Sharp slide ionization device based on electric tip spray and application of sharp slide ionization device

The technology of sharp glass ionization and sharp glass slide is applied in the field of sharp glass ionization device, which can solve the problems of analyte contamination and complex composition, and achieve the effects of anti-cross-contamination, easy construction and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

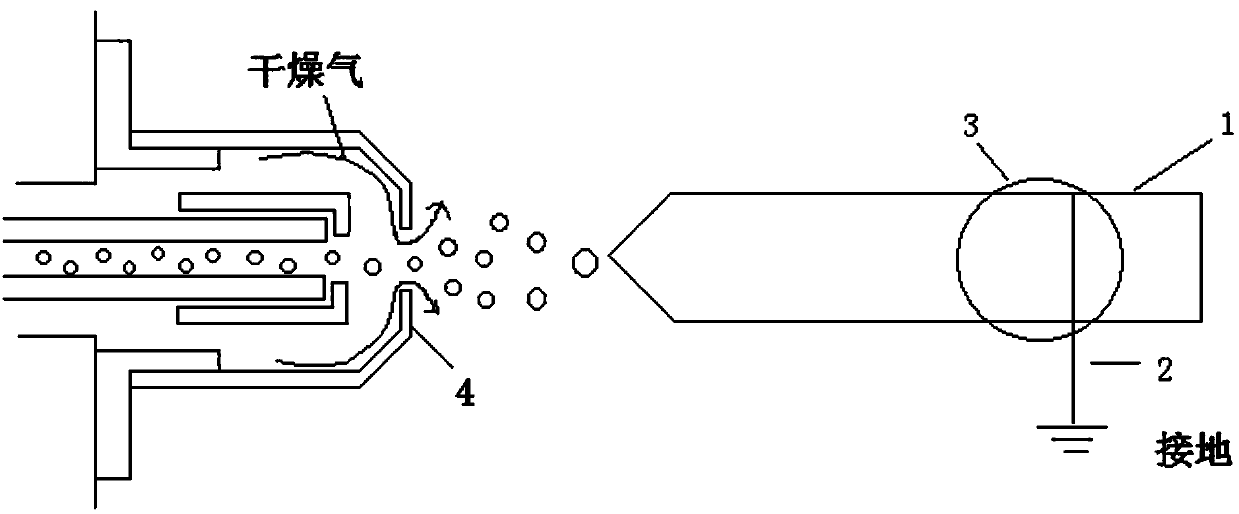

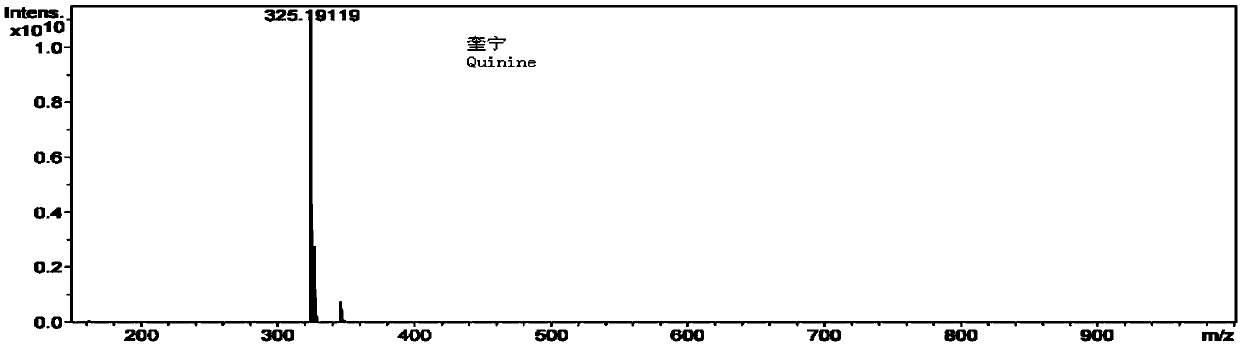

[0048] A tip slide ionization device capable of direct analysis of tip spray, comprising tip slide 1 and electrode 2; The injection port of 4 is aligned left and right, the tip is aligned with the injection port at an angle of 7.5° downward, and the tip slide 1 is 10 mm away from the injection port of mass spectrometer 3 . Then ground the electrode 2, and then drop the solution to be tested on the surface of the tip glass slide 1; the tip of the glass dropper is carefully polished with sandpaper until the tip thickness is ≤0.3mm and the width is ≤0.2mm; the electrode 2 is copper electrode; the mass spectrometer 3 is a Fourier transform mass spectrometer, which is produced by Bruker, Germany.

[0049] solariX 70FT-MS type, the mass spectrometry analysis conditions of the solariX 70FT-MS are as follows: set solariX70FT-MS to positive ion detection mode. Drying gas: flow rate 1.0ml / min, temperature 200°C; voltage 4.5kV, ion accumulation time 0.2sec, flight time 0.8ms. Other par...

Embodiment 2

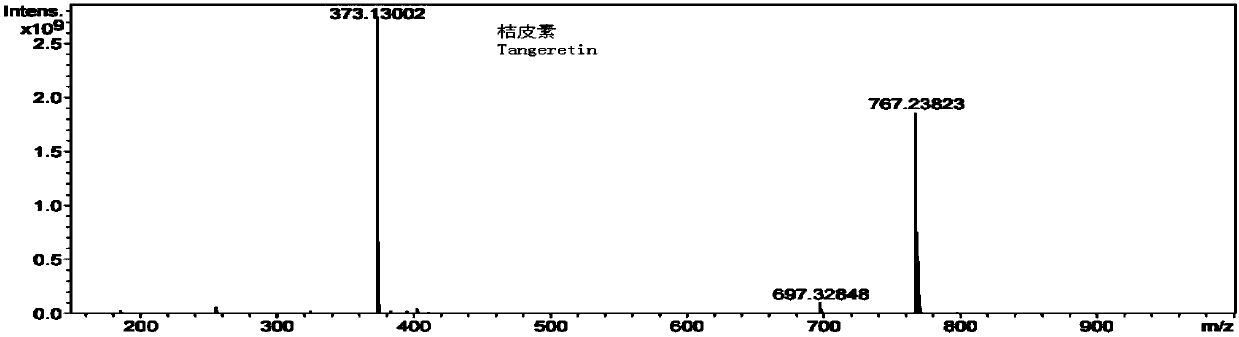

[0057] A device that can realize direct analysis of tip spray, including a tip slide 1 and an electrode 2; the tip slide is fixed on the stage 3 and the height is adjusted, and the tip of the tip slide 1 is in use with the sample injection of the mass spectrometer 4 Align the mouth left and right, the tip is 7.5° obliquely down to the injection port, the tip slide 1 is 10mm away from the mass spectrometer 4 injection port, and then the electrode 2 is grounded, and then the solution to be tested is dripped on the tip slide 1 surface; The tip glass slide 1 is a glass dropper tip carefully polished to a thickness of 0.2mm and a width of 0.13mm through sandpaper; the electrode 2 is a copper electrode; the mass spectrometer 3 is a Fourier transform mass spectrometer, solariX 70FT from Bruker, Germany -MS type, the mass spectrometry analysis conditions of the solariX 70FT-MS are as follows: set the solariX 70FT-MS to negative ion detection mode: flow rate 1.0ml / min, temperature 200°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com