Patents

Literature

54results about How to "Environmentally friendly and pollution-free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel environmental-friendly wear and high-temperature resistant friction plate

ActiveCN102478090ANo environmental protection and no pollutionEnvironmentally friendly and pollution-freeFriction liningEngineeringTemperature resistance

A novel environmental-friendly wear and high-temperature resistant friction plate relates to the field of production and processing of automobile parts; a technological process comprises the following steps of: drying asbestos-free cloth; preparing a resin alcoholic solution, wherein the ratio of phenolic resin to hexamethylene tetramine to alcohol is 1:1:5; dipping the asbestos-free cloth by resin; orderly airing the asbestos-free cloth dipped with the resin on a material frame; starting a rubber mixing mill, adjusting the roller spacing to be 1-2mm, and placing styrene-butadiene rubber on a rubber mixing mill for mastication; adding an accessory ingredient padding for mixing; adding a solvent naphtha padding for pulping; carrying out rubber dipping on the asbestos-free cloth dipped with the resin through a rubber dipping machine; tailoring the asbestos-free cloth dipped with a sizing material, and winding the tailored asbestos-free cloth on a blank; putting the blank wound with the asbestos-free cloth in a pressing machine, and carrying out hot-press forming on the blank; putting the formed blank in a drying oven for carrying out thermal treatment; after finishing the thermal treatment, polishing the product with a machine tool; and checking the packaging and putting the product in storage. The novel environmental-friendly wear and high-temperature resistant friction plate has the beneficial effects of environmental friendliness, abrasion resistance and high temperature resistance.

Owner:来安县隆华摩擦材料有限公司

Anticorrosion type spraying quick-setting rubber asphalt waterproof coating

InactiveCN102965015AEnvironmentally friendly and pollution-freeGood acid and alkali resistanceConjugated diene hydrocarbon coatingsNatural rubber coatingsBitumen emulsionSpray coating

The invention relates to an anticorrosion type spraying quick-setting rubber asphalt waterproof coating. The coating is an anticorrosion type water-based spraying coating prepared by adding a preservative into a liquid rubber asphalt mastic emulsion component which is prepared from modified-emulsified asphalt and high-molecular polymer rubber latex, and then mixing the liquid rubber asphalt mastic emulsion component with a coagulating agent component in proportion. Besides environmentally-friendly and non-pollution properties, the anticorrosion coating provided by the invention has the advantages of excellent acid-base resistance property, water resisting property, hot brine resisting property, heat and humidity resisting property and temperature change resisting property, accords with the requirement on heavy corrosion protection in the anticorrosion coating and can be widely used for heavy corrosion protection coating on the surface of concrete, metal and wood and the like in various buildings and structures, over-ground, underground or underwater steel structures, chemical engineering machines, pipelines, tanks, ships, bridges, docks and the like.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

