Patents

Literature

55results about How to "Reduce machining workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

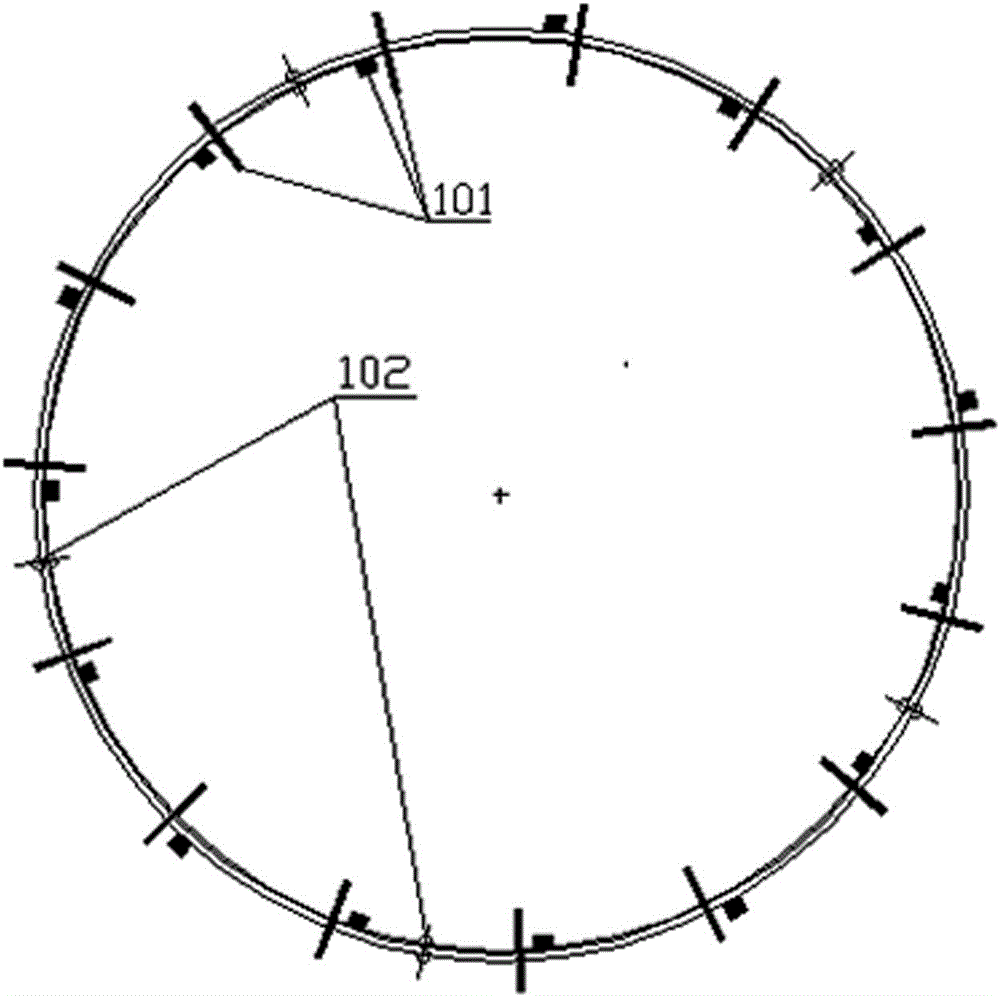

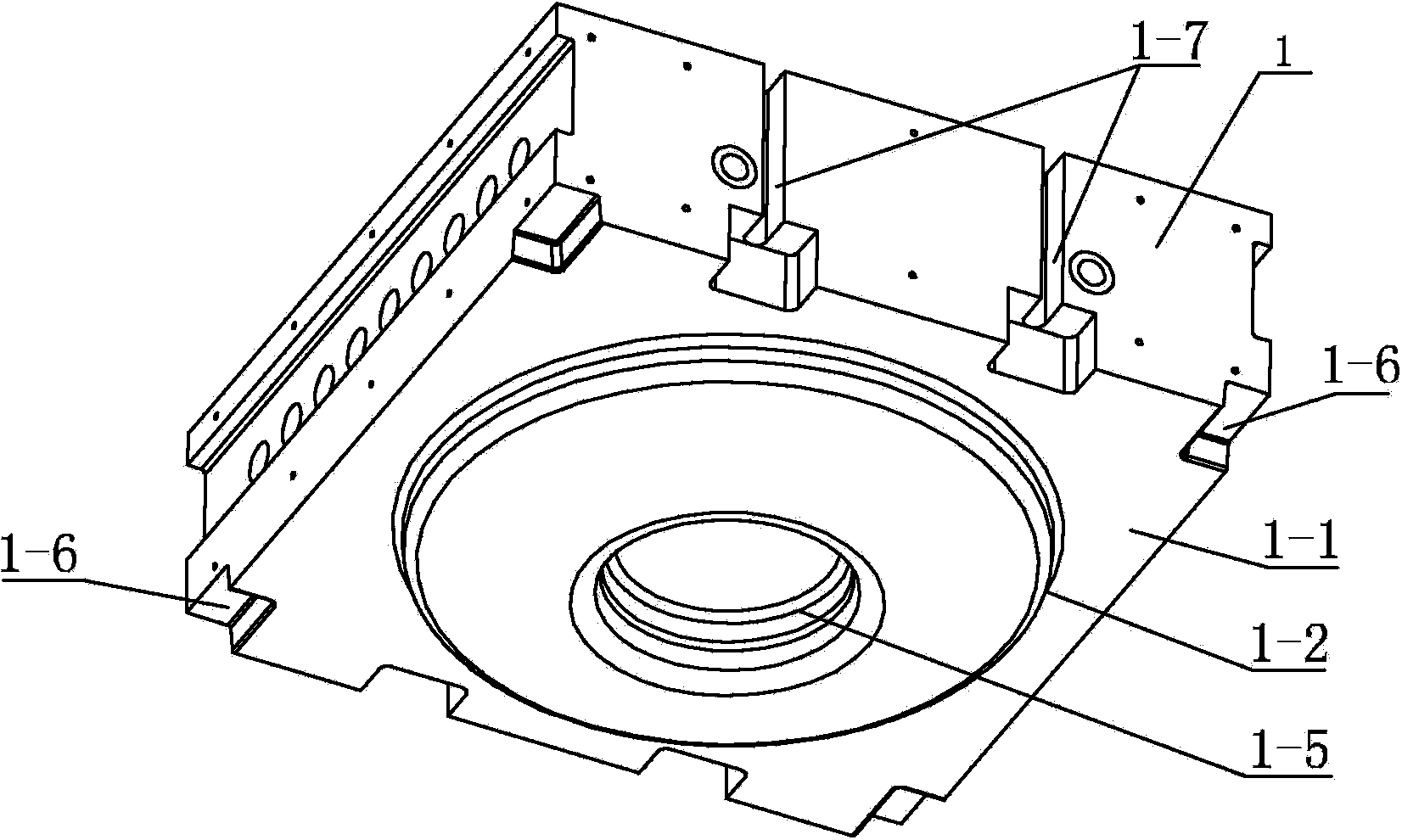

Forging process of bearing ring

ActiveCN104827245AEliminate Inherent DefectsIncrease tightnessBearing componentsEngine componentsPunchingMedium frequency

The invention relates to a forging process of a bearing ring. The process includes following steps that: 1) in first firing, a medium-frequency induction heating furnace is adopted to heat an ingot to 1200 DEG C, dead head pressing, chamfering and sprue filing are performed; 2) in second firing, re-heating, upsetting and drawing out are performed on the machined ingot; 3) in third firing, re-heating, upsetting, rotary flattening, punching and reaming are performed on the machined ingot; 4) in fourth firing, the machined ingot is re-heated, and upsetting is performed on the machined ingot in a mold ring, so that the machined ingot can be in a technique size, the mold is removed, and reaming is performed on the machined ingot, so that the machined ingot can be in a technique size, and total forging ratio is controlled to be larger than 5; 5) groove turning is performed, the machined ingot is subjected to cold rolling and reeling on a closed shaping and reaming machine, and rolling paths and chamfered angles are molded with one step, truing is performed, and two end surfaces are subjected to soft grinding; 6) the machined ingot is pre-heated to 800 DEG C to 850 DEG C, after crack detection is performed, when the temperature of the machined ingot is lower than 450 DEG C, the machined ingot is put into the furnace so as to pre-heated to 600 DEG C to 650 DEG C, and heat preservation is performed on the machined ingot, and the machined ingot is put in to the furnace of which the temperature ranges from 950 DEC C to 1000 DEC and is rapidly heated to 1140 DEC C to 1200 DEC C, and water quenching is performed, and instantly, tempering from 550 DEC C to 600 DEC C is performed on the machined ingot, and the machined ingot is cooled to 400 DEC C to 450 DEC C in the furnace, and the machined ingot is taken out from the furnace and cooled. With the forging process adopted, inherent defects of metal can be eliminated, and the service life of a bearing can be prolonged.

