Patents

Literature

386results about How to "Keep the fragrance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method allowing lower broken rice rate

The invention relates to a processing method allowing lower broken rice rate and belongs to the technical field of rice processing. The processing method includes the steps of rice screening, stone removal, magnetic separation, moisture measurement and drying or atomizing, hulling, husked rice separation, thickness classification, moisture measurement and drying or atomizing, rolling, white rice classification, cooling, polishing, color sorting, water content detection, and sterilizing and packaging. The rice processed by the processing method is low in broken rice rate, long in shelf life and good in glossiness, and flavor of the rice is rarely lost.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

Refined rice processing method

InactiveCN104815714AGuaranteed purityHigh purityGrain huskingGrain polishingBroken riceMoisture measurement

The invention discloses a refined rice processing method. The refined rice processing method comprises the following steps of rice screening, stone removal, magnetic separation and rice shelling, rice-bran separating, secondary shelling, thickness grading, moisture measurement and drying or atomizing, rice milling and white rice grading, rice cooling, polishing, color sorting, secondary white rice grading and moisture content detection, and packaging. The refined rice processing method comprises a plurality of impurity removal steps, and consequently, the purity of rice is guaranteed, the produced rice is high in purity, and the safety and the processing efficiency in the processing process are guaranteed. In the rice shelling and rice milling steps of the refined rice processing method, the material temperature is strictly controlled so that the material can be always kept in a relative low temperature appropriate environment, and the crack ratio and the broken rice rate can be reduced and the complete particle rate can be increased; the original faint scent of rice is maintained. The refined rice processing method is used for solving the problems of surface damage and uneven polishing in the rice polishing process by controlling the polishing water temperature and the dampening amount; as a result, the surfaces of all the rice grains polished can be kept smooth and clean, and the quality guarantee period of the rice can be prolonged.

