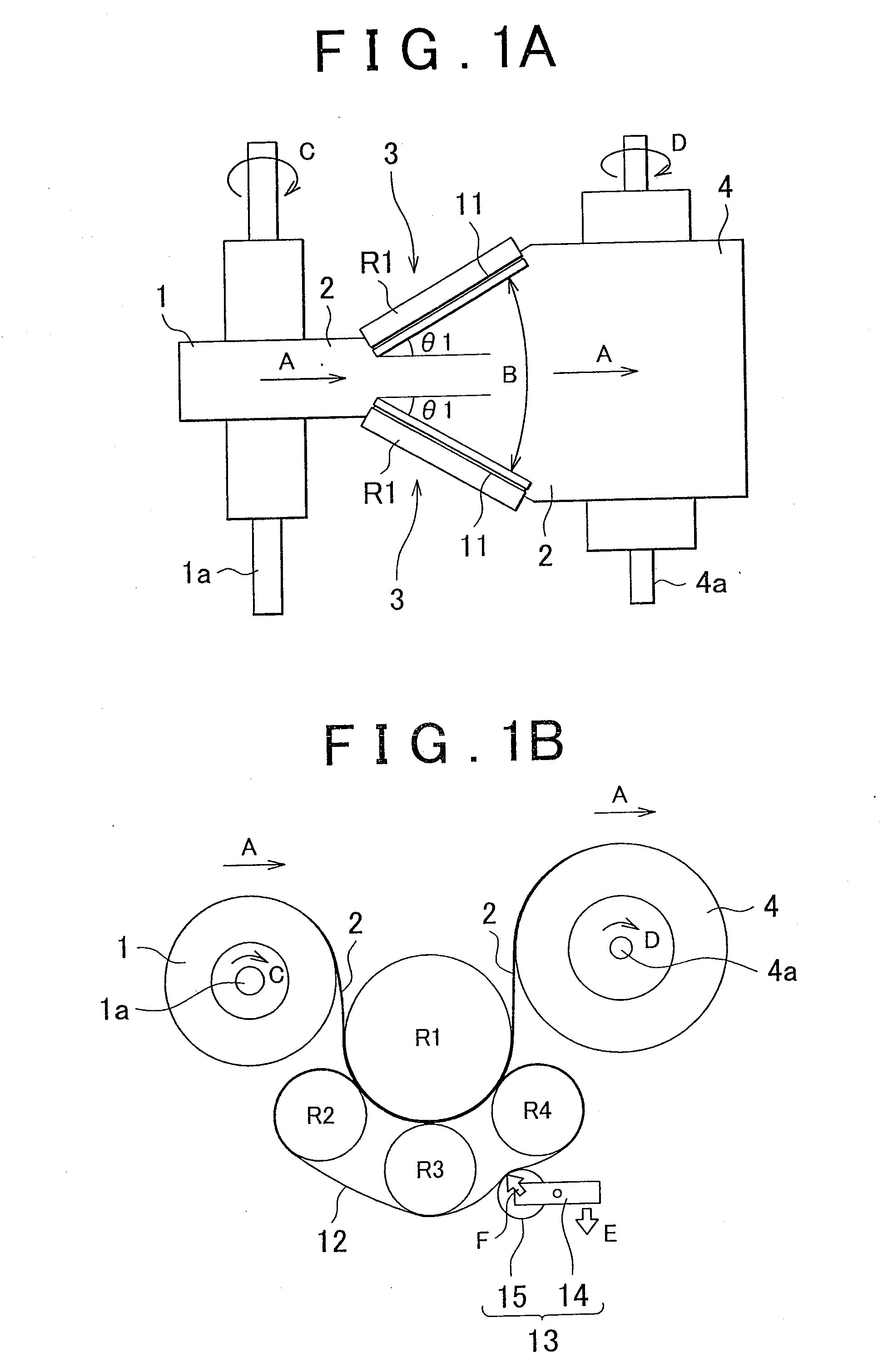

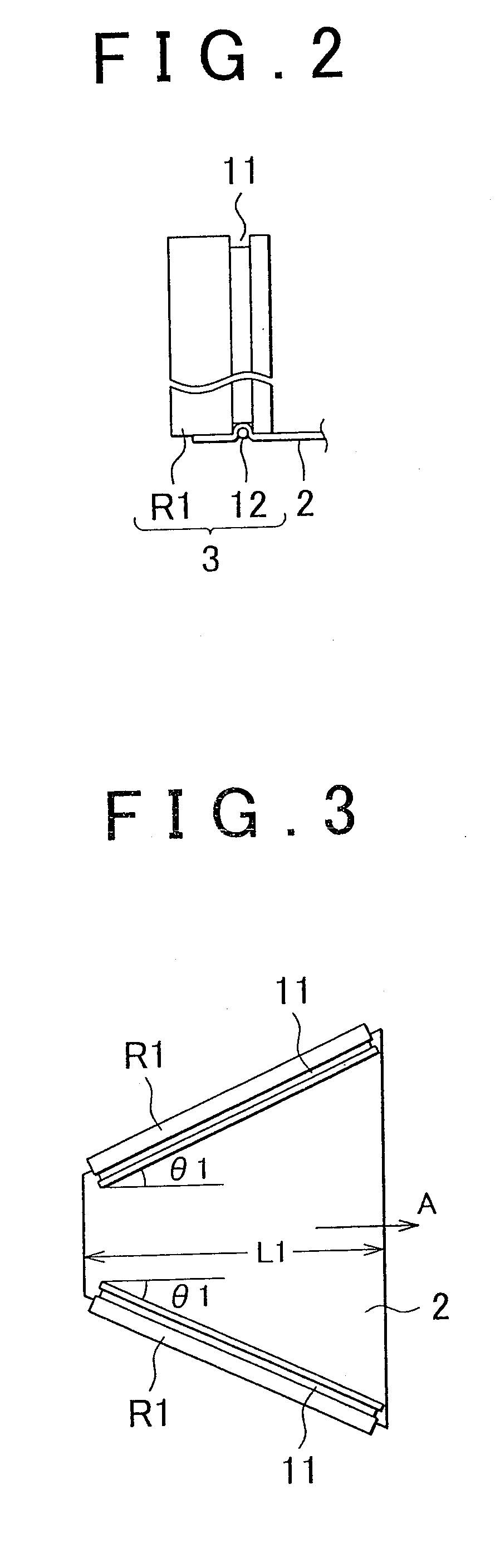

Film stretcher

InactiveUS20110200702A1Speed of can varySuppress decrease pinching forceDough-sheeters/rolling-machines/rolling-pinsConfectioneryEngineeringMechanical engineering

A film stretcher that transports a film material in a predetermined transport direction while holding an end of the film material in a width direction of the film material to stretch the film material in the width direction includes a holding unit that includes a stretching roll having an annular groove formed on an outer periphery of the stretching roll and an endless wire fitted in the annular groove over a predetermined rotation angle range of the annular groove in a circular arc shape so that the end of the film material in the width direction of the film material is pinched. The stretching roll is inclined so as to open toward a downstream side in the transport direction of the film material. The holding unit transports the film material in the transport direction while pinching the film material using the stretching roll and the endless wire, whereby the film material is stretched in the width direction.

