Patents

Literature

68 results about "Tissue fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

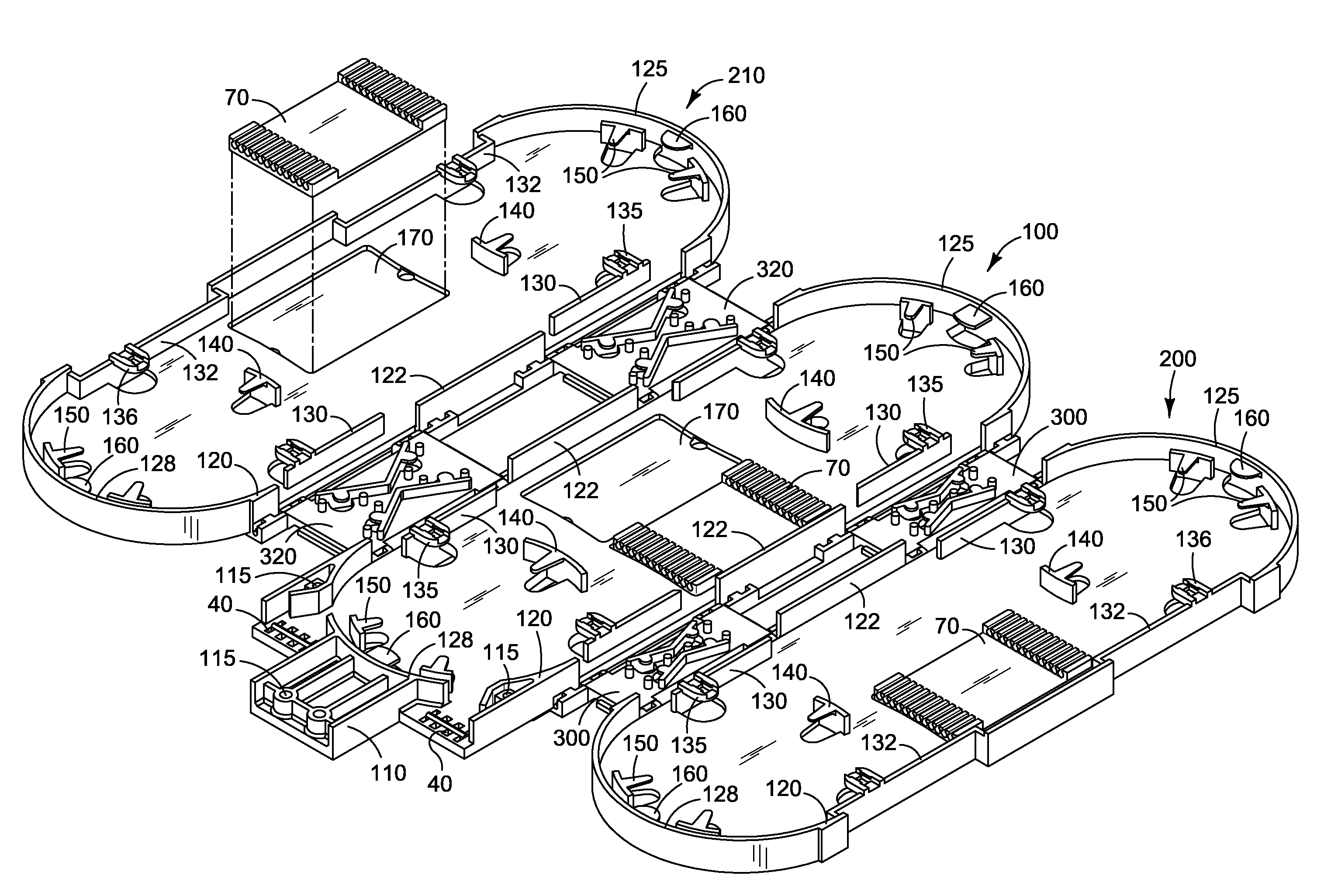

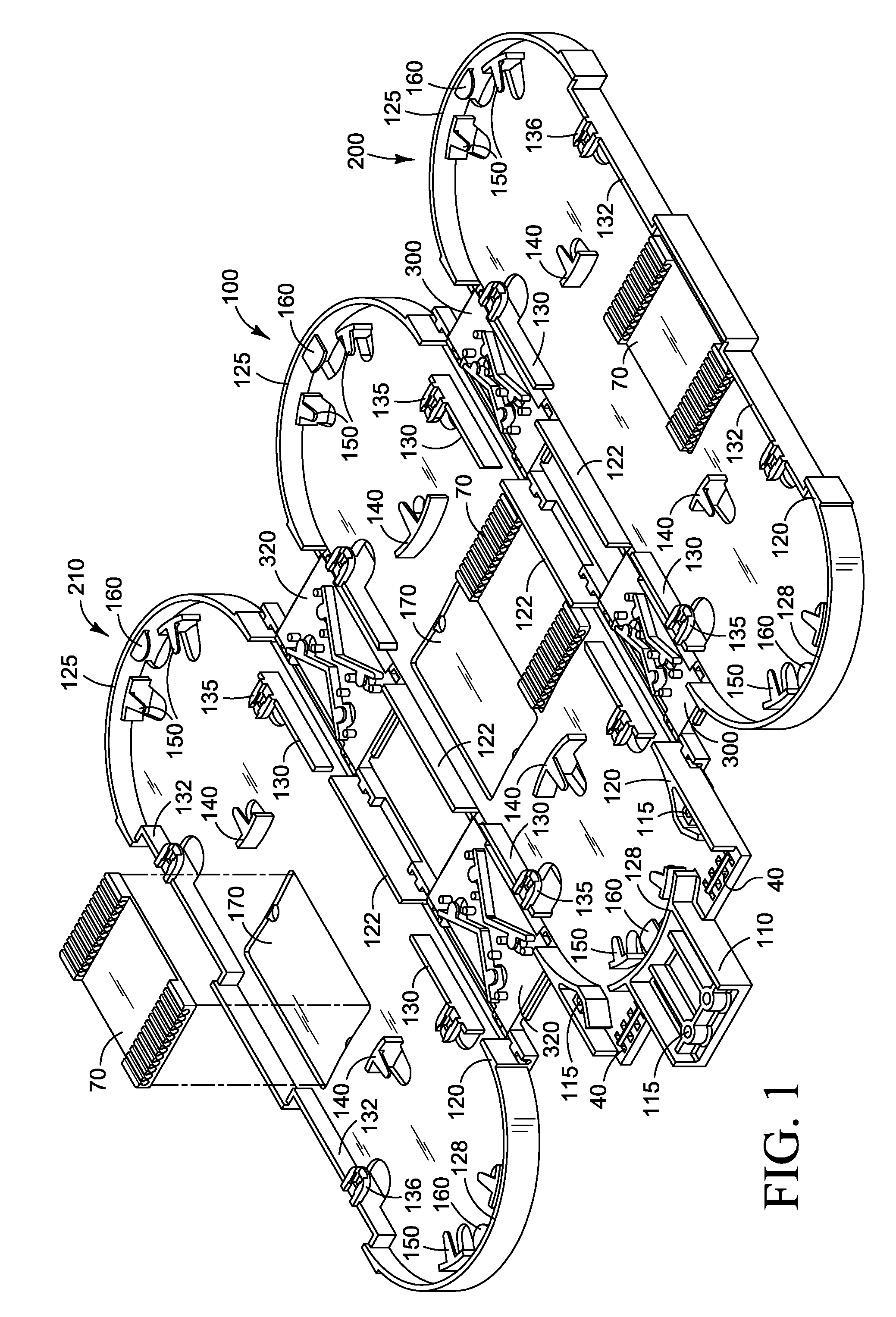

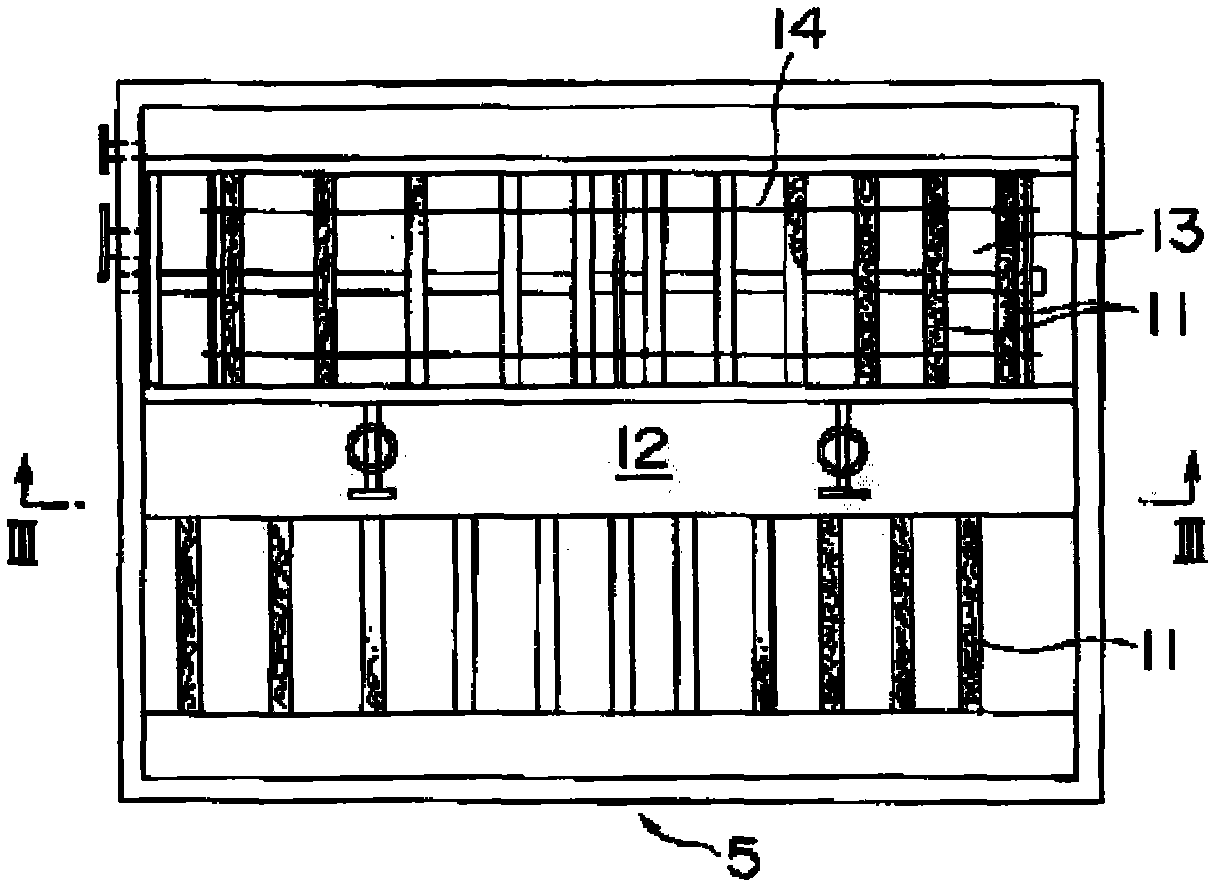

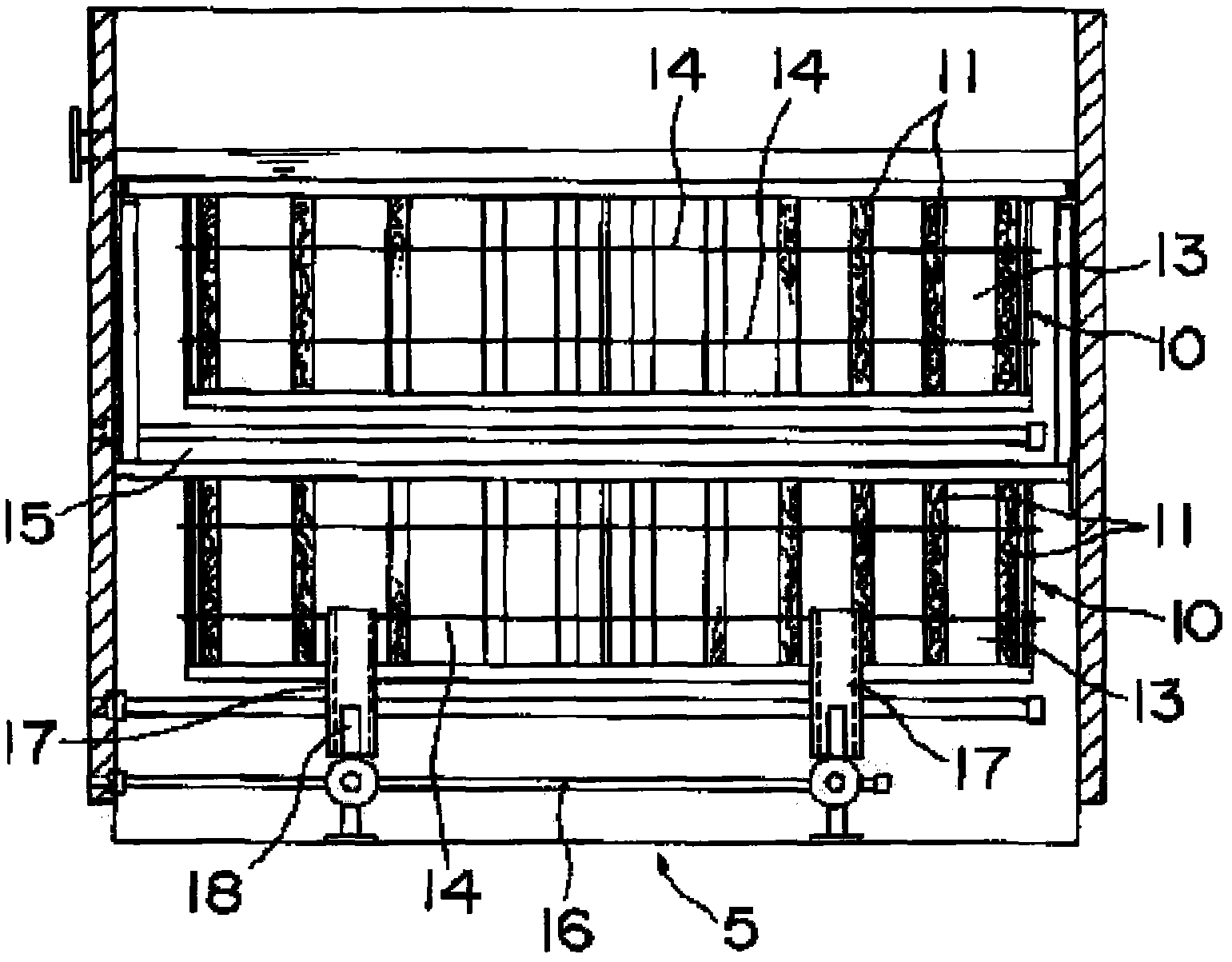

Fiber optic categorization and management tray

A fiber optic splice organizer stores optical fiber splices and sufficient slack to permit the fibers to be readily separated, such as for reorganization or to remake a splice. Multiple hinges connect a plurality of fiber trays side by side to provide pivotable connections between trays. A flat orientation of the trays enables splicing and coiling of fibers as they are loaded into a tray. The trays then pivot into a fiber storage position. Special features of the hinges provide support for fibers and splices as they are loaded into the trays. The hinges protect the fibers as the trays are pivoted as well as when the trays are in their folded position for storage without requiring buffer tubes. Multiple architectures for the organization of fibers are enabled without violating minimal bend radii, and while providing for ease of separation of individual fibers or groups of fibers.

