Patents

Literature

69results about How to "Realize automatic control operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

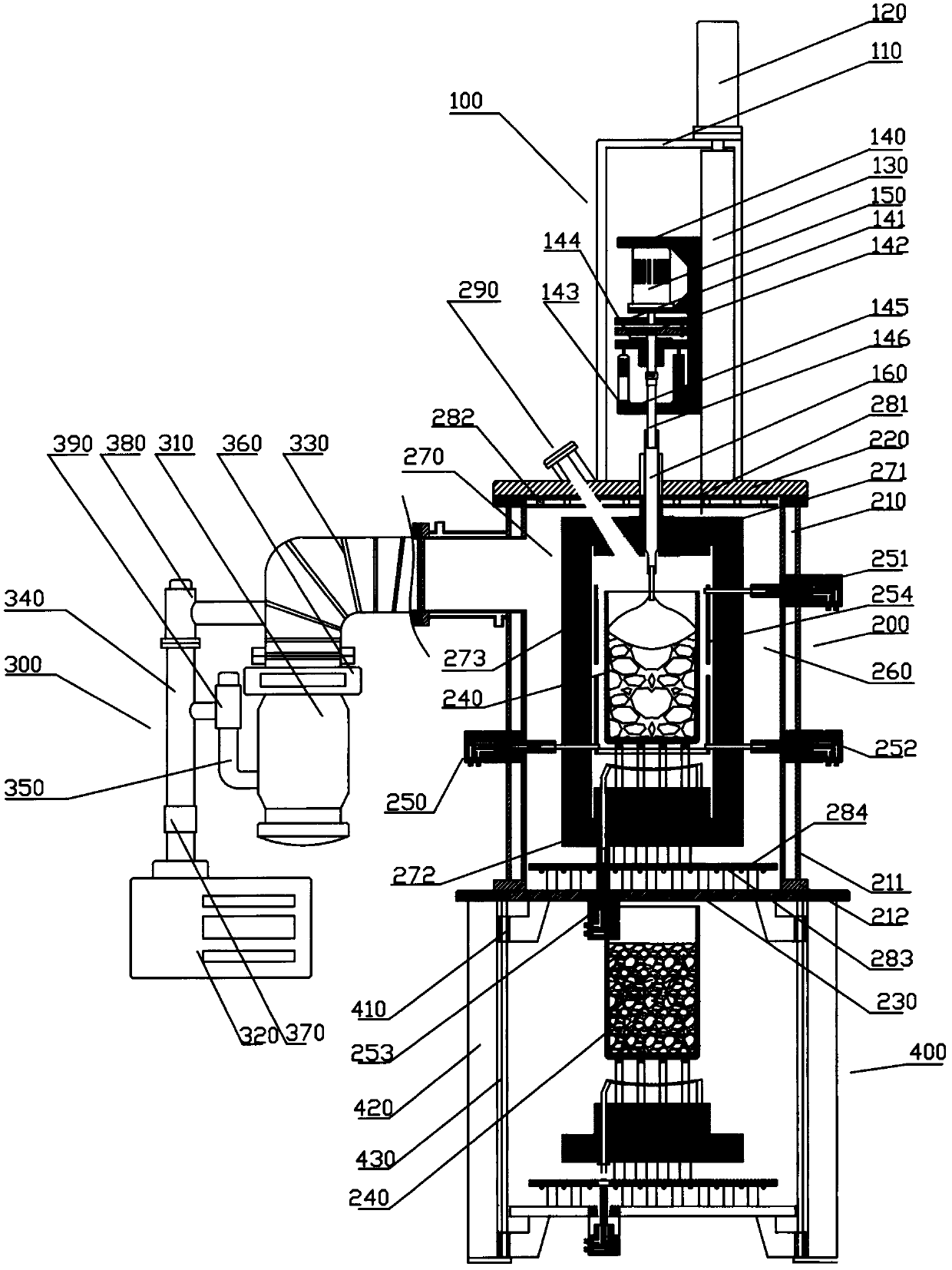

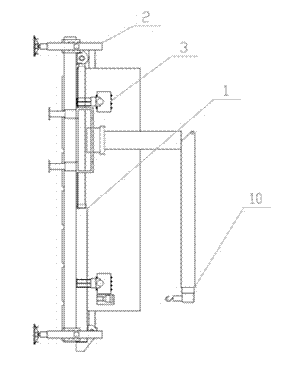

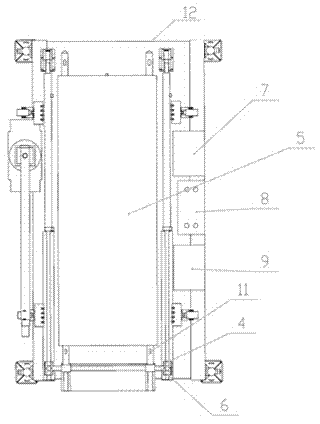

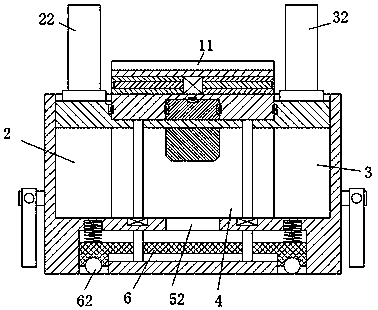

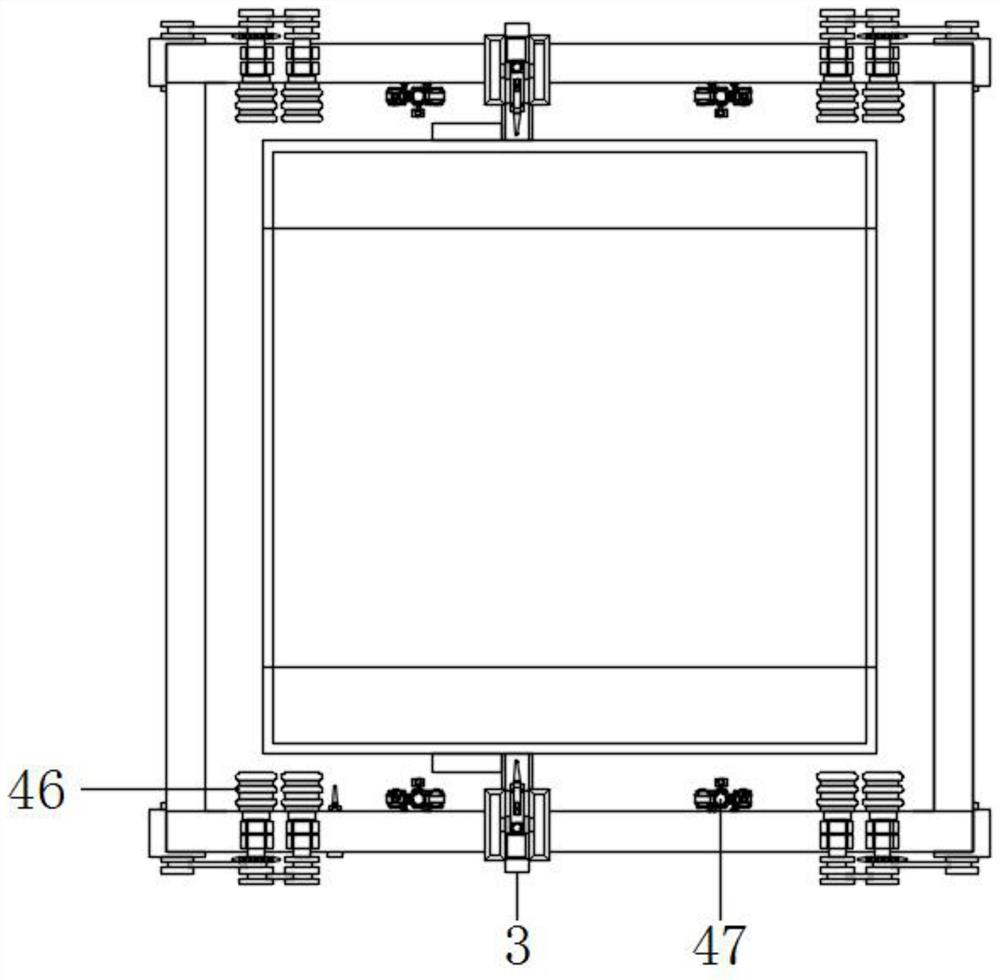

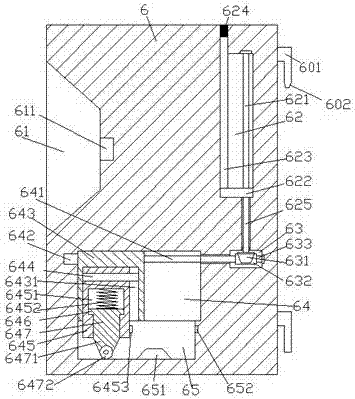

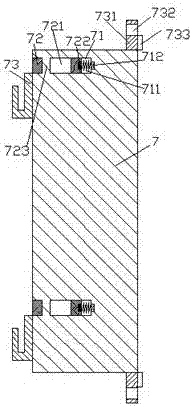

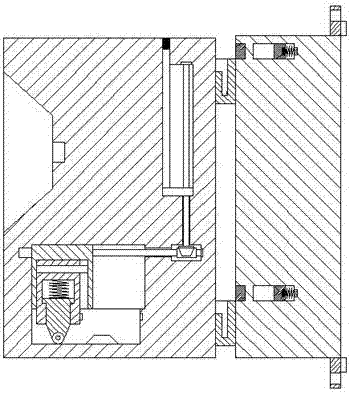

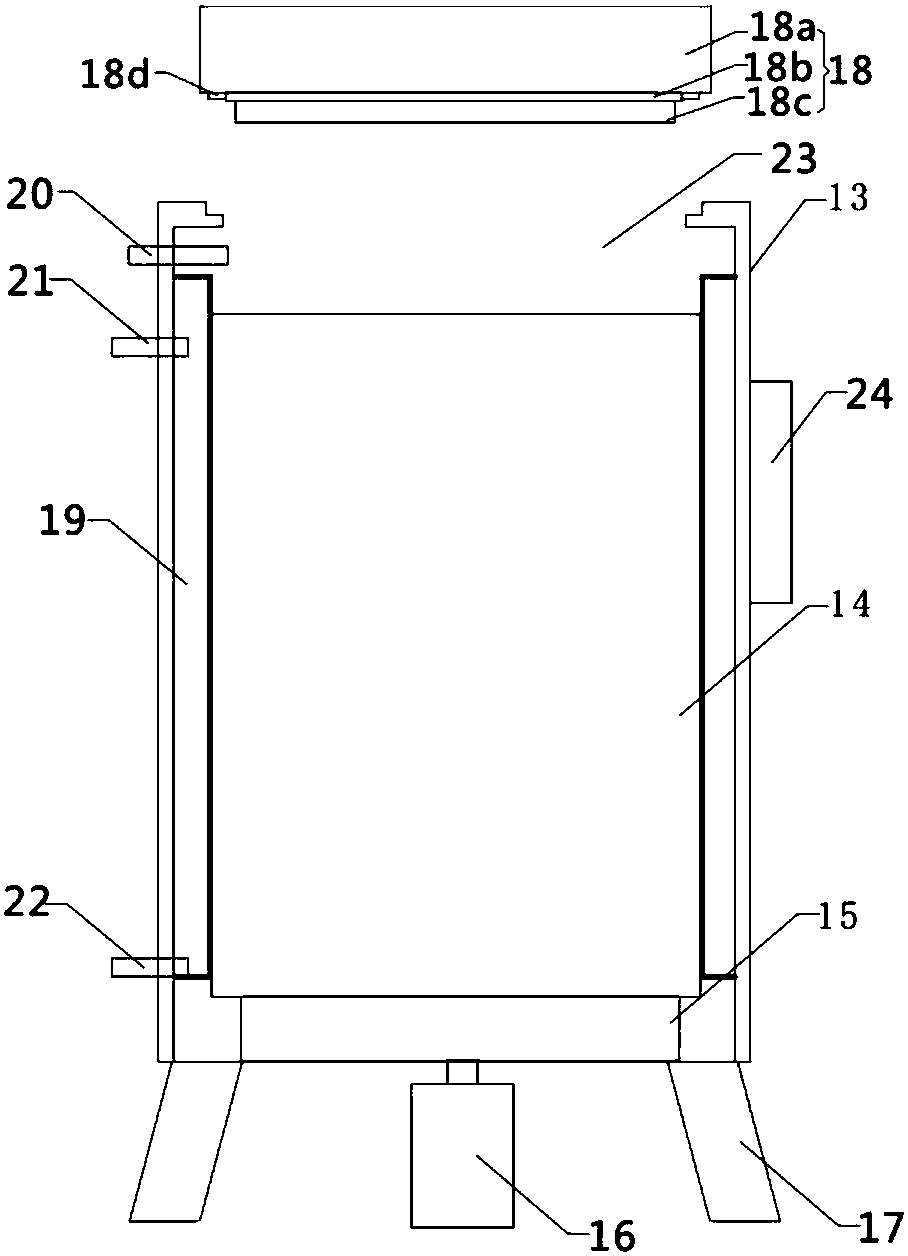

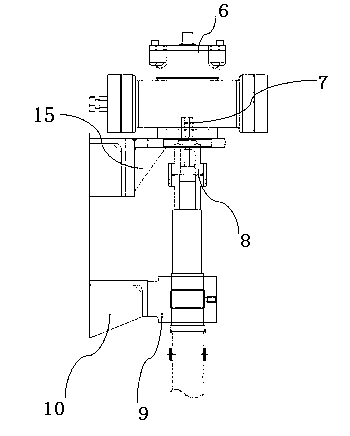

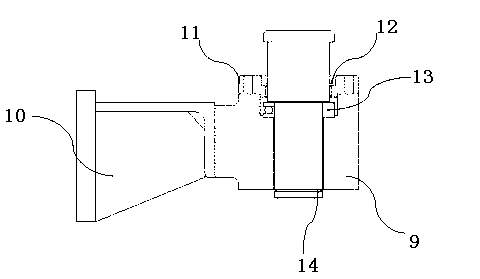

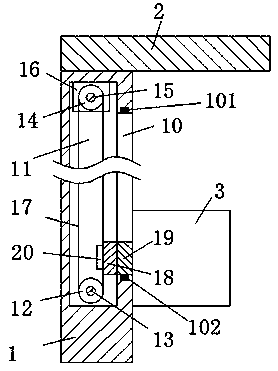

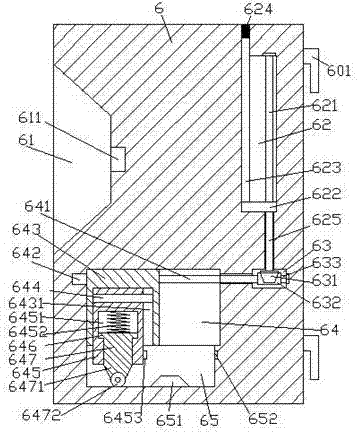

Large-size sapphire crystal growing furnace

InactiveCN103374753ARealize automatic control operationImprove seeding efficiencyPolycrystalline material growthBy pulling from meltAutomatic controlCrucible