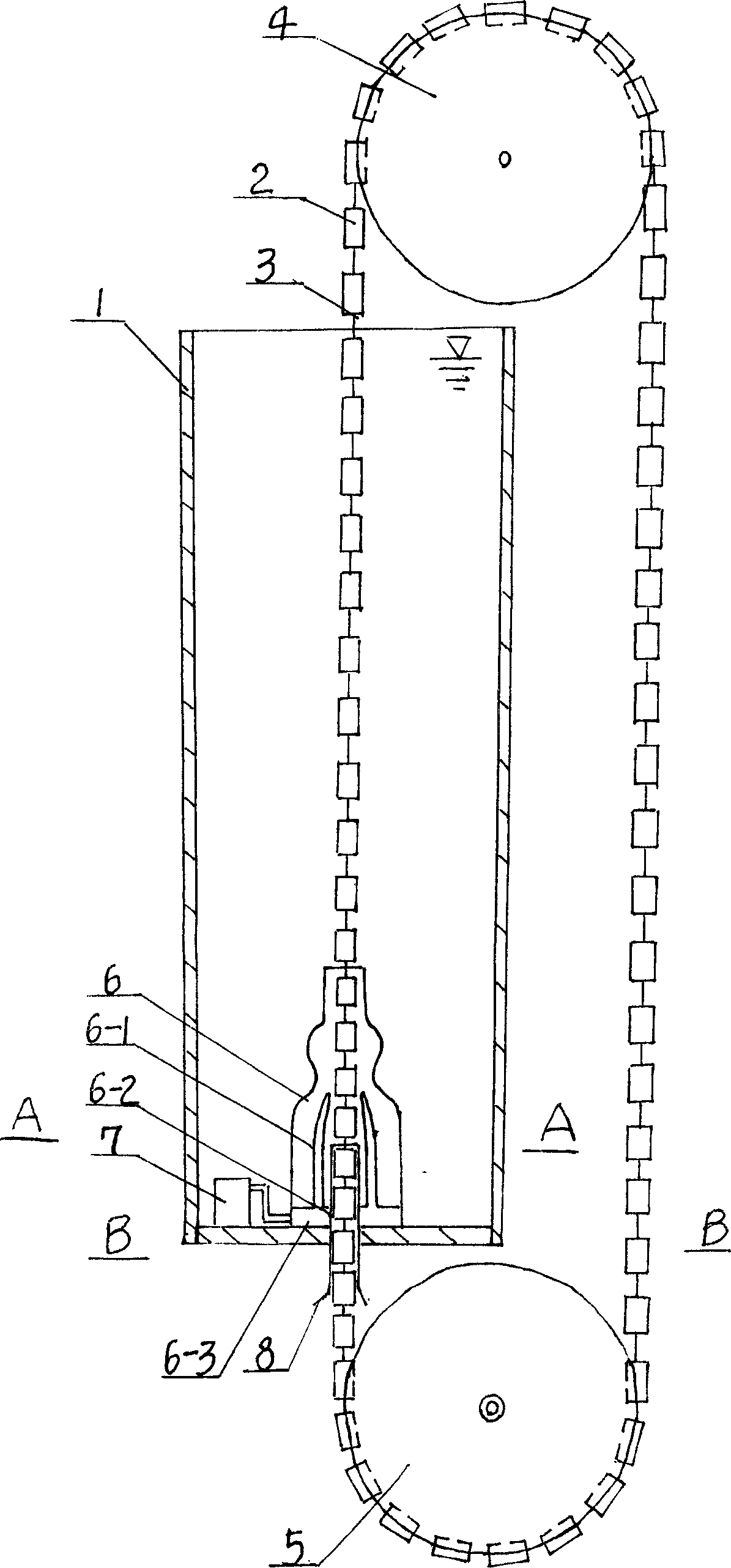

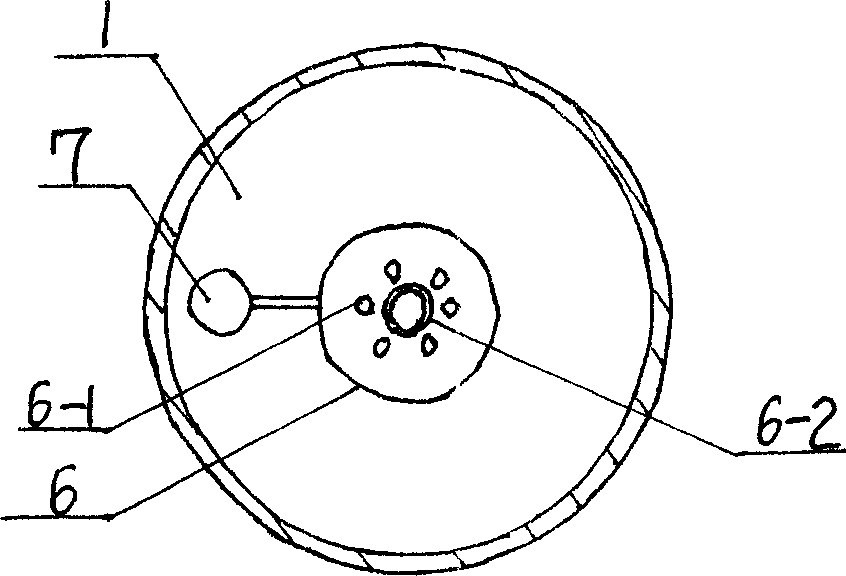

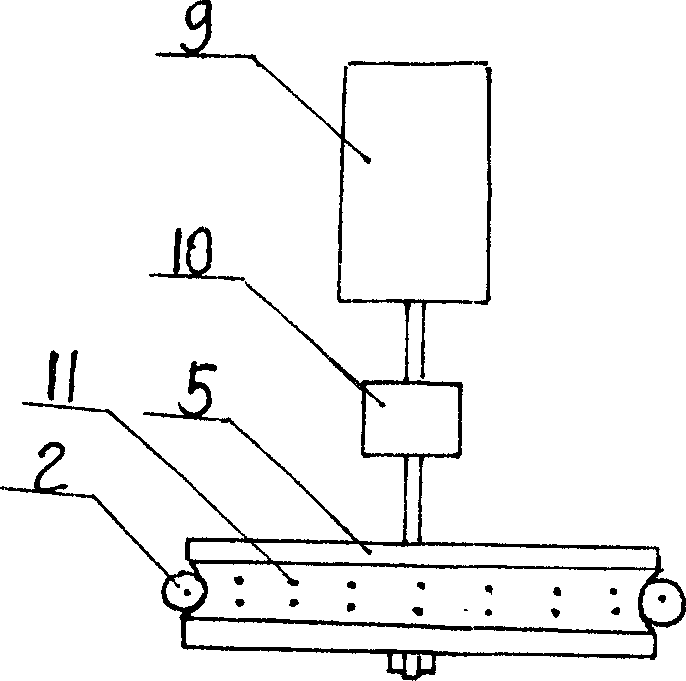

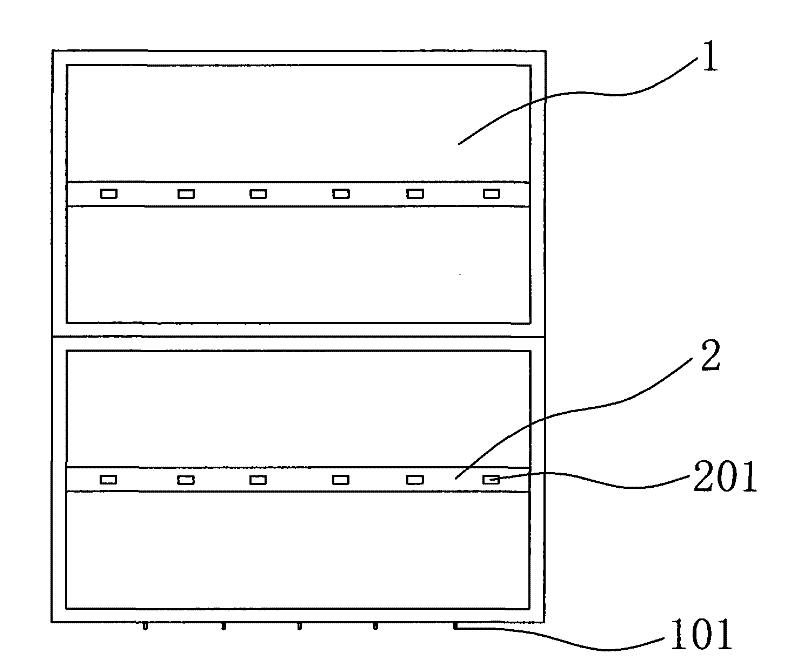

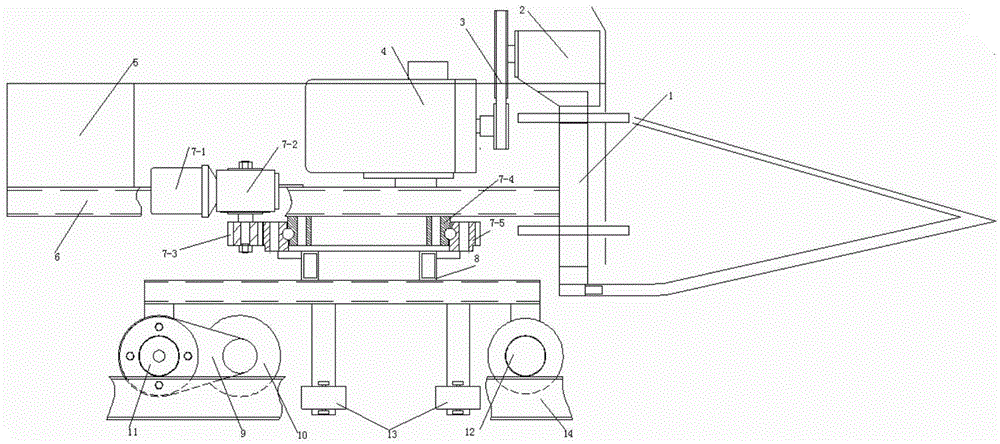

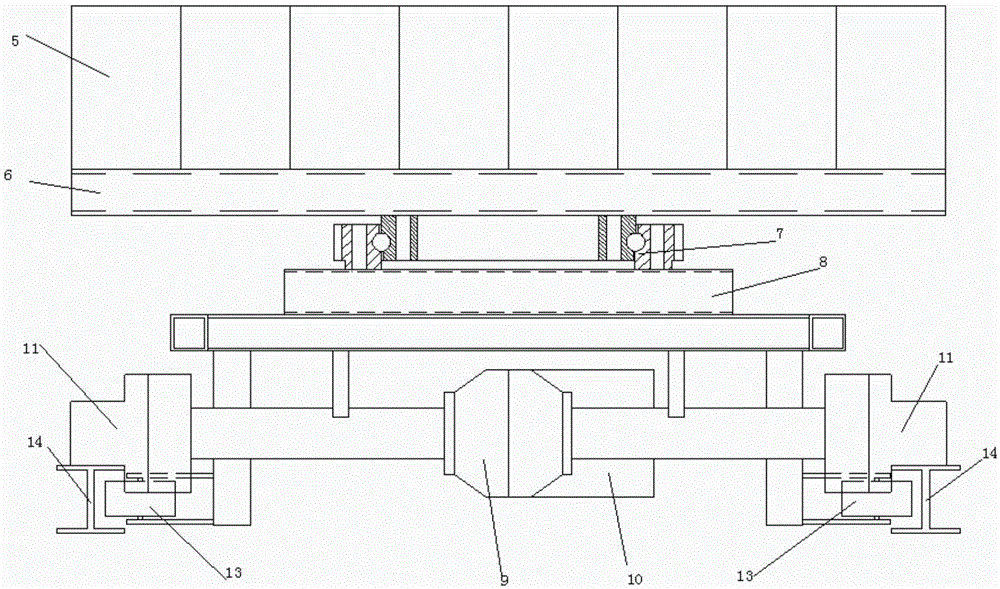

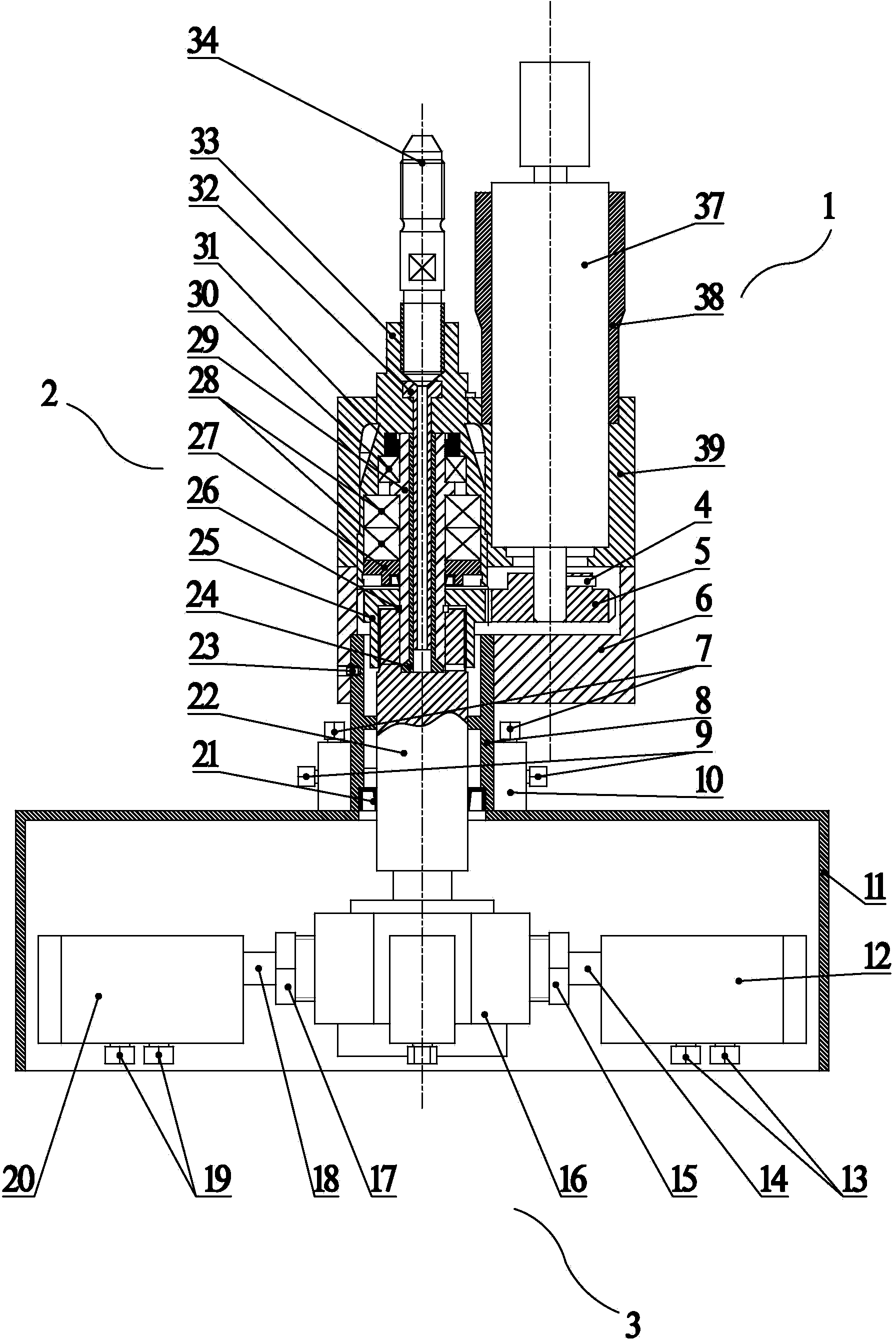

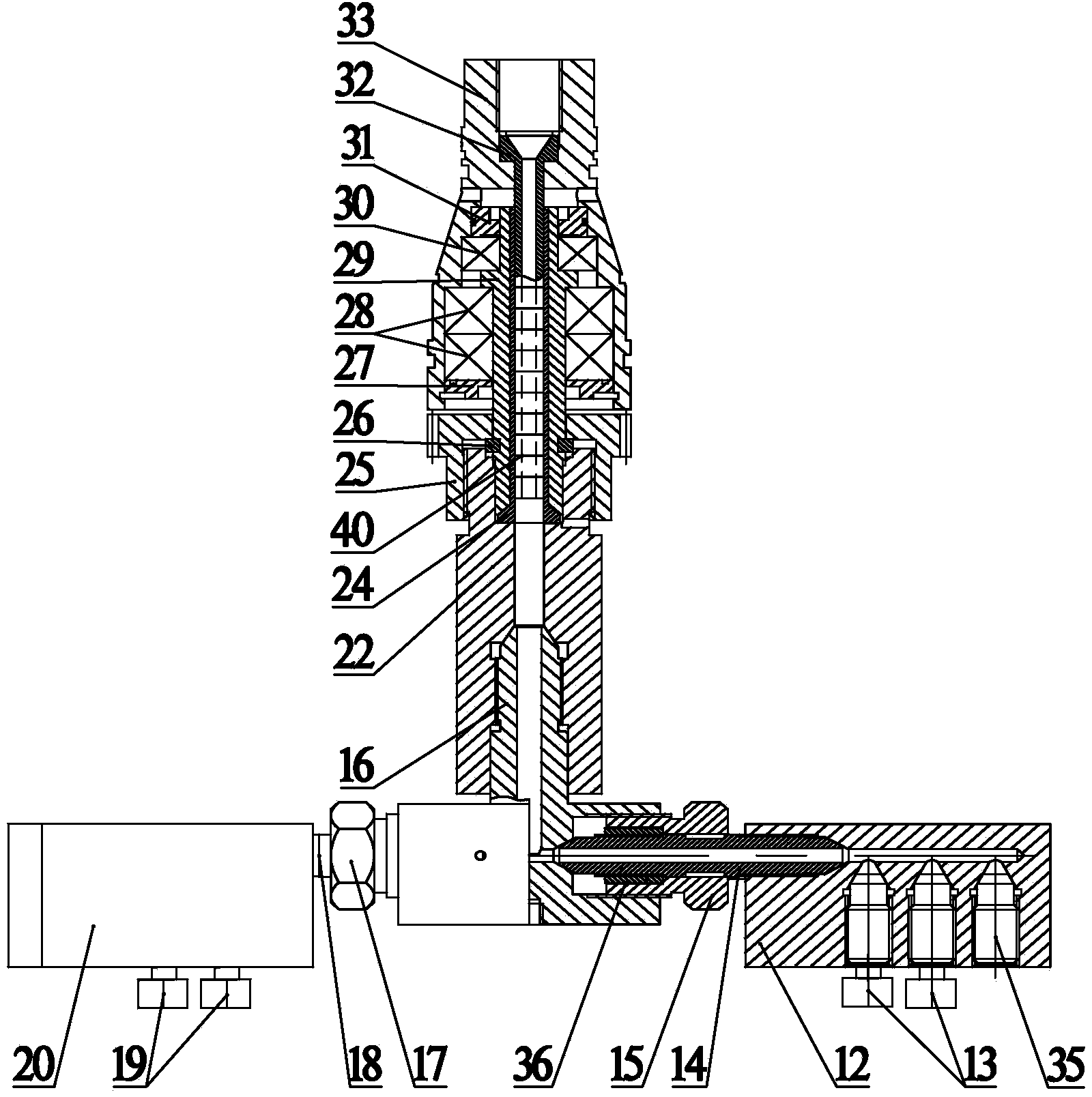

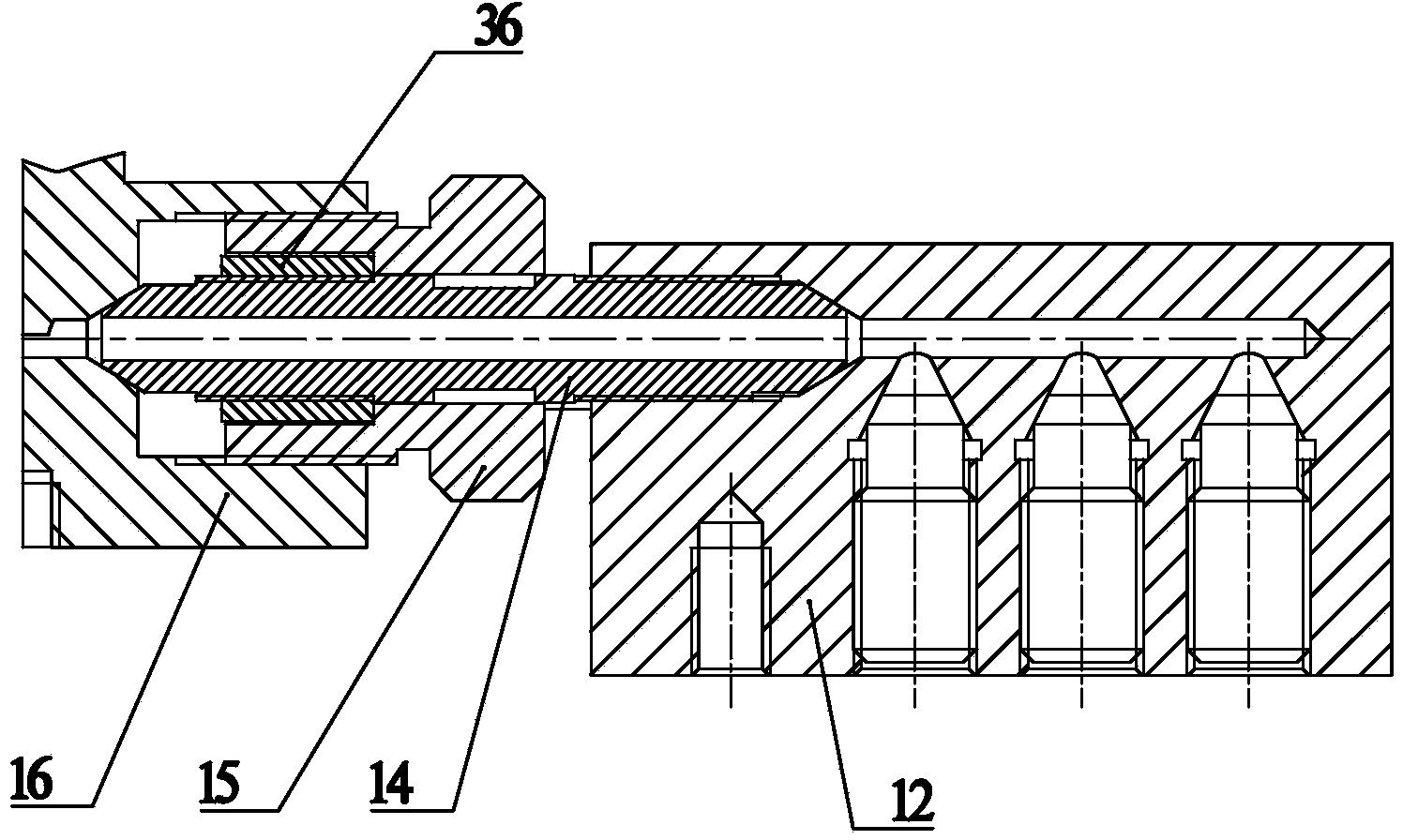

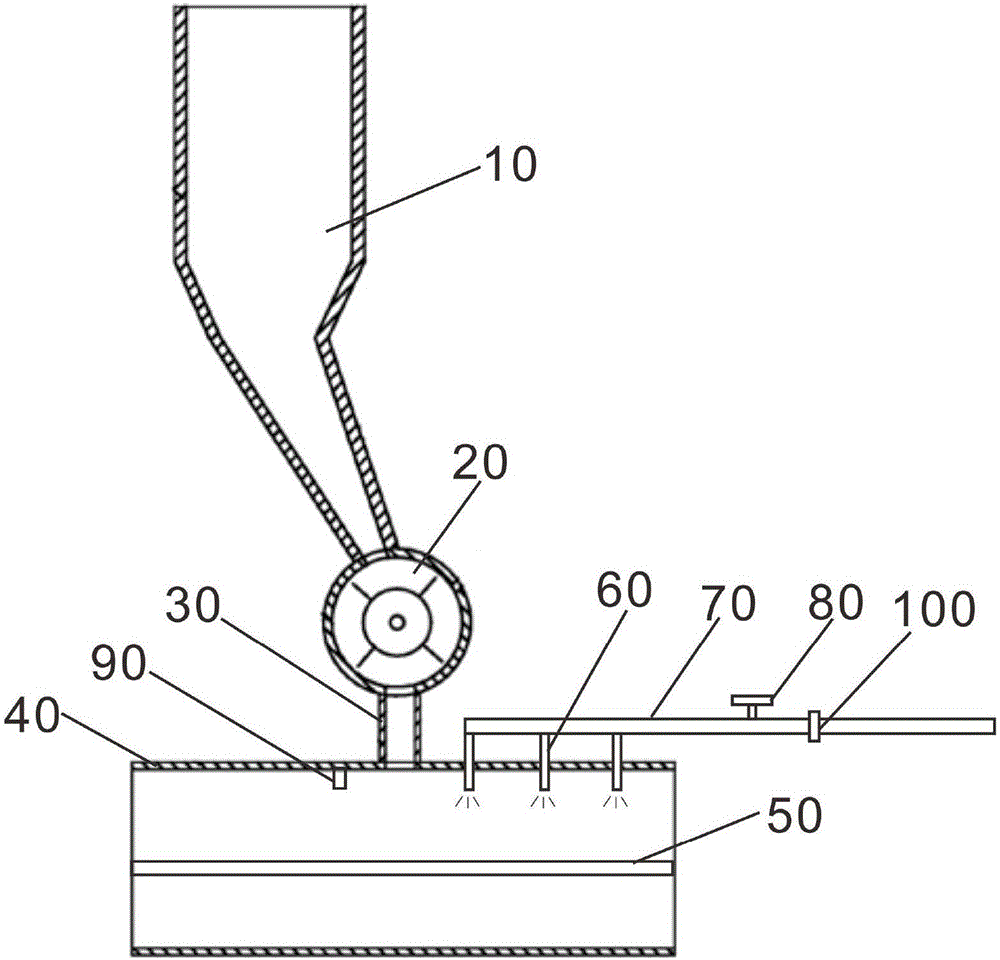

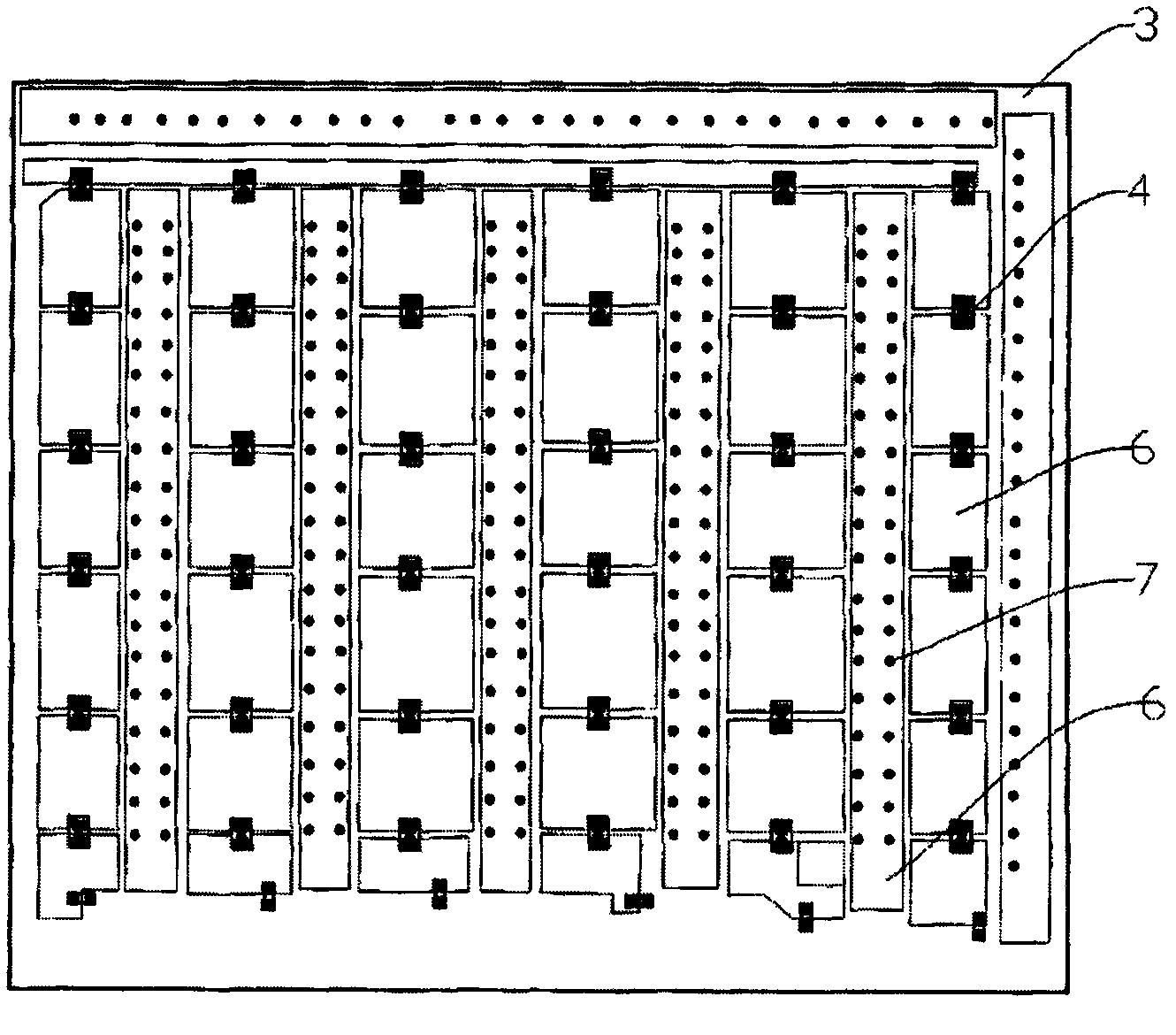

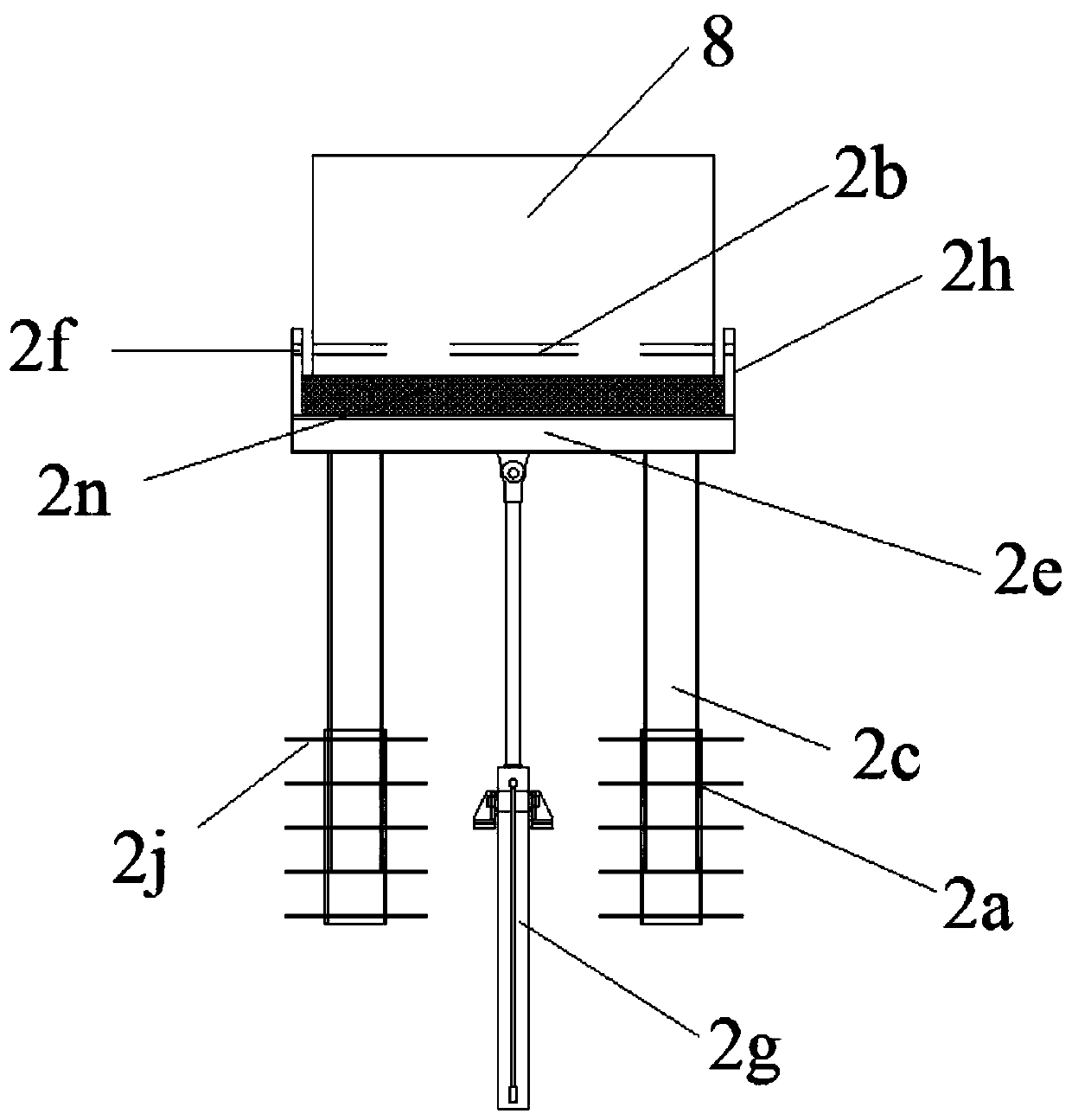

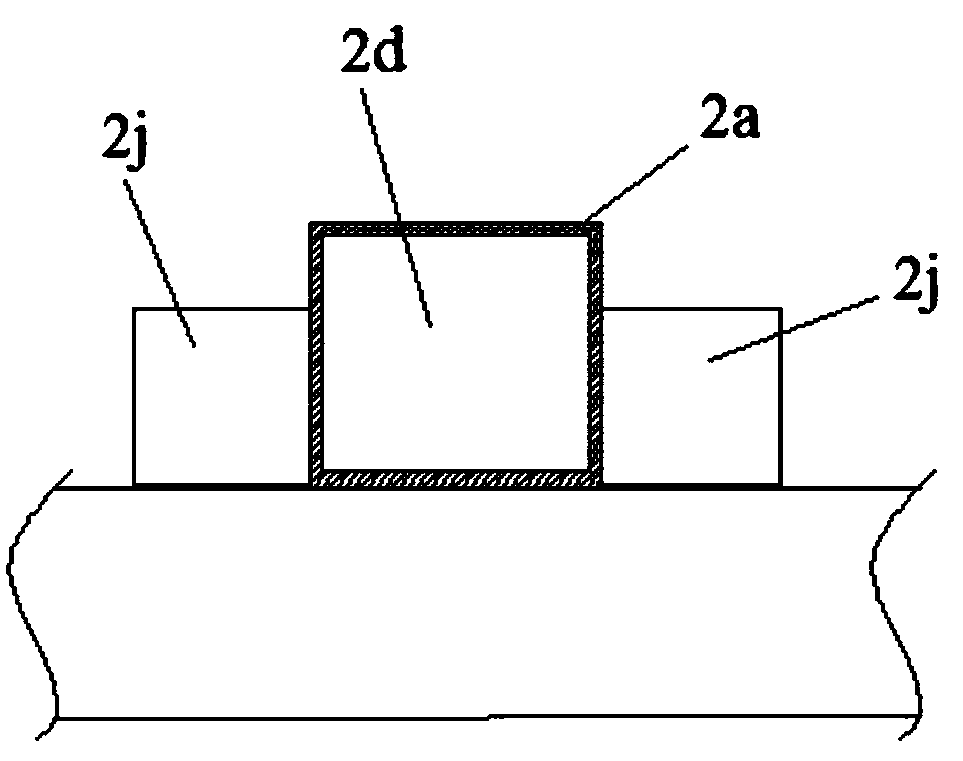

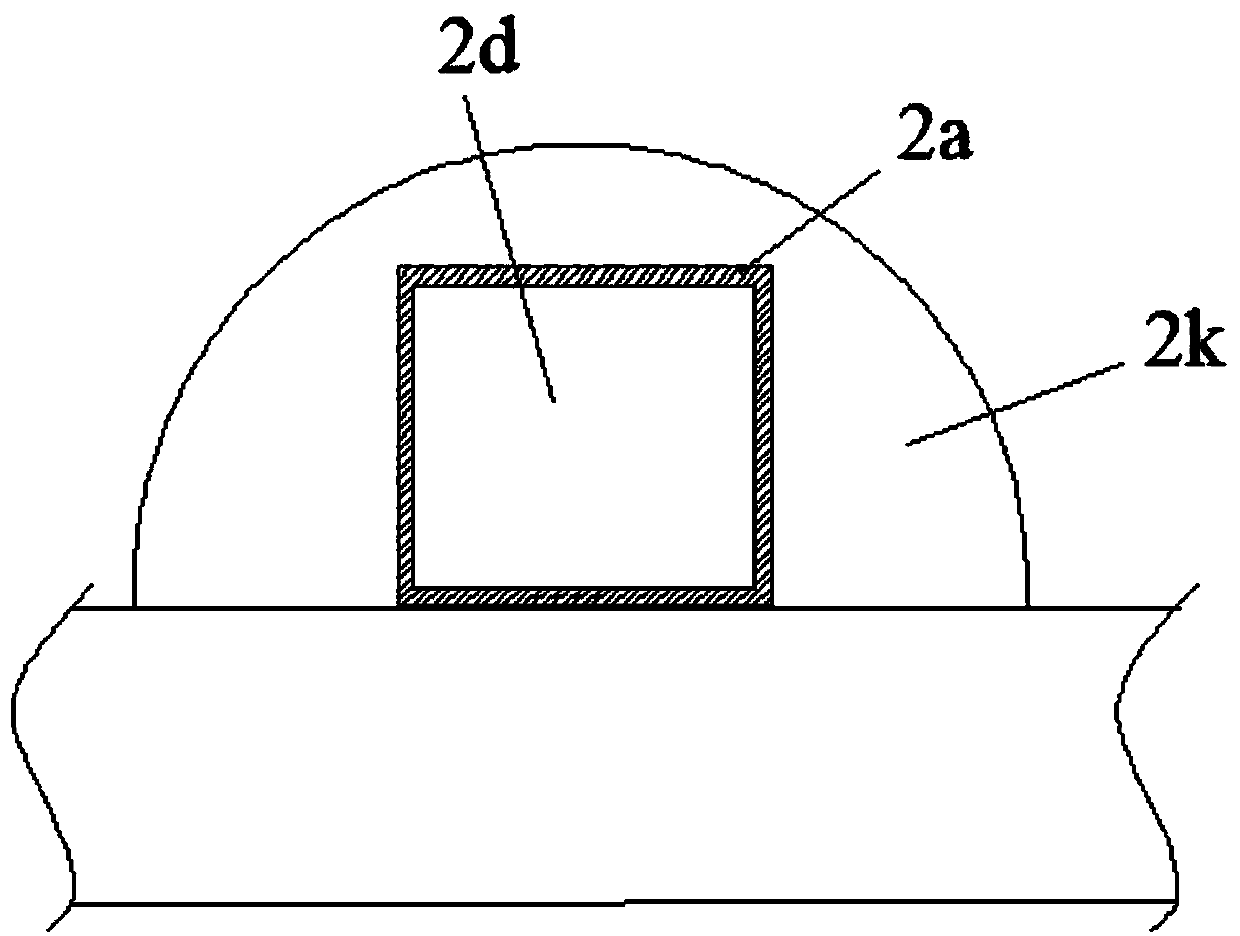

Rail bearing type field machine-transplanted seedling tray precision drilling complete equipment

InactiveCN101836531ATake advantage ofLabor savingSeed depositing seeder partsRegular seed deposition machinesEngineeringSeedling

The invention relates to farmland sowing equipment, in particular to rail bearing type field machine-transplanted seedling tray precision drilling complete equipment for operation in a field, and aims to solve the technical problems of structures, sowing efficiency and the utilization of natural resources of the conventional similar equipment. The equipment comprises seedling tray components and mechanical sowing equipment and adopts the design key point that the seedling tray components are a combined type seedling tray arranged in the field; and a travelling wheel of a machine frame of the mechanical sowing equipment slides on a track of the rail bearing type seedling tray for sowing. An integrated ejector pin is arranged in a roller of a seed falling component, and the integrated ejector pin integrates a row of thimbles along an axial direction; the integrated ejector pin is connected with ejector pin rings, and an assembly gap is reserved between the two adjacent ejector pin rings on the integrated ejector pin; a base plate of the mechanical sowing equipment is rotationally connected with a balanced support frame; and independent pulleys are connected to both ends of the balanced support frame, and each independent pulley only contacts one seedling tray component. The equipment not only reduces the labor cost and improves the sowing efficiency, but also utilizes the natural resources fully, is pollution-free and environmental-friendly, and has high popularization and application value.

Owner:宁波市镇海区精量农业科技开发有限公司

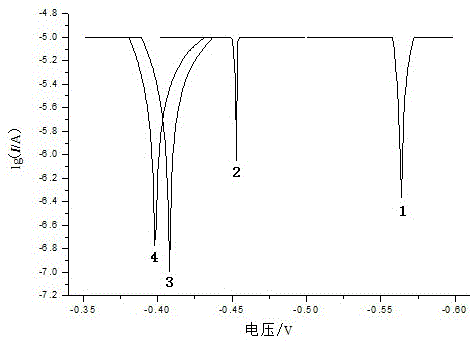

Hydraulic buoyancy gravity generation technology device

InactiveCN1831327AShort construction periodHigh quality and low priceHydro energy generationMachines/enginesGravitational forceElectricity

The invention is a novel hydraulic-buoyancy-gravity generating set, comprising cylindrical upright water tower, hydraulic-buoyancy-gravity generator, hydraulic- buoyancy-gravity converter and generating set, generating electricity by hydraulic power, buoyancy and gravity, able to maximum recycle hydroenergy resources and largely reduce per kw investment and largely shorten construction cycle of generating engineering. And it can make generating engineering constructed in mountain areas, plains, places rich with water resources, and places short of water resources.

Owner:HEBEI AGRICULTURAL UNIV.

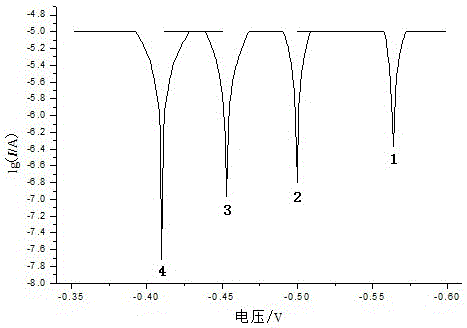

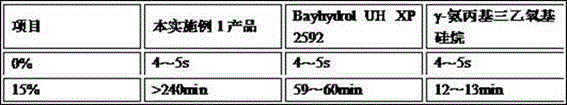

Preparation method of environment-friendly metal antiseptic silane modified waterborne polyurethane resin and antiseptic treatment method