Owner:GONZALES CURTIS PAUL +1

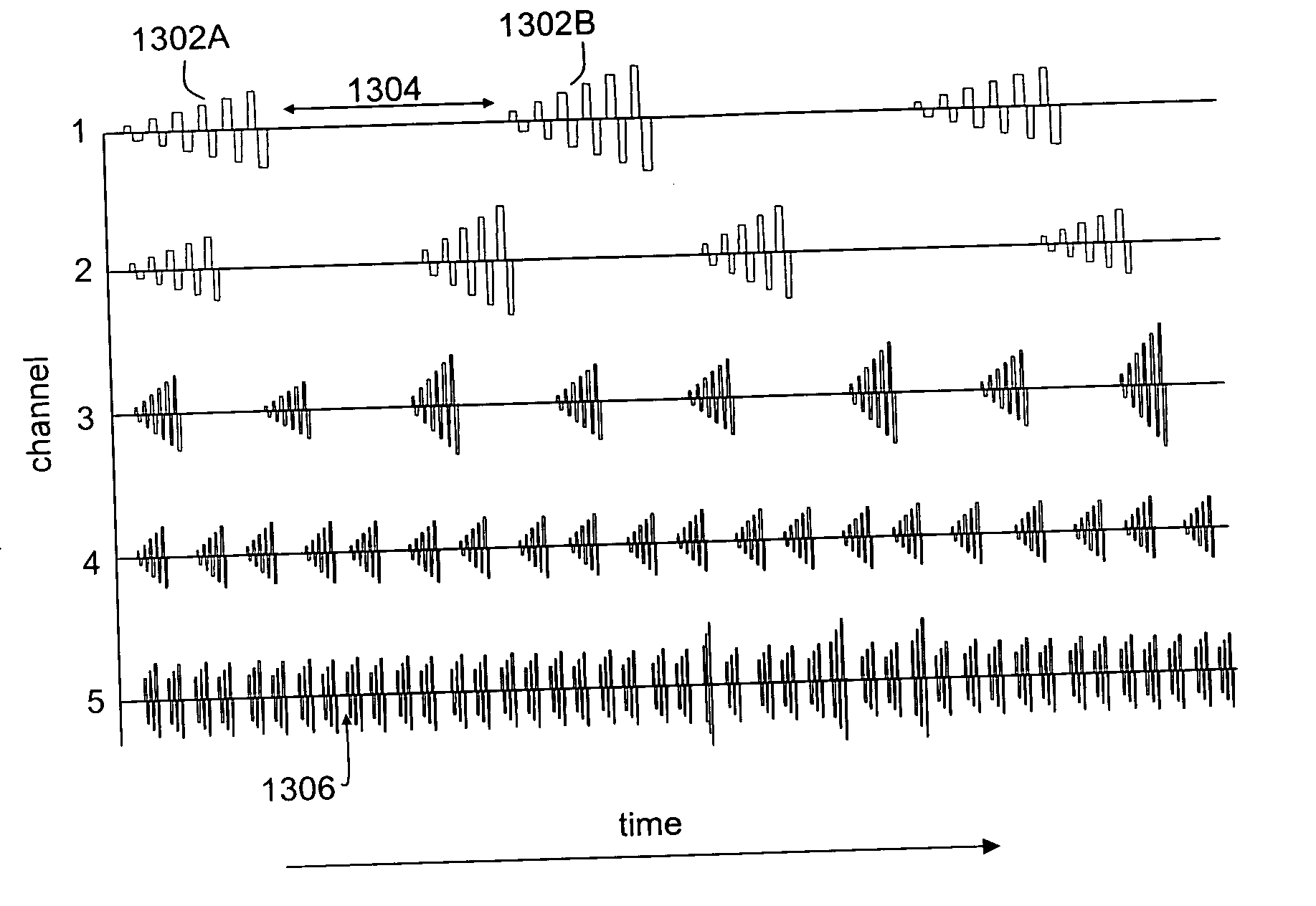

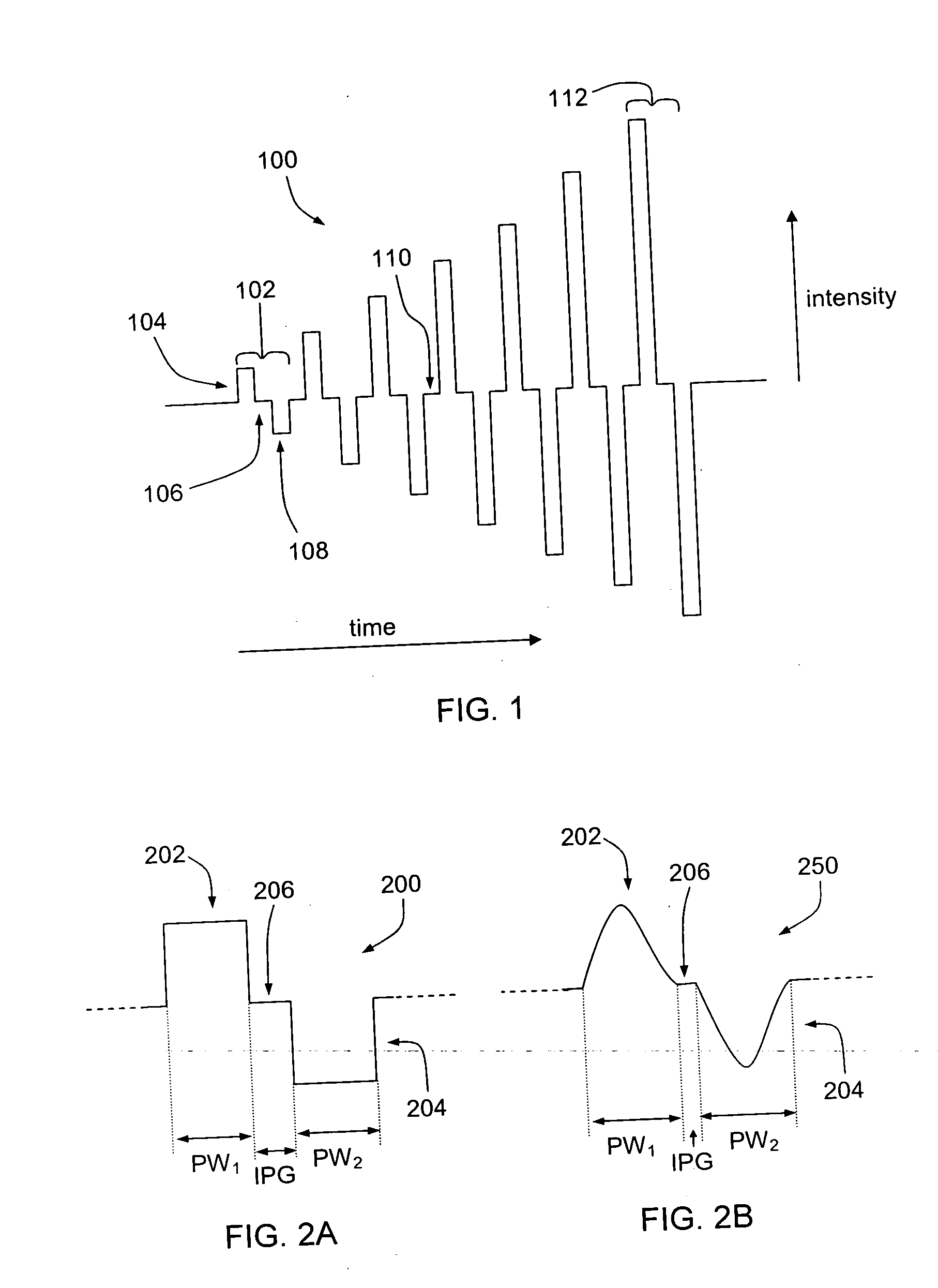

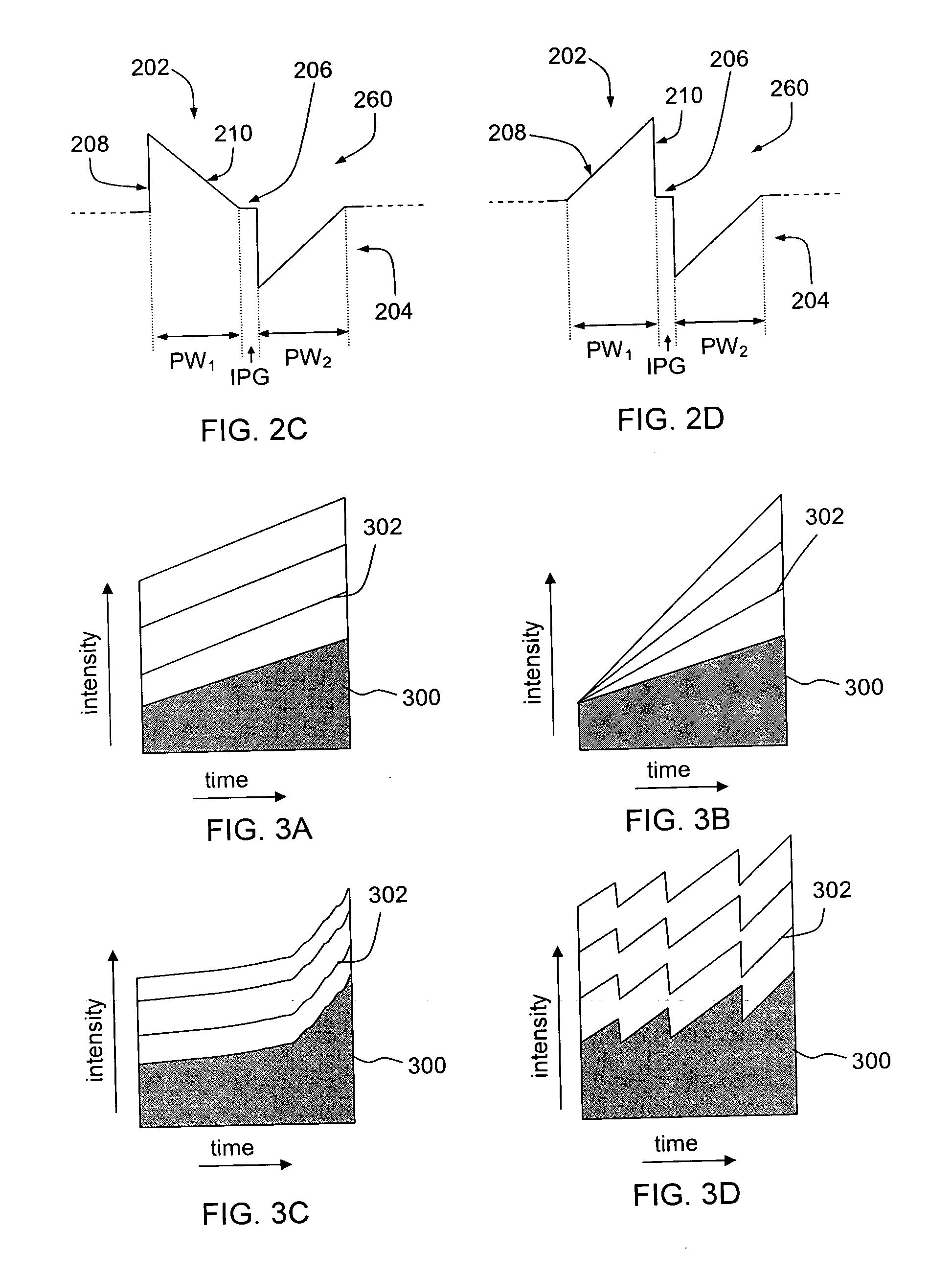

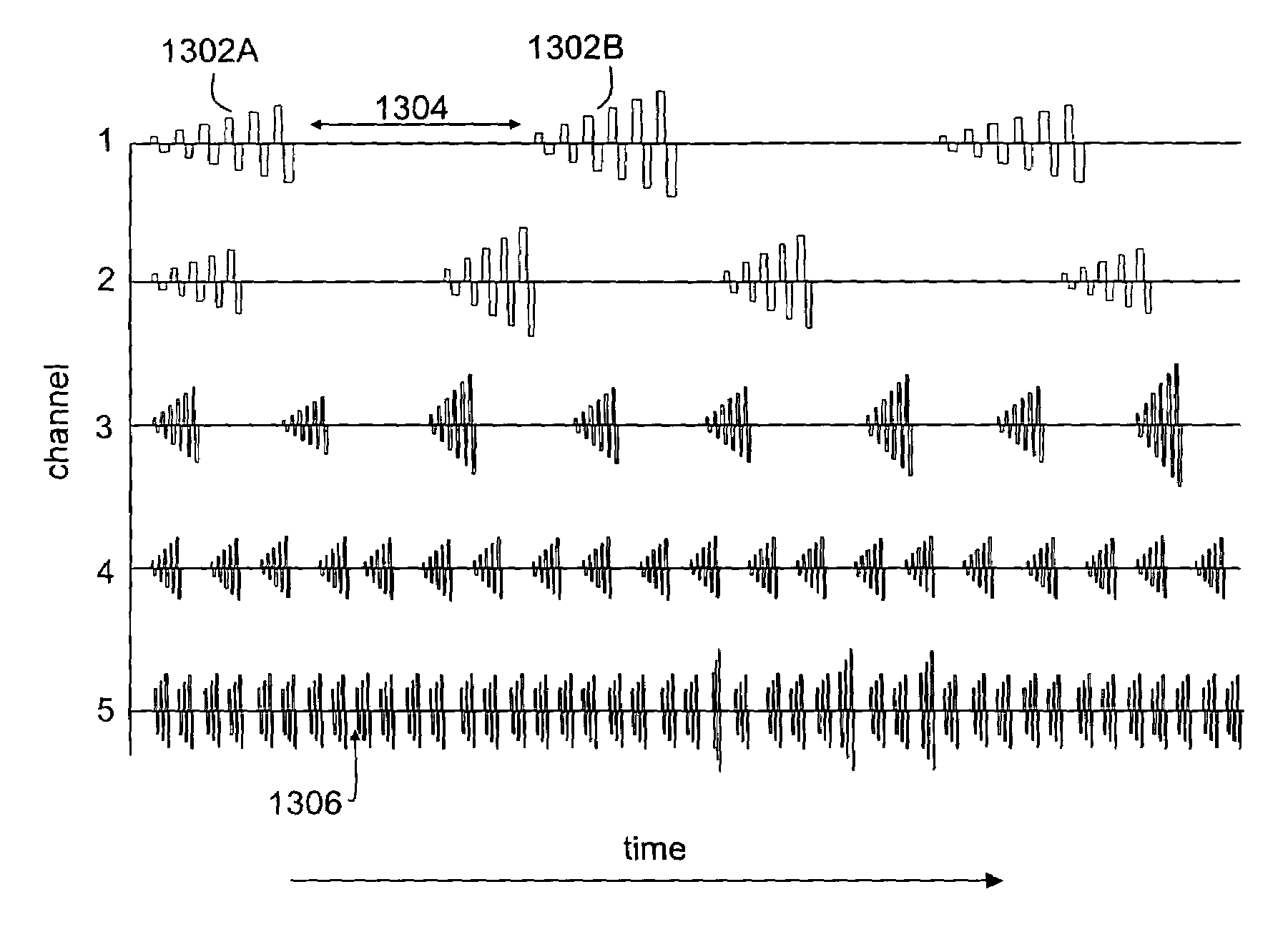

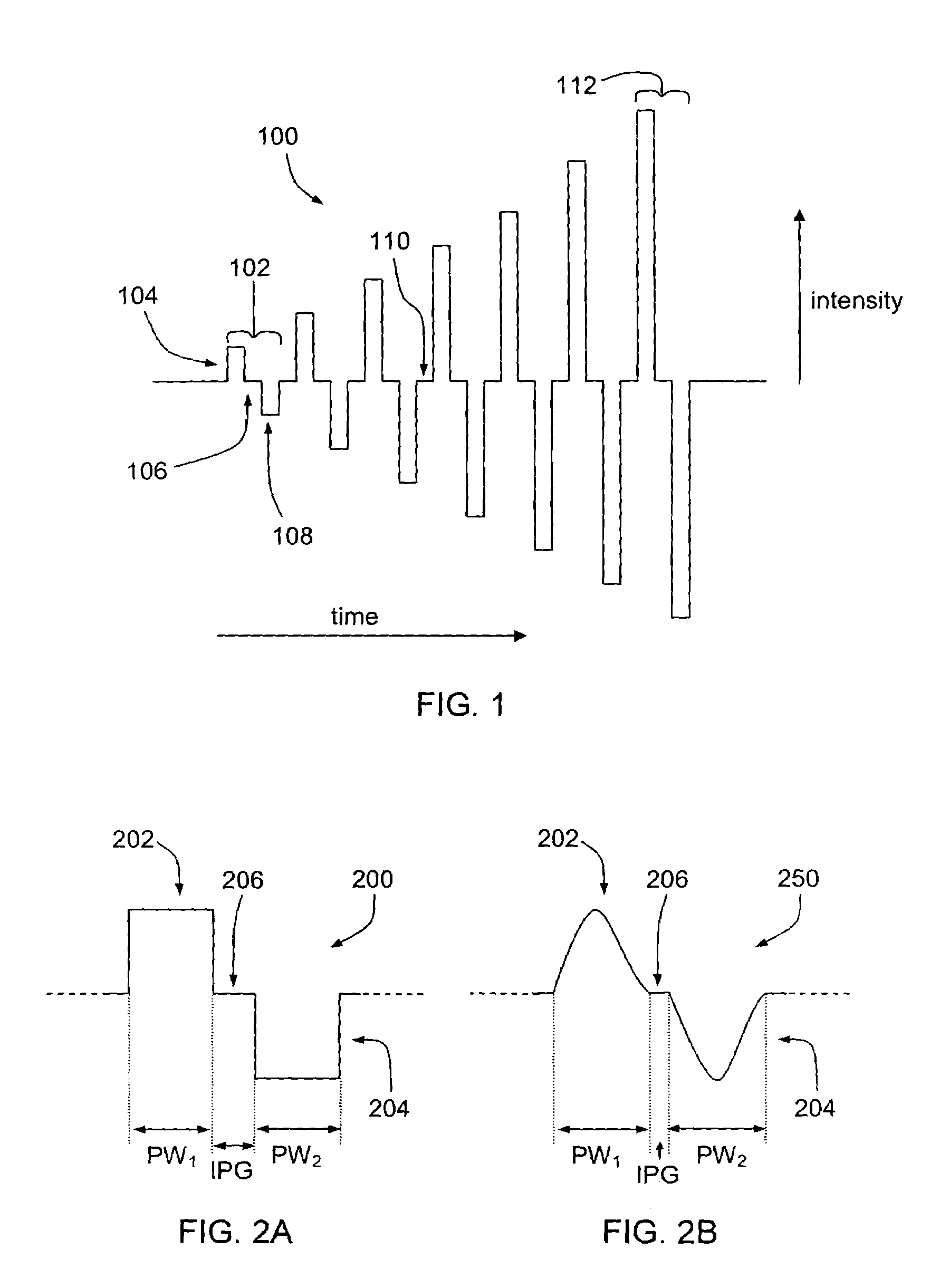

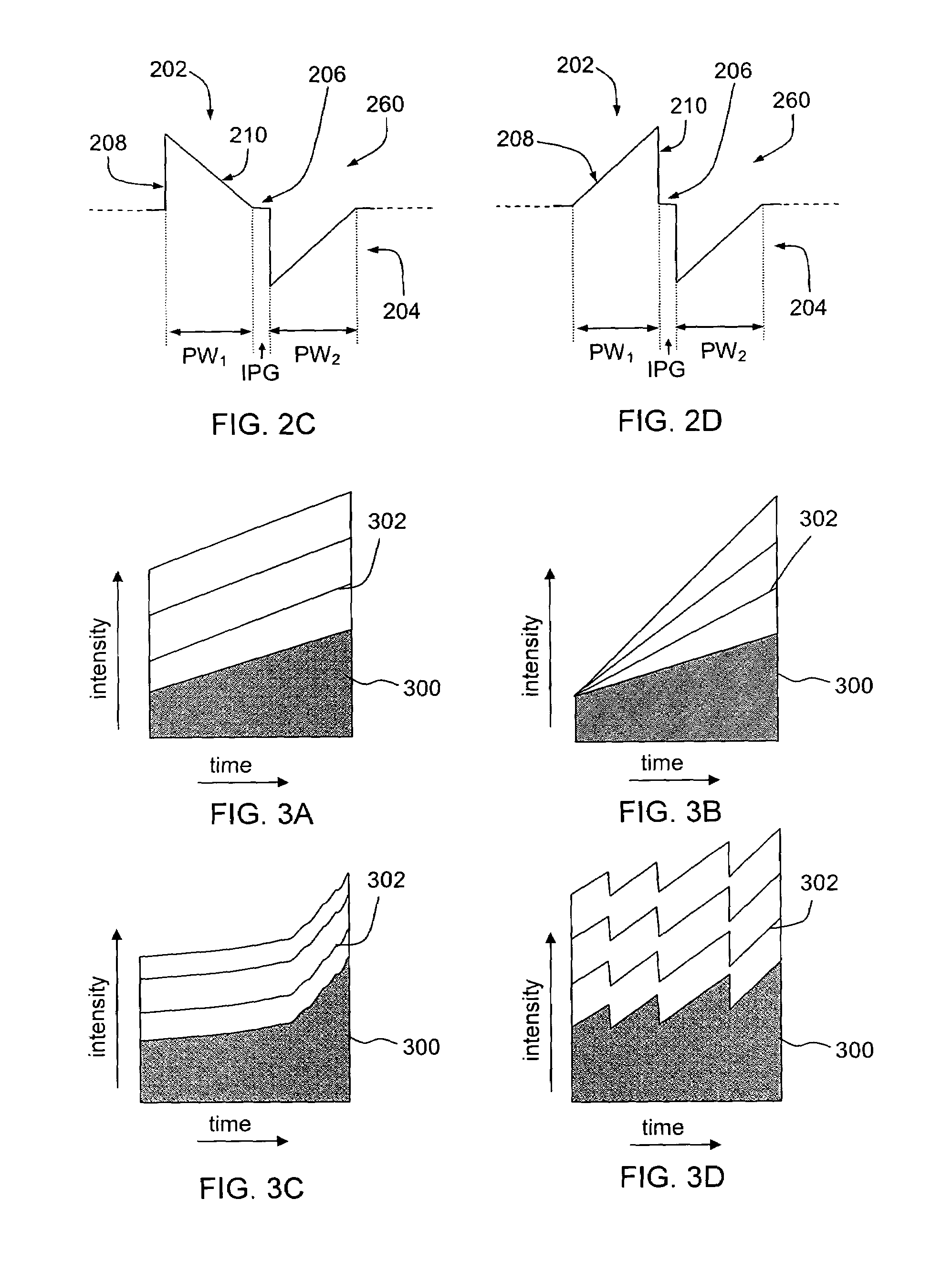

Pulse burst electrical stimulation of nerve or tissue fibers

A method for stimulating nerve or tissue fibers and a prosthetic hearing device implanting same. The method comprises: generating a stimulation signal comprising a plurality of pulse bursts each comprising a plurality of pulses; and distributing said plurality of pulse bursts across one or more electrodes each operatively coupled to nerve or tissue fibers such that each of said plurality of pulse bursts delivers a charge to said nerve or tissue fibers to cause dispersed firing in said nerve or tissue fibers.

Owner:COCHLEAR LIMITED

Pulse burst electrical stimulation of nerve or tissue fibers

A method for stimulating nerve or tissue fibers and a prosthetic hearing device implanting same. The method comprises: generating a stimulation signal comprising a plurality of pulse bursts each comprising a plurality of pulses; and distributing said plurality of pulse bursts across one or more electrodes each operatively coupled to nerve or tissue fibers such that each of said plurality of pulse bursts delivers a charge to said nerve or tissue fibers to cause dispersed firing in said nerve or tissue fibers.

Owner:COCHLEAR LIMITED

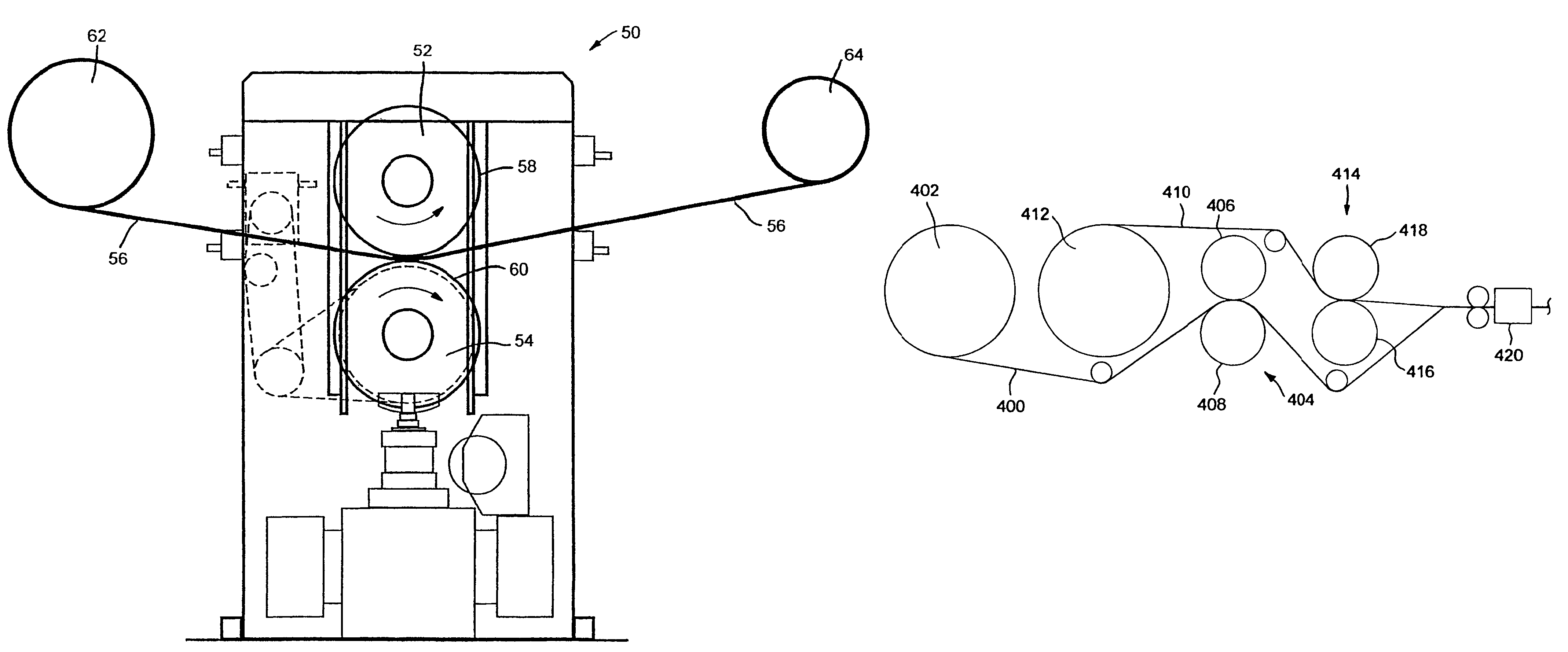

Rolled single ply tissue product having high bulk, softness, and firmness

InactiveUS6887348B2Good sheet softnessGood strength characteristicNon-fibrous pulp additionNatural cellulose pulp/paperMedicineHardness

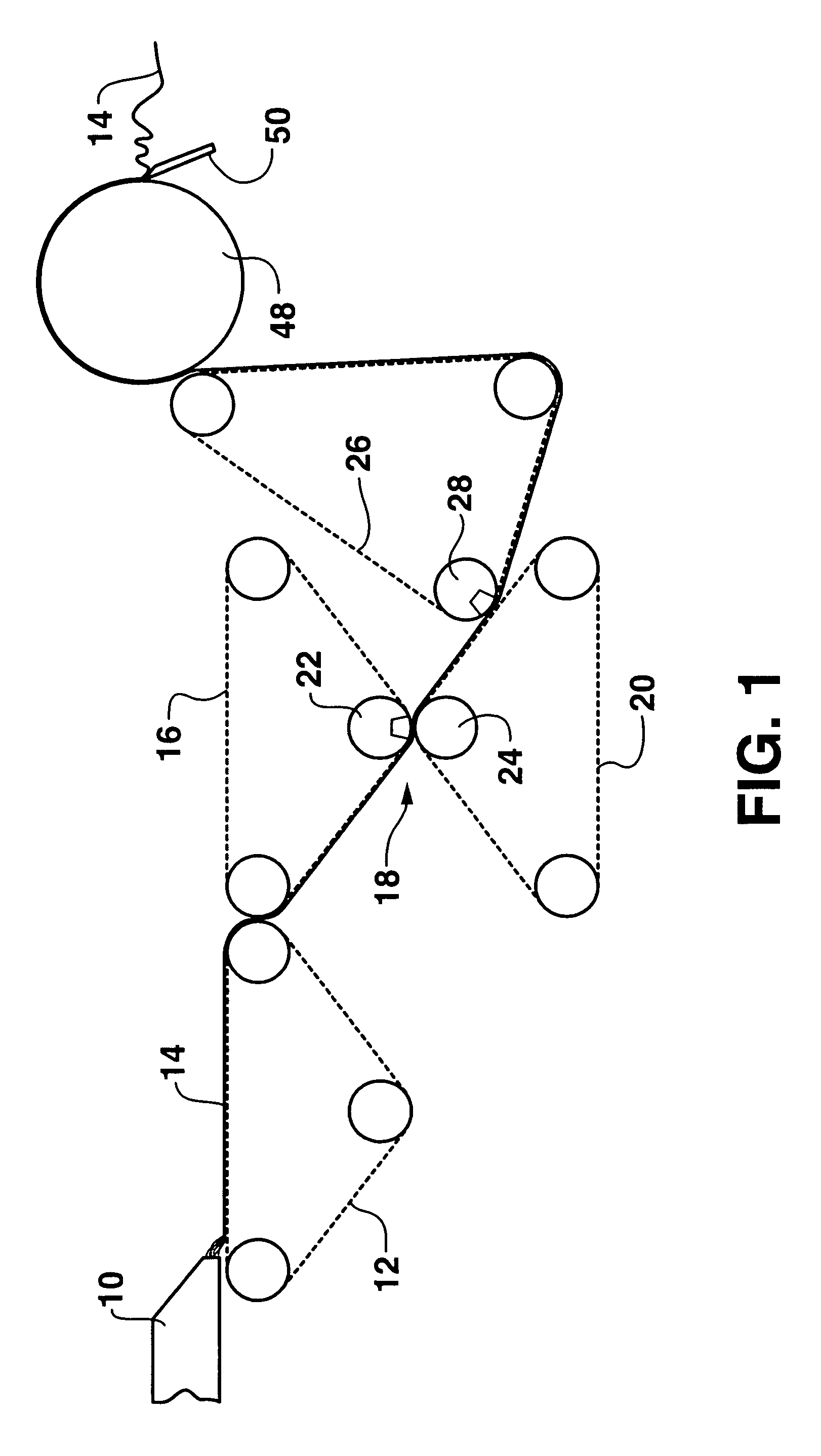

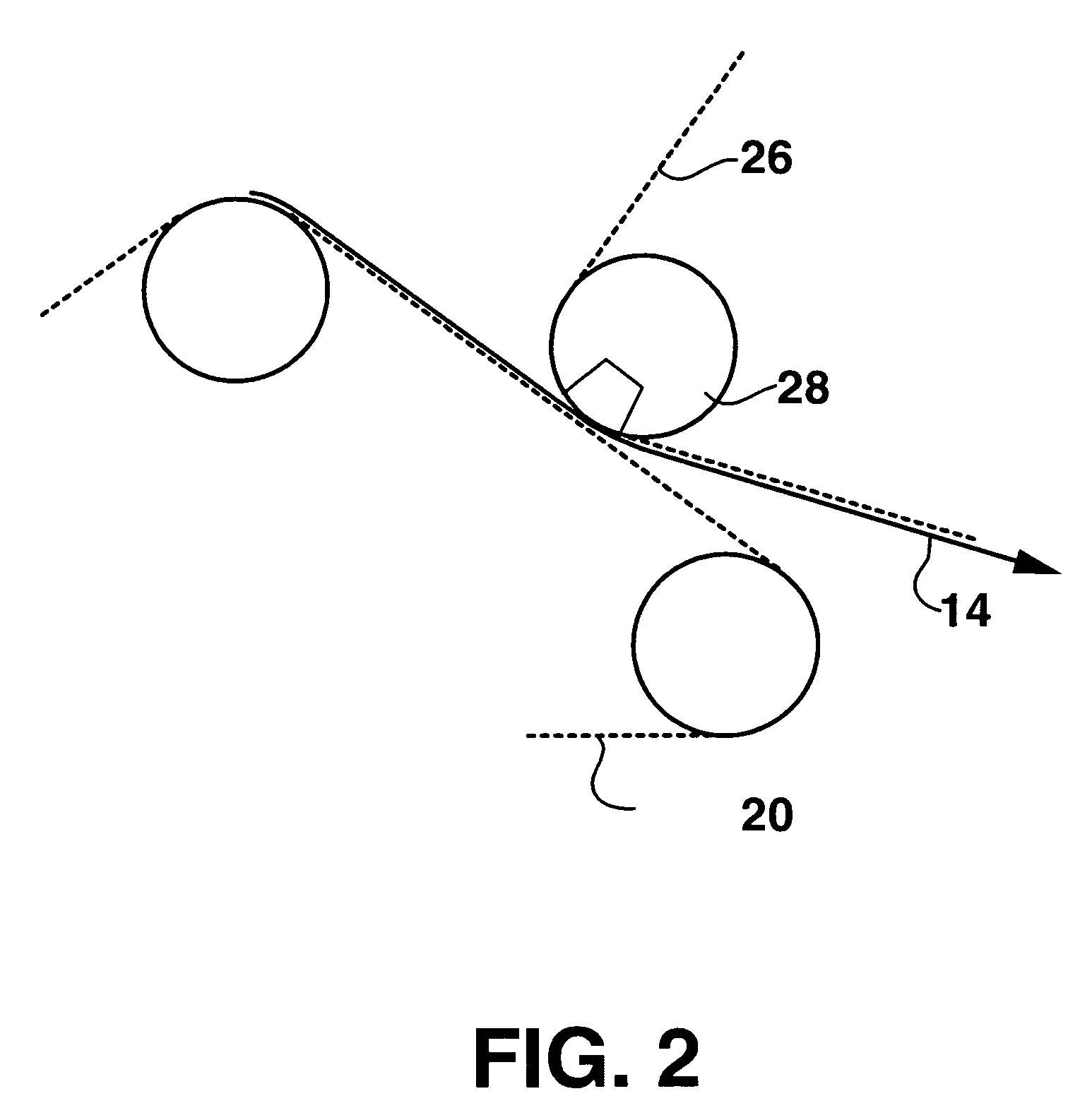

Spirally wound paper products are disclosed having desirable roll firmness characteristics and softness properties. The rolled products can be made from a single ply tissue web formed according to various processes. Once formed, the tissue web is subjected to a shear-calendering device that increases the fuzz-on-edge properties of the web and preserves the bulk of the web when wound.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Rolled tissue products having high bulk, softness, and firmness

Owner:KIMBERLY-CLARK WORLDWIDE INC

Shear-calendering processes for making rolled tissue products having high bulk, softness and firmness

Spirally wound paper products are disclosed having desirable roll firmness characteristics and softness properties. The rolled products can be made from a single ply tissue web formed according to various processes. Once formed, the tissue web is subjected to a shear-calendering device that increases the fuzz-on-edge properties of the web and preserves the bulk of the web when wound.

