Supporting hinged shaft forging technology

A technology of technology and hinge shaft, which is applied in the field of forging technology, can solve the problems of short service life, large amount of material waste, material waste, etc., and achieve the effect of improving service life, reducing processing amount, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

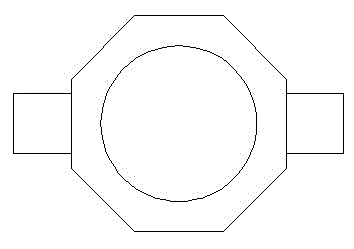

[0013] Embodiment 1: as figure 1 As shown, a supporting hinge shaft forging process, the process includes the following steps: (1) chamfering one end of the steel ingot blank, pressing the other end to the riser to make a clamp, cutting off the excess length, cutting the nozzle, and deburring; (2) Put the blank into the leaking plate and upset to the design size; (3) Take out the blank and press the square chamfer, pull out the eight sides to round to the design size, and tweezer; (4) Pull out the rod, forge the steps at both ends to the design size, and then Put the two ends into the mold and upset to the design size; (5) Flatten the two ends to the design size, repeatedly close all directions, and punch holes on both sides with a punch; (6) Use the horse rod to ream the hole twice to reach the design size; (7) Flatten both ends so that the thickness reaches the design size, then fill the inner hole with a punch, and finally level it; (8) After the red measurement size is qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com