Owner:TOYOTA JIDOSHA KK +1

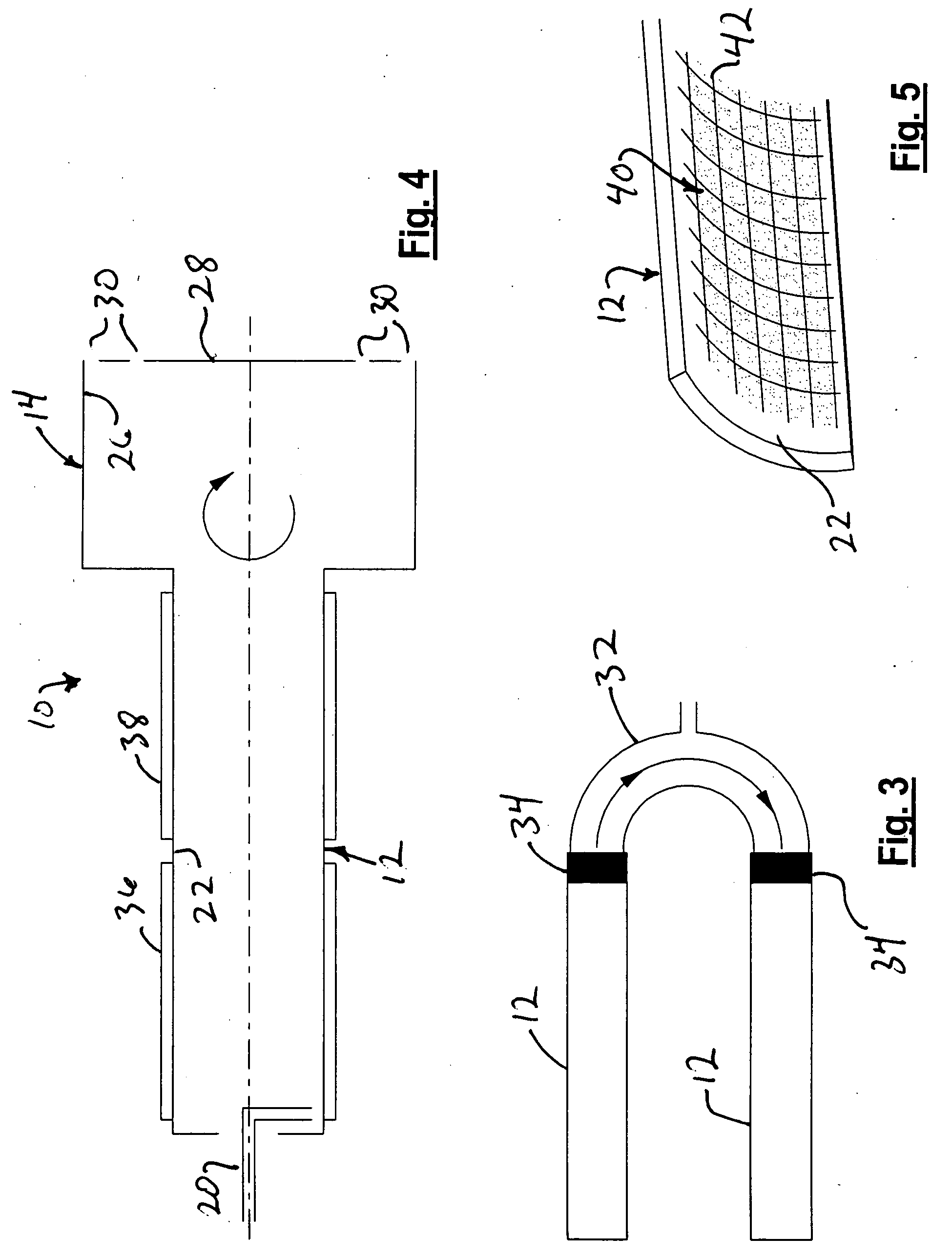

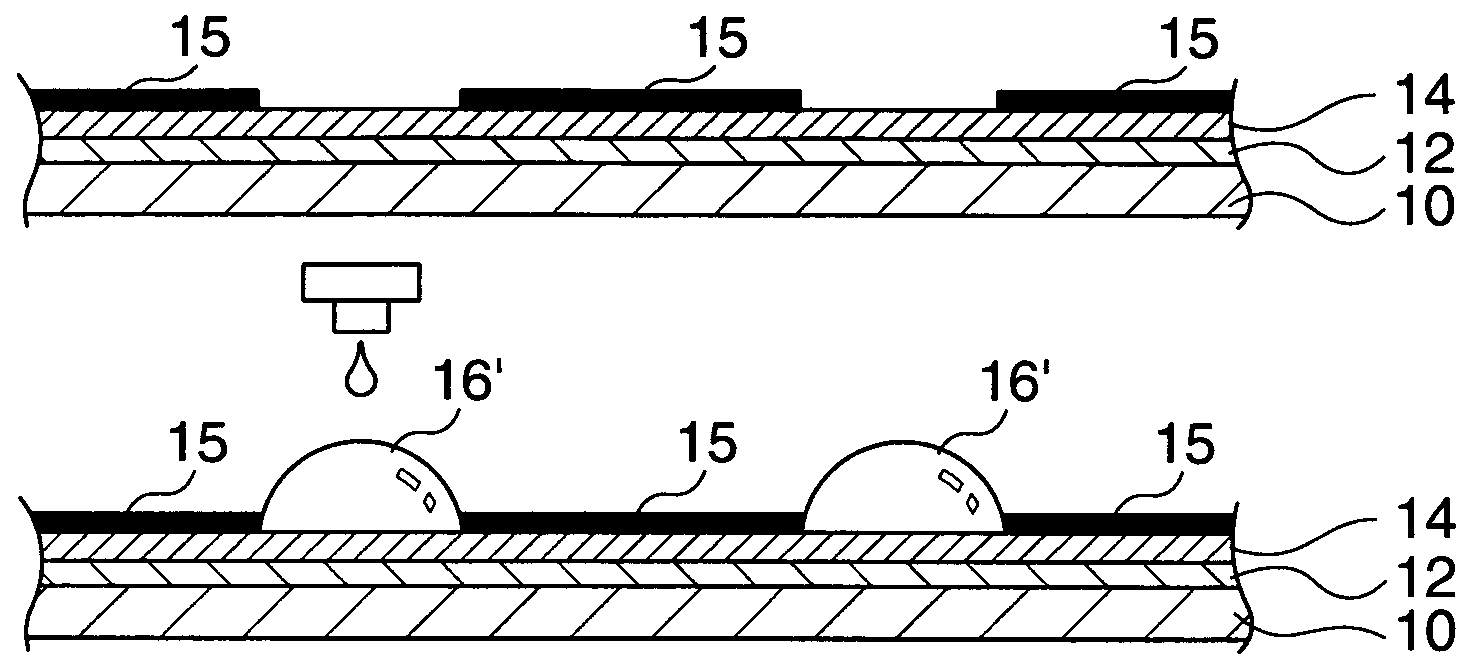