Owner:ANHUI YOUYUAN FOOD

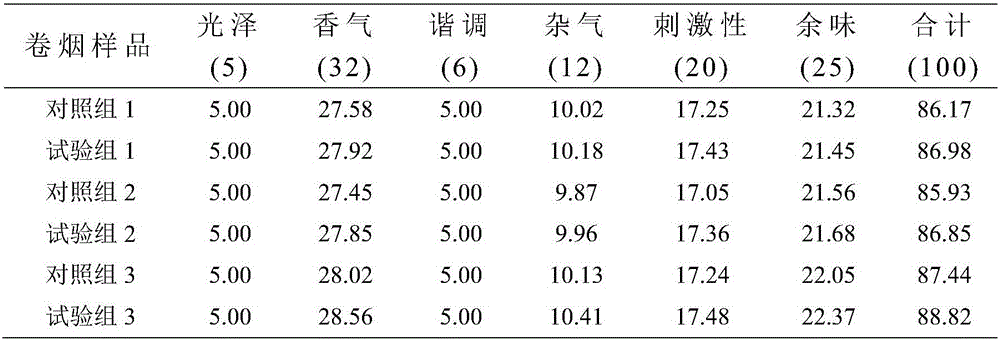

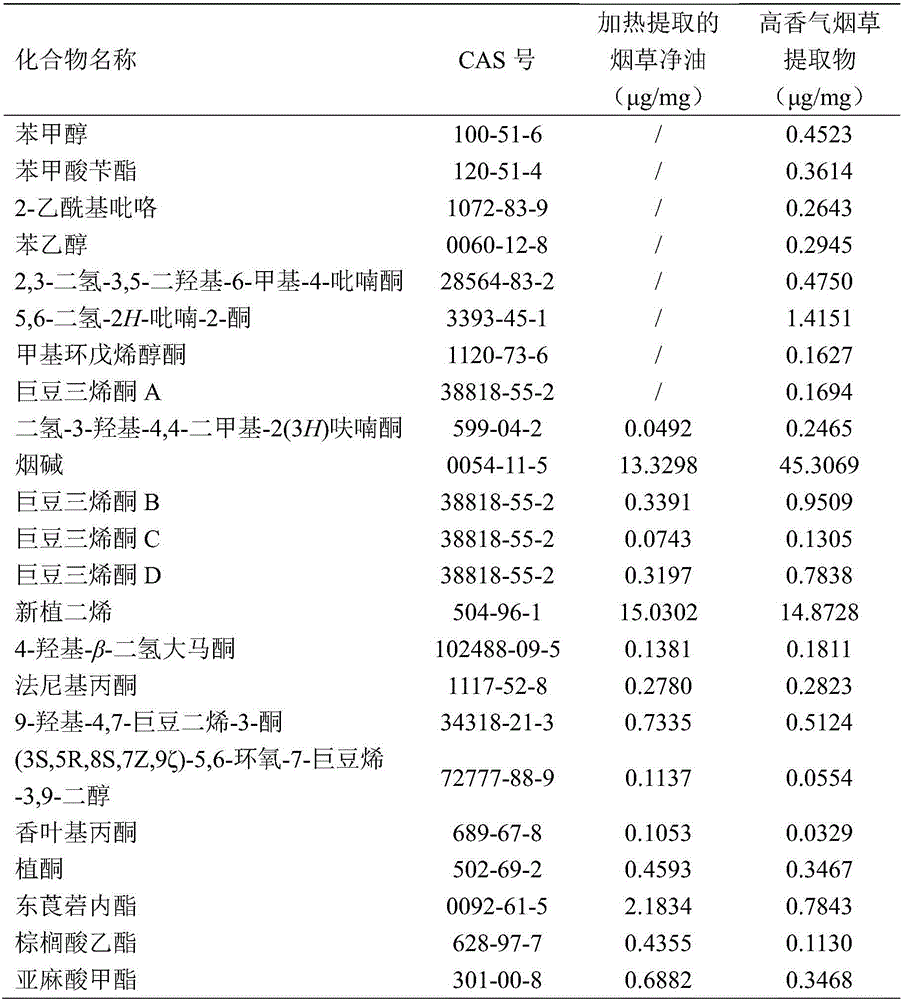

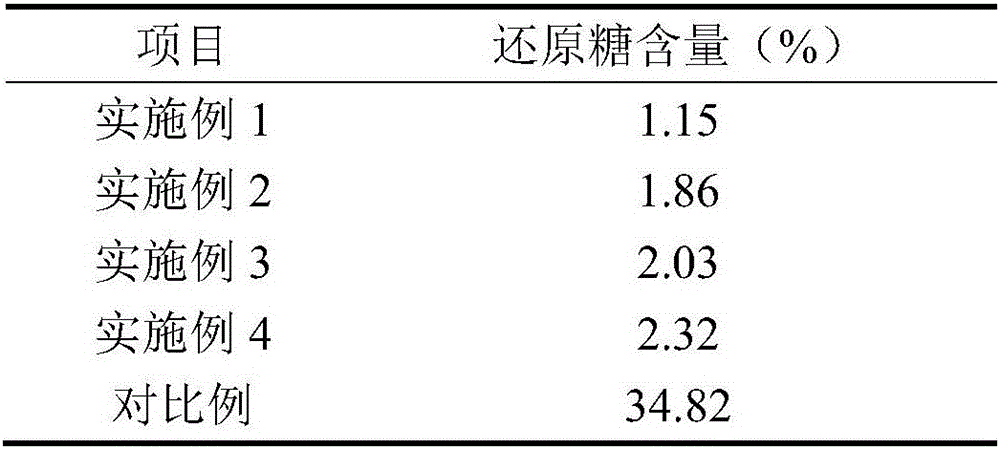

Preparation method of high-nicotine tobacco extract

ActiveCN106509981AHigh extraction rateAvoid destructionTobacco treatmentMaillard reactionDistillation

The invention discloses a preparation method of a high-nicotine tobacco extract. The preparation method of the high-nicotine tobacco extract belongs to the field of tobacco additives, and mainly comprises three steps of raw material pretreatment, subcritical extraction and molecular distillation. A baking process is adopted for pretreating tobacco leaves, so that reducing sugar of tobacco and a nitrogen-containing compound are promoted to generate maillard reaction, substances such as pyrone and furanone are produced, the baking aroma is improved, the reducing sugar content is reduced, the suction offensive odor is reduced, meanwhile, combined-state nicotine in the tobacco leaves is converted into a free state, and the content of the free-state nicotine is improved. A weak polar solvent is adopted for subcritical extraction, so that the extraction rate of tobacco feature aroma substances and the free-state nicotine can be improved; and low-temperature molecular distillation is combined, so that low-boiling-point aroma substances and the nicotine can be effectively enriched, the damage on thermosensitive substances due to high temperature is avoided, and meanwhile, the content of macromolecular substances such as pectin and protein in an extract is reduced. The method is simple in preparation process, simple and convenient to operate, and suitable for industrial production and application.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Processing method of handmade yellow tea

ActiveCN103444916ATo achieve aromaYellowish colorPre-extraction tea treatmentClimate change adaptationMoisture regainTea leaf