Owner:KIMBERLY-CLARK WORLDWIDE INC

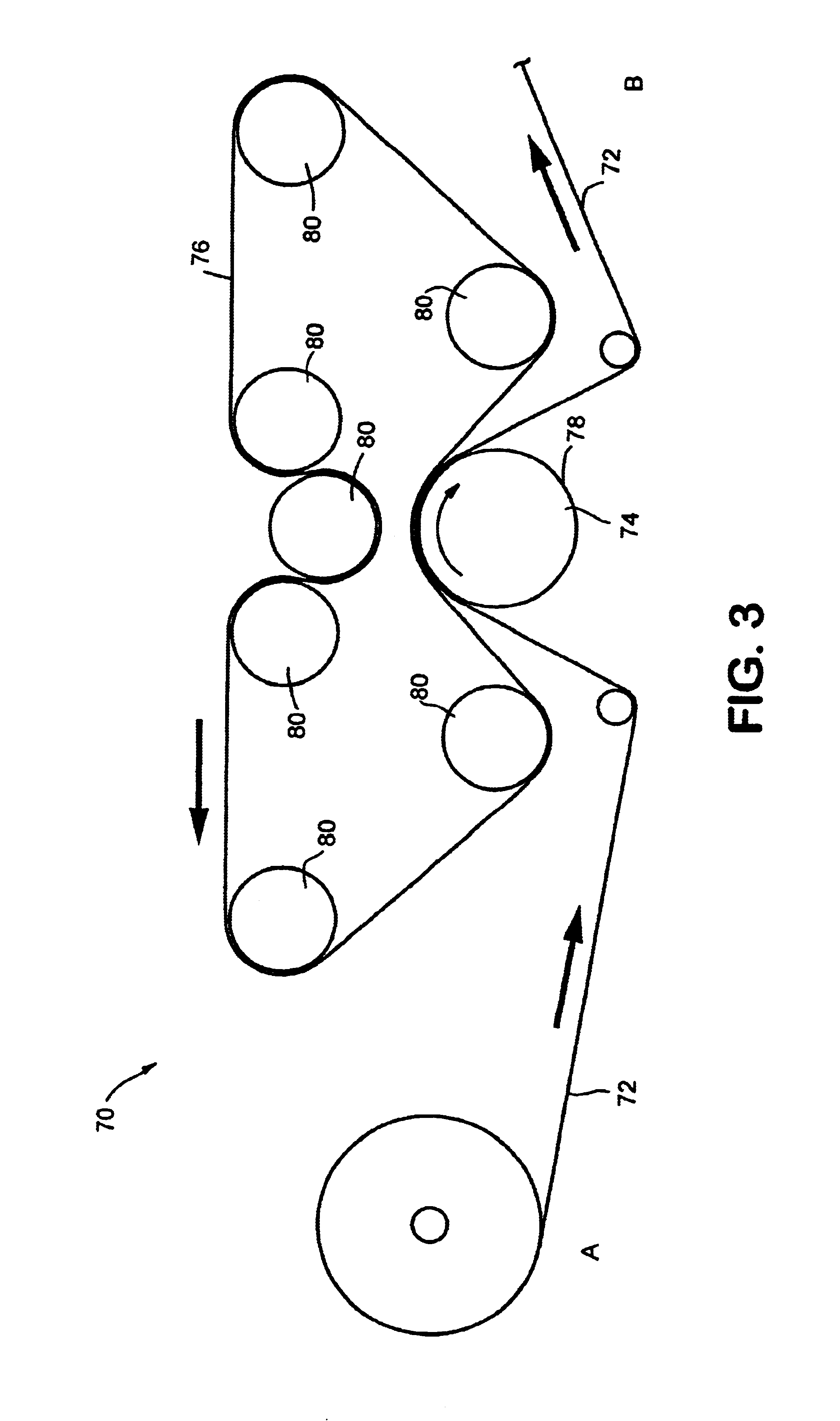

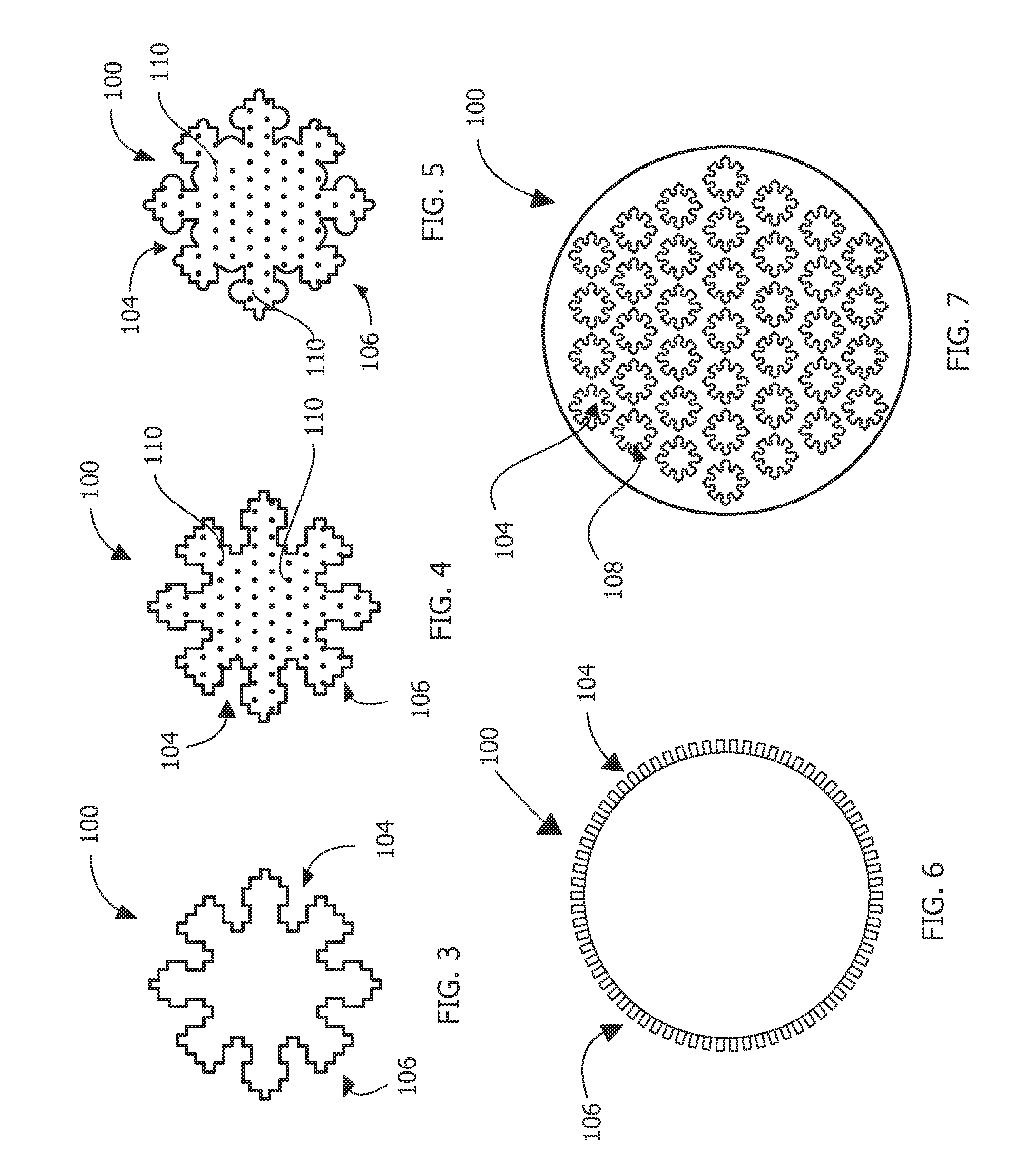

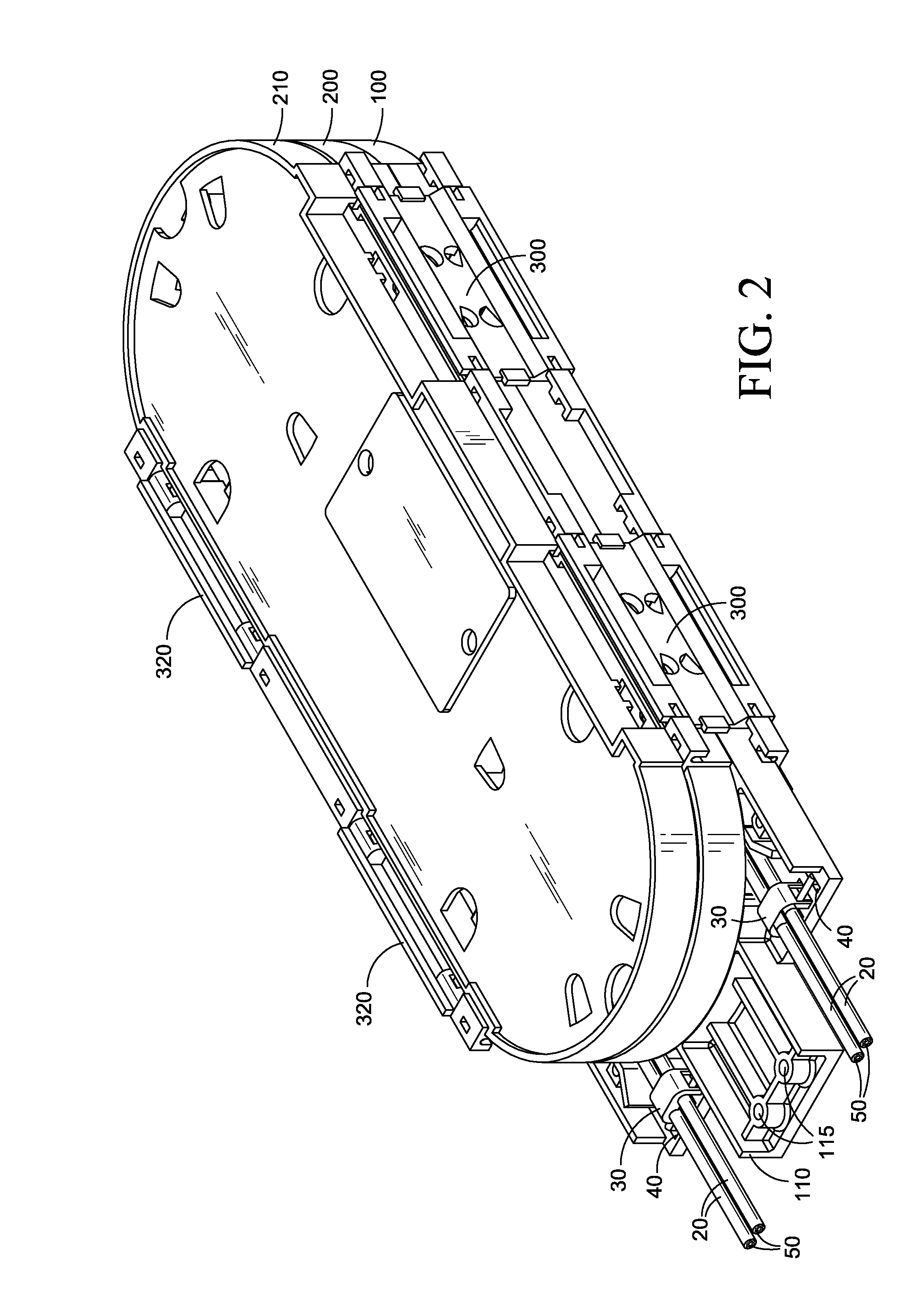

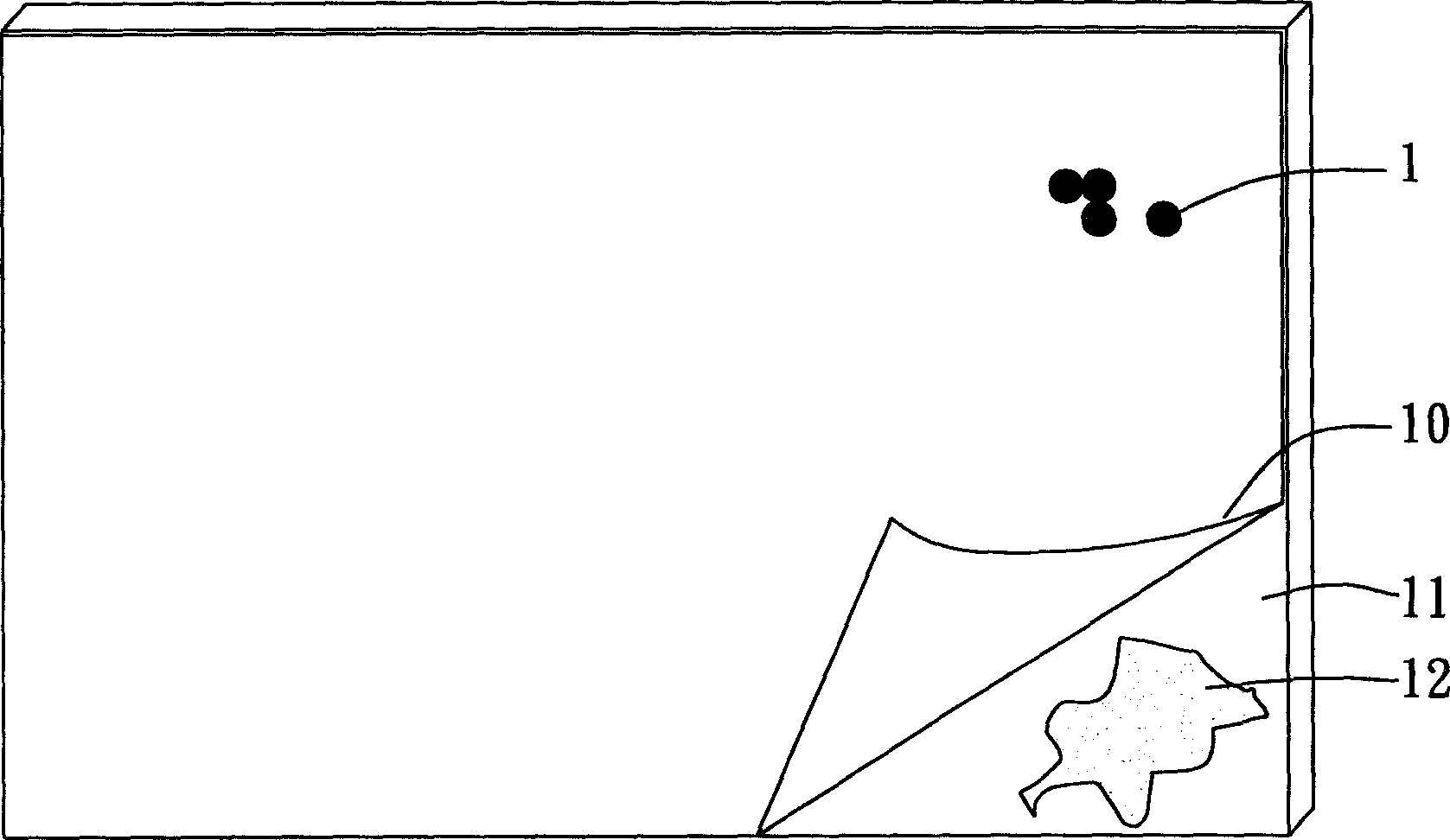

Tissue fiber scaffold and method for making

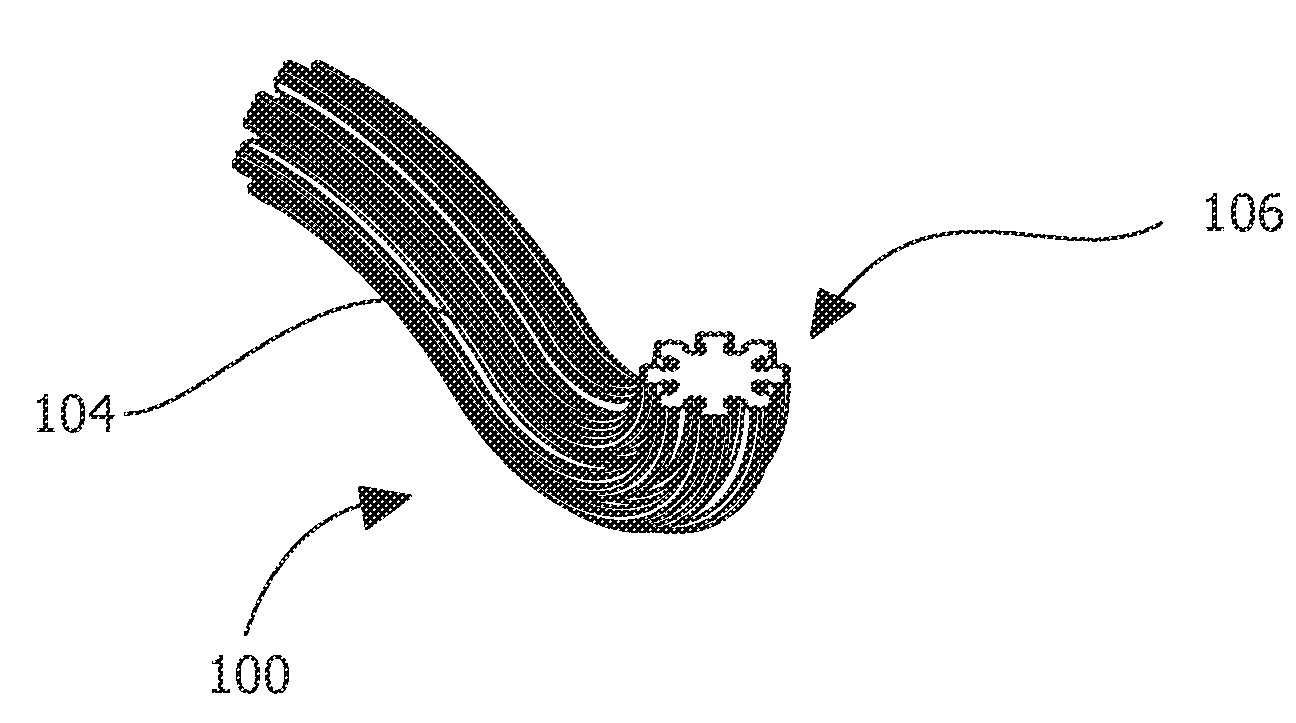

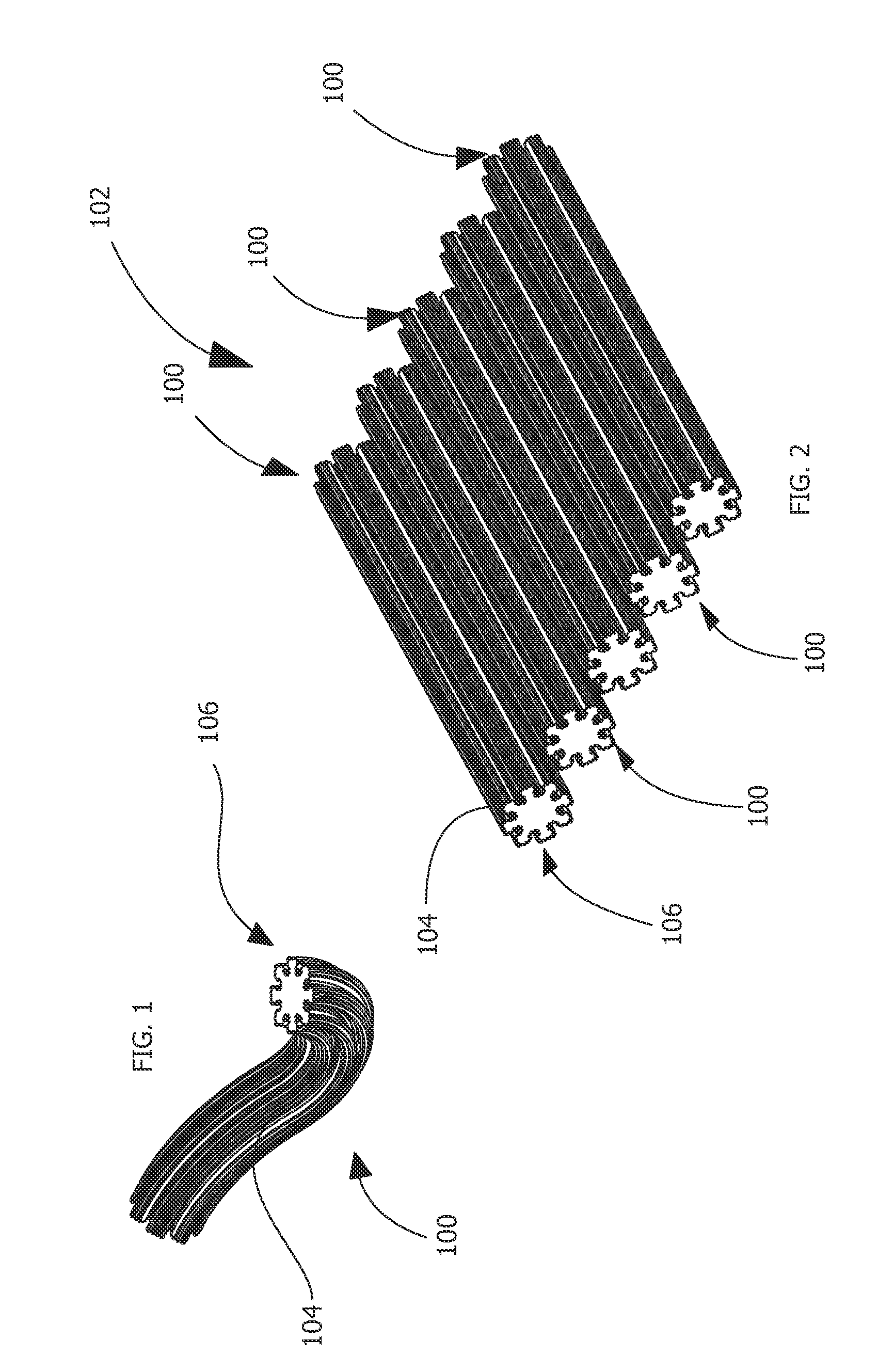

InactiveUS20110076771A1Increase surface areaImprove interlockConfectioneryFilament/thread formingEngineering tissueTissue fiber

The present disclosure relates to a fiber, a method of forming a fiber, a system for forming a fiber, and a method of engineering tissue from a fiber. The fiber includes an engineered geometric feature forming a non-Euclidian geometry.

Owner:ARMARK AUTHENTICATION TECH +1

Fiber optic categorization and management tray

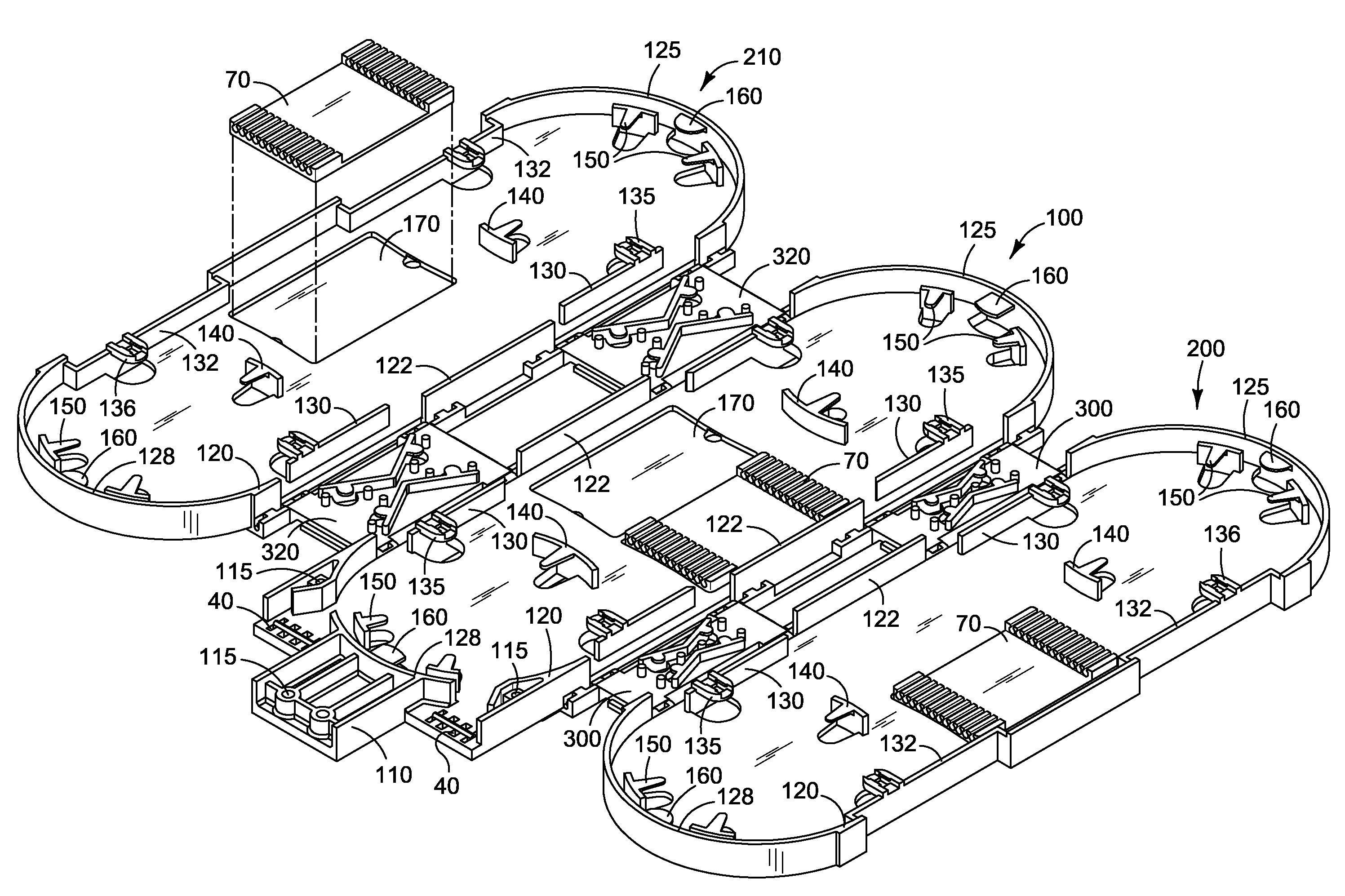

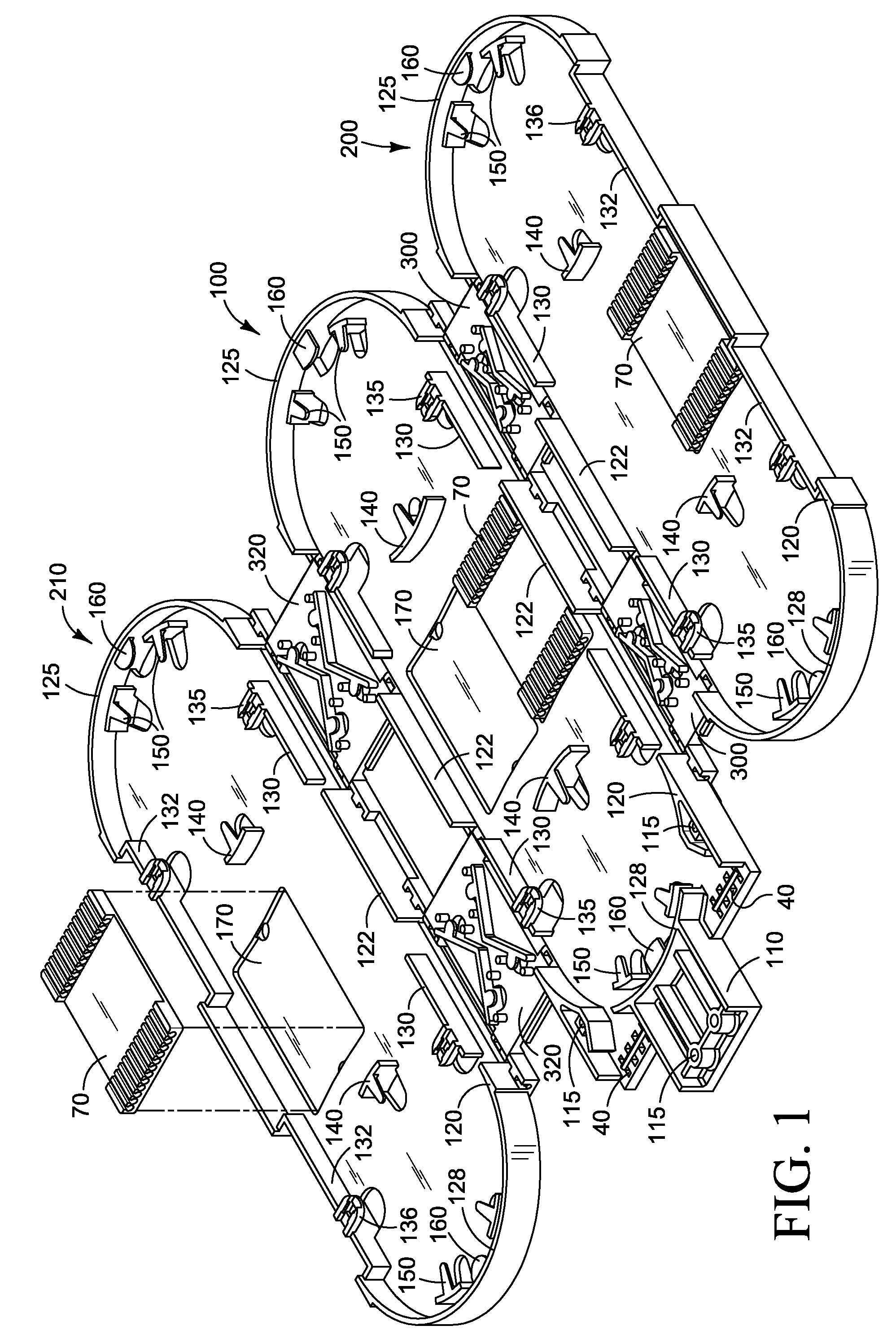

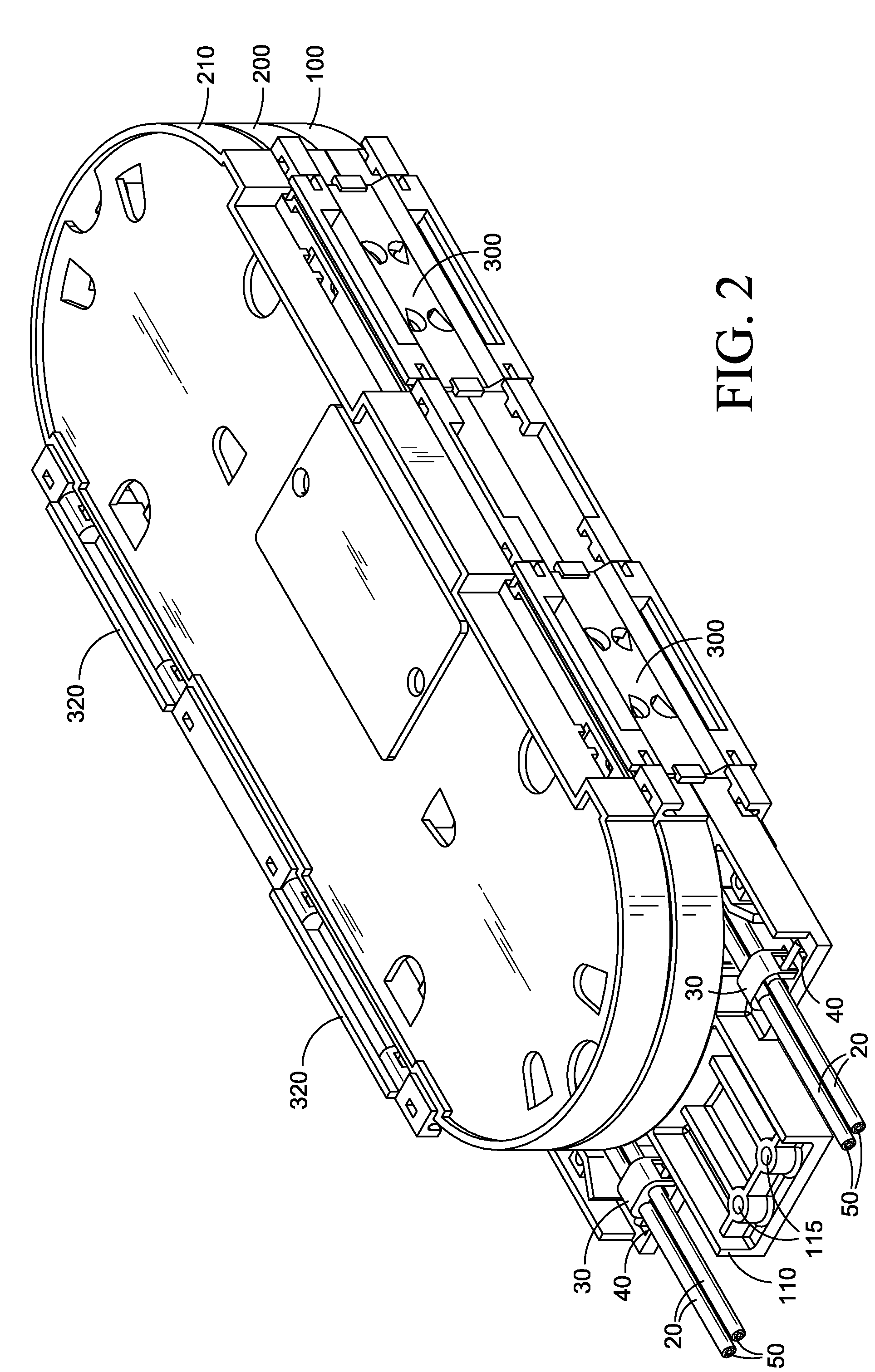

InactiveUS20080226250A1Easy to manageImprove protectionCoupling light guidesEngineeringOptical fiber connector

A fiber optic splice organizer stores optical fiber splices and sufficient slack to permit the fibers to be readily separated, such as for reorganization or to remake a splice. Multiple hinges connect a plurality of fiber trays side by side to provide pivotable connections between trays. A flat orientation of the trays enables splicing and coiling of fibers as they are loaded into a tray. The trays then pivot into a fiber storage position. Special features of the hinges provide support for fibers and splices as they are loaded into the trays. The hinges protect the fibers as the trays are pivoted as well as when the trays are in their folded position for storage without requiring buffer tubes. Multiple architectures for the organization of fibers are enabled without violating minimal bend radii, and while providing for ease of separation of individual fibers or groups of fibers.

