Patents

Literature

53results about How to "Same flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

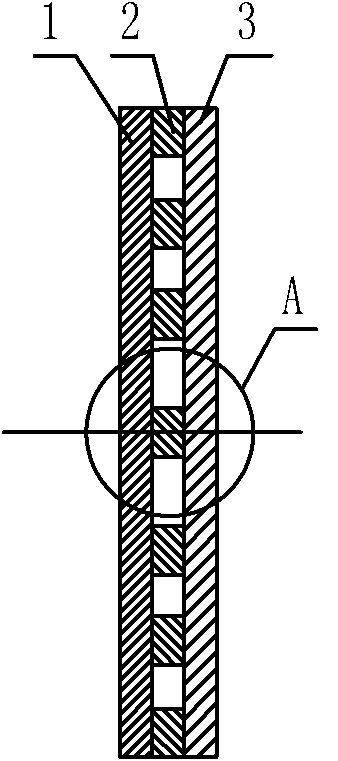

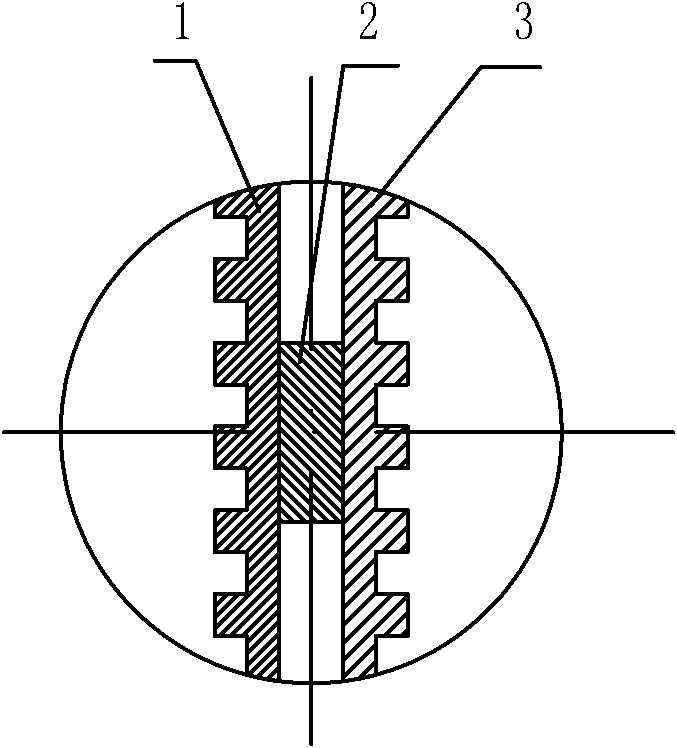

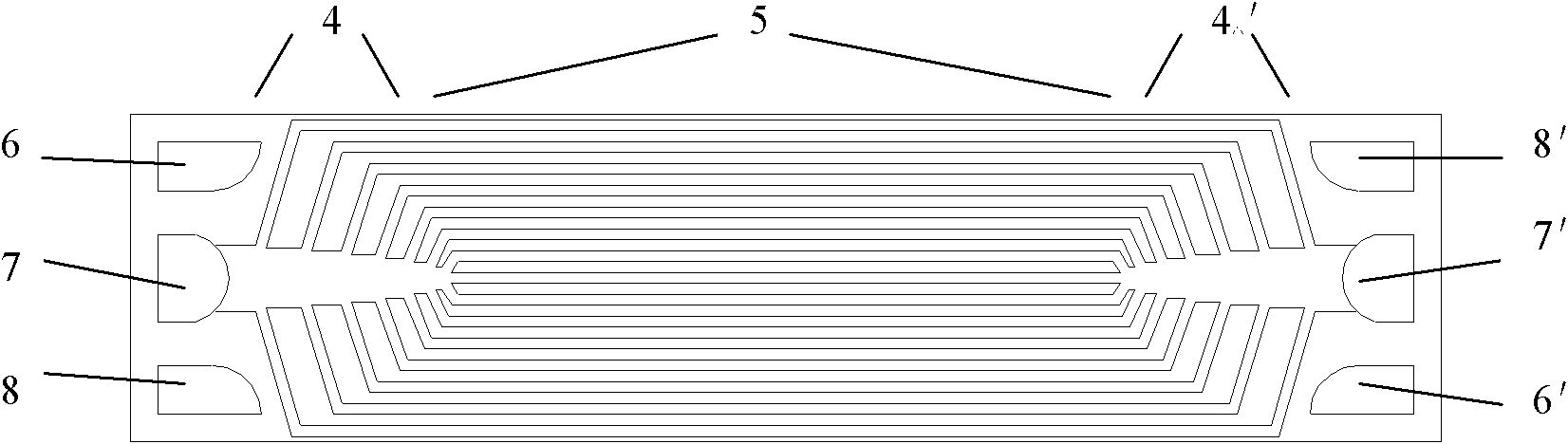

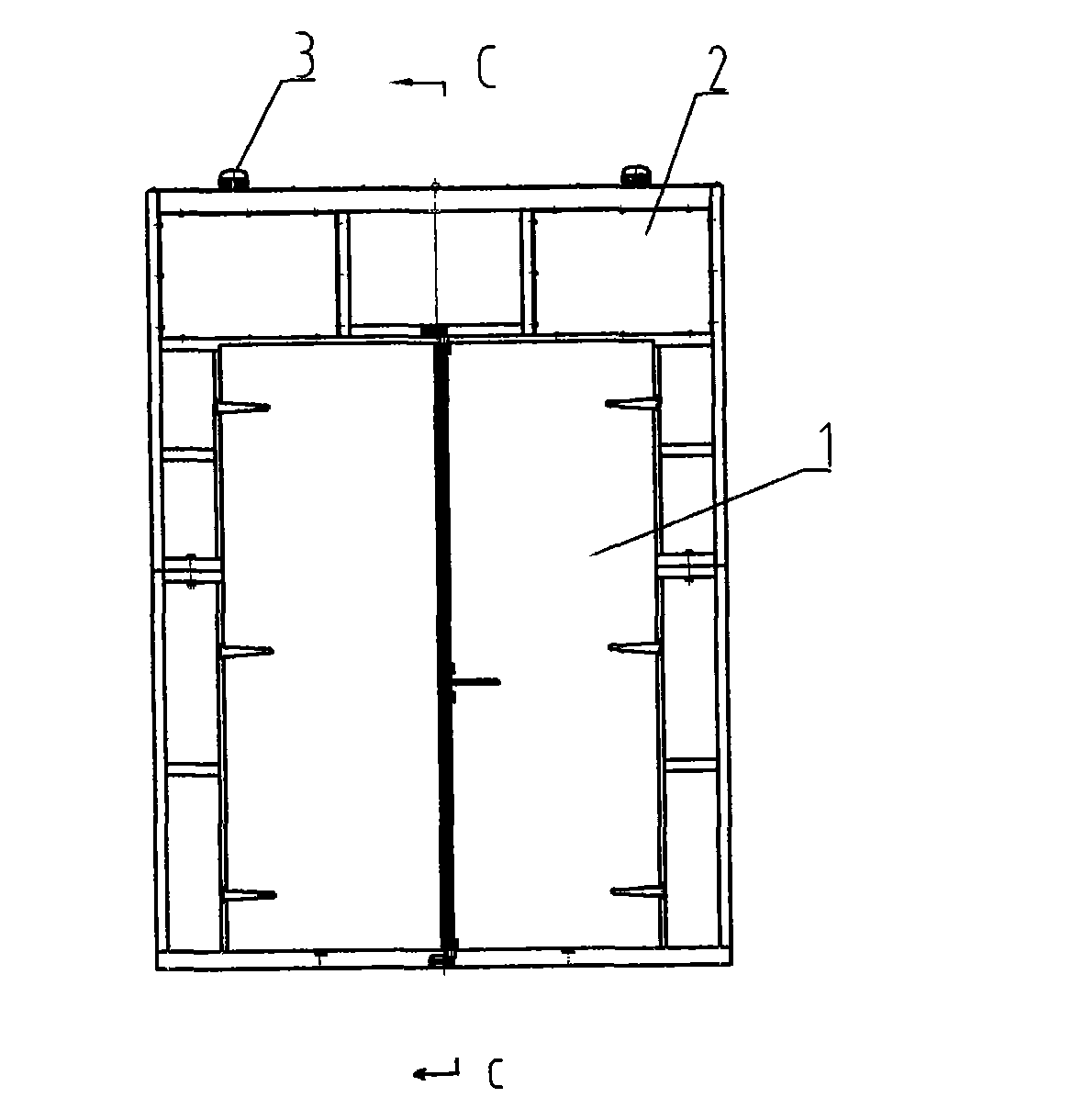

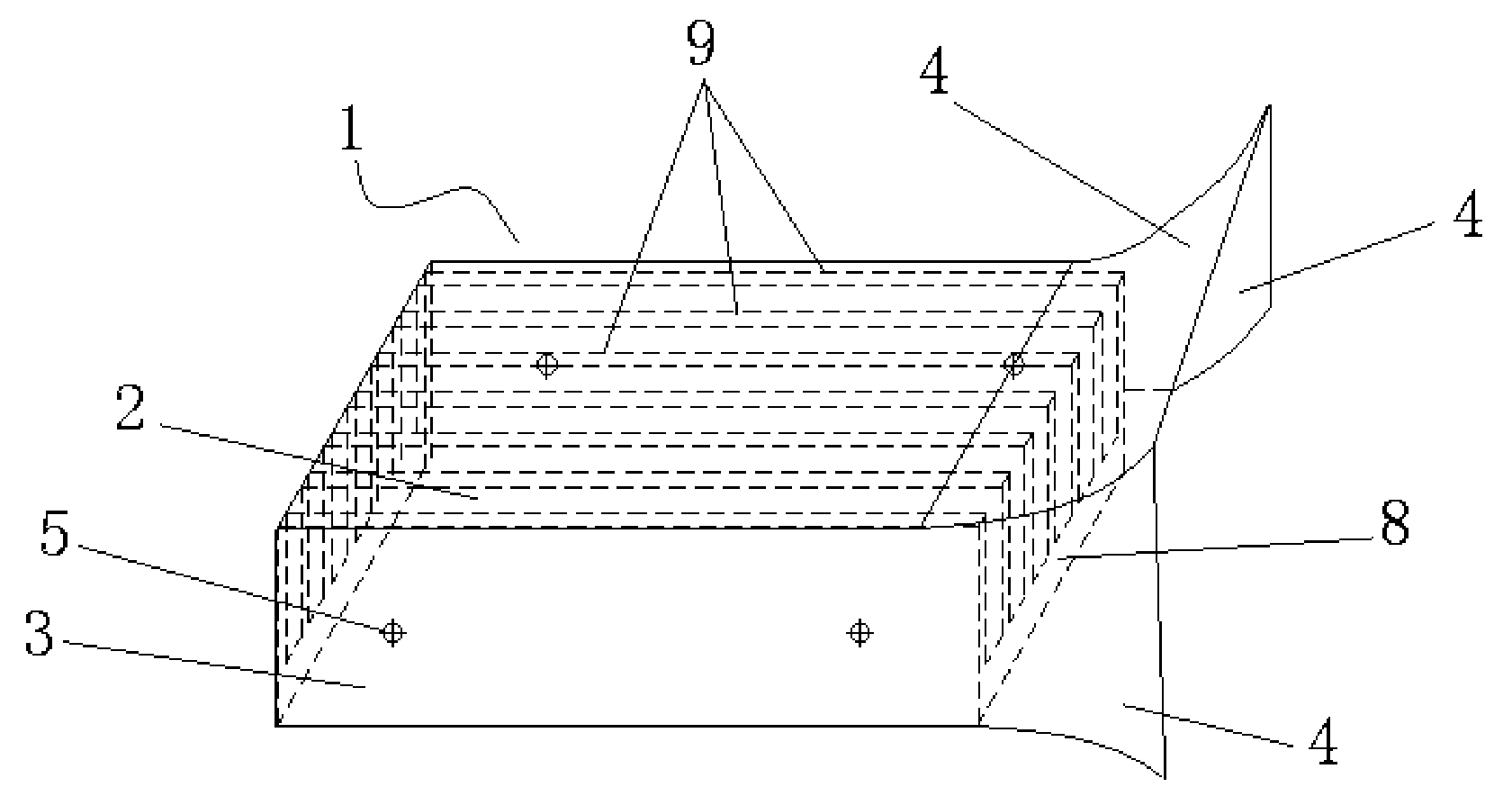

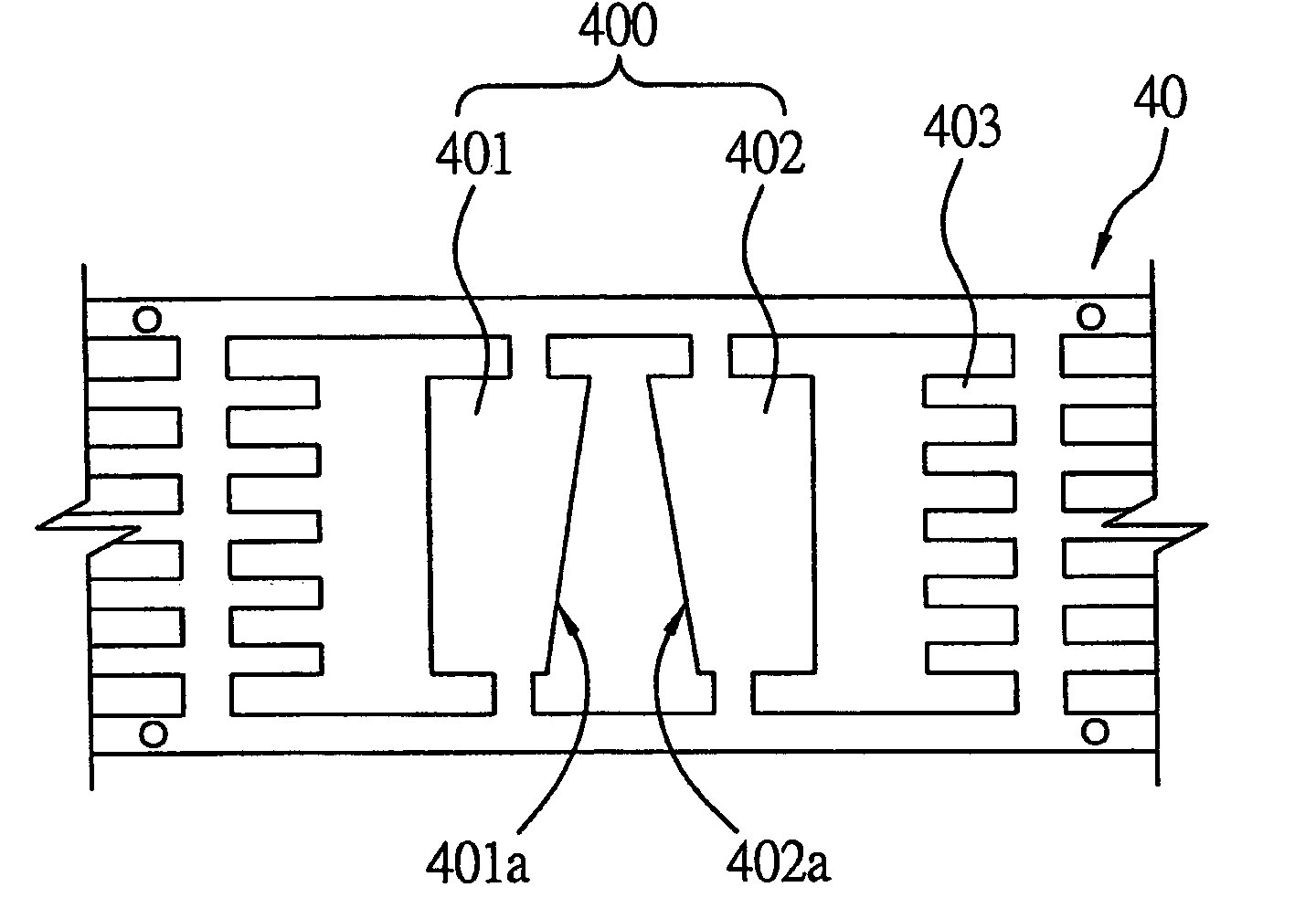

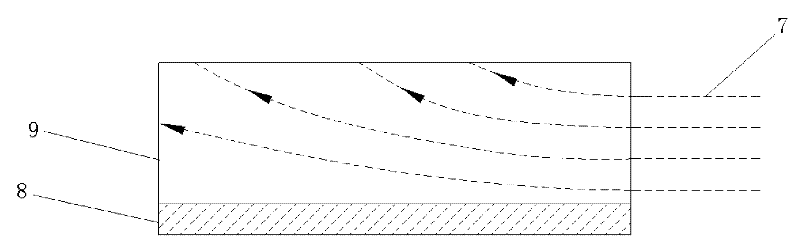

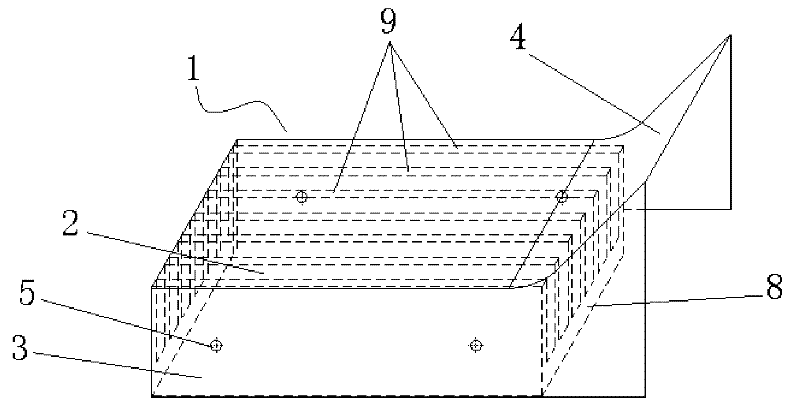

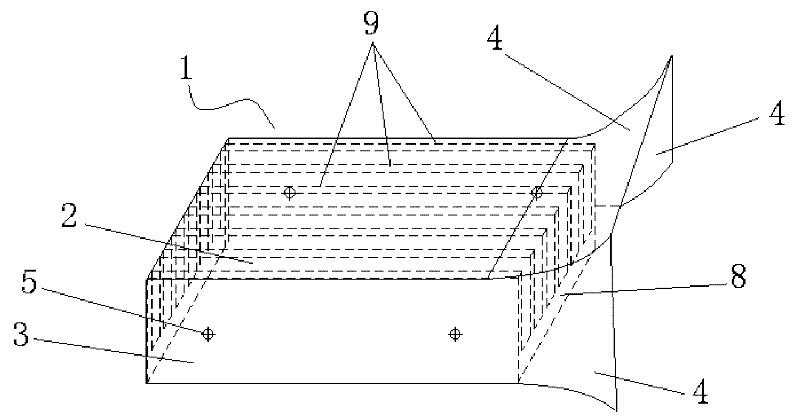

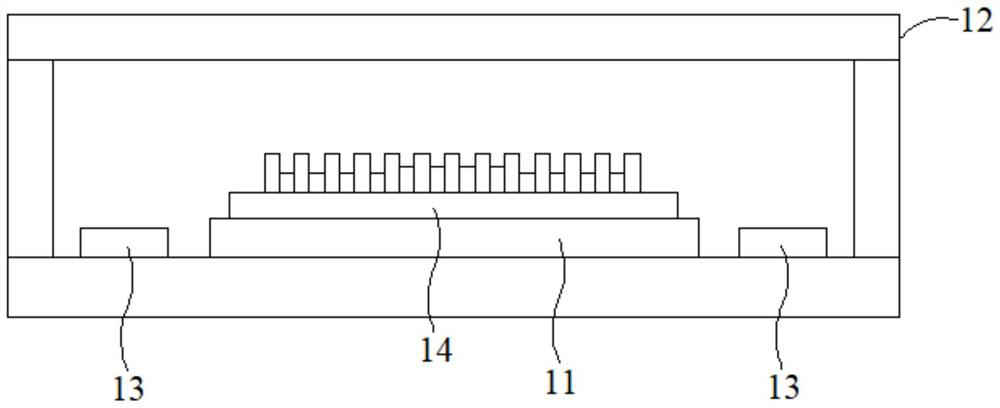

Tree-structured flow field proton exchange membrane fuel cell bipolar plate

InactiveCN101944618AEvenly distributedReduce resistanceCell electrodesFuel cell detailsEngineeringProton exchange membrane fuel cell

The invention relates to a proton exchange membrane fuel cell bipolar plate, in particular to a tree-structured flow field proton exchange membrane fuel cell bipolar plate. The bipolar plate comprises an anode plate, a cathode plate and a support frame, wherein the anode plate and the cathode plate are fixedly connected through the support frame which is positioned between the anode plate and thecathode plate; an anode flow field is arranged on the left side face of the anode plate; and a cathode flow field is arranged on the right side face of the cathode plate. The bipolar plate is characterized in that: the two end parts of the anode flow field and the cathode flow field are tree-structured flow fields and the middle parts are parallel flow fields. The bipolar plate can improve the property and stability of a fuel cell.