InactiveCN105017500AIncrease the degree of cross-linkingImprove adhesionMetallic material coating processesPolymer scienceIce water

The invention relates to a preparation method of environment-friendly metal antiseptic silane modified waterborne polyurethane resin and an antiseptic treatment method, and belongs to the technical field of metal surface antiseptic treatment. The preparation method comprises the steps that polyhydric alcohols, polyisocyanates and a hydrophilic chain-extending agent react for 2 h and then added with a cross-linking agent, a reaction continues to be carried out for 3 h at 80 DEG C, the mixture is added with triethylamine for neutralizing after being cooled to 60 DEG C, and a waterborne polyurethane prepolymer is obtained; then the waterborne polyurethane prepolymer is cooled by ice water to room temperature and added with water under strong stirring for high-speed dispersion, a silane coupling agent is added to terminate the prepolymer, high-speed dispersion is carried out for 30 min, standing and defoaming are carried out, and therefore the metal antiseptic silane modified waterborne polyurethane resin is obtained. The invention further discloses the antiseptic treatment method for metal. The antiseptic treatment method comprises the steps that the obtained antiseptic resin is placed in a container, evenly attached to the surface of the purified metal and then driven at room temperature. By using the antiseptic resin for treating the surface of metal, the antiseptic performance is remarkably improved, the technology is simple, a coating film is thin, and the cost is low.

Owner:广东德丽雅新材料有限公司 +1

Rail sleeper type field machine-transplanted seedling tray precision sowing complete equipment

InactiveCN101836531BTake advantage ofLabor savingSeed depositing seeder partsRegular seed deposition machinesEngineeringSeedling

Owner:宁波市镇海区精量农业科技开发有限公司

Full-electric greenhouse harvester

InactiveCN105052385ARealize automatic harvestingRealize the collectionHarvestersDrive wheelGreenhouse

The invention discloses a full-electric greenhouse harvester. The full-electric greenhouse harvester comprises a header, a speed reducer, a belt transmission device, a header driving motor, a storage battery set, an upper framework, a header rotation device, a lower framework, an electric driving axle, driving wheels, driven wheels and rail clamping wheels. The harvester is simple in design and easy to operate, and the functions of advancing, backing and walking speed adjusting and function of enabling the header to rotate within 360 degrees in the horizontal plane so as to adjust the harvesting direction can be achieved. A rail type walking system is adopted for the harvester, and therefore the harvester can transfer to work and operate continuously between adjacent pools and complete all harvesting tasks in a greenhouse; the harvesting efficiency can be 8-10 times that of workers, and therefore the labor cost for greenhouse maintenance is substantially lowered. In the harvesting process, the harvester can convey harvested plants rightwards in a vertical mode and place the plants on a channel between the pools in order, and therefore the plants can be conveniently collected and treated.

Owner:ZHEJIANG UNIV

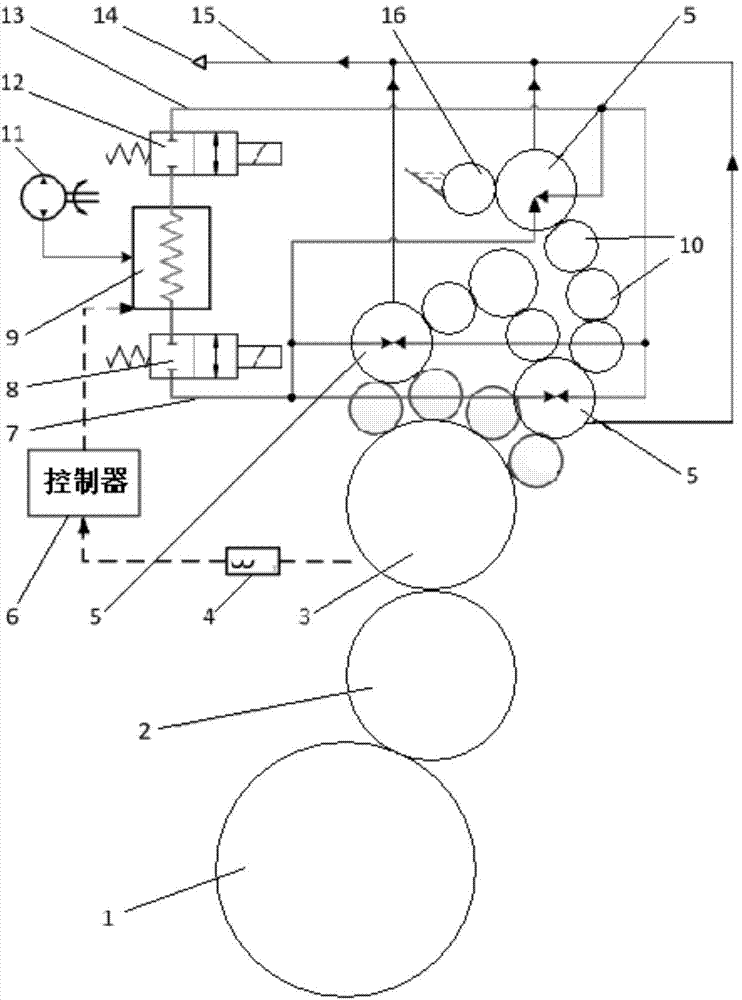

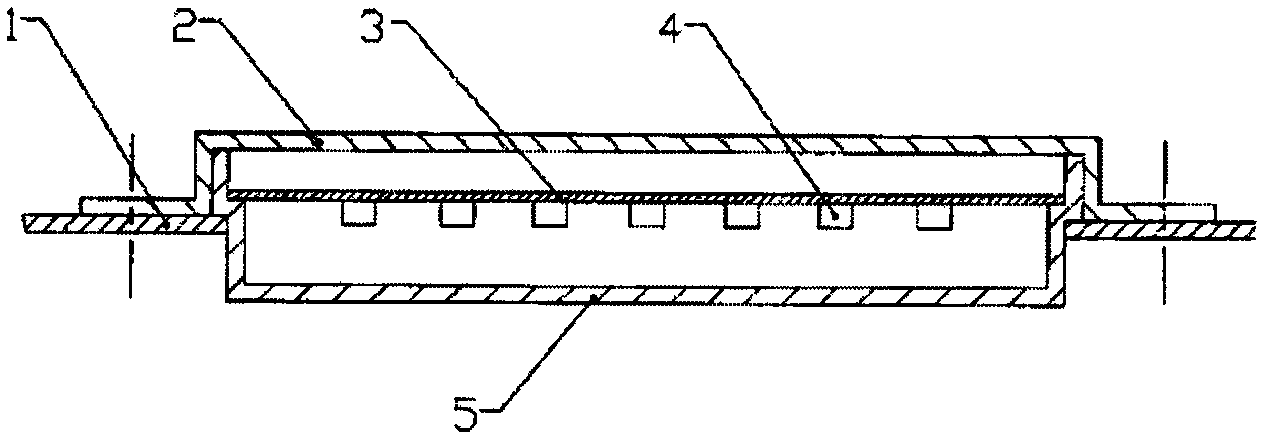

Printing plate temperature control device for waterless offset printing