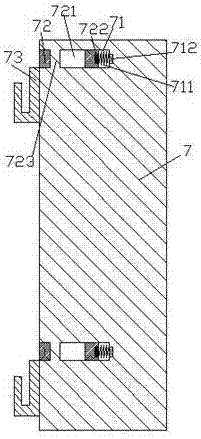

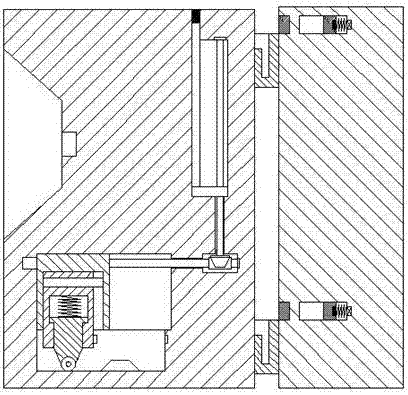

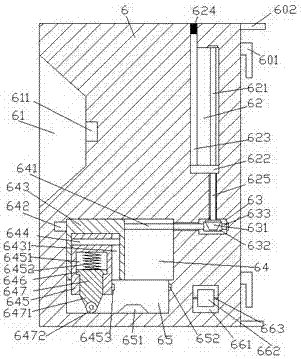

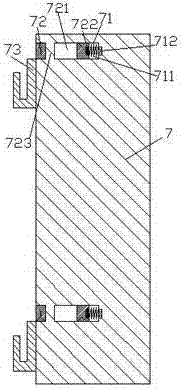

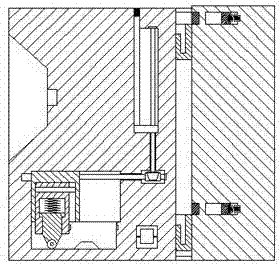

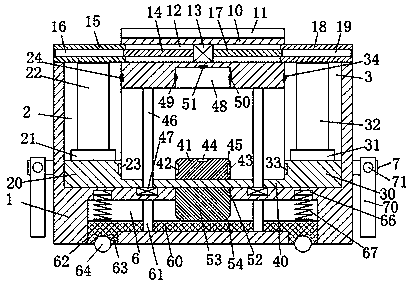

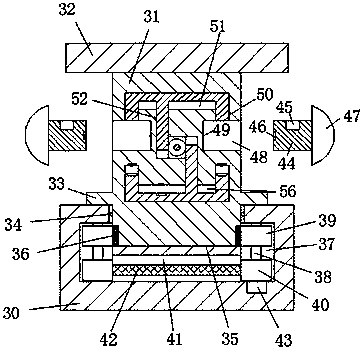

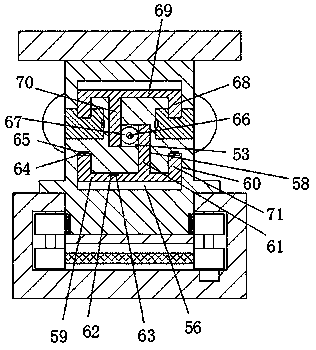

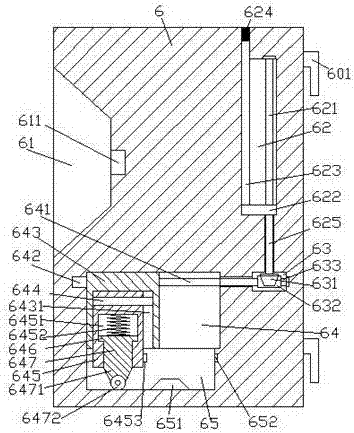

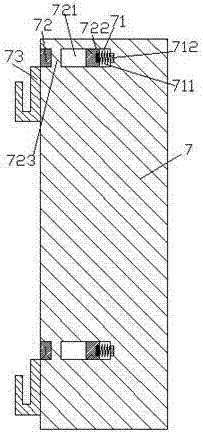

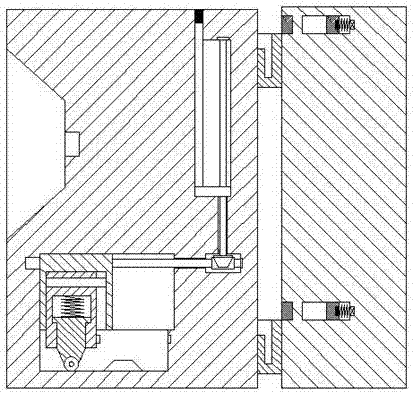

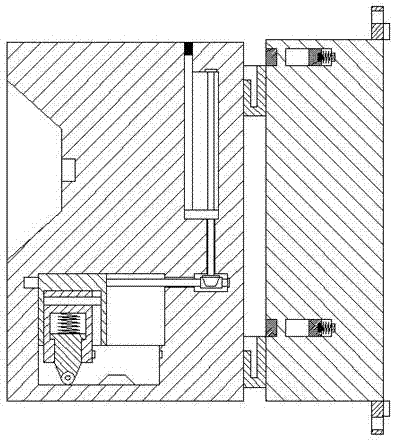

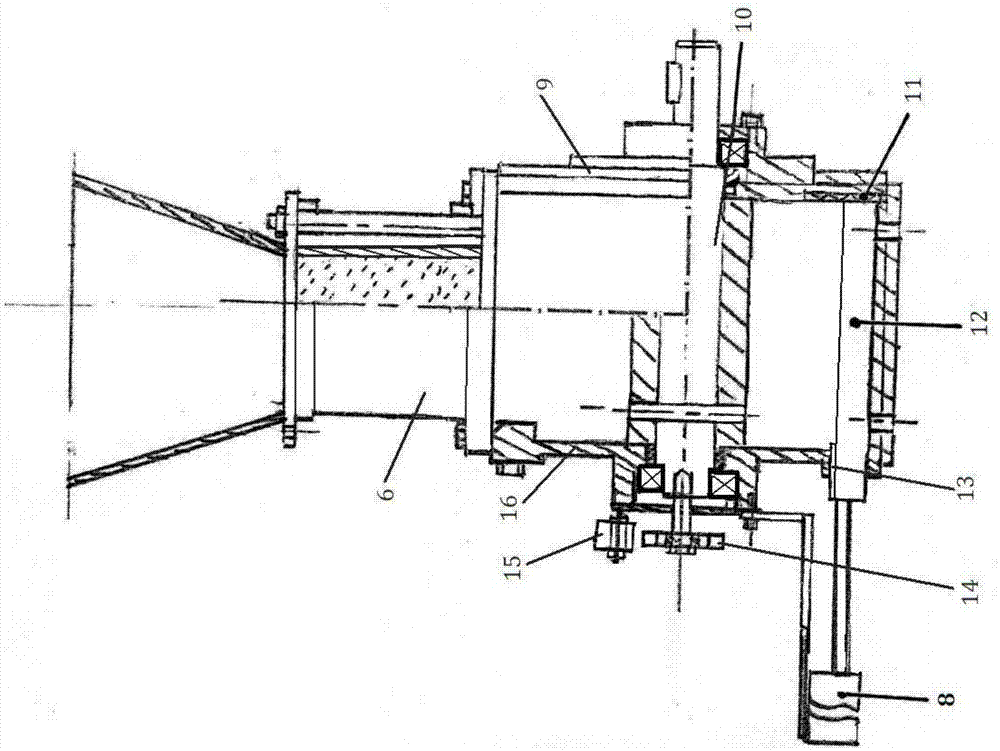

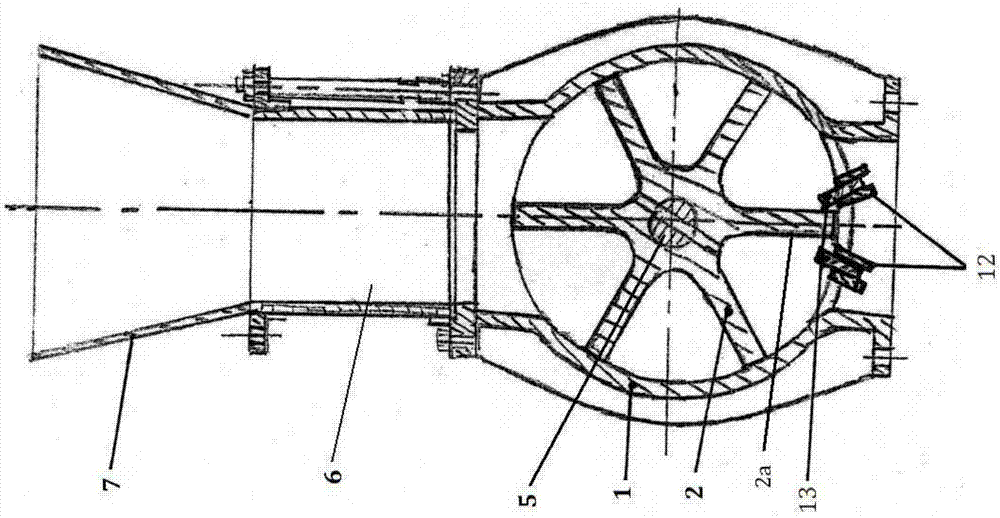

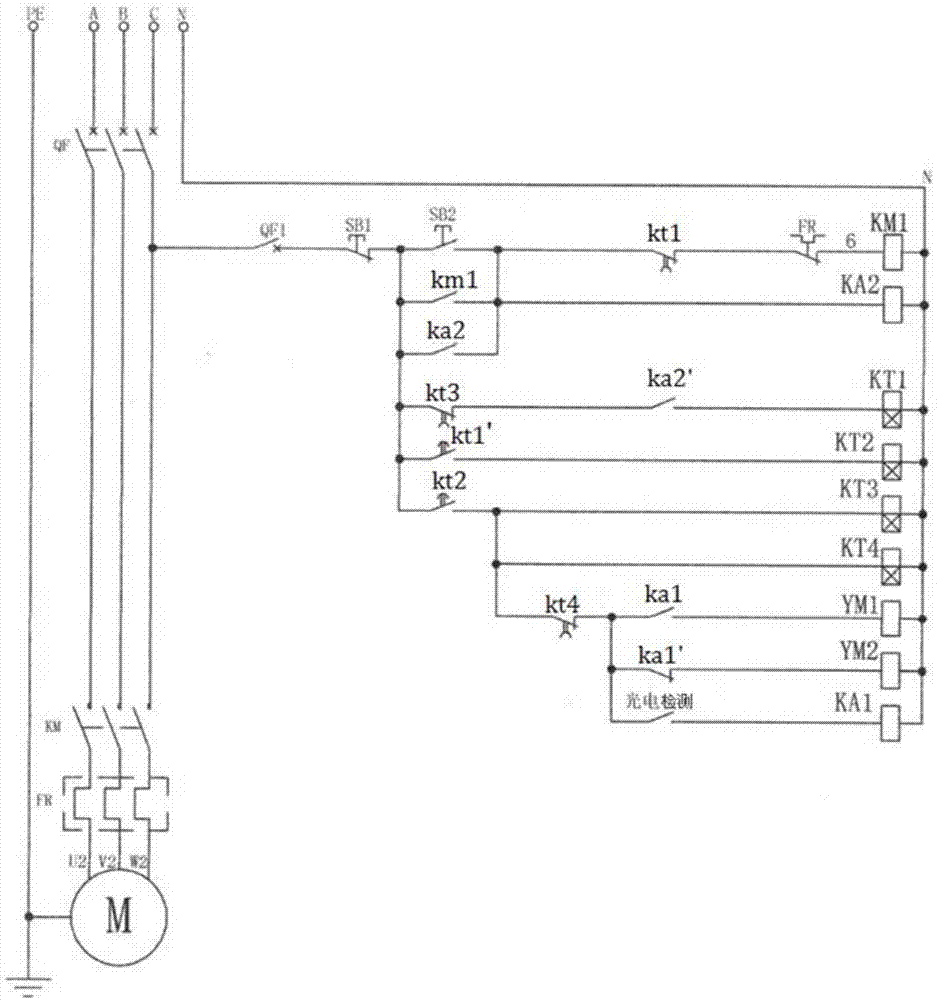

The invention relates to a large-size sapphire crystal growing furnace. A seed crystal mounting room is arranged above a heating barrel; a vacuumizing assembly is communicated with the heating barrel; an inner cavity of the heating barrel is a sealed cavity; a hoisting motor is arranged above a bracket; a hoisting straight-line guide rail is arranged inside the bracket below the hoisting motor and is connected with the hoisting motor through a shaft coupler; the hoisting motor rotates to drive a slide block in the hoisting straight-line guide rail to hoist; a rotary motor fixing seat is arranged on the hoisting straight-line guide rail and is connected with the slide block in the hoisting straight-line guide rail; the rotary motor is mounted on the rotary motor fixing seat; a seed crystal mounting rod is connected with the rotary motor; an upper furnace cover and a lower furnace cover are respectively arranged at upper and lower ends of a double-layered water cooling barrel to form a sealed cavity; a crucible is arranged in the cavity and a heating system is arranged at the outer side of the crucible; and a seed crystal mounting rod stretches into the crucible of the heating barrel. The device disclosed by the invention realizes automatic control and operation, improves the seeding efficiency and enhances the seeding effect; and a large-size sapphire crystal can be produced by the large-size sapphire crystal growing furnace.

Owner:WUJIANG YATAI VACUUM EQUIP TECH

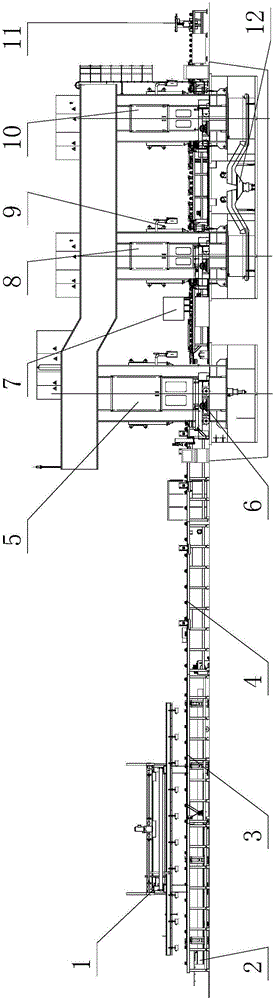

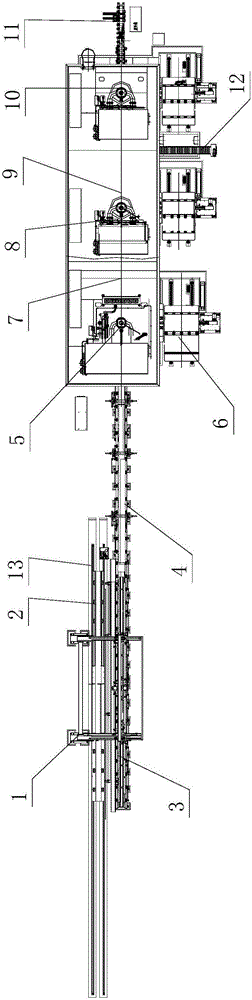

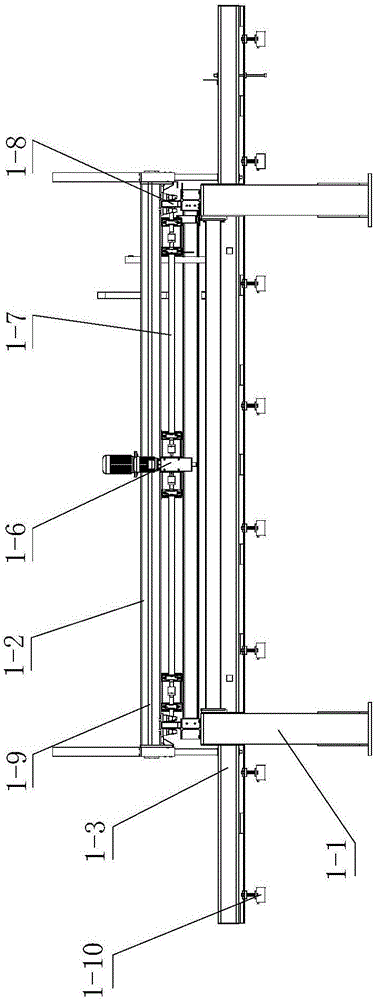

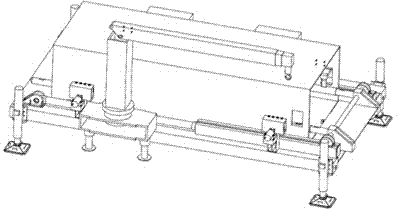

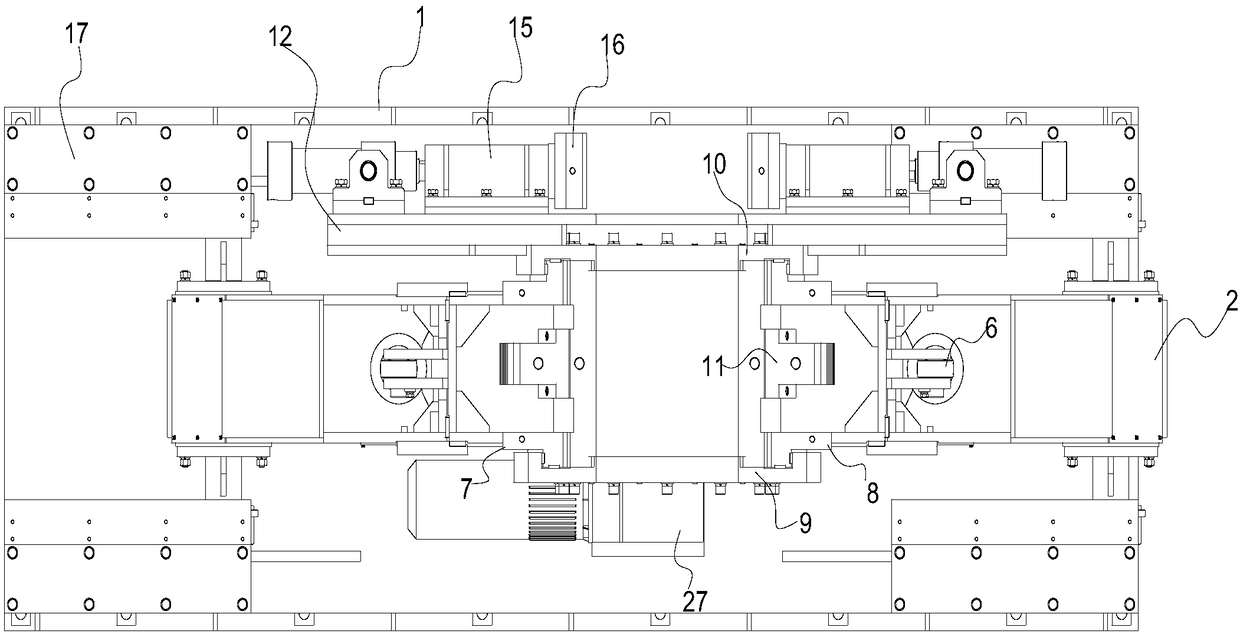

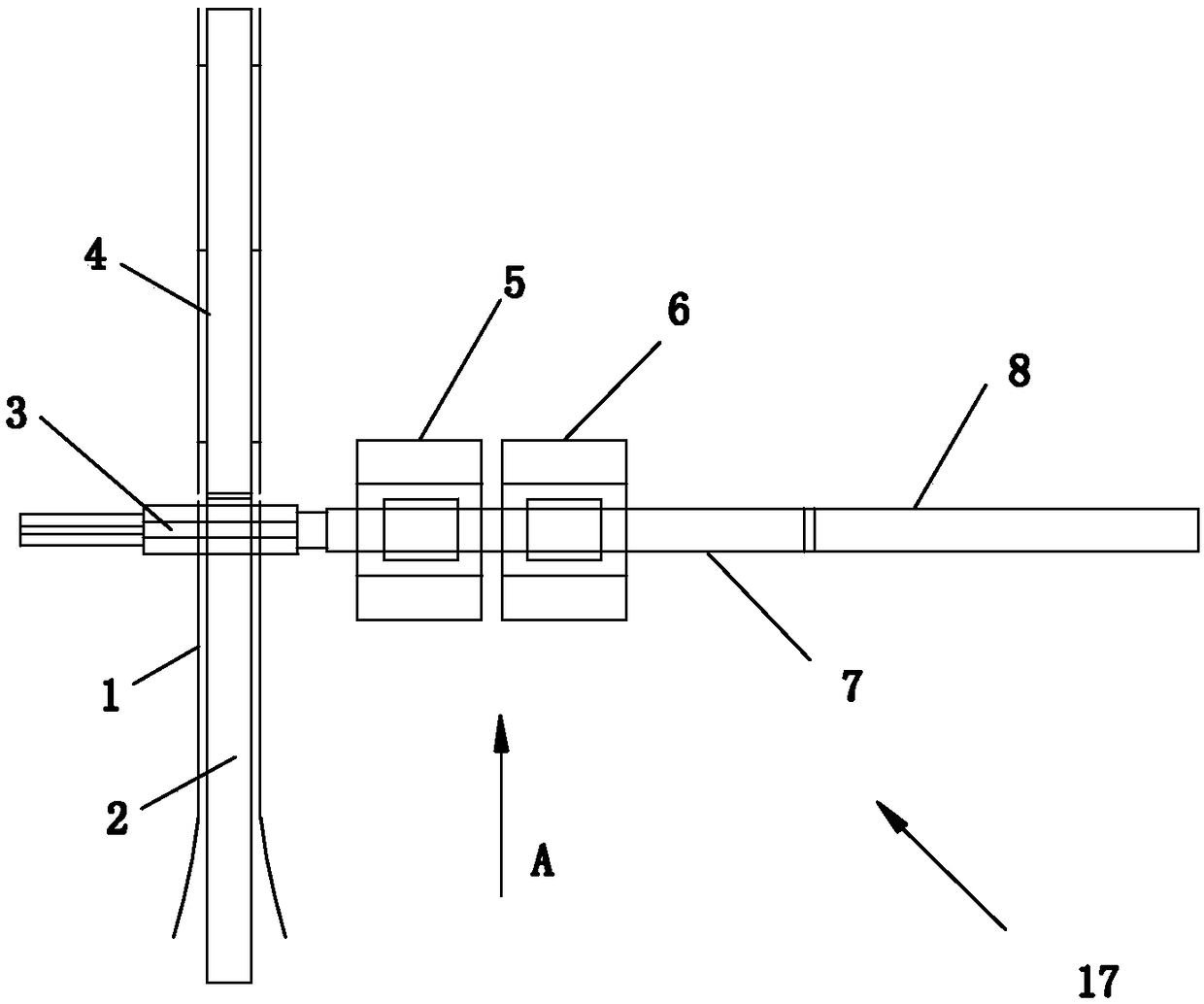

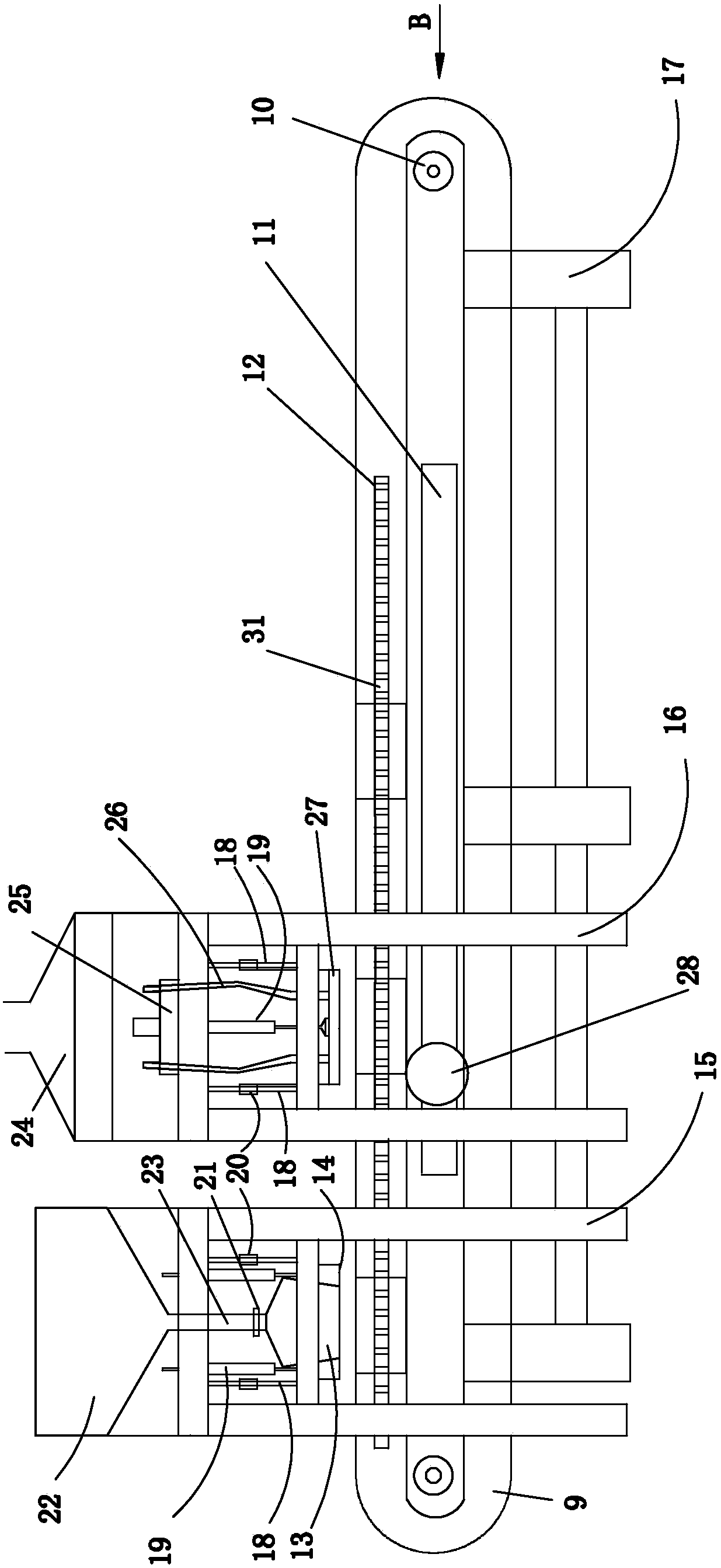

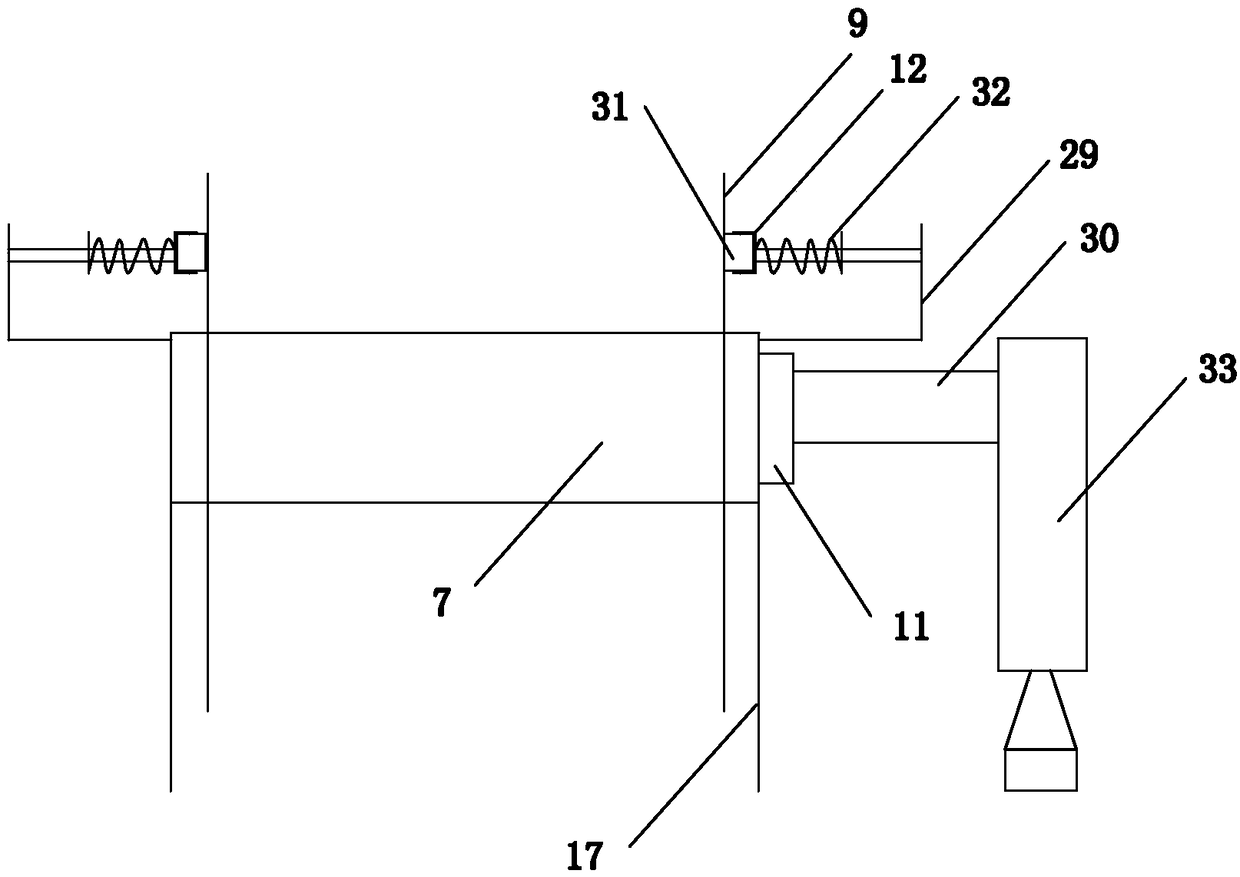

Full-automatic intelligent track shoe blanking production line

ActiveCN106424326AReduce labor intensityRealize automatic control operationMetal-working feeding devicesMetal working apparatusProduction lineMachining

The invention relates to a full-automatic intelligent track shoe blanking production line. The full-automatic intelligent track shoe blanking production line is characterized in that the production line comprises a conveying trolley, a destacking device, an overturning device, a roll gang, a workpiece cutting-off hydraulic machine, a die change device, a 2D vision camera length detecting device, a workpiece punching hydraulic machine, a workpiece necking hydraulic machine, blocking and positioning mechanisms, a 3D vision camera hole site dimension detecting device and a waste conveying device; and the destacking device, the overturning device, the roll gang, the workpiece cutting-off hydraulic machine, the die change device, the 2D vision camera length detecting device, the workpiece punching hydraulic machine, the workpiece necking hydraulic machine, blocking and positioning mechanisms, the 3D vision camera hole site dimension detecting device are all controlled by a main PLC. The full-automatic intelligent track shoe blanking production line has the advantages that manual intervention is avoided, time and labor are saved, and the labor intensity of operators is relieved; workpiece positioning during supplying and feeding is accurate, operation is convenient, the automation is high, precision and machining efficiency of track shoe blanking can be greatly improved, and the full-automatic intelligent track shoe blanking production line is especially suitable for blanking and pressing processes for track shoe profiles of various specifications.