Owner:WUHAN UNIV OF TECH

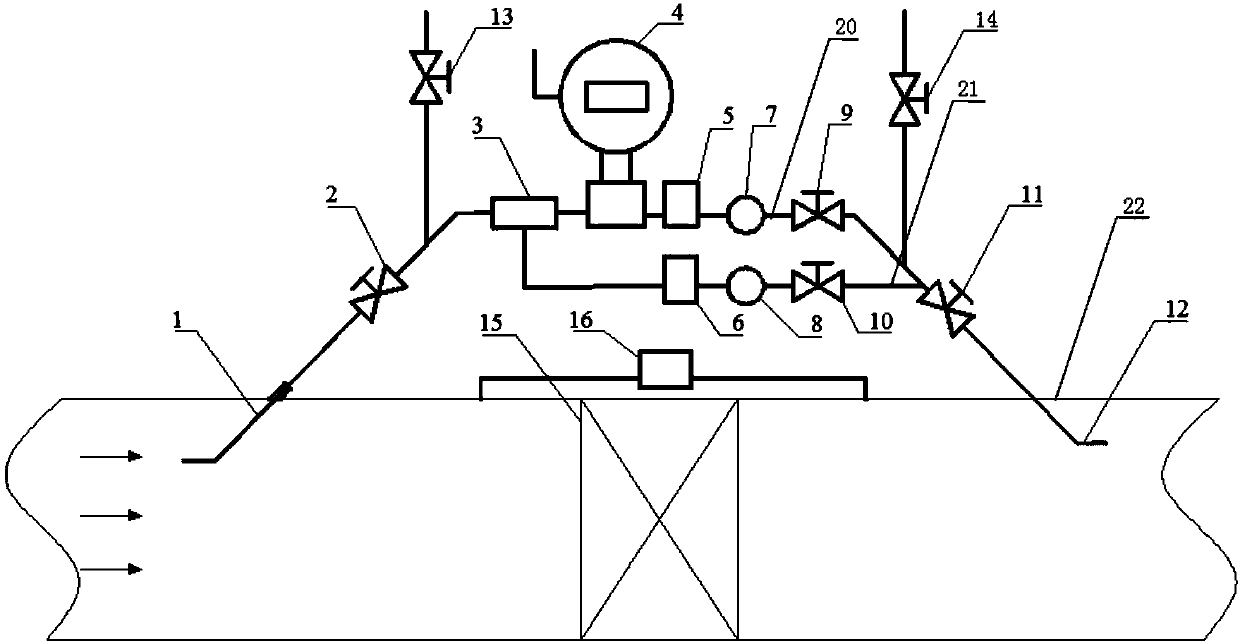

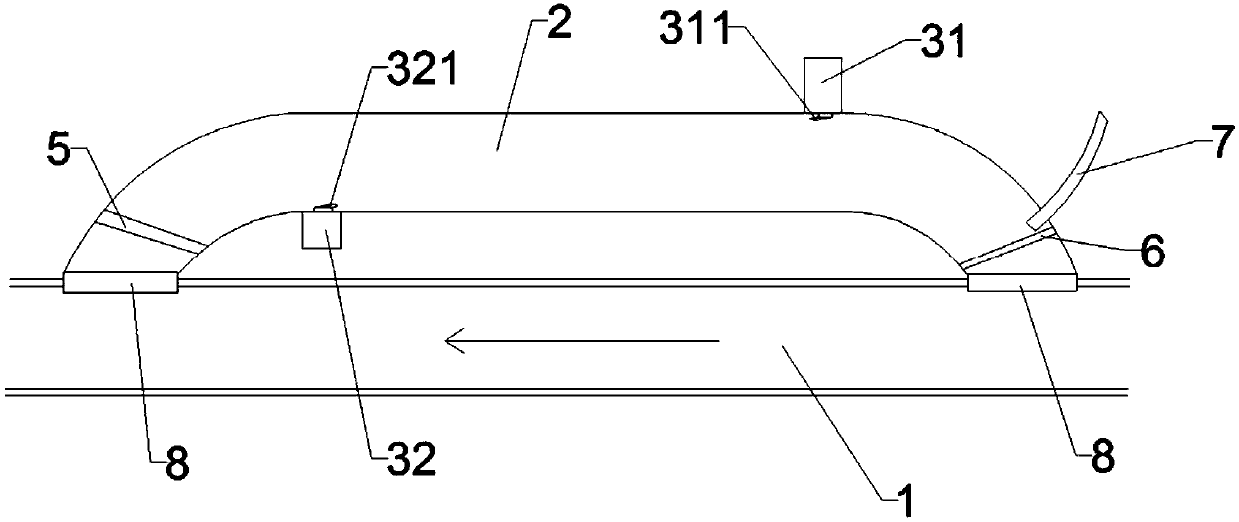

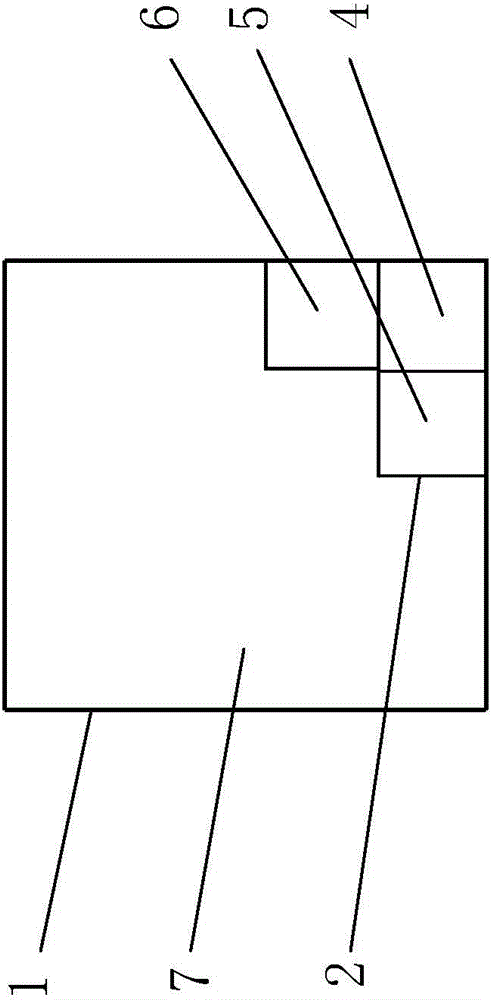

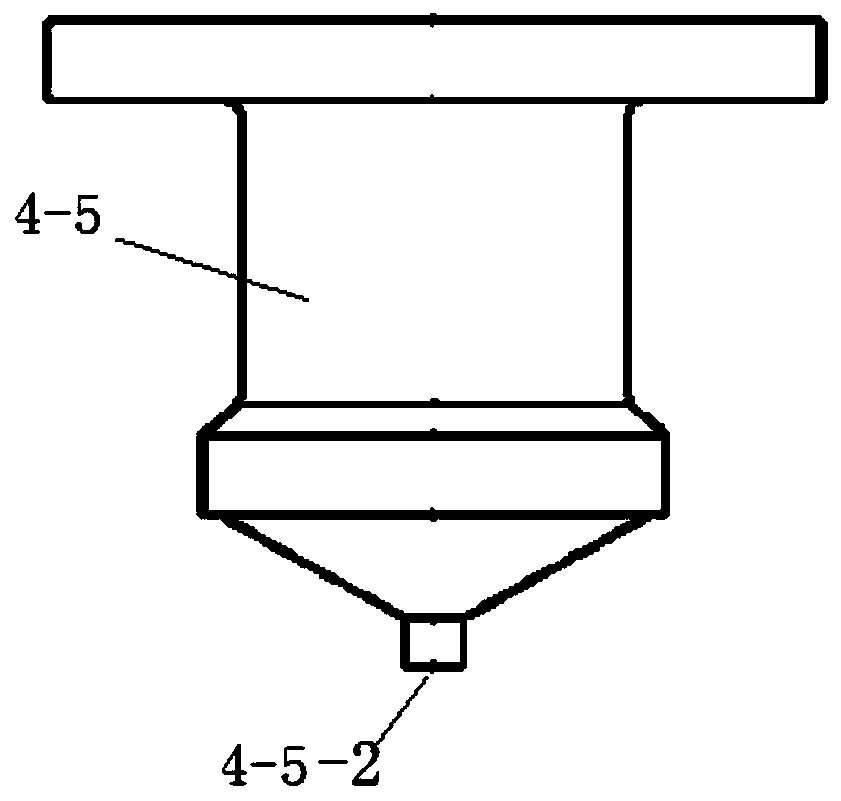

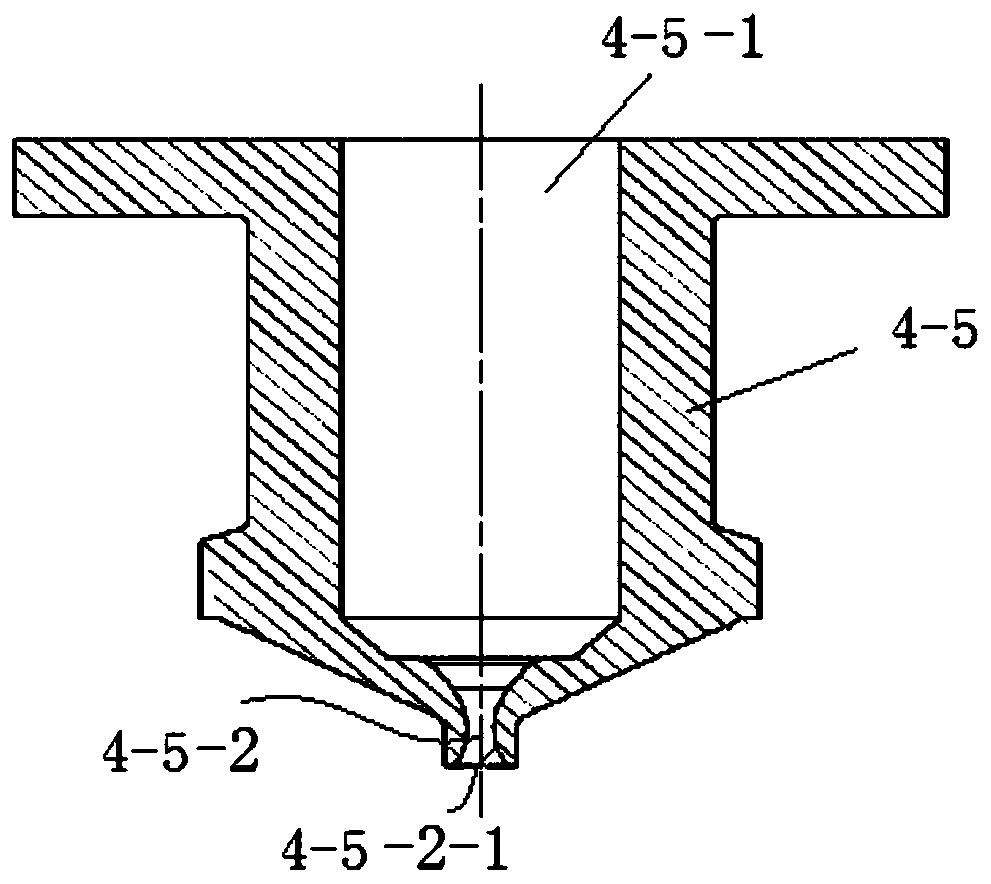

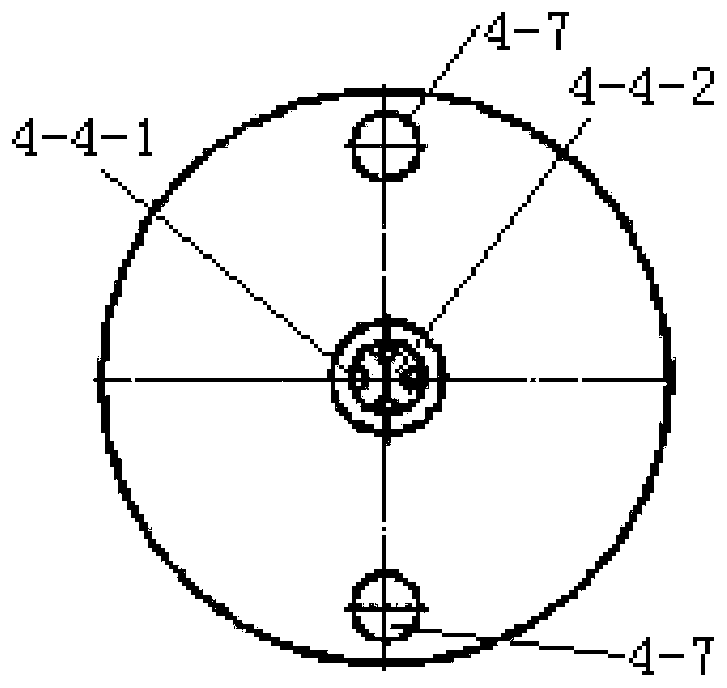

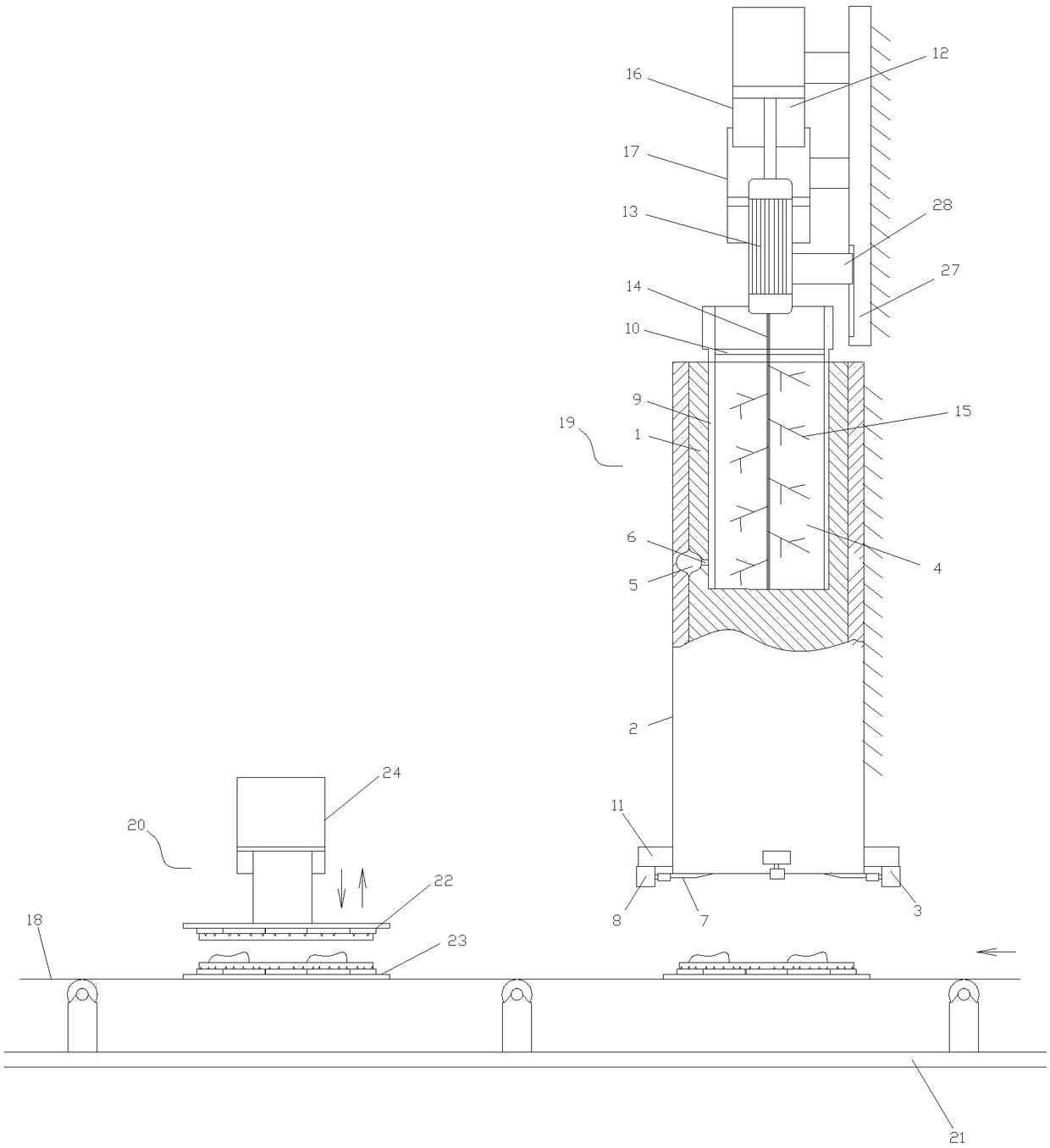

Monitoring device and method for aerosol in pipeline and pipeline system

ActiveCN107727541ASame flow rateHigh precisionNuclear energy generationParticle size analysisHydrologyControl valves

The invention discloses a monitoring device and method for aerosol in a pipeline and a pipeline system. The monitoring device comprises a variable diameter mechanism, a detection circuit, a sampling mechanism, a backflow mechanism, a first detection mechanism, a second detection mechanism and a first control valve, wherein the variable diameter mechanism can control the opening of the pipeline; the detection circuit is provided with a measuring device for testing the aerosol concentration and the particle size distribution; the inlet end of the sampling mechanism is communicated with the pipeline positioned at the upstream of the variable diameter mechanism, and the outlet end of the sampling mechanism is communicated with an inlet of the detection circuit; the outlet end of the backflow mechanism is communicated with the pipeline positioned at the downstream of the variable diameter mechanism, and the inlet end of the backflow mechanism is communicated with an outlet of the detectioncircuit; the first detection mechanism is used for detecting the flow rate of gas in the pipeline; the second detection mechanism is used for detecting the flow rate of gas in the detection circuit; and the first control valve is used for controlling the flow rate of the gas in the detection circuit. The monitoring device disclosed by the invention has the benefit that the opening of the variablediameter mechanism can be dynamically adjusted, so that the flow rate of sample gas is the same as that of the gas in the pipeline, and the measuring accuracy is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

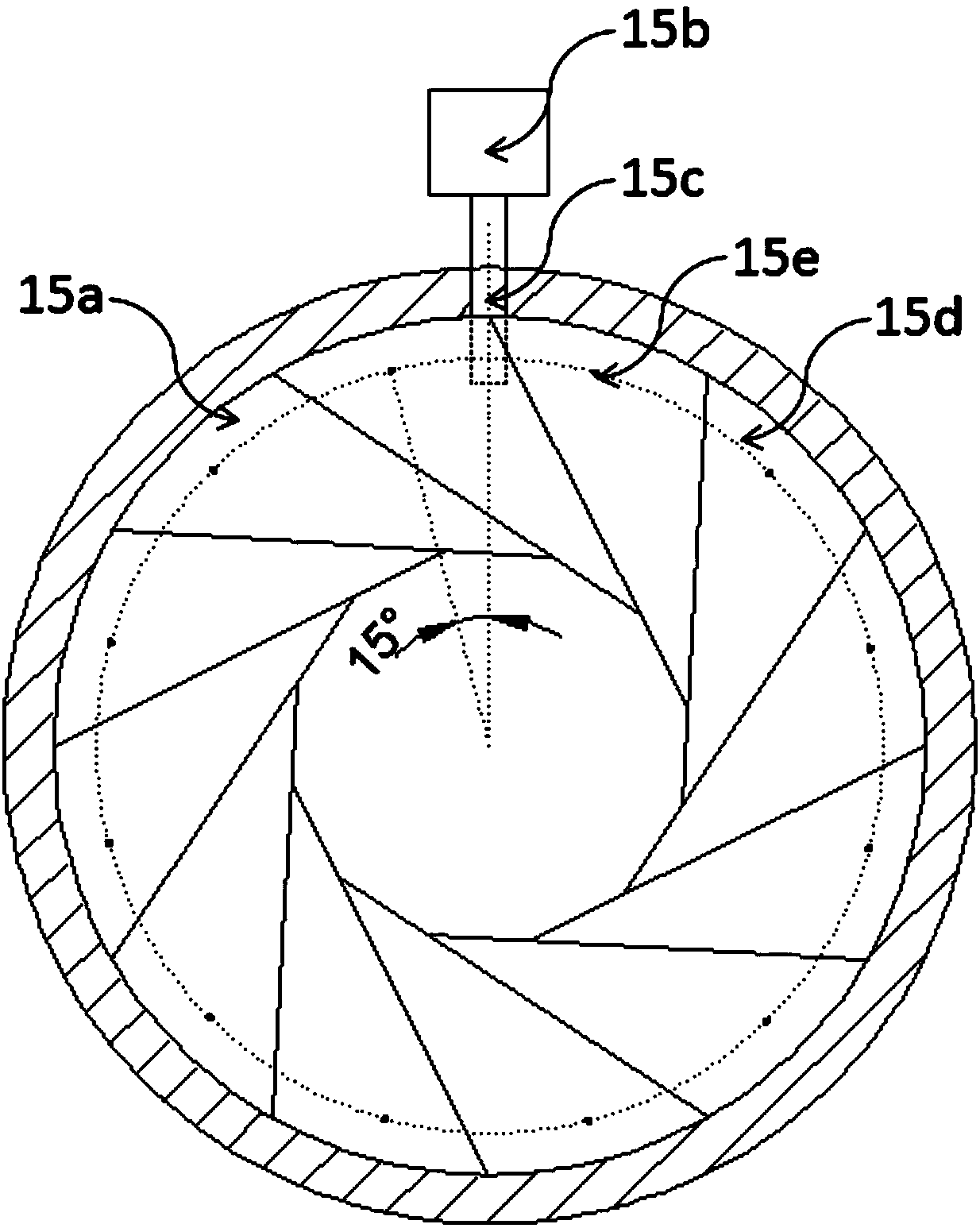

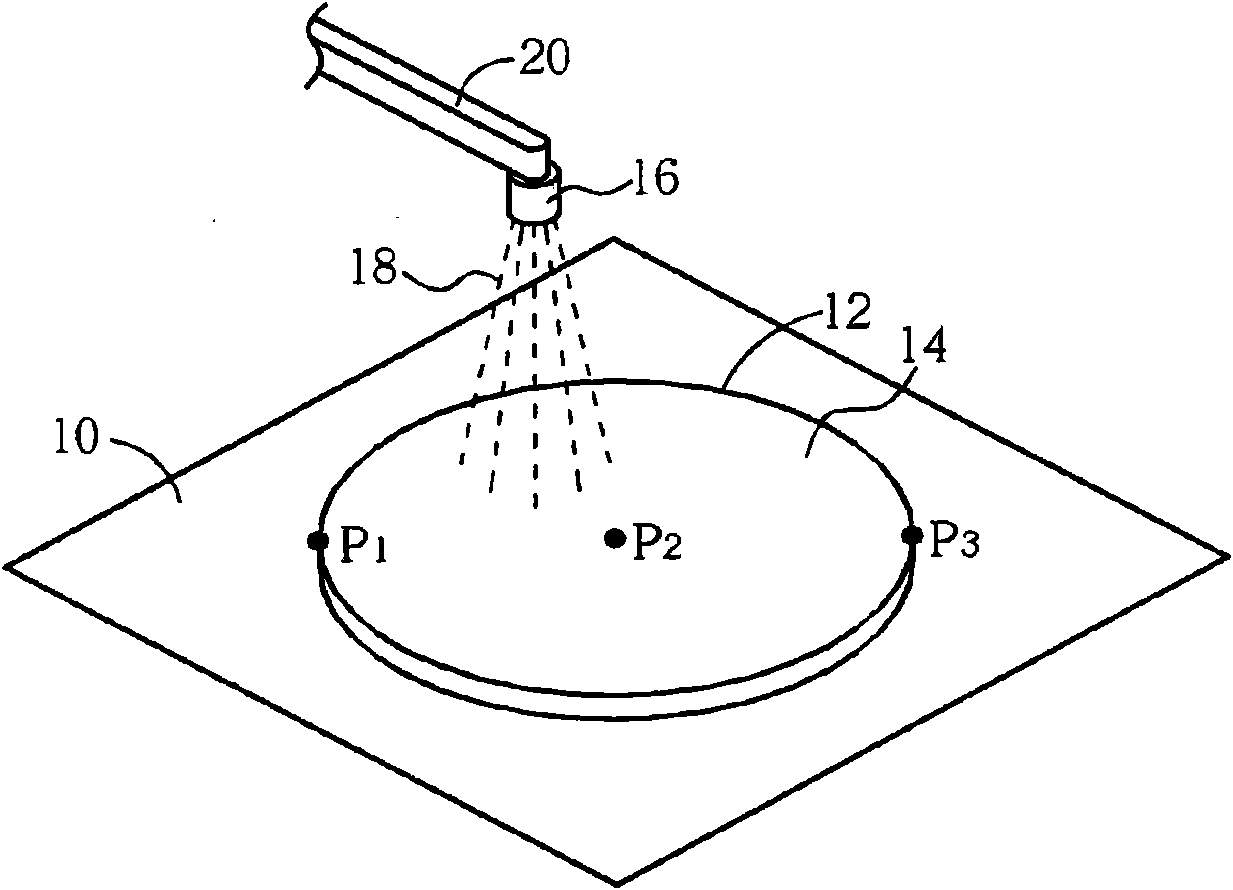

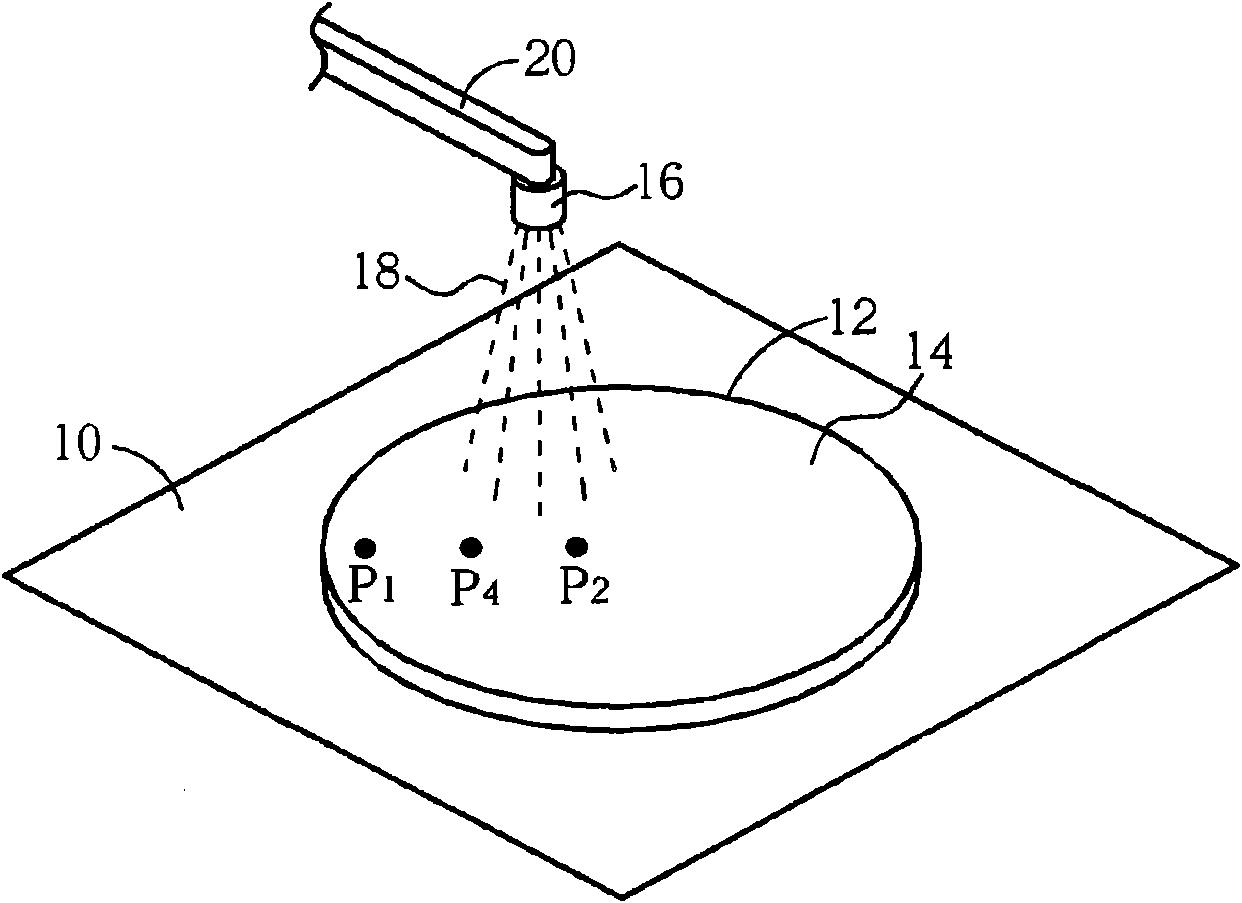

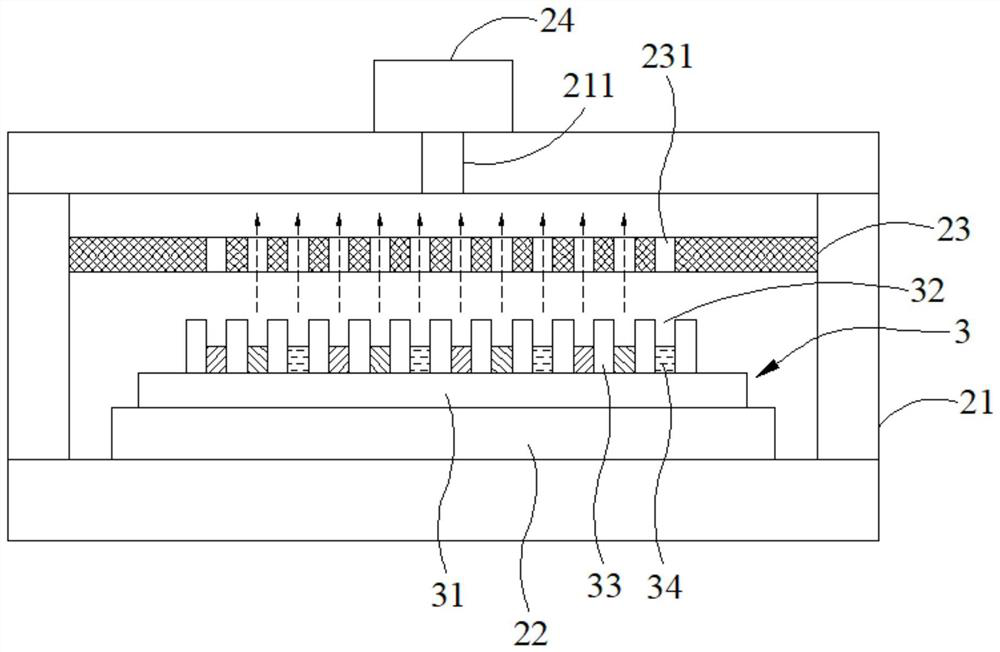

Method and device for cleaning wafer

InactiveCN102148131ASame flow rateThe same timeSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringSet point

The invention discloses a method and a device for cleaning wafers. The method for cleaning wafers comprises the following steps: providing a platform for bearing and rotating a wafer, wherein the wafer is provided with a surface to be cleaned; arranging a nozzle above the wafer for spraying cleanout fluid on the surface to be cleaned; then cleaning: rotating the wafer; and moving the nozzle at non-constant velocity to a second set point from a first set point on the surface to be cleaned so that the time the first set point exposes to the cleanout fluid is same with the time the second set point exposes to the cleanout fluid. In addition, the nozzle moves slowly when close to the edge of the wafer, and moves faster when close to the centre of a circle of the wafer.

