Patents

Literature

79results about How to "Less auxiliary equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

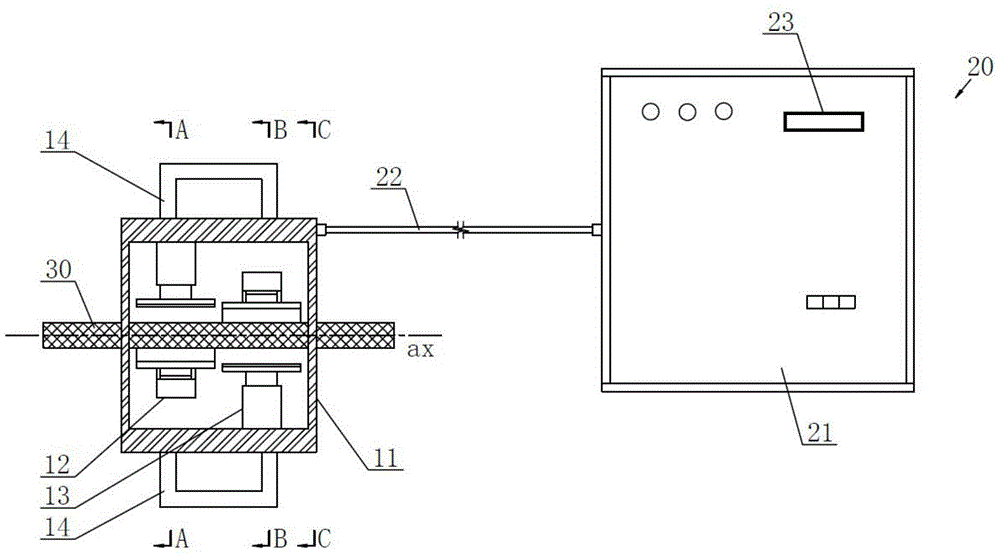

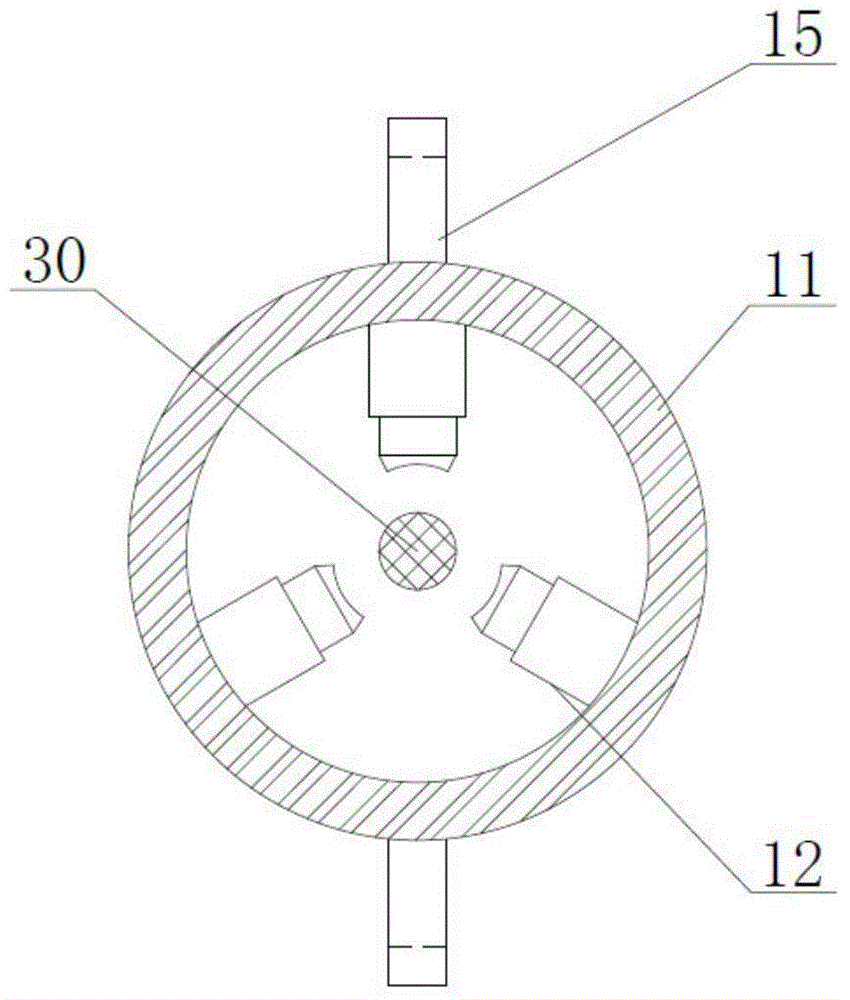

Detection method and detection device of grouting reinforcement effect in tunnel

InactiveCN101846604AQuick evaluationQuantitative evaluationMaterial strength using tensile/compressive forcesSoil massClassical mechanics

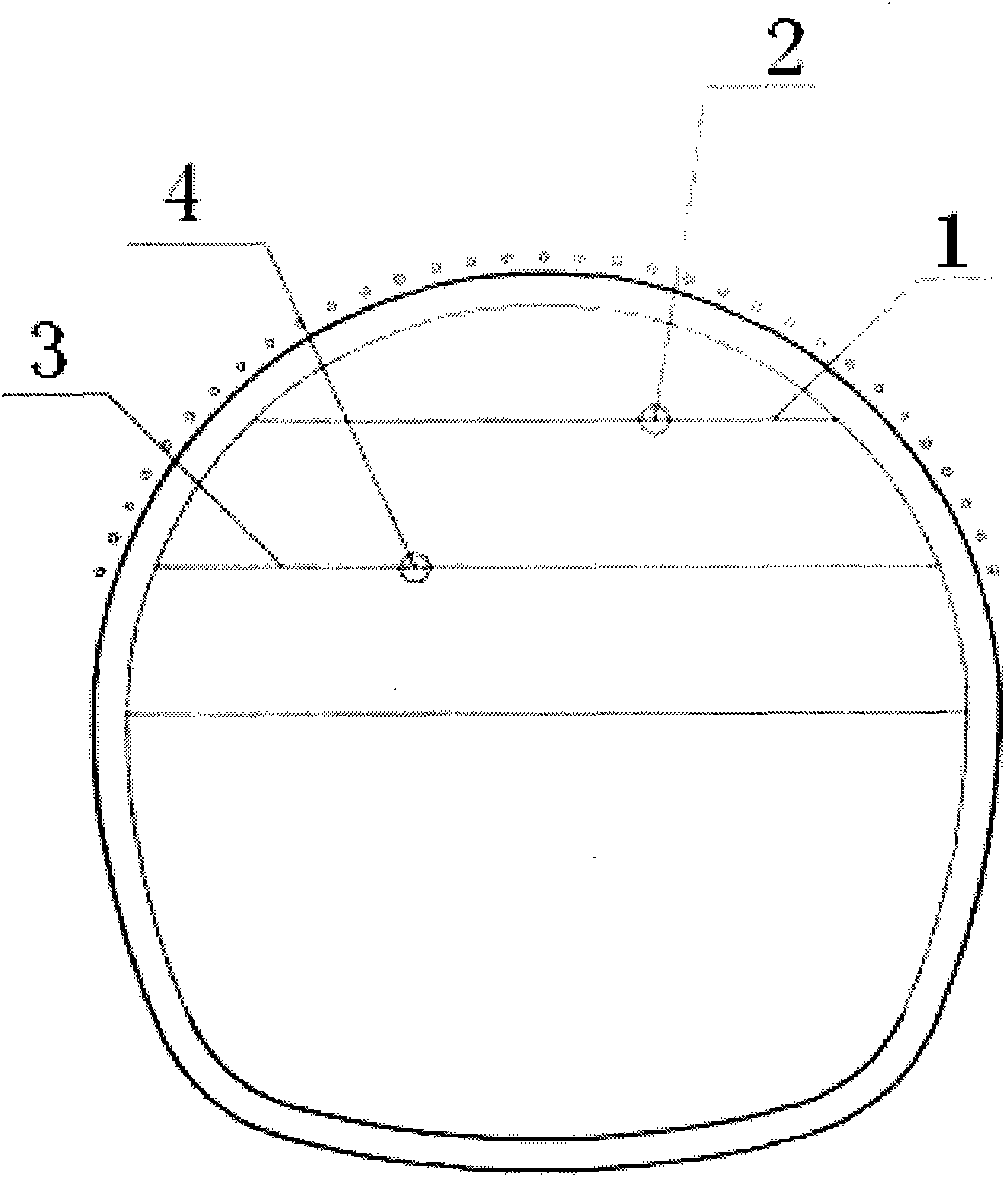

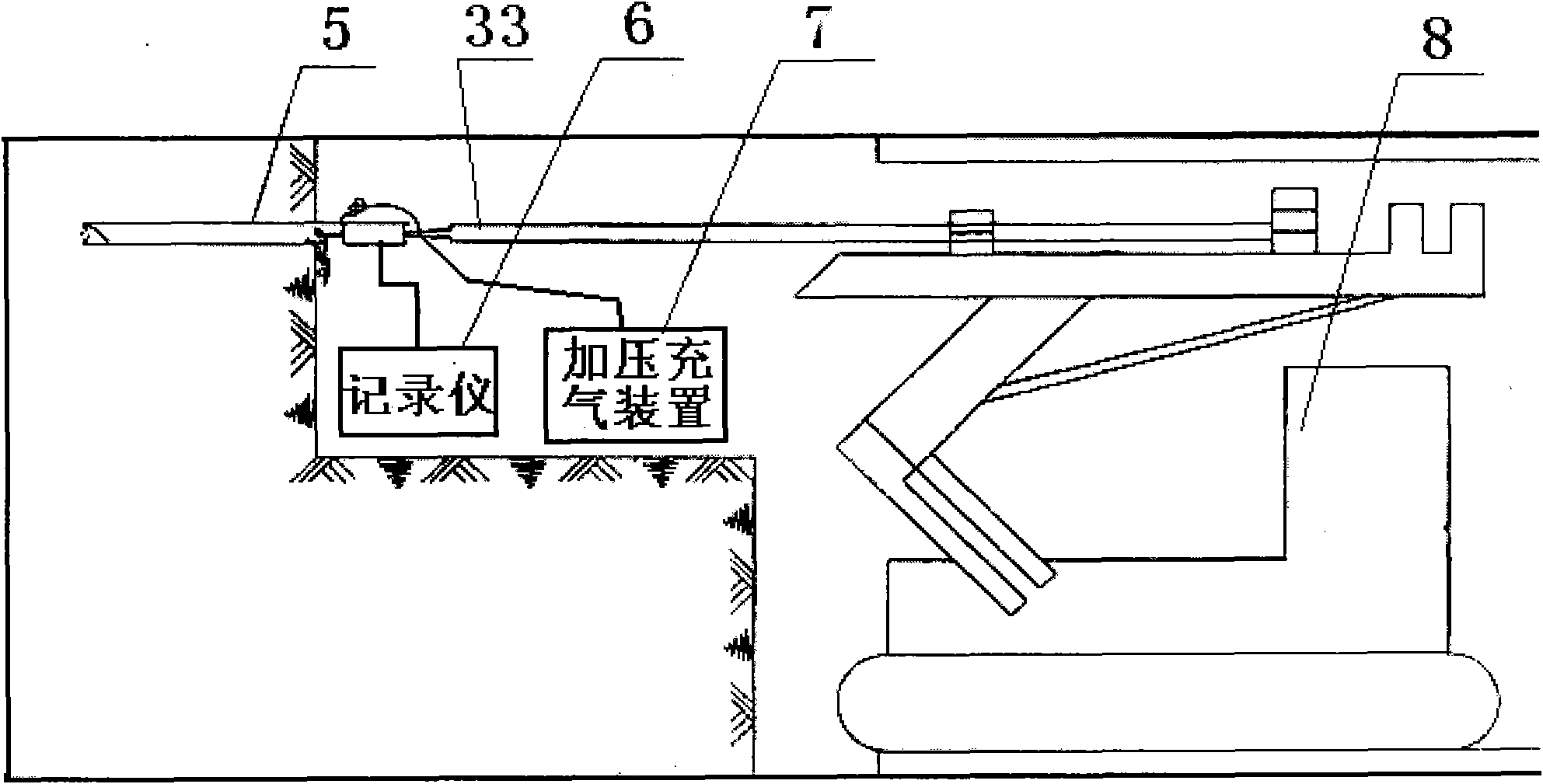

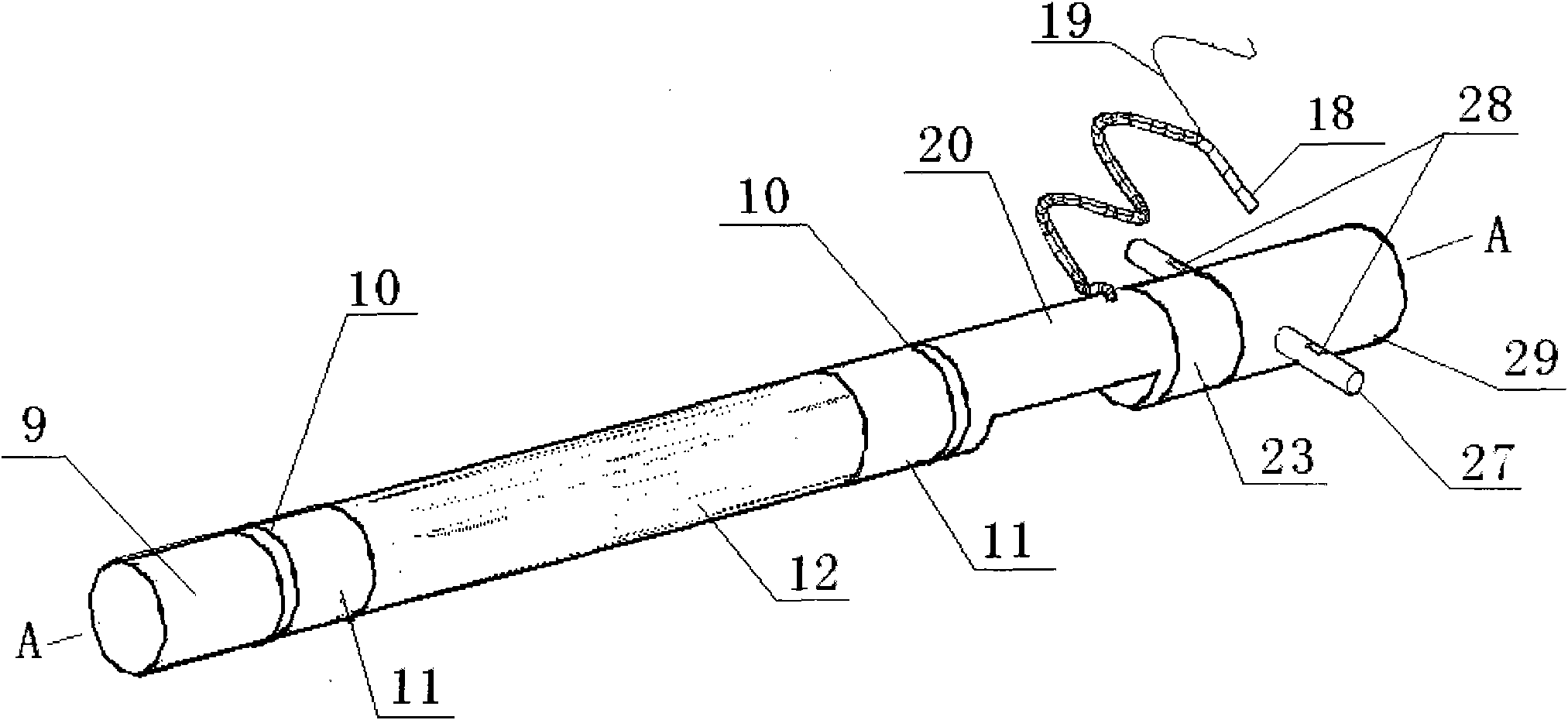

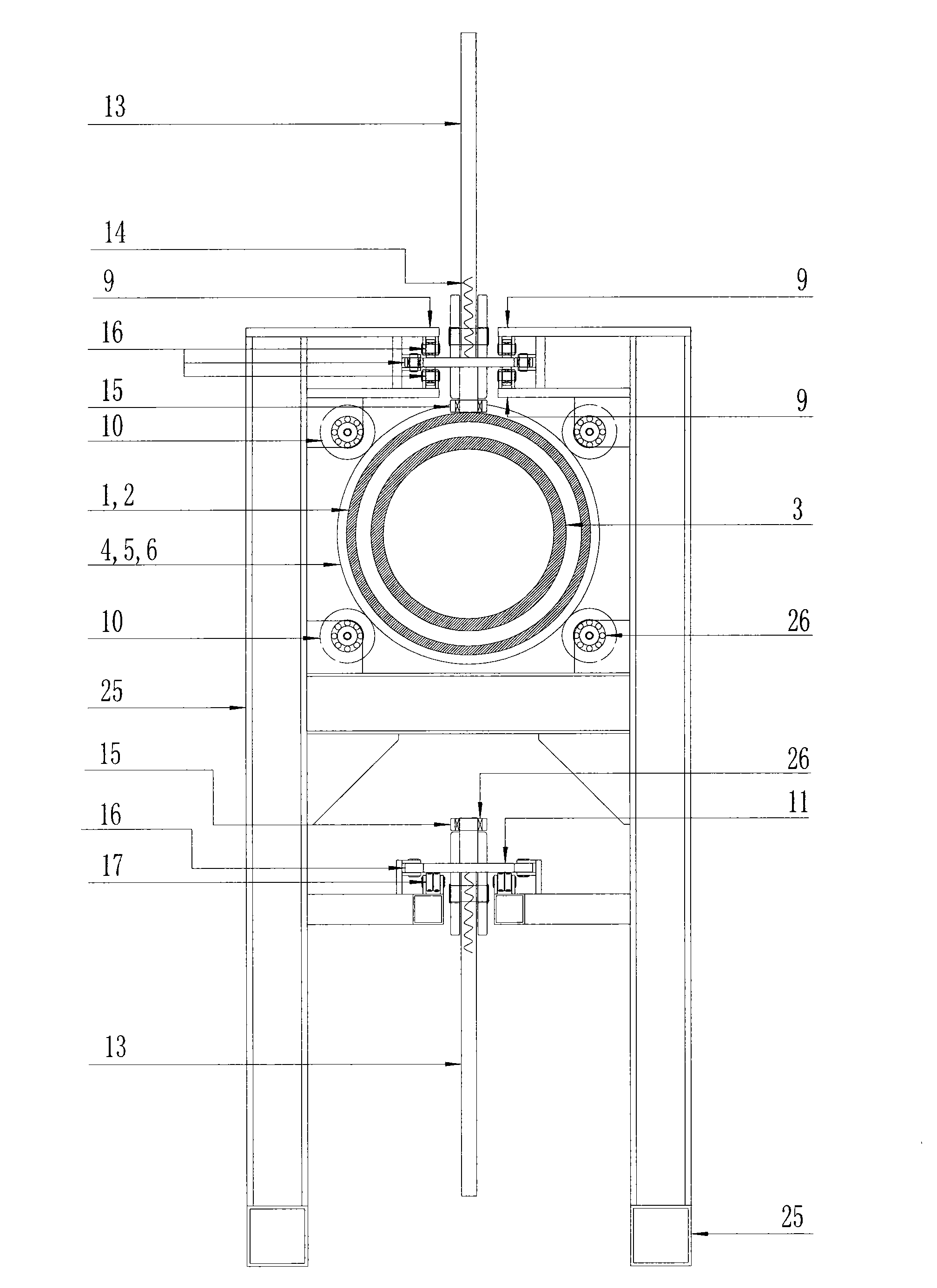

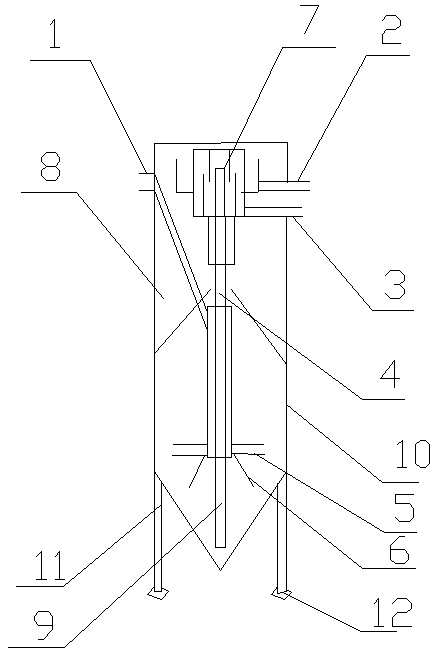

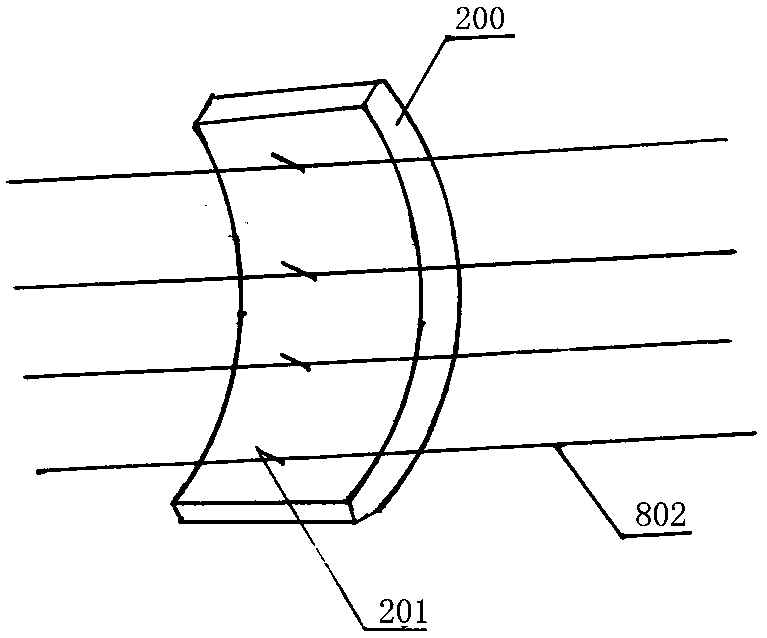

The invention relates to a detection method and a detection device of grouting reinforcement effect in a tunnel, belonging to the field of tunnel engineering. The detection method of grouting reinforcement effect in the tunnel comprises the following steps: horizontally and respectively drilling the detection device into tunnel headings before and after grouting by using a drilling machine; forming an elliptical pilot tunnel in soil mass; inflating and pressurizing the measuring gas chamber of the device, and detecting the displacement of the short axis and the long axis of the elliptical pilot tunnel under the pressure at all levels; computing mechanical parameters (coefficient KO of earth pressure at rest, Poisson ratio mu and elastic modulus E) of the soil mass before and after grouting according to the elasticity theory formula; comparing the mechanical parameters of the soil mass before and after grouting; and making a conclusion of the grouting reinforcement effect according to the variation of the mechanical parameters of the soil mass before and after grouting. The core component of the detection device is the measuring gas chamber which is composed of a tubular expanded inner cavity and a rubber expanded film, and after the device is drilled into the soil mass, the displacement sensor and the pressure sensor of the measuring gas chamber are used for detecting field data. The invention has simple operation and can quickly, quantitatively and scientifically evaluate the grouting reinforcement effect.

