Patents

Literature

41results about How to "Uniform and stable flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and technology for wet desulfurization and denitrification of flue gas of coal-fired boiler and treatment of wastewater

ActiveCN105833695AReduce the temperatureIncrease humidityGas treatmentDispersed particle separationFlue gasSupergravity

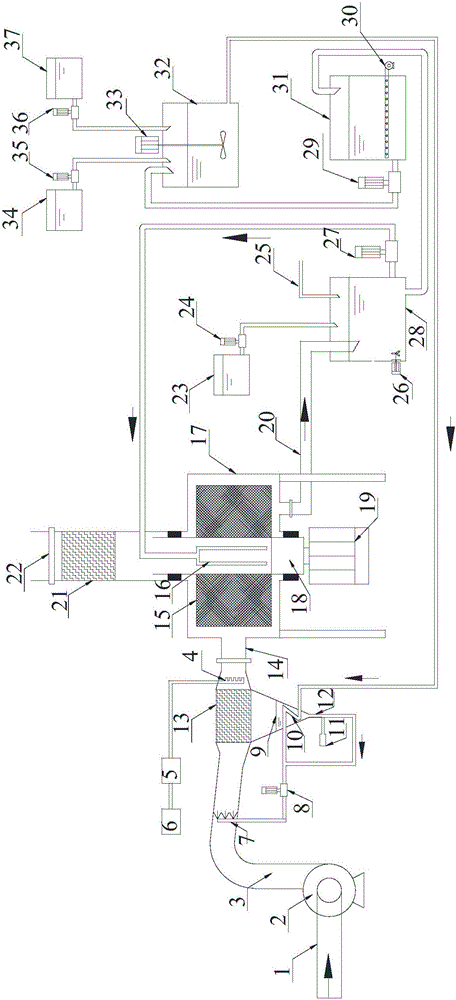

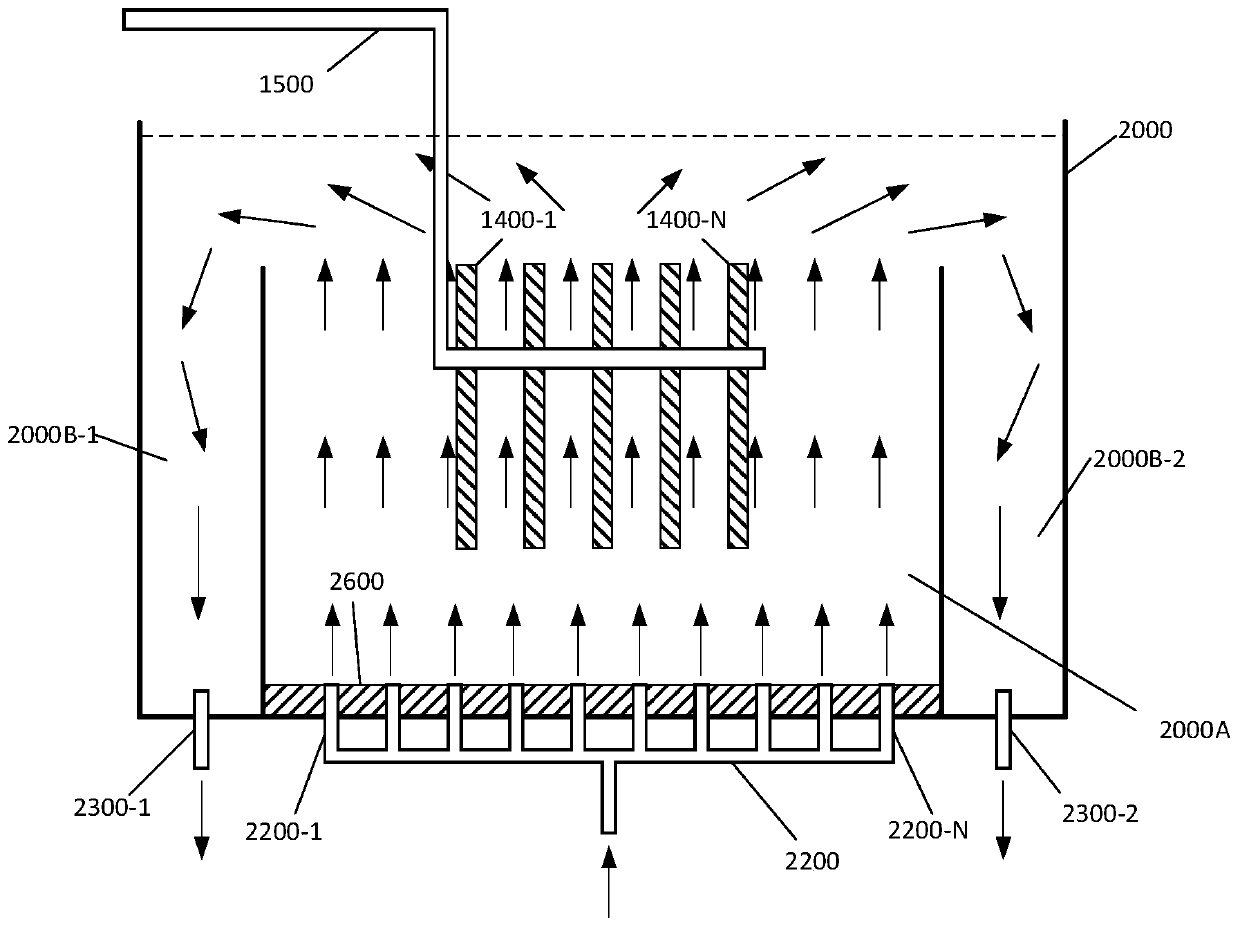

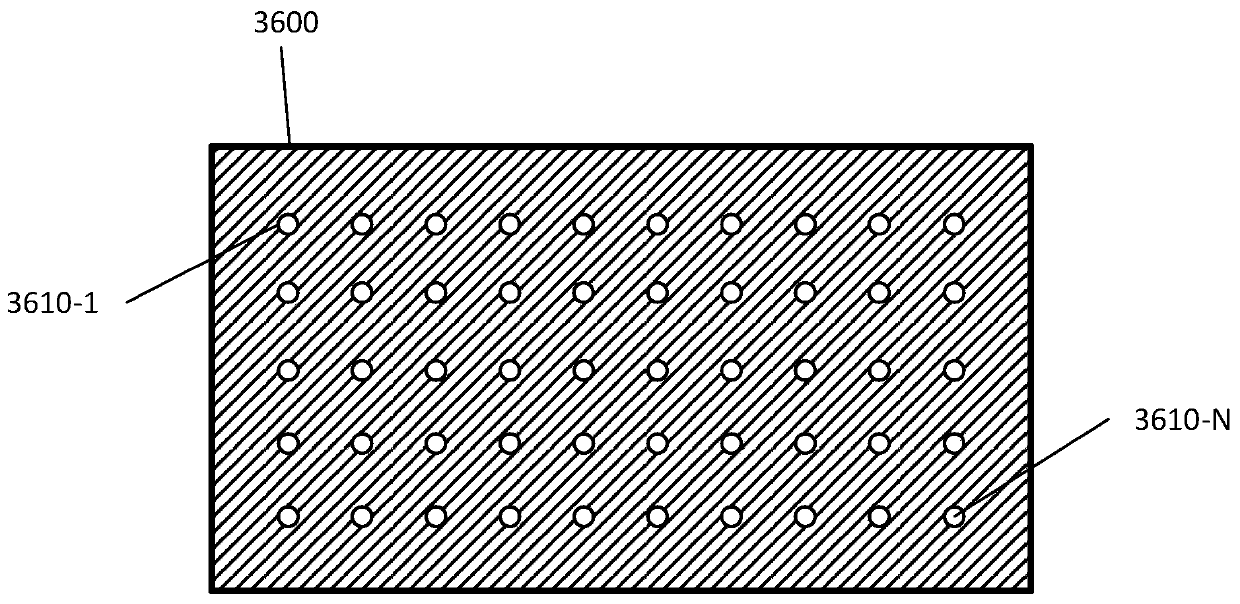

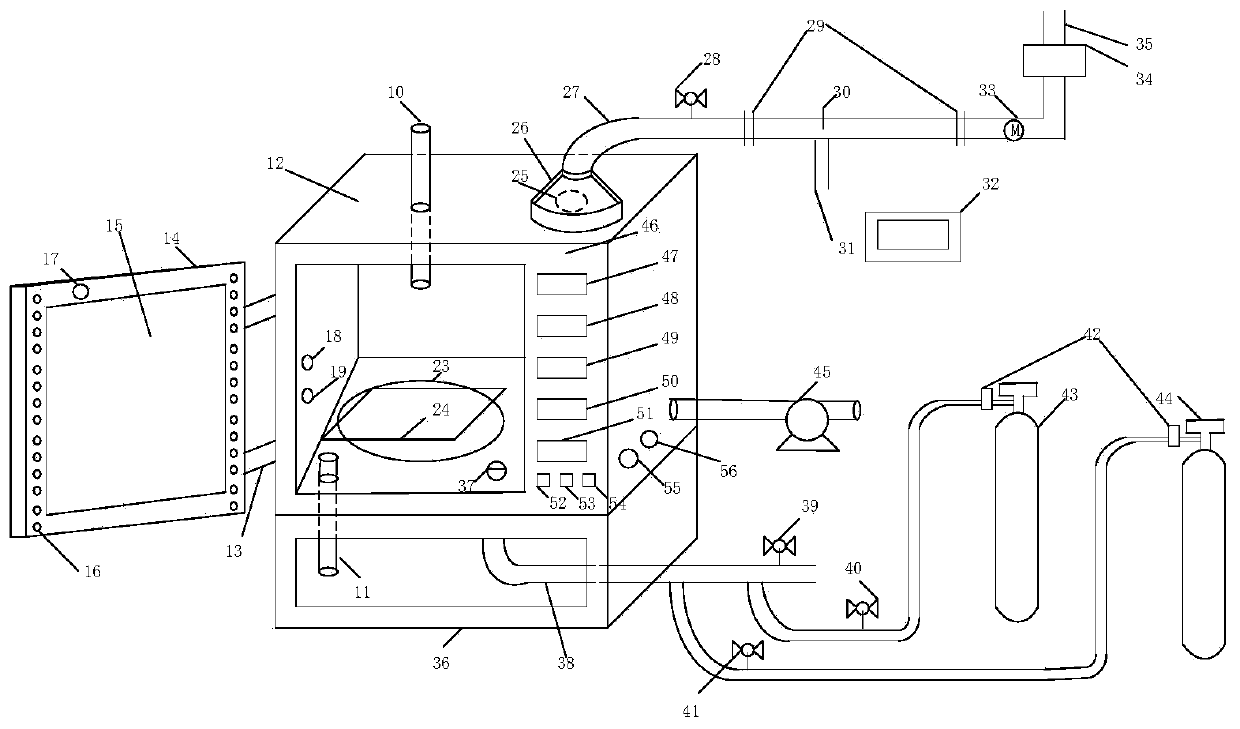

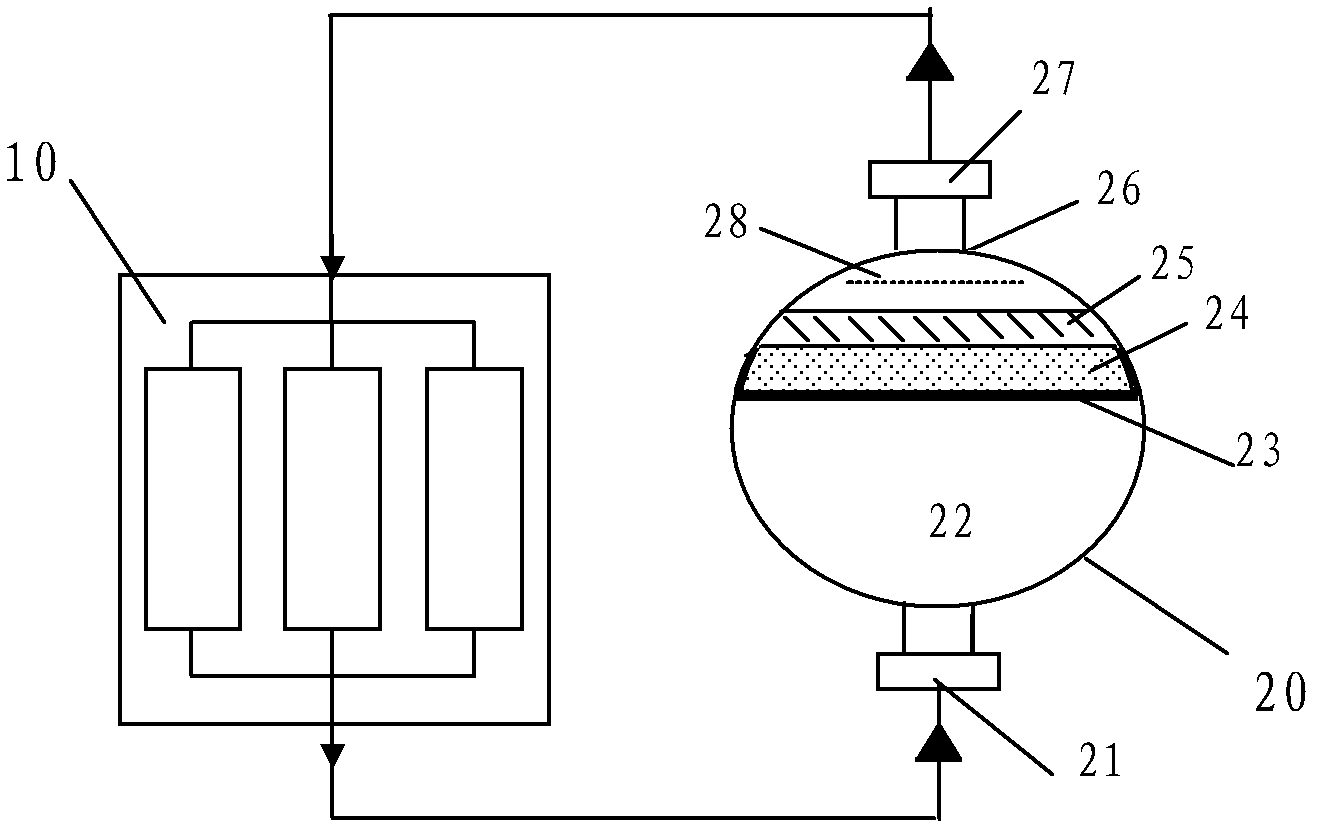

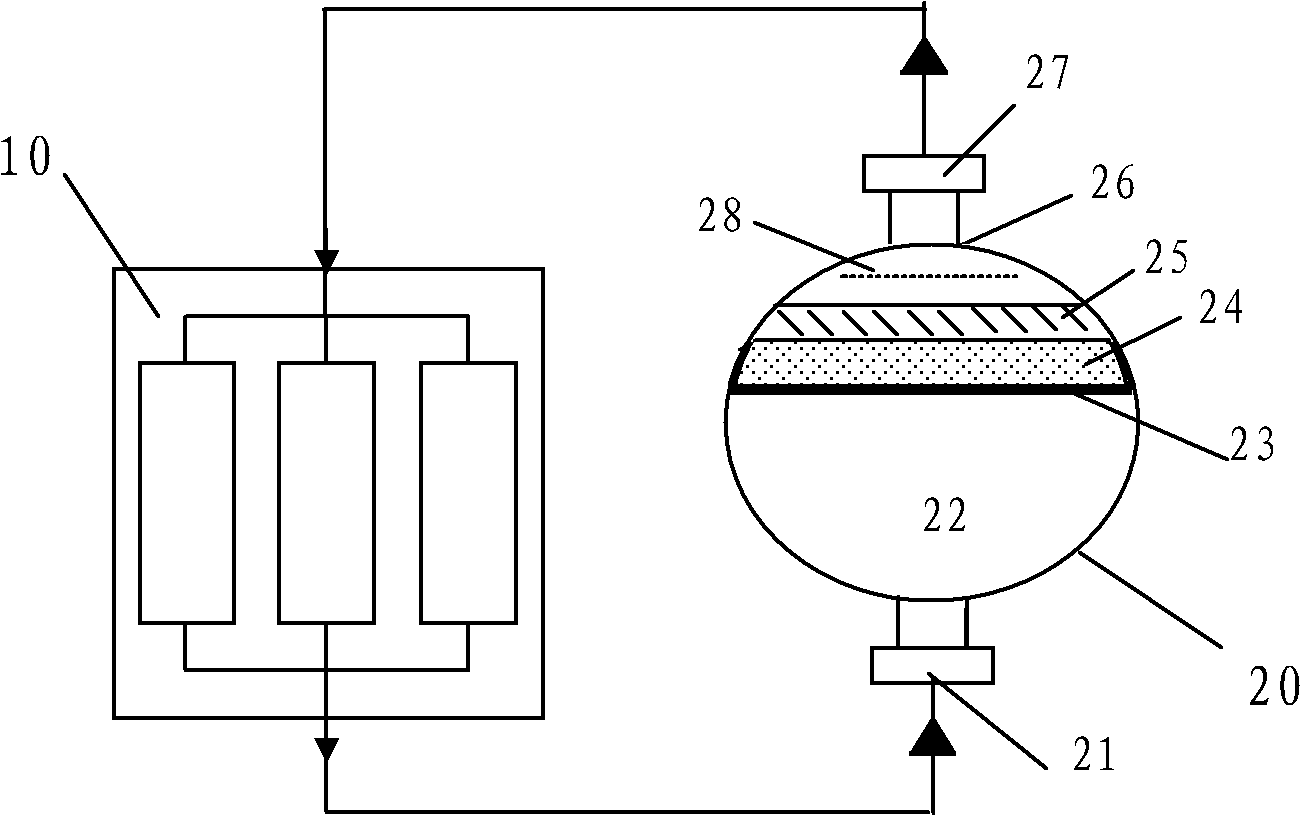

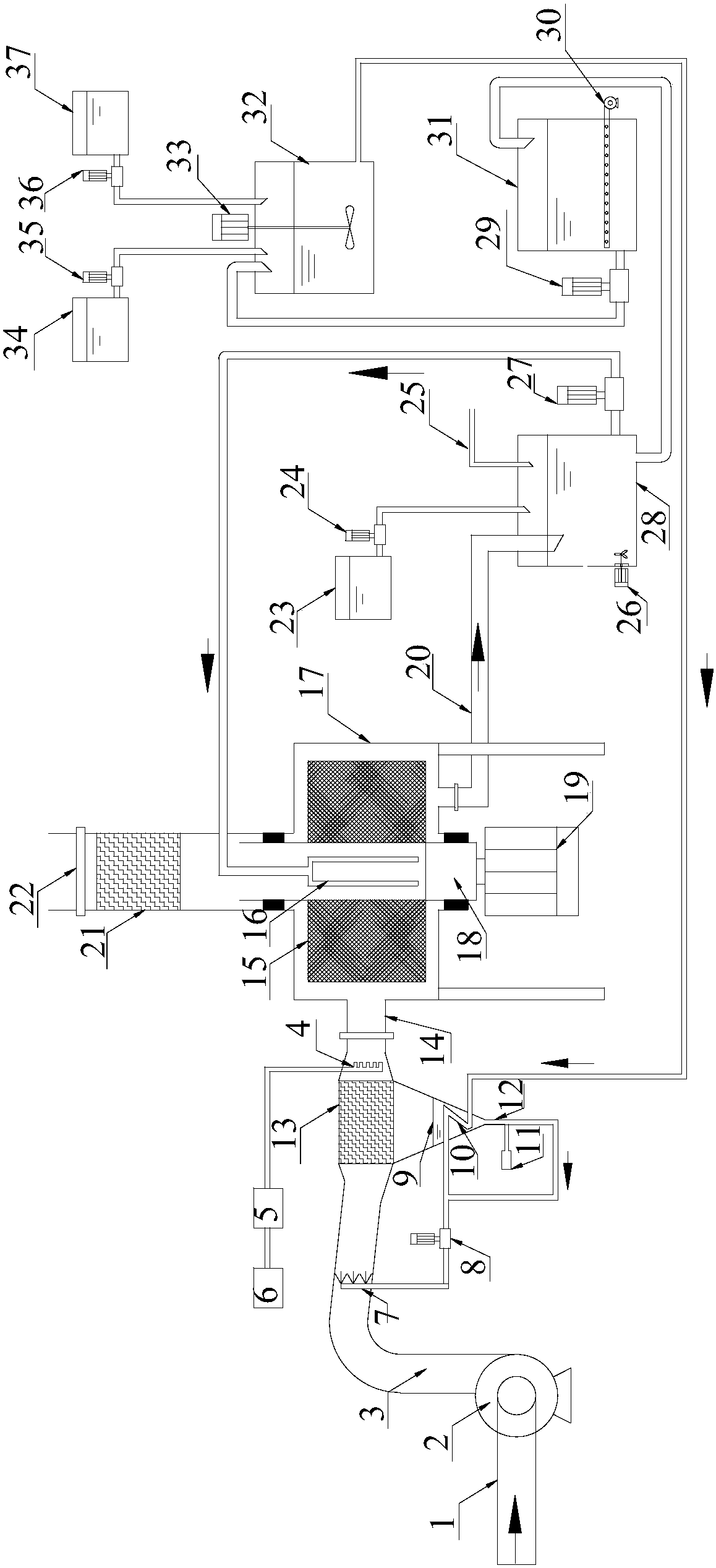

The invention discloses a device and technology for wet desulfurization and denitrification of flue gas of a coal-fired boiler and treatment of wastewater .The technological process includes the steps that the flue gas enters a wastewater evaporative cooling stage through a draught fan outlet to be cooled and then enters an ozonation stage, the flue gas is fully mixed with ozone to be oxidized and then enters a supergravity device through a supergravity desulfurization and denitrification device inlet, the flue gas is subjected to forcible absorption with desulfurization and denitrification absorption liquid in a packed bed on a rotor, and finally the flue gas is demisted by a demister and then discharged through a flue gas outlet of the supergravity device .Replacement absorbent slurry is subjected to oxidation and denitrification treatment in sequence and then returned to the evaporative cooling stage to perform spraying cooling on the flue gas .By means of the device and the technology, desulfurization and denitrification efficiency is improved, and meanwhile water consumption is low; wastewater generated in desulfurization and denitrification is subjected to innocent treatment, sulfate is collected, and thus the coal-fired flue gas can meet stricter discharge standards.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH +1

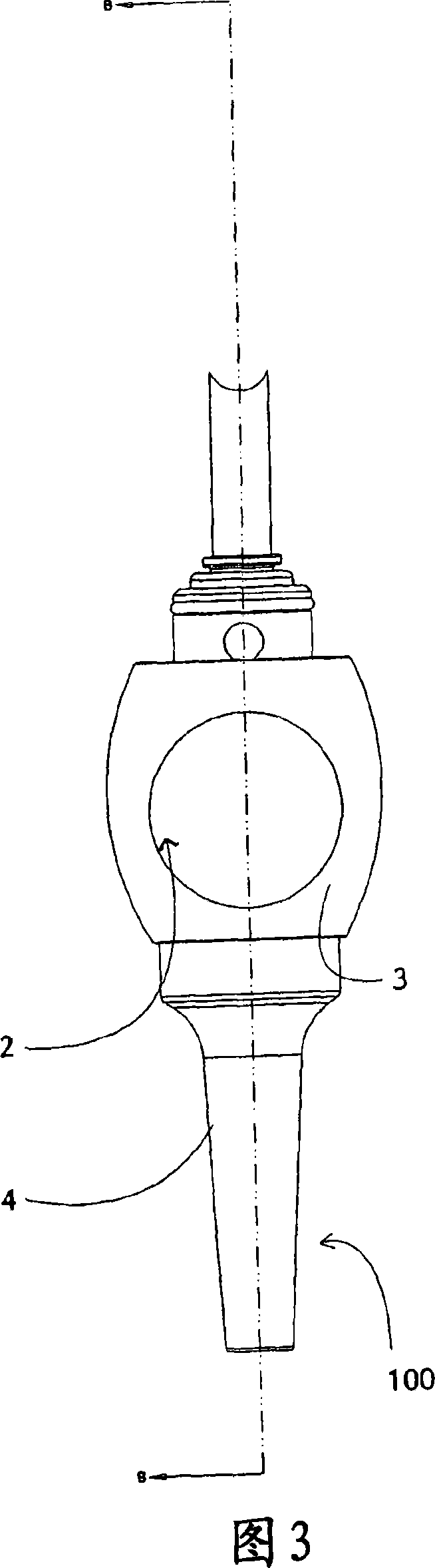

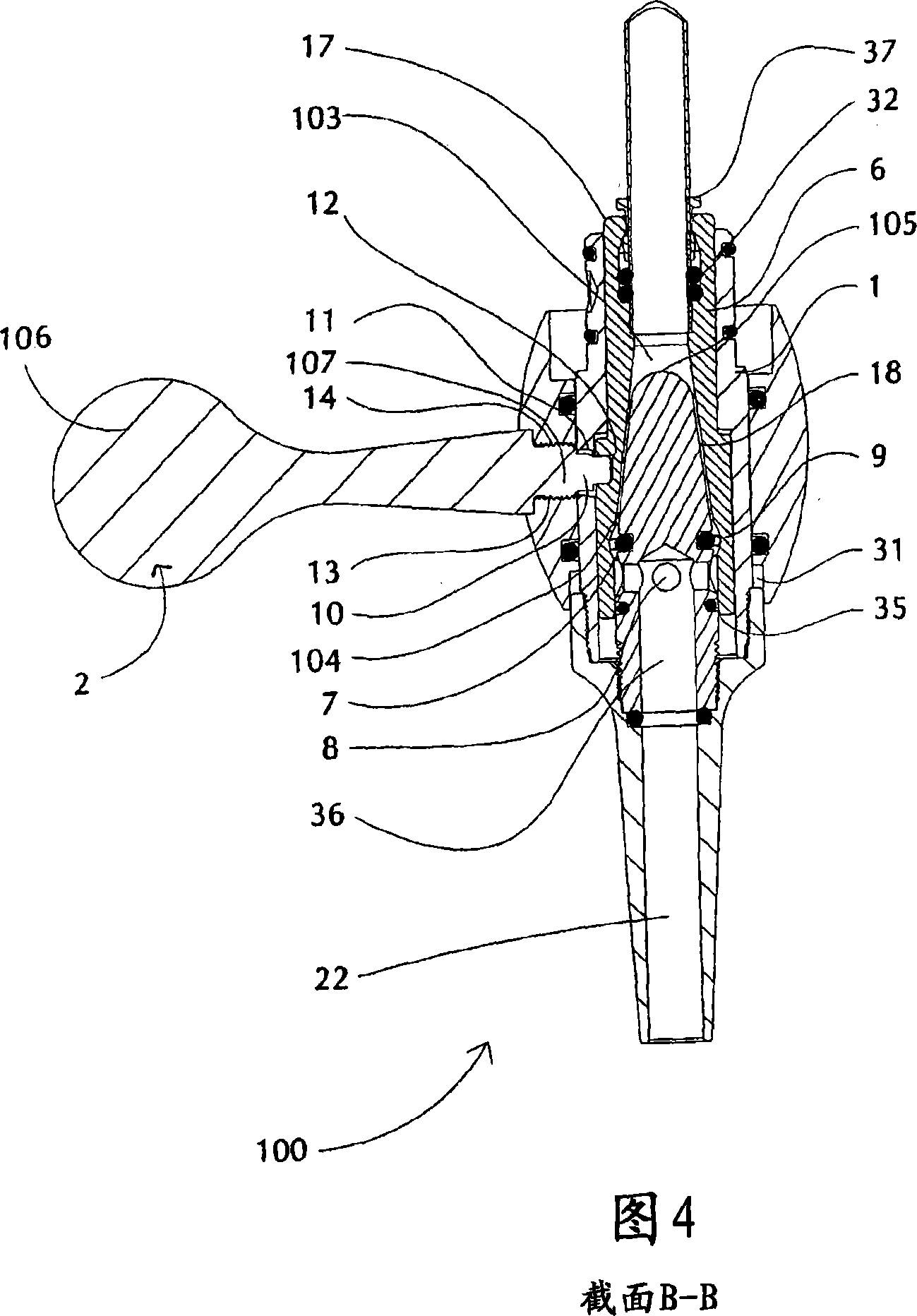

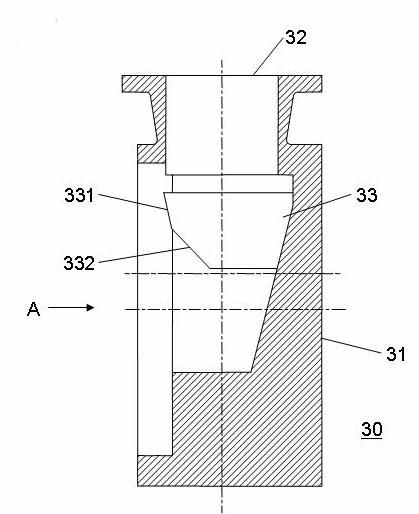

Beverage dispensing valve

InactiveCN101049901AUnimpeded flowUniform and stable flow rateLiquid flow controllersLiquid dispensingEngineeringMechanical engineering

A beverage dispense valve comprising (i) a valve body; (ii) a female taper member inside the valve body the internal diameter increasing in a downstream direction away from the beverage inlet port; (iii) a male taper member, the external diameter of the taper portion increasing in a downstream direction so as to be at least partially complementary to the female taper member, and having a hollow outlet portion downstream of the taper portion, one taper member being slidable relative to the other forming a flow regulator; (iv) one or more apertures penetrating through the male taper member to allow beverage to pass into the interior of the outlet portion, (v) a valve closure arrangement for sealing flow between the beverage inlet port and the beverage outlet port; and (vi) an actuating mechanism outside the valve body to operate both the flow regulator and the valve closure arrangement. The beverage dispense valve described allows simultaneous control of the flow rate of beverage through the valve in unison with the opening and closing of the valve.

