Burner with gas combing device

A gas and burner technology, applied in the field of stoves, can solve the problems of inconsistent flame state, affecting combustion effect and combustion performance, achieve uniform and stable combustion, and suppress the effect of flameout noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

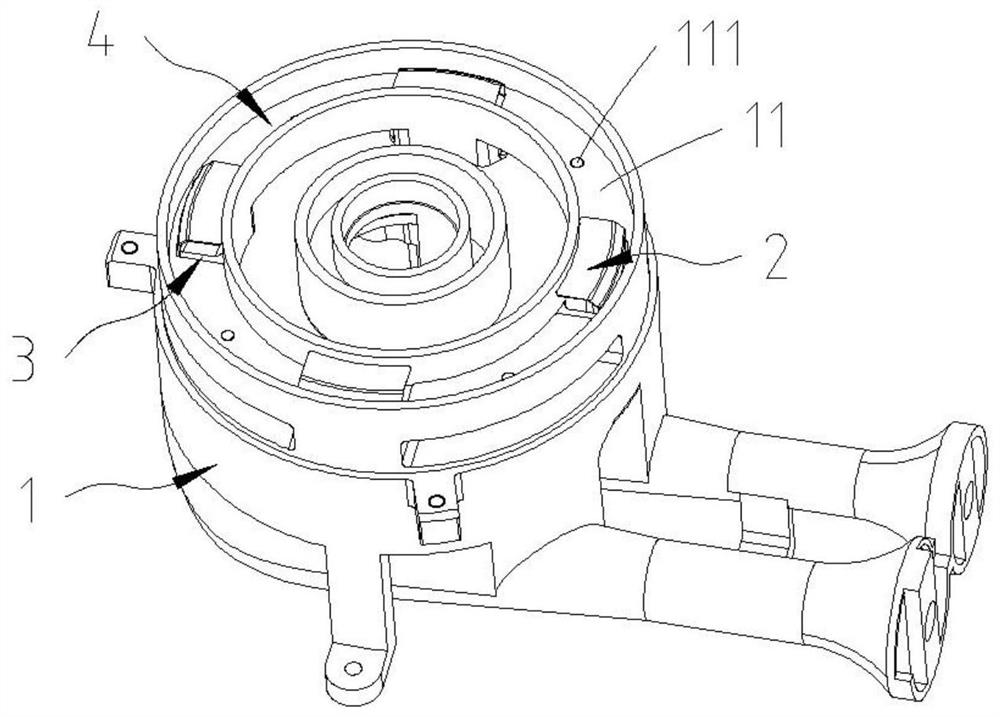

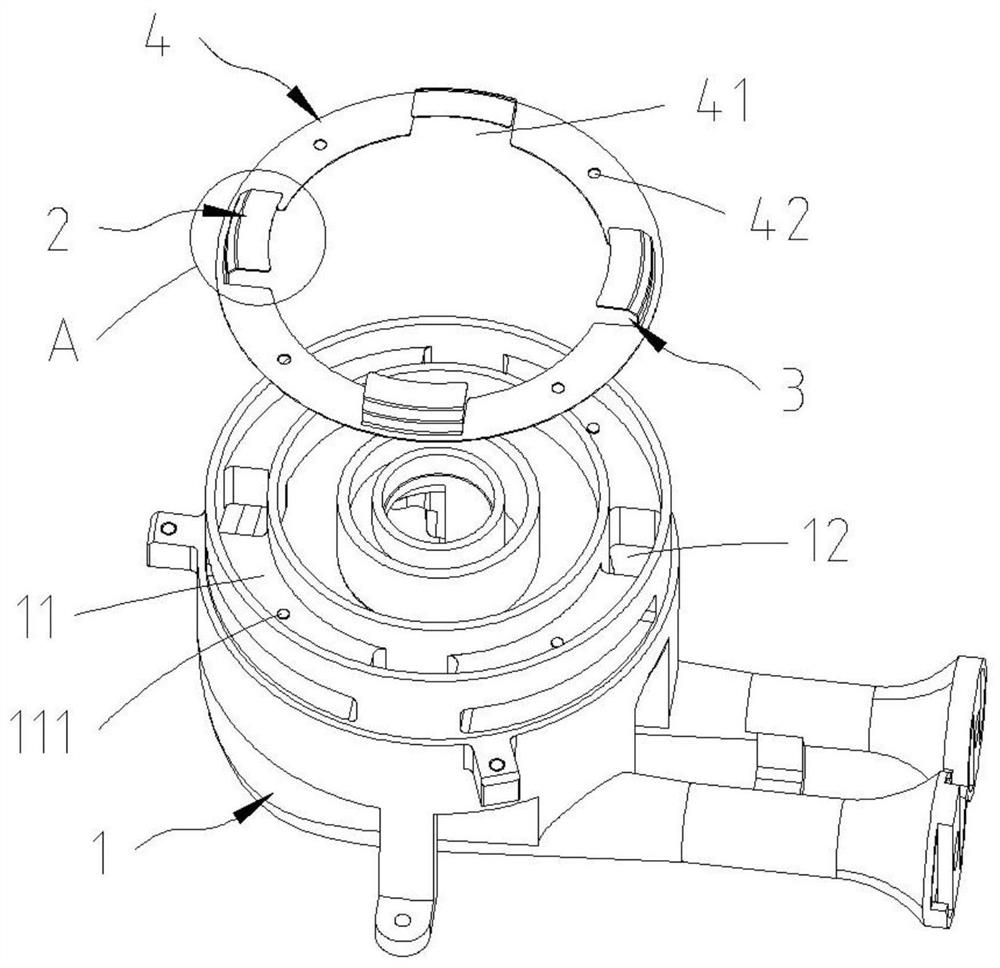

Embodiment 1

[0031] The gas flow path of the outer ring of the existing burner is: after the gas flows out from the gas channel of the burner head, it is generally divided into two parts, one part directly flows upward into the cavity of the fire cover, and the other part flows to the left and right sides of the gas channel outlet of the burner head. side flow. First gradually fill the outer ring air chamber of the burner and then overflow to the cavity of the fire cover, and the gas in the cavity of the fire cover flows out from the fire hole of the fire cover and burns. Because the gas flow rate directly upwards from the gas channel of the burner head is greater than the gas flow rate from the outer ring air cavity of the burner head, the gas flow rate flowing into each position of the fire cover cavity is different. When the existing burner executes the flameout operation, the gas flow rate of the gas channel of the burner drops suddenly. After the gas in the corresponding local fire co...

Embodiment 2

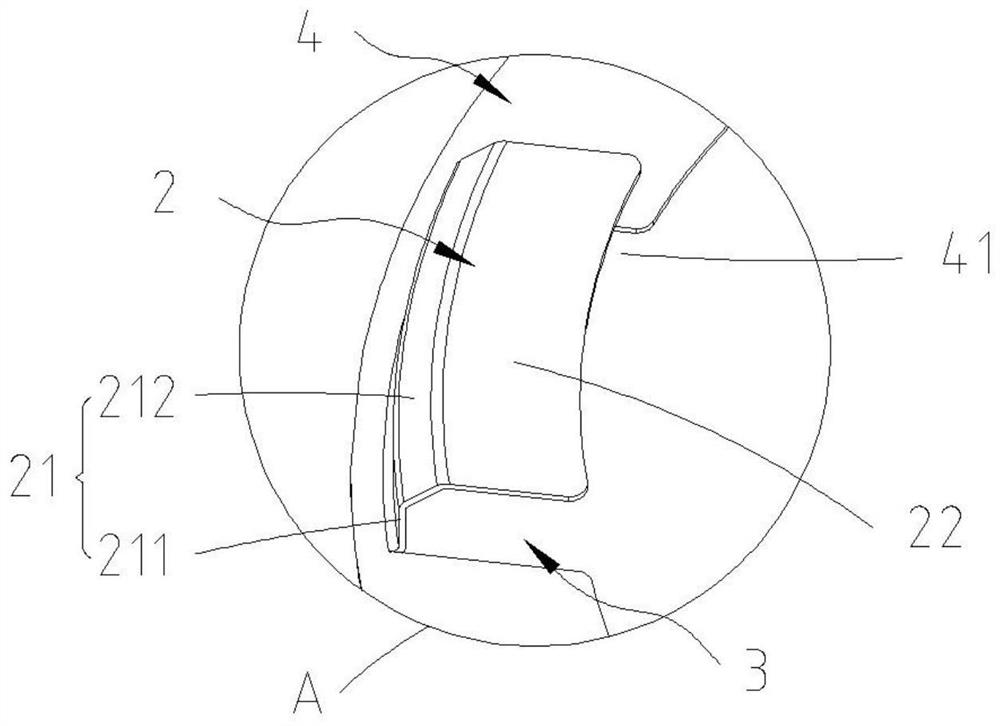

[0047] Such as Figure 4 As shown, the difference between this embodiment and embodiment 1 lies in the structure of the barrier structure 2 . Specifically, the blocking structure 2 is a baffle (not shown in the figure) arranged obliquely in the vertical direction, the baffle is