Owner:BEIJING JIAOTONG UNIV

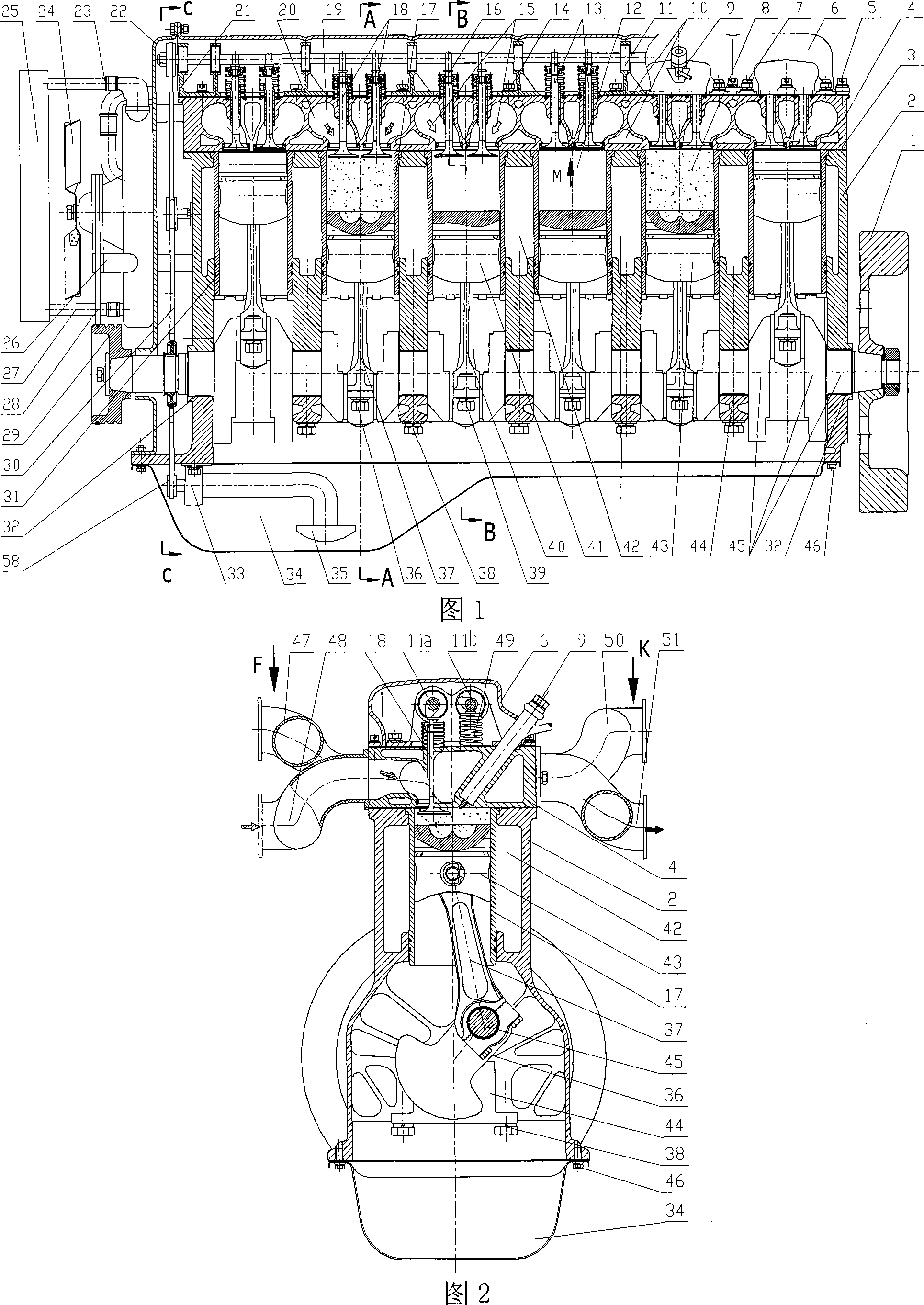

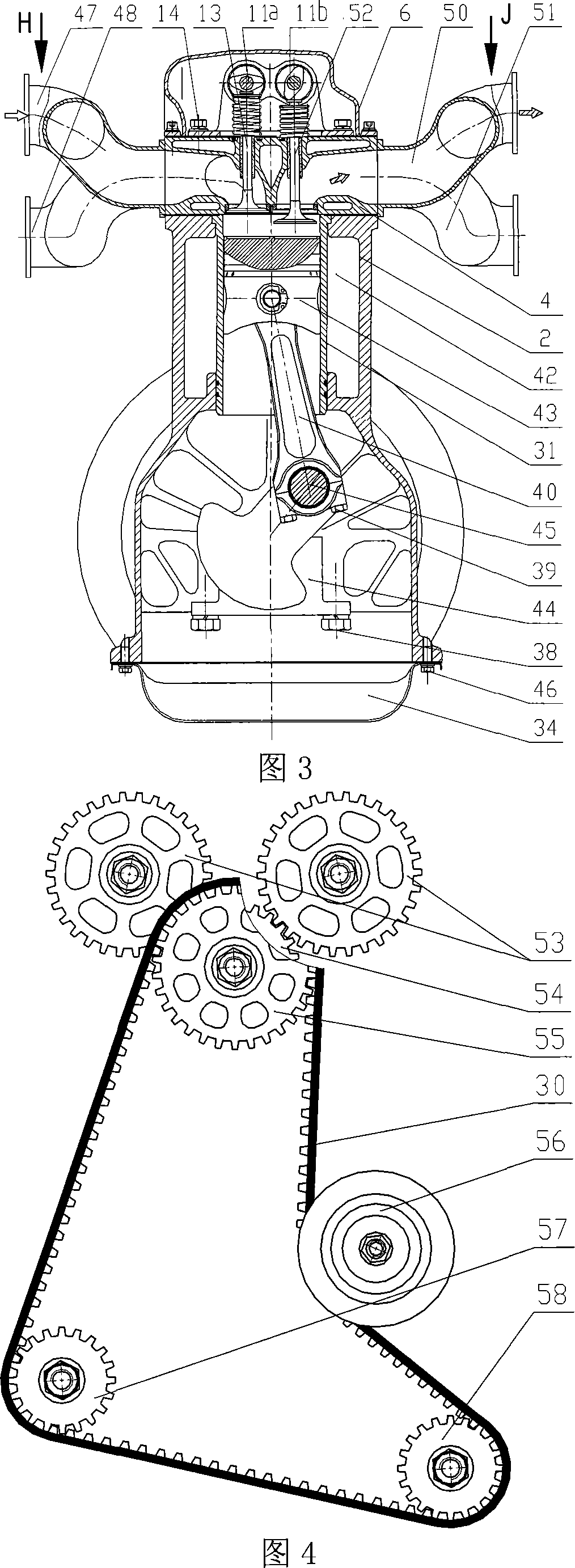

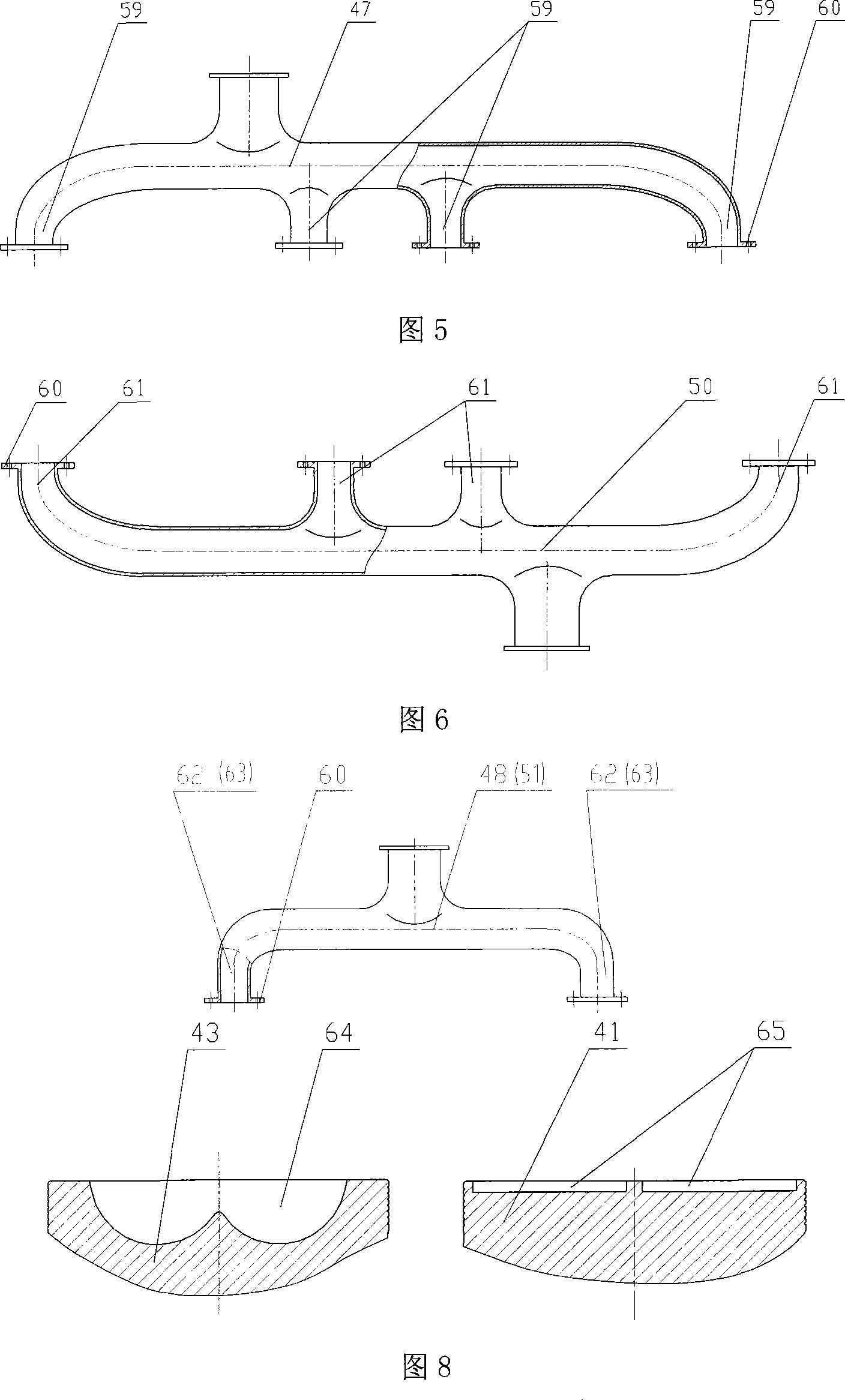

Self-driven integral air compressor

An integrative air compressor of self-driven type comprises a machine body, a power cylinder and an air cylinder. The power cylinder and the air cylinder, which are arranged alternately, are mounted on the machine body and share a crankshaft. One end of the machine body is provided with an end cover and a driving timing gear system arranged at the corresponding end plane of the machine body is in the end cover of the machine body. A first camshaft, a second camshaft and an oil pump spindle, which are arranged on the fitting seat of the camshaft, are connected with the timing gear arranged on the crankshaft by a timing synchronous cog belt and a timing gear pair of the driving timing gear system. A plurality of corresponding cams on the first camshaft respectively correspond to the inlet valve component of each power cylinder and the air cylinder. A plurality of corresponding cams on the second camshaft respectively correspond to the exhaust valve component of each power cylinder and the air cylinder. The invention has the advantages of compact structure, high energy utilization efficiency, good matching performance of the power part and the air part, less assistant equipments, longer service life, reliable performance, easy operation and no need of special staring equipment.

Owner:HUNAN UNIV

Repeating aircraft catapult

InactiveCN101954974AWeight increaseIncrease maximum speedLaunching/towing gearShortest distancePower equipment

The invention relates to a repeating aircraft catapult which is a device for supplying power for aircraft in short distance on land, warships and aircraft carrier decks. The repeating aircraft catapult comprises a first-level acceleration main shaft, a second-level acceleration main shaft, a transmission shaft, an acceleration spiral orbit, a deceleration spiral orbit, a counterweight spiral orbit, a change gear, a rotary power source, an acceleration orbit, a main shaft positioning wheel, a transmission trolley, a trolley starting hook, a trolley arm, an arm closing spring, a trolley acceleration wheel, a trolley positioning wheel, a trolley pass-back orbit, a pass-back motor, a trolley starting wheel, a starting wheel motor, a starting wheel switch, a pressure switch, an equipment main switch, a main power supply, an equipment steel skeleton, a bearing or bearing bush, an electromagnet and the like. The repeating aircraft catapult can accelerate 40-ton aircraft to 80 m / s in 105-m distance within 5 s. The invention has the characteristics of less auxiliary equipment, simple maintenance and mature power equipment technology, can adopt gas engines, steam turbines and the like, and can continuously accelerate aircraft take-off.

Owner:栾远刚

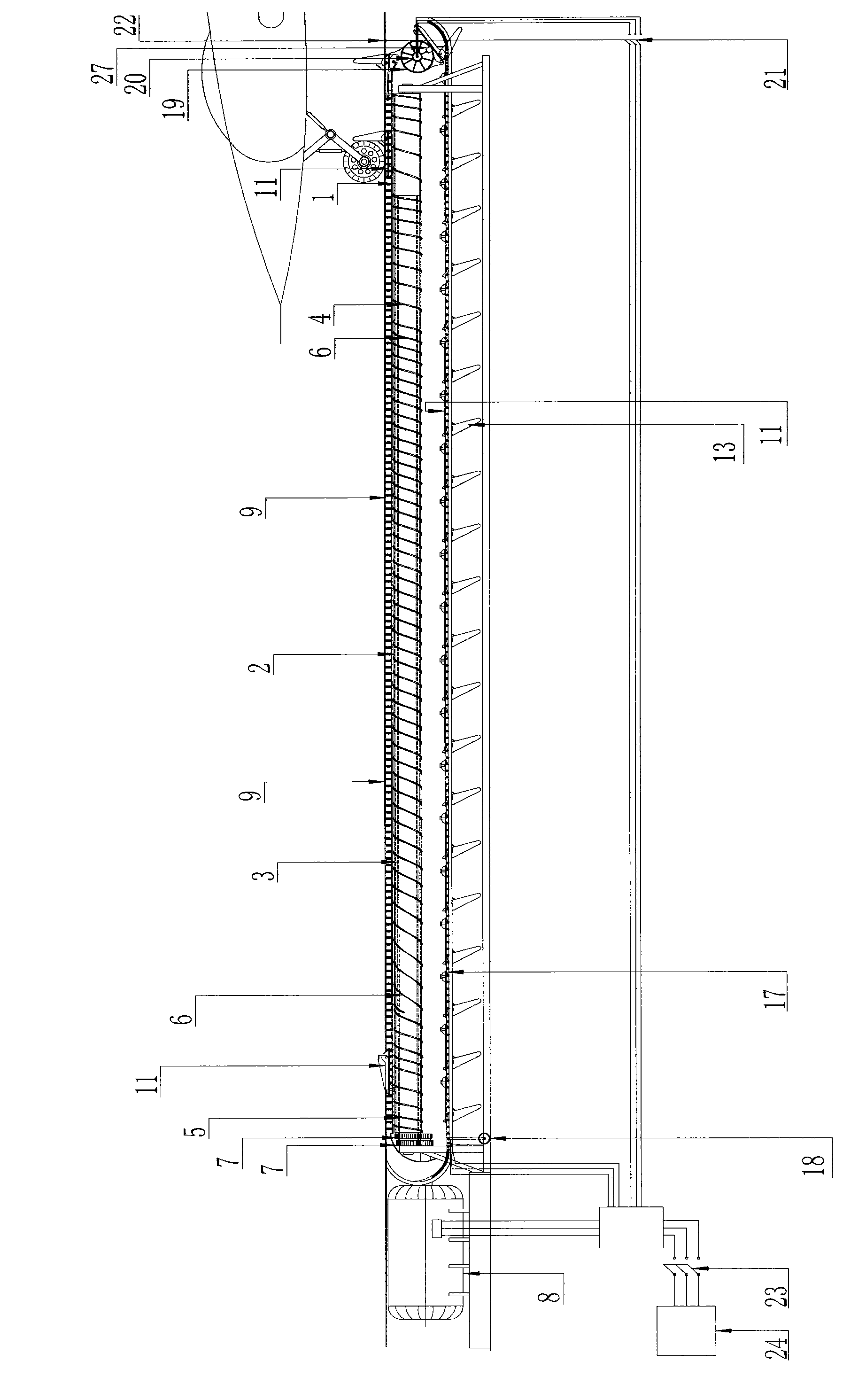

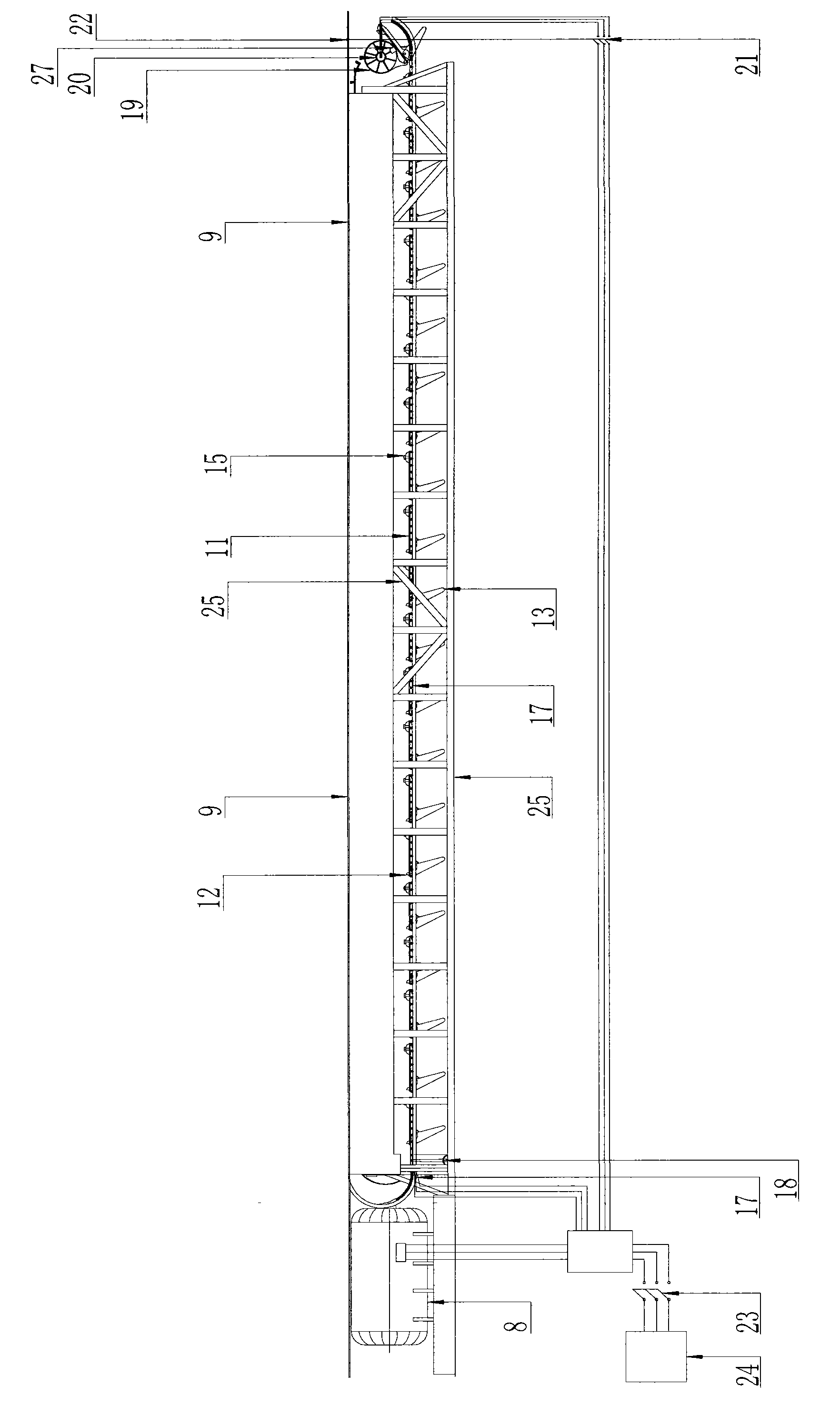

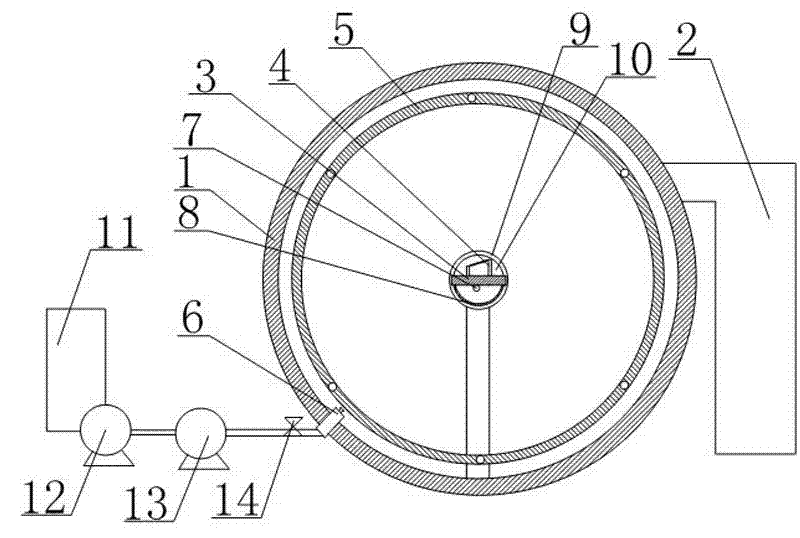

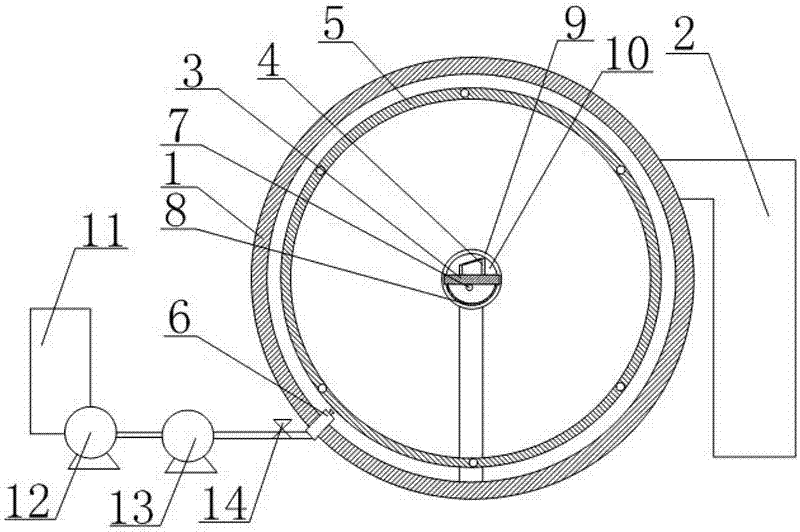

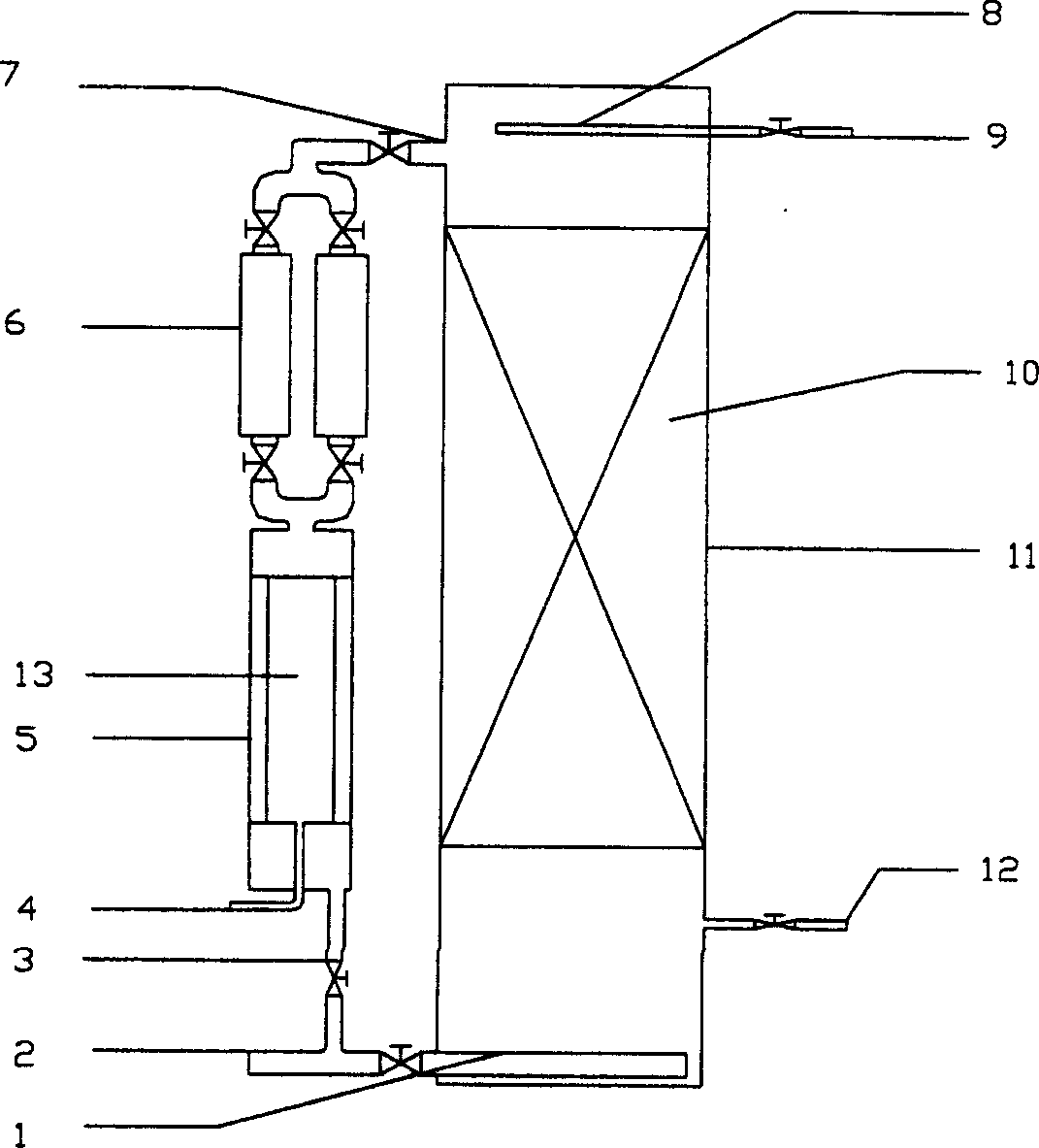

Continuous suspended dirt filtering device and filtering and back-flushing method

InactiveCN108236800ALess investmentReduce energy consumptionLoose filtering material filtersGravity filtersMultiple formsFilter media

The invention relates to a continuous suspended dirt filtering device and a filtering and back-flushing method. Traditional sand filtration devices comprise rapid filter tanks, double-layer filter tanks and pressure filters, are in multiple forms but have common problems, namely halting back-flushing problems that filtering mediums are fixed in the filtering process and are blocked by suspended solids after being used for filtration for a period of time, the filtration speed is reduced, the filtration resistance is increased, and the water production capacity is reduced. The continuous suspended dirt filtering device comprises a sand filtration tank (10) connected with a clean water outlet pipe (3), wherein the clean water outlet pipe is connected with a sand-water separator (7), the sand-water separator is connected with a dirt discharging pipe (2) and an air sand lifting pipe (4) respectively, the air sand extraction pipe is connected with a water inlet pipe (1), an air lifting pump(9) and a water inlet distribution pipe (5) respectively, and the water inlet distribution pipe is connected with a backflow sand hopper (6). The continuous suspended dirt filtering device is appliedto the further purification of sewage in the subsequent sewage treatment process.

