Patents

Literature

826results about How to "Improve seeding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structurally modified acellular tissue engineering scaffolds and methods of production

ActiveUS20070248638A1Seed efficiency be facilitateImprove seeding efficiencyCell culture supports/coatingUnknown materialsBiomedical implantFreeze dry

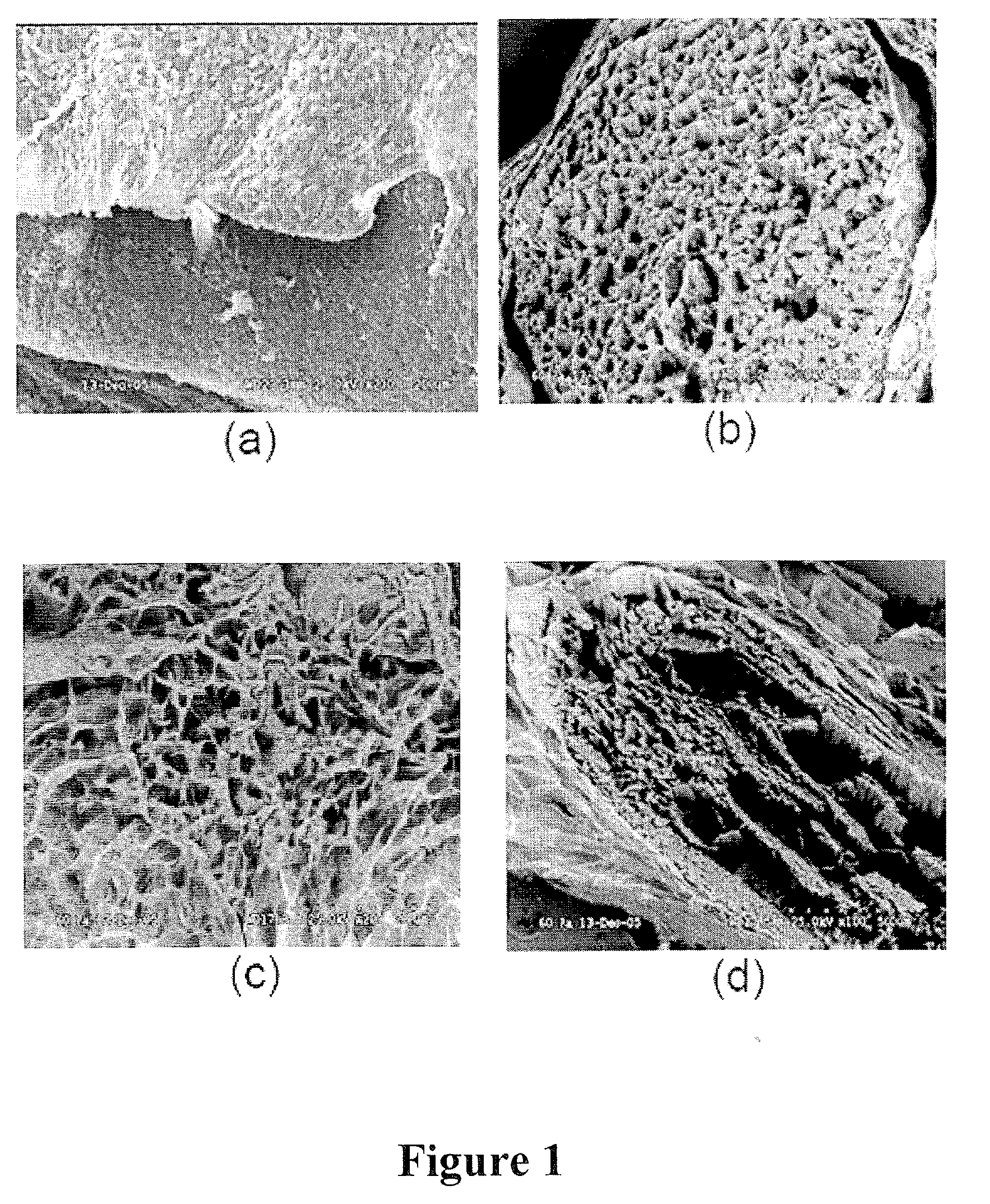

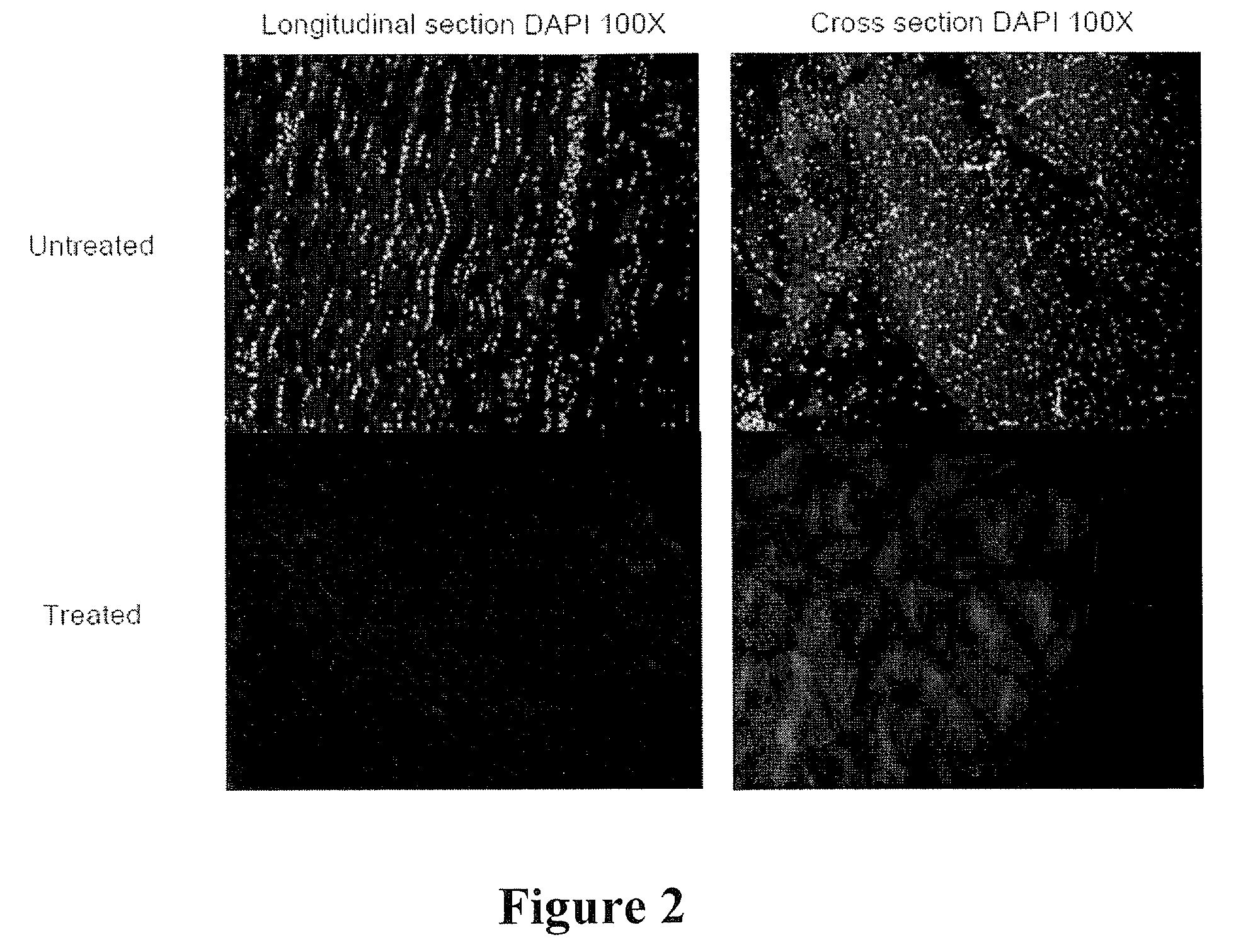

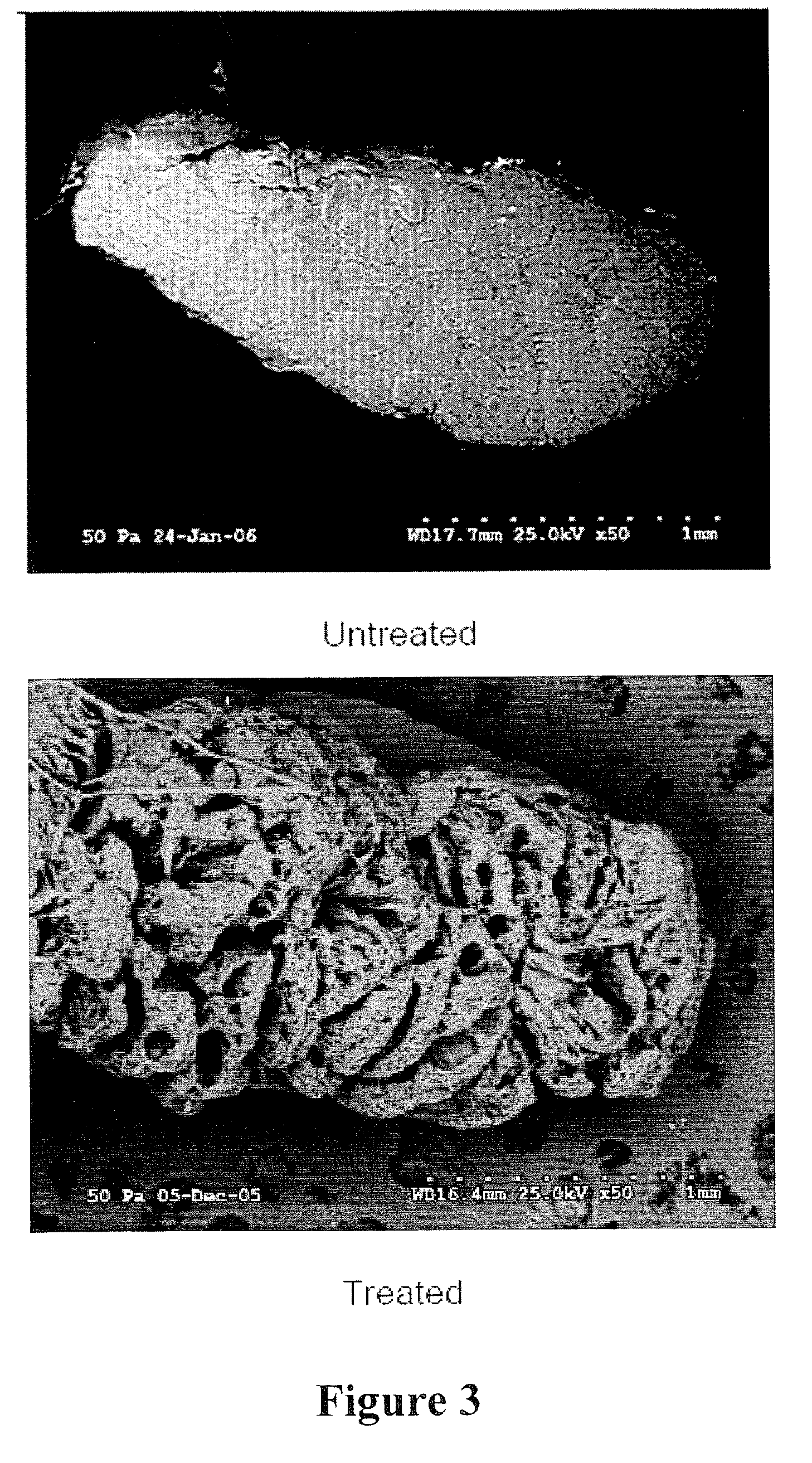

Methods are provided for producing a bioscaffold from natural tissues by oxidizing a decellularized tissue to produce a bioscaffold having pores therein. The pore size and porosity is increased to better accommodate intact cells so that live cells can better infiltrate and inhabit the bioscaffold. The bioscaffold may be freeze-dried or lyophilized, sterilized and (optionally) aseptically packaged for subsequent use. A further aspect of the present invention is a bioscaffold produced by the processes described herein. Methods of treatment using the bioscaffold as a graft or as a biomedical implant for implantation are also provided. Also provided are methods of seeding a bioscaffold with mammalian cells, wherein the seeding carried out either in vitro or in vivo, and wherein a bioscaffold produced as described herein is utilized for said seeding.

Owner:WAKE FOREST UNIVERSITY

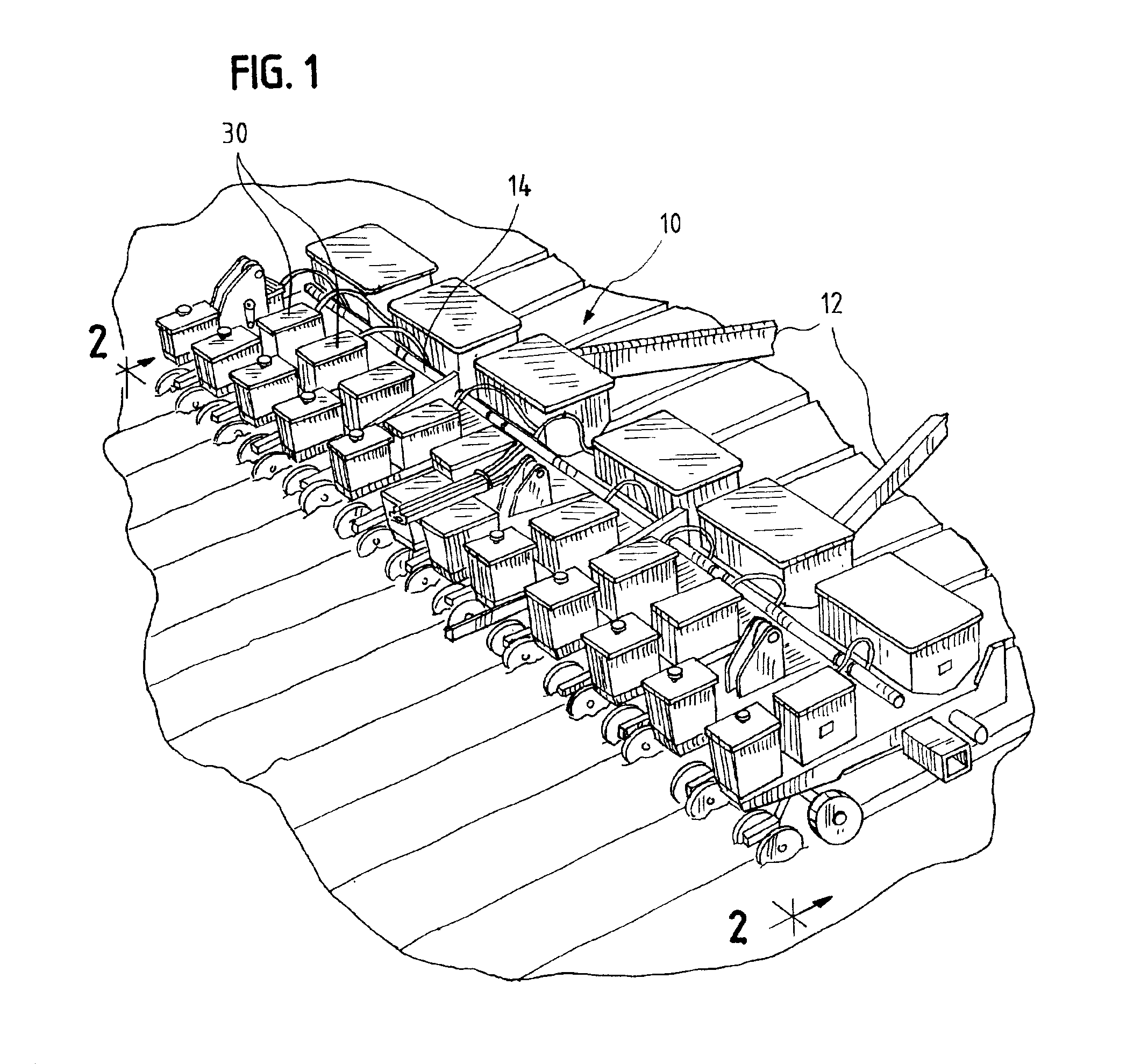

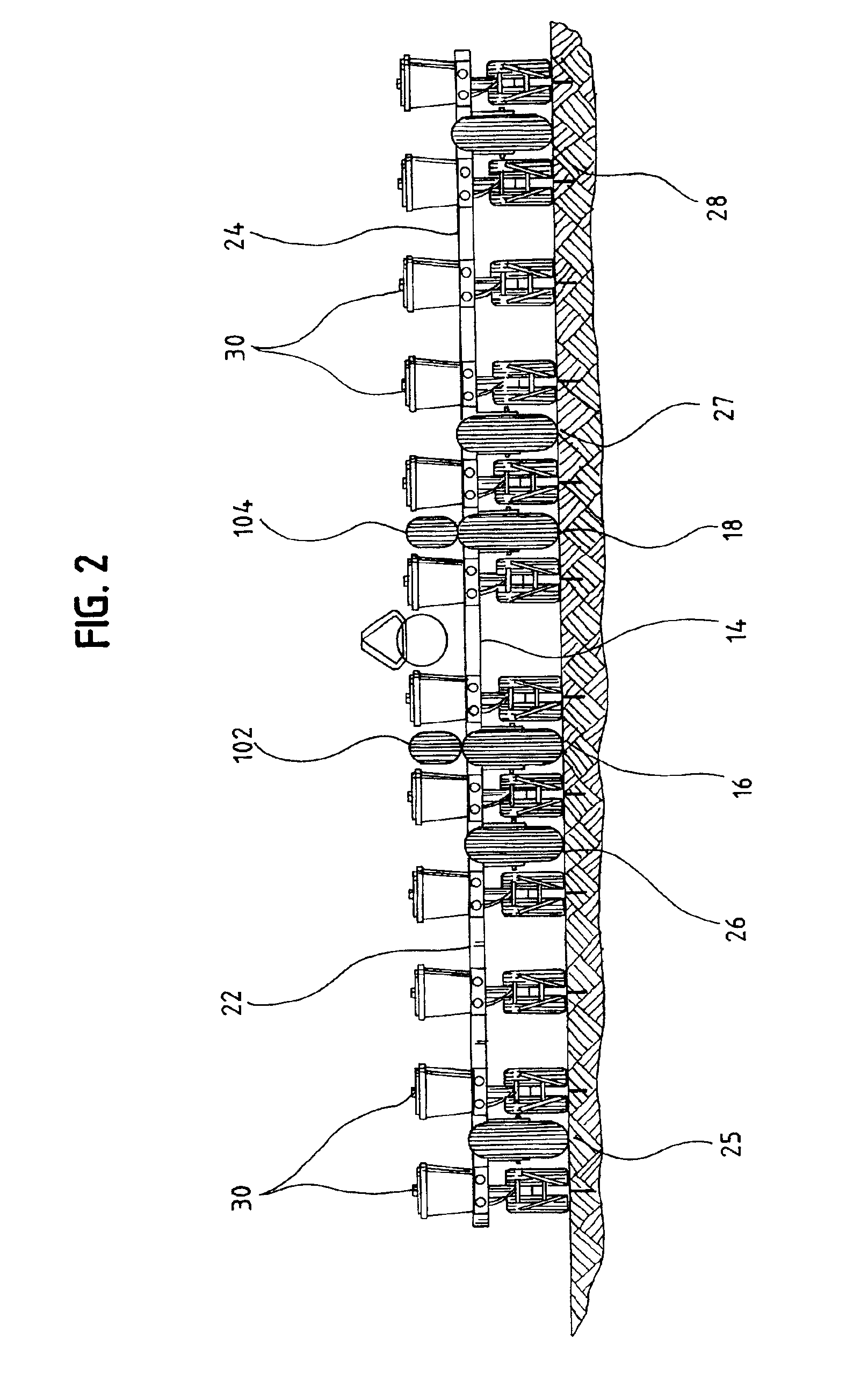

Method and apparatus for improving the efficiency of a John Deere vacuum planter

The efficiency of a John Deere planter to plant corn seed is improved where the planter is of the type having a vacuum operated metering unit enclosing a seed disk and a double eliminator. To improve the efficiency a kit is provided including an improved seed disk, an improved double eliminator, and an alignment tool for properly aligning the double eliminator with respect to the seed disk. When the parts are installed and properly aligned the planter can accept corn seed in the range of 1200 seeds per pound to 2800 seeds per pound without requiring readjustment of the vacuum setting or replacing the seed disk.