InactiveCN104325789AEasy to controlReduced sealing requirementsRotary lithographic machinesPrinting press partsTemperature controlHeat flow

The invention discloses a printing plate temperature control device for waterless offset printing. The device comprises a vortex tube used for generating cold and heat air flows, wherein a heat flow end of the vortex tube is provided with an adjusting valve which is used for adjusting the temperature and flux of the air flows output from a cold flow end and the heat flow end. The device is characterized by further comprising a temperature sensor, a controller and at least one temperature control ink roller, wherein the temperature ink roller is arranged between an ink fountain roller and a printing plate cylinder of a waterless offset printing machine; the cold flow end and the heat flow end of the vortex tube are respectively connected to the temperature control ink roller by a pipeline; a first stop valve is arranged at the upstream of the pipeline connected with the cold flow end; a second stop valve is arranged at the upstream of the pipeline connected with the heat flow end; the temperature sensor is used for detecting the surface temperature of the printing plate cylinder of the waterless offset printing machine, and transmits the temperature to the controller; the controller generates a control signal according to a predetermined proper printing temperature range to control the actions of the adjusting valve, the first stop valve and the second stop valve. The printing plate temperature control device for waterless offset printing disclosed by the invention is simple in structure and highly efficient in control.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Gel casting forming method for high-voltage dielectric ceramic

ActiveCN101544027AOvercome surface oxidation of green bodyEnvironmentally friendly and pollution-freeCeramic shaping apparatusClay processing apparatusIonNon toxicity

The invention relates to a casting formingmethod for producing dielectric ceramic. Barium titanate powders, dispersants, agarose and deionized water are mixed through ball milling according to a certain proportion; experiment on the rheological property is carried out on the obtained suspension liquid after ball milling for certain time, and casting is carried out under the room temperature; and green bodies obtained by casting together with molds are put in a drying oven of 90 DEG C. The method has the advantages that firstly the defects of the traditional forming method are overcome, the gel casting technology is adopted for forming, and novel environment-friendly and non-pollution nontoxic gel system agarose is used, great improvement is made in regulating the gel technology, the gel forming time is controlled through changing the using amount of the components of a gel system, the gel temperature, and the like, so that forming in short time can be realized, and the settlement of suspended solids is reduced to obtain evenly formed ceramic green bodies with little defect. Compared with other methods, the invention has the advantages of moderate reaction conditions, simple technological operation, non-toxicity, no pollution, high forming quality of green bodies, small internal stress and small cracks, so that the dielectric ceramic has a broader application prospect in the high voltage field.