Owner:HARBIN SHUNZHI TECH CO LTD

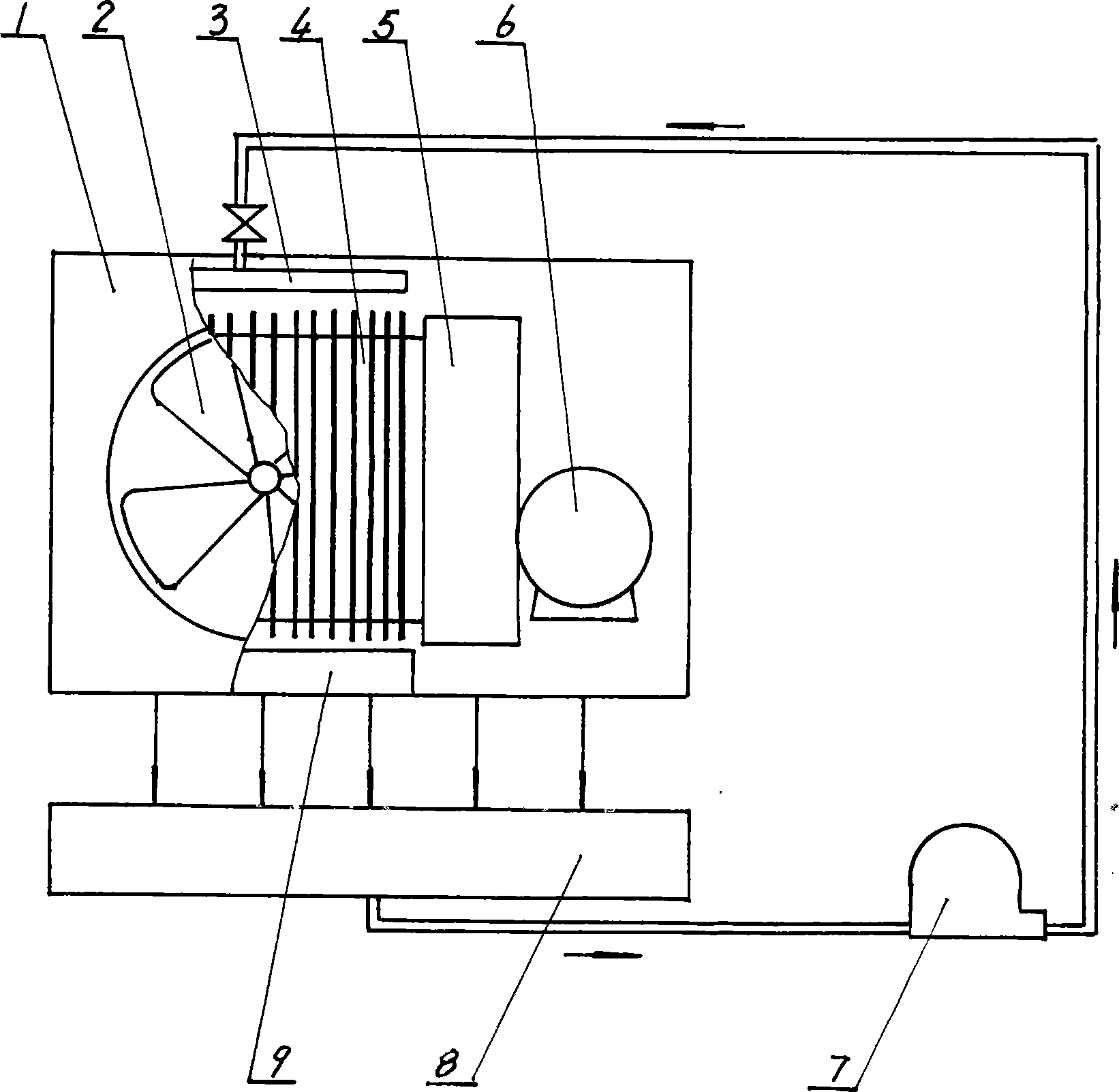

Compression type refrigerating and heating outdoor heat exchange device

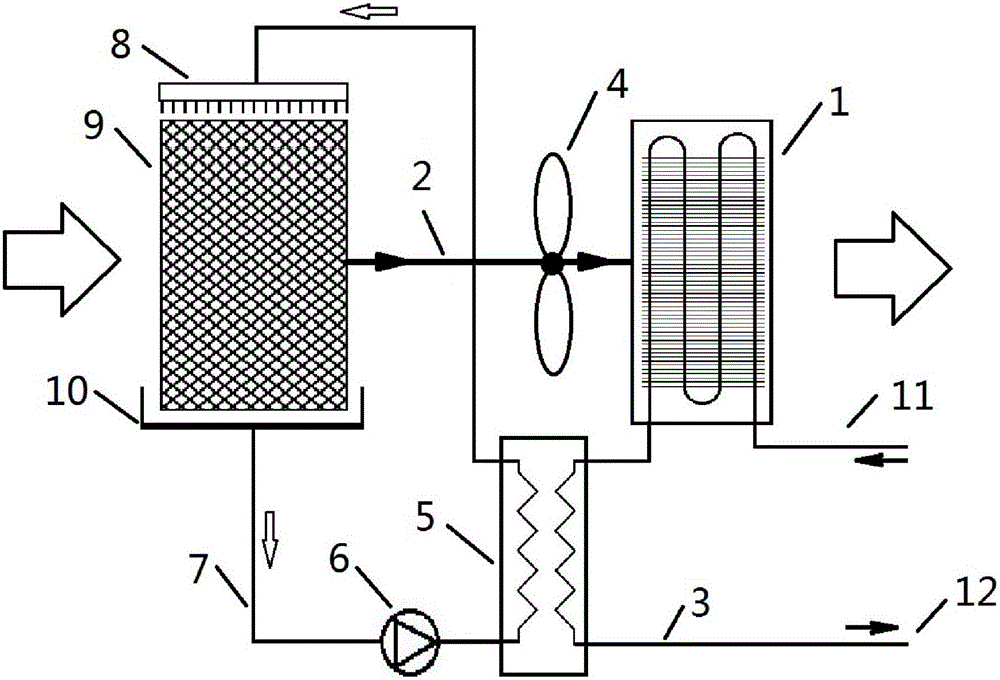

InactiveCN105716314ALower condensation temperatureImprove energy efficiency ratioEvaporators/condensersCompression machines with reversible cycleEvaporationEngineering

The invention discloses a compression-type refrigeration and heating outdoor heat exchange device, which includes a refrigerant circulation heat exchange assembly, a water circulation heat exchange assembly and an air convection heat exchange assembly; the refrigerant circulation heat exchange assembly includes a finned surface heat exchanger, a refrigerant, Refrigerant pipeline inlet, refrigerant pipeline outlet, refrigerant circulation pipeline and water-refrigerant heat exchanger, water circulation heat exchange components include circulating water pump, circulating water pipeline, circulating water, water-refrigerant heat exchanger, water distributor, evaporative heat and moisture exchange Air convection heat exchange components include evaporative heat and moisture exchangers, fans and finned surface heat exchangers. The present invention lowers the condensation temperature of the refrigerant during refrigeration, improves the refrigeration efficiency, and fully utilizes the latent heat of the air during heating to improve the heating efficiency. At the same time, the outer surface of the finned surface heat exchanger is clean and the thermal resistance is small; at the same time, it has a simple structure. , less auxiliary equipment, convenient operation and maintenance, etc., can greatly improve the energy efficiency ratio of the unit.

Owner:向君

Wet sludge treatment method and equipment thereof

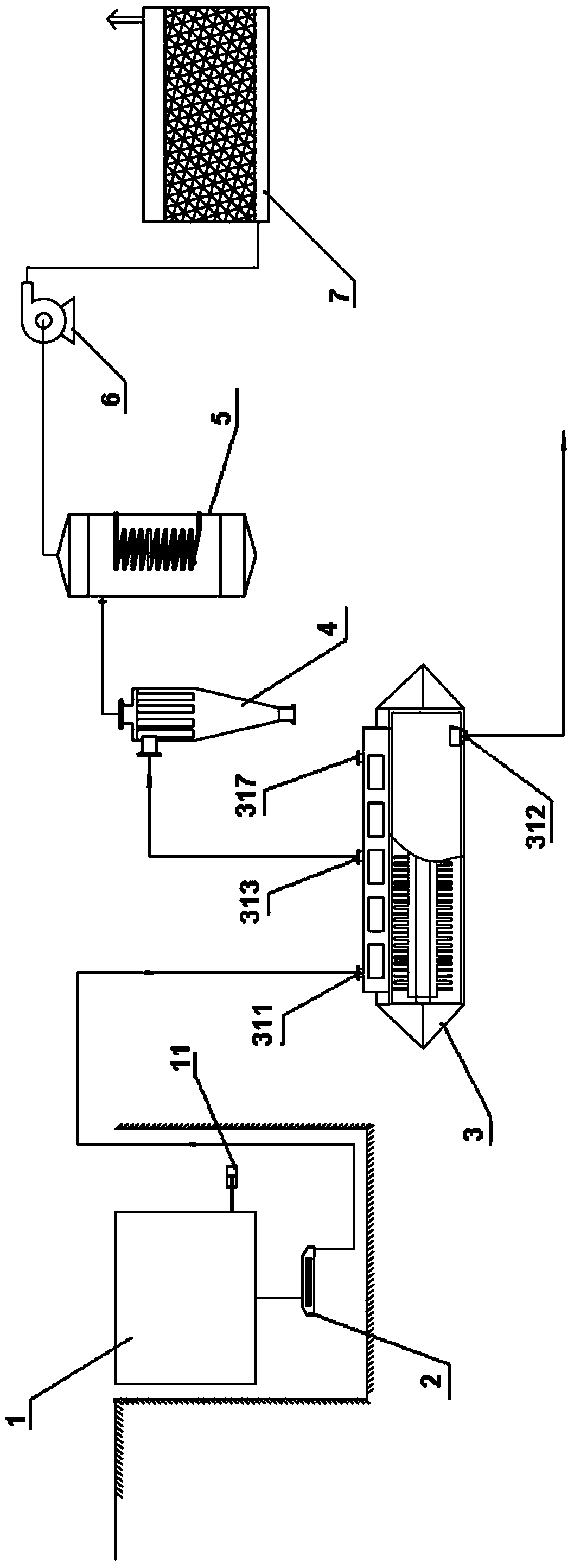

InactiveCN103524013AReduce speedRealize integrationSludge treatment by de-watering/drying/thickeningDeodrantsLand resourcesMunicipal sewage

The invention relates to a wet sludge treatment method and equipment thereof. Wet sludge is conveyed into sludge drying and forming equipment to be dried and formed through a wet sludge conveying pump from a wet sludge cabin; generated tail gas is sucked out through a draught fan, is fed into a dust collector for dust removal, and subsequently is fed into a condenser for condensation; uncondensed gas is fed into a deodorization device for smell gas removal, and is discharged until the gas meets the discharge standard. The wet sludge treatment method has the advantages that the heat conduction efficiency is high, the energy consumption is small, the process is simple, the reliability is high, a land is saved, the operation cost is low, and the like; municipal sewage and sludge can be treated in scale; a land resource is saved; the great significance in energy conservation is achieved.