Owner:GONZALES CURTIS PAUL +1

Construction method for skin tissue engineering rack containing epidermal growth factor

The construction process of skin tissue engineering rack containing epidermal growth factor with fetus calf or ox tendo achillis as basic material includes dewatering, defatting, primary enzyme treatment to reduce the covalent bond among tissue fibers, dialysis, secondary enzyme treatment to remove antigenic determinant, dissolving with acetic acid to obtain no-antigenicity collagen solution and collagen sponge film, soaking in propanetriol to adsorb, drying, mixing water solution of heparin and acetic acid, water solution of epidermal growth factor and propanetriol wetted collagen sponge film, and final freeze drying. The rack has no antigenicity, high strength, high flexibility, convenient operation implantation, no toxicity to wound, and capacity of inducing wound cell growth and promoting wound healing.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST +1

Manufacturing method of dustless cleaning cloth

InactiveCN1719308AReduce manufacturing costHigh cleanabilityStatic indicating devicesWoven fabricsYarnFiber

The present invention relates to a production method of dust-free cleaning cloth and its finished product. Said method includes the following steps: 1. adopting extremely fine denier profiled fiber with spade-shaped structure as tissue fibre base material; 2. weving yarn bundle made of said base material into a base cloth; 3. making said base cloth into which a cleaning agent is added into cloth roll; 4. thermosetting said cloth roll; 5. cutting the cloth roll into required size by means of thermal cutter, laser or ultrasonic wave; and 6. finishing to obtain the finished product.

Owner:SUNRAY SCI & TECH

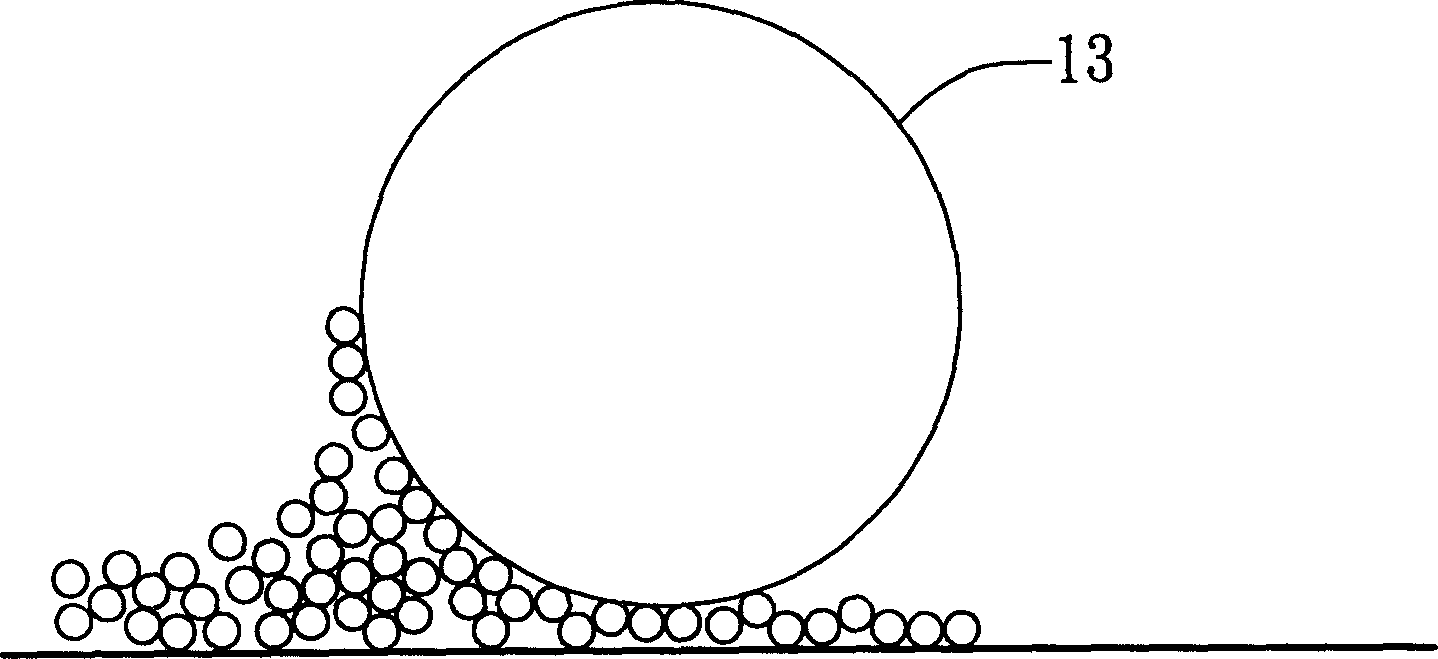

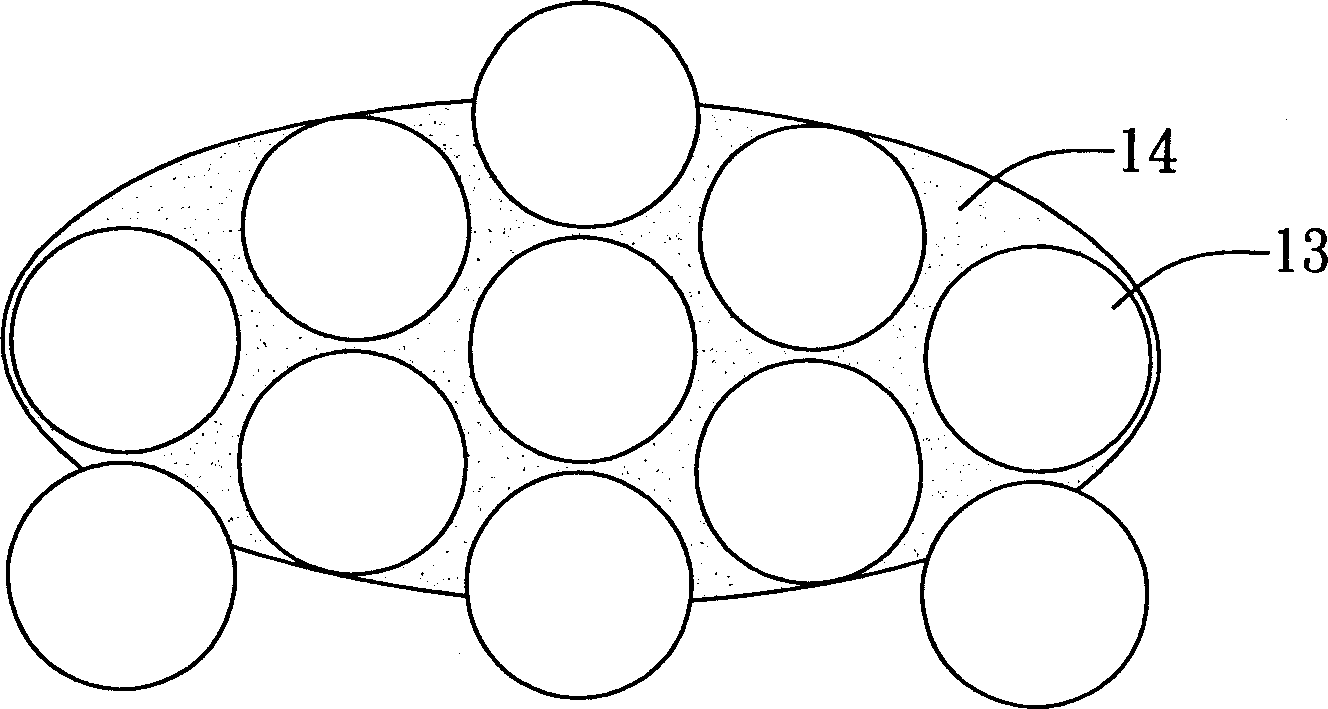

Wastewater treatment method

InactiveCN102079614AEfficient degradationEfficient removalMultistage water/sewage treatmentBiological water/sewage treatmentVoid ratioSludge

The invention provides a wastewater treatment method which comprises the steps: wastewater enters biomass enrichment culture equipment after regulated by a regulating tank, is subjected to biomass treatment by using microorganisms, enters an aeration tank set for aeration treatment, and settles in a settling tank; settled sludge in the settling tank reflows to the aeration tank set, the regulating tank and the biomass enrichment culture equipment through a sludge reflowing tube at a reflowing ratio of 0.5-10 times; and an air supply tube supplies air to the aeration tank set and the biomass enrichment culture equipment, wherein the microorganisms are Bacilli. The biomass enrichment culture equipment comprises a polyporic tissue fiber body with volume weight of 0.04-0.08g / cm<3> and voidage of above 90 percent. According to the method provided by the invention, by adapting to the change of processing conditions, such as water quality, water yield, load, temperature and the like the purification treatment of the wastewater in the expectation is successfully realized.

Owner:青海洁神环境科技股份有限公司

Bush forging technology

The invention discloses a bush forging technology, including the following steps of: 1, chamfering one end of a steel ingot workblank, pressing feeder head at the other end to form pincers handles, cutting off excessive length, cutting water gap, and burring; 2, vertically placing the workblank into an upsetting plate part in a mold; 3, taking out the mold, punching a through hole by using a punch; 5, leveling the end face, penetrating a rod into an inner hole to press to be hexagonal and rounding, clearing angles, and enlarging the hole to the designed size; 6; leveling the end face, penetrating the rod again, pressing the small end to be hexagonal and drawing out, chamfering and rounding, leveling the end face, and slight enlarging the inner hole again to the designed size; 7, leveling and reshaping; 8, thermal processing after the infrared measured size is qualified. The bush forging technology has the advantages of being simple and convenient in technology, according to the bush forging technology, qualified product can be directly obtained by forging, the tissue fibers of the product is prevented from being damaged by turning processing, the service life is improved, and meanwhile, the processing amount is reduced, the material is saved, and the cost is lowered.

