Recycling treatment process for chlorohydric acid pickling liquid waste

A technology of pickling waste liquid and treatment process, which is applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Product quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

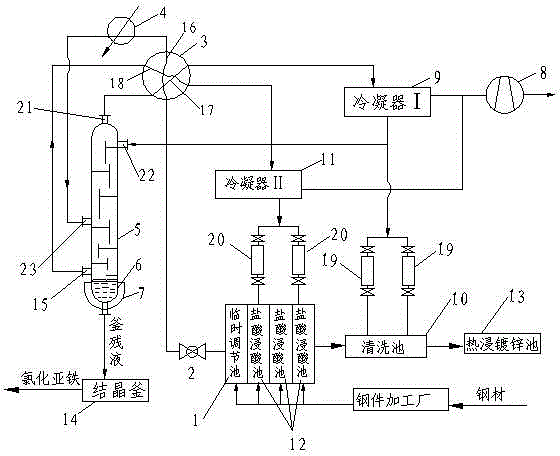

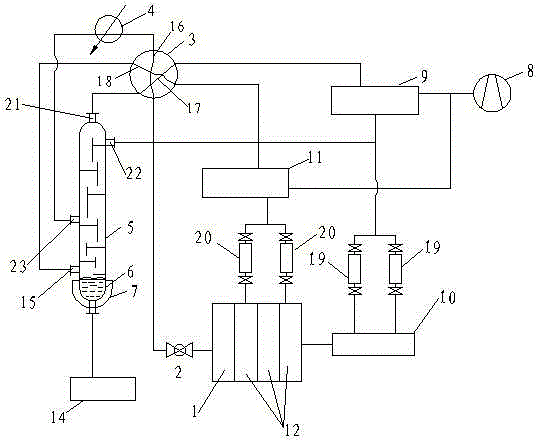

[0027] see figure 2 , the device used in the resource treatment process of hydrochloric acid pickling waste liquid in the present invention is formed by connecting commercially available conventional parts in a conventional manner, which mainly involves 1) the connection of each part involved in the hydrochloric acid pickling waste liquid entering the rectification tower, ②The connection of the various components involved in the outflow of steam from the top of the rectification tower, ③The connection of the various components involved in the recovery of the recovered dilute hydrochloric acid solution to the hydrochloric acid pickling tank, ④The connection of the vacuum pump, the connection relationship of each component is as follows:

[0028] ①The connection of the various components involved in the hydrochloric acid pickling waste entering the rectification tower: the suction end of the chemical pump 2 is connected to the temporary adjustment tank 1, the water outlet is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com