Owner:JIANGSU JINYUAN FORGE

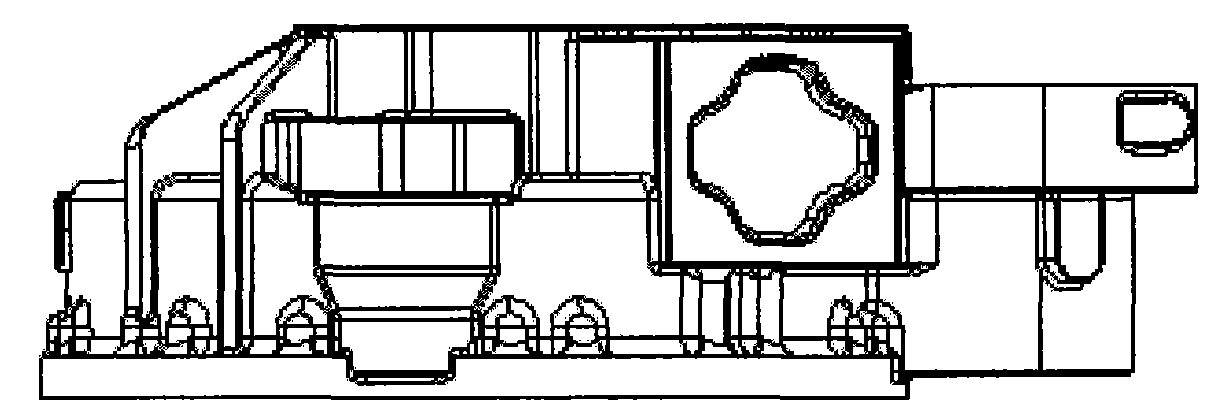

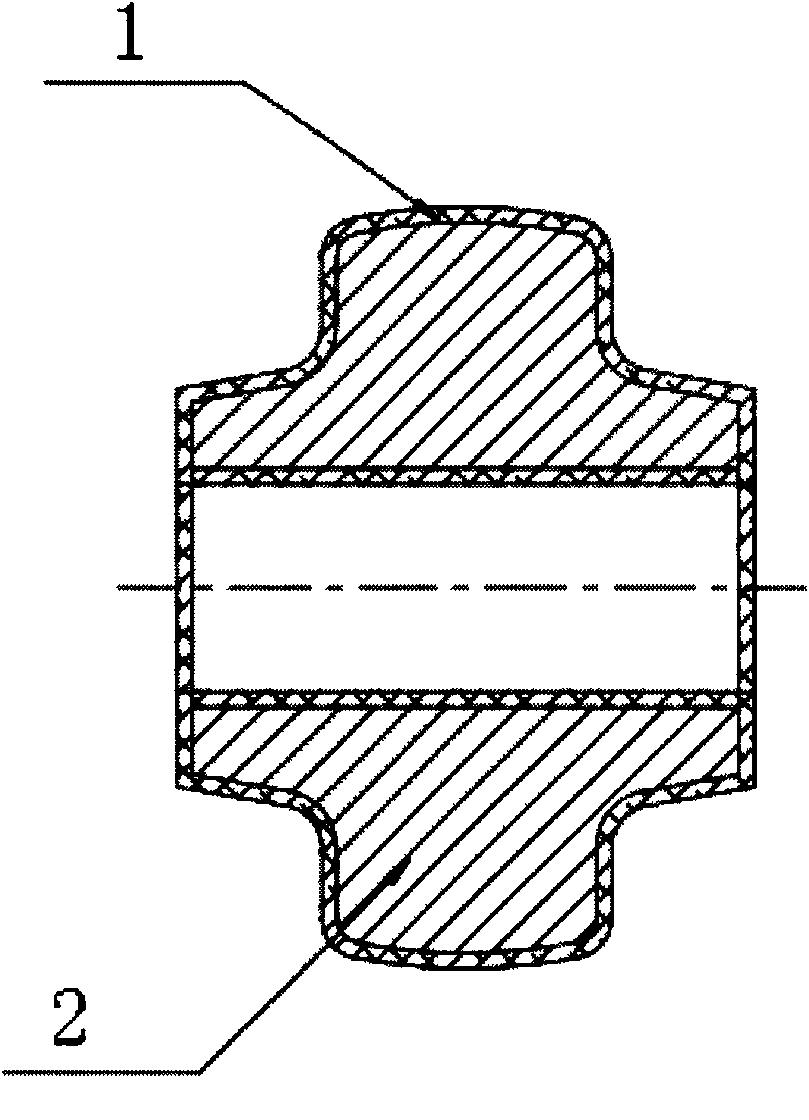

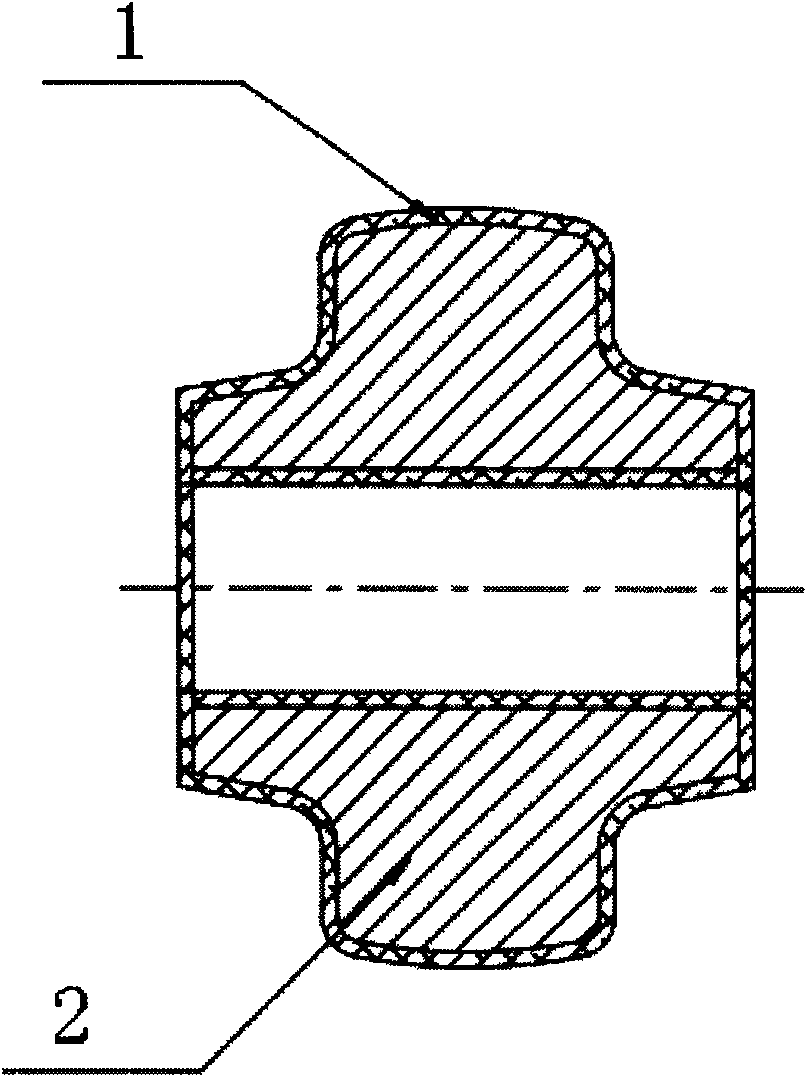

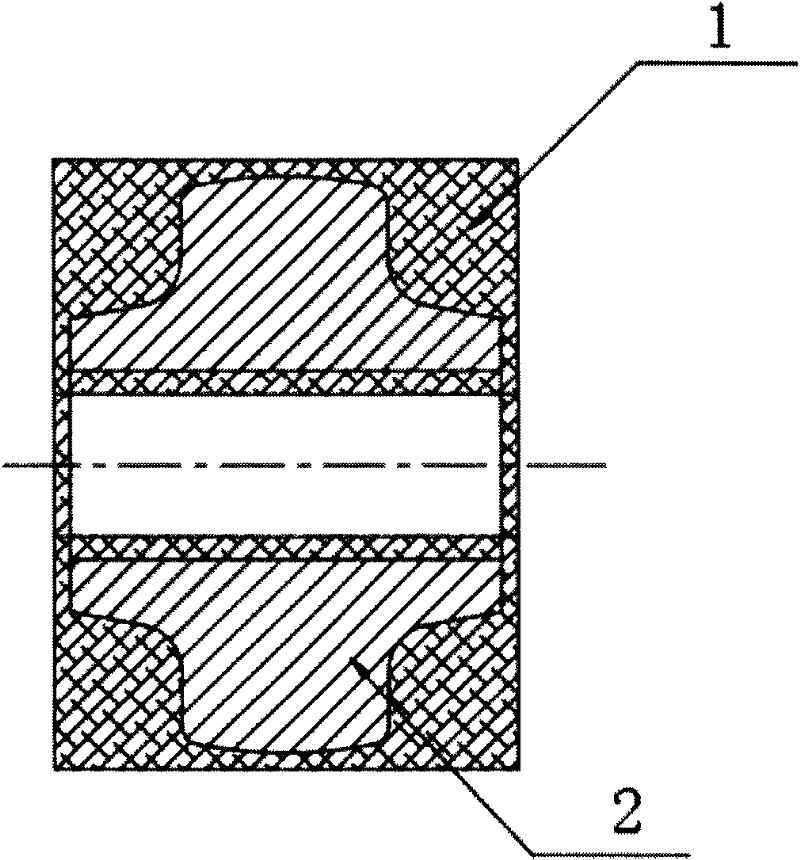

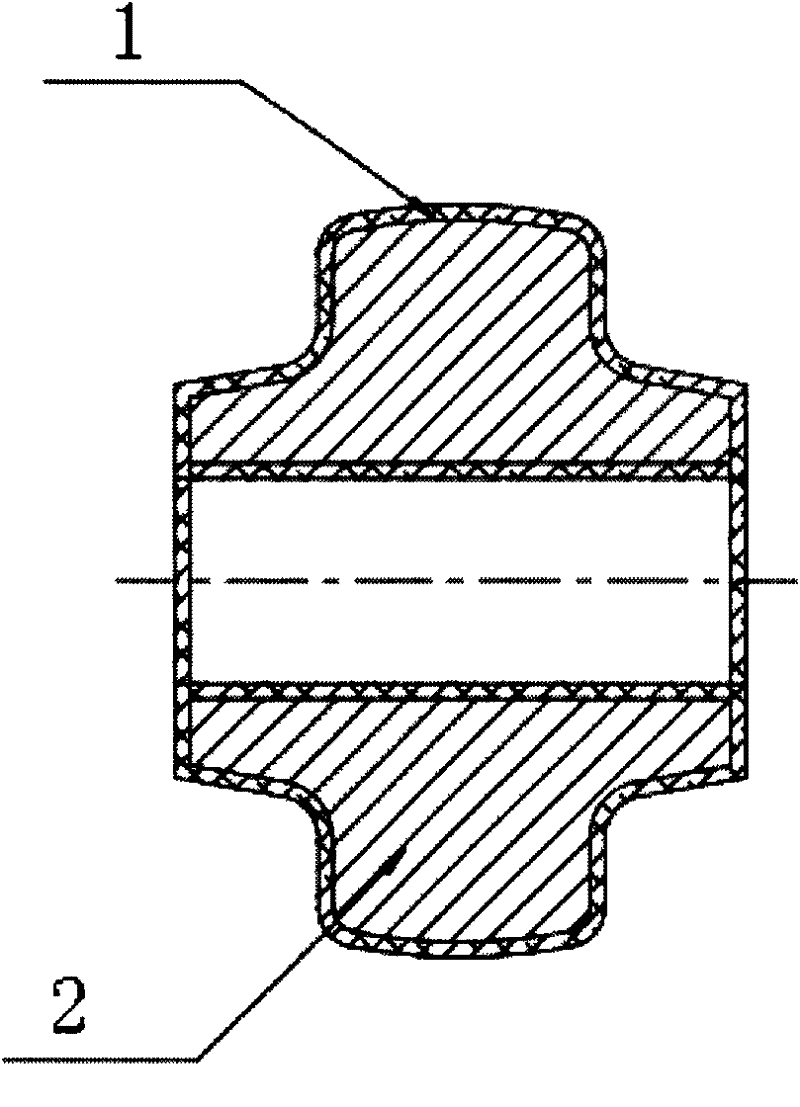

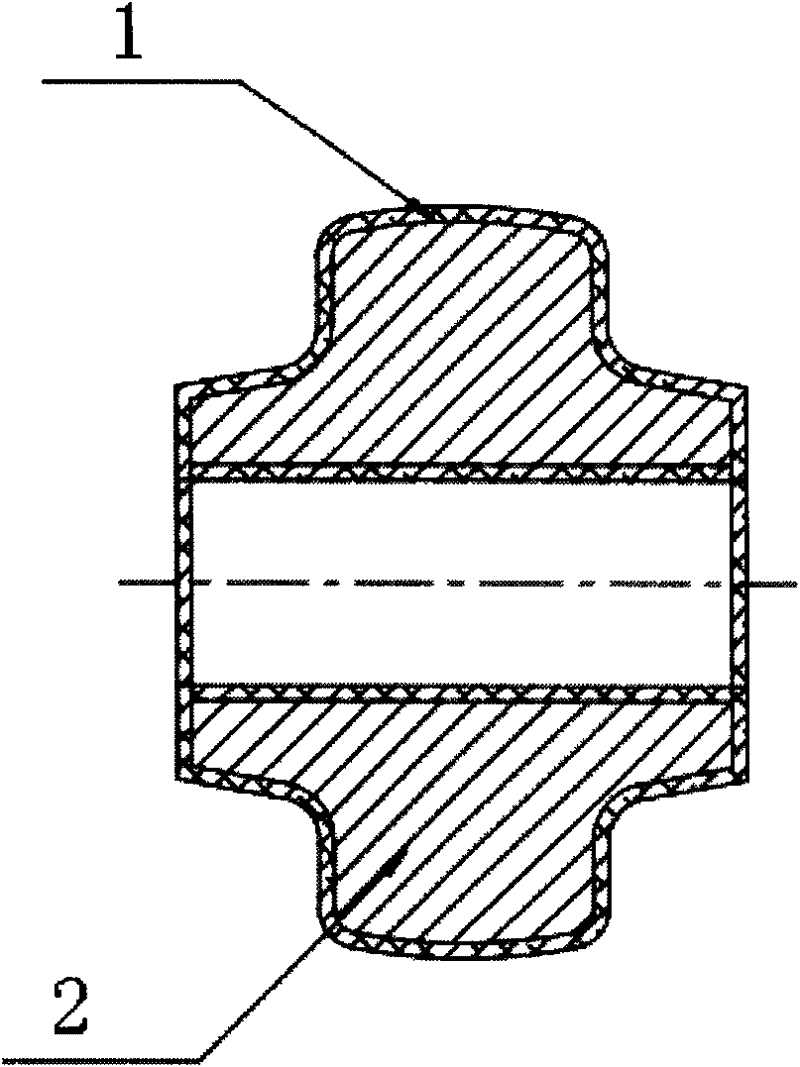

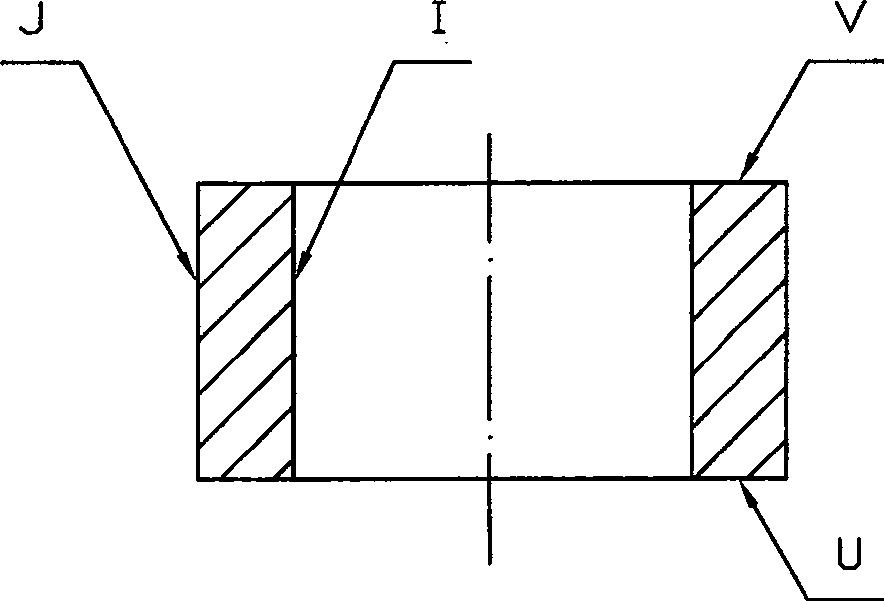

Rolling piston and manufacturing method thereof for rotary type cold compressor

ActiveCN101158356ASufficient supplyFair priceRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigeration compressorHigh energy

The invention provides a rolling piston used for a rotary refrigeration compressor and the manufacture method thereof. The material of the rolling piston is a precise steel pipe made of GCr15 bearing steal cold rolled; the manufacture method of the invention is that (1) the GCr15 bearing steal is selected to be cold rolled to the steel pipe meeting required internal diameter, external diameter and thickness of the rolling piston; (2) the steel pipe is cut according to the length of the rolling piston material; (3) the cut steel pipe is disposed by hot controllable gas; (4) all surfaces of the steel pipe are kibbled; (5) the steel pipe is disposed by heat stabilization; (6) all surfaces of the steel pipe are finely grinded. The invention has the advantages that the made rolling piston has obvious predominance on the anti-wear performance and high contact fatigue life. The work load of the cutting process can be reduced by 50%, and the utilization ratio of the steel material can reach more than 90%, thus reducing the manufacture cost. The invention saves the casting method, avoids the environmental pollution and high energy consumption, and is a good energy-saving method with environmental protection.

Owner:NINGBO YONGWEI GROUP

Rolling piston for refrigeration compressor and manufacturing method thereof

ActiveCN105041658ASufficient supplyLow priceRotary piston pumpsRotary piston liquid enginesRefrigeration compressorMaterials science

Provided is a rolling piston for a rotary type refrigeration compressor. The rolling piston is made of a steel tube which is formed by conducting cold-rolling on carburizing steel. Chemical components of the carburizing steel include 0.17%-0.23% of C, 0.17%-0.37% of Si, 0.80%-1.10% of Mn, 1.00%-1.30% of Cr, 0.04%-0.10% of Ti and the balance Fe. The rolling piston has the advantages that the supply of goods is ample, the price is low, the cost is reduced, and the environment is not polluted.

Owner:NINGBO YONGWEI GROUP

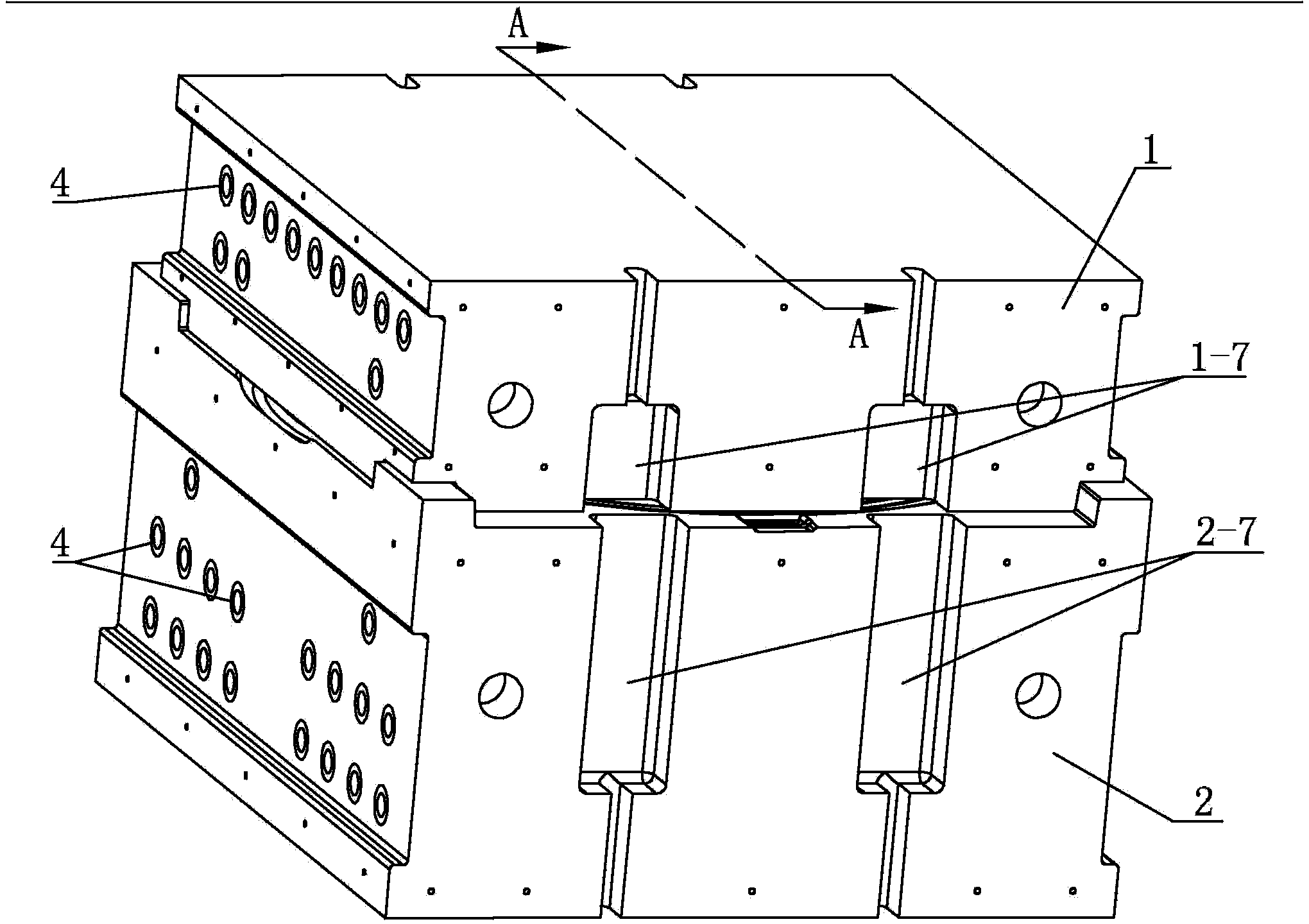

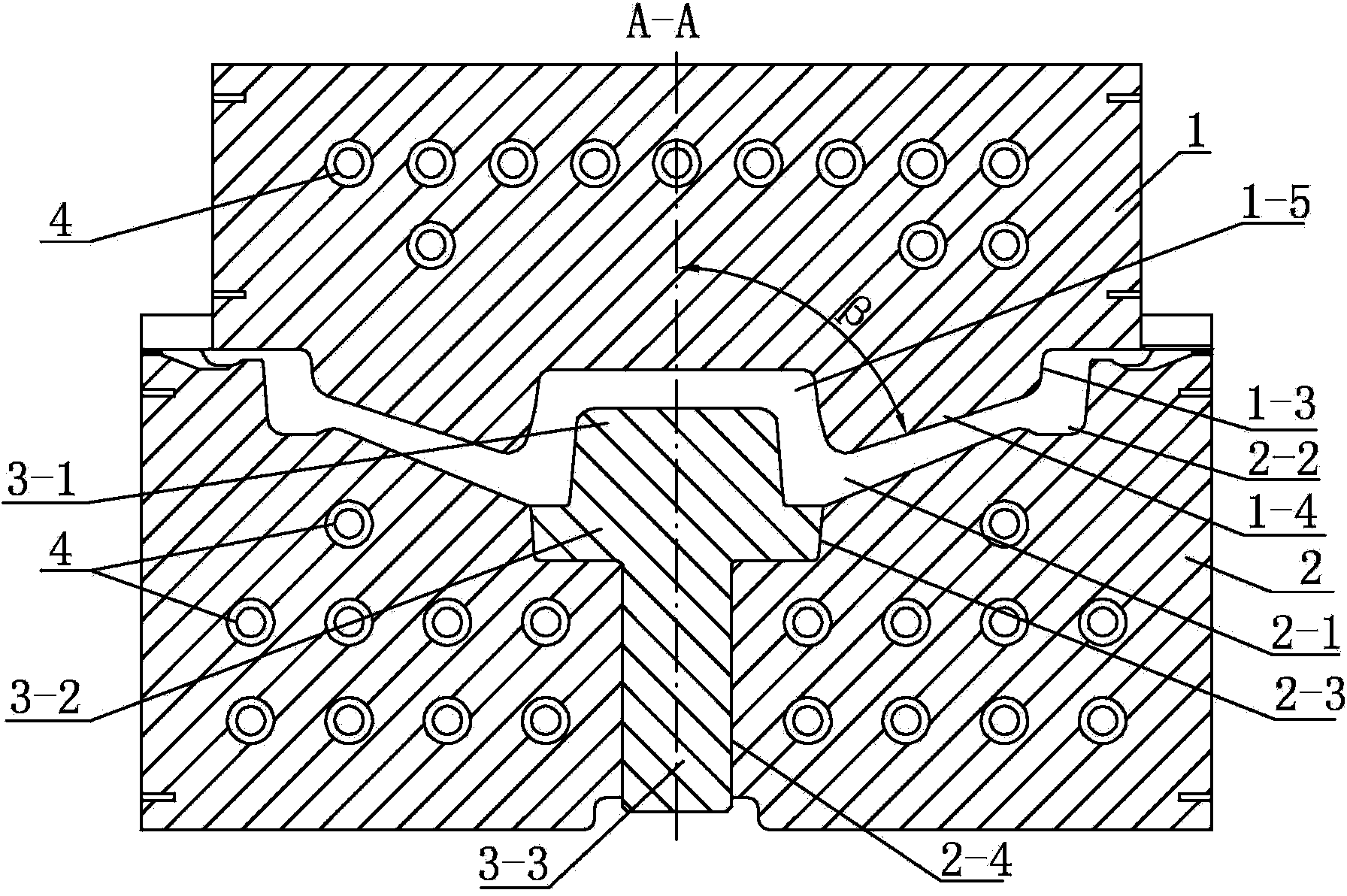

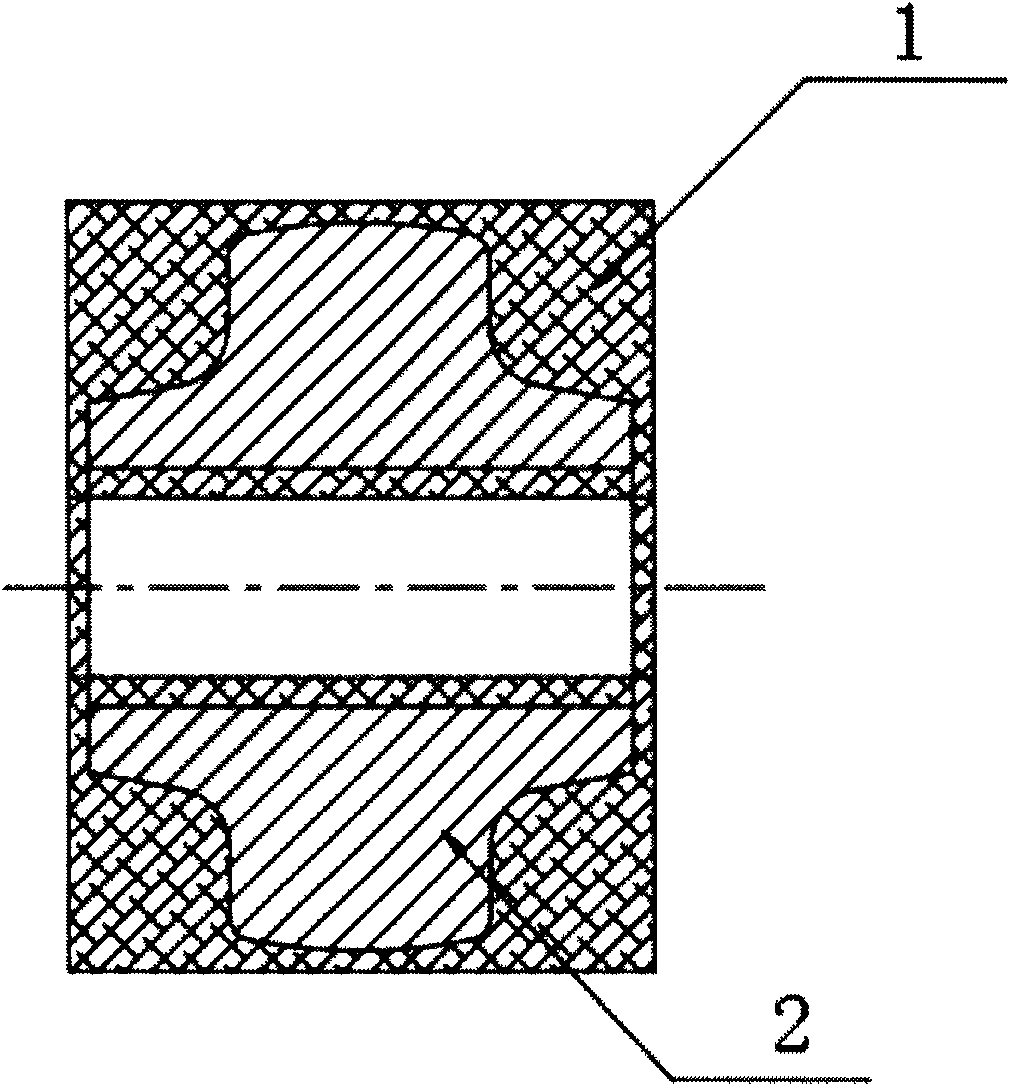

Isothermal die forging forming die and method for rare earth magnesium alloy thin webbed supporting fork

ActiveCN105397010AQuality improvementExtended service lifeForging/hammering/pressing machinesEngine componentsRare earthMagnesium alloy

The invention relates to a forming die and method for magnesium alloy thin webbed supporting fork forgings, in particular to an isothermal die forging forming die and method for a rare earth magnesium alloy thin webbed supporting fork. The problems that rare earth magnesium alloy thin webbed supporting fork forgings are prepared through conventional forging, blank manufacturing and forming are hard, forming defects are prone to occurring, the structure performance of the magnesium alloy forgings is hard to control, and the performance is low are solved. The forming method comprises the main steps that 1, blank manufacturing is carried out; 2, forging forming is carried out; 3, cooling is carried out; 4, primary acid pickling is carried out; 5, damage repairing is carried out; 6, final forging is carried out; 7, secondary acid pickling is carried out, wherein a magnesium alloy forging obtained in the sixth step is subjected to acid pickling, graphite on the surface is cleaned away, and a formed forging with the treated surface is obtained; and 8, the formed forging with the treated surface obtained in the seventh step is put into an aging oven to be subjected to aging treatment, and the finished rare earth magnesium alloy thin webbed supporting fork is manufactured. The forming die and method are used for preparing of the magnesium alloy thin webbed supporting fork.