Owner:天通新环境技术有限公司

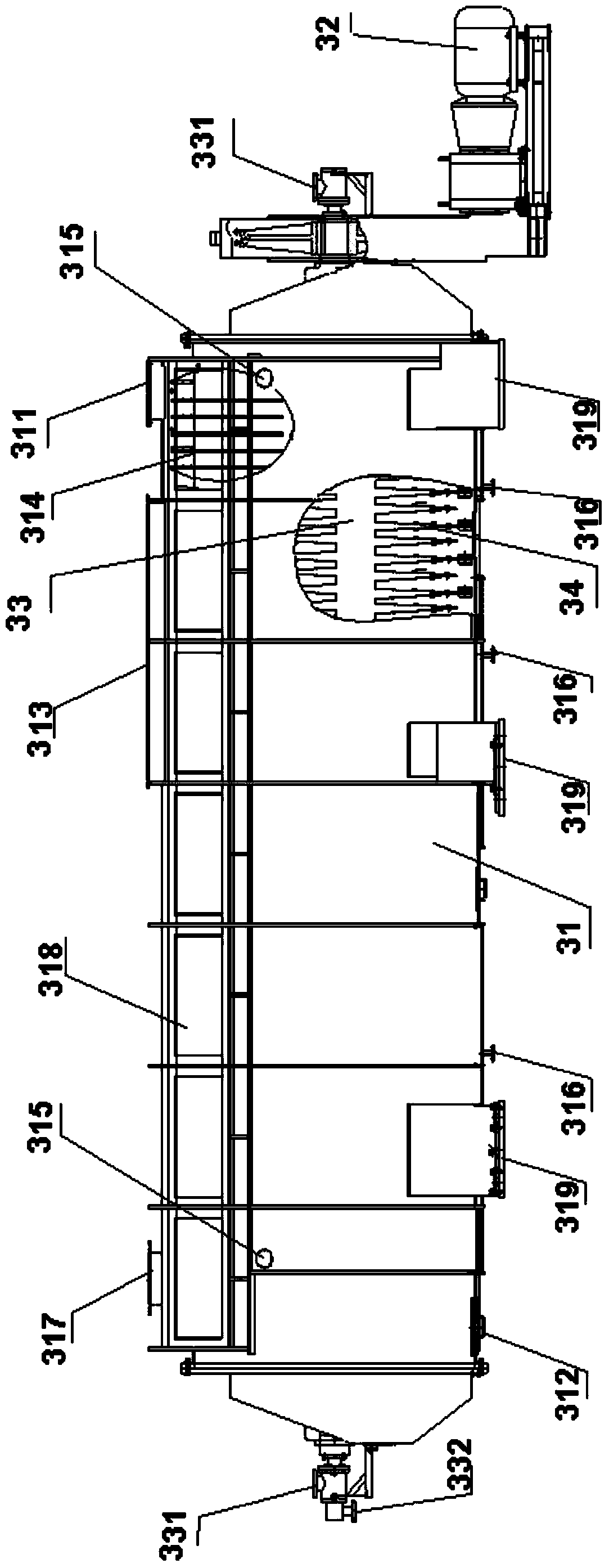

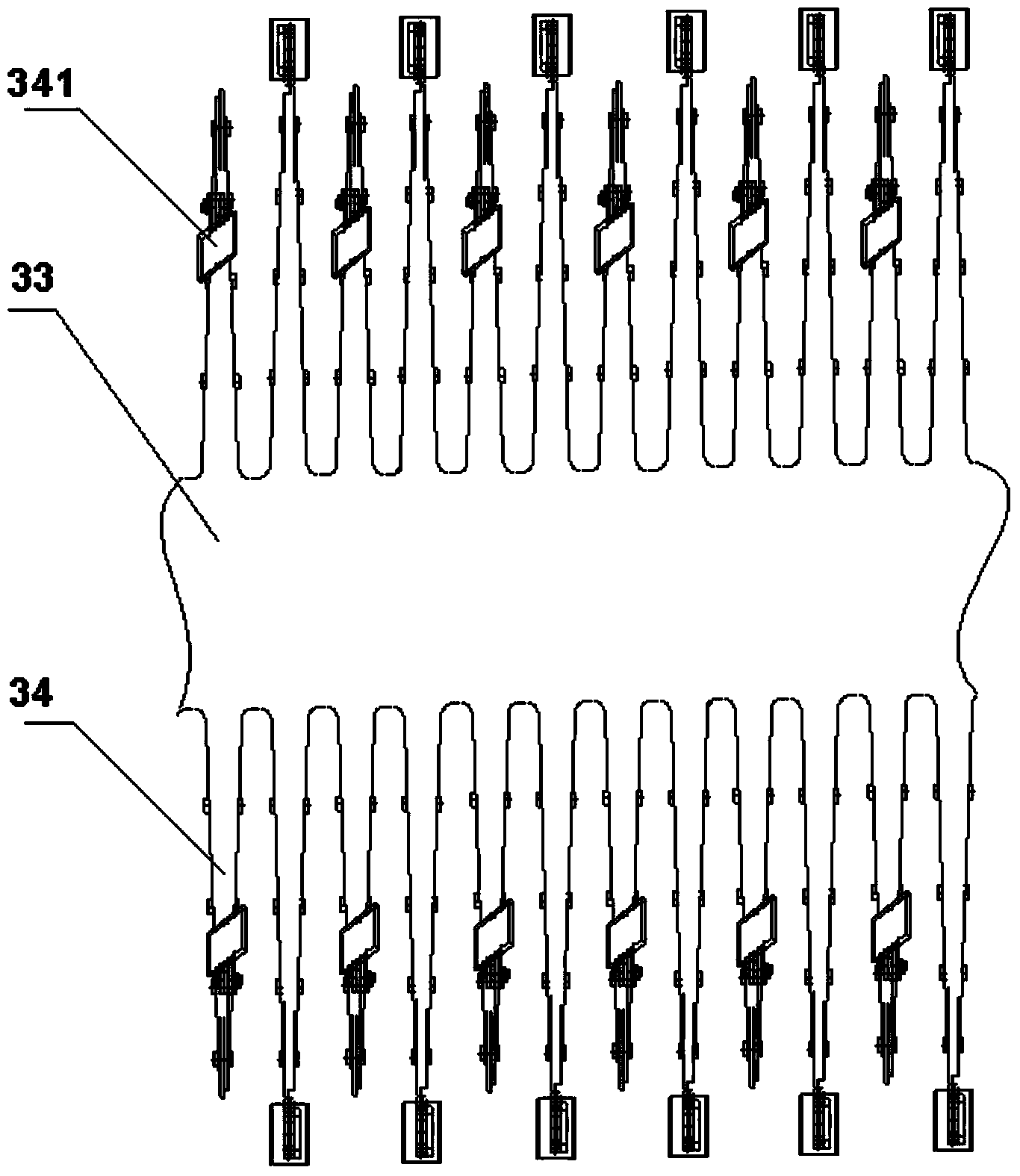

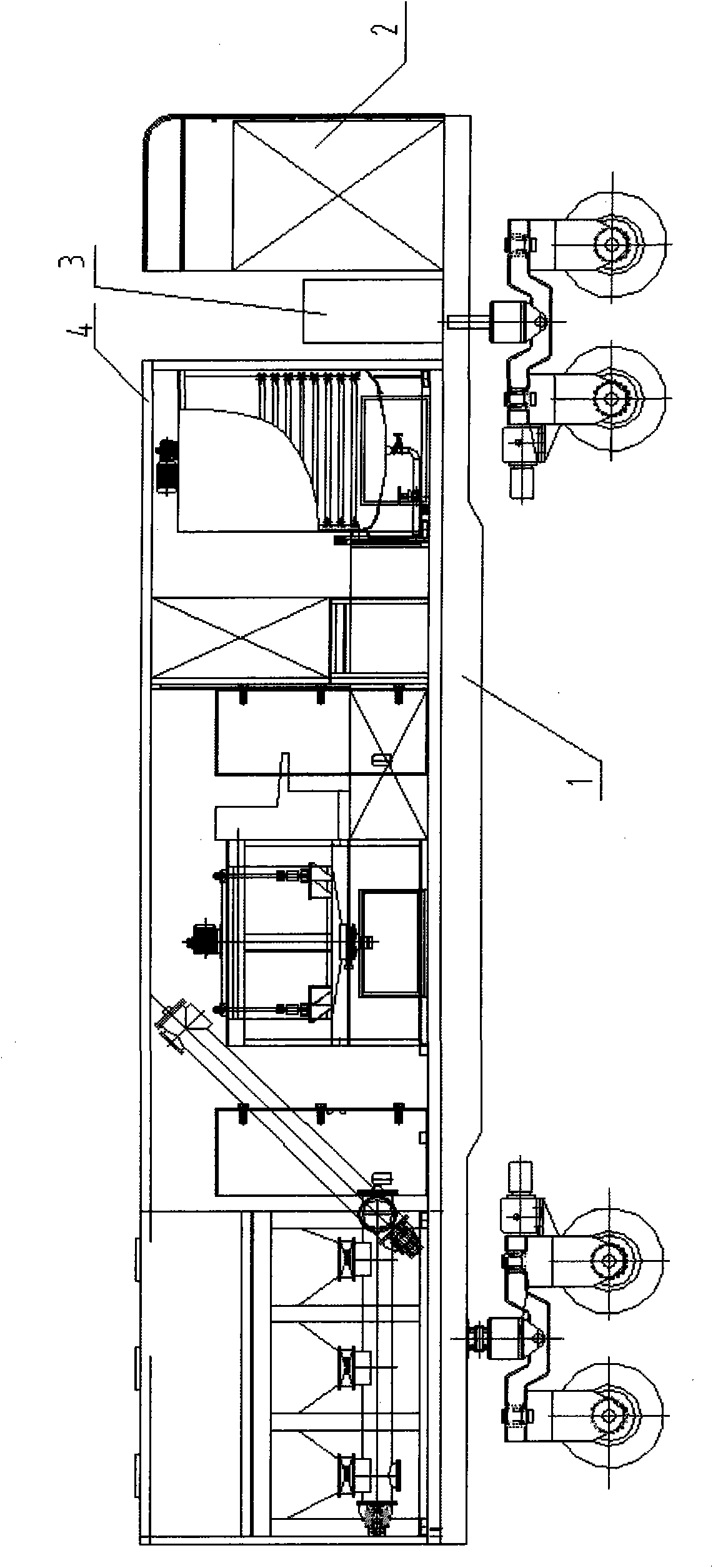

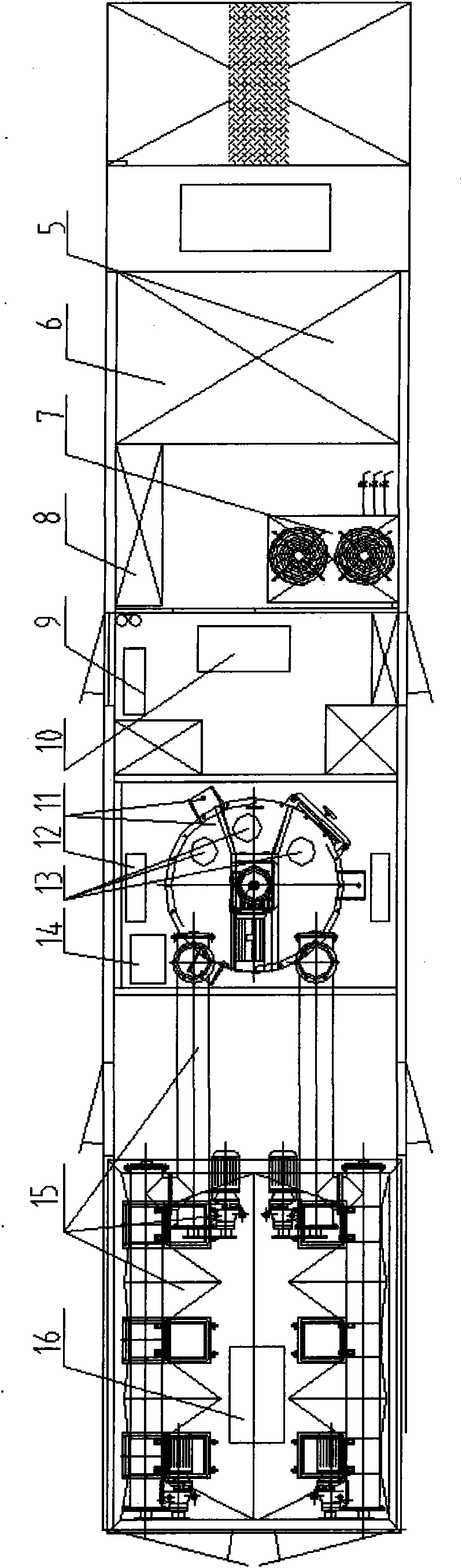

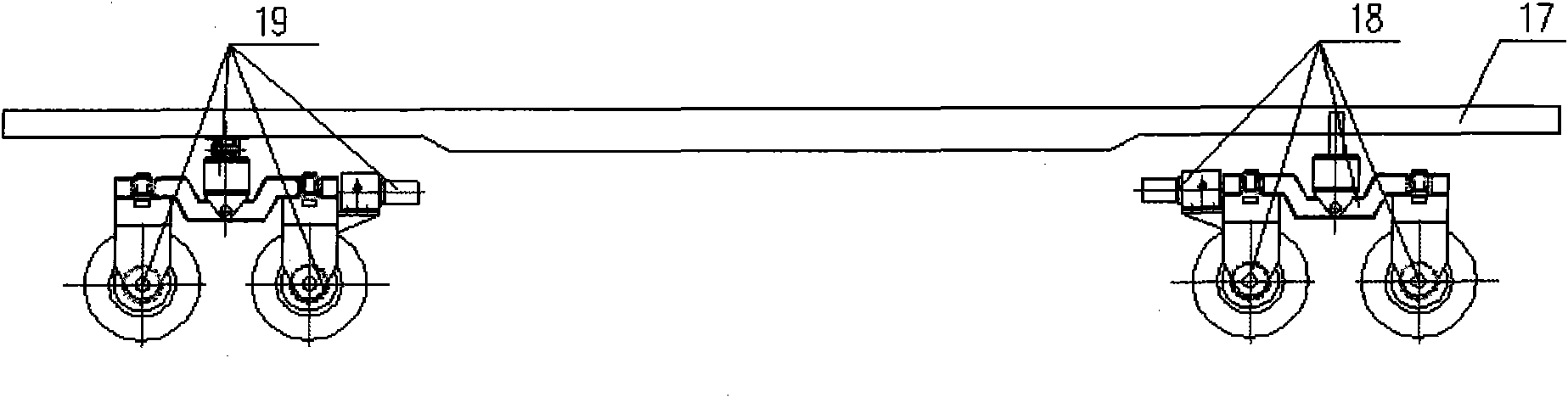

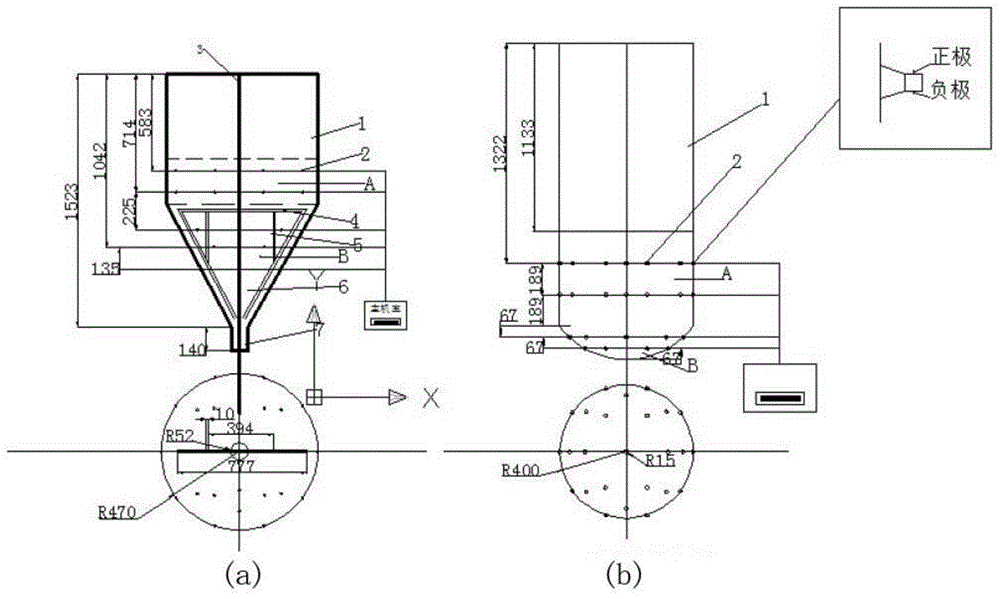

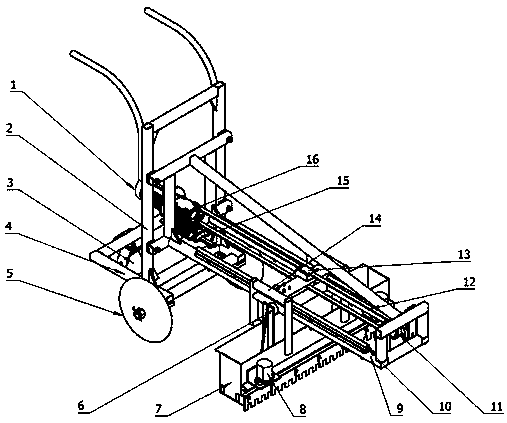

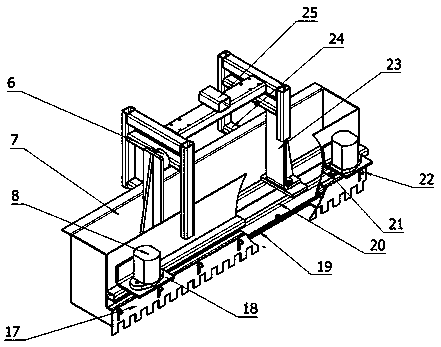

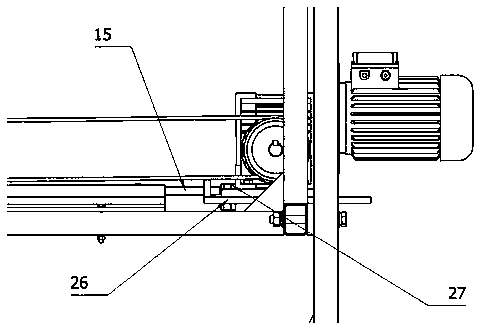

Tire type online traveling cement-emulsified asphalt mortar stirring and pouring vehicle

InactiveCN101913203ALess auxiliary equipmentAutomated control of construction productionCement mixing apparatusAutomatic controlEngineering

The invention discloses a tire type online traveling cement-emulsified asphalt mortar stirring and pouring vehicle which comprises a special chassis and a vehicle-mounted container framework, wherein the special chassis comprises a traveling system and can carry out online traveling or inter-plate traveling, and the spacing interval between traveling tire groups is adjustable; a stirring tank is arranged in the vehicle-mounted container framework, and a liquid material and dry material supply system is connected at the outside of the stirring tank; and the liquid material and dry material supply system comprises a dry powder bin and a liquid material storage tank, and the dry powder bin is connected into a cylindrical tank body of the stirring tank through a screw conveyor. The tire type online traveling cement-emulsified asphalt mortar stirring and pouring vehicle adopts the tire type online or inter-plate traveling way, the design of the large-capacity bin and the material storage tank and high and low elastic modulus cement-emulsified asphalt mortar universal formula program software for realizing the arbitrary adjustment of a mortar formula, thereby automatically controlling the material mixing process, the loading process and the metering process, improving the construction efficiency, saving the production cost, leading the production quality of mortar to meet the requirements on construction technical conditions and leading the construction process to realize energy conservation and environmental protection.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

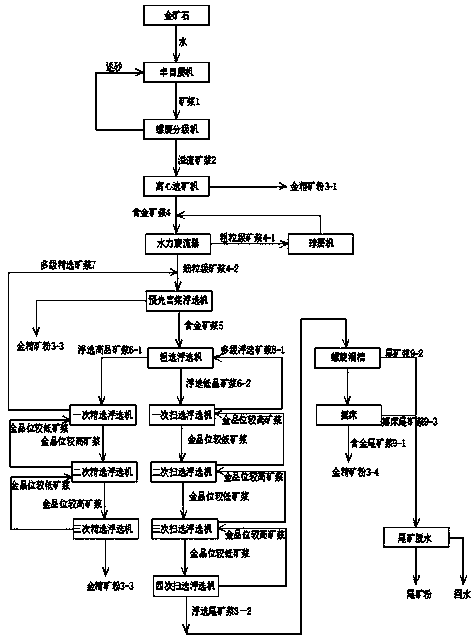

Beneficiation method suitable for alterated rock type gold ores

ActiveCN111229452ANo pollution in the processFull recoverySolid separationMining engineeringGold ore

The invention discloses a beneficiation method suitable for alterated rock type gold ores, and belongs to the technical field of gold ore beneficiation. The problems that a traditional beneficiation method for the alterated rock type gold ores is serious in pollution, high in energy consumption and low in gold-bearing ore recovery rate are solved. The method comprises the four steps of ore grinding, centrifugal reselection, flotation and tailing reselection. According to the beneficiation method, the reselection process of combining centrifugal reselection, a flotation process, a spiral chuteand a table concentrator, namely, the technological process of combining reselection, flotation and reselection is adopted, and after the gold-bearing ores with the grade of 1.5-5 g / t are subjected tobeneficiation process enrichment and separation, finally the gold-bearing grade in final gangue is about 0.10 g / t, and the recovery rate of the gold-bearing ores reaches 97%; and the method is extremely efficient, and the beneficiation process is environmentally friendly and free of pollution in the whole process.

Owner:甘肃省天水李子金矿有限公司

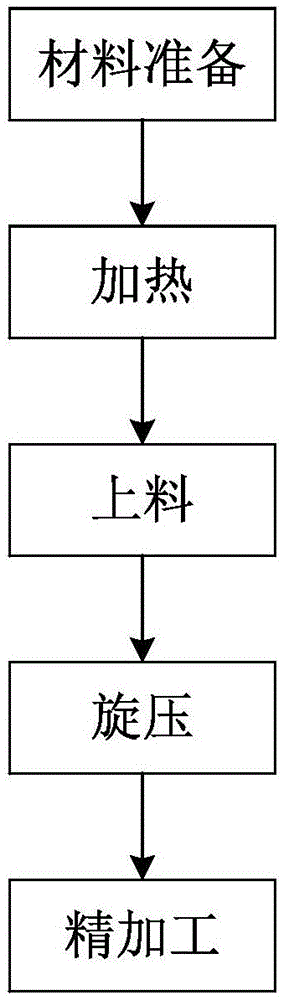

Brute-force hot-spinning accurate plastic forming method for hollow train shaft workblank

ActiveCN105081041AReduce processing workloadHigh forming precisionVehicle componentsMaterials preparationBrute force

The invention relates to a brute-force hot-spinning accurate plastic forming method for hollow train shaft workblank and belongs to the technical field of plastic forming of long-shaft parts. According to the brute-force hot-spinning accurate plastic forming method, the problems that hollow train shaft moulds are difficult to manufacture and complex in manufacturing process are solved. The brute-force hot-spinning accurate plastic forming method comprises the steps of material preparing, heating, feeding, spinning and refining. By means of a brute-force hot-spinning technique, the rotating speed of work pieces, the feeding speed of a rotary wheel and the axial moving speed of a rotary wheel frame are controlled by a numerical controlling technique. Thus, high-accuracy hollow train shaft workblank can be obtained in a spinning manner, and quick accurate plastic forming of the hollow train shaft workblank can be achieved. The brute-force hot-spinning accurate plastic forming method is simple in manufacturing procedure, good in metal fiber flow direction, small in machining allowance, high in material utilizing rate, mouldless in forging, low in manufacturing cost and suitable for large batch production of various specifications of hollow train shafts.

Owner:QINGDAO ZHONGTIANPENG FORGING MFG CO LTD

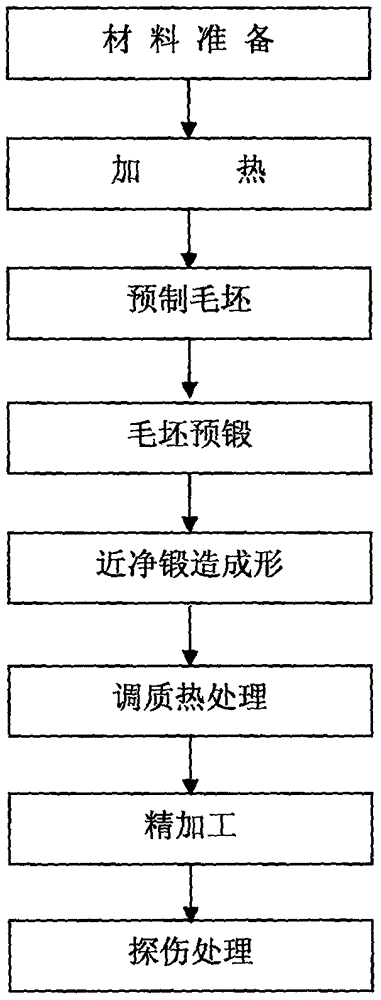

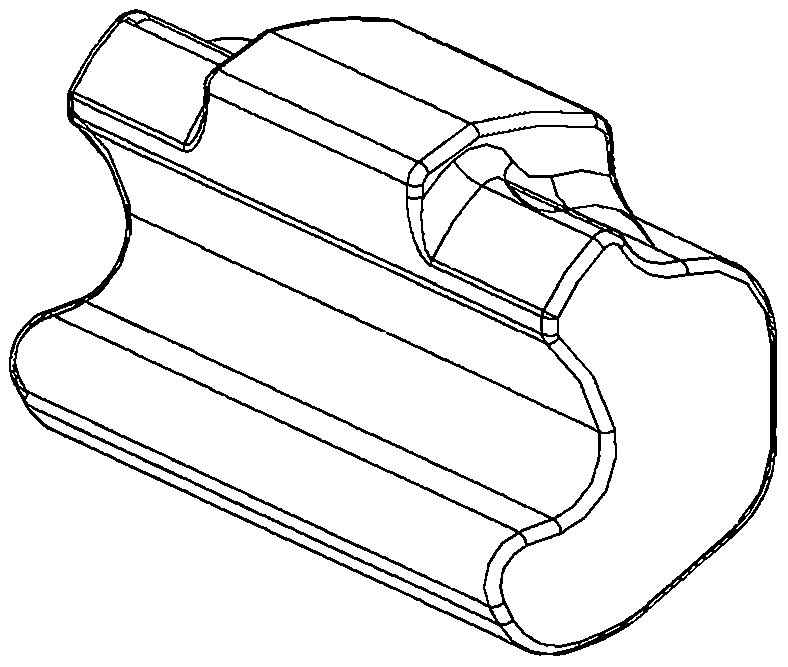

Near-net forging forming method of railway vehicle coupler knuckle

ActiveCN106077380AHigh forming precisionNo machining process requiredMetal-working apparatusMaterials preparationHigh volume manufacturing

The invention discloses a near-net forging forming method of a railway vehicle coupler knuckle. The problems that forging forming of the railway vehicle coupler knuckle is difficult, and the machining and manufacturing process is complex are solved. The near-net forging forming method comprises the steps of material preparation, heating, prefabrication of blanks, preforging, closed die-forging, waste heat quenched-tempered heat treatment, finish machining, flaw detection and the like. A closed die-forging technology is adopted so that near-net forming of the coupler knuckle can be achieved, energy and materials are saved, the outer contour shape and size do not need to be machined, and the utilization ratio of the materials can reach 92% or above. In the whole forming process, workpieces are always in a three-dimensional stress state, and products have a compact structure, high toughness, good fatigue performance and long service life. The defects of air holes, shrinkage porosity, inclusions, cracks and the like in existing casted coupler knuckles are overcome, and the problems of complex process and difficult forming in the existing coupler knuckle forging manufacturing process are solved. The near-net forging forming method is simple in manufacturing process, high in material utilization rate and suitable for mass production and manufacturing of railway vehicle coupler knuckle products of various types.

Owner:JILIN UNIV +1

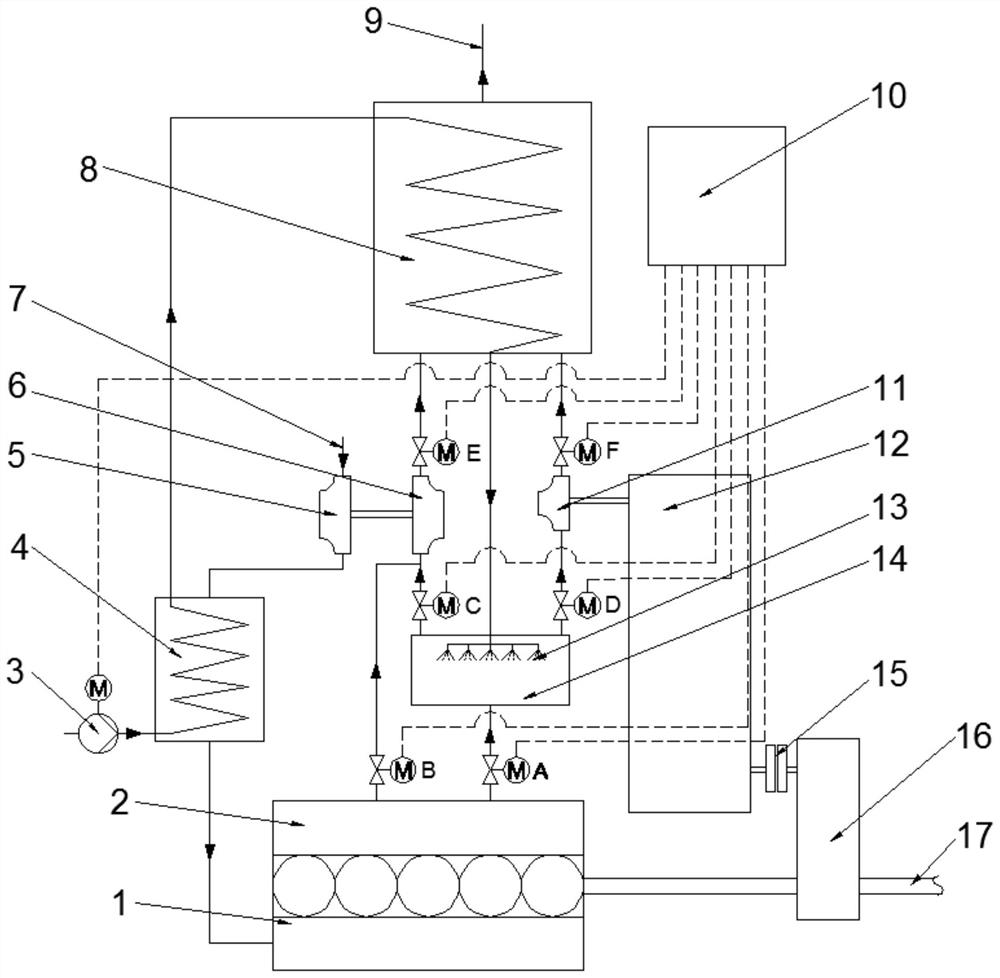

Waste heat comprehensive energy recovery device for diesel engine

PendingCN112392626ALower exhaust gas temperatureIncrease external output powerInternal combustion piston enginesExhaust apparatusEnergy recyclingEvaporator

The invention provides a waste heat comprehensive energy recovery device for a diesel engine, and belongs to the technical field of energy recovery. When the waste heat comprehensive energy recovery device is used, water firstly absorbs heat through a pressurized air heat exchanger and then enters a flue gas heat exchanger to further absorb flue gas heat, generated steam or a generated steam-watermixture is atomized through a spray head, and then enters an evaporator to be mixed with high-temperature flue gas from a smoke exhaust main pipe of the diesel engine to be quickly vaporized into water vapor, on one hand, a mixture of the flue gas and the water vapor drives a waste gas turbocharger to provide supercharged air for the diesel engine, and on the other hand, the mixture drives a power turbine is driven to work; and energy recovered by the power turbine is finally fed back to an output shaft of the diesel engine through a gear transmission device, so that the energy is effectivelyutilized. The system can recycle supercharged air, lubricating oil and exhausted flue gas waste heat energy of the diesel engine to the maximum extent, the exhausted flue gas temperature of the diesel engine is effectively reduced, the proper environment temperature is provided for tail gas desulfurization of the diesel engine, the external output power of the diesel engine is increased, and thefuel consumption rate of the diesel engine is reduced.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