Owner:VEN HUIZEN DALE A

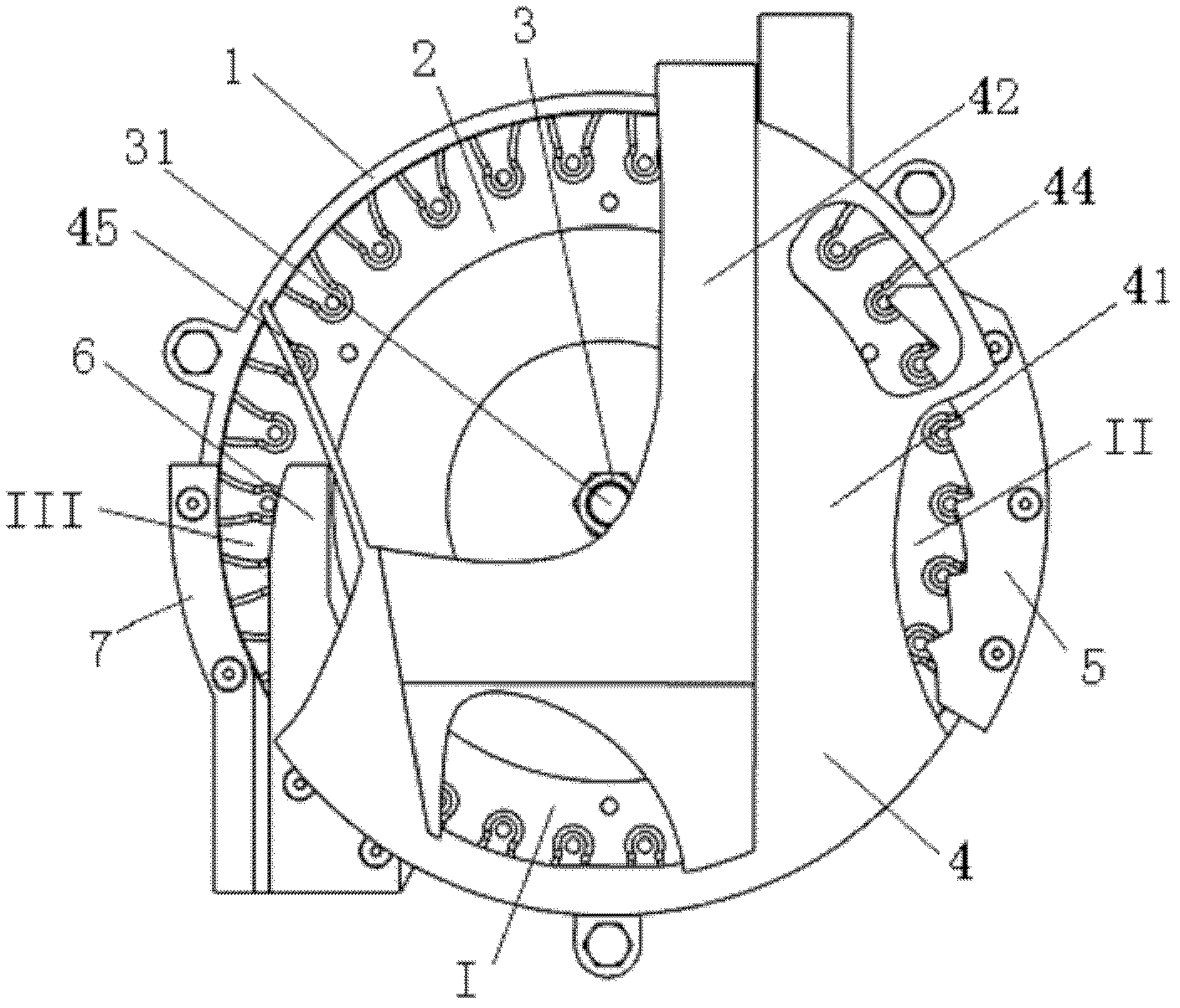

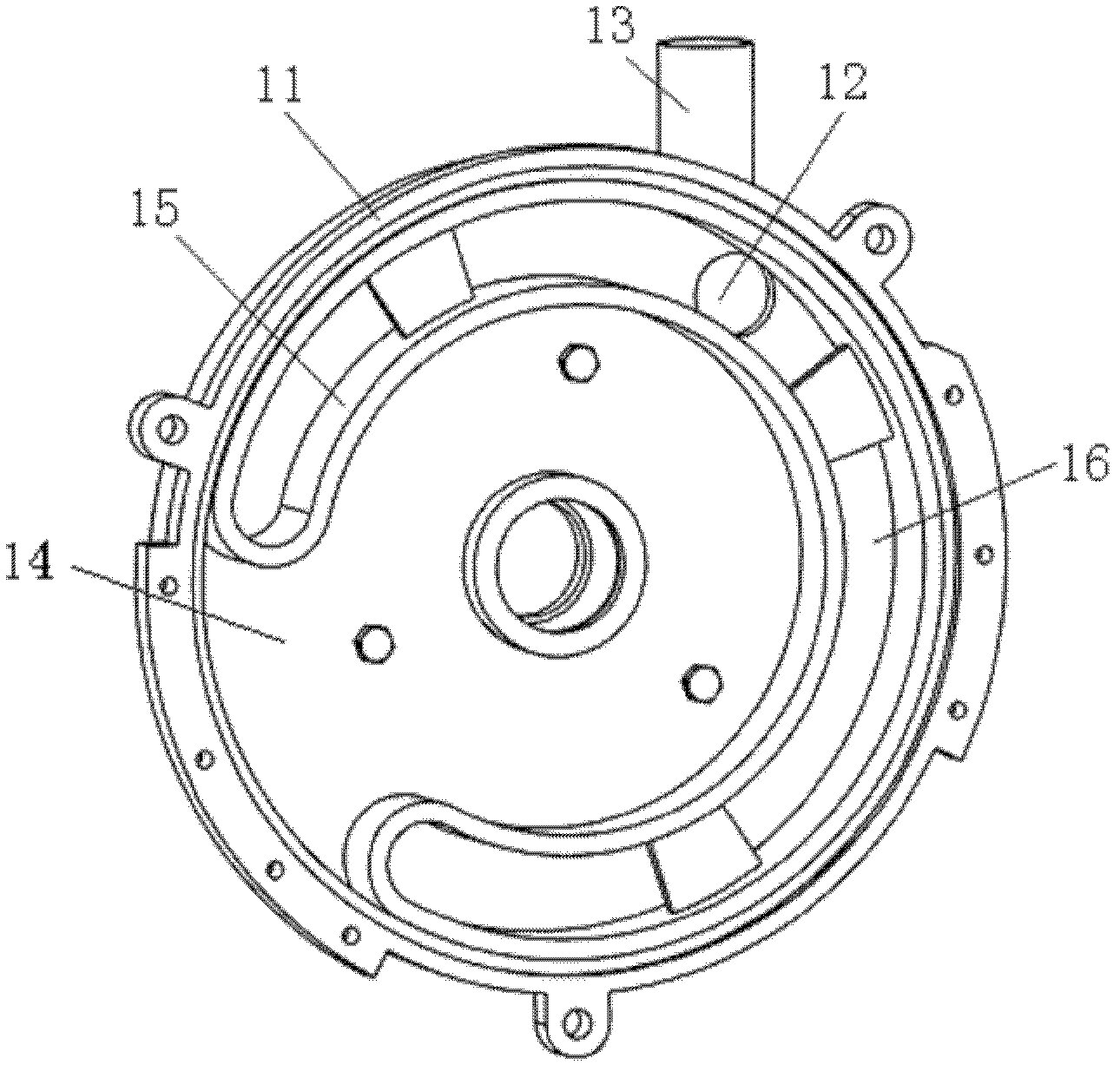

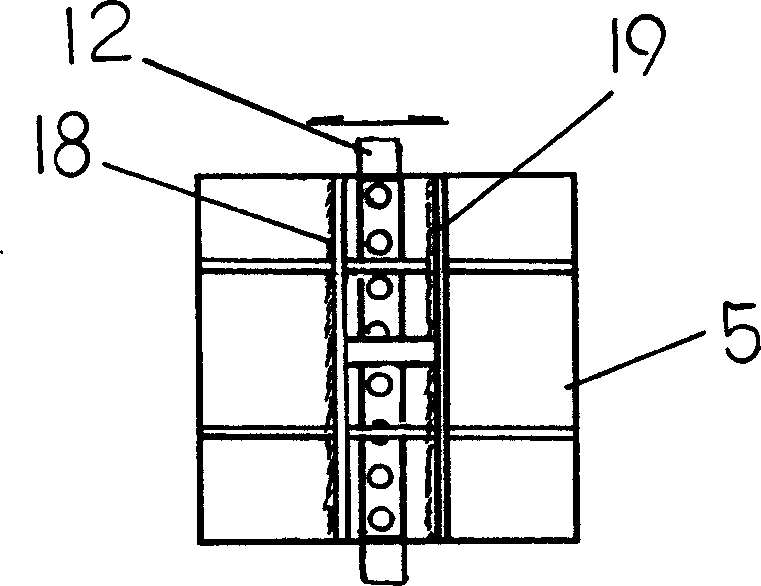

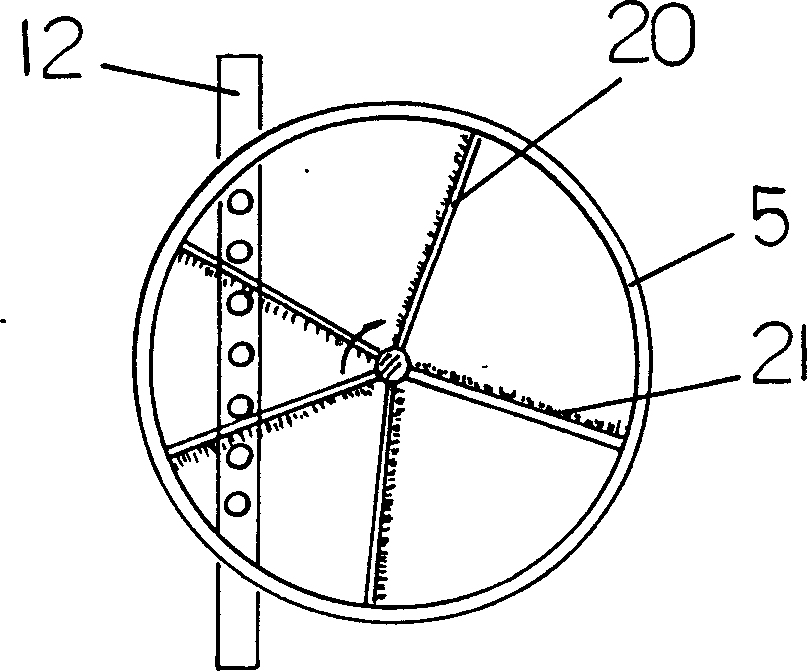

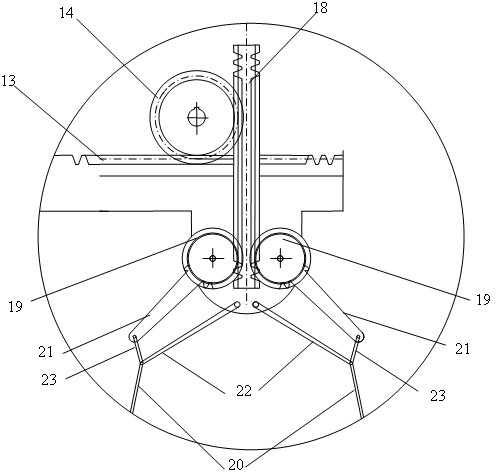

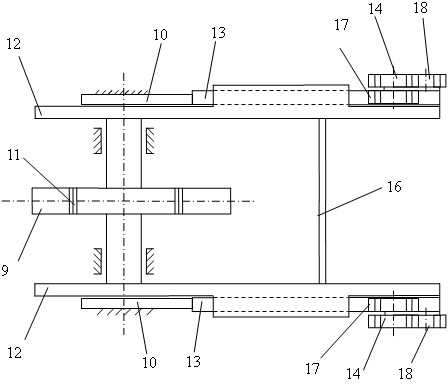

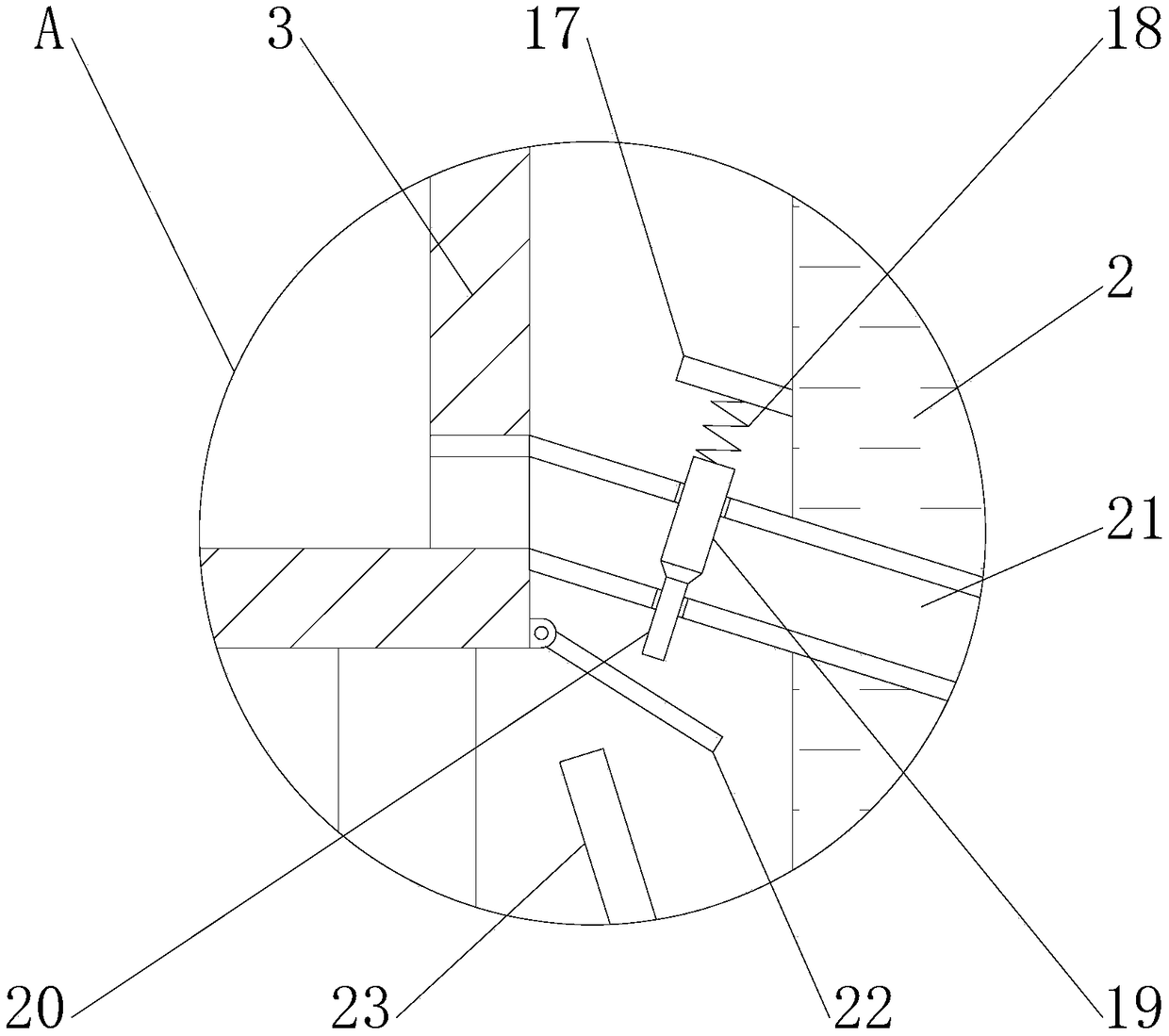

Air suction and mechanical auxiliary planting combined type corn precision seed-metering device and seed metering method thereof

InactiveCN102577716AGood seed performanceGood filling performanceSeed depositing seeder partsSingle grain seedersAgricultural engineeringGasket

The invention relates to an air suction and mechanical auxiliary planting combined type corn precision seed-metering device and a seed metering method thereof. The air suction and mechanical auxiliary planting combined type corn precision seed-metering device is characterized by comprising a round bottom casing provided with an air suction port and an air pipe, an inner cavity of the bottom casing is provided with a sealing gasket with an arc-shaped groove, and the air suction port is located in the arc-shaped groove. One side of a seed metering plate is rotatably attached to a side wall of the arc-shaped groove, the other side of the seed metering plate is provided with a seed supporting plate, the seed metering plate is a disk with the circumference provided with a plurality of round suction holes, the seed supporting plate is an annular plate with the circumference provided with a plurality of indent clamping openings, and each round suction hole corresponds to each indent clamping opening in a one-to-one mode. The seed metering plate is driven by a transmission mechanism to rotate relative to the bottom casing, and an upper cover is arranged on the outer side of the seed metering plate and fixed on the bottom casing. A cavity arranged between the upper cover and the seed metering plate is divided into a seed filling area, a seed clearing area and a seed metering area, a seed clearing knife is arranged in the seed clearing area, and a seed discharging knife and a seed guiding plate are arranged in the seed metering area. The air suction and mechanical auxiliary planting combined type corn precision seed-metering device is simple in structure, can effectively solve the problems that an air suction type seed-metering device is high in seeding absence rate and the seeding absence at the edge of a field is severe, and can be widely applied to a corn precision seeding process.

Owner:CHINA AGRI UNIV

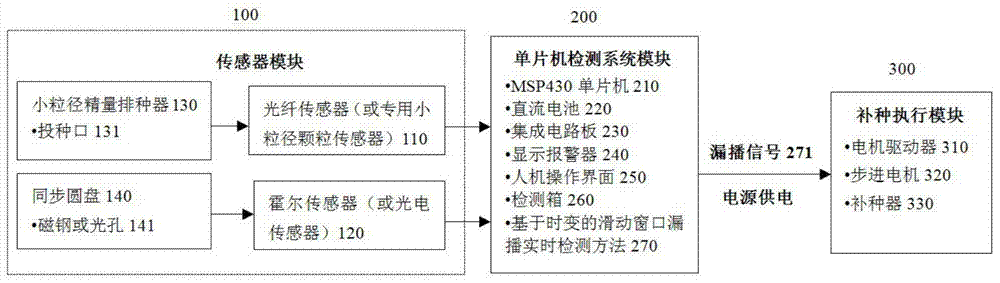

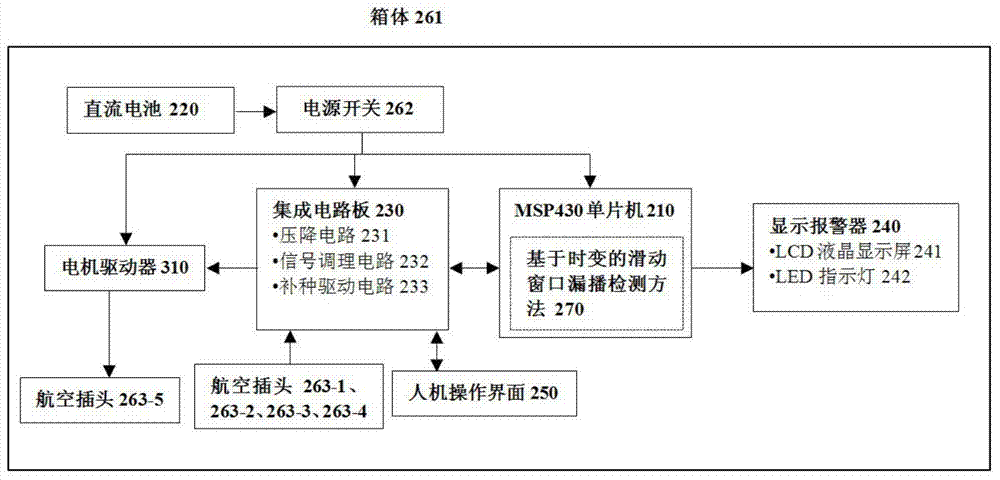

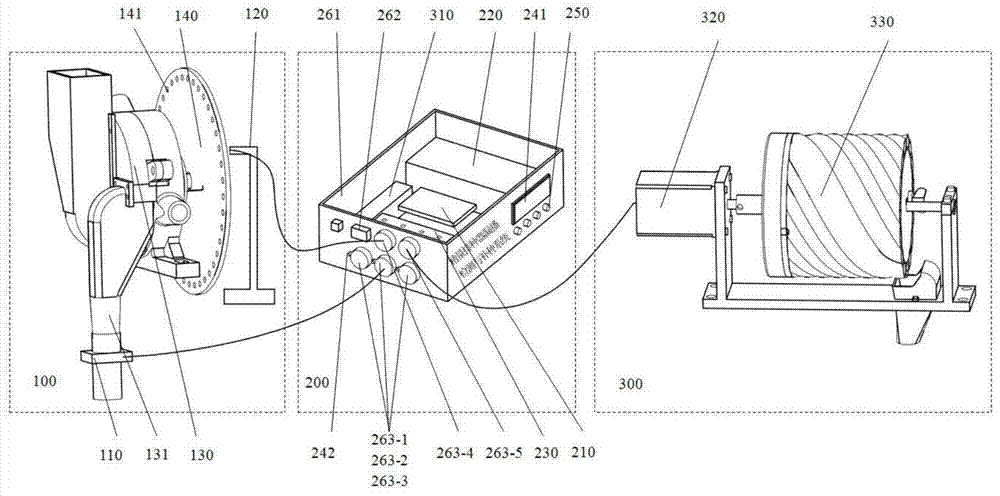

Miss-seeding real-time detection and automatic seed supplying system of small grain size precise seeding apparatus

ActiveCN104488419AReal-time detection of missing broadcastShort detection hysteresisAgriculture gas emission reductionSeed depositing seeder partsMicrocomputerMicrocontroller

The invention discloses a miss-seeding real-time detection and automatic seed supplying system of a small grain size precise seeding apparatus. The system comprises a sensor module, a singlechip microcomputer detection system module and a seed supplying executing module. By adopting a miss-seeding real-time detection method of the small grain size precise seeding apparatus with a time-varying sliding window, the system transfers a standard seeding pulse sequence and a seeding seed flow sequence detected to a singlechip microcomputer control system by virtue of a sensor for statistic analysis so as to obtain a broken bar coefficient, a spare missing seedling coefficient and a miss-seeding coefficient and can be used for precisely judging the miss-seeding state according to a miss-seeding coefficient threshold vale and a miss-seeding judging rule for displaying and alarming, and meanwhile, the system drives a seed supply system to compensate seeds after miss seeding. The system disclosed by the invention can be used for immediately and accurately compensating the seeds, so that the seeding quality and the production efficiency of a small grain seed precise direct seeding machine, such as oilseed rape, are improved, and the mechanical and intelligence levels of a oilseed rape seeder is gradually improved.

Owner:HUAZHONG AGRI UNIV

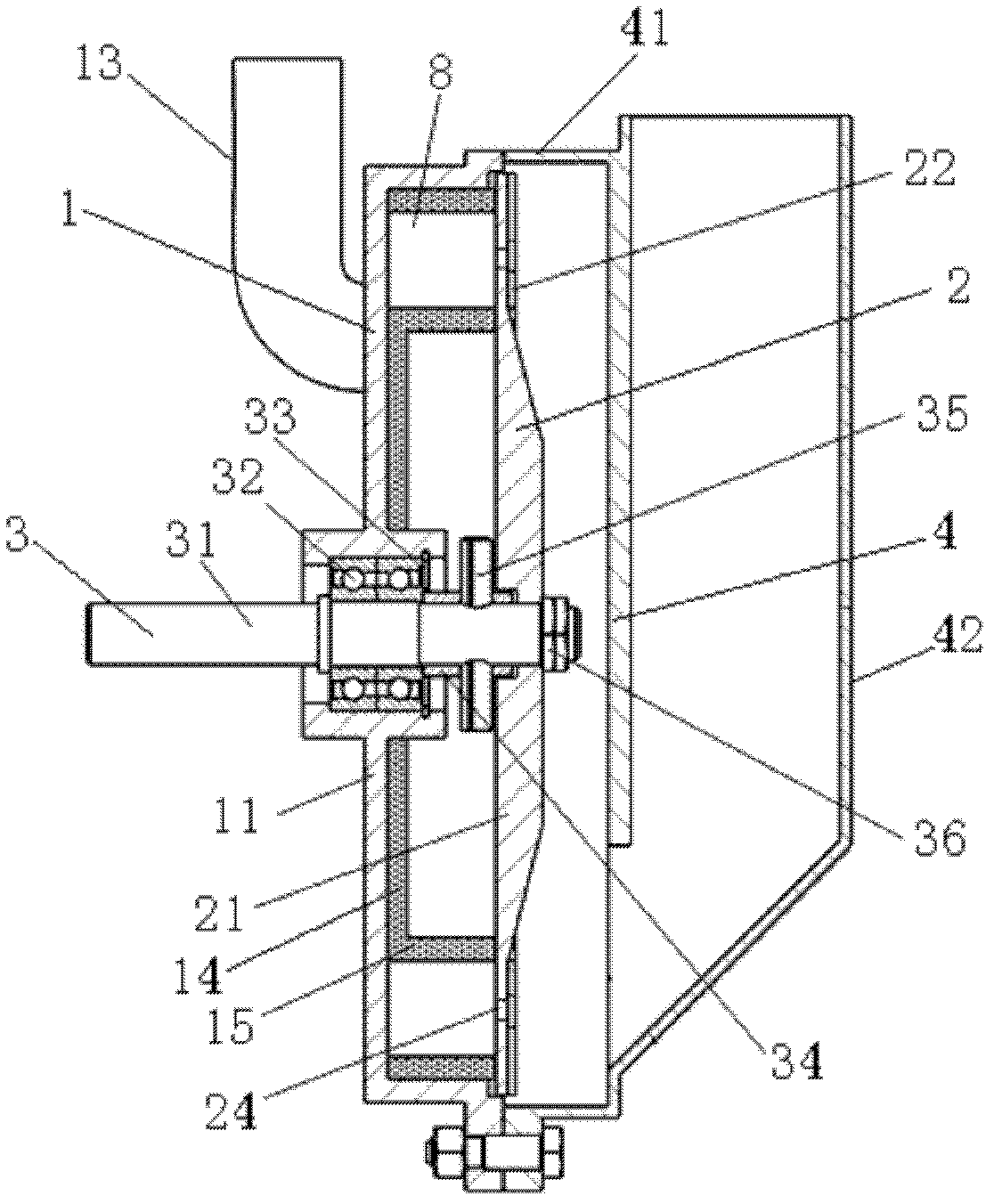

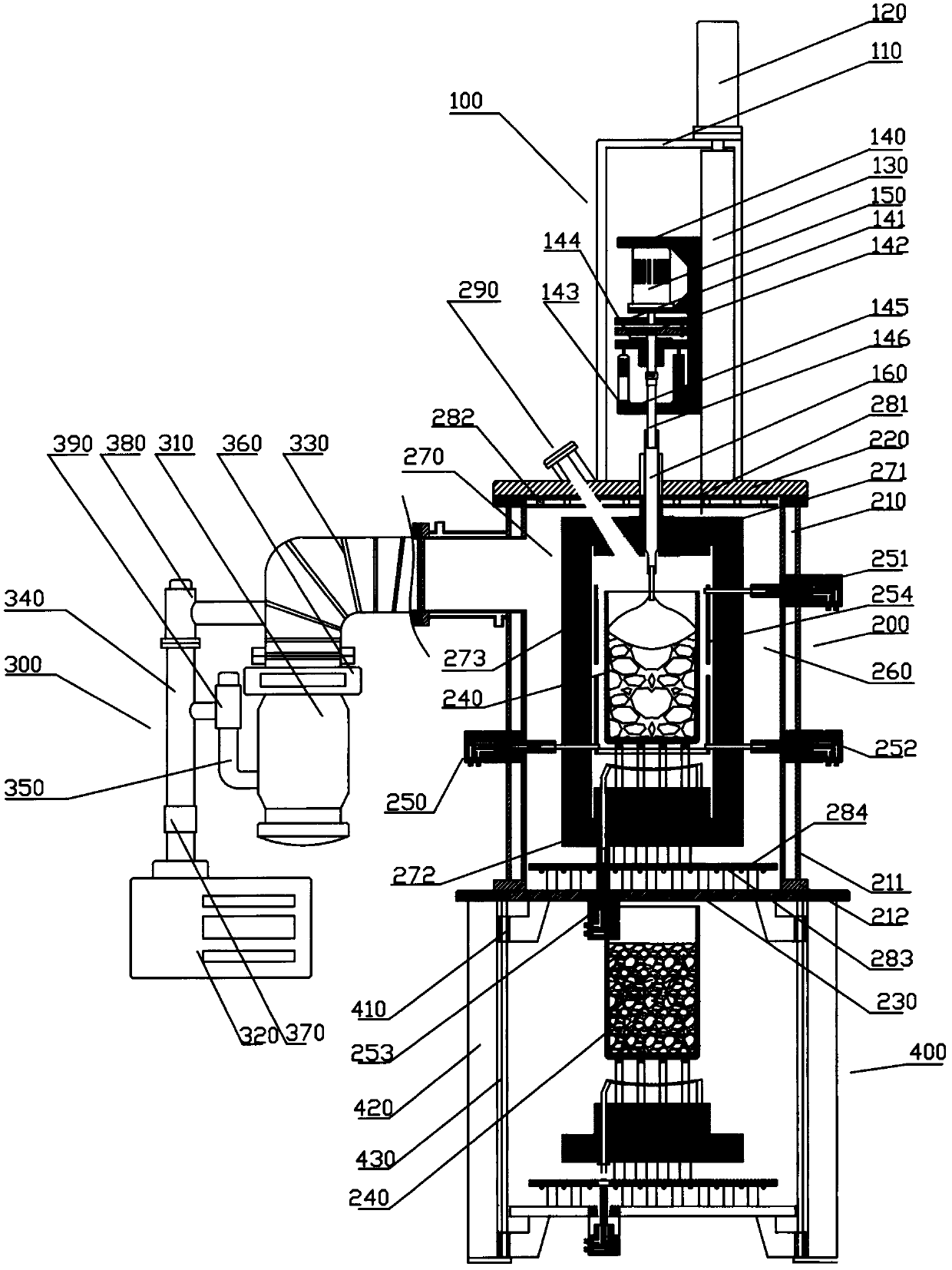

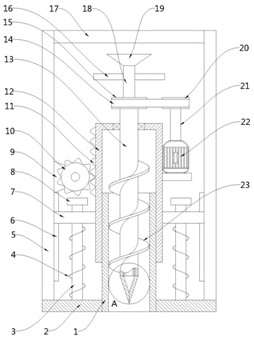

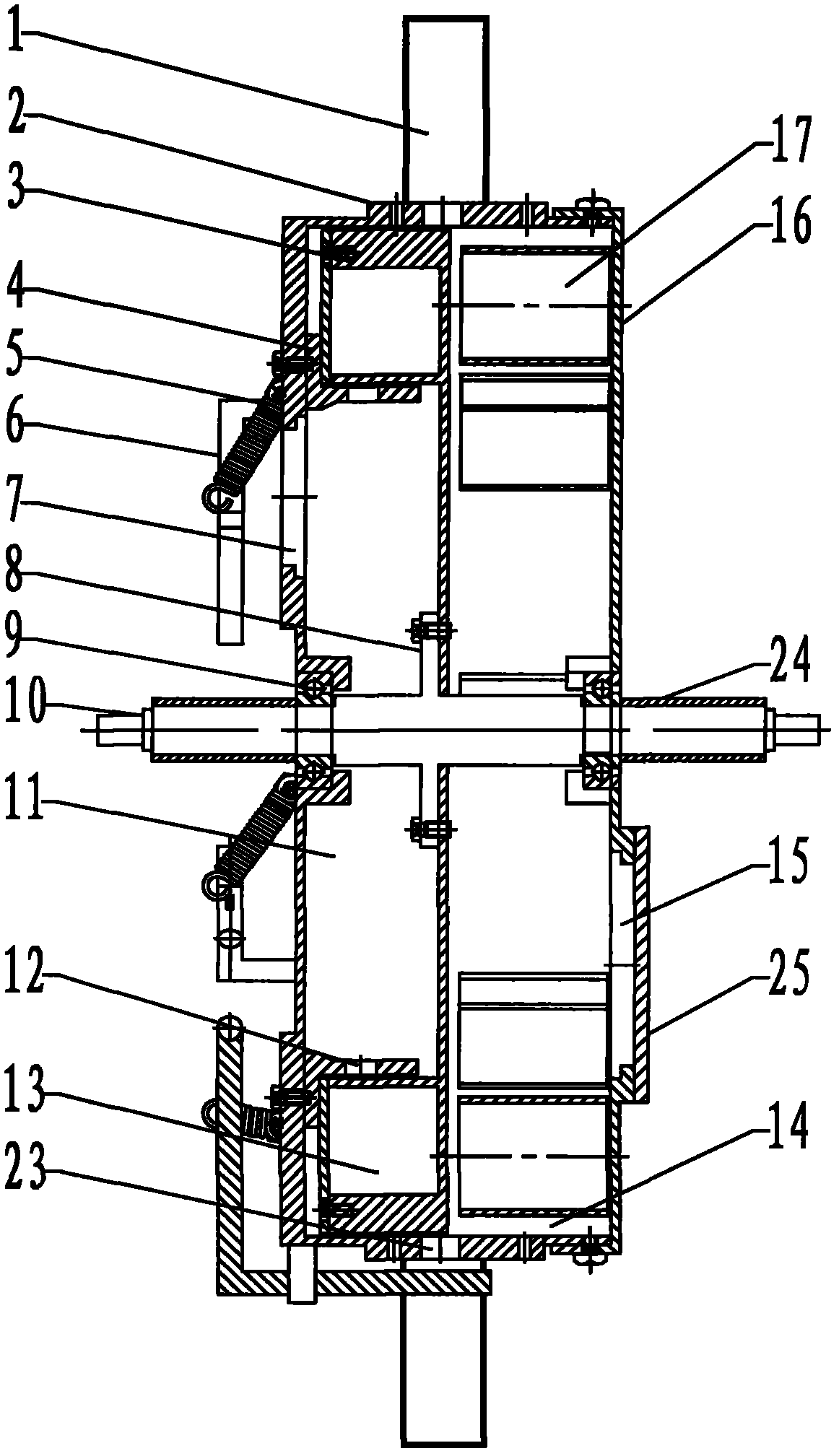

Large-size sapphire crystal growing furnace

InactiveCN103374753ARealize automatic control operationImprove seeding efficiencyPolycrystalline material growthBy pulling from meltAutomatic controlCrucible

The invention relates to a large-size sapphire crystal growing furnace. A seed crystal mounting room is arranged above a heating barrel; a vacuumizing assembly is communicated with the heating barrel; an inner cavity of the heating barrel is a sealed cavity; a hoisting motor is arranged above a bracket; a hoisting straight-line guide rail is arranged inside the bracket below the hoisting motor and is connected with the hoisting motor through a shaft coupler; the hoisting motor rotates to drive a slide block in the hoisting straight-line guide rail to hoist; a rotary motor fixing seat is arranged on the hoisting straight-line guide rail and is connected with the slide block in the hoisting straight-line guide rail; the rotary motor is mounted on the rotary motor fixing seat; a seed crystal mounting rod is connected with the rotary motor; an upper furnace cover and a lower furnace cover are respectively arranged at upper and lower ends of a double-layered water cooling barrel to form a sealed cavity; a crucible is arranged in the cavity and a heating system is arranged at the outer side of the crucible; and a seed crystal mounting rod stretches into the crucible of the heating barrel. The device disclosed by the invention realizes automatic control and operation, improves the seeding efficiency and enhances the seeding effect; and a large-size sapphire crystal can be produced by the large-size sapphire crystal growing furnace.

Owner:WUJIANG YATAI VACUUM EQUIP TECH

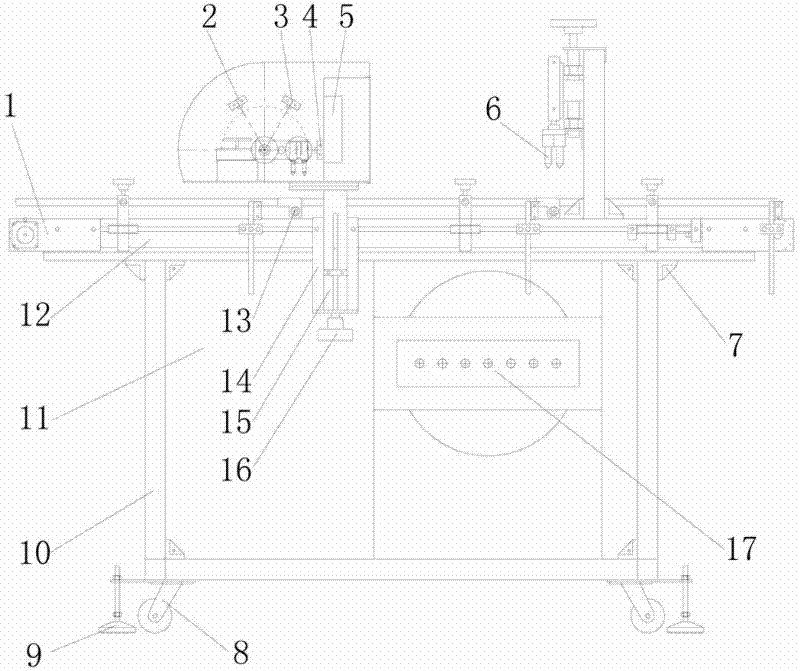

Perforating machine for thin film

The invention discloses a perforating machine for thin film. The perforating machine for the thin film comprises a rack, a thin film unwinding roller, a tearing heat knife device, a thin film punching device, a thin film winding buffering device and a PLC control device, wherein the thin film unwinding roller, the tearing heat knife device, the thin film punching device and the thin film winding buffering device are arranged on the rack in sequence, and are connected with the PLC control device. The perforating machine for the thin film is simple in structure and convenient to use, reduces consumption of manual labor, matches early-stage thin film perforation with an automatic planting machine, and improves economic benefit and efficiency of seeding. The separation distance of holes, the sizes of the holes and the shapes of the holes can be adjusted at will through replacement of perforating dies according to the requirements of use. A multi-area punching device can also be added to punch holes with different arrangements in the thin film.