Owner:CHONGQING YANLIAN HEAVY MACHINERY EQUIP

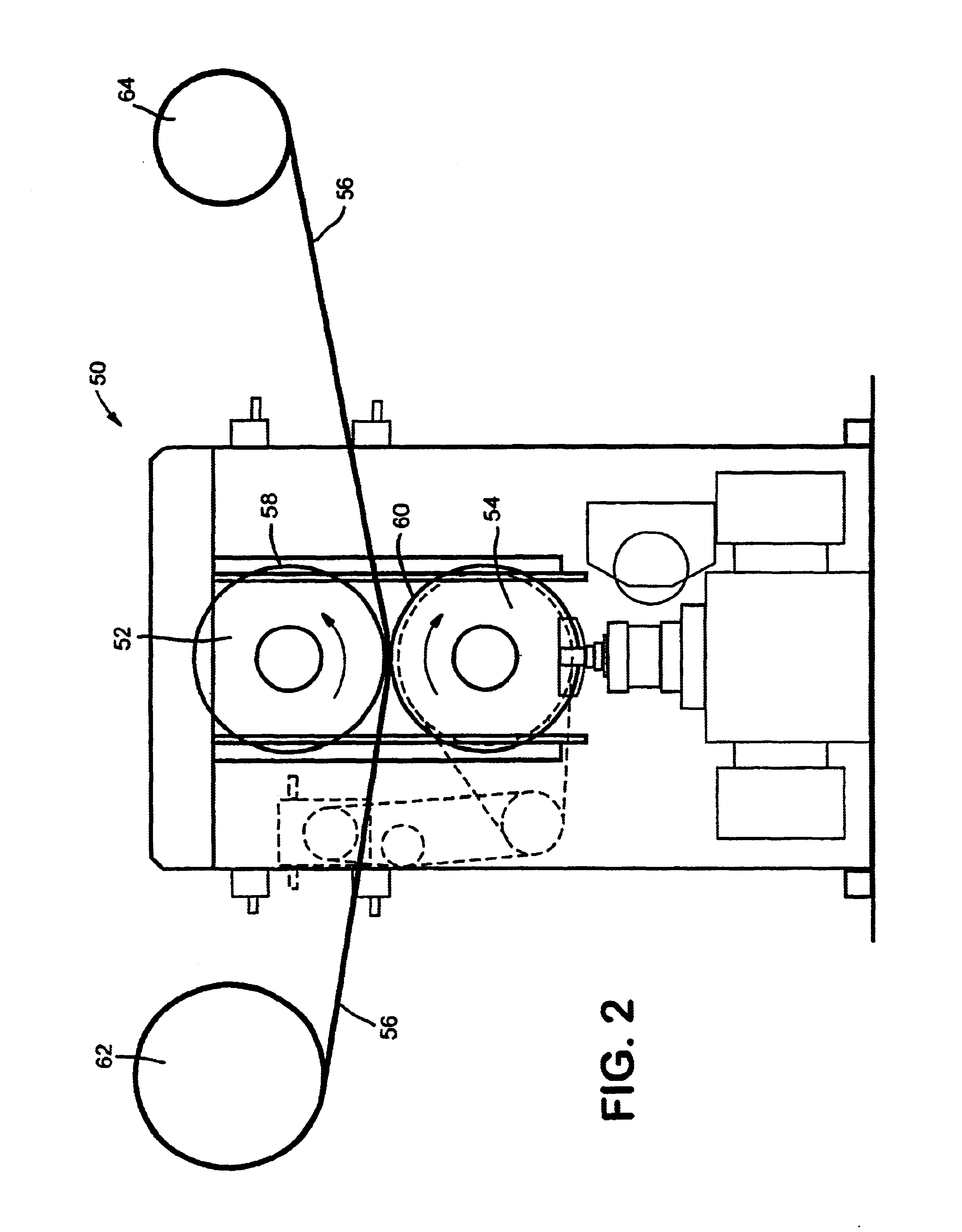

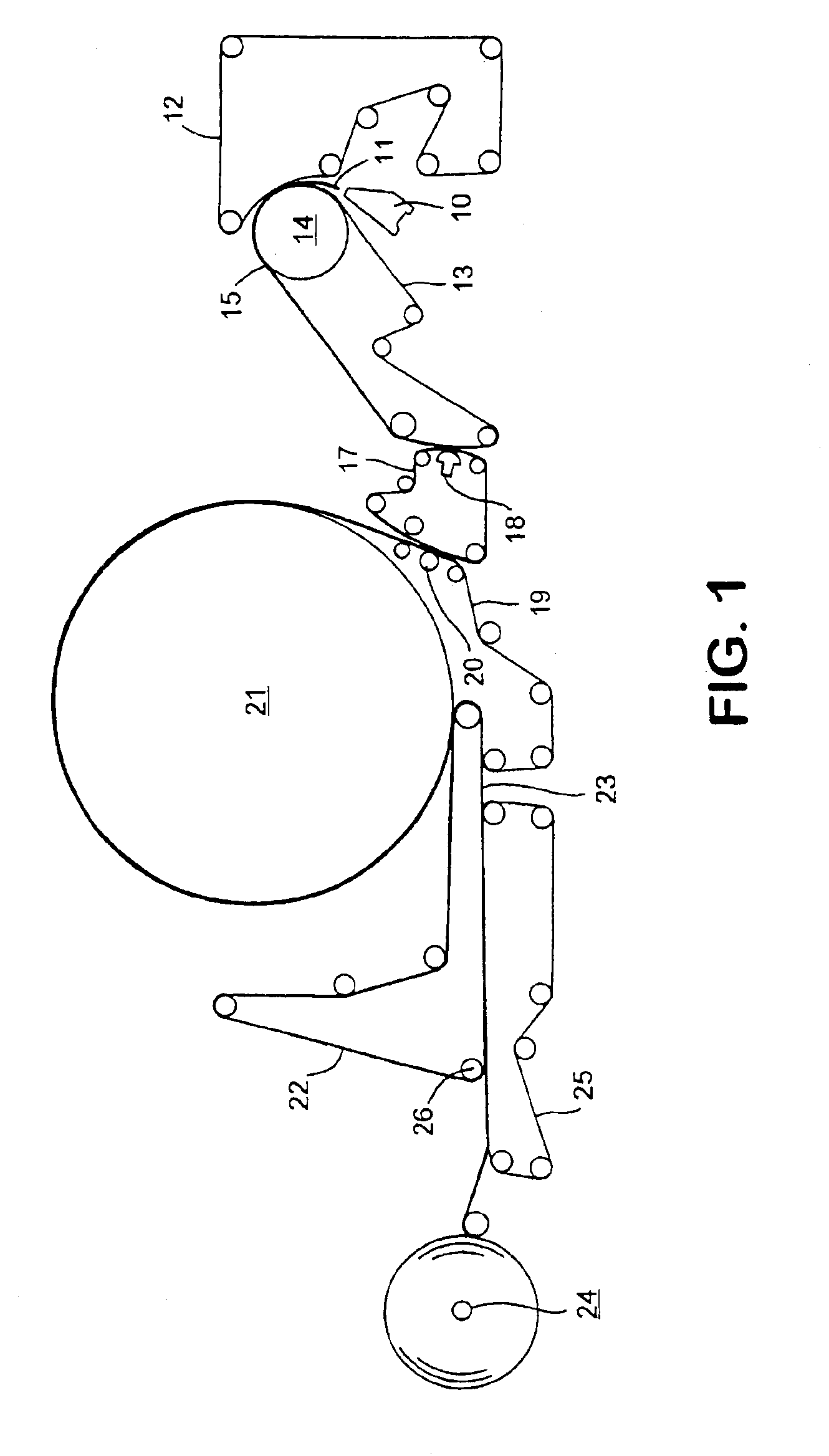

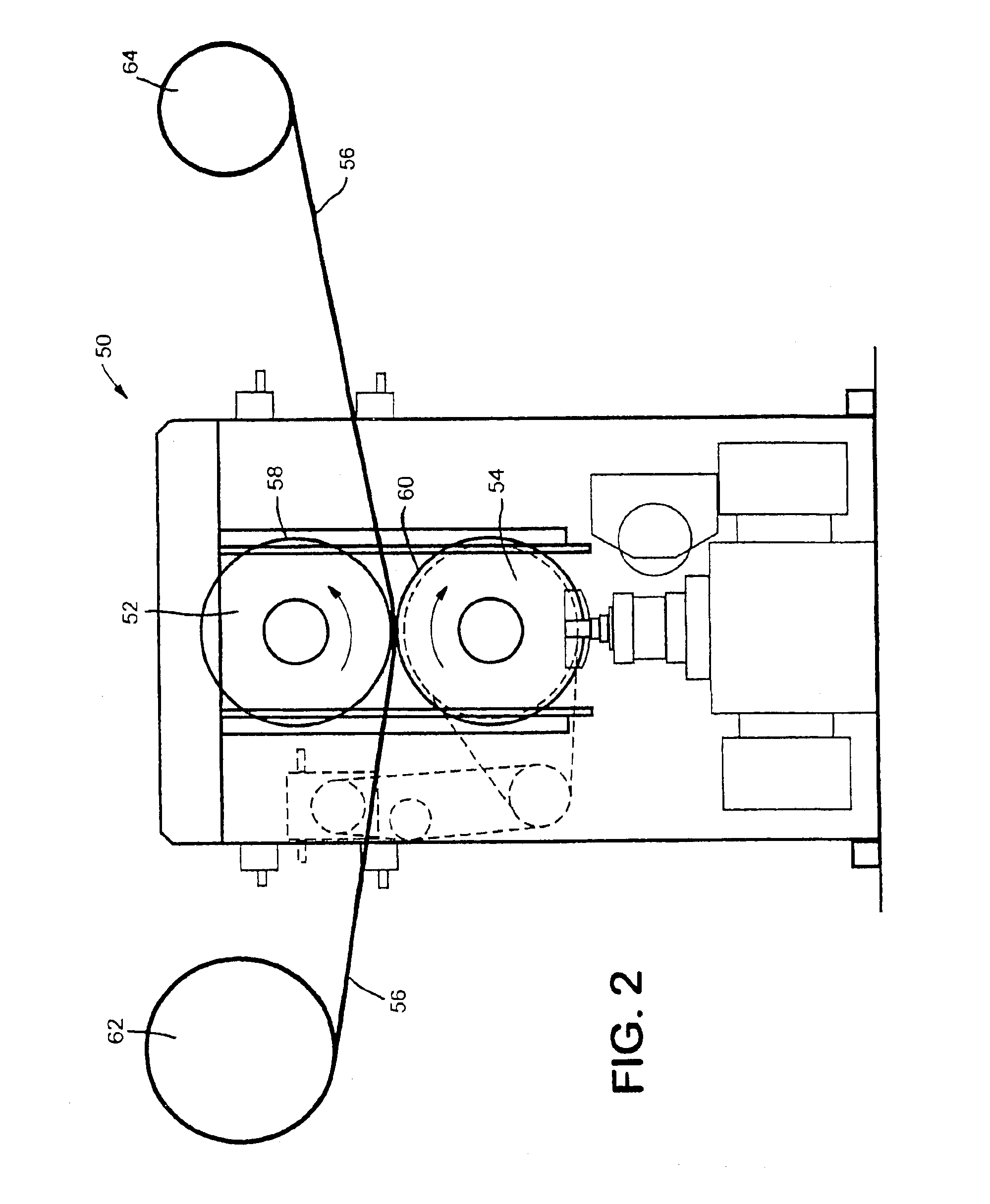

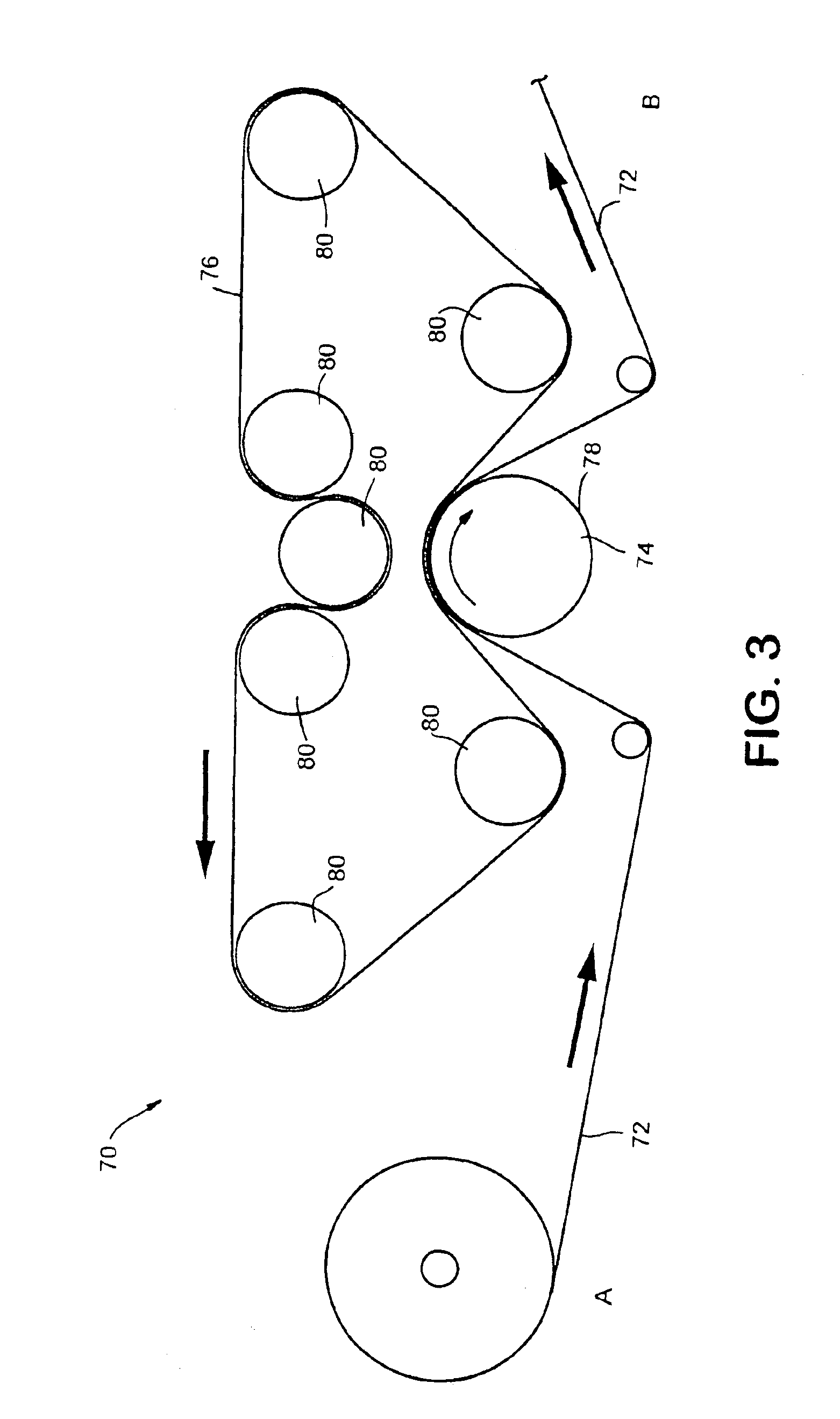

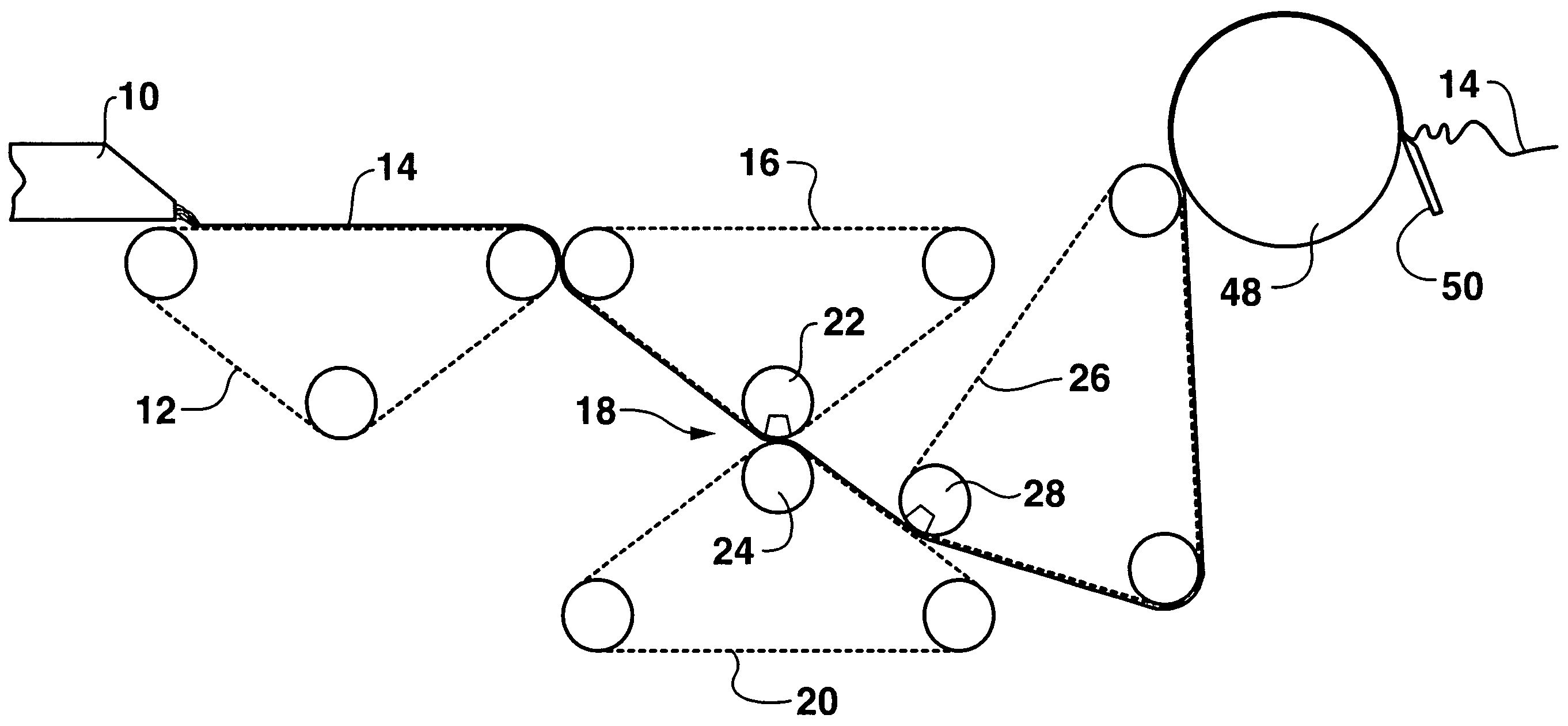

Method for producing wet-pressed, molded tissue products

ActiveUS7462257B2Increase bulkLow densityNon-fibrous pulp additionNatural cellulose pulp/paperSuction forceEngineering

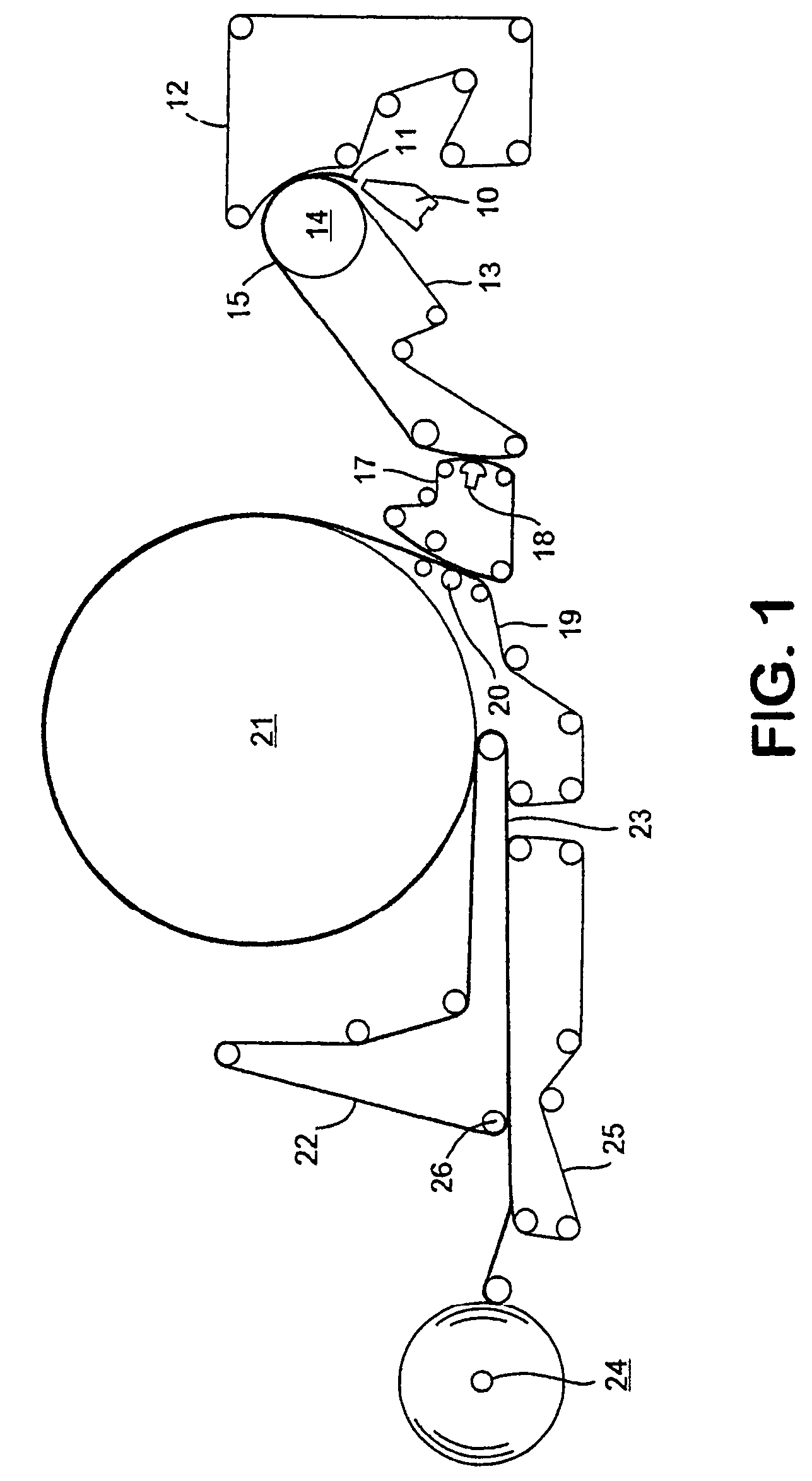

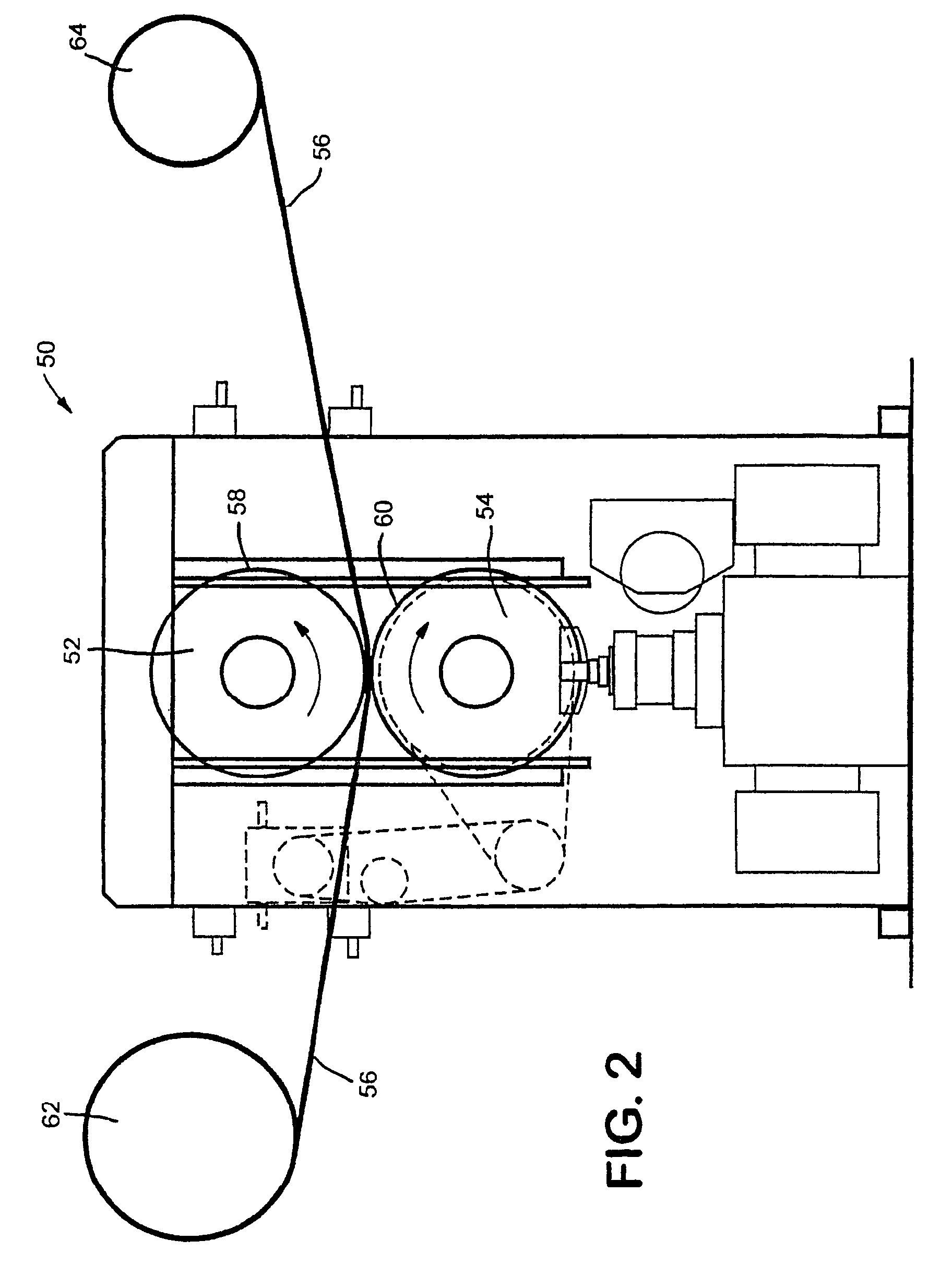

A process for producing tissue webs is disclosed. The process may include the step of partially dewatering a tissue web, subjecting the web to at least one deflection against a fabric, such as a coarse fabric, and then creping the web. During the process, after being dewatered, the tissue web is transferred from a transfer conveyor to the fabric using a pneumatic force, such as a suction force. In order to prevent liquids from rewetting the tissue web as the tissue web is being transferred to the fabric, the transfer conveyor is made from a material that inhibits or prevents liquids from flowing into the tissue web. For instance, in one embodiment, the transfer conveyor may comprise a felt comprised of small capillary materials. The felt may have an intake rate, for instance, of less than about 150 μL / s when wet, may have a mean free pore size of less than about 20 microns, and may have a minimum pore size of less than about 5 microns.

Owner:KIMBERLY-CLARK WORLDWIDE INC

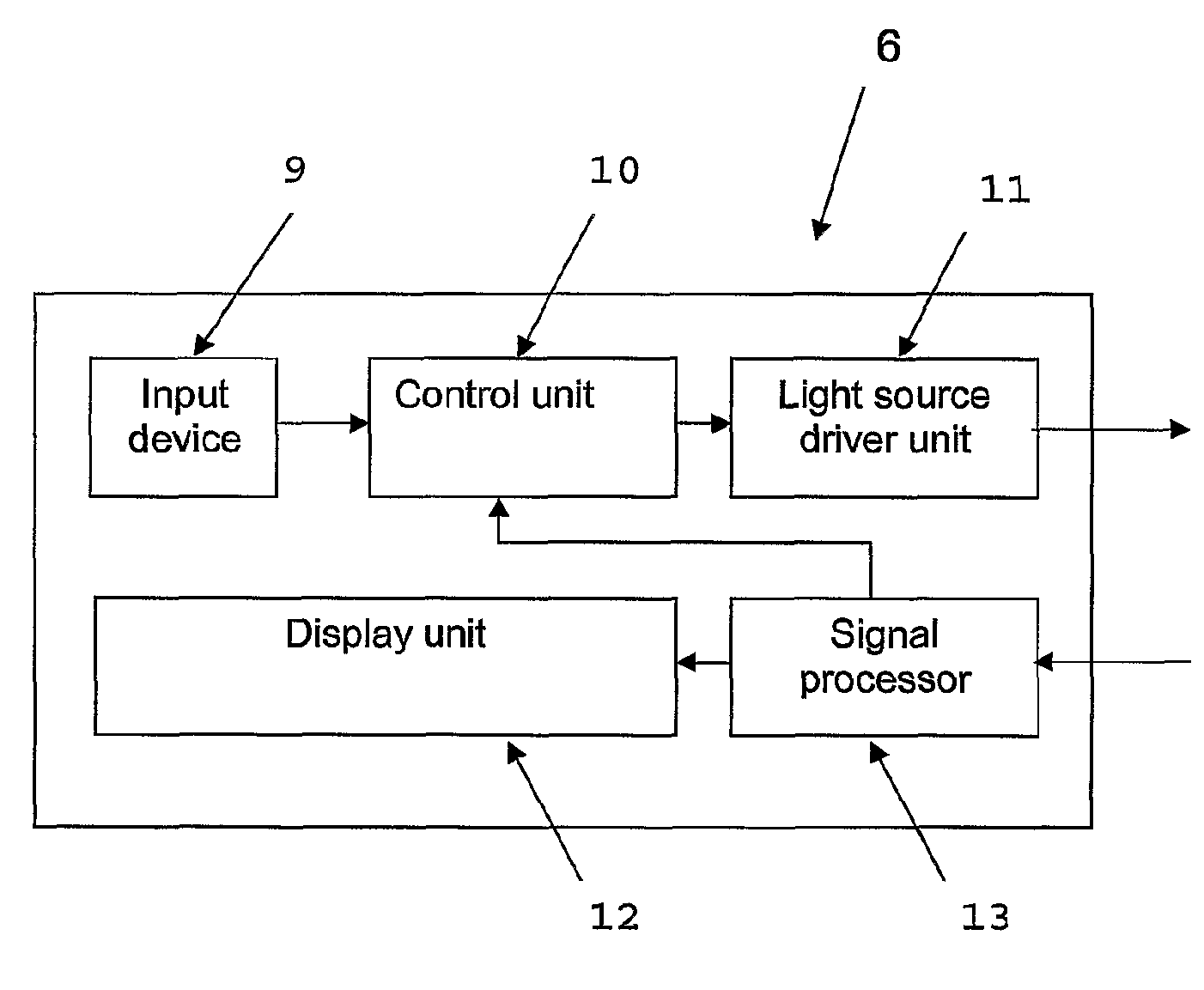

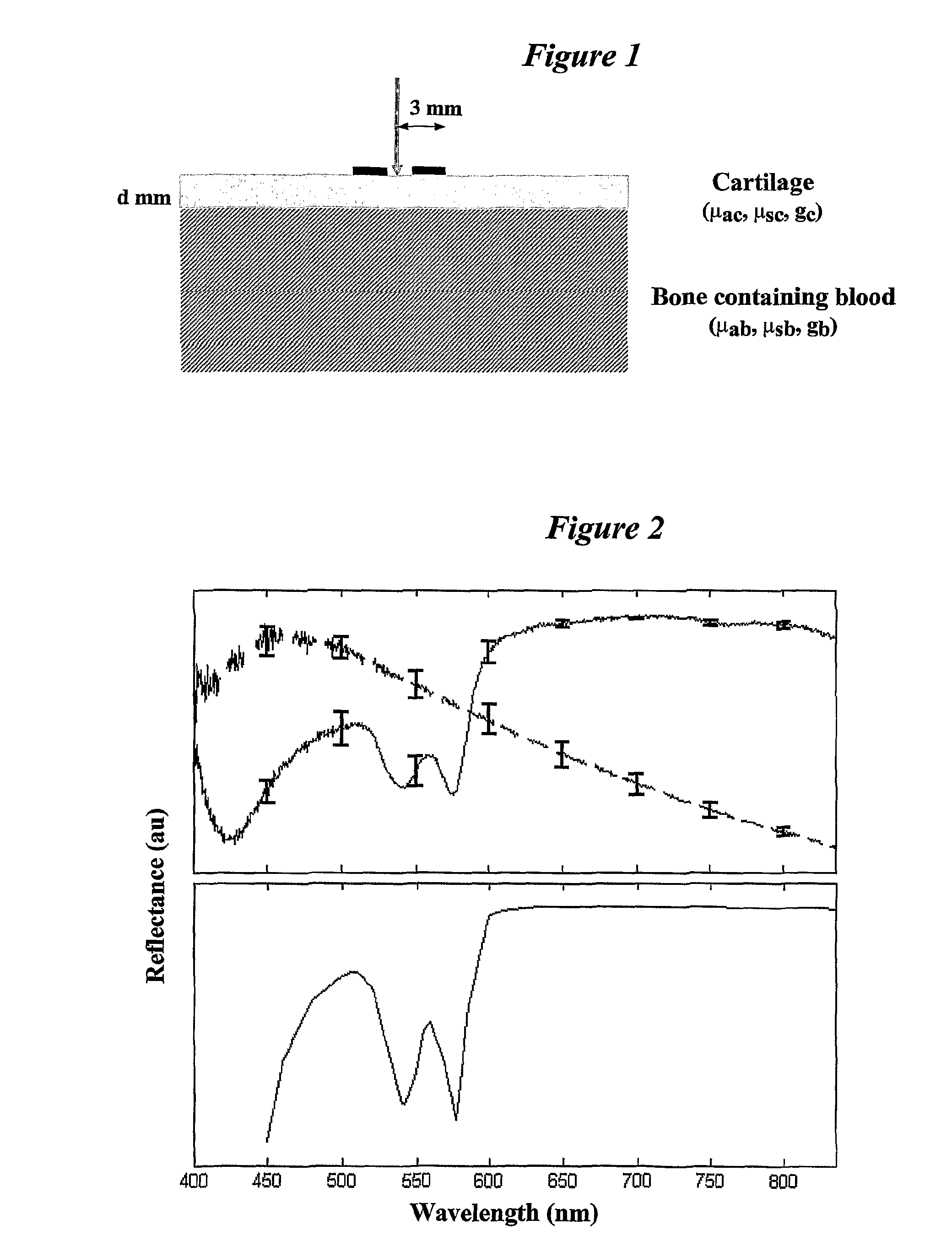

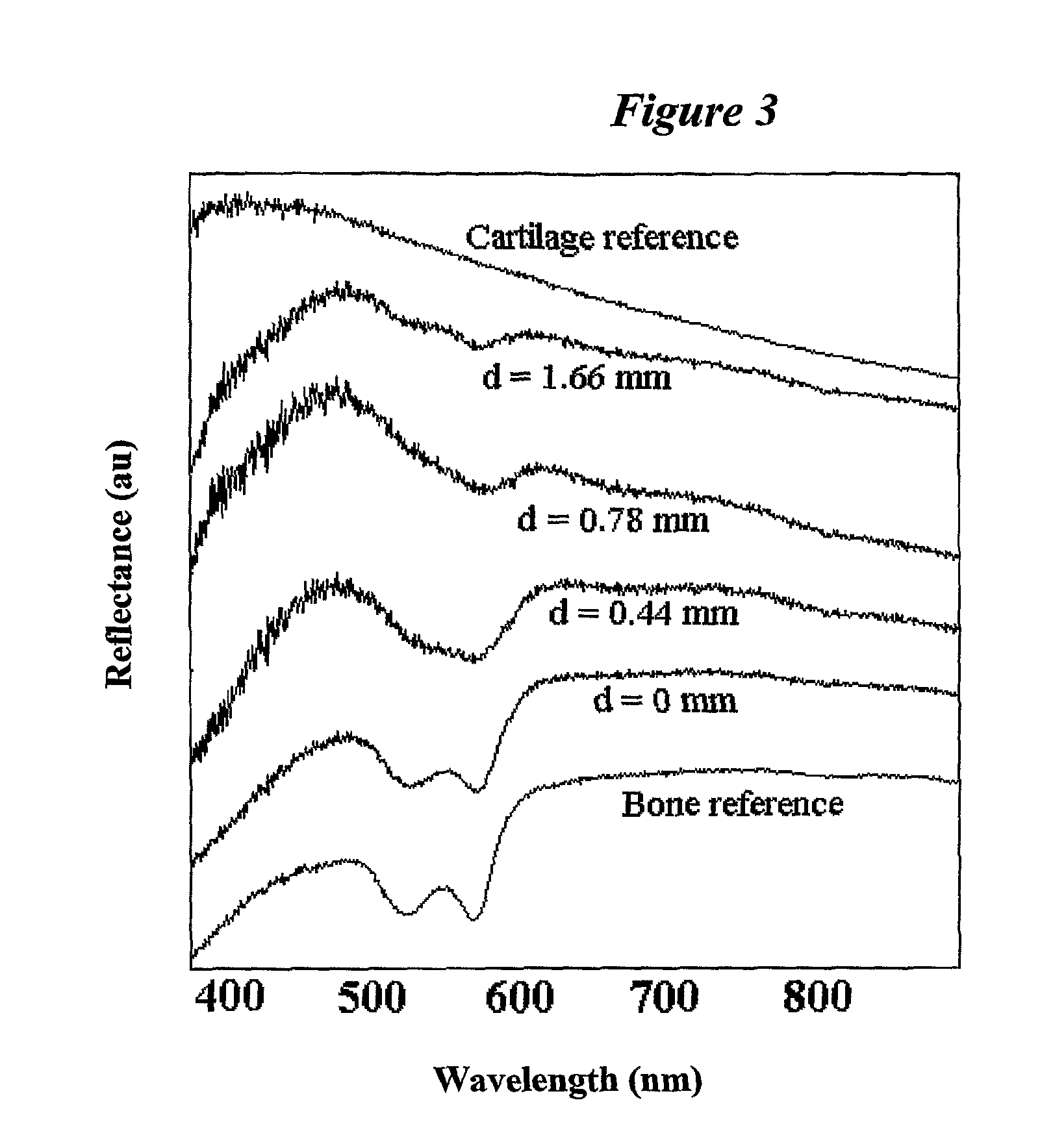

Arrangement and method for assessing tissue qualities

ActiveUS8170649B2Ultrasonic/sonic/infrasonic diagnosticsPolarisation-affecting propertiesMedicineSurface roughness

