Preparation method of environment-friendly metal antiseptic silane modified waterborne polyurethane resin and antiseptic treatment method

A water-based polyurethane and silane modification technology, applied in metal material coating process, coating and other directions, can solve the problems of poor water resistance, reduced interface adhesion, and poor water stability of a single silanized film, and achieves low cost, Improved anti-corrosion performance and thin coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Take 8g of dimethylolpropionic acid and dissolve it in 20g of N-methylpyrrolidone, then mix it with 110g of polytetramethylene ether glycol, add 55g of isophorone diisocyanate while stirring at room temperature, catalyst butyltin dilaurate 0.2 g, then slowly raise the temperature to 80°C for 2h, then add 2.5g of trimethylolpropane, react at 80°C for 3h, then cool down to 60°C, add 5.5g of triethylamine to neutralize for 20min;

[0031] 2. Use ice water to cool down to about 25°C, stir with a gear disperser at 2500r / min at high speed, first add 160g of water to disperse, then add 15g of γ-aminopropyltriethoxysilane, disperse at high speed for 30min, and let it stand for defoaming. Prepare the anticorrosion resin for subsequent use;

[0032] 3. Purify the metal pattern: degrease and polish the metal, then rinse with water, then use hydrochloric acid solution to remove rust, then rinse with water, and finally rinse with deionized water and dry;

[0033] 4. Dilu...

Embodiment 2

[0039] Dilute the anti-corrosion resin synthesized in Example 1 with water to a solid content of 10%, immerse the purified metal iron plate sample in the diluted water-based resin for 5 minutes, take out the metal sample, and dry it at room temperature for 24-28 hours.

[0040] Performance Testing:

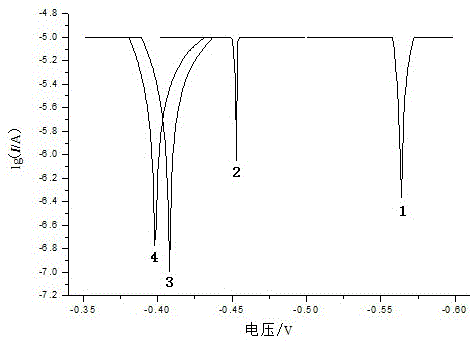

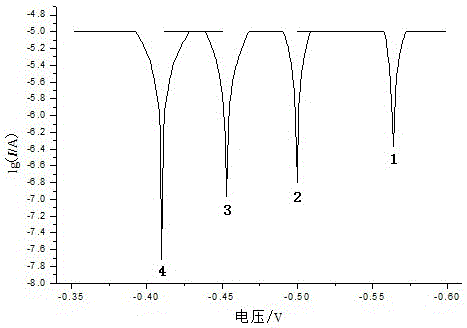

[0041] The performance of this product is compared with that of silane (γ-aminopropyltriethoxysilane) hydrolyzate and German Bayer Bayhydrol UH XP 2592 product in different solid contents, see Table 1, and the Tafel curve test is shown in Table 1. figure 1 .

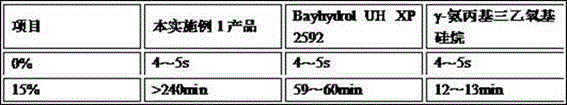

[0042]Table 2 5%CuSO4 pitting test data

[0043] project This embodiment 2 product Bayhydrol UH XP 2592 γ-Aminopropyltriethoxysilane 0% 4~5s 4~5s 4~5s 10% 175~180min 29~30min 9~10min

Embodiment 3

[0045] 1. Preparation of water-based polyurethane prepolymer: Mix polytetramethylene ether glycol PTMEG, isophorone diisocyanate, dimethylol propionic acid and solvent at room temperature, then slowly heat up to 80°C, react for 2 hours, and then Add trimethylolpropane, continue to react at 80°C for 3h, cool down to 60°C after the reaction is completed, add triethylamine and solvent, and neutralize for 20min to obtain a water-based polyurethane prepolymer;

[0046] 2. Preparation of silane-modified waterborne polyurethane: Cool the waterborne polyurethane prepolymer prepared above to 22°C with ice water, stir vigorously at 1500r / min, add water to disperse at high speed, and add γ-aminopropyltriethoxy Silane, capping the prepolymer, dispersing at a high speed for 30 minutes, standing for defoaming, and preparing an environmentally friendly metal anti-corrosion silane-modified waterborne polyurethane resin.

[0047] The total amount of prepolymer is the mass sum of polyol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com