arranged above the opening of the annular support 4, and the lower side of the baffle is connected to the annular support 4 , and abut against the outer ring wall of the air mixing chamber through the outer side of the annular support 4 . The upper side of the deflector extends obliquely upwards to and abuts against or connects to the inner ring wall of the gas mixing chamber, so that the deflector, the bottom of the gas mixing chamber and the inner ring wall jointly define a combing channel with left and right air outlets .

[0048] In this embodiment, the deflector is an arc surface, and the deflector is formed by partially cutting and stamping the annular support 4 and then turning upwards, and the...

Embodiment 3

[0051] Such as Figure 5 As shown, the difference from Embodiment 1 is that the gas combing device of this embodiment omits the annular support. Specifically, an installation groove 13 is provided on the outer ring wall of the gas mixing chamber 11 corresponding to the outlet of the gas channel. The blocking structure 2 is in the shape of a "7", and the outer lower end surface is provided with an outwardly extending installation part 203. During installation, The installation portion 203 of the blocking structure 2 is inserted into the installation groove 13 , and the inner side abuts against the inner ring wall of the air mixing chamber 11 facing the installation groove 13 .

[0052] It can be seen that by omitting the annular support and inserting the mounting part 203 of the blocking structure 2 into the mounting groove 13, the inner side of the blocking structure 2 abuts against the inner ring wall of the gas mixing chamber 11, not only realizing the stabilization of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com