Owner:XIAN YISH ELECTRIC

Technology for processing plant leaves

InactiveCN101618626AImprove cleanlinessIncrease surface tensionLamination ancillary operationsDrying solid materials with heatEnvironmental resistanceCompound a

The invention relates to a technology for processing plant leaves, comprising the following technological steps: selecting leaves and removing dirt, namely, selecting the leaves with a certain area and no toxicity and removing the dirt after picking; drying and smoothing, namely, putting the plant leaves in a dry clip and carrying out drying and smoothing processing; and compounding a film, namely, bonding the film and the surfaces of the plant leaves. The step of picking the leaves and removing the dirt and the step of compounding the film also can have one or more following technological steps: surface wax removal, vein planishing, ultrasonic washing, drying and smoothing, surface roughening and mechanical rolled flattening. The invention has the characteristics of simple technology, low cost, extensive application of the plant leaves after being processed, environmental protection, no pollution, superior degradable performance and the like.

Owner:蒋海贵

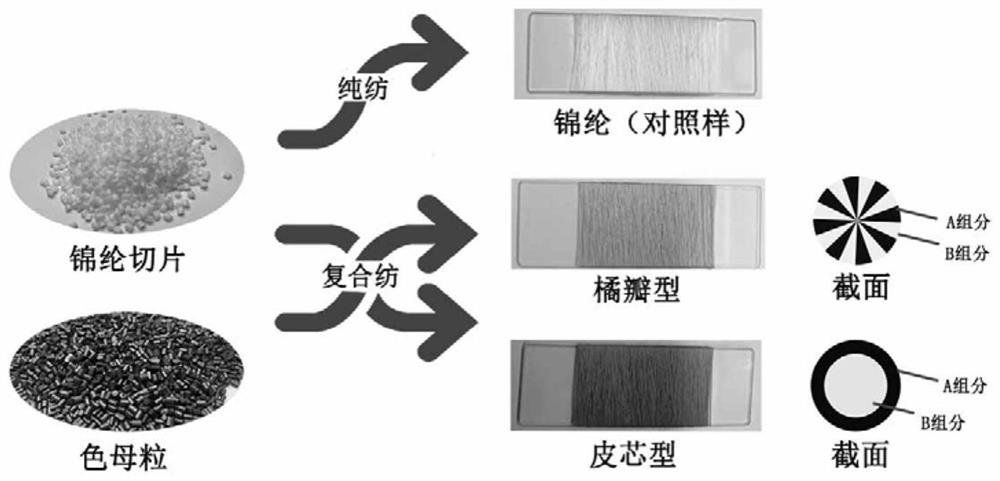

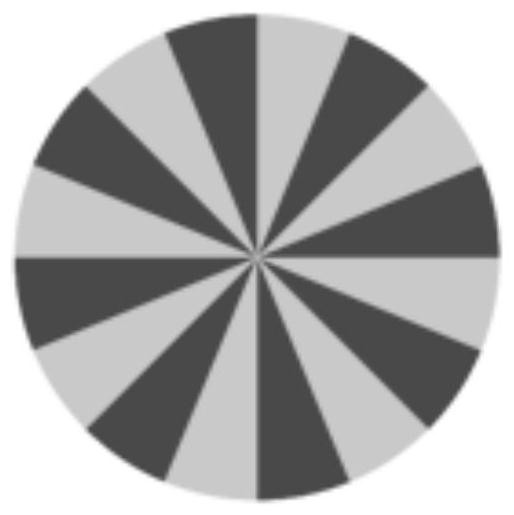

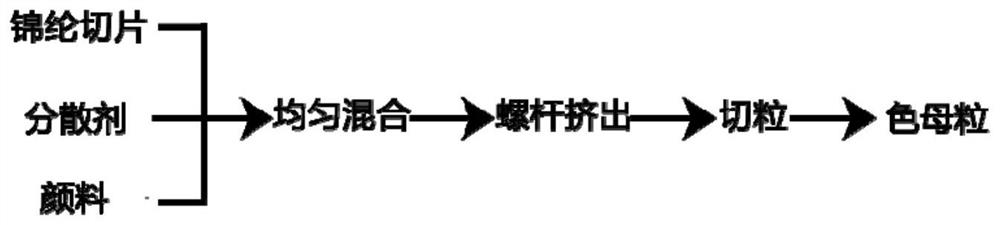

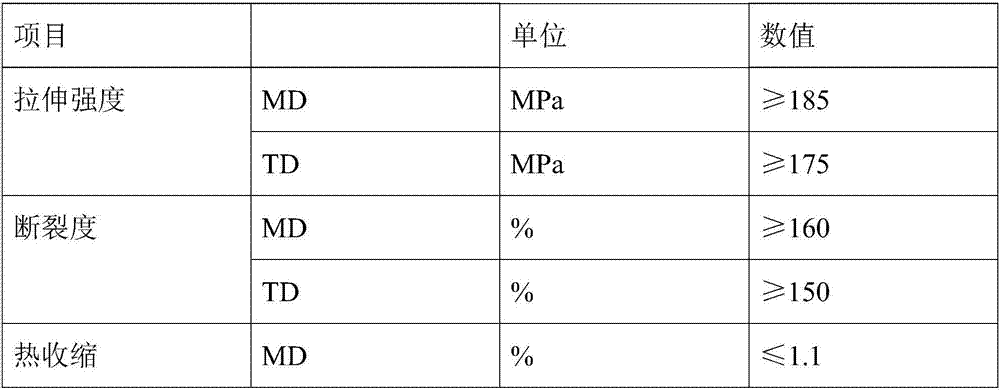

Colorful fiber preparation method based on composite spinning technology and fabric prepared by method

PendingCN113308761APrecise color systemHigh color fastnessWeft knittingFilament/thread formingColour fastnessChemical treatment

The invention relates to the technical field of colorful superfine fiber preparation, in particular to a colorful fiber preparation method based on a composite spinning technology. The method comprises the following steps of (1) preparing color master batches; and (2) preparing colorful fibers, and then carrying out multi-phase separation by a physical or chemical treatment process to obtain superfine colorful fibers. The invention also provides a fabric prepared by the preparation method. According to the invention, orange petal composite spinning and a stock solution dyeing technology are combined for the first time, and the colorful fibers are prepared on the basis of the color juxtaposition principle, so that the purpose of spinning infinite types of color fibers by utilizing limited types of color master batches is achieved; and the problems that dyeing is difficult, the dyeing cost is high, pollution is serious and the dyeable color is single in the field of colored fibers at present are solved, meanwhile, the chromaticity of the fibers is accurately controlled, and the problem that the color difference of the fibers among batches is difficult to control during large-batch dyeing is solved. The preparation method disclosed by the invention is simple, environment-friendly, uniform in dyeing, high in color fastness and low in energy consumption.

Owner:QINGDAO UNIV +1

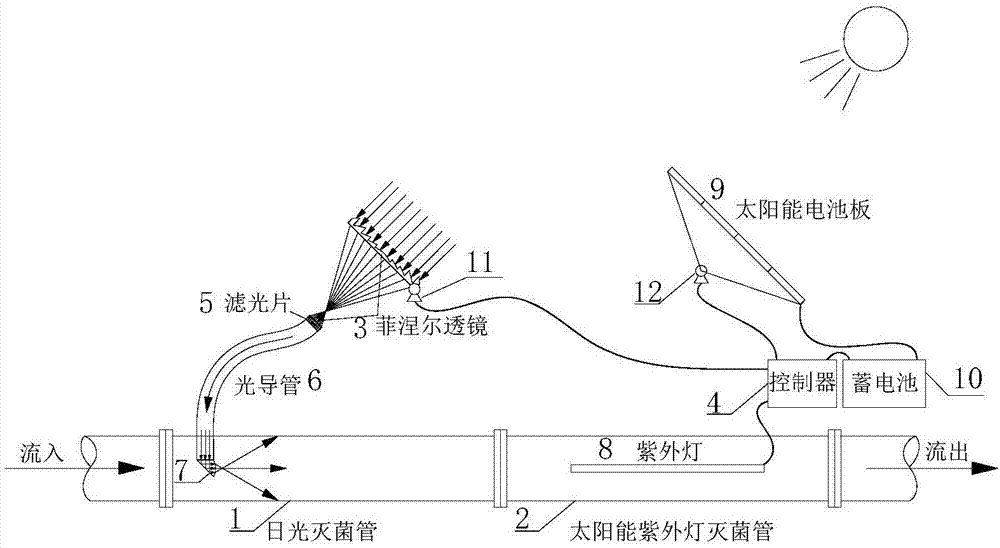

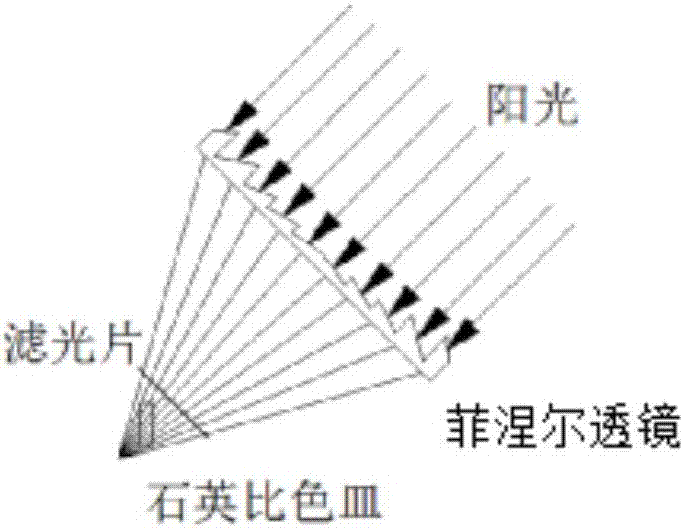

Solar water supply pipe network ultraviolet sterilization device

ActiveCN107162096AEnvironmentally friendly and pollution-freePollutedWater/sewage treatment by irradiationEnergy based wastewater treatmentAutomatic controlUltraviolet

The invention discloses a solar water supply pipe network ultraviolet sterilization device which comprises a plurality of sunlight sterilization pipes installed in series. The side wall of each sunlight sterilization pipe is communicated with one end of a light pipe, the other end of the light pipe is provided with a light filter, two Fresnel lenses in opposite directions are arranged on one side of the light filter, the light filter is positioned on a focusing light path of the two Fresnel lenses, each sunlight sterilization pipe is further provided with a prism, and the Fresnel lenses are automatically controlled by a controller to track the sun. By combining electric energy with solar energy, the device has the advantages of environmental protection and no pollution.

Owner:HEFEI UNIV OF TECH

Ultrahigh pressure rotating sealed water jet cleaner

InactiveCN104384128AImprove sealingSolve the sealing problemCleaning using liquidsGear wheelHigh pressure water

The invention discloses an ultrahigh pressure rotating sealed water jet cleaner. The ultrahigh pressure rotating sealed water jet cleaner is characterized by comprising a driving mechanism, a rotary sealing mechanism, a water inlet connecting member, a spray head mechanism, an upper casing and a lower casing, wherein the upper casing and the lower casing are fixedly connected; the rotary sealing mechanism comprises a water inlet pipe connector, a sealing outer casing, a sealing inner channel, a supporting shaft sleeve, a sealing medium channel and a driven gear. According to the ultrahigh pressure rotating sealed water jet cleaner disclosed by the invention, rotary dynamic sealing of ultrahigh water jet flow is realized by combined seal of end face seal and clearance seal; the seal between an ultrahigh pressure static part and a rotating part can be effectively realized; the utilization rate of high-pressure water is improved; the effect of removing rust by water jet is improved.