Owner:TIANJIN TIANDUAN PRESS CO LTD

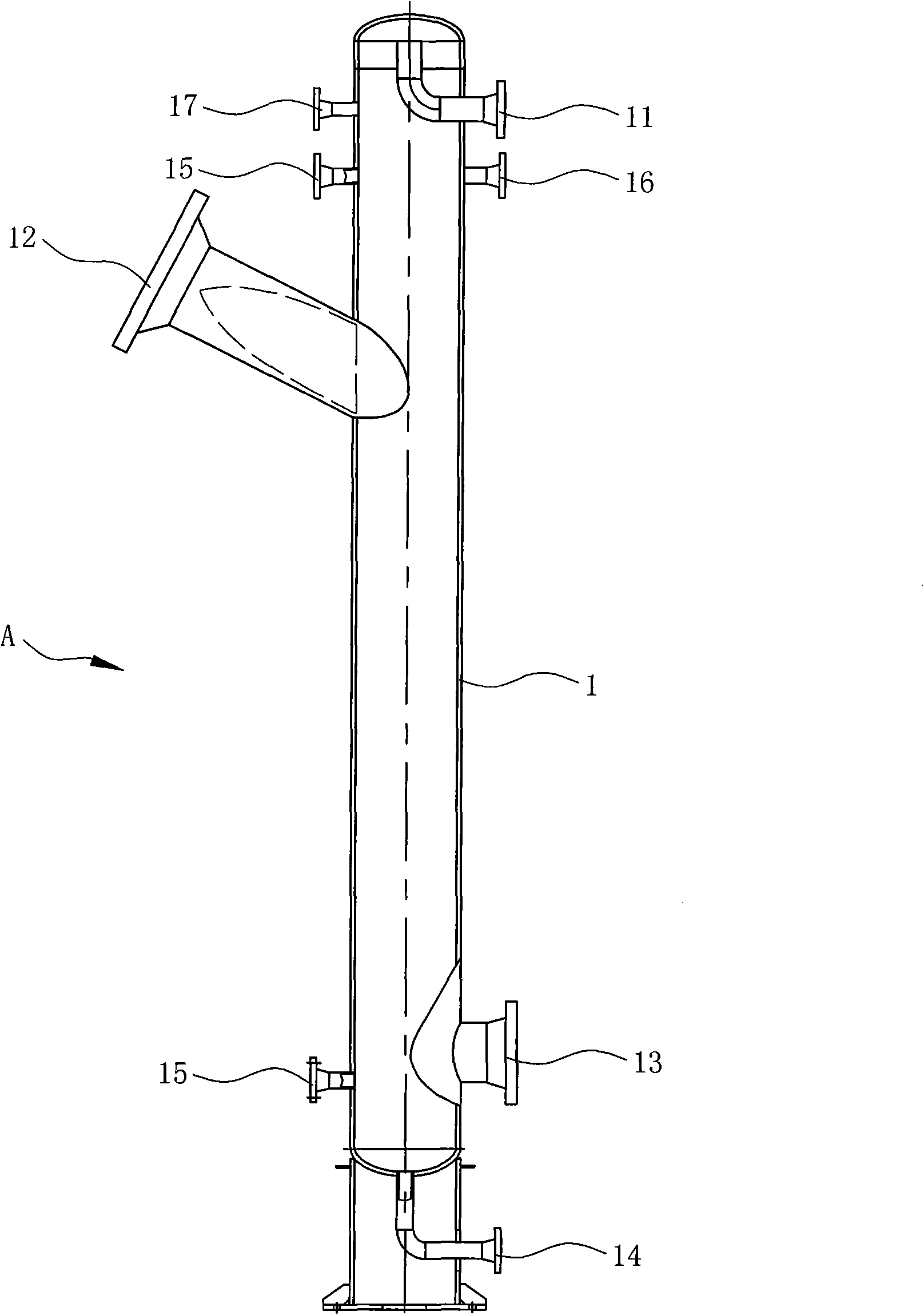

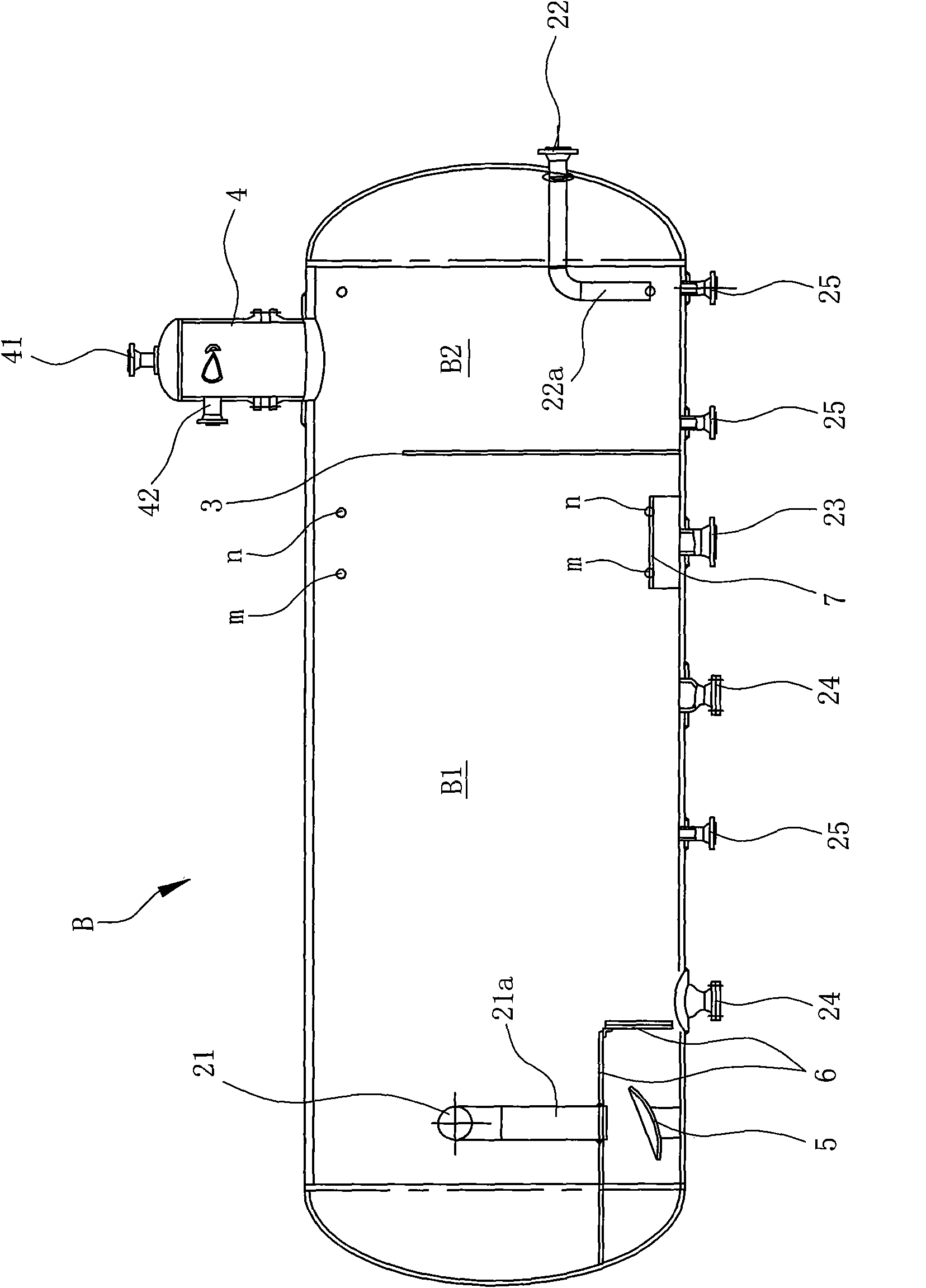

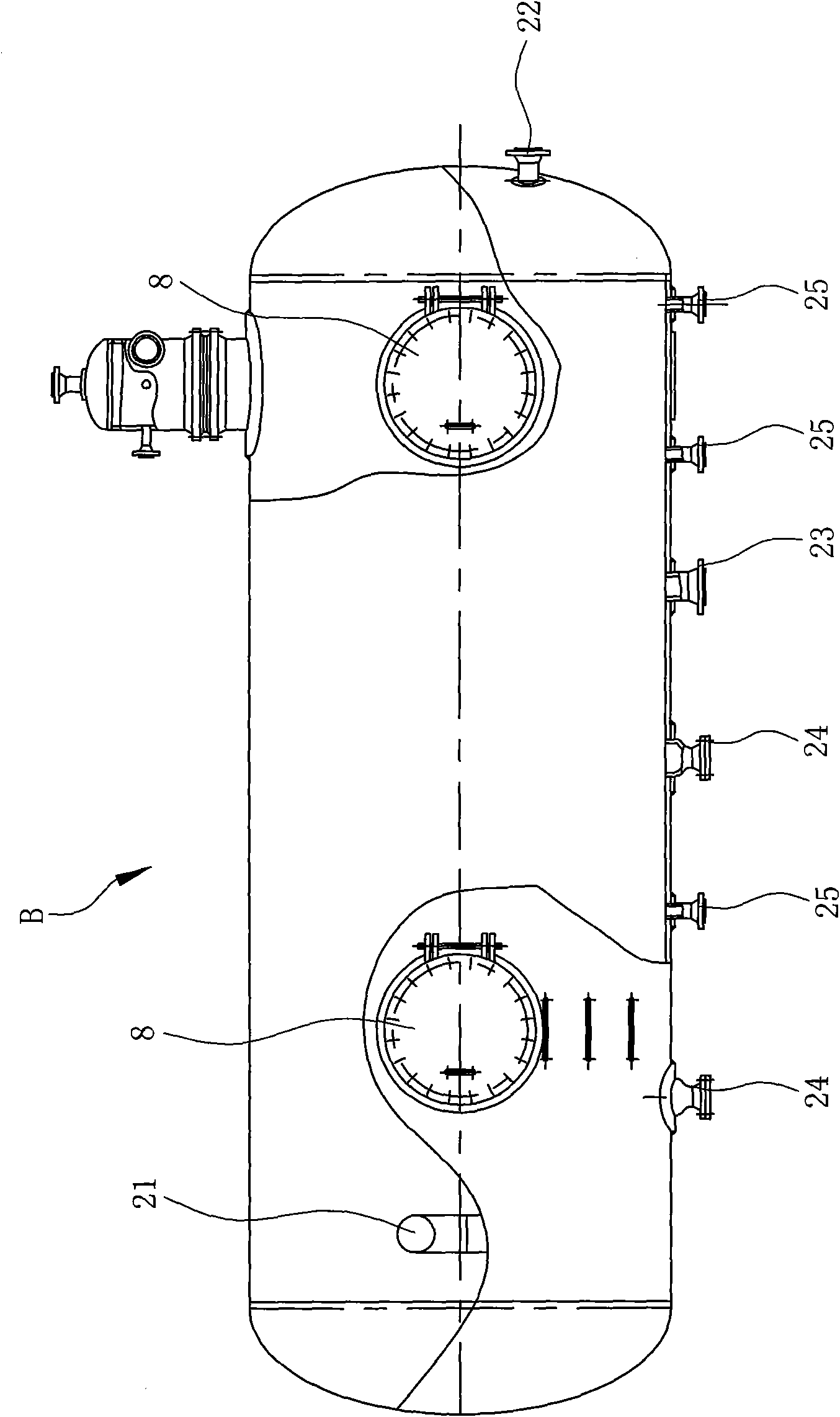

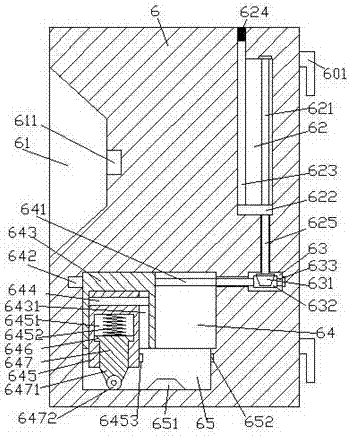

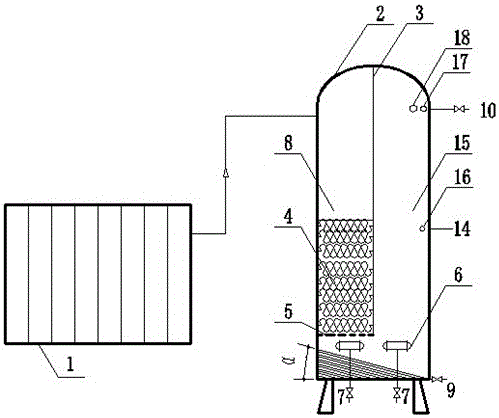

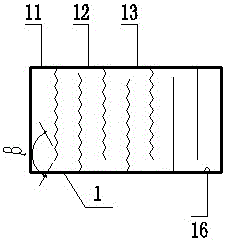

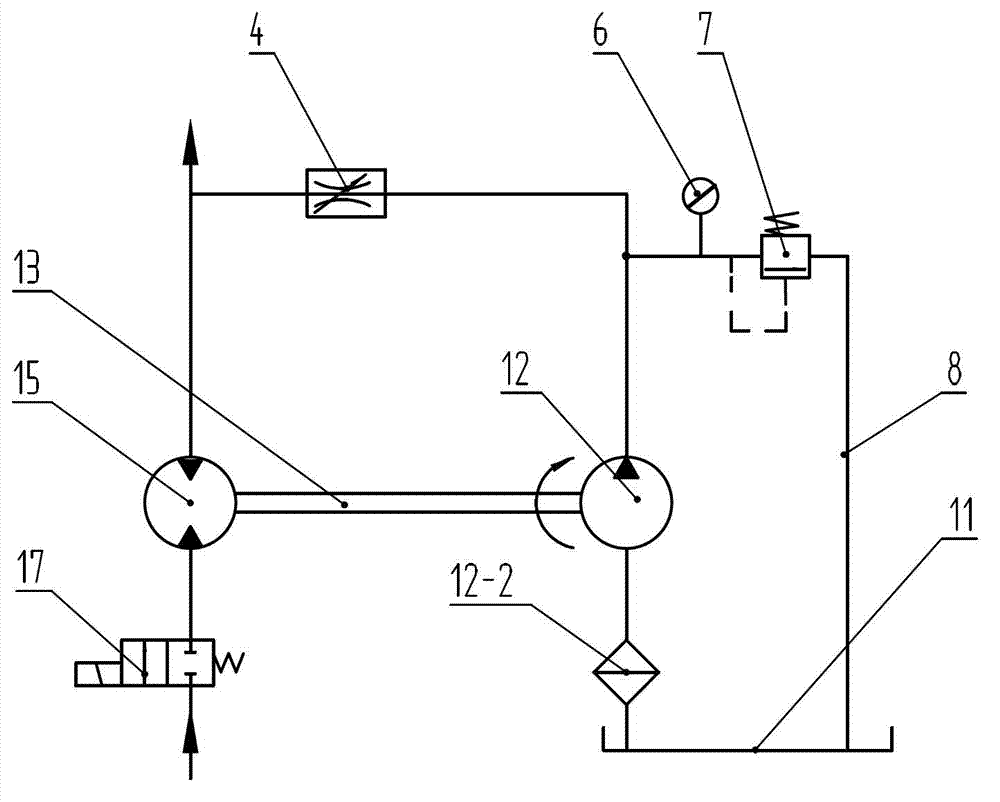

Gas-oil-water three-phase separating device

InactiveCN101584945AEasy to separateEasy to handleLiquid degasificationLiquid separationVapor–liquid separatorWater discharge

The invention discloses a gas-oil-water three-phase separating device, which comprises a columnar whirl gas-liquid separator (A) and a horizontal three-phase separator (B). The horizontal three-phase separator (B) comprises a horizontal tank (2) with a vertical baffle plate (3) which divides the inside of the horizontal tank (2) into a liquid collecting region (B1) and an oil collecting region (B2). Gap is arranged between the top of the baffle plate (3) and the top of the horizontal tank (2), the horizontal tank (2) is provided with a liquid inlet tube (21), an oil discharge tube (22), a water discharge tube (23) and a gas collecting bag (4), the liquid outlet tube (13) of the whirl gas-liquid separator (A) is communicated with the liquid inlet tube (21), and the gas outlet tube (11) of the whirl gas-liquid separator (A) is communicated with the gas collecting bag (4). The horizontal three-phase separator separates the gas phase, oil phase and water phase with a few amounts in a mixed solution through a gravity method so that the gas has single collecting space, so as to reduce the space of the gas at the top of the horizontal tank. The horizontal tank has a volume decreased by 1 / 3 with respect to the same raw oil treatment capability and is extremely applicable to an ocean platform.

Owner:宁波威瑞泰默赛多相流仪器设备有限公司 +2

Wall-mounted new energy vehicle charging device

InactiveCN107097672AReduce laborRealize automatic control operationCharging stationsCoupling device detailsNew energyElectric machine

The invention discloses a wall-mounted new energy vehicle charging device. The device comprises a charging box and a hanging frame, a first sliding cavity is formed in the charging box, a guide sliding groove is formed in the inner bottom wall of the first sliding cavity, a first screw extending left and right is arranged in the first sliding cavity, and the left end of the first screw is connected with a first motor; the first screw is matched and connected with a first sliding block through threads, and a first sliding groove is formed in the first sliding block; a guide sliding rod which extends left and right is arranged in the first sliding groove, and a second sliding block is matched and connected with the guide sliding rod in a sliding mode; the bottom of the second sliding block extends into the guide sliding groove and is matched and connected with the guide sliding groove in a sliding mode; a second sliding cavity is formed in the second sliding block, a third sliding block is arranged in the second sliding cavity, and a first spring is arranged at the bottom of the third sliding block; a pushing sliding block penetrating through the bottom end surface of the second sliding block is arranged at the bottom of the third sliding block, a connecting part is arranged at the bottom of the pushing sliding block, and a rolling wheel is arranged at the bottom of the connecting part. The device is simple in structure and convenient to operate, power supply inserting connection can be automatically carried out, installation and dismounting are convenient, and the safety is high.

Owner:苏州玛斯堡威电子科技有限公司

Recycling treatment process for chlorohydric acid pickling liquid waste

InactiveCN103553256ASolve inseparableVolatileChlorine/hydrogen-chlorideWaste water treatment from metallurgical processLiquid wasteChloride

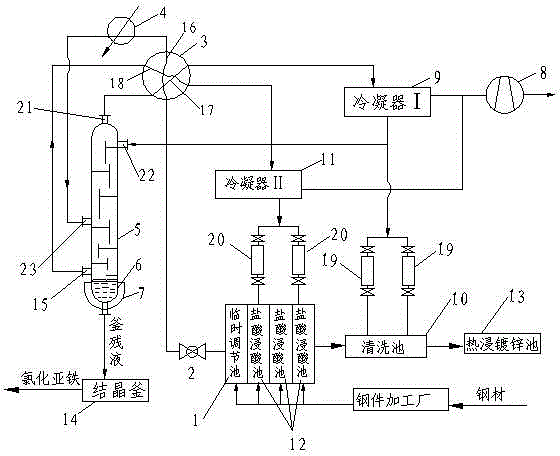

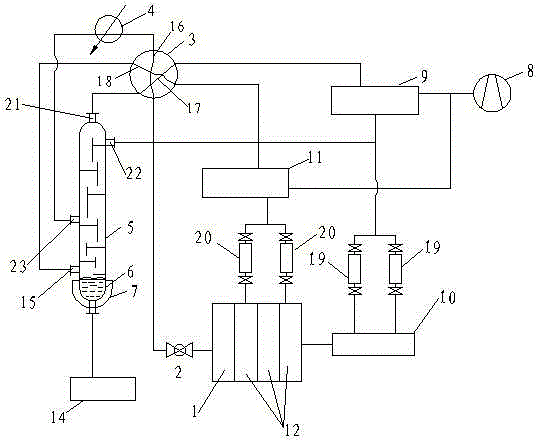

The invention discloses a recycling treatment process for chlorohydric acid pickling liquid waste. The process comprises the following steps: adjusting the acidity of CaCO3 of the chlorohydric acid pickling liquid waste to 99.65-124.56g / L; adding ferrous chloride so as to enable ferrite to be in a saturation condition; heating to the bubble point, then feeding the mixture into a rectifying tower and separating, wherein the pressure in the rectifying tower is 61.05-67.50Kpa; recovering a 10-15% diluted hydrochloric acid liquid and ferrous chloride crystals. Through reasonable parameter control and decompressing and rectifying processes, hydrochloric acid liquor applicable to acid pickling steel pieces as well as a coagulant capable of being used for sewage and wastewater treatment or a chemical raw material ferrous chloride can be recovered just by means of materials generated in the steel piece acid pickling process without spending other raw materials, so that the cost is greatly saved. The process is process-investment-saving, low in energy consumption and easy for mastering of operation, and can be continuously operated or intermittently operated in batches, thereby realizing automatically controlled operation.

