Rubber baseorganic ceramic grinding block and preparation method thereof

A technology of organic ceramics and grinding blocks, which is applied in the direction of grinding/polishing equipment, grinding devices, manufacturing tools, etc., can solve the problems of weak adhesion of the two layers, easy to fall off, and affect the service life of the grinding brush, so as to improve the gloss Curing speed, not easy to fall off, and the effect of improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

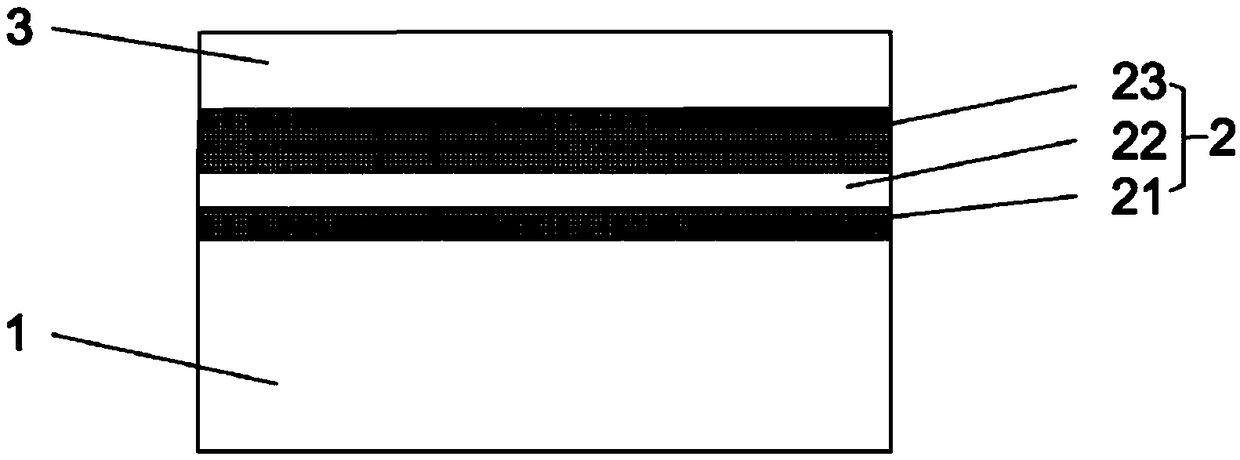

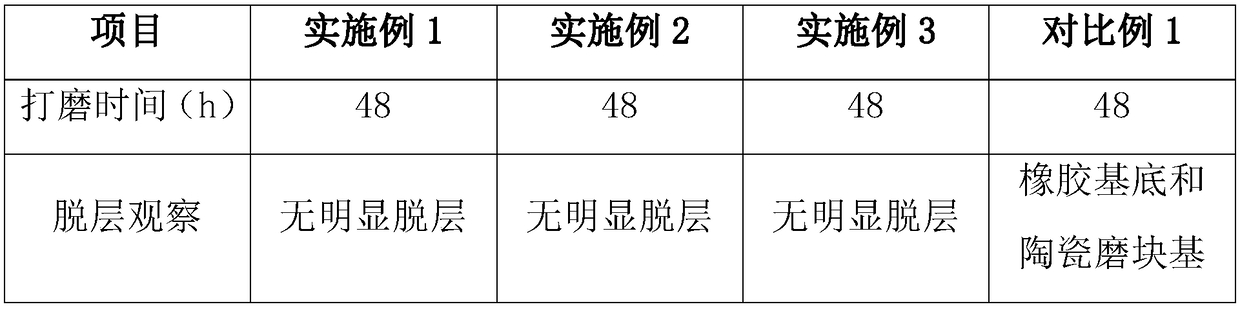

[0032] A rubber-based organic ceramic abrasive block, comprising a ceramic abrasive block base body 1, an adhesive layer 2 bonded to the ceramic abrasive block base body 1, and a rubber layer 3 bonded to the adhesive layer 2, the adhesive layer 2 From bottom to top, there are vinyl silane coupling agent coating 21 , solvent-free light-curing acrylic resin coating 22 and PU hot melt adhesive covering film 23 .

[0033] Further, the solvent-free photocurable acrylic resin coating 22 is made of the following raw materials in parts by weight: 100 parts of polyurethane acrylate resin, 3 parts of photosensitizer, 2 parts of hydrophobic nano-silica, 15 parts of diabase, 5 parts of plasticizer, 5 parts of stabilizer, 1 part of preservative, 2 parts of toughening agent, 2 parts of antioxidant.

[0034] Further, the photosensitizer is a mixture of arylthiohalide and benzophenone in a weight ratio of 1:1.

[0035] Further, the hydrophobic nano-silica is made by the following method. Aft...

Embodiment 2

[0043] A rubber-based organic ceramic abrasive block, comprising a ceramic abrasive block base body 1, an adhesive layer 2 bonded to the ceramic abrasive block base body 1, and a rubber layer 3 bonded to the adhesive layer 2, the adhesive layer 2 From bottom to top, there are vinyl silane coupling agent coating 21 , solvent-free light-curing acrylic resin coating 22 and PU hot melt adhesive covering film 23 .

[0044] Further, the solvent-free photocurable acrylic resin coating 22 is made of the following raw materials in parts by weight, 100 parts of polyurethane acrylate resin, 8 parts of photosensitizer, 5 parts of hydrophobic nano-silica, 22 parts of diabase, and 8 parts of plasticizer, 8 parts of stabilizer, 2 parts of preservative, 5 parts of toughening agent, 5 parts of antioxidant.

[0045] Further, the photosensitizer is a mixture of arylthiohalide and benzophenone in a weight ratio of 5:1.

[0046] Further, the hydrophobic nano-silica is made by the following method...

Embodiment 3

[0054] A rubber-based organic ceramic abrasive block, comprising a ceramic abrasive block base body 1, an adhesive layer 2 bonded to the ceramic abrasive block base body 1, and a rubber layer 3 bonded to the adhesive layer 2, the adhesive layer 2 From bottom to top, there are vinyl silane coupling agent coating 21 , solvent-free light-curing acrylic resin coating 22 and PU hot melt adhesive covering film 23 .

[0055] Further, the solvent-free photocurable acrylic resin coating 22 is made of the following raw materials in parts by weight: 100 parts of polyurethane acrylate resin, 5 parts of photosensitizer, 3.5 parts of hydrophobic nano-silica, 20 parts of diabase, and 6 parts of plasticizer, 6 parts of stabilizer, 2 parts of preservative, 3.5 parts of toughening agent, 3.5 parts of antioxidant.

[0056] Further, the photosensitizer is a mixture of arylthiohalide and benzophenone in a weight ratio of 3:1.

[0057] Further, the hydrophobic nano-silica is made by the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com