Device for continuously performing primer spraying, drying and electroplating in vacuum chamber

A technology of vacuum chamber and primer, applied in the direction of spraying device, vacuum evaporation coating, device for coating liquid on the surface, etc., can solve the problems of environmental pollution, long production cycle, high labor cost, etc., and achieve the elimination of environmental pollution and saving Time cost, the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

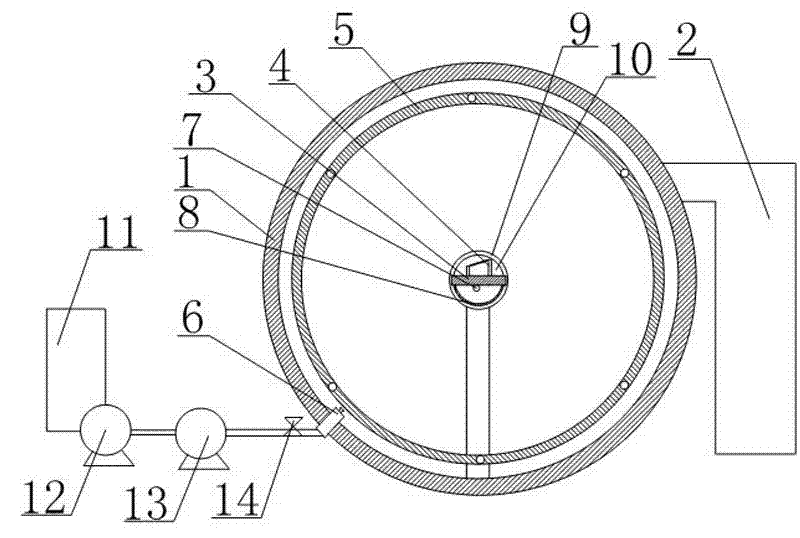

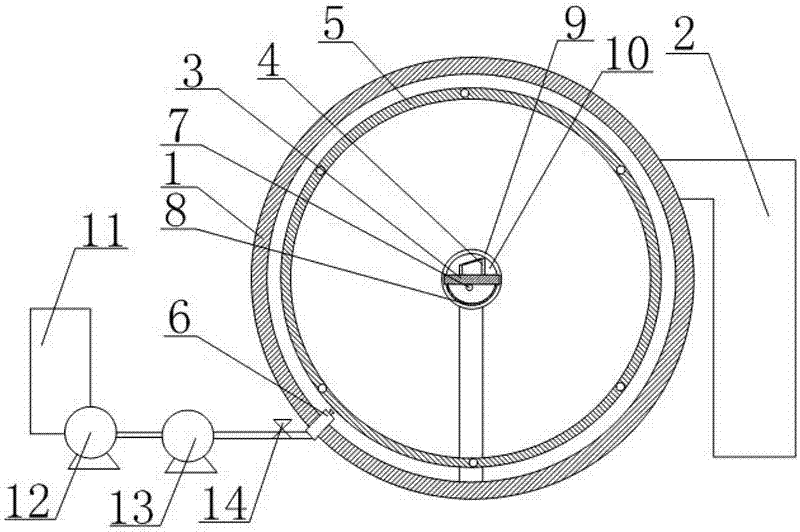

[0024] like figure 1 As shown, the present invention comprises a vacuum chamber 1, and the vacuum chamber is connected with a vacuum pump 2, and a turret 5 is arranged in the vacuum chamber 1, and a hanging port is arranged on the turret 5, which is used for articulated substrate workpieces. An electroplating table 3 is provided, and two rows of electroplating electrodes 4 are arranged on the electroplating table 3. A drying cylinder is installed on the lower surface of the electroplating table 3 for placing a dryer 7. Both ends of the electroplating table 3 are provided with gears 9 , a coaxial device 10 is connected between the two gears 9, a protective cover 8 is connected on the coaxial device 10, and the cross section of the protective cover 8 is semicircular; a nozzle 6 is arranged on the vacuum chamber 1, and the nozzle 6 is connected with the The paint supply system outside the vacuum chamber 1 is connected, and the paint supply system includes a paint storage bucket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com