Oblate flange complete fiber forging technology

A full-fiber, oblate-shaped technology, applied in the field of mechanical parts forging technology, can solve the problems of difficult forming, tissue fiber breakage, complex manufacturing process, etc., and achieve the effect of improving material utilization, dense internal and external organization, and enhanced mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following describes the full-fiber forging process of oblate flanges in combination with specific oblate flanges:

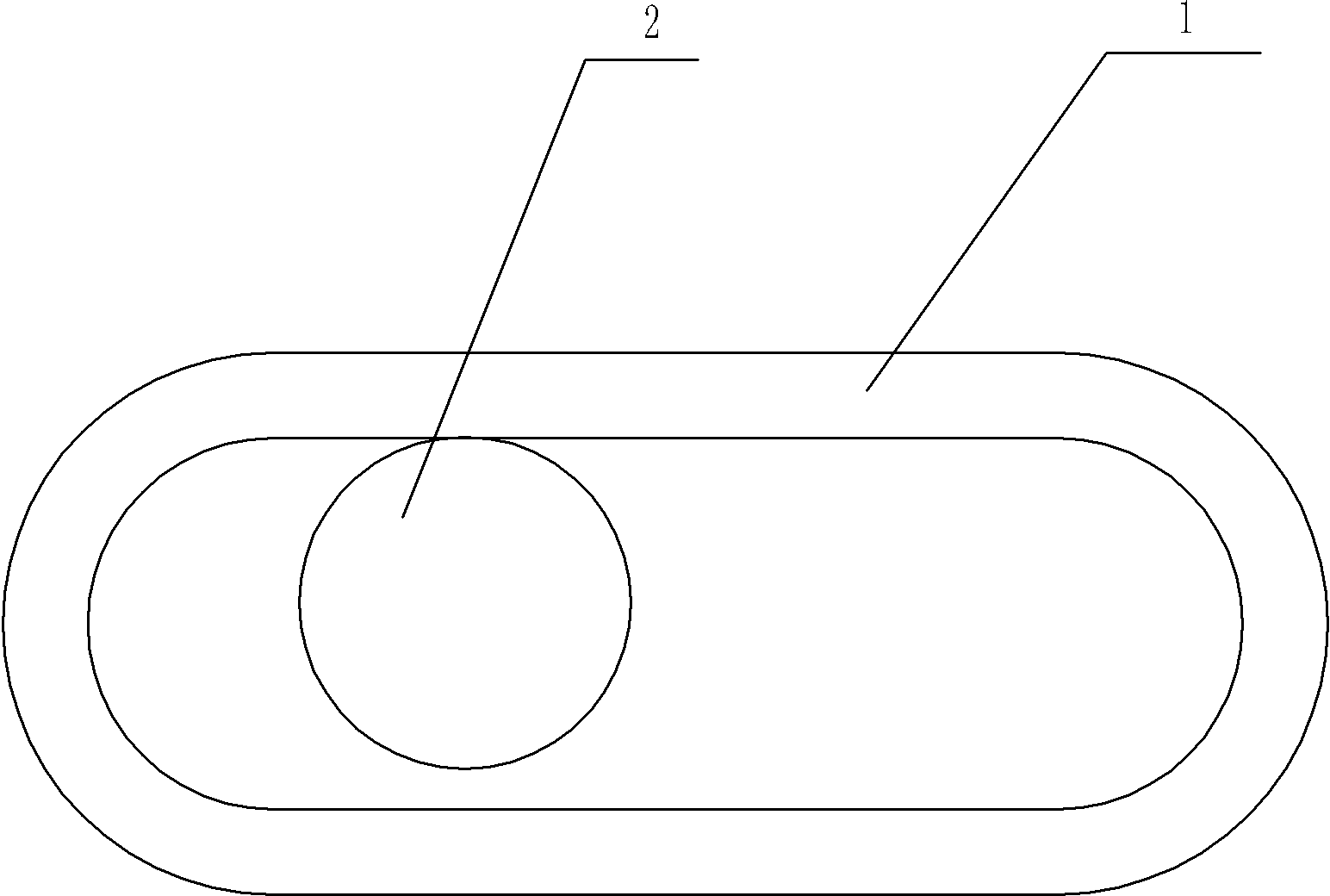

[0019] See figure 1 As shown, a full-fiber forging process for oblate flanges includes the following steps:

[0020] 1. Calculate the size and cutting of forging material:

[0021] (1) Riser pressing and chamfering of forgings at 1230-850°C;

[0022] (2) Upsetting the forging to Φ900mm at 1230-800°C, using a 700mm upper flat anvil and lower turntable, pulling 8 times according to the program, and cutting 680mm×1500mm;

[0023] 2. Rounding of the outer ring of the forging material: the forging is subjected to rotary upsetting, rotary flattening, rounding, and punching at 1230-750°C;

[0024] 3. Forging punching: punching Φ275mm for forgings at 1230-750°C;

[0025] 4. Use the mandrel for local elongation at the inner hole: ream the forging at 1230-700 ° C, flatten it, insert the mandrel Φ270 mm for local elongation, and flatten;

[0026] 5. Reaming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com