Owner:SCOTSMAN BEVERAGE SYST

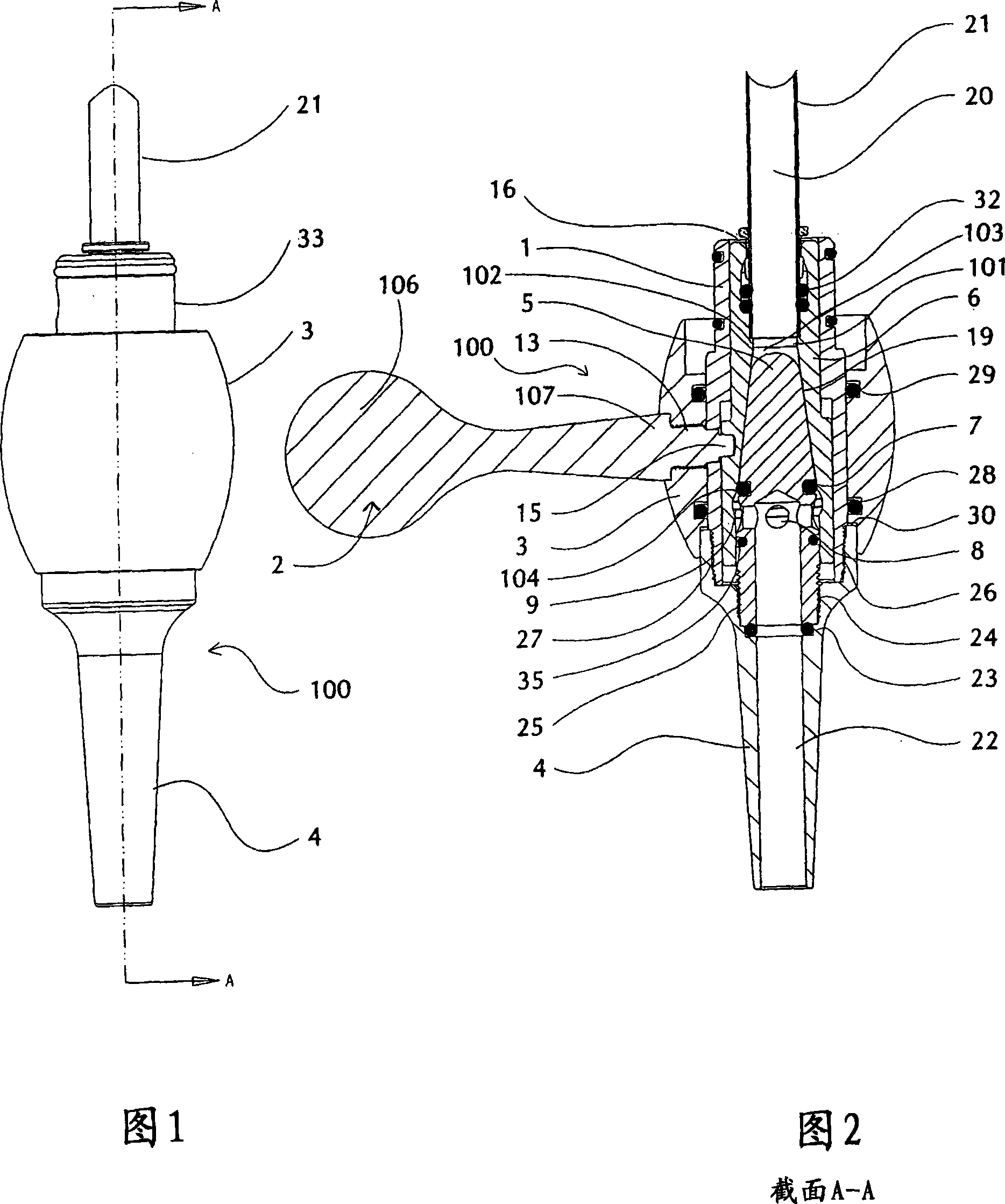

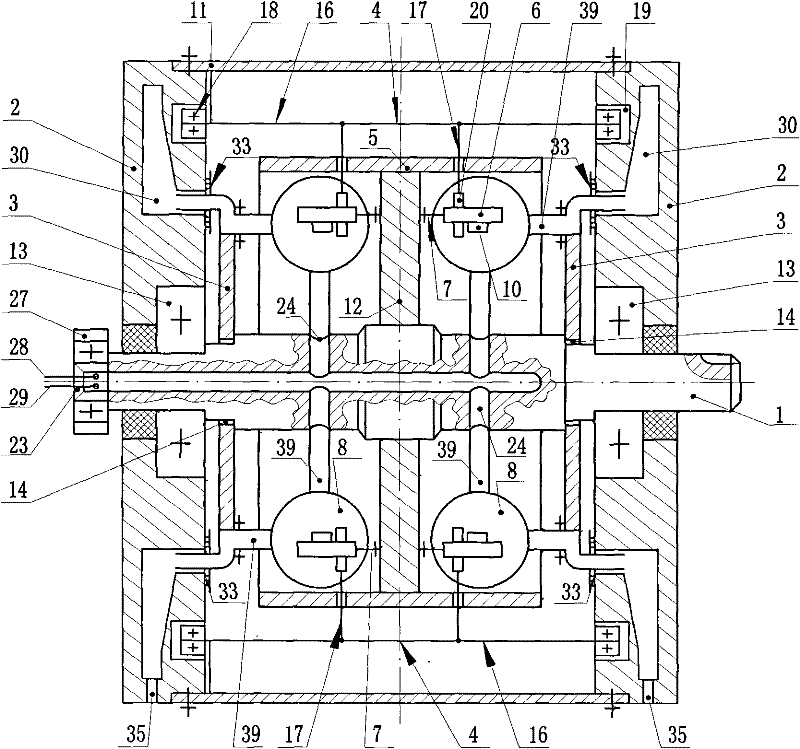

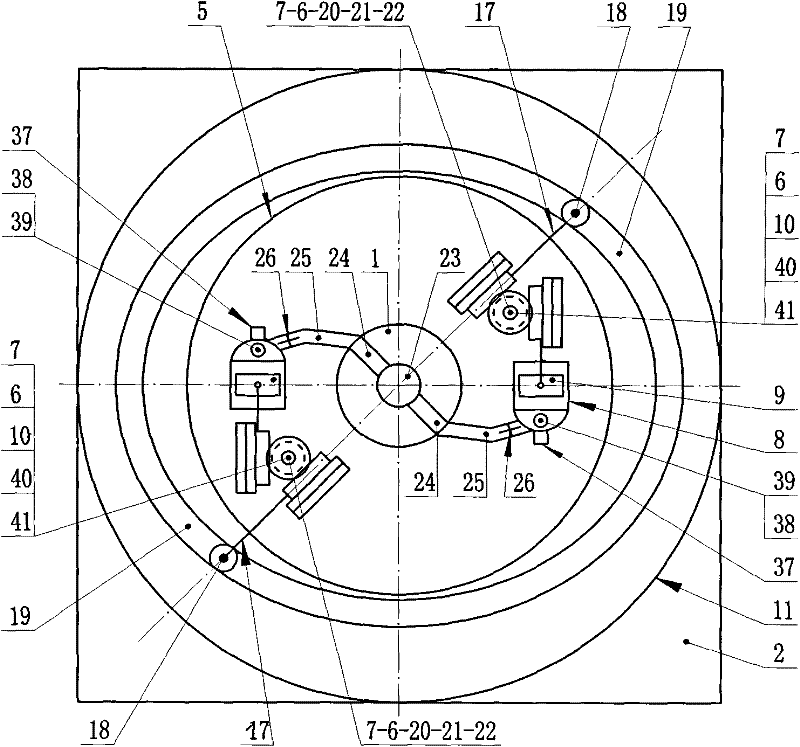

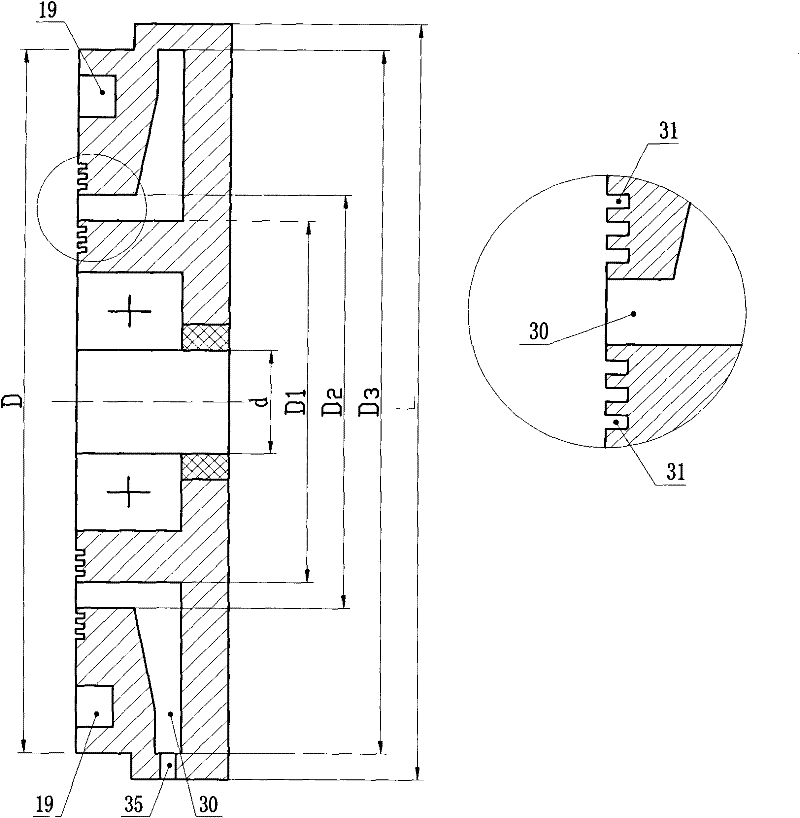

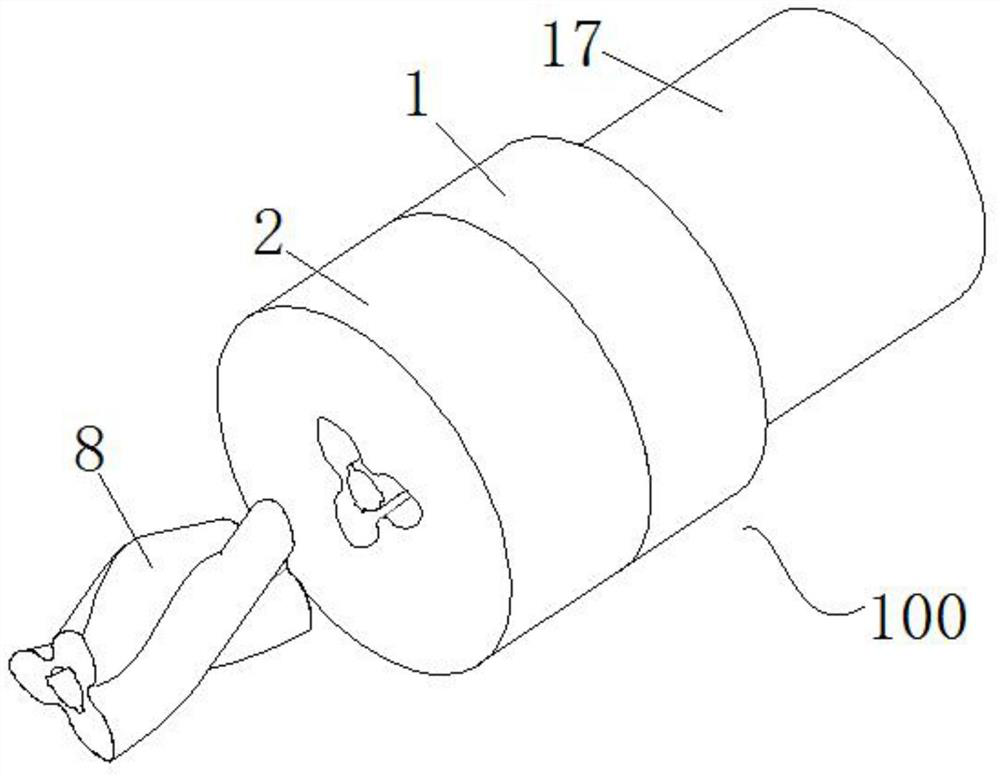

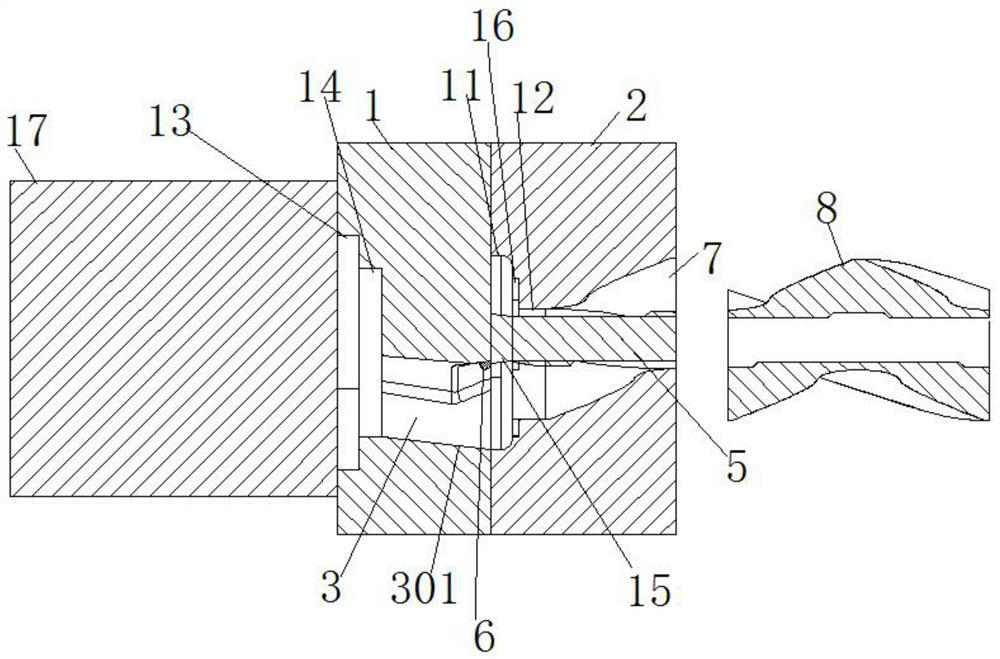

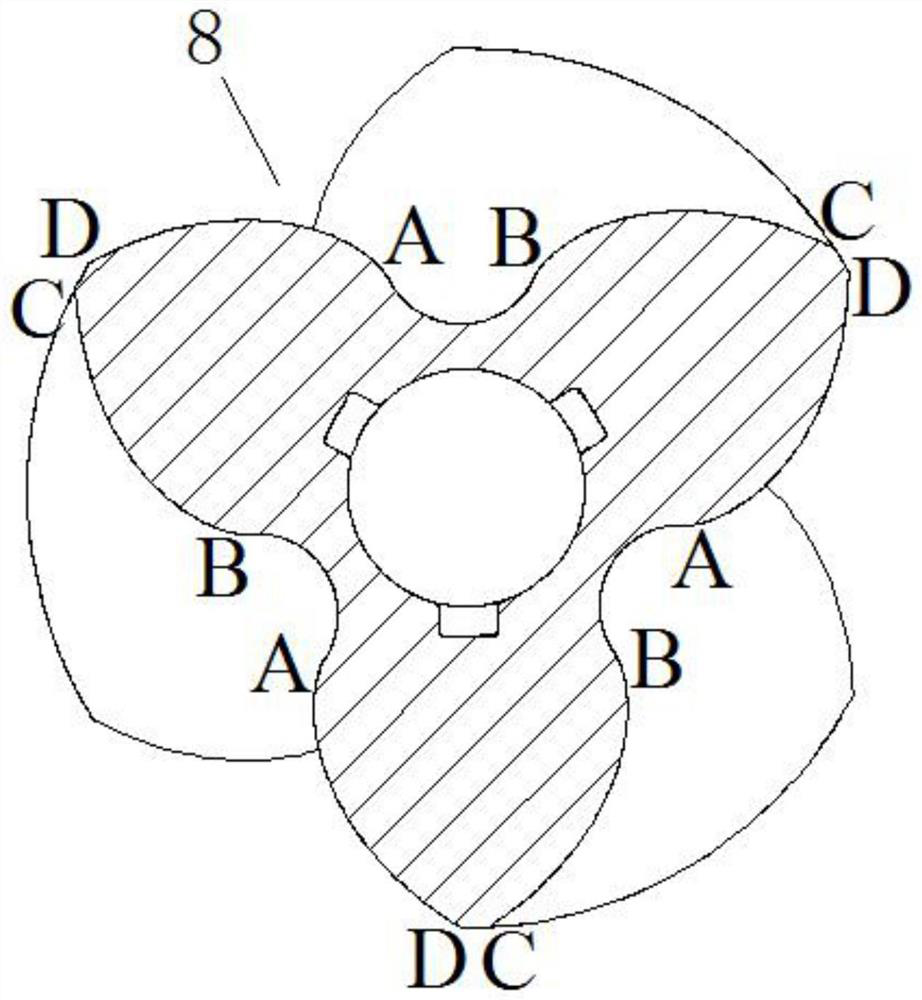

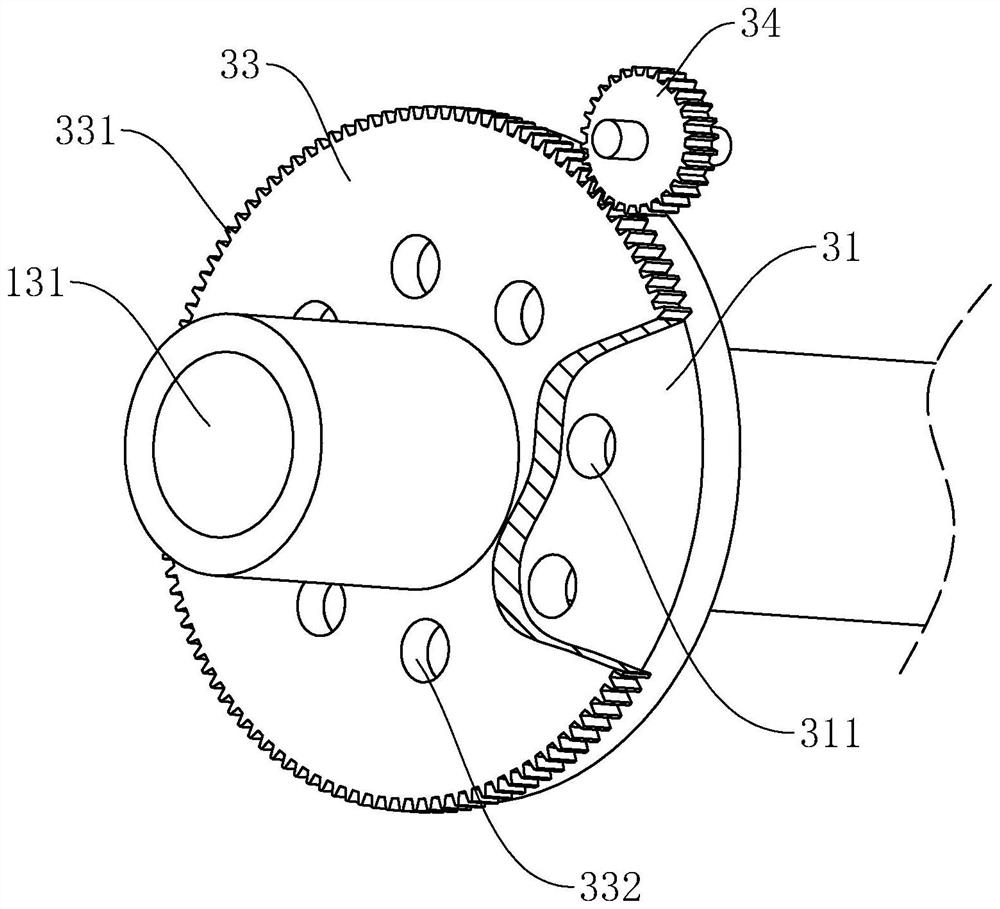

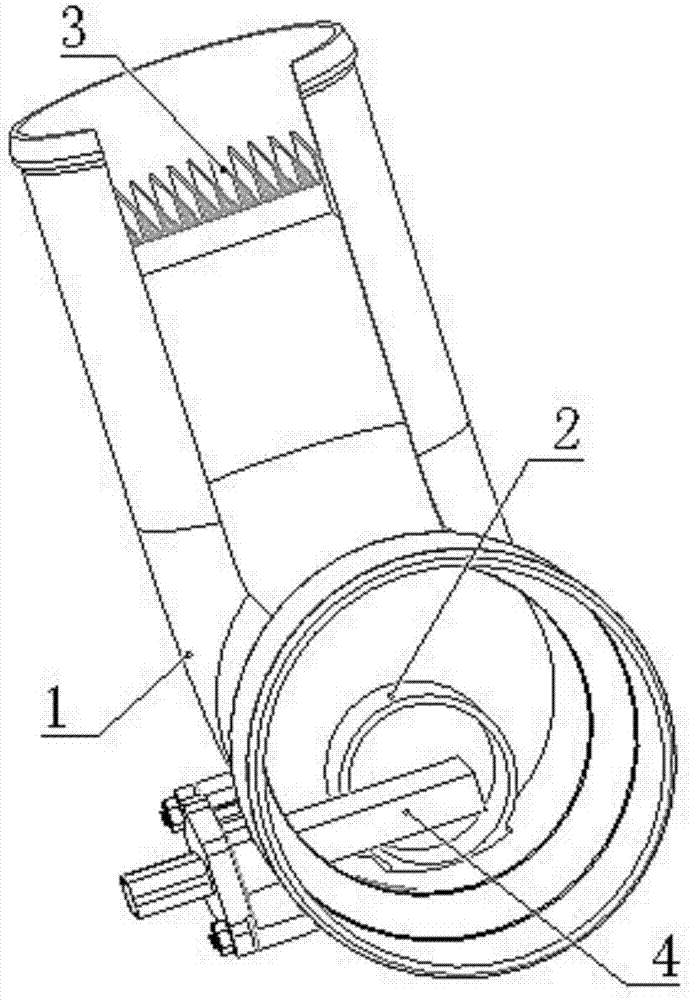

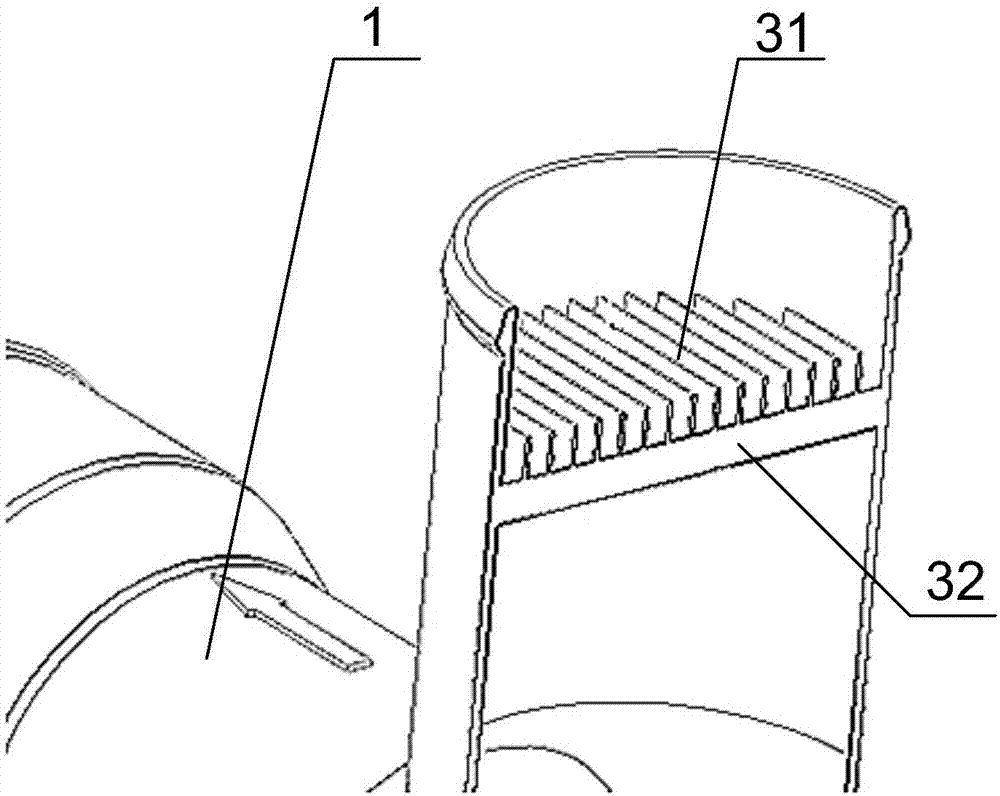

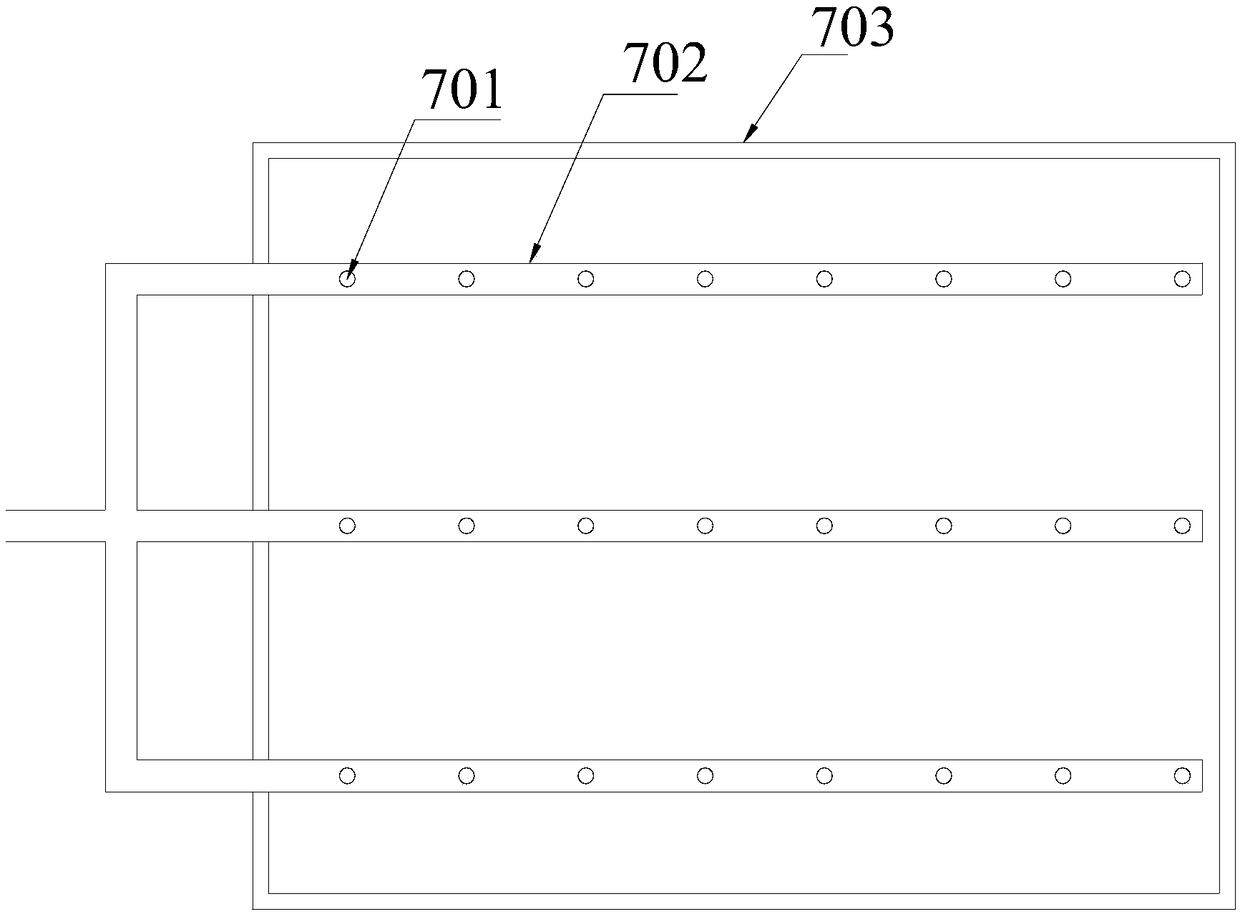

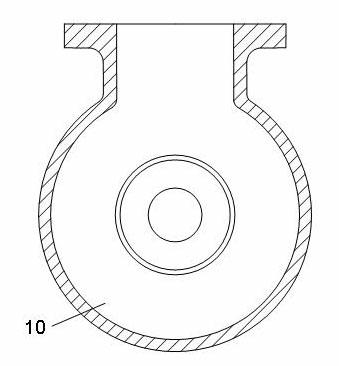

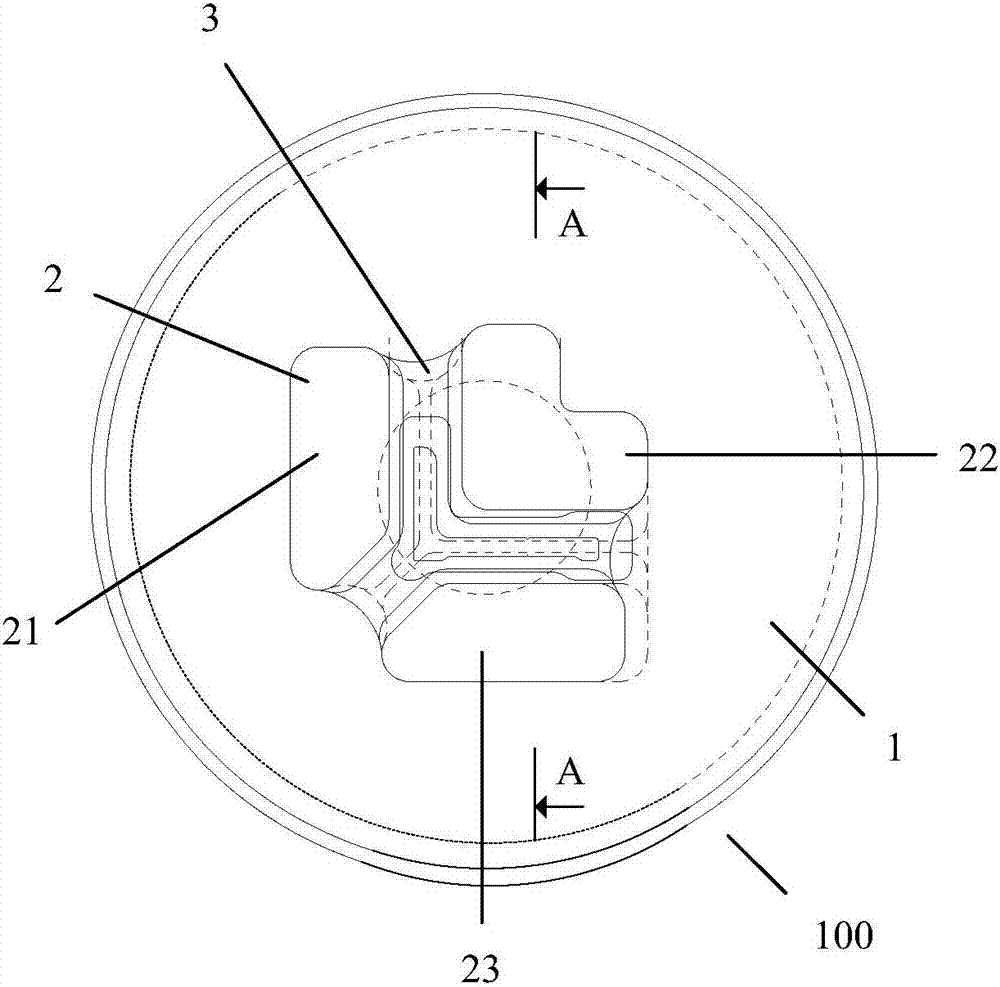

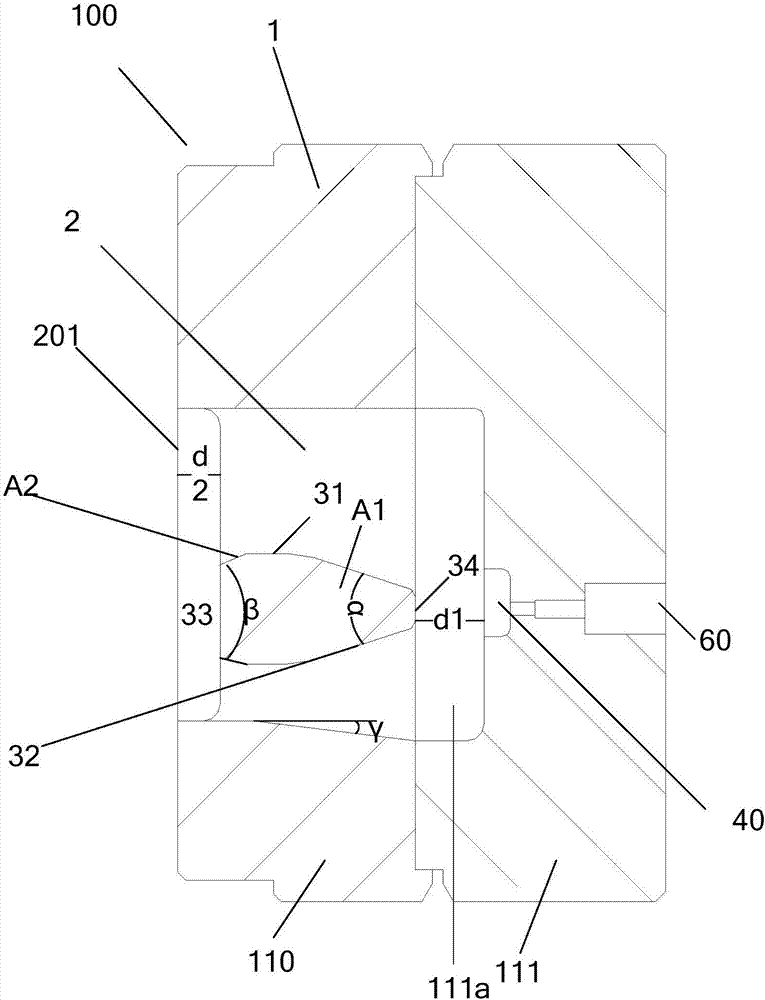

Rotary engine with double rows of pistons

InactiveCN102536446AEasy to achieve static and dynamic balanceQuality improvementInternal combustion piston enginesRotary engineGasoline

A rotary engine with double rows of pistons belongs to the field of power machinery and consists of a spindle (1), two symmetrical opposite elliptical track groove discs (2), two symmetrical air exhaust double-layered sleeves (3), double-T-shaped rolling connecting rods (4), a bidirectional cylindrical rotating cylinder (5), turning gears (6), gear shafts (7), crank connecting rod piston type single-cylinder engine heads (8), pistons (9), piston rod racks (10), a cylindrical shell (11) and the like. Two or four or a plurality of even-number engine heads (8) are respectively symmetrically mounted on two side surfaces of an engine head tray (12) around centers of the two side surfaces, so that a rotary engine head assembly with double rows of pistons is formed; two rolling connecting rod bearings (18) are inserted into two symmetrical opposite elliptical track grooves (19); and the two piston rod racks (10) and two vertical rod racks (20) are respectively meshed with the two turning gears. The rotary engine is simple and compact in structure, long in service life, stable in running and low in vibration and noise, is high-efficiency, energy-saving and emission-reduction, not only can be made into a gasoline engine, but also can be made into a diesel engine, and is applicable to various types of fuels.