Owner:YUNNAN AGRICULTURAL UNIVERSITY +1

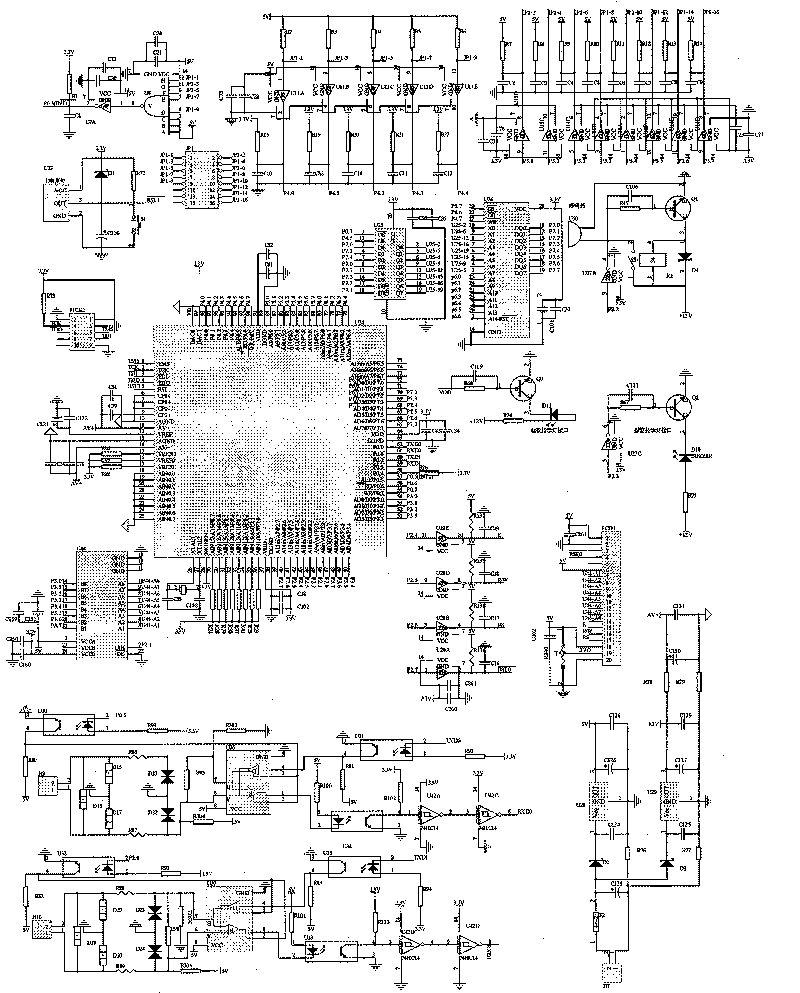

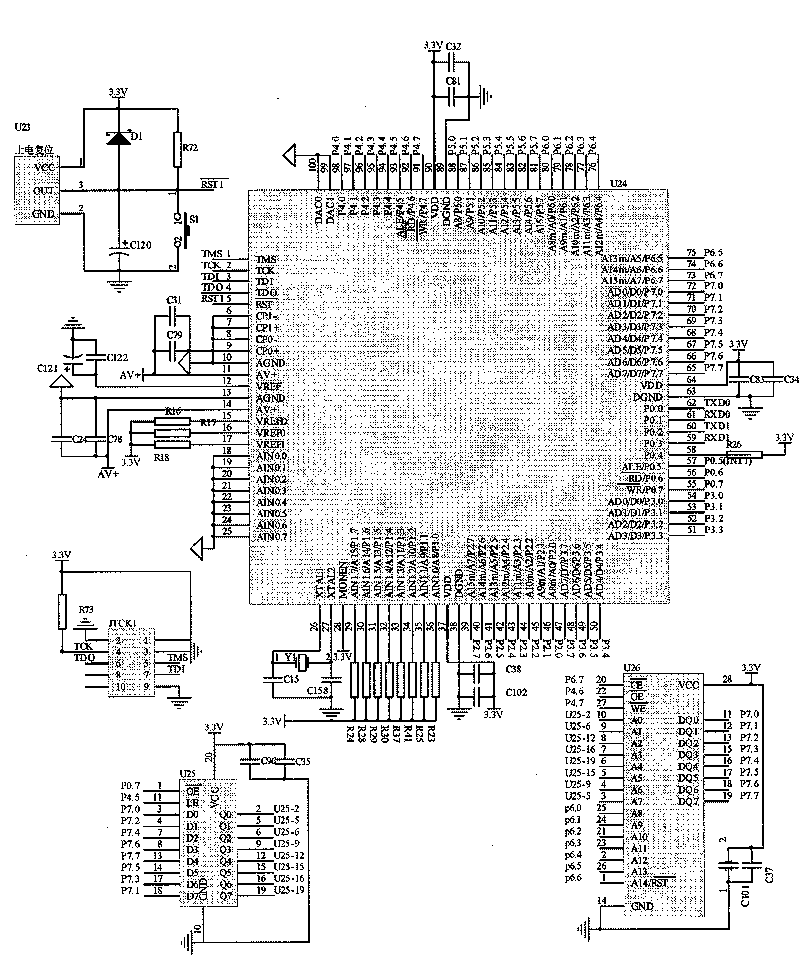

Hydraulic support end socket electro-hydraulic controller

InactiveCN101737072ASolve the problem of mutual communicationSolve functionMine roof supportsAsynchronous serial communicationAutomatic control

The invention discloses a hydraulic support end socket electro-hydraulic controller in which a liquid crystal display unit is connected with a parallel data bus P3 port of an MCU and a control bus pin; a keyboard scanning unit is connected with a scanning signal output bus P5 port of the MCU, an input signal receiving pin and an interrupt signal receiving pin; a drive circuit unit is connected with a buzzer control pin of the MCU, an alarm lamp control pin and a power light control terminal 3.3V power; an RS-485 interface unit is connected with an asynchronous serial communication pin and a read / write control pin of the MCU; a power supply unit is respectively connected with the corresponding power terminals of the MCU unit, the liquid crystal display unit, the keyboard scanning unit, the drive circuit unit and the RS-485 interface unit; and the JP1 port of the keyboard input unit is connected with a JP1 port of the keyboard scanning unit. The invention can control corresponding functions of the hydraulic support by a centralized control program or the hydraulic support end socket electro-hydraulic controller according to the position of the coal cutter, thus realizing safe and reliable automatic control on the hydraulic support at the coal face.

Owner:TAIYUAN UNIV OF TECH

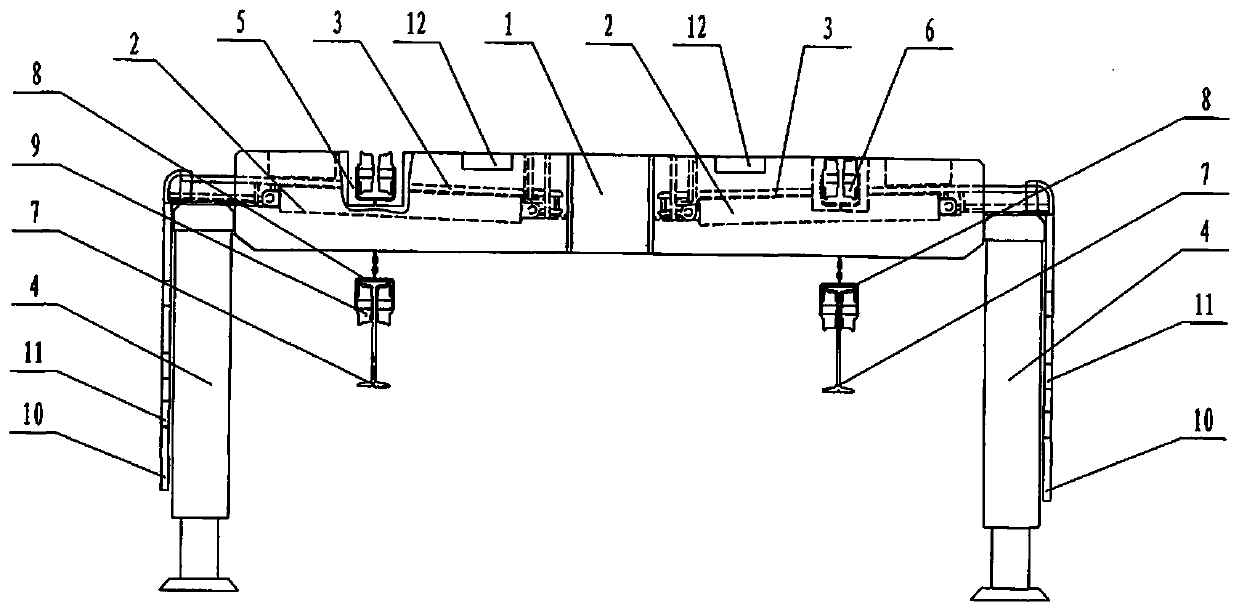

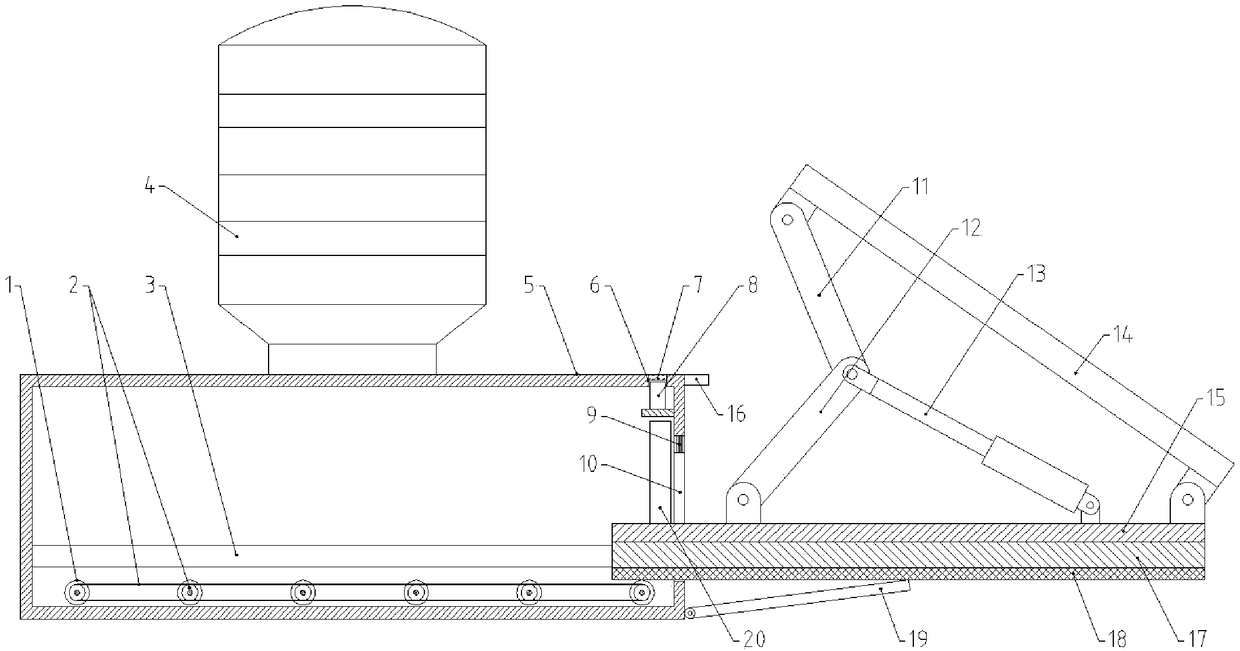

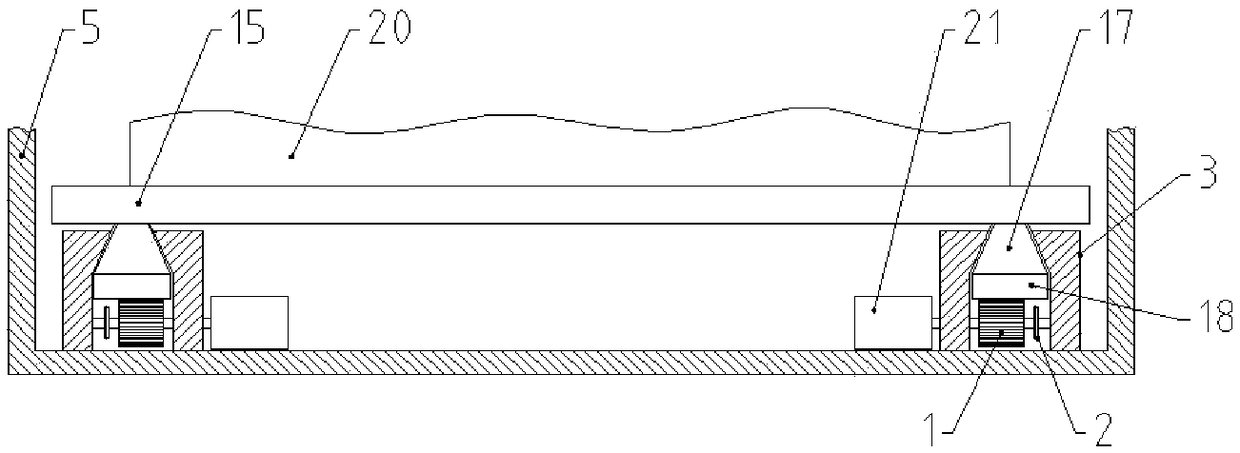

Mineral transport automatic butt joint system

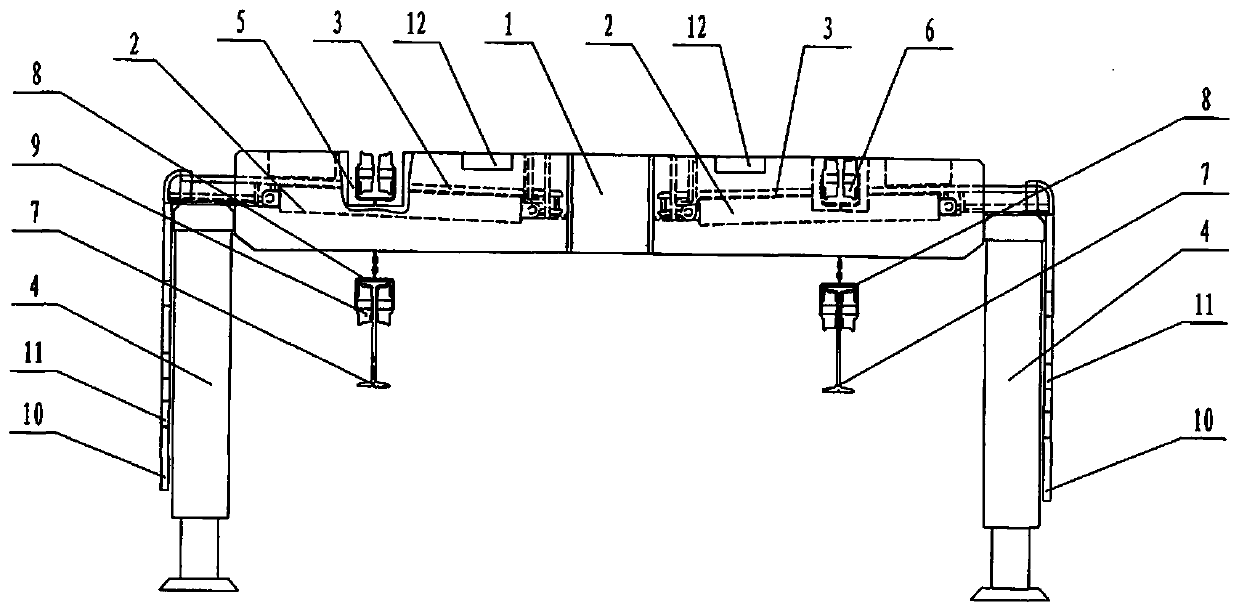

The invention discloses a mineral transport automatic butt joint system and relates to mineral transport equipment. The mineral transport automatic butt joint system utilizes a telescoping oil cylinder to adjust platform height, utilizes a hoisting device to hoist a transport belt vehicle, utilizes a hydraulic suspension positioner to position the belt vehicle and utilizes a near sensor to detect a butt joint position so that automatic butt joint of the transport belt vehicle and the butt joint device is realized. The number and length of the transport belt vehicles are automatically increased to appropriate values. The bottom in the system is provided with a belt conveying system connected to a transport truck or a mineral transport system. The mineral transport automatic butt joint system is especially suitable for places where continuous mining devices such as a coal cutter and a heading machine are used, and realizes long-distance automatic transport and automatic transport based on different distance. PLC controls a hydraulic valve block to realize automatic control operation. The mineral transport automatic butt joint system realizes seamless butt joint, greatly improves a mineral transport system and improves transport efficiency by more than 20%. Through connection with a heading machine and a coal cutter, cutting and transport synchronization is realized and a wide development space is provided.

Owner:TAISHAN MEDICAL UNIV

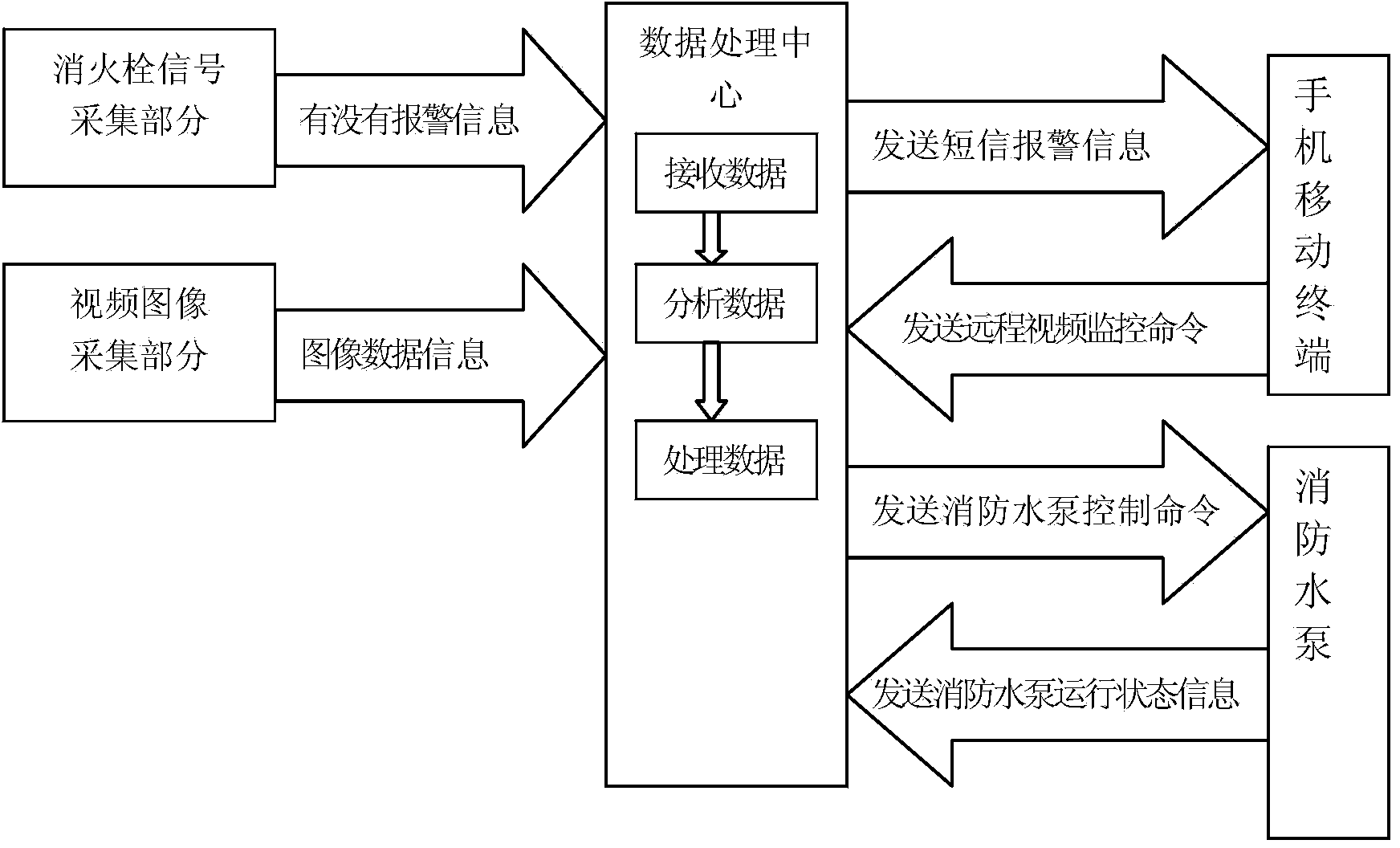

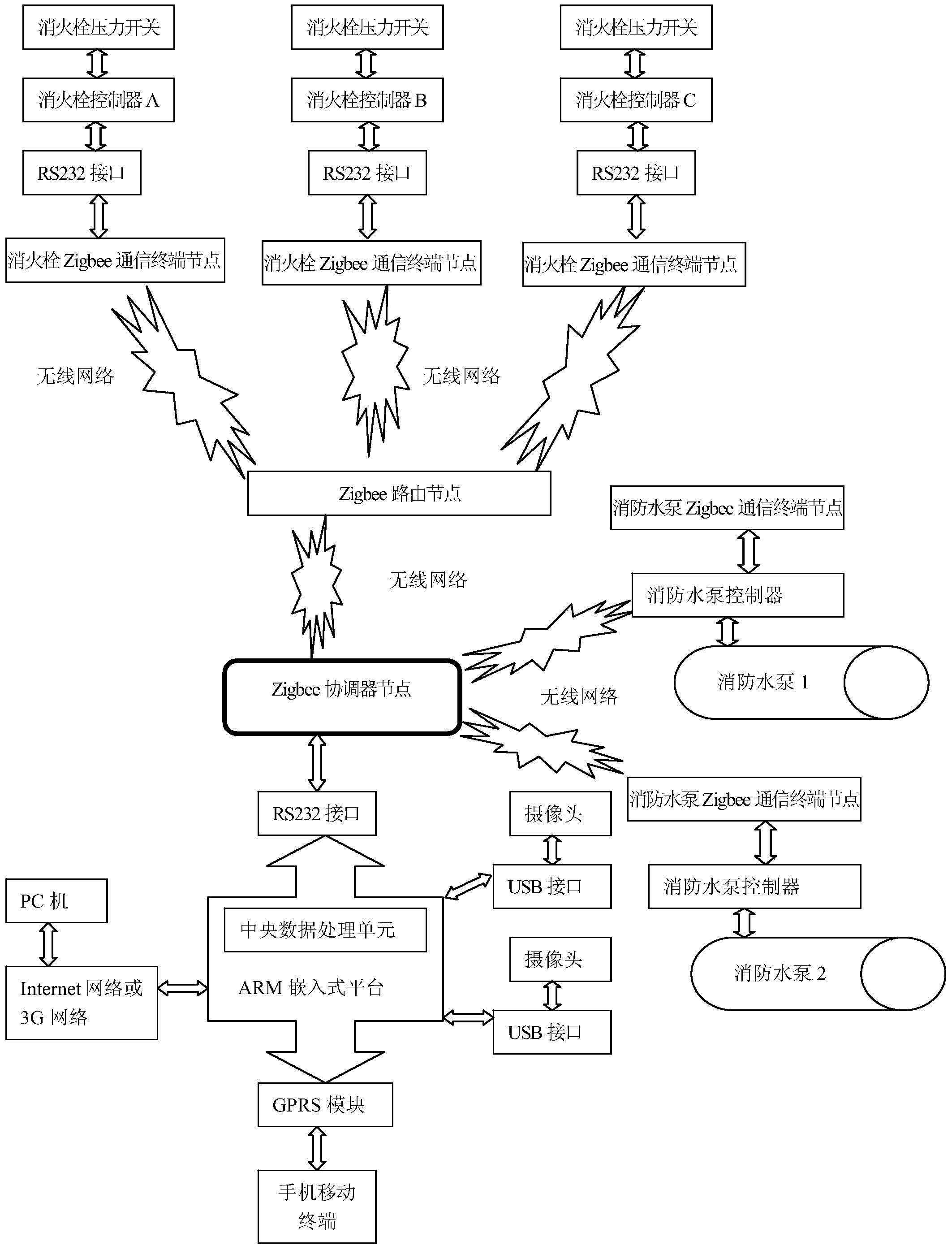

Fire pump linkage control system based on wireless sensor network and working method thereof

ActiveCN103949031ARemote control startRemote control operabilityFire rescueTransmissionEmbedded technologyAutomatic control

The invention discloses a fire pump linkage control system based on a wireless sensor network and a working method thereof. The fire pump linkage control system based on the wireless sensor network comprises a data processing center, a plurality of fire hydrant signal collecting parts, a wireless sensor network system and a plurality of fire pump control parts. The fire pump linkage control system based on the wireless sensor network integrates an embedded technology of an internet of things system, a Zigbee wireless communication technology and basic procedures of the fire pump linkage control systems and is capable of ensuring that fire-fighting and warning signals reach a fire pump control room in a wireless network transmission manner, so that the automatic control operation of fire pumps is realized, and the linkage control management of the fire pumps develops towards the intellectualization direction.