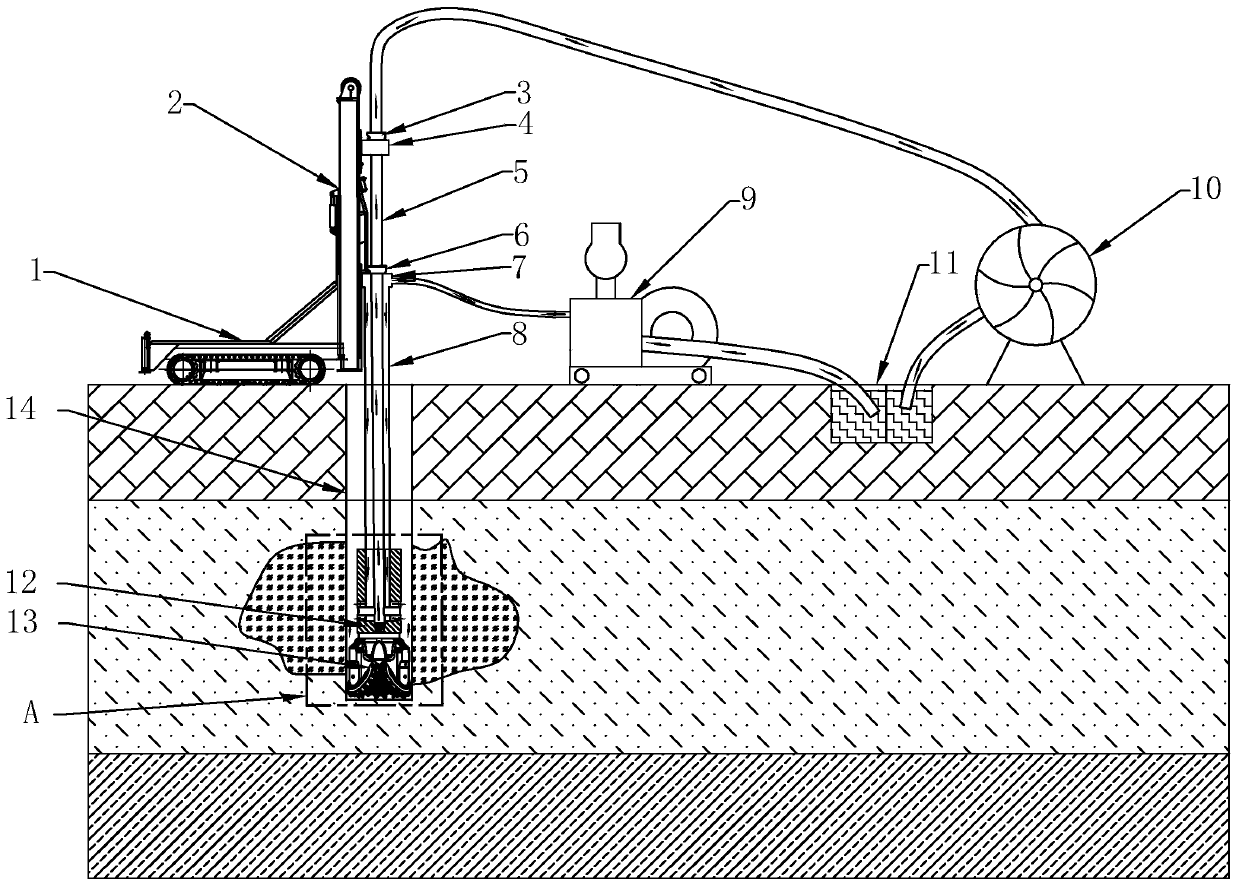

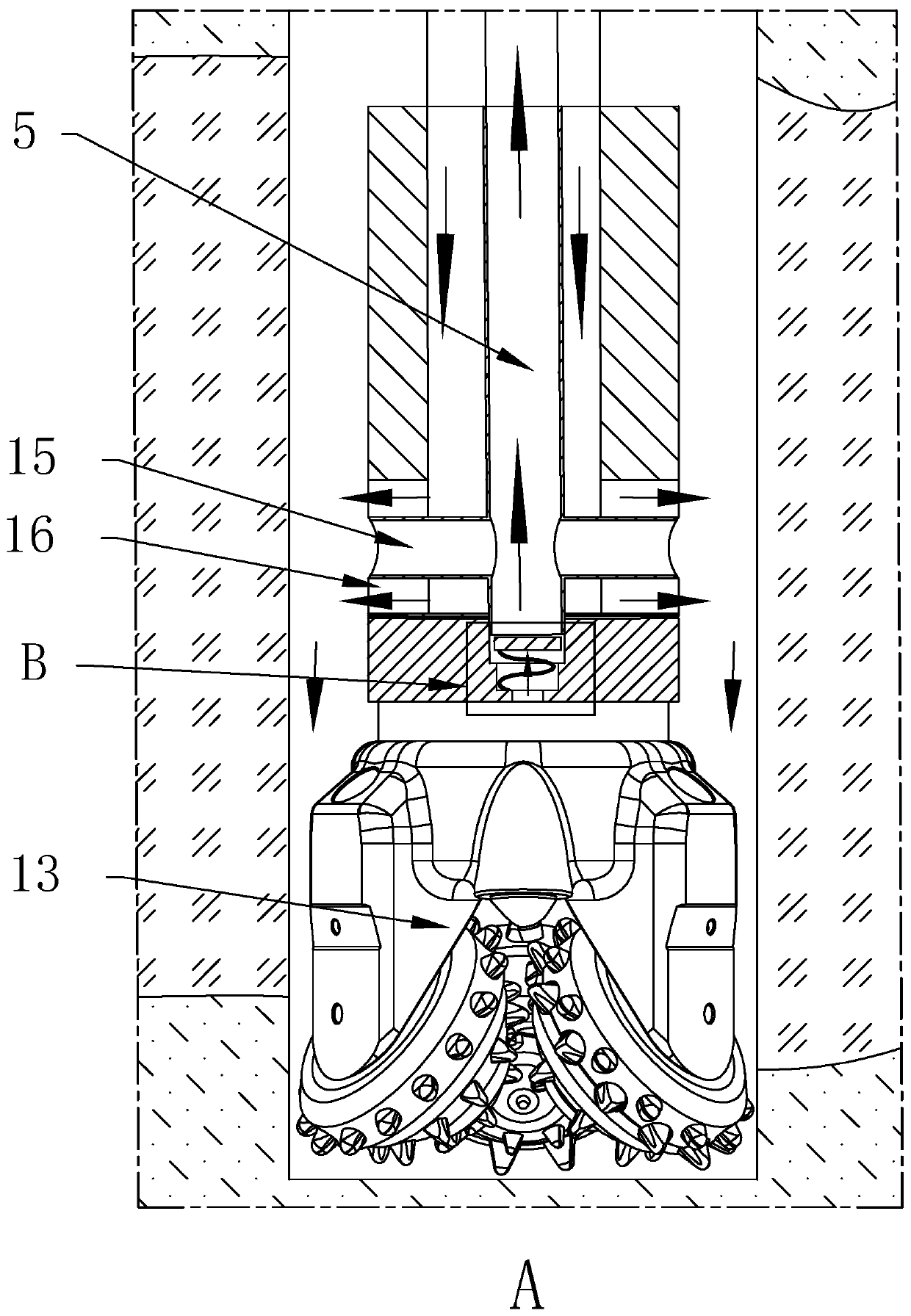

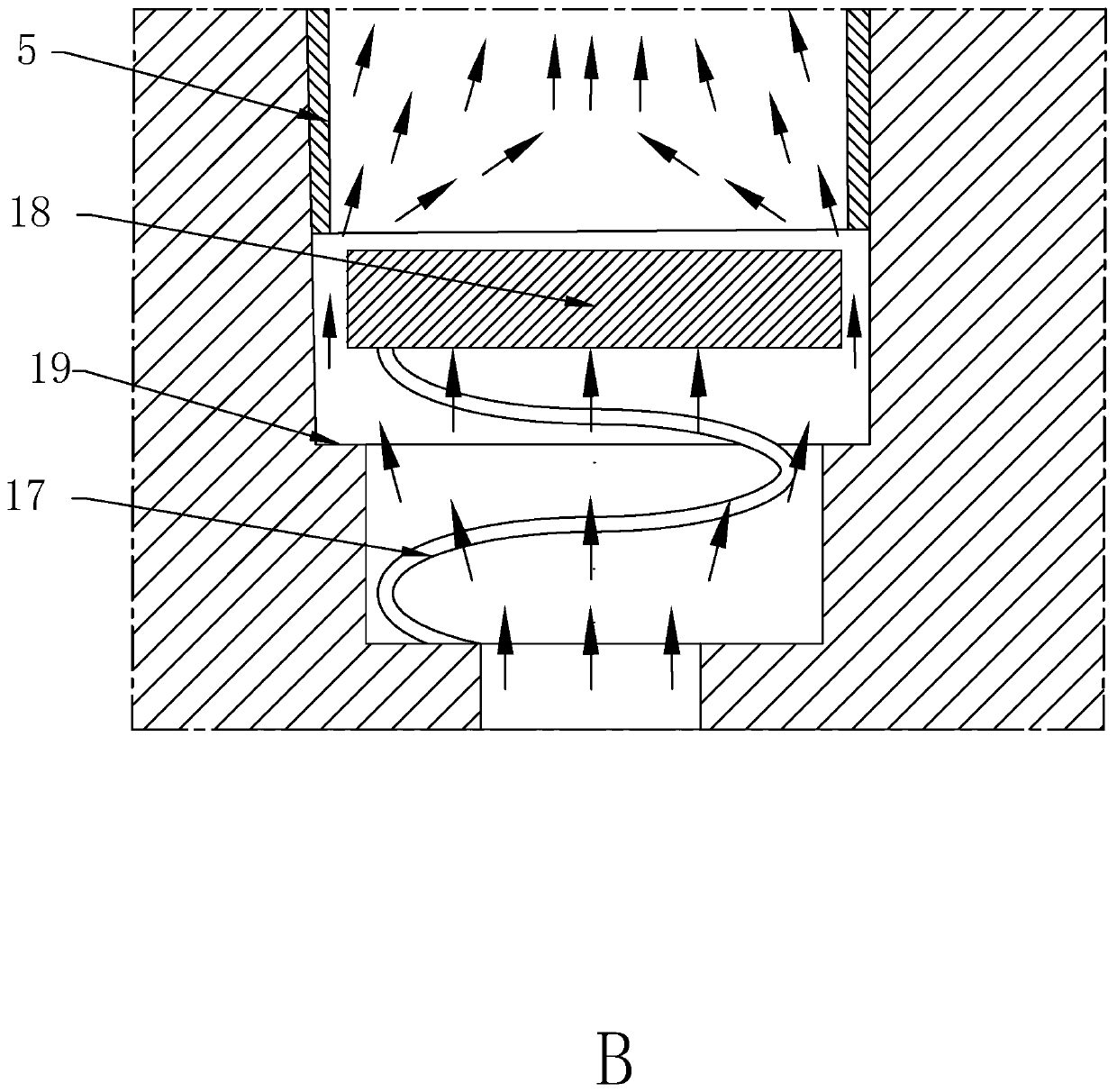

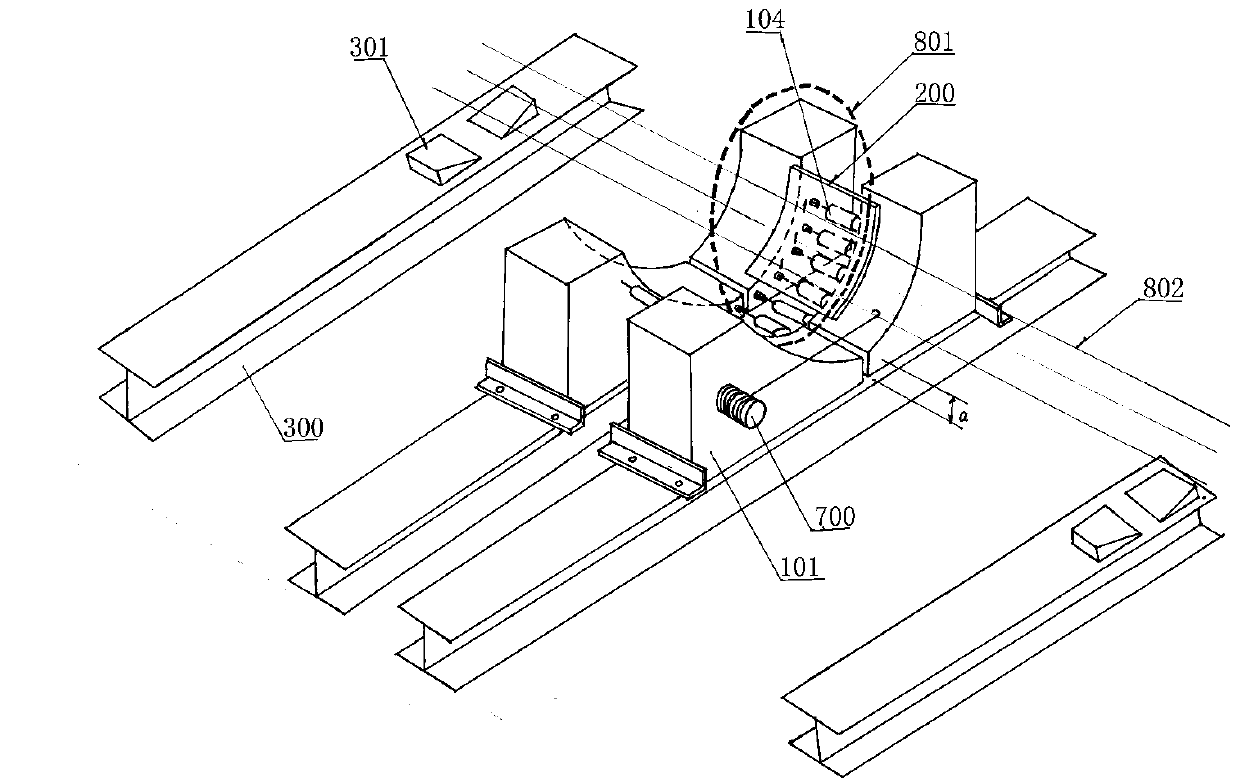

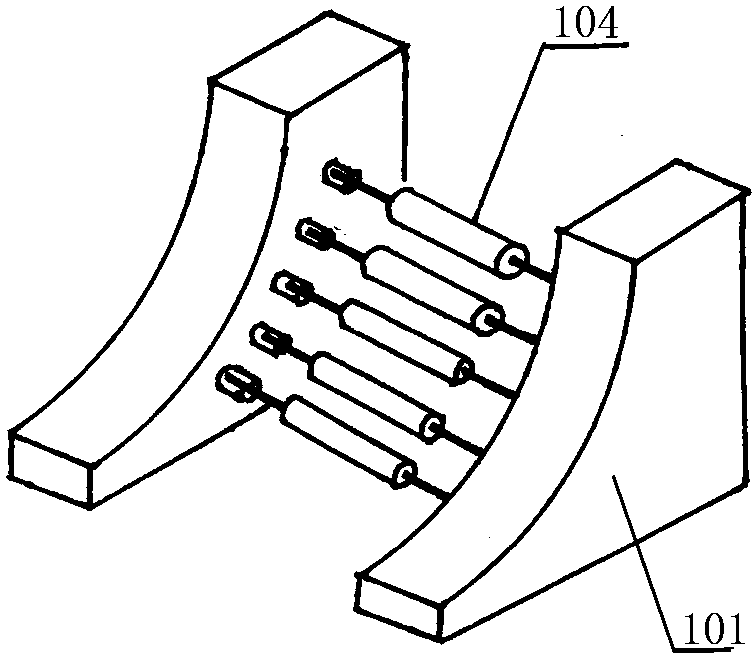

Rotary excavating drilling system and soil and underground water in-situ repair process adopting same

PendingCN110761713ASimple equipmentLess auxiliary equipmentDerricks/mastsContaminated soil reclamationDrilling systemEnvironmental geology

The invention discloses a rotary excavating drilling system and a soil and underground water in-situ repair process adopting the same. According to the rotary excavating drilling system, a rotary excavating and guide drilling integrated drilling machine is adopted to complete different angles of drilling and withdrawal rotary jet grouting operation. Through the repair process, adopted equipment issimple, and fewer accessory devices are adopted. The same rotary excavating drilling machine can implement the vertical jet injection process and the multi-branch well withdrawal jet grouting process, and the two processes can be selected according to the distribution difference of polluted spaces. The vertical jet injection process is selected to implement in-situ injection repair on scattered spot polluted sites. The multi-branch well withdrawal jet grouting process is selected to implement in-situ injection repair on large-area surface polluted sites. The spot-surface combined space stereoscopic repair effect can be achieved. Compared with the vertical injection process, the multi-branch well repair process has the advantages that single-pass long-distance and large-area repair can berealized, the repair efficiency can be improved, the repair period can be shortened, and the repair cost can be reduced.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

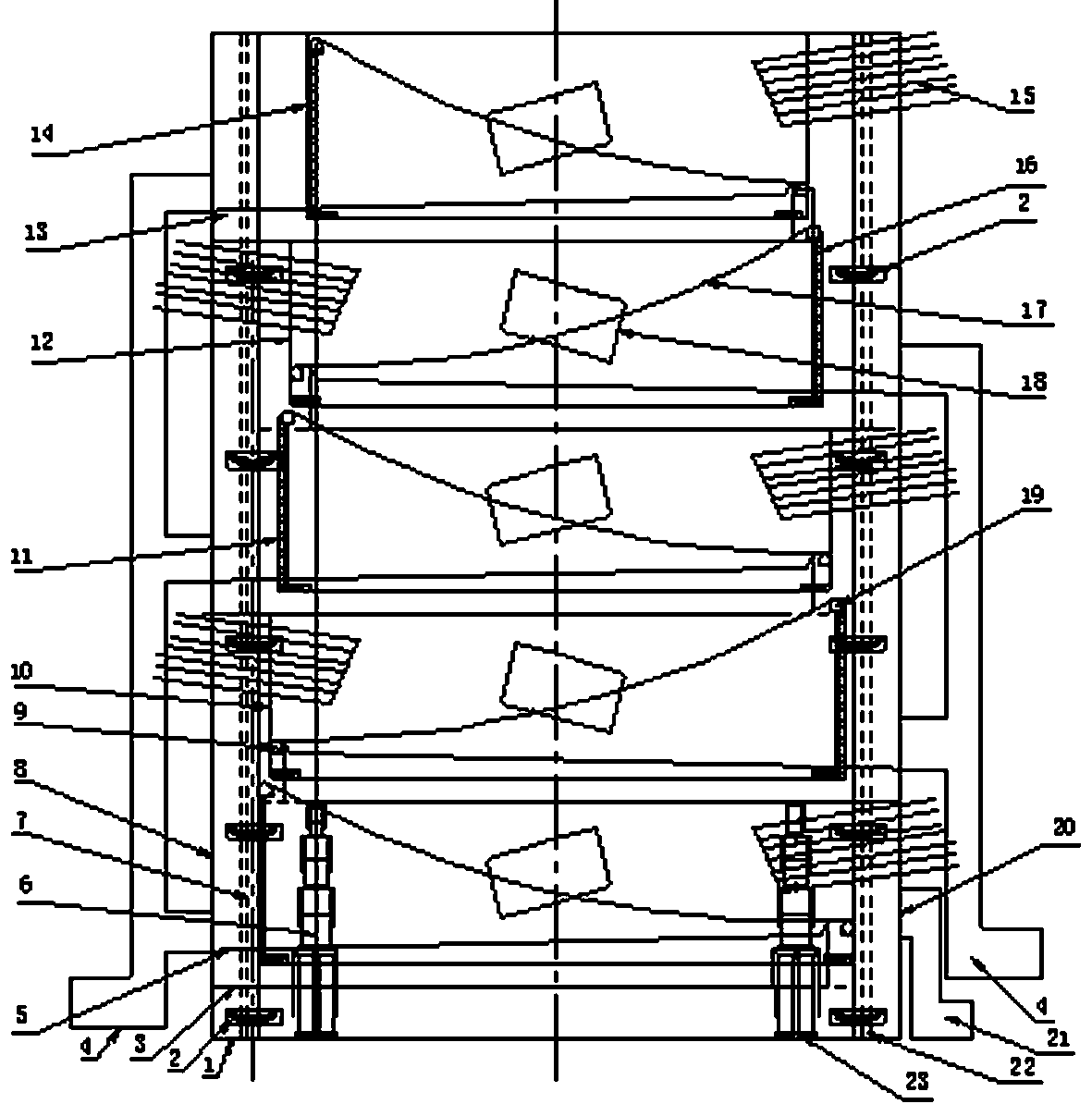

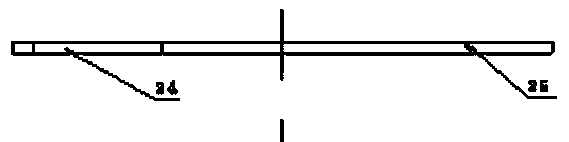

Direct strong convection board used for hood-type annealing furnace and automatically suitable for cold-rolling strip steel bandwidth and working method thereof

InactiveCN101892377AGood thermal cycle performanceEliminate stickingFurnace typesHeat treatment furnacesShielding gasStrip steel

The invention relates to a direct strong convection board used for a hood-type annealing furnace and automatically suitable for a cold-rolling strip steel bandwidth and a working method thereof. The direct strong convection board comprises a flow guide pipe and a flow guide plate with a flow guide channel. The direct strong convection board is characterized by the thermal cycle paths of sequentially passing through a heating hood, an inner hood, protective gas inside a furnace after middle temperature rising and convection, an outer ring of a steel coil and a core part of a thermal radiation steel coil in the heating process and sequentially passing through a cooling hood, the inner hood, the protective gas inside the furnace after middle temperature decreasing and convection, the outer ring of the steel coil and the core part of the thermal radiation steel coil in the cooling process. The direct strong convection board fulfills the aims of enforcing middle convection effect and reducing the unbalance of inner and outer temperatures.

Owner:SHANDONG IRON & STEEL CO LTD

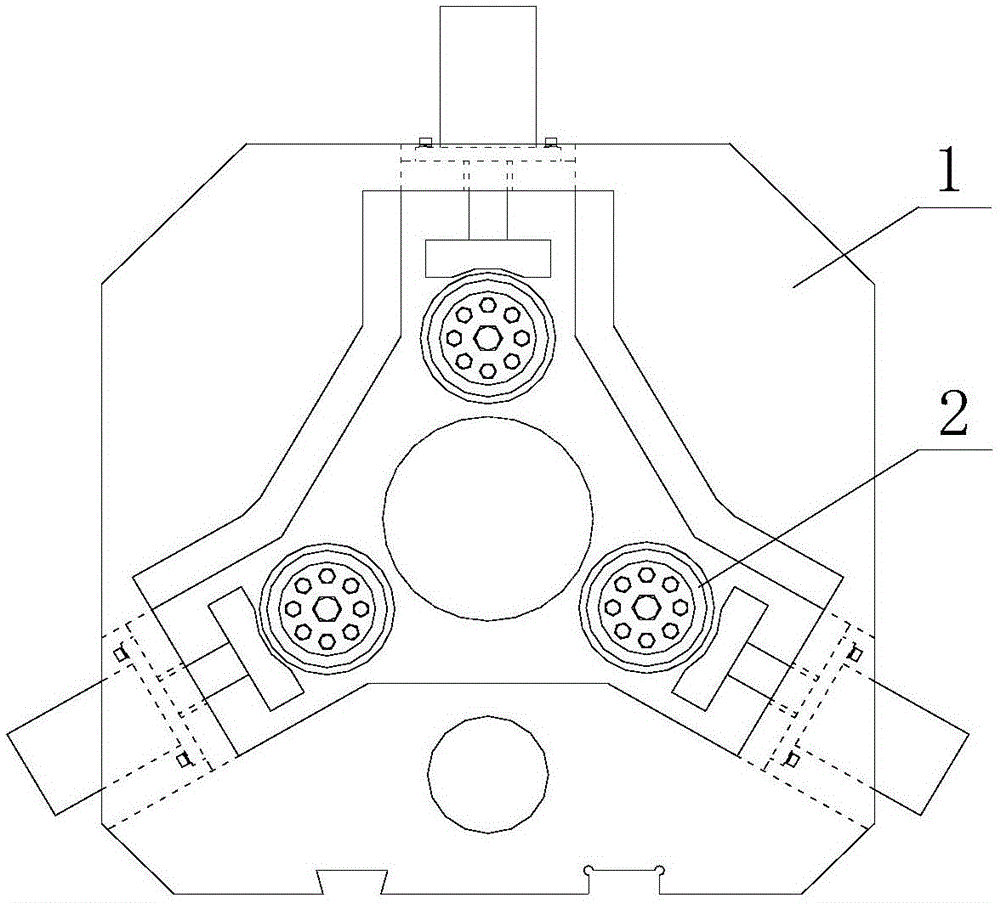

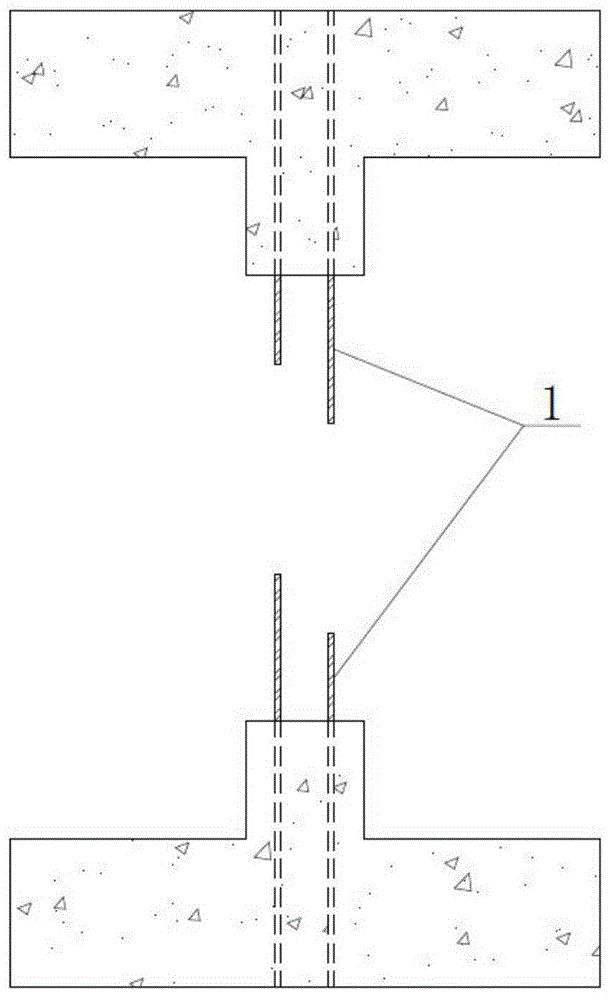

Fast steel bar straightener and method for utilizing straightener for straightening steel bars

The invention provides a fast steel bar straightener and a method for utilizing the straightener for straightening steel bars, relates to the technical field of steel bar machining, and aims at the problems that when a reserved steel bar straightening method frequently used in an existing reverse construction method is used, the straightening efficiency is low, the straightening effect is poor, and the adverse effect on the mechanical property of the reserved steel bars is caused. The straightener comprises a sleeve and a hydraulic device which are communicated. At least two hydraulic jack assemblies are arranged on the inner wall of the sleeve. Each hydraulic jack assembly is provided with three separated hydraulic jacks uniformly distributed in the radial direction of the axis and communicated with the hydraulic device. The separated hydraulic jacks can be ejected in under the effect of the hydraulic device, so that the steel bars penetrating through the sleeve are hooped and straightened. The method comprises the steps that 1, the reserved steel bars penetrate through the sleeve so as to be enclosed among the separated hydraulic jacks; 2, the reserved steel bars are extruded, hooped and straightened gradually by the separated hydraulic jacks; 3, the step 1 and the step 2 are repeated to gradually straighten the reserved steel bars from the fixed ends to the free ends.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

Combined multifunctional steel bar cage manufacturing framework and manufacturing method

The invention belongs to the technical field of civil engineering and discloses a combined multifunctional steel bar cage manufacturing framework and manufacturing method. The combined multifunctionalsteel bar cage manufacturing framework comprises a framework body, a main rib positioning plate and bearing beams. The framework body is provided with arc moulding beds matched with a steel bar cageto be manufactured; the main rib positioning plate rolls in a matching manner or is slidably supported on the moulding beds, main rib placing grooves are distributed in the main rib positioning plate,and main ribs of the steel bar cage are matched in the main rib placing grooves; and the bearing beams are used for supporting and steadying the steel bar cage in a welding process. The combined multifunctional steel cage manufacturing framework is reasonable in design, steady in support, convenient for machining and rapid in disassembly and assembly, not only can be used in a machining shed, butalso can be used nearby a construction site and a pile site for directly hoisting the steel bar cage or steel bar framework to be directly in position.

Owner:HENAN HIGHWAY ENG GROUP

Quantitative test method for endogenous excitation load of equipment under joint action of unbalanced turbulence force and unbalanced turbulence moment

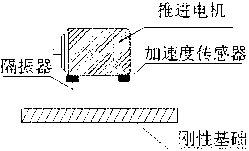

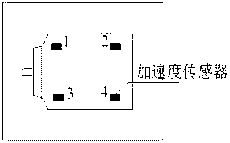

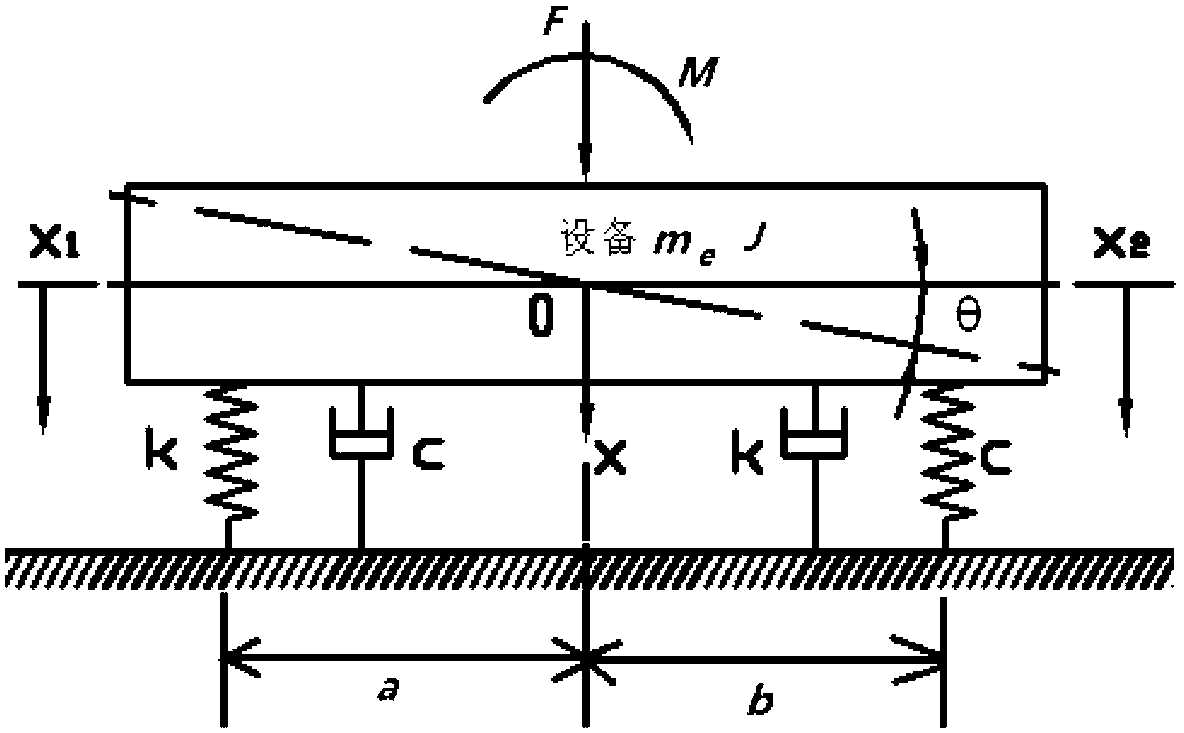

The purpose of the invention aims to provide a quantitative test method for endogenous excitation load of equipment under a joint action of unbalanced turbulence force and unbalanced turbulence moment. The method comprises the following steps: selecting a group of two same vibration isolators to be respectively arranged on machine legs of tested equipment, fixing the vibration isolators onto a rigid rack, and installing four acceleration transducers in the vibration isolator positions of the machine legs of the tested equipment; starting the tested equipment, and respectively obtaining signals of two groups of acceleration transducers to obtain the average velocity value of two groups; replacing the two vibration isolators, starting the tested equipment, respectively obtaining the signals of the two groups of acceleration transducers to obtain the average velocity value of the two groups, and therefore obtaining the unbalanced turbulence force of the tested equipment, the unbalanced turbulence moment of the equipment, the equivalent mass of the equipment and the equivalent inertia moment of the equipment. The quantitative test method has the characteristics of good stability and controllability, low cost, less auxiliary equipment, simplicity and convenience.