Owner:青岛亚桑国际贸易有限公司 +1

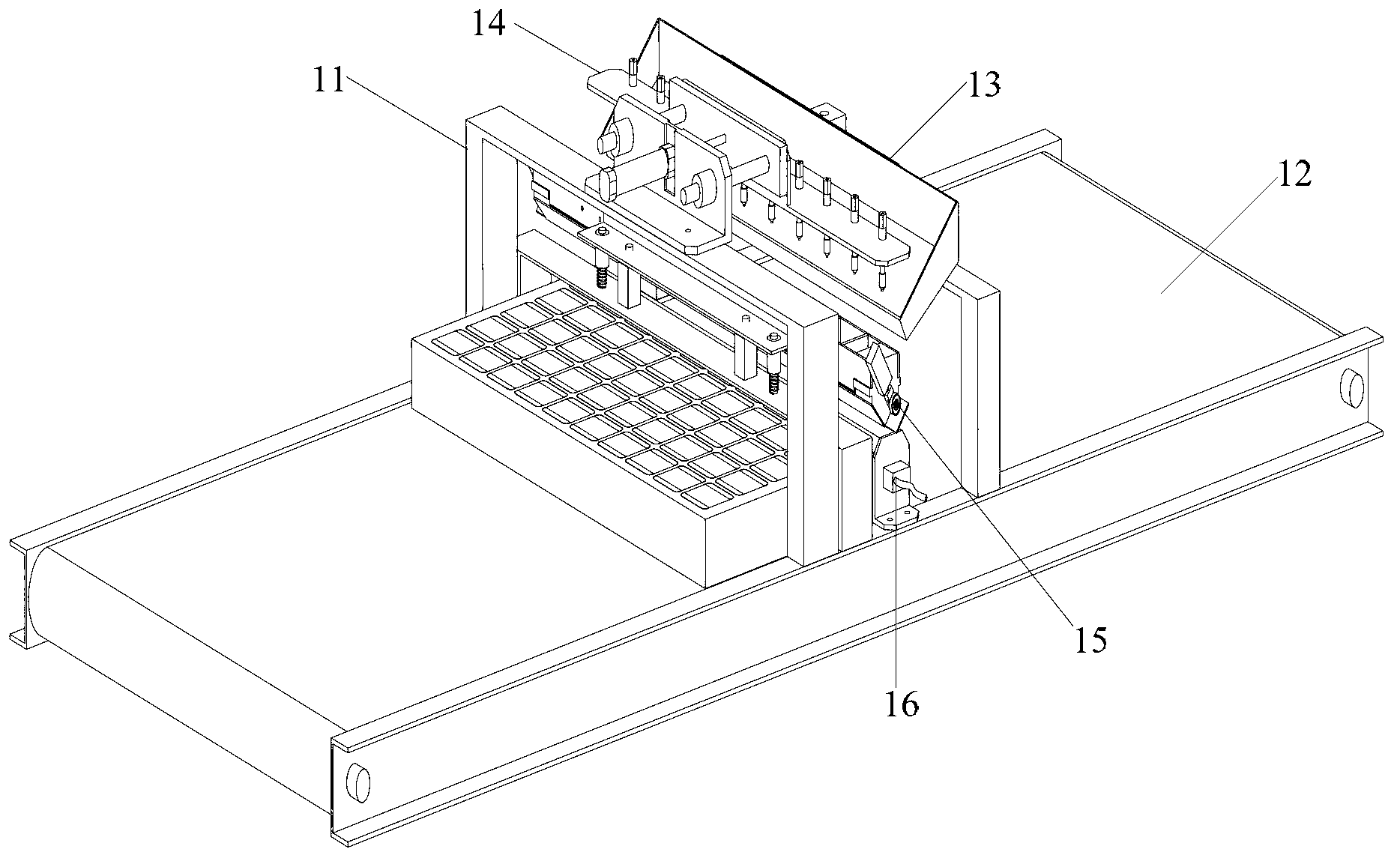

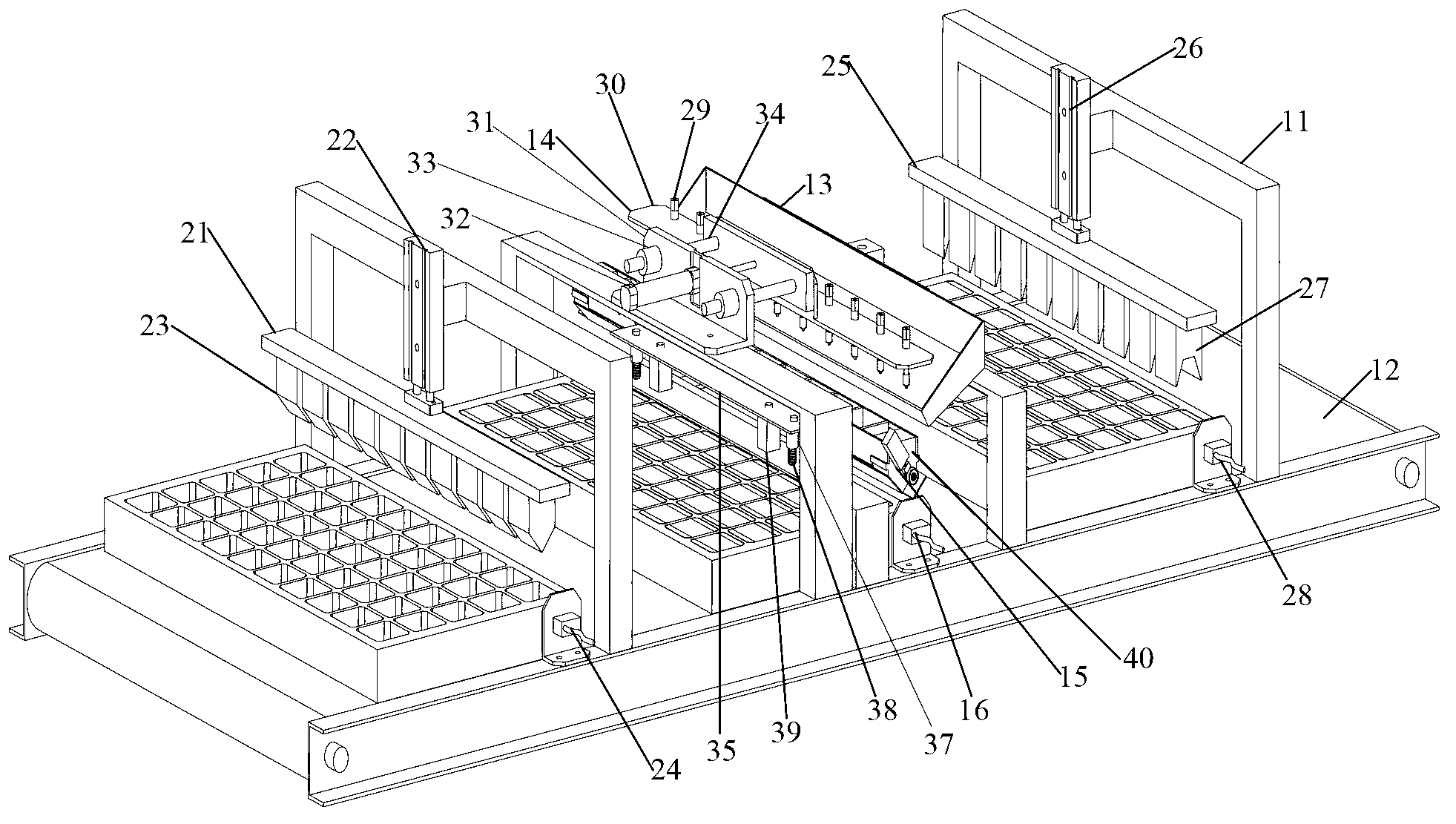

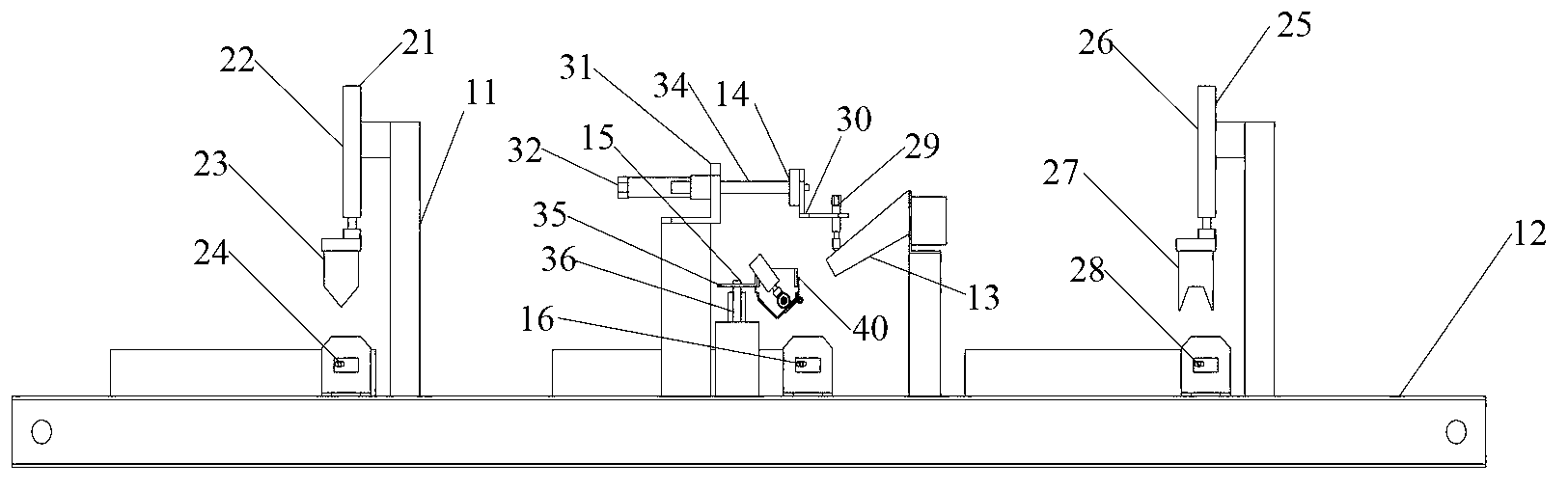

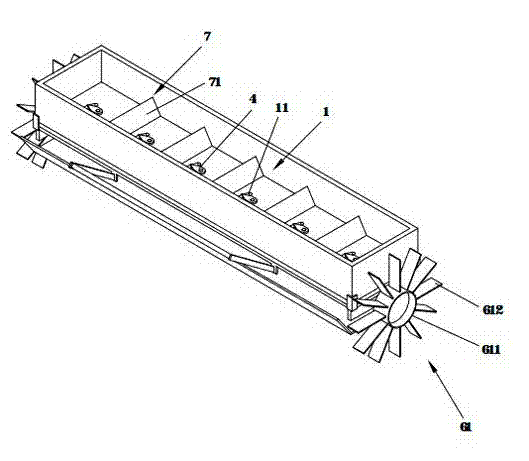

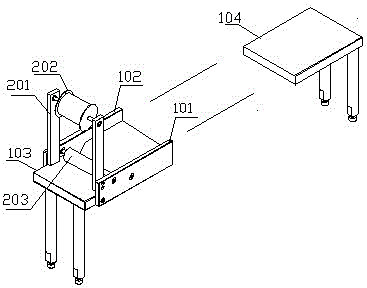

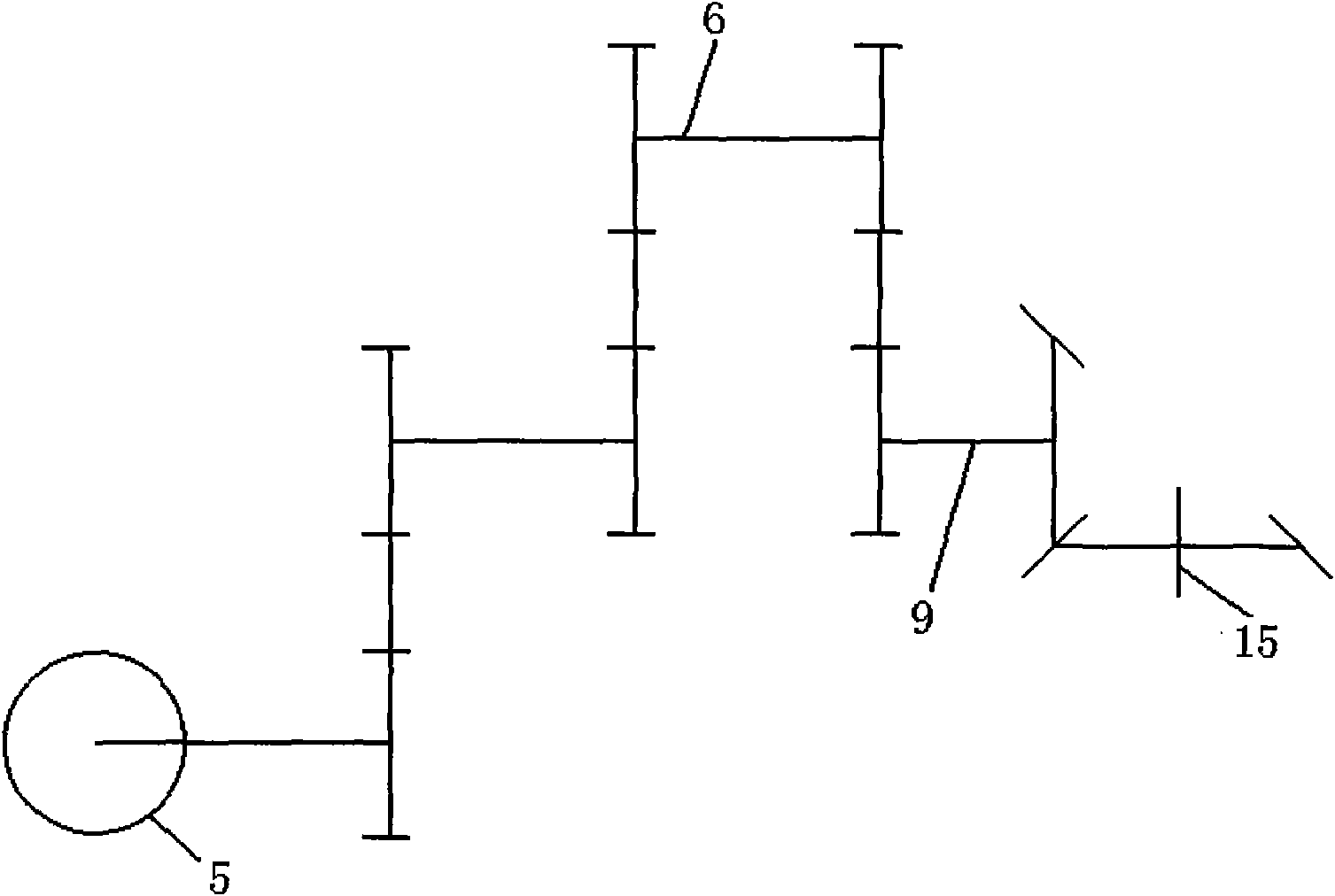

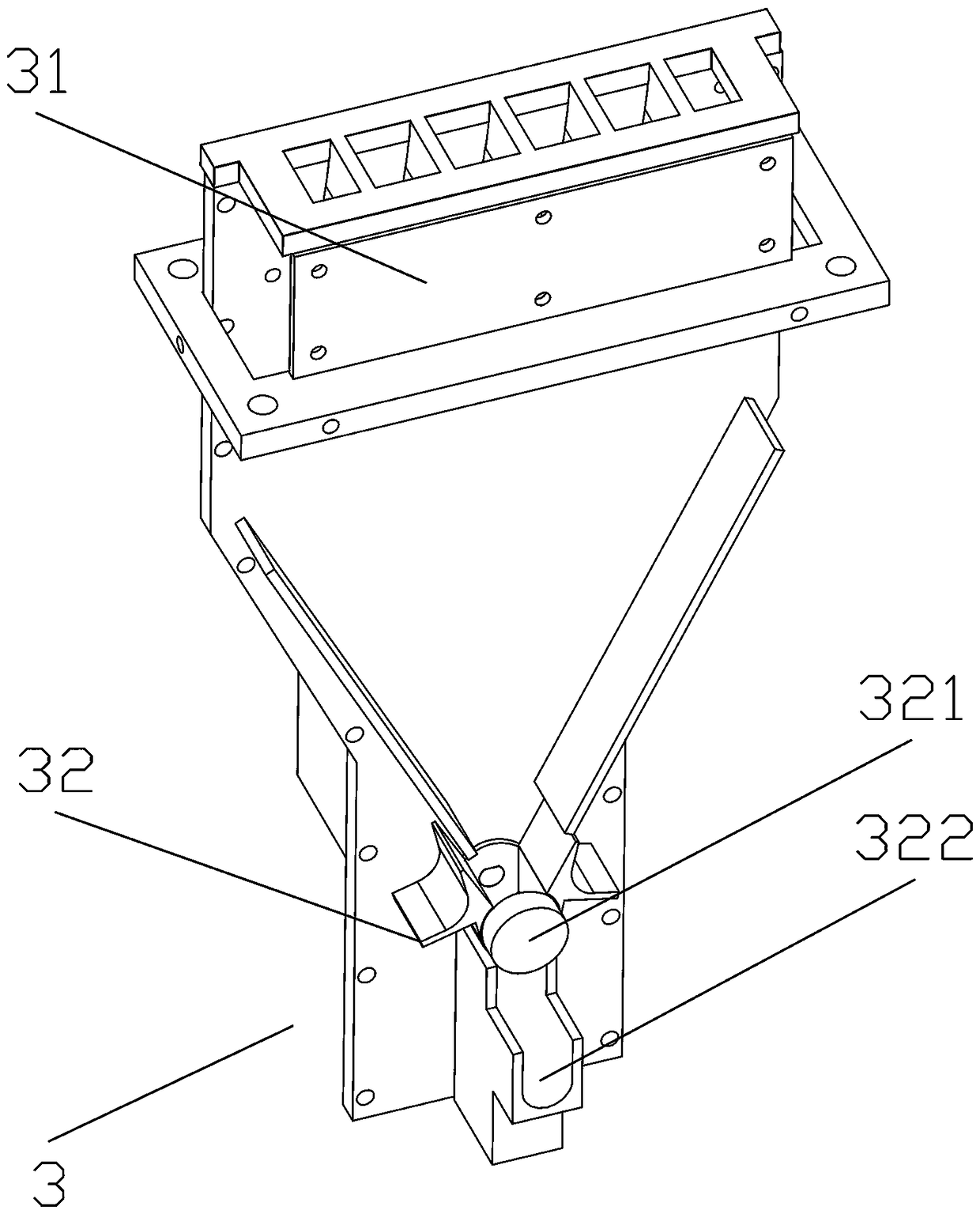

Directional sowing device for long seeds

ActiveCN103069953AImprove seeding efficiencySeed depositing seeder partsRegular seed deposition machinesEngineeringSowing

The invention provides a directional sowing device for long seeds. The device comprises a rack, an aperture disk conveyor, a seed groove, a seed absorbing and arranging unit and a direction regulating unit, wherein the rack is used for bearing the aperture disk conveyor; the aperture disk conveyor is used for conveying an aperture disk provided with multi-row aperture holes; the seed groove is arranged above the aperture disk conveyor on the rack, and is used for accommodating the long seeds to be sown; the seed absorbing and arranging unit is arranged above the aperture disk conveyor on the rack, and is used for absorbing a plurality of long seeds from the seed groove and placing into the direction regulating unit; and the direction regulating unit is arranged above the aperture disk conveyor on the rack, and is used for performing a direction regulating process on the plurality of long seeds and placing the seeds into one row of aperture holes of the aperture disk. According to the provided directional sowing device for the long seeds, the plurality of long seeds are absorbed each time through the seed absorbing and arranging unit and are placed into one row of aperture holes of the aperture disk at the sowing position after the direction regulating process by the direction regulating unit to finish the directional sowing in one row of aperture holes, so that the sowing efficiency is improved.

Owner:北京市农林科学院智能装备技术研究中心

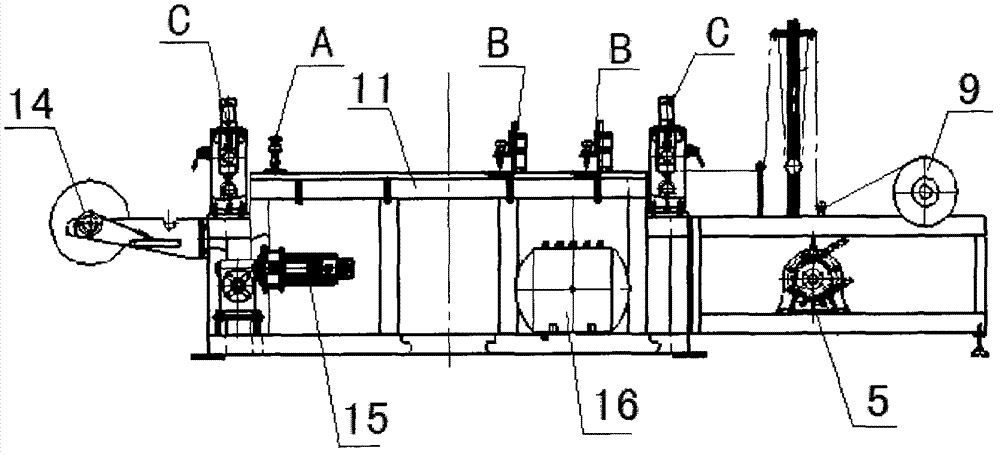

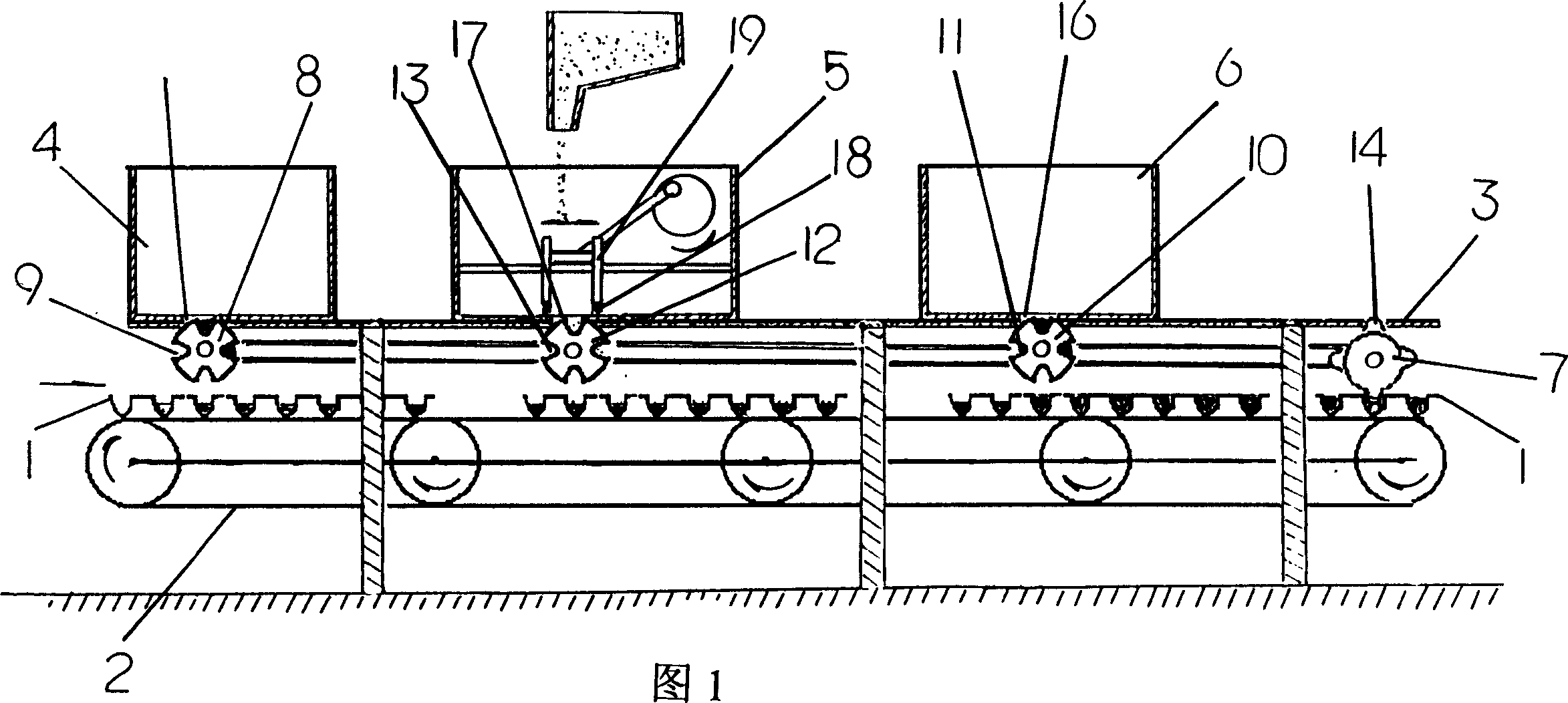

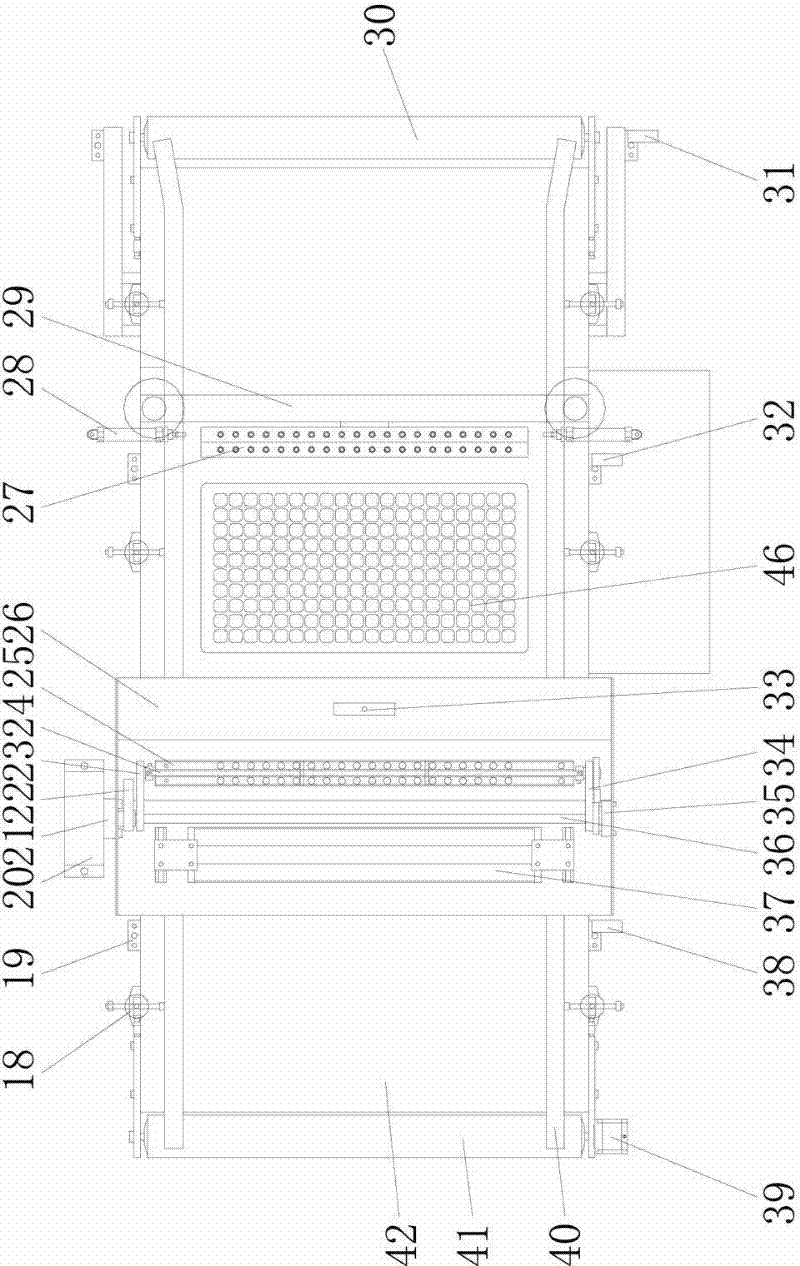

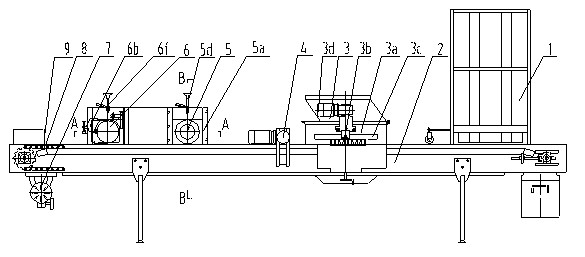

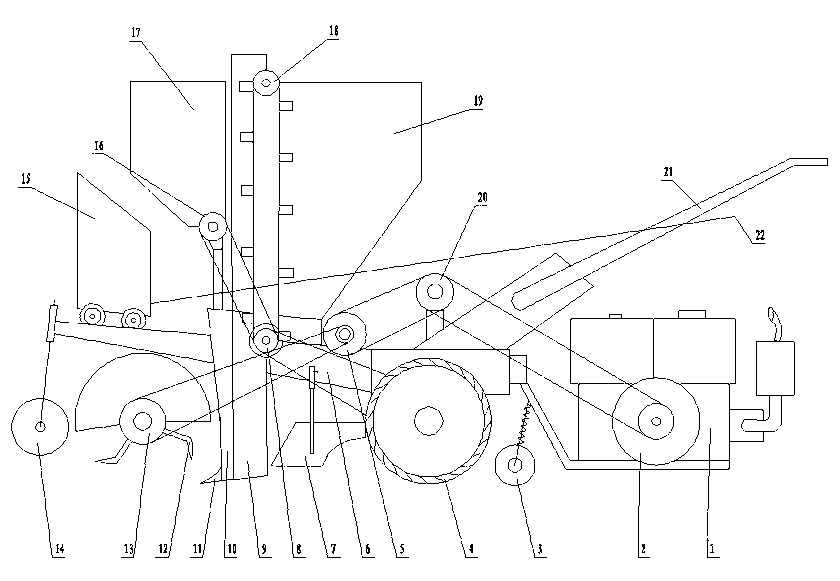

Automatic sowing machine for culturing seddlings in plastic tray

InactiveCN1596577AImprove seedling qualityImprove seeding efficiencyCultivating equipmentsRegular seed deposition machinesEngineeringUltimate tensile strength

An automatic sower for culturing seedlings in plastic trays features that the plastic trays are put on the streamline mechanism composed of conveying belts, and the basic soil applicator, seed sowing unit, covering soil applicator and soil pressing roller are sequentially arranged on the machine frame above said plastic trays.