Owner:苏州创彦物联网科技有限公司

Convenient building construction equipment

InactiveCN107093817AReduce laborRealize automatic control operationCoupling device detailsBridge erection/assemblySoftware engineeringPower transmission

The invention discloses convenient building construction equipment, which comprises a power transmission cabinet and a hanging bracket, and is characterized in that the power transmission cabinet is internally provided with a first sliding connection cavity, the inner bottom end of the first sliding connection cavity is provided with a movement-guiding sliding connection groove, the first sliding connection cavity is internally provided with a first screw connection rod which is arranged in a transversely expanding manner, the left end of the first screw connection rod is connected with a first motor, the first screw connection rod is matched with a first sliding connection block in a screw connection manner, the first sliding connection block is internally provided with a first sliding connection groove, the first sliding connection groove is internally provided with a movement-guiding sliding connection rod which is arranged in a transversely expanding manner, the movement-guiding sliding connection rod is connected with a second sliding connection block in a matched sliding connection manner, the bottom of the second sliding connection block penetrates into the movement-guiding sliding connection groove and is connected with the movement-guiding sliding connection groove in a matched sliding connection manner, the second sliding connection block is internally provided with a second sliding connection cavity, the second sliding connection cavity is internally provided with a third sliding connection block, the bottom of the third sliding connection block is provided with a first compression spring, the bottom of the third sliding connection block is provided with a pushing sliding connection block which longitudinally penetrates through the bottom end face of the second sliding connection block, the bottom of the pushing sliding connection block is provided with an engagement segment, and the bottom of the engagement segment is provided with a transfer wheel. The building construction equipment is simple in structure, convenient to operate, capable of automatically operating, providing power and plugging, convenient to install and remove and high in safety.

Owner:SHISHI CHUANLANG MACHINERY DESIGN CO LTD

Noninvasive and minimally invasive detection and diagnosis device

InactiveCN108478194AEasy to detect and diagnoseEasy to operateOperating tablesCoupling device detailsAutomatic controlDisplay device

The invention discloses a noninvasive and minimally invasive detection and diagnosis device which comprises a device body, a left containing groove and a right containing groove. The left containing groove and the right containing groove are arranged on the top end face of the machine body, are in left-right symmetry arrangement and extend downwards, and a protruding seat is fixedly arranged at aposition, between the left containing groove and the right containing groove, on the top end face of the device body. The device is convenient and quick in operation, small in size and capable of realizing automatic control operation, and a displayer and a diagnostor can be controlled to extend when needed for the convenience of detecting and diagnosing conditions of a patient; the displayer and the diagnostor can be automatically on after extending and can be automatically off after contracting, so that electric shock accidents are prevented effectively, and usability and stability of the device are improved; by arranging four moving rollers, using range of the device is widened greatly, and maneuverability of the device is improved.

Owner:慈溪市隆诚贸易有限公司

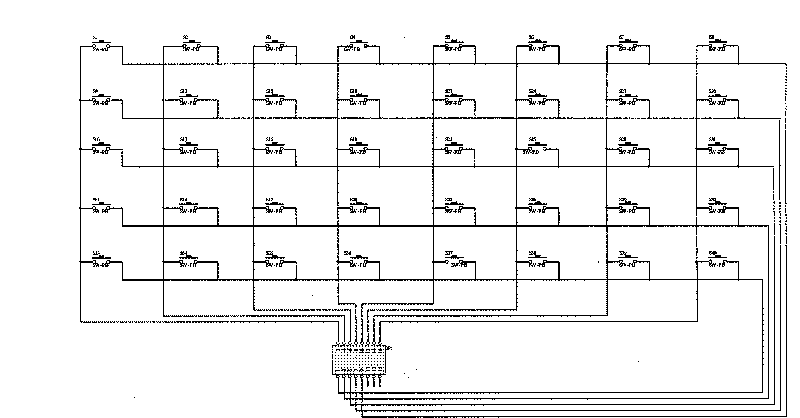

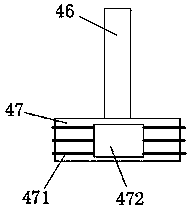

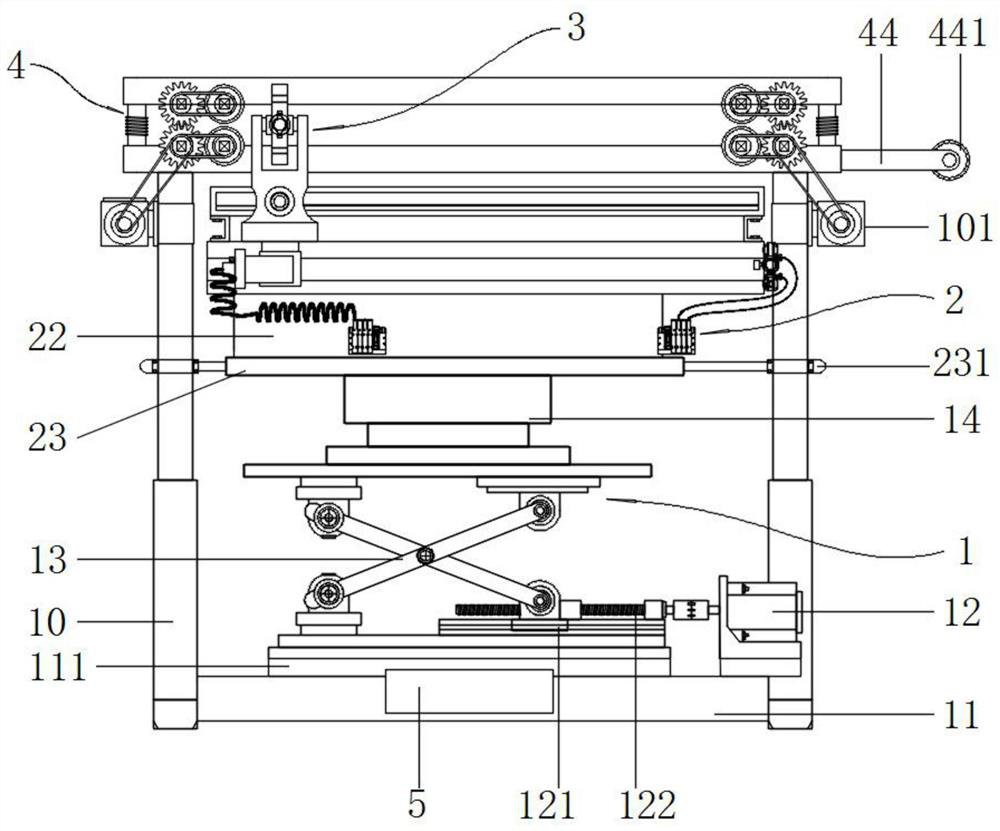

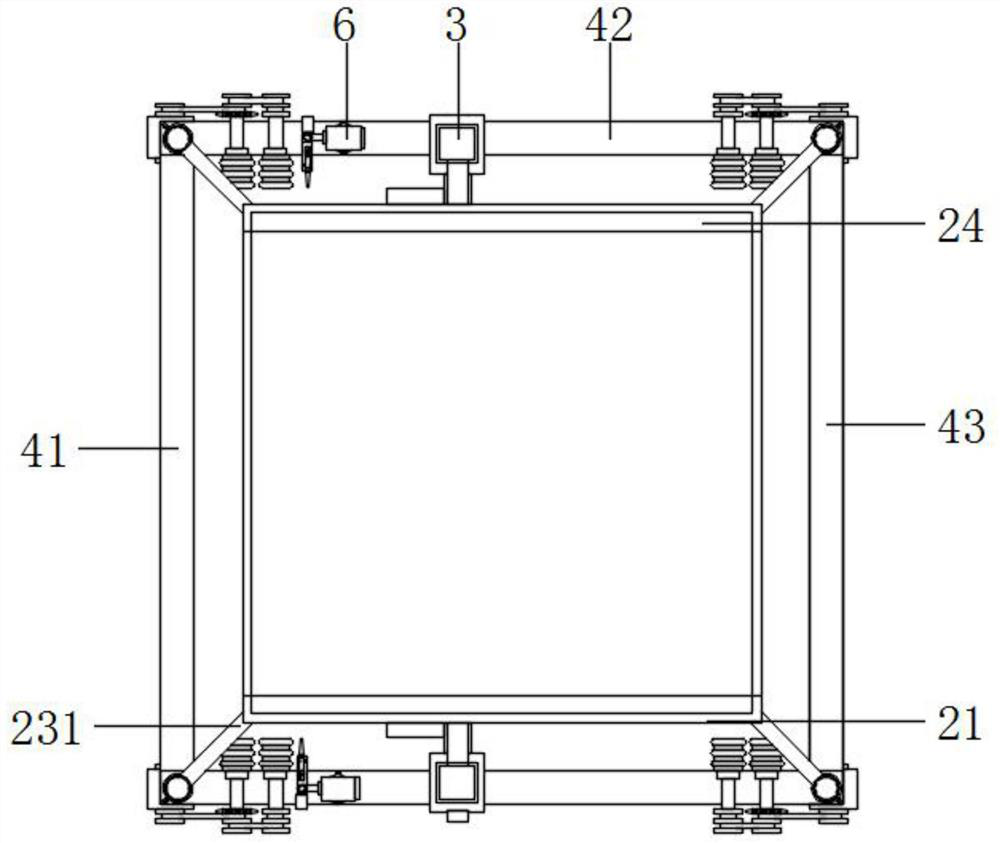

Automatic rack equipment of textile embroidery machine

The invention discloses automatic rack equipment of a textile embroidery machine, and relates to the technical field of embroidery machines. The automatic rack equipment comprises a lifting device, the lifting device is mainly composed of hydraulic support rods, a base, a motor B, a shear fork frame and an I-shaped table, the hydraulic support rods are vertically mounted at four corners of the base, a sliding table is arranged in the center of the top of the base, the motor B is mounted on one side of the sliding table, the shear fork frame is mounted at the top of the sliding table, one footof the shear fork frame is fixedly connected to the position, close to the front end, of the surface of the sliding table, the bottom of the other foot of the shear fork frame is connected with a sliding block A, the bottom of the sliding block A is in relative sliding connection with the sliding table, and a screw rod is arranged in the sliding block A in a penetrating mode. The position of embroidery cloth can be automatically adjusted, so that the embroidery cloth is effectively matched with a machine head to continuously carry out long-pattern embroidery, manual adjustment is not needed, the burden of workers is reduced, meanwhile, the distance between embroidery cloth and the machine head can be effectively adjusted, embroidery precision and work efficiency are improved, and pattern errors are reduced.

Owner:周建明

Portable dust remover

InactiveCN107134686AReduce laborRealize automatic control operationEngagement/disengagement of coupling partsEngineeringScrew thread

The invention discloses a portable dust remover, and the dust remover comprises a power-on platform and a hanging rack. The interior of the power-on platform is provided with a first sliding cavity, and the internal bottom of the first sliding cavity is provided with a guide chute. The interior of the first sliding cavity is provided with a first stud which is extended laterally. The left side end of the first stud is in power connection with a first power unit, and the first stud is in screw-thread fit connection with a first sliding block. The interior of the first sliding block is provided with a first chute. The interior of the first chute is provided with a guide sliding rod which extends laterally. The guide sliding rod is in smooth fit connection with a second sliding block, and the bottom of the second sliding blocks is pushed into the guide chute and achieves the smooth fit connection. The interior of the second sliding block is provided with a second sliding cavity, and the interior of the second sliding cavity is provided with a third sliding block. The bottom of the third sliding block is provided with a first elastic piece, and is also provided with a press sliding block which passes through the bottom end face of the second sliding block. The bottom of the press sliding block is provided with a connection segment, and the bottom of the connection segment is provided with a rotating wheel. The dust remover is simple in structure, is convenient to operate, can achieve the operation and power supply plugging, is convenient for installation and disassembly, and is high in safety.

Owner:南安市申达鑫通商贸有限公司

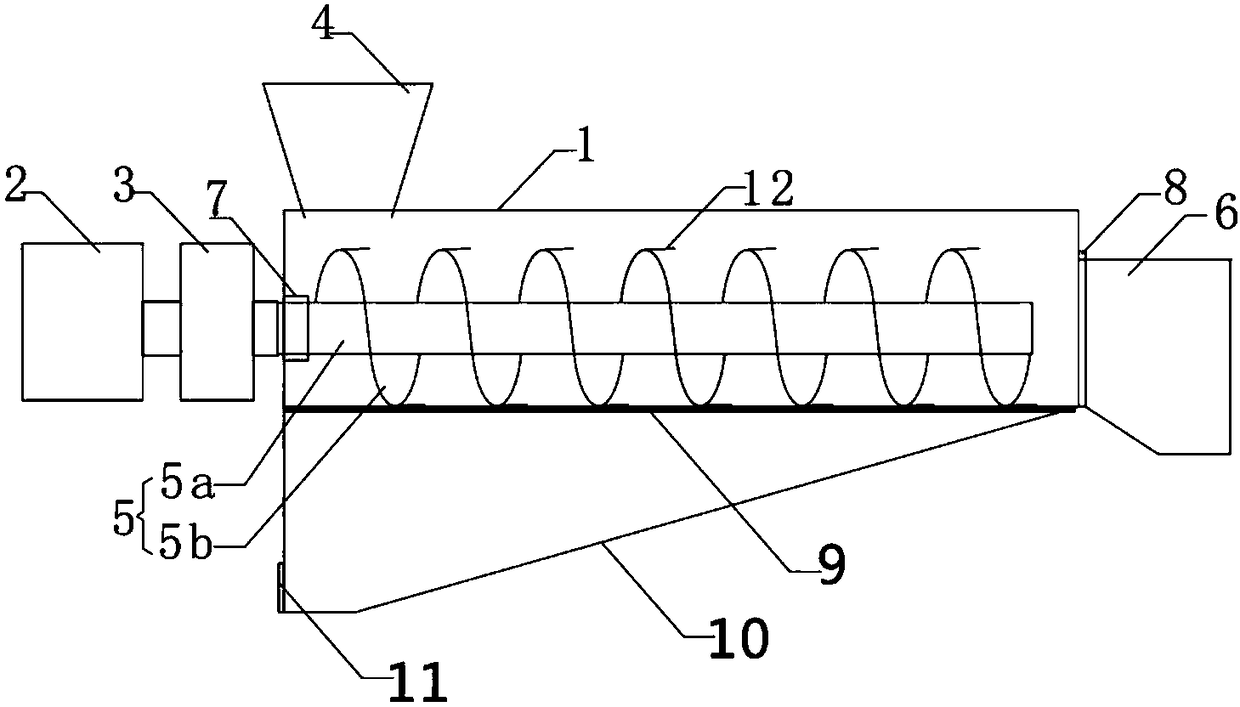

Device for treating and storing traditional Chinese medicine residues

InactiveCN108220129AReduce pollutionEasy maintenanceBioreactor/fermenter combinationsBiological substance pretreatmentsMedicineReducer

The invention relates to a device for treating and storing traditional Chinese medicine residues. The device comprises a traditional Chinese medicine residue squeezing device and a traditional Chinesemedicine residue storage device, wherein a feeding hole of the traditional Chinese medicine residue squeezing device is welded on a screw presser housing, and a squeezing motor and a speed reducer are positioned outside the screw presser housing; a squeezing cavity is formed in the screw presser housing; a squeezing packing auger comprises a rotating shaft and a stirring blade; the squeezing motor is connected with the speed reducer; an output shaft of the speed reducer is connected with the rotating shaft, and a bearing seat is arranged at the end of the rotating shaft; a residue outlet is welded at the tail of the screw presser housing, and a residue outlet switch board is arranged at the residue outlet; an outer barrel support of the traditional Chinese medicine residue storage deviceis welded with a storage shell so as to form a whole; an inner barrel rotary disc is positioned in the storage shell and is connected with an inner barrel rotating motor positioned at the bottom end of the storage shell; a storage inner barrel is arranged in the storage shell and is movably arranged on the inner barrel rotary disc; a residue storage feeding hole is formed in the top of the storageshell; an end cover is arranged on the residue storage feeding hole. After the traditional Chinese medicine residues are squeezed, the water content is reduced to about 30%.

Owner:TIANJIN UNIV

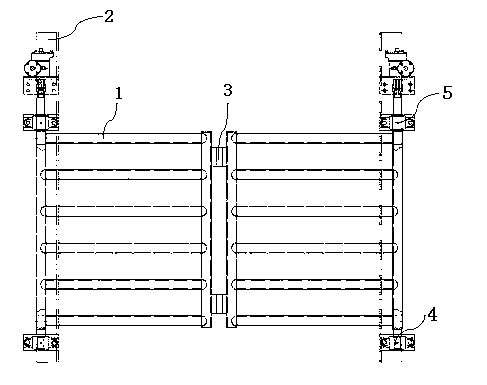

Safety gate

InactiveCN103213892ACompact and reasonable structureEasy maintenanceMine liftsAutomatic controlProgrammable logic controller

The invention discloses a safety gate and belongs to the technical field of mine caging. The safety gate comprises two gate bodies which are matched with each other in opening and closing. The gate bodies are respectively hinged on a gate post through bearings. Each bearing comprises a bearing block and a bearing block base which are matched in use. A hydraulic system controlling the gate bodies to be opened and closed is respectively arranged between each gate body and the corresponding gate post. Each hydraulic system controlled by a programmable logic controller (PLC) module comprises a rack oil cylinder and a coupler which are mutually connected and each coupler is connected with the corresponding gate body. The safety gate is reasonable and compact in structure, easy to maintain and repair, capable of achieving automatic control operation, avoiding fault caused by manual operation, facilitating transportation of materials and devices large in length or size, shortening a transporting cycle and improving transporting capability and suitable for being popularized and used in production operation.