Owner:ARTHREX

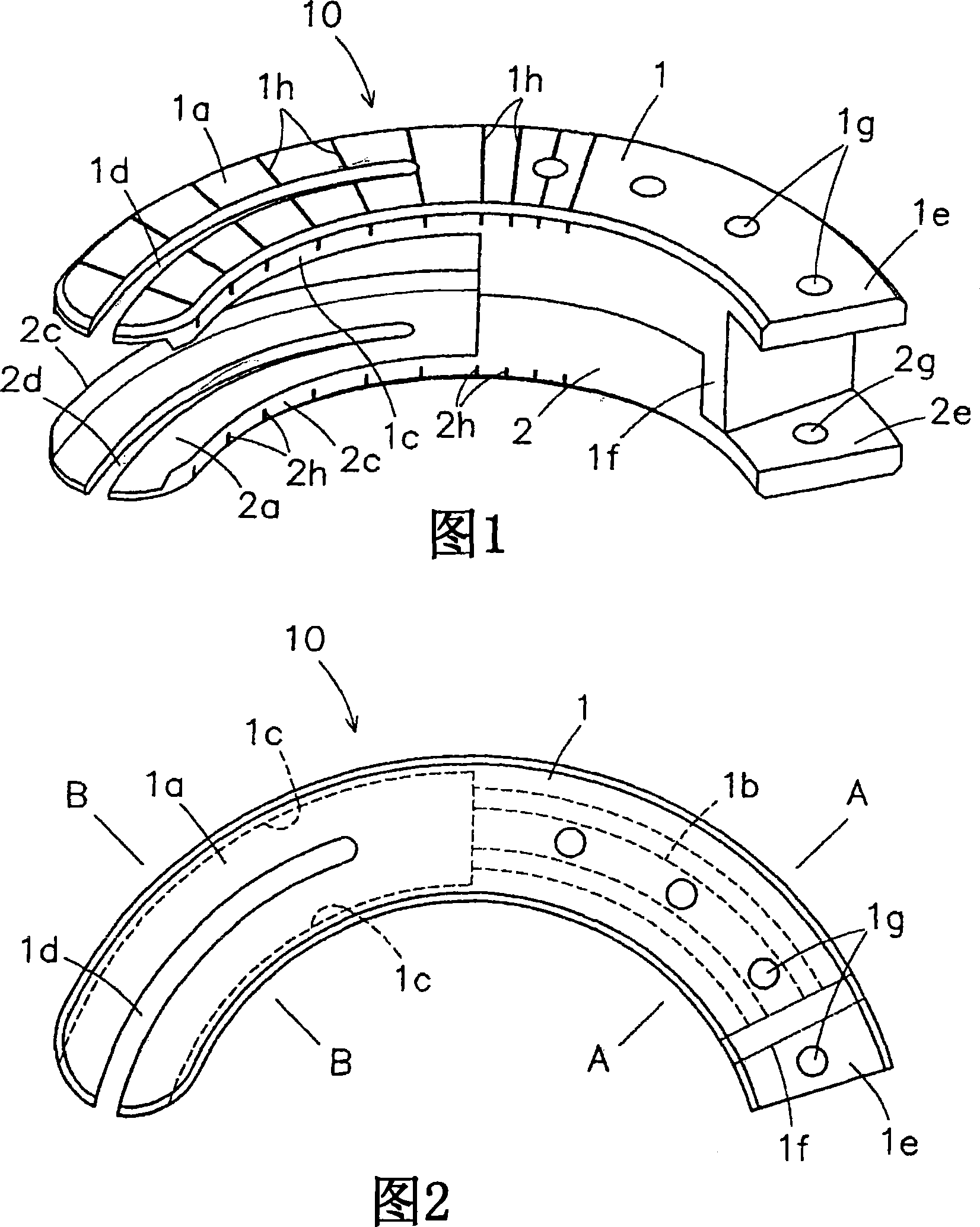

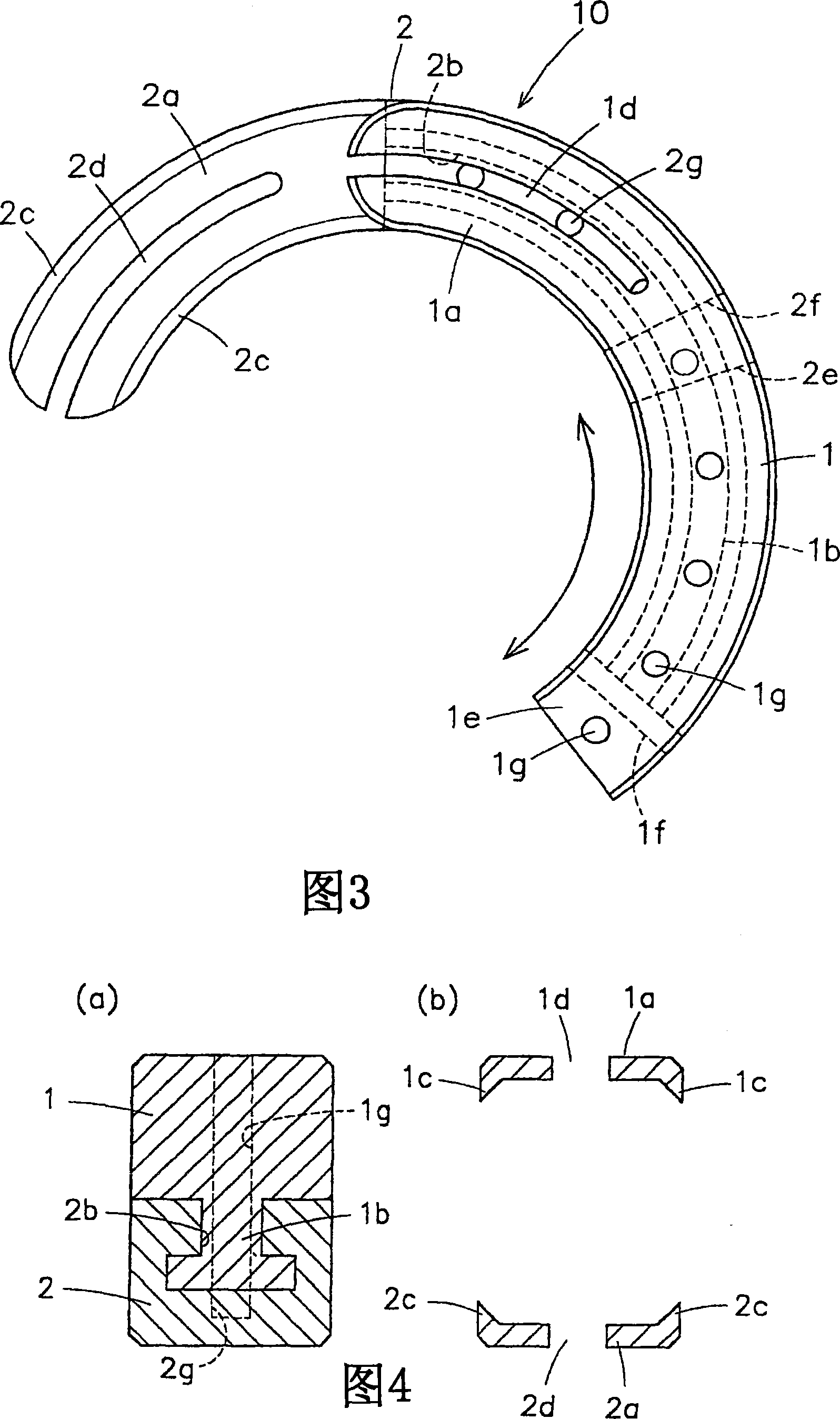

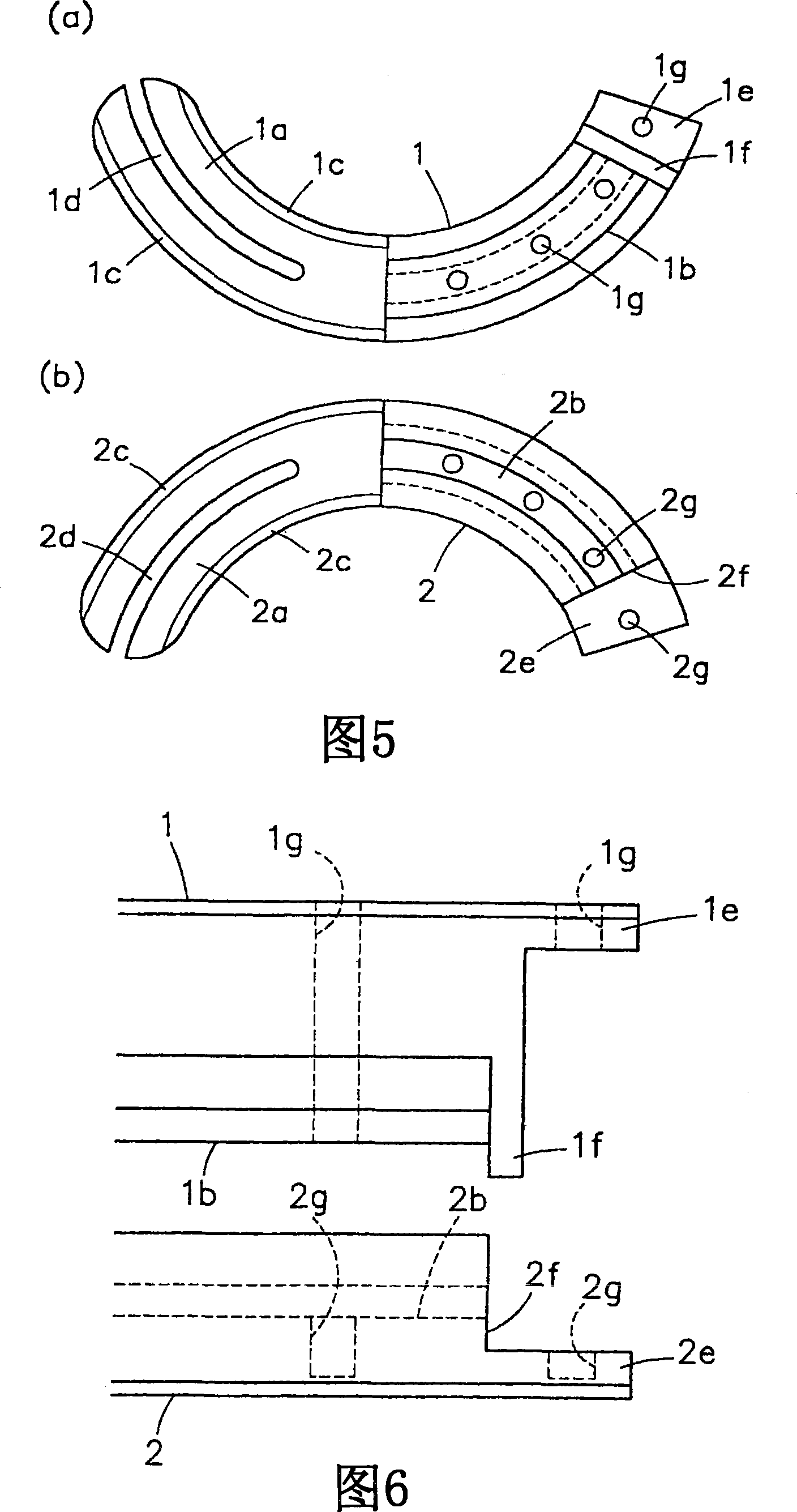

Artificial intervertebral disk insertion jig, jig set, and artificial intervertebral disk

InactiveCN101014292APrevent incomplete retentionPrevent slidingSpinal implantsOsteosynthesis devicesBone conduction hearingIntervertebral disk

A self-sustained artificial intervertebral disk that has flexible nearly ideal mechanical transformation characteristics and durability, exhibiting high vertebra bonding fixing force; and an artificial intervertebral disk insertion jig capable of easily and securely inserting and setting this artificial intervertebral disk between adjoining vertebrae. There is provided an artificial intervertebral disk comprising a core material constituted of a texture structure obtained by forming an organic fiber into a triaxial or further multiaxial three-dimensional woven texture, or knitted texture, or composite texture thereof and, superimposed on both upper and lower surfaces of the core material, plates of a polymer capable of being in vivo decomposed and absorbed which contains a bioactive bioceramic powder. Preferably, the superimposed plates are those having a multiplicity of holes made therethrough, the through-holes optionally packed with a material capable of being in vivo decomposed rapidly and absorbed, the material exhibiting bone conduction and / or bone induction properties. Further, there is provided an insertion jig comprising a combination of upper jig and lower jig fitted together so as to be capable of avoiding detachment in the vertical direction and capable of sliding back and forth, and further comprising an upper holding part and lower holding part for holding the artificial intervertebral disk, respectively disposed in front parts of the upper jig and lower jig.

Owner:TAKIRON CO LTD

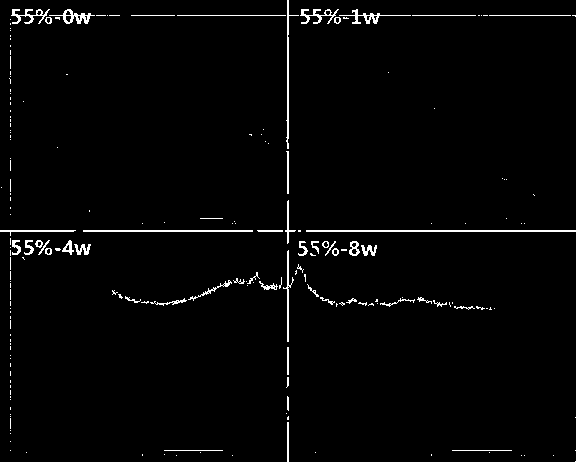

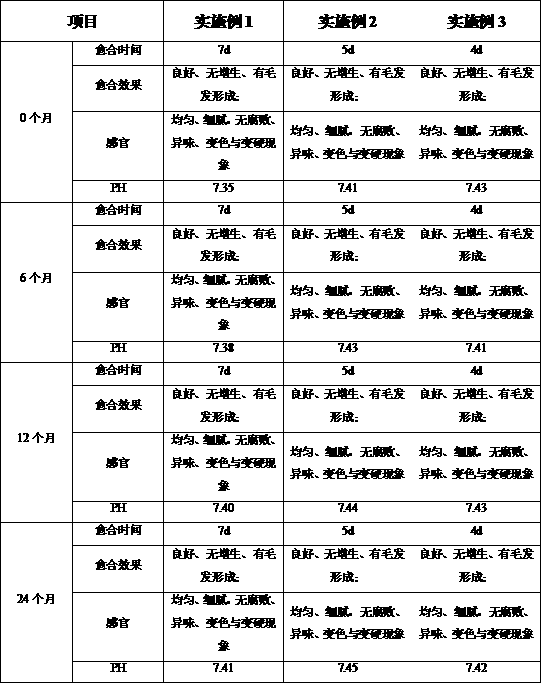

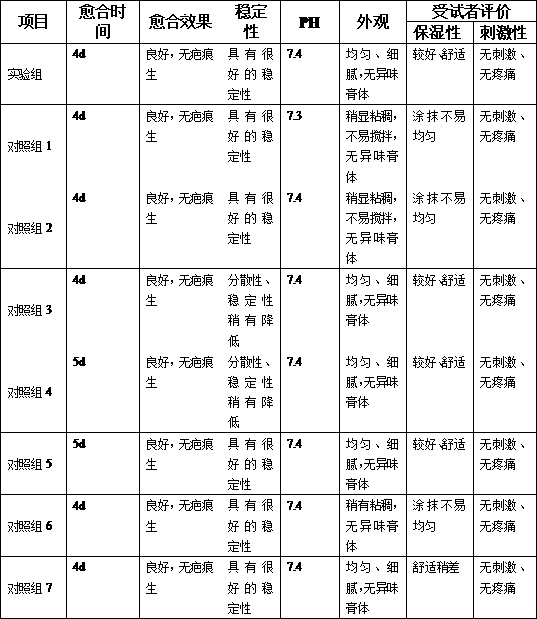

Wound depth repairing regenerative dressing formula and preparation method thereof

InactiveCN110025813APromote formationPromote healingAbsorbent padsBandagesPolyethylene glycolIon exchange

The invention discloses a wound depth repairing regenerative dressing formula and a preparation method thereof. The formula includes: bioactive regenerated silicon powder, medical grade sodium hyaluronate, carboxymethyl chitosan, medical vitamin E oil, medical white vaseline, medical liquid paraffin, medical lanolin and polyethylene glycol 4000. The remarkable effects of the formula is that the implementation is simple, and the above formula adopts a specific ratio, which can realize ion exchange in cells and form a three-dimensional network structure consistent with the original skin, and realizes the ordered growth of a new tissue fiber layer, the regeneration of capillaries and hair follicles, the regeneration repairing of wound endogenous tissue and the inhibition of scar formation. The formula is fused with a specific proportion while preparation is carried out, the operation is simple, the wound can be quickly healed, and the regeneration repairing of wound endogenous tissue canbe realized.

Owner:BEIJING BEST LIFE REGENERATIVE MEDICINE TECH CO LTD

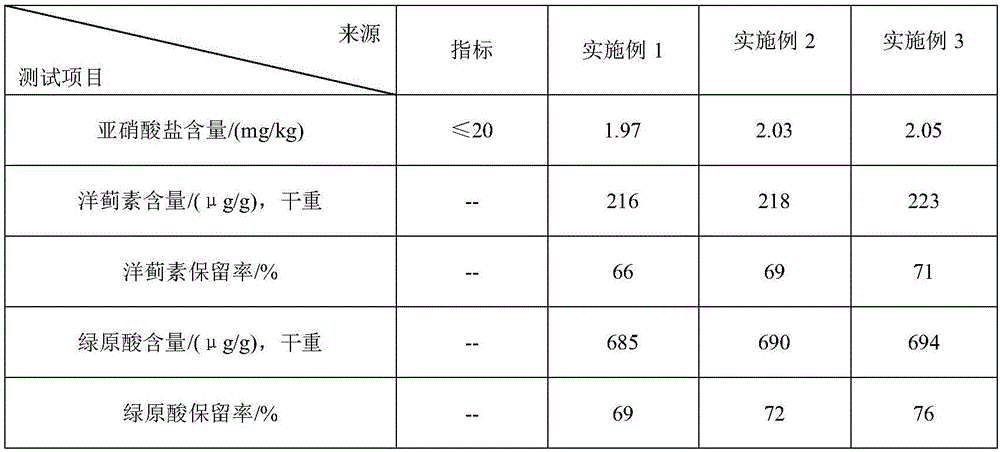

Preparing method for artichoke pickled vegetables

ActiveCN106579186AReduce green tasteHigh acceptanceLactobacillusFood ingredient as mouthfeel improving agentFlavorChlorogenic acid

The invention belongs to the technical field of food processing, and particularly relates to a preparing method for artichoke pickled vegetables. The preparing method includes the specific steps of A, raw material pretreating; B, pickling; C, primary inoculating; D, primary fermenting; E, secondary inoculating; F, secondary fermenting. After artichoke bracts or stems are subjected to two times of fermentation, tissue fibers are obviously tenderized, and the coarse texture taste is improved; artichoke is subjected to two times of fermentation, the green and astringency taste is obviously reduced, the slightly-sour flavor and the rich sauce fragrance flavor are generated, and the acceptability in the consumer market is improved; the nitrite content of the pickled vegetables prepared with the method is low; bioactive products such as cynarin and chlorogenic acid are reserved to a large degree.

Owner:HUNAN UNIV OF ARTS & SCI

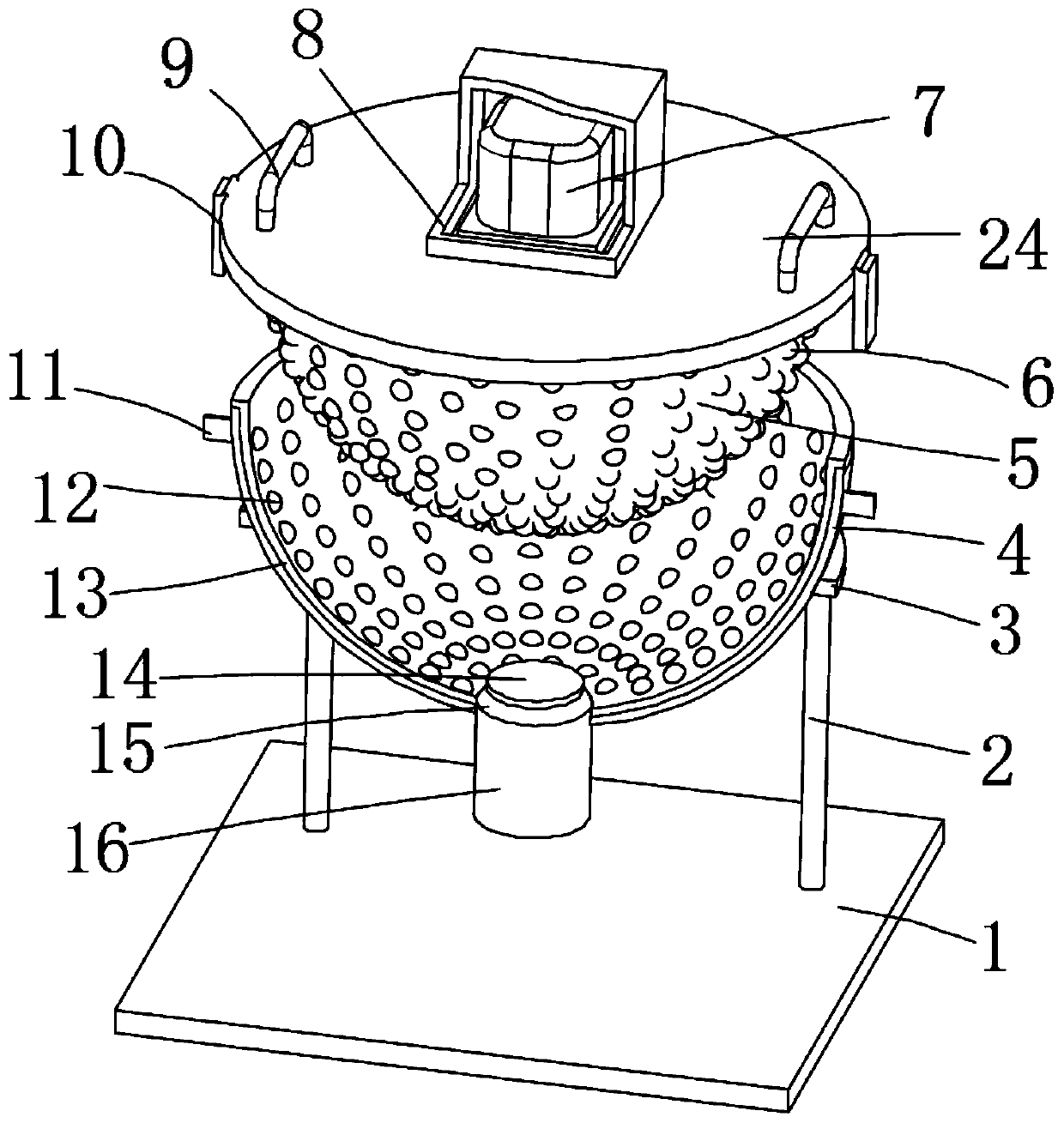

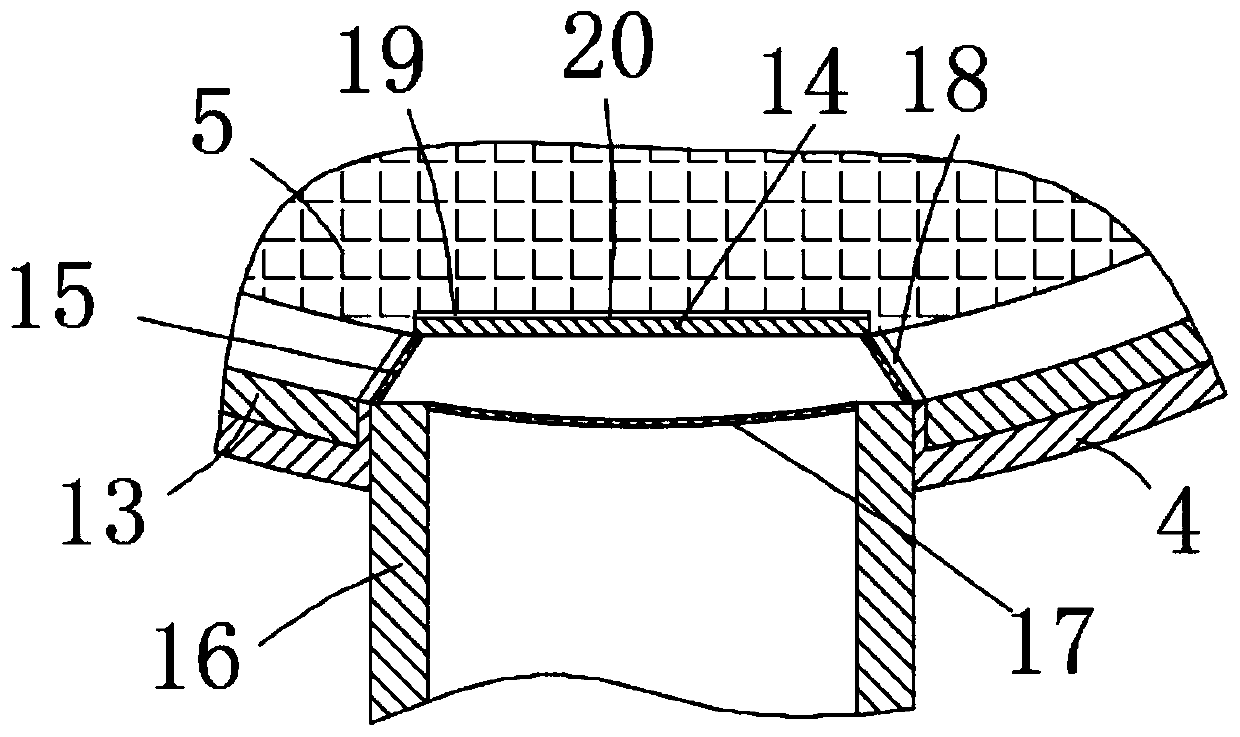

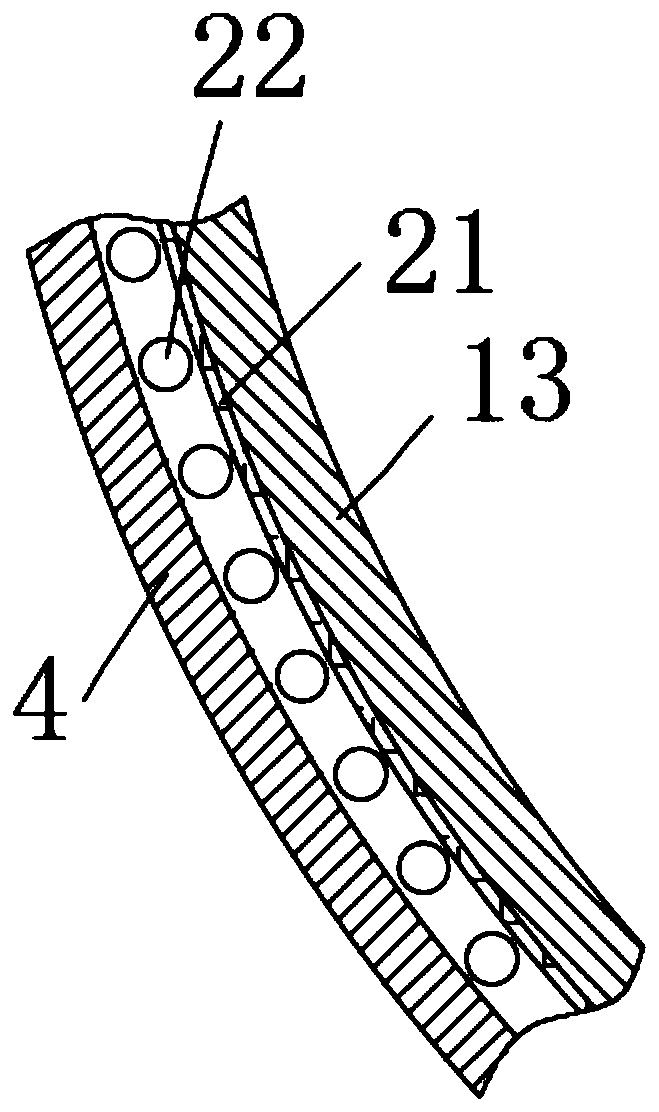

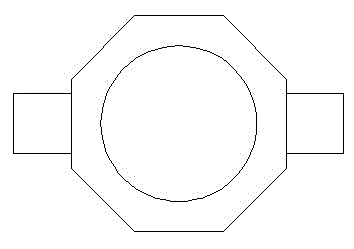

Grinding and extracting device

InactiveCN110876980AExtraction speed slowed downEasy to cleanGrain treatmentsStationary filtering element filtersEngineeringTissue fiber

The invention discloses a grinding and extracting device, and relates to the technical field of grinding. The grinding and extracting device aims to solve the problem of filter screen blockage. The grinding and extracting device particularly comprises an outer shell body and a shell cover, the outer wall of the top of the outer shell body is overlapped with an inner shell body, the inner wall of the side face of the inner shell body is provided with a fixed grinding ball, the inner wall of the top of the shell cover is connected with a grinding body through a bearing, the outer wall of the side surface of the grinding body is provided with a movable grinding ball which is staggered and distributed with the fixed grinding ball, a liquid outlet hole is formed in the outer wall of the bottomof the outer shell body, the inner wall of the side face of the liquid outlet hole is in thread connection with a liquid outlet barrel, the outer wall of the top of the liquid outlet barrel is weldedwith a filter screen ring, and two annular uniformly distributed scrapers are welded to the outer wall of the bottom of the grinding body. According to the grinding and extracting device, the filter screen ring is prevented from being blocked by solid debris and reducing the liquid extraction speed, cleaning of the filter screen ring is facilitated, the filtering effect on the liquid can be improved, the tissue fibers of the plant are softened, and the extraction efficiency of the juice is improved.

