Chemical polishing device and method for inner surface of 3D printing high-temperature alloy pipeline

A technology of inner surface polishing and high-temperature alloy, which is applied in the field of 3D printing metal inner surface treatment, can solve the problems of low efficiency and difficulty in polishing the inner surface of 3D printing pipelines, and achieve high polishing efficiency, stable and uniform internal liquid flow rate, and internal smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

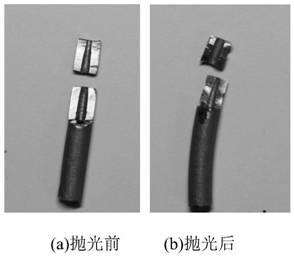

[0065] Step 1, 3D printing superalloy pipeline 6 pre-cleaning

[0066] Put the 3D printed superalloy pipeline 6 into the ultrasonic tank, add ethanol and use ultrasonic cleaning for 5 minutes to remove impurities on the inner and outer surfaces, and then blow dry.

[0067] Step 2, 3D printing the superalloy pipeline 6 surface to remove the oxide layer

[0068] Soak the cleaned 3D printed superalloy pipeline 6 in dilute sulfuric acid with a mass fraction of 3% for 5 minutes to remove the oxide layer on the inner surface. 3D printing superalloy piping6.

[0069] Step 3, chemical polishing of the inner surface of pipeline 6

[0070] Place the 3D printed superalloy pipeline 6 with a clean inner surface obtained in step 2 in the chemical polishing device for the inner surface of the 3D printed superalloy pipeline, and add a superalloy chemical polishing agent into the acid tank 4, An acid-resistant hose 8 is used to connect the inlet and outlet of the pipeline 6 . Add water int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com