Owner:桂先富

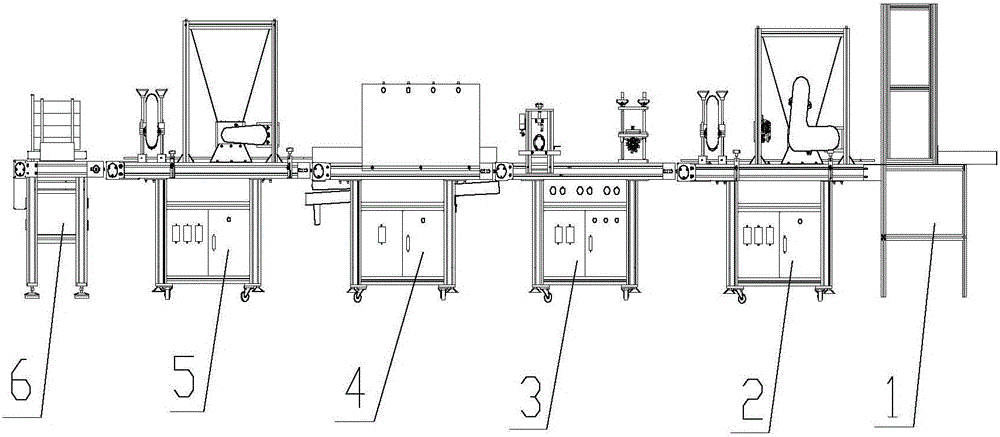

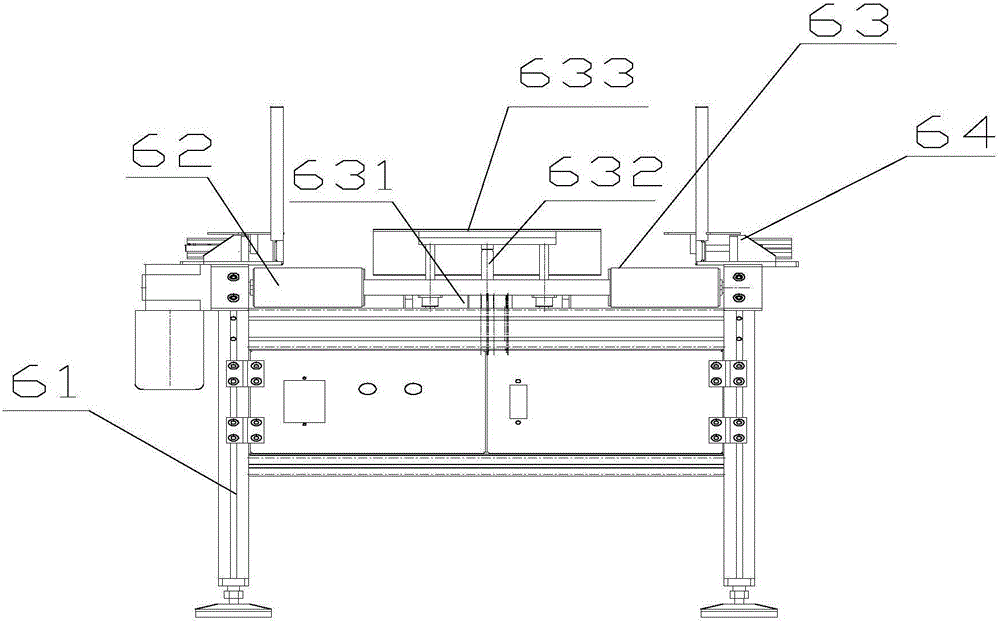

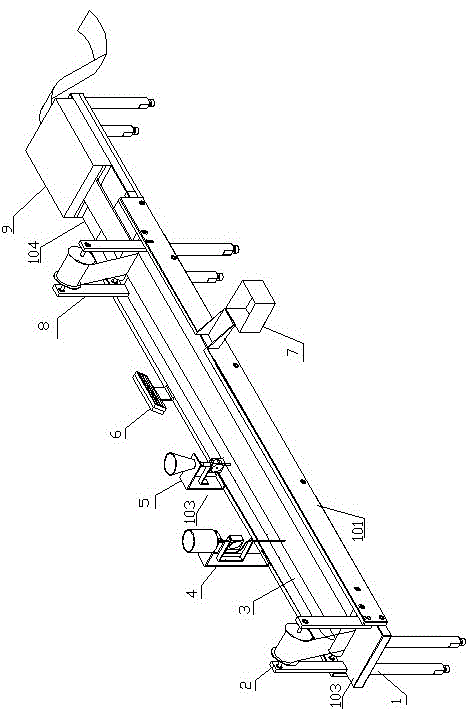

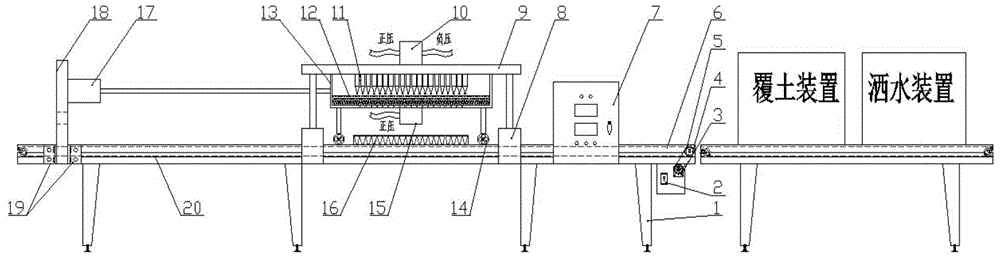

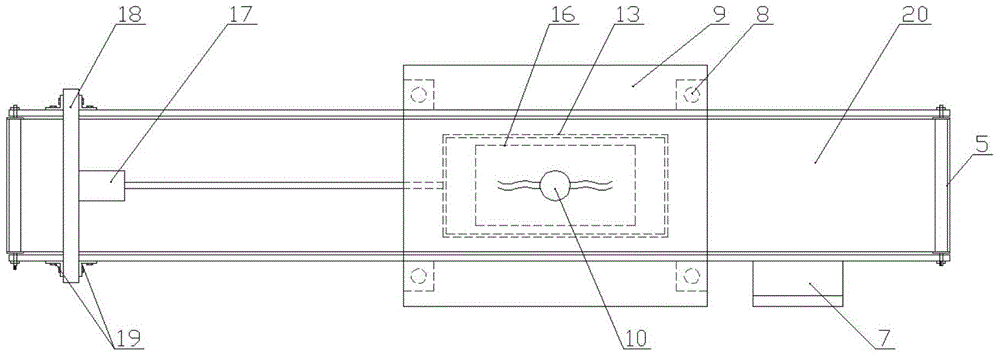

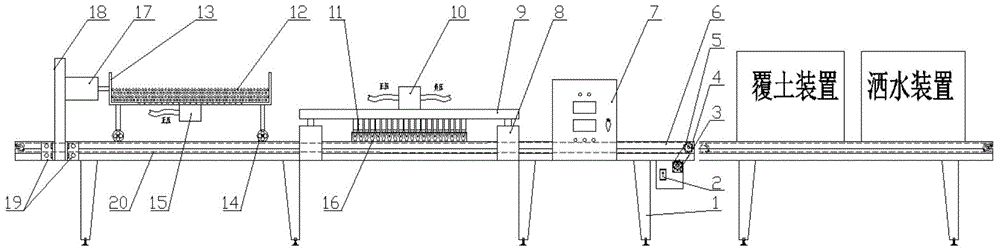

Automated sowing streamline for breeding plug tray

InactiveCN105830592AWith automatic operationImprove work efficiencyCultivating equipmentsSeed depositing seeder partsEngineeringConveyor belt

The invention discloses an automatic seedling tray seeding assembly line. The seeding assembly line is sequentially fixed with a seedling tray upper tray device, a substrate laying device, a precision roller sowing device, a spraying device, a substrate covering device, and a seedling tray stacking device. A seedling raising tray is placed above the seedling raising tray upper plate device, and the seedling raising tray is pushed to the sowing line along the conveyor belt. The working efficiency of the assembly line of the present invention is 10 times that of the traditional artificial seedling raising mode, reduces the labor cost by two-thirds, and can significantly improve the quality of seedling raising. The operation is simpler, the work efficiency and quality are higher, the commonality of parts is better, the reliability and safety are higher, and the market prospect is very broad.

Owner:山东中天盛科自动化设备有限公司

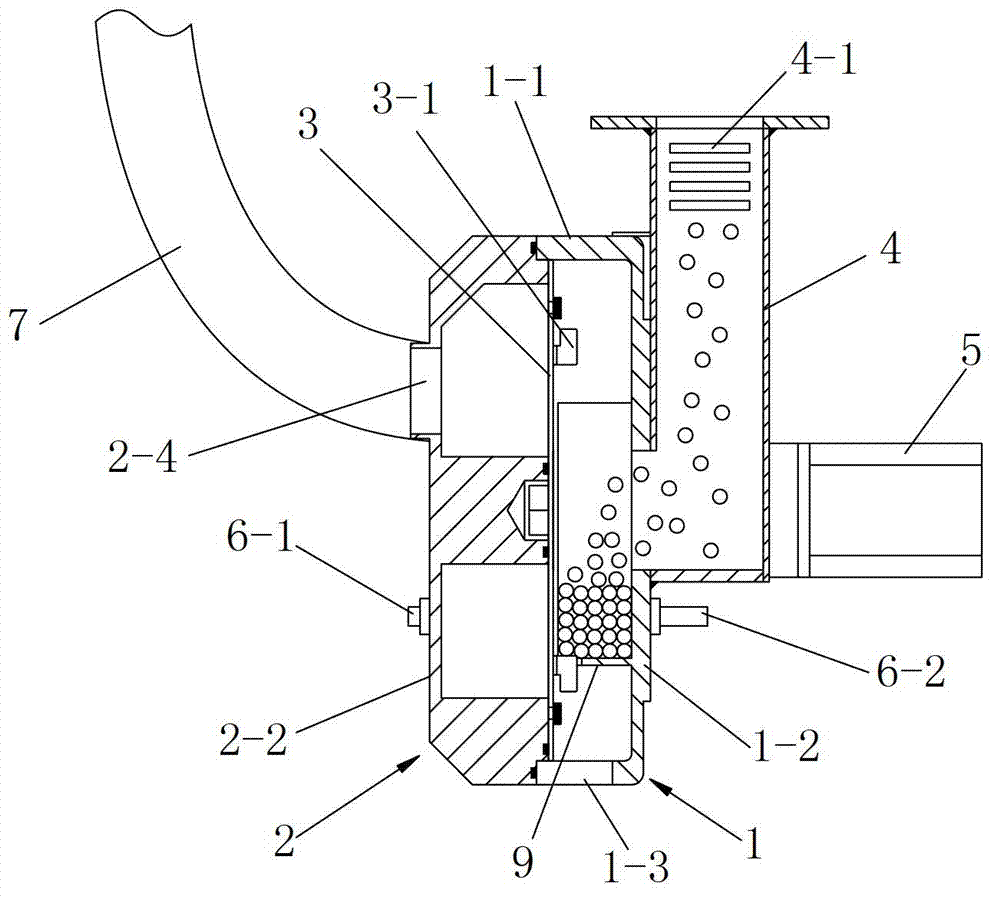

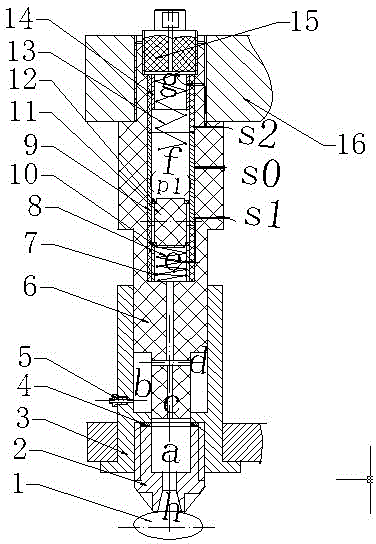

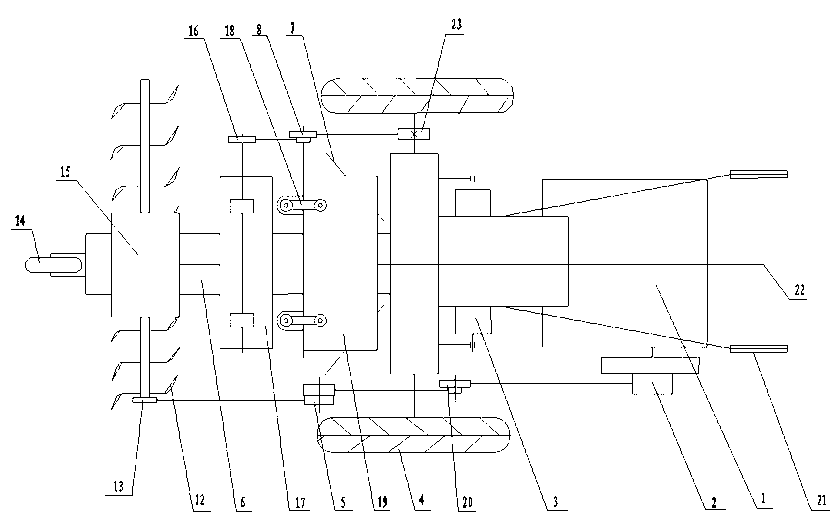

Air-suction-type seed sowing device for seeding machine

ActiveCN102771232ASimple structureNovel and reasonable designSeed depositing seeder partsControl systemAgricultural engineering

The invention discloses an air-suction-type seed sowing device for a seeding machine. The air-suction-type seed sowing device comprises a seed pickup device. The seed pickup device comprises a shell, a cover plate and a seed storage plate. A motor is arranged on one side of the cover plate. The output shaft of the motor stretches into the shell. A seed sowing disc is installed on the part of the output shaft in the shell. A plurality of seed suction ports I are arranged in the seed sowing disc. A seed outlet is arranged in the bottom of the shell. A seed inlet pipe is arranged on one side of the cover plate far away from the shell. A seed inlet is arranged in the cover plate. A sealing cover device is installed on one side of the shell far away from the seed inlet pipe. The sealing cover device comprises a boarding I. A baffle I is arranged on the boarding I. An air outlet I is arranged on the baffle I. An air damper corresponding to the position of the seed suction ports I which are arranged at the lowest position of the seed sowing disc is arranged in the boarding I. The air-suction-type seed sowing device additionally comprises a monitoring and control system which is used for monitoring whether the seed suction ports I suck seeds in real time and controlling the motor. Since the air-suction-type seed sowing device is driven by the motor, the defect that a floor wheel slips in the prior art is avoided, the situation of miss seeding can be automatically detected and the seeds can be replenished in time.

Owner:西安远景智能控制有限公司

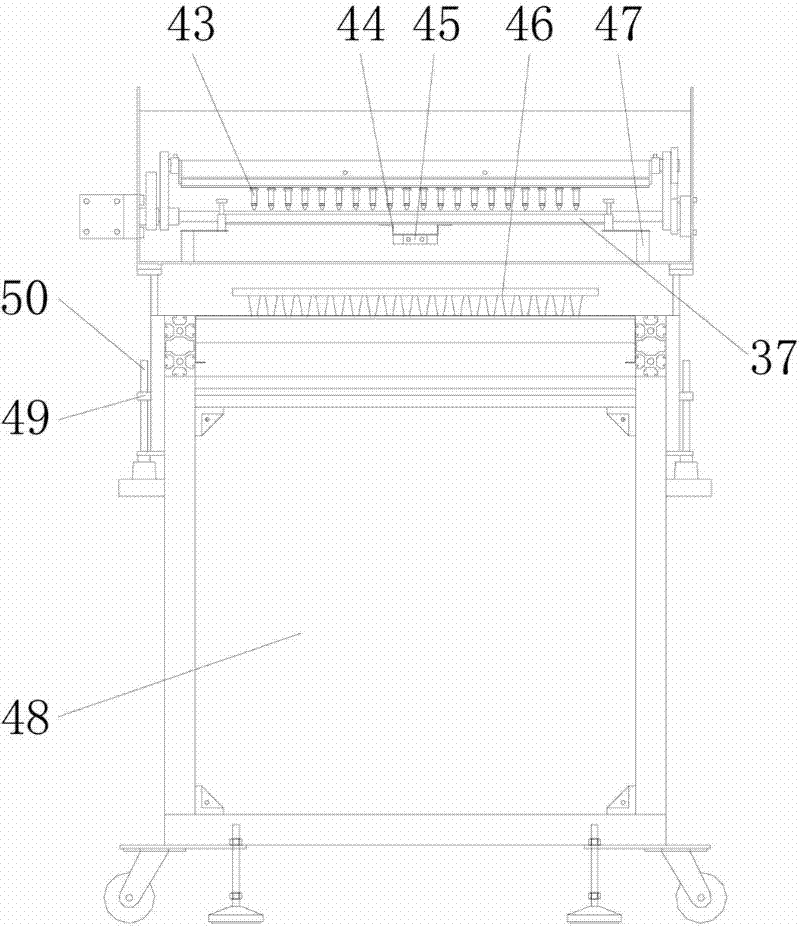

Tray seeder with self-cleaning suction nozzles

ActiveCN102550174AImprove adaptabilityPromote high yield and high qualitySeed depositing seeder partsSingle grain seedersControl systemSolenoid valve

The invention discloses a tray seeder with self-cleaning suction nozzles. The tray seeder comprises a frame unit, a holing system unit, a seeding system unit and a control system unit, wherein a conveyer belt transmission device pulled by a stepping motor is arranged on an upper end face of the frame unit; the holing system unit is provided with a holing supporting beam which stretches across frame main girders; a group of holing heads are arranged on each row of holing beam; a seeding beam connecting rod is fixed between a pair of swing arms of a swing mechanism of the seeding system unit; at least one row of seeding beams are fixed on the seeding beam connecting rod; a row of self-cleaning suction nozzles are arranged on the lower side of each row of seeding beam; a vibrating seed tray for accommodating seeds is arranged below the self-cleaning suction nozzles; the control system unit comprises a control box, a group of air-operated solenoid valve components, a group of photoelectric sensors, photoelectric sensor reflectors matched with the photoelectric sensors, and a sensor contact block fixed on a swing shaft of the seeding system unit; and the control system unit controls the start / stop of electric parts of each unit. By the tray seeder, the seeding efficiency and seeding precision can be improved, and high quality and high yield of seedlings are guaranteed.

Owner:BEIJING KINGPENG INT HI TECH CORP

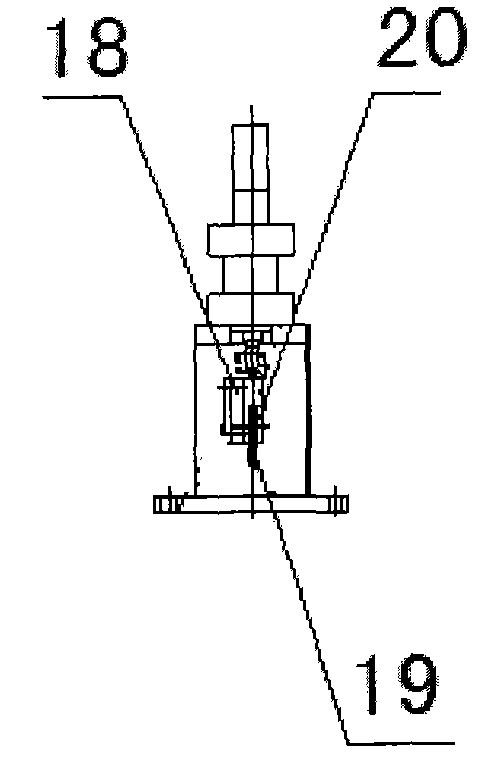

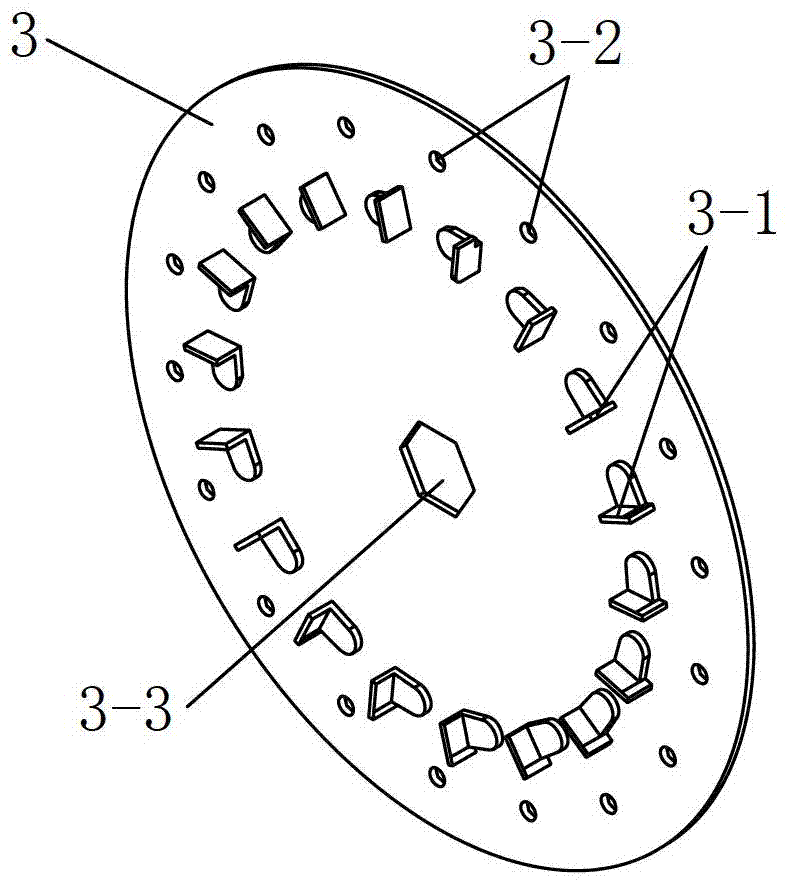

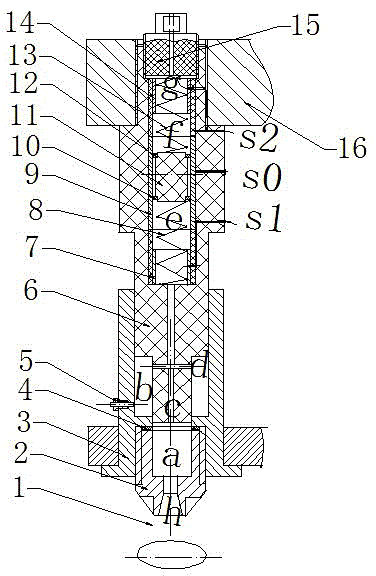

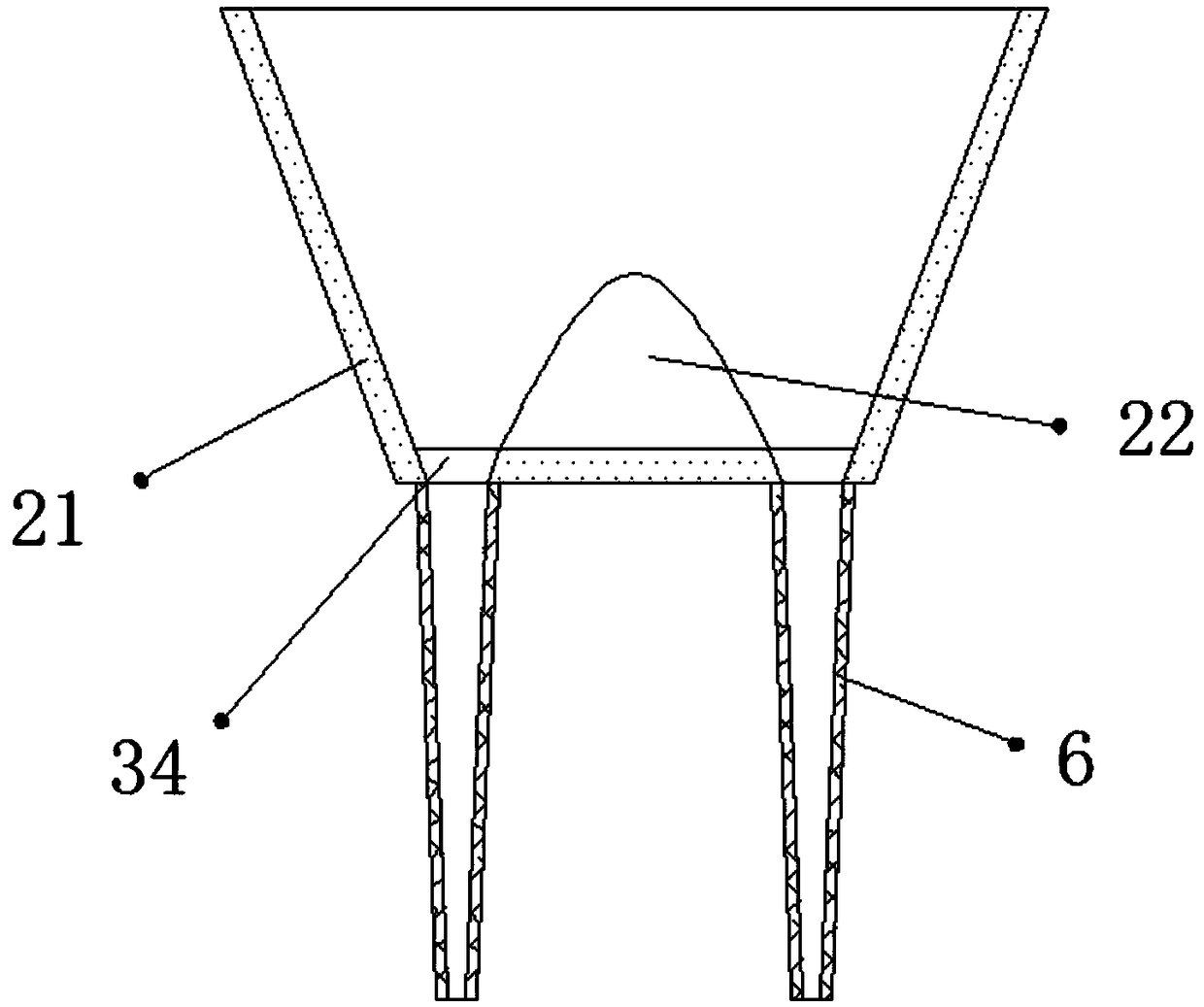

Pneumatic blockage-preventing and seed-leakage-free plug seedling and precision seed arrangement method and device

ActiveCN104067737ASolve the blockageImprove seeding efficiencySeed depositing seeder partsRegular seed deposition machinesEngineeringSeedling

The invention discloses a pneumatic blockage-preventing and seed-leakage-free plug seedling and precision seed arrangement method and device. A piston block detection switch is adopted for detecting seed leakage and blockage of a suction nozzle in seed sucking unit parts of a precision seed arrangement device and controlling the movement of a multi-suction nozzle seed sucking system. Seed sucking unit parts on the multi-suction nozzle seed sucking system are arranged corresponding to positions of holes in a seedling plug, and each seed sucking unit part is provided with a piston block detection switch; a piston block is in a middle balance position when not working, and when a pneumatic force changes, a piston movement relative to an air chamber is generated, and thus a corresponding switching function is realized. When the suction nozzles do not suck seeds, the pressure in the suction nozzles is a smaller negative pressure, the piston block does not move, and a leak-suction-preventing switch is turned on; when a pressure force in each hole after the suction nozzles suck the seeds is a larger negative pressure, the piston block downwards moves, and a normal seeding switch is turned on; when seeds are discharged at a positive pressure, the suction nozzles cannot discharge the seeds due to blockage, the piston block is forced to upwards move, and a blockage-preventing switch is turned on. The pneumatic type blockage-preventing and seed-leakage-free plug seedling and precision seed arrangement method and device are capable of realizing blockage-preventing and seed-leakage-free fine-sowing processes of all suction nozzles, and can be applied to accurate sowing of plug seedling.