Owner:UNITED MICROELECTRONICS CORP

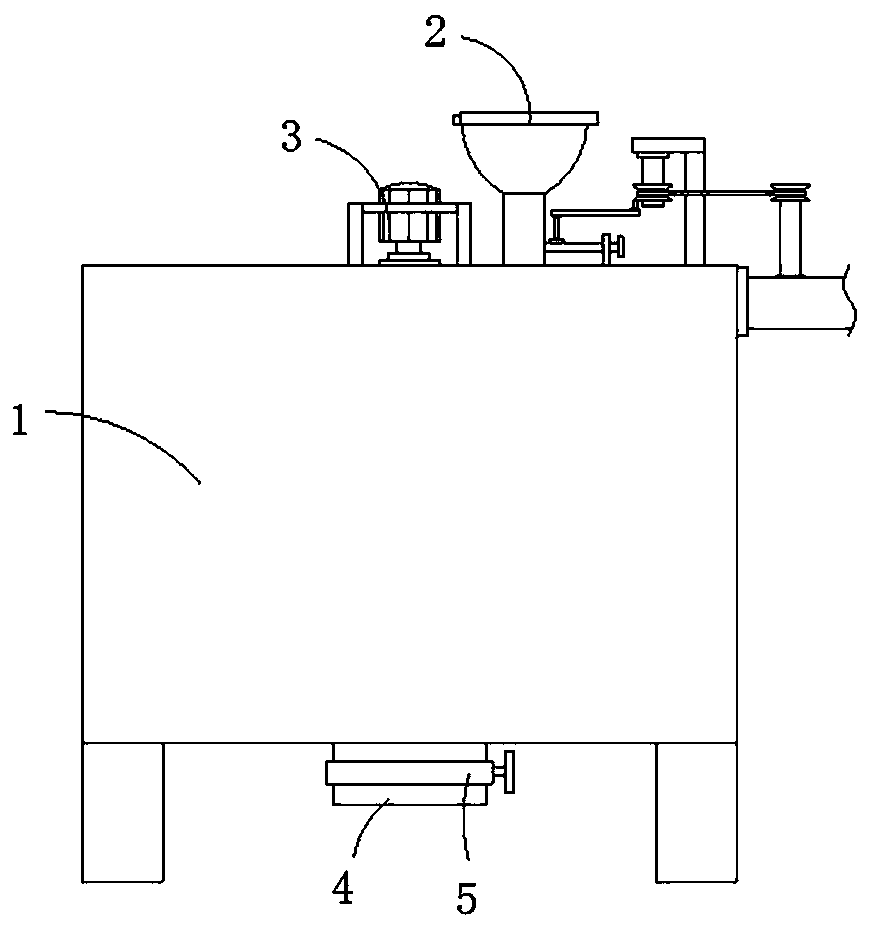

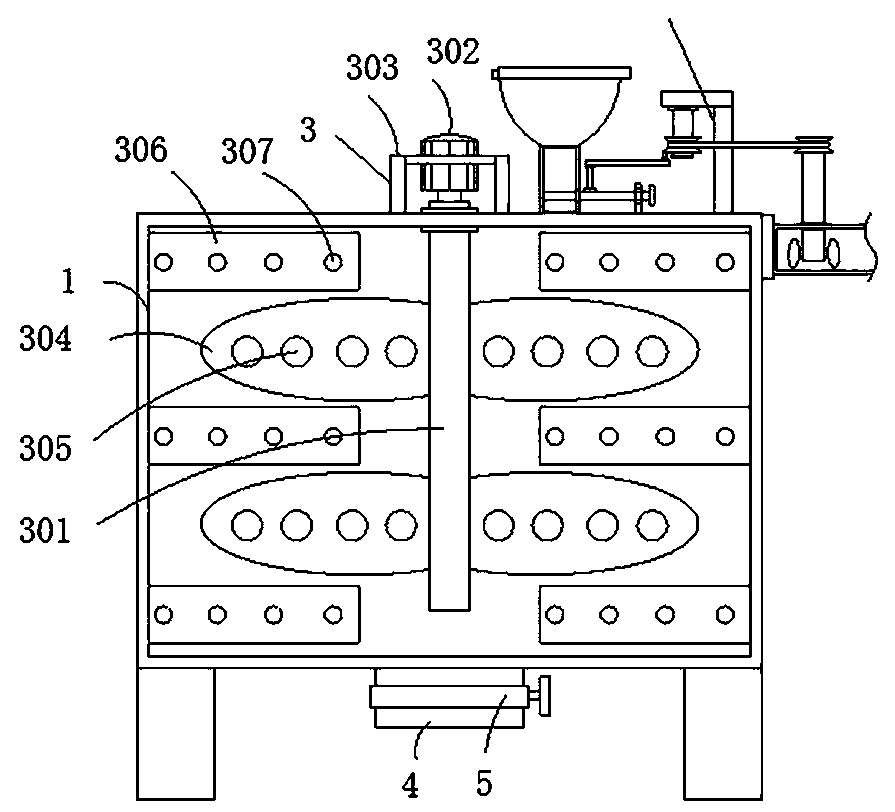

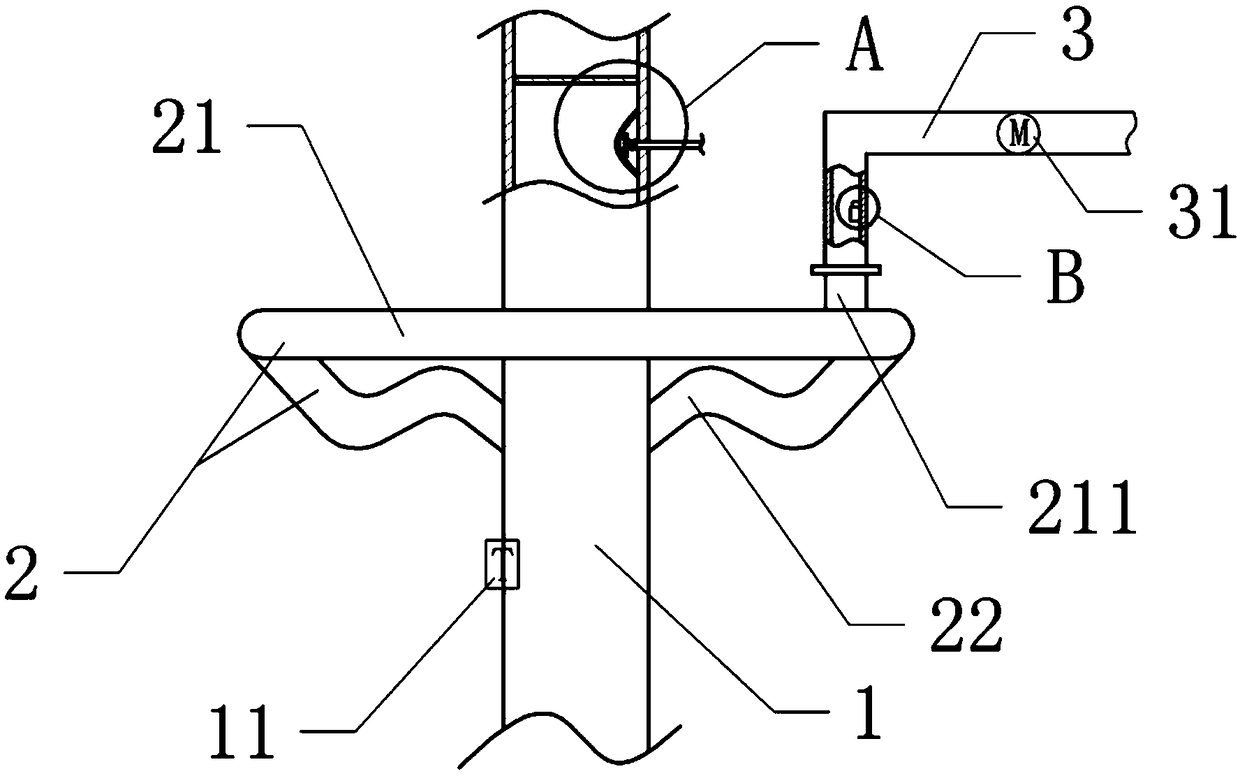

Sewage treatment uniform dosing device based on water flow transmission

InactiveCN109173769AUniform governanceImprove processing efficiencyRotary stirring mixersTransportation and packagingDrive wheelWater flow

The invention discloses a sewage treatment uniform dosing device based on water flow transmission and relates to the technical field of sewage treatment. The sewage treatment uniform dosing device comprises a mixing box, a dosing mechanism, a mixing mechanism, a water outlet pipe and a shut-off valve. The dosing mechanism is connected to the middle of the mixing box. The top of the water outlet pipe is fixedly communicated with the middle of the bottom of the mixing box. The shut-off valve is fixedly connected to the water outlet pipe. The dosing mechanism comprises a connecting pipe, a waterinlet pipe, a rotating rod, fan blades, a driving wheel, a belt, a driven wheel, a fixing rod, a fixing frame, a connection rod, a connecting plate, a movable rod, an insert plate, a dosing tube, a through hole and an agent storage box. Water flows drive the insert plate to control the dosing amount of the dosing pipe so that a certain amount of an agent is conveniently added into the waste waterand the errors are reduced. In water feeding, the agent and water are uniformly mixed so that the mixing efficiency of the wastewater treatment is increased.