Owner:HARBIN ENG UNIV

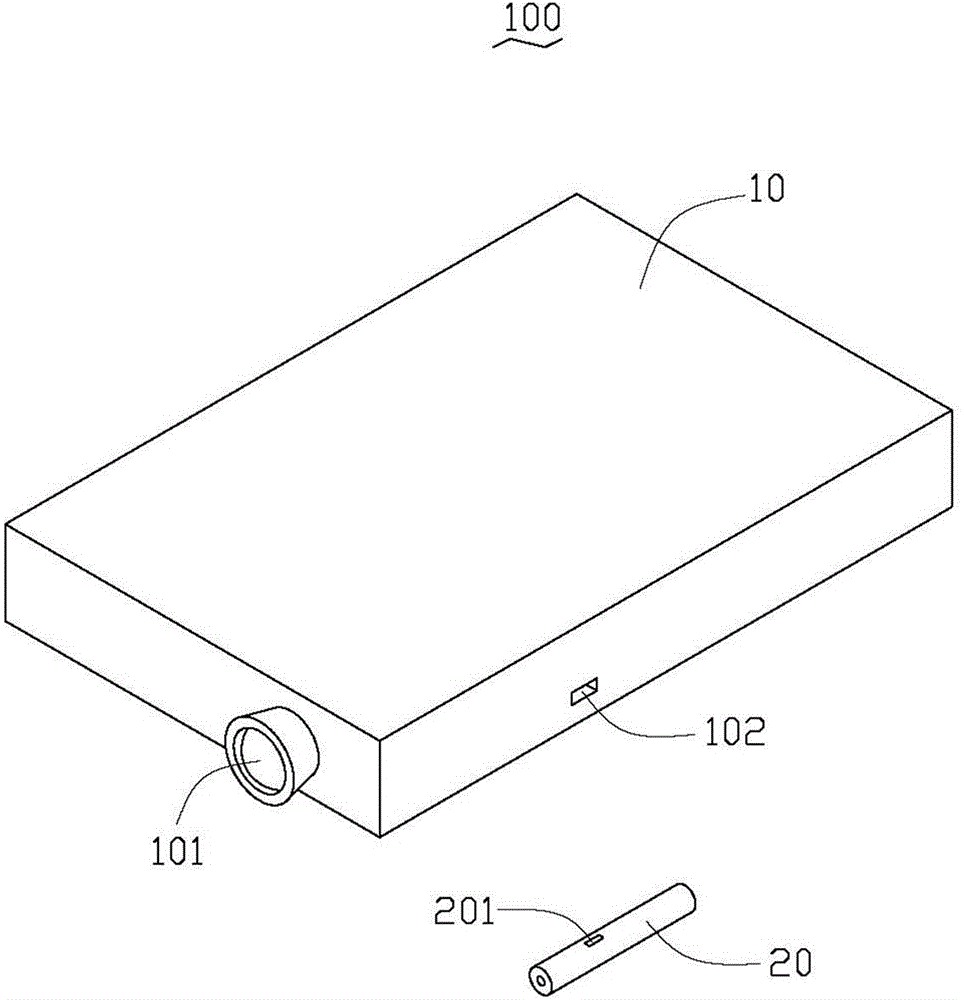

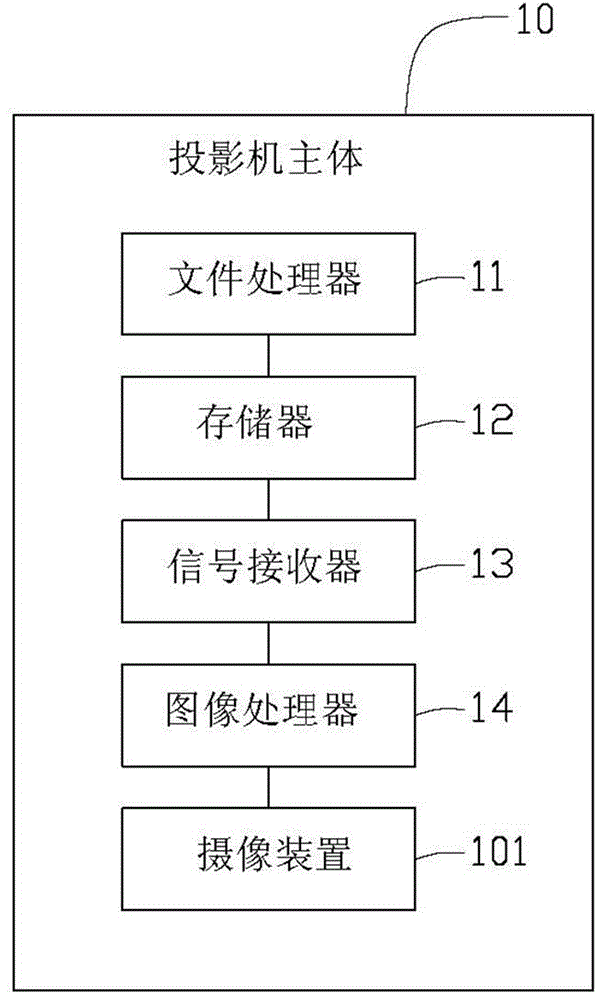

Projection system and projection method

InactiveCN104796675ALess auxiliary equipmentSimple structurePicture reproducers using projection devicesProjection systemInfrared tracking

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Device for continuously performing primer spraying, drying and electroplating in vacuum chamber

InactiveCN102226267AReduce processSave time and costSpraying apparatusVacuum evaporation coatingPulp and paper industryVacuum chamber

The invention discloses a device for continuously performing primer spraying, drying and electroplating in a vacuum chamber. The device comprises the vacuum chamber (1) and a vacuum pump (2) connected with the vacuum chamber (1), wherein the inside of the vacuum chamber (1) is provided with an electroplating platform (3) and a rotational stand (5); and the electroplating platform (3) is provided with two rows of electroplating electrodes (4). The device is characterized in that the inside of the vacuum chamber (1) is provided with at least one nozzle (6); the nozzle (6) is connected with a paint supply system through a pipe, and the paint supply system is outside the vacuum chamber (1); and the electroplating platform (3) is provided with at least one dryer (7). By adopting the device, the primer spraying, drying, film coating, finish spraying and drying processes of the traditional technology can be completed in the vacuum chamber, the processes, auxiliary equipment and site can be reduced and the cost can be lowered; and the device is good for the health of workers and the problem of environmental pollution can be eliminated.

Owner:谢德培

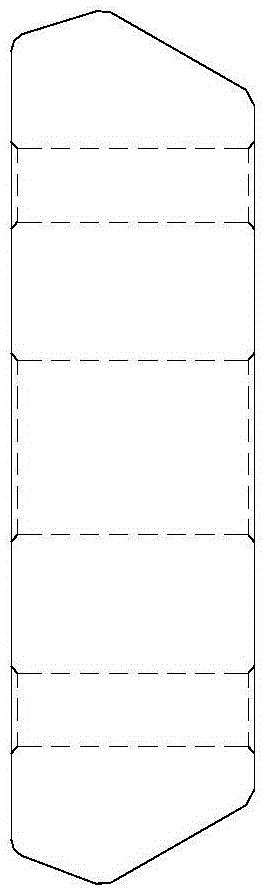

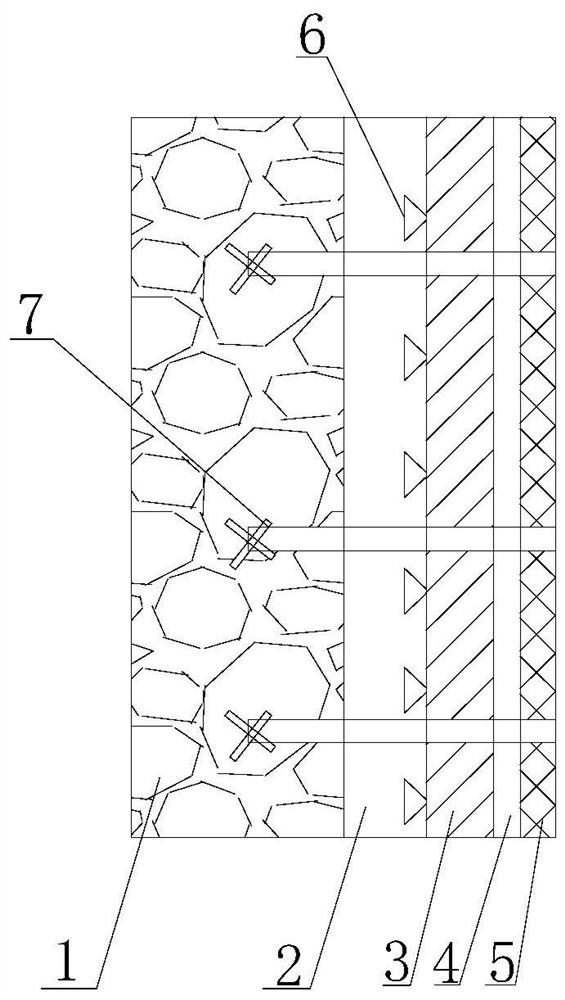

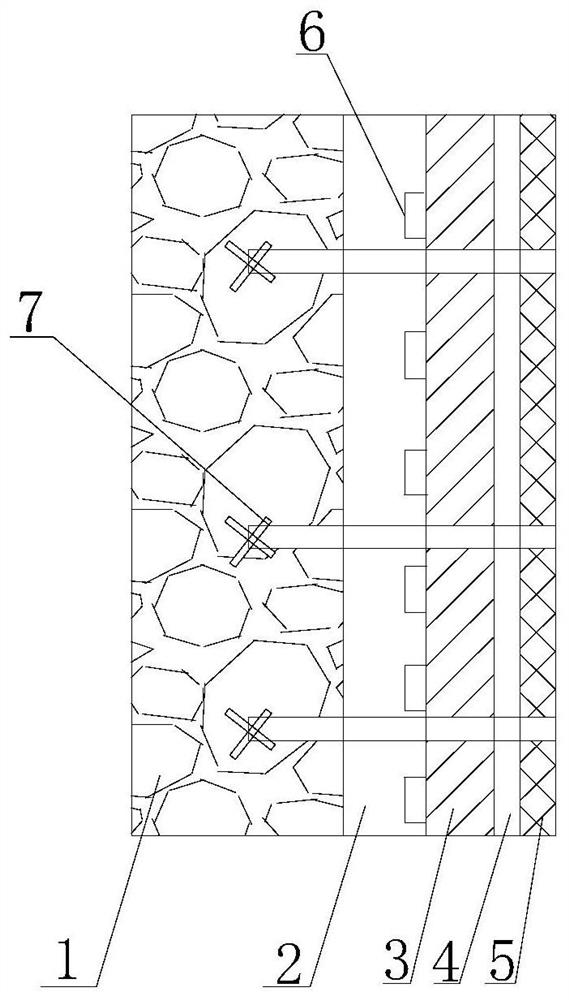

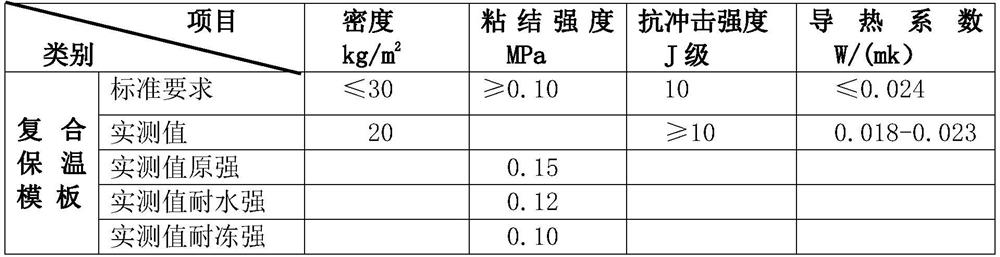

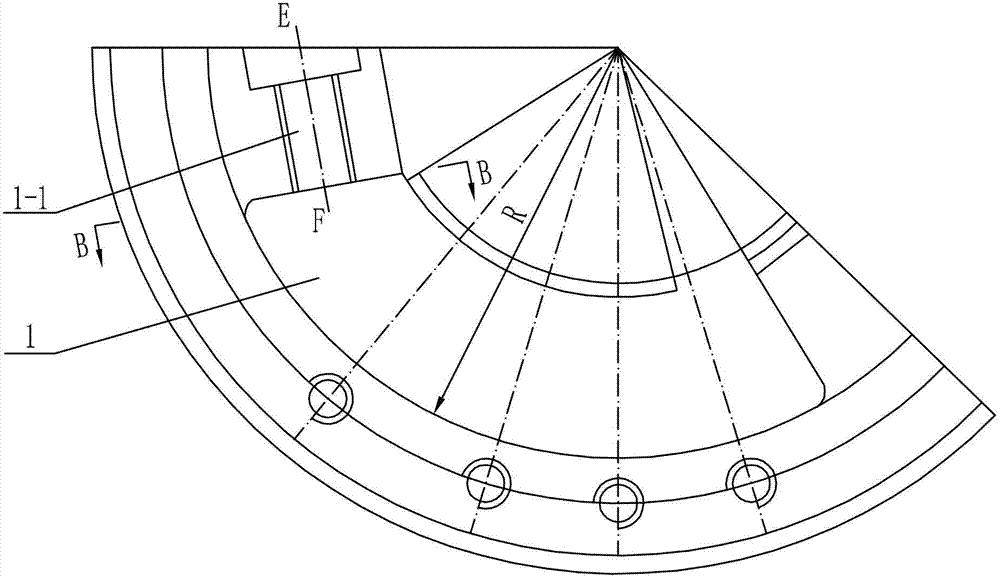

Light, fireproof and low-heat-conducting-property integrated disassembly-free composite heat preservation formwork and preparation process thereof

PendingCN112761283ALow thermal conductivityUse thinWallsClimate change adaptationMortise and tenonHeat conservation

The invention belongs to a light, fireproof and low-heat-conducting-property integrated disassembly-free composite heat preservation formwork and a preparation process thereof. The light, fireproof and low-heat-conducting-property integrated disassembly-free composite heat preservation formwork comprises an inner protective layer connected with a concrete pouring wall, wherein a heat preservation material layer, an inorganic material protective layer and an outer anti-cracking layer are sequentially arranged outside the inner protective layer; the inner protective layer and the heat preservation material layer are connected in a reinforced mode through a mortise and tenon joint reinforcing structure, and the inorganic material protective layer and the outer anti-cracking layer are connected in a reinforced mode through a mortise and tenon joint reinforcing structure; and the outer anti-cracking layer, the inorganic material protective layer, the heat preservation material layer and the inner protective layer are fixedly connected with the concrete pouring wall through connecting anchor bolts. The light, fireproof and low-heat-conducting-property integrated disassembly-free composite heat preservation formwork has the advantages of being reasonable in structural design, small in heat conductivity coefficient, low in weight, convenient to construct and good in fireproof performance.

Owner:河南省澳科保温节能材料技术开发有限公司

Ladder-shaped internal threaded hole processing method of steam turbine outer ring part

ActiveCN102848032ALess auxiliary equipmentEasy to processThread cutting machinesPower stationEngineering

The invention provides a ladder-shaped internal threaded hole processing method of a steam turbine outer ring part and relates to a processing method of the steam turbine outer ring part. The processing method solves the problems that in the ladder-shaped internal threaded hole processing process of the steam turbine outer ring part of the existing power station, a single screw tap is adopted for drilling, the interference between the single screw tap and the circular arc surface exists, the processed circular arc surface is easily damaged, the screw tap in the multi-cone structure is adopted for processing the ladder-shaped internal threaded hole, the processing complexity is caused, and the processing efficiency is low. The processing method has the main steps of 1, outer ring part installation and clamping alignment; 2, bottom hole drilling; 3, threaded turning of the ladder-shaped internal threaded hole; and 4, tolerance zone turning of the ladder-shaped internal threaded hole. The processing method is used for the processing of the ladder-shaped internal threaded hole of the steam turbine outer ring part.

Owner:HARBIN TURBINE +1

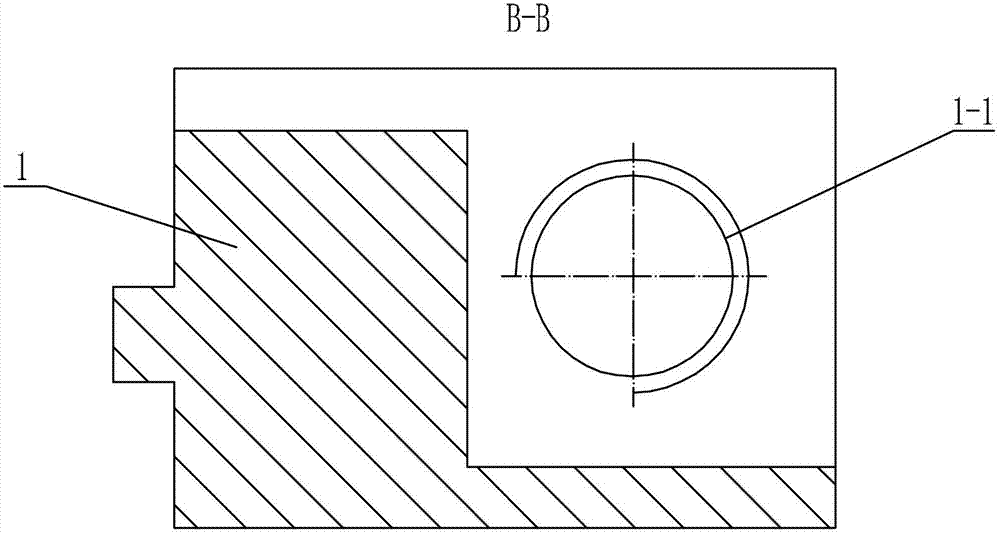

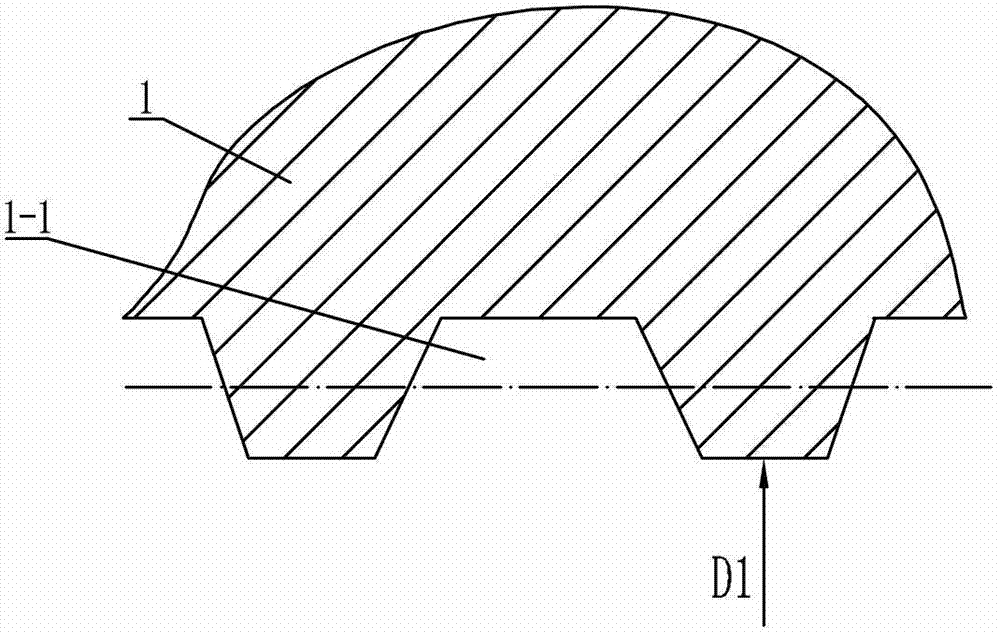

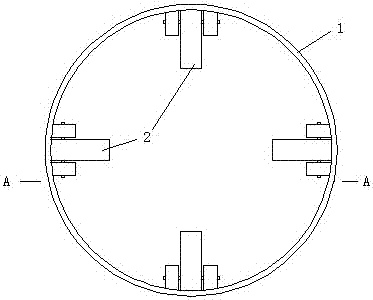

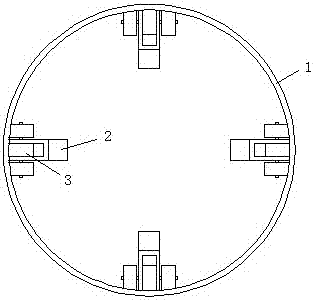

Buckle pipe type pile extractor

InactiveCN107083773AQuick and easy pile extractionLess auxiliary equipmentBulkheads/pilesEngineeringBuilding construction

The invention relates to a buckle pipe type pile extractor and relates to technical field of civil construction equipment. The buckle pipe type pile extractor is capable of reducing construction cost and shortening the construction period and comprises a buckle pipe and four pile pulling clamping blocks which are pivoted on the lower portions of the inner walls of the buckle pipe and can pivot vertically; the buckle pipe is a straight pipe with open upper and lower ends; the four pile pulling clamping blocks are symmetrically arranged in the circumferential direction of the buckle pipe; four limiting clamping blocks are fixed to the lower portions of the inner walls of the buckle pipe and are arranged under the four pile pulling clamping blocks correspondingly; and when each pile pulling clamping block pivots to the position where the length direction is perpendicular to the central axis of the buckle pipe, each pile pulling clamping block abuts against the corresponding limiting clamping block under the pile pulling clamping block, and the inner end of each pile pulling clamping block is located on the inner side of the corresponding limiting clamping block. The pile pulling device provided by the invention is suitable for pulling out waste pipe piles buried in the soil body.