Owner:方保林

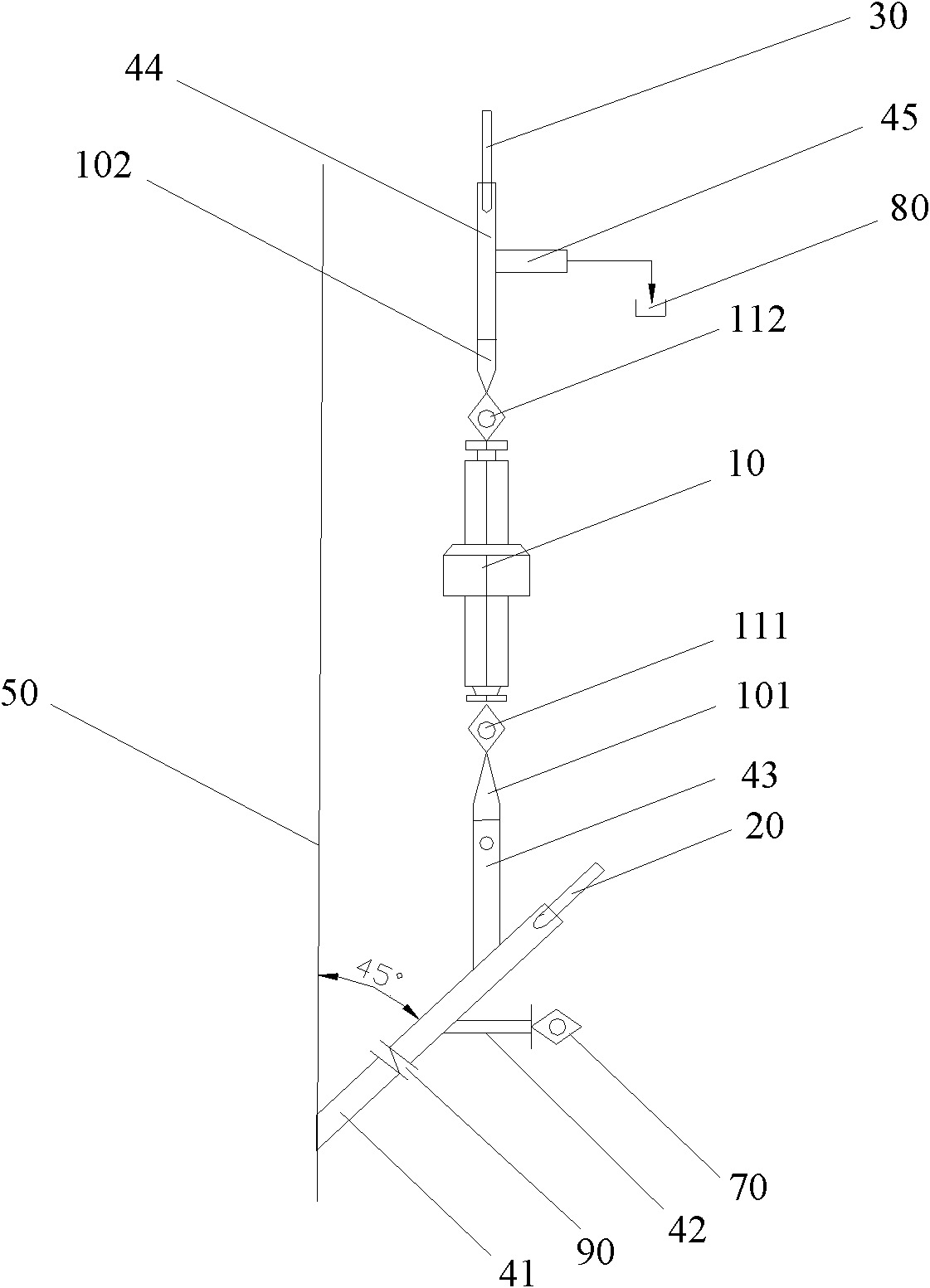

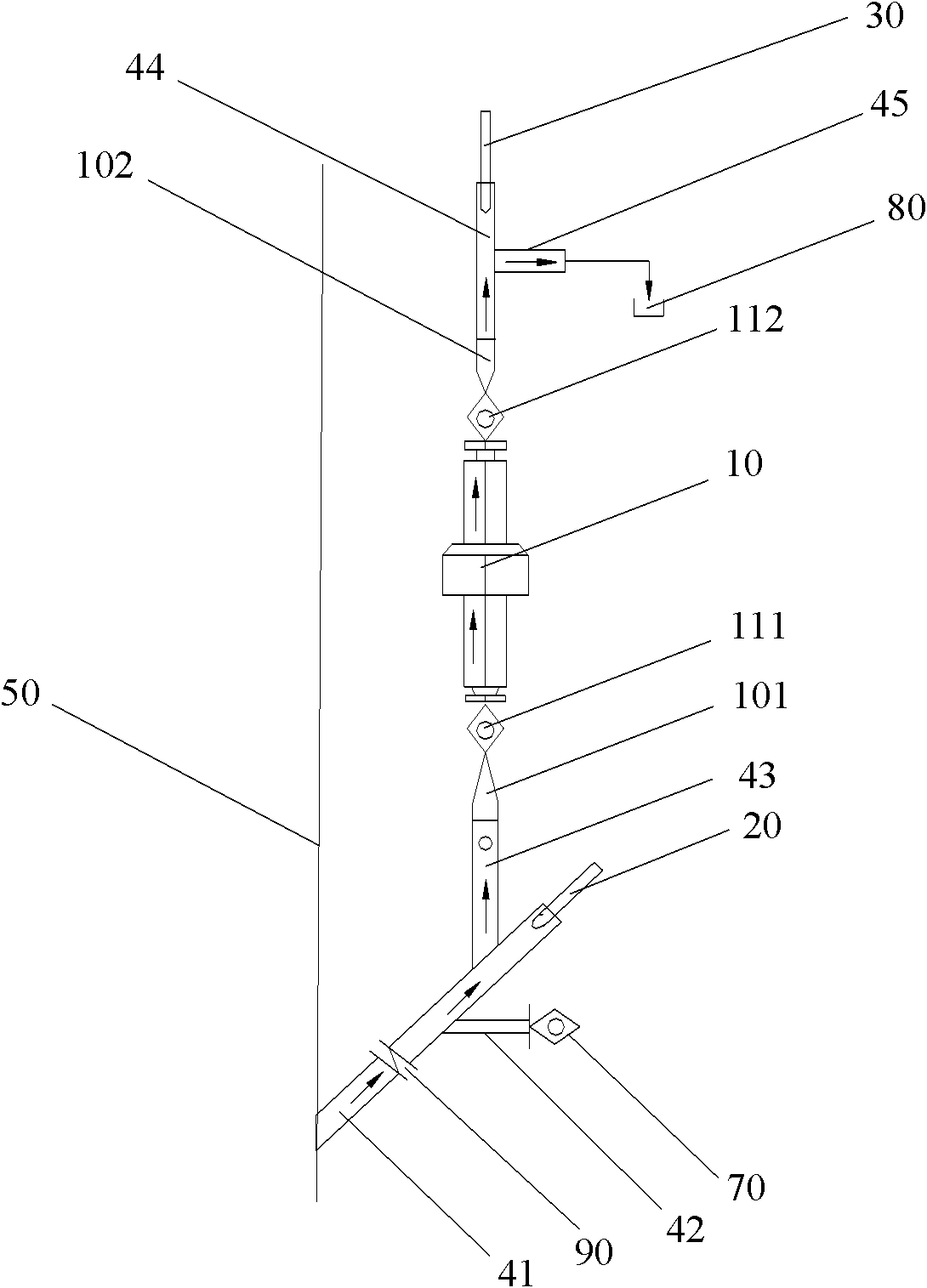

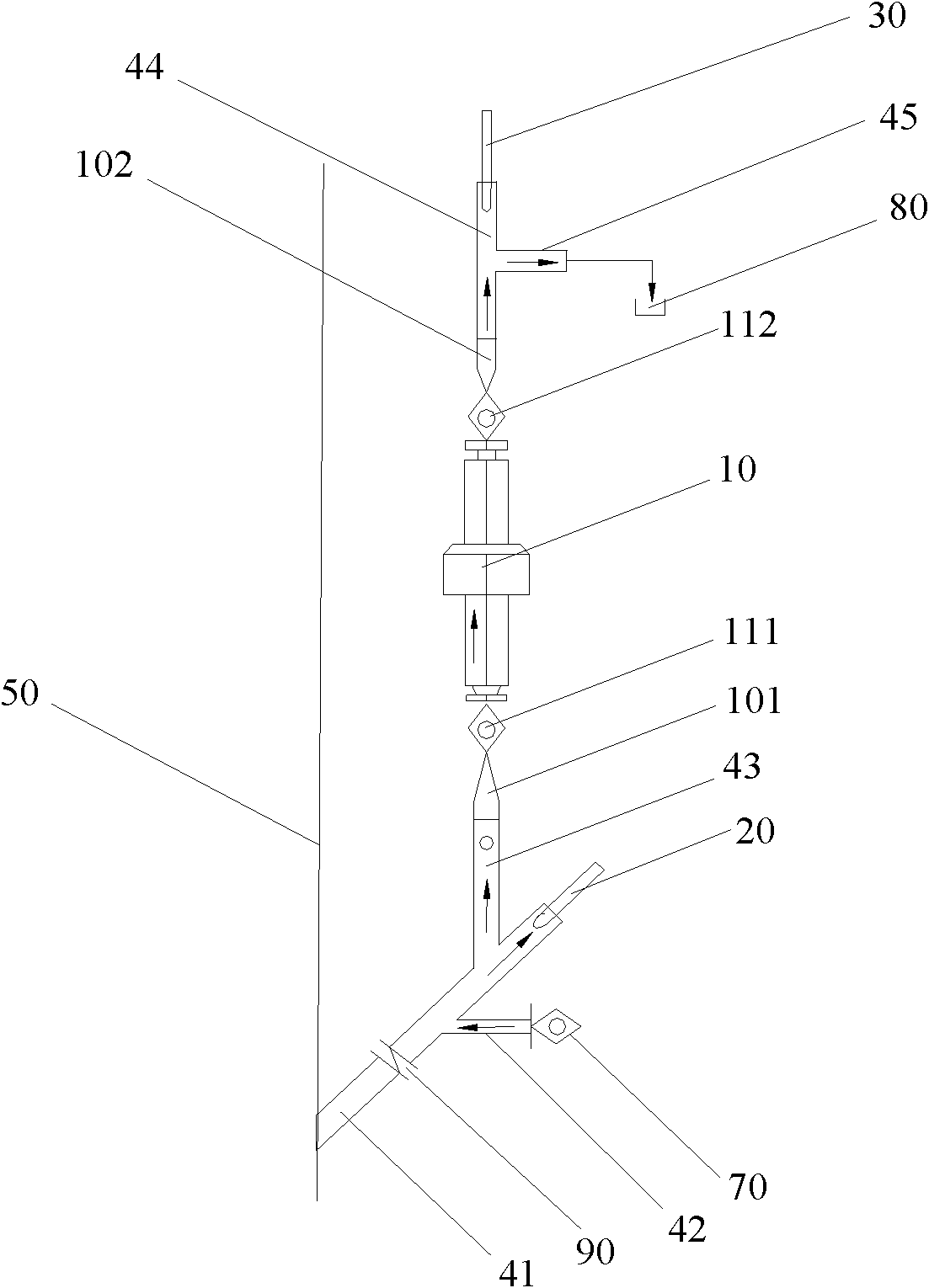

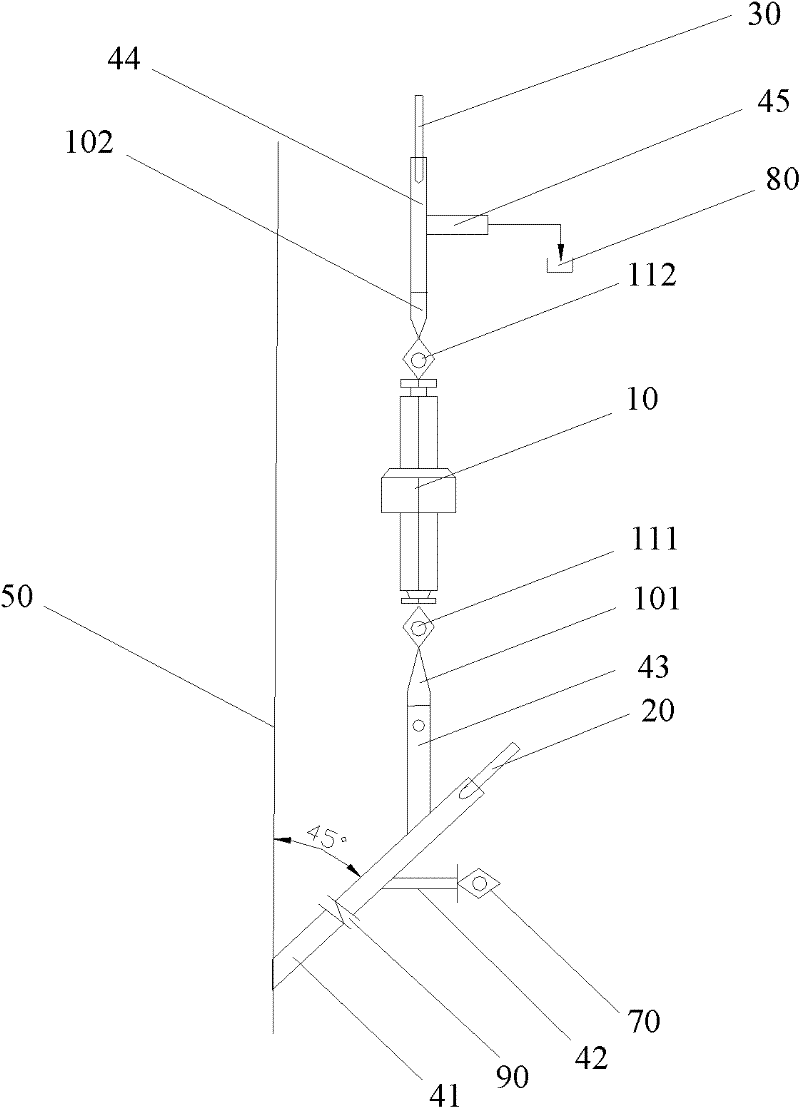

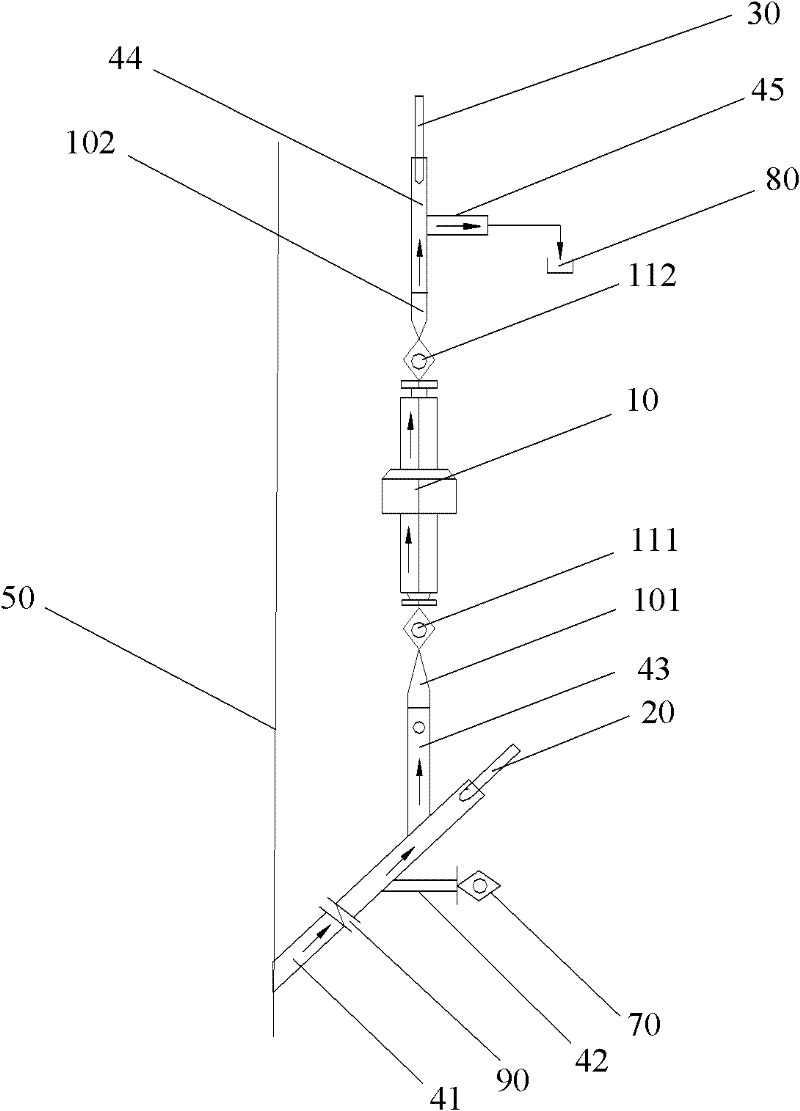

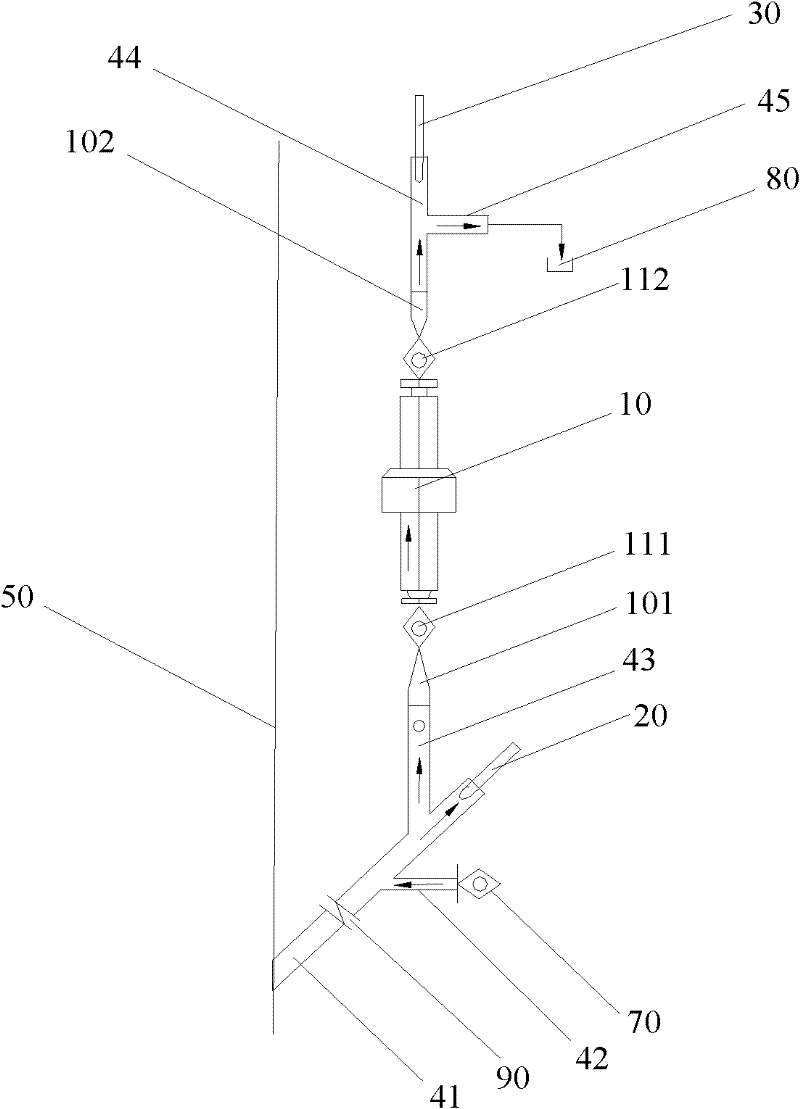

Device for measuring density and pH value of slurry

ActiveCN102012352AUniform and stable flow rateStable flow rateSpecific gravity using flow propertiesPH meterAir sample

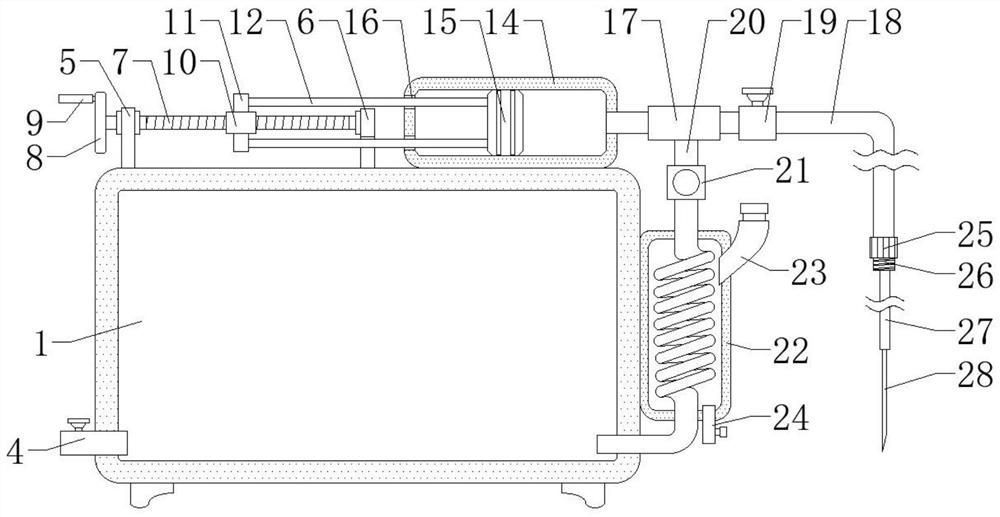

The invention discloses a device for measuring the density and the pH value of slurry. The device comprises an air sampling pipe component, a densitometer, a first pH meter and a second pH meter, wherein the air sampling pipe component comprises a first branch pipe, a second branch pipe, a third branch pipe, a fourth branch pipe and a fifth branch pipe; the lower end of the first branch pipe is connected with the lower end of an absorption tower; the first pH meter is inserted into the first branch pipe; the second branch pipe is horizontally communicated with the first branch pipe; the free end of the second branch pipe is connected with a flushing water pipe; the upper end and lower end of the third branch pipe are respectively communicated with the lower ends of the first branch pipe and the densitometer; the upper end of the densitometer is communicated with the lower end of the fourth branch pipe; the second pH meter is inserted into the fourth branch pipe; the fifth branch pipe is vertically communicated with the fourth branch pipe; and the central lines of the third branch pipe, the fourth branch pipe and the densitometer are positioned on the same straight line and are parallel to the wall of the absorption tower. The device for measuring the density and the pH value of slurry can prolong the service life of the densitometer and the pH meters and reduce the maintenance workload of field equipment.