Owner:DALIAN MARITIME UNIVERSITY

Micro powder conveying device

InactiveCN106044298AGuaranteed to workAvoid wastingConveyorsLoading/unloadingEngineeringControl valves

The invention relates to a micropowder conveying device, which includes a feed hopper, a solenoid valve, a feed pipe and a conveying pipe. The conveying pipe is provided with a filter screen for filtering dust, and the filter screen is detachably installed on the side wall of the conveying pipe. , the top of the delivery pipeline is provided with an atomizing nozzle, a water supply pipeline and a control valve, one end of the water supply pipeline is connected to the atomization nozzle, the other end is connected to the water supply tank, and the control valve is set on the water supply pipeline to control the opening and closing of the water supply pipeline Closed, the control valve is connected with the solenoid valve at the same time, when the solenoid valve is opened, the control valve is triggered to open at the same time. The invention sprays atomized water vapor through the atomizing nozzle, so that the dust falls together with the water vapor to achieve the purpose of dust reduction. At the same time, the filter screen can filter out a part of the dust, so that the dust will not fly and float into the external environment, thereby avoiding dust. Harmful to the health of the staff, it can also avoid the waste of raw materials, reduce the labor intensity of workers, and ensure the normal operation of the conveying device.

Owner:扬州锦盛微粉有限公司

Degradable transparent conductive film and production method thereof

InactiveCN101996697AImprove performanceHigh strengthConductive layers on insulating-supportsCable/conductor manufactureAluminium chlorideTransparent conducting film

The invention relates to a degradable transparent conductive film which consists of a carrier film and a conductive film. The innovation point is characterized in that the carrier film is a degradable polyethylene carrier film; and the conductive film is an aluminum oxide transparent conductive film which is evaporated on the surface of the degradable polyethylene carrier film in vacuum. A production method of the degradable transparent conductive film comprises the following steps of: preparing the degradable polyethylene carrier film by using polyethylene and a photosensitive catalyst; preparing the aluminum oxide transparent conductive film by aluminum chloride used as a raw material and evaporating the degradable polyethylene carrier film and the aluminum oxide transparent conductive film in vacuum to prepare the degradable transparent conductive film. In the invention, the transparent conductive film has the prominent advantages of degradation and no pollution, and the production method of the transparent conductive film is simple and easy to operate, and has the advantages of low cost, energy-saving and environment protection.

Owner:TIANJIN JINSHENGYU PLASTIC PROD SCI & TECH CO LTD

Waterborne paint used for furniture

InactiveCN107828296AEnvironmentally friendly and pollution-freeImprove adhesionCoatingsAcrylic resinPolyvinyl alcohol

The invention discloses a water-based paint for furniture. The water-based paint for furniture is made of the following raw materials in parts by weight: 20-30 parts of absolute ethanol; 10-14 parts of limonene; 4-7 parts of polyvinyl butyral ; 5-11 parts of glycerol; 1.5-3.2 parts of ethyl acetate; 3-7 parts of polyethylene glycol; 13-15 parts of acrylic resin; 8-11 parts of zeolite powder; 1-3 parts of leveling agent; 1.3 parts of toluene ~2.4 parts; 4~6 parts of calcium carbonate; 2~4 parts of dipropylene glycol methyl ether; 1~4 parts of organic tin drier. The furniture paint has the advantages of environmental protection, no pollution and good bonding performance.

Owner:徐州隆邦家具有限公司

Cement-based wood crack elastic repairing agent

InactiveCN105753396AEnvironmentally friendlyEnvironmentally friendly and pollution-freeSolid waste managementSaw dustDefoaming Agents

The invention relates to a cement-based wood crack elastic repairing agent.The cement-based wood crack elastic repairing agent is composed of, by weight, 20-40 parts of cement, 5-30 parts of saw dust, 5-10 parts of rubber powder, 0.1-0.3 part of cellulose ether, 0.05-0.8 part of lignocelluloses, 0.1-0.02 part of a water reducing agent, 0.2-0.5 part of a defoaming agent, 45-60 parts of lightweight calcium powder, 1-2 parts of a surfactant and 0.3-0.8 part of a shrinkage reducing agent, wherein water addition quantity is 23-28% of the weight of powder.The cement-based wood crack elastic repairing agent has the advantages of environment friendliness and freeness of pollution; the repairing agent can be prepared in required quantity when needed, so that waste is reduced, and fine adjustment of thickness of the repairing agent can be realized according to crack sizes; the repairing agent is elastic after being dried, high in adhesiveness to wood and free of shrinkage; the repairing agent is applicable to cracks in a range of 0.1-10mm, thereby being extensive in application range.

Owner:西卡德高(上海)建材有限公司

Environment-friendly PVC film and preparation method thereof

InactiveCN106967258AEnvironmentally friendly and pollution-freeImprove stabilityEnvironmental resistancePollution

The invention provides an environment-friendly PVC film and a preparation method thereof. The environment-friendly PVC film comprises, by mass, 80 to 90 of PVC, 40 to 45 of DOP, 2 to 5 of calcium carbonate, 2 to 3 of a stabilizing agent, 5 to 10 of soybean oil, 0.5 to 2 of TiO2 and 0.2 to 0.4 of pigment. The preparation method comprises the following steps: preparing the above substances according to the above ratio and then carrying out uniform mixing under stirring at a rotating speed of 1300 to 1400 rpm; carrying out internal mixing at 140 to 150 DEG C for 4 to 5 min and refining at 160 to 170 DEG C for 6 to 7 min; and then carrying out cooling to 150 to 160 DEG C and successively carrying out extrusion, filtering, calendaring, warm processing, cooling and setting, and trimming. The preparation method is environment friendly and free of pollution; and the PVC film prepared in the invention is durable and has long service life.

Owner:佛山市宏尔塑胶制品有限公司

Chargeable straw type humidifier adopting leadless piezoelectric ceramic technology

PendingCN110631158AReduce health and environmental problemsGreen and non-toxicMechanical apparatusSpace heating and ventilation safety systemsPlug and produceEnvironmentally friendly

The invention provides a chargeable straw type humidifier adopting a leadless piezoelectric ceramic technology. According to the chargeable straw type humidifier adopting the leadless piezoelectric ceramic technology, potassium-sodium niobate based leadless piezoelectric ceramic is adopted as a core element for ultrasonic atomization, and compared with the conventional lead-bearing material, the potassium-sodium niobate based leadless piezoelectric ceramic has the characteristics of being green, non-toxic, environmentally friendly, and pollution-free, and can effectively reduce the health andenvironment problems brought during use and waste of lead-bearing elements. Meanwhile, the straw type humidifier is small in size and convenient to carry, is equipped with lithium batteries capable ofbeing repeatedly charged, can be used anytime and anywhere and realizes plug and play function when in use only by preparing a cup or a tin of purified water, thereby being rather convenient.

Owner:桐乡清锋科技有限公司

Novel environmental-friendly wear and high-temperature resistant friction plate

ActiveCN102478090BNo environmental protection and no pollutionEnvironmentally friendly and pollution-freeFriction liningEnvironmental resistanceEngineering

A novel environmental-friendly wear and high-temperature resistant friction plate relates to the field of production and processing of automobile parts; a technological process comprises the following steps of: drying asbestos-free cloth; preparing a resin alcoholic solution, wherein the ratio of phenolic resin to hexamethylene tetramine to alcohol is 1:1:5; dipping the asbestos-free cloth by resin; orderly airing the asbestos-free cloth dipped with the resin on a material frame; starting a rubber mixing mill, adjusting the roller spacing to be 1-2mm, and placing styrene-butadiene rubber on a rubber mixing mill for mastication; adding an accessory ingredient padding for mixing; adding a solvent naphtha padding for pulping; carrying out rubber dipping on the asbestos-free cloth dipped with the resin through a rubber dipping machine; tailoring the asbestos-free cloth dipped with a sizing material, and winding the tailored asbestos-free cloth on a blank; putting the blank wound with the asbestos-free cloth in a pressing machine, and carrying out hot-press forming on the blank; putting the formed blank in a drying oven for carrying out thermal treatment; after finishing the thermal treatment, polishing the product with a machine tool; and checking the packaging and putting the product in storage. The novel environmental-friendly wear and high-temperature resistant friction plate has the beneficial effects of environmental friendliness, abrasion resistance and high temperature resistance.

Owner:来安县隆华摩擦材料有限公司

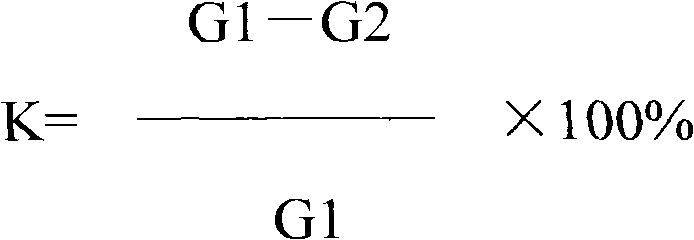

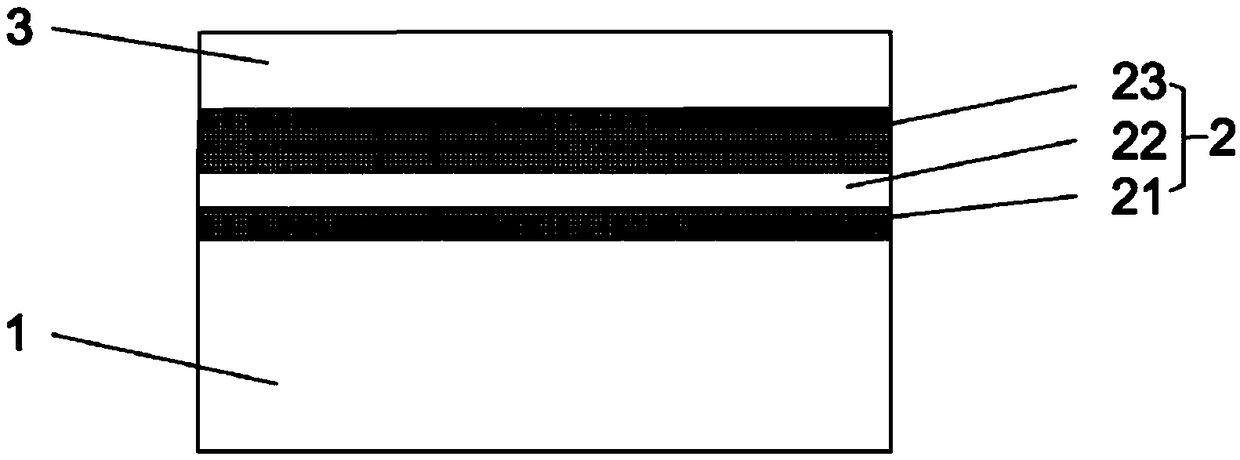

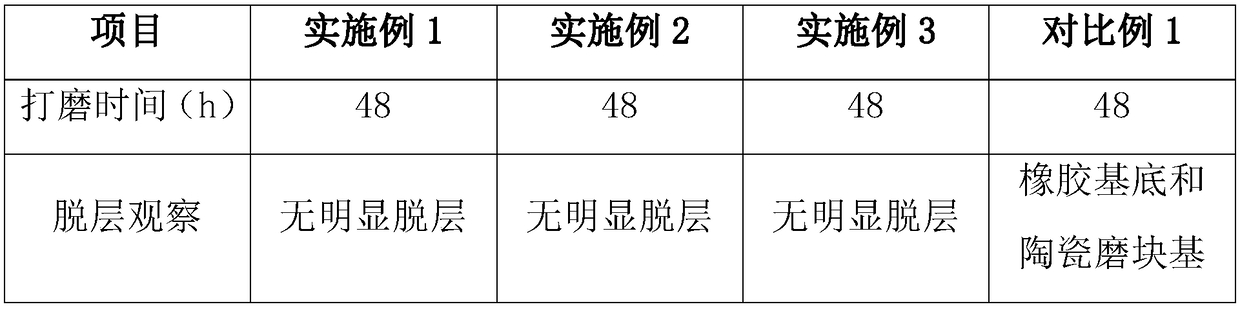

Rubber baseorganic ceramic grinding block and preparation method thereof

PendingCN109333390ASimple structureHigh bond strengthGrinding devicesPolyurea/polyurethane coatingsHot-melt adhesiveEnergy consumption

The invention belongs to the technical field of grinding tools, and particularly relates to a rubber baseorganic ceramic grinding block and a preparation method thereof. The rubber baseorganic ceramicgrinding blockcomprises a ceramic grinding block base body, an adhesive layer bonded to the upper part of the ceramic grinding block base bodyand a rubber layer bonded to the upper part of the adhesive layer. According to the rubber baseorganic ceramic grinding block, the phenomenon of delaminating of an inorganic and organic bonding faceis avoided, the ceramic grinding block basebody and rubberlayer bond firmlyand not prone to being fallen off, and thusthe service life of the grinding block is longer; in addition, by using a PU hot melt adhesive covering film, the grinding block has the advantages of environmental protection and no pollution, long time heating baking and curing are not required, thus energy consumption is low, and rapid production is facilitated; and the preparation method of the rubber baseorganic ceramic grinding block is simple and easy to operate, and is suitable for large-scale production.

Owner:东莞市鼎泰鑫电子有限公司

Fatty alcohol for preparing washing fluid and preparation method of fatty alcohol

ActiveCN104987958AImprove decontamination abilityExcellent decontaminationOrganic compound preparationSurface-active detergent compositionsPotassium hydroxideStearic acid

The invention discloses fatty alcohol for preparing washing fluid and a preparation method of the fatty alcohol. The washing fluid prepared from the fatty alcohol (FCM) according to the scheme has reliable and efficient dirt-removing power, cannot be adhered to hands, and is harmless to a cleaned object. According to the technical scheme, the fatty alcohol (FCM) for preparing the washing fluid comprises 7 to 9 percent by weight of oleic acid (C20), 2 to 4 percent by weight of stearic acid, 9 to 11 percent by weight of triethanolamine, 1.5 to 3.5 percent by weight of sodium hydroxide or potassium hydroxide, 1 to 3 percent by weight of sodium dodecyl benzene sulfonate, 7 to 9 percent by weight of lauric acid (C12) and the balance of pure water.

