Near-net forging forming method of railway vehicle coupler knuckle

A technology for forging molding and railway vehicles, which is applied to metal processing equipment, etc., can solve the problems of forging knuckle manufacturing difficulties and complicated manufacturing processes, and achieve the effects of saving machining workload, high forming precision, and reducing heating times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

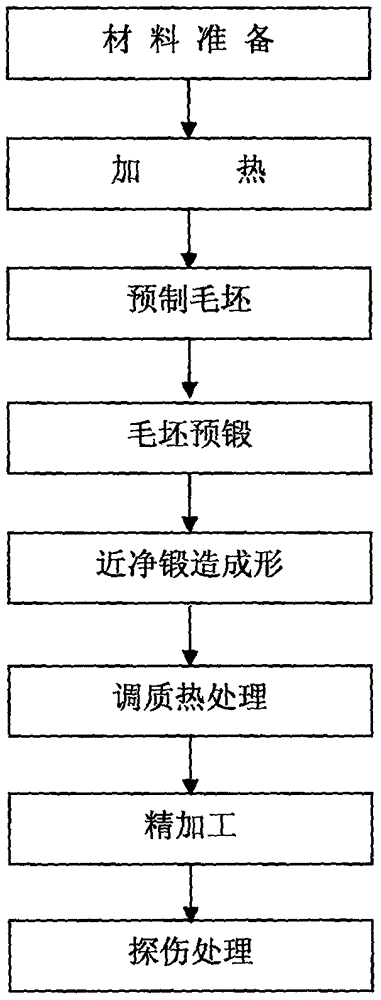

[0037] Such as Figure 1-6 As shown, the railway vehicle coupler knuckle of the present invention has a near net forging forming method, comprising the following steps:

[0038] Step (a), material preparation: according to the product model, the round steel of the corresponding specification is cut to a certain length with a band saw;

[0039] Step (b), heating: using 1500KW intermediate frequency induction heating equipment to heat the billet to 1150°C±20°C;

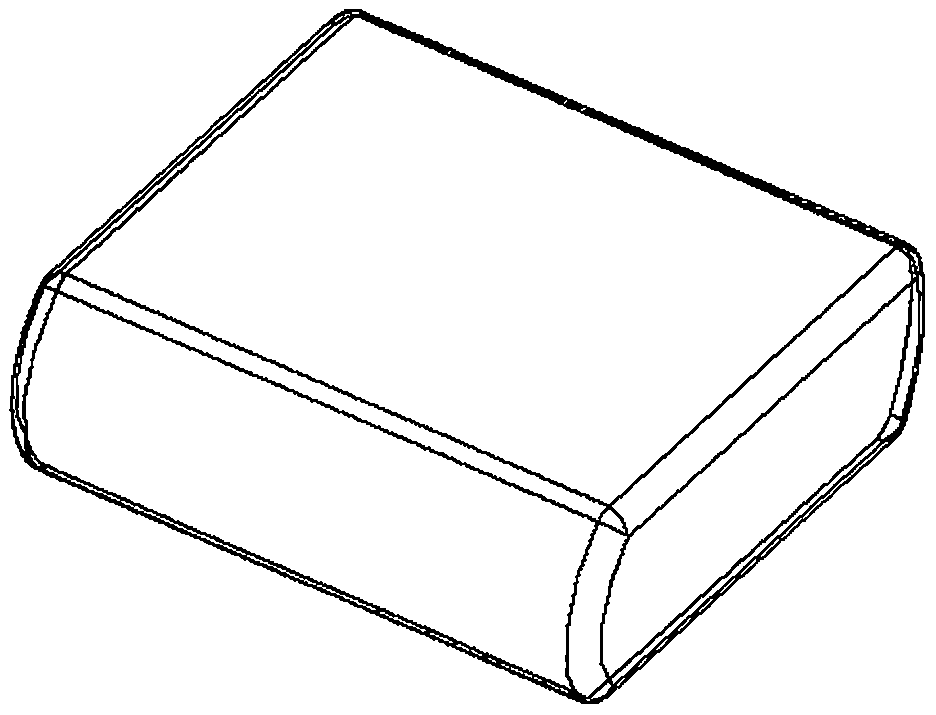

[0040] Step (c), prefabricating the blank: placing the heated blank on an 800-ton multi-directional forging device for multi-directional forging to prefabricate the blank.

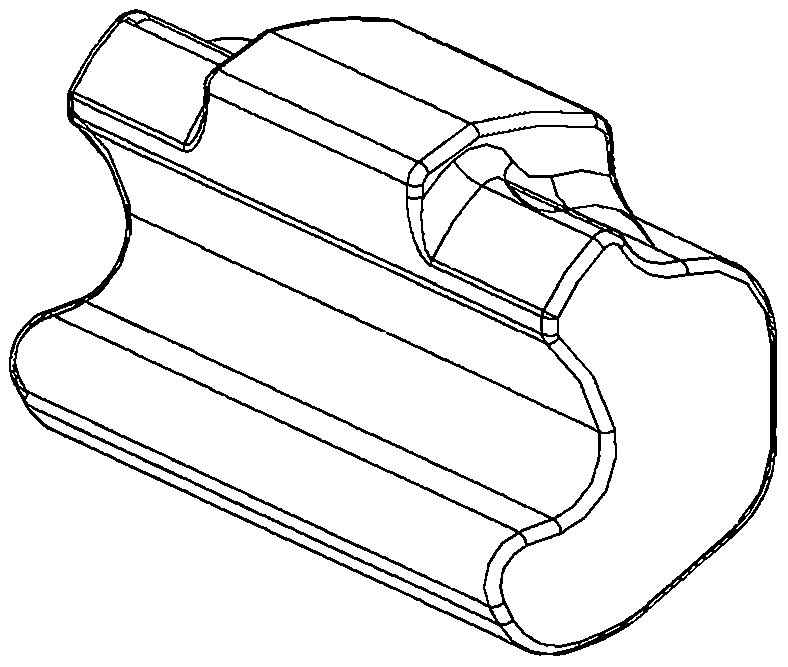

[0041] Step (d), blank pre-forging: the pre-fabricated blank is closed forged in the pre-forging die on the 2000-ton multi-directional forging equipment, and pre-forged into a blank of a certain shape and size;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com