Owner:武汉光谷环保科技股份有限公司

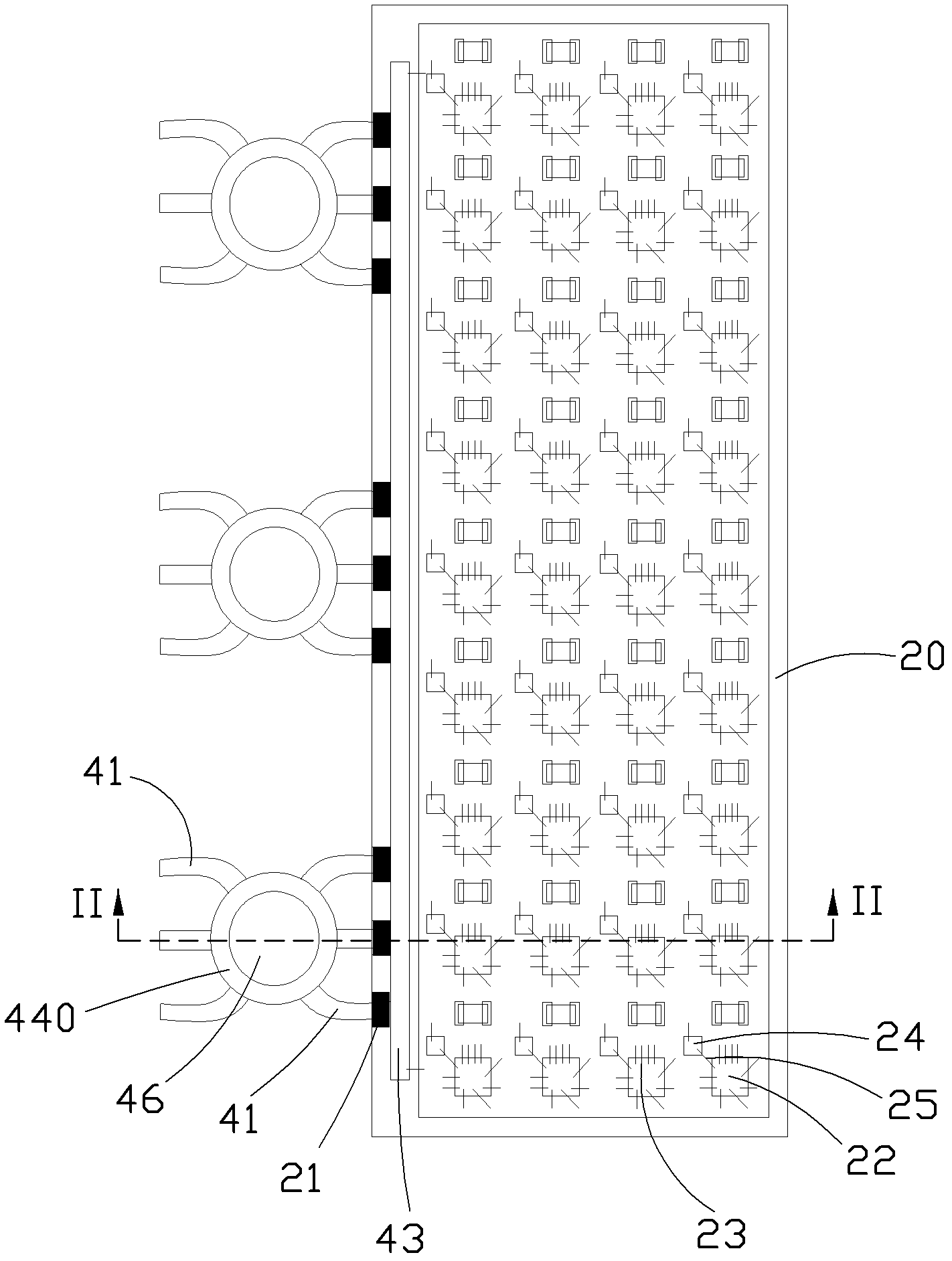

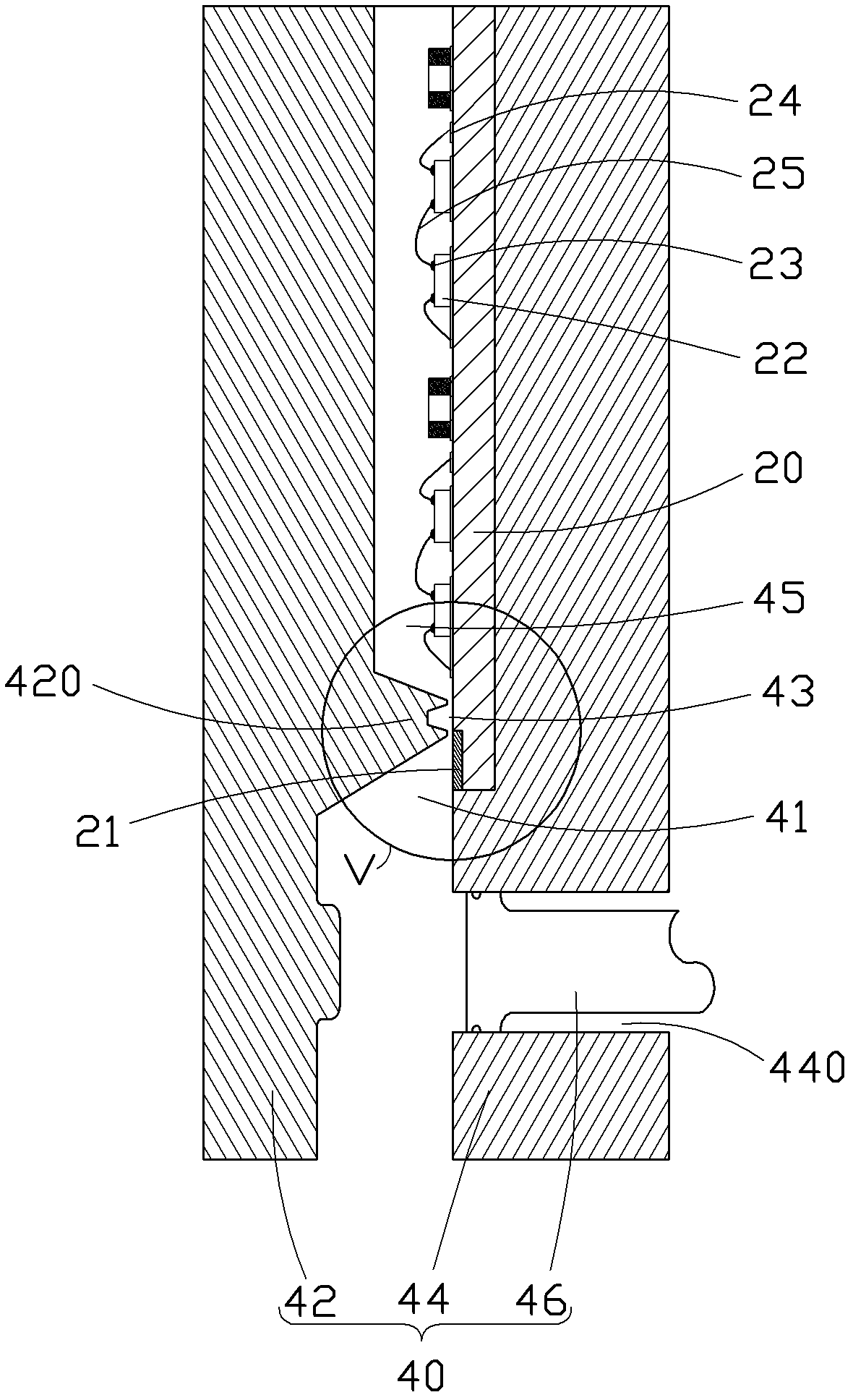

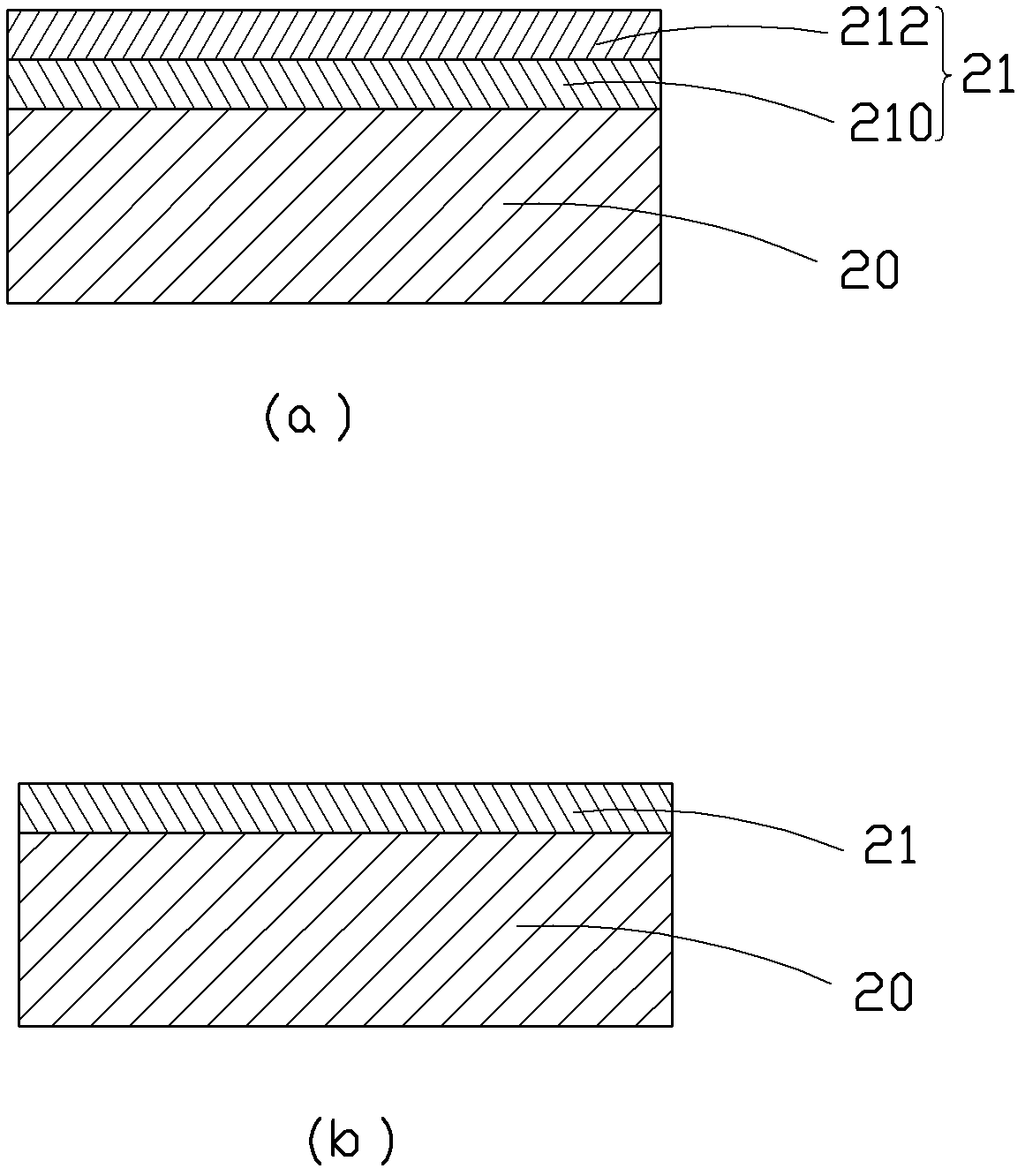

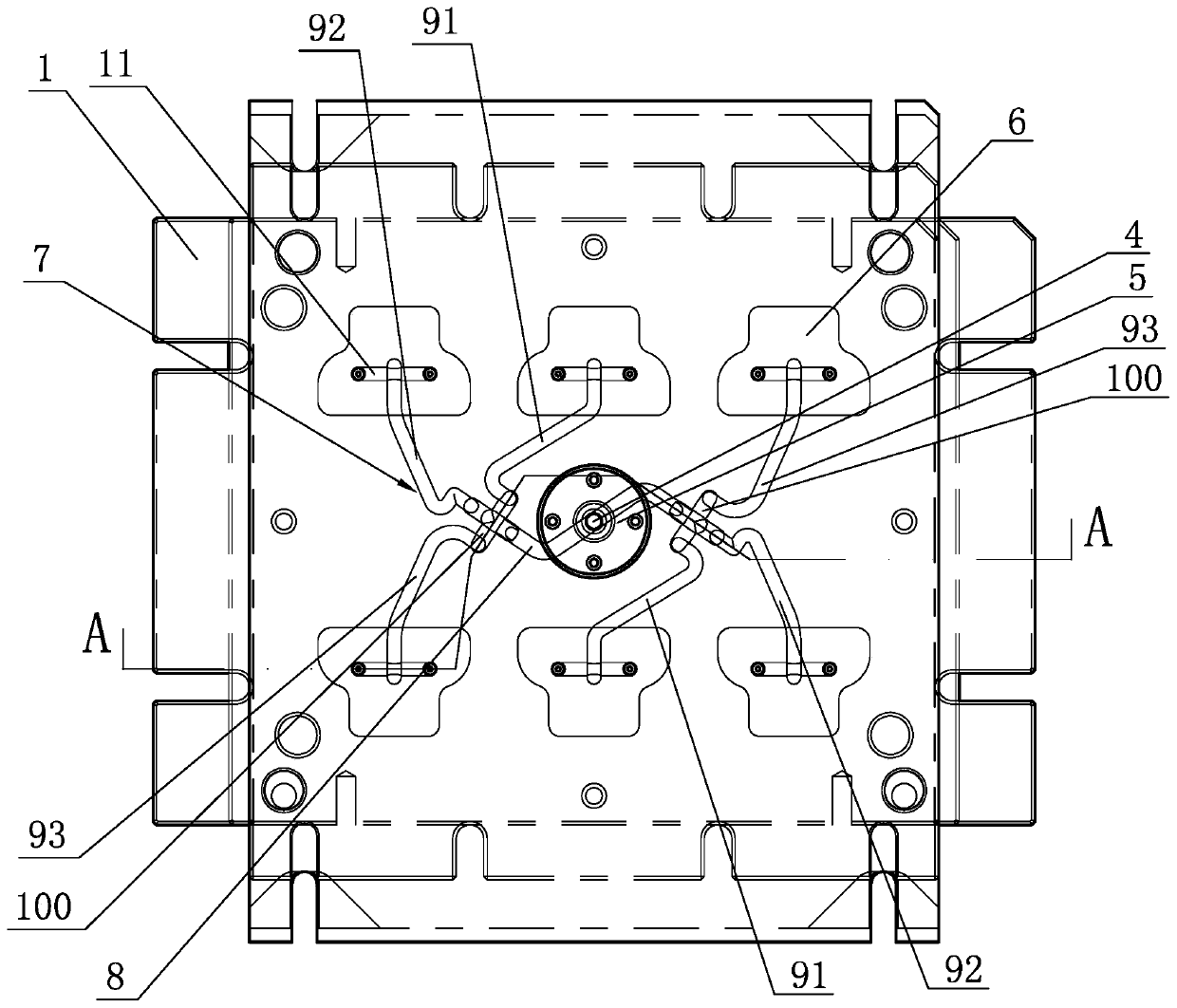

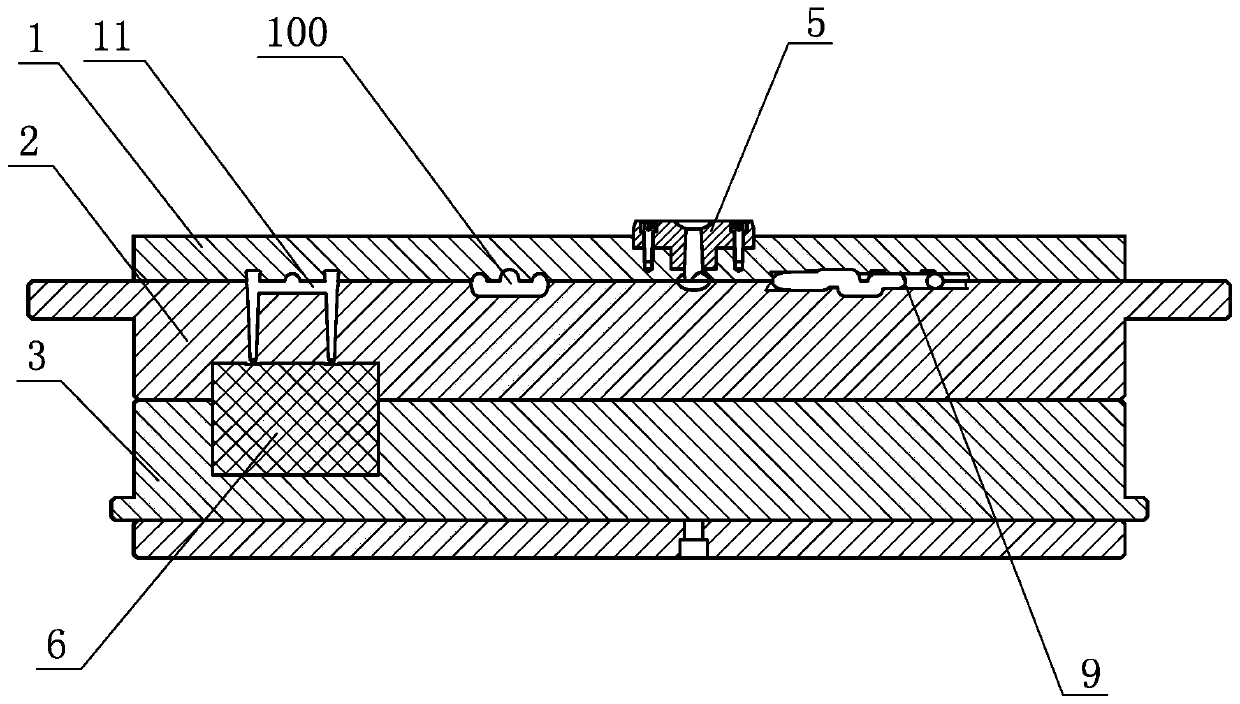

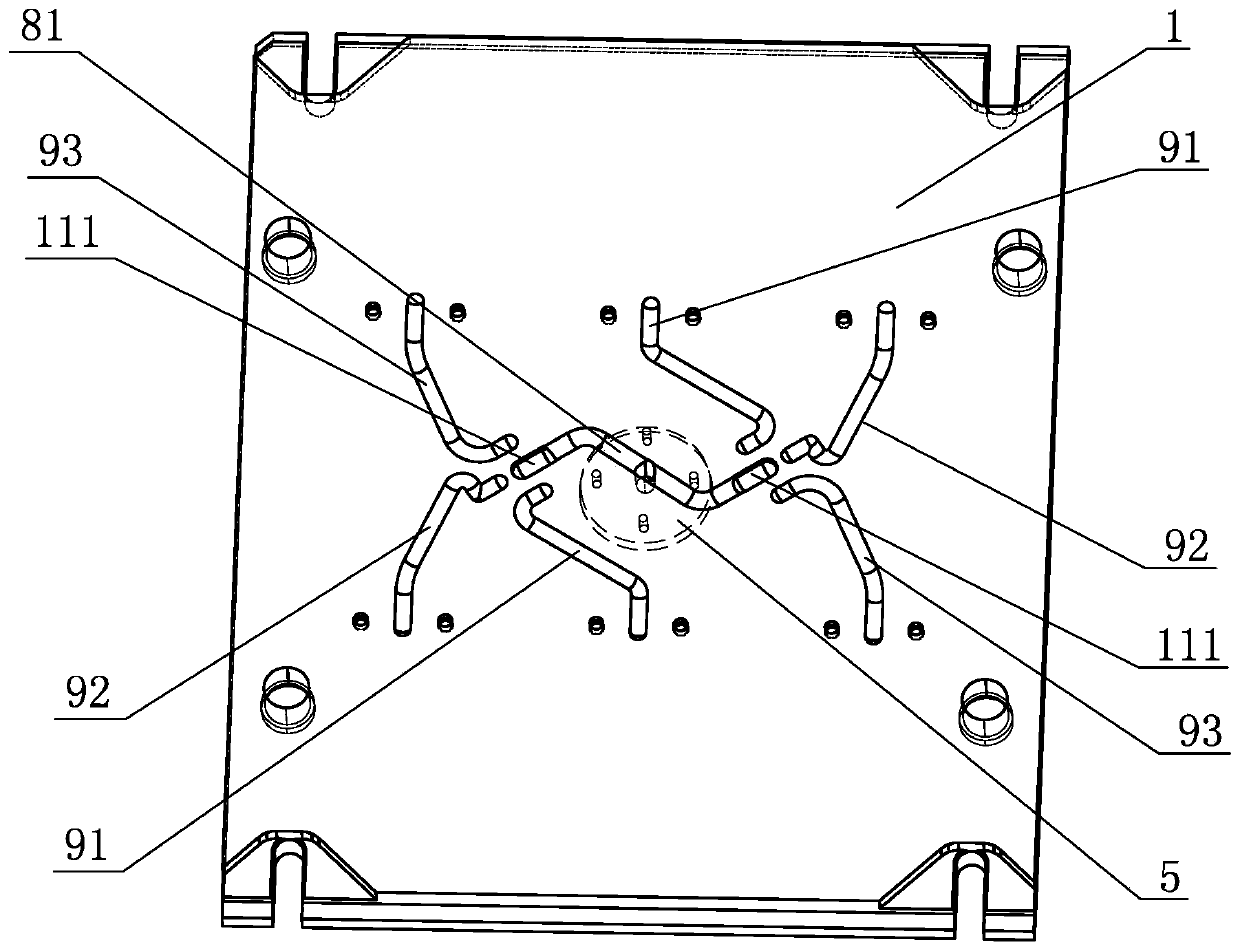

Mould casting device and method for semiconductor package

InactiveCN103021902AReduce air pocketsFlows and fills evenlySemiconductor/solid-state device detailsSolid-state devicesPistonComposite material

The invention relates to a mould casting device for semiconductor package. The device comprises an upper mould plate, a lower mould plate arranged opposite to the upper mould plate and a piston. The lower mould plate is provided with a plurality of piston ports to accommodate the piston and a pit opened toward the upper mould plate. The pit and the upper mould plate jointly form a mould cavity to accommodate a substrate. The upper mould plate is protruded toward the pit and is adjacent to the protruding part of the piston port. The protruding part close to the lower mould plate is provided with a gap opposite to the pit. An inlet and an outlet communicated with the piston ports and the mould cavity are respectively formed on both sides of the gap, so that a sealing compound injected from the piston ports is injected to the mould cavity along the inlet, the gap and the outlet so as to cover the substrate.

Owner:SHUNSIN TECH (ZHONG SHAN) LTD

Etching groove, method for conveying etching liquid and etching system

InactiveCN110060945AUniform and stable flow rateStable flow rateSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

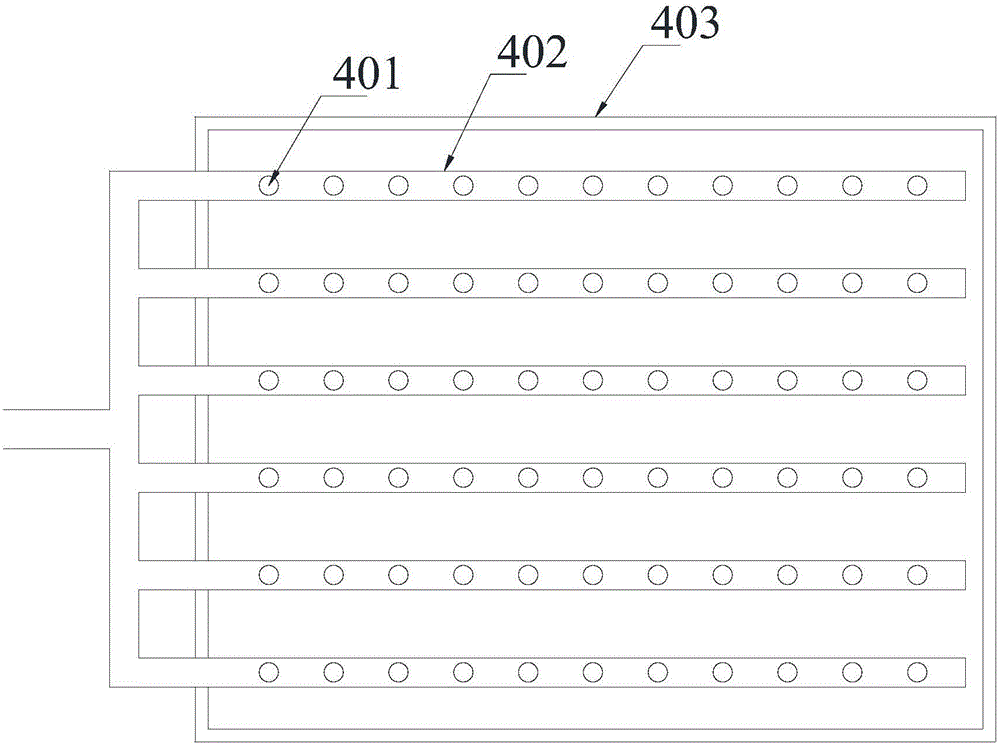

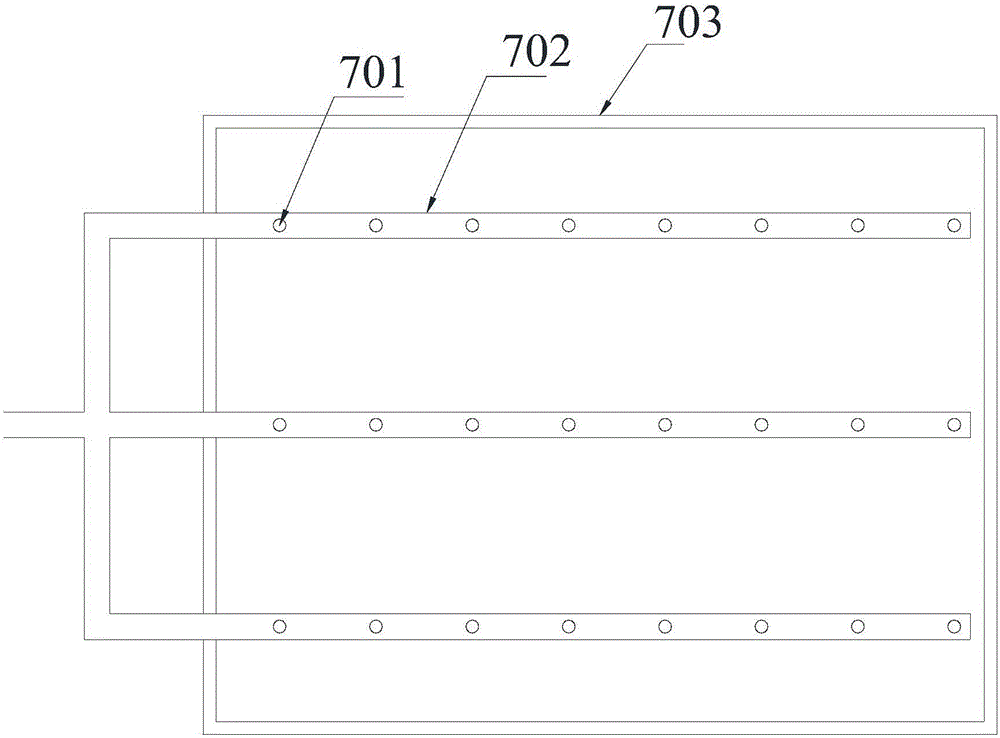

The invention relates to an etching groove. The etching groove comprises a plurality of conveying nozzles, wherein the plurality of conveying nozzles are uniformly distributed at the bottom of the etching groove, and the plurality of conveying nozzles are configured to convey the etching liquid to the etching groove in parallel.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