Owner:HUAIHAI INST OF TECH

Mechanical sugarcane planting method

The invention provides a mechanical sugarcane planting method. The method comprises following steps: S1: soil preparation; S2, variety selection and seed stem preparation; S3, mechanical planting; S4,field management; S5, mechanical harvesting. The whole process of the mechanical sugarcane planting method adopts steps of mechanical soil preparation, planting, management and harvesting, agricultural improvement and agricultural equipment adjustment are combined, set indexes in all planting links are controlled strictly, mechanical accurate planting can be realized, sugarcane quality can be improved, sugarcane yield can be increased, the sugarcane yield reaches 7 tons / mu or higher, wherein the yield of a big stem variety reaches 4700 pieces / mu, each piece is 1.50 kg or heavier, the yield ofa medium stem variety reaches 5500 pieces / mu, each piece is 1.3 kg or heavier, average sucrose content of the sugarcane in the maturation stage reaches 14% or higher; meanwhile, compared with traditional sugarcane cultivation, the method has the advantages that production cost is saved by 15% or more and benefit is increased by 10% or higher.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

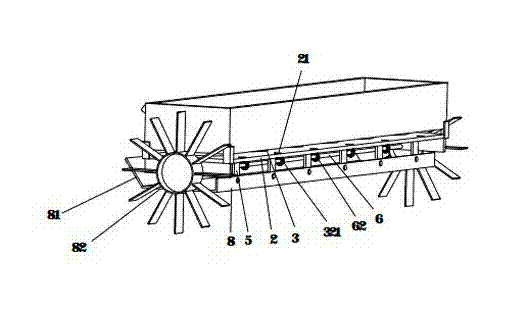

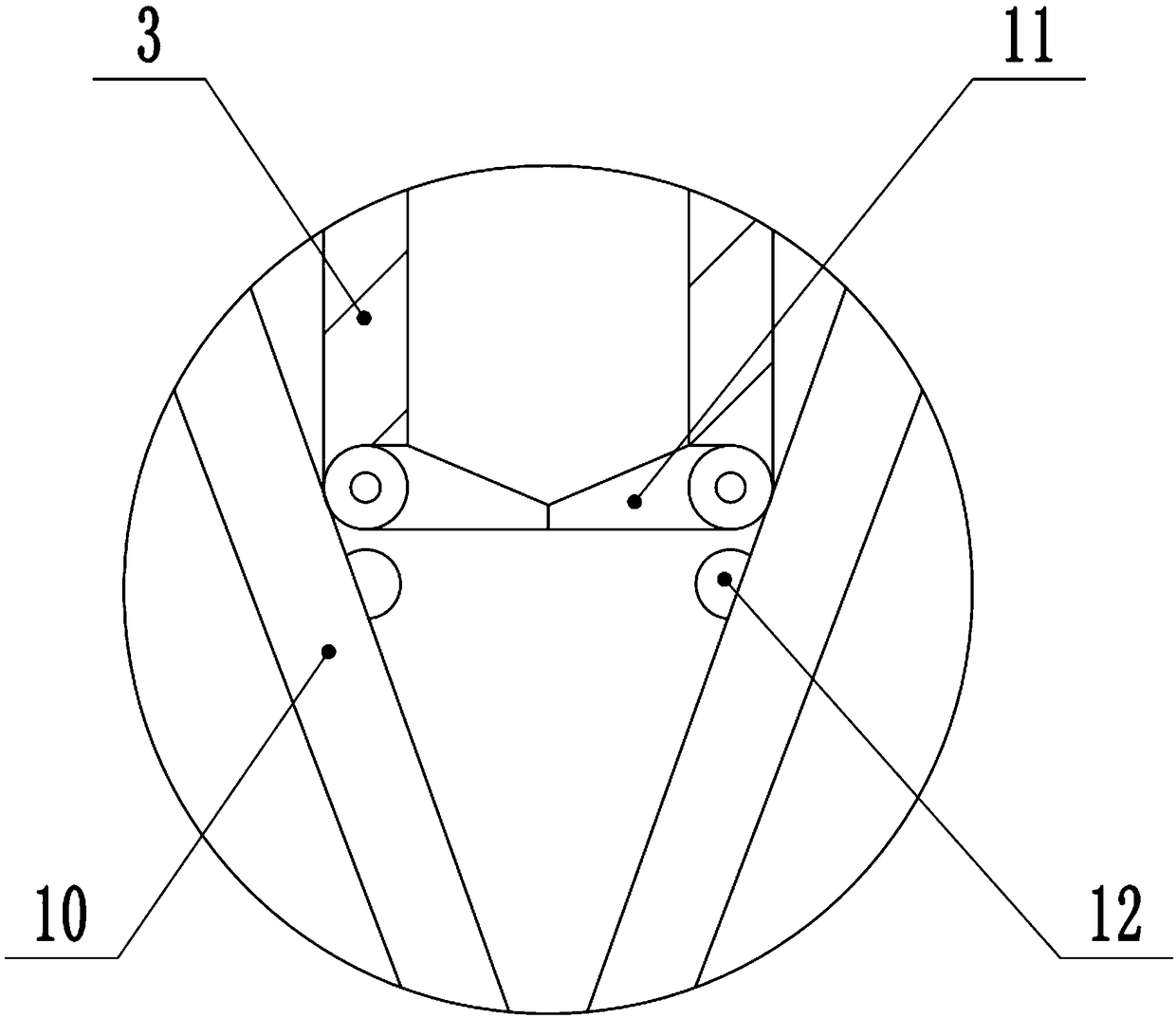

Vibrating type paddy planter

InactiveCN103733778ANo mechanical damageNo cloggingSeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringBud

The invention discloses a vibrating type paddy planter which mainly comprises a rack with a walking device, wherein a seeding device is arranged on the rack; the seeding device comprises a seed box, a horizontal seed guide plate and an intermittent seeding mechanism; the horizontal seed guide plate is fixed on the rack through a vibrator; multiple seed guide slots are formed in the horizontal seed guide plate; one end of the seed guide slot is connected with the seed box through a falling hopper, and the other end is connected with the intermittent seeding mechanism; the intermittent seeding mechanism comprises a seed guide pipe and a seeding stop tongue which can be intermittently opened; the seed guide pipes and the seed guide slots are in para-position connection to realize discharge of paddy seed buds; the seeding stop tongue is arranged in each seed guide slot; the seed guide slot is started or stopped through the intermittent mechanism. The vibrating type paddy planter disclosed by the invention has the advantages of relatively small overall volume and high sowing precision, is flexible and convenient to use, avoids mechanical damage to the buds and effectively improves the sowing efficiency.

Owner:HUNAN AGRICULTURAL UNIV

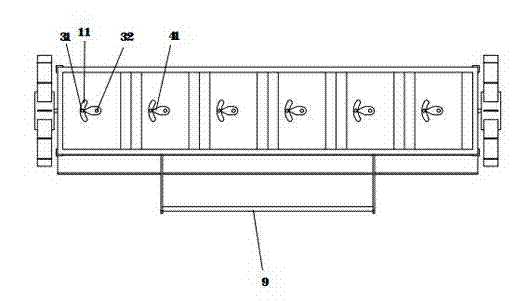

Improved seeding machine

ActiveCN102918962ANot easy to pile upImprove seeding efficiencySeed depositing seeder partsBroadcast seedersDrive shaftAgricultural engineering

The invention discloses an improved seeding machine which comprises a plurality of seeding units. Each seeding unit comprises a material bin, the bottom of the material bin is provided with a seed leaking groove, and a support plate is further arranged under the material bin. A seeding plate is arranged between the material bin and the support plate, a seed delivery hole is arranged on the seeding plate, a seeding hole is arranged on the support plate, and the seeding plate is connected with a drive shaft. A poking piece coaxial with the seeding plate is installed and located above the seed leaking groove, the drive shaft is used for driving the seeding plate and the poking piece to rotate along the axes, the poking piece is provided with a disturbance end, the width of the disturbance end changes gradually along the vertical direction of the axis of the drive shaft, and the width of the position of the disturbance end close to the axis of the drive shaft is larger than that of the position of the disturbance end away from the axis of the drive shaft. The improved seeding machine is low in cost, simple in structure and high in seeding efficiency.

Owner:扎赉特旗兴义农丰农牧机械装备有限公司

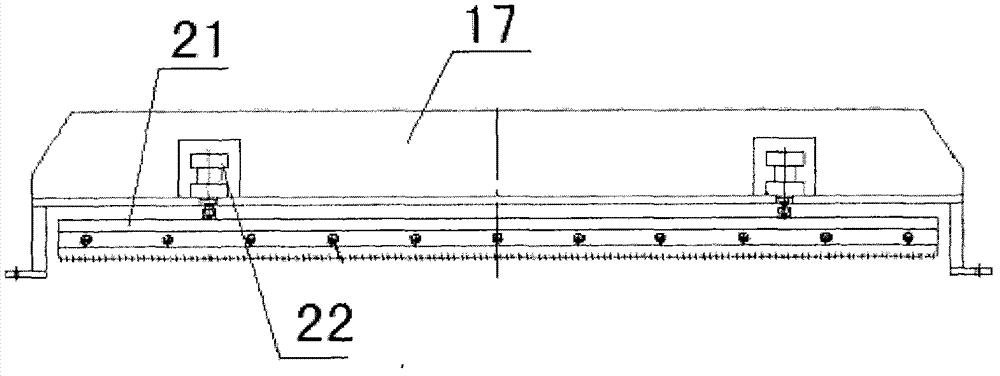

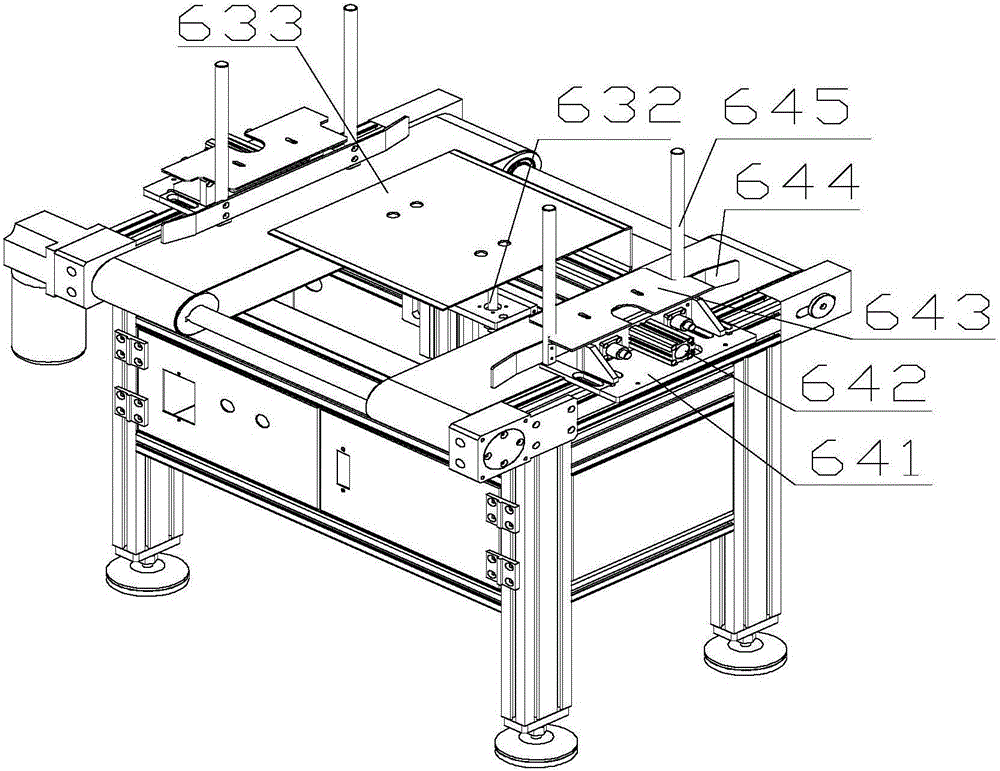

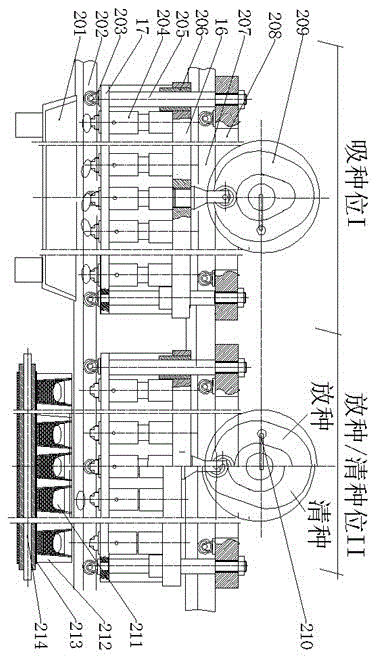

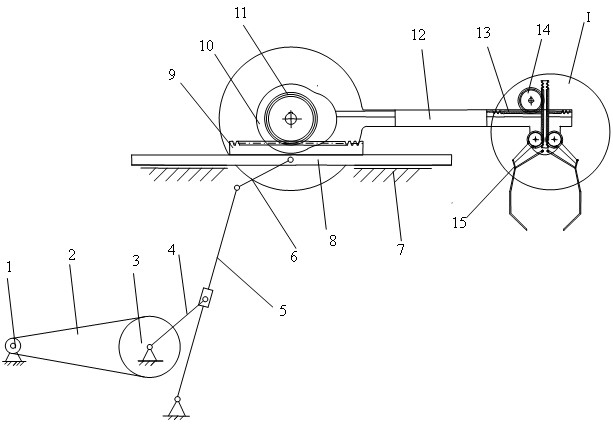

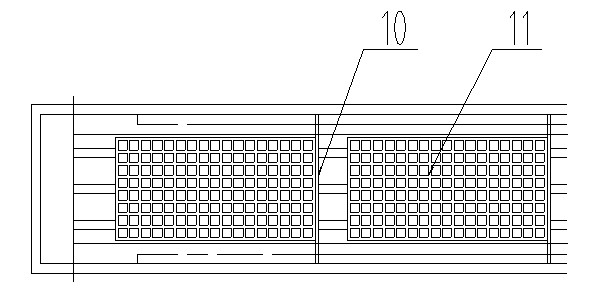

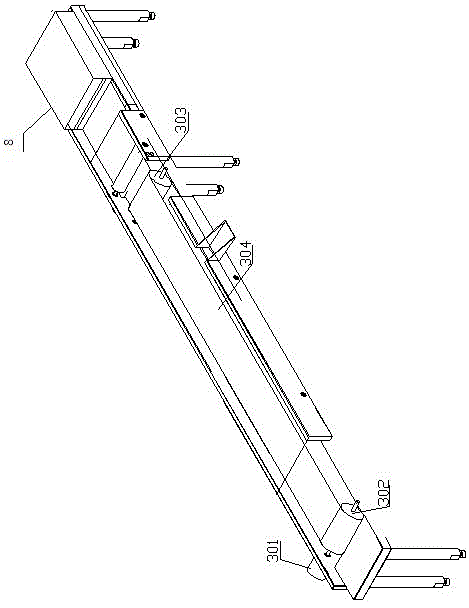

Automatic bowl plate feeding mechanism on rice seeding production line

InactiveCN102598931ASwing back and forthImprove seeding efficiencyProgramme-controlled manipulatorTransplantingProduction lineReciprocating motion

The invention discloses an automatic bowl plate feeding mechanism on a rice seeding production line, which comprises a crank mechanism, a rocker, a connecting rod, a rack, a sliding block, gear racks, two cams, a first gear, two mechanical arms, two gear rack push rods, a pair of second gears, two manipulators, a reinforcing rod, a pair of third gears, two two-sided gear racks, two pairs of fourth gears and two paws, wherein a crank of the crank mechanism drives the rocker to swing, so that the sliding block does reciprocation motion, and further, the mechanical arms can swing back and forth; the gear rack push rods are arranged in the mechanical arms, and slide relative to the mechanical arms, one ends of the gear rack push rods are contacted with the cams, and the gear racks on the other ends of the gear rack push rods are meshed with the gears on the mechanical arms; the pair of gears which are coaxial are meshed with the two-sides gear rack, and the manipulators are driven to open or close; and the crank rotates by a cycle, the mechanical arms rotate by a certain angle, at a bowl plate stacking position, the manipulators grab a bowl plate, then the mechanical arms rotate back to an initial position, and the manipulators loose the bowl plate and place onto a seeding production line, so that the manual operation can be reduced, and the mechanical seeding efficiency can be improved.

Owner:ZHEJIANG SCI-TECH UNIV

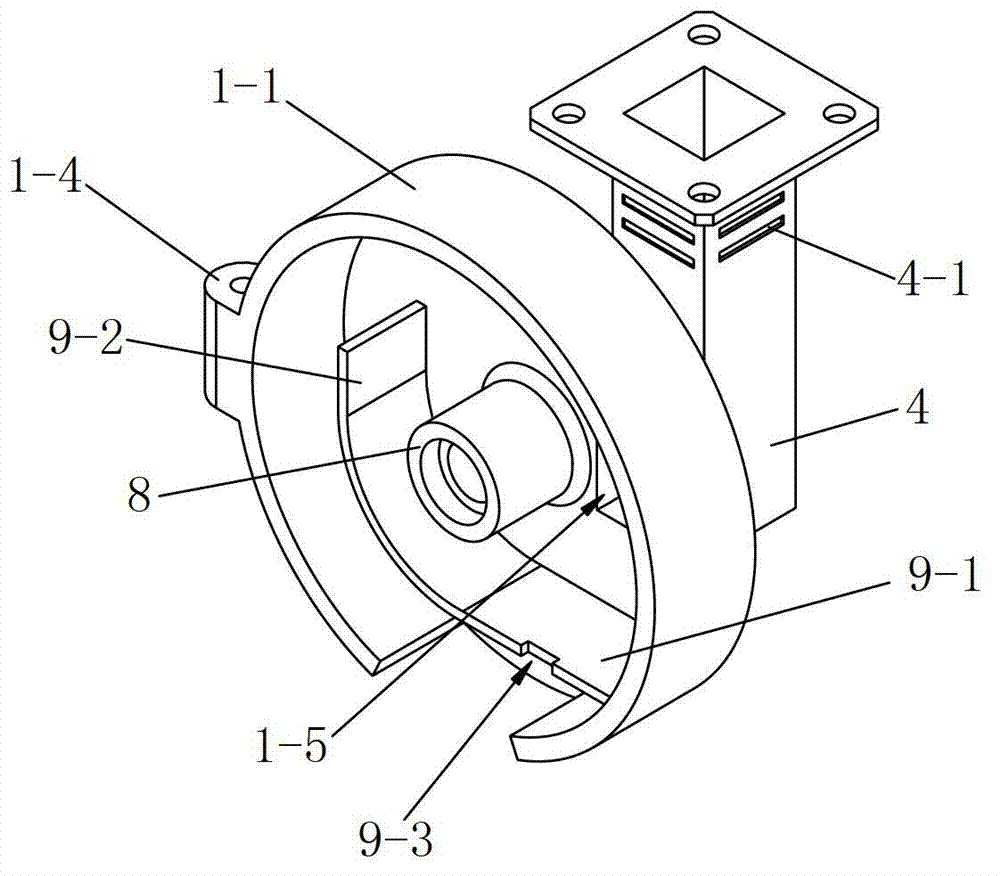

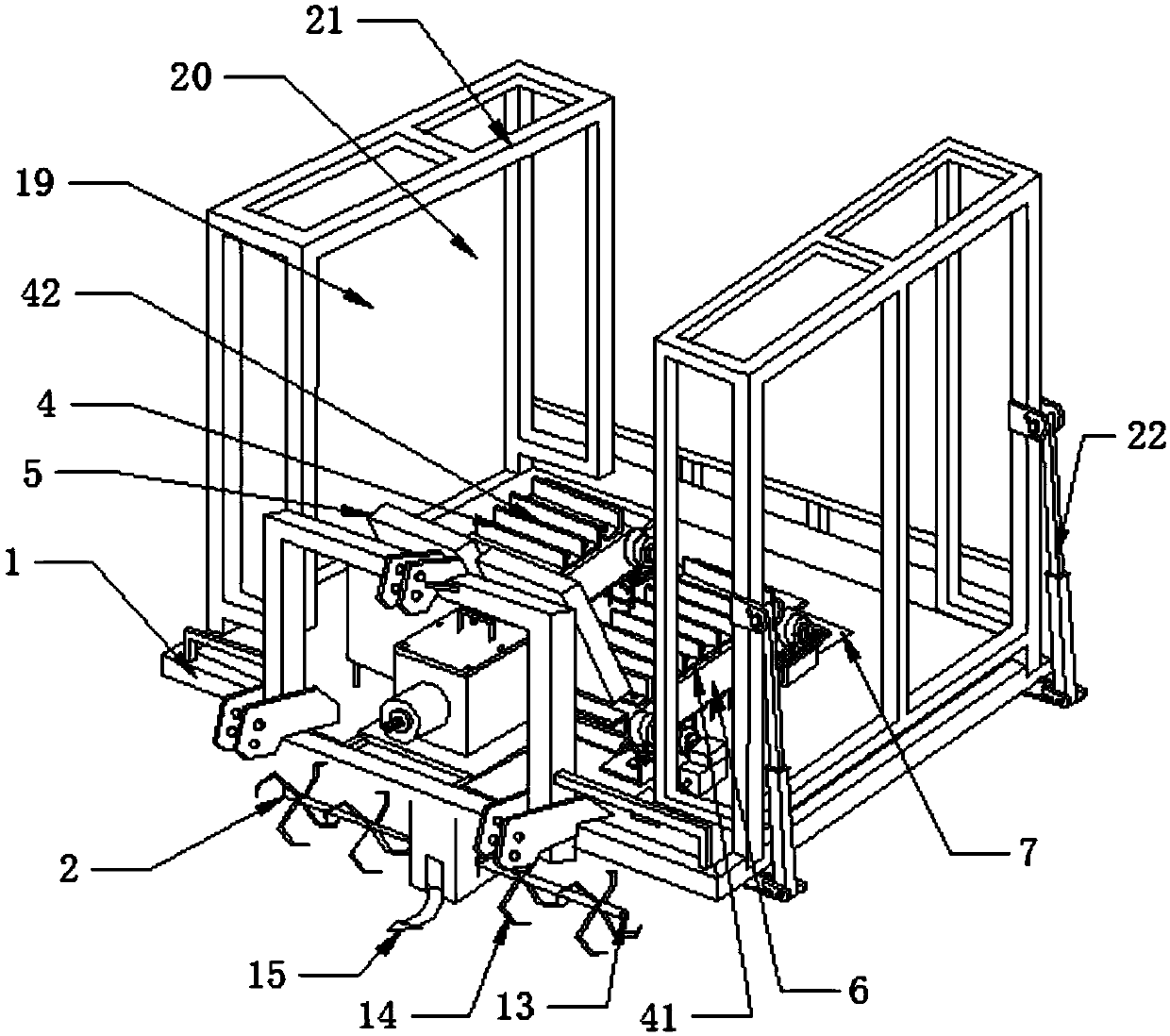

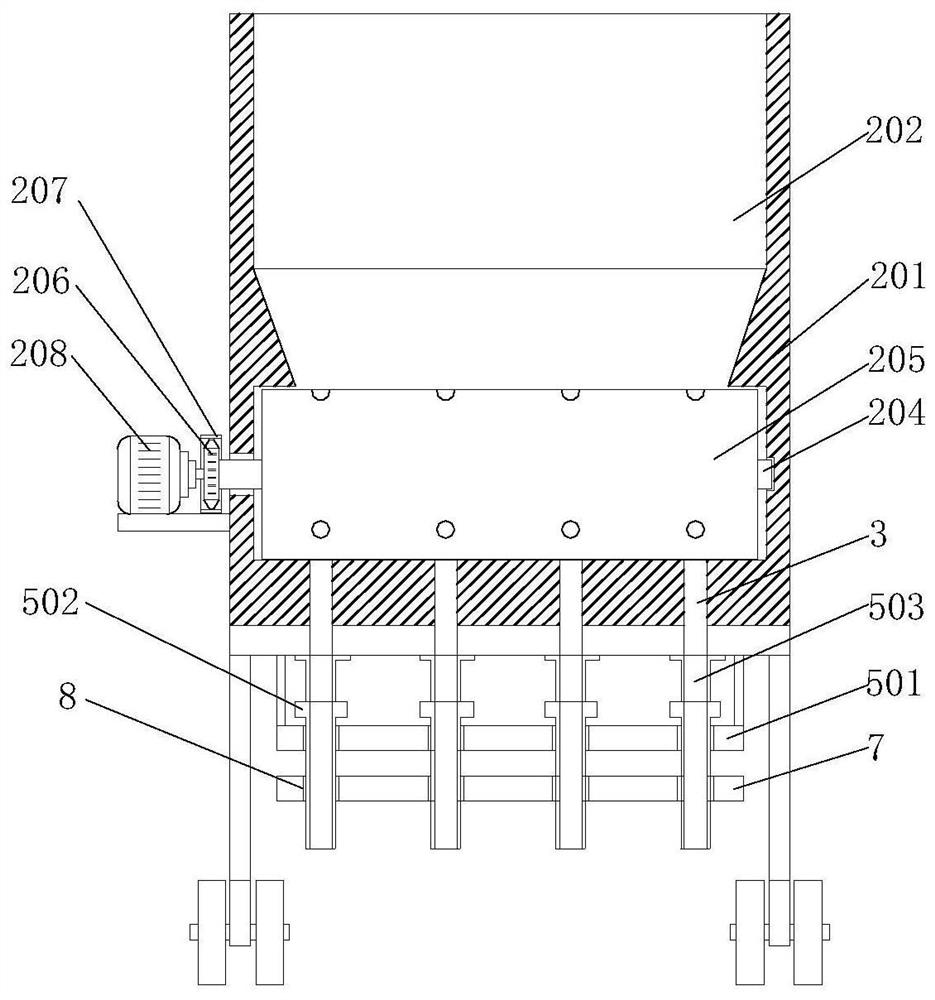

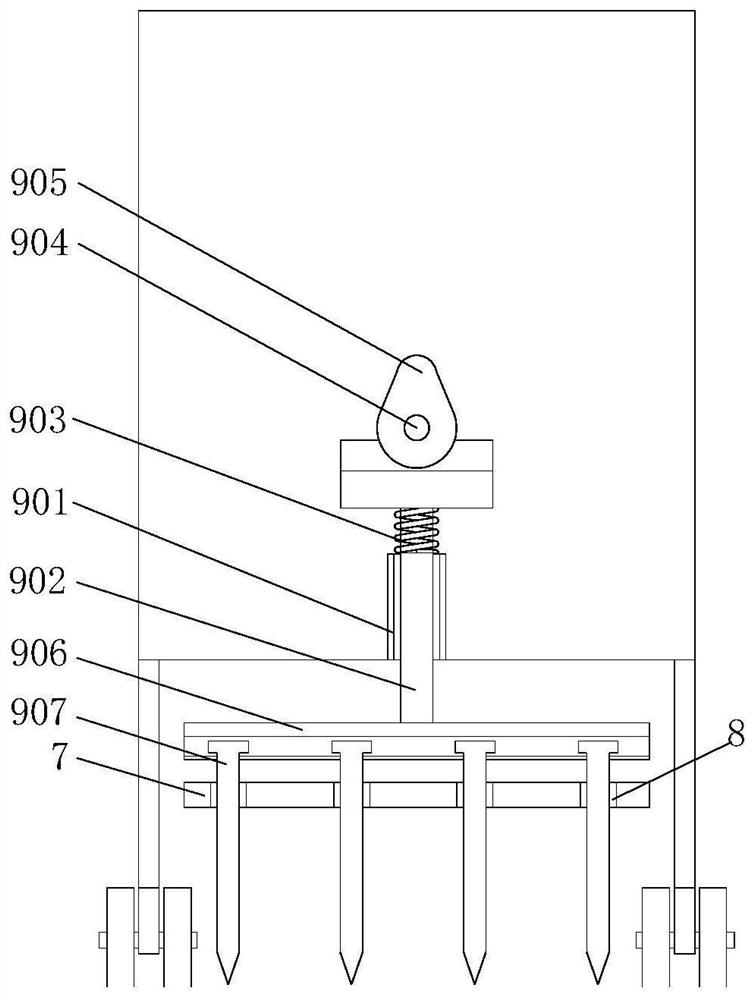

Vacuum adsorption plug seedling precision seeder

InactiveCN102273345ANot easy to damageAccurate broadcastSeed depositing seeder partsSingle grain seedersSeederCoupling

