Pyrolysis oil-gas separation metering equipment

A metering equipment and oil cracking technology, which is applied in the field of waste organic matter cracking, can solve the problems of small and medium cracking devices that are difficult to separate oil and gas in time, and achieve the effect of simple structure and less auxiliary equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0024] The invention provides a pyrolysis oil-gas separation and metering device to solve the problems that it is difficult for small and medium-sized crackers to realize oil-gas separation in time and real-time oil output metering of cracked oil.

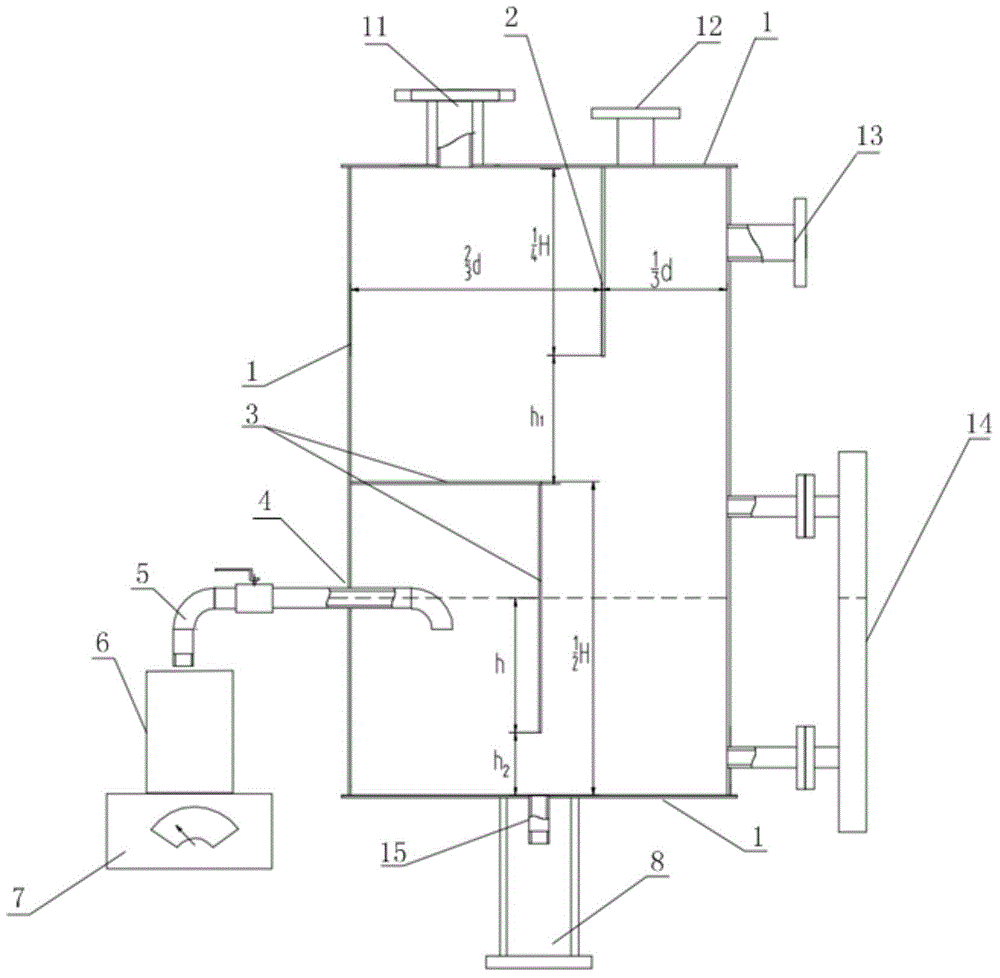

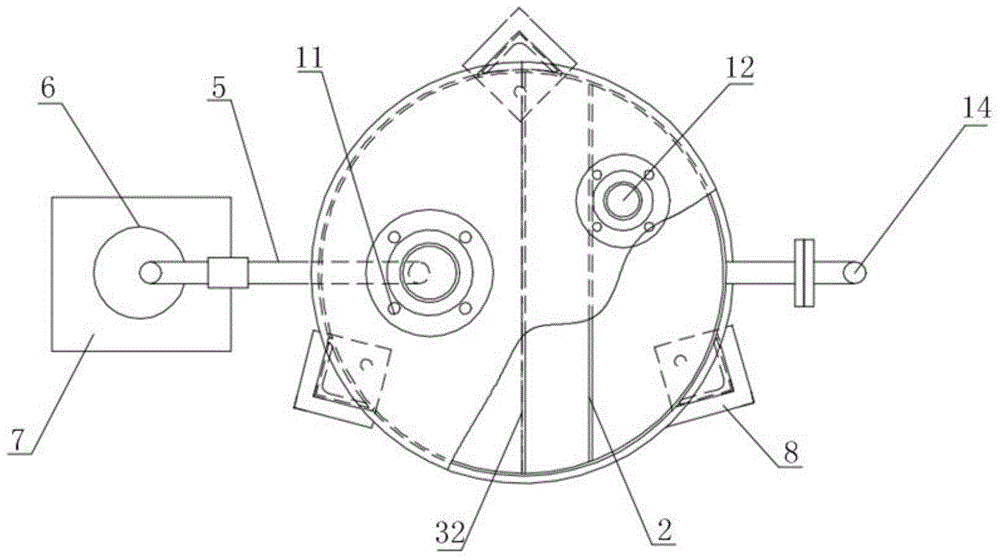

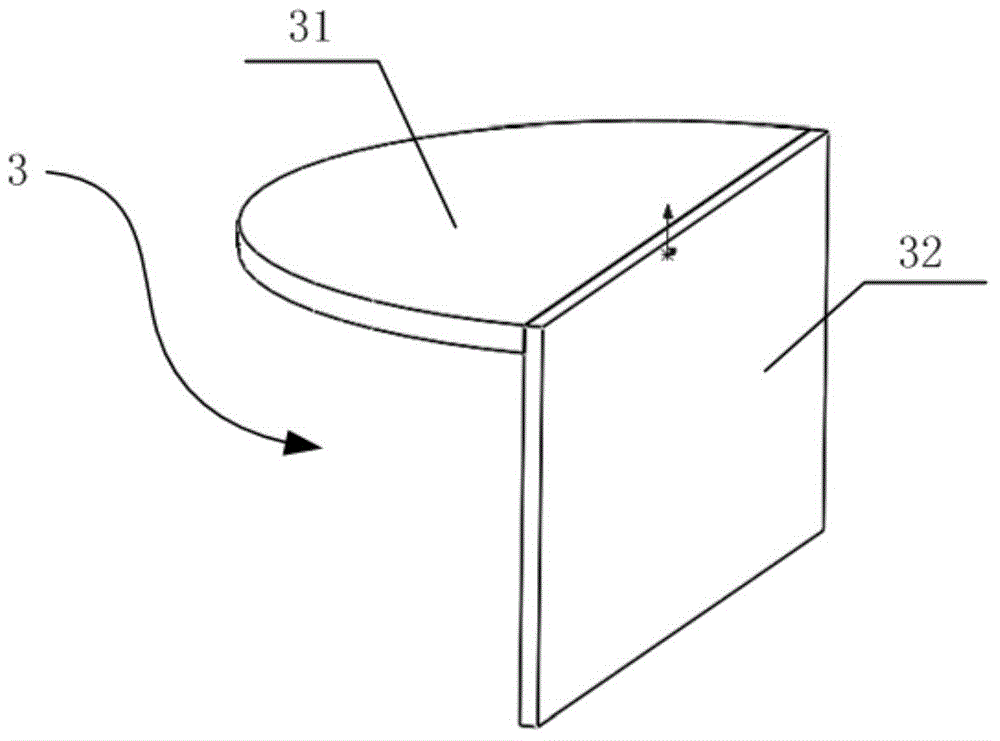

[0025] attached figure 1 Among them, H is the height of the cylinder, d is the diameter of the cylinder, p is the working pressure of the oil-gas mixture, h is the depth of the vertical liquid baffle inserted into the liquid surface, h1 is the gas channel, h2 is the liquid channel, γ is the cracked oil density .

[0026] figure 1 Shown is an overall schematic diagram of a pyrolysis oil-gas separation metering device according to an embodiment of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com