Owner:HARBIN INST OF TECH

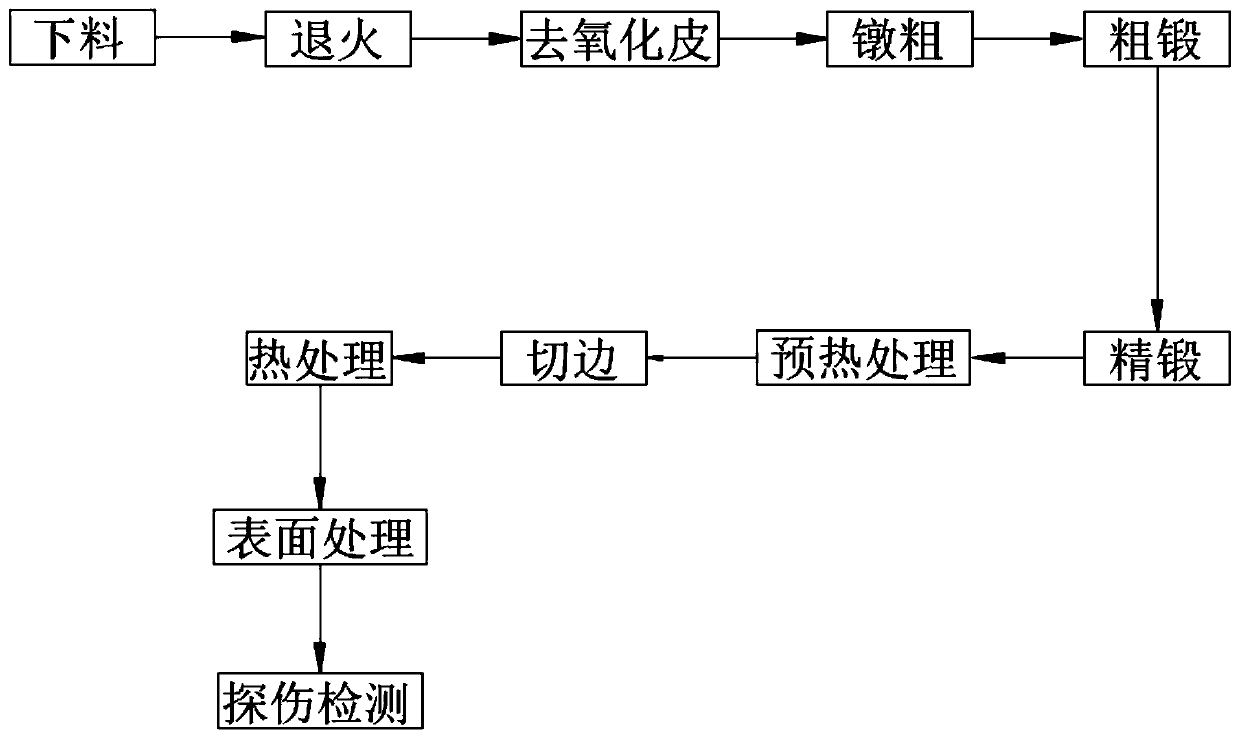

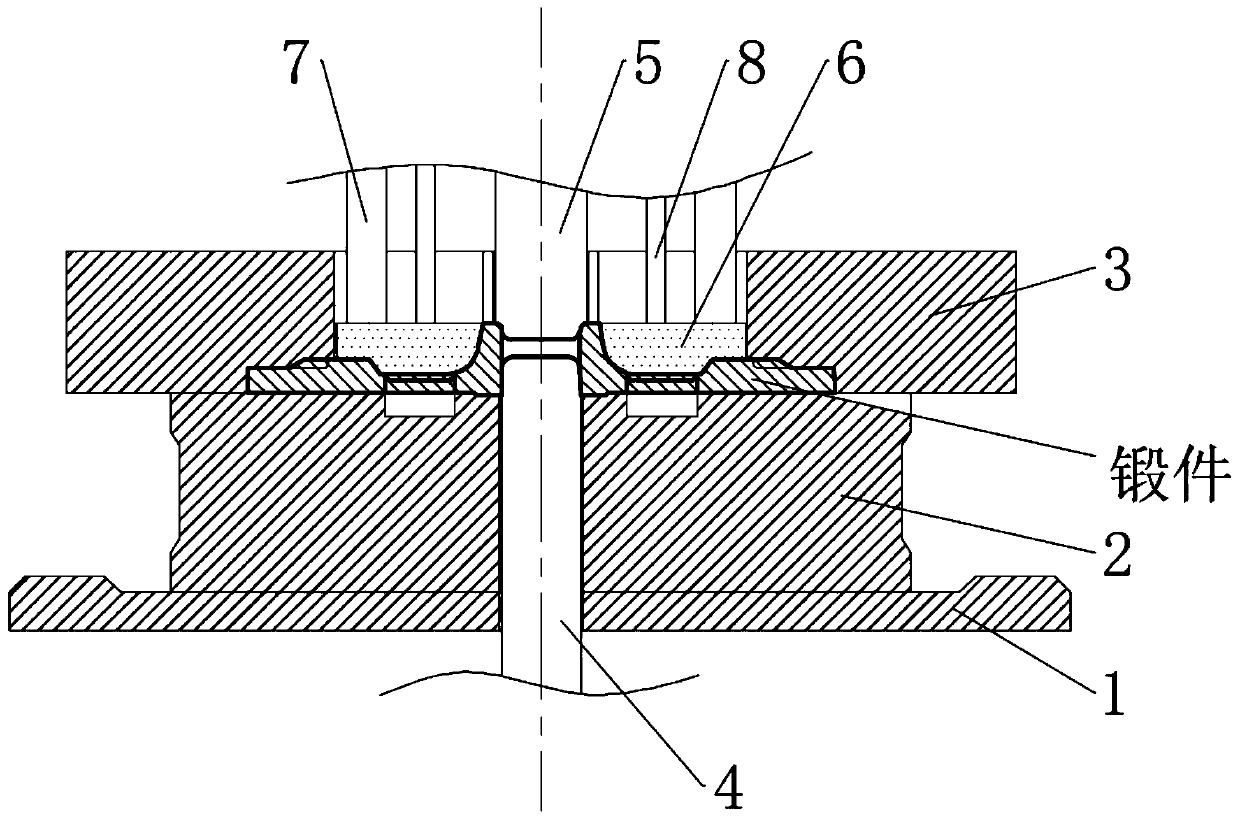

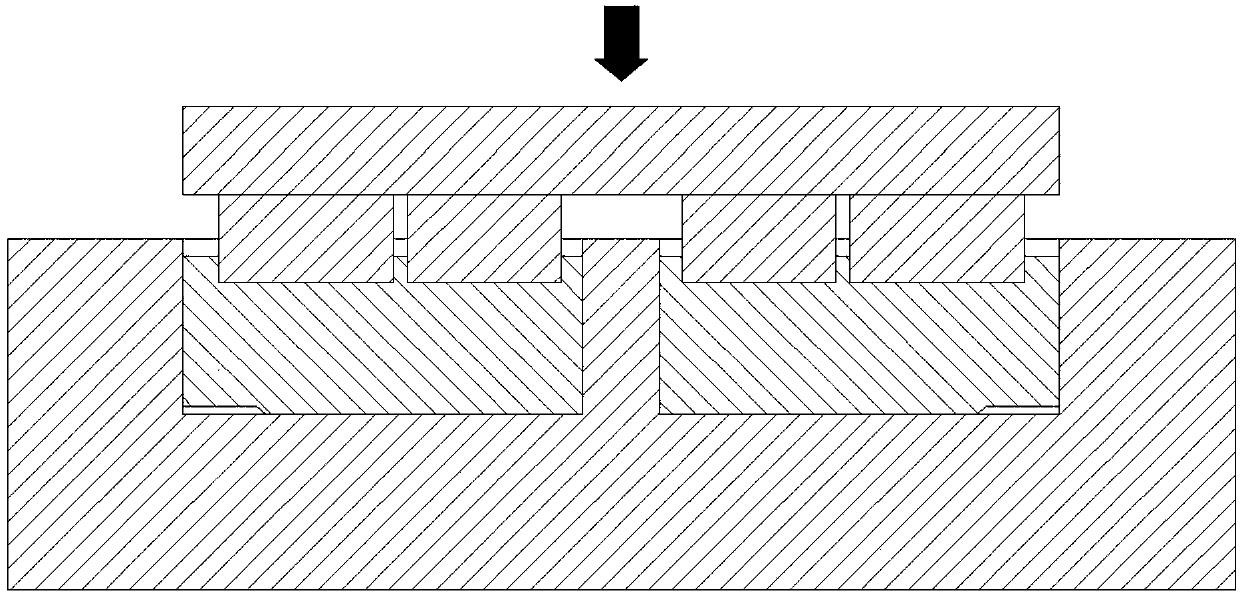

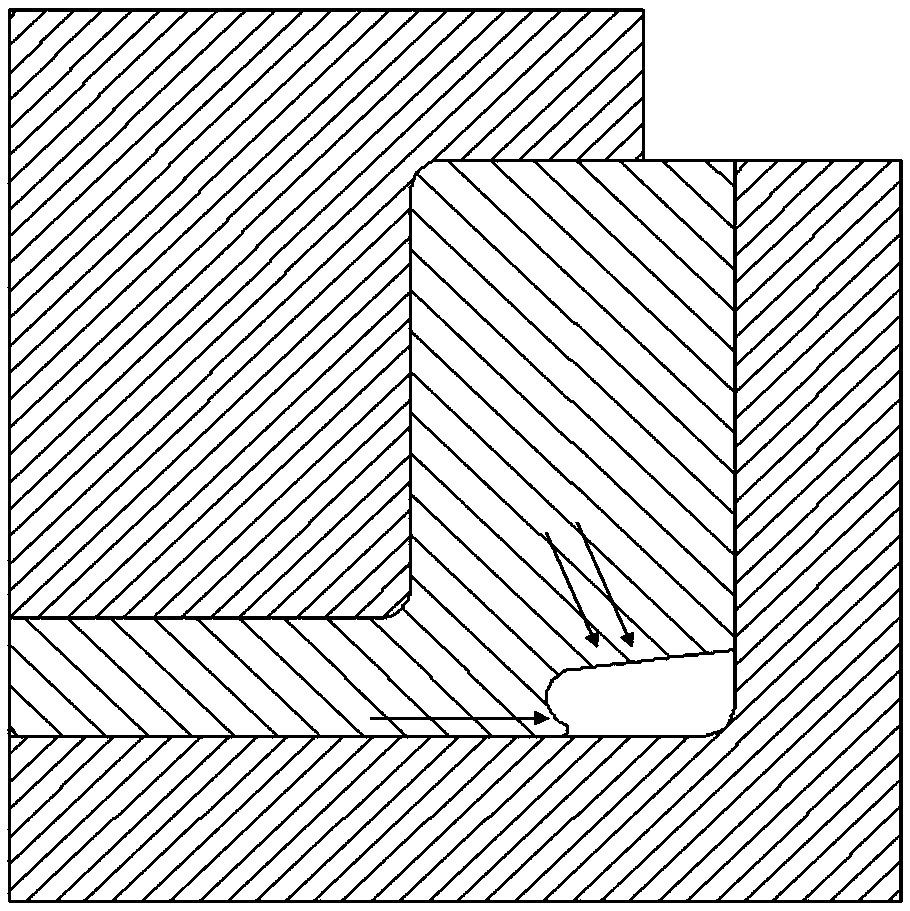

Forging technology for synchronous waste-removing and weight-reduction of forge piece

ActiveCN110722078AAvoid local deformationEasy to useForging/hammering/pressing machinesForging press detailsTemperature controlPunching

The invention discloses a forging technology for synchronous waste-removing and weight-reduction of a forge piece, and belongs to the technical field of forge piece processing. A weight-reduction partand an installation hole part of the forge piece can be achieved in the forging process; by installing a fractional punching mechanism in an existing precision forging die, the forge piece can be directly formed at a time in the forging process based on a thermal stress principle and a plastic deformation rule of the forge piece, and local deformation of the forge piece is prevented. Wastes are removed at a time, the machining difficulty and cumbersome operation brought by a machining process after forging are avoided, and the cost is further reduced; moreover, punching burrs on a non-machining surface can be avoided, and the whole machining workload is reduced; assisted by precise temperature control in the whole process, the shape of the flange hub forge piece can be obtained, dimensional deviations are not likely to be produced, structures in metal can be improved, the mechanical performance and the physical performance of the metal are improved, and therefore, the flange hub forgepiece higher in use performance and longer in life.

Owner:浙江众盈汽车零部件有限公司

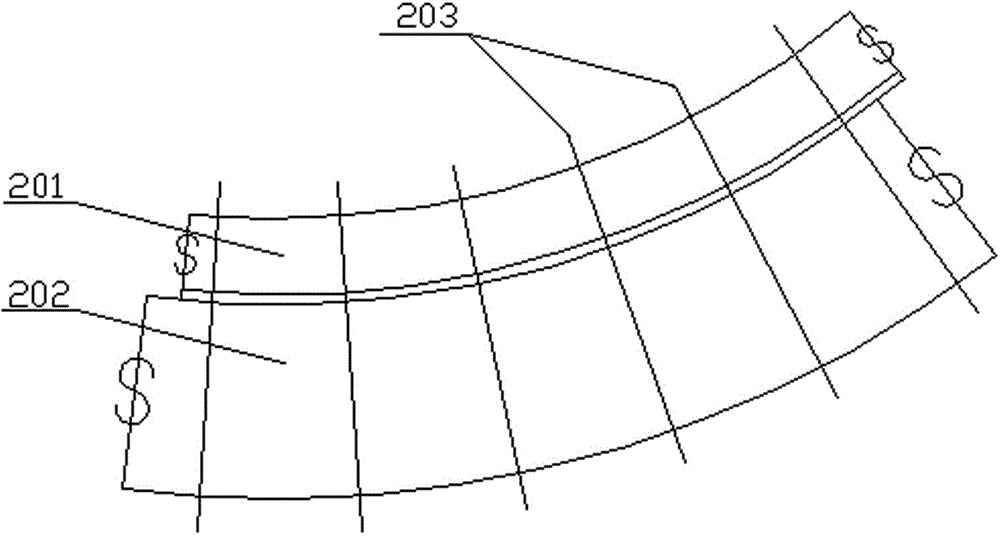

Welding method of maritime crane barrel neck opening

The invention discloses a welding method of a maritime crane barrel neck opening. The welding method comprises the following steps: welding a rolling passage plate, welding an annular plate assembly, welding an annular plate assembly and a rolling passage plate, welding a box body structure and a peripheral plate, welding a lower cone, and finally folding the box body structure and a cone. The welding method has the advantages that the maritime crane barrel neck opening is manufactured according to the welding method strictly through repeated verifications of a plurality of items, so that the allowance can be effectively reduced, the welding workload is reduced, the machining workload is reduced, the deformation of the barrel neck opening can be well controlled, the qualified rate of finished products is improved, and the welding method is beneficial to popularization.

Owner:南通中集太平洋海洋工程有限公司

Lost foam casting process for flywheel cover of heavy truck engine

InactiveCN103894548AReduce pollutionHigh precisionFoundry mouldsFoundry coresSurface brightnessPolystyrene

The invention relates to a lost foam casting process for a flywheel cover of a heavy truck engine. The lost foam casting process comprises the following steps of manufacturing a model of which the shape and the size are consistent with those of a casting from expanded plastics prepared by mixing expandable polystyrene and polymethyl methacrylate, coating the model with a refractory and air-permeable material, drying, hardening the model, placing the model in a sand box, filling dry sand, performing vibration ramming, pouring metal liquid, and performing vacuumizing to form negative pressure in the pouring process to realize the replacement of the foam model by the metal liquid and enable the foam model to disappear without traces. According to the process, various problems of a plurality of defects in the casting, surface roughness, high raw material consumption, severe environmental pollution and the like in a conventional sand mold casting process for the flywheel cover of the heavy truck engine are solved, and the lost foam has the advantages of high inner quality, surface brightness and cleanliness, high production efficiency, slight environmental pollution and the like.

Owner:HANZHONG YANHANG PRECISION MACHINERY MFG

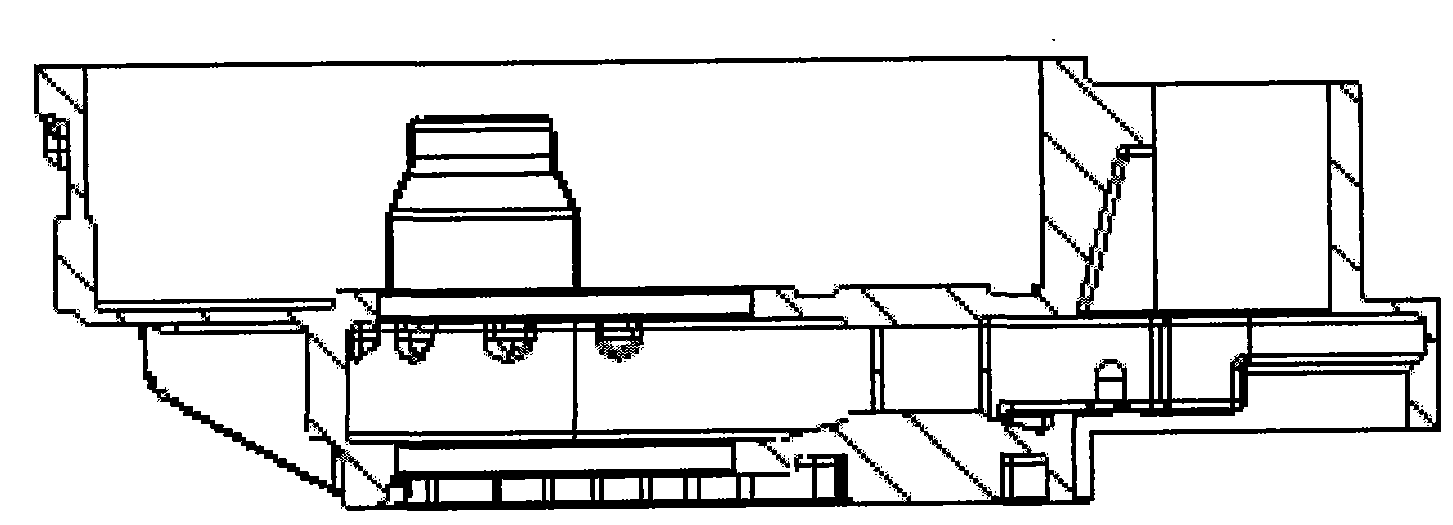

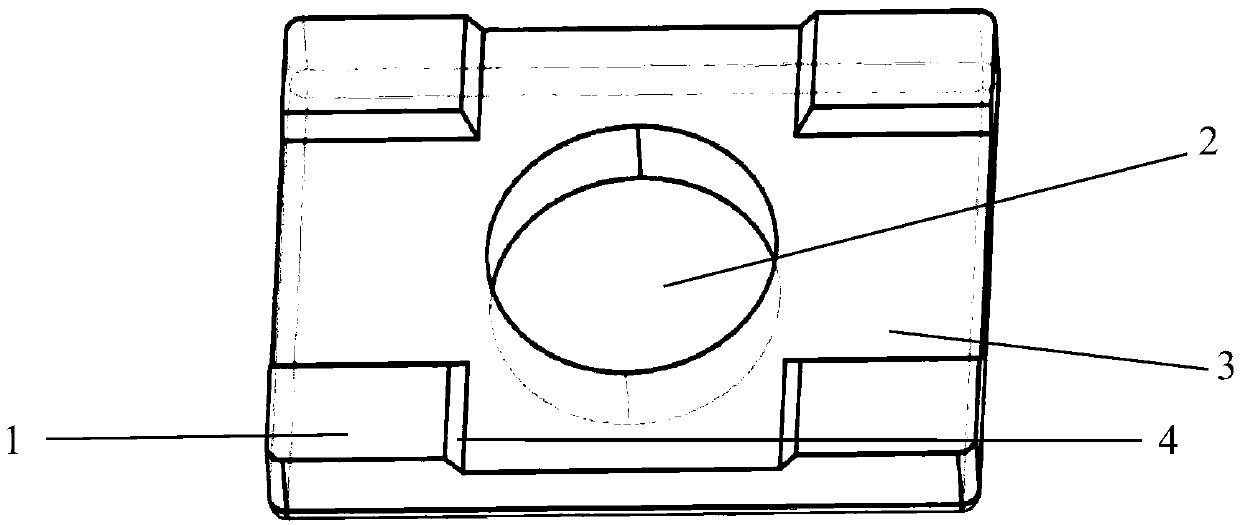

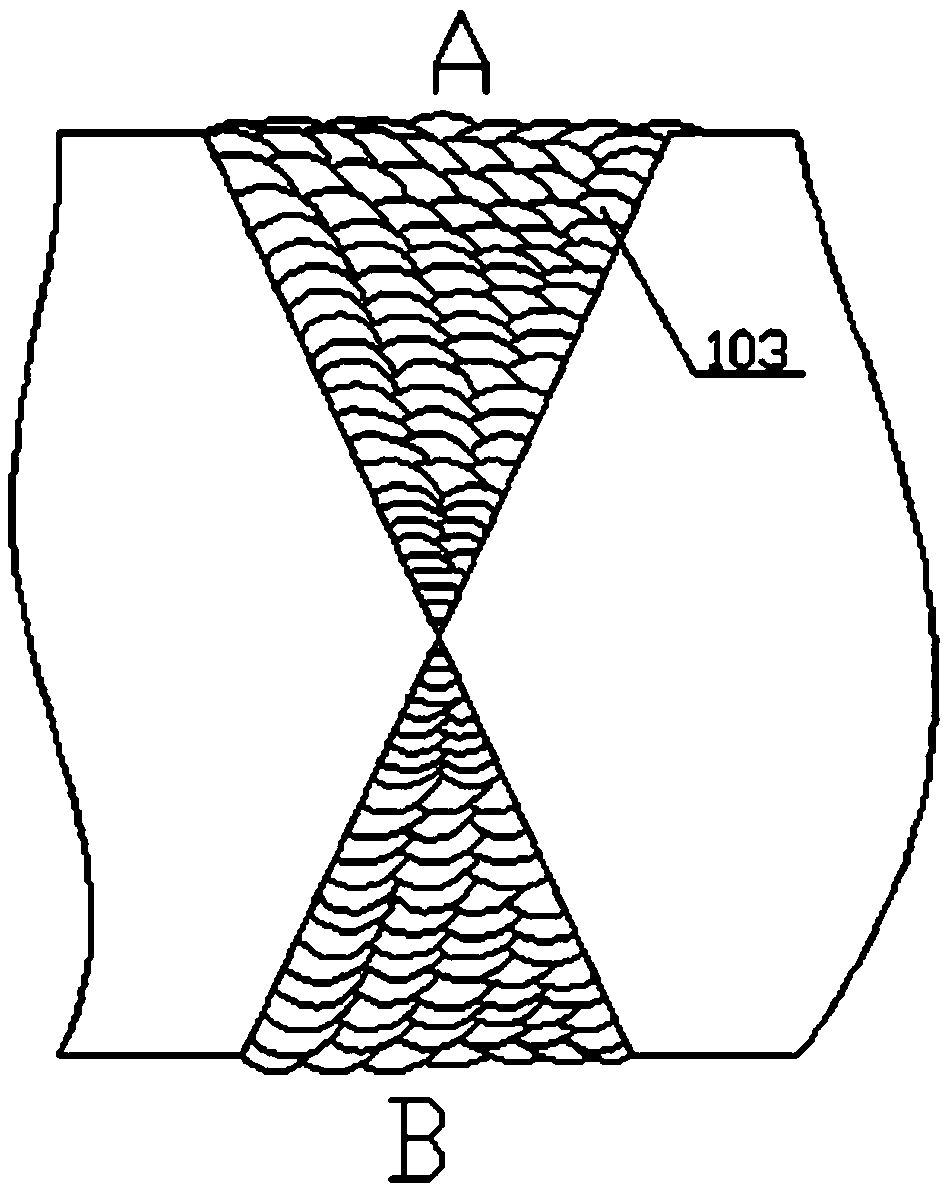

AZ80A magnesium alloy engine case isothermal forging forming mould and method

ActiveCN103433416AQuality improvementExtended service lifeForging/hammering/pressing machinesStructure propertyMetallurgy

The invention relates to a magnesium alloy forged piece forming mould and method, in particular relates to an AZ80A magnesium alloy engine case isothermal forging forming mould and method, which aim at solving the problems of difficulty in forming, non-uniform structure property of magnesium alloy and low performance existing in conventional forging preparation of an AZ80A magnesium alloy forged piece. The forming mould comprises an upper mould, a lower mould, an ejection rod and multiple electric heating rings, wherein the upper end of a first cylinder is connected with a body, the lower end of the first cylinder is connected with the large-diameter end of a first circular truncated cone, coaxial first conical grooves are formed in the middles of the first circular truncated cone and the first cylinder, the diameters of the cross sections of the first conical grooves are gradually increased from top to bottom, four corners of the upper end surface of the lower mould are respectively provided with a positioning convex platform, the upper mould covers the lower mould, the four positioning convex platforms are arranged in corresponding positioning grooves, the upper mould and the lower mould are respectively provided with the electric heating rings, a second cylinder of the ejection rod is inserted into an ejection hole, and small circular truncated cones are arranged in the first conical grooves. The forming mould and method are used for preparing an AZ80A magnesium alloy engine case.

