Combined multifunctional resistance furnace

A multi-functional, resistance furnace technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problems of unfavorable furnace observation, experimental operation and maintenance, equipment installation and movement, and many auxiliary equipment, etc., and achieve compact structure , less auxiliary equipment, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

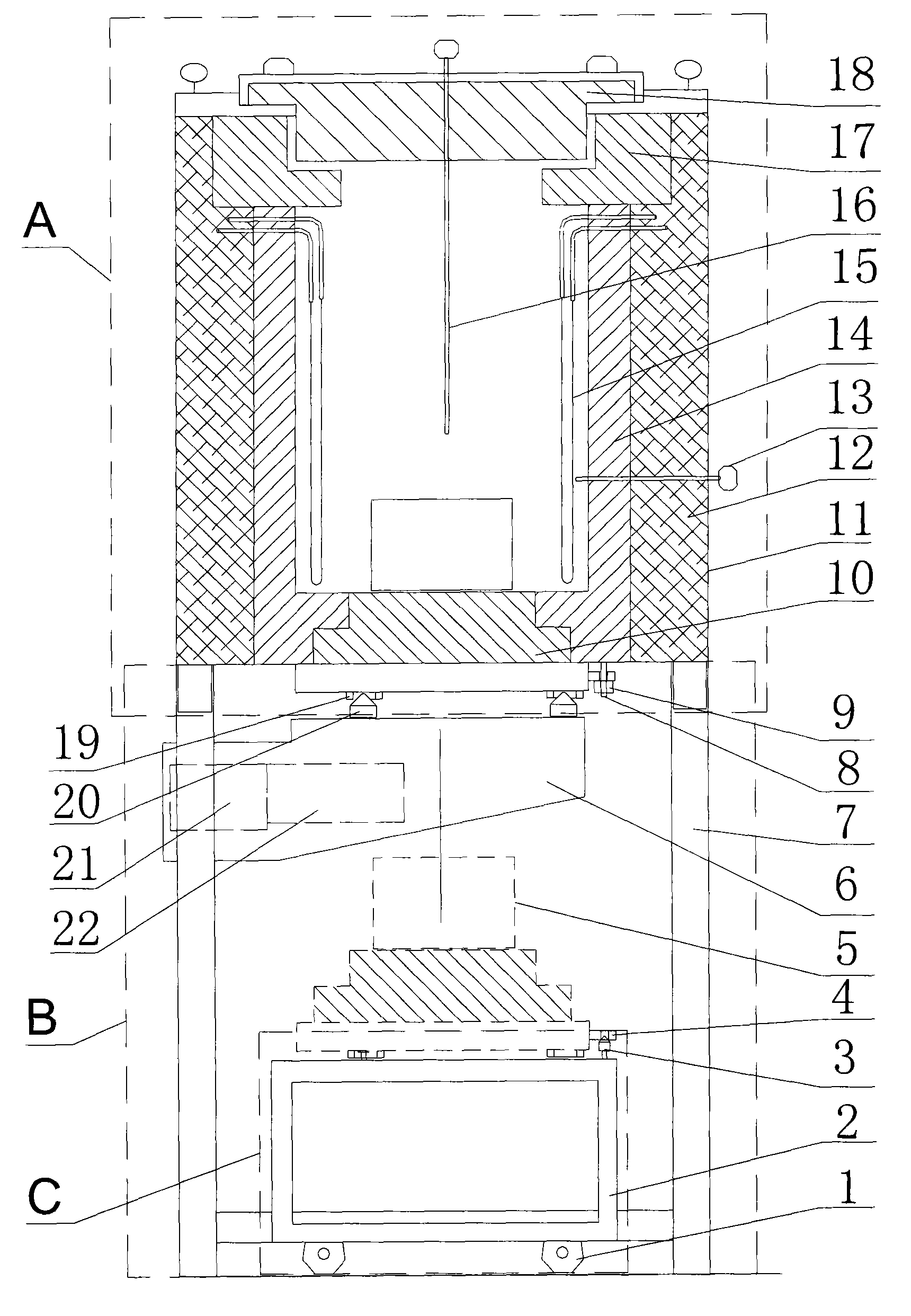

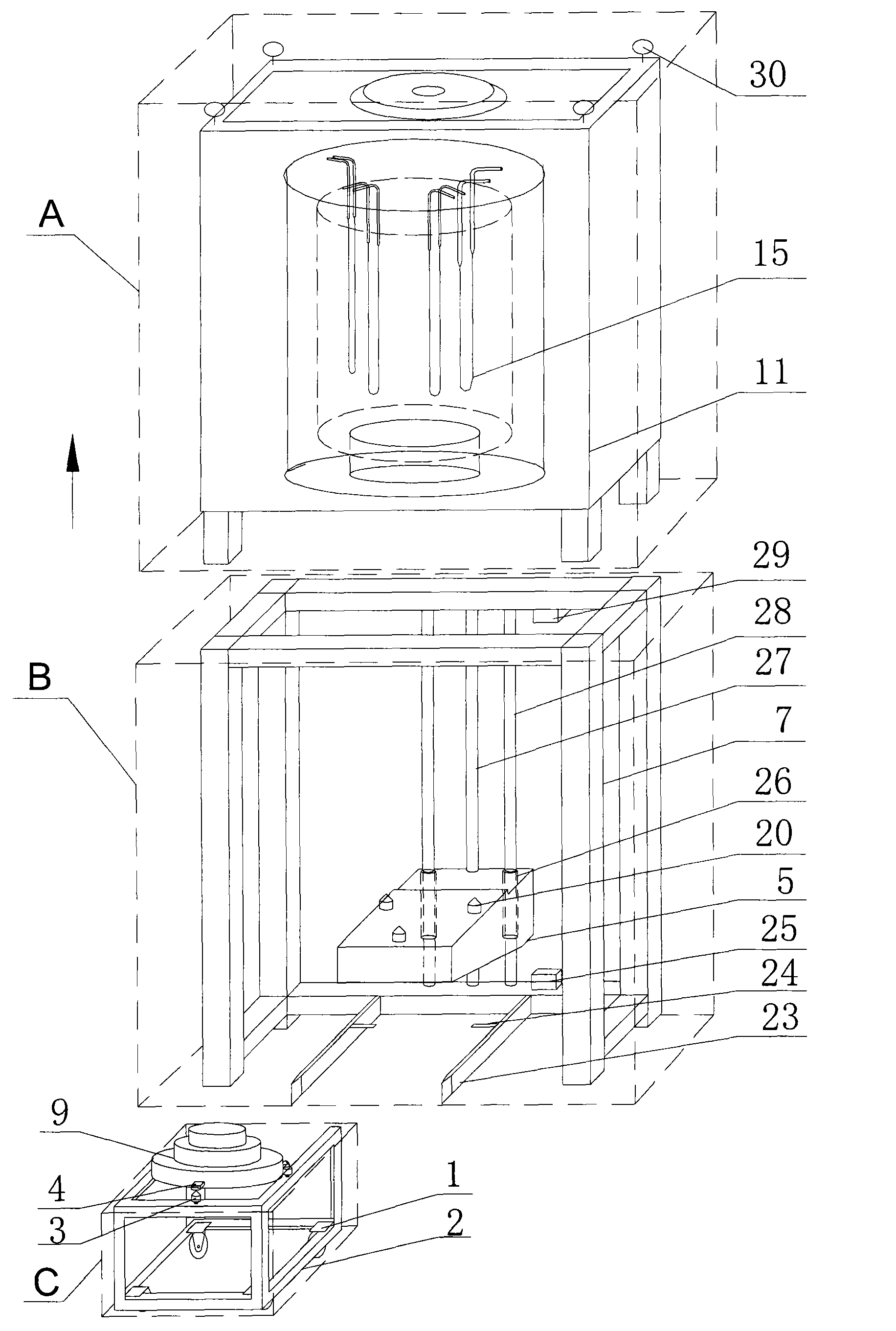

[0019] This combined multifunctional resistance furnace is composed of three parts: furnace body A, lifting system B, and trolley C. Such as figure 1 , figure 2 As shown, the furnace body A includes positioning holes 4 outside the lower furnace base, studs 8, bolts 9, lower furnace base 10, furnace shell 11, heat-resistant fiber 12, furnace body temperature measuring thermocouple 13, furnace lining 14, U-shaped silicon Molybdenum rod heating element 15, material temperature measuring thermocouple 16, annular inner cover 17, upper furnace cover 18, positioning hole 19 at the bottom of the lower furnace base, and lifting lug 30. Lifting system B includes a lifting platform 6, a furnace rack 7, a conical positioning pin 20 in the bottom hole of the lower furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com