The invention belongs to field of tea leaf, and in particular relates to a processing method of handmade yellow tea. The processing method of handmade yellow tea comprises the following steps: picking fresh tea leaves, washing fresh tea leaves, sunning, performing primary roasting, shaping, spreading and cooling, performing primary drying, performing primary piling for yellowing, performing secondary drying, performing secondary piling for yellowing, extracting stalks, and refiring for extracting aroma. The processing method of the handmade yellow tea is a special processing method of Huoshan yellow tea, the fresh leaves are washed and dedusted to keep clean, the piling for yellowing is performed in a moisture regain machine after the primary drying is performed with the stacking thickness of about 10cm, piling for yellowing is performed after the primary drying is performed, secondary piling for yellowing is performed after the secondary drying is performed so as to further convert inclusions and achieve unique aroma taste of the yellow tea. By adopting the processing method, the processed Huoshan yellow tea has the characteristics of being similar in form of sparrow tongue, slight yellow of color and luster, lasting fragrance, mellow taste, sweet aftertaste, yellow bright, clean soup color, being durable for making tea, and being capable of being preserved for two years after being sealed at a normal temperature.

Owner:安徽抱儿钟秀茶业科技有限公司

Passion fruit-kiwi fruit composite juice and preparation method thereof

The present invention relates to a passion fruit-kiwi fruit composite juice and a preparation method thereof. The juice comprises 20-30% of a fruit-kiwi fruit juice, 10-15% of a kiwi fruit juice, 3-5% of honey, and the balance of water. The preparation method comprises: cleaning and cutting the passion fruit; taking the flesh with seeds; carrying out juicing on the flesh with seeds; cleaning the kiwi fruit; removing peel and carrying out juicing on the flesh of the kiwi fruit; uniformly mixing the resulting two juices; heating to a temperature of 20-60 DEG C; adding pectinase and amylase to carry out an enzymolysis treatment; adding water and honey to the filtered juice to adjust the taste; adopting a bacteria removal filtration membrane to remove partial bacteria; carrying out homogenizing and degassing on the bacteria-removed juice; carrying out vacuum packaging; and carrying out hyperpressure sterilization to perform an enzyme inactivation treatment to obtain the composite juice. With the preparation method of the present invention, the unique flavor of the passion fruit and the kiwi fruit fragrance can be maintained, the produced juice has characteristics of original juice remaining, original taste remaining, natural and persistent fragrance, and pure flavor, the juice quality is improved, and the pursuit of the majority of consumers on the natural juice is met.

Owner:HEPING WEIKANG AGRI TECH CO LTD

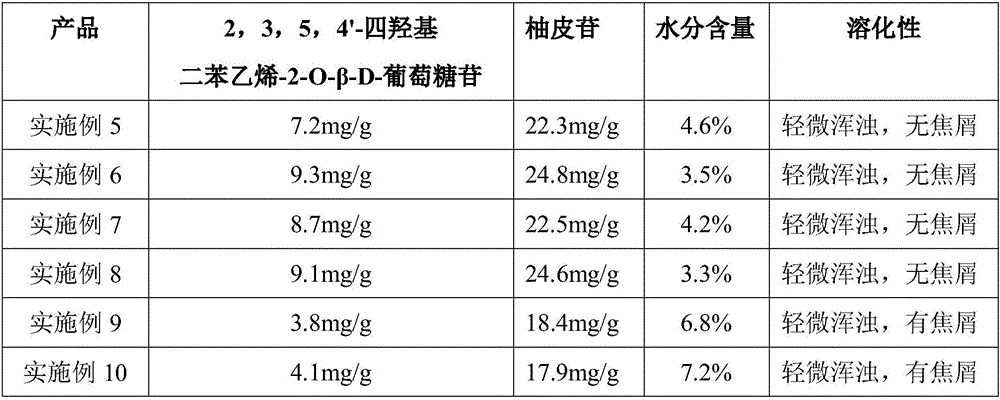

Debitterizing method for shaddock peel and application thereof

InactiveCN103637032APreserve efficacyModerate sweetnessConfectionerySweetmeatsFood technologyThrombus