Simulation experiment device and method

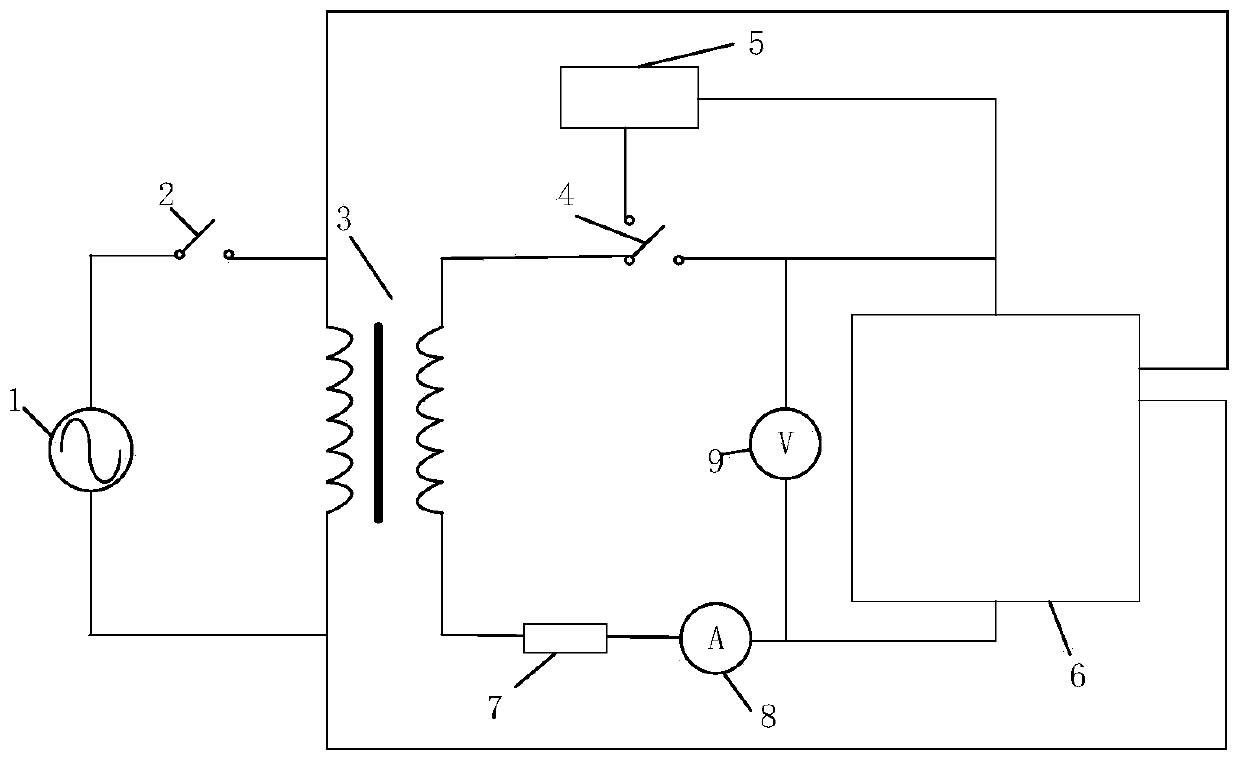

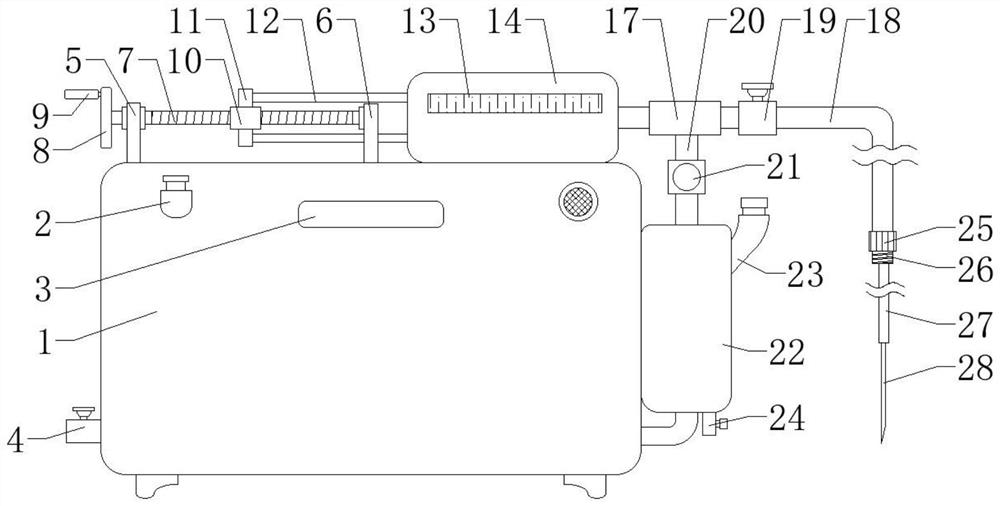

PendingCN111276027AEasy to understandUniform and stable flow rateEducational modelsExperimental testingElectrical resistance and conductance

The invention discloses a simulation experiment device and method. The primary side of the single-phase power frequency experiment transformer is connected to a power frequency mains supply through anair protection switch. One end of the secondary side of the single-phase power frequency experiment transformer is connected with an output double-touch switch; the output double-touch switch is divided into two paths, one path is connected with an experiment box through a rectifying device and a voltmeter, the other path is directly connected with the voltmeter and the experiment box, and the other end of the secondary side of the single-phase power frequency experiment transformer is connected with the voltmeter and the experiment box through the protective resistor and the ampere meter insequence; the power frequency mains supply supplies power to the experiment box; the controllable temperature of the experiment box is room temperature to 600 DEG C, and the experiment box is used forproviding a constant-temperature and constant-atmosphere experiment environment for the sample to be detected. According to the invention, actual operation conditions of electrical materials or devices can be simulated, and various experiment tests can be carried out.

Owner:XI AN JIAOTONG UNIV +3

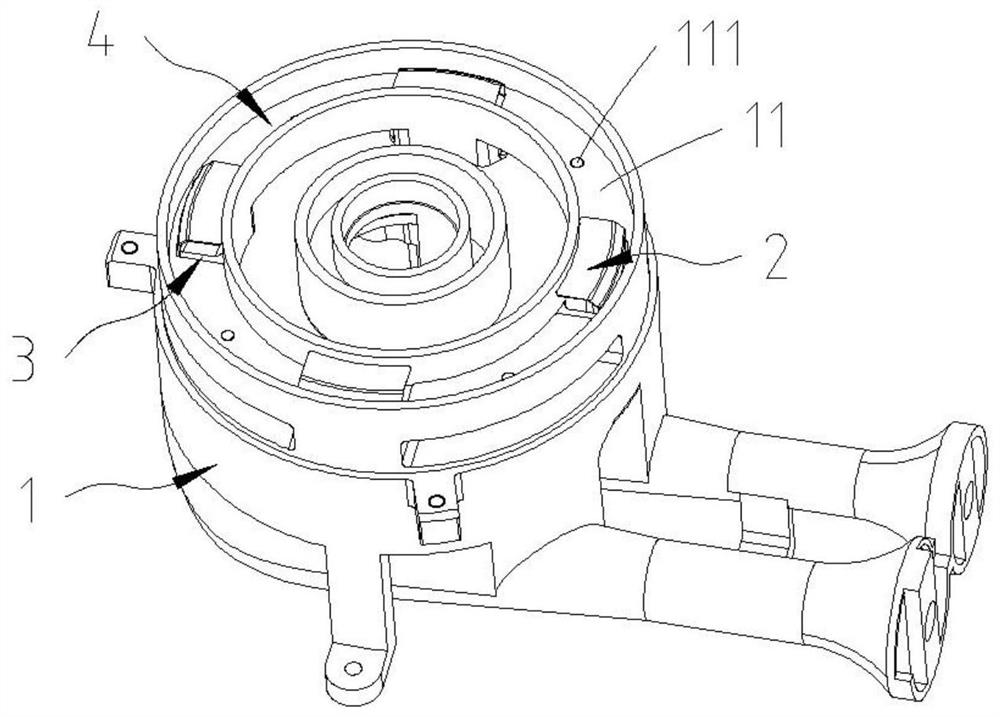

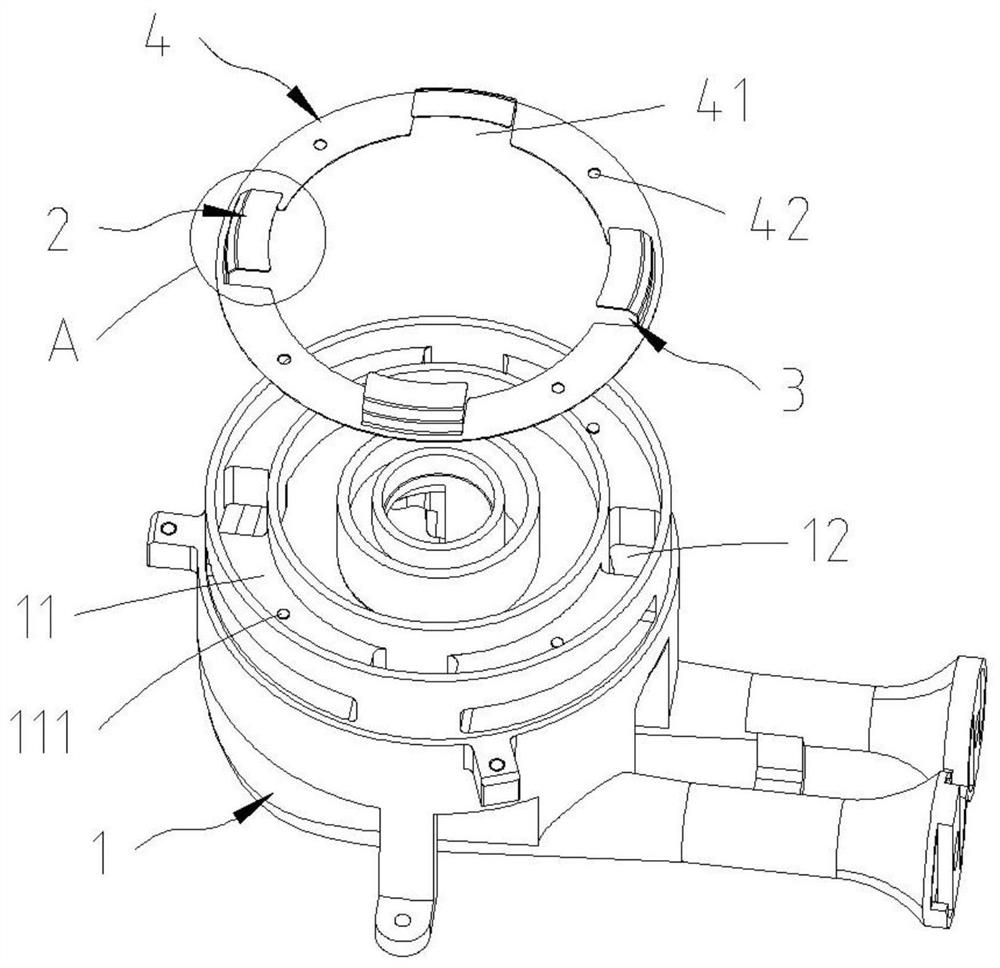

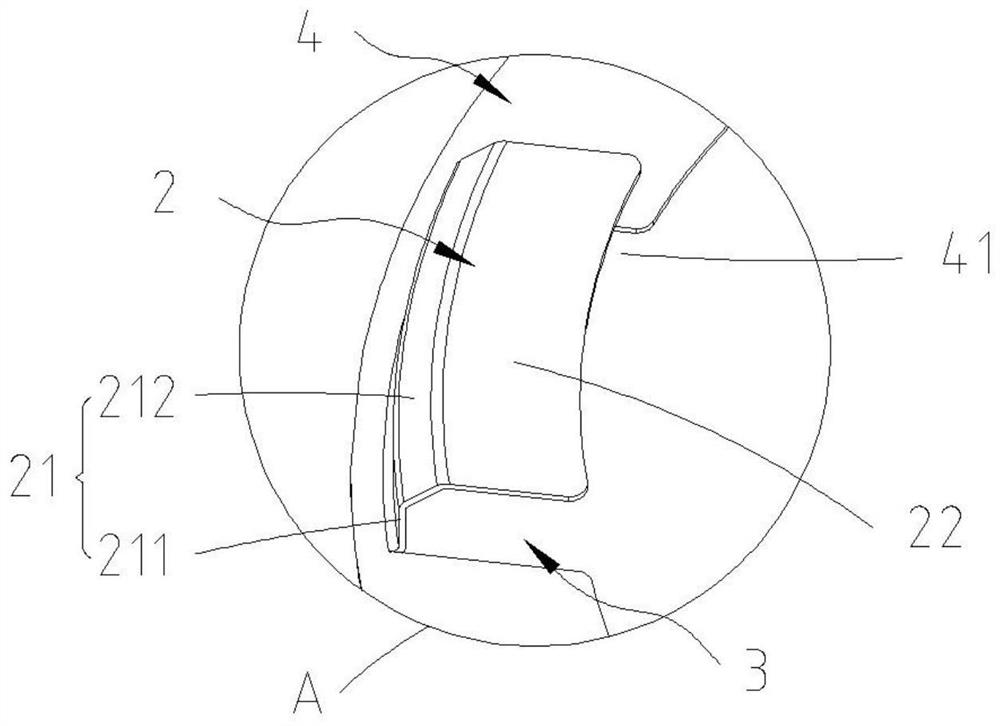

Burner with gas combing device

PendingCN111964105ASame flow rateUniform and stable flow rateDomestic stoves or rangesGaseous fuel burnerEngineeringMechanical engineering

The invention discloses a burner with a gas combing device. The burner comprises a burner body and the gas combing device. The burner body is provided with a gas mixing cavity and at least two gas channels. The gas combing device comprises a blocking structure arranged in the gas mixing cavity and located above gas channel outlets. The blocking structure is provided with a gas combing channel communicating with the gas channels, or the blocking structure, the bottom and surrounding wall of the gas mixing cavity jointly define the gas combing channel communicating with the gas channels. The left side and / or right side of the gas combing channel are / is provided with gas outlets / a gas outlet communicating with the gas mixing cavity. The burner is provided with the blocking structure, thus when gas flow flows into the gas mixing cavity, the flow speed is lowered, the flow direction is changed, the flow direction and flow speed of the gas flowing into the gas mixing cavity are combed, burning is more uniform and stable, and meanwhile flameout noise can be effectively restrained.

Owner:VATTI CORP LTD

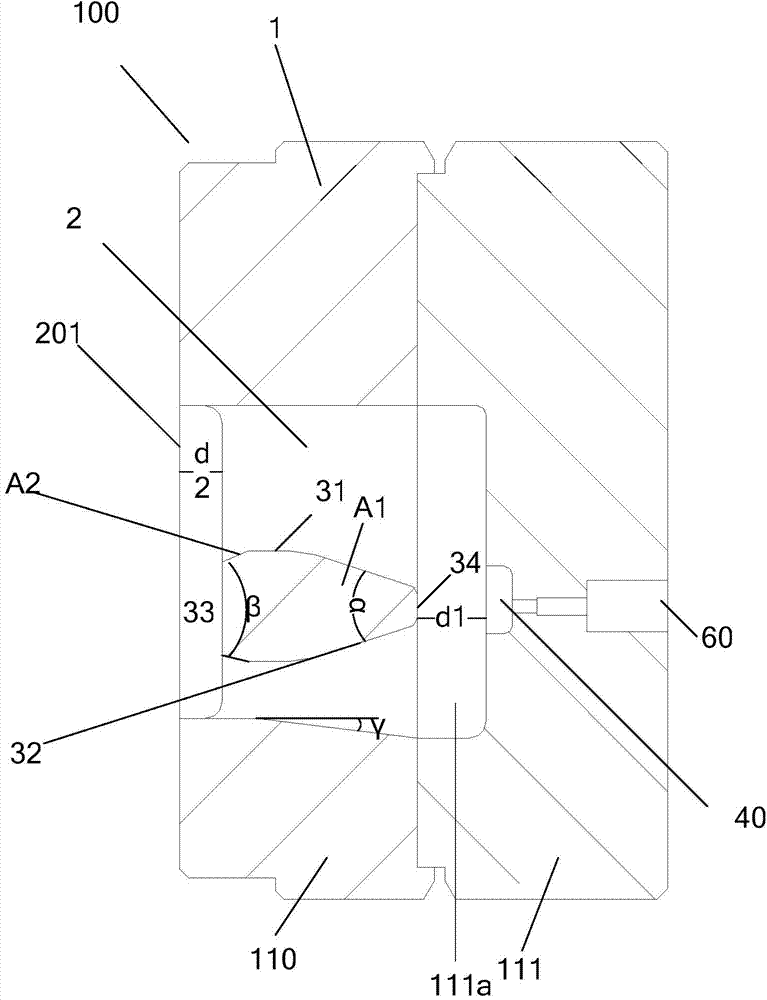

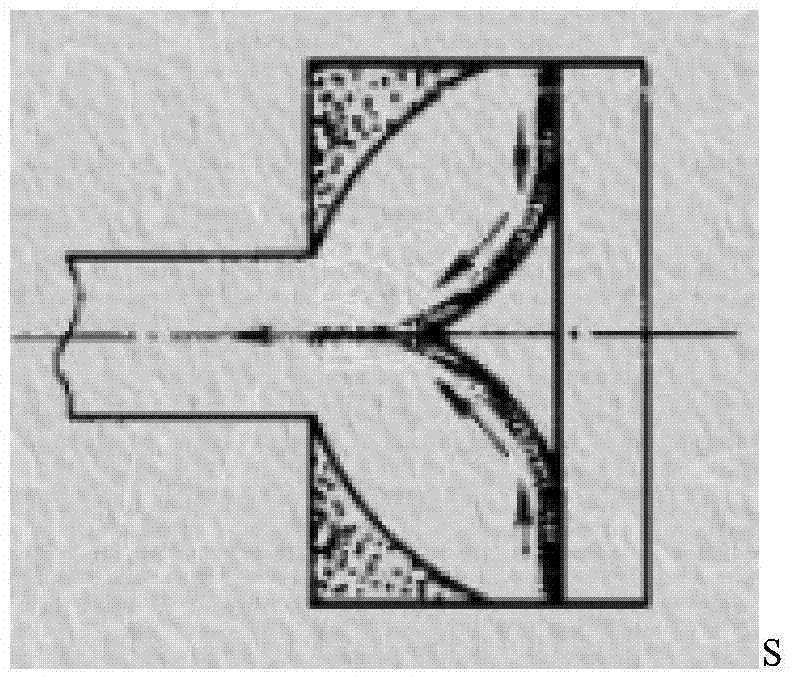

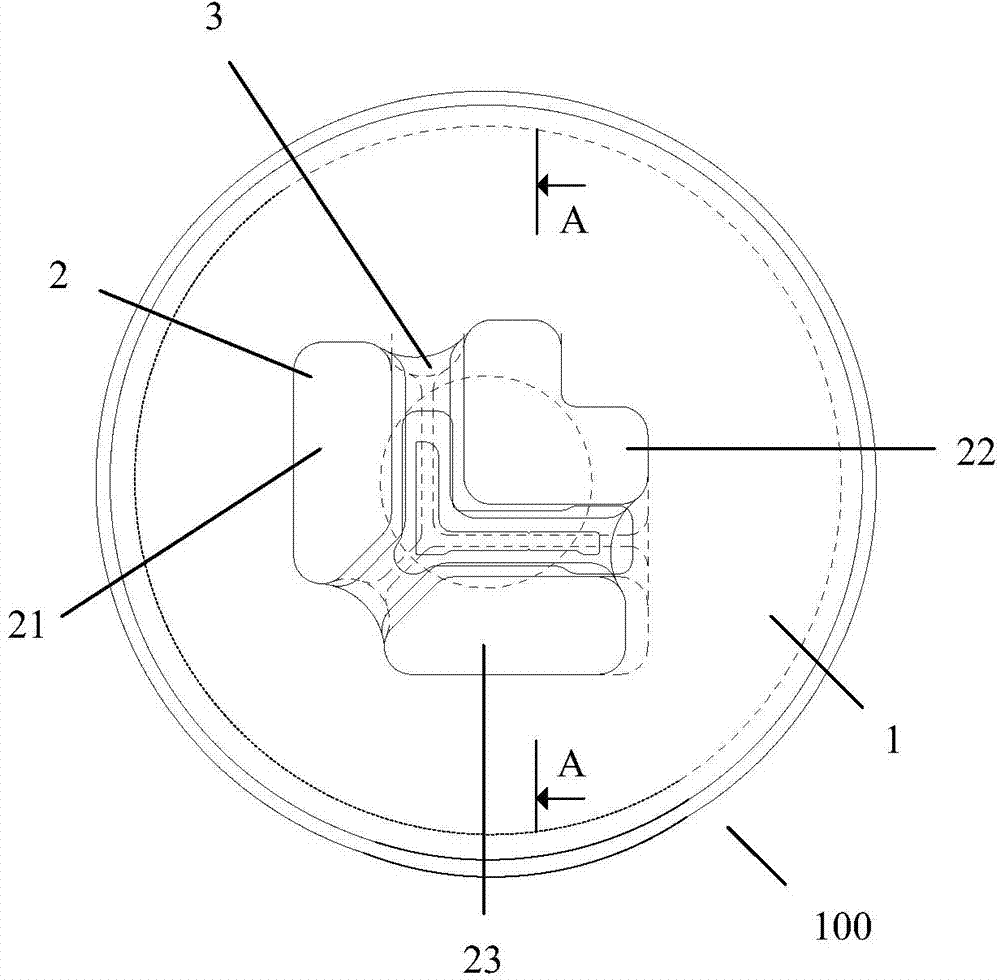

Extrusion device and extrusion method for hollow helicoid rotor profile with internal key groove

The invention discloses an extrusion device and an extrusion method for a hollow helicoid rotor profile with an inner key groove. The device comprises an upper die and a lower die, wherein one end of the upper die is provided with at least one diversion chamber, and the other end of the upper die is provided with at least two shunting holes communicating with the diversion chamber; a shunting bridge is arranged between every two adjacent shunting holes; a blocking table is arranged at the intersection of every two shunting bridges; the end, away from the diversion chamber, of the upper die is connected with a die core; the end, connected with the upper die, of the lower die is at least provided with a first-stage welding chamber, the end, far away from the upper die, of the welding chamber communicates with an orifice of the lower die, and the end, far away from the upper die, of the die core is sequentially inserted into the welding chamber and the orifice of the lower die; the diversion chamber, the shunting holes, the welding chamber and the orifice of the lower die communicate in sequence; and a transition key structure and a key structure which are connected in a matching manner are arranged on the outer wall of the die core. According to the extrusion method based on the device, light alloy is adopted for direct extrusion forming of the hollow rotor, the machining efficiency and blank utilization rate are high, and the production cost is low.

Owner:SHANDONG UNIV

High-gloss colorful pearlescent PET master batch and preparation method thereof

InactiveCN110157165AStrong restrictive abilityThe solution is limitedManufacturing technologyLubricant

The invention discloses a high-gloss colorful pearlescent PET master batch. The high-gloss colorful pearlescent PET master batch comprises, by weight, 75-85 parts of PET, 8-15 parts of PMMA, 3-8 partsof a toner, 0.2-3 parts of a scraping resistant agent and 0.1-0.5 part of a lubricant. A preparation method of the high-gloss colorful pearlescent PET master batch comprises the following steps: rawmaterials are weighed according to above weight part proportions, are added into a high-speed mixer, and are uniformly stirred, the obtained mixture is added into a homodromous double screw extruder,and is blended, extruded and drawn, the obtained mixture is pelletized to obtain a preliminary master batch, and the preliminary master batch is dried to obtain the finished master batch. Compared with the prior art, the preparation method prepares the high-gloss colorful pearlescent PET master batch with a face pearl-like gloss without adding pearl powder; and he pearlescent master batch has theadvantages of good dispersibility and tinting strength, dust-free and environmentally-friendly processing and using process, simple manufacturing technology, low production cost and wide uses.

Owner:广东一龙新材料科技有限公司

Multicompressor parallel connection unit using flooded type shell and tube evaporator

The invention relates to a multicompressor parallel connection unit using a flooded type shell and tube evaporator, and belongs to multicompressor units. The multicompressor parallel connection unit solves the problem that liquid refrigerant is returned to the unit along with gas refrigerant existing in the prior art. The multicompressor parallel connection unit using a flooded type shell and tube evaporator comprises a multicompressor parallel connection unit and the flooded type shell and tube evaporator, wherein the multicompressor parallel connection unit is formed by connecting a plurality of compressors in parallel; the flooded type shell and tube evaporator is connected with an expansion valve of the unit; a heat exchange tube is arranged in an evaporator shell; the liquid refrigerant discharged out of the expansion valve enters the shell of the evaporator for being evaporated into gas refrigerant and is returned to the multicompressor parallel connection unit by an interface of the outlet end of the shell; and in the shell, a metal sheet is arranged between the last row of heat exchange tube and the outlet of the shell, and a refrigerant gas and liquid separating device is arranged between the last row of heat exchange tube and the metal sheet. The flooded type shell and tube evaporator disclosed by the invention can ensure that the liquid refrigerant is not returned to the multicompressor parallel connection unit because the metal sheet and the liquid and gas mechanical separating device are adopted in the shell and the tubes, thereby protecting the compressors to normally run.

Owner:CLIMAVENETA CHATUNION REFRIGERATION EQUIP SHANGHAI

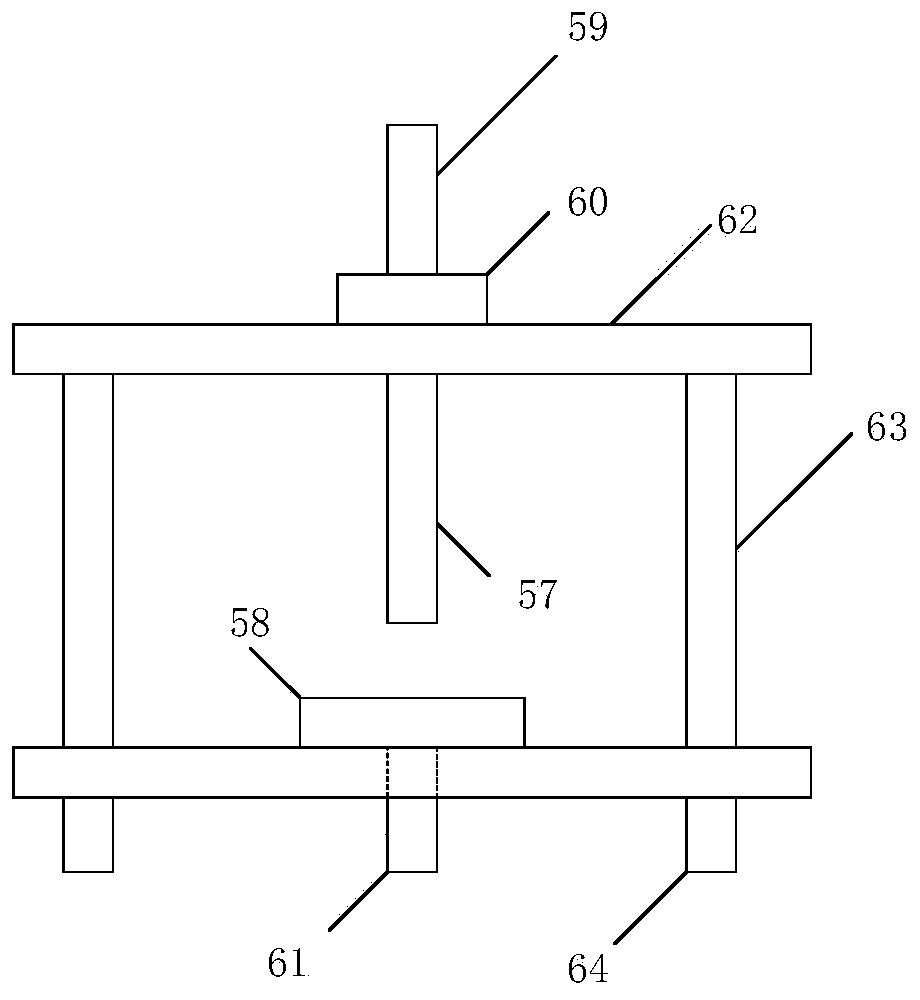

Cardioangiography booster device special for department of cardiology

InactiveCN111760118ASteady injectionUniform and stable flow rateInfusion syringesMedical devicesCircular discMedical equipment

The invention discloses a cardioangiography booster device special for the department of cardiology, and relates to the technical field of cardiology medical equipment. The cardioangiography booster device comprises a liquid storage tank, wherein the left side of the top end of the liquid storage tank is fixedly connected with a support plate and a U-shaped support plate; and the support plate andthe U-shaped support plate are fixedly connected through the optical axis parts of the two ends of a screw rod through bearings. According to the cardioangiography booster device special for the department of cardiology, through cooperation of the arranged screw rod, a disc, a rotating rod, a threaded barrel, a connecting block, sliding rods, a sealing pipe and a rubber plug, the disc can be driven to rotate through the rotating rod, the disc drives the screw rod to rotate to enable the threaded barrel to move rightwards, and then the two sliding rods push the rubber plug to slide leftwards in the sealing barrel; therefore, contrast agent in the sealing barrel can be stably conveyed into blood vessel of a patient for contrast; and compared with contrast by using a manual injector, unstable flow velocity caused by different pressing forces can be avoided, and the flow velocity can be kept in a uniform and stable state.

