Acetylene preheating and humidifying method

An acetylene and preheater technology, applied in chemical instruments and methods, hydrocarbons, organic chemistry, etc., can solve problems such as acetylene decomposition and explosion, and achieve the effects of increasing humidity, facilitating connection and improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention uses the annular steam preheater 2 to preheat and humidify the acetylene gas.

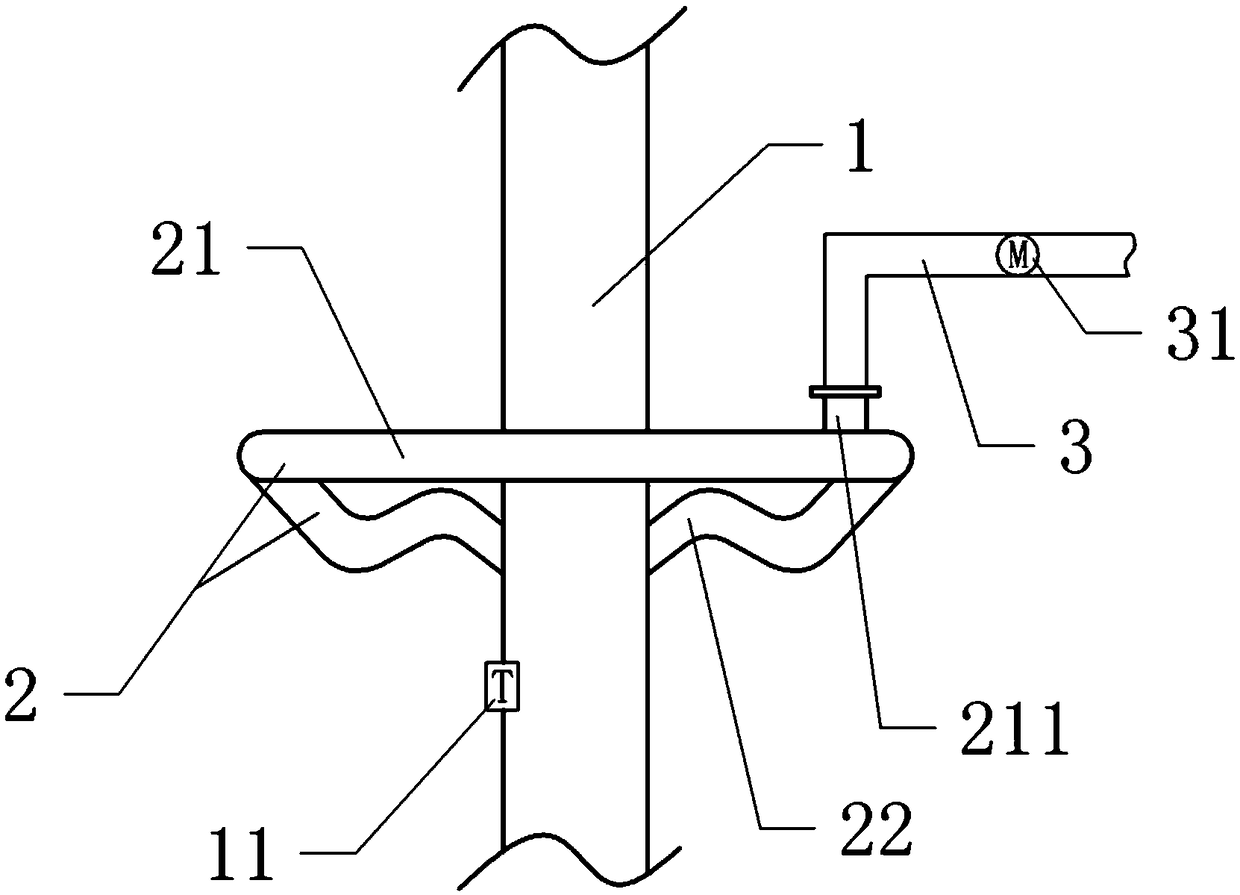

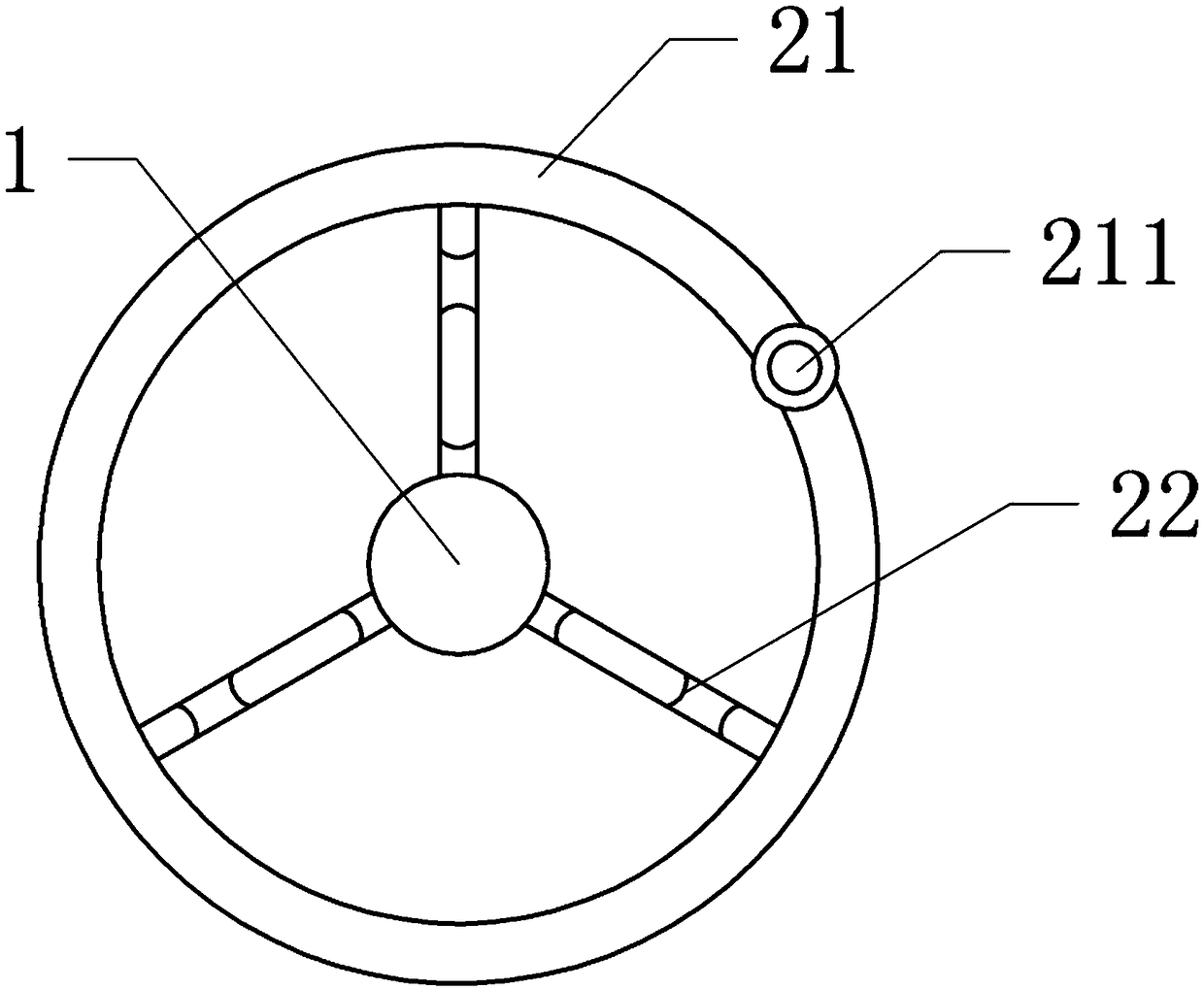

[0037] Such as figure 1 , figure 2 As shown, the annular steam preheater 2 includes a closed steam annular pipe 21 and a plurality of branch pipes 22 communicated with the steam annular pipe 21, and the branch pipes 22 are evenly distributed between the steam annular pipe 21 and the acetylene inlet pipe 1, and this implementation In the example, there are three branch pipes 22, and the branch pipes 22 are curved; the steam inlet 211 is provided on the upper right side of the steam annular pipe 21.

[0038] A method for preheating and humidifying acetylene, comprising the following steps:

[0039] Step 1, set the steam annular pipe 21 of the annular steam preheater 2 on the acetylene intake pipe 1, then connect the bottoms of the three branch pipes 22 to the acetylene intake pipe 1, and arrange the three branch pipes 22 evenly on the acetylene intake pipe 1; and on t...