Owner:周金顺

High-aluminum carbonaceous refractory material capable of improving erosion resistance and preparation method of high-aluminum carbonaceous refractory material

InactiveCN109852156AImprove compactnessReasonable formulaFireproof paintsAnti-corrosive paintsFiltrationPolystyrene

The invention discloses a high-aluminum carbonaceous refractory material capable of improving erosion resistance. The material comprises the following components: in terms of mass percentage, 15-22% of polystyrene resin, 8-12% of organosilicon resin, 5.5-7.5% of C9 petroleum resin, 4.8-6.4% of metal silicon powder and the balance water. The invention also discloses a preparation method of the high-aluminum carbonaceous refractory material capable of improving the erosion resistance, and the preparation method includes the following step: performing compounding and mixing, preparing modified amaleic acid solution, performing secondary mixing, and conducting filtration. The formula is more reasonable, after different treatment are performed on the polystyrene resin, organosilicon resin andC9 petroleum resin, the compactness of the molecular structure of the product can be increased through combined addition of multiple high-aluminum carbonaceous materials including the metal silicon powder, silicon carbide and aluminum oxide, so that the erosion resistance and corrosion resistance of the product are improved; and the adopted materials are non-toxic, and the high-aluminum carbonaceous refractory material has the advantages of environmental protection and no pollution.

Owner:盐城紫环工业机械有限公司

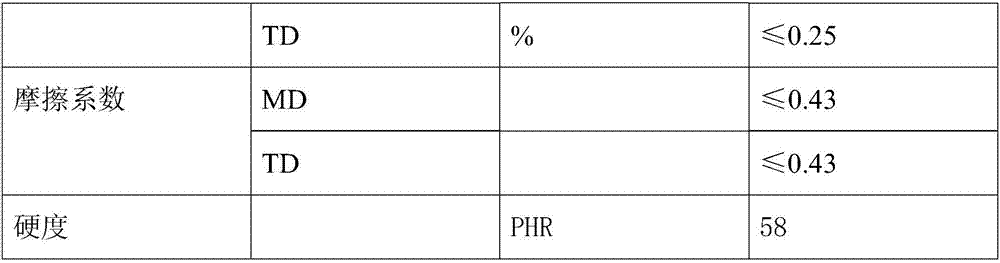

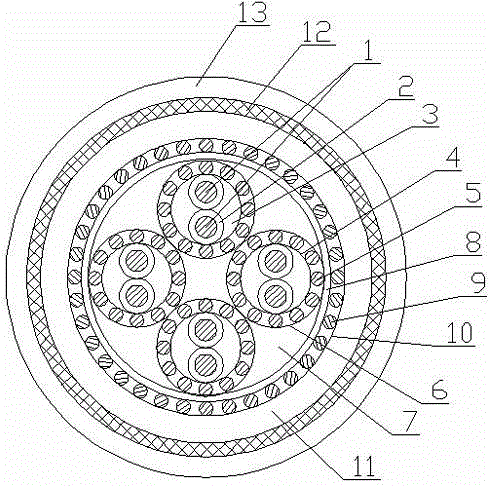

Environment-friendly comprehensively protected electronic computer shielded cable

InactiveCN104425066AImprove the protective effectEnvironmentally friendly and pollution-freeInsulated cablesInsulated conductorsShielded cableElectrical conductor

The invention discloses an environment-friendly comprehensively protected electronic computer shielded cable, which comprises conductors, the conductors are wrapped by insulating layers, flame-retardant material is filled to form round cross sections after the conductors wrapped by the insulating layers are arranged in pairs, flame-retardant tape layers are wound on the round cross sections, and are wrapped by single-phase shielding layers, flame-retardant tape layers are then wound on the single-phase shielding layers, so that a plurality of conducting monomers are formed, flame-retardant material is filled to form a round cross section after the conducting monomers are combined, a flame-retardant tape layer is wound on the round cross section, and is wrapped by a main shielding layer, a flame-retardant tape layer is wound on the main shielding layer, and an internal sheath layer, a steel tape armor layer and an external sheath layer are sequentially arranged outside the flame-retardant tape layer. The environment-friendly comprehensively protected electronic computer shielded cable has the following advantages: the environment-friendly comprehensively protected electronic computer shielded cable has the characteristics of environment-friendliness and no public hazards; not only can termite and mouse resistance be enhanced, but also the resistance of the sheath of the cable to mechanical damage, environmental stress and the like is enhanced; the flame-retardant property of the environment-friendly comprehensively protected electronic computer shielded cable reaches class A.