The invention relates to a food technology, in particular to a debitterizing method for shaddock peel and application thereof. The method comprises the following steps: firstly, putting the shaddock peel into a hypertonic solution to steep until the bitter and hemp taste of the shaddock peel is removed; preparing a syrup solution; putting the debitterized shaddock peel into the syrup solution to sugar, and then baking the sugared shaddock peel until the moisture content is 10 to 20 percent so as to obtain shaddock peel sugar. The shaddock peel sugar prepared by the method reserves the drug action of the shaddock, has the effects of invigorating stomach, moistening lung, enriching blood, cleaning bowels, relaxing bowels and the like, can reduce the viscosity of blood and reduce the thrombus formation, and is a healthcare food. The shaddock peel sugar is appropriate in sweetness, soft and crispy, and moderate in sweet and sour, simultaneously does not have bitter and hemp taste, and reserves the fresh scent of the shaddock peel, so that the shaddock peel sugar is a high-grade green food suitable for all ages and sexes, and is applicable to be popularized and eaten. In addition, the method disclosed by the invention has simple steps and good debitterizing effect and is low in cost; the obtained debitterized shaddock peel can also be used for preparing shaddock peel preserved fruit, honey pomelo tea, pomelo peel jam and grapefruit beverage.

Owner:重庆市柚神酒业有限责任公司

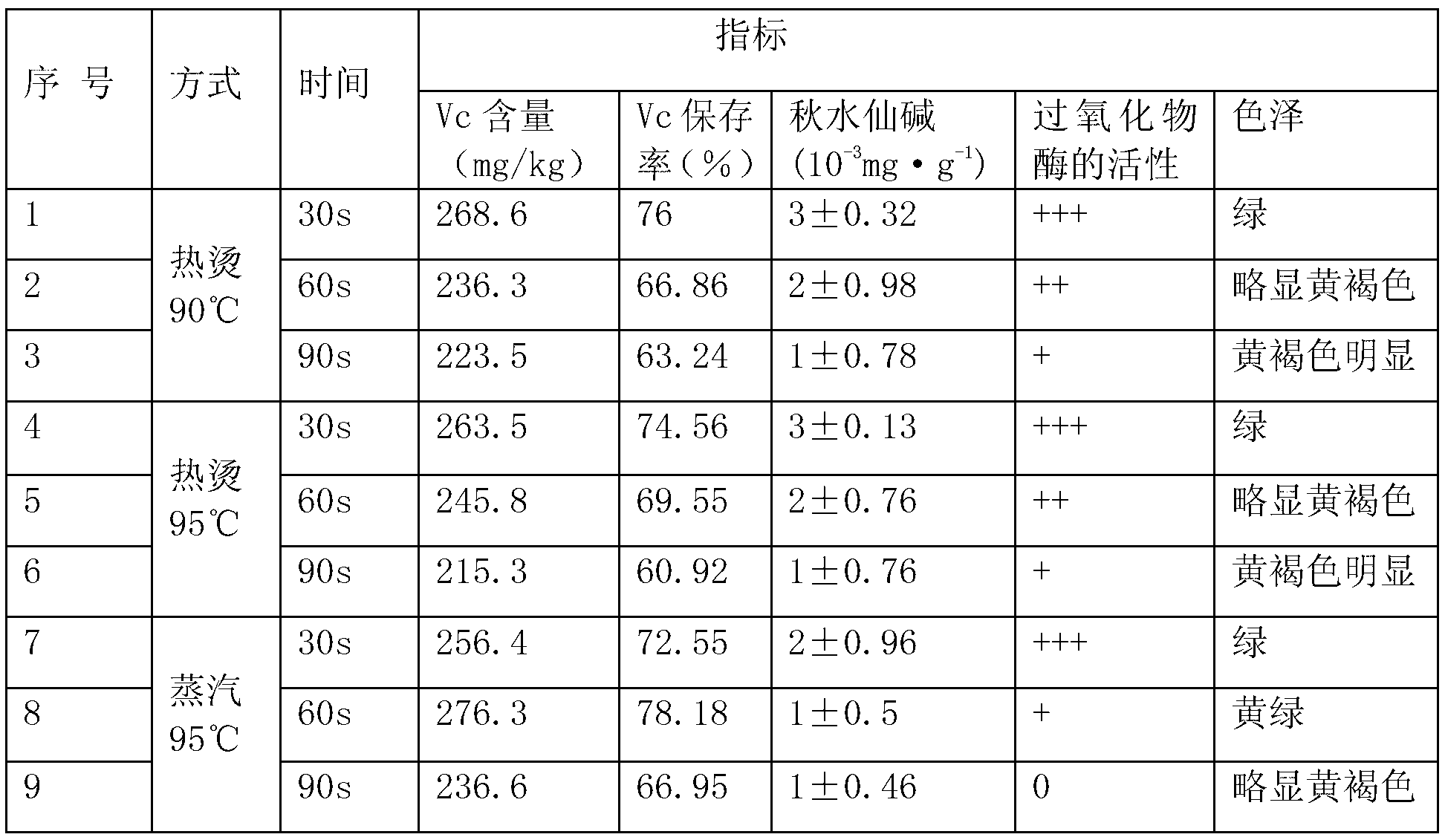

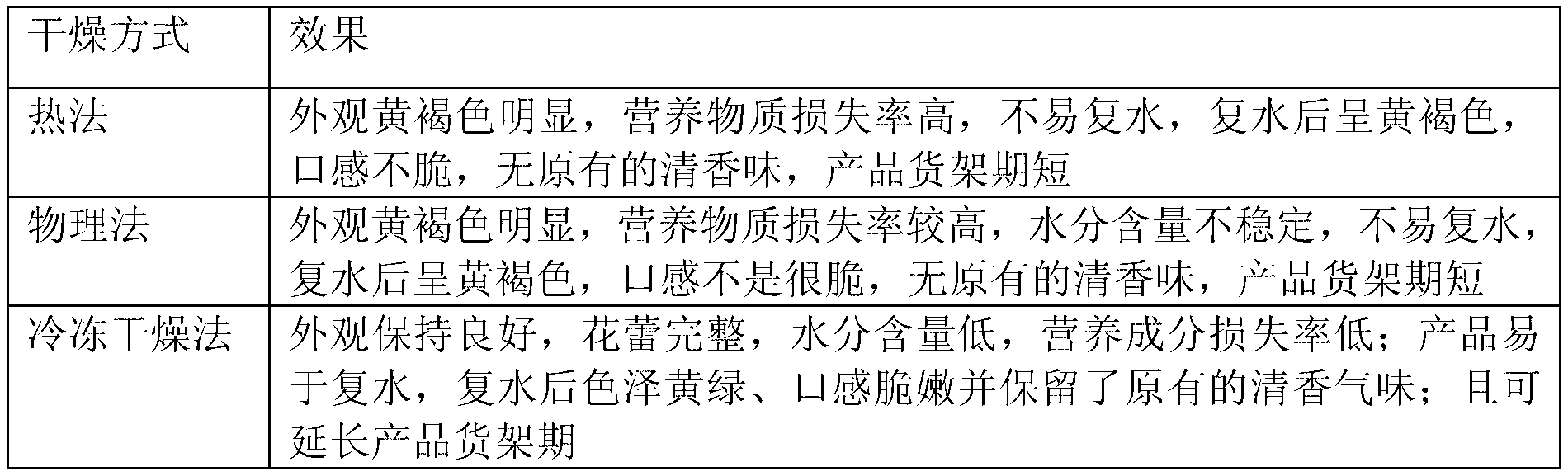

Processing method for vacuum freeze drying of Hemerocallis fulva L.

ActiveCN103283819AYellow-green colorCrisp and tenderFruit and vegetables preservationVitamin CAdditive ingredient

