Gas-oil-water three-phase separating device

A three-phase separation and three-phase separator technology, applied in liquid separation, separation method, liquid degassing and other directions, can solve the problems of unsatisfactory separation effect, not very suitable, large volume, etc., achieve ideal separation effect, maintenance and repair Effortless work and improved metering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

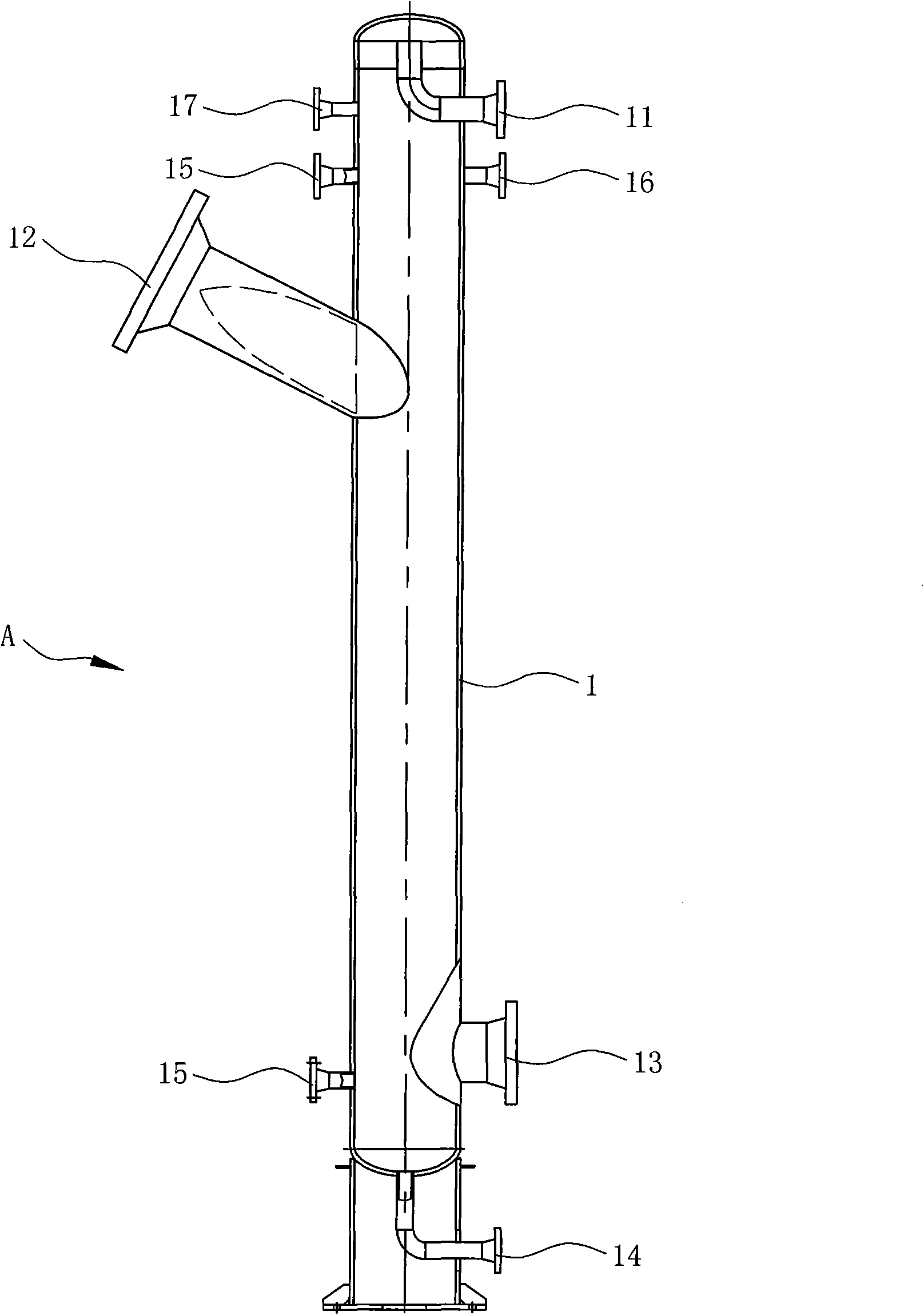

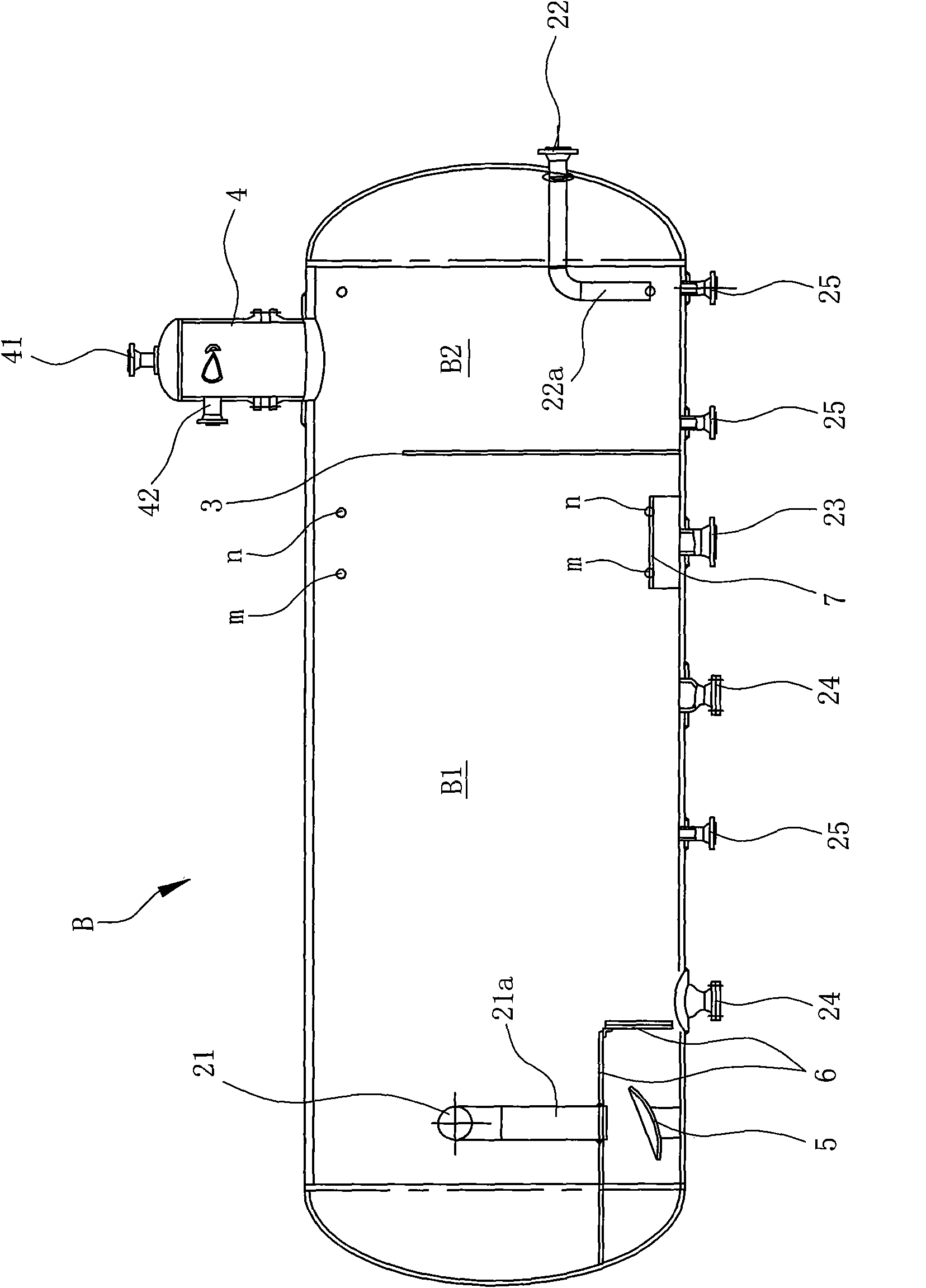

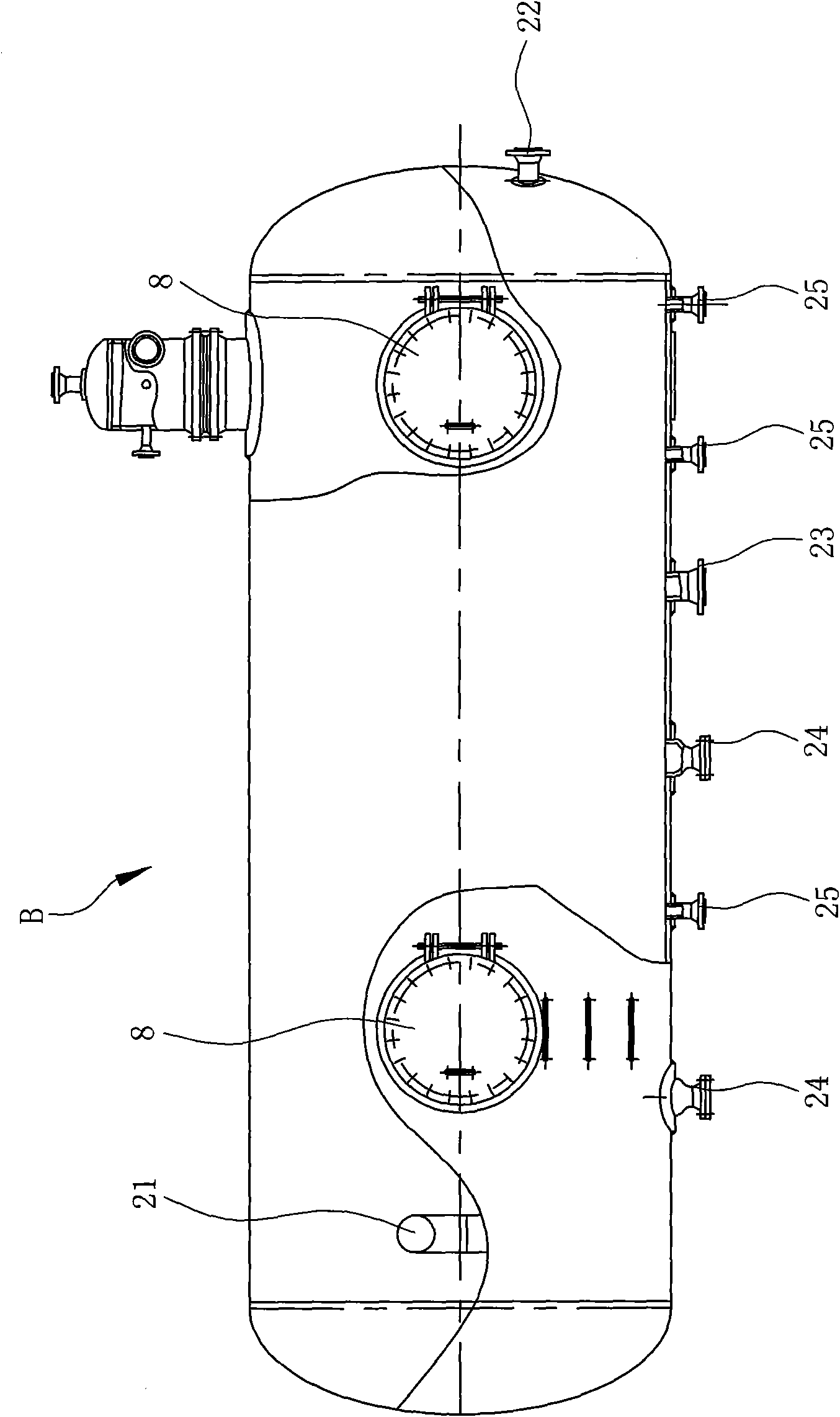

[0029] like Figure 1 ~ Figure 4 As shown, the gas-oil-water three-phase separation device includes a columnar cyclone gas-liquid separator A and a horizontal three-phase separator B communicating with the columnar cyclone gas-liquid separator A;

[0030] Wherein, the columnar cyclone gas-liquid separator A includes a columnar body 1, the upper, middle, lower, and bottom of the sidewall of the columnar body 1 are respectively provided with outlet pipes 11 communicating with the inside of the columnar body 1 , Crude oil inlet pipe 12, liquid outlet pipe 13, sewage outlet pipe 14, the connecting end of the crude oil inlet pipe 12 is inclined downward relative to the columnar cylinder 1, and is tangent to the side wall of the columnar cylinder 1;

[0031]Two liquid level transmitter pressure connection pipes 15, a temperature transmission pressure connection pipe 16 and a pressure gauge connection pipe 17 are also arranged on the cylindrical cylinder body 1, wherein the two liqui...

Embodiment 2

[0046] like Figure 5 As shown, the difference between Embodiment 2 of the present invention and Embodiment 1 is that: the crude oil inlet pipe 12 is in an inverted L shape, the end of the vertical part 12a of the crude oil inlet pipe 12 opens downward, and the horizontal direction of the crude oil inlet pipe 12 The end of the portion 12b is tangent to the side wall of the cylindrical body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com