Owner:江苏金宏泰科技股份有限公司

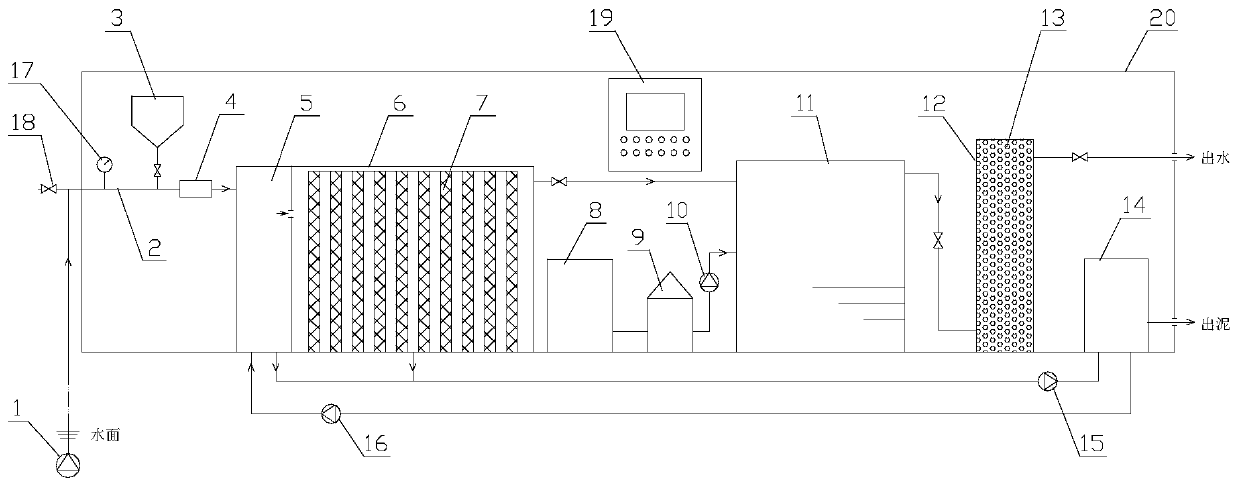

Energy-saving efficient integrated wastewater treatment device

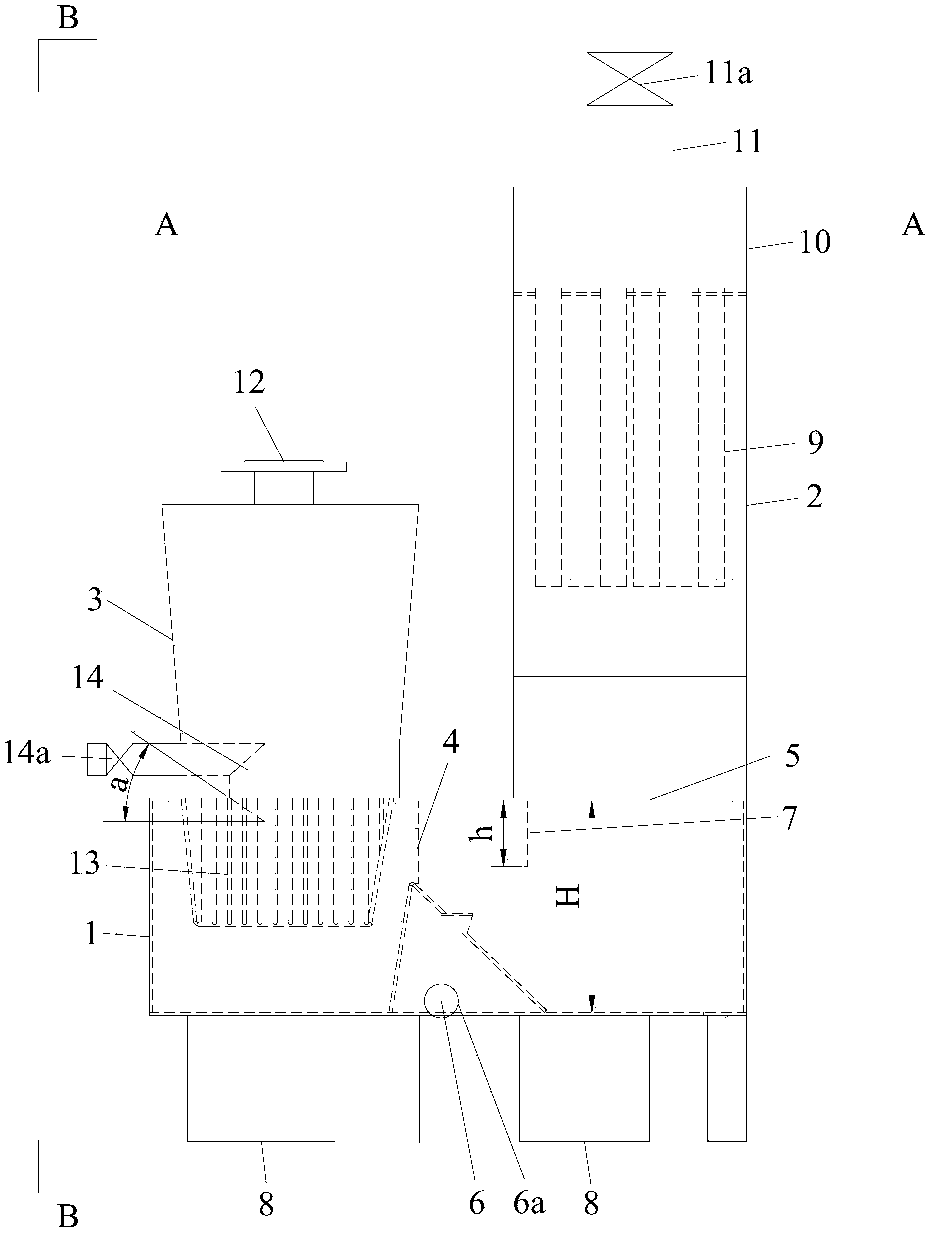

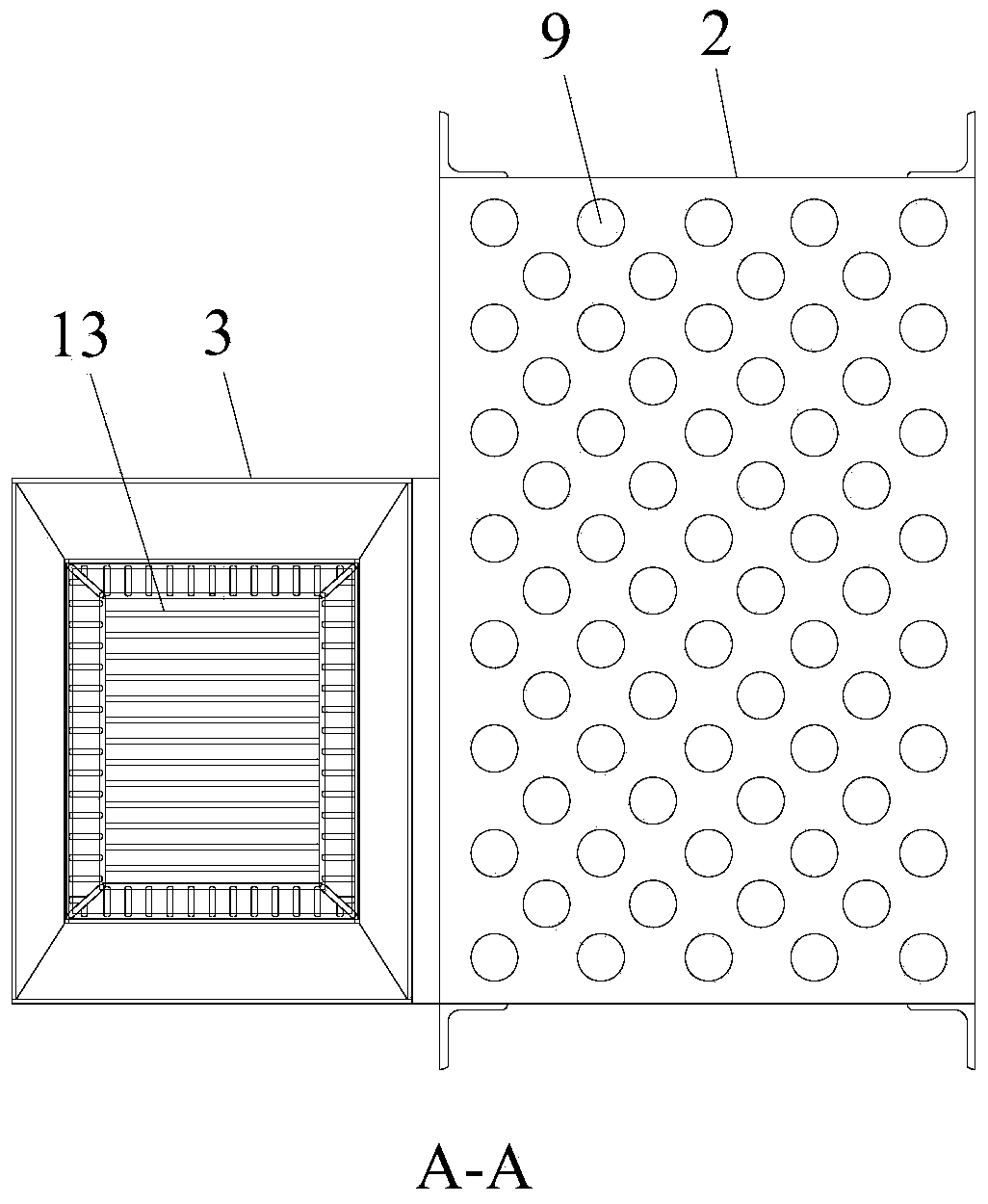

PendingCN106082559AThe device is compactSmall footprintWater treatment parameter controlWater contaminantsSmall footprintNational level

The invention discloses an energy-saving efficient integrated wastewater treatment device. The energy-saving efficient integrated wastewater treatment device comprises a baffling chemical feeding and mixing trough and an advanced oxidation reactor. A baffling channel is formed in the baffling chemical feeding and mixing trough, one end of the baffling channel is connected on an inlet water lifting pump, the other end of the baffling channel is connected on the advanced oxidation reactor through a pipe, and a plurality of folded plates are evenly distributed in the baffling channel. A separating folded plate is arranged at the top of the advanced oxidation reactor and divides the advanced oxidation reactor into a first reaction area and a second reaction area, a water inlet is formed in the top of the first reaction area, a water outlet is formed in the top of the second reaction area, annular perforated aerator pipes are arranged at the bottoms of the first reaction area and the second reaction area respectively, a baffle with meshes is arranged at the bottom of the first reaction area, a filler area is arranged on the baffle with the meshes, and the filler area is filled with particle filler. The energy-saving efficient integrated wastewater treatment device is compact in structure, small in occupied area and high in treatment efficiency; waste water is subjected to decoloring and COD reduction treatment with an advanced oxidation method, and it is guaranteed that the treated wastewater meets the requirements of the national-level A standard.

Owner:江苏艾特克环境工程设计研究院有限公司 +1

Self-suction environment-friendly gasification inverse combustion heating furnace

InactiveCN104019444AReal-time adjustment of combustion operating loadCompact structureSolid fuel combustionCombustion apparatusCombustion chamberSlag

The invention discloses a self-suction environment-friendly gasification inverse combustion heating furnace. The self-suction environment-friendly gasification inverse combustion heating furnace comprises a combustion chamber, a heat exchange chamber and a gasification chamber. The combustion chamber is arranged horizontally, the gasification chamber and the heat exchange chamber are vertically distributed above the combustion chamber, and therefore a U-shaped furnace body structure for gasification sectional combustion is formed. A turbulent flow baffle extends downwards from the position, close to a first channel, of the inner side of a top plate of the combustion chamber, and the positions, corresponding to the gasification chamber and the heat exchange chamber, of the bottom of the combustion chamber are respectively provided with a slag pit. An air supply port is formed in the combustion chamber, a smoke discharging pipeline enabling negative pressure to be formed in the U-shaped furnace body structure is arranged at the top of the heat exchange chamber, a gasification agent supply port is formed inside the gasification chamber, and the air supply port, the smoke discharging pipeline and the gasification agent supply port are provided with valves used for regulating and controlling operating conditions of the U-shaped furnace body structure together. The self-suction environment-friendly gasification inverse combustion heating furnace is simple in structure, convenient and rapid to operate, high in combustion efficiency, low in environment pollution, and capable of reducing investment cost and operating cost.

Owner:GUANGDONG EMICRONET NEW ENERGY TECH

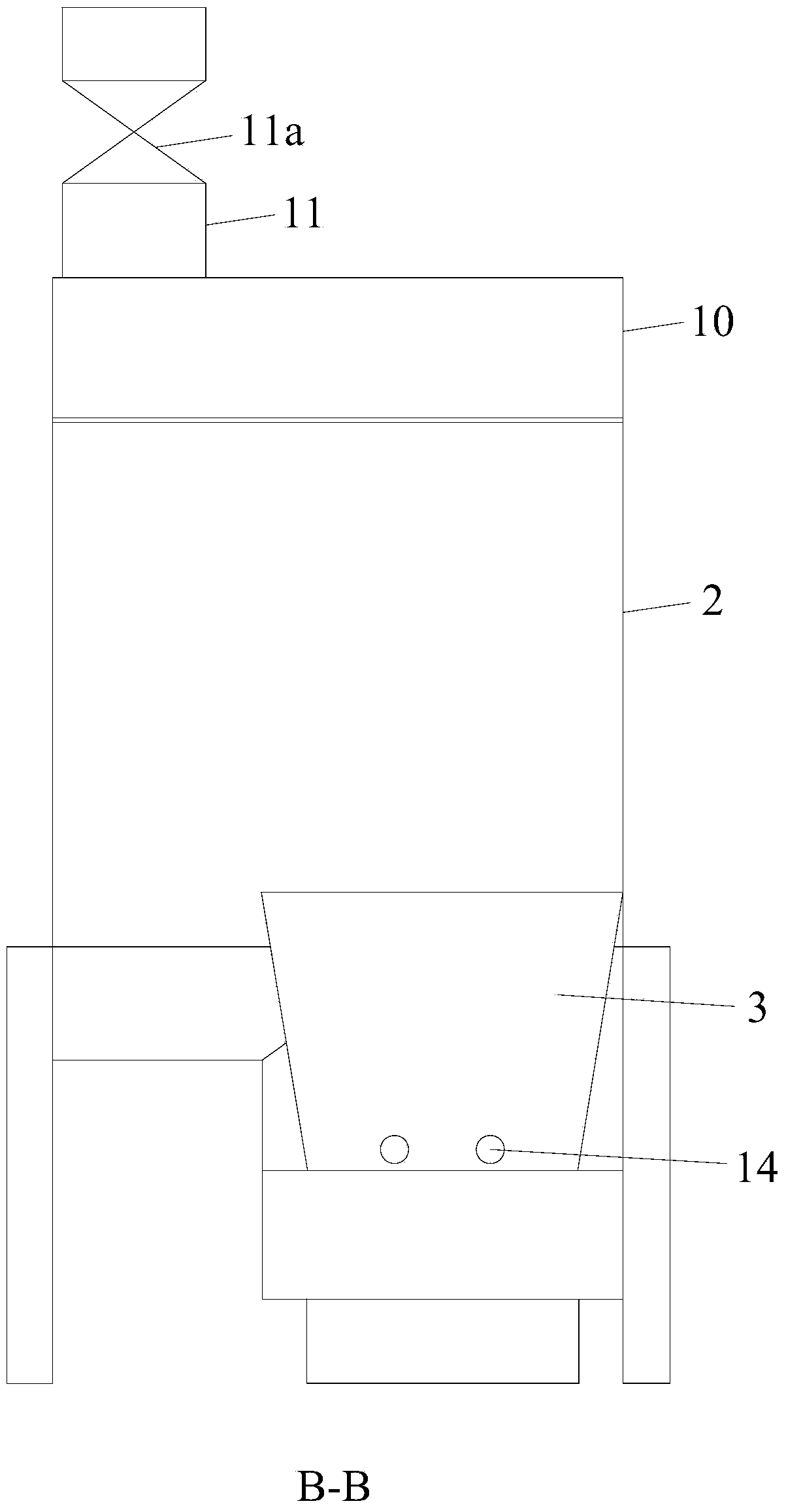

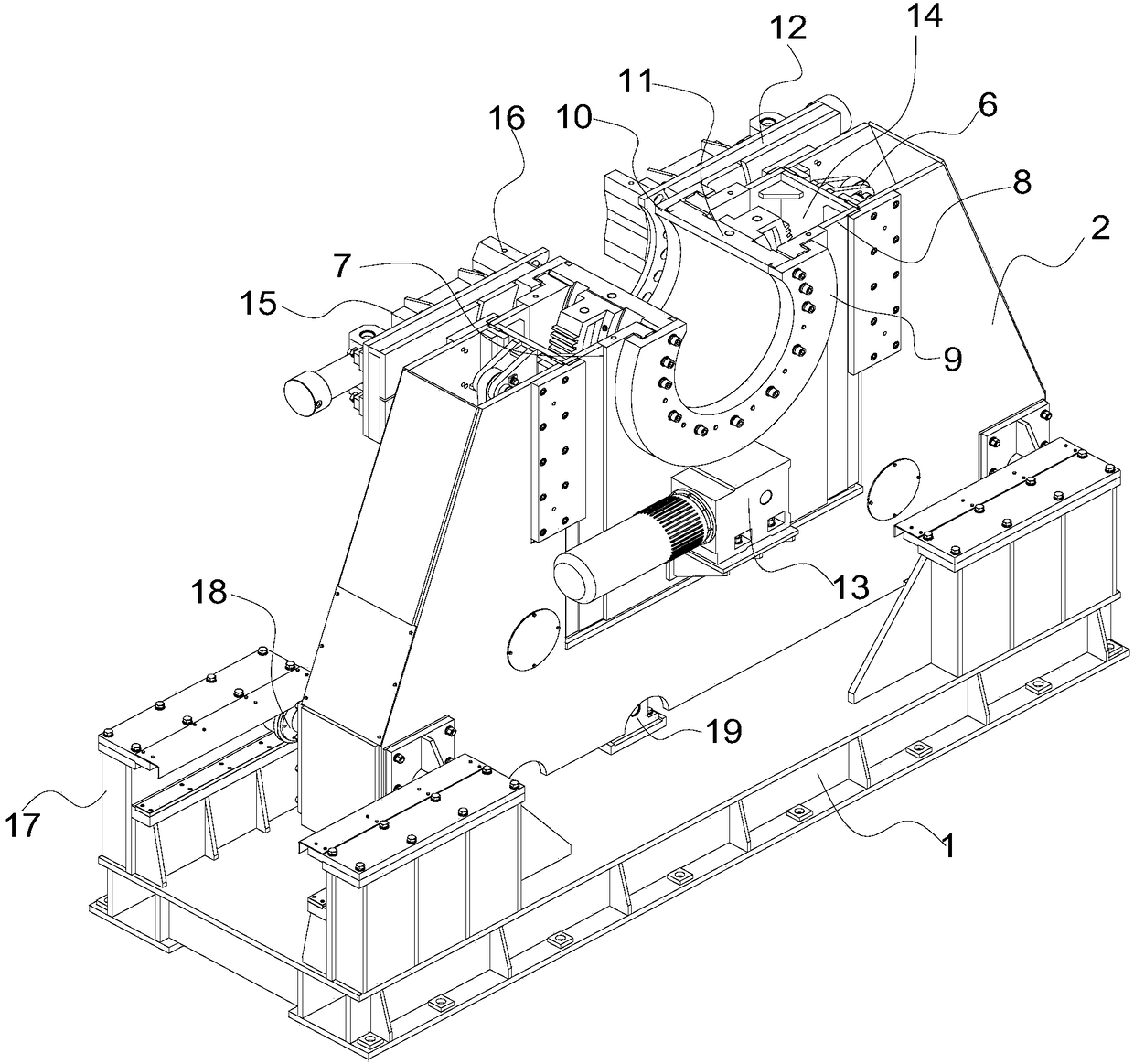

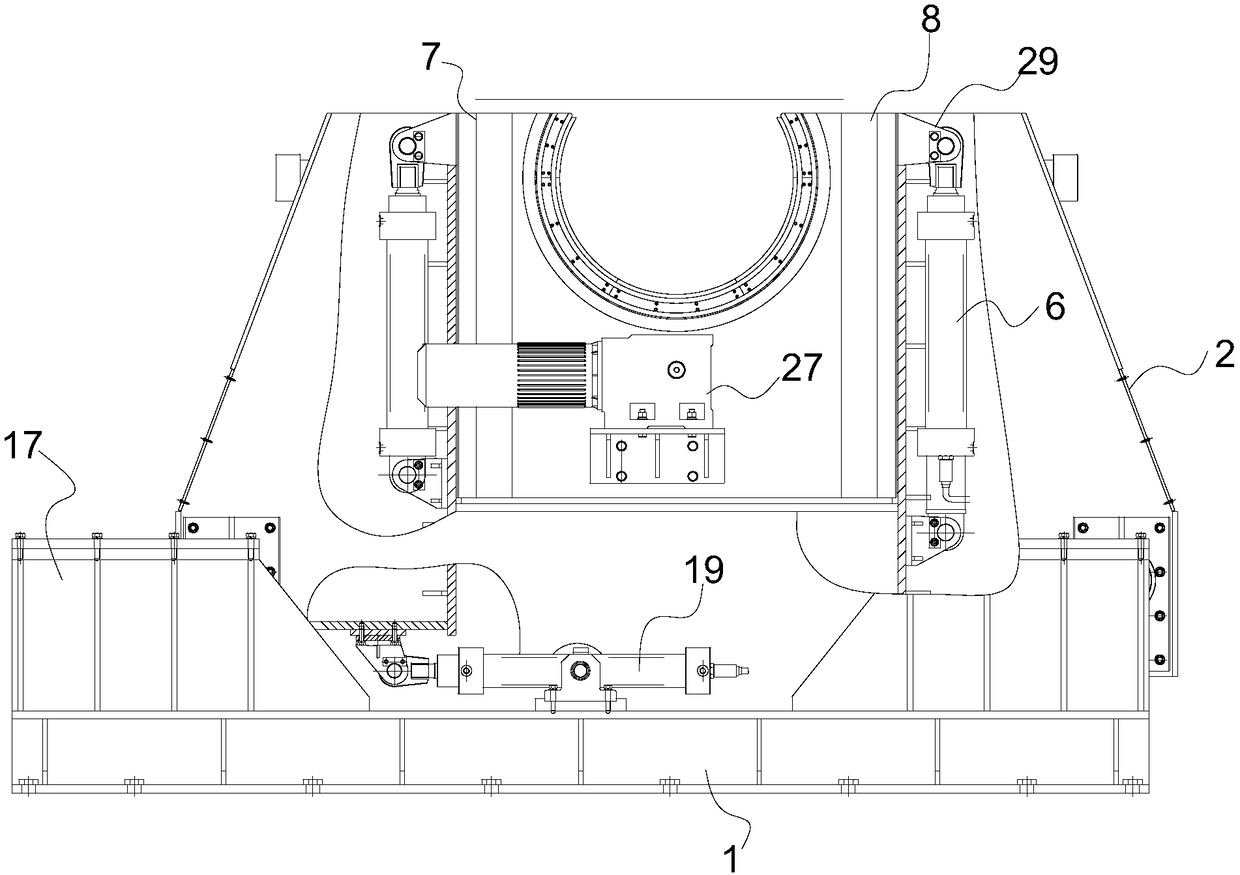

Turnover machine

PendingCN108580588ARealize automatic control operationStable performanceMetal-working feeding devicesPositioning devicesAutomatic controlVehicle frame

The invention discloses a turnover machine. The turnover machine comprises a base, a machine frame, a lifting mechanism, a rotary mechanism and a clamping mechanism, wherein the lifting mechanism comprises a first lifting frame, a second lifting frame, a first backing ring and a second backing ring; the rotary mechanism is connected between the first backing ring and the second backing ring in a sliding manner and comprises a rotary part, a rotary support and a driving mechanism which is arranged in the machine frame and is used for driving the rotary part to rotate; rotary space for the rotation of the rotary part is formed between the rotary part and the first lifting frame and between the rotary part and the second lifting frame; the clamping mechanism comprises clamping oil cylinders arranged at the two ends of a circular arc opening of the rotary support, and clamping heads connected to the ends, close to the circular arc opening, of the clamping oil cylinders; and two clamping heads are oppositely arranged. The accurate overturning of straightening materials is realized through the transverse movement, lifting, rotation and clamping of the turnover machine. The turnover machine integrates machinery, electricity and liquid, can realize automatic control operation, is safe and reliable, has stable performances and high result intensity and is simple to operate.

Owner:成都莱克冶金机械设备制造有限公司

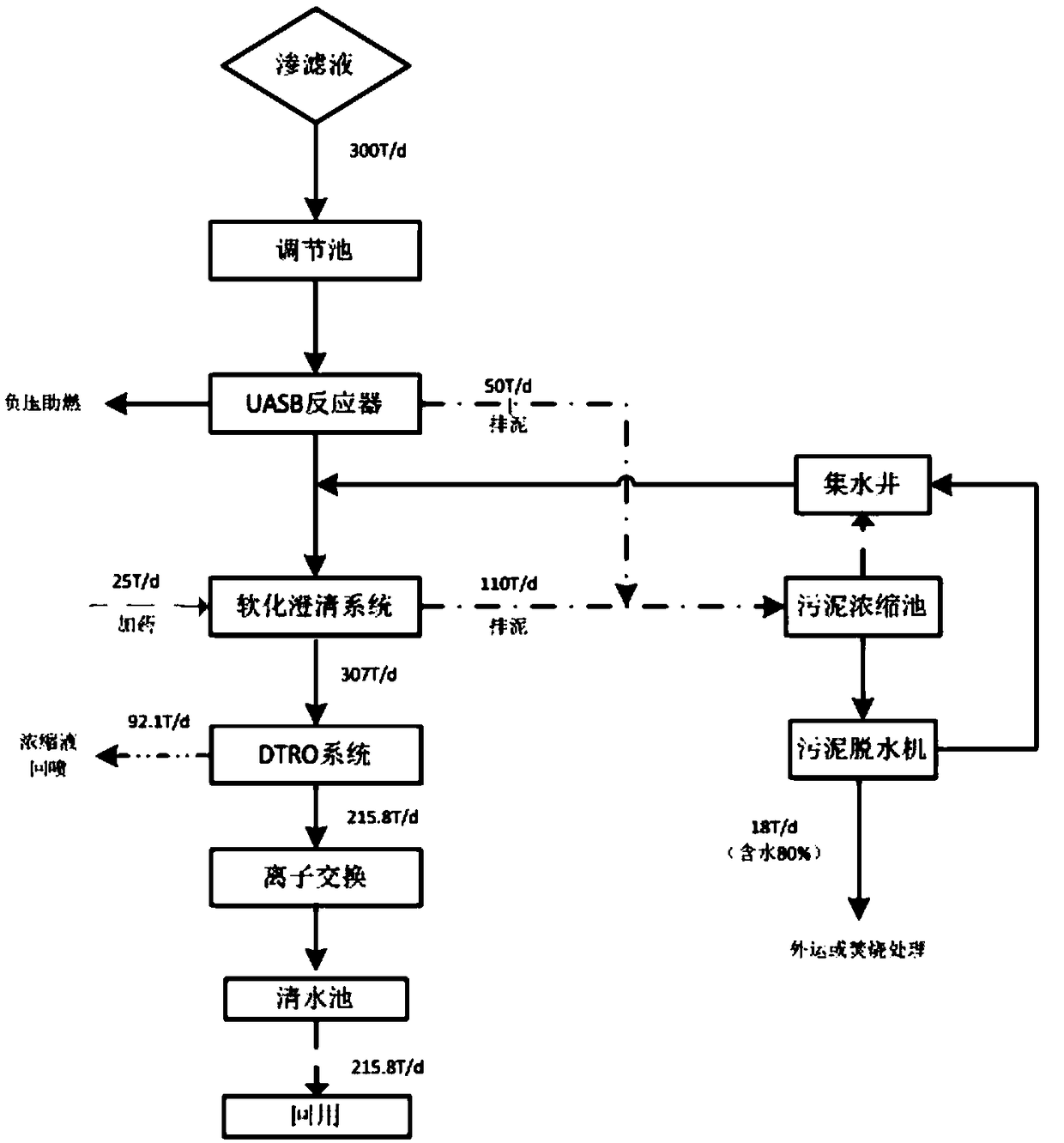

Treatment method for landfill leachate in incineration plant

InactiveCN109231721ALow running costLow construction costScale removal and water softeningTreatment involving filtrationIon exchangeOperational maintenance

The invention provides a treatment method for landfill leachate in an incineration plant. The treatment method comprises the steps that raw landfill leachate is subjected to anaerobic reaction treatment and reverse osmosis treatment. Preferably, the treatment method further comprises the steps of pretreatment, chemicals feeding for softening and flocculation precipitation treatment, and ion exchange treatment. A process and equipment which are high in energy consumption and operating cost are avoided, so that the operating cost is greatly lowered. The treatment method has a good operating, operation and maintenance environment, and is very important in the aspects of prolonging the service life of a system and ensuring stable operation of the system; and most operation can be automaticallycontrolled, engineering operation is stable, and the service life of a film assembly is long.