Owner:湖南朝露生物科技有限公司

Green asparagus fresh juice alimentary paste and the processing method thereof

InactiveCN101116456AMaintain nutritional contentKeep the fragranceDough treatmentFood preparationAdditive ingredientPreservative

A green asparagus fresh juice nutritious noodle and a method of preparation relates to a nutritious noodle made by green asparagus fresh juice and the processing method thereof. The green asparagus fresh juice noodle comprises flour and green asparagus fresh juice, wherein the weight ratio of flour to the green asparagus fresh juice is 1:0.3 to 0.35, the processing method is that: 1. according the following weight ratio to mix materials, flour is 1000 shares, green asparagus fresh juice is 300 to 500 shares, salt is 8 to 9 shares and dietary alkali is 7 to 8 shares; 2. the materials are mixed evenly, and then are added an amount of water to knead into the dough; 3. the dough is pressed and cut into pieces; 4. the noodle is dried at a normal temperature to become the finished product. The invention has the advantages that the invention is capable of fully keeping nutrient contents and scent taste of green asparagus fresh juice, green asparagus which is ground into juice in order to crush up the tissue fiber of the green asparagus is easy to be absorbed by human body, in addition, due to no antiseptic agent and artificial color not added in the technical process of production, the products are not polluted, thereby, the green asparagus fresh juice alimentay noodle is nutrition, health care and environmental protection food wanted by modern people.

Owner:陈远捷

Supporting hinged shaft forging technology

The invention discloses a supporting hinged shaft forging technology. The supporting hinged shaft forging technology includes following steps: (1) chamfering one end of a steel ingot blank, pressing a dead head at the other end of the steel ingot blank so as to form a pincer handle, cutting an unnecessary segment of the steel ingot blank, cutting a water gap, and removing burrs; (2) placing the steel ingot blank into a hole disk, and performing upsetting on the steel ingot blank; (3) fetching out the steel ingot blank, chamfering four edges of the steel ingot blank, rounding the steel ingot blank from all directions, and filing the pincer handle; (4) drawing the steel ingot blank into a pole, forging the pole until steps at two ends of the pole are forged to the designed dimension, and then placing the two ends of the pole into a die, and performing upsetting on the pole; (5) smoothing the two ends of the pole, repeatedly shrinking the pole in all the directions, and using a punch to push double sides of the pole; (6) using a martensite rod to perform chambering twice; (7) smoothing two end faces of the pole, enabling the thickness of the two end faces of the pole to reach the designed size, and inserting the punch into a round inner hole so as to smooth the round inner hole; (8) performing heat treatment after the size of the pole is qualified through measurement. The supporting hinged shaft forging technology has the advantages of being simple and convenient, can be used to directly obtain a qualified product through a forging method, prevents lathing from damaging tissue fibers of the product, prolongs use life of the product, and simultaneously reduces a processing volume, saves materials, and reduces cost.

Owner:CHONGQING YANLIAN HEAVY MACHINERY EQUIP

Peanut-protein plant-based chicken steak and dry-process preparation method thereof

PendingCN112806470AStrong tissue fiberMeet needsProteins working-up by texturisingFood ingredientsBiotechnologyCellulose

The invention provides a peanut-protein plant-based chicken steak. The peanut-protein plant-based chicken steak comprises 90-120 parts of peanut tissue protein, 3-6 parts of chenopodium quinoa protein, 15-18 parts of wheat protein, 17-20 parts of mung bean protein, 11-15 parts of gellan gum, 12-17 parts of carrageenan, 7-10 parts of sodium alginate, 4-9 parts of sodium methyl cellulose and 6-10 parts of curdlan. Further, the invention further discloses a preparation method for the dry-process plant-based chicken steak. According to the preparation method, the peanut tissue protein serves as a main raw material, high-performance high-acyl gellan gum, curdlan and vegetable meat gum serve as binders, and other adjuvants are added. The produced chicken steak has very high tissue fiber feeling, the elasticity and toughness of the chicken steak can reach 90% of real chicken, the produced product is high in nutritive value, and the nutritive value is almost the same as that of the real chicken. The product can meet the requirements of some vegans, and the price of the product is far lower than that of the real chicken.

Owner:好福(上海)食品科技有限公司

Method of preparing pawpaw skin cleaning article

A process for preparation of a pawpaw skin cleaning article comprises first, getting fresh pawpaw to disintegrate, second, adding common salt which is stirred as the common salt is added till reaching saturation, and adding 2 to 30% metallic ion complex agent to homogenize, third, grinding through a colloidal mill and / or a homogenizer, and leading particle size of particles which are contained to reach 0.5 to 80um, fourth, adjusting pH value between 2.3 and 4.5, fifth, packing according to weights, and filling inert gas to remove oxygen, finally, evacuating and sealing. Extra juice can be pressed to make pawpaw face washing mud, and 1 to 6 times bath salt (NaCl) can be added to make pawpaw bath salt, tissue fibers of pawpaw are softer, which do not dissolve in water, and the pawpaw can not harm skin through fine grinding. Common salt has the functions of cleaning and inhibiting bacteria, common salt which is added in pawpaw juice can improve skin cleaning effect of the pawpaw juice. The pawpaw skin cleaning article has functions of skincare and whitening as removing dirt and cleaning skin, and skin cleaning is led to be more thoroughly, and the effect is better.

Owner:张定忠 +1

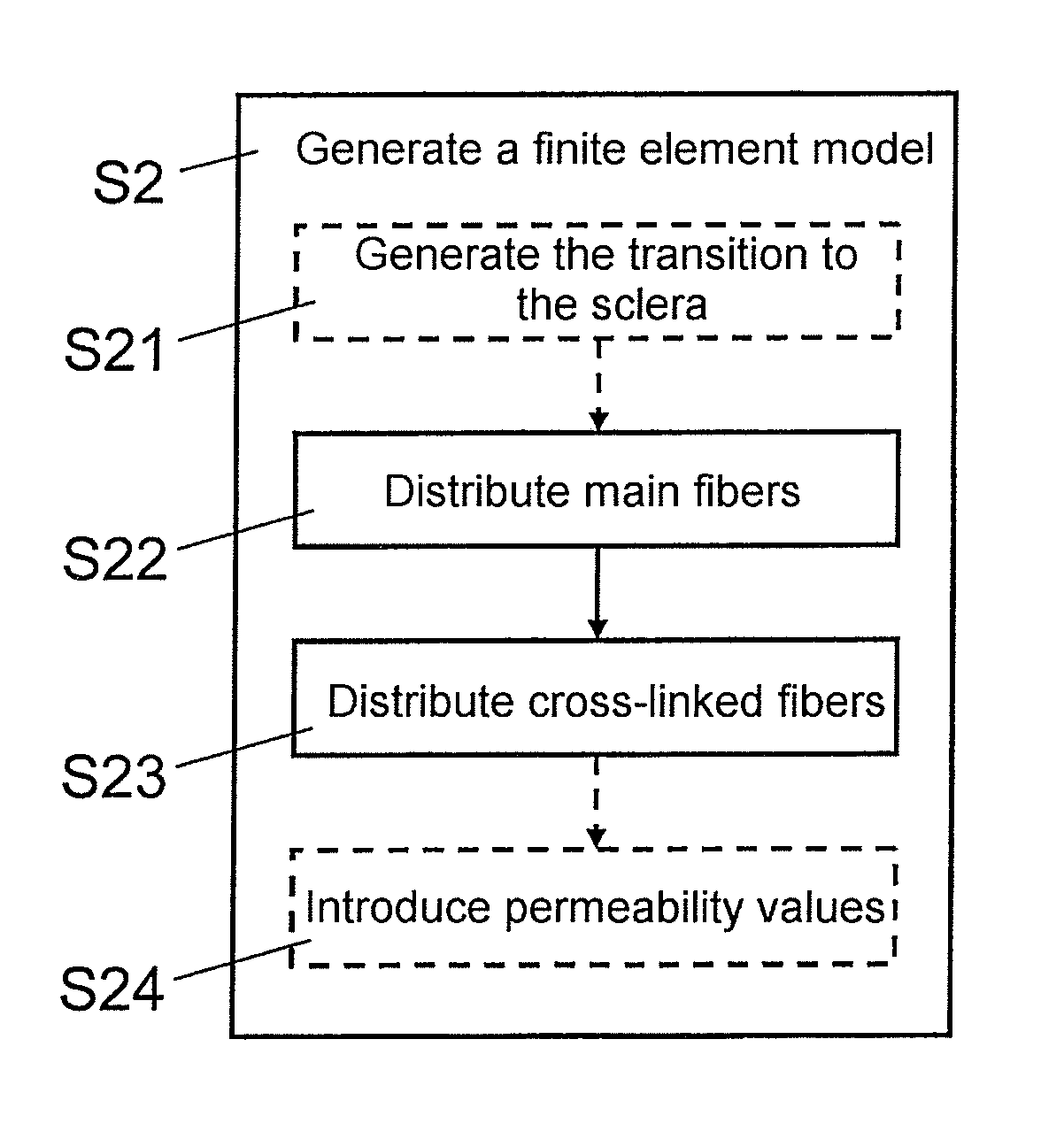

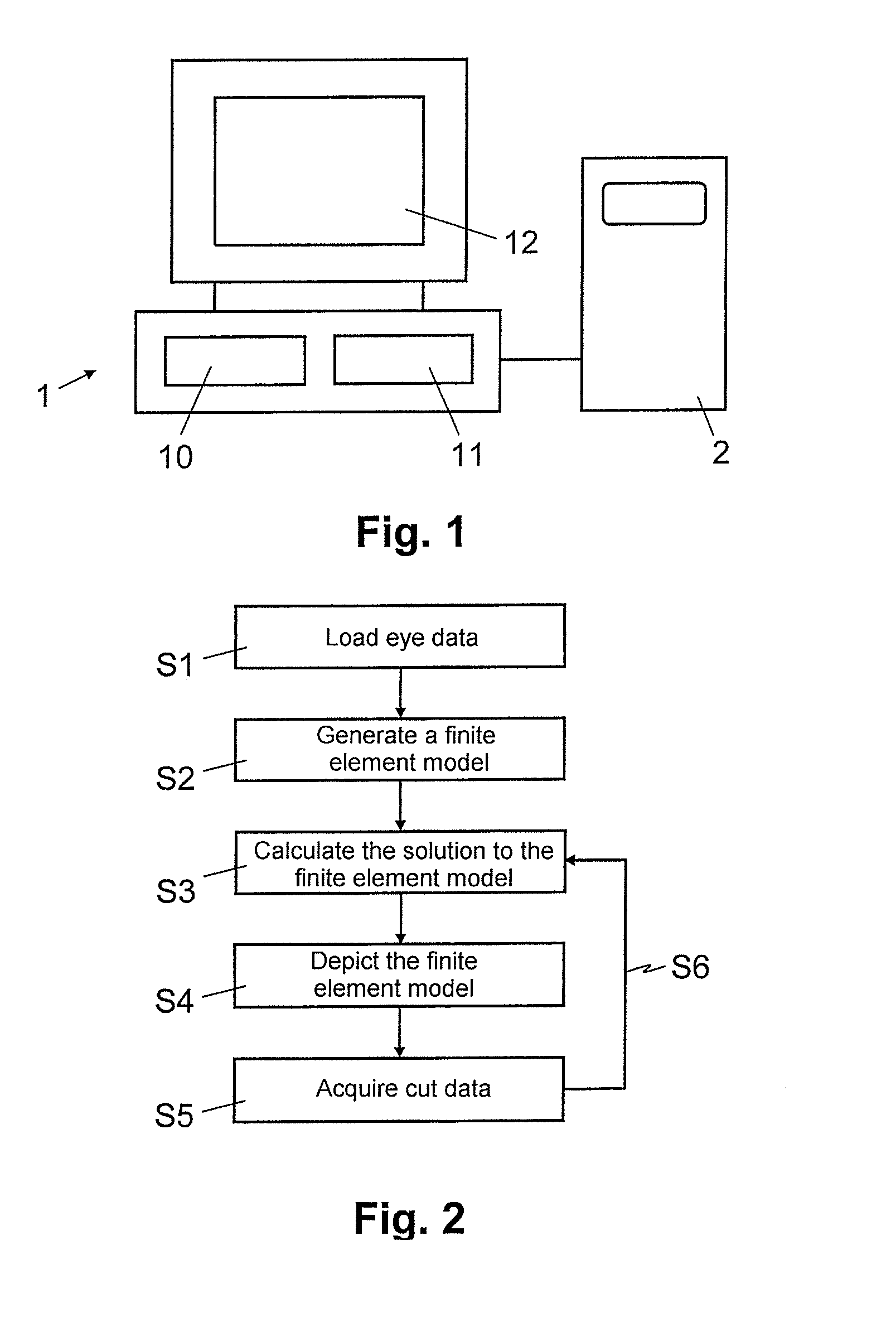

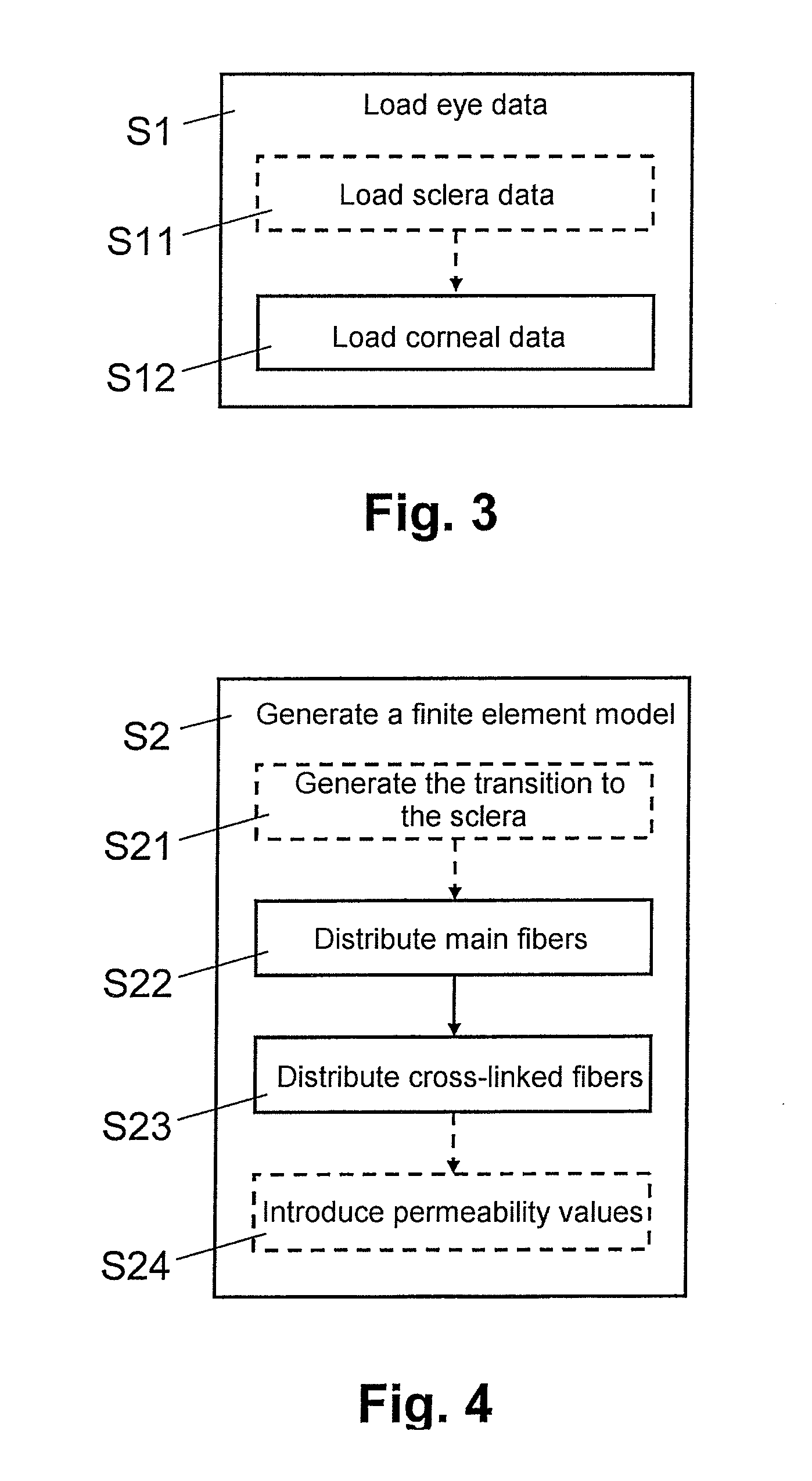

Device and method for modelling a cornea

A patient-specific finite element model of the cornea is generated for the purposes of modeling a cornea for simulating tissue cuts in the cornea. A first group of tissue fibers, with main fibers that extend parallel to the surface of the cornea, is distributed in the finite element model in accordance with a first distribution function. Moreover, a second group of tissue fibers, with inclined cross-linked fibers that do not extend parallel to the surface of the cornea, is distributed in the finite element model in accordance with a second distribution function. Here, the second distribution function distributes the cross-linked fibers with a non-uniform weighting function over the depth of the cornea, from the outer surface of the cornea to the inner surface of the cornea.

Owner:OPTIMO MEDICAL

Phenolic plastic inspection well cover, and preparation method thereof

InactiveCN107325481AImprove compactnessHigh mechanical strengthArtificial islandsUnderwater structuresFlexural strengthShock resistance

The invention discloses a phenolic plastic inspection well cover, and a preparation method thereof. The phenolic plastic inspection well cover is prepared via moulding processing of the below raw materials using a hot pressing mould. The raw materials comprise 50 to 60 parts of phenolic resin, 30 to 40 parts of glass fiber, 20 to 30 parts of cotton fiber, 10 to 20 parts of quartz sand, 2 to 5 parts of graphite powder, and 0.5 to 1 part of a catalyst. The phenolic plastic inspection well cover is provided with 2 to 5 layers of glass fiber net; moulding processing is carried out using a phenolic plastic inspection well cover hot pressing mould; and the preparation method comprises steps of phenolic plastic raw material and filling material preparation, mixing and blending, charging, preheating, and high temperature hot pressing. The beneficial effects are that: the raw materials are common and cheap; thievery prevention is realized; the phenolic plastic inspection well cover is excellent in compactibility; tissue fiber direction uniformity is excellent; well cover mechanical strength and surface hardness are high; deformation is not easily caused; wear resistance, impact resistance, and shock resistance are excellent; and bending strength is high.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

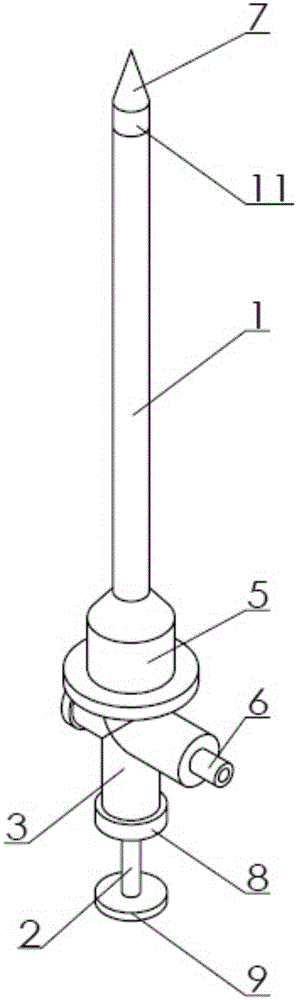

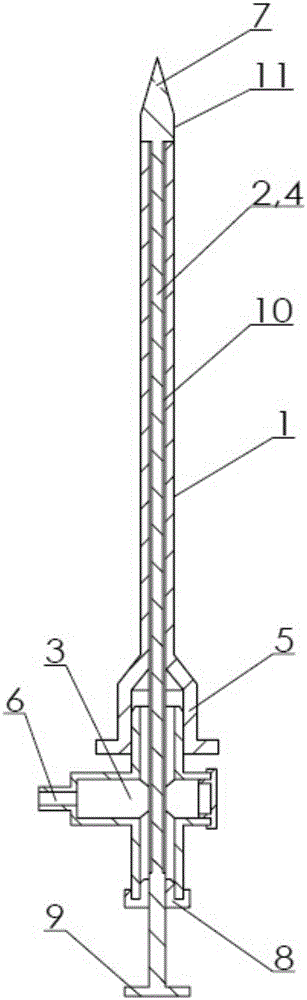

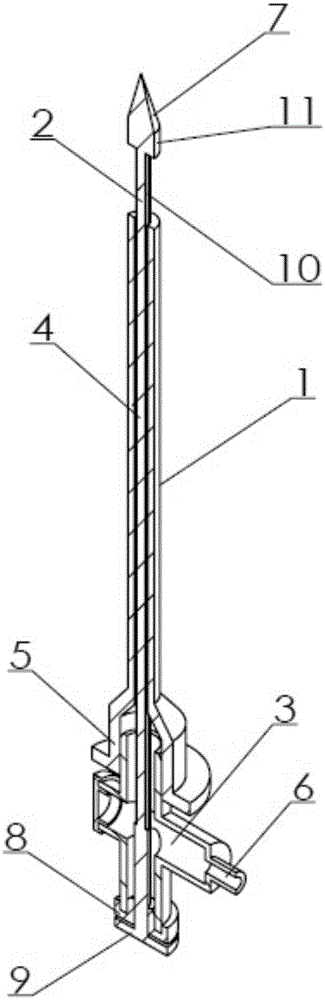

Coaxial push-in-type tree injection tool

The invention discloses a coaxial push-in-type tree injection tool. The tool is characterized by comprising a syringe needle, a core rod and a conversion connecting portion, wherein a flow pass extending towards the front end is arranged inside the syringe needle, a connector is arranged at the rear end of the syringe needle and connected with the conversion connecting portion, and the conversion connecting portion is provided with a hose connector; a conical end is arranged at the front end of the core rod, the diameter of the conical bottom of the conical end is equal to the outer diameter of the front end of the syringe needle, the rear end of the core rod penetrates through the flow pass, the connector and the conversion connecting portion, and the rear end of the core rod outside the conversion connecting portion is connected with a pressing plate; when the conical end is flush with the front end of the syringe needle, a distance is maintained between the pressing plate and the conversion connecting portion, and the portions, inside the flow pass and the conversion connecting portion, of the core rod are provided with longitudinal grooves. Tree trunk tissue fiber will not be cut off, later wound healing and growth are facilitated, a needle hole will not be blocked, the infusion coverage diffusion area can also be increased, uniform distribution and transportation of liquid medicine or a nutrient solution are facilitated, and fast absorption is facilitated.

Owner:南通腾舟船舶机械有限公司

All fiber forging technology of cross shaft forging piece

InactiveCN105945202ALow technical requirementsIncrease productivityMetal-working apparatusEngine componentsLower faceMechanical property

The invention discloses an all fiber forging technology of a cross shaft forging piece. The all fiber forging technology of the cross shaft forging piece comprises the following steps: (1) the first fire, heavy pressing and upsetting-stretching of a blank: upsetting vertical materials by an upper flat anvil and a lower flat anvil; (2) the second fire, forming: forging through and compacting the blank, then finishing all directions of the blank, and pressing 90 degrees triangular pressing shoulders in from the upper face and the lower face, finally turning 90 degrees to form opposite grooves; (3) the third fire, forming in a mould: stretching the blank for forming four sections of small circles to the size of the forging piece. The technology is low in skill requirement of a worker, convenient to operate and high in production efficiency; the loose tooling forging is accurate in shape and high in size accuracy, so that the accessorial blocks of the technology are few and the machining allowance is small; an all fiber forging method is used, so that abundant raw materials are saved and the machinery machining working hours are reduced; by means of the complete and streamlined tissue fiber, the mechanical property of the products is greatly improved and the service life is increased.

Owner:ANHUI RUIJIE FORGING

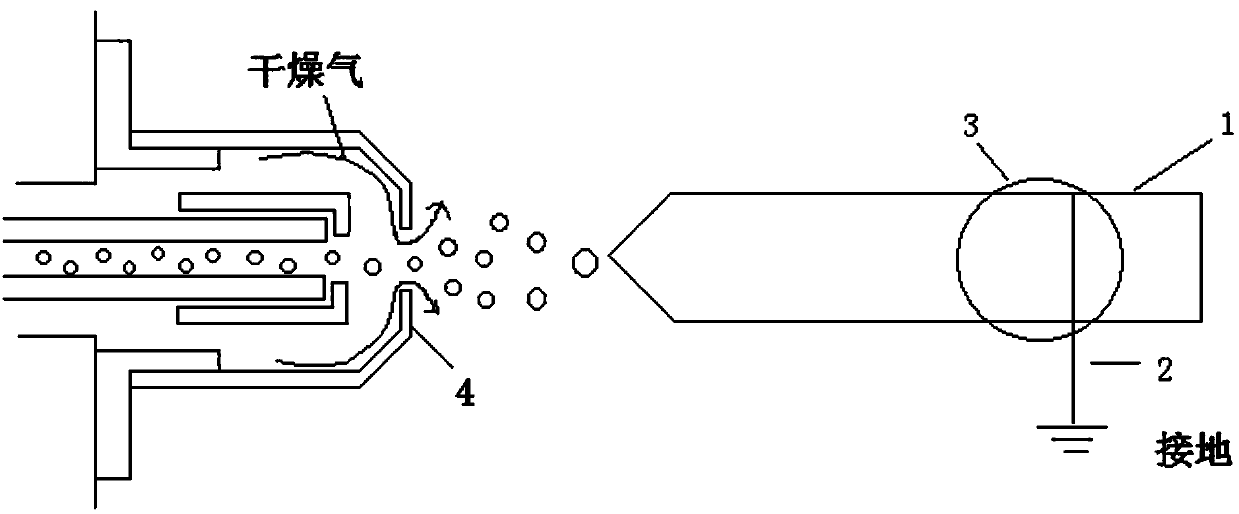

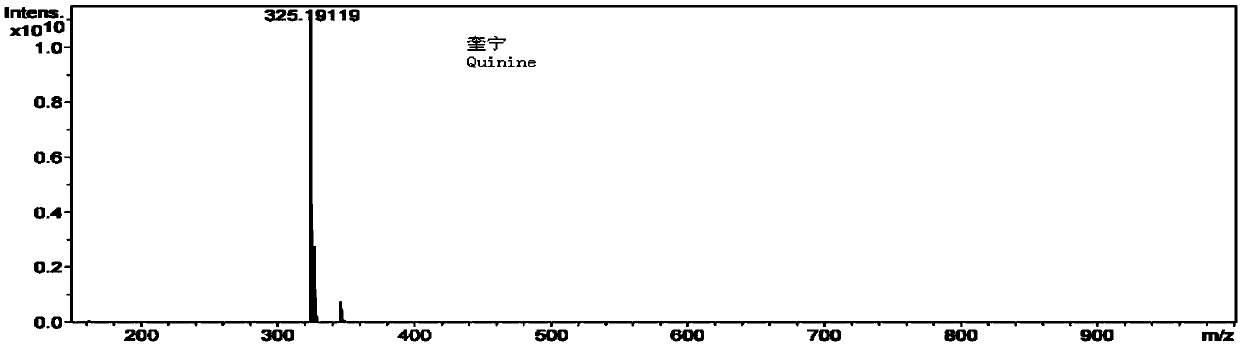

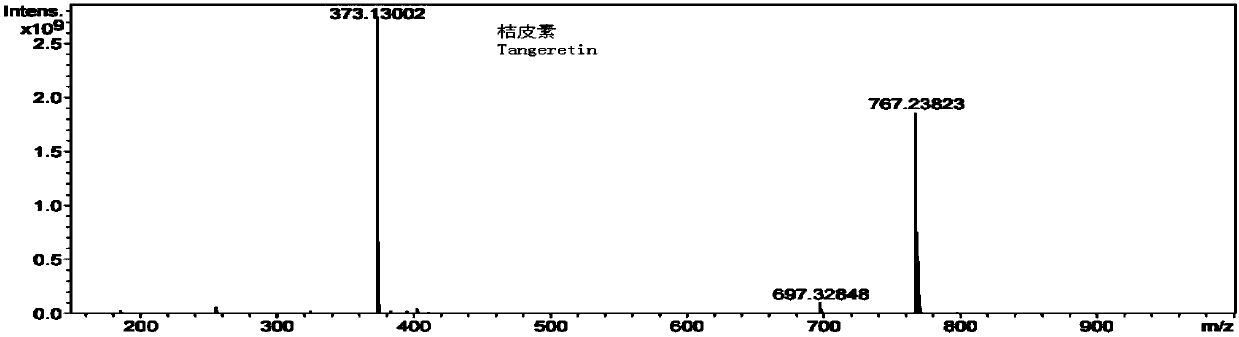

Sharp slide ionization device based on electric tip spray and application of sharp slide ionization device

InactiveCN108037174AEasy direct injection analysisThe generation of the positive ion mode facilitates the movement of the solution to the tip and contributes to theMaterial analysis by electric/magnetic meansAdditive ingredientCopper wire

The invention relates to a sharp slide ionization device based on electric tip spray and the application of the sharp slide ionization device. The ionization device comprises a sharp slide, an electrode and an objective table, wherein the sharp slide is made of glass and is cylindrical; a tip is arranged at the front end of the sharp slide; the sharp slide is placed on the objective table and fixed by a copper wire; the middle rear part of the sharp slide is wound with the copper wire as one end of the electrode; the other end of the electrode is grounded; the sharp slide is formed by grindingthe front end of a glass dropper with sand paper; the tip at the front end of the sharp slide is less than or equal to 0.3mm in thickness and less than or equal to 0.2mm in width; the tip of the sharp slide and a sample introduction port of a mass spectrometer are aligned at the right and left to form 1000-5000V voltage; and a distance between the tip of the sharp slide and the sample introduction port is greater than or equal to 10mm. The device is simple in structure, easy to construct, convenient and quick to operate and resistant to cross contamination, can be conveniently used for directsample introduction and analysis of a sample solution and solves the problem of certain contamination on an analyte due to complicated ingredients of filter paper, leaves, toothpicks and tissue fibers of the existing electric tip spray substrate materials.