Owner:浙江工业大学上虞研究院有限公司

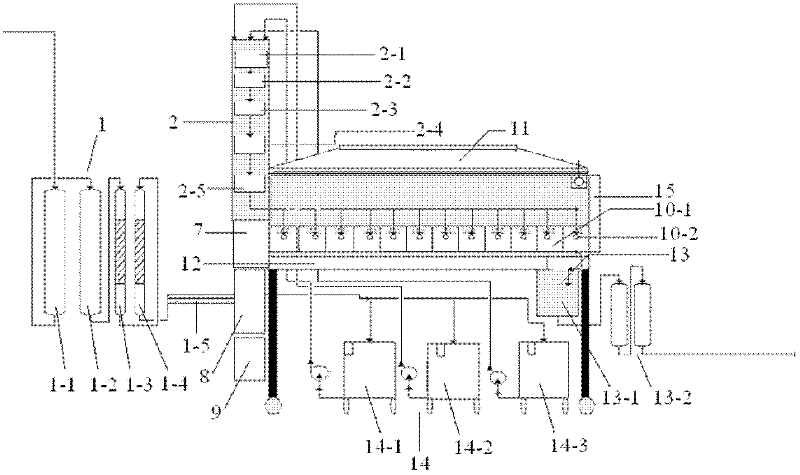

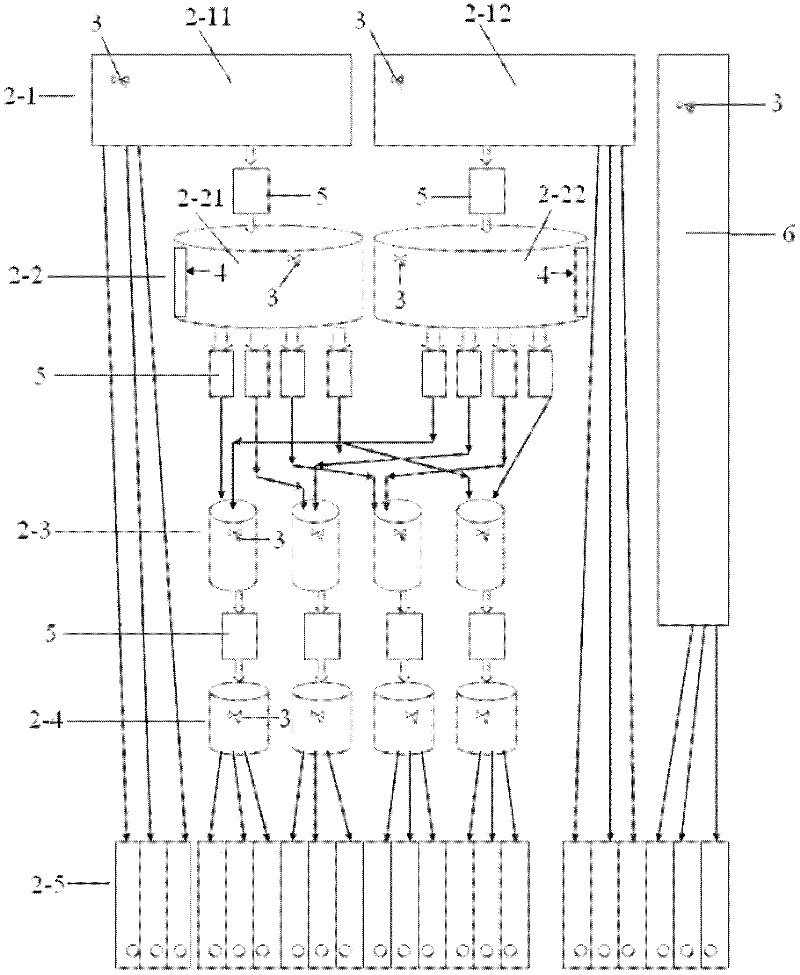

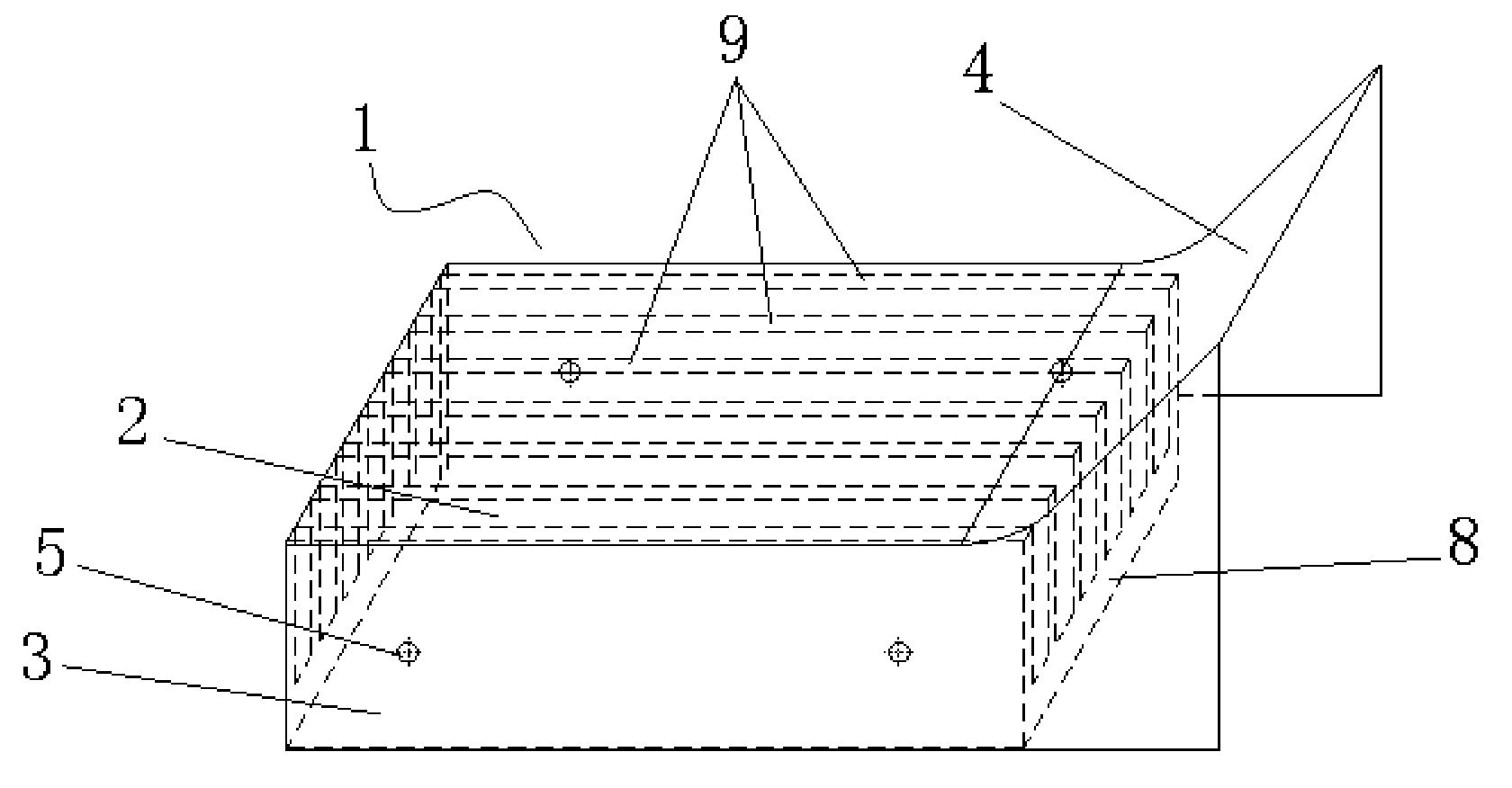

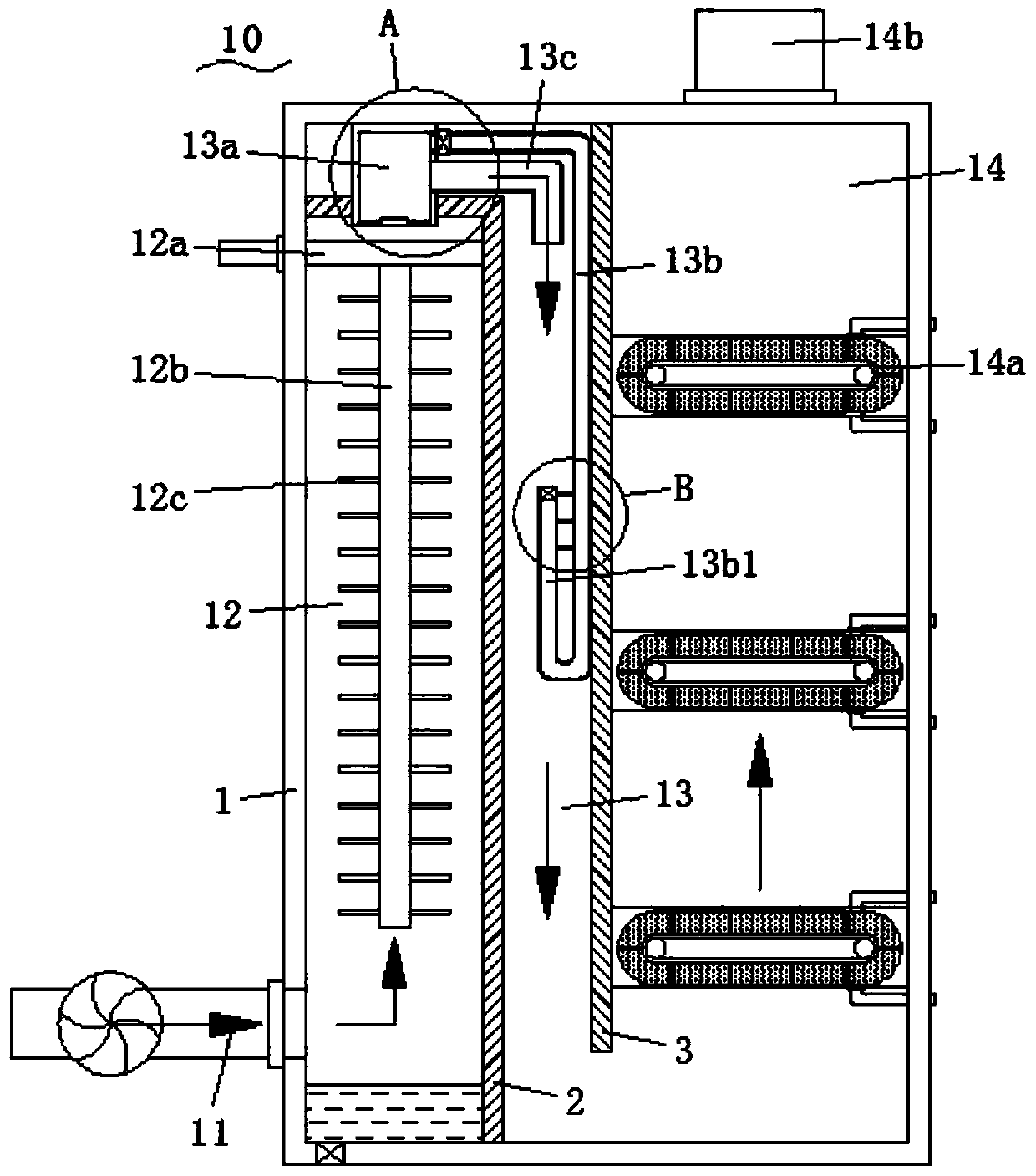

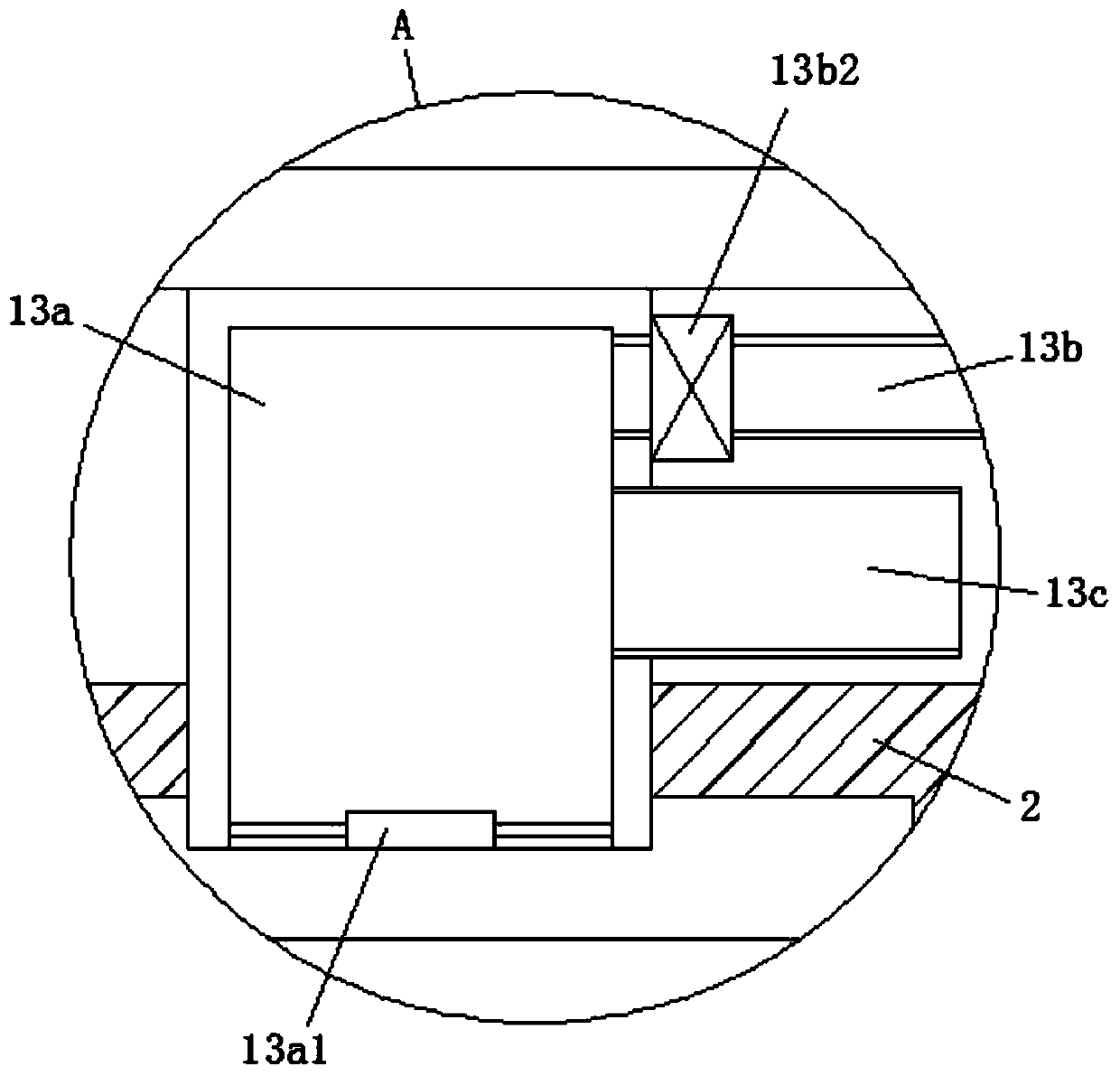

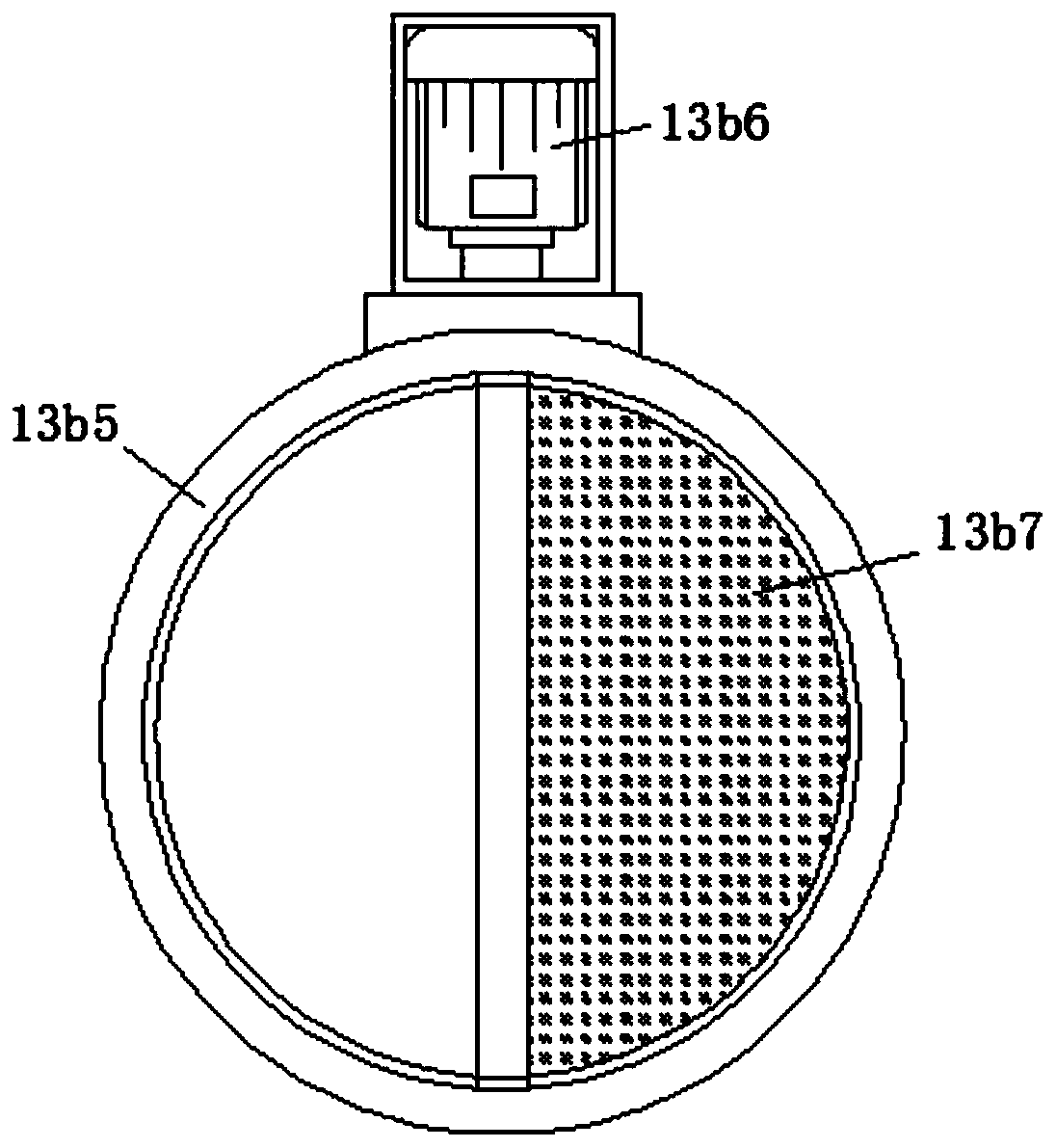

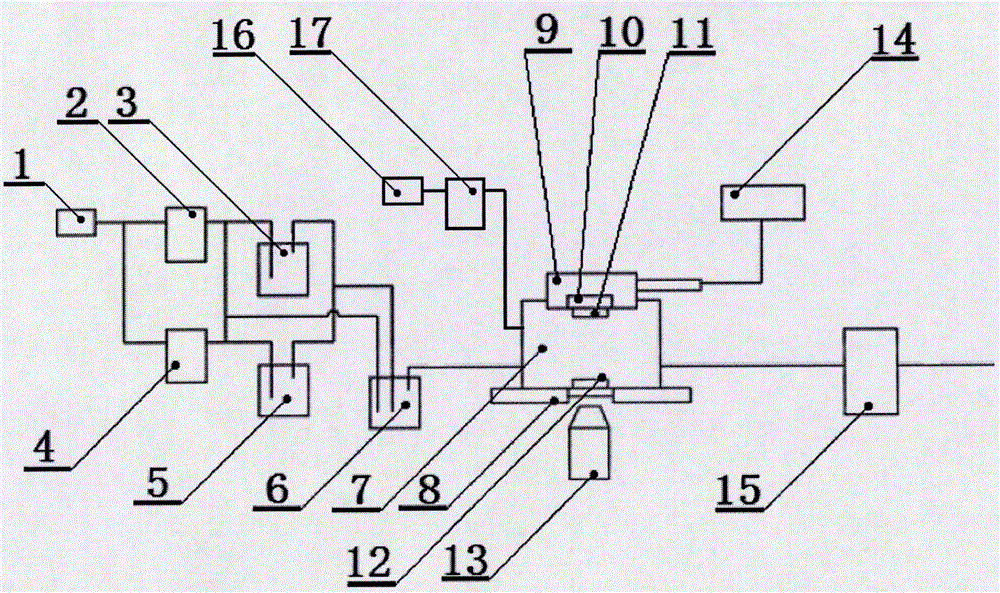

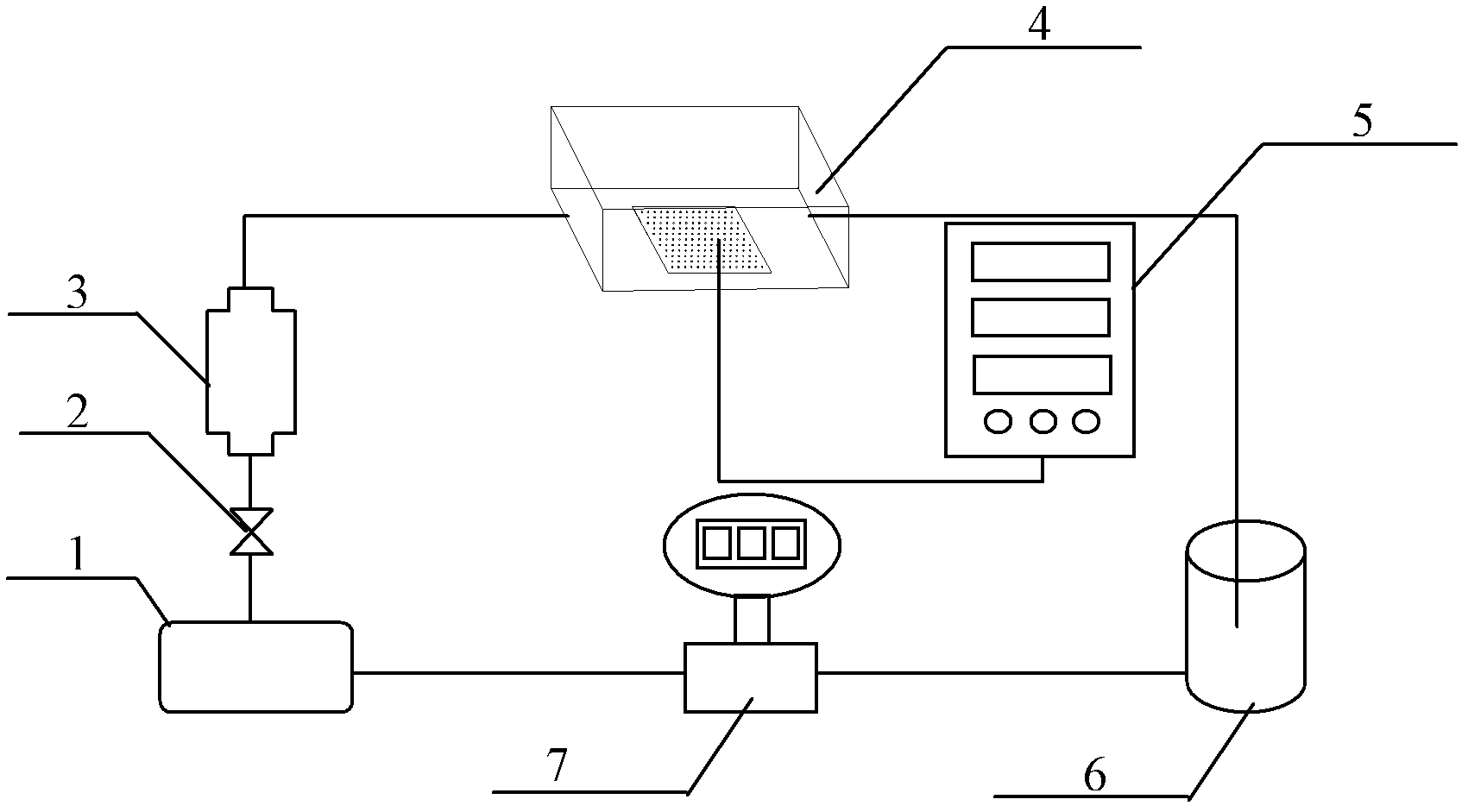

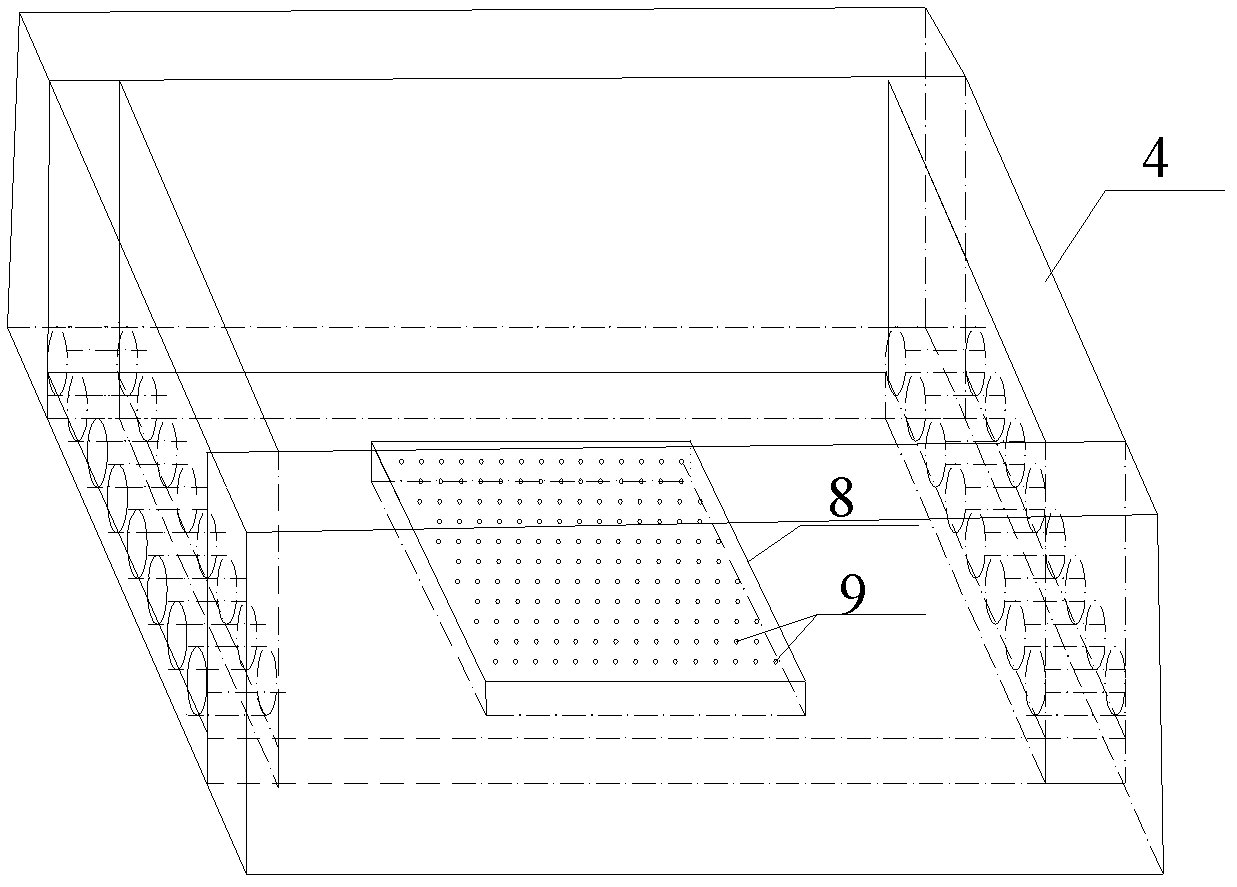

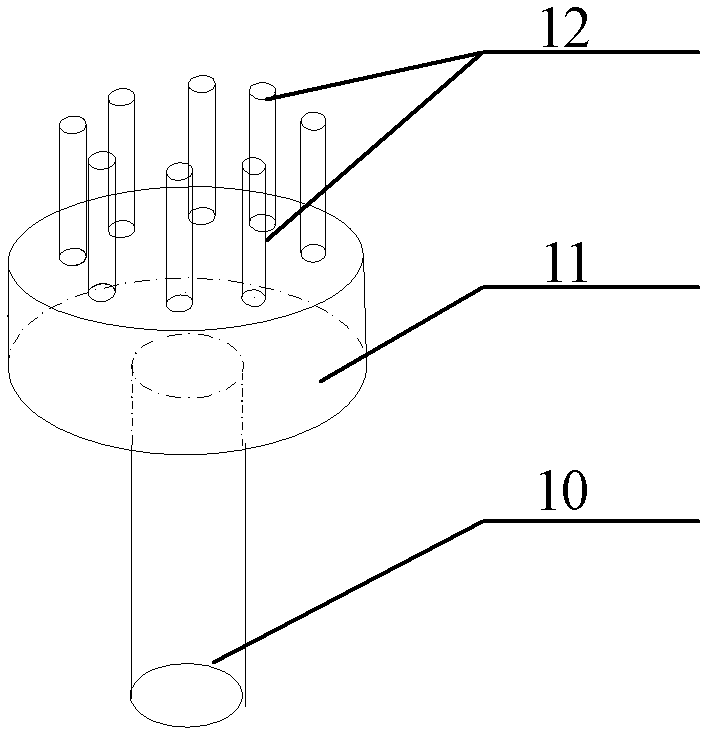

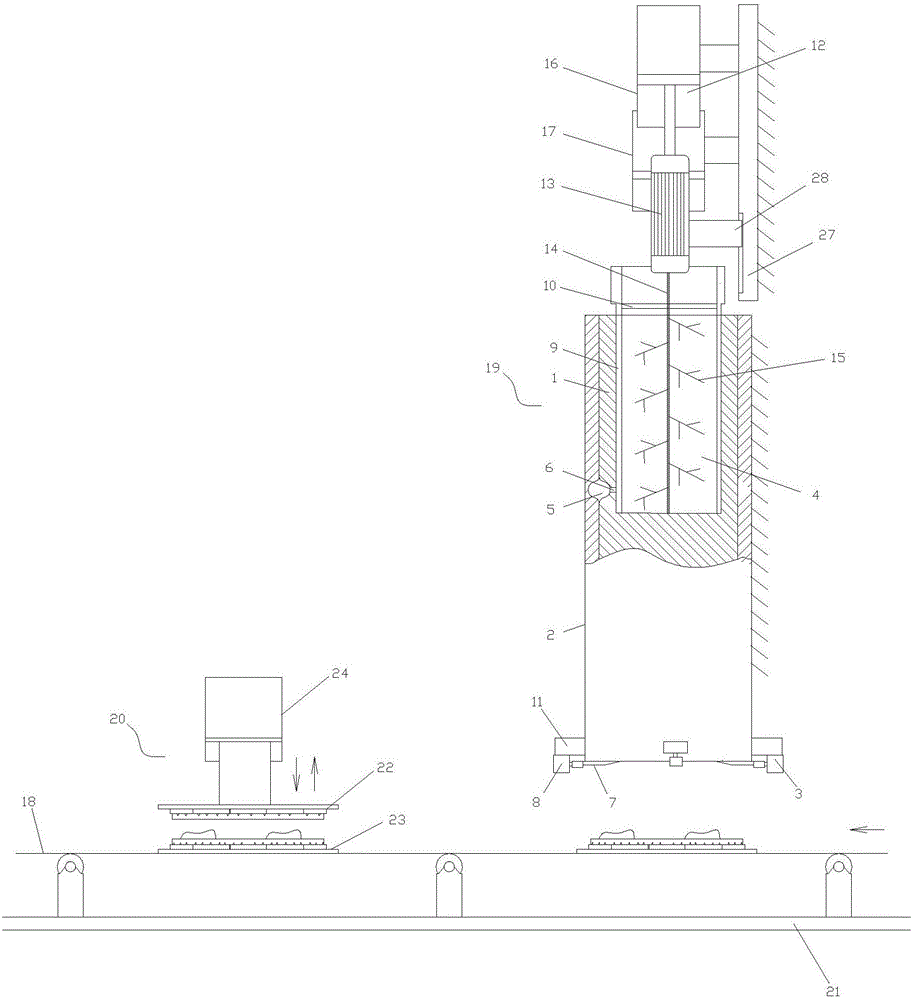

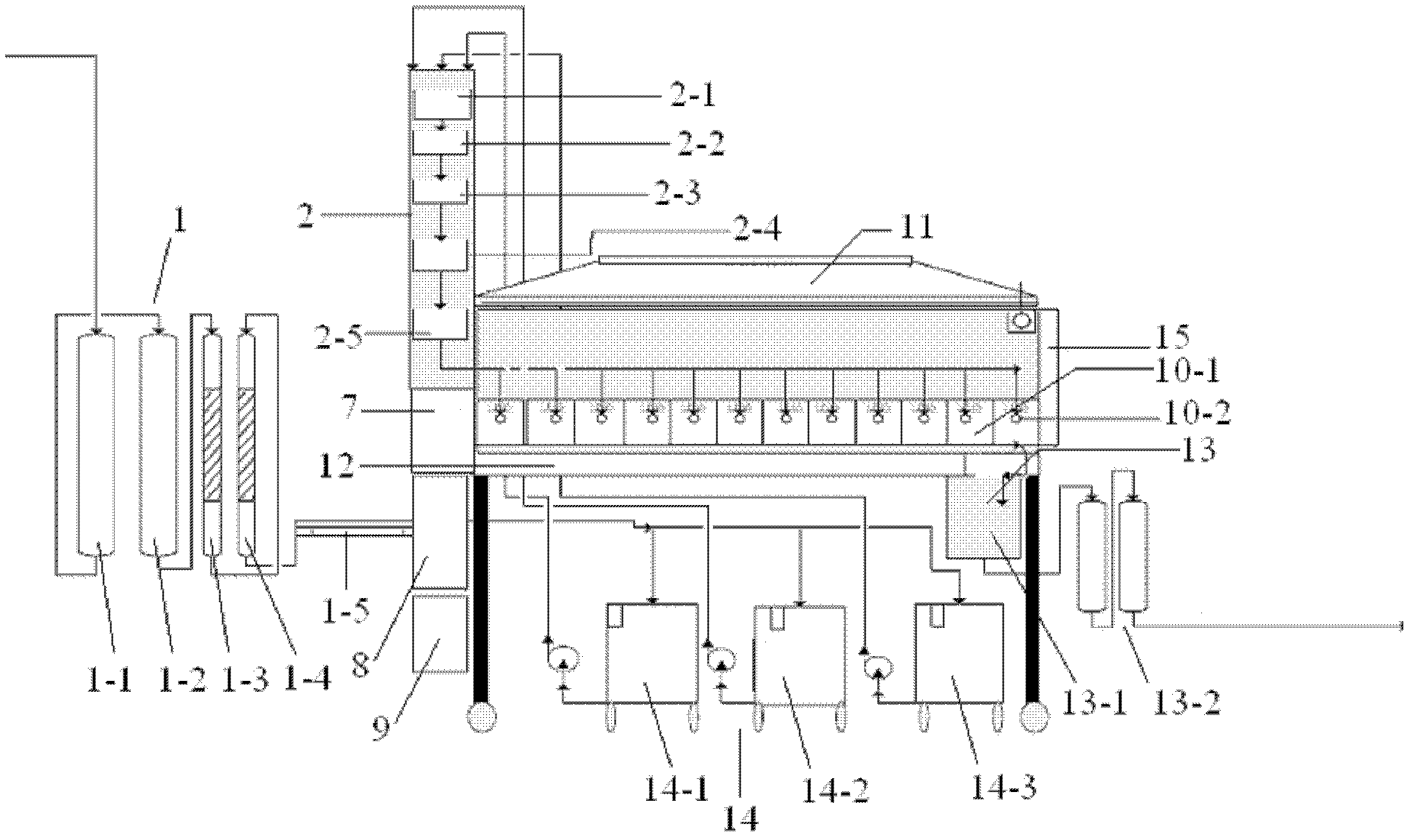

Automatic natural environment continuous waterflow simulation test device

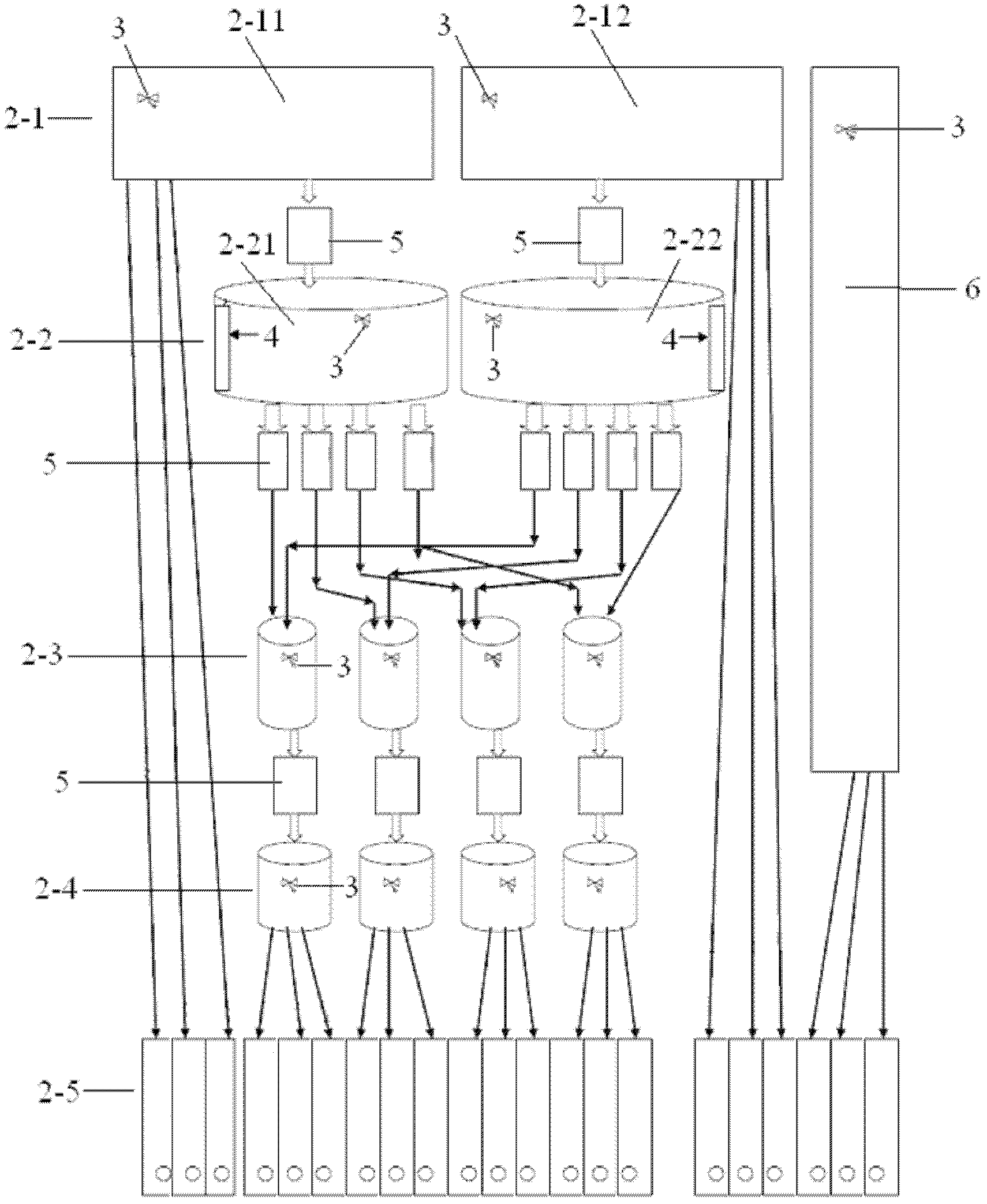

ActiveCN102642984AGuaranteed temperatureRealize automatic monitoring and recordingMultistage water/sewage treatmentCollection systemDevice simulation

The invention relates to an automatic natural environment continuous waterflow simulation test device, which comprises a water conditioning system, a dilution table, a biological test culture cabinet, a temperature and illumination control system, a data monitoring and acquiring system, a wastewater collection system, a water storage system and the like. Compared with the prior art, the automaticnatural environment continuous waterflow simulation test device has the advantages that the device is evidently effective in natural waterflow dynamic environment simulation, stable in long-time operation, high in safety, simple in regulation, high in automation level, easy to demount for washing and easy to replace. Whole-course automatic monitoring, tracking and recording of the whole test process by a computer can be realized, reliability and stability in operation of the long-term waterflow test can be guaranteed by the test device, and the test device is applicable to GLP (good laboratory practice) tests of short or long toxicity of various relevant aquatic organisms published by the OECD (organization for economic cooperation and development) and the EPA (environmental protection agency).