Owner:BEIJING TDR ENVIRON TECH CO LTD

Intelligent traffic information acquisition device

InactiveCN108506677AEasy to viewEasy maintenanceClosed circuit television systemsStands/trestlesAutomatic controlEngineering

The invention discloses an intelligent traffic information acquisition device. The intelligent traffic information acquisition device comprises a supporting column fixed on a road, and a protective plate fixedly arranged on the top of the supporting column, wherein an acquisition device which can slide up and down is arranged at the right end of the supporting column; a lifting driving device is used for driving the acquisition device to lift up and down, thus facilitating the maintenance of the acquisition device and causing a monitoring probe in the acquisition device to be conveniently installed and disassembled; a rotation driving device is used for driving the monitoring probe so as to adjust the angle of the monitoring probe, thus facilitating the monitoring probe to shoot and acquire information of illegal vehicles on road surfaces at different angles; and the monitoring probe is automatically deenergized during disassembly, thus avoiding electric shock accidents. The shooting and acquisition range of the monitoring probe is greatly widened; the illegal vehicle information acquisition efficiency of the monitoring probe is improved; the automatic control operation is realized; and the manufacturing cost of the device is reduced.

Owner:福州和信城电子科技有限公司

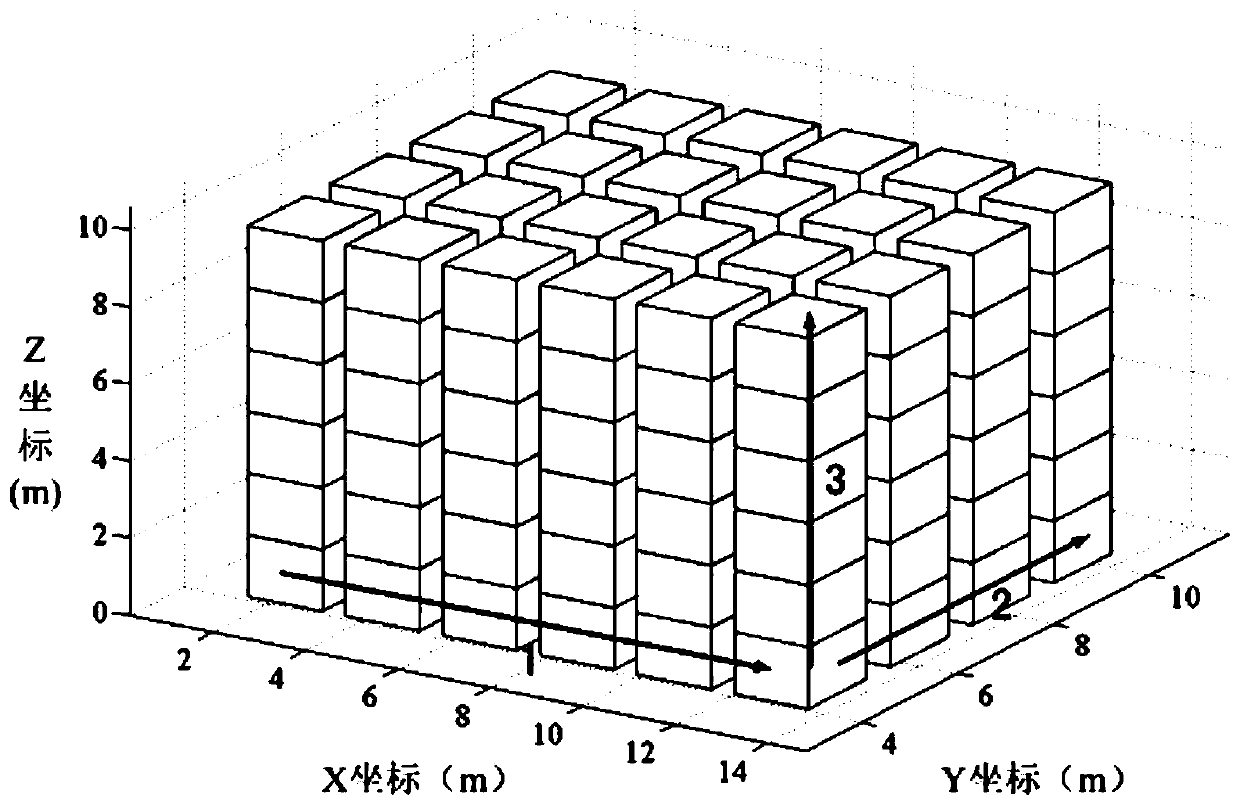

Crane cargo unloading sequence automatic generation method and system

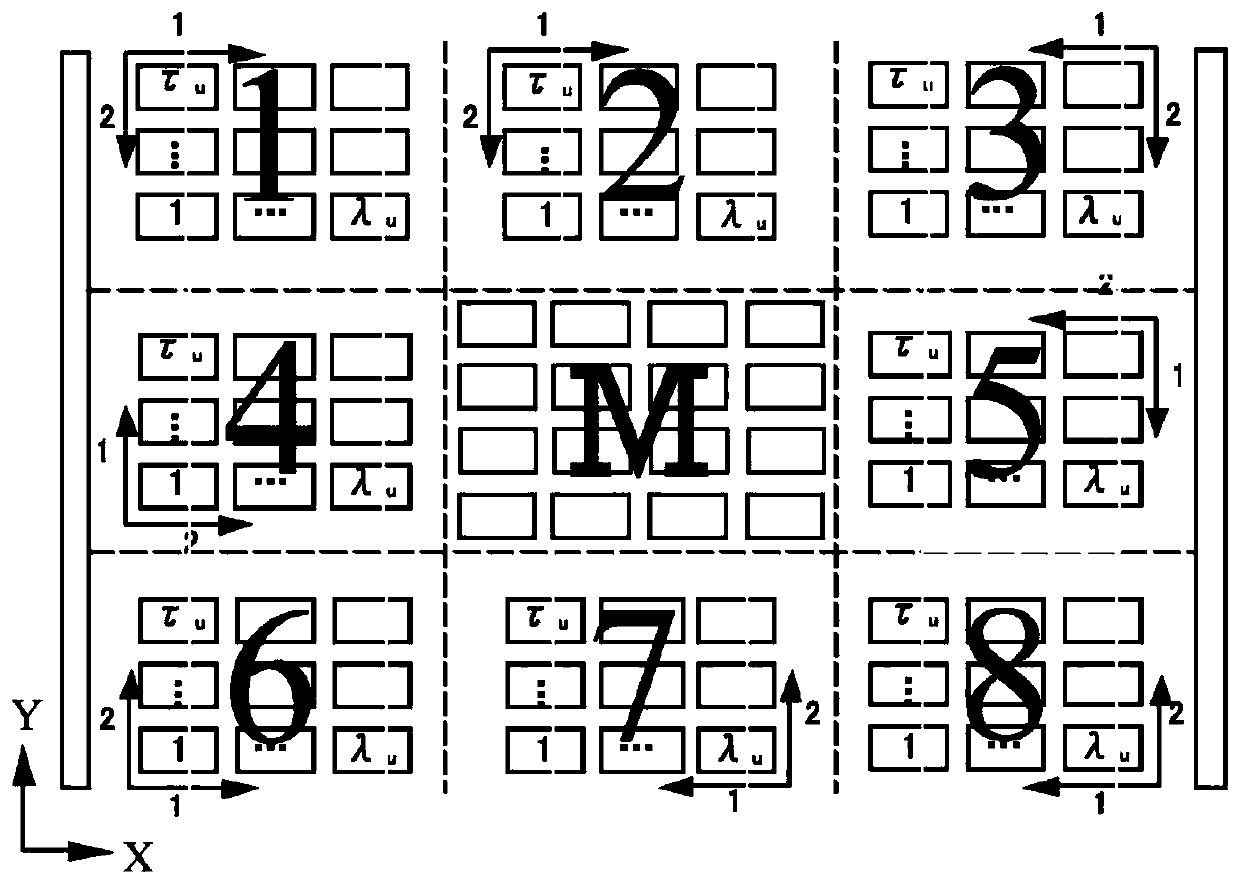

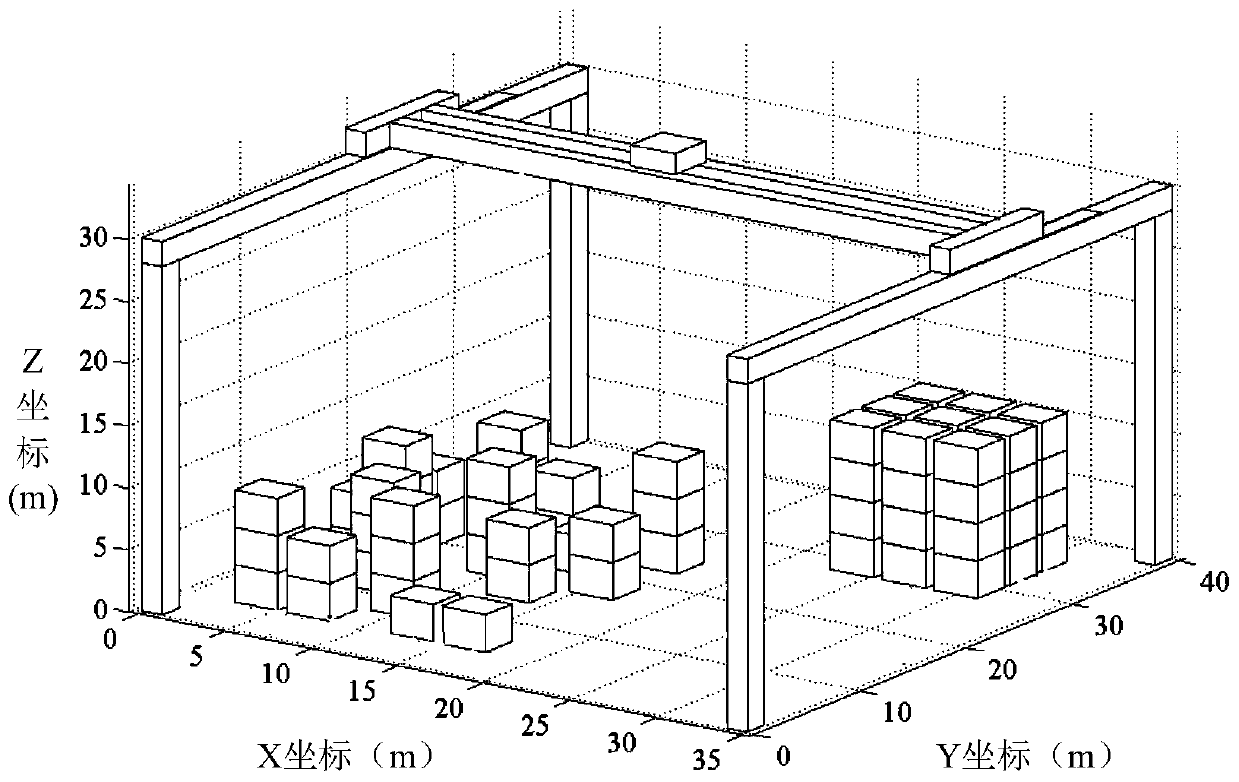

ActiveCN110888905ARealize automatic control operationRealize automatic continuous operationDigital data information retrievalDesign optimisation/simulationThree-dimensional spaceSequence database

The invention provides a crane cargo unloading sequence automatic generation method and system, and the method comprises the steps: defining a plurality of unloading regions at the periphery of an initial position before cargo handling according to the relative position relation of the unloading regions relative to the initial position before cargo handling; establishing a three-dimensional spacecoordinate system by taking limit position points of cargos loaded by the crane in three movement directions of large movement, small movement and vertical descending as original points and taking themovement directions of a small trolley, a large trolley and a hoisting mechanism of the crane as X, Y and Z directions respectively; establishing a corresponding relationship between the unloading position and a three-dimensional space coordinate system to obtain an unloading position information database of each unloading area; and formulating an unloading sequence rule for each unloading area,and rearranging the corresponding unloading position information database according to the unloading sequence rule to obtain an unloading sequence database. According to the method, a theoretical research method is organically combined with actual loading and unloading operation requirements and operation characteristics of the crane, and the cargo unloading sequence of the crane is automaticallygenerated.

Owner:APPLIED TECH COLLEGE OF SOOCHOW UNIV

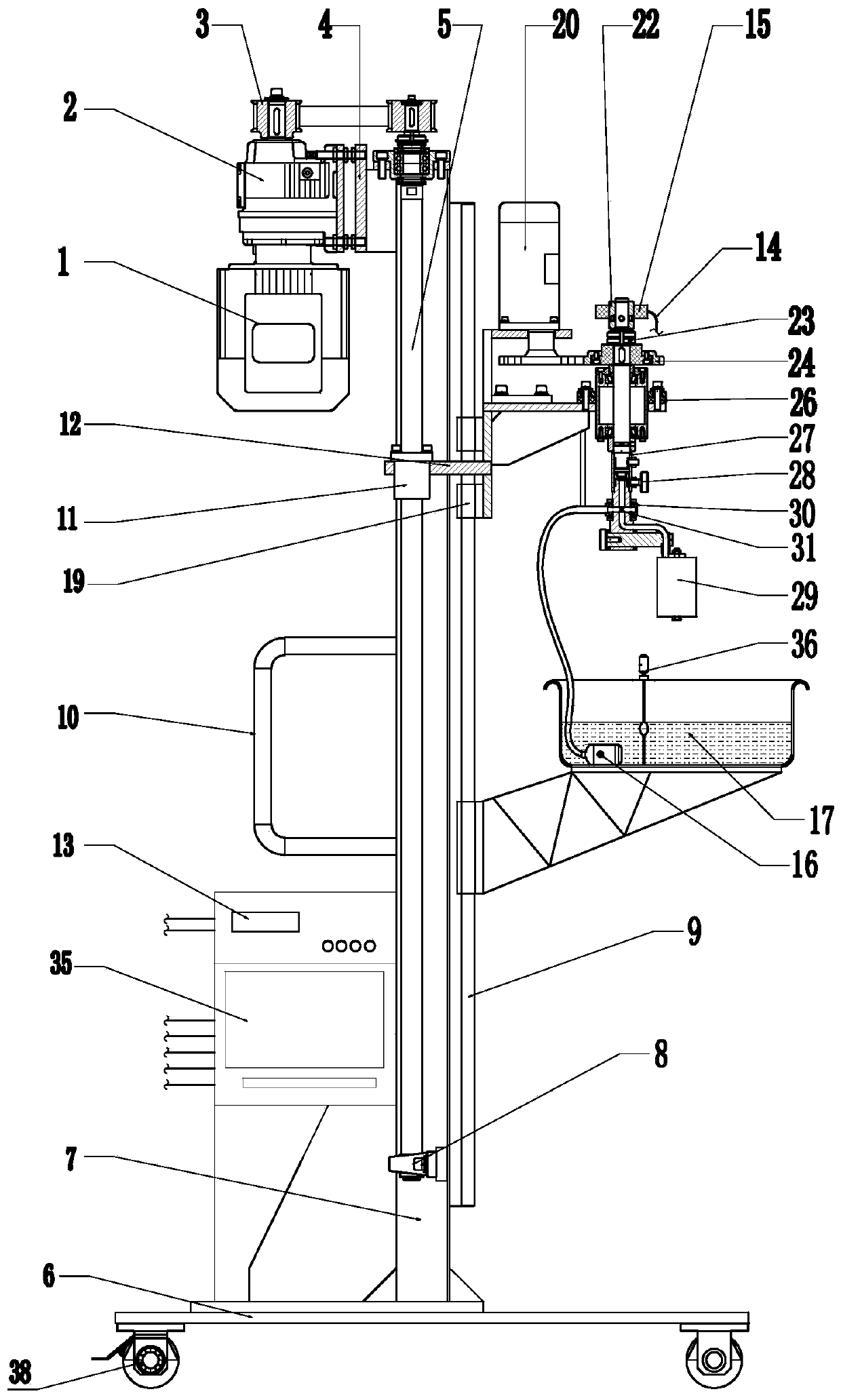

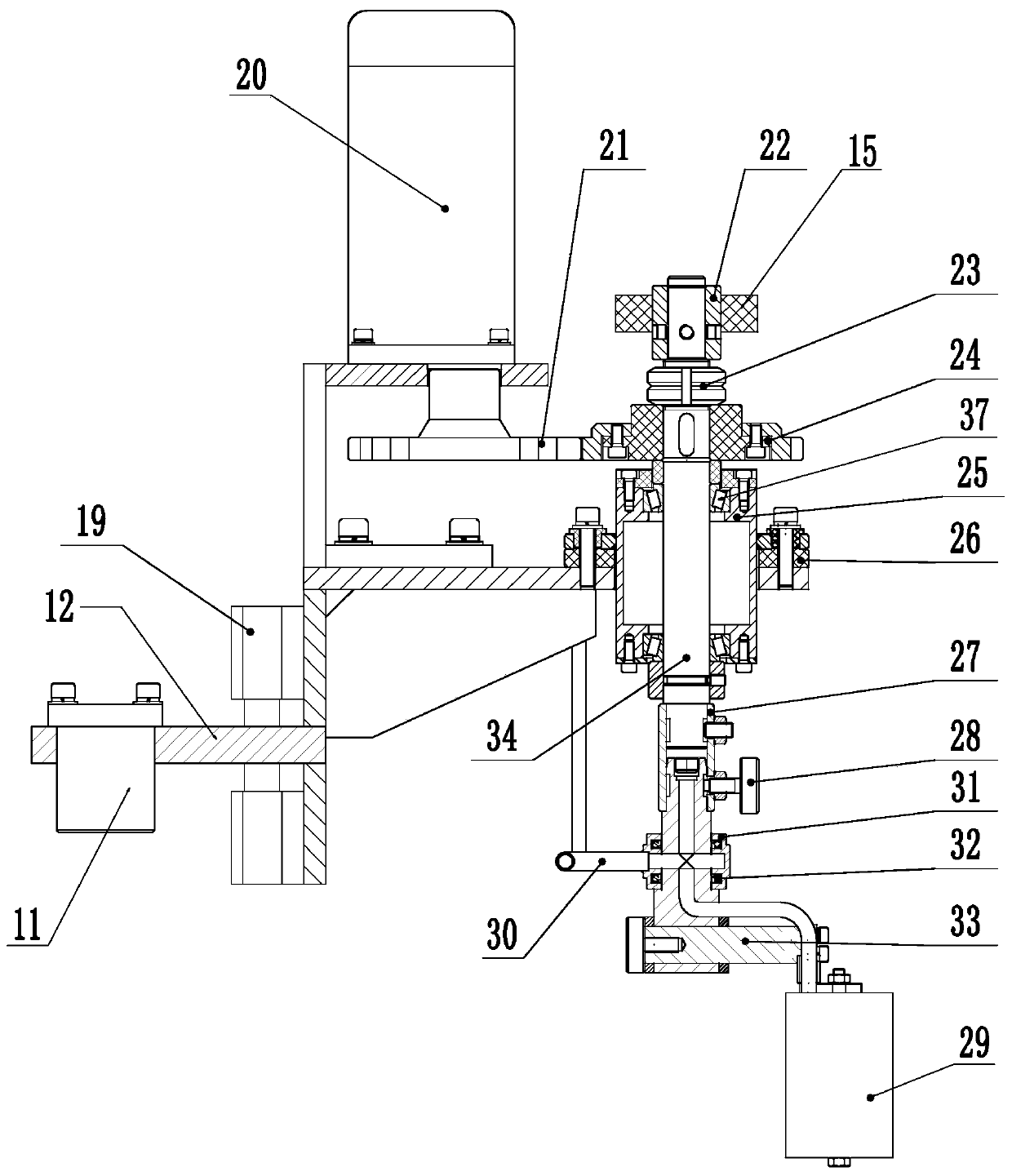

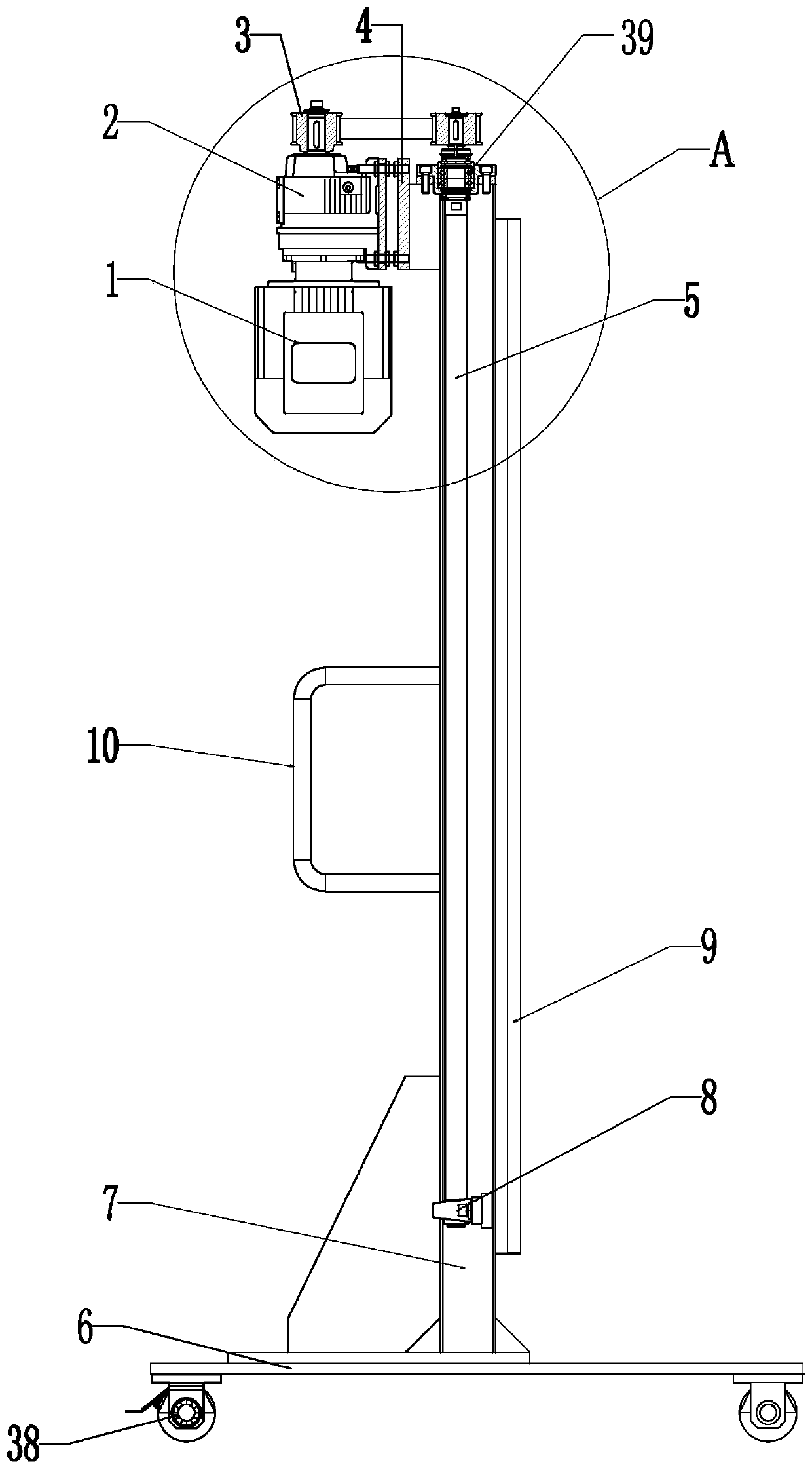

Automatic control type brushing plating device for spindle hole of engine

PendingCN110306218ARealize automatic controlRealize automatic control operationCellsAutomatic controlEngineering