Embodiment 2

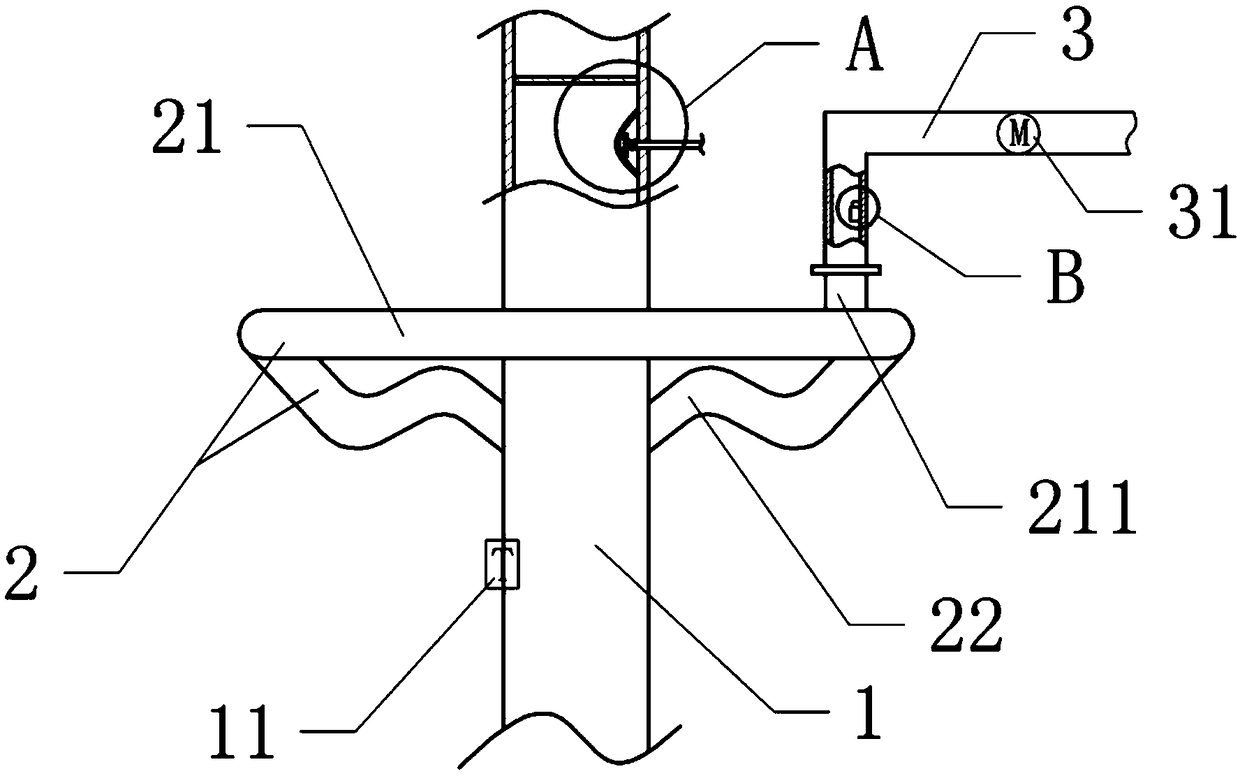

[0044] On the basis of embodiment 1, embodiment 2 is as image 3 , Figure 4 , Figure 5As shown, a pressing piece 4 is fixed on the upper part of the branch pipe 22 in the acetylene inlet pipe 1 . The right end of pressing sheet 4 is fixed on the right part of acetylene inlet pipe 1 inwall, and the left end of pressing sheet 4 sticks with the left part of acetylene inlet pipe 1 inner wall, and pressing sheet 4 is memory metal sheet, and the thickness of pressing sheet 4 is 3mm. The side wall of the acetylene inlet pipe 1 is slidably connected with a push rod 5 that runs through the acetylene inlet pipe 1. The push rod 5 is located between the pressing plate 4 and the steam ring pipe 21. The right end of the push rod 5 is fixedly connected with the switch of the steam control valve. The left end of 5 fixes the limit block 51, is provided with spring between the limit block 51 and the acetylene intake pipe 1 right part inwall, and the spring is welded between the limit block ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com