Owner:SHANGHAI RES INST OF CHEM IND +1

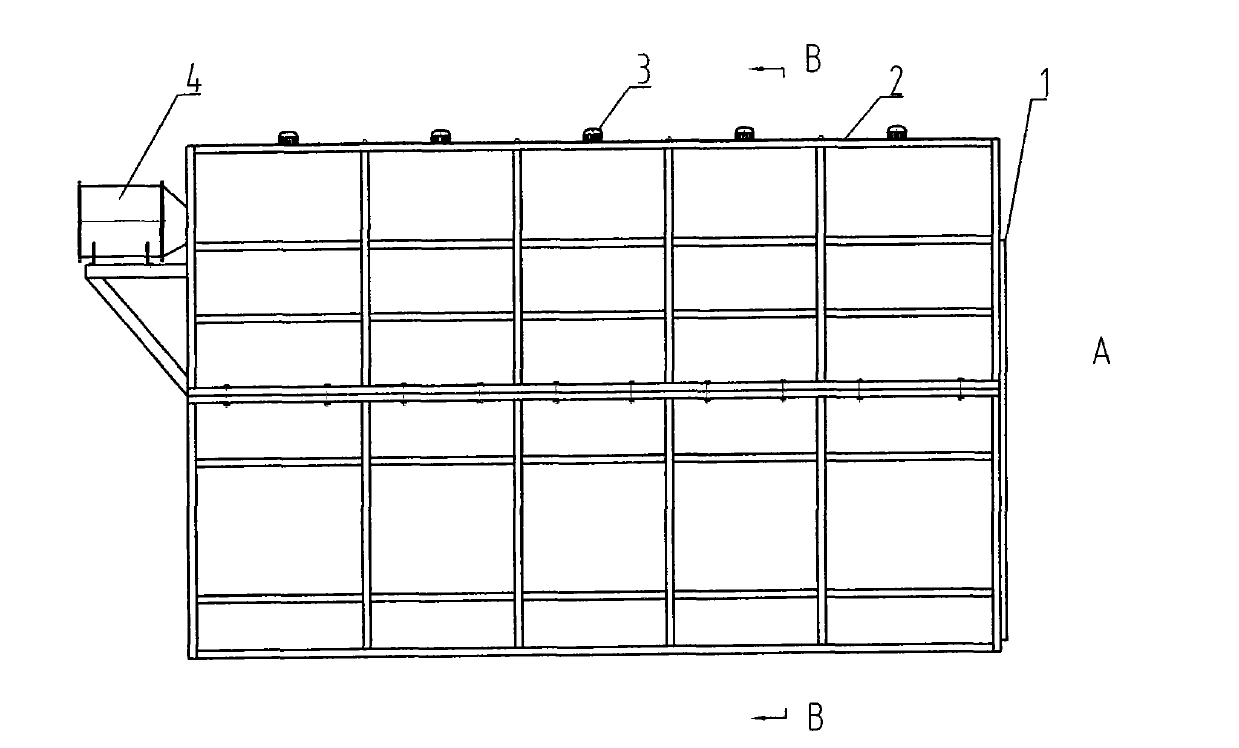

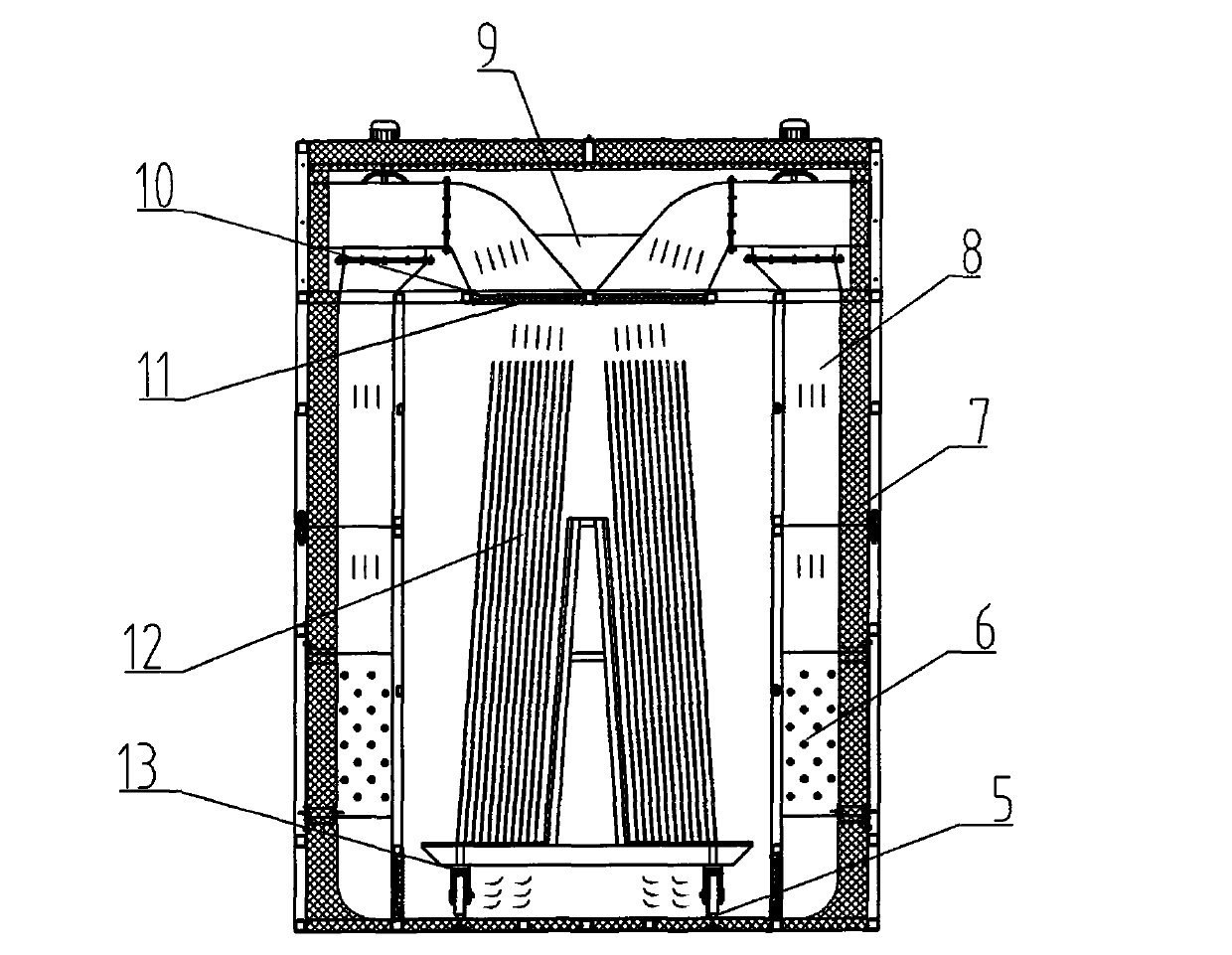

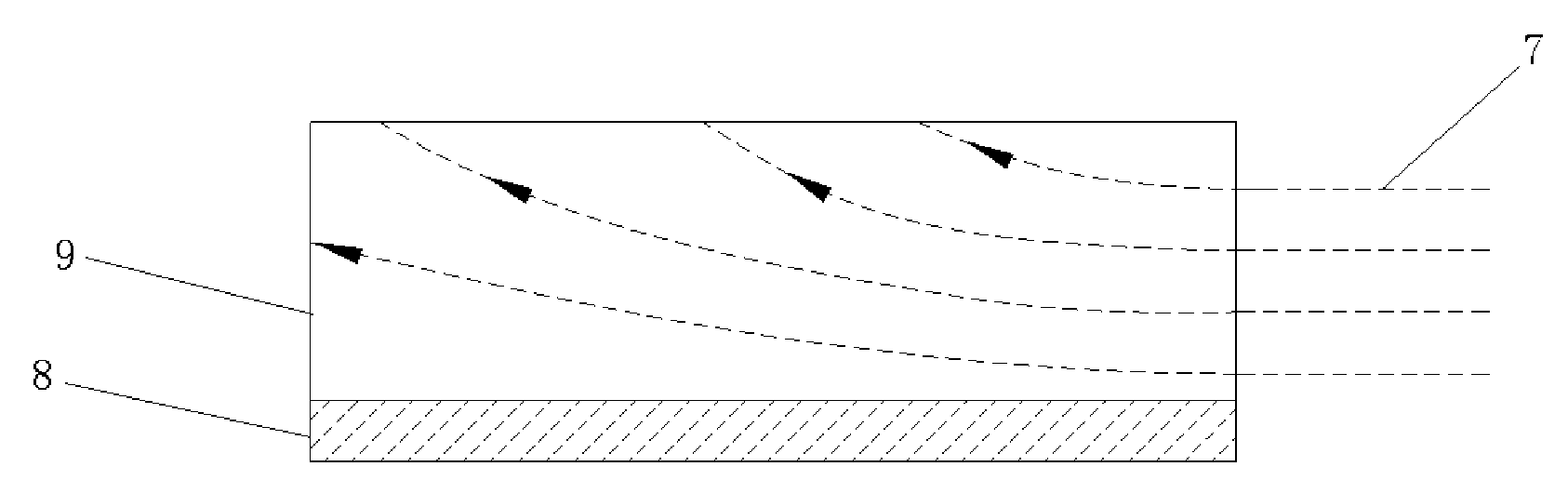

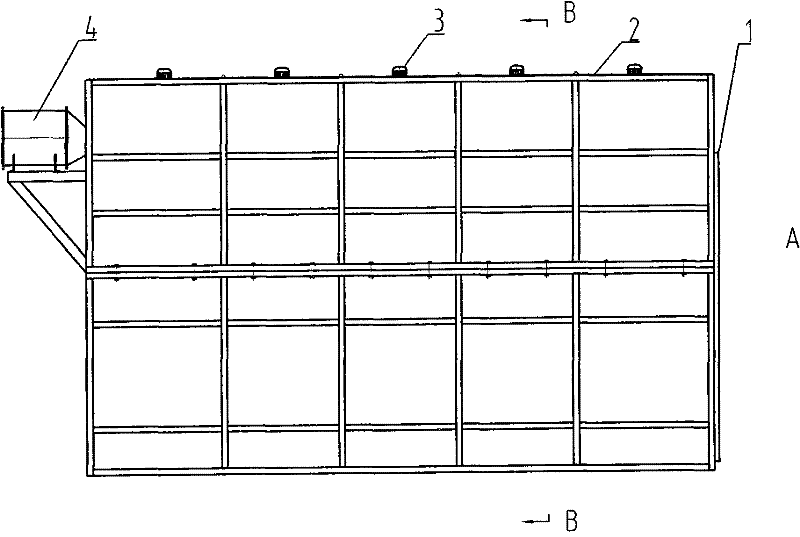

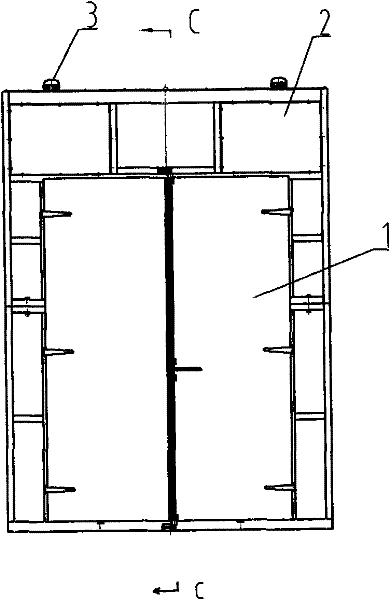

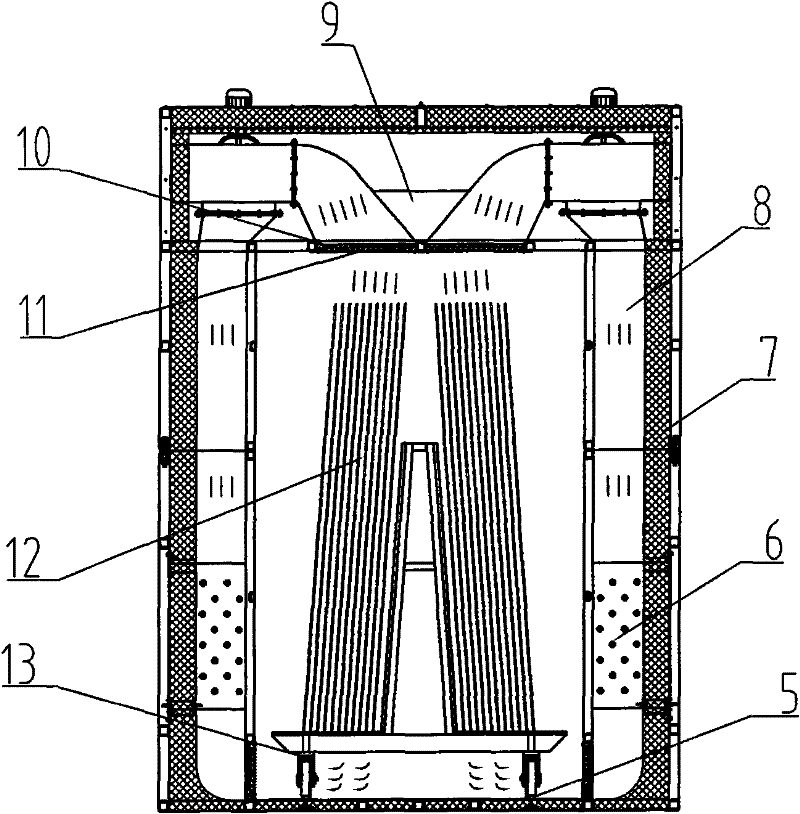

Homogeneous furnace for toughened glass

InactiveCN102020416AImprove temperature uniformitySame flow rateGlass productionToughened glassThermal cycle

The present invention relates to improvement of structure of homogeneous furnace capable of carrying out anti explosive treatment on toughened glass. The invention provides a homogeneous furnace for toughened glass which is energy-saving and highly production efficient. The homogeneous furnace comprises a furnace body, a furnace door and an air cooler being installed on both sides of the furnace body respectively. The structure of the furnace is characterized in that a temperature-insulating layer is installed on the periphery of the furnace body, thermal cycle ducts are installed at the two sides of the furnace body and at the temperature-insulating layer on the top, a heater and a circulating fan are installed at the bottom and the top of the thermal cycle duct respectively, and a cooling cycle duct is installed between the thermal cycle ducts on the top of the furnace body.

Owner:辽宁北方机械股份有限公司

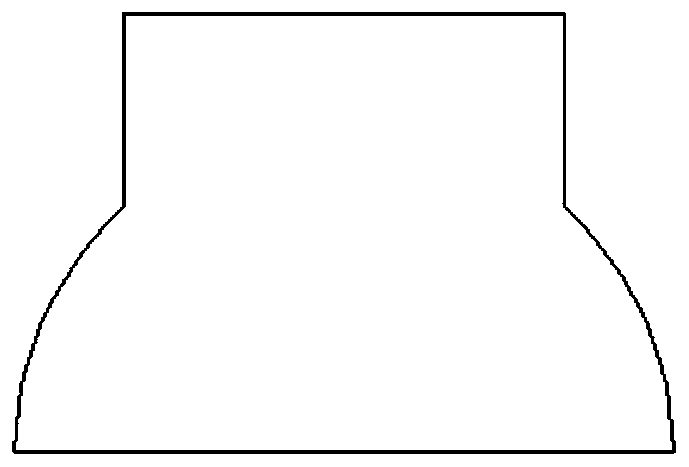

Radiation device with wind scooper

InactiveCN101827513ALow costImprove the protective effectSemiconductor/solid-state device detailsSolid-state devicesHeat conductingWind field

The invention relates to a radiation device with a wind scooper. Conventional radiators have the disadvantages of the low wind speed of a high-temperature area, the high wind speed of a low-temperature area and poor radiation effect. The radiation device with the wind scooper comprises a heat-conducting pedestal and a radiation fin set arranged on the heat-conducting pedestal. The radiation device is characterized in that: the TT-shaped wind scooper is sleeved on the periphery of the radiation fin set; and one end of the wind scooper is externally extended to form a wind inlet with an externally-extended surface, while the other end is provided with a TT-shaped wind outlet. The radiation device with the wind scooper has the advantages of making the flow speed of airflows flowing through the radiator higher than that of an external wind field, increasing the airflow and flow speed of the high-temperature area of the radiator, not decreasing the airflow and the flow speed of a downstream area of the radiator and improving radiation performance from three aspects.

Owner:郏松筠

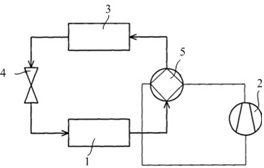

Air conditioner

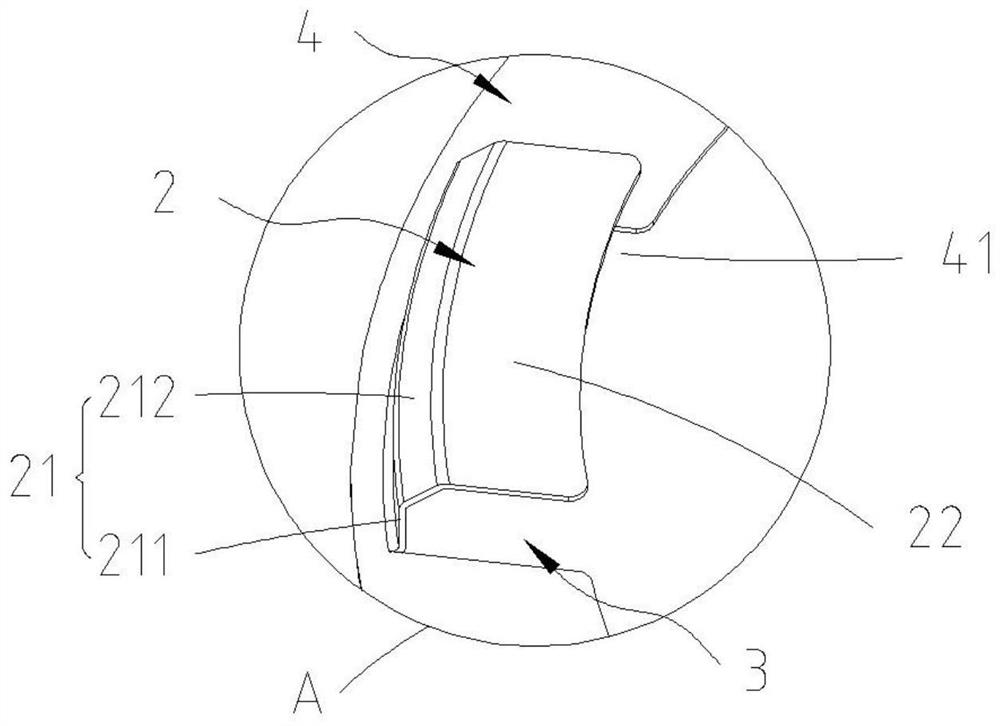

InactiveCN111780255AEvenly distributedImprove heat transfer effectCompression machines with non-reversible cycleSpace heating and ventilation detailsRefrigerantMechanical engineering

The invention discloses an air conditioner. A heat exchanger applied to a heat exchanging loop comprises flat pipes and a distributor. The distributor is used for distributing a gas-liquid two-phase refrigerant uniformly to multiple flat pipes. A flow jetting cavity and a backflow cavity are formed in the distributor. The refrigerant in the refrigerating pipeline is jetted into the flow jetting cavity and accelerates and flows, and dispersed bubble flow is formed. The refrigerant in the flow jetting cavity is jetted into the flat pipes, and the refrigerant, which is not jetted into the flat pipes, in the flow jetting cavity flows back to the backflow cavity and flows back to the flow jetting cavity and enters next flowing circulation. By means of the distributor, it can be achieved that under variable working conditions, the two-phase refrigerant is distributed uniformly inside different flat pipes in the same process, the heat exchanging effect of the heat exchanger is improved, and then the integral heat exchanging effect of the air conditioner is improved.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Waterproof roll production workshop waste gas treatment device and treatment process thereof

ActiveCN110935262ARealize diversion and guidanceRealize the deceleration effectCombination devicesUsing liquid separation agentProcess engineeringGuide tube

The invention belongs to the technical field of waste gas treatment, and discloses a waterproof roll production workshop waste gas treatment device and a treatment process thereof. The treatment device comprises: a gas collection device, a pretreatment device, a speed reduction device and an adsorption device which are sequentially arranged in a waste gas circulation direction; the speed reductiondevice comprises a flow dividing buffer assembly, the shunting buffer assembly comprises a gas-guide tube, and a first flow dividing tube and a second flow dividing tube which are connected to one side of the gas-guide tube; the gas-guide tube is connected with the top of the pretreatment device, the flow dividing ratio of the first flow dividing tube to the second flow dividing tube is 1:4-2:3,the gas outlet end of the first flow dividing tube is bent to form a bent part, and the outlet end of the bent part faces the second flow dividing tube to form opposite gas outlet of the first flow dividing tube and the second flow dividing tube; in conclusion, based on the arrangement of the flow dividing buffer assembly, flow dividing and guiding of the waste gas are achieved, the waste gas after flow dividing forms flow velocity offset in an opposite guiding mode, and therefore, the speed reduction effect of the waste gas is effectively achieved.

Owner:TIANJIN JOABOA TECH CO LTD

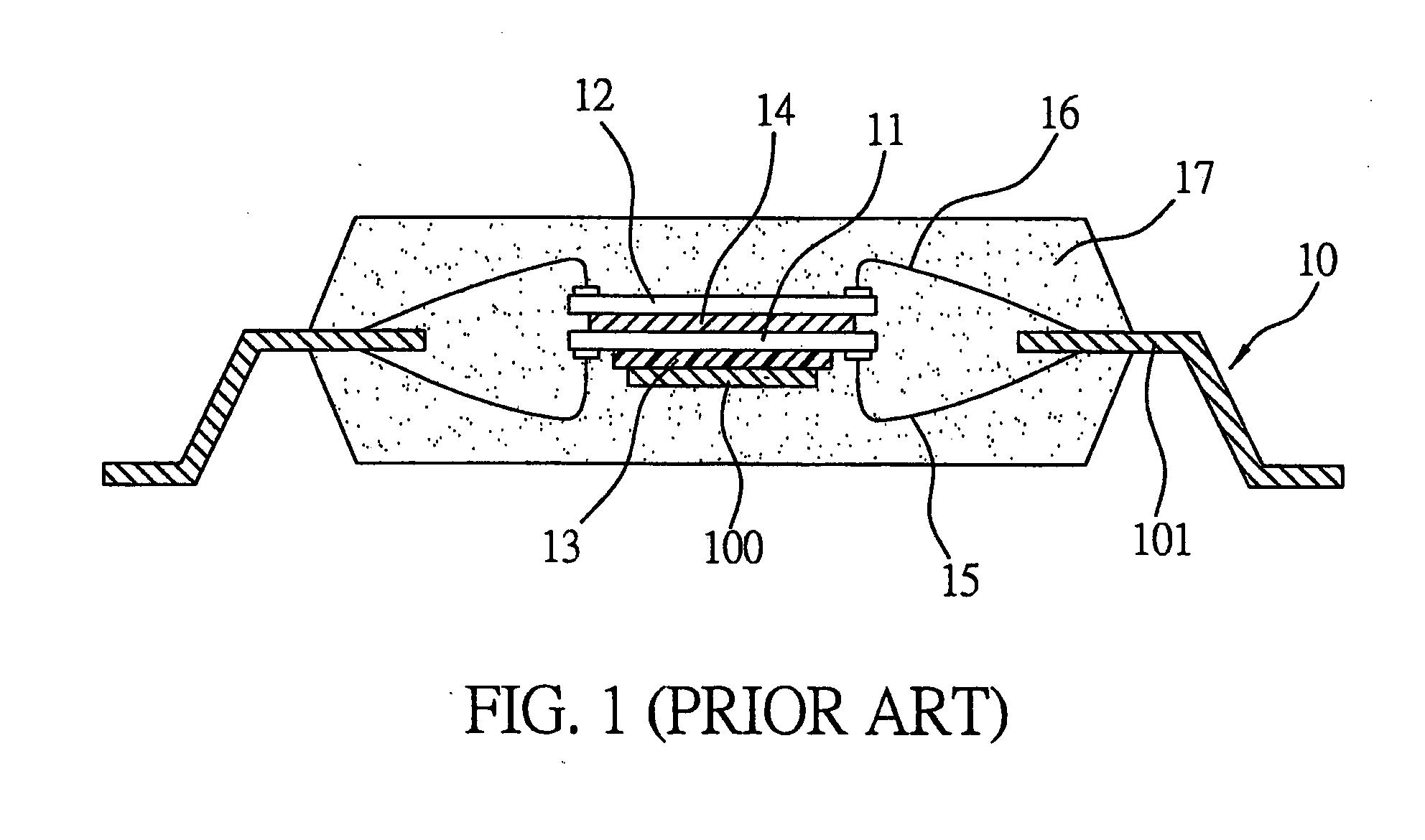

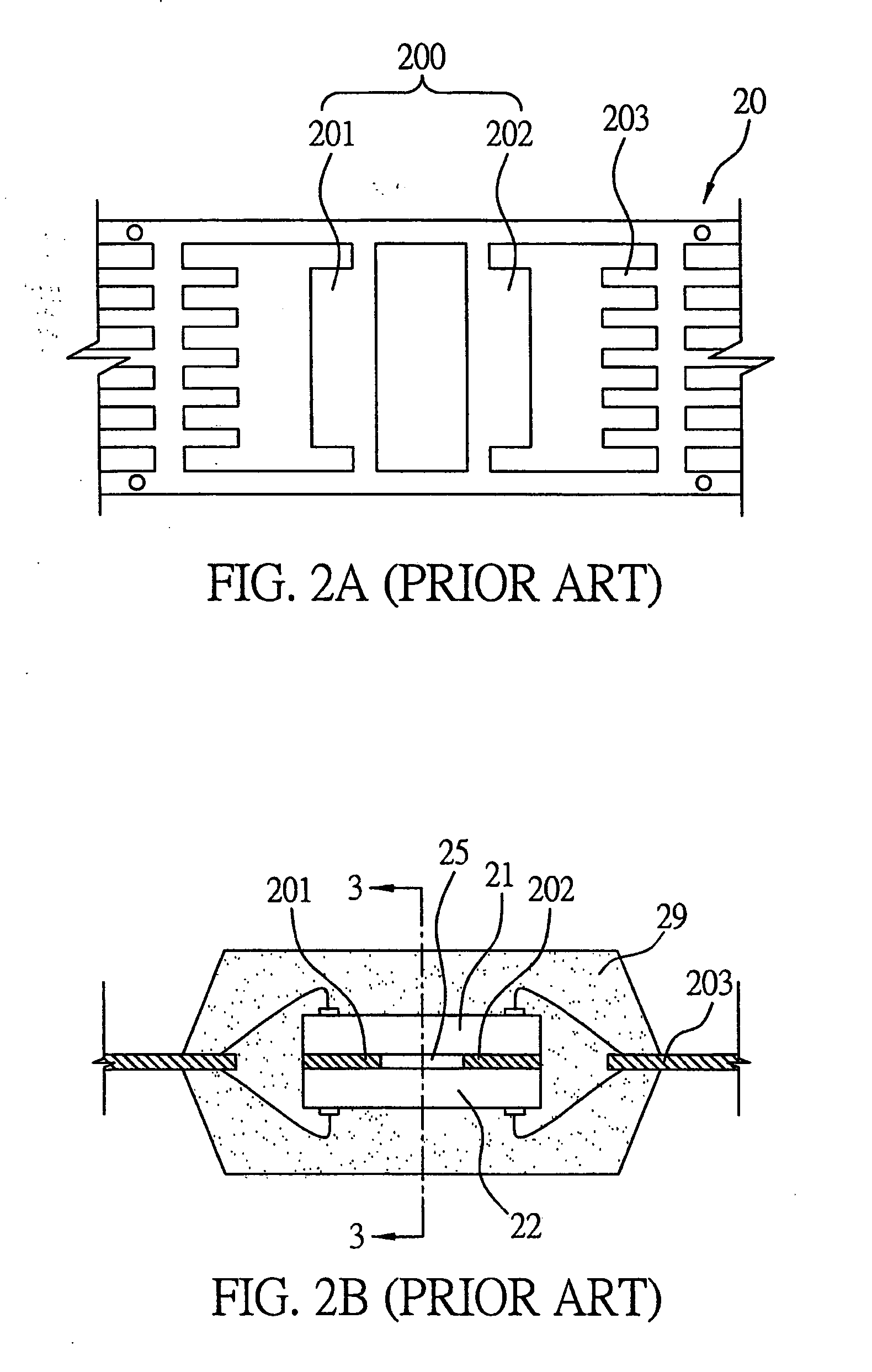

Lead frame structure and semiconductor package integrated with the lead frame structure

InactiveUS20070111395A1Reduce flow ratePrevent void formationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A lead frame structure is provided, which includes a die pad having a first mounting portion and a second mounting portion separated from the first mounting portion by a gap. The first and second mounting portions are formed with corresponding blocking surfaces bordering the gap, so as to allow a flow rate of an encapsulating resin flowing through the gap during a molding process to be reduced by the blocking surfaces, such that different portions of the encapsulating resin respectively flowing above, in and below the die pad can have substantially the same flow rate, thereby preventing bonding wires from being deformed to cause short circuit and avoiding formation of voids. A semiconductor package with the lead frame structure is also provided.

Owner:SILICONWARE PRECISION IND CO LTD

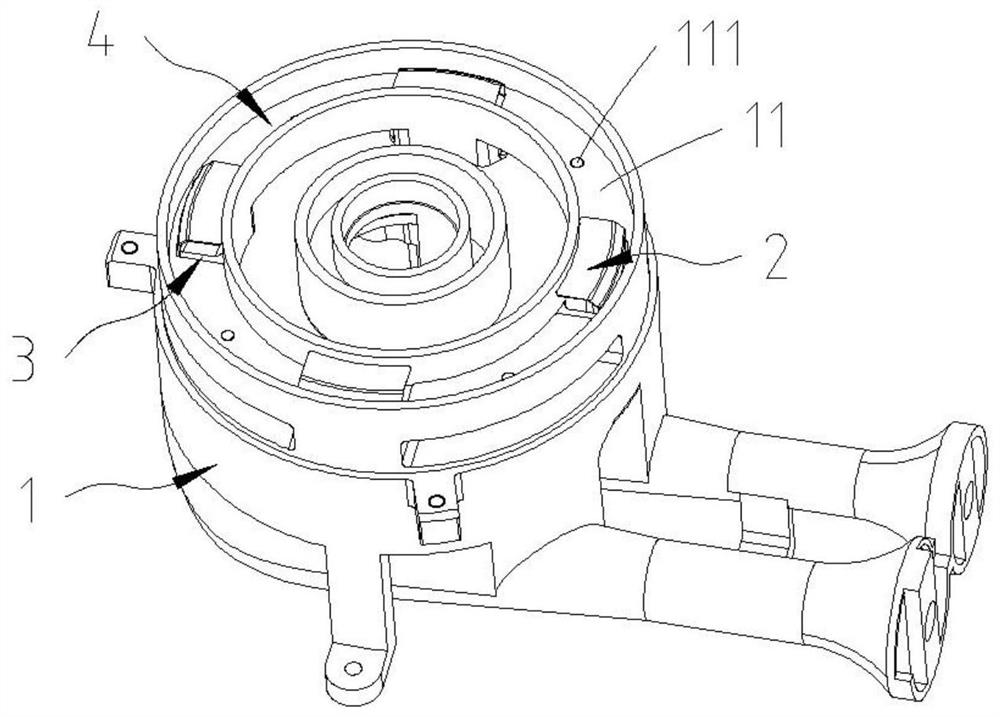

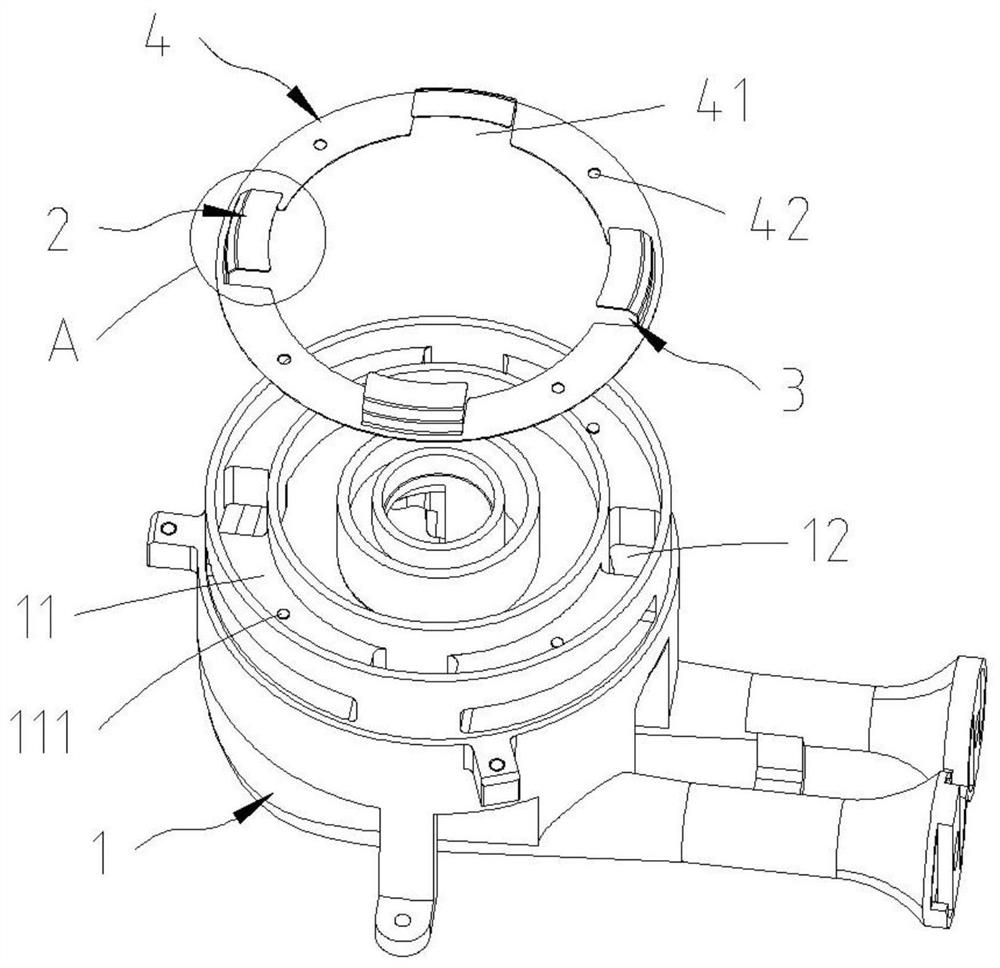

Burner with gas combing device

PendingCN111964105ASame flow rateUniform and stable flow rateDomestic stoves or rangesGaseous fuel burnerEngineeringMechanical engineering

The invention discloses a burner with a gas combing device. The burner comprises a burner body and the gas combing device. The burner body is provided with a gas mixing cavity and at least two gas channels. The gas combing device comprises a blocking structure arranged in the gas mixing cavity and located above gas channel outlets. The blocking structure is provided with a gas combing channel communicating with the gas channels, or the blocking structure, the bottom and surrounding wall of the gas mixing cavity jointly define the gas combing channel communicating with the gas channels. The left side and / or right side of the gas combing channel are / is provided with gas outlets / a gas outlet communicating with the gas mixing cavity. The burner is provided with the blocking structure, thus when gas flow flows into the gas mixing cavity, the flow speed is lowered, the flow direction is changed, the flow direction and flow speed of the gas flowing into the gas mixing cavity are combed, burning is more uniform and stable, and meanwhile flameout noise can be effectively restrained.