Owner:潘丽胜

Extrusion die and aluminum alloy profile extrusion method

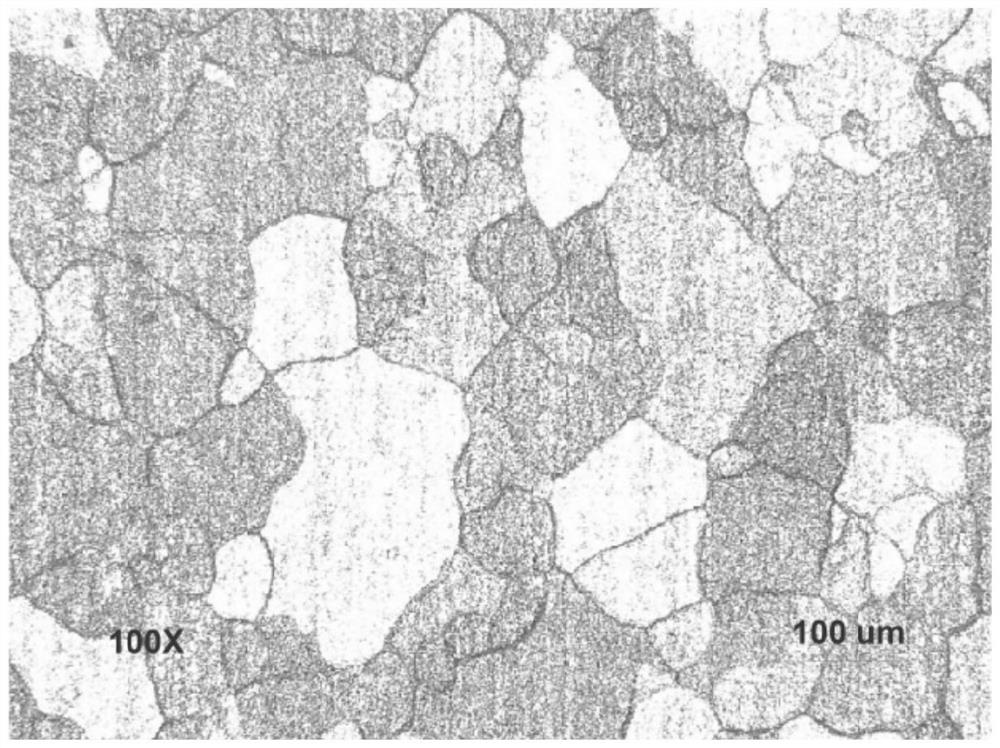

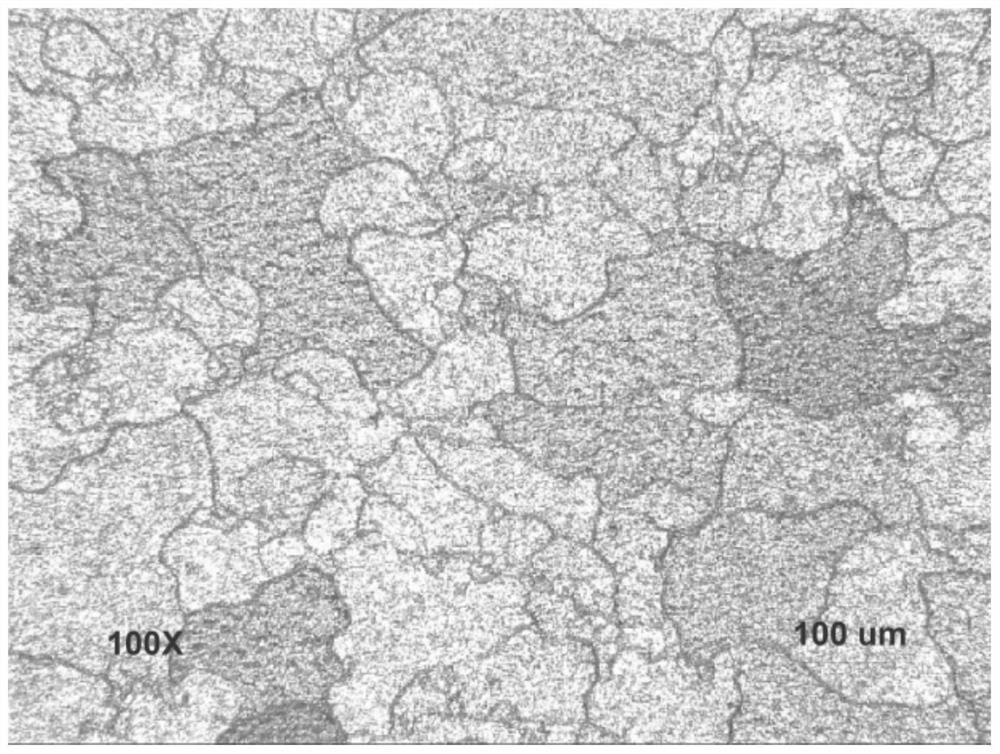

The invention provides an extrusion die and an aluminum alloy profile extrusion method. The extrusion die comprises a body and an extrusion channel, wherein the extrusion channel is arranged in the body, runs through the body and comprises a flow guide groove, a conical groove and a working belt which are connected in sequence, and the flow guide groove, the conical groove and the working belt are the same in section shape. According to an aluminum alloy profile, because the ingredient proportion, the extrusion process parameters and the extrusion die are adjusted, so that the hardness is larger than or equal to HB95, and coarse grains on the surface layer and the section are less than or equal to 94 microns.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

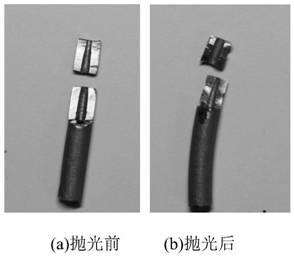

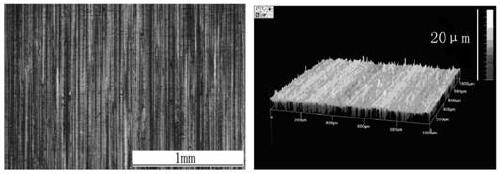

Chemical polishing device and method for inner surface of 3D printing high-temperature alloy pipeline

The invention relates to a chemical polishing device and method for an inner surface of a 3D printing high-temperature alloy pipeline, and belongs to the technical field of inner surface treatment of3D printing metals. In the chemical polishing device, the 3D printing high-temperature alloy pipeline and an acid-proof hose are positioned in a constant-temperature control tank and outside an acid liquid tank; the acid liquid tank is positioned in the constant-temperature control tank; the 3D printing high-temperature alloy pipeline communicates through an acid-proof rigid tube through the acid-proof hose; one end of the acid-proof rigid tube communicates with an acid-proof circulating pump; the other end of the acid-proof rigid tube communicates with a high-temperature alloy chemical polishing agent in the acid liquid tank; and an acid-proof valve and an acid-proof flowmeter are arranged on the acid-proof rigid tube. The chemical polishing method is achieved through the chemical polishing device and comprises the steps that the 3D printing high-temperature alloy pipeline is subjected to heat preservation for 10 min at the temperature of 50 DEG C to 60 DEG C, the chemical polishing agent is introduced into the pipeline at the flow velocity of 400 ml / min, and polishing is carried out for 20 min at the temperature of 50 DEG C to 60 DEG C. According to the chemical polishing deviceand the chemical polishing method, operation is simple, automatic circulating polishing can be achieved, flow velocity of the chemical polishing agent can be effectively controlled to be steady and uniform, the inner surface is flat after polishing, and the removing amount is uniform.

Owner:BEIJING POWER MACHINERY INST

Aluminum alloy extrusion die

The invention discloses an aluminum alloy extrusion die. The die comprises a die shell, and an extrusion chamber and a die bridge which are arranged in the die shell, the die bridge is connected with the die shell, the extrusion chamber is divided into N extrusion subchambers; and the die bridge comprises a first outer wall and a second outer wall, the vertical section of the die bridge comprises a first vertical section portion, and the first vertical section portion gradually narrows along the pushed extrusion direction of fluidic aluminum alloy, wherein an angle between the first outer wall and the second outer wall in the first vertical section portion is a first predetermined angle, and extends along a first predetermined length. The die bridge is arranged in a feeding chamber to make the fluidic aluminum alloy divided by the die bridge and the fluidic aluminum alloy entering the center of the feeding chamber blocked and rubbed by the die bridge in order to realize slow flow in the extrusion process, so the flow velocities of center metal and edge metal are balanced, and the discontinuity phenomenon is reduced.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

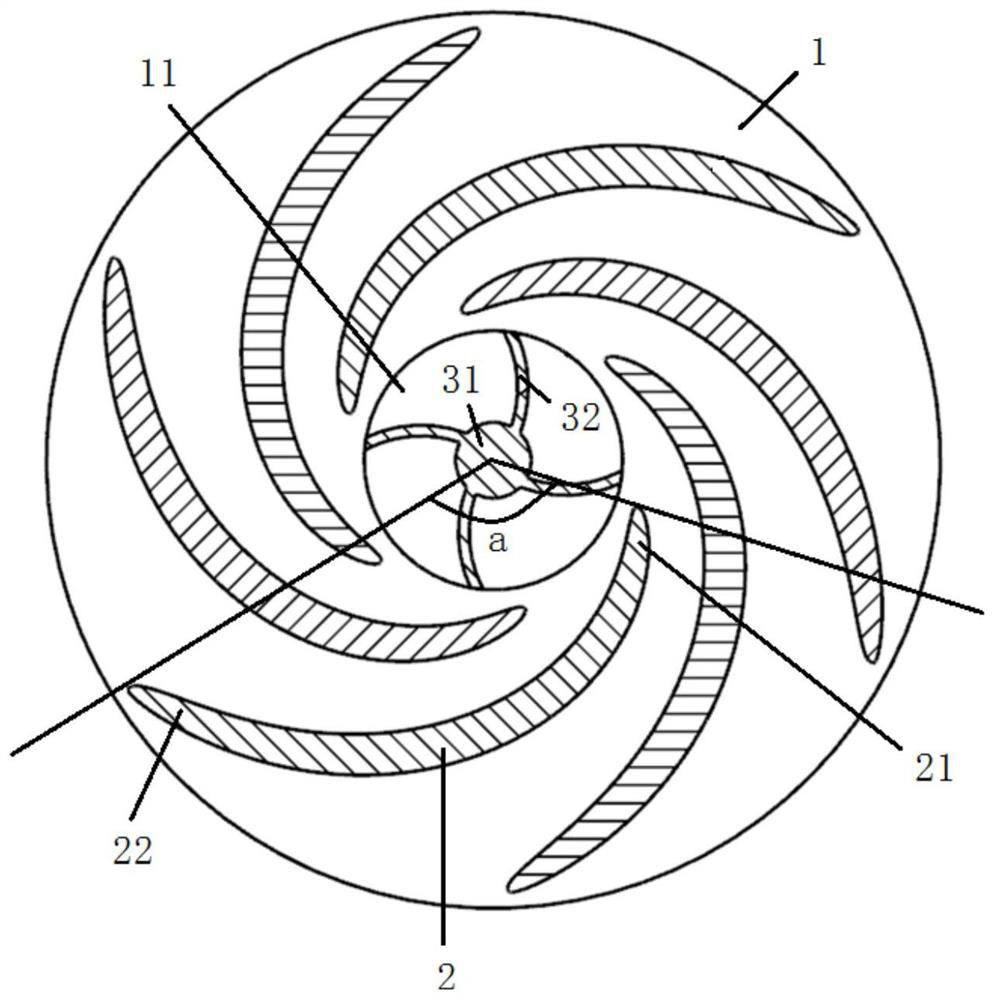

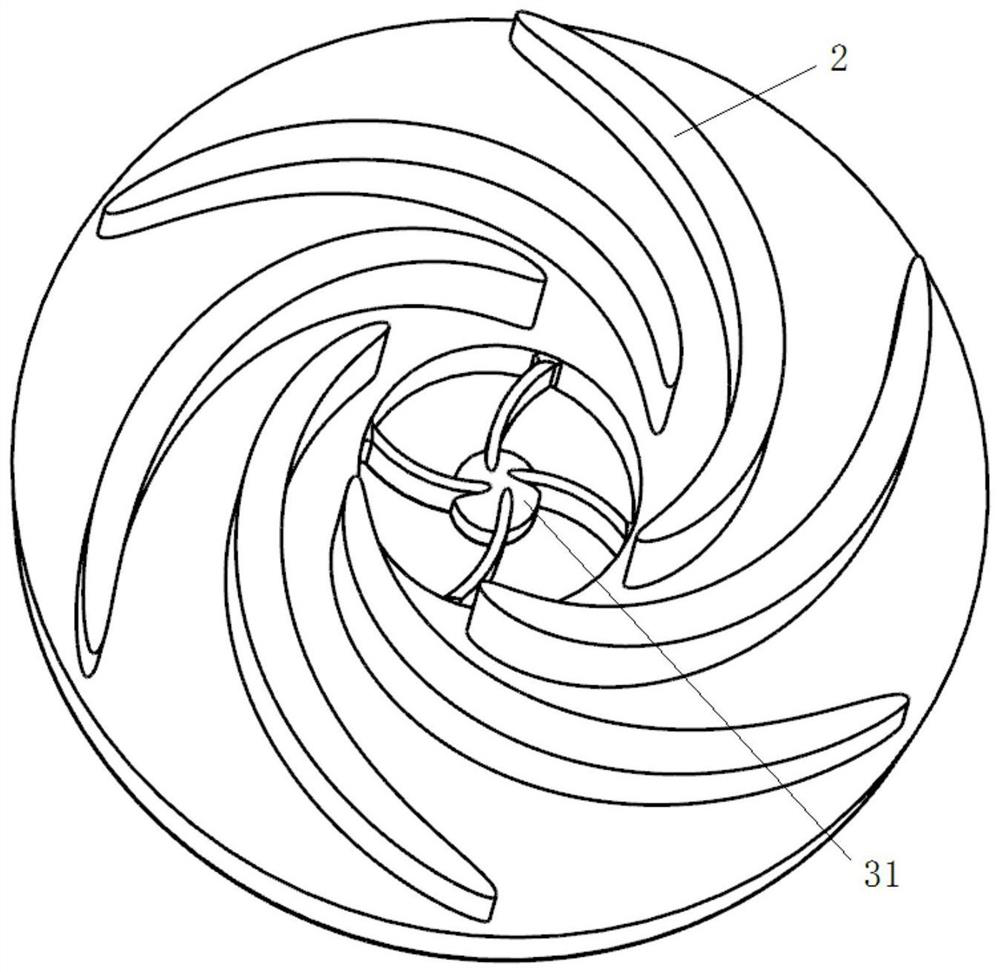

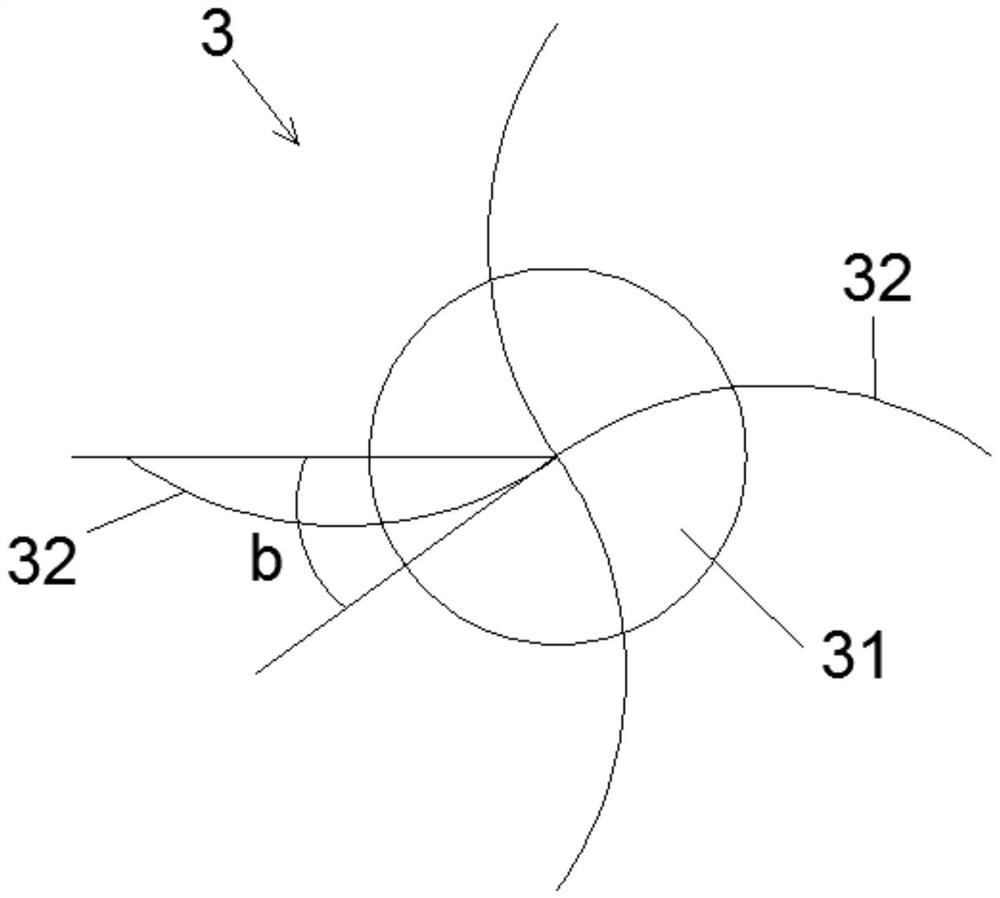

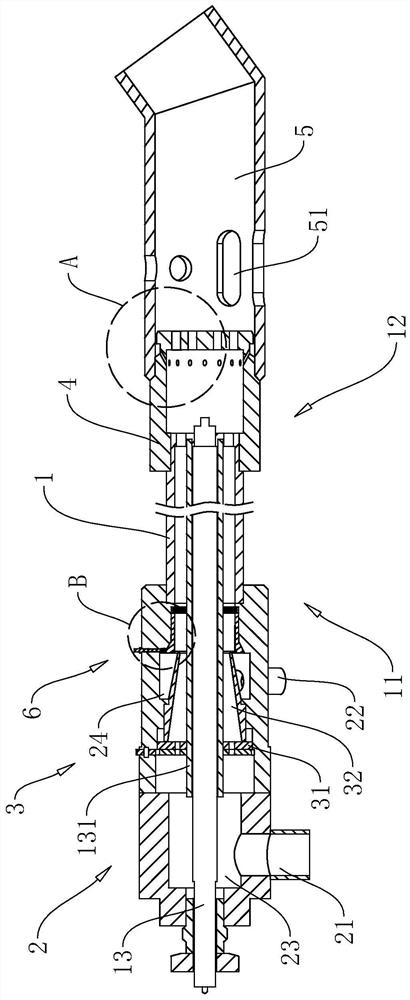

Centrifugal impeller for blood pump and blood pump

PendingCN114588529APrevent the formation of blood clotsIncrease structural strength and stabilityBlood pumpsIntravenous devicesPhysicsEngineering

The invention discloses a centrifugal impeller for a blood pump and the blood pump. The centrifugal impeller for the blood pump comprises a round bottom plate, and a through hole is formed in the middle of the bottom plate to form a secondary flow channel; the centrifugal blades are arranged on the upper surface of the bottom plate, each centrifugal blade is a banana-shaped blade with a thick middle part and two thin ends, the wrap angle of each centrifugal blade is greater than or equal to 90 degrees, and the centrifugal blades radially extend from the outer edge of the through hole to the periphery of the bottom plate. The supporting structure comprises a supporting shaft and a supporting blade, the supporting shaft is arranged in the center of the through hole, one end of the supporting blade is connected with the supporting shaft, and the other end of the supporting blade is connected with the bottom plate. According to the banana-shaped blade structure with the wrap angle larger than or equal to 90 degrees, blood damage and thrombus in the impeller can be reduced. The supporting structure is arranged in the through hole of the bottom plate and can support the centrifugal impeller to rotate at a high speed, the overall structural strength and stability are improved, the flow speed of blood in the secondary flow channel can be increased by arranging the supporting blades, thrombus is avoided, and the dynamic balance of the rotor is improved.

Owner:BEIHANG UNIV

Full-premixing gas gun with flame stabilizing function

ActiveCN113932219AReduce flowReduce the possibility of gas leaksGaseous fuel burnerEngineeringMechanical engineering

The invention relates to a full-premixing gas gun with a flame stabilizing function, and belongs to the field of burners. The full-premixing gas gun comprises a premixing pipe and an ignition electrode, wherein the ignition electrode is located in the premixing pipe, a ventilation seat cylinder is arranged at one end of the premixing pipe, the ventilation seat cylinder communicates with the premixing pipe, an air connector and a gas connector are arranged on the ventilation seat cylinder, the air connector and the gas connector communicate with the ventilation seat cylinder, and the air connector is located on the side, far away from the premixing pipe, of the gas connector; and a flow control mechanism is arranged in the ventilation seat cylinder, the flow control mechanism comprises a throttling disc, the throttling disc is located between the air connector and the gas connector, the throttling disc divides an inner cavity of the ventilation seat cylinder into an air cavity and a gas cavity, a pressure change hole is formed in the throttling disc, the air cavity communicates with the air connector, and the gas cavity communicates with the gas cavity. According to the full-premixing gas gun, the stability of two airflow directions in the ventilation seat cylinder is improved through the flow control mechanism, and the effect of reducing the probability that gas flows to the air cavity and leaks is achieved.

Owner:JIANGSU OUBIAO

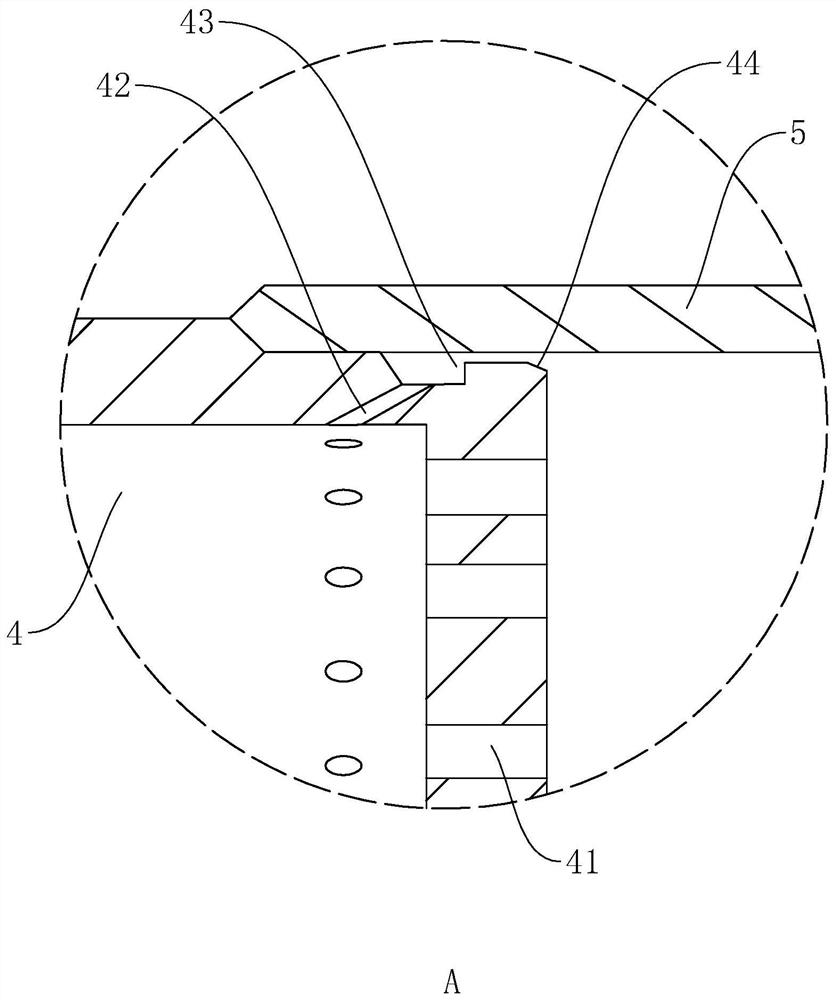

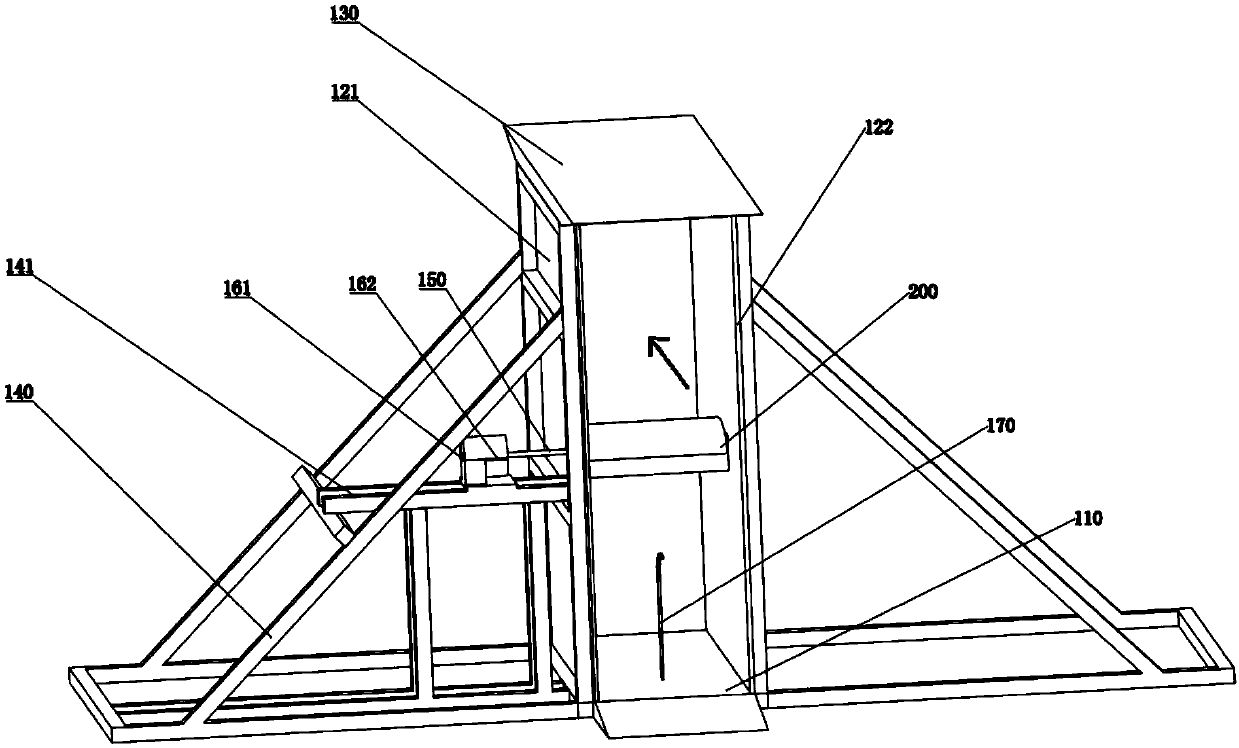

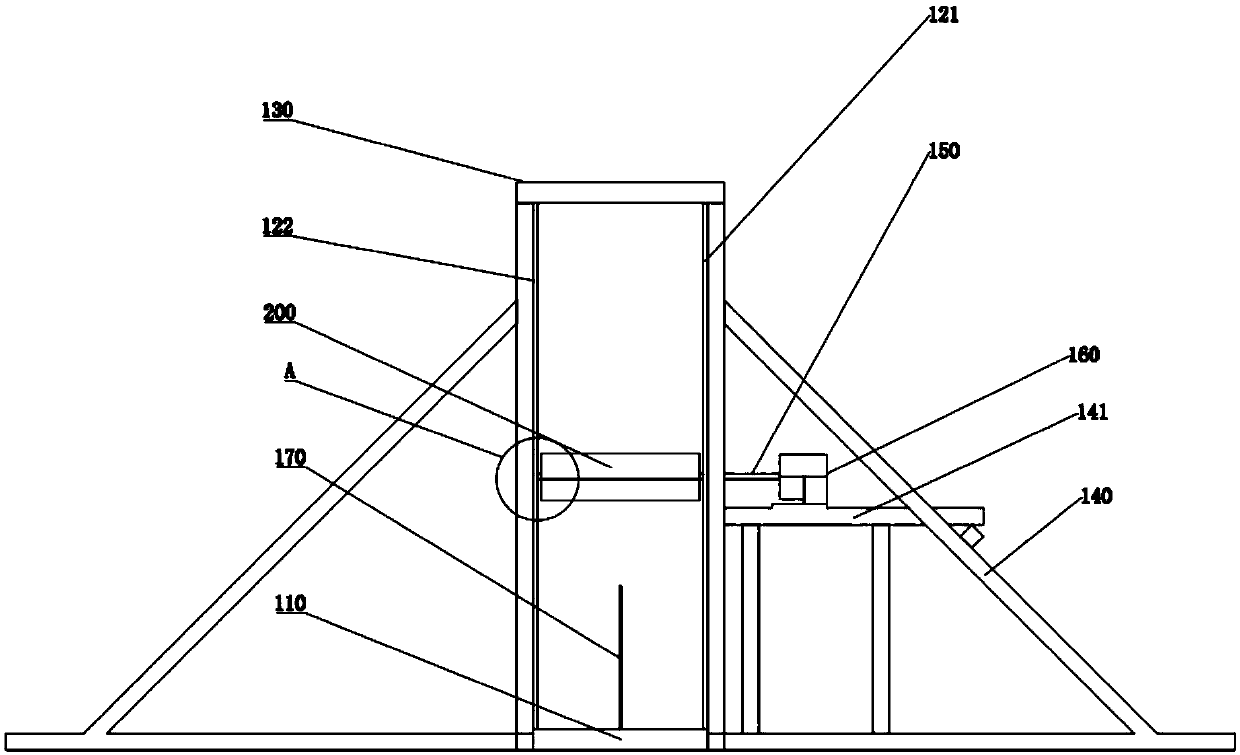

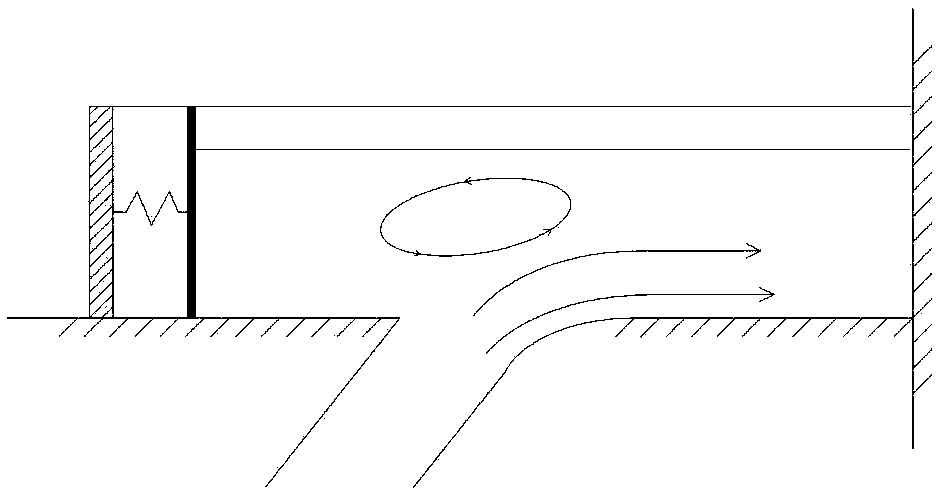

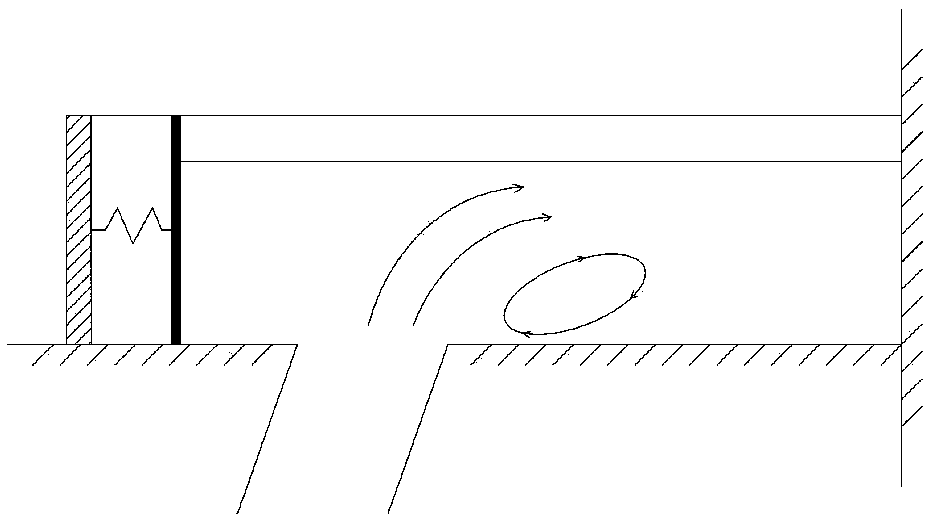

Two-dimensional airfoil wind tunnel test bench

PendingCN109540453AAffect test resultsFlow field stabilityAerodynamic testingEngineeringAngle of attack

The invention discloses a two-dimensional airfoil wind tunnel test bench. The two-dimensional airfoil wind tunnel test bench comprises: a base horizontally and fixedly mounted on the floor of a wind tunnel test section, wherein the base comprises a base main body and two slopes, the two slopes are respectively arranged at two ends of the base main body in the vertical direction, and the base mainbody and the floor form transition through the slopes; two separators which are vertically oppositely arranged on the base main body, wherein curve transition is arranged between the air inlet ends and the air outlet ends of the two separators; a cover plate horizontally arranged at the top portions of the separators; a rod-type balance having one end rotationally passing through one of the separators and connected with the airfoil between the two separator; an angle regulation mechanism fixedly installed at the outer sides of the separators, detachably connected at the other end of the rod-type balance and configured to regulate the angle of attack of the airfoil; and a wind speed sensor arranged between the two separators. The two-dimensional airfoil wind tunnel test bench can ensure accurate two-dimensional airfoil experiments in the wind tunnel.

