Solid-liquid separation disc filtering system

A technology of disc filtration and solid-liquid separation, applied in the direction of fixed filter element filter, filtration separation, separation method, etc., can solve problems such as unstable operation, inconvenient maintenance, and limitation of the length of the turntable system, and achieve the effect of flexible filtration system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

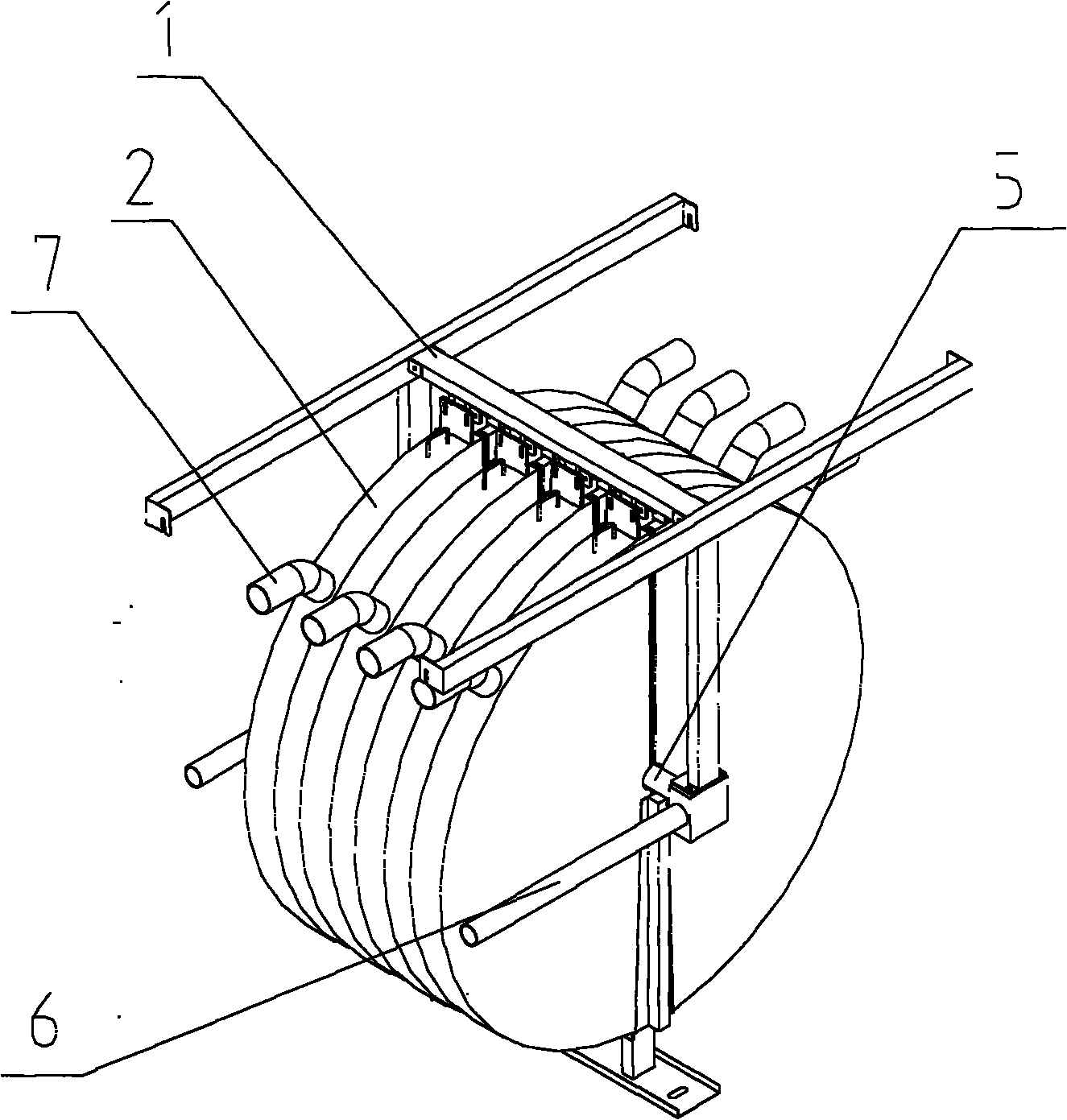

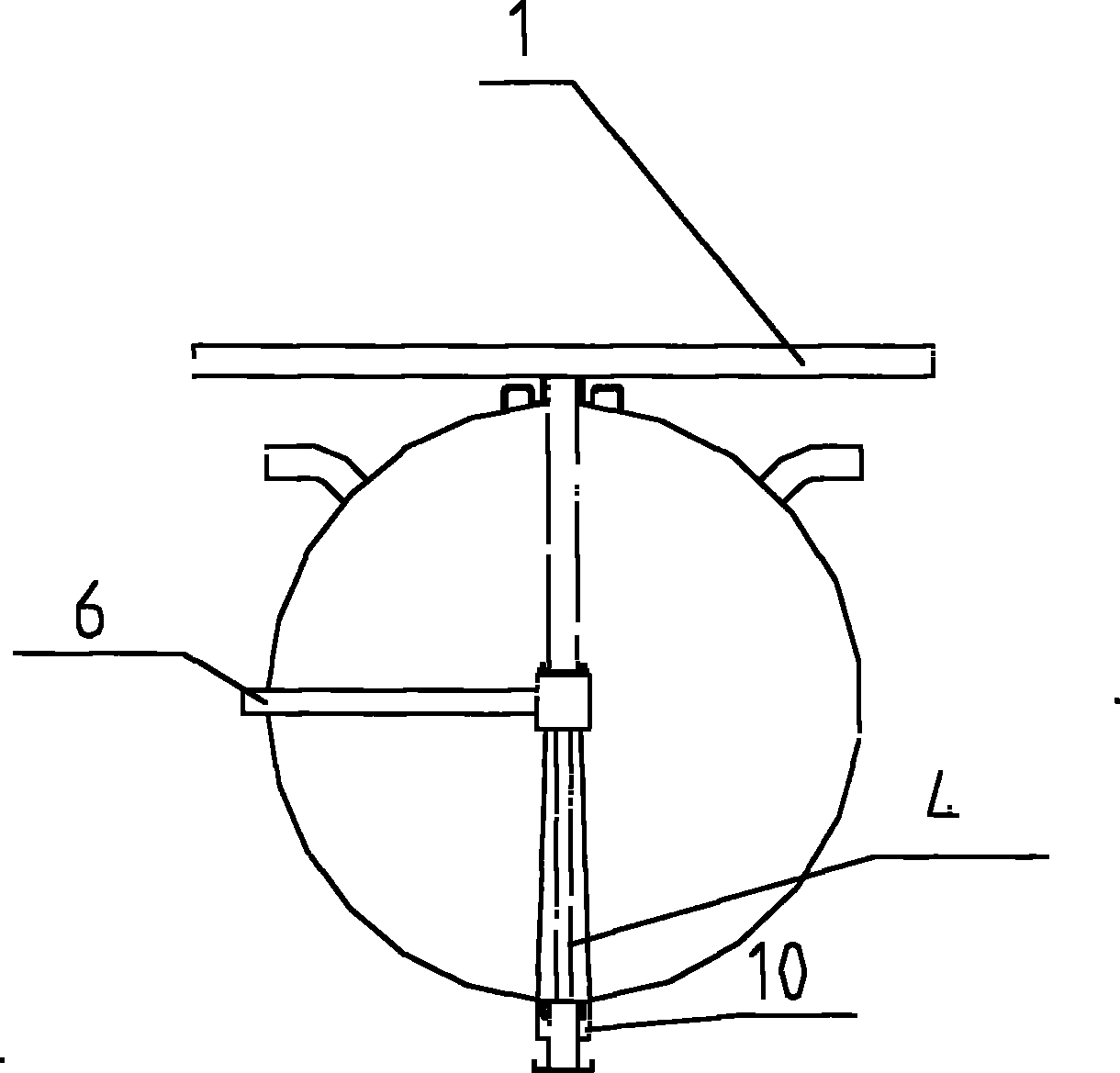