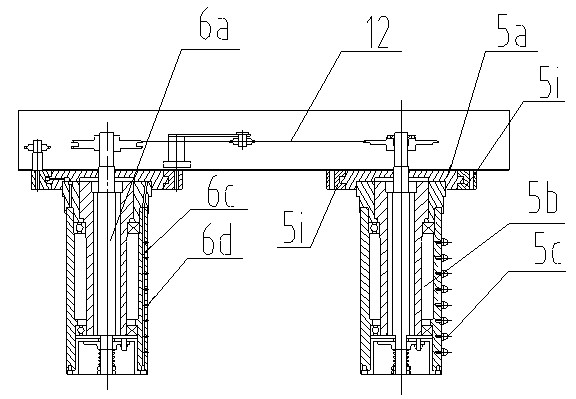

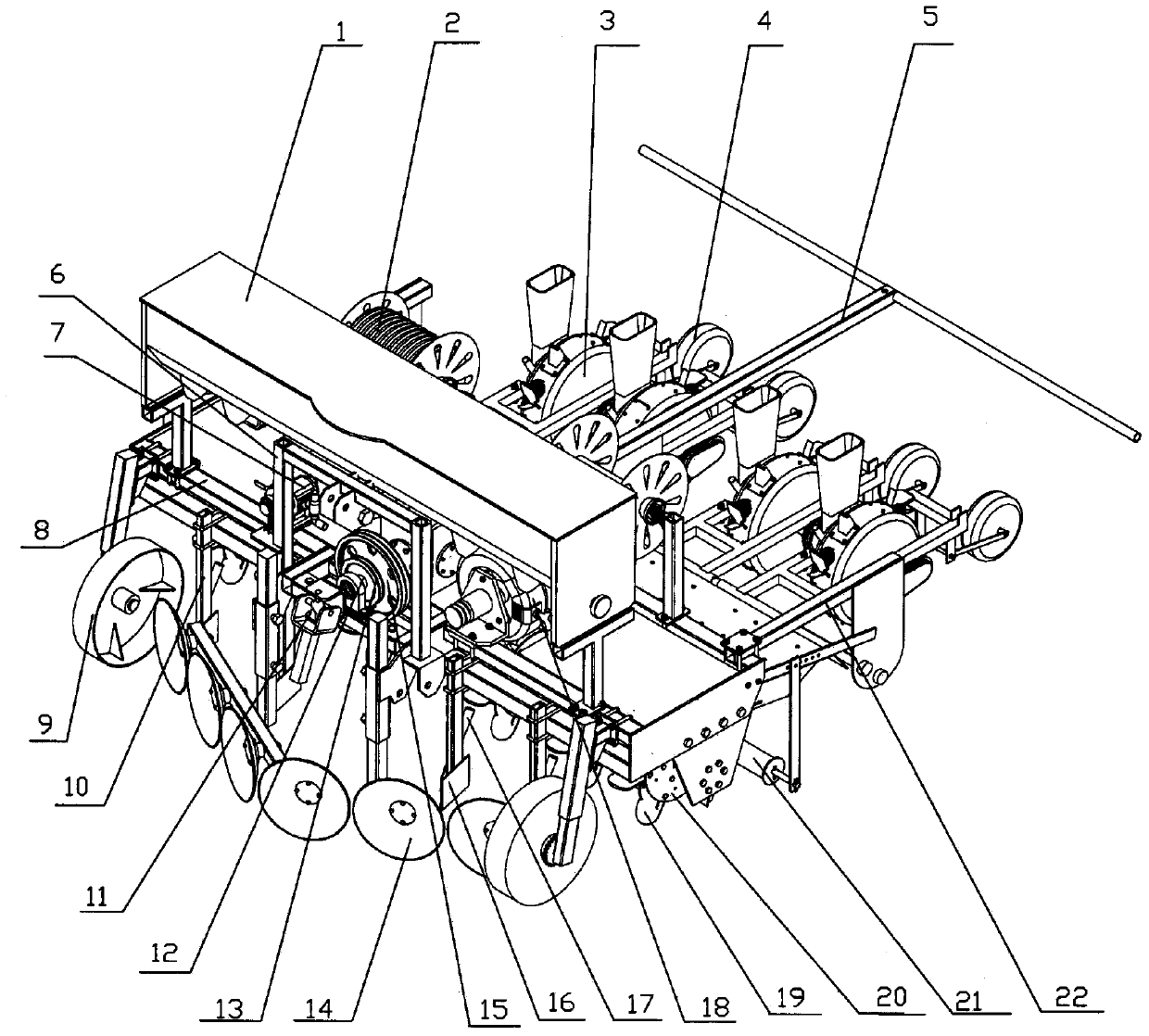

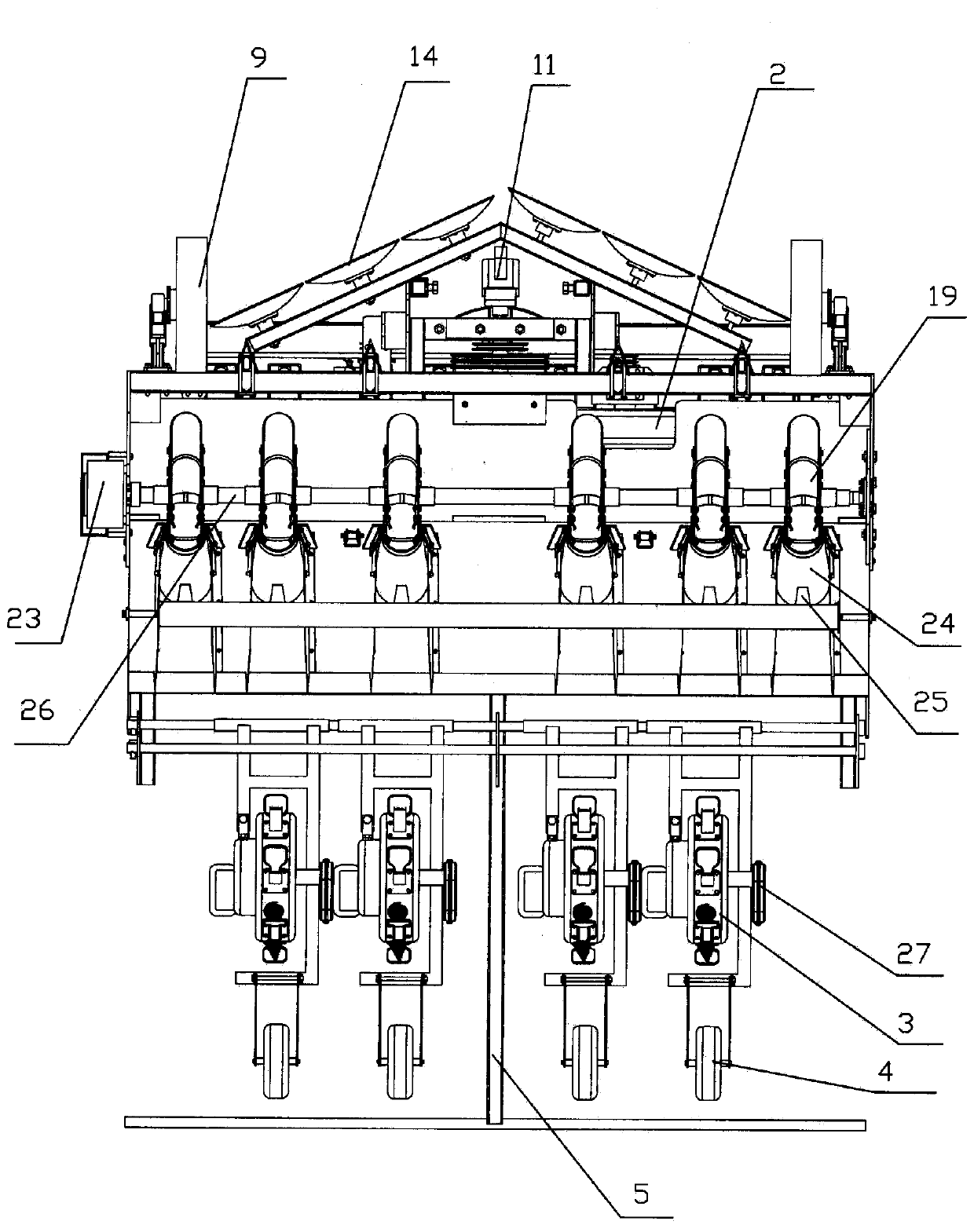

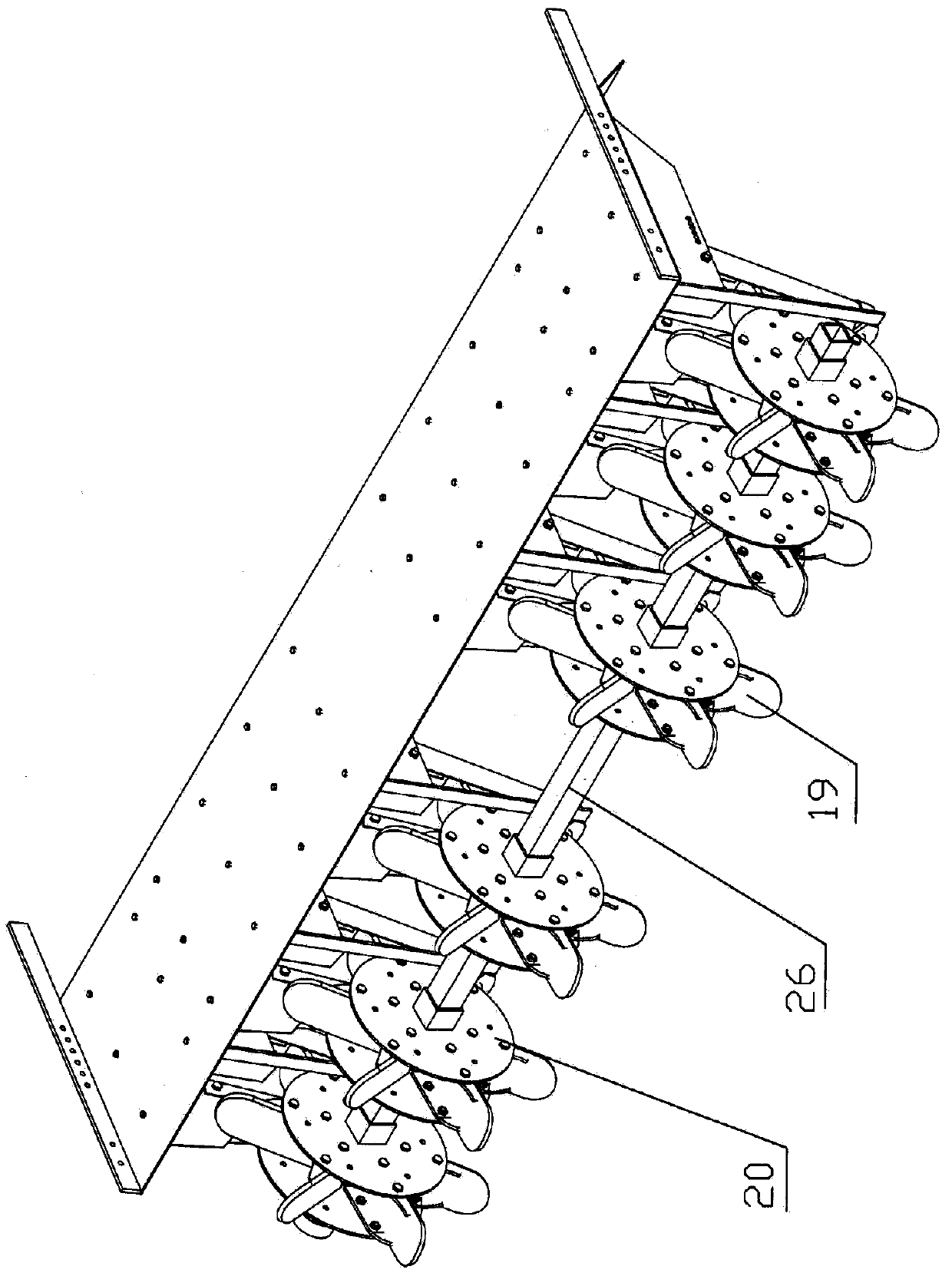

Vacuum adsorption seedling seedling precision seeder, including a conveying device (8) installed on the frame (2) driven by a geared motor (7), located above the conveying device and arranged in sequence from the input end to the output end of the conveying device The tray feeding device (1), covering soil flattening device (3), leveling device (4), pressure hole device (5), vacuum adsorption seeding device (6), in the pressure hole device (5) and vacuum adsorption sowing A synchronous transmission device (12) is connected between the devices (6), and horizontal push rods (10) are evenly distributed on the conveying surface of the conveying device. The invention can realize continuous and automatic completion of seeding and seedling raising work on the entire assembly line, improve seeding continuity and seeding efficiency, and realize seedling seeding seeding of various seed plug trays.

Owner:中国机械总院集团云南分院有限公司 +1

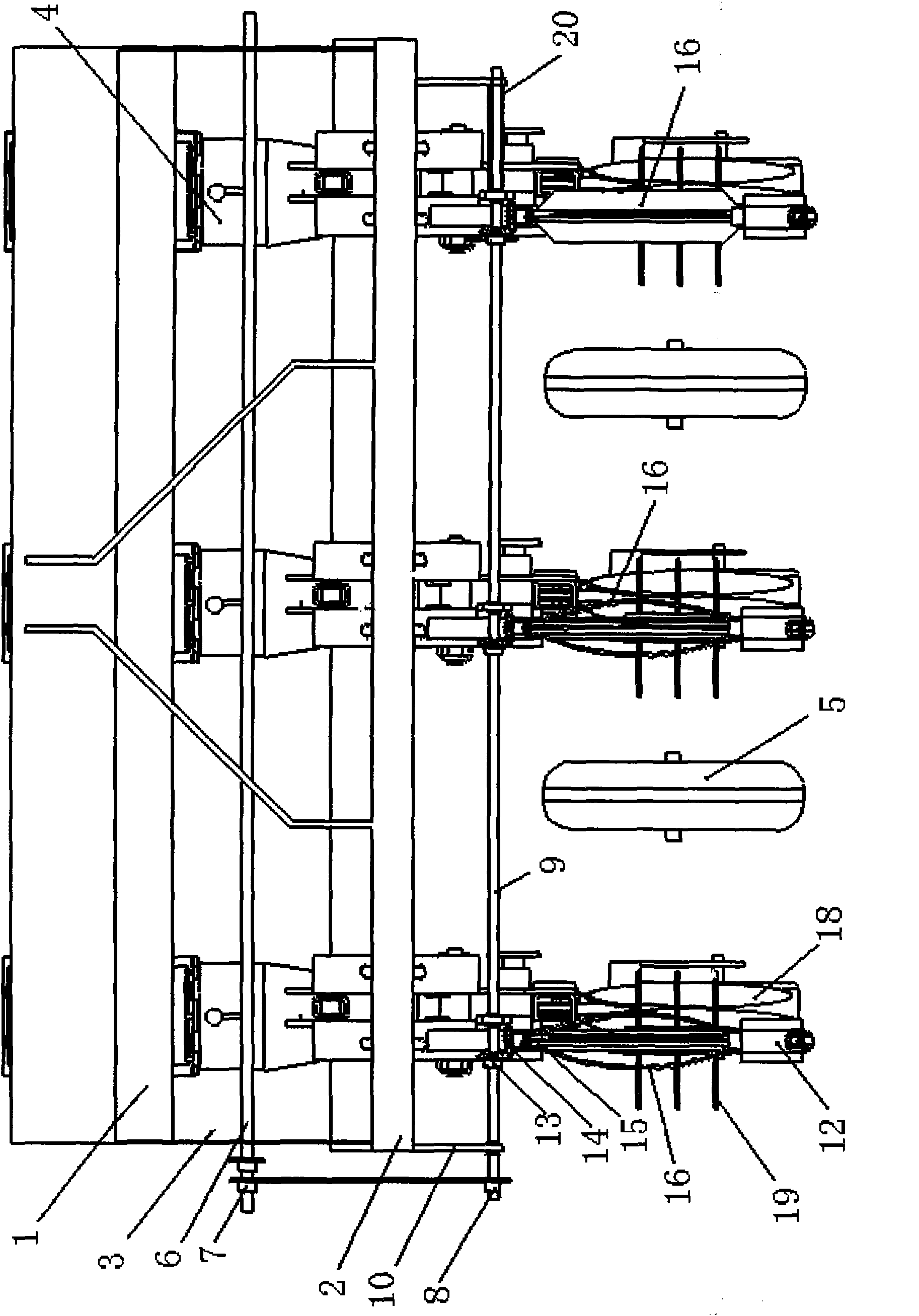

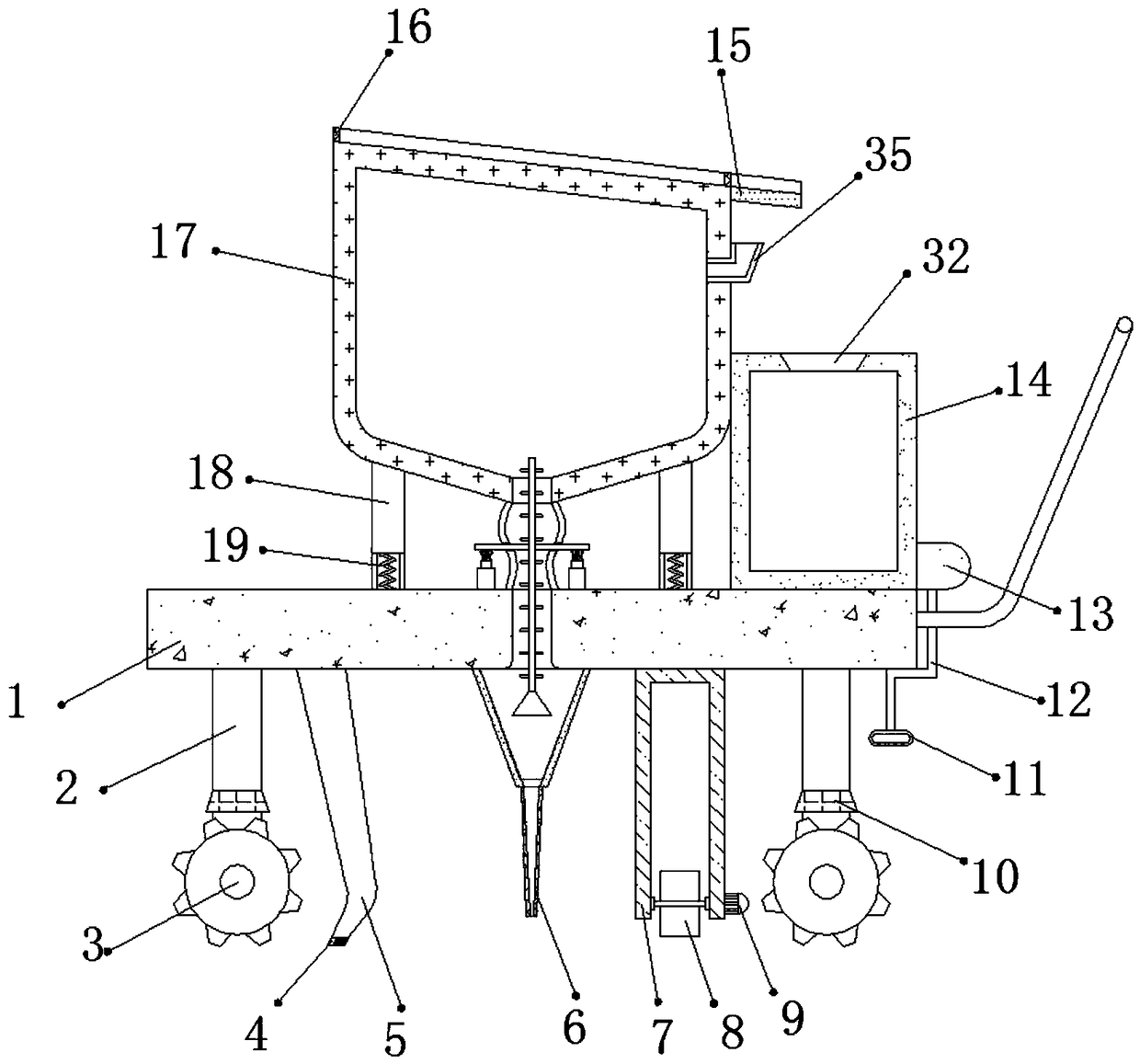

Multifunctional sowing and fertilizing laminator

ActiveCN103988611AWide range of applicationsImprove efficiencyWatering devicesPressurised distribution of liquid fertiliserAgricultural engineeringSowing

A multifunctional sowing and fertilizing laminator comprises a frame (8), a soil scraper (14) arranged in front of the frame and used for flattening land, a ground wheel (9) arranged in front the frame, a gear box arranged on the frame, a box power input and a transmission device; a ditching and fertilizing device is arranged in the front of the frame, the rear part of the frame is provided with a film and soil laminating device and a sowing device, and the laminator also comprises a drug spraying device. Soil covering is carried out before adopting the laminator, the laminator is suitable for dry and wet soil, and can realize multi-row sowing, the row number and the row spacing can be adjusted, and the laminator can be made to realize four-row sowing or six-row sowing, is suitable for many crops, and has a high multi-row sowing efficiency. The laminator has many uses, realizes one time completion of sowing, fertilizing, laminating, drip irrigation pipe laying and drug spraying, is an all-in-one machine very suitable for plastic film mulching cultivation, and can realize cultivating work through installing an intertill device and dismounting the sowing and soil covering devices.

Owner:日照新睿招商发展有限公司

Astragalus seeding machine

ActiveCN108718561AExcellent solutionSolve AbsorbencySpadesPloughsAgricultural engineeringScrew thread

The invention relates to the technical field of seeding, and discloses an astragalus seeding machine, which comprises a frame, wherein a seeding pipe is fixedly connected on the frame; a feeding holeis arranged on the seeding pipe; the seeding pipe is threaded with a plowing rod; a drill bit is arranged on the plowing rod; the drill bit comprises two drill plates hinged at the end part of the plowing rod; the end parts of the two drill plates are butted against each other, and a wedge block is hinged at the end part of the seeding pipe; a cavity is formed in the plowing rod, a through hole isformed in the plowing rod, a water tank and a piston cylinder are fixedly connected on the frame, a piston is slidably connected in the piston cylinder, a piston rod is fixedly connected on the piston, the plowing rod is provided with a sliding groove in the axial direction of the piston rod, the end part of the piston rod is slidably connected in the sliding groove, an air bag is fixed on the frame, a pressure valve is arranged between the air bag and the seeding pipe, one side of the piston cylinder communicated with the water tank is communicated with the cavity, the other side of the piston cylinder is communicated with the air bag, and a first one-way valve is arranged between the piston cylinder and the air bag. According to the invention, the plowing, fertilizing and watering can be carried out before seeding, and favorable conditions for the growth of the seeds are improved.

Owner:贵州黔峰百草科技发展有限公司

Seed paper tape sowing method

The invention relates to a seed paper tape sowing method. A seed paper tape is prepared by the steps of sending a paper tape into a paper tape conveying device by a paper tape feeding device, enabling the paper tape to move from an inlet to an outlet at a constant speed along with a conveyor belt of the conveying device, sequentially fixing a dispensing device, a seed spreading device and a spread seed blowing device above the conveyor belt, fixing a spread seed collecting device, corresponding to the spread seed blowing device, below the conveyor belt, and fixing a seed paper tape finished product packaging device at the outlet end of the conveyor belt. The seed paper tape sowing method comprises the steps of 1, firstly, leveling soil; 2, removing a plastic package from a seed paper tape finished product and tiling the seed paper tape; 3, covering with soil, namely after the seed paper tape is sowed, uniformly covering the tiled seed paper tape with soil; and 4, watering and irrigating. The seed paper tape sowing method provided by the invention has the advantages of solving the problem of separation of high-quality seeds with good methods, being beneficial to the integration of propagating, breeding and promoting of high-quality seeds, facilitating the simplified sowing, saving high-quality seeds and labor force, and enabling the cost to be reduced and the benefit to be increased.

