Well repair automation integrated control system

A technology of overall control and main control system, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as dangerous work intensity, and achieve the effect of reducing work intensity and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

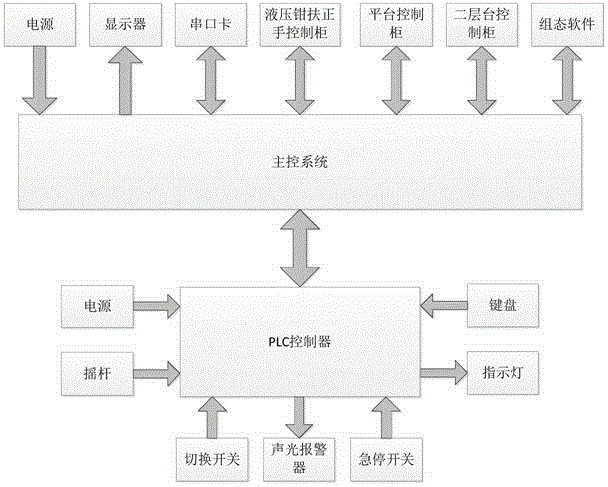

[0019] Such as figure 1 As shown, it is an embodiment of the overall workover automation control system of the present invention. The system includes a main control system and a PLC controller. Clamp righting hand control cabinet, the PLC of the platform control cabinet, the second-floor platform control cabinet and the hydraulic tong righting hand control cabinet are respectively connected to Kingview software through the 485 interface; the PLC controller and the main control system are connected through 485 interface connection, the PLC controller is also connected with an emergency stop switch, a rocker, a switch, an audible and visual alarm and a keyboard, and the configuration king software can read the status of the rocker, switch, etc. in the PLC controller in real time, When a key is pressed, according to the set parameters and the state of the switch, commands are sent to the platform, the second floor platform, hydraulic clamps, etc. for remote control.

[0020] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com