Owner:VATTI CORP LTD

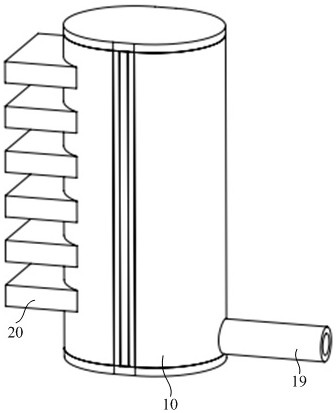

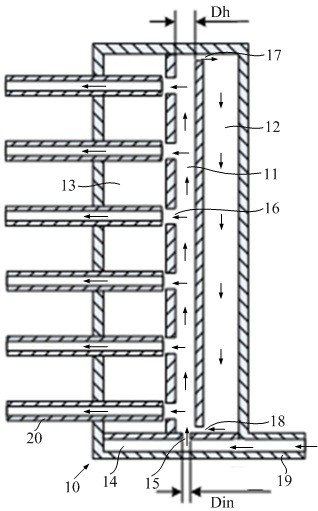

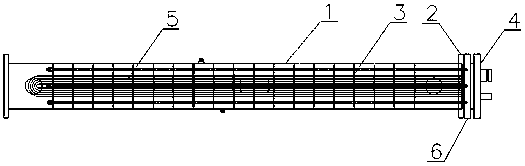

Rectangular dry type shell-and-tube heat exchanger

PendingCN107631521AConsistent heat transfer capabilityReduce the static pressure difference of the liquid columnEvaporators/condensersHeat exchanger casingsEngineeringPlate heat exchanger

The invention relates to a rectangular dry type shell-and-tube heat exchanger. The rectangular dry type shell-and-tube heat exchanger comprises a tube pass and a broken-line-shaped shell pass, whereinthe tube pass is composed of a channel and U-shaped heat exchange tubes, and the broken-line-shaped shell pass is composed of a shell, a tube sheet and spoilers; a tube pass inlet and a tube pass outlet are formed in the channel; and a shell pass inlet and a shell pass outlet are formed in the shell. The rectangular dry type shell-and-tube heat exchanger is characterized in that the shell is a rectangular shell; one end of the shell is closed; the tube sheet is arranged at the other end surface of the shell; the multiple U-shaped heat exchange tubes are arranged in the shell in a rectangularmode; the end parts of the U-shaped heat exchange tubes are supported by the tube sheet; the channel is arranged on the outer side of the tube sheet and is used for performing shunting on the U-shapedheat exchange tubes; and a rectangular sealing gasket is arranged between the channel and the tube sheet.

Owner:江苏世林博尔制冷设备有限公司

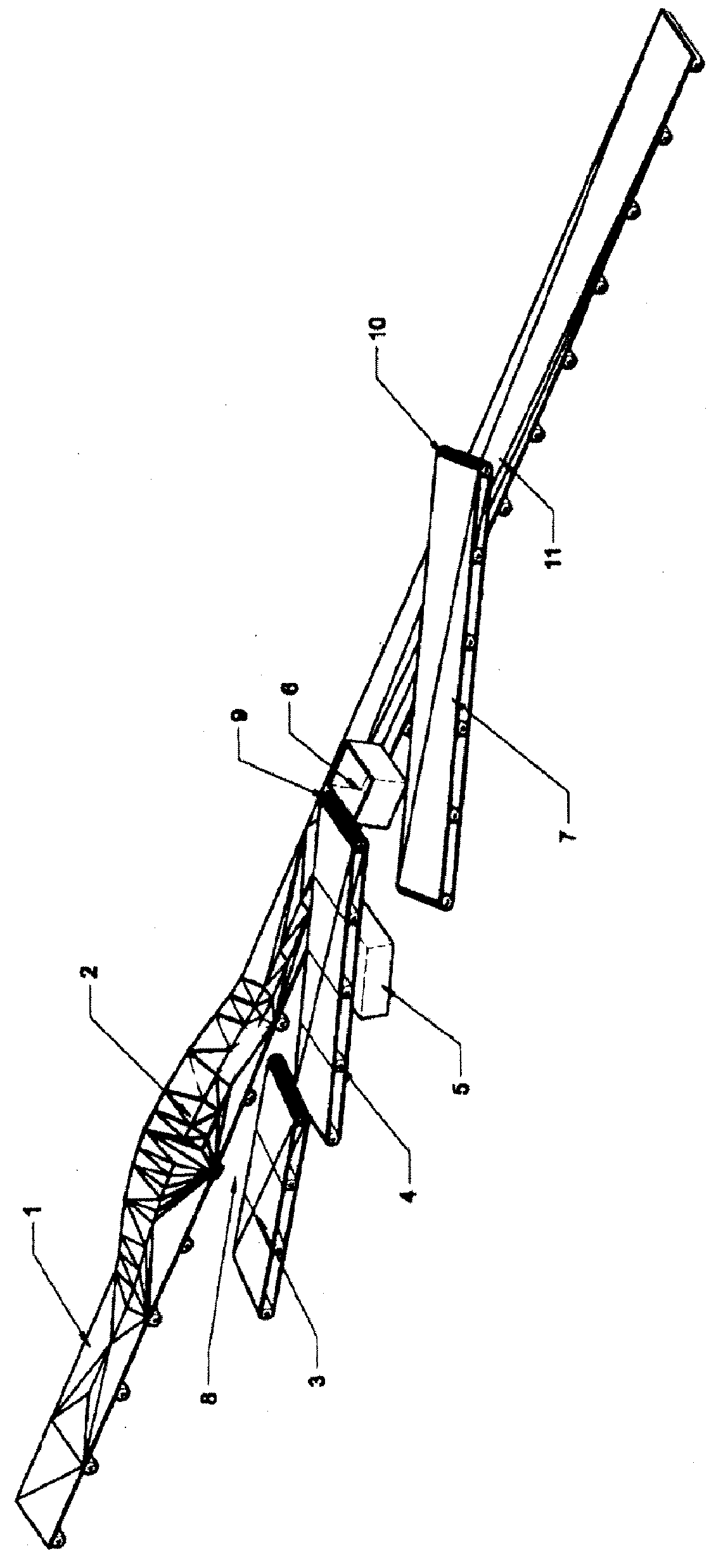

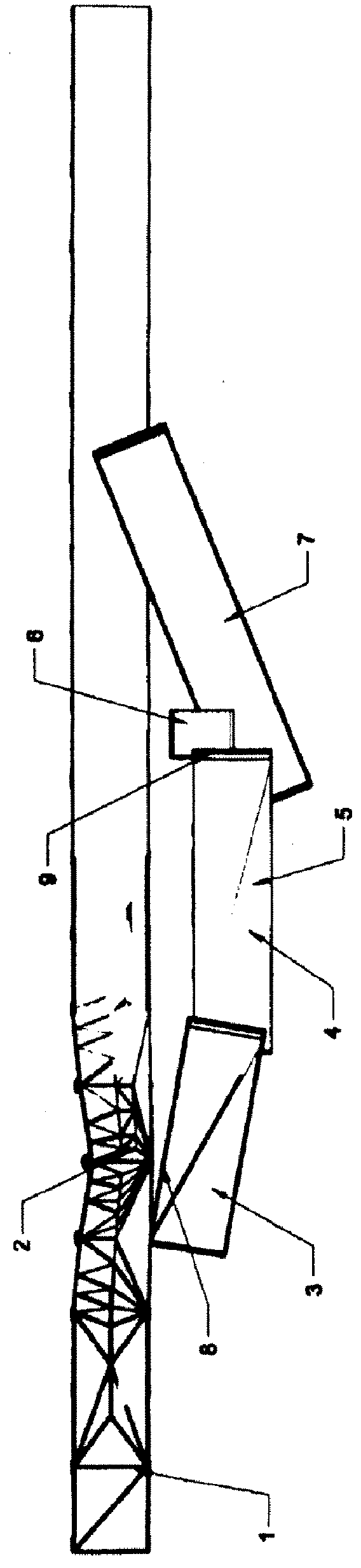

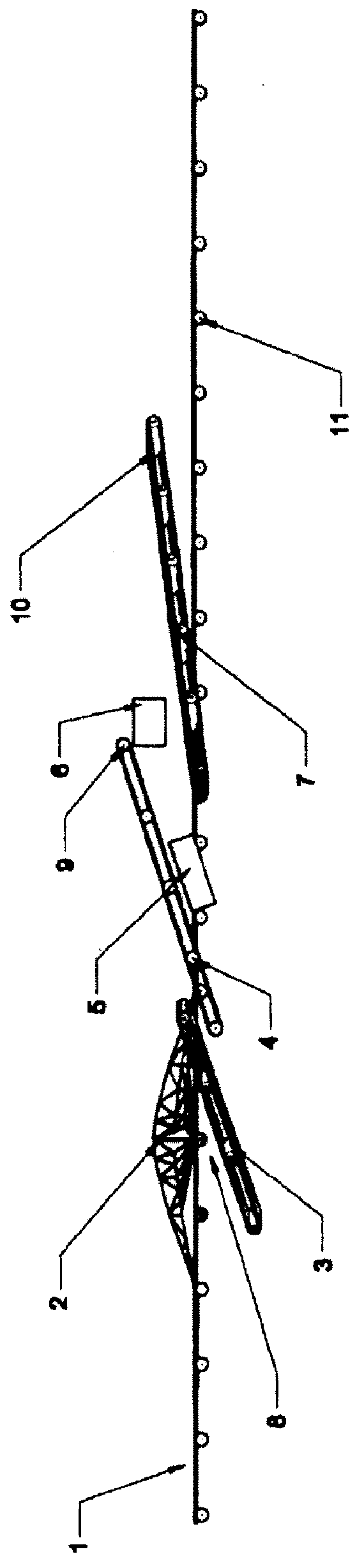

Parallel Belt Sampler

InactiveUS20130047750A1Lower speedReduce speedWithdrawing sample devicesConveyor partsMaterial transferEngineering

Apparatus for sampling material being conveyed on a primary conveyor comprises a diverter arranged to divert material onto a sampling conveyor running alongside the primary conveyor where it can be weighed by a weightometer and elevated to a discharge point before falling into a falling-stream sample cutter. Material is then returned to the primary conveyor at by a return conveyor. Options include the use of an impact conveyor between the diverter and the sampling conveyor, and the configuration of the sampling conveyor with a wider belt running at a slower speed to improve accuracy.

Owner:NEWCASTE INNOVATION LTD

Gas extraction pipeline methane concentration detecting device

InactiveCN109540792AEasy to operateThe detection process is fastMaterial analysis by optical meansProduct gasEngineering

The invention relates to the technical field of concentration measurement, and in particular relates to a gas extraction pipeline methane concentration detecting device. The device is arranged on a gas extraction pipeline, and comprises a branch pipeline, a laser emitting component, a laser receiving component, a control room and an air guiding mechanism. The branch pipeline has an upstream end and a downstream end. The upstream end and the downstream end are communicated with the extraction pipeline respectively. The laser emitting component is arranged on the branch pipeline to emit laser todetect methane. The laser receiving component and the laser emitting component are arranged on the branch pipeline oppositely, and the laser receiving component is used for receiving the laser. The control room is connected with the laser emitting component and the laser receiving component and is used for analyzing the methane concentration. The air guiding mechanism is arranged on the branch pipeline, is arranged outside the laser receiving component and the laser emitting component, and is used for introducing gas in the extraction pipeline into the branch pipeline to make the gas flow rate in the branch pipeline and the extraction pipeline the same. The gas extraction pipeline methane concentration detecting device provided by the invention has the advantages of high detection speed and accurate detection.

Owner:CCTEG SHENYANG RES INST +1

Device used for in situ measurement of solvent vapor expansion in polymer thin film

PendingCN106645075ASame flow rateReal-time research expansionFlow control using electric meansFluorescence/phosphorescenceSolvent vaporFluorescence

The invention relates to the field of high polymer material processing, in particular to a device used for the in situ measurement of solvent vapor expansion in a polymer thin film. The device comprises nitrogen tanks, flow controllers, solvent tanks, a mixing chamber, a sample cavity, a quartz crystal microbalance, a first sample, a second sample and one series of flow controller airflow systems, wherein the first sample is fit to the bottom of the quartz crystal microbalance for measuring an expansion degree; the second sample is arranged above the transparent glass of the bottom center of the sample cavity for epifluorescence imaging; a second nitrogen tank is introduced into the sample cavity through a third flow controller; through the series of flow controller airflow systems, dry nitrogen is introduced into a solvent storage tank to generate solvent vapor in a foaming way, then, the solvent vapor is introduced into the sample cavity, and meanwhile, the air pressure of the solvent vapor is controlled; film thickness before and during solvent vapor annealing is carried out can be obtained through the measurement of a difference value of the resonant frequency of the quartz crystal microbalance when a thin film is in the presence and in the absence.

Owner:JINHUA VOCATIONAL TECH COLLEGE

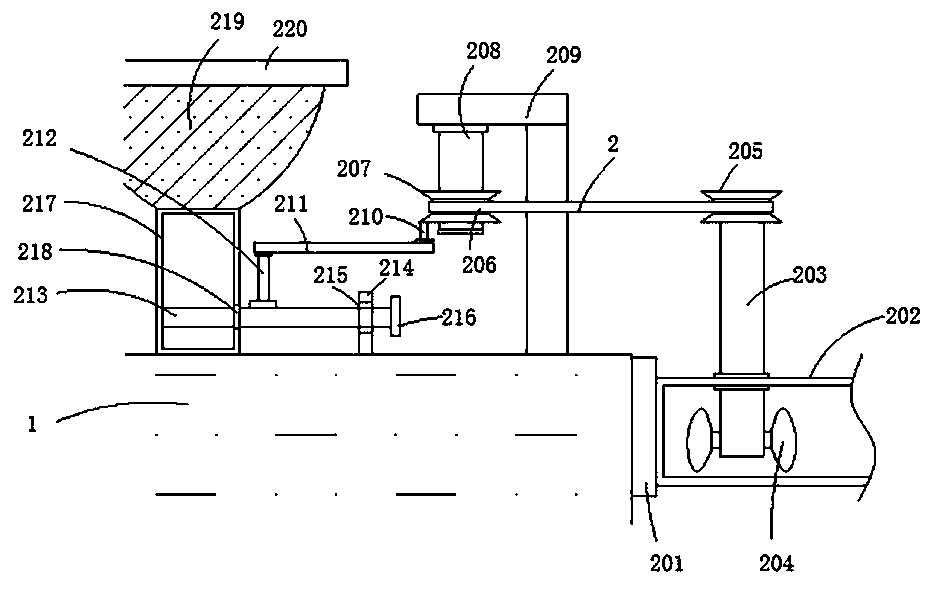

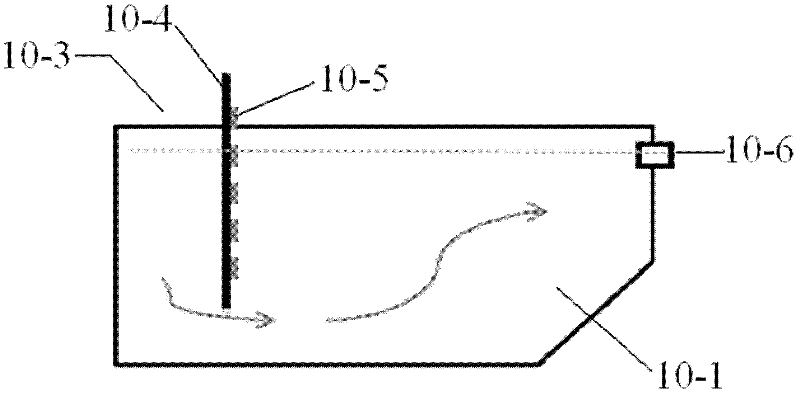

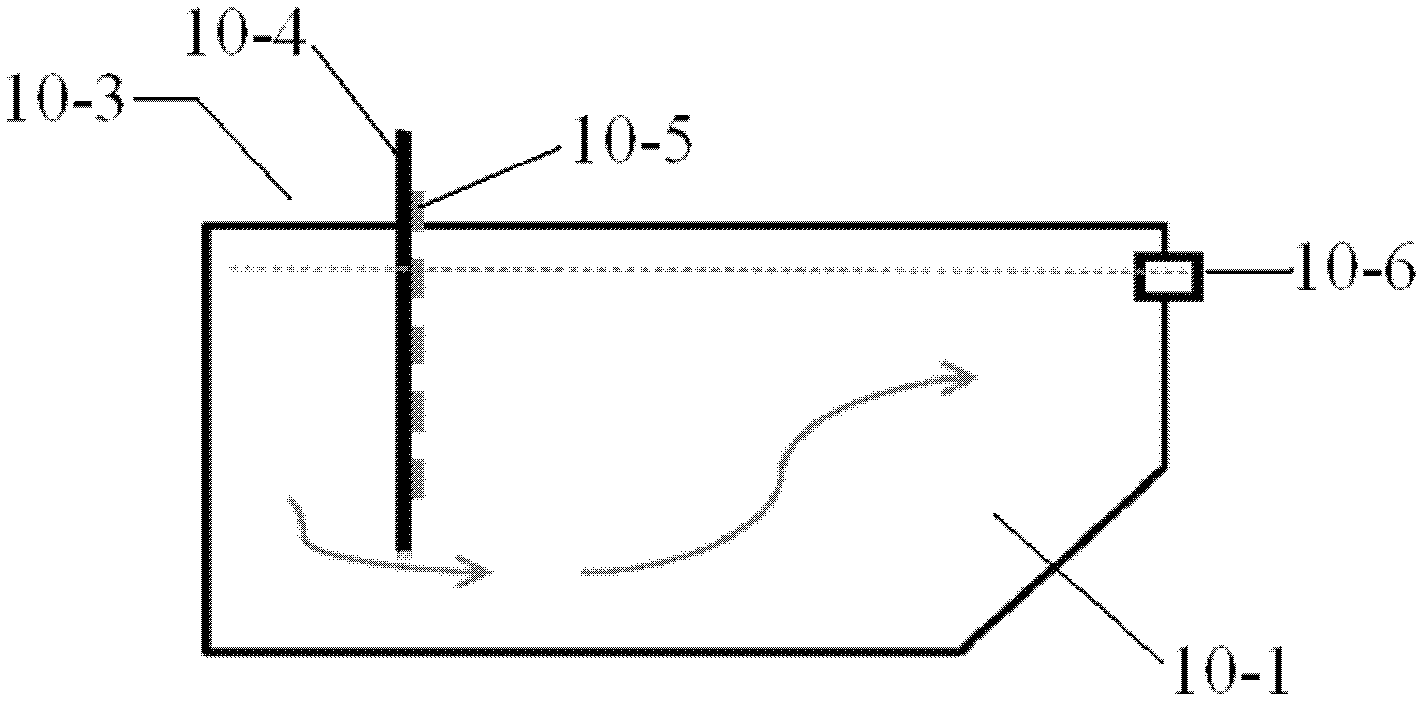

Apparatus for measuring wetting condition of surface of metal in oil/water double phase flow system, and method thereof

The invention discloses an apparatus for measuring the wetting condition of the surface of a metal in an oil / water double phase flow system, and a method thereof, and belongs to the field of the measurement of the oil / water wetting condition of the surface of the metal. The apparatus comprises a liquid storage tank, a volume flow meter, a circulating pump, a flow velocity adjusting valve, a disc water separator, a sample cell, a test sample, miniature conductivity sensors, and a signal processing and displaying circuit. The apparatus utilizes the miniature conductivity sensors inlayed in the surface of the test sample to measure the conductivity of a liquid film on the surface of the metal nearby probes, and the measurement result can reflect the wetting condition of the surface of the metal nearby the probes because of the substantial difference of the conductivities of oil and water. The signal obtained through measuring by the miniature conductivity sensors is displayed by light emitting diodes to obtain the percentage of the water wetting (or oil wetting) of the surface of the test sample. The apparatus and the method can realize the measurement the wetting condition of the surface of the metal in the oil / water double phase fluid of different components at different flow velocities.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

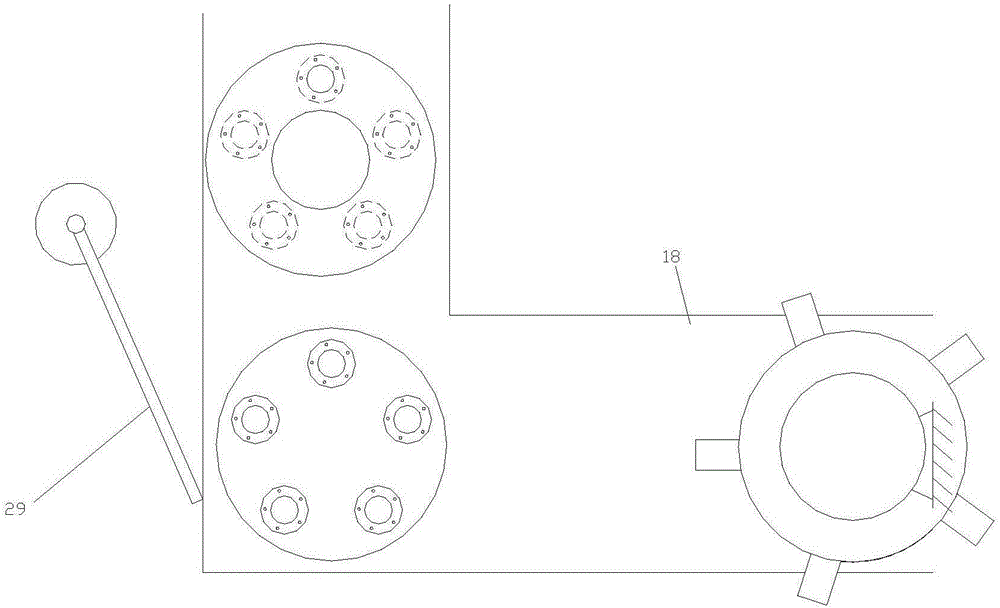

Novel stuffing filling equipment

ActiveCN106622518ASame weightThe same extrusion force makes the flow rate of stuffing flow consistentFood coatingFood shapingEngineeringMechanical engineering

The invention discloses novel stuffing filling equipment and belongs to the technical field of food processing. The novel stuffing filling equipment comprises a machine frame, a conveying belt, a mashing and stuffing dividing integrated system and a stuffing filling system. The mashing and stuffing dividing integrated system comprises a storage inner cylinder, a masher, a sealing outer cylinder and a spiral storage channel, wherein the storage inner cylinder is provided with a storage cavity, the masher can work within the full-length range of the storage cavity, the outer surface of the storage inner cylinder is sleeved with the sealing outer cylinder, and the spiral storage channel is arranged between the storage inner cylinder and the sealing outer cylinder. The cylinder wall of the storage inner cylinder is provided with a plurality of stuffing outlets which communicate with the spiral storage channel and the storage cavity. Through the spiral storage channel, stuffing is divided into stuffing flows with a fixed sectional area, the flow speeds of the stuffing flows are made to be consistent under the same extrusion force in the storage cavity, and accordingly the effect that the flows are identical is ensured; and on that basis, the weights of all stuffing bodies are completely consistent through precise splitting of a splitting mechanism, and finally precise stuffing dividing is achieved.

Owner:CHONGQING NIANJI FOOD

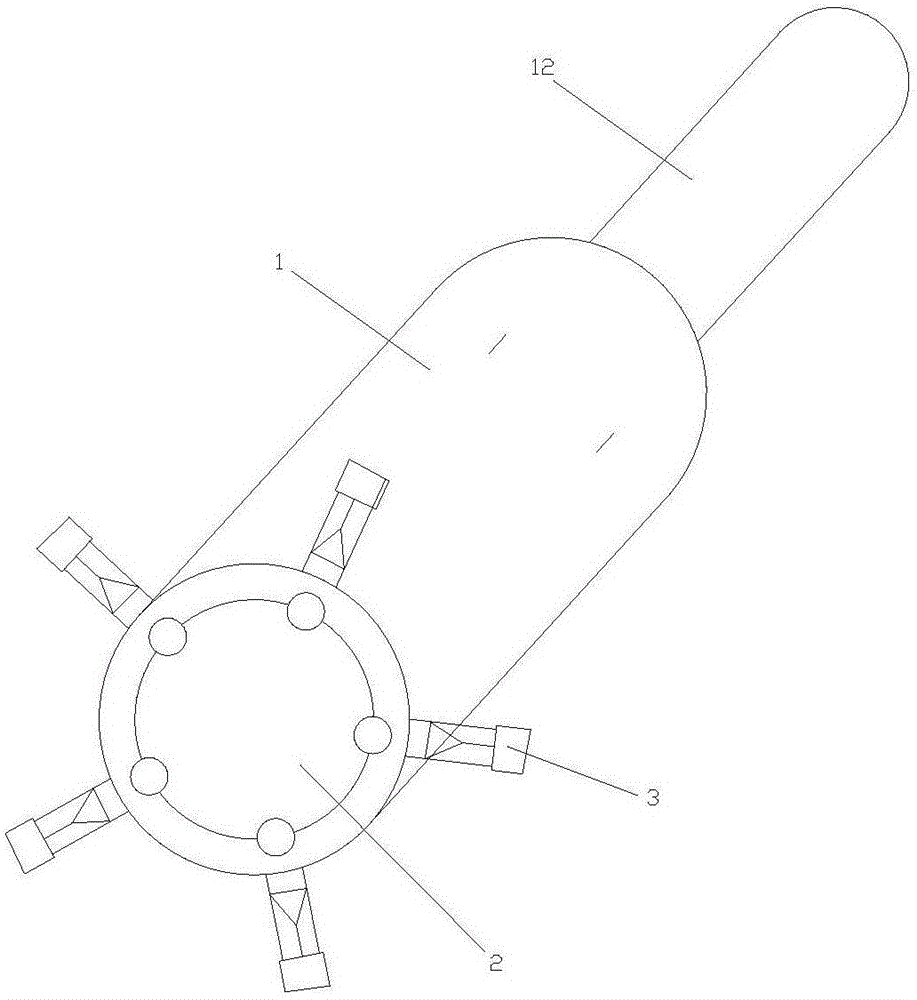

Mud suction pipe of single-pipe suction dredge

InactiveCN104353267ASame flow rateImprove stabilitySettling tanks feed/dischargeBulk conveyorsMixed flowEngineering

The invention discloses a mud suction pipe of a single-pipe suction dredge. The mud suction pipe comprises a pipe body, baffles and circular holes, wherein the baffles connected with the inner side wall of the pipe body is arranged inside the pipe body; the baffles divide the internal part of the pipe body into an area I, an area II, an area III and an area IV; the plurality of horizontally arrayed circular holes are formed in the side wall of the pipe body in each area to enable the internal part of each area to be communicated with the outside. Through the adoption of the technical scheme, the areas in the pipe body are separated and not communicated, so that the independent operation of each area can be guaranteed, and further the mixed flow is avoided; the hole diameters of the circular holes are the same, and the hole pitches of the circular holes in the areas are the same, so that the processing is facilitated, the fact that the flow speeds of liquid entering the areas are the same is guaranteed, and the flowing stability of the liquid in the pipe body can be improved.

Owner:山东华能金昊环境工程有限公司

Clamp and method for removing burrs of central flow channel of aero-engine oil nozzle through abrasive particle flow

ActiveCN111015523AHigh surface finishImprove efficiency and consistencyAbrasive machine appurtenancesParticle flowInjector nozzle

The invention discloses a clamp and a method for removing burrs of a central flow channel of an aero-engine oil nozzle through an abrasive particle flow. A clamp comprises a first clamp upper mold anda first clamp lower mold which are used for clamping the oil nozzle, wherein a central hole for the abrasive particle flow to enter an inlet is formed in the part, at the position opposite to the inlet of the oil nozzle, of the first clamp upper mold, a baffle is arranged at the position, right opposite to an outlet of the oil nozzle, of the first clamp lower mold, a gap is reserved between the baffle and the outlet, discharging holes are formed in the periphery of the baffle, and the discharging holes are used for allowing the abrasive particle flow flowing out of the outlet of the oil nozzle to flow out of the first clamp lower mold; and a abrasive material is forced to flow out along the inner wall of a conical hole of the oil nozzle by utilizing the damping effect of the baffle on theflowing-out abrasive material, so that the burrs on the inner wall of the conical hole are removed, therefore, the burrs on the whole central flow channel of the oil nozzle can be effectively removed, and the surface smoothness is improved. The clamp is suitable for the abrasive particle flow process, the deburring efficiency and consistency can be improved, and the defects caused by a traditional machining technology are overcome.