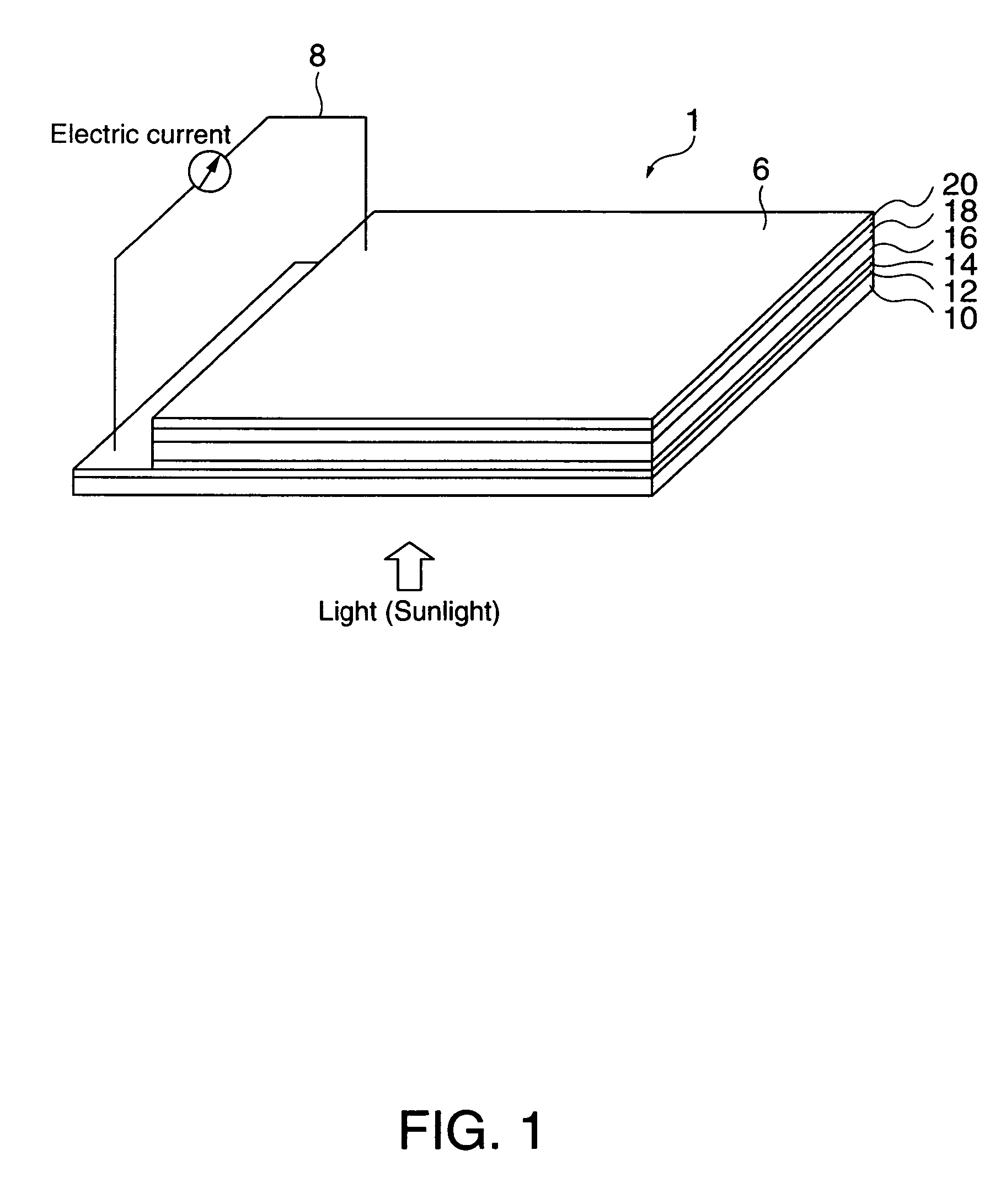

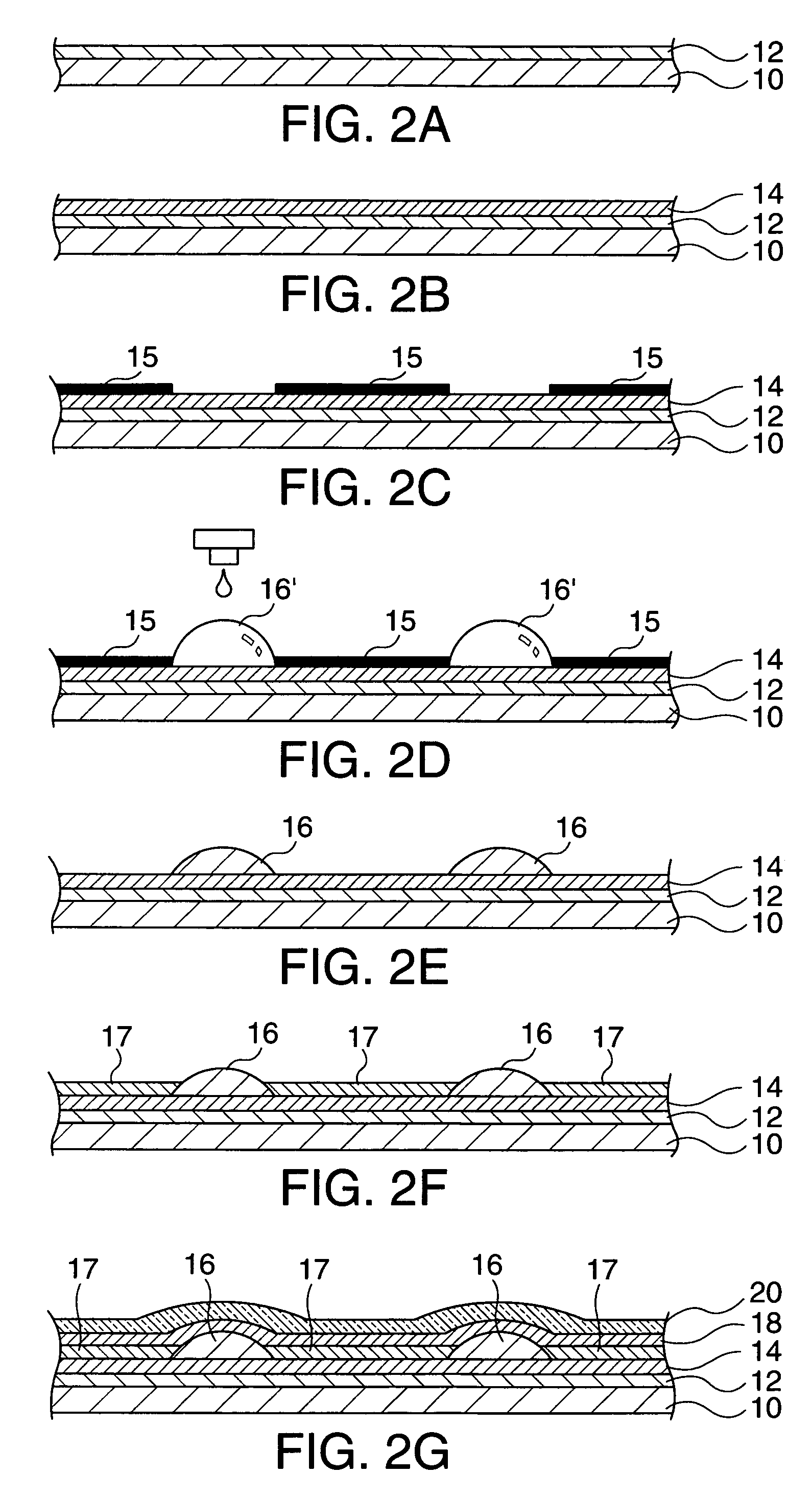

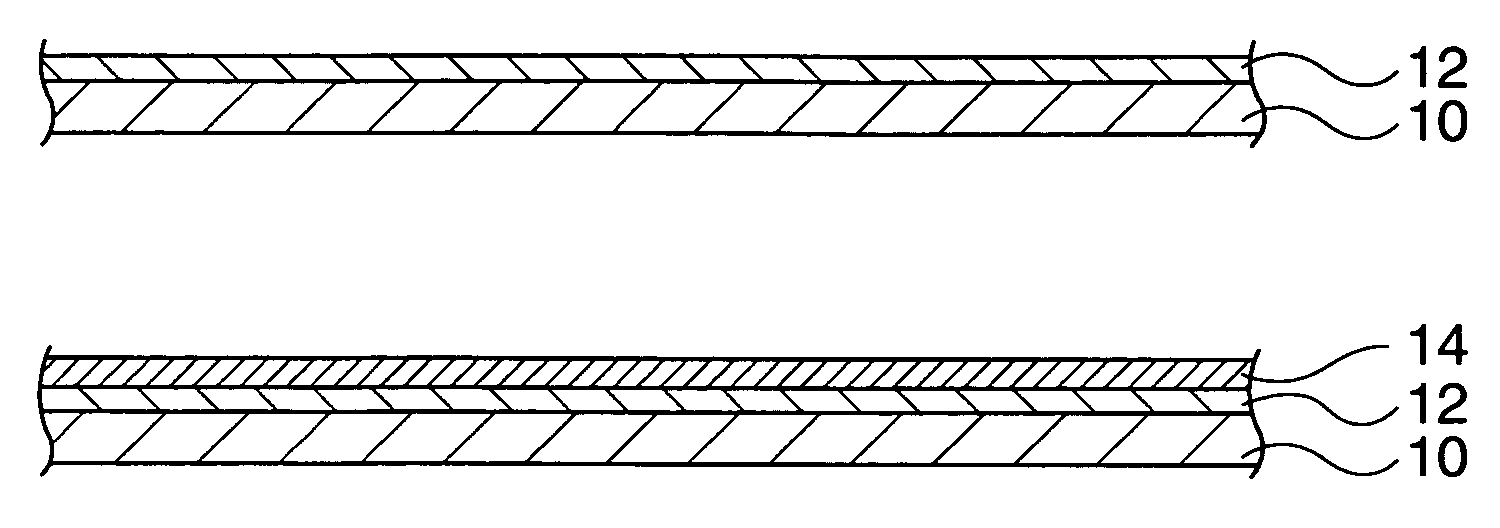