Owner:JILIN UNIV

Positive-pressure combustion low-NOx combustor

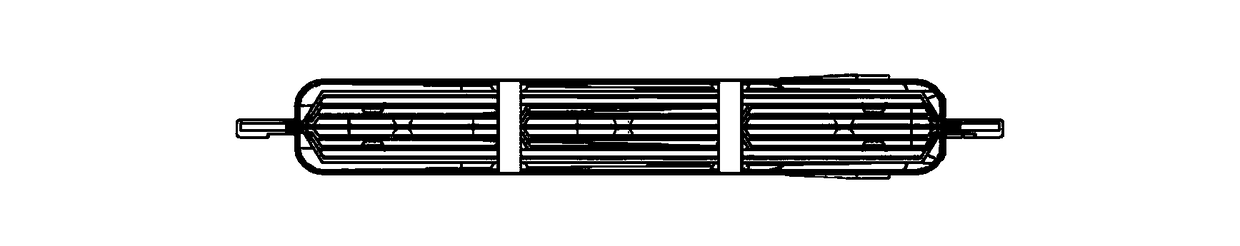

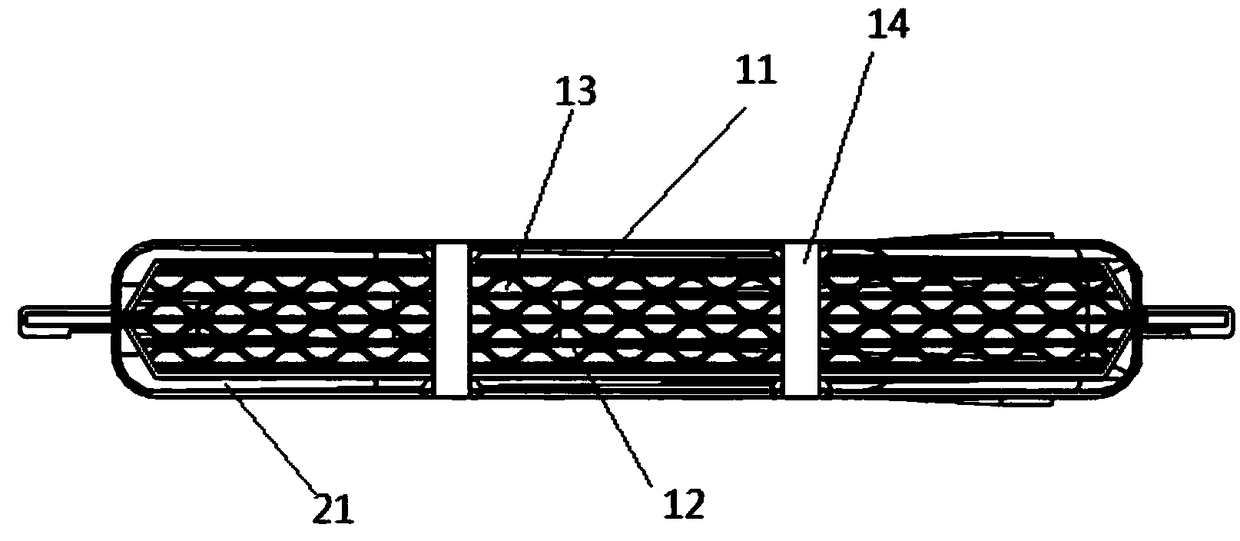

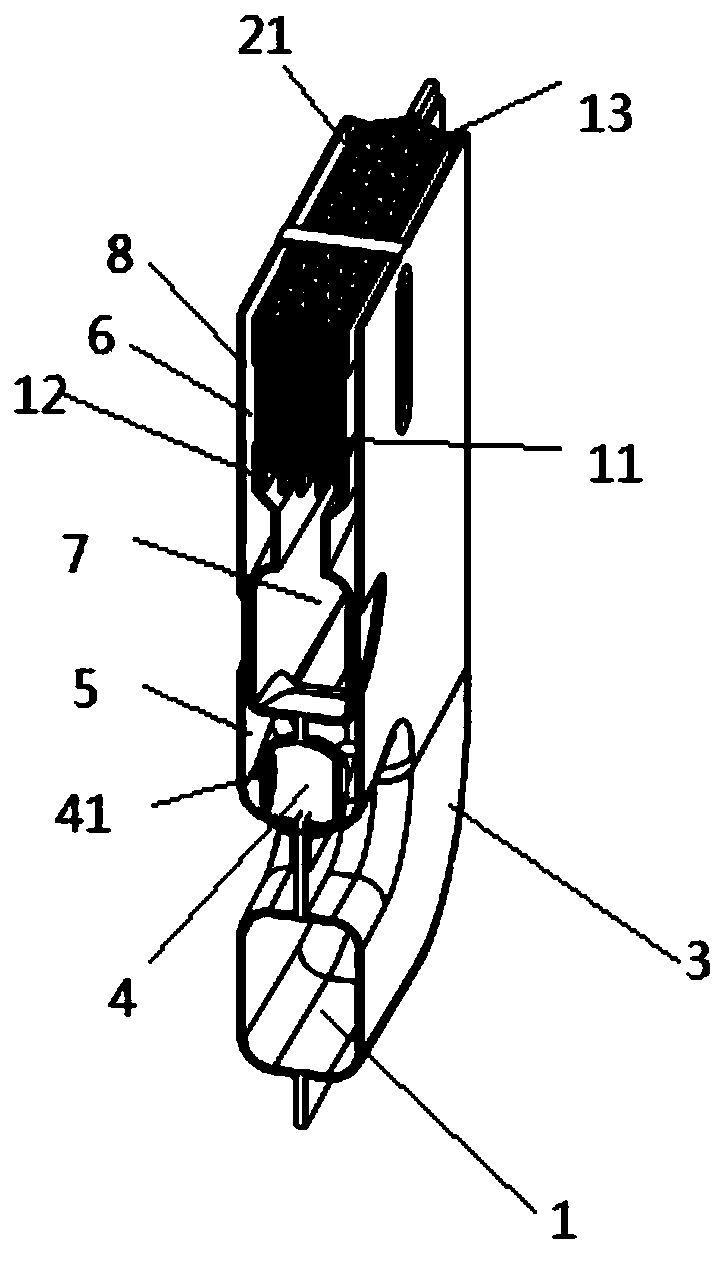

PendingCN108930963AUniform and stable flow rateUniform and stable velocity fieldGaseous fuel burnerIndirect carbon-dioxide mitigationLow noiseCombustor

The invention relates to a positive-pressure combustion low-NOx combustor. A fire hole module of the combustor comprises semicircular fire hole plates (11) and a linear fire hole plate (12); and the linear fire hole plate (12) is clamped between the two semicircular fire hole plates (11) to form a semicircular fire hole (13). Compared with the prior art, the positive-pressure combustion low-NOx combustor has the advantages of simple structure, full gas combustion, low nitric oxides, low noise and the like.

Owner:SHANGHAI HESEN ELECTRO MACHINERY

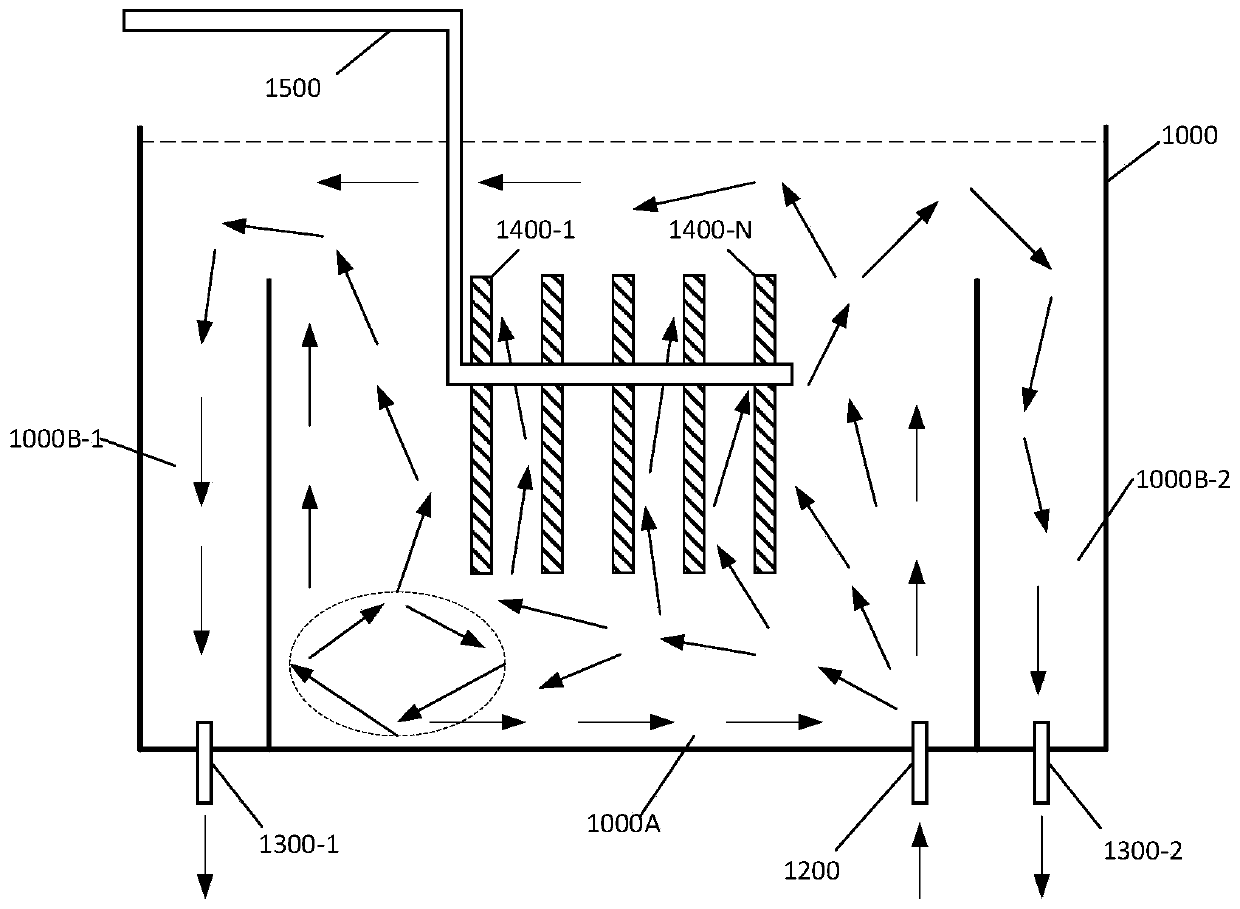

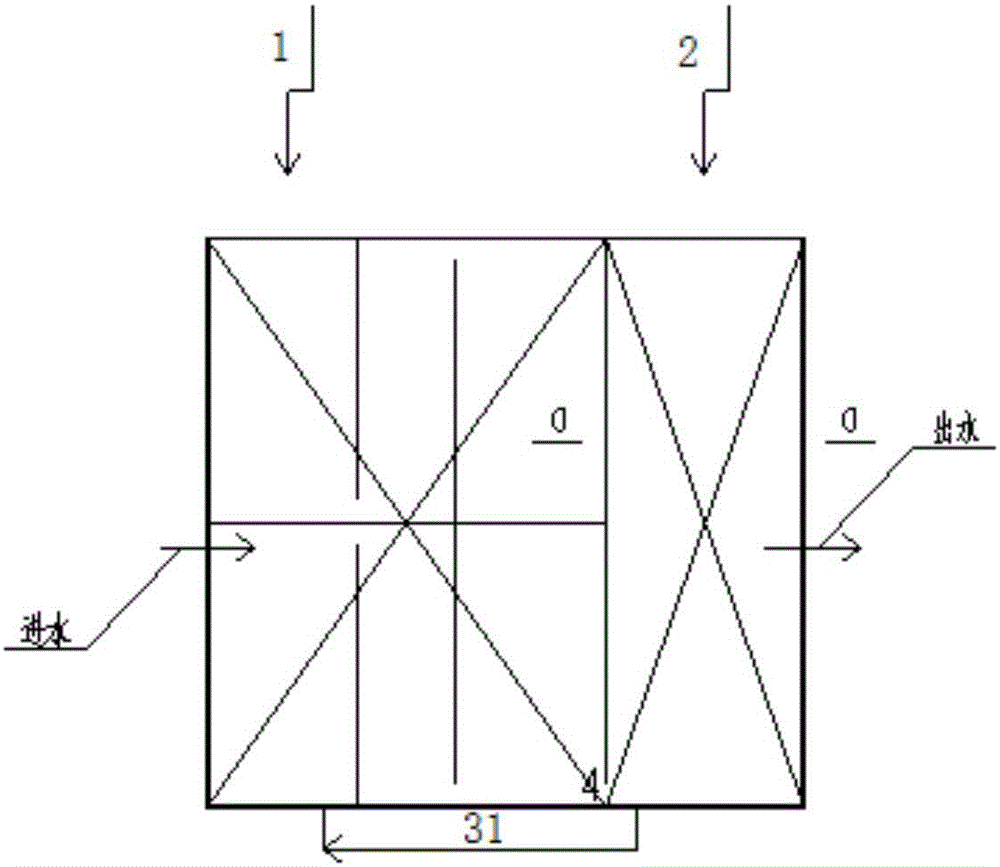

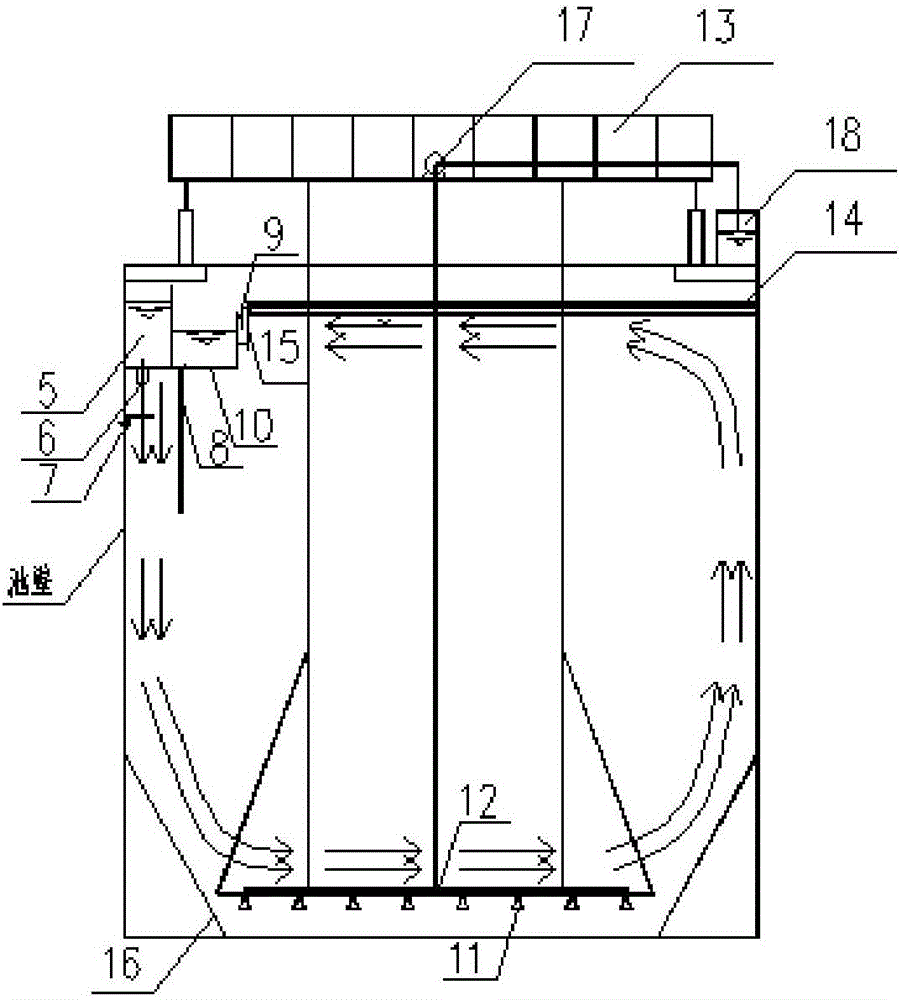

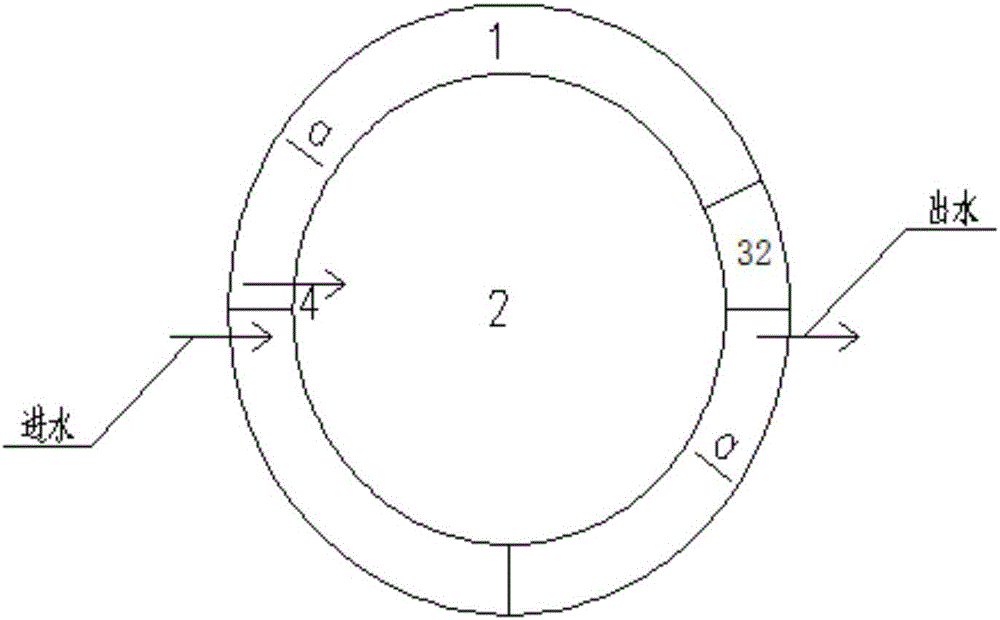

Baffled sedimentation tank and baffled sedimentation process

InactiveCN106422435AEasy loadingSolve the loadSettling tanks feed/dischargeTreatment involving sedimentationSludgeWater flow

The invention provides a baffled sedimentation tank and a baffled sedimentation process; the sedimentation tank is selected from any one of the below, firstly, the sedimentation tank includes a water inlet tank, a water outlet tank, bottom slopes and a suction dredger; the water inlet tank is arranged along the pond length direction, the water inlet tank is adjacent to the water outlet tank and in parallel to the water outlet tank; the bottom slopes are arranged at both sides of the inner wall of the baffled sedimentation tank; the mud dredger includes a mud dredging pipe and a mud dredging unit; the mud dredging pipe is arranged in the baffled sedimentation tank, and the mud dredging pipe is connected with the mud dredging unit; secondly, the sedimentation tank includes a water inlet tank, a water outlet tank, a bottom slope, a suction dredger and a center cylinder; the water inlet tank is arranged along the periphery of the baffled pond, and the center cylinder is arranged in the center of the baffled sedimentation tank. The baffled sedimentation tank and the baffled sedimentation process are small in land area, and can avoid riffle, vortex, short current, stagnant water, sludge deposit, and other phenomenon of an ordinary sedimentation tank; the water flow field is evenly distributed, the volume utilization rate of the pond body is high, and the sedimentation efficiency is high.

Owner:SHANGHAI ATON ENVIRONMENTAL LIABILITY

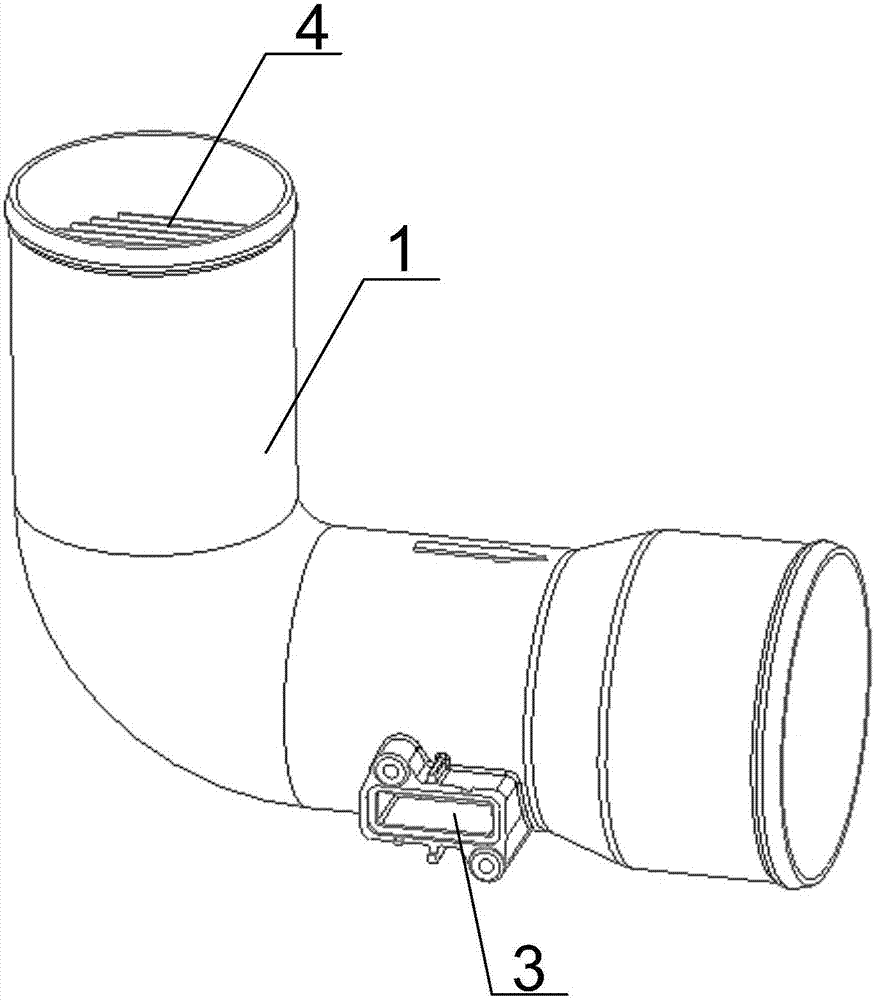

Intake flow sensor adaptive pipeline and engine intake system

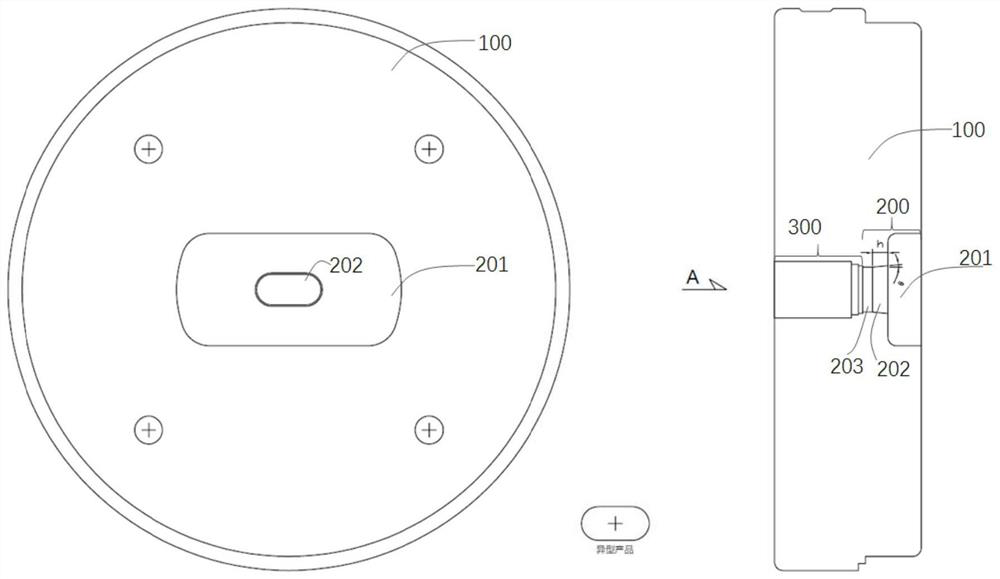

InactiveCN107956610AConsistent intake flowUniform and stable flow rateMachines/enginesAir intakes for fuelEngineeringStreamflow

The invention discloses an intake flow sensor adaptive pipeline and an engine intake system. The intake flow sensor adaptive pipeline comprises an elbow pipe, a flow stabilization pipe, an intake flowsensor and a rectification component, wherein two ends of the elbow pipe are an air inlet end and an air outlet end, the flow stabilization pipe is positioned at an elbow of the elbow pipe, the axisof the flow stabilization pipe is parallel to that of the air outlet end, the intake flow sensor is fixed onto the elbow pipe and positioned at an outlet of the flow stabilization pipe, and the rectification component is arranged in the air inlet end of the elbow pipe. Gas is centralized at the elbow of the elbow pipe to form a flow stabilization area, the flow stabilization pipe is arranged in the flow stabilization area to centralize the gas, the intake flow sensor is arranged at the outlet of the flow stabilization pipe, stable gas flow can be detected, the gas passes the rectification component in the air inlet end before entering the elbow pipe, the gas is rectified by the rectification component, so that the flow speed of the gas entering the elbow pipe is stable and uniform, consistency of intake flow speed in the pipeline is ensured, repetition of the calibration process of MAF (mass air flow) is avoided, and manpower and financial resources are saved.