Owner:西安成立航空制造有限公司

Radiation device with wind scooper

InactiveCN101827513BLow costImprove the protective effectDigital data processing detailsSemiconductor/solid-state device detailsHeat conductingWind field

The invention relates to a radiation device with a wind scooper. Conventional radiators have the disadvantages of the low wind speed of a high-temperature area, the high wind speed of a low-temperature area and poor radiation effect. The radiation device with the wind scooper comprises a heat-conducting pedestal and a radiation fin set arranged on the heat-conducting pedestal. The radiation device is characterized in that: the TT-shaped wind scooper is sleeved on the periphery of the radiation fin set; and one end of the wind scooper is externally extended to form a wind inlet with an externally-extended surface, while the other end is provided with a TT-shaped wind outlet. The radiation device with the wind scooper has the advantages of making the flow speed of airflows flowing through the radiator higher than that of an external wind field, increasing the airflow and flow speed of the high-temperature area of the radiator, not decreasing the airflow and the flow speed of a downstream area of the radiator and improving radiation performance from three aspects.

Owner:郏松筠

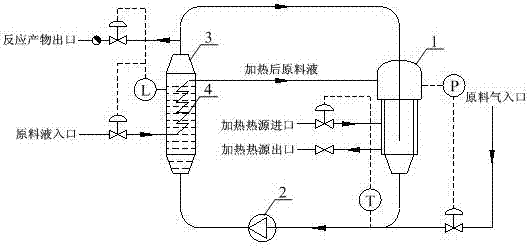

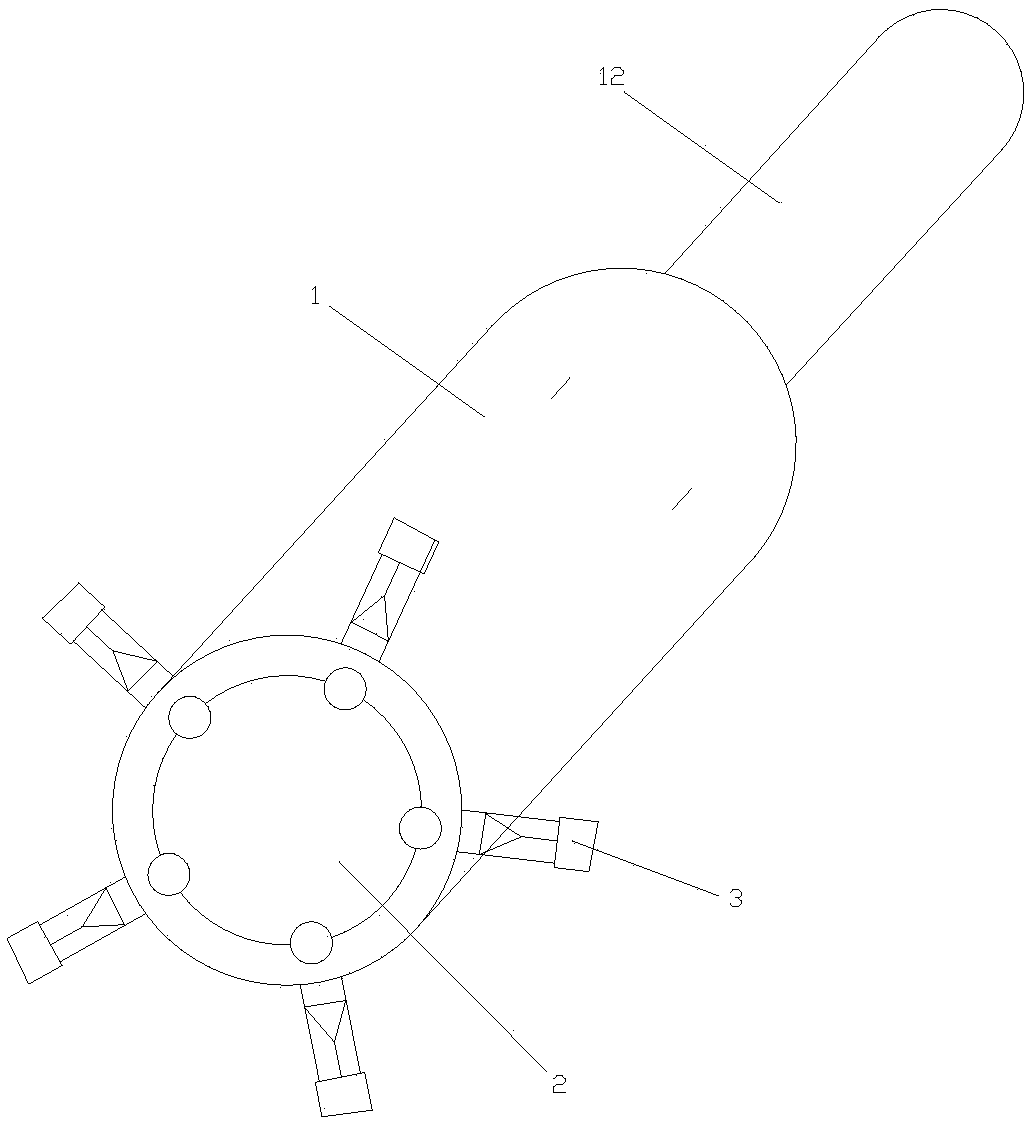

Gas-liquid reaction method and special device

ActiveCN107233851ASame flow rateRaise the temperature of the liquidSequential/parallel process reactionsChemical/physical/physico-chemical stationary reactorsGas liquid reactionMixed flow

The invention discloses a gas-liquid reaction method and a special device. During the reaction, a raw material liquid enters a tubular reactor from a raw material liquid inlet of the tubular reactor, and raw material gas is fully mixed with a reaction liquid or the raw material liquid at a mixed flow circulating pump inlet and subjected to a gas-liquid reaction in a circulating pipeline and the tubular reactor along the flow path; energy supplement is performed by the aid of a ripening reactor outer jacket at the initial stage of the reaction, and automatic energy supplement is set after the reaction system is stabilized; forced circulating reaction is adopted. The working performance is good, the yield is effectively increased, and byproducts are reduced or avoided.

Owner:JIANGSU JIUJIUJIU TECH

Vacuum drying device

PendingCN112838180ASame liquiditySame flow rateSolid-state devicesSemiconductor/solid-state device manufacturingSuction forceEngineering

The invention provides a vacuum drying device which comprises a box body, a heating mechanism, a mask plate and an air exhaust mechanism, the mask plate is arranged on the side, away from the bottom of the box body, of the heating mechanism, and a display substrate comprises a plurality of sub-pixel units which are arranged in an array mode and used for being filled with ink materials. The mask plate is provided with a plurality of sub-pixel openings corresponding to the sub-pixel units on the display substrate in a one-to-one mode, a suction force of the air exhaust mechanism is evenly dispersed to the sub-pixel units on the display substrate through the sub-pixel openings in the mask plate, and it is guaranteed that the volatilization direction and the volatilization speed of solvents in ink materials in the sub-pixel units are the same, therefore, the surface flatness of a film layer formed after the ink material in each sub-pixel unit is dried is kept consistent.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Homogeneous furnace for toughened glass

InactiveCN102020416BImprove temperature uniformitySame flow rateGlass productionToughened glassThermal cycle

The present invention relates to improvement of structure of homogeneous furnace capable of carrying out anti explosive treatment on toughened glass. The invention provides a homogeneous furnace for toughened glass which is energy-saving and highly production efficient. The homogeneous furnace comprises a furnace body, a furnace door and an air cooler being installed on both sides of the furnace body respectively. The structure of the furnace is characterized in that a temperature-insulating layer is installed on the periphery of the furnace body, thermal cycle ducts are installed at the two sides of the furnace body and at the temperature-insulating layer on the top, a heater and a circulating fan are installed at the bottom and the top of the thermal cycle duct respectively, and a cooling cycle duct is installed between the thermal cycle ducts on the top of the furnace body.

Owner:辽宁北方机械股份有限公司

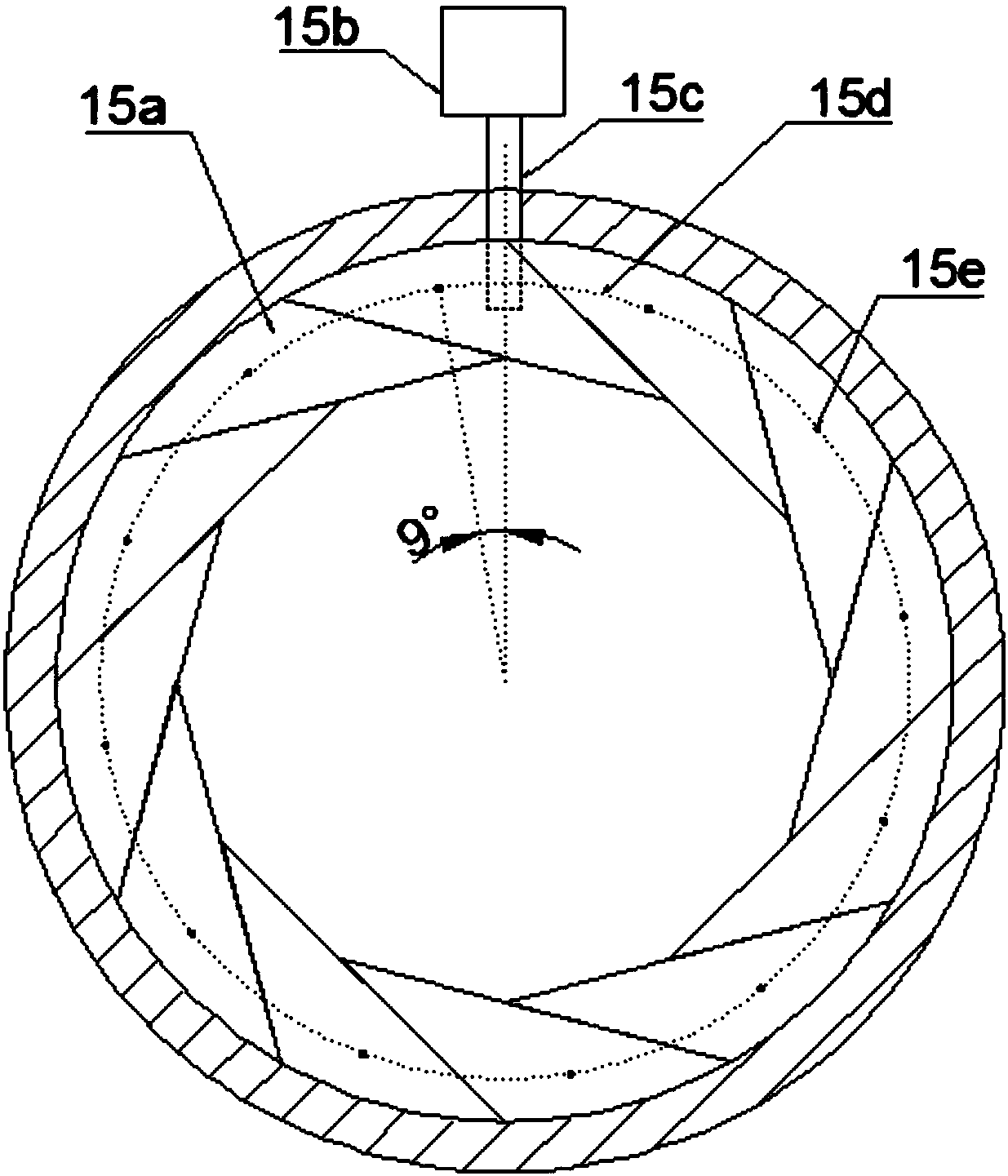

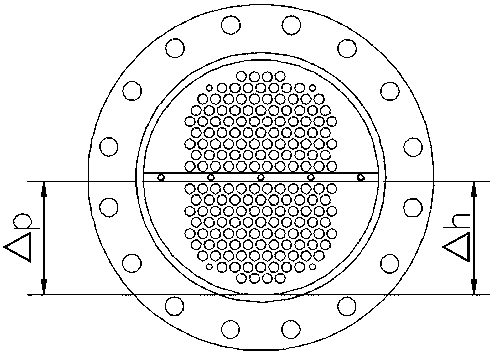

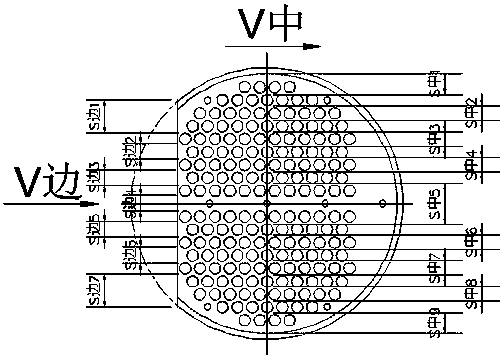

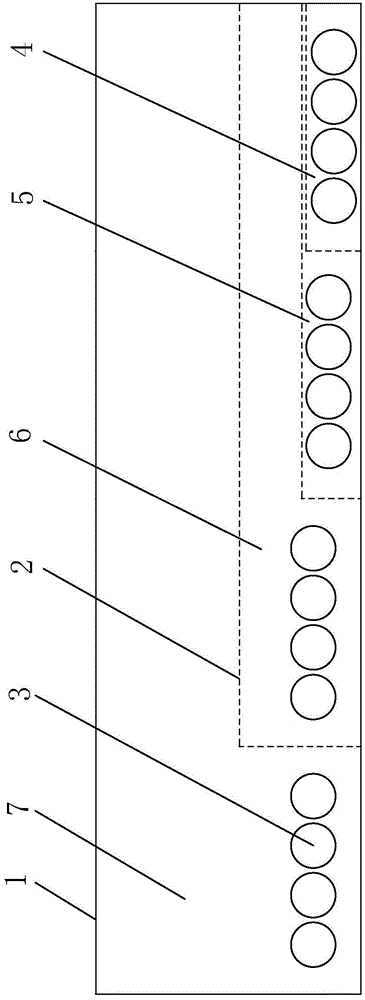

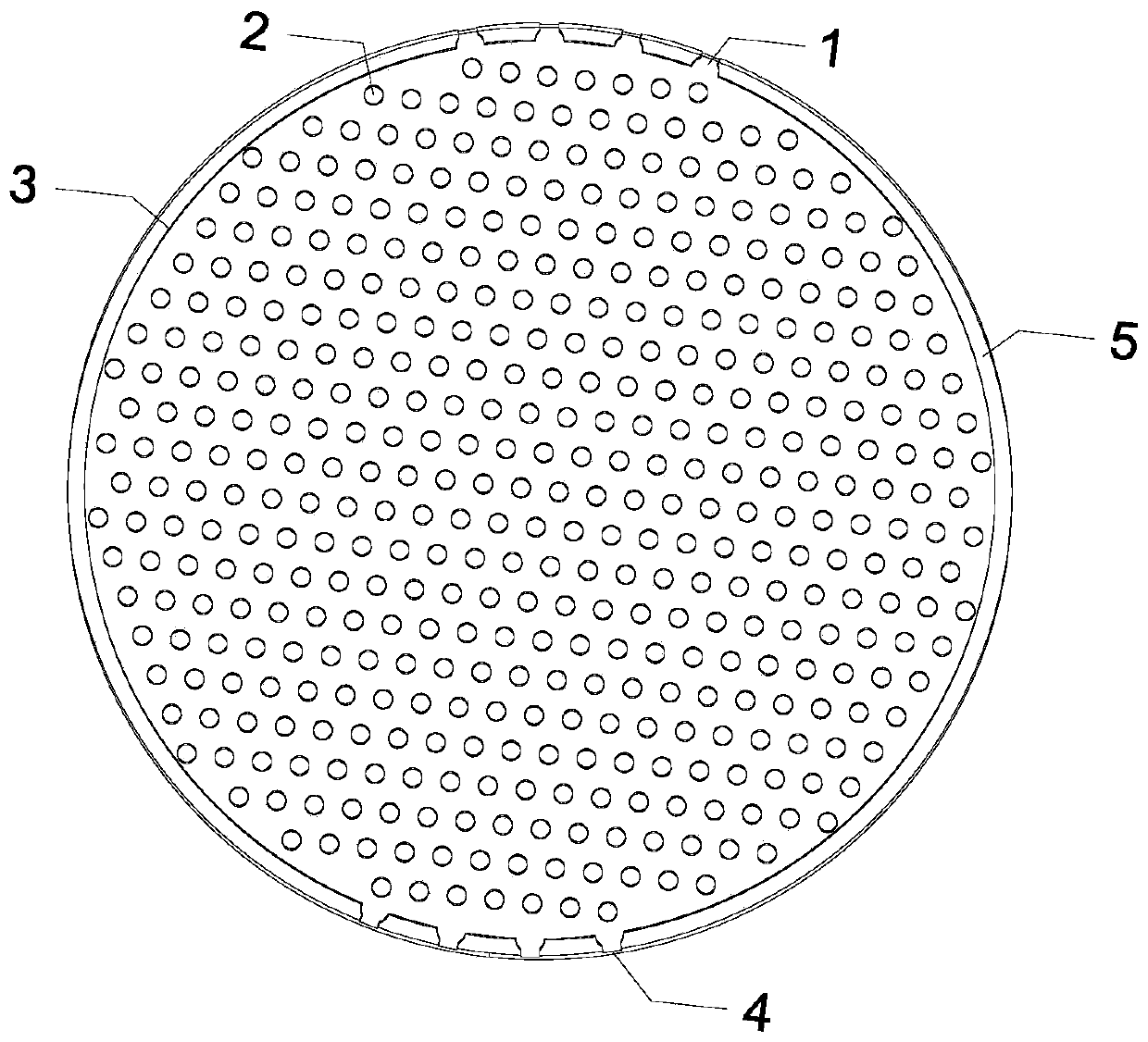

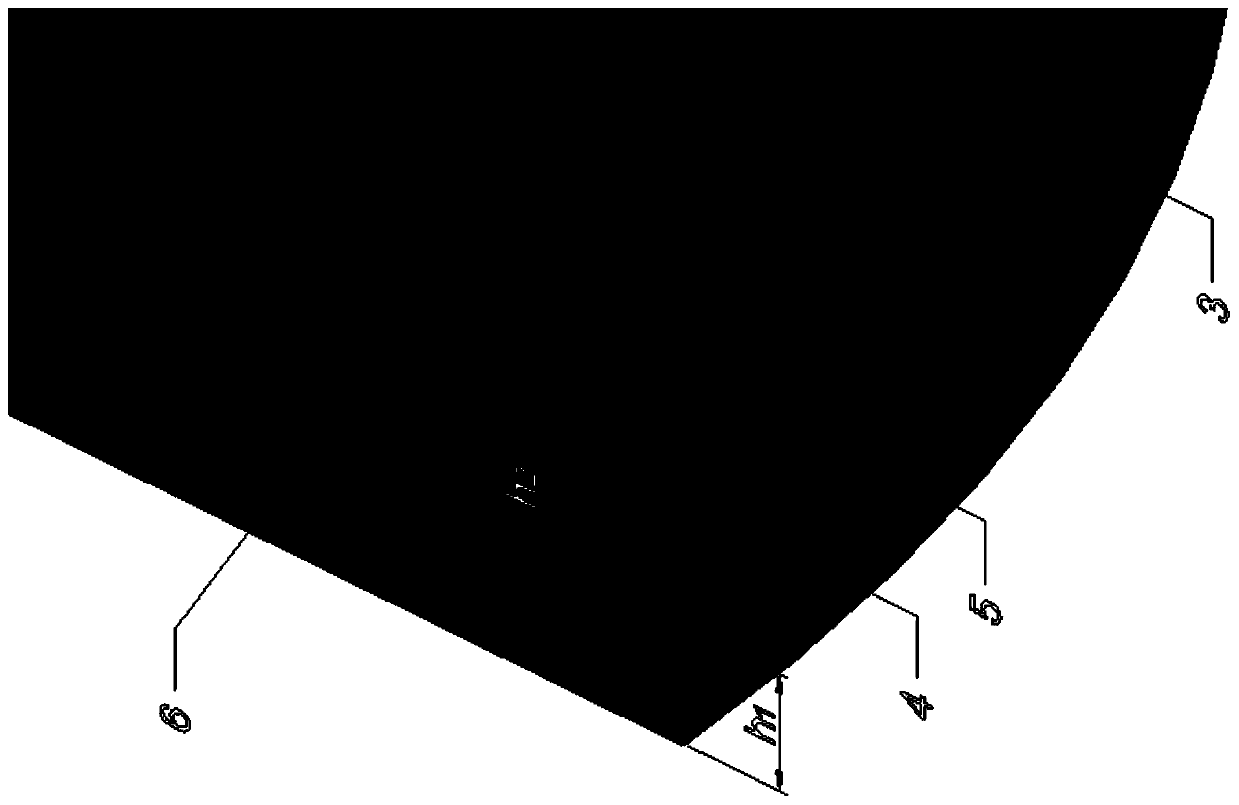

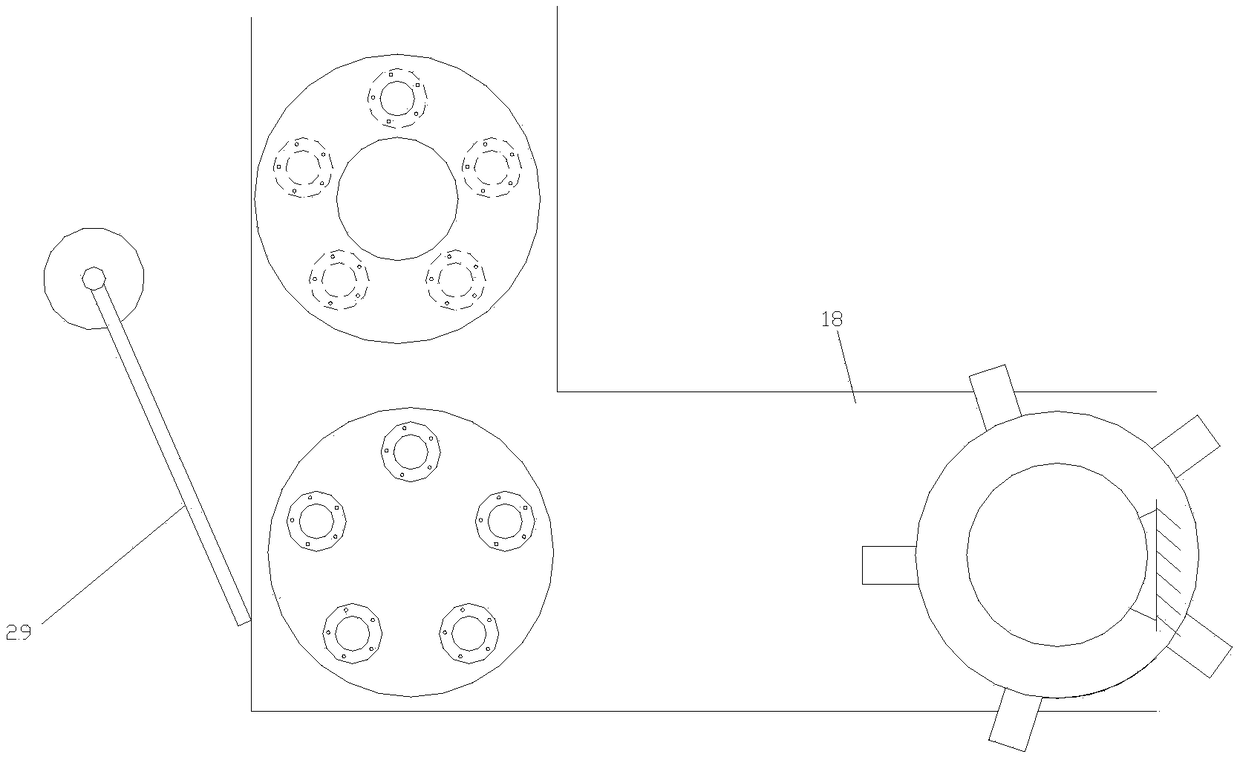

Fuel cell cooling flow field plate

The invention discloses a fuel cell cooling flow field plate, wherein the outer wall of the flow field plate has a circular shape; a flow field plate outer ring is arranged on the periphery of the outer wall of the flow field plate; a variable-diameter inlet flow channel is arranged on the upper side of the flow field plate; a variable-diameter outlet flow channel is arranged on the lower side of the flow field plate; the width dimension of each variable-diameter structure is greater than that of the corresponding inlet or outlet flow channel; and a cylindrical cooling flow channel is arranged on one side in the cooling flow field plate. The inlet flow channel and the outlet flow channel are variable-diameter structures so as to avoid the negative pressure caused by the backflow of a coolant at an outlet. The regularly distributed cylindrical cooling flow channel is arranged inside the flow channel so that the coolant can be evenly distributed at various positions in the flow channel, achieves uniform heat exchange with various positions of a bipolar plate, and has low flow resistance. The fuel cell cooling flow channel provided by the invention can improve the cooling effect of the cooling flow field plate, improves the power generation efficiency and durability of a fuel cell, makes the distribution of the coolant uniform, reduces local hot spots, and reduces the flow resistance of the coolant.