The invention belongs to the technical field of engine component remanufacturing devices and provides an automatic control type brushing plating device for a spindle hole of an engine. The automatic control type brushing plating device for the spindle hole of the engine aims to solve the problem that an existing brushing plating device for engine spindle hole re-machining is unreasonable in structural design and instable in re-machining quality. A PLC programmable microcomputer controller adopted by the automatic control type brushing plating device for the spindle hole of the engine is connected with and controls a sliding connection seat mechanism, a brushing plating pen power supply mechanism, a brushing plating pen driving mechanism, a detachable and replicable type plating pen mechanism and a plating solution conveying pump through wires. An equipment base body mechanism comprises a moving locating trolley, a stand column, a bearing support, a bearing connection seat, a guiding sliding rod and a moving locating handle. The bearing support and the bearing connection seat are installed and connected on the stand column body, and the bearing support and the bearing connection seat are connected with a lifting power mechanism. The sliding connection seat mechanism and the brushing plating pen power supply mechanism are connected to the guiding sliding rod. The brushing plating pen power supply mechanism is connected with the brushing plating pen drive mechanism. The brushing plating pen drive mechanism is connected with the detachable and replicable type plating pen mechanism and a plating solution conveying mechanism. The automatic control type brushing plating device for the spindle hole of the engine is novel and practical in structure and suitable for re-machiningand repair of the spindle hole of the engine body.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Bridge maintenance equipment

InactiveCN107069306AImprove work efficiencyReduce laborCoupling device detailsBridge erection/assemblyBridge maintenancePetroleum engineering

The invention discloses a bridge maintenance device, which comprises an electric connection frame body and a hanging frame. An operation groove is arranged in the left end surface of the electric connection frame body, and an external connection electric hole is arranged in the operation groove. A switch door is provided on the left end of the slot, and the left end of the switch door is hinged through a hinge, and a handle is provided at the external position of the switch door, and a fishing hook is correspondingly arranged on the right side of the connecting frame, and a first slide is arranged in the connecting frame. Shift chamber, the bottom end of the first slide chamber is provided with a guide slide groove, the first slide chamber is provided with a first screw-shaped rod extending left and right, and the left end of the first screw-shaped rod is connected with the first driving machine , the first helical rod is screw-fitted with the first sliding block, the first sliding block is provided with a first sliding groove, and the first sliding groove is provided with a guide sliding rod extending left and right, guiding The sliding bar is slidably connected with the second sliding block; the invention has simple structure, convenient operation, automatic operation, power supply insertion, convenient installation and disassembly, and high safety.

Owner:XIAMEN MAIFENGWEI MACHINERY CO LTD

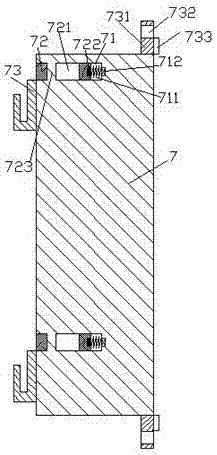

Fully-mechanized excavation supporting device with emulsion capable of being automatically proportioned

InactiveCN109838263ARealize automatic control operationReduce labor intensityMixing methodsMixer accessoriesAutomatic controlEmulsion

The invention discloses a fully-mechanized excavation supporting device with emulsion capable of being automatically proportioned. Thus, the problems in the prior art, that excavation and supporting operation of fully-mechanized excavation faces cannot be synchronously and continuously performed, and the concentration of emulsion is not easy to control, can be solved. The device includes an emulsion automatic proportioning device and multiple supporting top beams; an oil cylinder is sleeved at the internal of each supporting top beam, and the adjacent ends of the oil cylinders are in fixationwith the supporting top beams; telescoping beams are fixed on the other ends of the oil cylinders; hydraulic props are vertically fixed on one sides of the telescoping beams; the upper end faces of the supporting top beams are provided with grooves; the grooves and the corresponding lower end faces of the supporting top beams are connected to sliding bodies through iron chains; and the sliding bodies on the lower end faces of the supporting top beams are provided with I-steel. The device is reasonable in design and compact in structure, and can maintain the original stress of roadways and theunchanged of rock stratum after excavation in a short time, so that conditions can be provided for subsequent and permanent supporting, and high supporting efficiency can be achieved; and automatic control operation can be realized, and labor intensity can be mitigated.

Owner:沈阳知源科技有限公司

Equipment for bridge maintenance

InactiveCN107134680AReduce laborRealize automatic control operationCoupling device detailsBridge maintenancePetroleum engineering

The invention discloses a bridge maintenance equipment, which comprises an electrical connection frame body and a hanging frame. A control slot is arranged in the left end surface of the electrical connection frame body, and an external connection hole is arranged in the control slot. A switch door is located on the left end of the control slot, and the left end of the switch door is hinged through a hinge, and a handle is provided on the outer position of the switch door, and a fishing hook is provided on the right side of the connecting frame. A sliding chamber, the bottom end of the first sliding chamber is provided with a guiding sliding groove, the first sliding chamber is provided with a first screw-shaped rod extending left and right, the left end of the first screw-shaped rod is connected to the first drive Machine connection, the first screw-shaped rod is screw-fitted with the first sliding block, the first sliding block is provided with a first sliding groove, and the first sliding groove is provided with a guide sliding rod extending left and right , the guide sliding rod is slid and connected with the second sliding block; the invention has the advantages of simple structure, convenient operation, automatic power supply insertion, convenient installation and disassembly, and high safety.

Owner:XIAMEN MAIFENGWEI MACHINERY CO LTD

Self cleaning type airlock

The application of the invention provides a self cleaning type airlock. The compositions of the self cleaning type airlock comprise an impeller machine shell, an impeller assembly, a control circuit and a cleaning knife assembly. The cleaning knife assembly comprises a pneumatic cleaning knife, a sliding rail, a buffering pad and a blade detecting part, the sliding rail is axially mounted at a discharging opening of the impeller machine shell, and the knife edge of the pneumatic cleaning knife radially extends into the circumference rotatably covered by an impeller; and the blade detecting part comprises an impeller synchronizing wheel mounted at the end cap external shaft end of an impeller shaft and a non-contacting sensor arranged on one side of the impeller synchronizing wheel. The cleaning knife assembly in the technical scheme can cut off and clean impurities entwined on the impeller within an extremely short time, and automatic control operation can be achieved.

Owner:王丕新

Solar aviation obstruction light

InactiveCN108317475AReduce exposure timeReduced service lifeElectric circuit arrangementsLighting elementsAviationHigh probability

The invention discloses a solar aviation obstruction light and relates to the technical field of an aviation obstruction light. The problems, in the existing solar aviation obstruction light, that a solar panel is exposed outside for a long time and has high probability of damage and the service life of the solar panel is shortened because the solar battery panel is fixed outside are solved. The solar aviation obstruction light comprises a box body; an obstruction light is arranged at the top of the box body; a horizontal flat plate is arranged in the box body; a solar panel mechanism is arranged on the upper surface of the flat plate; sliding strips with conical cross sections are arranged on the two sides of the lower surface of the flat plate correspondingly; racks are arranged at the bottoms of the sliding strips; a guide groove matched with the sliding strips is formed at the inner bottom of the box body; the upper part of the cross section of the guide groove is conical and the lower part of the cross section of the guide groove is rectangular; a plurality of gears matched with the racks are arranged at the bottom of the guide groove; the plurality of gears are connected through a chain wheel and chain mechanism; one of the gears is connected with a driving motor; and an opening for the flat plate to exit and enter is formed in one side of the box body.

Owner:HENAN CHANGMING HANGBIAO ELECTROMECHANICAL EQUIP CO LTD

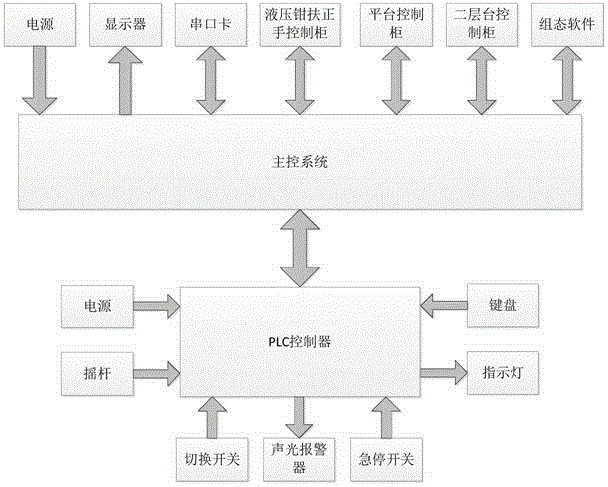

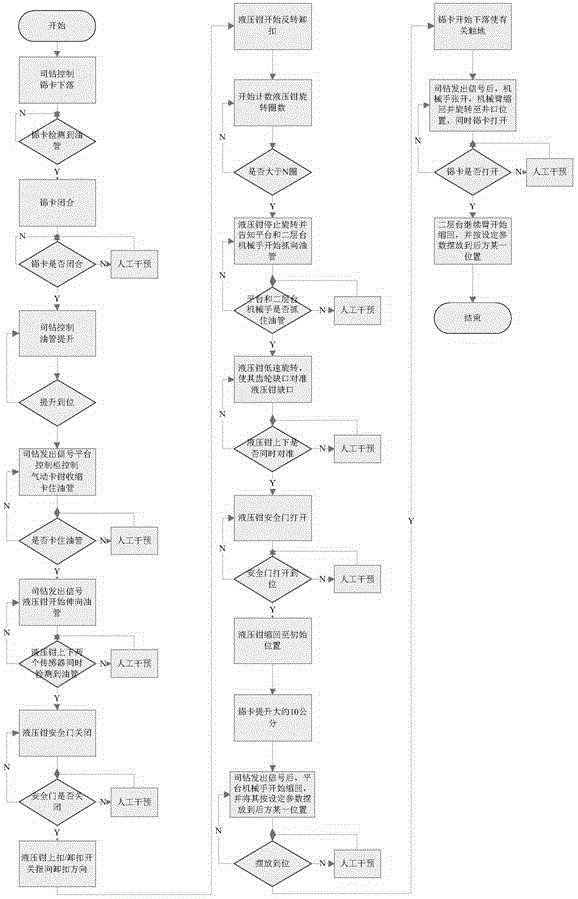

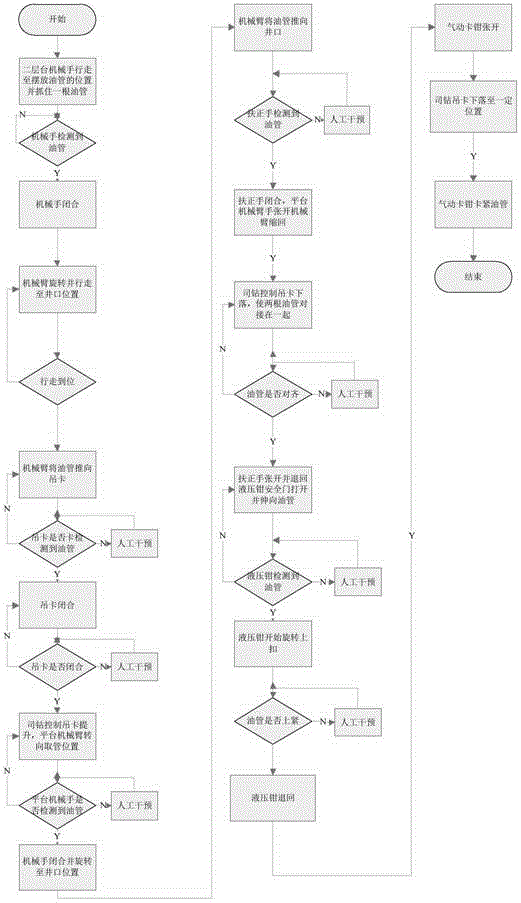

Well repair automation integrated control system

InactiveCN105022342AMonitor work statusReduce work intensityProgramme control in sequence/logic controllersProgrammable logic controllerControl system

The invention discloses a well repair automation integrated control system, which solves problems of dangerousness and high labor intensity of workers in the drill raising and dropping process in the prior art. The well repair automation integrated control system comprises a main control system and a PLC (programmable logic controller), and is characterized in that the main control system is respectively connected with a platform control cabinet, a racking platform control cabinet and a hydraulic clamp centralizing hand control cabinet through 485 interfaces, and PLCs of the platform control cabinet, the racking platform control cabinet and the hydraulic clamp centralizing hand control cabinet are connected to kingview software through 485 interfaces; and the PLC is connected to the main control system through a 485 interface, and the PLC is further connected to an emergency stop switch, a rocker, a change-over switch and a keyboard. The well repair automation integrated control system can realize automatic drill raising and dropping, can use machinery to replace manual work to complete arrangement of oil pipes, thereby greatly reducing the labor intensity and the dangerousness of workers.

Owner:BEIJING HERCULES INTELLIGENT EQUIP TECH CO LTD

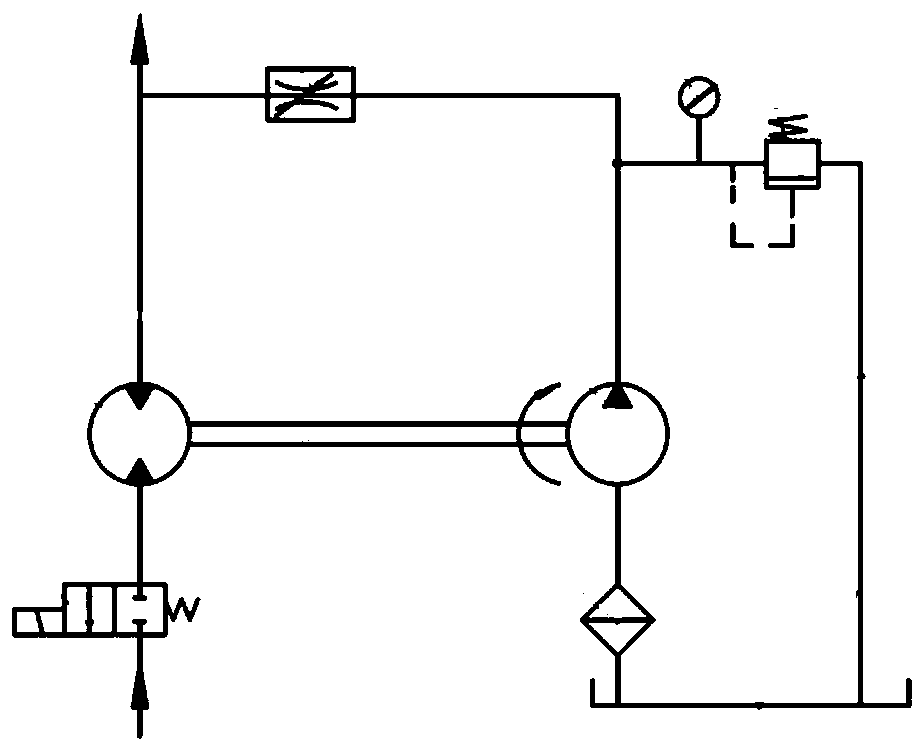

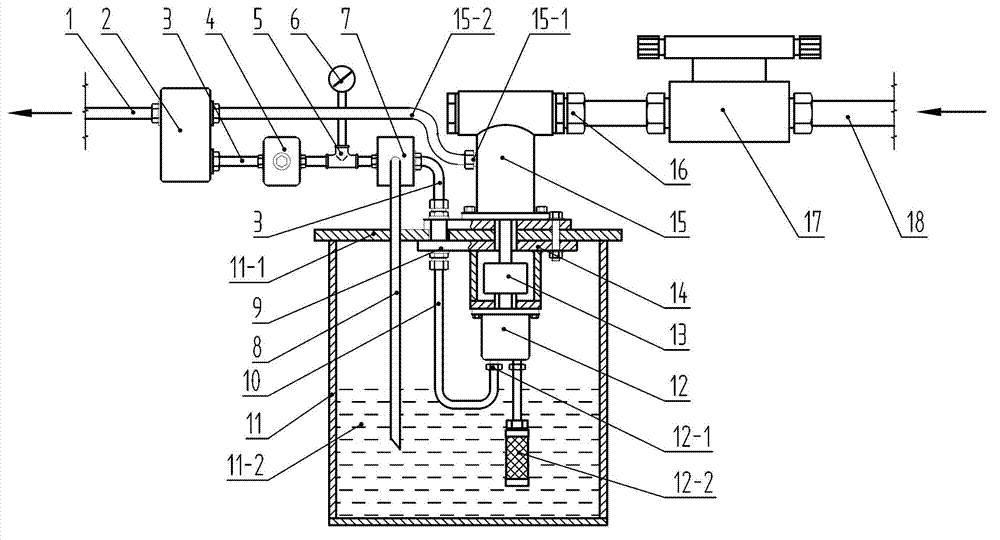

Automatic proportioning device for mining emulsion

InactiveCN102886226AThe size of the proportioning concentration is flexibleHigh precisionMixing methodsMixer accessoriesHydraulic pumpHigh pressure water

The invention discloses an automatic proportioning device for a mining emulsion, relating to mining equipment. According to the invention, a high-pressure water mesh in an underground coal mine is used as a power, an impeller-type hydraulic motor is driven to work by high-pressure water, and a hydraulic pump is driven to work by the impeller-type hydraulic motor via a shaft coupler; and emulsified oil from the oil outlet of the hydraulic pump is joined with the high-pressure water from the water outlet of the impeller-type hydraulic motor in a three-way tube joint, so as to realize proportioning for the emulsion. The flow of the emulsified oil is controlled via an overflow valve, a throttle valve and a pressure gauge, thus realizing random adjustment for the proportioning concentration of the emulsion. The adjustment range of the proportioning concentration of the emulsion can achieve 1.5%-10%; and the water inflow of the impeller-type hydraulic motor is controlled by virtue of a two-position four-way electromagnetic directional valve, and the two-position four-way electromagnetic directional valve can be randomly accessed to a pump station control system, thus realizing integrated control.

Owner:徐州雷曼机械科技有限公司

Mobile and container-type integrated treatment equipment for black and odorous water body

InactiveCN110697930AReduce volumeSmall footprintWater treatment compoundsTreatment involving filtrationAmmoniacal nitrogenEmergency treatment

The invention discloses mobile and container-type integrated treatment equipment for a black and odorous water body. The equipment comprises a box body, wherein the inside of the box body is providedwith a water taking module, a dosing flocculation and sedimentation module, a filtering module, a radical active oxygen advanced oxidation module, a post-adsorption module, and a sludge treatment module, wherein the water taking module is used to extract the black and odorous water body, the dosing flocculation and sedimentation module is used to add a flocculant into the black and odorous water body, the filtering module is used to remove particles or solid impurities in water, the radical active oxygen advanced oxidation module is used to remove organic pollutants in water, and the post-adsorption module is used to further remove ammonia nitrogen and total phosphorus in water. The equipment adopts a unique mobile-type, modularization, and container-type design, the equipment is small insize, small in land occupied area, mobile, and flexible in placement, and can be used as emergency treatment equipment. Compared with the traditional in-situ treatment technology, the equipment has high efficiency, quick effects and low cost.

Owner:GUANGDONG INST OF ANALYSIS CHINA NAT ANALYTICAL CENT GUANGZHOU

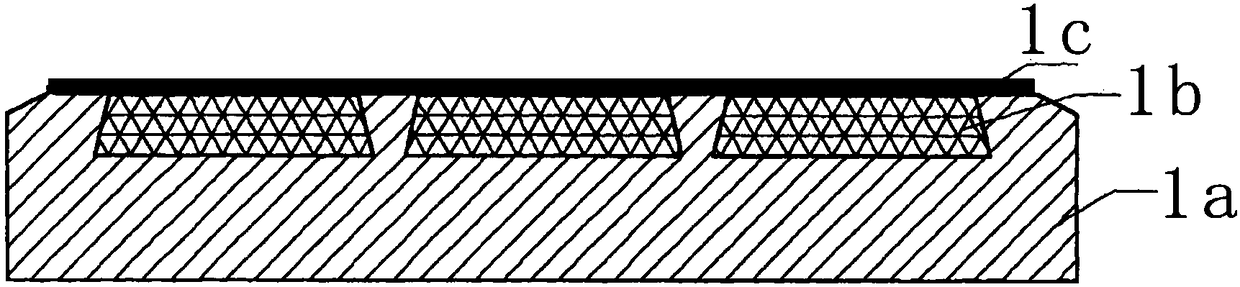

Self-insulation block production equipment

PendingCN108340531ARealize automatic control operationIncrease productivityDomestic articlesThermal insulationEngineering

The invention discloses self-insulation block production equipment, and belongs to the technical field of building material processing. The self-insulation block production equipment comprises a machine frame and a conveying plate link chain, wherein the machine frame is sequentially provided with a filling device and an autoclaved molding device, the conveying plate link chain is provided with apropeller, and guard plates for clamping concrete blocks are arranged on the two sides of the conveying plate link chain. The autoclaved molding device comprises a steam chamber which is vertically and slidably installed on the machine frame and is connected to a steam source, the steam chamber is connected to a power plant, and air outlet holes corresponding to the filling hole positions are formed in the side which the stem chamber faces the conveying plate link chain. The self-insulation block production equipment further comprises a stem recovery device. The automatic streamlining operation of online filling and online autoclave molding of the self-insulation block is achieved, so that an insulation block and a concrete block become an organic integration of the self-insulation block,the product quality and heat insulation effect are improved, the defect that a thermal insulation block on a self-insulation block produced by a traditional technology is prone to being separated is overcome, at the same time, the production efficiency is improved, and labor and production costs are reduced effectively.

Owner:青岛创高世纪信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com