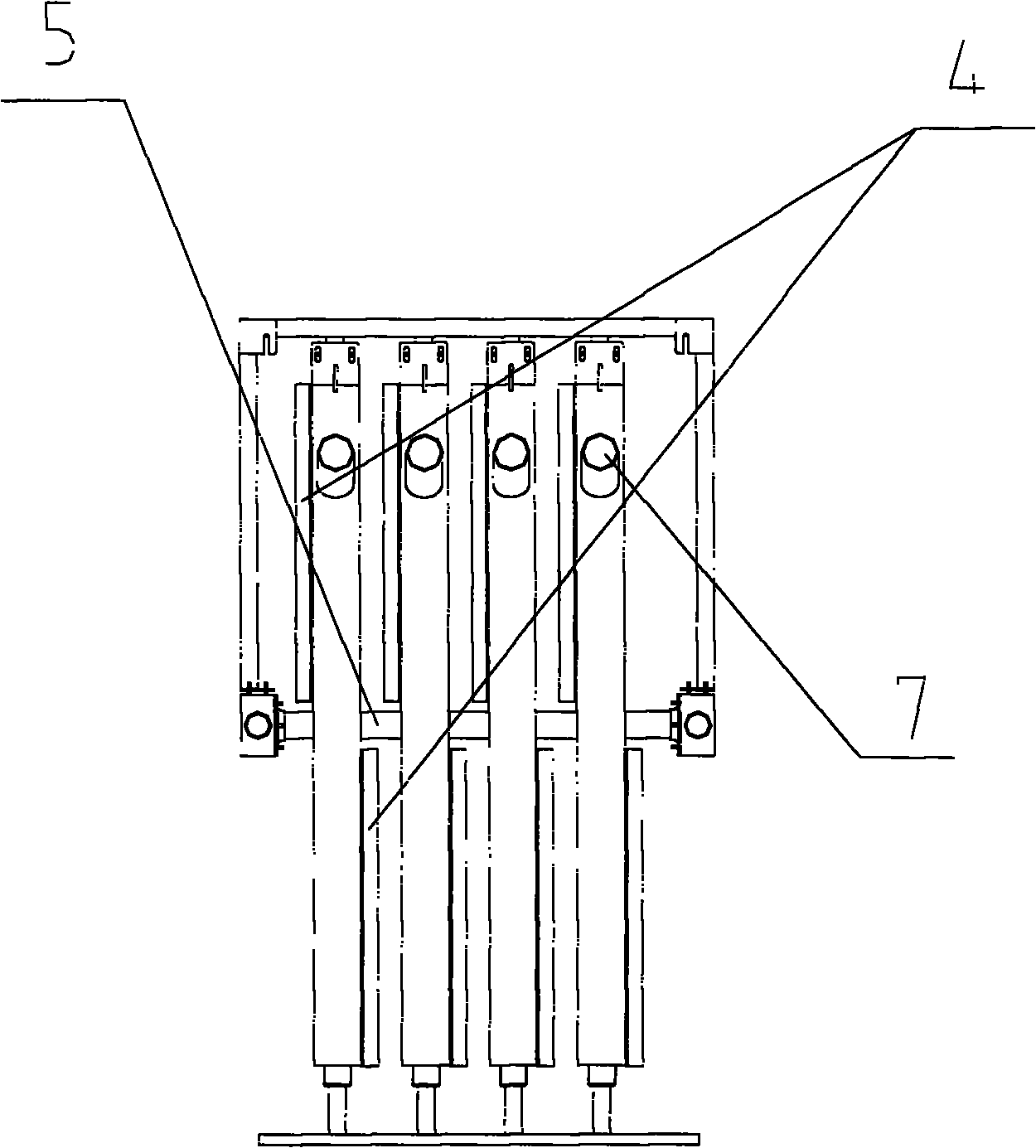

[0026] The following is attached Figure 1-4 The disc filter system of the present invention is described in more detail.

[0027] The suction disc 4 is connected to the hollow shaft 5 through a spring, and communicates with the hollow shaft 5 through a hose. During the filtering process of the disc filter system of the present invention, the filter disc 2 is stationary, and the suction disc 4 moves along the surface of the filter disc 2 in a circle. When carrying out the back suction cleaning process, the motor drives the suction disc 4 to make a circular motion, and every two oppositely arranged suction discs 4 form a group to carry out back suction on both sides of the filter disc 2 . Compared with the central drum of other disc filter systems, the circularly rotating suction disc 4 has a much smaller diameter and weight (the backwash water volume is about 2% of the total filtered water volume), so the required motor power is also much smaller , the system is more energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com