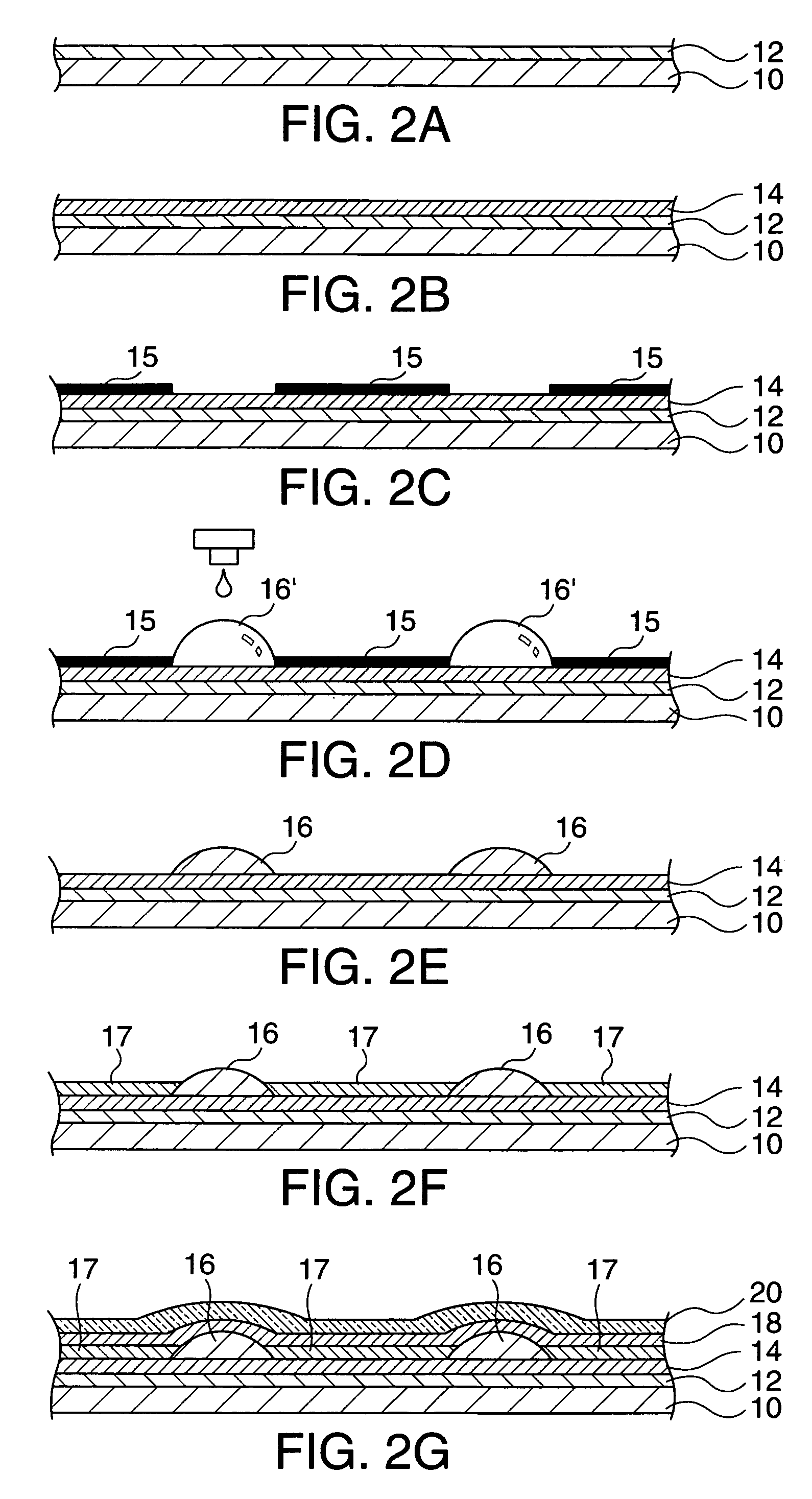

Method for manufacturing photoelectric transducer, and electronic apparatus

InactiveUS7524718B2Low costThin filmFinal product manufactureMaterial analysis by optical meansTransducerPhotoelectric conversion

