Oil-water separation tank

A technology of oil-water separation tank and oil tank, which is applied in liquid separation, separation method, liquid separation through thermal diffusion, etc., can solve the problems that oil-water cannot be separated, shorten the time of oil-water separation, etc., achieve simple and effective liquid temperature, reduce production cost, The effect of raising the temperature of the liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and example the present invention will be further described:

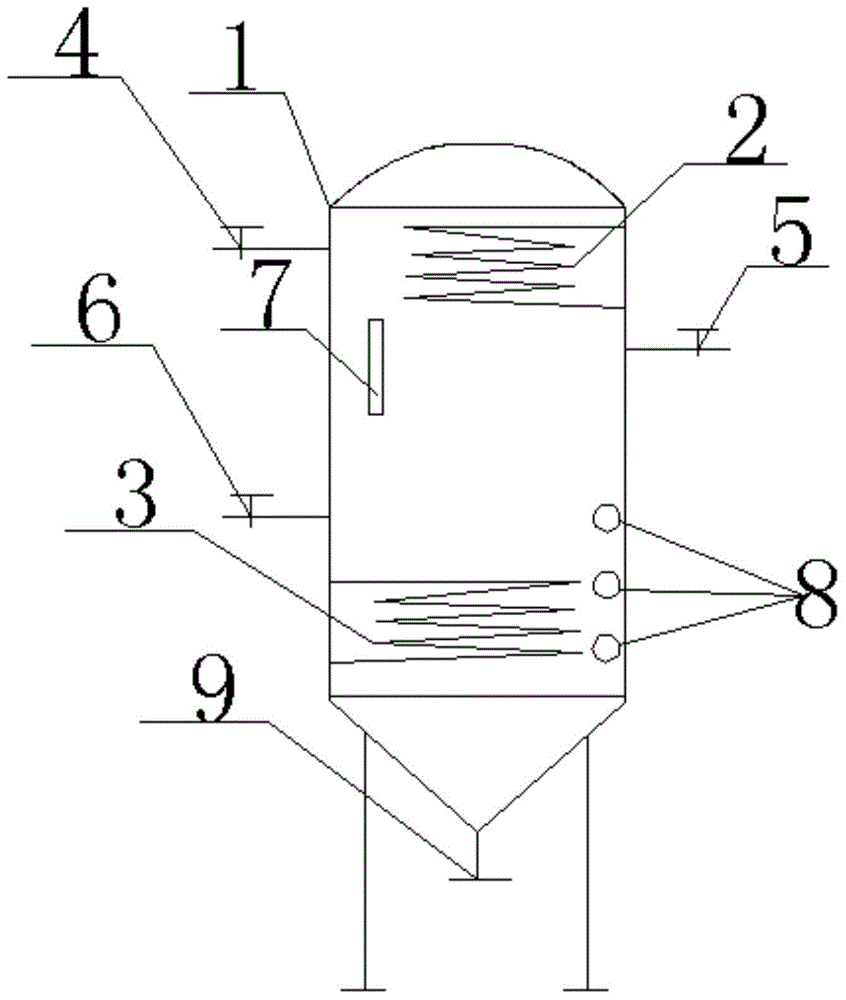

[0012] Such as figure 1 As shown, the oil-water separation tank includes: an oil tank 1, a condensation coil 2, a heating coil 3, a vent valve 4, a feed port 5, a discharge port 6, a sight glass 7 and a water cut port 8, and the oil tank is divided into 1 It is divided into three parts: heating zone, condensation zone and observation zone. The oil tank 1 is divided into inner and outer layers, and the inner layer is a sealed space when the vent valve 4, the feed port 5, the discharge port 6 and the water cut port 9 are closed. The condensing coil 2 is wound in the outer chamber at the top of the oil tank 1 to form a condensation zone, and the heating coil 3 is coiled in the outer chamber at the bottom of the oil tank 1 to form a heating area. The upper right half of the oil tank 1 is provided with There is a feed port 5, the lower half of the left side of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com