Owner:WEICHAI POWER CO LTD

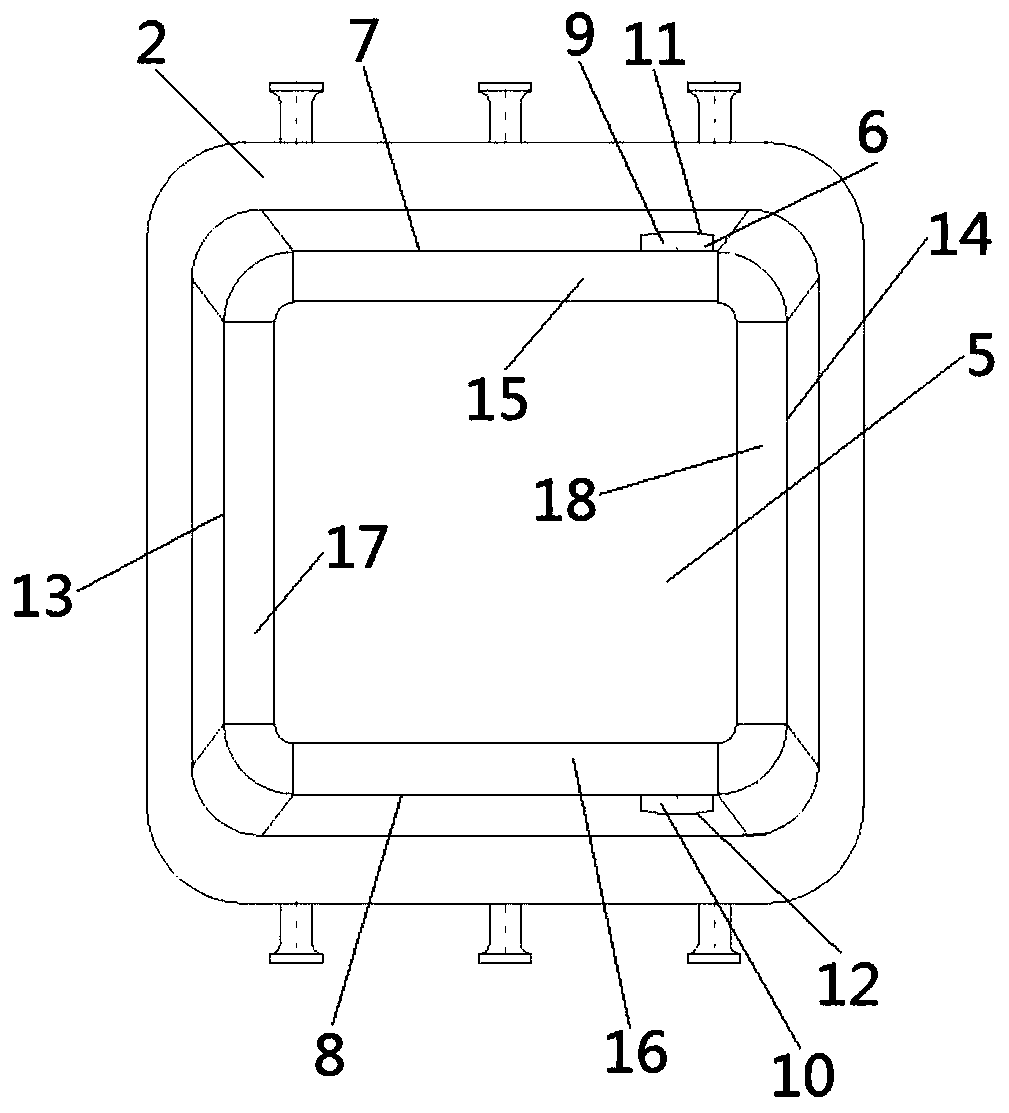

Air chopped slag treatment device for steelmaking slag treatment

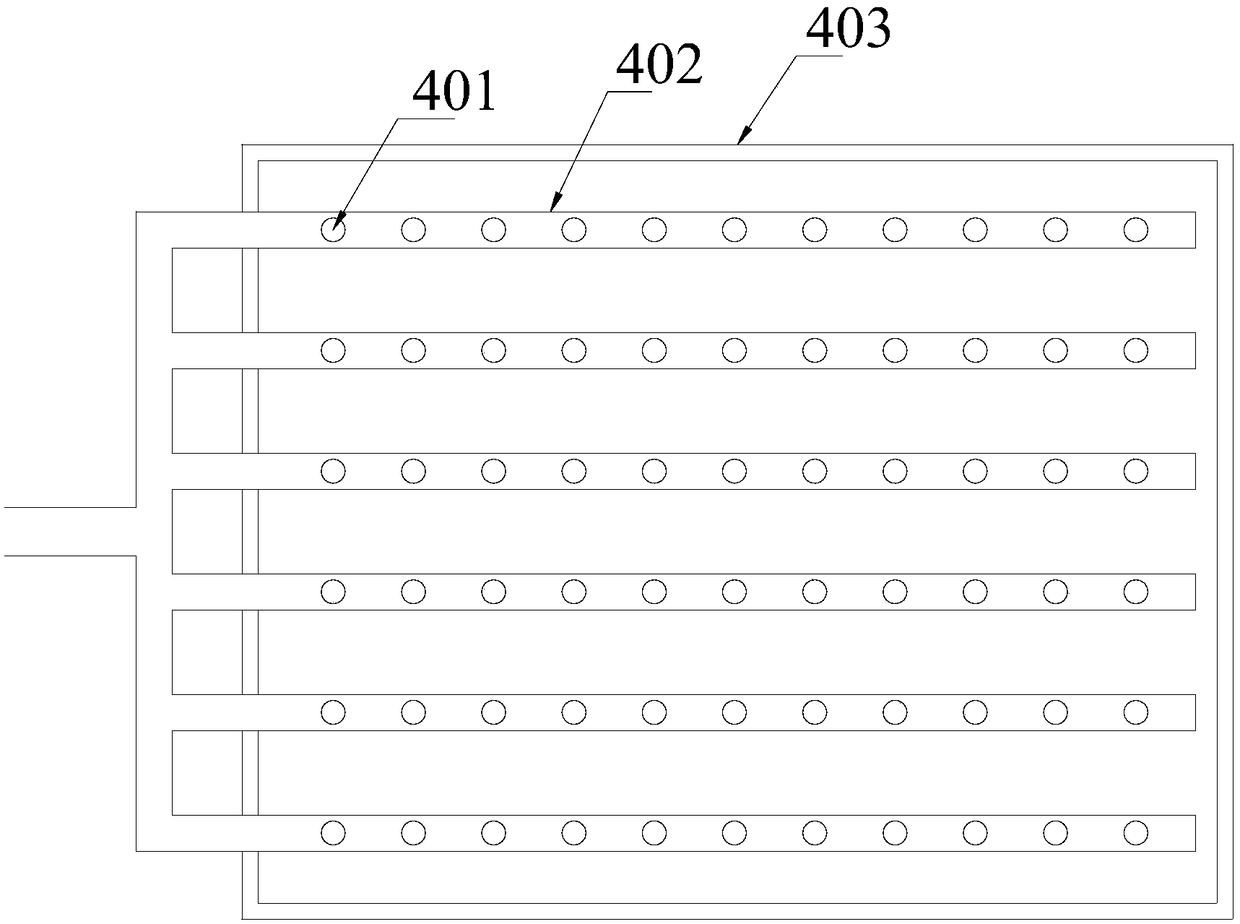

PendingCN110628970AImproved granulationImprove flow trajectoryRecycling and recovery technologiesProcess efficiency improvementSlag

The invention provides an air chopped slag treatment device for steelmaking slag treatment applied to the energy-saving and environment-friendly steel slag technical field. A middle slag ladle (2) ofthe air chopped slag treatment device for steelmaking slag treatment is located below a large slag ladle (1), the lower portion of the middle slag ladle (2) communicates with a deslagging launder (3),a granulator (4) is located below the deslagging launder (3), a middle slag tank passing pipeline (5) is located in the middle slag ladle (2), the inner wall of the middle slag tank passing pipeline(5) is provided with slag launders (6) which are vertically arranged, and each slag launder (6) extends to the lower portion of the middle slag tank passing pipeline (5) from the upper portion of themiddle slag tank passing pipeline (5). The air chopped slag treatment device for steelmaking slag treatment can effectively guide the flowing state and the flowing speed of the steel slag in the middle slag tank, it is ensured that the slag flow is uniform and stable before passing through the granulator, the stability of the slag flow in front of the granulator can be improved, the slag flow evenly passes through the position in front of the granulator, and the steel slag granulation effect is ensured.

Owner:MAANSHAN IRON AND STEEL COMPANY

A coal-fired boiler flue gas wet desulfurization and denitrification and wastewater treatment device and process

ActiveCN105833695BReduce the temperatureIncrease humidityGas treatmentDispersed particle separationSlurrySpray cooling

The invention discloses a device and technology for wet desulfurization and denitrification of flue gas of a coal-fired boiler and treatment of wastewater .The technological process includes the steps that the flue gas enters a wastewater evaporative cooling stage through a draught fan outlet to be cooled and then enters an ozonation stage, the flue gas is fully mixed with ozone to be oxidized and then enters a supergravity device through a supergravity desulfurization and denitrification device inlet, the flue gas is subjected to forcible absorption with desulfurization and denitrification absorption liquid in a packed bed on a rotor, and finally the flue gas is demisted by a demister and then discharged through a flue gas outlet of the supergravity device .Replacement absorbent slurry is subjected to oxidation and denitrification treatment in sequence and then returned to the evaporative cooling stage to perform spraying cooling on the flue gas .By means of the device and the technology, desulfurization and denitrification efficiency is improved, and meanwhile water consumption is low; wastewater generated in desulfurization and denitrification is subjected to innocent treatment, sulfate is collected, and thus the coal-fired flue gas can meet stricter discharge standards.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH +1

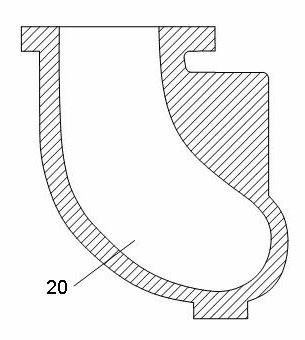

Water suction chamber of multistage centrifugal pump

The invention discloses a water suction chamber of a multistage centrifugal pump. The water suction chamber comprises a shell body, wherein a water inlet is disposed at the upper end of the shell body, and one end of the front end surface of the shell body is connected with a water inlet chamber and communicated with the inlet of an impeller. The centrifugal pump further comprises a flow guide plate, wherein the flow guide plate is disposed in the shell body and located at a middle position above a shaft hole in the shell body. A liquid entering in the water suction chamber can be divided into two parts flowing downwards via the flow guide plate, thereby efficiently reducing the reflux of the liquid, and benefiting to ensure the flow speed of the liquid entering in the water suction chamber to be uniform and stable. Additionally, the speed of a water flow in a whole flow passage can be kept uniform and stable via an optimized design for the flow passage of the shell body. Moreover, the water suction chamber of a multistage centrifugal pump further has the advantages of being simple in structure and easy in processing.

Owner:KSB SHANGHAI PUMP

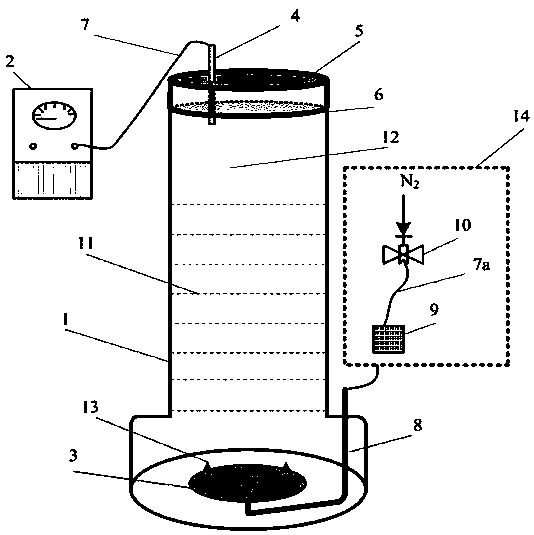

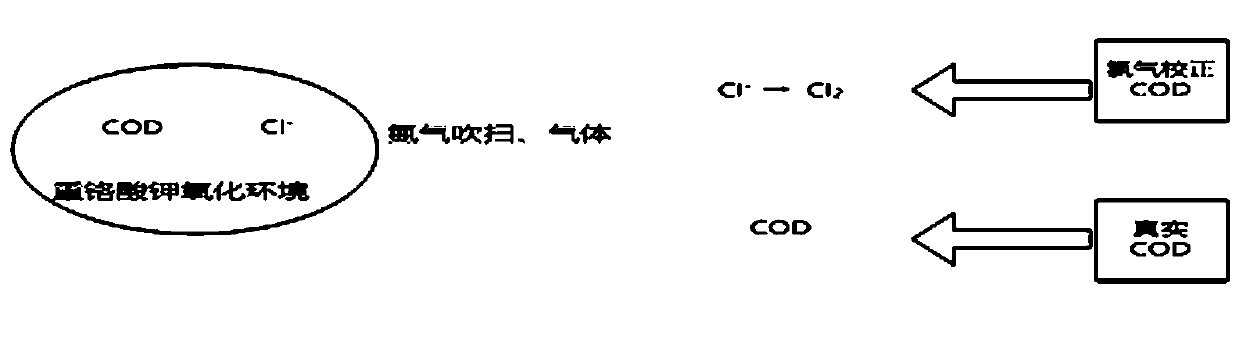

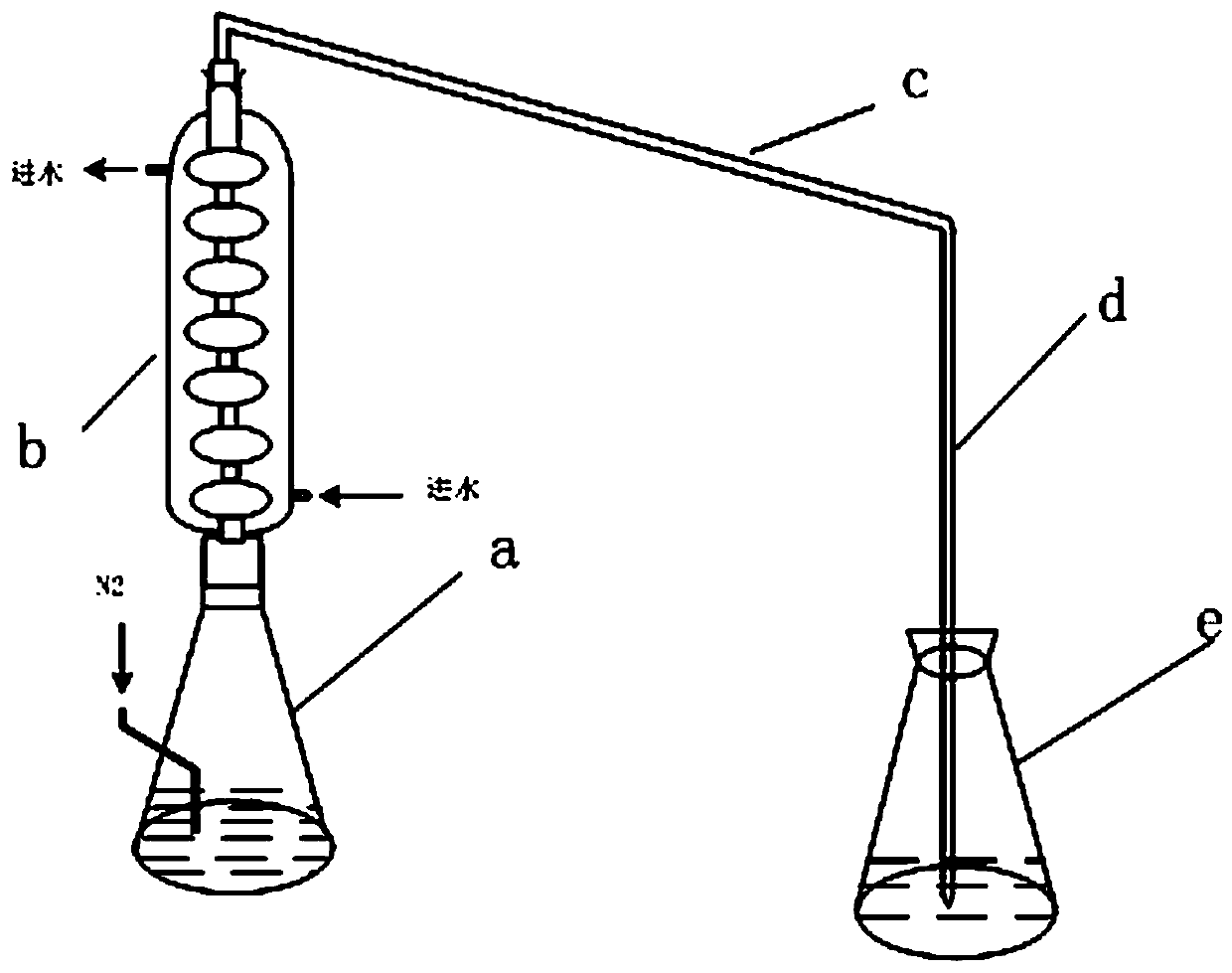

Method and device for improving COD detection precision of high-chlorine wastewater

The invention discloses a method and a device for improving the COD detection precision of high-chlorine wastewater. Self-vacuumizing, a sand core plate and an electronic valve control technology areintroduced into COD detection, specially for improving the COD detection precision of high-chlorine wastewater in a laboratory. The method and the device have the advantages that the method is convenient to realize, simple in principle, high in practicability degree and high in chlorine absorption efficiency, so that the COD detection precision of high-chlorine wastewater is effectively improved,the accuracy of data is greatly ensured, and the detection level is improved.

Owner:克拉玛依市三达检测分析有限责任公司

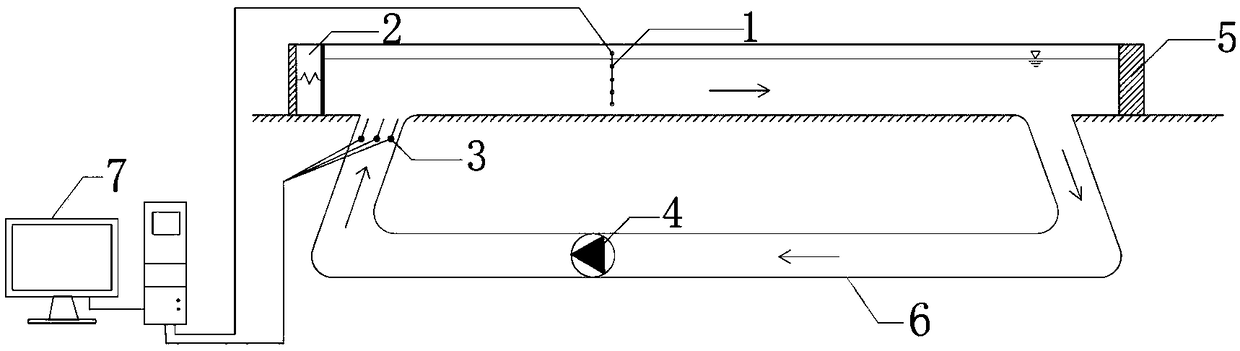

Intelligent adaptive flow guiding device for wave flow test pool and flow guiding method thereof

The invention discloses an intelligent adaptive flow guiding device for a wave flow test pool and a flow guiding method thereof. The intelligent adaptive flow guiding device comprises a computer, a pool, a flow and wave making system, a circulation system, an intelligent flow guiding system and a flow rate monitoring system; the flow and wave making system comprises a flow and wave making device and a wave breaking device; the circulation system includes a circulation line and a water pump; the intelligent flow guiding system includes a flow guide plate for intelligently adjusting the inflow direction in real time and a stepping motor connected with the flow guide plate, the flow guide plate is disposed at an inflow nozzle of the circulation line, and the stepping motor is connected to thecomputer; the flow rate monitoring system includes a flow rate monitoring sensor for real-time monitoring of speed distribution and flow conditions, and the flow rate monitoring sensor is connected to the computer. The invention can accurately simulate the working conditions under a plurality of different water depth and flow rate combinations, can achieve the optimal uniformity effect, obtain the maximum uniform flow range, and provide technical support for the fluid mechanics experiment.

Owner:TIANJIN UNIV

Runner structure of a rubber mold

The invention discloses a runner structure of a rubber mold. A runner comprises a first-stage runner with a circular cross section, at least two second-stage runners, two chambers used for overturningrubber materials and a third-stage runner. The middle portion of the first-stage runner communicates with a rubber injection hole. The two ends of the first-stage runner are connected with the chambers correspondingly. The first-stage runner comprises an upper half runner arranged on a runner plate and a lower half runner arranged on an upper mold plate. Each chamber comprises an inlet connectionpipe and at least one outlet connection pipe, wherein the inlet connection pipe is composed of an upper half inlet connection pipe arranged on the runner plate and a lower half inlet connection pipearranged on the upper mold plate, the cross section of the upper half inlet connection pipe is in an inverted-U shape, the cross section of each outlet connection pipe is in a U shape, and the outletconnection pipes are arranged on the upper mold plate. The runner structure has the beneficial effects that the rubber materials pass through the chambers which are used for overturning the rubber materials, the rubber materials at the position of an inner core and the rubber materials at the positions attaching to the wall of the runner are mixed to enable the temperature to be uniform, flowing is more balanced, forming of a product is facilitated better, and the vulcanizing efficiency of the product in a cavity and the yield are increased.

Owner:NINGBO TUOPU GROUP CO LTD

Aluminum alloy extrusion die

ActiveCN104772359BUniform and stable flow rateLess squeezeExtrusion diesEngineeringAluminum extrusion

The invention discloses an aluminum alloy extrusion die. The die comprises a die shell, and an extrusion chamber and a die bridge which are arranged in the die shell, the die bridge is connected with the die shell, the extrusion chamber is divided into N extrusion subchambers; and the die bridge comprises a first outer wall and a second outer wall, the vertical section of the die bridge comprises a first vertical section portion, and the first vertical section portion gradually narrows along the pushed extrusion direction of fluidic aluminum alloy, wherein an angle between the first outer wall and the second outer wall in the first vertical section portion is a first predetermined angle, and extends along a first predetermined length. The die bridge is arranged in a feeding chamber to make the fluidic aluminum alloy divided by the die bridge and the fluidic aluminum alloy entering the center of the feeding chamber blocked and rubbed by the die bridge in order to realize slow flow in the extrusion process, so the flow velocities of center metal and edge metal are balanced, and the discontinuity phenomenon is reduced.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

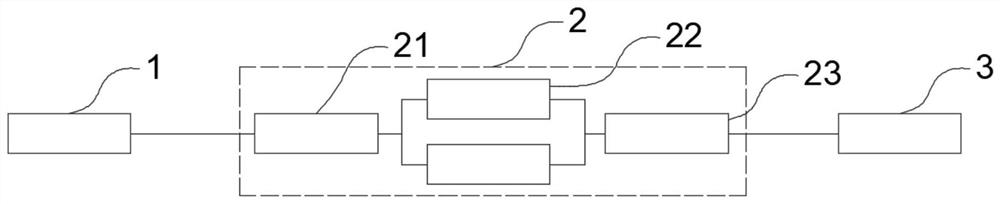

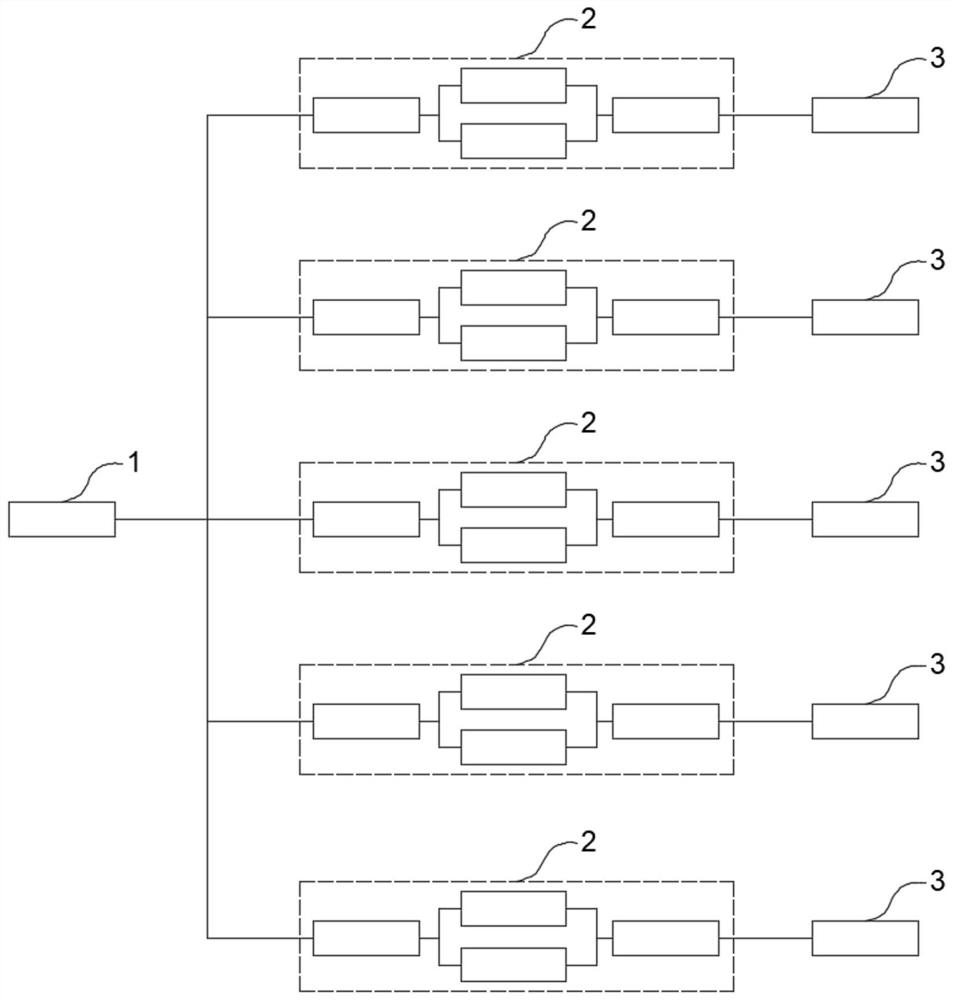

Filling and plugging machine and filling method thereof

ActiveCN112977908AImprove stabilityUniform and stable flow rateLiquid materialPeristaltic pumpMedical equipment

The invention provides a filling and plugging machine and a filling method thereof, and relates to the technical field of medical equipment. The filling and plugging machine comprises a liquid distributor, multiple liquid flowing pipelines and multiple filling needles, wherein the liquid distributor is provided with a plurality of matched liquid distribution outlets, each liquid distribution outlet communicates with one liquid flowing pipeline, each liquid flowing pipeline comprises a first liquid inlet pipe, at least one peristaltic pump liquid conveying pipe and a second liquid inlet pipe, the head end of each first liquid inlet pipe communicates with one liquid distribution outlet, the tail end of each first liquid inlet pipe communicates with an inlet of at least one peristaltic pump liquid conveying pipe, an outlet of each peristaltic pump liquid conveying pipe communicates with the head end of the corresponding second liquid inlet pipe, each filling needle communicates with the tail end of the second liquid inlet pipe in one liquid flowing pipeline, and therefore an independent filling channel is formed between the corresponding liquid distribution outlet of the liquid separator and the corresponding filling needle. According to the technical scheme of the filling and plugging machine and the filling method thereof, the problem that the filling accuracy is reduced due to the fact that the rates at the two stages are not uniform can be solved, and then the filling accuracy is improved.

Owner:康宁杰瑞(吉林)生物科技有限公司

Device for measuring density and pH value of slurry

ActiveCN102012352BUniform and stable flow rateStable flow rateSpecific gravity using flow propertiesAir sampleEngineering

The invention discloses a device for measuring the density and the pH value of slurry. The device comprises an air sampling pipe component, a densitometer, a first pH meter and a second pH meter, wherein the air sampling pipe component comprises a first branch pipe, a second branch pipe, a third branch pipe, a fourth branch pipe and a fifth branch pipe; the lower end of the first branch pipe is connected with the lower end of an absorption tower; the first pH meter is inserted into the first branch pipe; the second branch pipe is horizontally communicated with the first branch pipe; the free end of the second branch pipe is connected with a flushing water pipe; the upper end and lower end of the third branch pipe are respectively communicated with the lower ends of the first branch pipe and the densitometer; the upper end of the densitometer is communicated with the lower end of the fourth branch pipe; the second pH meter is inserted into the fourth branch pipe; the fifth branch pipe is vertically communicated with the fourth branch pipe; and the central lines of the third branch pipe, the fourth branch pipe and the densitometer are positioned on the same straight line and are parallel to the wall of the absorption tower. The device for measuring the density and the pH value of slurry can prolong the service life of the densitometer and the pH meters and reduce the maintenanceworkload of field equipment.

Owner:武汉光谷环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com