A method for manufacturing a photoelectric transducer, comprising: forming a first electrode on a substrate; forming a first conductivity-type semiconductor layer on the first electrode; forming an I type semiconductor layer on the first conductivity-type semiconductor layer; forming on the I type semiconductor layer a second conductivity-type semiconductor layer that is different from the first conductivity-type; and forming a second electrode on the second conductivity-type semiconductor layer, wherein the forming of the I type semiconductor layer includes: forming a precursor film of the I type semiconductor layer on the first conductivity-type semiconductor layer by arranging droplets containing a silicon compound in an island shape; and converting the precursor film into the I type semiconductor layer by carrying out heat treatment or photoirradiation treatment to the precursor film.

Owner:SEIKO EPSON CORP

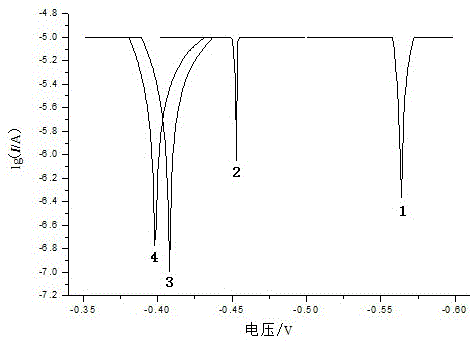

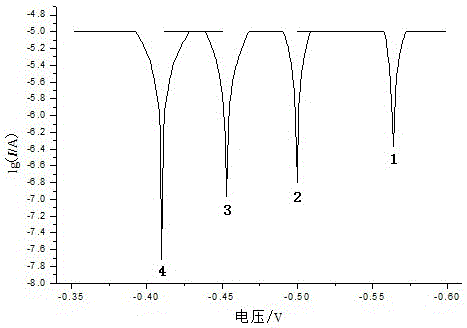

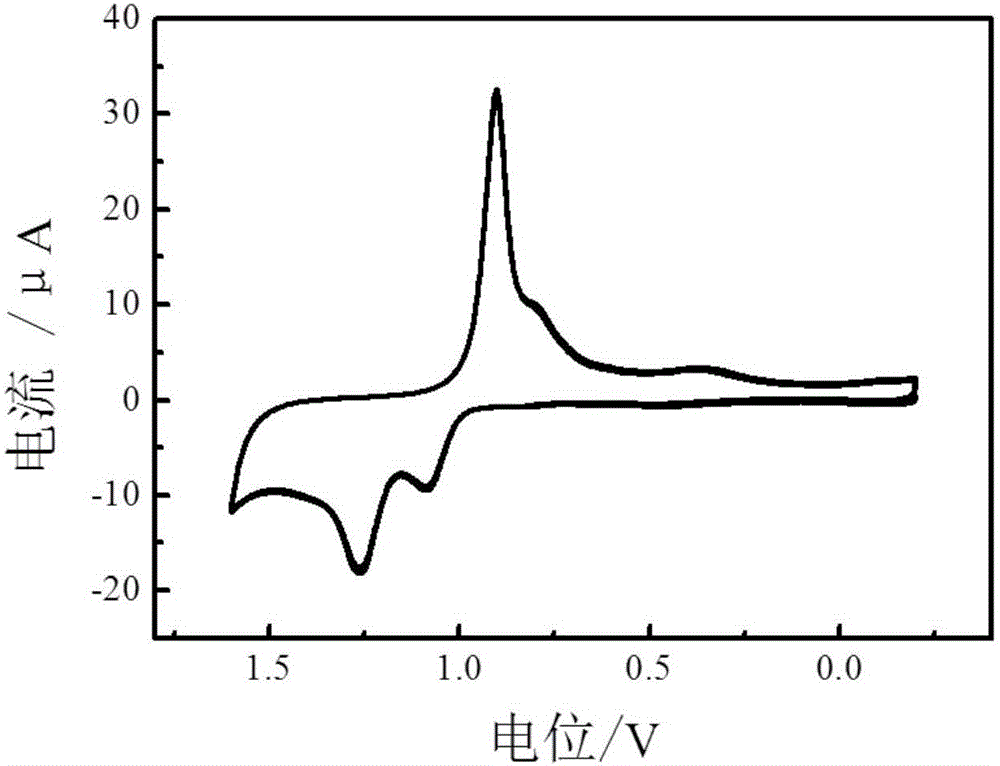

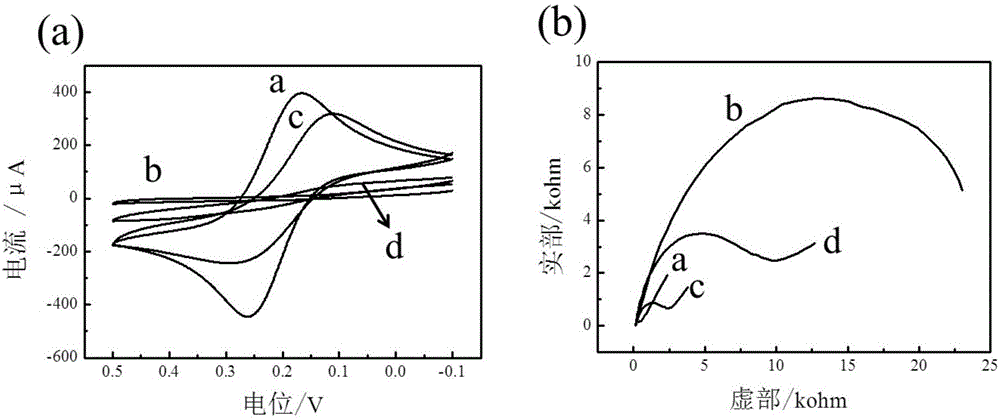

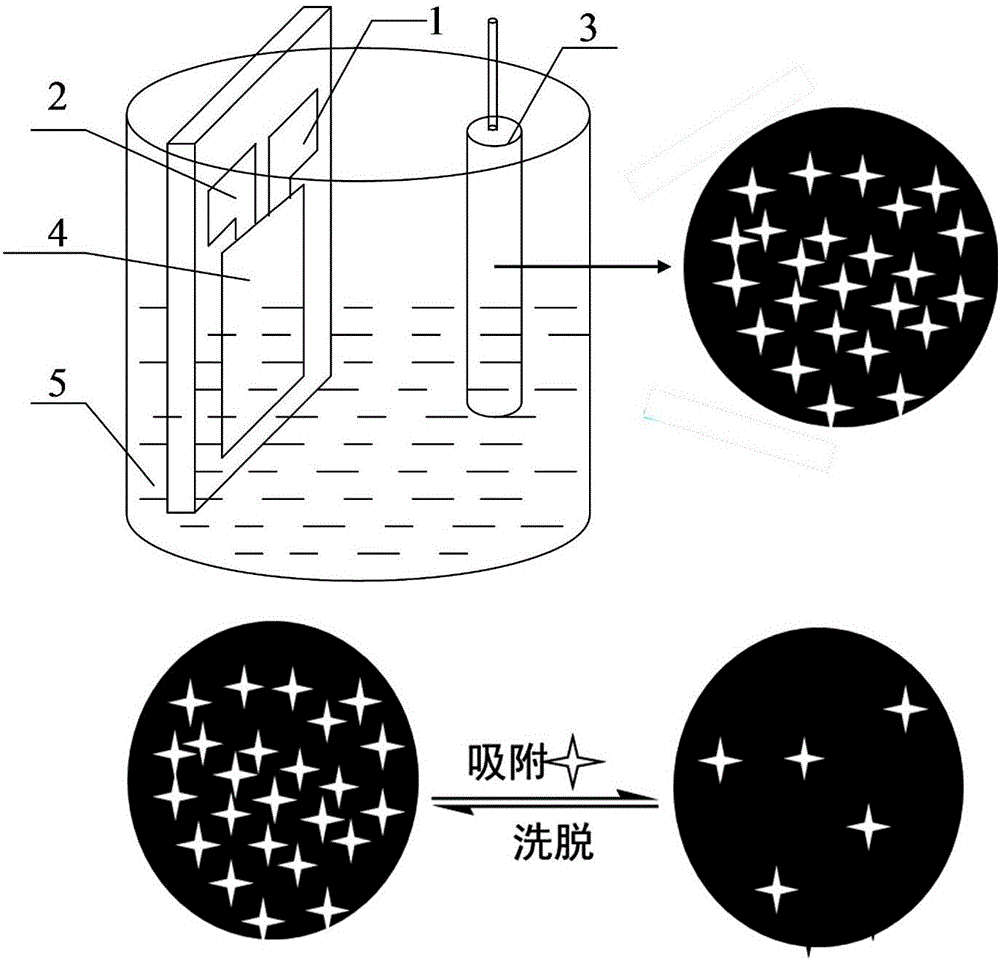

Organic electrochemical transistor sensor based on molecularly imprinted membrane

ActiveCN106770515AHigh sensitivityAchieve specific adsorptionMaterial electrochemical variablesFunctional monomerPower flow

The invention discloses an organic electrochemical transistor sensor based on a molecular imprinted membrane, characterized in that a gate electrode of the organic electrochemical transistor sensor adopts a gold electrode modified with the molecular imprinted membrane, and the gate electrode is obtained by that an object to be detected is used as a template molecule, the template molecule is polymerized with a corresponding functional monomer by cyclic voltammetry to form a polymer membrane on the surface of the gold electrode firstly, and then the template molecule in the polymer template is eluted; and the gate electrode regulates and controls the channel current between a source electrode and a drain electrode through the solution of the object to be tested to constitute the organic electrochemical transistor sensor for selectively recognizing the object to be detected. The invention combines the molecular imprinting technique with the organic electrochemical transistor device, uses the specificity selection of the molecular imprinting technique and the signal amplification function of the organic electrochemical transistor sensor to recognize the specificity of the object to be detected, can selectively absorb the micro and even trace object to be detected, and has good selectivity, high sensitivity and low detection limit.