Owner:HARBIN INST OF TECH

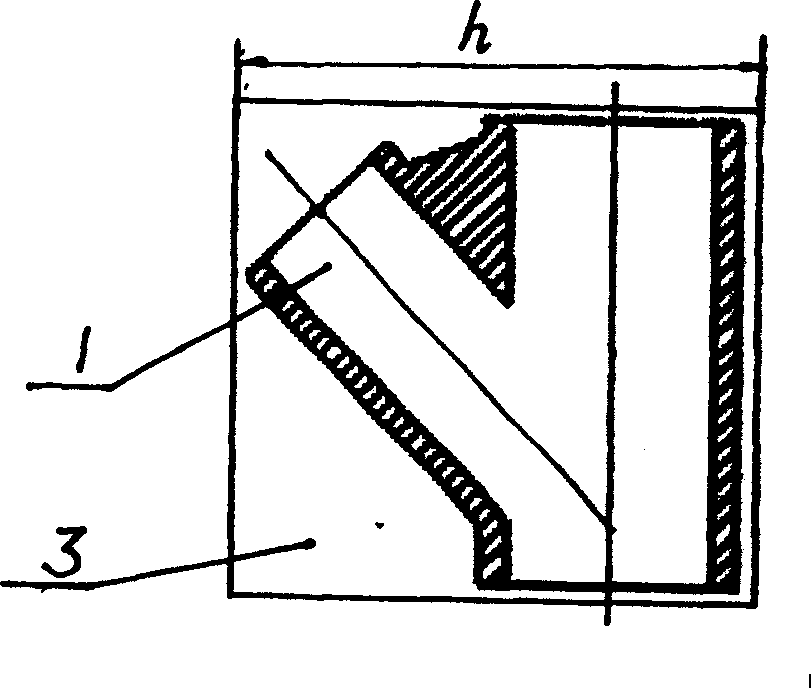

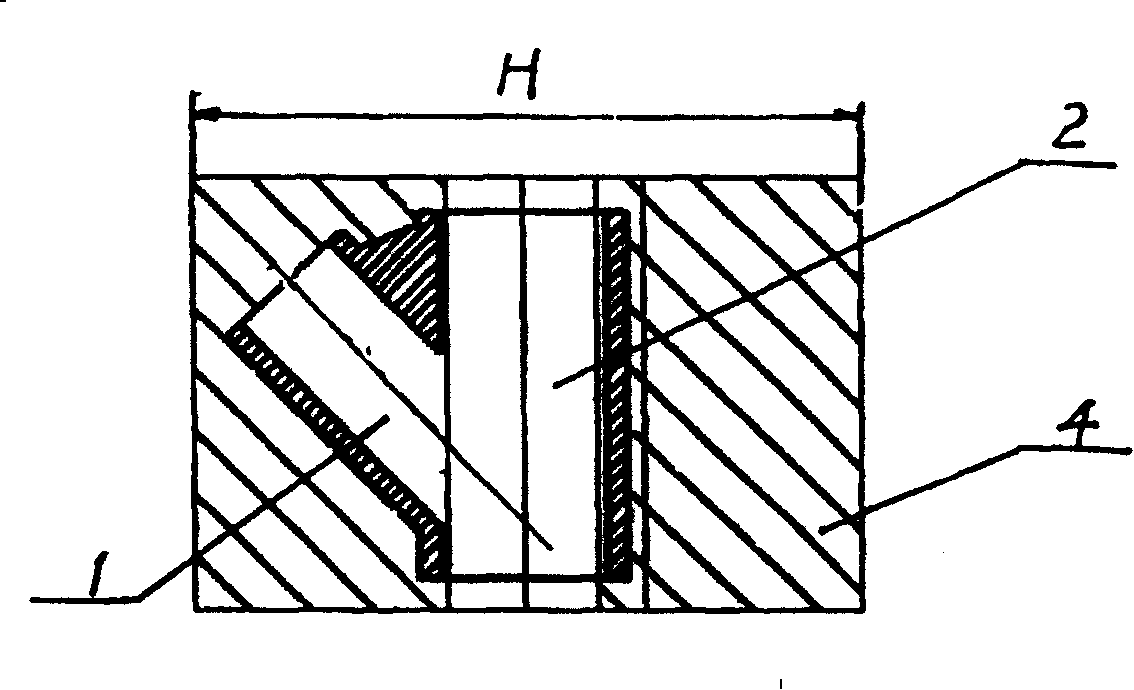

Precision forming method of aluminum alloy reinforcement plate rectangular forging part

ActiveCN109570418AImprove production efficiencySave materialMetal-working apparatusOblique planeAluminium alloy

Owner:HARBIN INST OF TECH

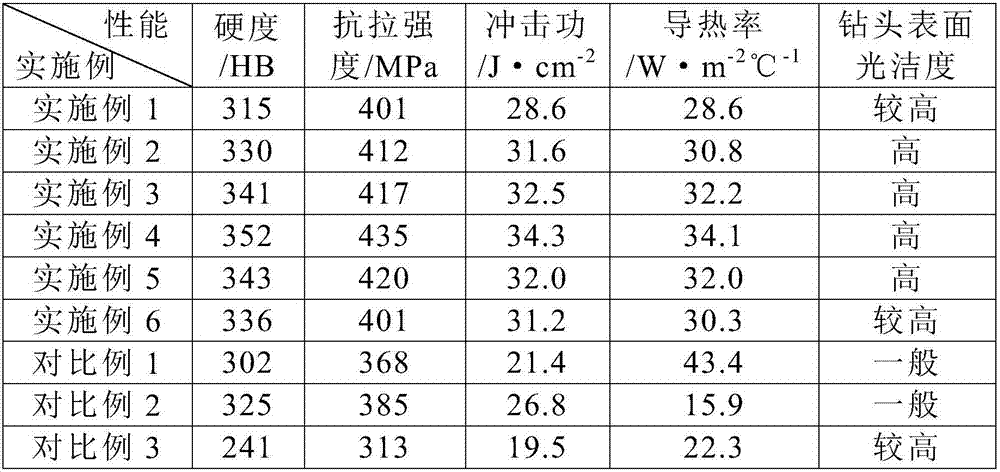

Dewaxing casting method for drill bit

InactiveCN106975729AImprove performanceReduce brittlenessFoundry mouldsFoundry coresWaxSand blasting

The invention relates to a dewaxing casting method for a drill bit and belongs to the technical field of casting. The casting method includes the steps of coating preparation, shell preparation, calcinations, melting casting and post-processing. The coating preparation includes the steps that materials are mixed, ultrasonic vibration is performed while mechanical stirring is performed for 8-15 hours, then plasma processing is performed for 3-5 minutes, and a basic coating is fabricated; and water is added to the basic coating to dilute the basic coating into a first-grade coating and a second-grade coating, and the viscosity of the first-grade coating is smaller than that of the second-grade coating. The shell preparation includes the steps that the coating is smeared on the preformed fusible wax mould surface, sand blasting and drying are performed, then dewaxing is performed, and a mould shell billet is fabricated. Smearing of the coating includes the steps of primary smearing and secondary smearing, in the primary smearing process, the first-grade coating is rotatably sprayed on the fusible wax mould surface, in the secondary smearing process, the fusible wax mould coated with the first-grade coating is soaked in the secondary coating and then taken out, and the steps of coating smearing, sand spraying and drying are repeatedly performed for 2-5 times. The drill bit prepared through the method is small in error, precise in size and smooth and clean in surface.

Owner:宁波神钻工具有限公司

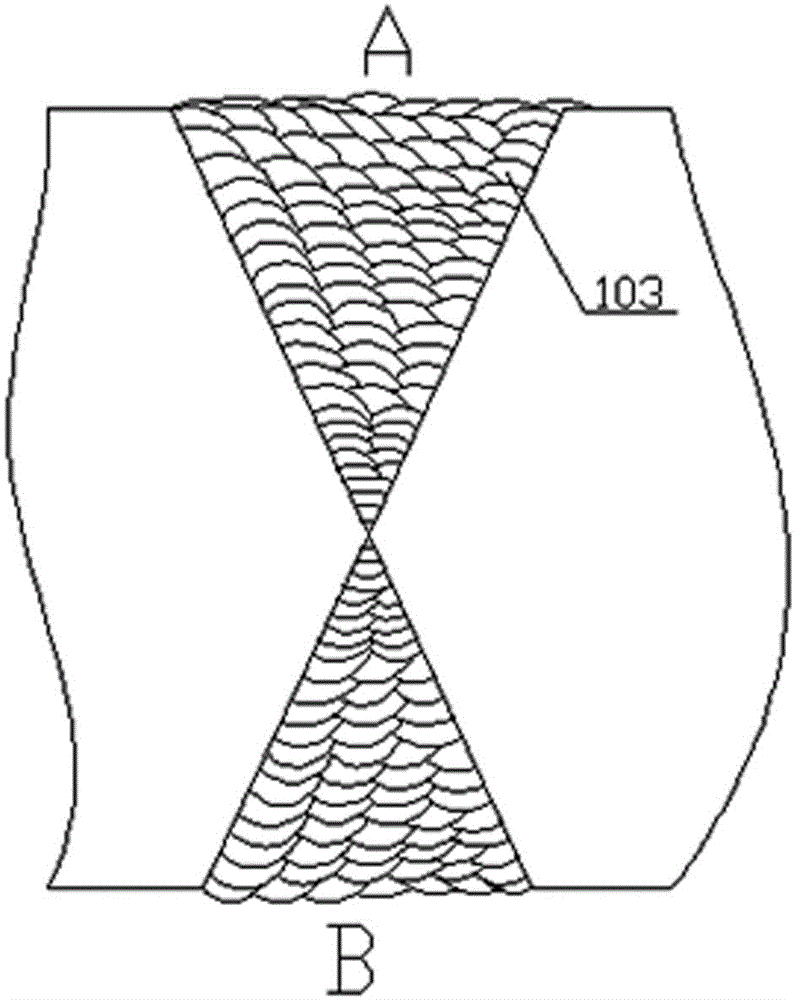

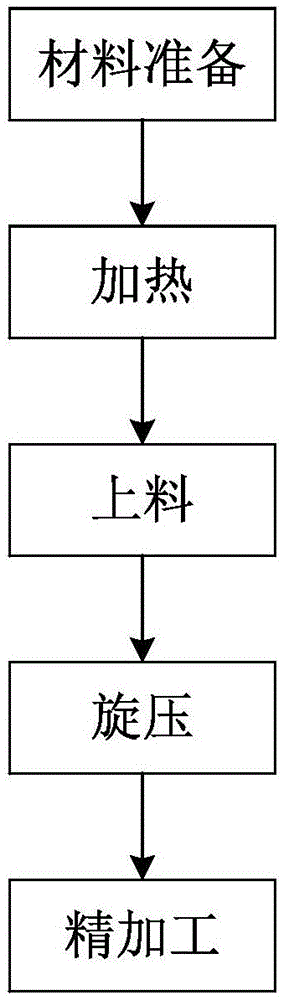

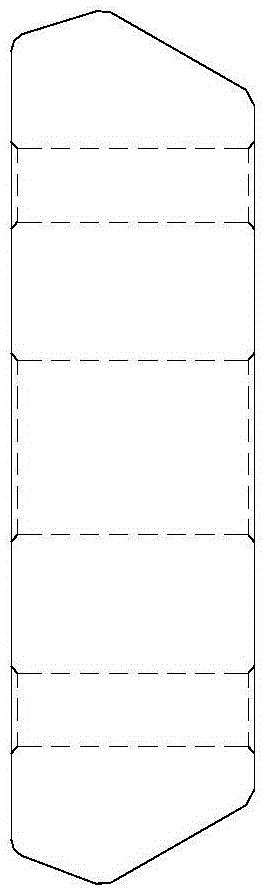

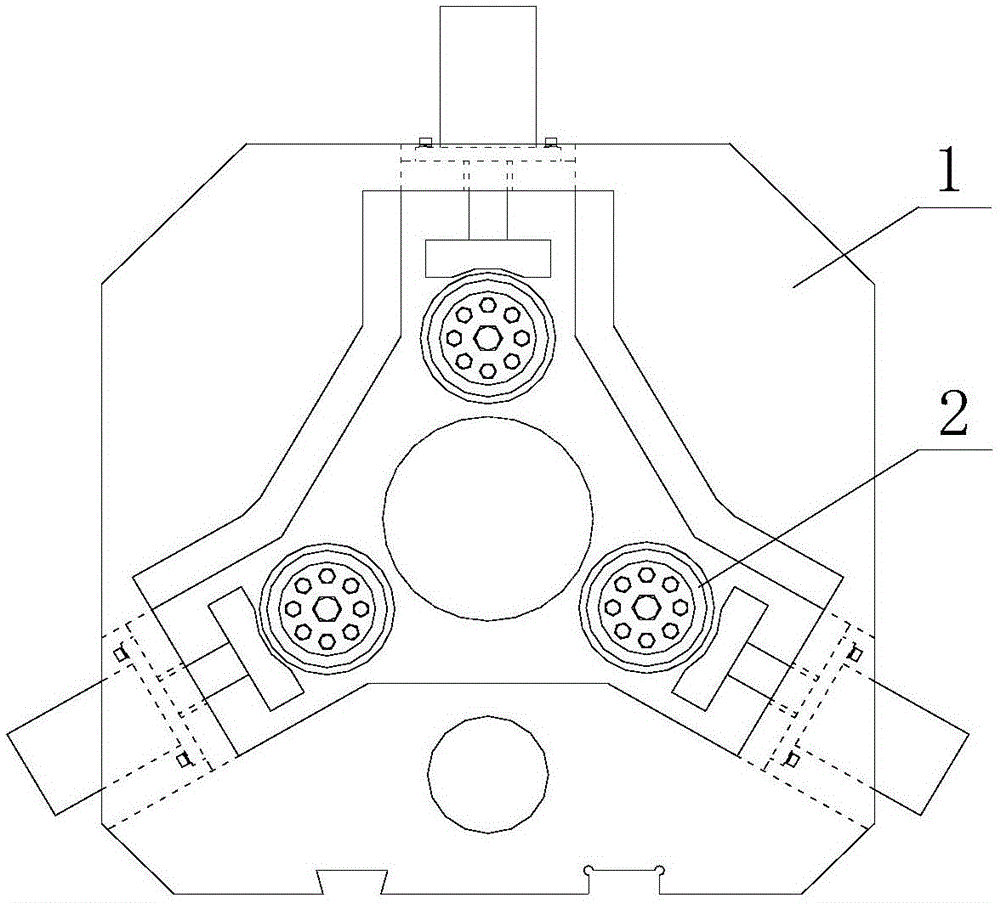

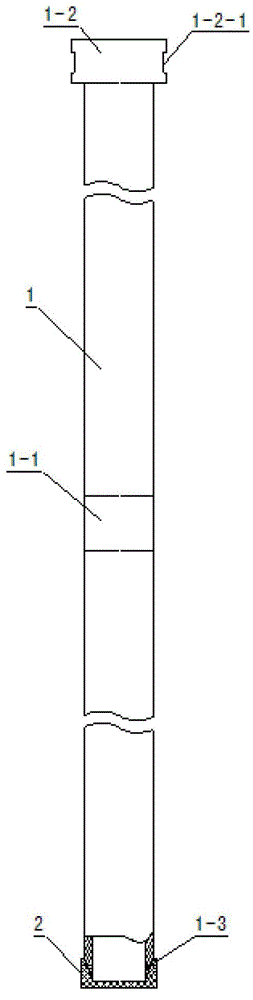

Brute-force hot-spinning accurate plastic forming method for hollow train shaft workblank

ActiveCN105081041AReduce processing workloadHigh forming precisionVehicle componentsMaterials preparationBrute force

The invention relates to a brute-force hot-spinning accurate plastic forming method for hollow train shaft workblank and belongs to the technical field of plastic forming of long-shaft parts. According to the brute-force hot-spinning accurate plastic forming method, the problems that hollow train shaft moulds are difficult to manufacture and complex in manufacturing process are solved. The brute-force hot-spinning accurate plastic forming method comprises the steps of material preparing, heating, feeding, spinning and refining. By means of a brute-force hot-spinning technique, the rotating speed of work pieces, the feeding speed of a rotary wheel and the axial moving speed of a rotary wheel frame are controlled by a numerical controlling technique. Thus, high-accuracy hollow train shaft workblank can be obtained in a spinning manner, and quick accurate plastic forming of the hollow train shaft workblank can be achieved. The brute-force hot-spinning accurate plastic forming method is simple in manufacturing procedure, good in metal fiber flow direction, small in machining allowance, high in material utilizing rate, mouldless in forging, low in manufacturing cost and suitable for large batch production of various specifications of hollow train shafts.

Owner:QINGDAO ZHONGTIANPENG FORGING MFG CO LTD

Underground continuous wall joint close grouting and covering construction method and expansion rubber plug

ActiveCN102747722AThe Effect of Optimal Grouting to Seal LeakageReduce machining workloadArtificial islandsUnderwater structuresStructural engineeringEngineering

The invention relates to an underground continuous wall joint close grouting and covering construction method and an expansion rubber plug. According to the construction method, an obligated grouting duct is arranged at the joint of a middle amplitude and a first amplitude of a slot wall; the end of the duct is provided with an expansion rubber plug with a grouting interface tube; the obligated grouting duct is communicated with a leakage gap on any position of the joint of the middle amplitude and the first amplitude; and the effect of grouting plugging leakage is superior to an embedded grouting tube provided with a spraying hole. By adopting the obligated grouting duct in the construction method, a great amount of embedded grouting tubes and corresponding machining amount can be saved, and the expansion rubber plug can be recycled. The obligated grouting duct is also suitable for leakage detection method and plugging type subsection grouting and leakage detection method in the prior art. The construction method can be applied to slot-type continuous structures with any forms of leakage-proof joints. The construction method is simple, steel products can be saved, and the grouting and covering effect is reliable.

