Portable dust remover

A dust collector, a convenient technology, applied in the direction of the coupling device, the device for joining/disconnecting the connecting parts, the parts of the connecting device, etc., can solve the problems of unstable connection, easy to generate arc, uneven plugging force, etc., to achieve Reduce the labor load of personnel, improve the tightness of plug-in connections, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

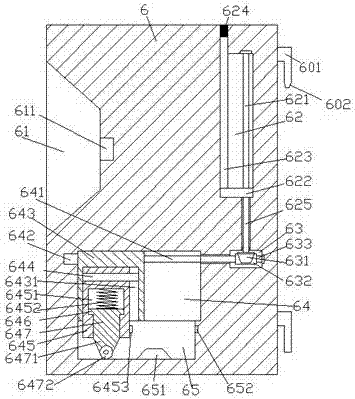

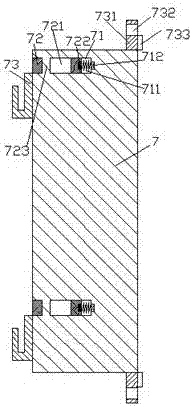

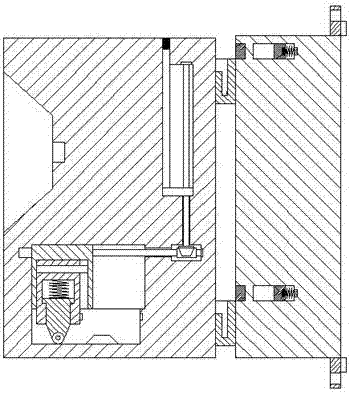

[0026] Such as Figure 1-Figure 8 As shown, a convenient dust collector device of the present invention includes a communication platform 6 and a hanging frame 7, a first sliding chamber 64 is provided in the communication platform 6, and the bottom end of the first sliding chamber 64 is provided with Guide chute 65, the first sliding cavity 64 is provided with a first stud 641 extending left and right, the left end of the first stud 641 is power connected with the first power device 642, and the first stud 641 A first sliding block 643 is threadedly connected to the column 641, and a first slide groove 6431 is arranged inside the first slide block 643, and a guide slide bar 644 extending left and right is arranged inside the first slide groove 6431, so that The guide slide bar 644 is smoothly connected with a second slider 645, and the bottom of the second slider 645 pushes into the guide chute 65 and is connected smoothly. The second slider 645 is provided with a first Two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com