Owner:徐鹤 +1

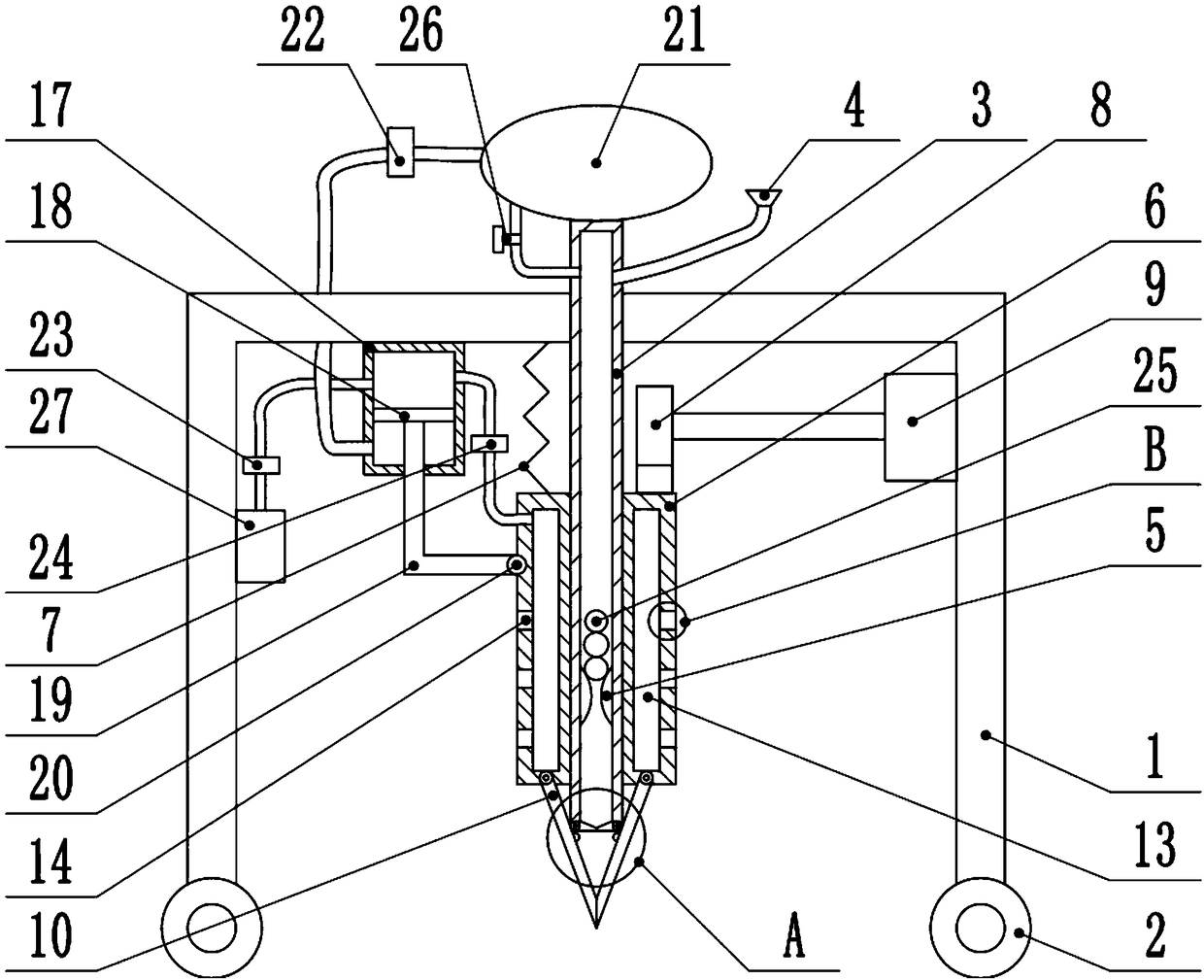

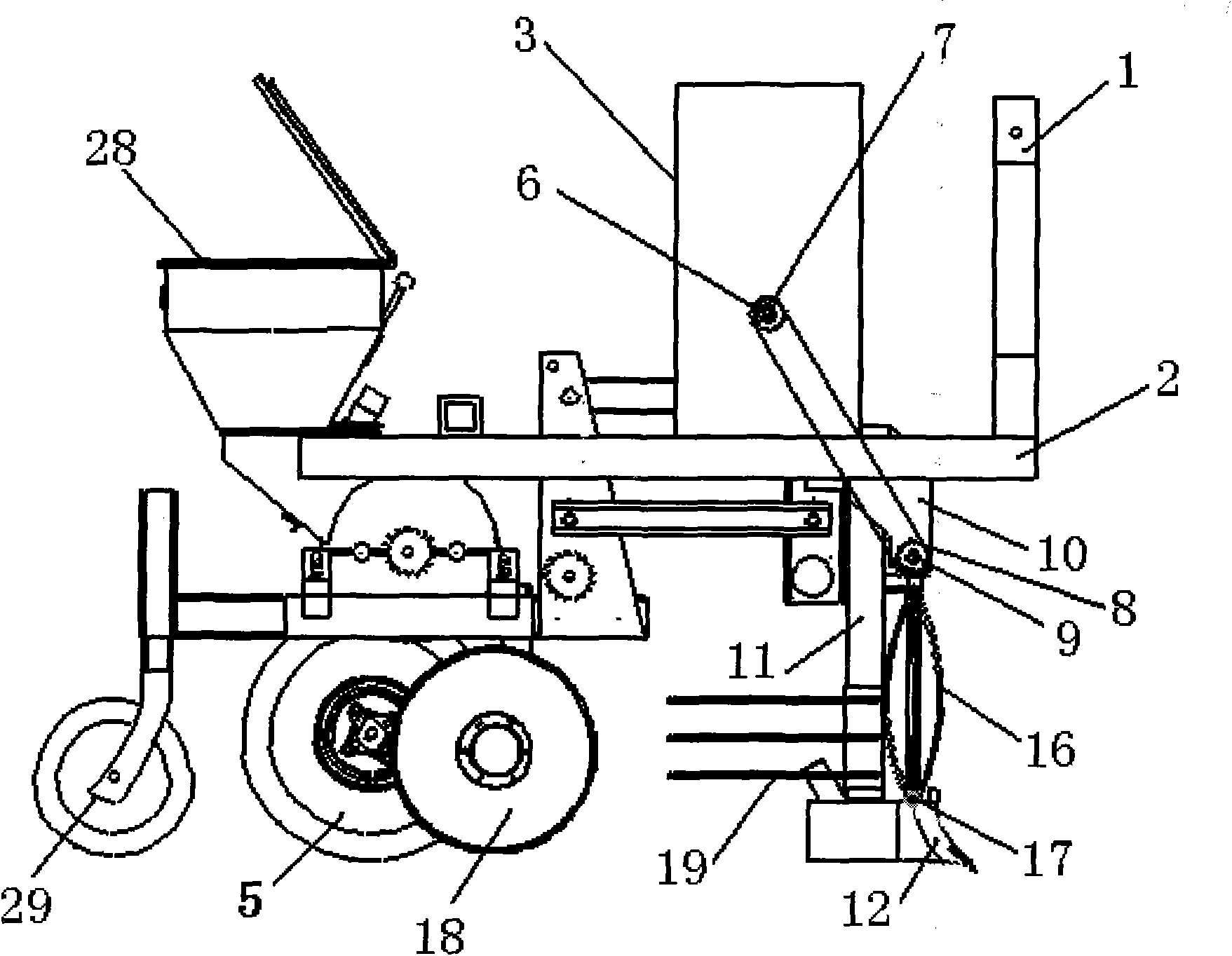

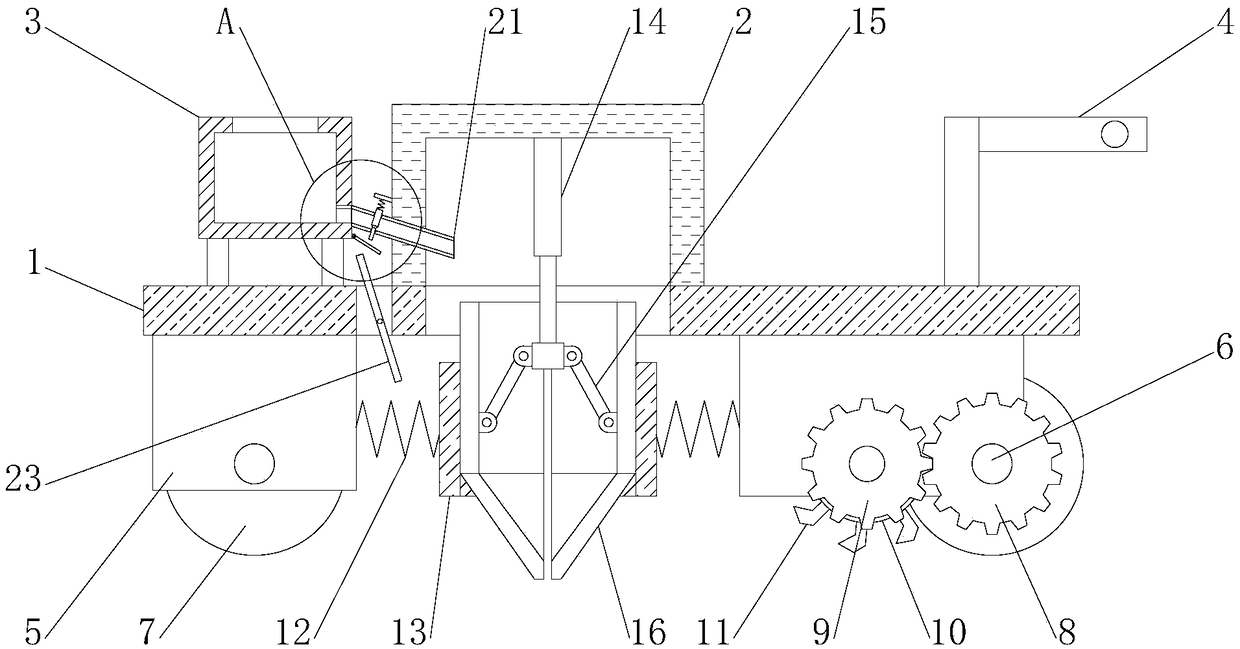

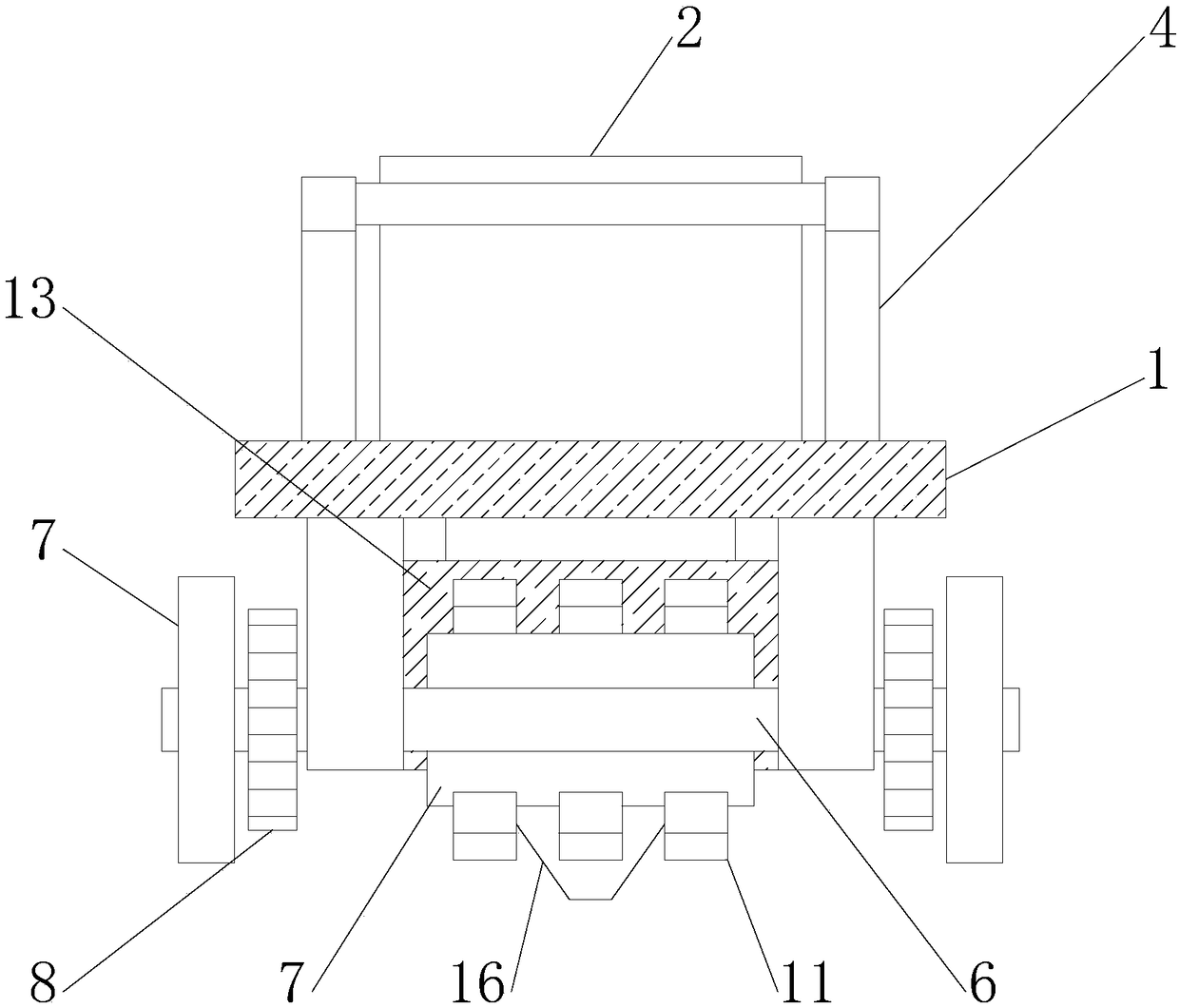

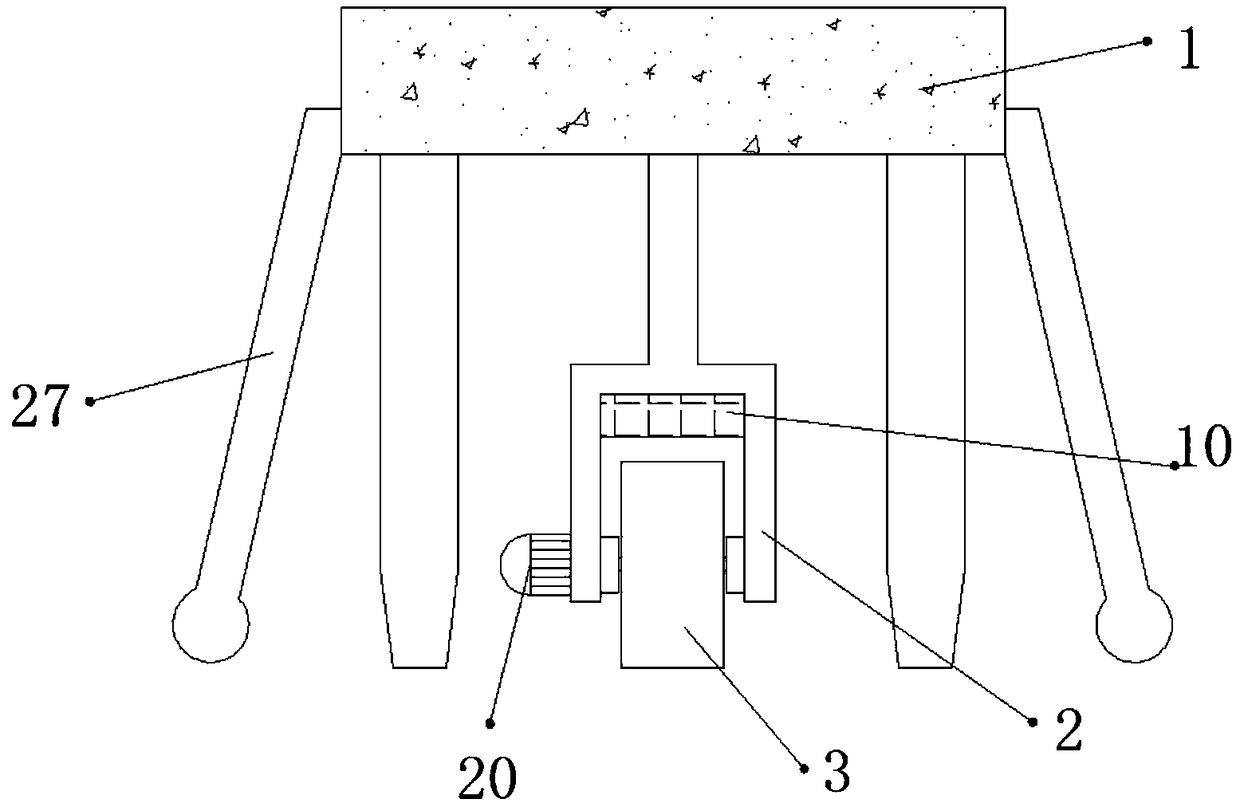

Self-propelled potato ridging and fertilizing planting machine

InactiveCN103250483AImprove germination rateImproves moisture retentionSpadesPloughsDrive wheelAgricultural engineering

The invention relates to a self-propelled potato ridging and fertilizing planting machine which comprises a fertilizer box arranged on a rack, a seed box and a fertilizing and seeding device arranged on the fertilizer box and the seed box. The self-propelled potato ridging and fertilizing planting machine is characterized in that walking wheels are arranged at two sides of the rack, and a depth adjusting wheel is arranged on the lower portion of the front end of the rack. The lower portion of the rack of the rear end of the depth adjusting wheel is sequentially provided with a rotary tillage device, a fertilizing pipe, a seeding pipe and a ridging device from front to rear. The rack of the rear end of the ridging device is provided with a press wheel, and a plough is fixed at the front end of the fertilizing pipe or the seeding pipe. A diesel engine and an operation hand rail are arranged at the rear end of the rack. A power output belt wheel on the diesel engine is connected with a drive wheel of the rotary tillage device through a transmission chain, a drive chain wheel is arranged on a fixed shaft of the walking wheels, and the drive chain wheel is connected with the fertilizing device and the seeding device through a transmission chain. According to the technical scheme, the self-propelled potato riding and fertilizing planting machine can finish planting procedures of rotary tillage, ridging, planting, fertilizing, pressing and the like at one time.

Owner:宁夏鸿景农机科技有限公司

Anti-blockage corn no-tillage seeder

InactiveCN101965768AAvoid cloggingPrevent entanglement of strawPlantingAgriculture gas emission reductionDrive shaftAgricultural engineering

The invention relates to an anti-blockage corn no-tillage seeder, which comprises a machine frame, a fertilizer tank, a plurality of no-tillage seeder single bodies and ground wheels. The fertilizer tank and the plurality of no-tillage seeder single bodies are arranged on the machine frame. The fertilizer tank is provided with a fertilizing shaft which is connected with the ground wheels by chain transmission. Each no-tillage seeder single body comprises a seeding box and a furrowing blade handle, which are arranged on the machine frame, wherein the bottom of the furrowing blade handle is connected with a fertilizing furrower; and a seeding furrower and a press wheel are connected with the machine frame at the rear side of each fertilizing furrower. The anti-blockage corn no-tillage seeder is characterized in that: a driving shaft parallel to the fertilizing shaft is connected below the machine frame and in front of the furrowing blade handles by a plurality of supporting frames; one end of the driving shaft is connected with the fertilizing shaft through chain transmission; the driving shaft is provided with driving bevel gears corresponding to the no-tillage seeder single bodies; the centers of driven bevel gears meshed with the driving bevel gears are fixedly connected with roller shafts; each roller shaft is provided with a roller for pushing straw aside; and the lower ends of the roller shafts are connected with the fertilizing furrowers rotationally.

Owner:CHINA AGRI UNIV

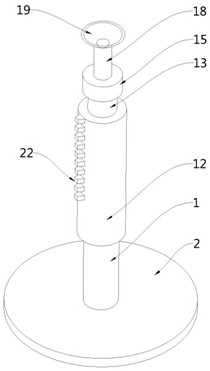

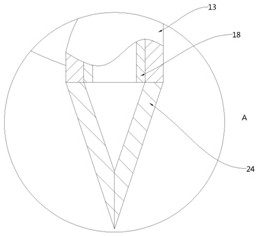

Automatic seeding device for yellow peach planting

InactiveCN111819954AImplement automatic seedingRealize automatic burialPlantingDibble seedersFruit treeEngineering

The invention provides an automatic seeding device for yellow peach planting, and belongs to the technical field of fruit tree planting. The automatic seeding device comprises a soil storage cylinderand an annular pressing plate fixedly arranged at the bottom of the outer side of the soil storage cylinder, wherein a supporting plate is fixedly arranged at the edge of the upper part of the annularpressing plate, and a top plate is fixedly arranged at the upper part of the supporting plate. The embodiment of the invention has the advantages of good seeding effect and high seeding efficiency; aconical body for storing yellow peach seeds can be formed at the bottom of a drill rod through the arrangement of material blocking pieces; after the material blocking pieces move to a preset depth of a soil layer, a material guide cylinder can be pressed down, and the material guide cylinder is used for driving the material blocking pieces to expand outwards, so that the yellow peach seeds are smoothly put into holes, and automatic sowing of the yellow peach seeds is achieved; soil formed during drilling can be temporarily collected through the soil storage cylinder and is refilled into theholes in cooperation with reverse rotation of a subsequent spiral plate, and thus automatic soil burying of the yellow peach seeds is achieved.

Owner:永新县果业局

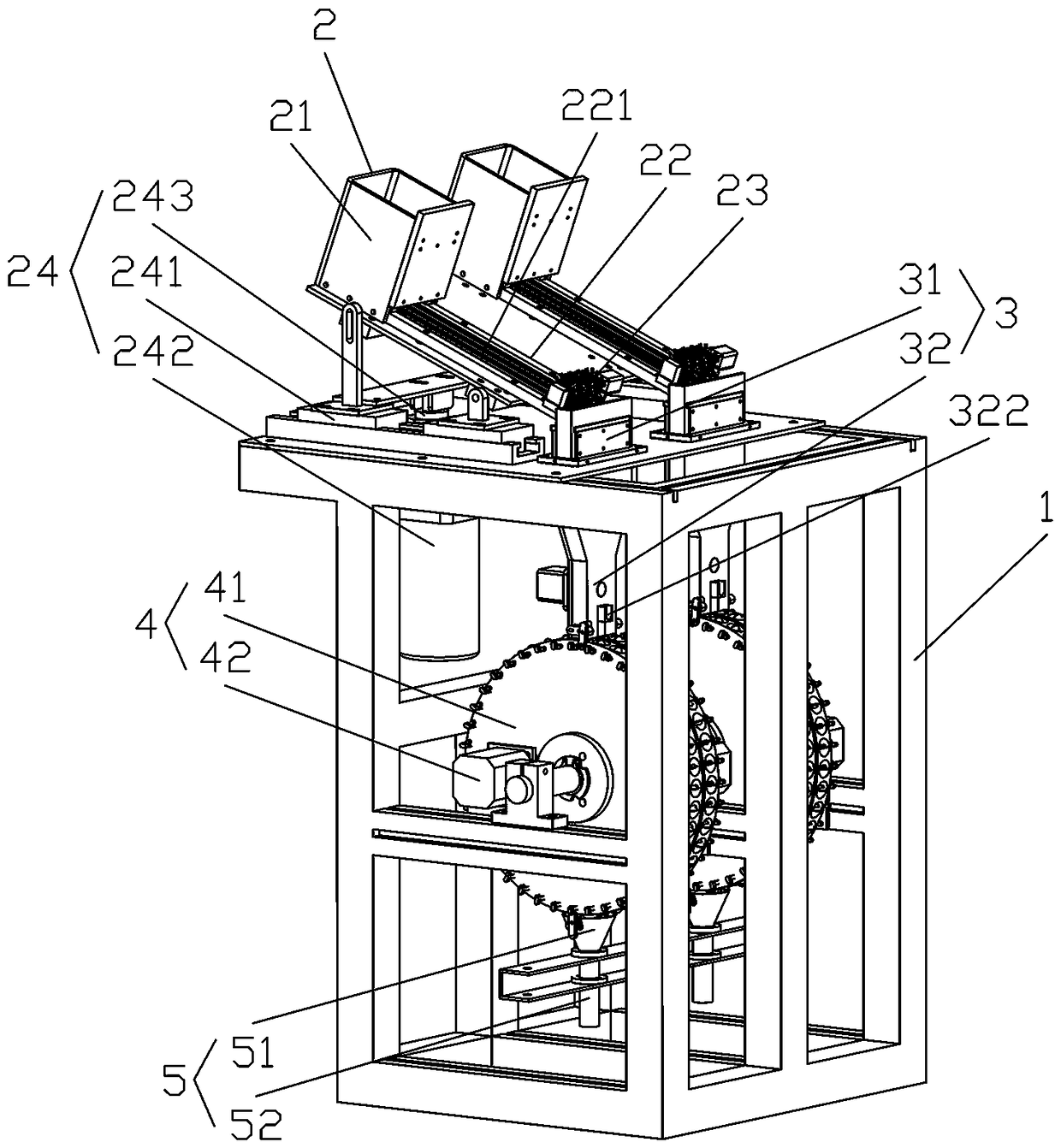

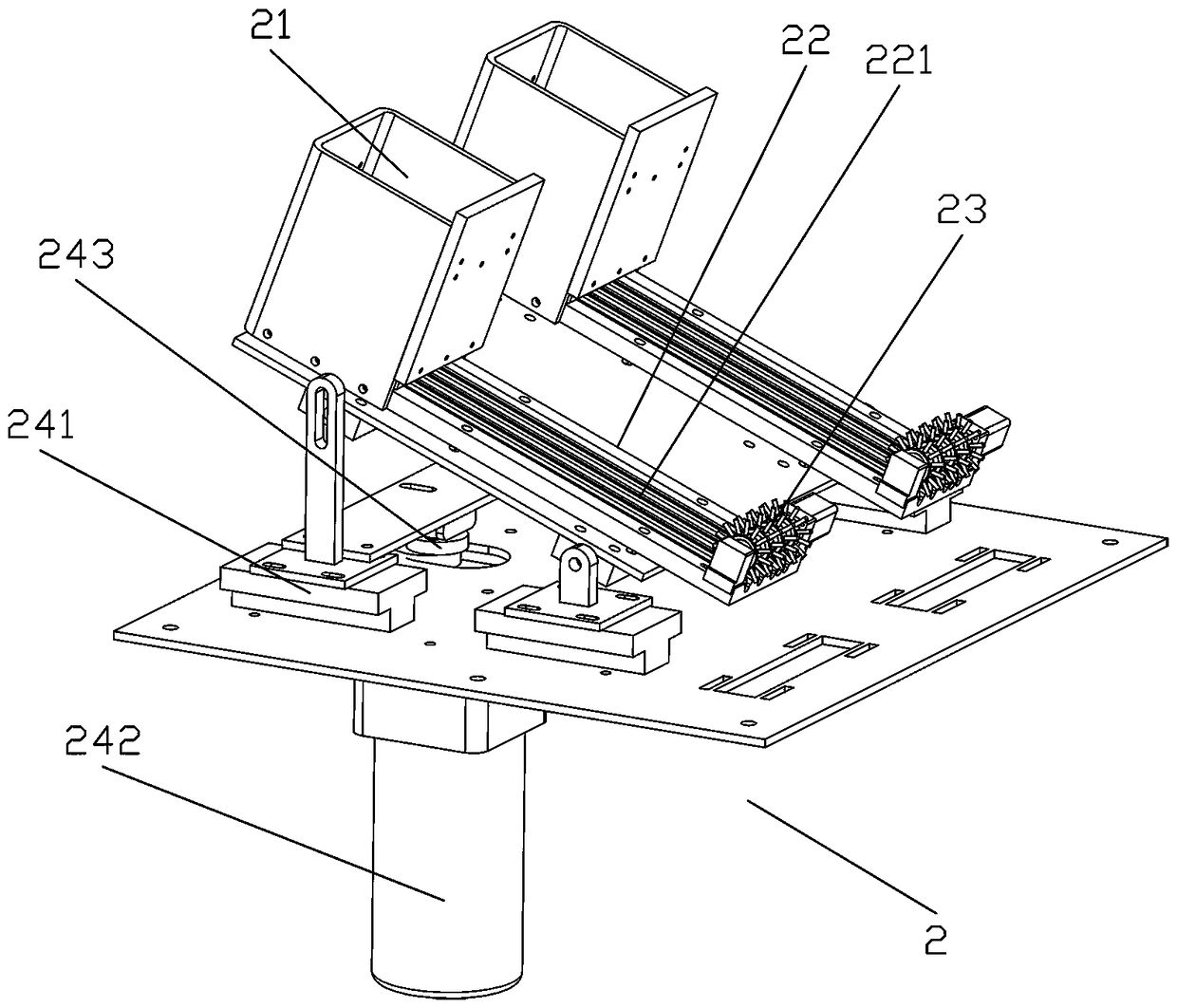

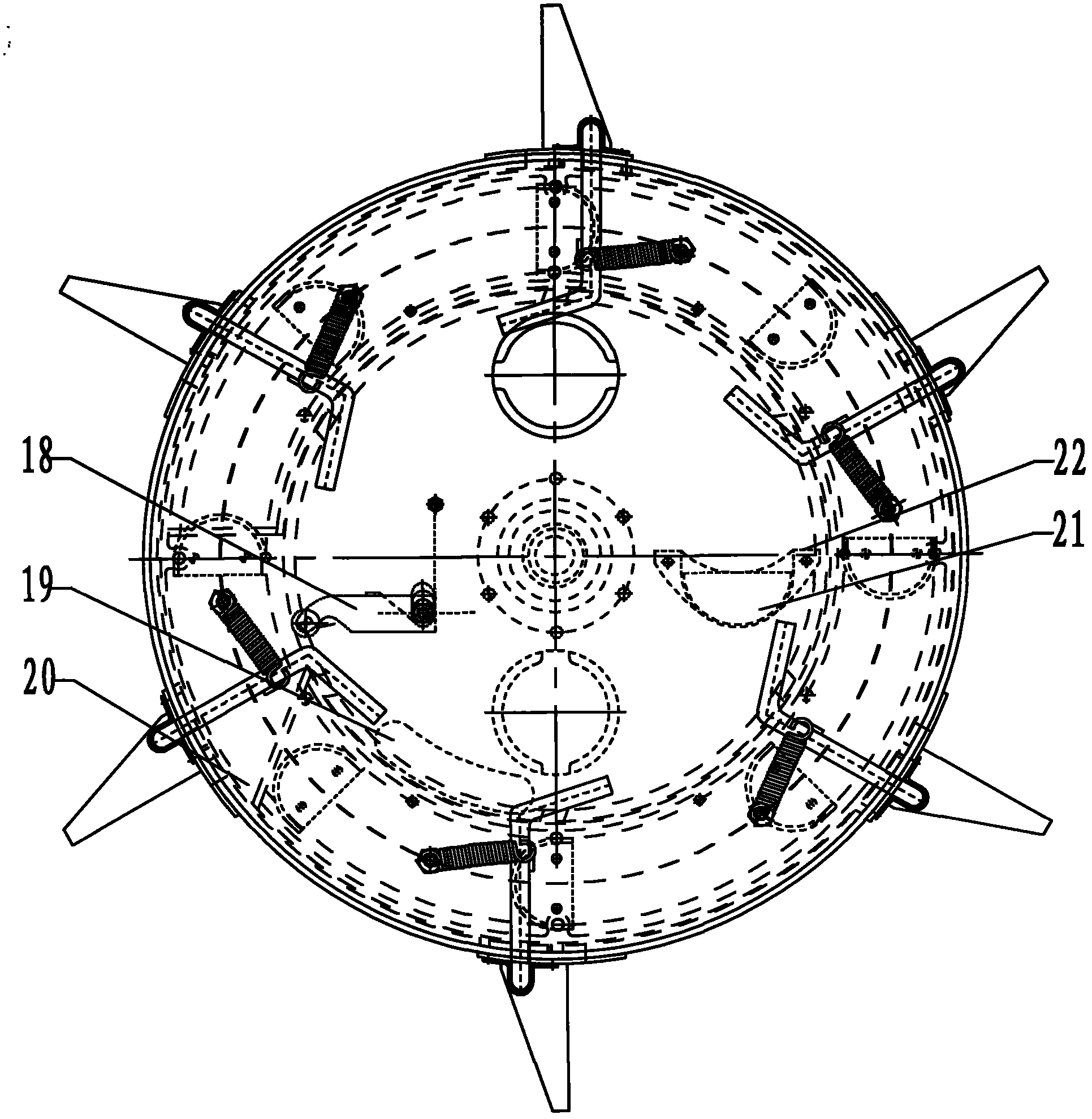

Precision hill-drop planter for rice

InactiveCN108076742AImprove seeding efficiency and seeding qualityIncrease rice yieldDibble seedersSeed depositing seeder partsEngineeringControl area

The invention relates to a precision hill-drop planter for rice. The precision hill-drop planter for the rice comprises a rack, and at least one group of grain feeding and setting area, at least one group of counting and screening area, at least one group of rotary transmission area and at least one group of funnel grain outlet area which are installed on the rack from top to bottom, wherein eachgrain feeding and setting area comprises a feeding hole, a slide setting plate and a grain feeding brush, the slide setting plate is arranged in an inclined way, the feeding hole is formed above the upper end of the slide setting plate, and the grain feeding brush is positioned above the lower end of the slide setting plate; the counting and screening areas are positioned under the grain feeding brushes; each counting and screening area comprises a counting induction area arranged at the upper end, and a screening control area positioned at the lower end; the rotary transmission areas are positioned under the screening control areas; each group of the rotary transmission area comprises two transmission plates which are installed side by side, and rotating shafts of the transmission platesare horizontally arranged.