Owner:天津市勘察设计院集团有限公司

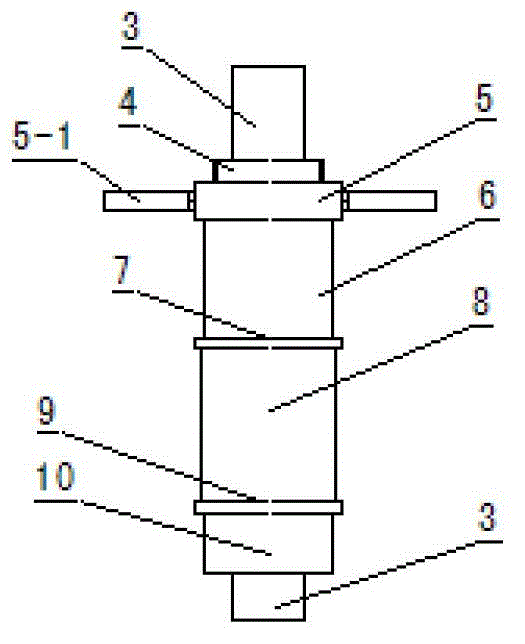

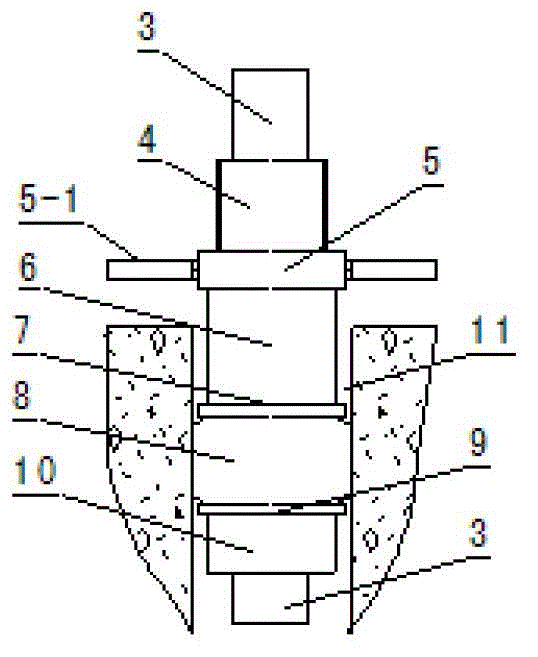

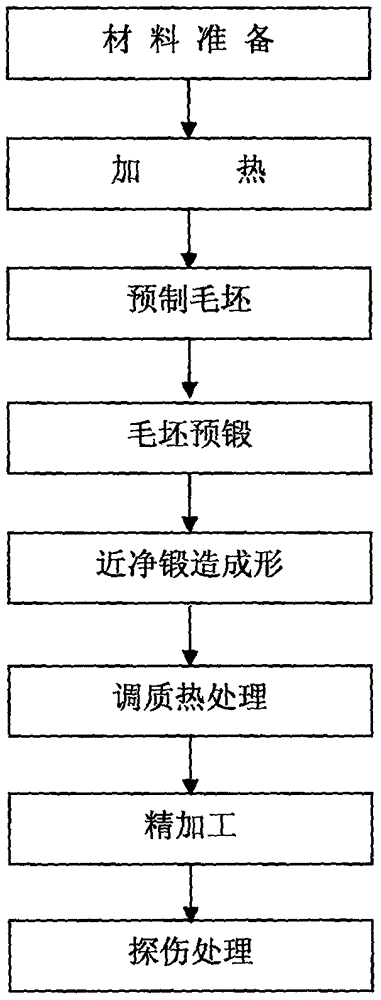

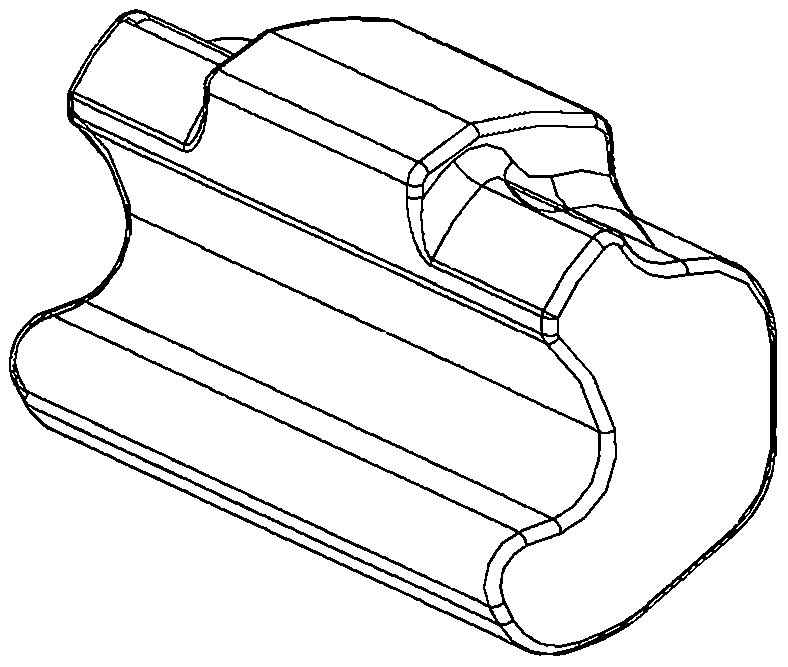

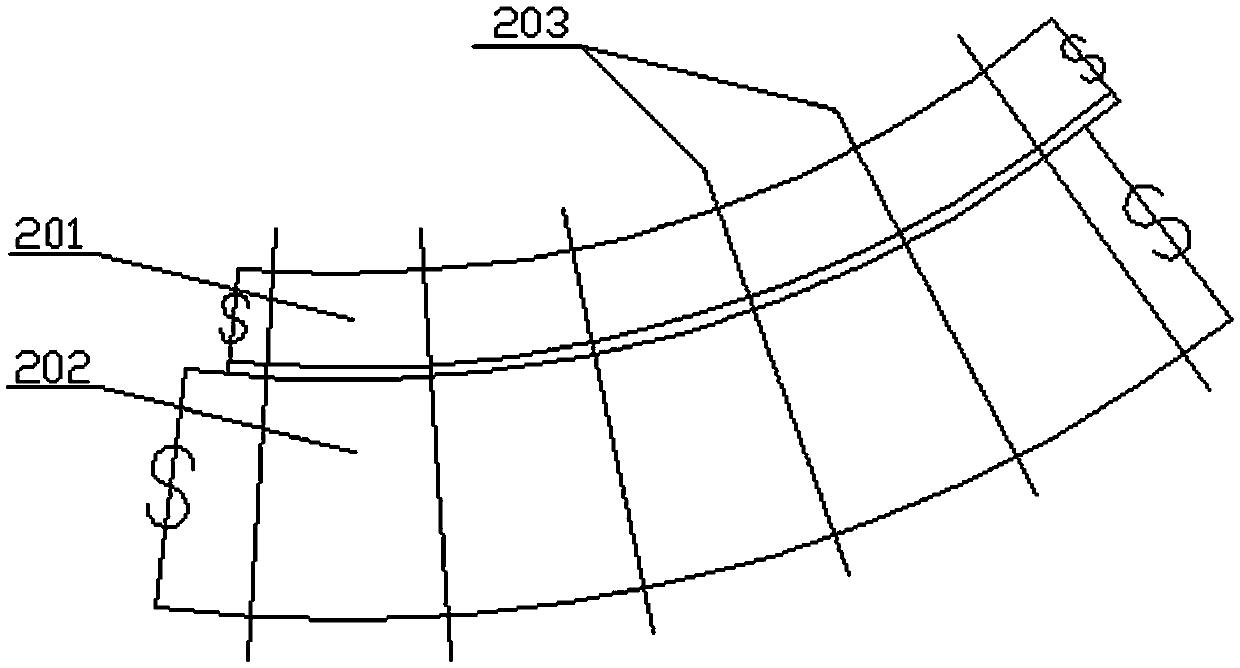

Near-net forging forming method of railway vehicle coupler knuckle

ActiveCN106077380AHigh forming precisionNo machining process requiredMetal-working apparatusMaterials preparationHigh volume manufacturing

The invention discloses a near-net forging forming method of a railway vehicle coupler knuckle. The problems that forging forming of the railway vehicle coupler knuckle is difficult, and the machining and manufacturing process is complex are solved. The near-net forging forming method comprises the steps of material preparation, heating, prefabrication of blanks, preforging, closed die-forging, waste heat quenched-tempered heat treatment, finish machining, flaw detection and the like. A closed die-forging technology is adopted so that near-net forming of the coupler knuckle can be achieved, energy and materials are saved, the outer contour shape and size do not need to be machined, and the utilization ratio of the materials can reach 92% or above. In the whole forming process, workpieces are always in a three-dimensional stress state, and products have a compact structure, high toughness, good fatigue performance and long service life. The defects of air holes, shrinkage porosity, inclusions, cracks and the like in existing casted coupler knuckles are overcome, and the problems of complex process and difficult forming in the existing coupler knuckle forging manufacturing process are solved. The near-net forging forming method is simple in manufacturing process, high in material utilization rate and suitable for mass production and manufacturing of railway vehicle coupler knuckle products of various types.

Owner:JILIN UNIV +1

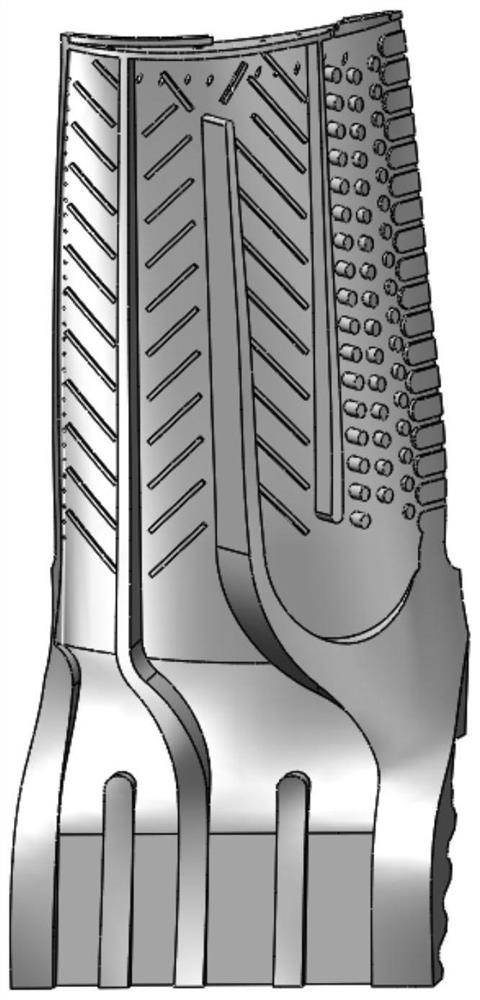

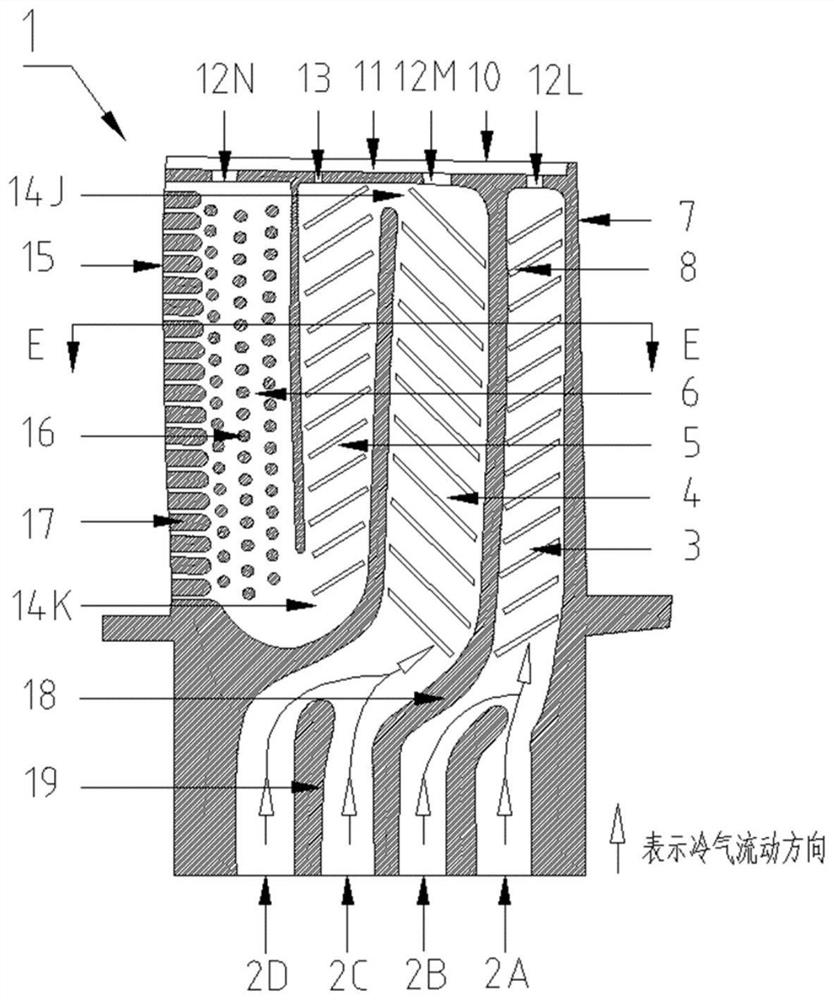

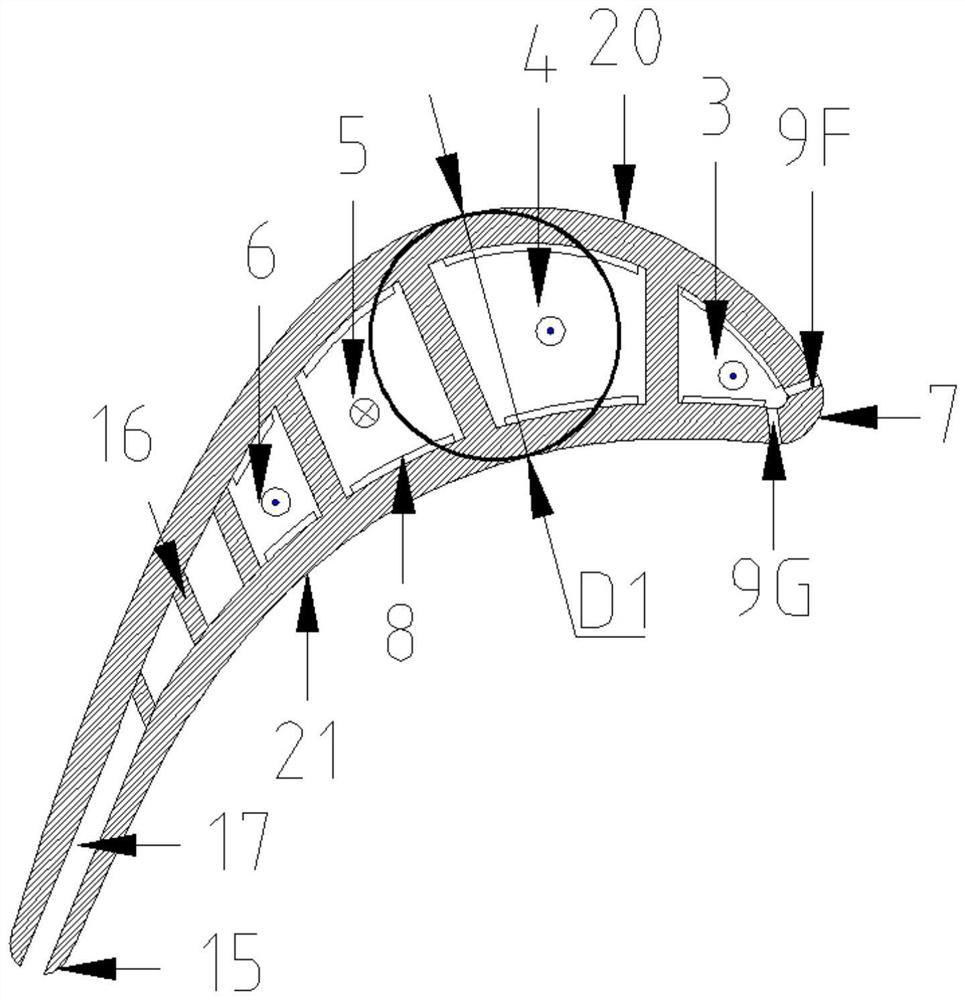

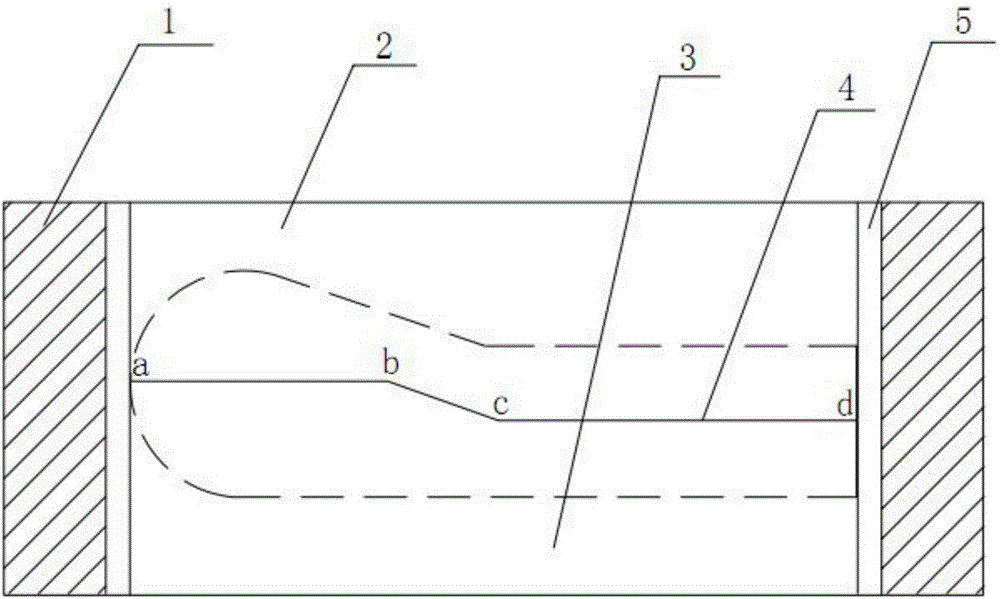

Cooling structure of turbine movable vane of gas turbine

ActiveCN111810245AImprove cooling effectReduce the temperatureBlade accessoriesEfficient propulsion technologiesSerpentine channelCooling effect

The invention discloses a cooling structure of a turbine movable vane of a gas turbine. The cooling structure comprises four channels sequentially distributed in the vane, a vane top part and a vane bottom part. The first channel is adjacent to the front edge of the vane, the second channel is a serpentine channel spaced from the first channel, the third channel is a serpentine channel spaced fromthe second channel, and the fourth channel is a serpentine channel formed by the third channel and the tail edge of the vane; the vane top part is located at the upper end of the first, second, thirdand fourth channels and is of an incomplete groove structure; and the vane bottom part is located at the lower end of the first, second, third and fourth channels. Compared with the prior art, the front edge of the vane, the vane top part and other parts of a vane body can be fully cooled, the cooling effect is good, and manufacturing is simple.