Owner:TIANJIN UNIV

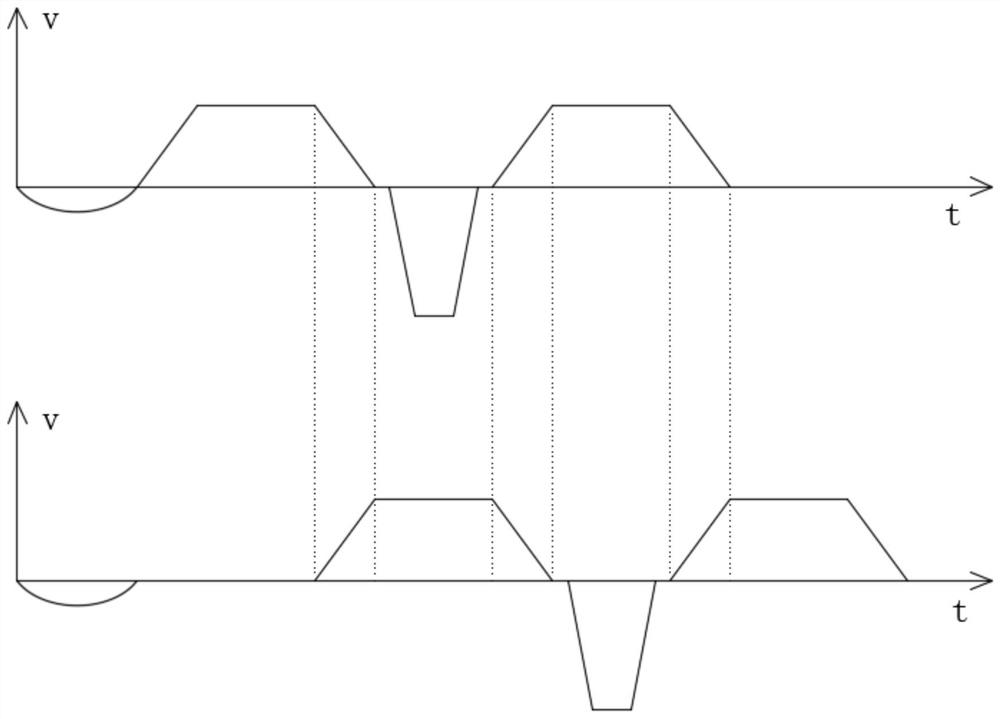

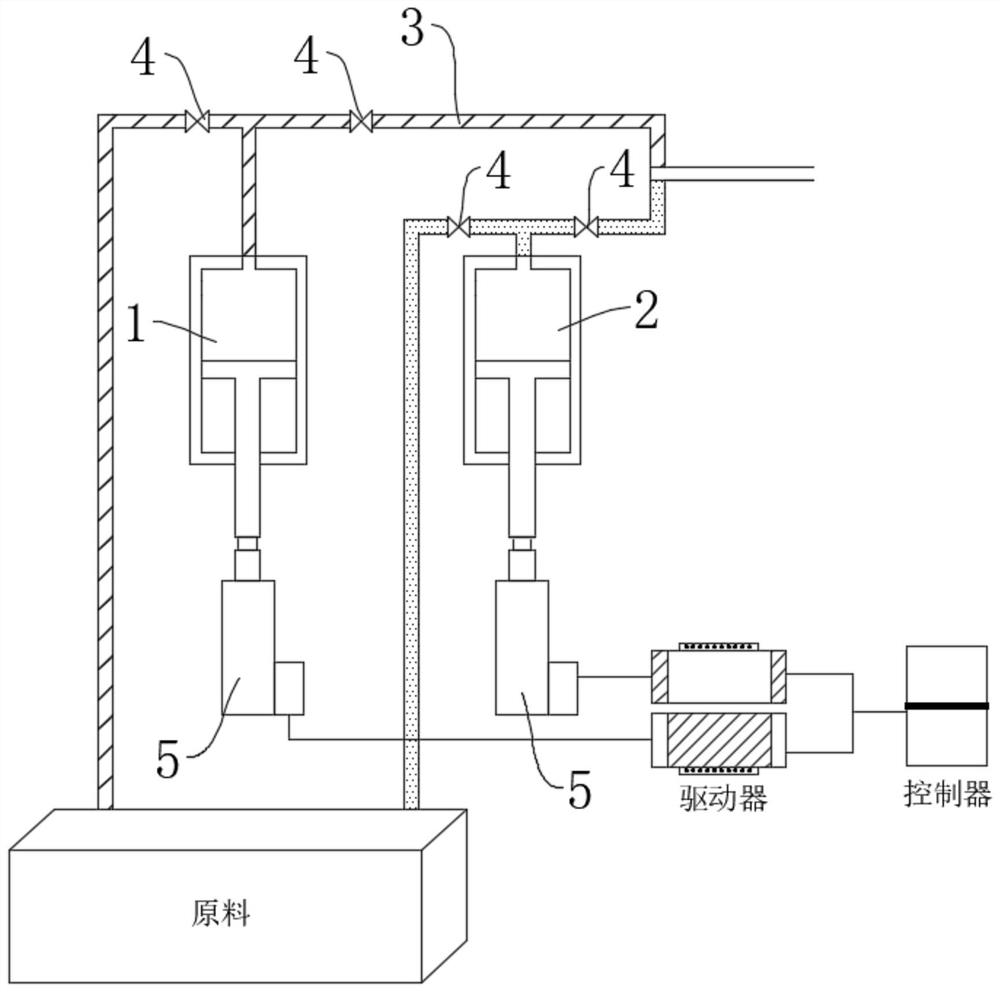

Double-piston-cylinder constant flow output method and device

InactiveCN113623191ASame flow ratePositive displacement pump componentsPump controlEngineeringMechanical engineering

The invention discloses a double-piston-cylinder constant flow output method. Each piston cylinder has a continuously circulating liquid suction stroke and a continuously circulating liquid discharge stroke; each liquid discharge stroke sequentially comprises an acceleration stage, a constant speed stage and a deceleration stage; the acceleration stage of one piston cylinder corresponds to the deceleration stage of the other piston cylinder, and the flow change rates of the two piston cylinders in the stage are the same; and the constant speed stage of one piston cylinder corresponds to the liquid discharge stroke of the other piston cylinder, and the sum of the liquid discharge flows of the two piston cylinders is constant at any moment. According to the double-piston-cylinder constant flow output method provided by the invention, the acceleration stage of one piston cylinder corresponds to the deceleration stage of the other piston cylinder, the constant speed stage of one piston cylinder corresponds to the liquid suction stroke of the other piston cylinder, and the flow change rates of the two piston cylinders are the same, so that the sum of the output flows of the two piston cylinders is a fixed value.

Owner:WUHAN UNIV OF TECH

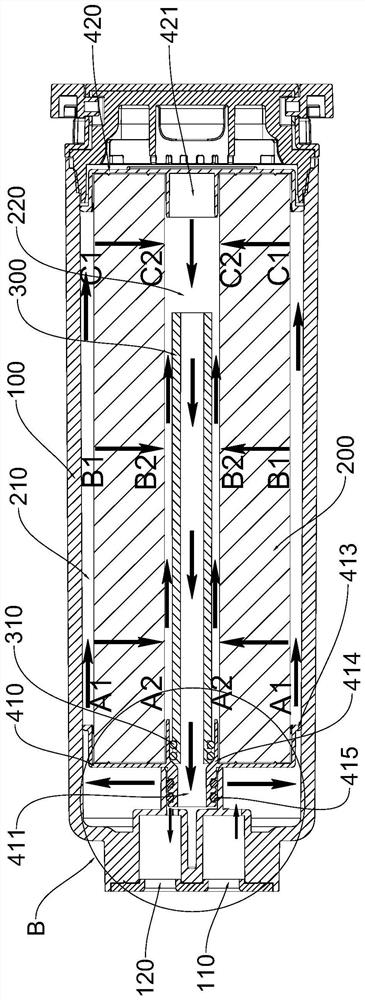

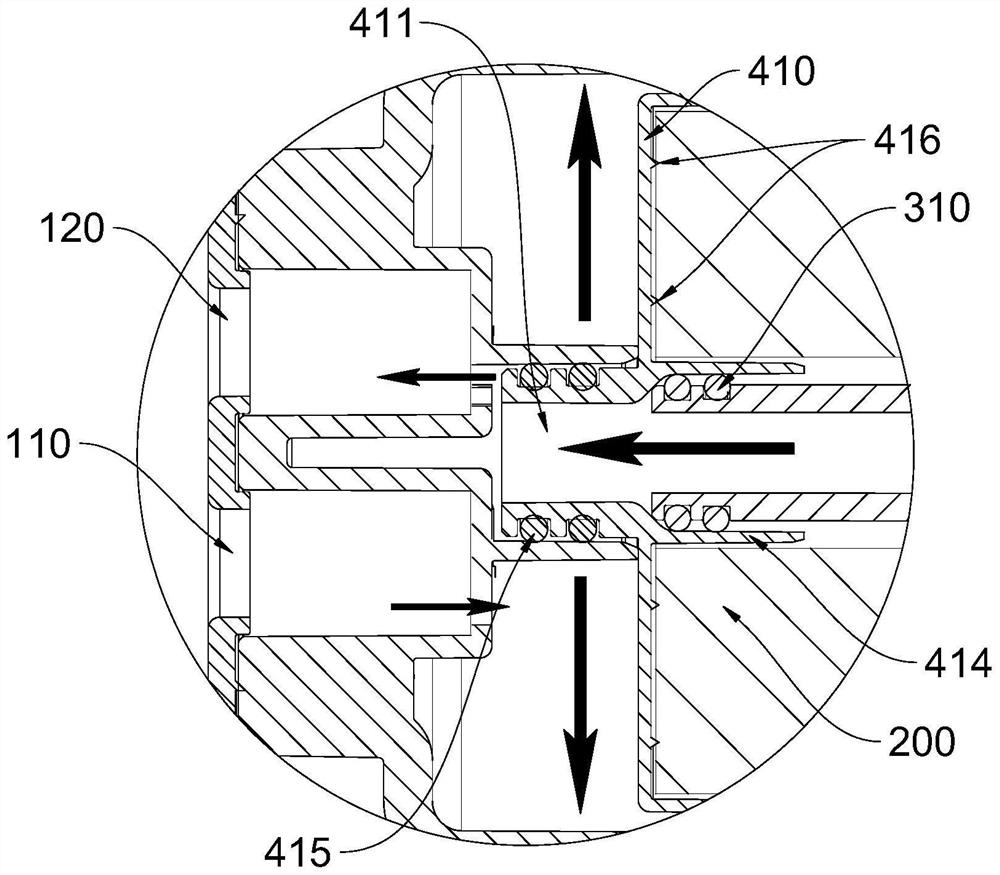

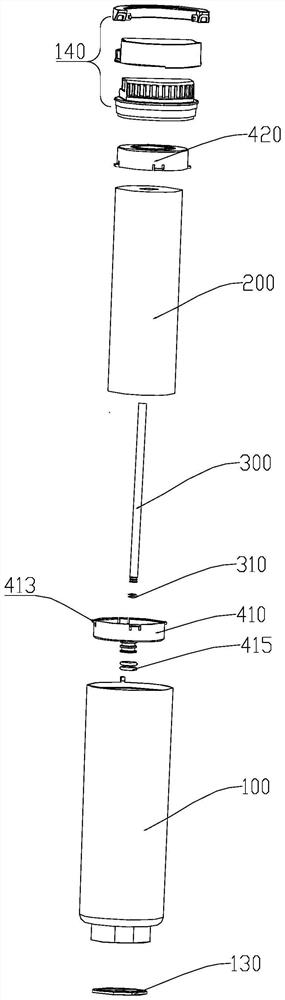

Filter element and water purification equipment

ActiveCN114405130AImprove filtering effectExtended service lifeSpecific water treatment objectivesTreatment involving filtrationAir compressionEnvironmental engineering

The invention relates to the field of water purifying and drinking equipment, and provides a filter element and water purifying equipment, the filter element comprises a shell, a filter element body, a central pipe and an air compression unit, the central pipe is arranged in a second flow channel, the first end of the central pipe is communicated with a water outlet channel, and the second end of the central pipe is communicated with the second flow channel and extends in the direction away from the water outlet channel; and the air compression unit is arranged in the second mounting cavity. The central pipe is arranged in the second flow channel of the filter element body and used for balancing the pressure difference between the water inlet path and the water outlet path, so that the flow speeds of all positions of the filter element body are the same, and the utilization rate of a filter material is increased; under the condition of the same volume and the same use amount of the filter material, the utilization rate of the filter material is effectively improved, so that the filtering performance of the filter element body is improved, the service life of the filter element body is prolonged, and the use cost of the filter element is reduced; and under the requirement of the same performance, the design consumption of a filter material can be reduced, the volume of the filter element is reduced by about 30% or above, and the product competitiveness is improved.

Owner:FOSHAN MIDEA CHUNGHO WATER PURIFICATION MFG +1

A new type of stuffing equipment

ActiveCN106622518BSame weightThe same extrusion force makes the flow rate of stuffing flow consistentFood coatingFood shapingEngineeringMechanical engineering

The invention discloses novel stuffing filling equipment and belongs to the technical field of food processing. The novel stuffing filling equipment comprises a machine frame, a conveying belt, a mashing and stuffing dividing integrated system and a stuffing filling system. The mashing and stuffing dividing integrated system comprises a storage inner cylinder, a masher, a sealing outer cylinder and a spiral storage channel, wherein the storage inner cylinder is provided with a storage cavity, the masher can work within the full-length range of the storage cavity, the outer surface of the storage inner cylinder is sleeved with the sealing outer cylinder, and the spiral storage channel is arranged between the storage inner cylinder and the sealing outer cylinder. The cylinder wall of the storage inner cylinder is provided with a plurality of stuffing outlets which communicate with the spiral storage channel and the storage cavity. Through the spiral storage channel, stuffing is divided into stuffing flows with a fixed sectional area, the flow speeds of the stuffing flows are made to be consistent under the same extrusion force in the storage cavity, and accordingly the effect that the flows are identical is ensured; and on that basis, the weights of all stuffing bodies are completely consistent through precise splitting of a splitting mechanism, and finally precise stuffing dividing is achieved.

Owner:CHONGQING NIANJI FOOD

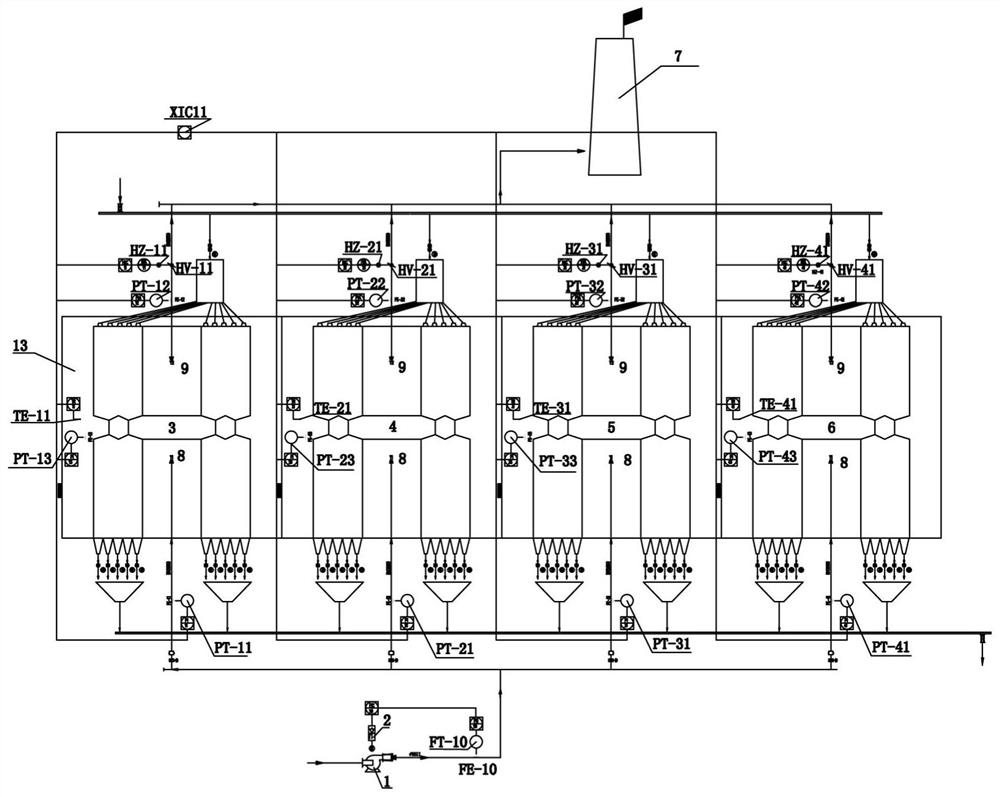

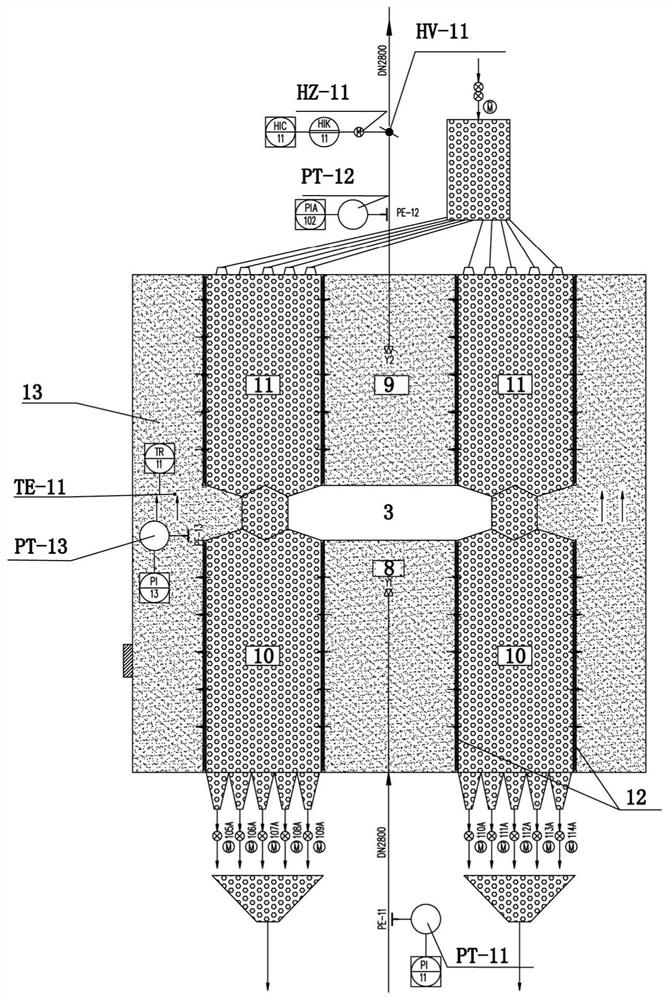

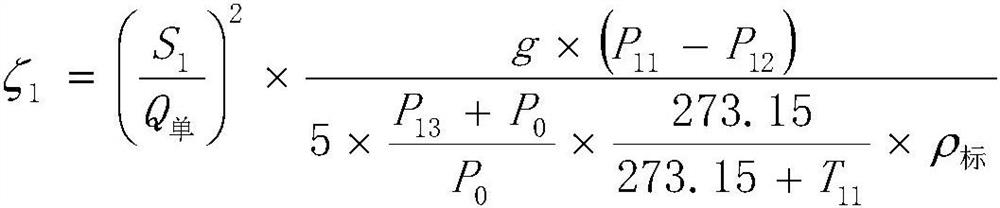

Automatic control device of active coke adsorption tower flue gas balance system

PendingCN112619356ASmall footprintLess investmentGas treatmentDispersed particle separationAutomatic controlEngineering

The invention belongs to the field of environmental protection production automation control, and particularly relates to an automatic control device of an active coke adsorption tower flue gas balance system, which is characterized by comprising a gas flow meter and a flow transmitter arranged on a booster fan outlet main pipe, and a pressure transmitter arranged on an inlet branch pipe of an air inlet chamber of each adsorption unit, the pressure transmitter and the thermal resistor of each adsorption unit transition air chamber, the pressure transmitter on the outlet branch pipe of each adsorption unit air outlet chamber, the electric butterfly valve on the outlet branch pipe of each adsorption unit air outlet chamber, and the pressure transmitter, the thermal resistor and the electric butterfly valve at different positions of each adsorption unit are connected with the PLC system. The device is not affected by the steps of element machining, manufacturing, assembling, welding and the like of each adsorption unit, the resistance coefficient zeta of each adsorption unit is measured under the actual production working condition, and therefore the smoke flow of each adsorption unit is obtained, the smoke amount is controlled by adjusting an outlet electric butterfly valve, and automatic control over the tower-attached smoke balance system is truly achieved.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Automatic natural environment continuous waterflow simulation test device

ActiveCN102642984BGuaranteed temperatureRealize automatic monitoring and recordingMultistage water/sewage treatmentCollection systemDevice simulation

The invention relates to an automatic natural environment continuous waterflow simulation test device, which comprises a water conditioning system, a dilution table, a biological test culture cabinet, a temperature and illumination control system, a data monitoring and acquiring system, a wastewater collection system, a water storage system and the like. Compared with the prior art, the automatic natural environment continuous waterflow simulation test device has the advantages that the device is evidently effective in natural waterflow dynamic environment simulation, stable in long-time operation, high in safety, simple in regulation, high in automation level, easy to demount for washing and easy to replace. Whole-course automatic monitoring, tracking and recording of the whole test process by a computer can be realized, reliability and stability in operation of the long-term waterflow test can be guaranteed by the test device, and the test device is applicable to GLP (good laboratory practice) tests of short or long toxicity of various relevant aquatic organisms published by the OECD (organization for economic cooperation and development) and the EPA (environmental protection agency).

Owner:SHANGHAI RES INST OF CHEM IND +1

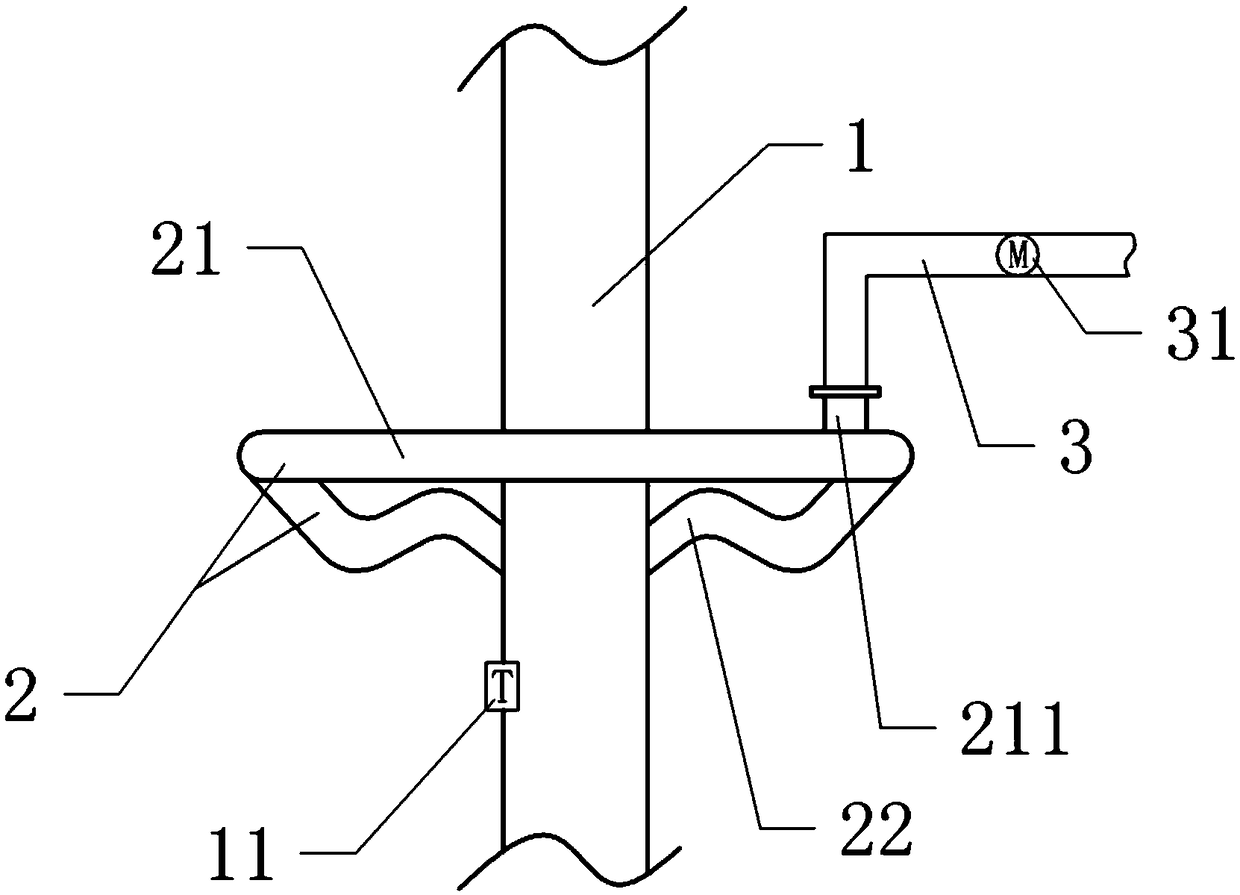

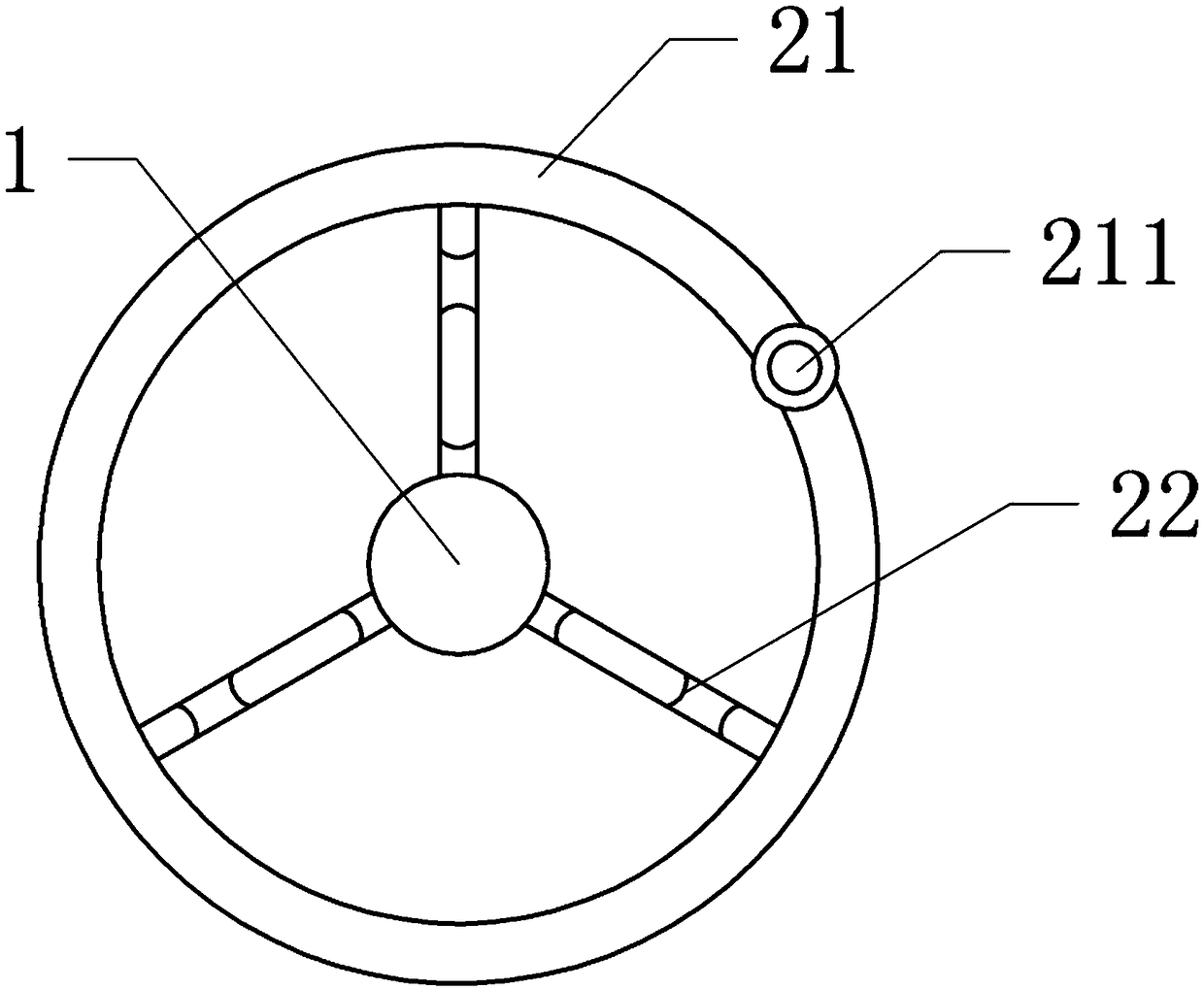

Acetylene preheating and humidifying method

ActiveCN109400436AAchieve heatingIncrease humidityHydrocarbon purification/separationHydrocarbonsWater vaporEngineering

The invention belongs to the technical field of methods for obtaining a polymer compound by carbon unsaturated bond reaction, and discloses an acetylene preheating and humidifying method, which includes the following steps: step I. mounting an annular steam preheating device comprising a steam annular pipe and a branch pipe on an acetylene inlet pipe, wherein the steam annular pipe is positioned at the periphery of the acetylene inlet pipe, and two ends of the branch pipe are respectively communicated with the steam annular pipe and the acetylene inlet pipe; step II. introducing water vapor into the steam annular pipe to enable the water vapor to enter into the acetylene inlet pipe through the branch pipe; step III. introducing acetylene gas into the acetylene inlet pipe to mix the acetylene with the water vapor, preheating and humidifying, and then entering into an acetylene dimerization reaction tower. The invention solves the problem that equipment is easy to explode when the conventional steam preheating device stops abnormally in the prior art.

Owner:重庆化医长寿化工集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com