Owner:HEFEI UNIV OF TECH

Method for manufacturing photoelectric transducer, and electronic apparatus

InactiveUS20060214088A1Reduce manufacturing costThin filmFinal product manufactureSemiconductor/solid-state device manufacturingTransducerPhotoelectric conversion

A method for manufacturing a photoelectric transducer, comprising: forming a first electrode on a substrate; forming a first conductivity-type semiconductor layer on the first electrode; forming an I type semiconductor layer on the first conductivity-type semiconductor layer; forming on the I type semiconductor layer a second conductivity-type semiconductor layer that is different from the first conductivity-type; and forming a second electrode on the second conductivity-type semiconductor layer, wherein the forming of the I type semiconductor layer includes: forming a precursor film of the I type semiconductor layer on the first conductivity-type semiconductor layer by arranging droplets containing a silicon compound in an island shape; and converting the precursor film into the I type semiconductor layer by carrying out heat treatment or photoirradiation treatment to the precursor film.

Owner:SEIKO EPSON CORP

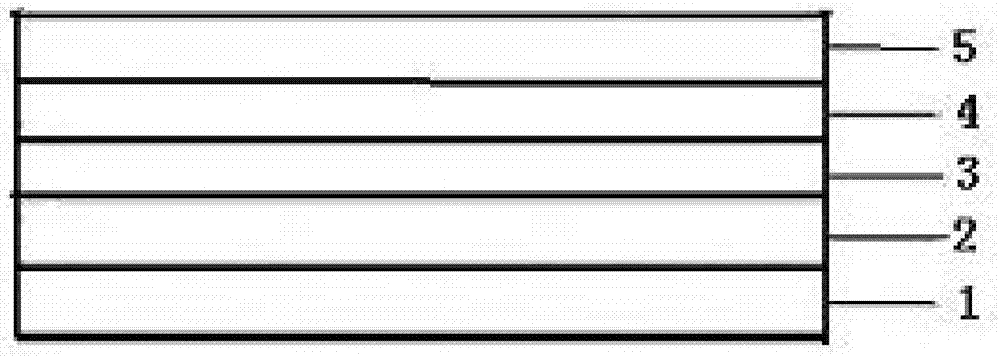

Novel mobile phone film

InactiveCN106976286ADoes not affect touch screen sensingReasonable structural designSynthetic resin layered productsCoatingsAntistatic agentAgricultural engineering

The invention provides a novel mobile phone film. The novel mobile phone film comprises a mobile phone film body, wherein the mobile phone film body is composed of an antistatic layer, a base layer, an anti-radiation layer, a light adjustment layer and a protective layer; the antistatic layer is arranged at the bottom of the mobile phone film body; the base layer is arranged above the antistatic layer; the anti-radiation layer is arranged above the base layer; the protection layer is arranged at the top of the mobile phone film body; the light adjustment layer is arranged below the protective layer. The novel mobile phone film is reasonable in structure design and convenient and practical; the novel mobile phone film can be used for effectively preventing static electricity from generation and has good light transmission property and good anti-radiation effect; meanwhile, touch induction of a mobile phone screen is not influenced.

Owner:合肥美凯电子有限公司

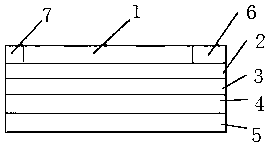

Tempered mobile phone film

InactiveCN107718809AReasonable structural designGood waterproof effectSynthetic resin layered productsGlass/slag layered productsTransmittanceFlexural strength

The invention provides a tempered mobile phone film. The tempered mobile phone film comprises a protective layer, a waterproof layer, a tempered layer, a dimming layer and an antistatic layer in orderfrom top to bottom. The tempering layer has the transmittance of 91.8%, and the flexural strength of 450 to 500Mpa. The dimming layer is prepared from photosensitive materials. The upper part of theprotective layer is provided with a mirror surface film, and the lower end of the protective layer is provided with a diatomite layer around a key hole. The tempered mobile phone film has reasonable structure design, is convenient and practical, has no influence on screen touching reaction of a mobile phone screen, water absorption materials are arranged around the key hole to prevent hands with water spots from being unable to use the key to unlock, waterproof materials are arranged under the water absorption material to prevent general liquid from continuing to permeate, and a waterproof effect is good.

Owner:朱建华

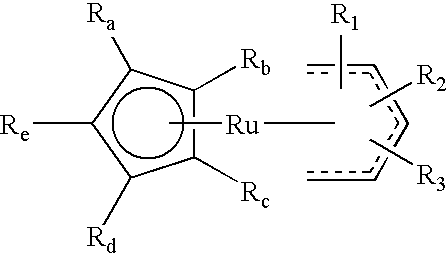

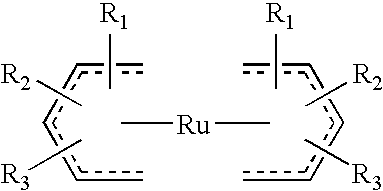

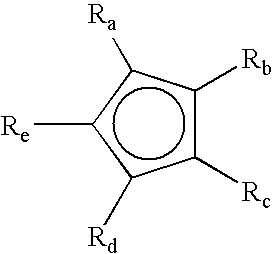

High nucleation density organometallic compounds

ActiveUS20080032503A1Increase nucleation densitySmoother filmGroup 8/9/10/18 element organic compoundsSemiconductor/solid-state device manufacturingRuthenium CompoundsNucleation

This invention relates to high nucleation density organometallic ruthenium compounds. This invention also relates to a process for producing a high nucleation density organometallic ruthenium compound comprising reacting a bis(substituted-pentadienyl)ruthenium compound with a substituted cyclopentadiene compound under reaction conditions sufficient to produce said high nucleation density organometallic ruthenium compound. This invention further relates to a method for producing a film, coating or powder by decomposing a high nucleation density organometallic ruthenium compound precursor, thereby producing the film, coating or powder.

Owner:PRAXAIR TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com