Owner:浙江燃创透平机械有限公司

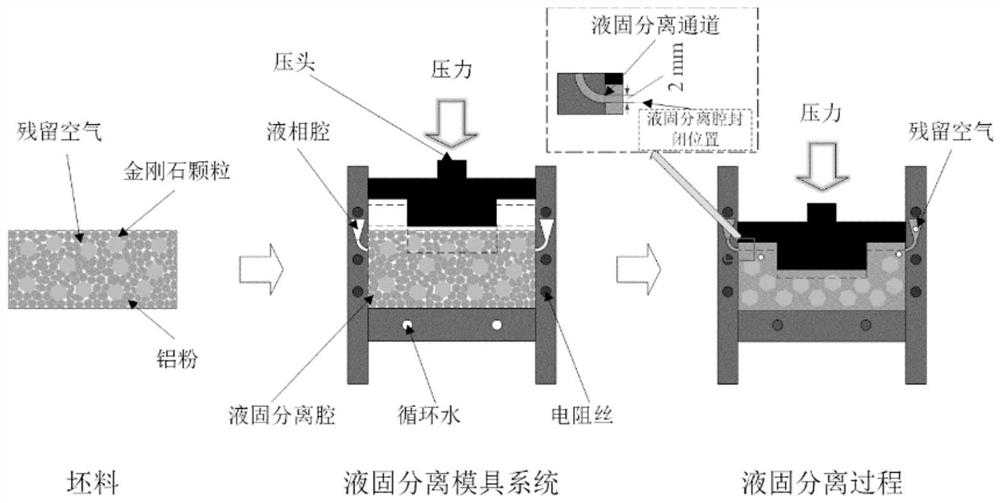

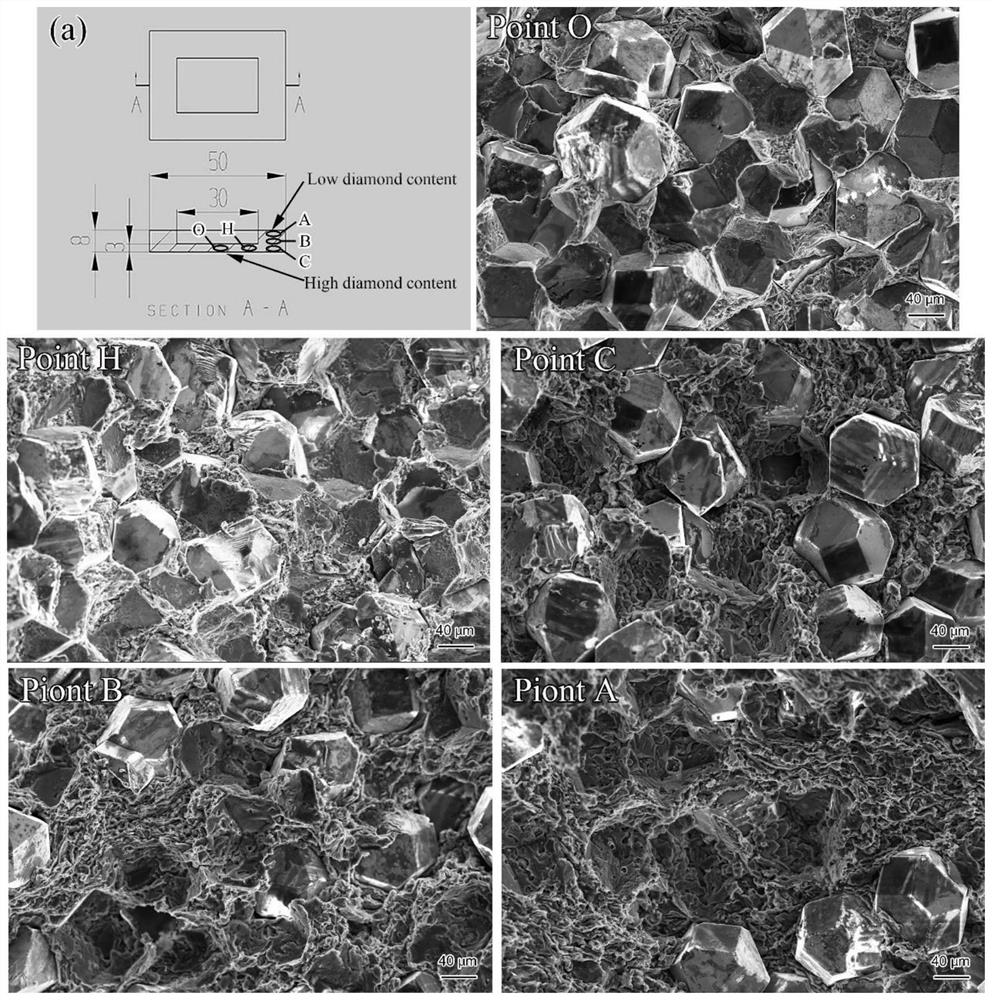

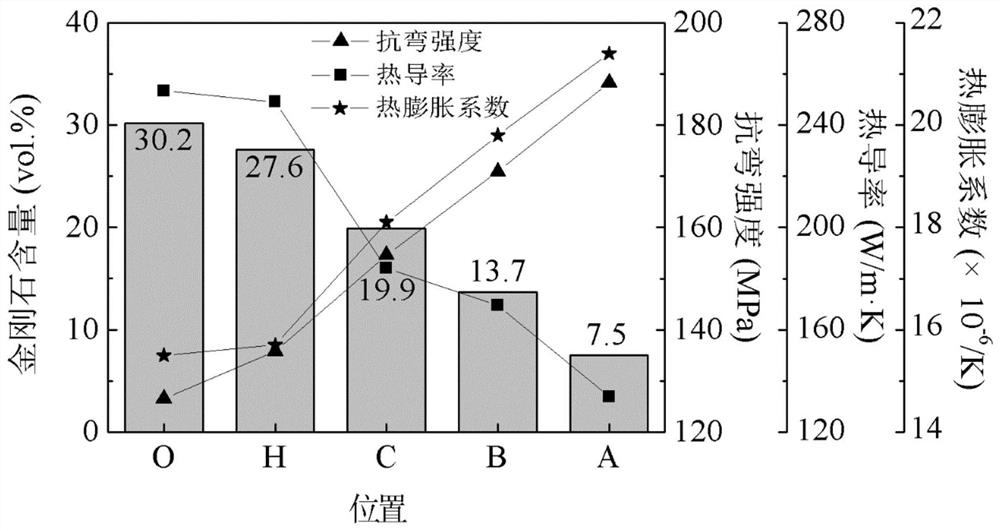

Preparation method of functionally gradient diamond/aluminum composite material packaging shell

ActiveCN113481402AShort processLow costSemiconductor/solid-state device detailsSolid-state devicesAl powderMold filling

The invention discloses a preparation method of a functionally gradient diamond / aluminum composite material packaging shell, and relates to a diamond / aluminum composite material and a near-net forming preparation method of the diamond / aluminum composite material. The preparation method of the functionally gradient diamond / aluminum composite material packaging shell comprises the specific steps that 1, diamond particles and aluminum powder are mechanically mixed according to a certain proportion and then pressed into a cold-pressed blank; 2, the cold-pressed blank is heated in a liquid-solid separation mold system to be in a liquid-solid mixed melting state; 3, the mold filling process is completed by liquid-solid mixed melting slurry under the action of pressure, and directional separation treatment is completed by part of the metal liquid phase through a liquid-solid separation channel so as to adjust the volume ratio of diamond on the top of a cavity; and 4, the remaining slurry is solidified layer by layer under the action of a bottom end cooling system, pressure maintaining is continuously conducted in the process, and finally a diamond / aluminum composite material gradient packaging shell is prepared. The chip bearing part at the bottom of a shell is high in diamond content, and has high thermal conductivity while the thermal expansion coefficient is matched with that of a chip; the diamond content at the top of a wall body is low, so that the welding compatibility with a cover plate material is ensured.

Owner:UNIV OF SCI & TECH BEIJING

Oblate flange complete fiber forging technology

The invention provides oblate flange complete fiber forging technology. A complete fiber flow of oblate flange forged piece metal is obtained. Machining allowance of a forged piece is reduced, a material using rate is improved, and process cost of heat processing after forging is reduced. Therefore, inside portion and outside portion of the forged piece are compactly organized, mechanical performance is enhanced, and heat treatment process pressure is reduced. The oblate flange complete fiber forging technology is characterized by comprising the following steps: (1) the dimensions of forged materials are calculated and blanking is conducted; (2) the outer circles of the forged materials are rounded; (3) the forged materials are punched; (4) local drawing-out is conducted on an inner hole through a mandrel; and (5) chambering is conducted on the forged piece obtained by the step (4) and the forged piece is flattened to form a flange.

Owner:WUXI HONGDA HEAVY IND

A laser cladding repair method for the surface of aircraft vertical pins and bolts

ActiveCN105349992BReduce use costReduce maintenance costsMetallic material coating processesHeat-affected zoneSlag

The invention discloses a laser cladding repairing method for airplane normal pin and bolt part surfaces. The method comprises the steps that spherical superhigh-strength steel metal powder is selected for faults such as mechanical and corrosive wear to the part surfaces, reasonable laser cladding technology parameters are adopted, appropriate heat treatment is adopted for removing residual stress and hydrogen atoms in the cladded parts, and therefore the performance of the airplane normal pin and bolt parts is recovered, and life extension repair is achieved. The deformation probability of the repaired normal pin and bolt parts is almost zero, and the depth of a heat affected zone is controlled within 0.5 mm; the repaired portion has no crack or melting or slag inclusion or other defects; and the using performance of normal pins and bolts is recovered. The airplane normal pin and bolt parts repaired through the method pass authentication before installation, and are installed and used successfully.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for casting high-precision drill

ActiveCN106984772AClear edges and cornersHigh dimensional accuracyFoundry mouldsFoundry coresWaxAfter treatment

The invention relates to a method for casting a high-precision drill and belongs to the technical field of casting. The method comprises the steps of shell making, roasting, melting casting and after-treatment, wherein the shell making step comprises the following sub-steps: coating the surface of a preformed fusible wax pattern with a coating, performing sand blasting and drying, and after that, performing dewaxing to manufacture a shell blank; the coating sub-step comprises first-time coating and second-time coating; during the first-time coating, a primary coating is rotationally sprayed onto the surface of the fusible wax pattern; during the second-time coating, the fusible wax pattern coated with the primary coating is immersed into a secondary coating and then taken out; the viscosity of the primary coating is smaller than that of the secondary coating; and the coating, sand blasting and drying substeps are repeated for 2-5 times. The manufactured drill is small in error, precise in dimension and smooth in surface.

Owner:宁波神钻工具有限公司

AZ80A magnesium alloy engine case isothermal forging forming mould and method

ActiveCN103433416BQuality improvementExtended service lifeForging/hammering/pressing machinesStructure propertyMetallurgy

The invention relates to a magnesium alloy forged piece forming mould and method, in particular relates to an AZ80A magnesium alloy engine case isothermal forging forming mould and method, which aim at solving the problems of difficulty in forming, non-uniform structure property of magnesium alloy and low performance existing in conventional forging preparation of an AZ80A magnesium alloy forged piece. The forming mould comprises an upper mould, a lower mould, an ejection rod and multiple electric heating rings, wherein the upper end of a first cylinder is connected with a body, the lower end of the first cylinder is connected with the large-diameter end of a first circular truncated cone, coaxial first conical grooves are formed in the middles of the first circular truncated cone and the first cylinder, the diameters of the cross sections of the first conical grooves are gradually increased from top to bottom, four corners of the upper end surface of the lower mould are respectively provided with a positioning convex platform, the upper mould covers the lower mould, the four positioning convex platforms are arranged in corresponding positioning grooves, the upper mould and the lower mould are respectively provided with the electric heating rings, a second cylinder of the ejection rod is inserted into an ejection hole, and small circular truncated cones are arranged in the first conical grooves. The forming mould and method are used for preparing an AZ80A magnesium alloy engine case.

Owner:HARBIN INST OF TECH

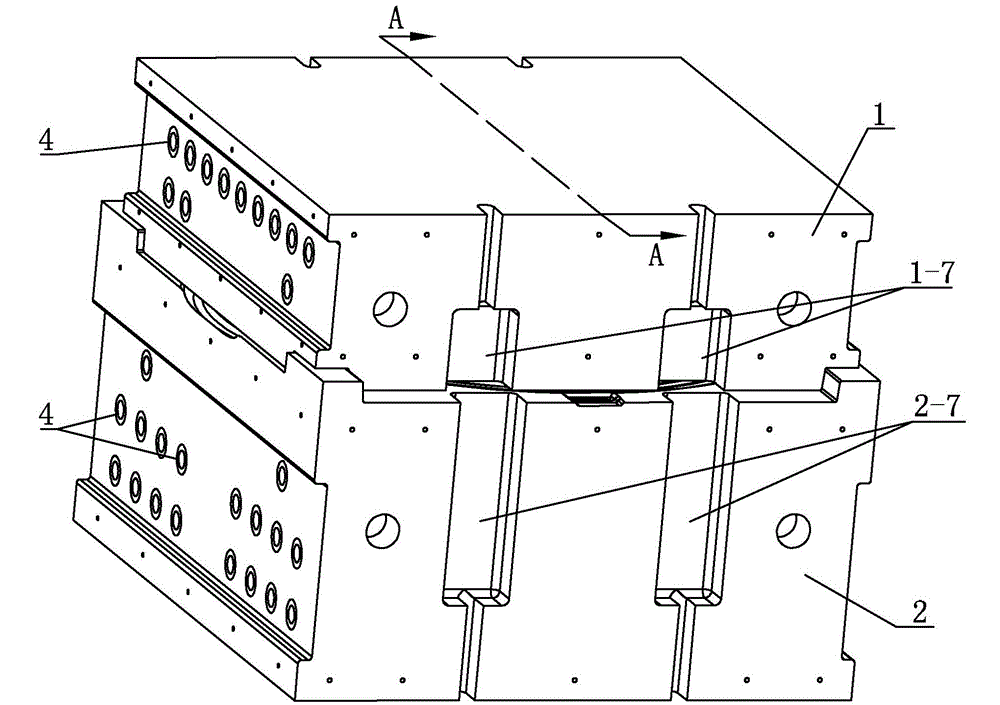

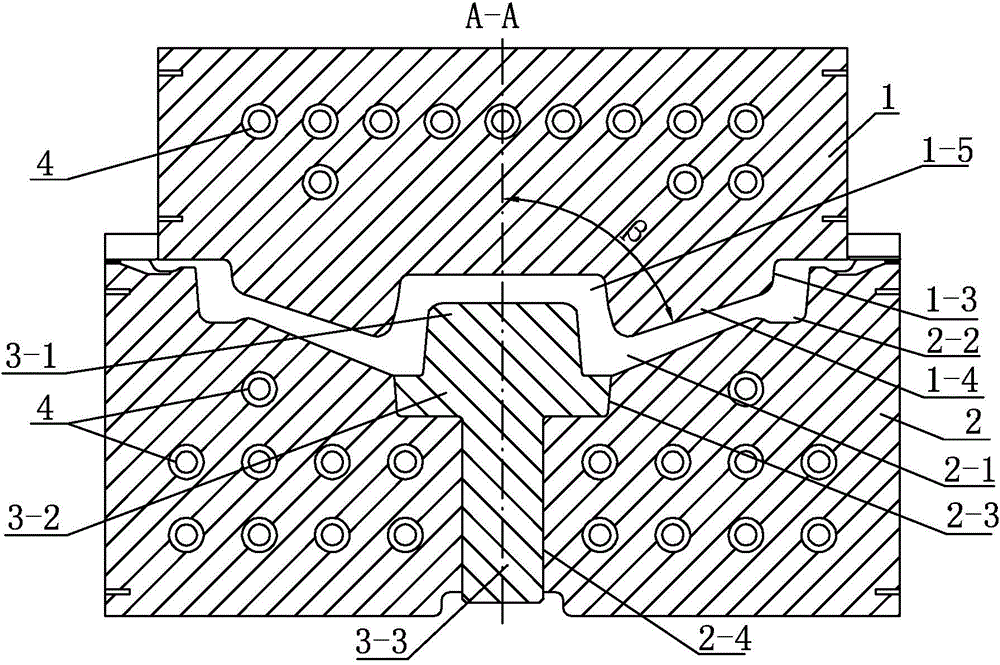

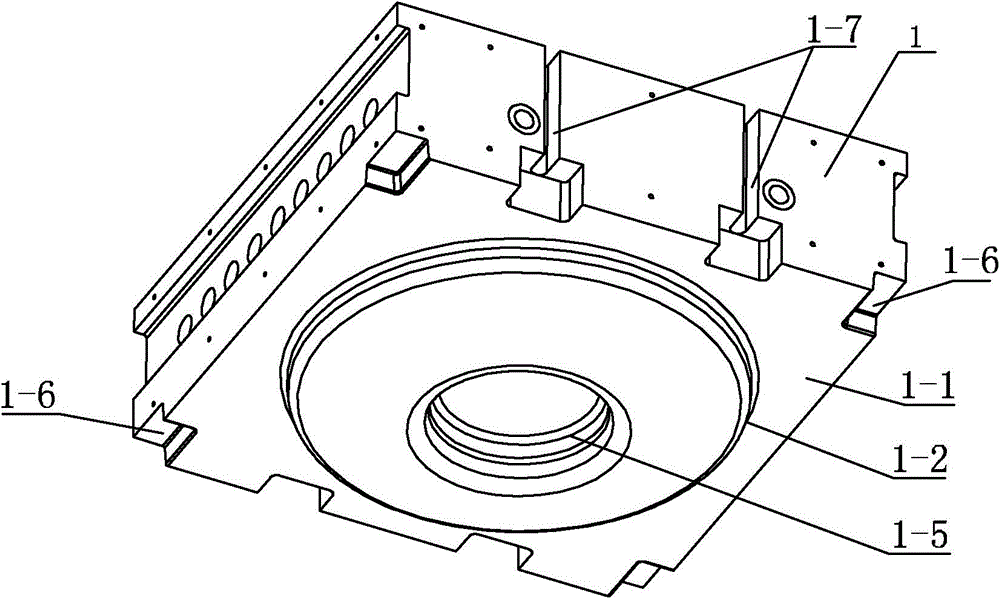

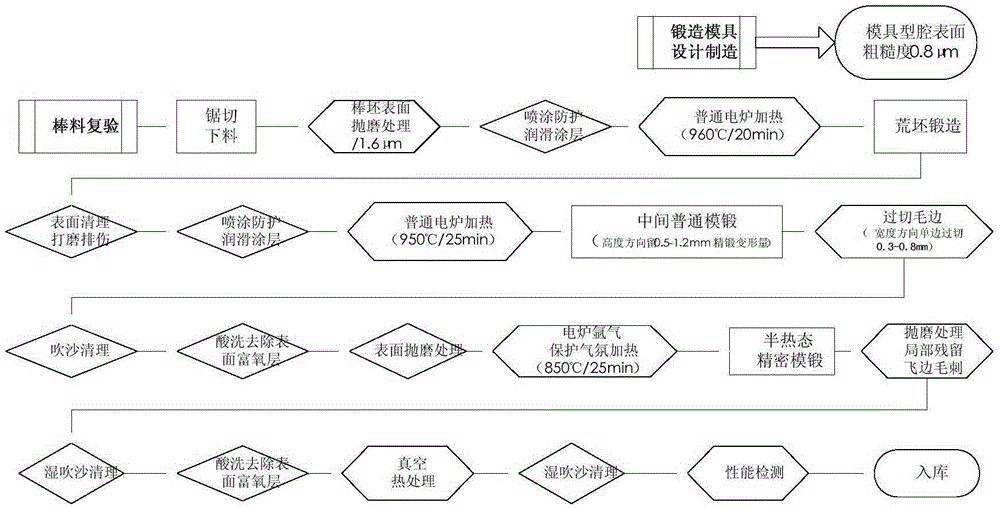

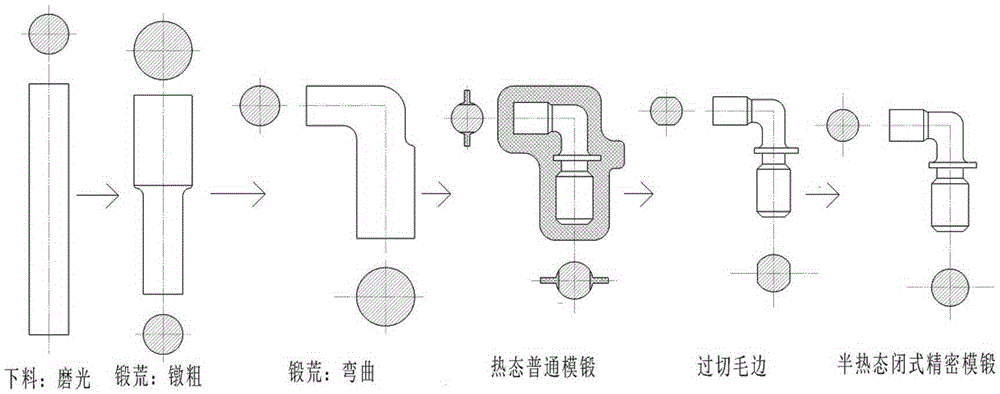

A Semi-hot Precision Die Forging Forming Process for Titanium Alloy Forgings

ActiveCN104525810BHigh fatigueExtended service lifeMetal-working apparatusSand blastingSurface roughness

The invention provides a titanium alloy forging semi-hot state precision die forging forming process. After titanium alloy bars are preheated through a machining die, a free forging device is adopted to forge the titanium alloy bars into billets with the shape and the size similar to those of die forgings, the surfaces of the billets are lubricated through a sprayer, and after the billets are heated, the titanium alloy billets are forged into common die forgings with the shape and the size similar to final precision die forgings through a common die forging device and the die; then burr cutting and surface processing are conducted, a closed precise forging die is adopted to complete precision die forging of final products, and then the final products are subjected to surface processing, heat processing and wet sand blasting. The surface roughness of each die forging is smaller than 3.2 micro meter, no trimming residue exists on the forgings, no streamline ends of the forgings are exposed, the machining allowance of machining surfaces of the forgings is smaller than 0.5 mm, the raw material consumption of the forgings is reduced, later machining workload for the forgings is greatly reduced, cost is saved, the fatigue property of the forgings is remarkably improved, and the service life of each forging is also remarkably prolonged.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

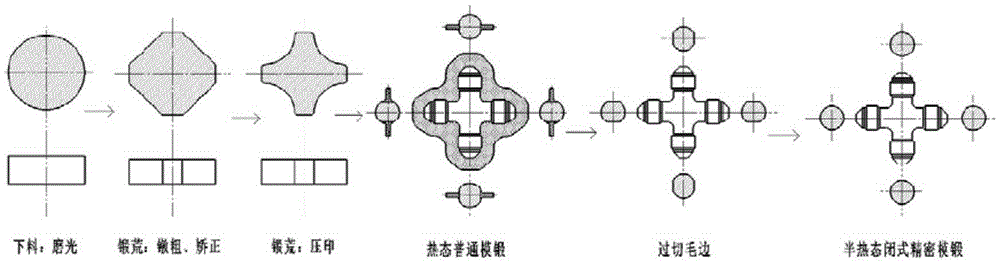

A die forging production method of hydraulic support connector of coal machine

InactiveCN104722688BReduce manufacturing costSmall sizeMetal-working apparatusEngineeringProjection plane

Owner:DINGXIANG COUNTY XINGHUI FORGING

Machining method of traveling thrust wheel of large excavator

The invention discloses a machining method of a traveling thrust wheel of a large excavator, which is characterized by comprising the following steps: firstly, casting silico-manganese steel into a thrust wheel blank and then carrying out machine finishing on the blank to obtain the finished product of the thrust wheel. The silico-manganese steel is prepared from the following components in percentage by weight: 0.14-0.25% of carbon, 0.8-2.0% of silicon, 0.8-2.0% of manganese, 0.35-1.2% of chromium, no more than 0.025% of sulfur, no more than 0.025% of phosphorus and the balance of ferrum and unavoidable impurities. In the invention, by adopting a casting method instead of a forging method, the section shape of the cast blank is approximate to that of the finished product, the size of the casting is easily controlled, and the machining allowance is smaller and uniform; and as the materials with higher strength grade are used instead of the original thrust wheel material, the mechanical properties and the service performances are not lower than the level of the original forging material, and the machining process is unchanged and is more easily operated.