Owner:铧巍牛咨询管理(上海)有限公司

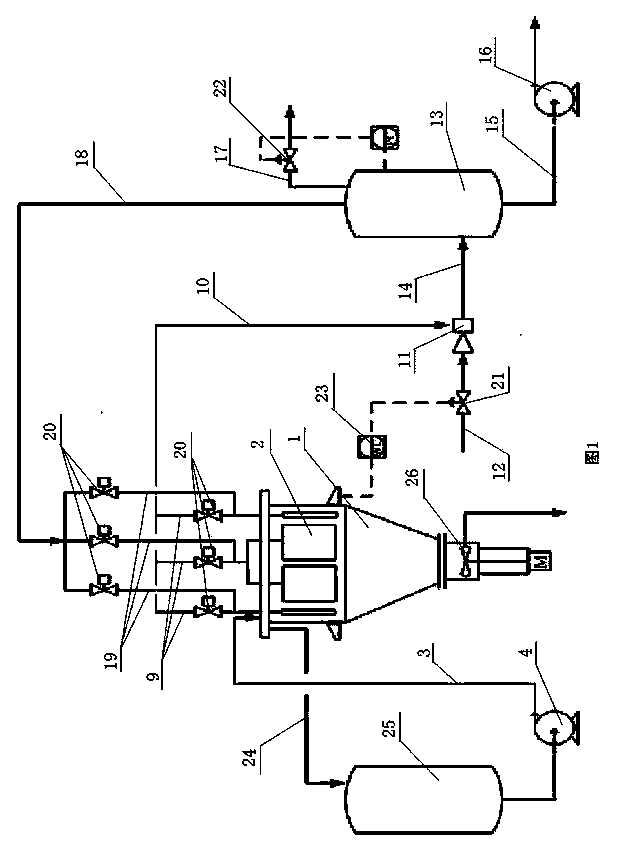

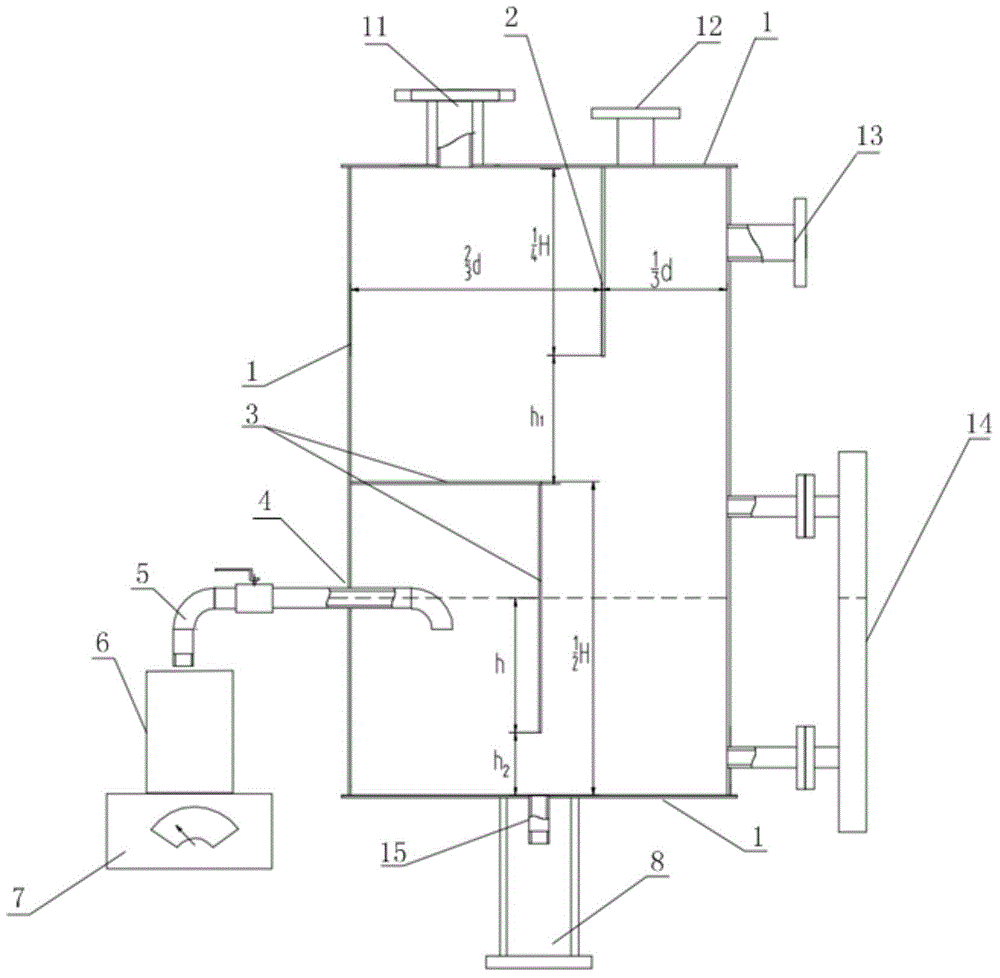

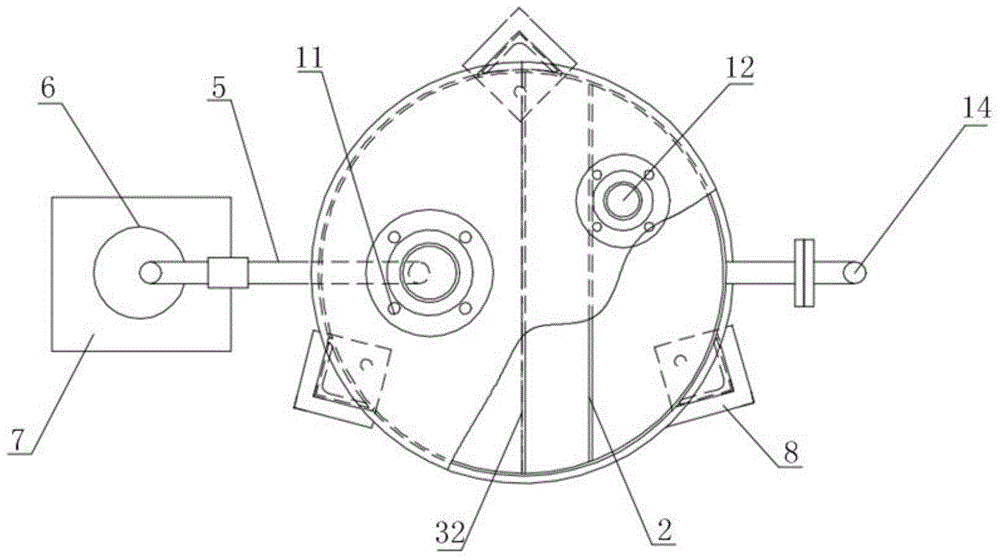

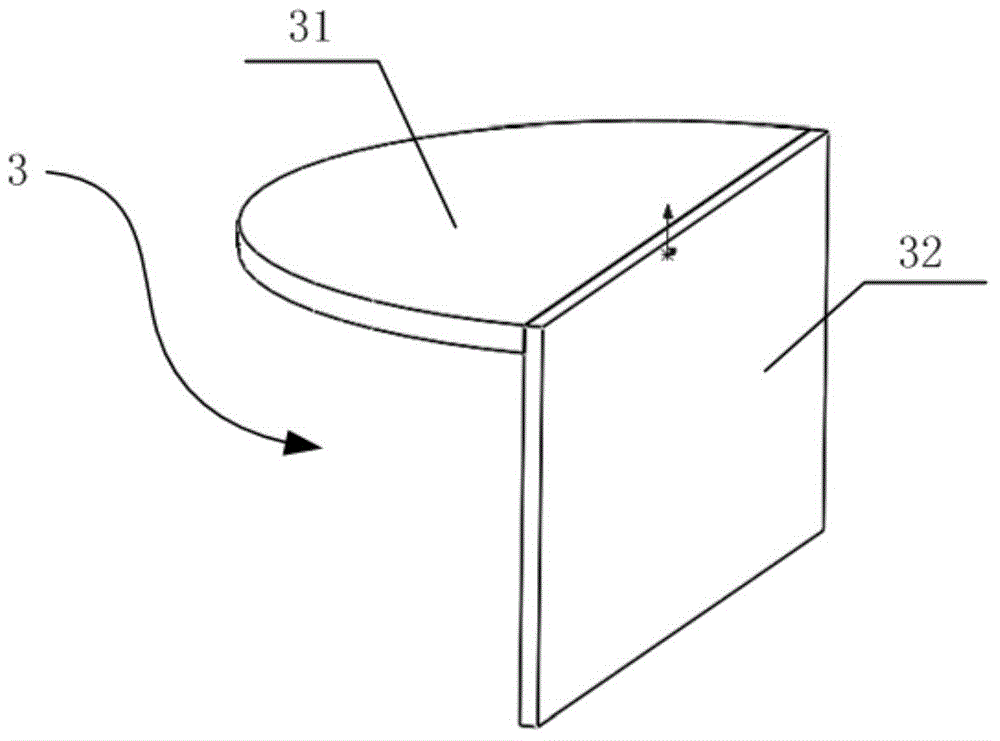

Apparatus for rapidly increasing sediment concentration of sand silo/thickener and improving fluidization property

InactiveCN104958935AFluid stabilitySolve the problem that the sand cannot reach the required concentrationSettling tanks feed/dischargeUltrasound - actionAcoustic wave

The invention relates to an apparatus for rapidly increasing sediment concentration of a mine vertical sand silo / deep-cone thickener and improving the fluidization property. The fluidization property of mortar discharged from the silo can be improved in a sound-field vibration way, and the concentration of the discharged tailing sand can be increased. The apparatus utilizes vibration ultrasonic to act on a sedimentation area and a compression area of mortar in a vertical sand silo / deep-cone thickener. The apparatus comprises a sedimentation area sound wave system and a compression area sound wave system, wherein the sedimentation area sound wave system is used for vibrating the sand and guaranteeing the sediment speed, and the compression area sound wave system is used for improving the fluidization property of the mortar. The apparatus is simple in process flow, convenient to install and capable of maintaining the flow state of mortar inside the sand silo stable. The target pressing phenomenon of the deep-cone thickener caused by the unfavorable control can be eliminated by utilizing the vibration ultrasonic wave of a sound field.

Owner:UNIV OF SCI & TECH BEIJING

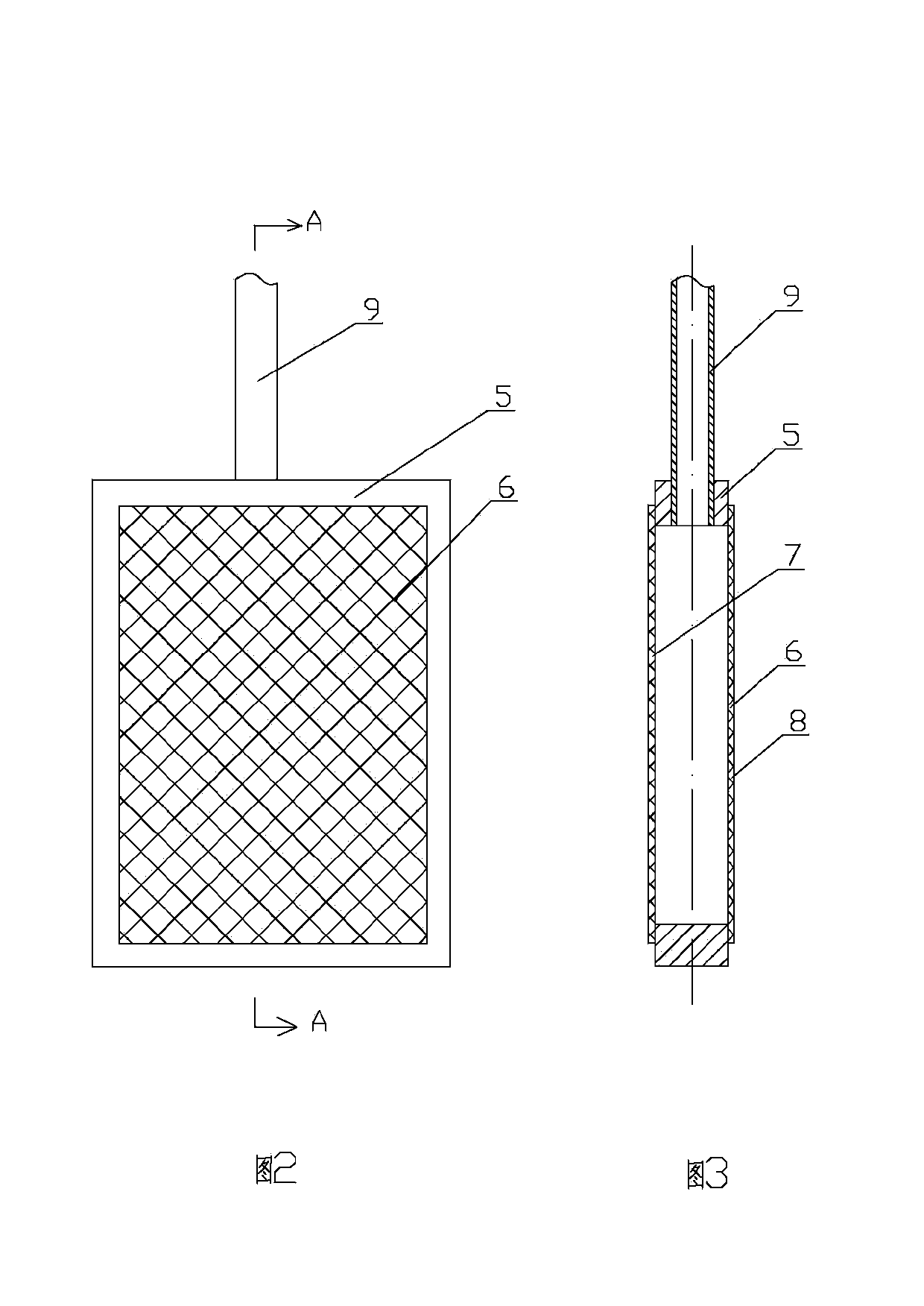

Automatic filter capable of controlling slurry density and application method thereof

ActiveCN103785211ASolve the problem of difficult to control moisture contentCompact and reasonable structureStationary filtering element filtersControl engineeringFilter press

The invention relates to the technical field of solid-liquid separation filter devices and provides an automatic filter capable of controlling the slurry density and an application method thereof. The automatic filter comprises a filter tank, filter rackets, a liquid outlet main pipe, an air ejector, a filtrate tank and a back flushing main pipe, wherein a feed pipe is fixedly installed at the upper end of the filter tank; a slurry pump is fixedly installed on the feed pipe; at least three filter rackets are fixedly installed in an upper inner cavity of the filter tank; each filter racket comprises a filter frame, a front filter screen and a rear filter screen; the front and rear filter screens are hermetically and fixedly installed on the front and rear sides of the filter frame respectively. The automatic filter has a reasonable and compact structure, is convenient to apply and manufacture, can achieve unattended operation through program control in the production process, is large in filter area, can achieve continuous production, basically needs fixed parts, has little auxiliary equipment, is convenient and reliable to use, is unnecessary to be removed and installed repeatedly, thus reducing the labor intensity, effectively solving the problem that the moisture contents of filter cakes of plate-and-frame filter presses are difficult to control and being higher in production efficiency.

Owner:新疆天利高新石化股份有限公司

Novel mortar spreading machine

InactiveCN110593537ARealize electronic control positioningRealize automatic feedingBuilding constructionsScreedReciprocating motion

The invention discloses a novel mortar spreading machine. The novel mortar spreading machine is more uniform in mortar spreading and achieves convenient mortar feeding, the mortar spreading width andheight can be adjusted, the structure is simple and compact, the number of auxiliary devices is small, and the novel mortar spreading machine has better adaptability to a small-sized construction site. The novel mortar spreading machine comprises a support assembly. A guide rail is installed on the support assembly. A material distribution hopper rack is arranged on the guide rail in a sliding fitmanner and connected with a drive device used for driving the material distribution hopper rack to conduct reciprocating motion along the guide rail. The lower side of the material distribution hopper rack is connected with a material hopper mechanism achieving automatic mortar discharge. The material hopper mechanism comprises a material distribution hopper and a pressing plate. The upper part of the material distribution hopper is open, and the lower part of the material distribution hopper is provided with a row of material discharge holes. A screed is installed below the material discharge holes. The screed is provided with comb teeth. The pressing plate is arranged in the material distribution hopper. The size of the plate face of the pressing plate is identical with the area of theopening on the upper part of the material distribution hopper. The pressing plate is used for pressing cement mortar in the material distribution hopper to the material discharge holes to be discharged. The pressing plate is connected with a locating mechanism controlling the position of the pressing plate.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

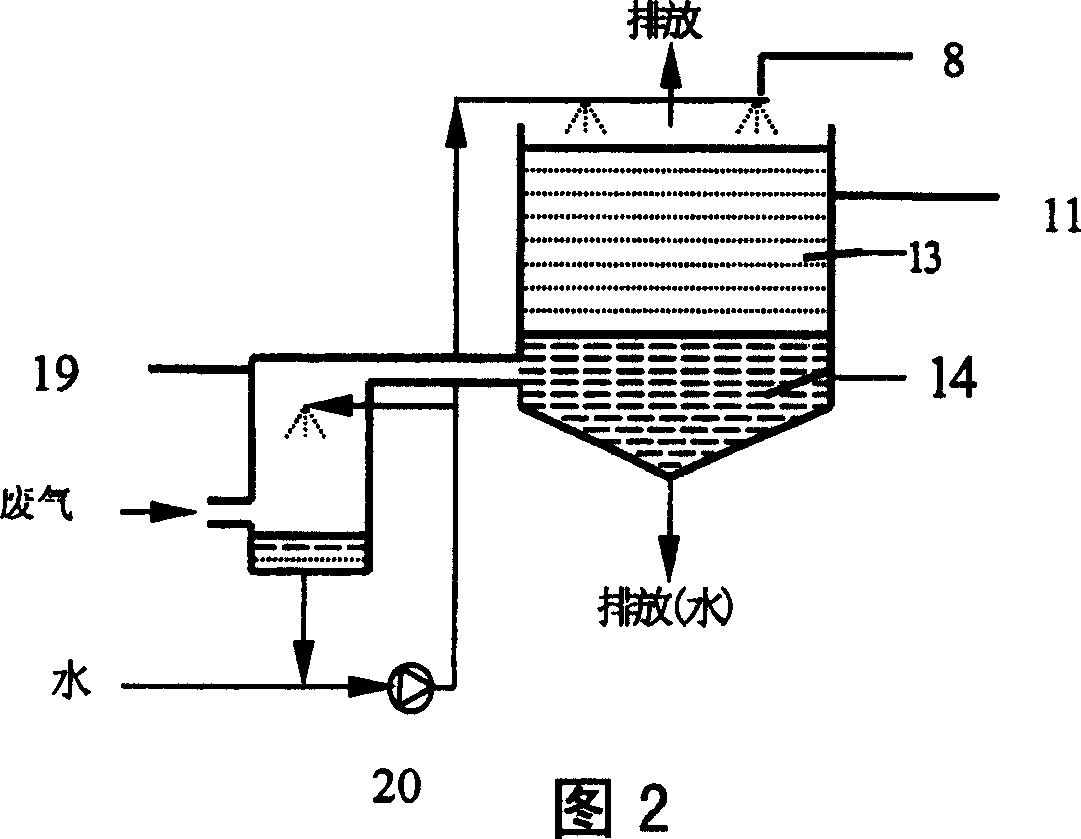

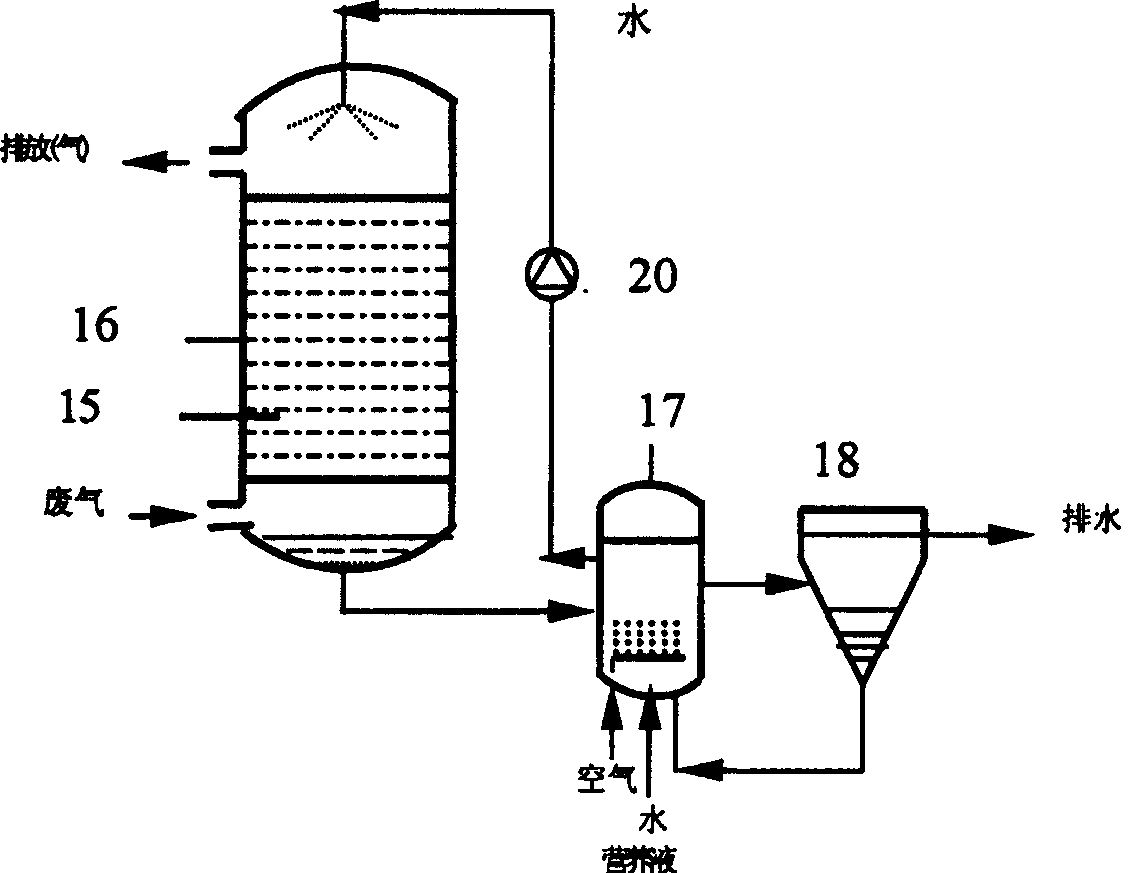

Waste gas treatment equipment for air film-biological reactor

InactiveCN1623631ALess auxiliary equipmentReduce energy consumptionDispersed particle separationAir quality improvementGas separationBioreactor

A gas film-type bioreactor system for treating waste gas is composed of a bioreactor, a gas separator, containing a gas film module and with concentrated gas flowing-back tube and gas outlet, and a drier. Said bioreactor containing filler in it has gas inlet, water outlet and gas outlet tube. Its advantage is through degradation of harmfull substance in waste gas.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