Owner:湖北鄂电萃宇电缆有限公司

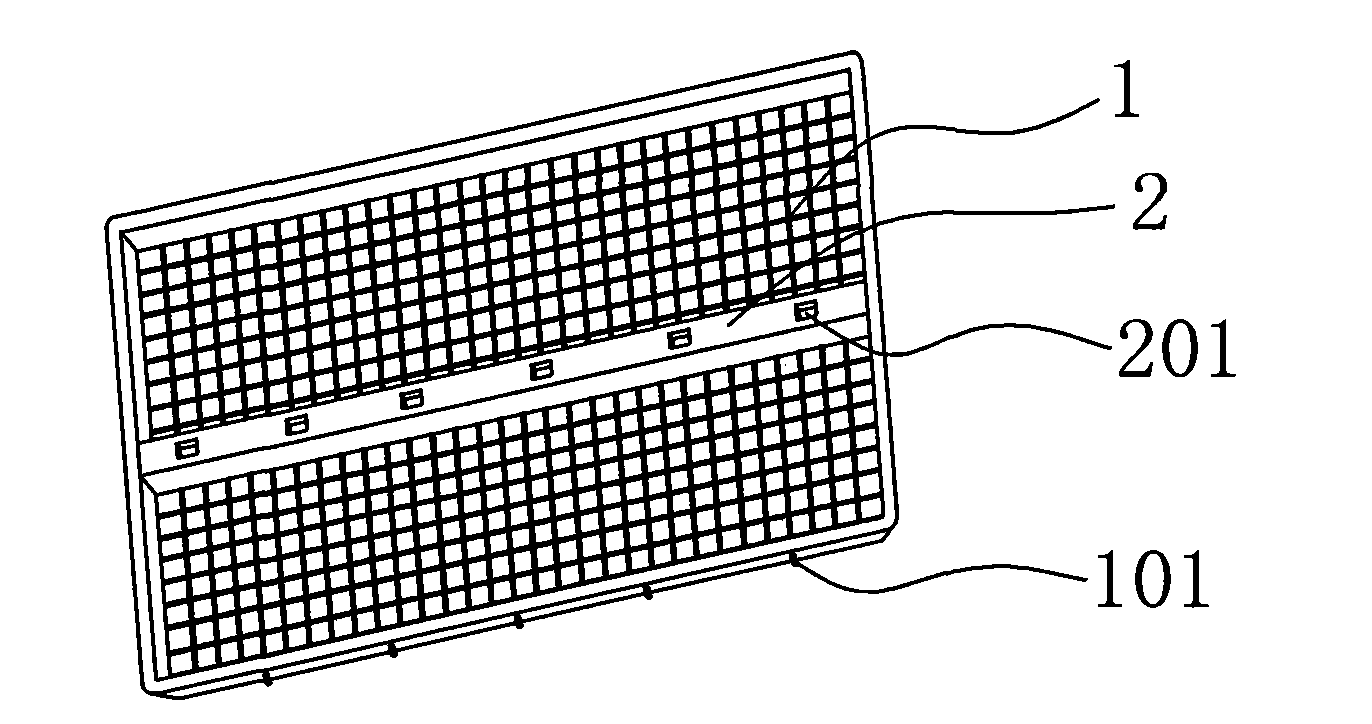

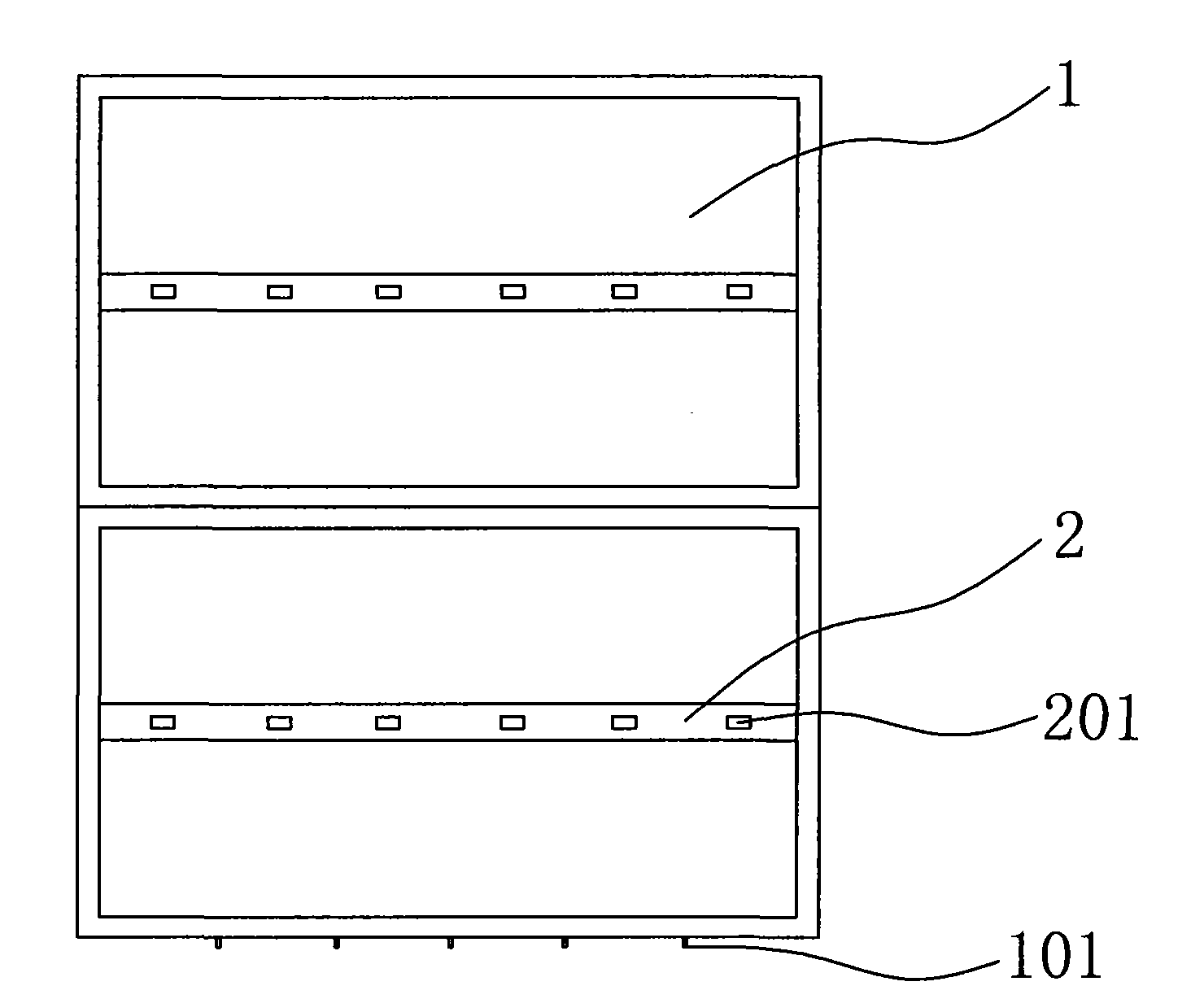

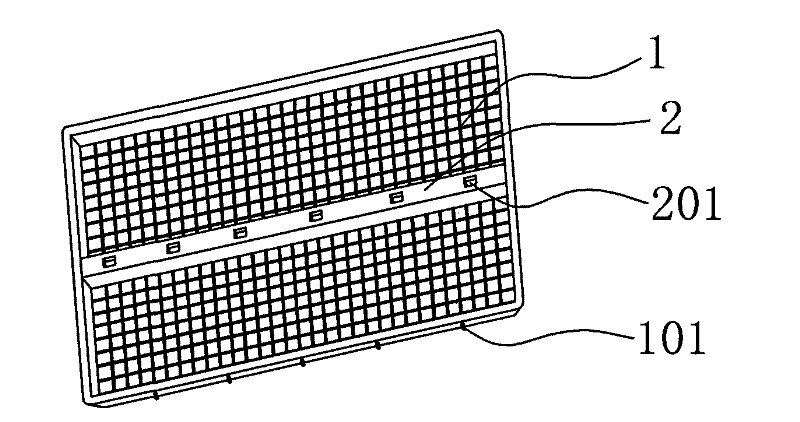

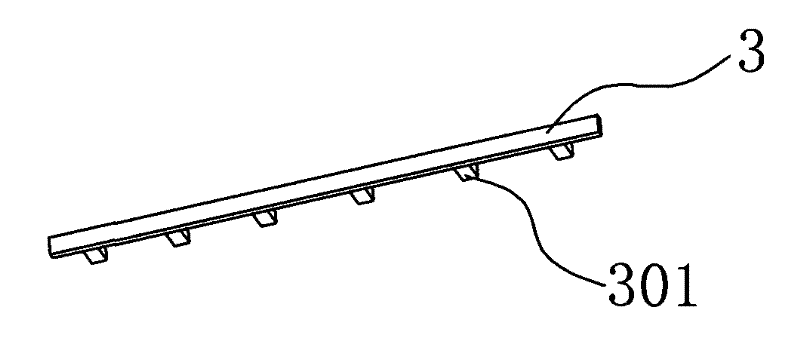

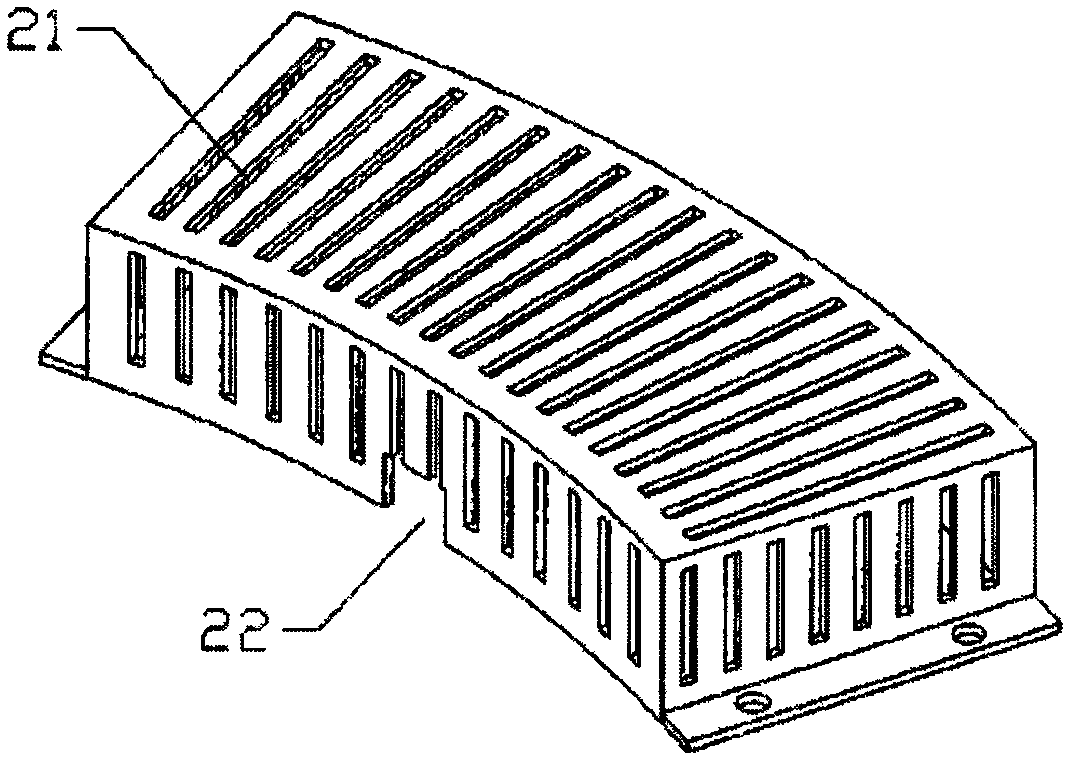

LED (Light-Emitting Diode) illuminating device and radiating structure thereof

InactiveCN102425733ASolve the cooling problemLow costPoint-like light sourceLighting heating/cooling arrangementsEngineeringCopper

The invention provides an LED (Light-Emitting Diode) illuminating device and a radiating structure thereof. In the LED illuminating device, a protective cover plate, an LED luminous module consisting of an LED substrate and LED particles, and a non-light tight plate are combined into a lamp; the lamp is connected with a power supply; the non-light tight plate and the protective cover plate constitute a box type structure; the LED substrate is fixedly arranged in the middle; a group of LED particles formed by connecting every 3-10 LED particles in series is fixedly welded on the LED substrate; a light diffusing film is attached to the inner side of the light-emitting wall of the non-light tight plate; the inner side of the enclosing wall of the non-light tight plate is provided with a reflecting layer; and light rays emitted by the LED luminous module can be uniformly and flexibly irradiated to a direction needing illuminating after being dispersed by the non-light tight plate. The invention further provides a radiating structure suitable for the LED illuminating device. The radiating structure consists of a substrate, LED particles and copper (or aluminum) coated on the front and back faces of the substrate. The LED illuminating device has a good radiating effect, low cost and long LED service life, contributes to saving energy and protecting the environment, and fully meets popularization and application of LEDs of different power.

Owner:GUANGZHOU ZHONGHENG OPTOELECTRONICS TECH

Split mounting type secondary lining arch segment jacking device for tunnel

ActiveCN109667608AImprove stabilitySimple structureUnderground chambersTunnel liningButt jointEngineering

The invention discloses a split mounting type secondary lining arch segment jacking device for a tunnel. The device comprises a jacking power mechanism installed on a trolley body frame; the upper part of the jacking power mechanism is connected with a cross beam, and the jacking power mechanism is used for driving the cross beam to move up and down; secondary lining arch segments are placed on the cross beam; two guiding elements are arranged on the trolley body frame and are respectively fixed at the left side and right side of the jacking power mechanism; a guiding hole is formed in each guiding element in a penetrating way from top to bottom; two stand columns are arranged under the cross beam and are respectively and fixed at the left side and right side of the jacking power mechanism; the lower parts of the two stand columns are respectively arranged in the corresponding guiding holes; when the cross beam moves up and down, the stand columns move up and down in the correspondingguiding holes. The split mounting type secondary lining arch segment jacking device for the tunnel can more conveniently realize the rapid and stable lifting of segments. The device is simple in structure and low in cost, and can effectively reduce the cost; by adopting hydraulic drive, the device has the advantages of being environmentally-friendly and free from pollution; due to the unique structural design, the subsequent butt joint operation for trolley installation is enabled to be simple and efficient.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Preparation method and applications of skincare product capable of activating cell activity

InactiveCN108420743AImprove immunityAnti agingCosmetic preparationsToilet preparationsFacial skinChemistry

The invention relates to the field of functional skincare products, and specifically relates to a preparation method and applications of a skincare product. The preparation method comprises followingsteps: dissolving isorhamnetin into isopropyl isostearate to prepare an oil phase, adding the oil phase into a reactor, pumping mannan into the reactor by a peristaltic pump under the liquid level; after a part of mannan is added, slowly pumping sodium pyrosulfate, filling argon into the reactor, carrying out reactions under conditions of heating and pressurizing, reacting mannan with isorhamnetinunder a pressurizing condition, reducing the pressure and cooling after a half of sodium pyrosulfate is added; dissolving VC into water, adding reducing groups at a temperature of 5-20 DEG C under protection, pumping sodium pyrosulfate to carry out reactions, adding residual mannan, pumping argon into the reactor to slowly pressurize the reactor, and carrying out reactions under stirring. The manufactured skincare product can prevent skin from contacting with the air, inhibit sebum secretion, sweat evaporation, and temperature rising of skin, promote the blood circulation of facial skin, andclean and nourish skin, and has a wide application range in the fields such as cosmetic products, healthcare products, and the like.

Owner:刘忠芳

A kind of electric ignition match and preparation method thereof

Owner:MINNAN NORMAL UNIV

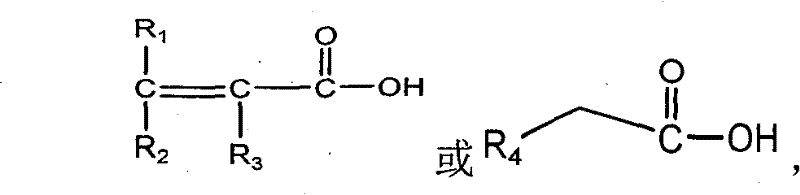

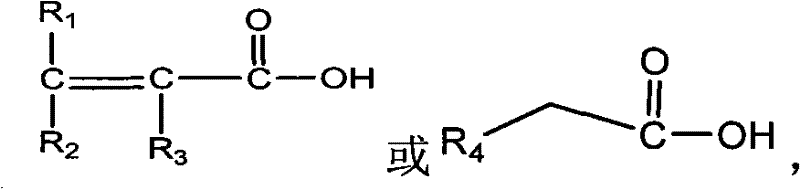

Preparation method of protonized ionic liquid modified rubber/inorganic filler composite material

InactiveCN101831093BThe synthesis process is simpleEnvironmentally friendly and pollution-freeProtonationVulcanization

The invention relates to a preparation method of a protonized ionic liquid modified rubber / inorganic filler composite material, which comprises the steps of: 1, preparing a structure of a functional protonized ionic liquid; and 2, ensuring that the functional protonized ionic liquid is used for an in situ modified inorganic filler reinforced rubber composite material. The invention can effectively lower the agglomeration among strong-polarity inorganic fillers, improves the diffusion of the fillers in a rubber base body, and is beneficial to improving the processing property, the vulcanization characteristic, the mechanical property, the abrasive resistance and the like of the rubber / inorganic filler composite material. The method has the characteristics of popularization and low cost, and can be widely applied to preparing various high-property rubber / inorganic filler composite materials.

Owner:SOUTH CHINA UNIV OF TECH

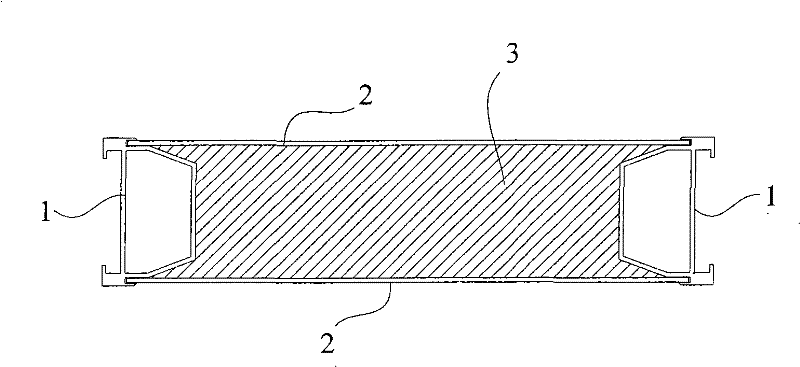

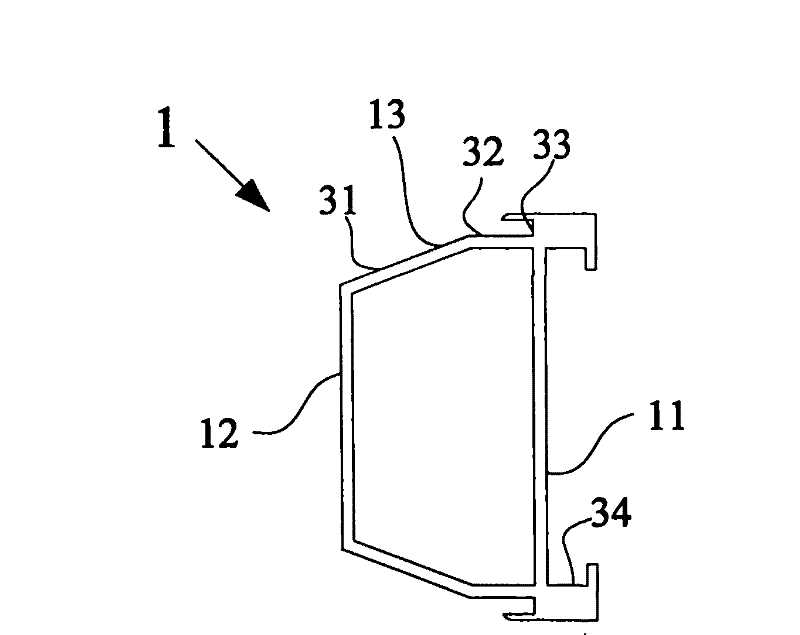

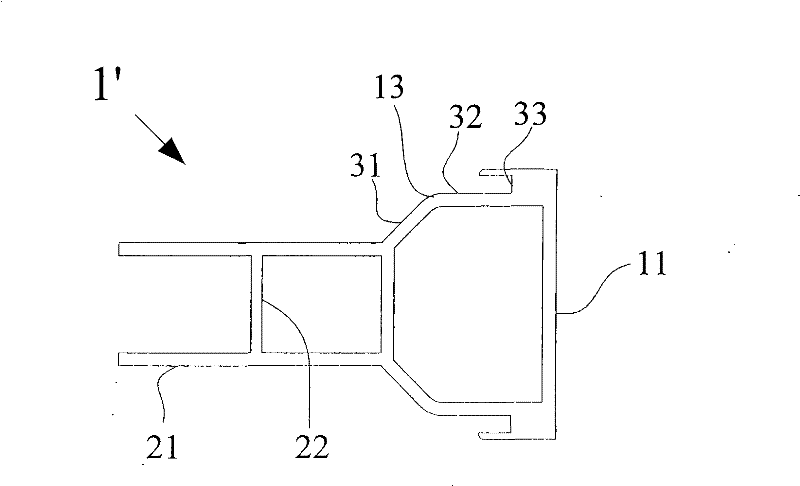

Sheet material

InactiveCN101509593BHigh strengthAvoid deformationThermal insulationSheets/panelsEngineeringHeat conservation

The invention provides a board which can be used for assembling doors, cabinets, furniture and office desktops / screens and the like. The board of the invention comprises a frame and two panels arranged at the two sides of the frame, wherein, the two panels and the frame form a cavity, and filler is arranged in the cavity. The board of the invention can effectively avoid rustiness, deformation, cracking and the like, meanwhile, the board has the characteristics of environment protection, corrosion-resistance, smooth surface, flexible and convenient assembly and the like; in addition the board features effective heat preservation / heat insulation, damp proof, sound insulation, fire prevention and flame retardance.

Owner:王连栋

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com