Owner:无锡得戟重工有限公司

Method for forging large bevel tee

Owner:SHANGHAI BOILER WORKS

A kind of rolling piston for refrigeration compressor and its manufacturing method

ActiveCN105041658BSufficient supplyLow priceRotary piston pumpsRotary piston liquid enginesRefrigeration compressorSteel tube

Provided is a rolling piston for a rotary type refrigeration compressor. The rolling piston is made of a steel tube which is formed by conducting cold-rolling on carburizing steel. Chemical components of the carburizing steel include 0.17%-0.23% of C, 0.17%-0.37% of Si, 0.80%-1.10% of Mn, 1.00%-1.30% of Cr, 0.04%-0.10% of Ti and the balance Fe. The rolling piston has the advantages that the supply of goods is ample, the price is low, the cost is reduced, and the environment is not polluted.

Owner:NINGBO YONGWEI GROUP

The Welding Method of the Neckline of Marine Crane

The invention discloses a welding method of a maritime crane barrel neck opening. The welding method comprises the following steps: welding a rolling passage plate, welding an annular plate assembly, welding an annular plate assembly and a rolling passage plate, welding a box body structure and a peripheral plate, welding a lower cone, and finally folding the box body structure and a cone. The welding method has the advantages that the maritime crane barrel neck opening is manufactured according to the welding method strictly through repeated verifications of a plurality of items, so that the allowance can be effectively reduced, the welding workload is reduced, the machining workload is reduced, the deformation of the barrel neck opening can be well controlled, the qualified rate of finished products is improved, and the welding method is beneficial to popularization.

Owner:南通中集太平洋海洋工程有限公司

Machining method of traveling thrust wheel of large excavator

InactiveCN101982556BIncrease profitGood welding performanceSoil-shifting machines/dredgersEndless track vehiclesSulfurManganese

The invention discloses a machining method of a traveling thrust wheel of a large excavator, which is characterized by comprising the following steps: firstly, casting silico-manganese steel into a thrust wheel blank and then carrying out machine finishing on the blank to obtain the finished product of the thrust wheel. The silico-manganese steel is prepared from the following components in percentage by weight: 0.14-0.25% of carbon, 0.8-2.0% of silicon, 0.8-2.0% of manganese, 0.35-1.2% of chromium, no more than 0.025% of sulfur, no more than 0.025% of phosphorus and the balance of ferrum andunavoidable impurities. In the invention, by adopting a casting method instead of a forging method, the section shape of the cast blank is approximate to that of the finished product, the size of thecasting is easily controlled, and the machining allowance is smaller and uniform; and as the materials with higher strength grade are used instead of the original thrust wheel material, the mechanical properties and the service performances are not lower than the level of the original forging material, and the machining process is unchanged and is more easily operated.

Owner:无锡得戟重工有限公司

Rolling piston and manufacturing method thereof for rotary type cold compressor

ActiveCN100520074CSufficient supplyFair priceRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigeration compressorChemical treatment

A rolling piston for a rotary refrigerating compressor and a manufacturing method thereof, wherein the rolling piston material is a precision steel pipe after cold rolling of GCr15 bearing steel, and the manufacturing method comprises the following steps: (1) selecting GCr15 bearing steel for cold rolling to conform to the rolling piston Steel pipes with required precision for inner diameter, outer diameter and thickness; (2) cutting steel pipes according to the length of the rolling piston material; (3) heat-treating the cut steel pipes with controllable gas; (4) coarsely grinding each surface of steel pipes; Chemically treated steel pipes; (6) Fine grinding all surfaces of steel pipes. The invention has the advantages that: the manufactured rolling piston has obvious advantages in wear resistance and high contact fatigue life. The cutting workload can be reduced by 50%, and the steel utilization rate can reach more than 90%, thus reducing the manufacturing cost. It also saves the casting method, avoids pollution to the environment and high energy consumption, and is a good method for energy saving and environmental protection.

Owner:NINGBO YONGWEI GROUP

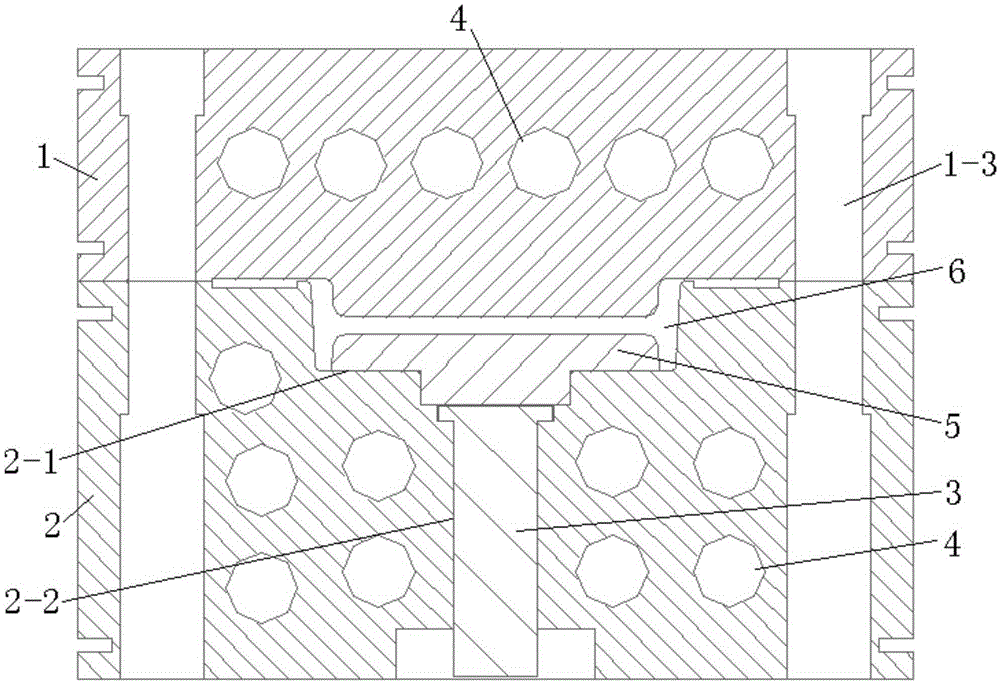

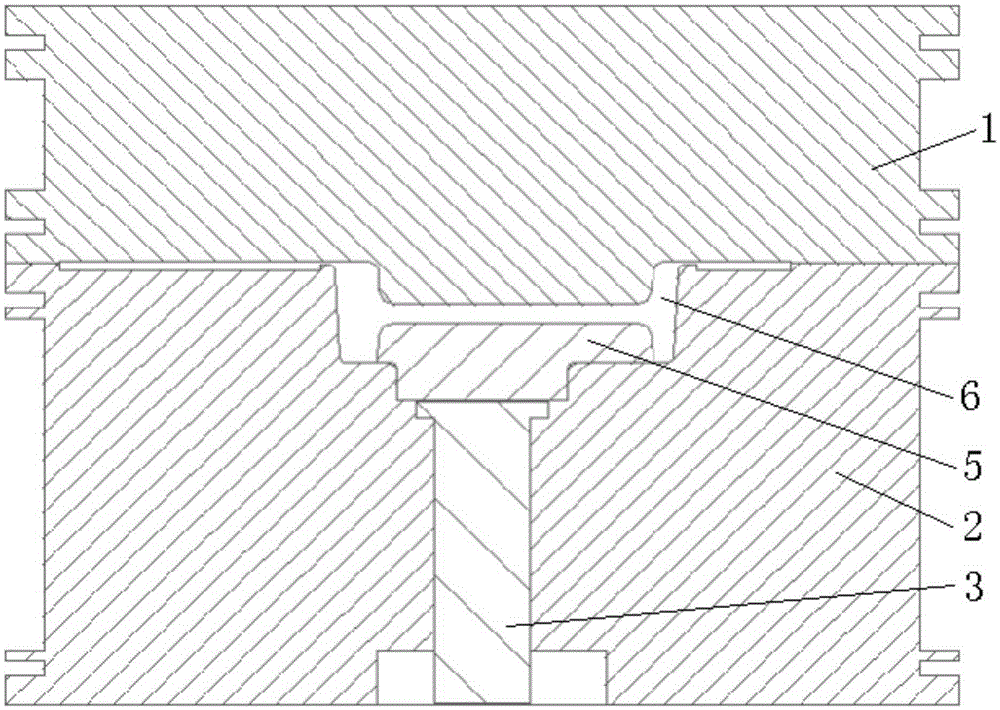

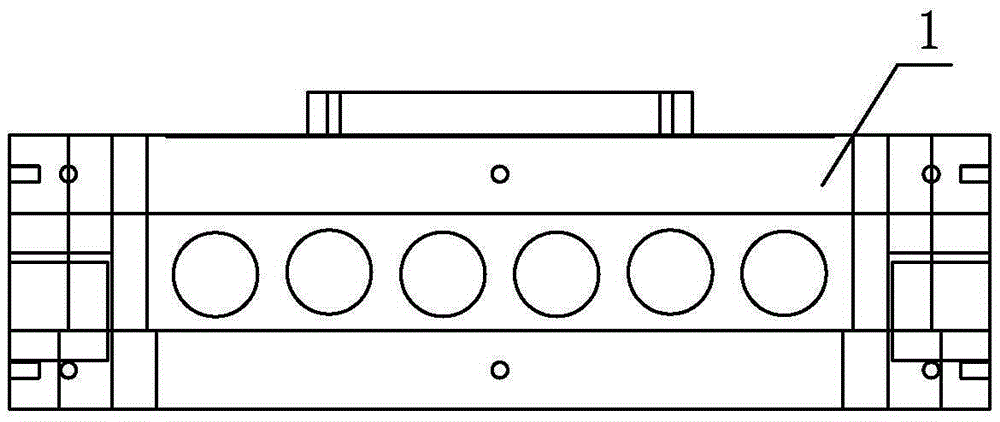

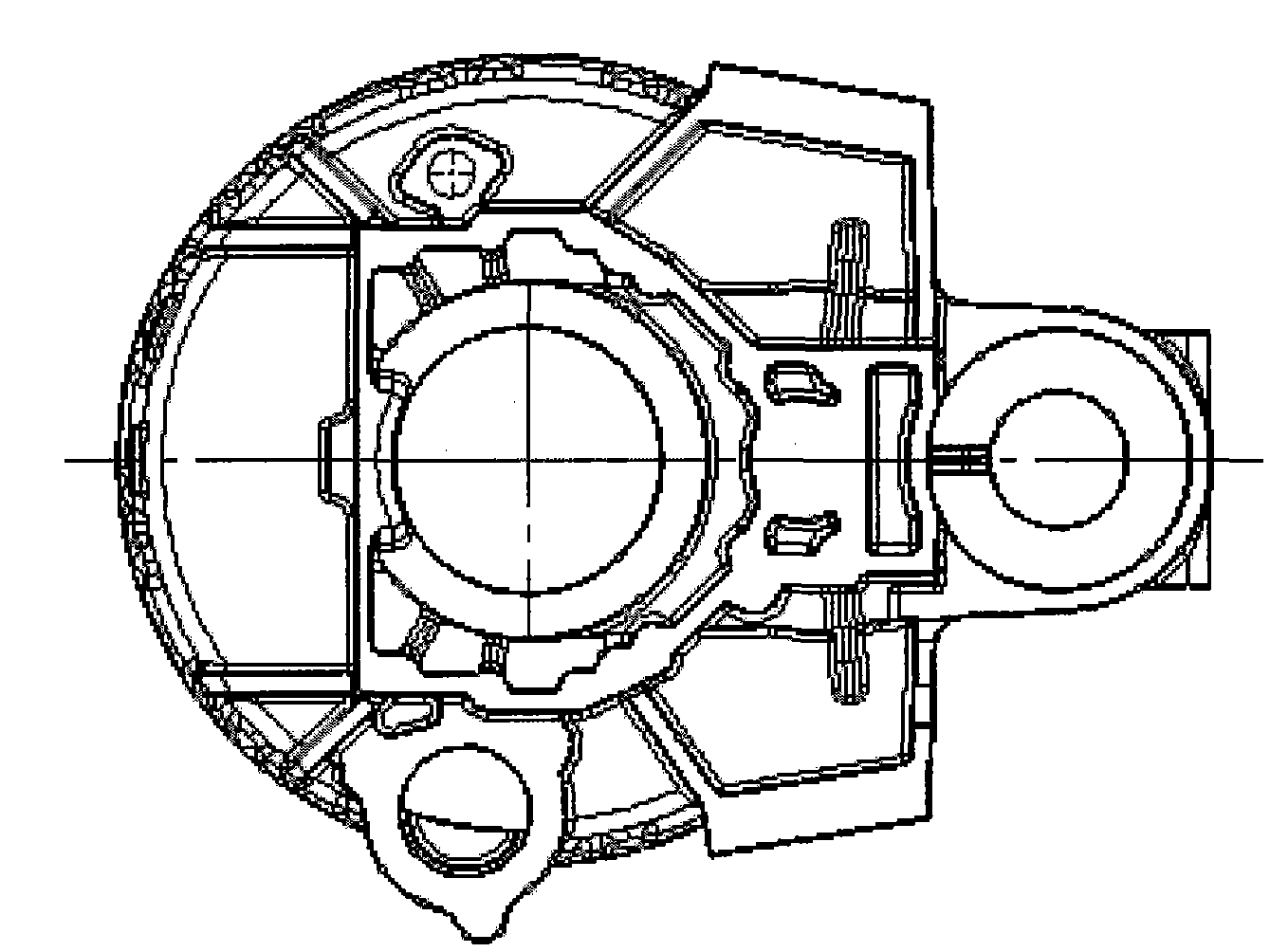

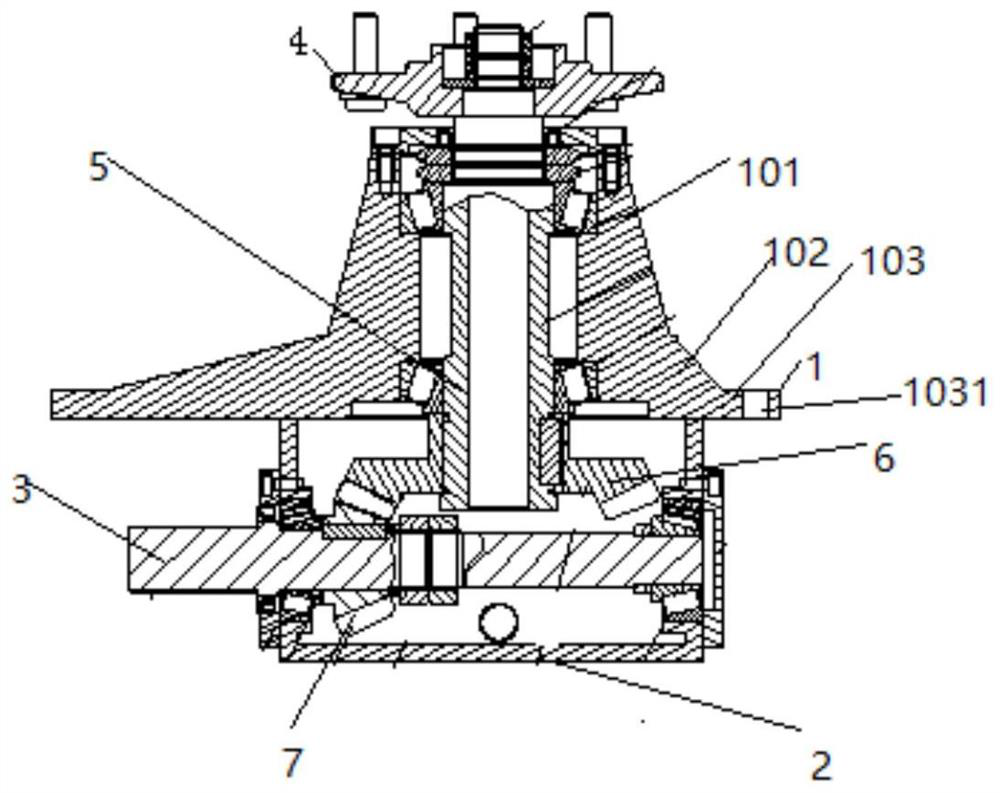

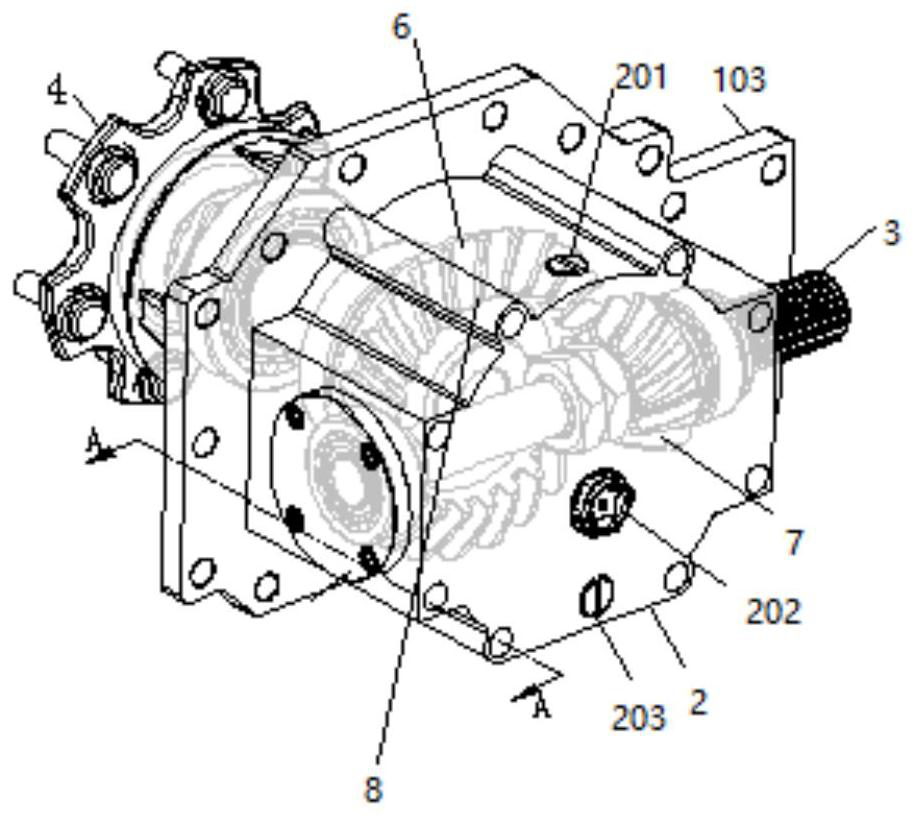

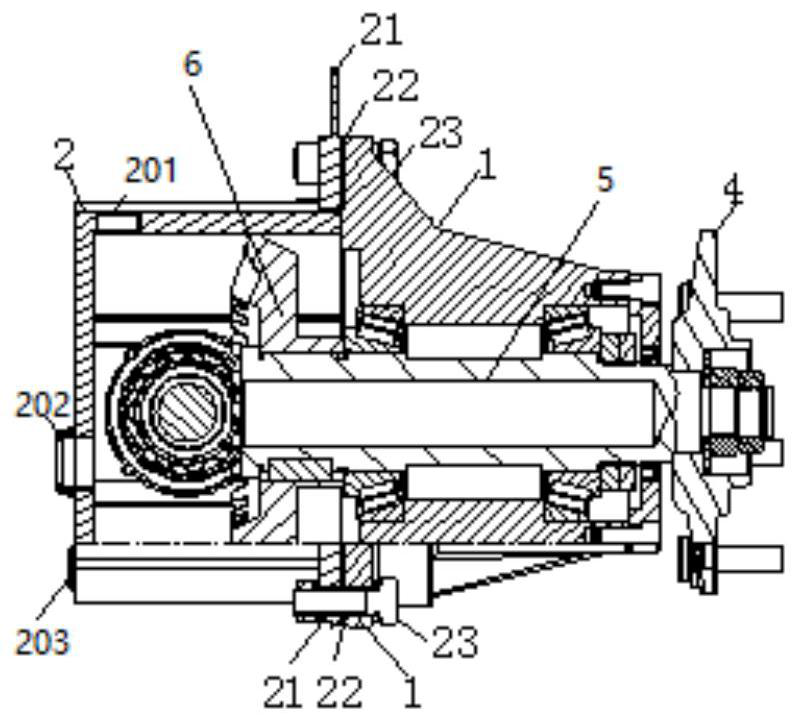

a wheel reducer

ActiveCN109606102BEasy to installReduce machining workloadControl devicesReduction driveStructural engineering

The present invention relates to the field of wheel-side reducers, in particular to a wheel-side reducer. The wheel-side reducer includes a reducer housing, and a transmission assembly for transmitting power is arranged inside the reducer housing; the reducer The device casing includes an outer casing and an inner casing, and the outer casing is connected with the inner casing. The invention adopts a split design, which is beneficial to the forming of precision alloy casting molds, reduces the workload of mechanical processing, is suitable for mass production, and reduces costs; at the same time, it facilitates the installation of subsequent parts.