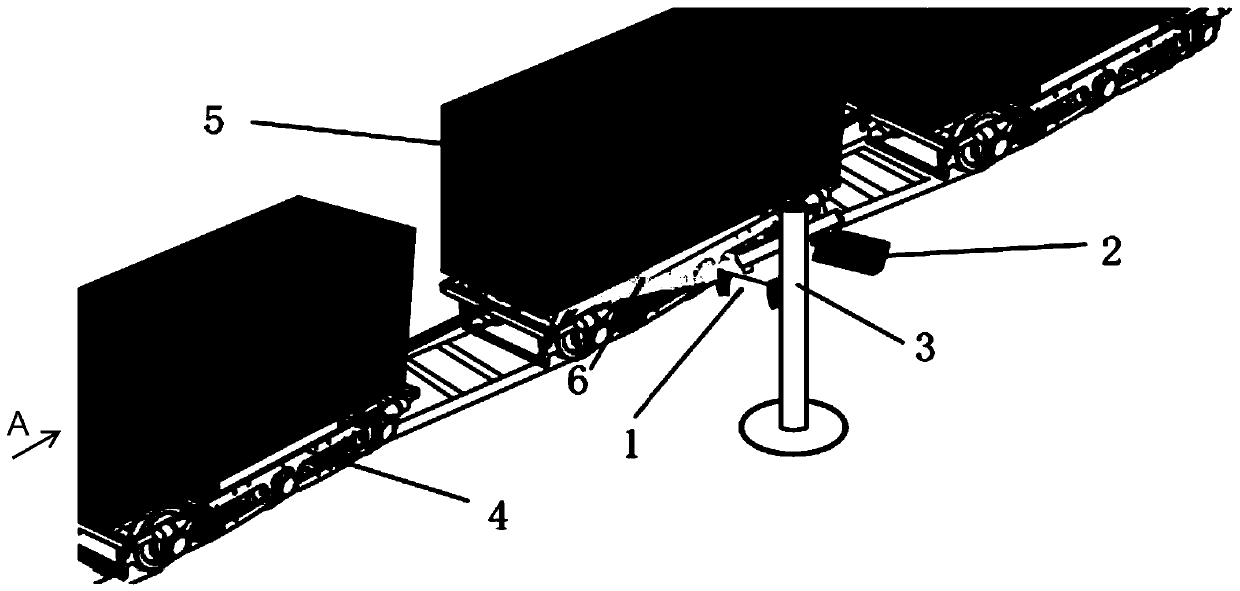

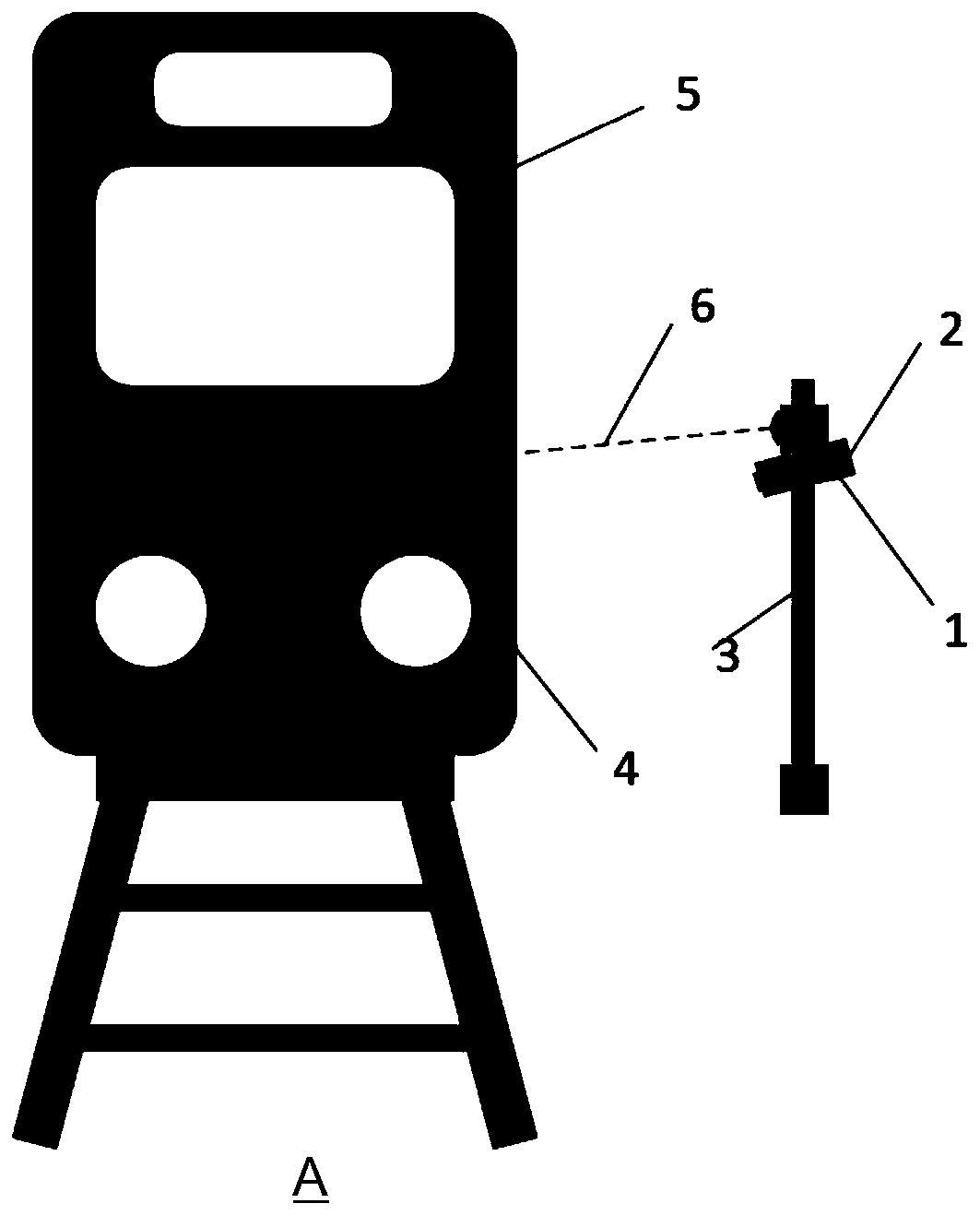

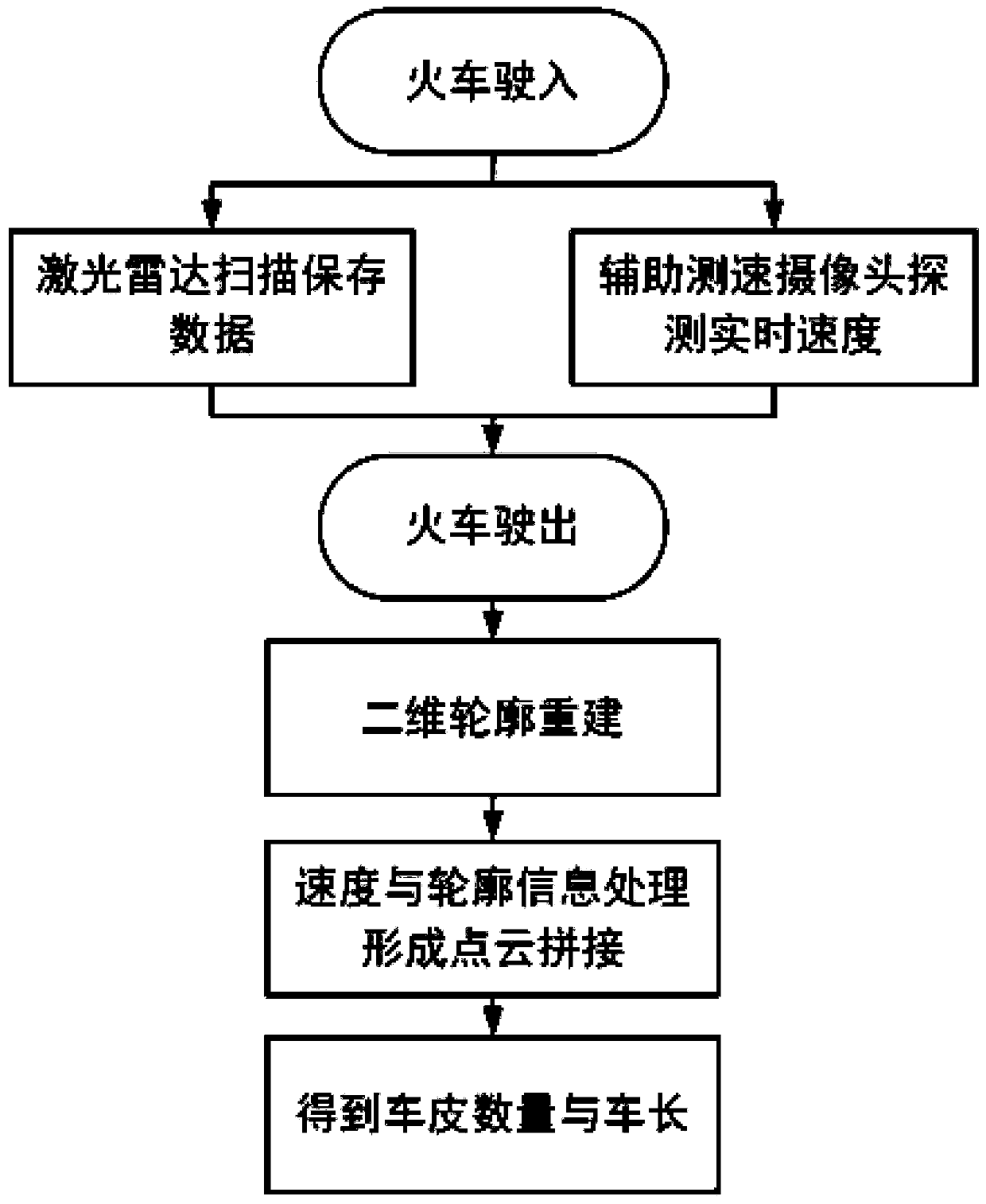

Train wagon number and length measuring system and method based on laser radar

InactiveCN111551122AGet real speedSimple structureVehicle route interaction devicesUsing optical meansRadarSimulation

The invention discloses a train wagon number and length measuring system and method based on a laser radar, and the system comprises laser radar which is used for obtaining the contour data of a trainwagon bracket in real time; a speed measuring device, used for acquiring the speed of the passing train in real time; and an industrial personal computer, used for extracting the contour data, acquired by the laser radar, of the train wagon bracket and the speed, acquired by the speed measuring device, of the train, and carrying out background data processing and result output. According to the invention, the laser radar is utilized to accurately obtain the number and length of train wagons, so that the dynamic carrying information of each trailer carriage is monitored and managed.

Owner:SHANGHAI ZHENHUA HEAVY IND +1

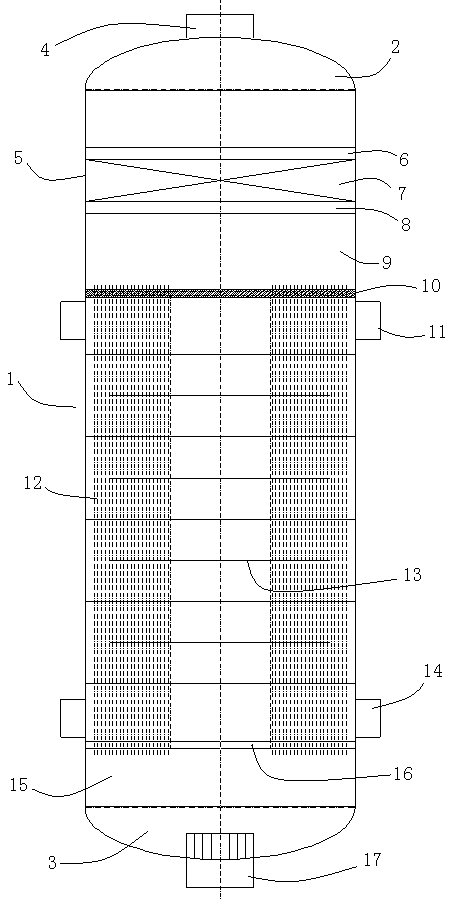

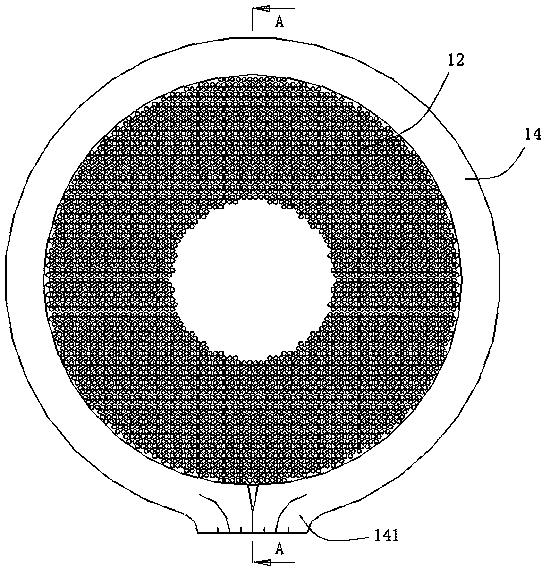

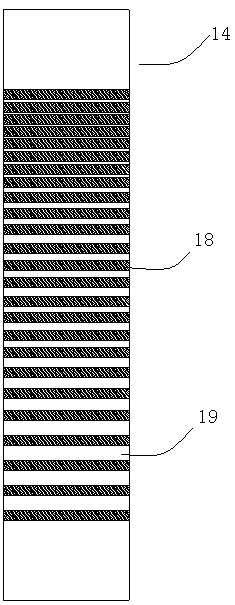

Isothermal adiabatic reactor for olefin and hydrogen peroxide epoxidation

PendingCN107855078AReduce decompositionHigh selectivityOrganic chemistryChemical/physical processesPtru catalystChemical physics

The invention relates to an isothermal adiabatic reactor for olefin and hydrogen peroxide epoxidation, and is particularly suitable for an epoxidation reaction of propylene and hydrogen peroxide. Thereactor comprises an upper end socket, a lower end socket, an isothermal catalytic reaction section, an upper pipe box, a lower pipe box and an adiabatic catalytic reaction section, wherein the upperpipe box and the lower pipe box are arranged at the two ends of the isothermal catalytic reaction section, and the adiabatic catalytic reaction section is arranged between the upper pipe box and the upper end socket; the adiabatic catalytic reaction section comprises an adiabatic section shell, a catalyst pressing plate and a supporting plate, the catalyst pressing plate and the supporting plate are fixedly connected with the adiabatic section shell, and an adiabatic section catalytic bed layer is arranged between the catalyst pressing plate and the supporting plate. According to the reactor,a traditional reaction process can be greatly simplified, few devices are used, and the process complexity is reduced; the temperature is easy to control, the service life of a catalyst is long, and the hydrogen peroxide can completely react in the equipment.

Owner:CHANGZHOU RUIHUA CHEM ENG&TECH

Refrigerator with air-cooling, water-cooling and evaporation cooling integration

InactiveCN101029781AGuaranteed safe operationImprove cooling effectCompression machines with non-reversible cycleRefrigeration compressorWater cycling

This invention relates to a refrigerator for cold storage equipment and air conditioner, which embraces wind cooling, water cooling and evaporation cooling. It consists of frame (1) and manifold-fin heat exchanger (4) within the frame, and liquid reservoir (9), pop cooling water recycle unit cooling fan (2), refrigerating compressor (6), gas separator (5,) etc. Cooling fan is installed on the same side with heat exchanger and pop cooling water recycle unit is placed above the heat exchanger. Refrigerating medium cooling is carried out by heat exchanger, shower cooling and evaporation cooling are carried out by drencher (3), and wind cooling and evaporation cooling performance improvement are done by cooling fan. Integrated together, performances of wind cooling, water cooling and evaporation cooling can be enhanced by each other to reach a better cooling result. Besides, it is compact in structure, with fewer accessories and less water consumption, and is safe to operate in high temperature season and is suitable for all kinds of cool reservation equipment and air conditioners.

Owner:SHANDONG INST OF POMOLOGY

Pyrolysis oil-gas separation metering equipment

InactiveCN104056518ASimple structureLess auxiliary equipmentCombination devicesPetroleum engineeringPyrolysis oil

The invention relates to pyrolysis oil-gas separation metering equipment which comprises a separating device cylinder body, a gas outlet, a gas baffle plate, a liquid baffle plate, a pyrolysis oil container and a metering scale, wherein an oil-gas mixture inlet and a pyrolysis oil injecting hole are formed in the top end of the cylinder body, the gas outlet is arranged in the upper part of the side wall of the cylinder body, the gas baffle plate is arranged at an inner cavity of the cylinder body, and is located between the oil-gas mixture inlet and the gas outlet, the upper side of the gas baffle plate is connected with the top wall of the cylinder body, two side edges of the gas baffle plate are respectively connected with the side wall of the cylinder body, the liquid baffle plate comprises a top plate and a side plate connected with the top plate, the edge of the top plate is arc-shaped, the side plate is rectangular, the top plate, the side plate and the inner wall of the separating device cylinder body are connected in a sealing manner, the top plate is located above an oil outlet, the lower end of the side plate is lower than a horizontal line in which the oil outlet is located, an oil outlet is arranged in the side wall of the lower part of the cylinder body, the pyrolysis oil container is communicated to the oil outlet through an oil conveying pipe, and the metering scale is arranged below the pyrolysis oil container. The pyrolysis oil-gas separation metering equipment provided by the invention is simple in structure, has few auxiliary equipment, and a person can know and master yield of pyrolysis oil in real time.

Owner:QINGDAO DONGFANG RECYCLING ENERGY +1

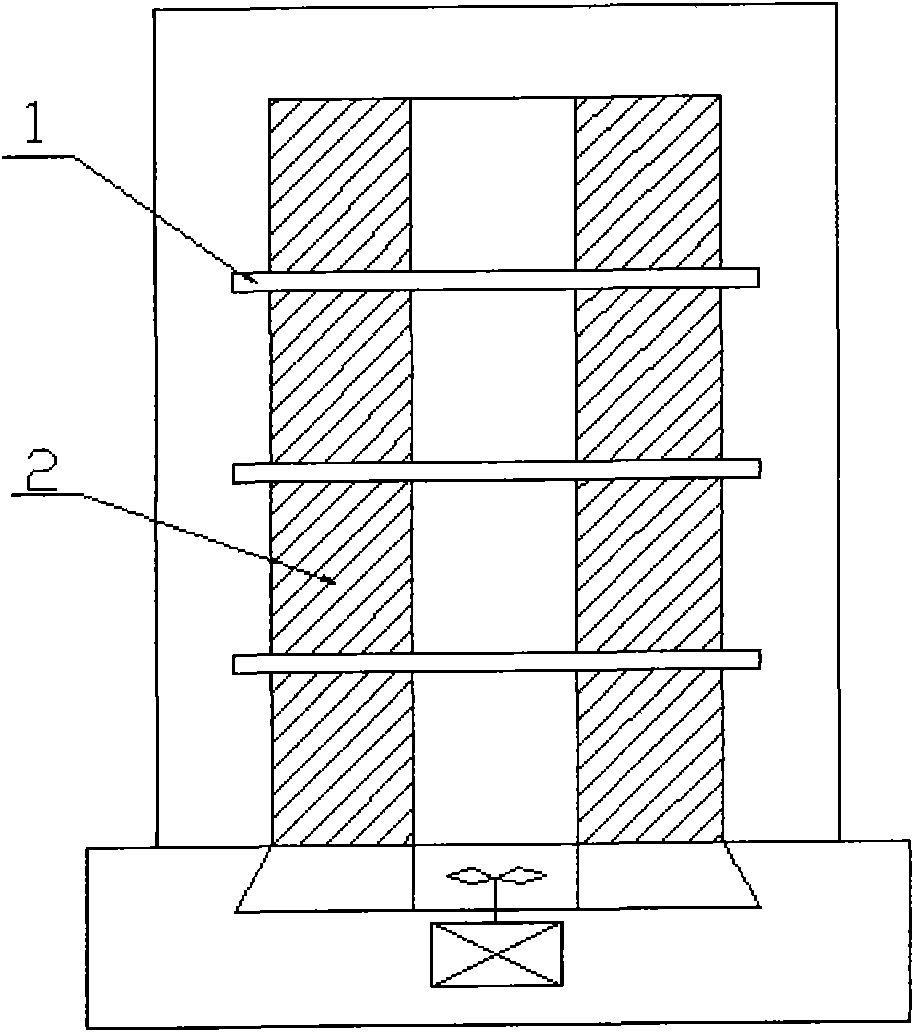

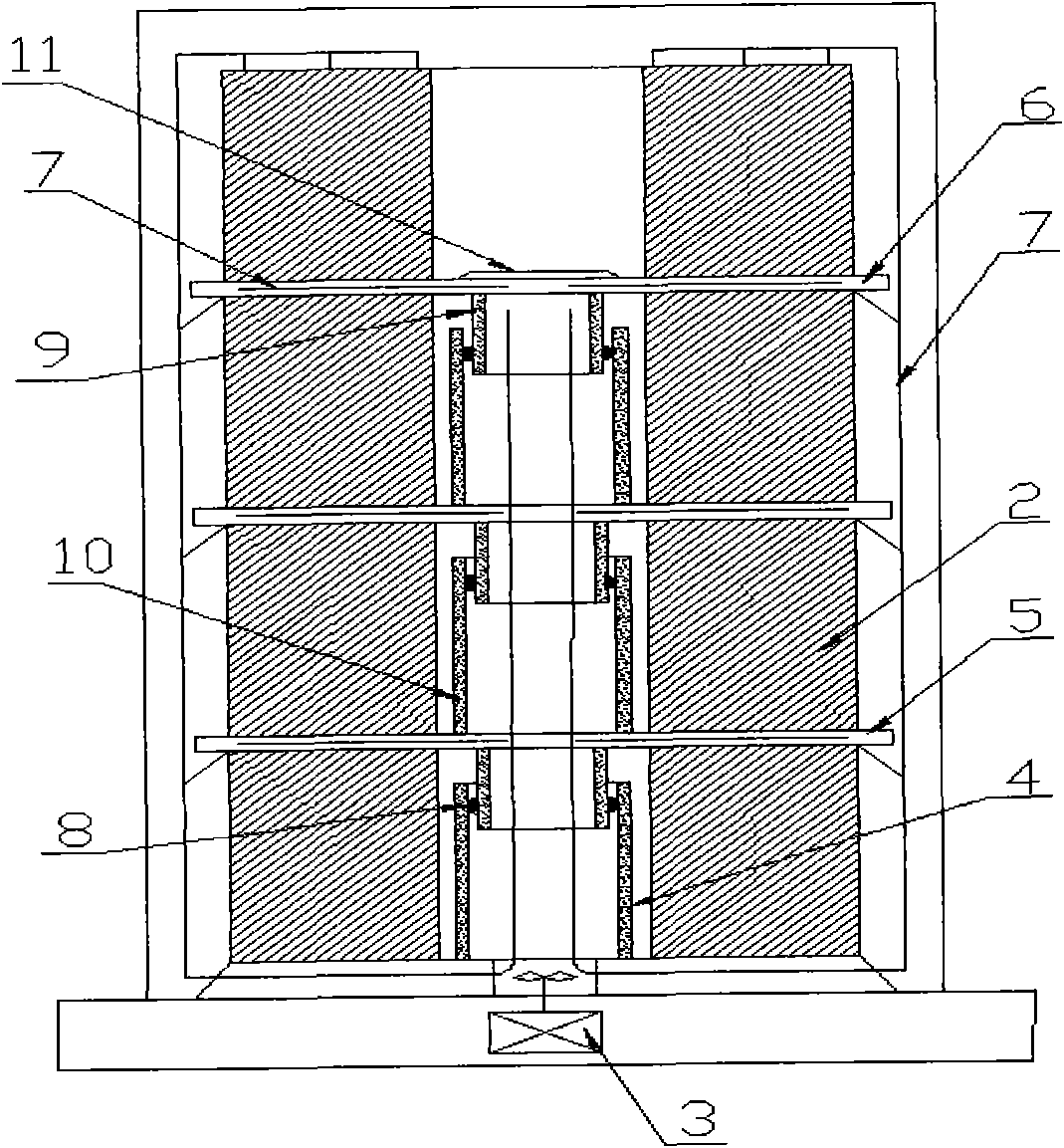

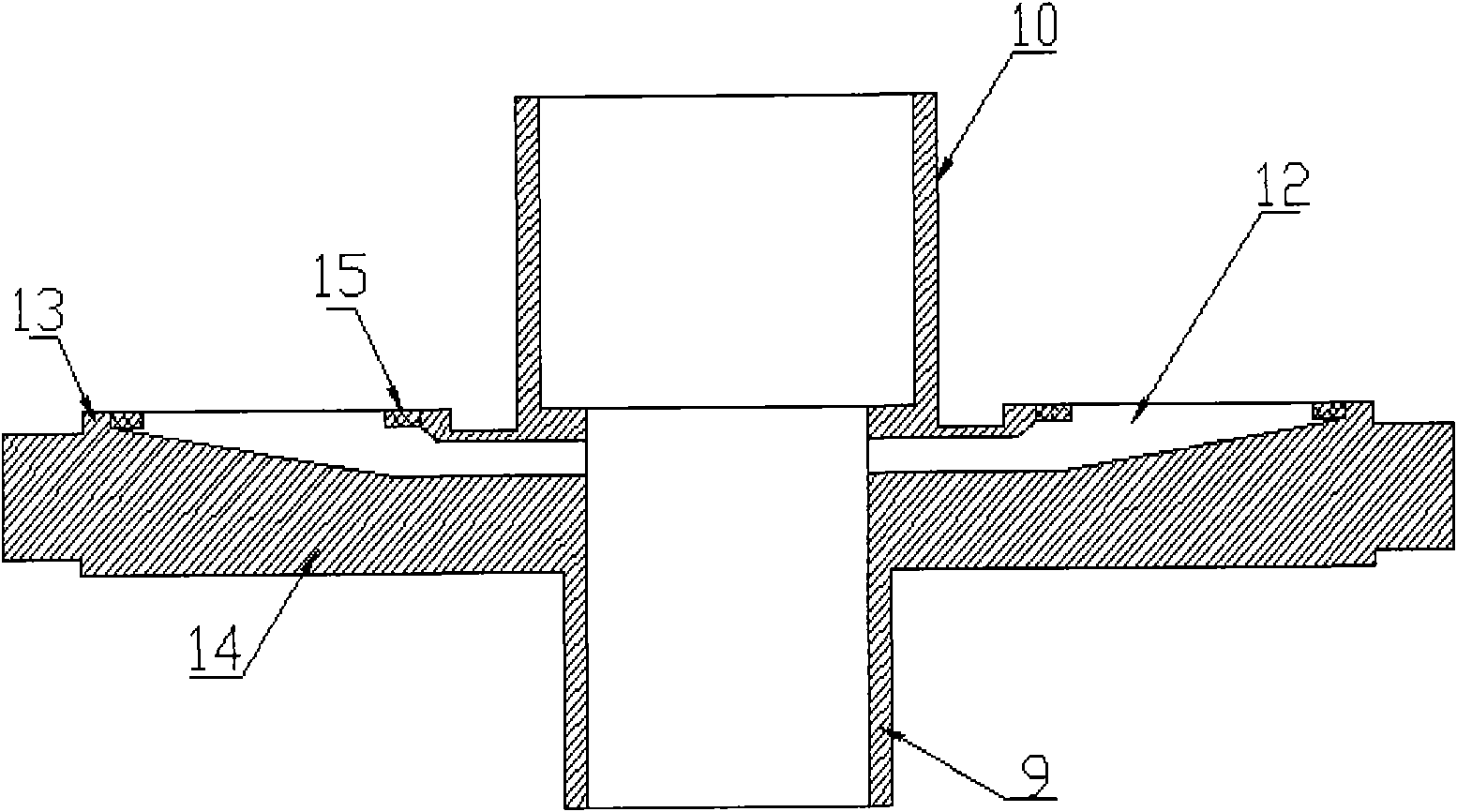

Multi-layer integrated type series-connection vertical telescopic dry-process vibration medium drainage screen

The invention discloses a multi-layer integrated type series-connection vertical telescopic dry-process vibration medium drainage screen. The medium drainage screen comprises a whole machine frame fixed on a support base, a left front-back movement track and a right front-back movement track; vertical supporting moving hydraulic cylinders are installed at the two ends of the upper portion of the left front-back movement rail and the two ends of the upper portion of the right front-back movement rail respectively, and a plurality of layers of screen frames and outer covers provided with screenmeshes are sequentially mounted on the inner side of the whole machine frame from bottom to top; the screen frame and outer cover of each layer comprises four damping devices, a screen frame and outercover body, a dense medium discharging channel and a clean coal and gangue outlet, wherein the screen frame and outer cover body is installed above cross beams arranged in the front-back direction and the left-right direction in the whole machine frame, four corners of the screen frame and outer cover body are located on the four damping devices correspondingly, and the dense medium discharging channel and the clean coal and gangue outlet are arranged at corresponding positions below the screen frame and outer cover body; and vibration motors are fixedly connected to the front sides and the rear sides of the screen frame and outer cover bodies, a screen telescopic power device and rotating shaft is arranged at a reserved position at the upper portion of one end of the screen frame and outer cover body of each layer, and a screen fixing device and rotating shaft is arranged at the reserved position at the upper portion of the other end of the screen frame and outer cover of each layer.

Owner:河北地质大学

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com