Owner:HUZHOU VOCATIONAL TECH COLLEGE

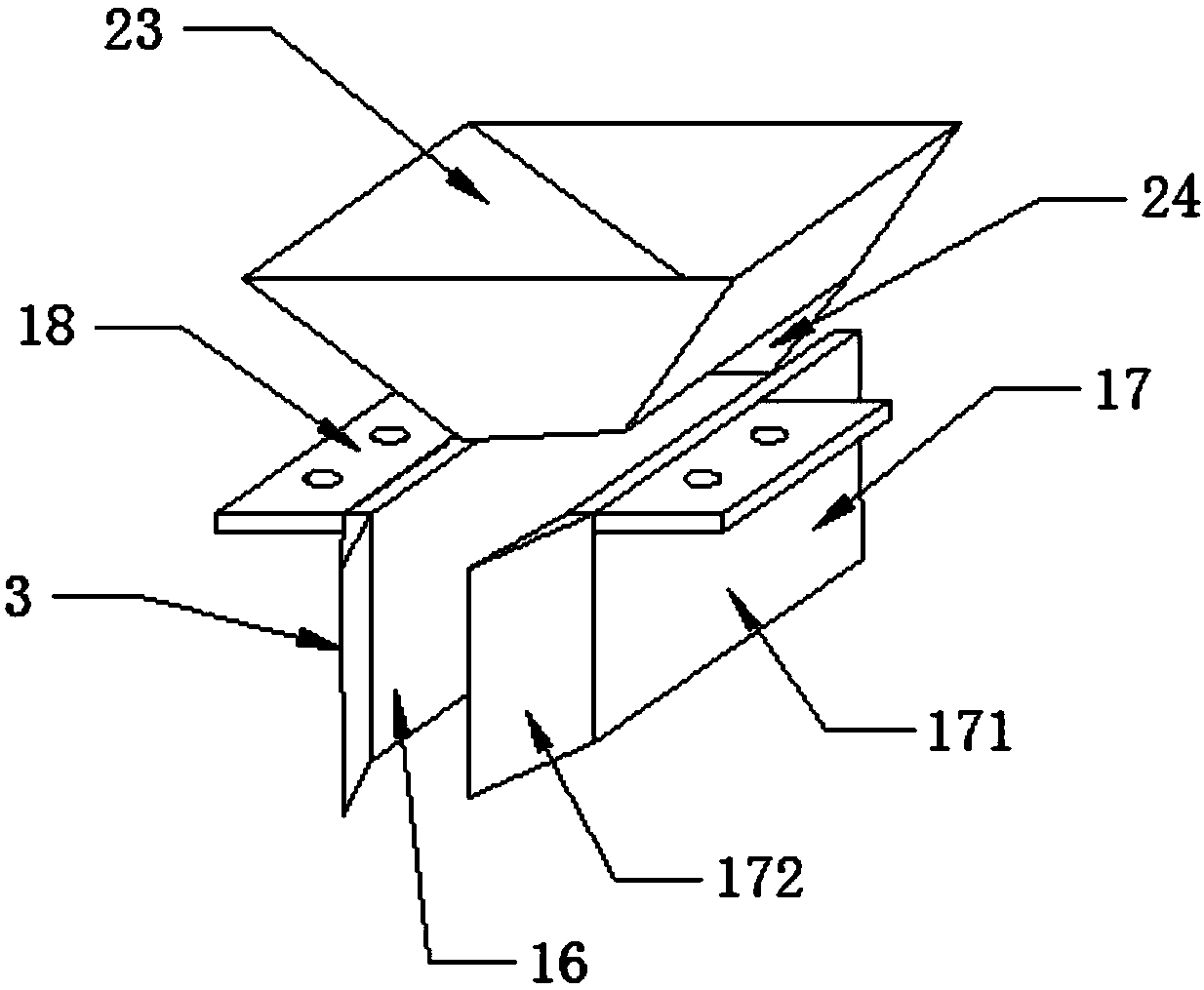

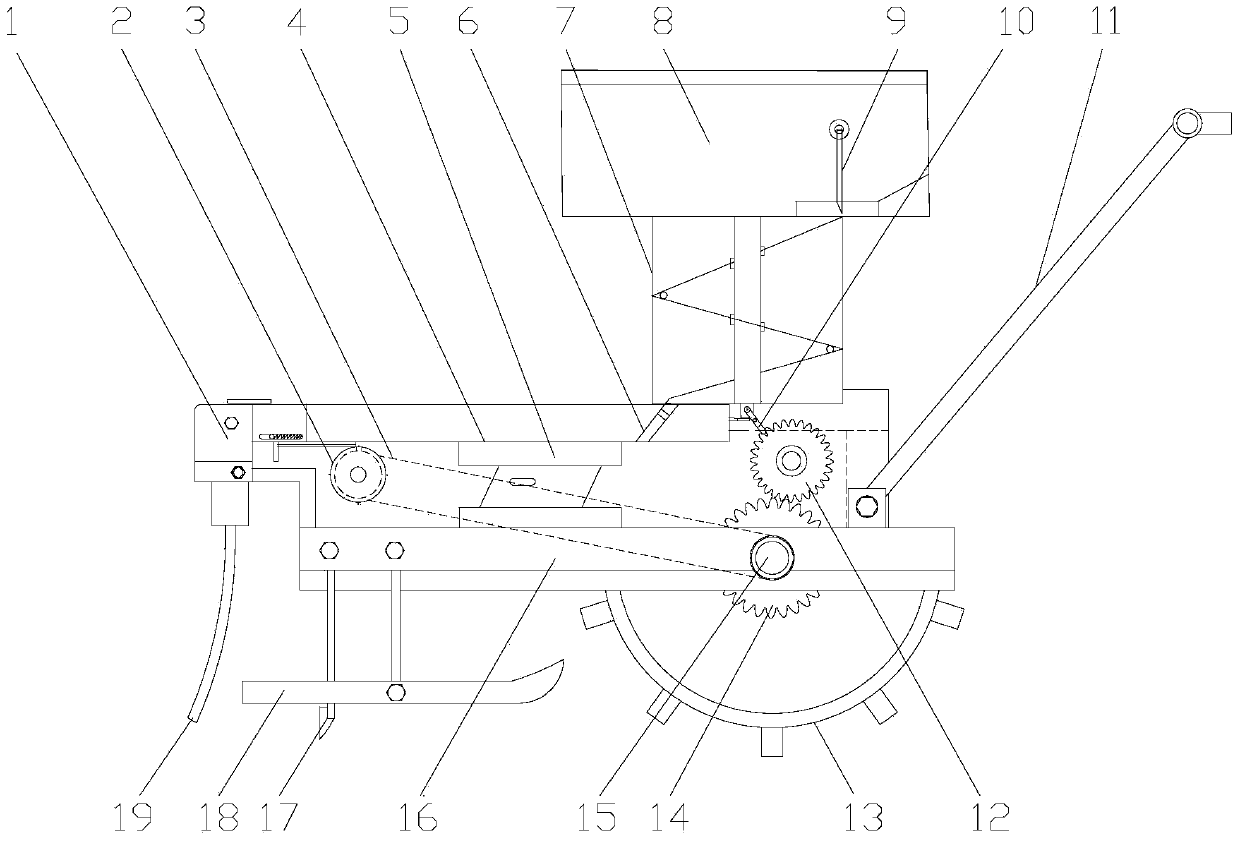

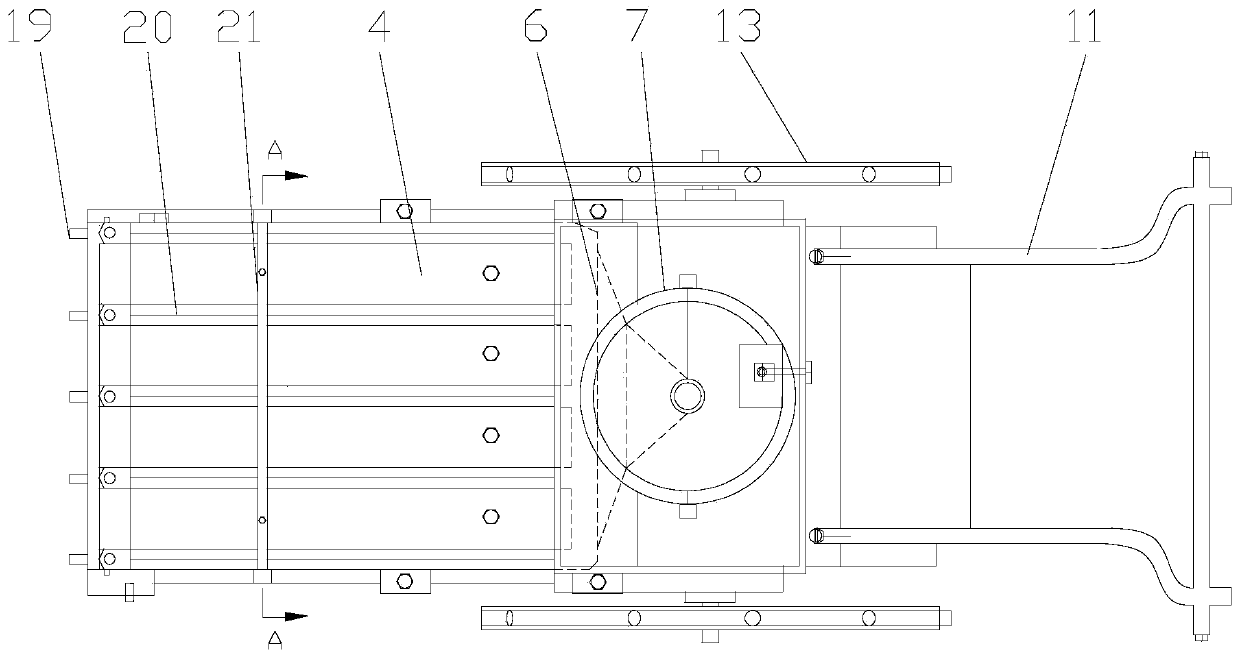

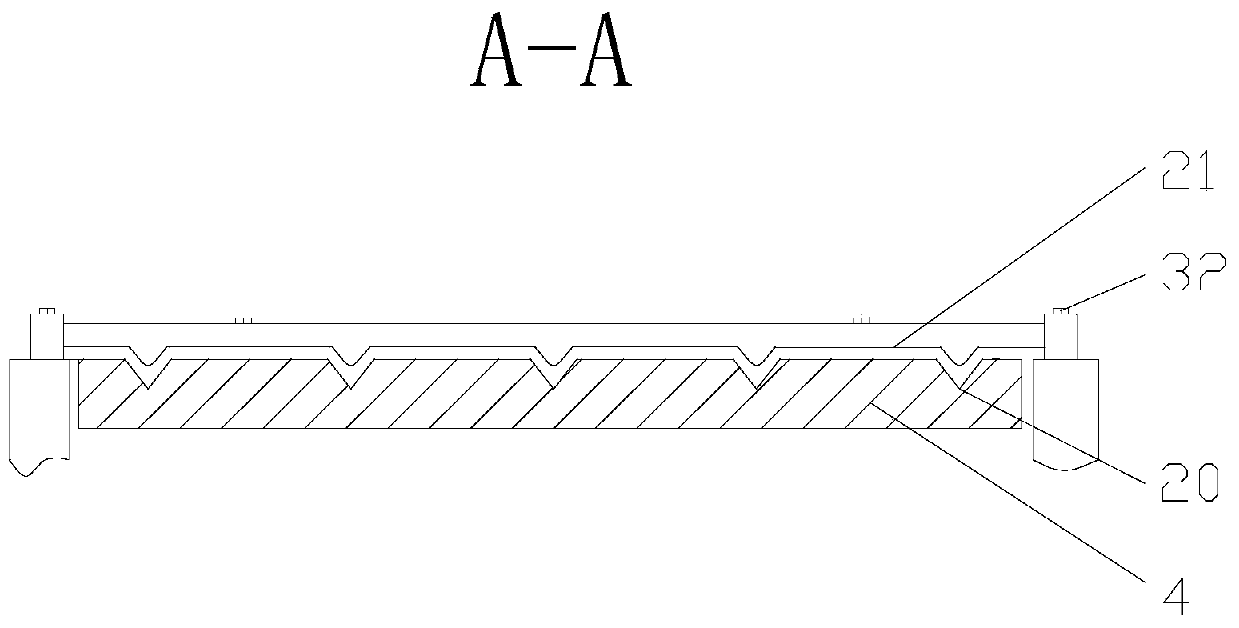

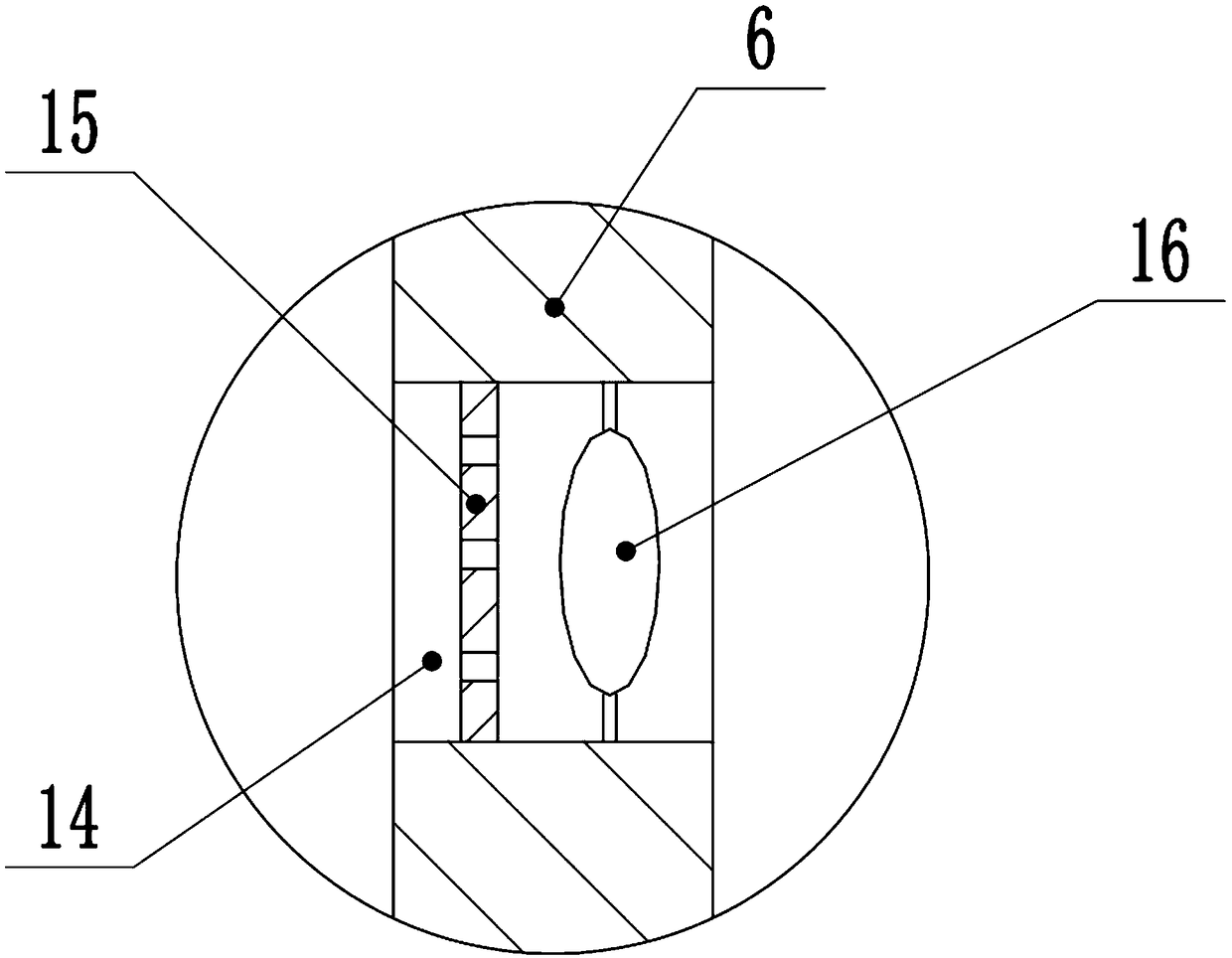

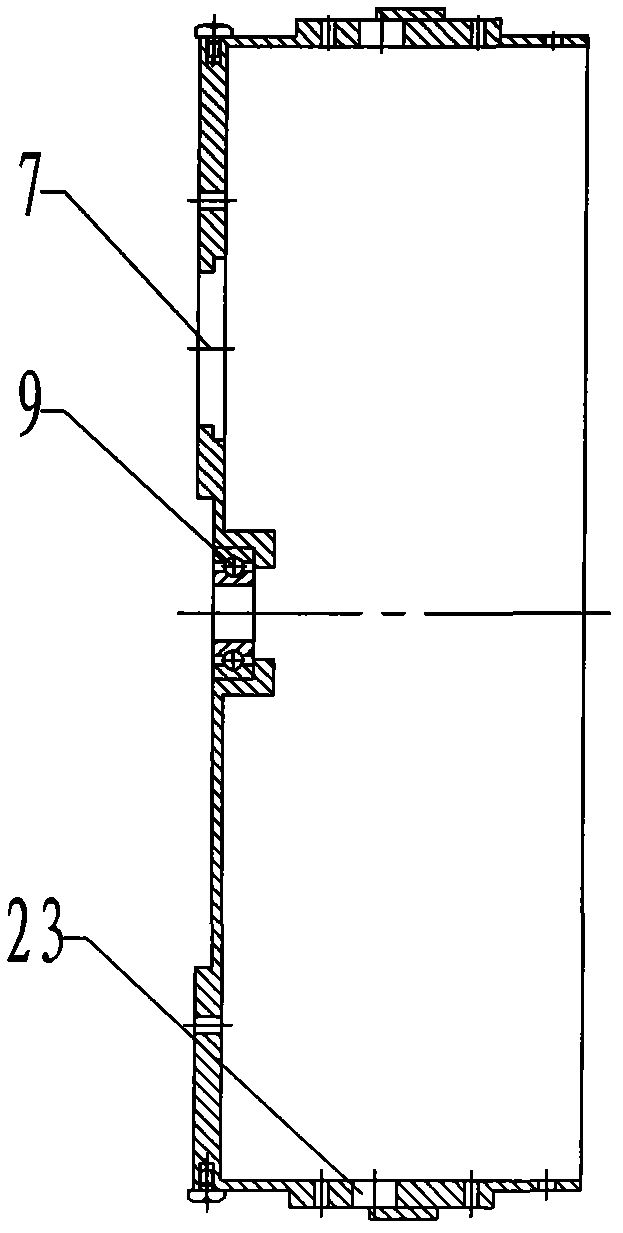

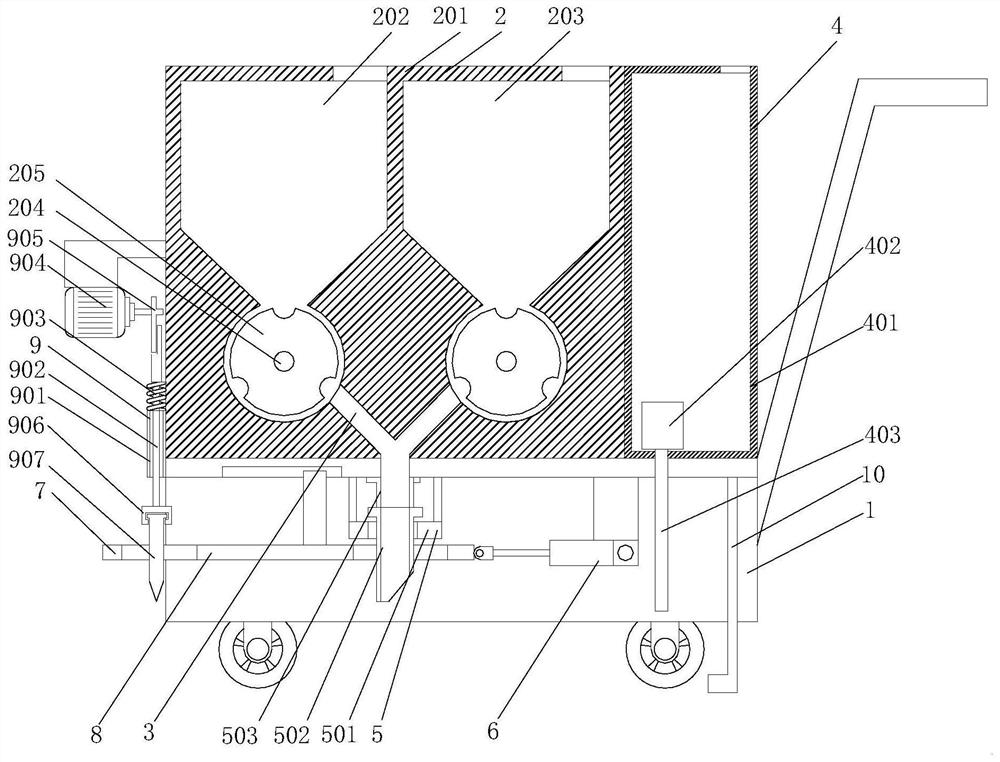

Movable bin single-seed precision hill seeder

InactiveCN102090186ACompact structureReduce volumeFertiliser distributersSeed depositing seeder partsSeederWhole body

The invention relates to a movable bin single-seed precision hill seeder and belongs to the technical field of a movable bin hill seeder. A plurality of seed falling ports (23) are uniformly distributed on the outer periphery of a roller (2). The roller (2) and an end cover (16) are buckled into one whole body and are arranged on a plate shaft (10) through a bearing (9). One end face of the roller (2) is provided with a switching device for a nozzle (1). A plurality of seed supplementing spoons (17) are uniformly distributed on the inner wall of the end cover (16) in a ring-shaped shape. A discharge plate (3) is arranged in the roller (2). A seed plate (4) is buckled inside the discharge plate (3). A cavity between the discharge plate (3) and the seed plate (4) is a seed charging bin (11). A cavity between the discharge plate (3) and the end cover (16) is a seed storage bin (14). The end face of the discharge plate (3), which is close to the seed storage bin (14), is provided with a seed inlet (21) and a seed overflowing port (19). A seed charging mechanism (18) is arranged in the seed charging bin (11). The movable bin single-seed precision hill seeder has the advantages of functions of automatically feeding, overflowing and cleaning seeds, accurate seeding capacity, no cavity, strong practicality and the like.

Owner:SHANDONG UNIV OF TECH

Device for sowing seeds during fruit planting

The invention discloses a device for sowing seeds during fruit planting. The device comprises a supporting plate, a shell, a storage box, a handle, side plates, rotating shafts, travelling wheels, first gears, second gears, rotary drums, shifting rods, first springs, limiting plates, an electric push rod, connecting rods, pipe bodies, a fixed plate, a second spring, a baffle plate, a fixed rod, ablanking pipe, a rotating plate and a rotary rod. The device for sowing seeds during fruit planting is simple in structure and convenient to operate; the soil is dug by means of the vertical movementof the pipe bodies, and a certain number of seeds are enabled to fall off for seeding while the pipe bodies move, so that the convenience of operation is improved, the amount of seeding each time is enabled to be the same, and the problem that the crop growth is affected due to the different number, caused by artificial sowing, of seeding each time is solved; by pushing the device to move, continuous sowing is facilitated; by driving the rotary drums to rotate, the shifting rods can more easily push the soil, the burying of the seeds is facilitated, the sowing efficiency is increased, and theworking hours are reduced.

Owner:镇江市丹徒区艺之林林果专业合作社

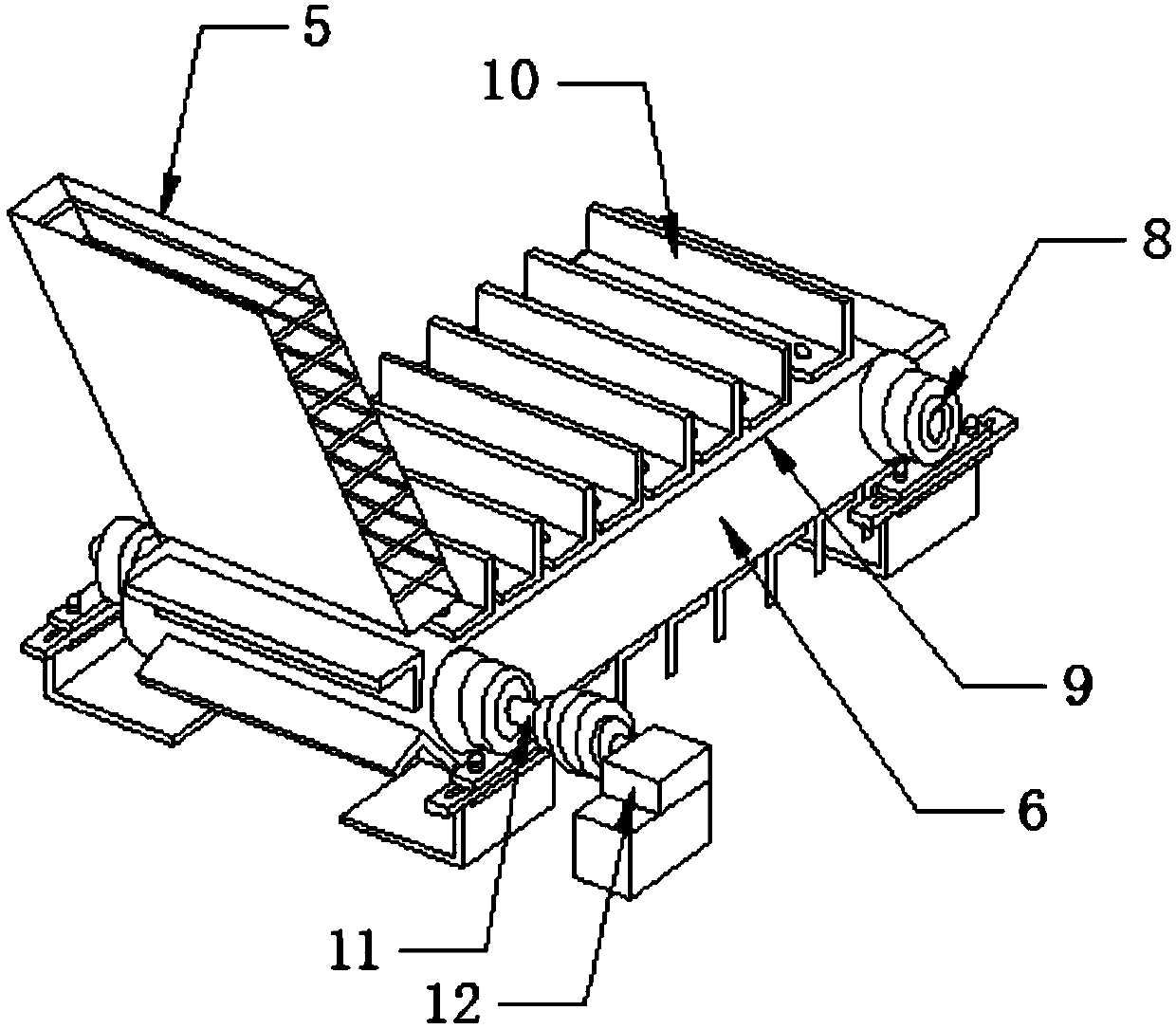

Novel precision tray seeder

InactiveCN104885659AEvenly distributedRealize one-time seedingSeed depositing seeder partsRegular seed deposition machinesSeederEngineering

The invention relates to a novel precision tray seeder, comprising a tray, a transmission mechanism, a seed supply mechanism, a seed suction and discharge mechanism and an intelligent controller. The intelligent controller performs linkage control on actions of the transmission mechanism, the seed supply mechanism and the seed suction and discharge mechanism to realize precision tray seeding. Compared with the prior art, the novel precision tray seeder has the advantages that the intelligent controller is used for accurately controlling all actions of the transmission mechanism, the seed supply mechanism and the seed suction and discharge mechanism of the whole seeder, so that once seeding of a whole tray can be realized, precision seeding of each single seed can be performed, the seeding efficiency is improved greatly, the effects of saving energy and saving seeds can be achieved, the stability is good, the probability of missing seed and the reseeding rate are low, seeds of crops can be distributed uniformly, and the effects of seed saving and high yield are achieved. The novel precision tray seeder is applicable to different crop seeds and different planting scales, high adaptability can be guaranteed by replacing a tray and adjusting a seed suction head on a seed suction plate, and the production efficiency is improved.

Owner:TONGJI UNIV

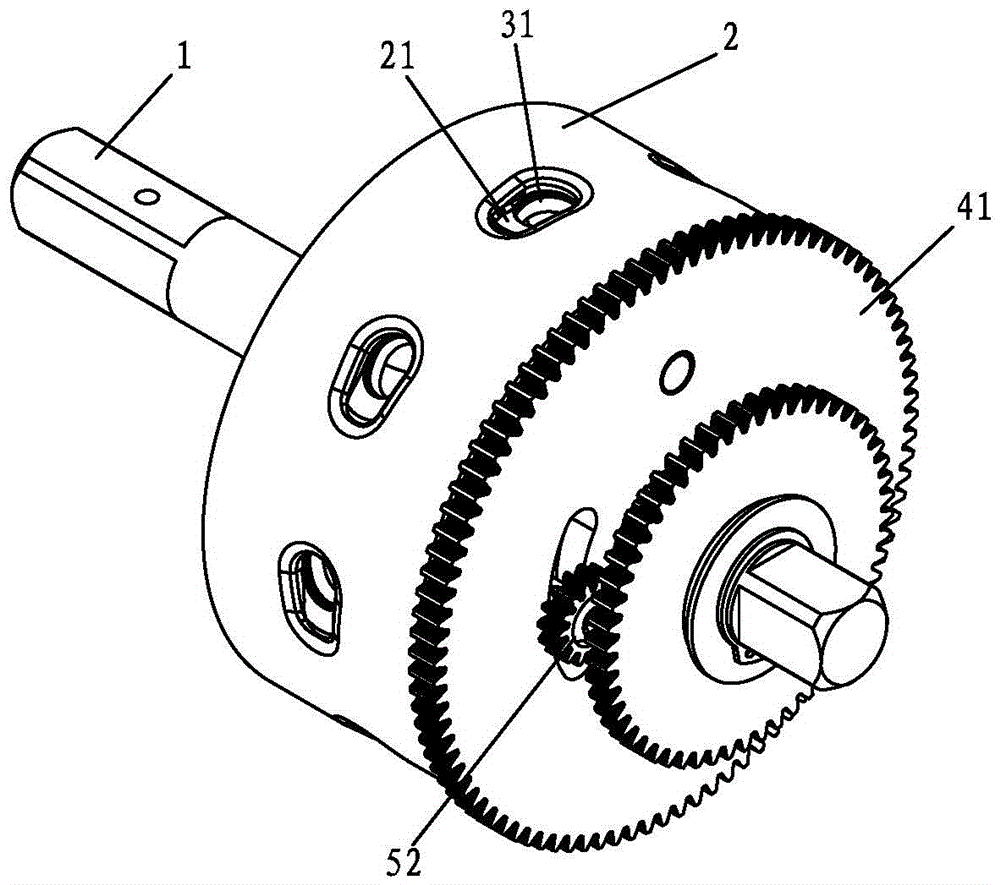

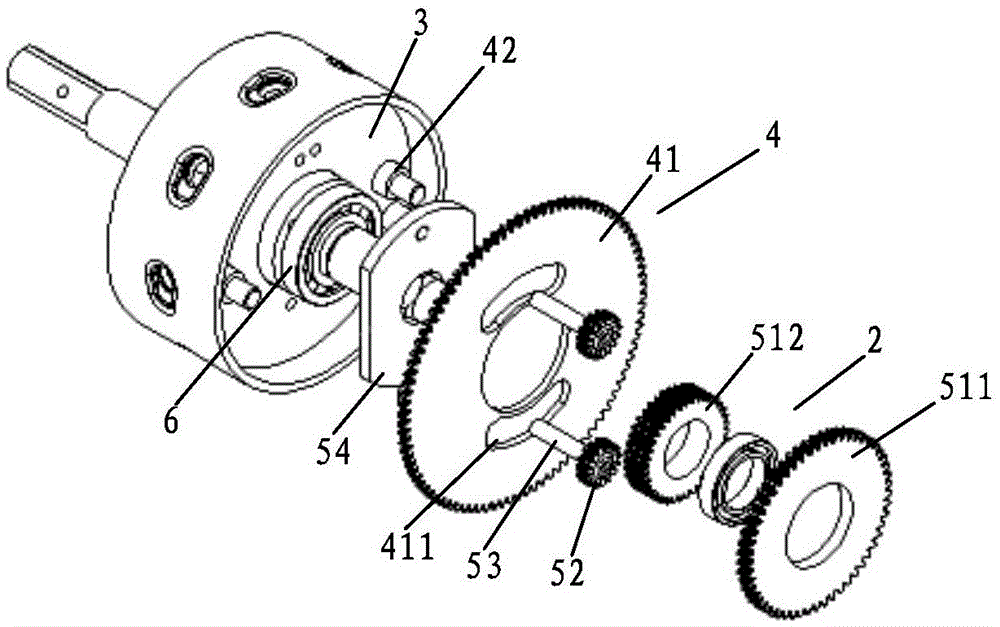

Seeding rate adjusting device for seed metering device

ActiveCN105594350AAdjust the size of the spaceWith electrical adjustment controlSeed depositing seeder partsLocking mechanismEngineering

The invention discloses a seeding rate adjusting device for a seed metering device. The seeding rate adjusting device comprises a spindle, an outer perforated wheel, an inner perforated wheel, a rotating drive mechanism and a locking mechanism, and the outer perforated wheel, the inner perforated wheel, the rotating drive mechanism and the locking mechanism are rotatably mounted on the spindle. The outer periphery of the outer perforated wheel is provided with through holes, the outer periphery of the inner perforated wheel is provided with grooves corresponding to the through holes, and the inner perforated wheel sleeves the outer perforated wheel rotatably, slidably and internally. The rotating drive mechanism is fixedly connected with the inner perforated wheel, and an output end of the locking mechanism slidably presses the inner perforated wheel to realize fixed connection between the inner perforated wheel and the outer perforated wheel. The inner perforated wheel is capable of rotating relative to the outer perforated wheel to realize a staggered, intersected or overlapped positional relation between the grooves and the through holes, and accordingly size adjustment of seed holding spaces between the through holes and the grooves is realized. The seeding rate adjusting device has the advantages of electrical regulation control, convenience in operation, high seeding efficiency, safety and reliability.

Owner:SOUTH CHINA AGRI UNIV

Corn seedling device capable of uniformly discharging kernels for agricultural planting

InactiveCN109479448AAvoid cloggingUniform grainPlantingGeneral water supply conservationWater resourcesAgricultural engineering

The invention discloses a corn seedling device capable of uniformly discharging kernels for agricultural planting. The corn seedling device comprises a vehicle plate, and is characterized in that Y-shaped mounting racks are formed in the middle of the two sides of the bottom part of the vehicle plate; the bottom parts of the two-sided inner walls of the two mounting racks are connected with wheelsthrough bearings; the top inner walls of the two mounting racks are provided with brush hairs; the one-sided outer wall of the left-sided mounting rack positioned at the bottom of the vehicle plate is provided with a second driving motor; the left side of the bottom part of the vehicle plate is provided with two ditching rods; the bottom parts of the two ditching rods are provided with shaving gears which are distributed equidistantly; a material distribution bin is arranged in the middle of the bottom plate of the vehicle plate; and a material distribution bulge is formed in the middle of the bottom inner wall of the material distribution bin. The corn seedling device disclosed by the invention has the advantages that corn kernels can be effectively prevented from being blocked, kernelsare discharged uniformly, the phenomena that operation personnel cannot conveniently walk after sowing or the seeds are trodden and exposed are avoided, and integration of ditching, sowing, soil covering and irrigation is realized, and thus, the sowing operation efficiency is improved, and the corn seedling device has a rainwater collection function so that water resources are saved.

Owner:卢振宇 +1

Agricultural fertilizing and seeding device with soil covering function

InactiveCN111937540AImprove growing conditionsEasy sowingPlantingDibble seedersAgricultural engineeringSoil cover

The invention relates to the technical field of agricultural fertilization and seeding, in particular to an agricultural fertilizing and seeding device with a soil covering function. In order to solvethe technical problems that an existing seeding device cannot conduct punching and fertilization at the same time, the seeding efficiency is low, and the seeding interval cannot be changed, the agricultural fertilizing and seeding device with the soil covering function is provided and comprises a cart, wherein the top of the cart is fixedly connected with a seeding device, and four material guidepipes are embedded in the bottom of the seeding device; and an irrigation device is fixedly connected to the right side of the seeding device, a soil covering plate is installed at the right side ofa watering pipe of the irrigation device, and a perforating device is fixedly connected to the left side of the seeding device. Seeds and fertilizer are mixed for use or separately used through the seeding device, seeding, fertilization, watering, pit filling and burying can be conveniently conducted on the seeds and the fertilizer at the same time, and the seeding efficiency is improved.

Owner:杨先文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com