Owner:CHERY COMML VEHICLE ANHUI

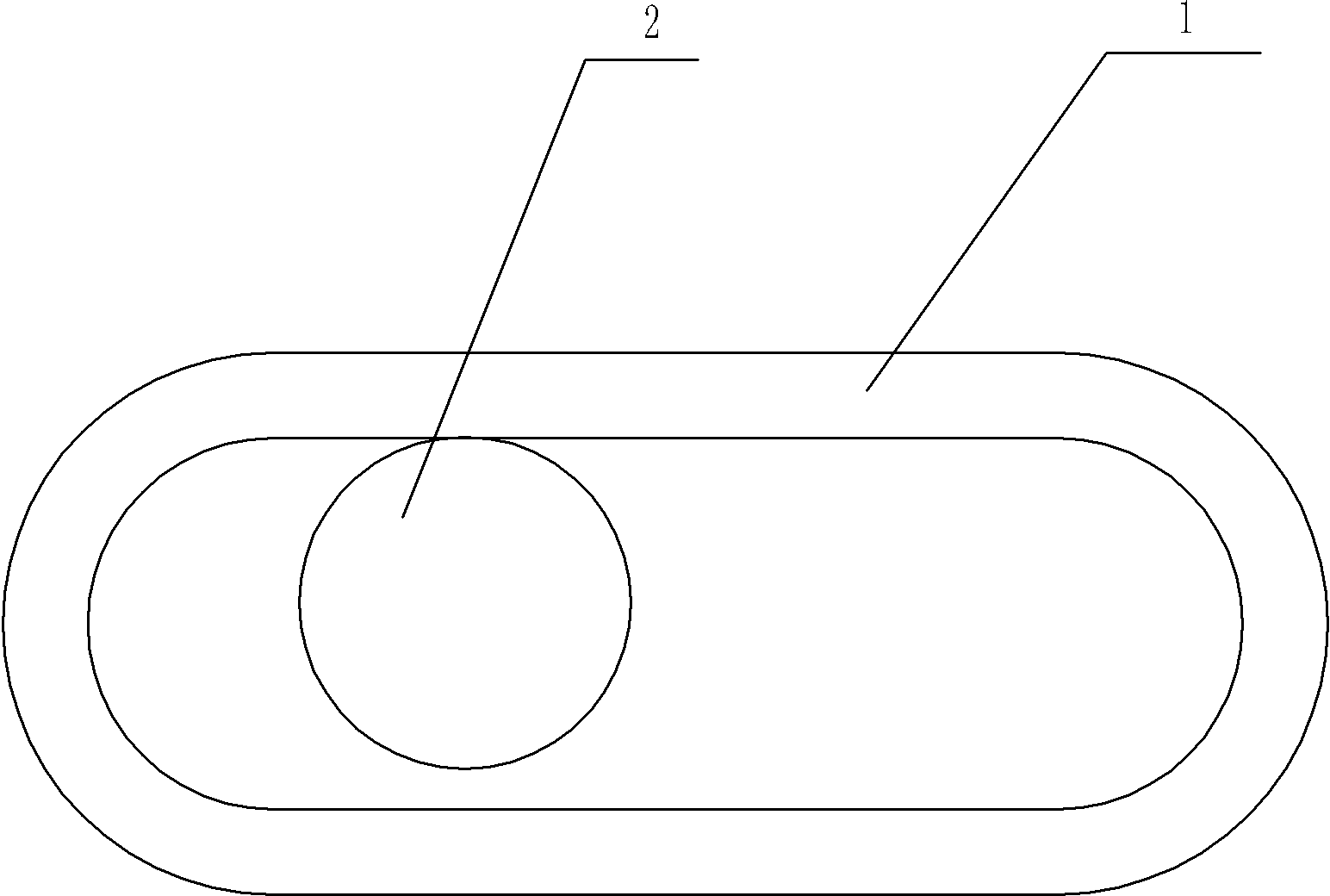

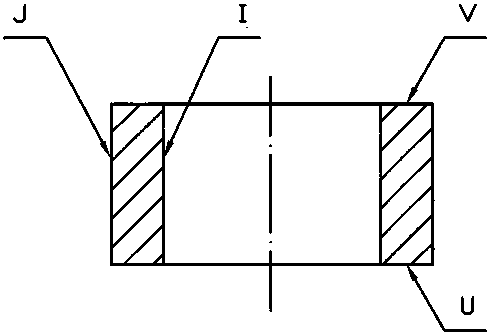

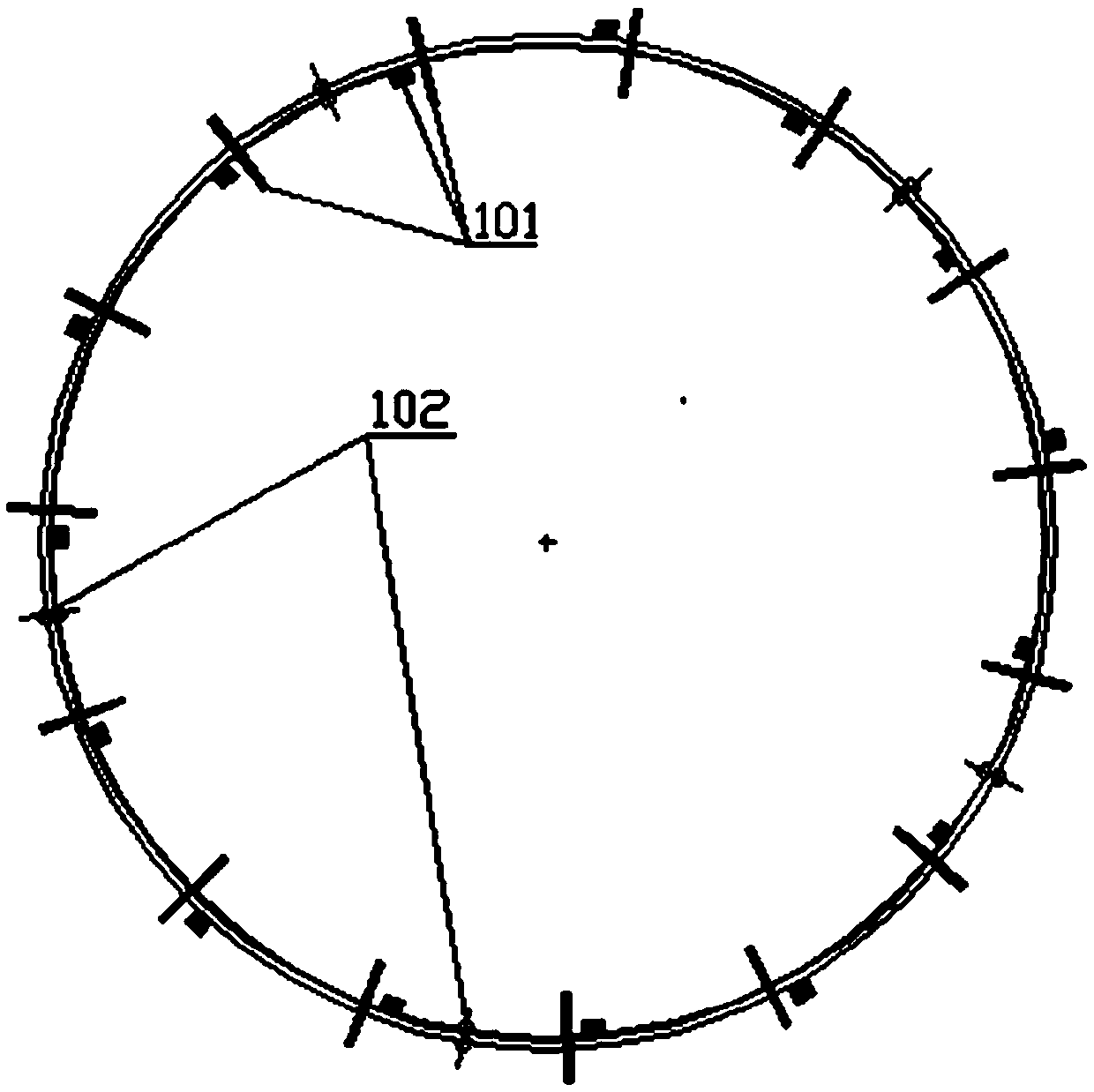

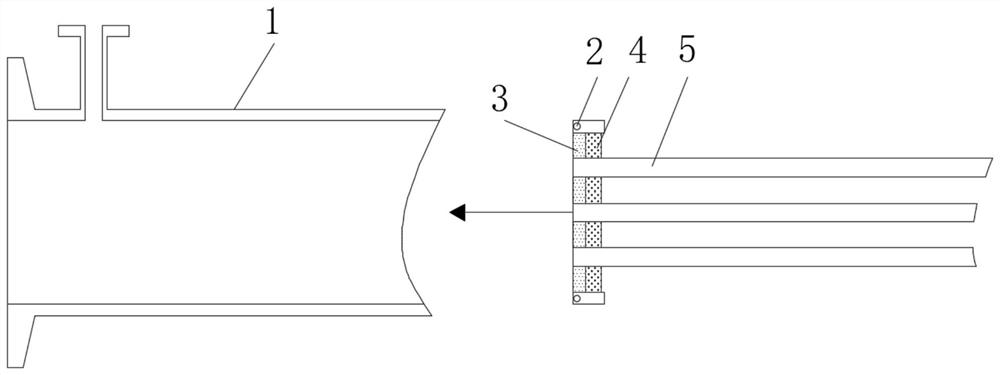

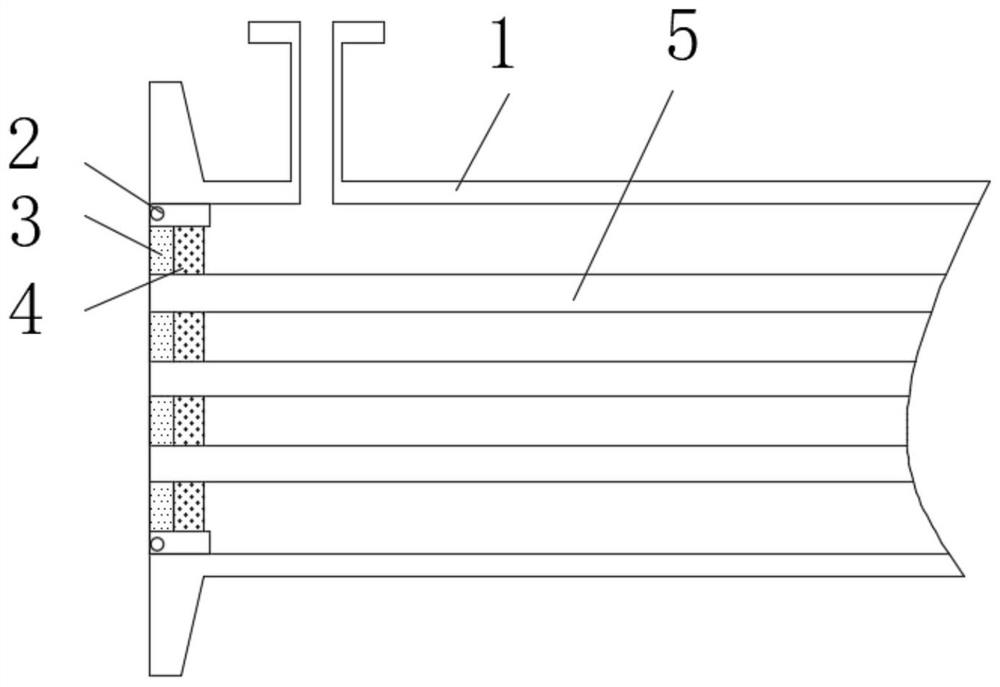

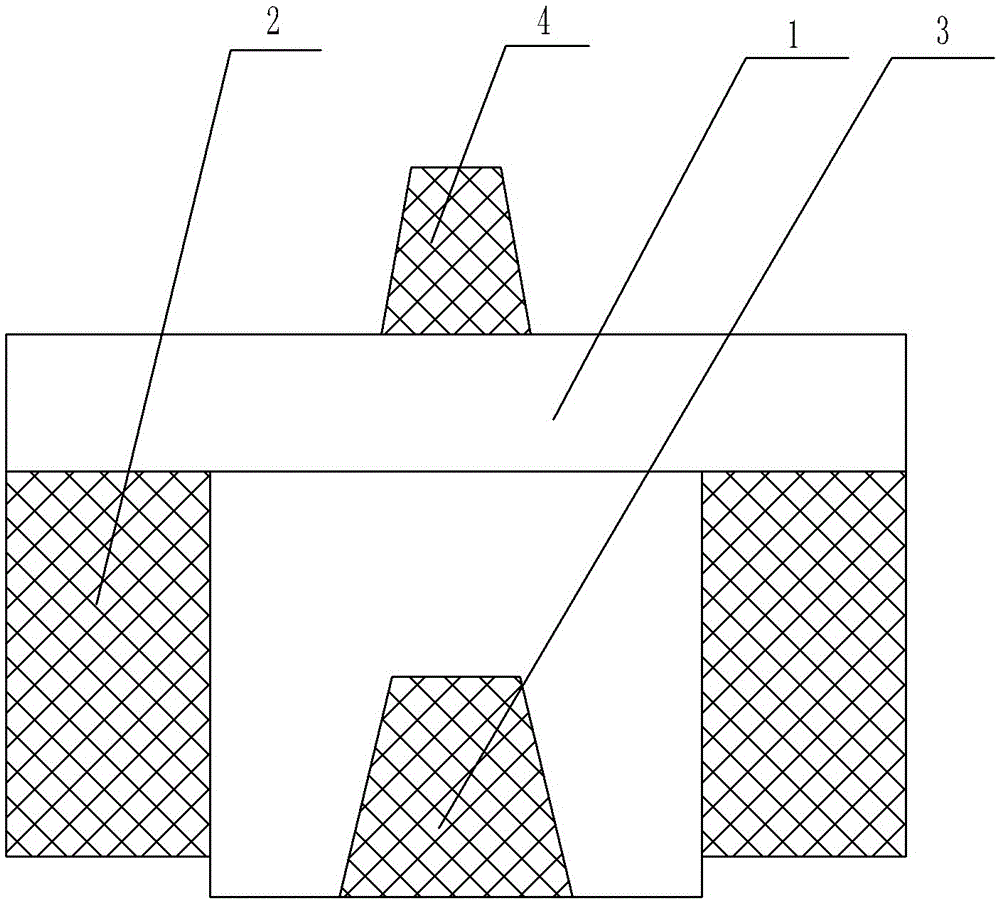

Ceramic membrane assembly device

PendingCN113893696ALow costReduced installation effortSemi-permeable membranesEngineeringCeramic membrane

The invention discloses a ceramic membrane assembly device, and belongs to the technical field of membrane equipment. The ceramic membrane assembly device comprises a membrane outer tube and a membrane element, wherein two sides of the membrane element are fixedly provided with membrane fixing pieces, the membrane element and the membrane fixing pieces are arranged in the membrane outer tube through a fixing glue, and the interior of each membrane fixing piece is provided with an O-shaped ring. According to the invention, the cost can be effectively reduced, the machining workload is greatly reduced, the installation workload of the membrane core piece is reduced, installation is easy, only the whole assembly needs to be installed into the membrane shell on site, the installation efficiency is high, the membrane core and the connecting piece of the ceramic membrane assembly are secondarily fixed through glue, and the leakage risk of the membrane core is reduced.

Owner:同舟纵横(厦门)流体技术有限公司

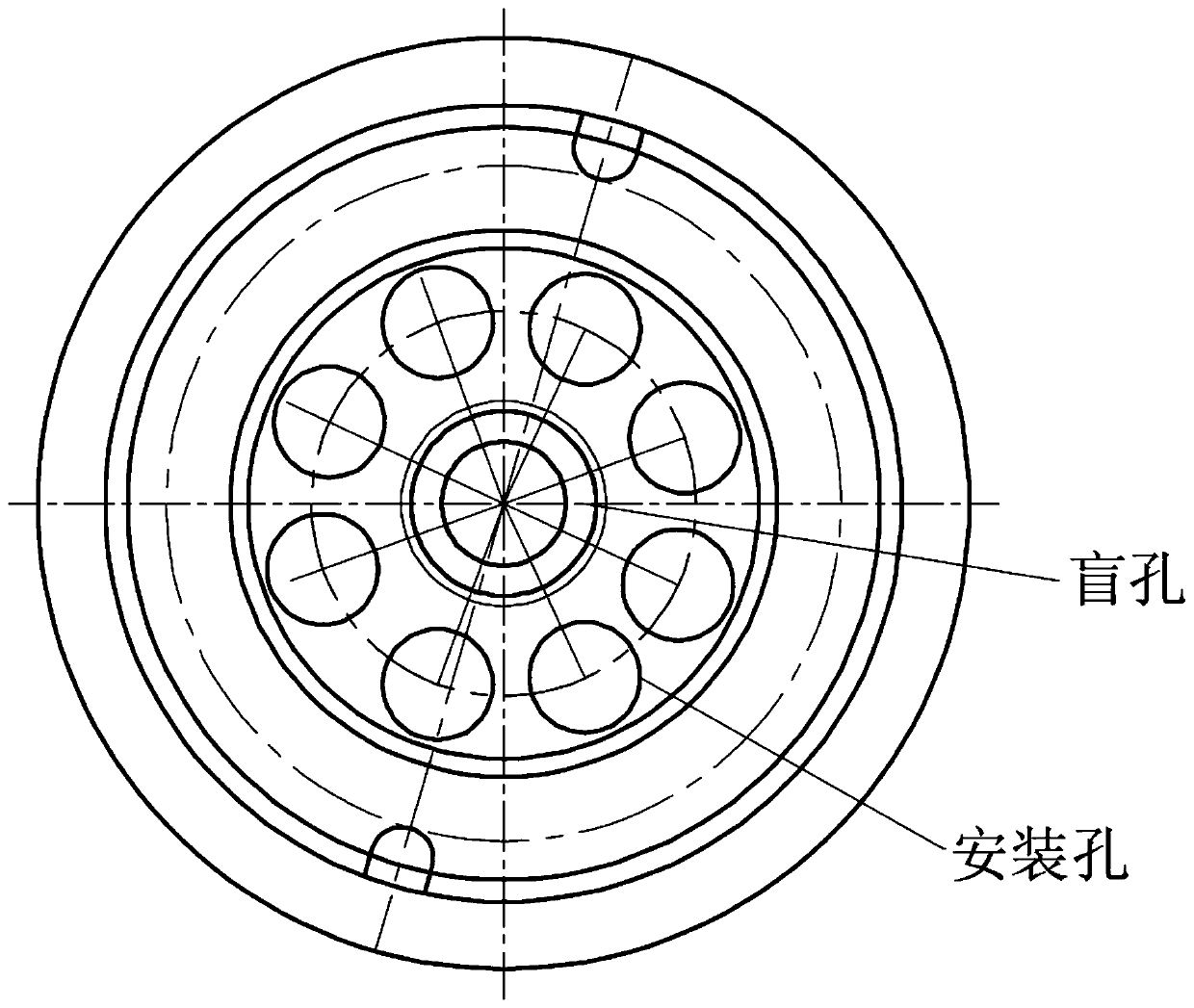

A kind of forging process of planet carrier flange forging

The invention discloses a planet carrier flange forge piece forging process which obtains a all-fiber stream line of planet carrier flange force piece metal, and therefore reduces forge piece machining allowance, improves the material utilization rate, reduces process cost of heat treatment after forging, enables inner tissue and outer tissue of a forge piece to be compact, enhances mechanical property, and reduces heat treatment process pressure. The planet carrier flange forge piece forging process is characterized in that the process includes the following steps of (1), calculating the sizes of forging materials and blanking; (2), upsetting and rounding the outer circles of the forging materials; (3), placing the forging materials in a leak plate which is similar to a planet carrier flange in shape, upsetting and planishing in a rotating mode; (4), punching blind holes in the forging materials through a lower punch; (5), upsetting and flattening the forging materials and punching holes through an upper punch; and (6), conning the forging materials obtained from the step (5) and forming the planet carrier flange.

Owner:WUXI HONGDA HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com