Owner:SHANGHAI INST OF TECH

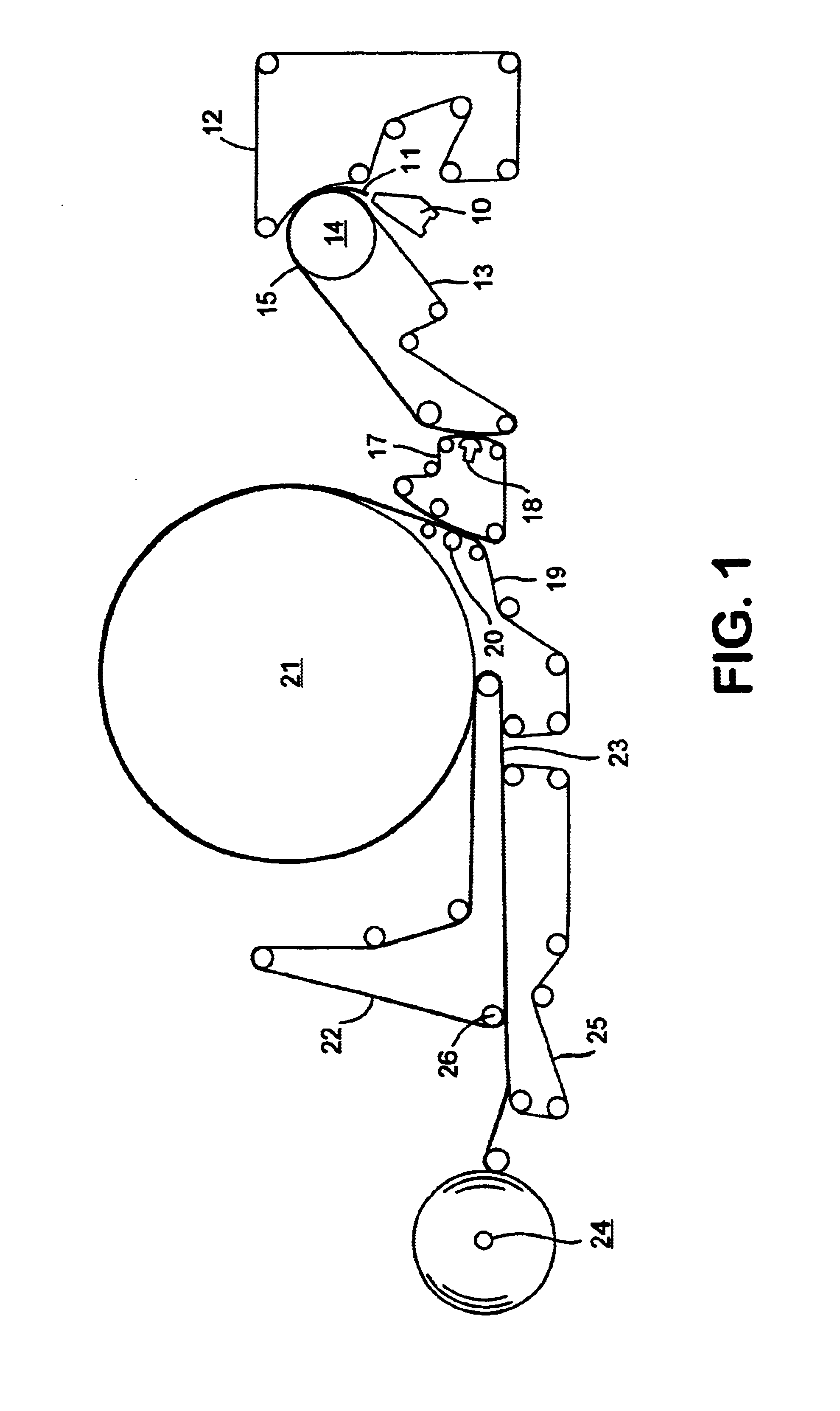

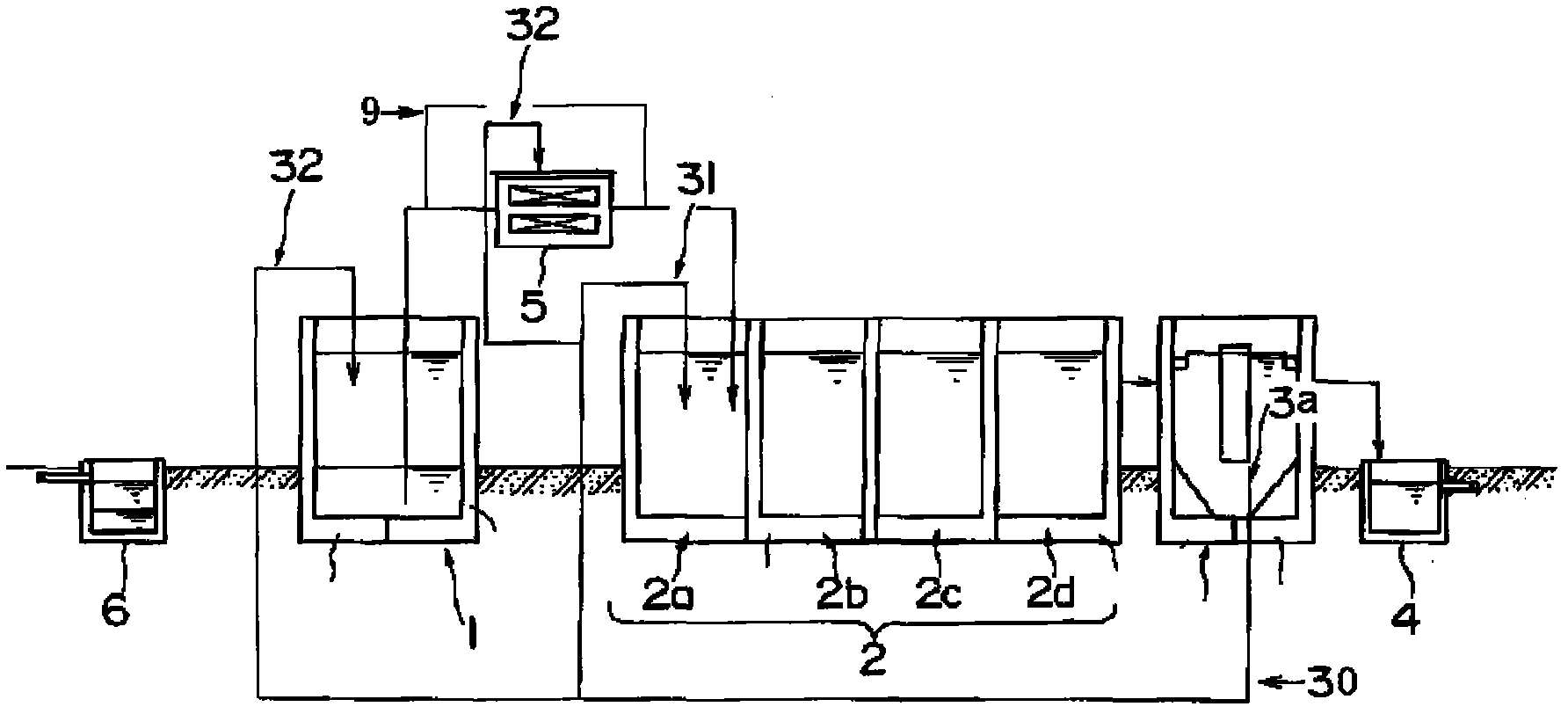

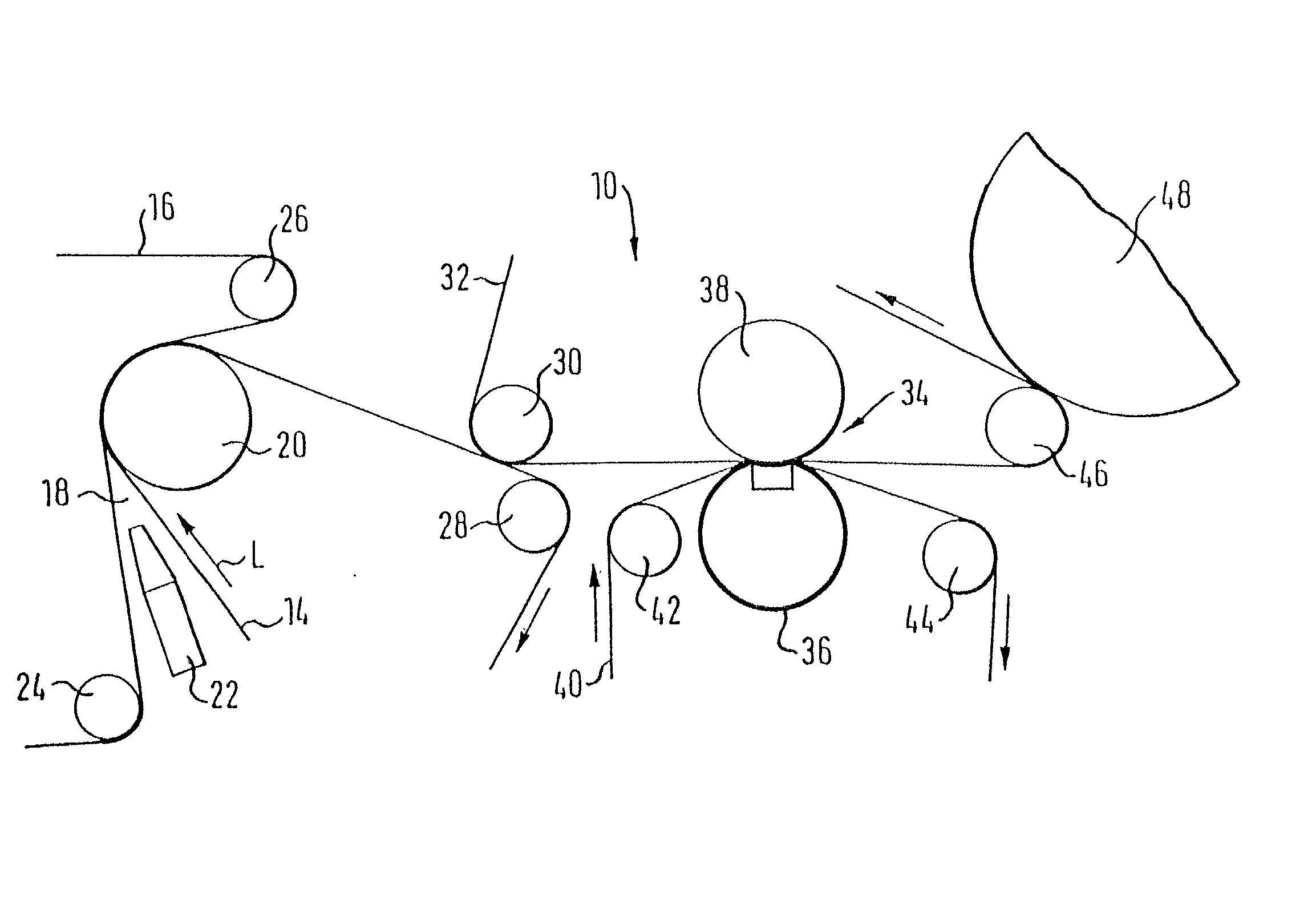

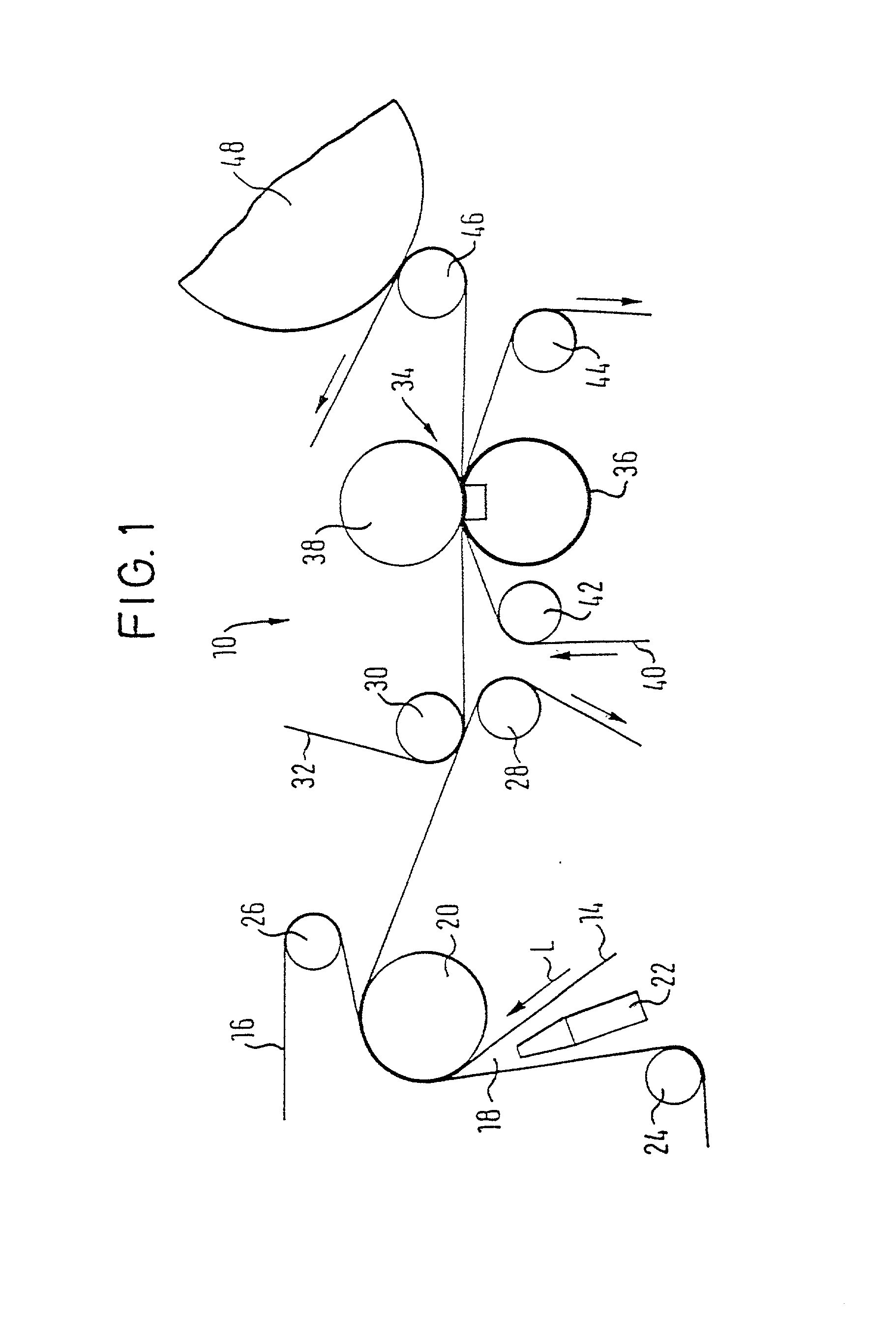

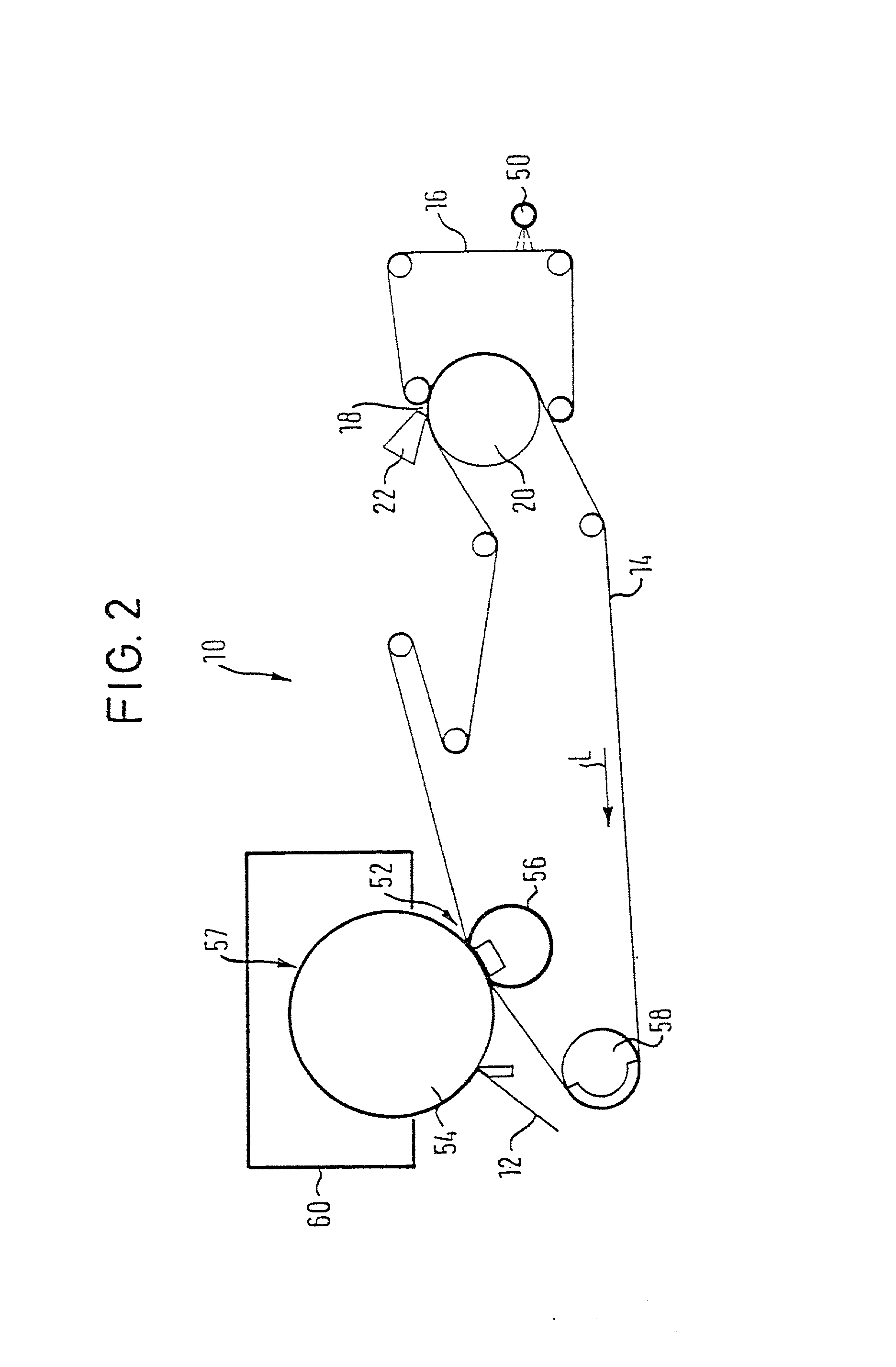

Machine and process for producing a tissue web

InactiveUS20020060043A1Increase specific volumeImprove water absorptionMachine wet endPress sectionBiomedical engineeringTissue fiber

The present invention is directed to a machine and process for producing a tissue web. The machine includes a forming area including at least one rotating continuous dewatering wire with zonally varied wire permeability, and at least one shoe press. The process includes dewatering the tissue web with at least the at least one continuous dewatering wire with zonally varied wire permeability, and pressing the tissue web in the at least one shoe press.

Owner:VOITH PATENT GMBH

Double protein meat and preparation method thereof

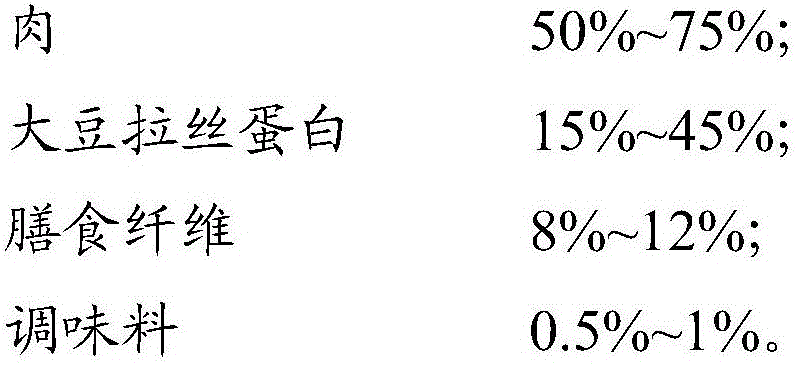

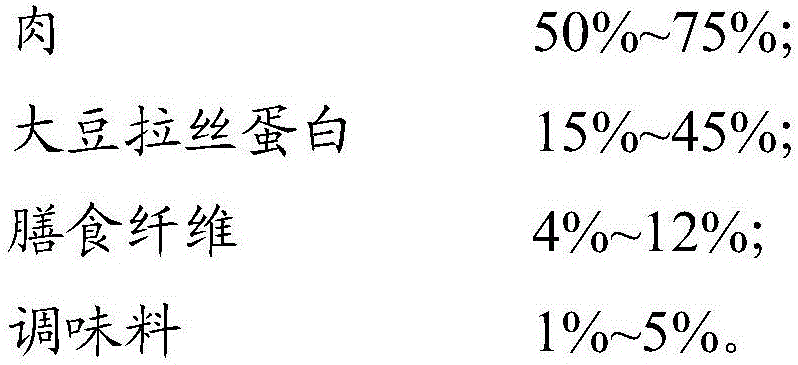

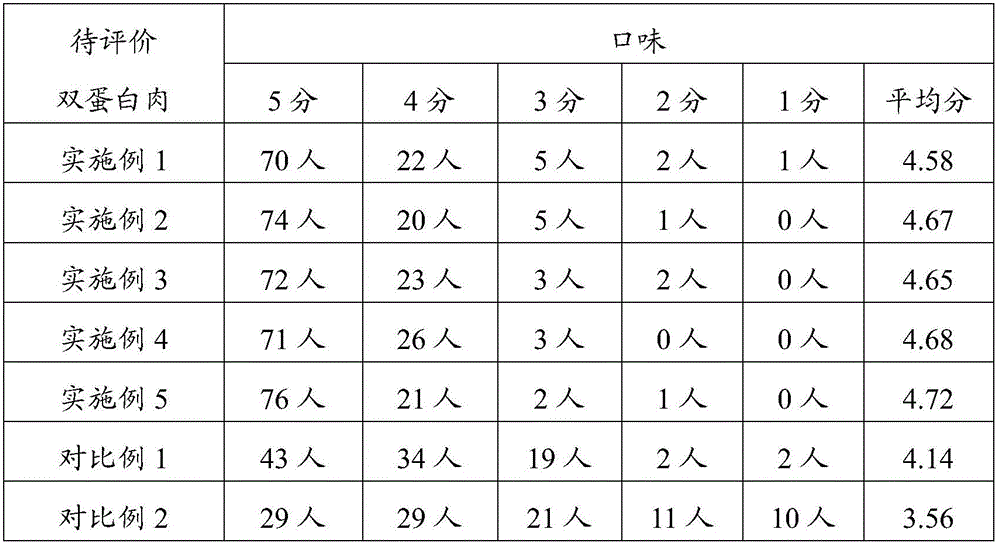

InactiveCN106107578AImprove surface smoothnessHigh hardnessFood ingredientsFood shapingDietary fiberTissue fiber

The invention discloses double protein meat, which is prepared from the following raw materials in percentage by weight: 50-75% of meat, 15-45% of soybean drawing protein, 4-12% of dietary fiber and 1-5% of seasonings. By adding the soybean drawing protein into the meat, the prepared double protein meat is improved in surface smoothness, tissue uniformity, hardness and elasticity; and the meat and the soybean drawing protein are used as the raw materials for preparing the double protein meat, so that the problems that the soybean drawing protein is not strong in meat feeling and coarse in tissue fiber can be solved, and the cost can be reduced.

Owner:河北康农食品有限公司

Preparation method for waterproof and heat-insulating self-leveling material

InactiveCN109280408AImprove insulation performanceStable covalent bond adsorptionCement coatingsCelluloseHigh pressure

The invention relates to a preparation method for a waterproof and heat-insulating self-leveling material, belonging to the technical field of building materials. According to the invention, Metasequoia glyptostroboides barks, nalgrass poles, Cyperus alternifolius leaves and red maple barks are mixed and ground; water molecules are pressed into tissue fibers at a high temperature and a high pressure; sodium ferrate oxidized lignin is added to generate carboxyl groups with hydroxyl groups on cellulose; meanwhile, ester groups have good heat-insulating performance and facilitate reinforcing hydrophobicity of a self-leveling material; modified and decomposed plant fibers are mixed with glucose for a reaction, and the glucose has rich hydroxyl groups which can react with the plant fibers withsurface grafted with a large number of carboxyl groups to form stable covalent bond adsorption; through a granular structure, the self-leveling material forms a plurality of micropores in a microstructure after construction curing, and gas is filled in pores to facilitate reinforcing the heat-insulating performance of the self-leveling material; thus, the self-leveling material has broad application prospects.

Owner:佛山齐安建筑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com