The invention discloses a processing method for vacuum freeze drying of Hemerocallis fulva L. The processing method comprises the following steps: S1, pre-freezing pretreated fresh Hemerocallis fulva L. at a temperature of -40 DEG C for more than 10 h; and S2, freeze drying the prefrozen Hemerocallis fulva L. at a temperature of -40 to -50 DEG C in a high vacuum state for 12 to 16 h. The invention has the following beneficial effects: pretreated Hemerocallis fulva L. has a yellowish green color and crisp and tender taste and is safe to eat since colchicine is inactivated; the process of vacuum freeze drying is employed, so the processed Hemerocallis fulva L. maintains good appearance, intact flower buds and the original color, fragrance, flavor and shape of Hemerocallis fulva L., water content in the processed Hemerocallis fulva L. is low, a loss late of nutritional ingredients like protein, vitamin C, a dietary fiber and the like is low, and a storage life of the processed Hemerocallis fulva L. is long; rehydration of the processed Hemerocallis fulva L. is easy, and the processed Hemerocallis fulva L. has a yellowish green color and crisp and tender taste and retains original delicate fragrance after rehydration.

Owner:四川省宕府王食品有限责任公司

Drying method for Chinese medical extract

InactiveCN106123496AKeep the fragranceModerate colorDrying solid materials with heatDrying solid materials without heatMedicinal herbsMedicine

The invention relates to a drying method for Chinese medical extract, in particular to a vacuum drying method for Shouhui cathartic extract. The vacuum drying method adopts circulating hot water with the temperature being controlled automatically to serve as a medium for heating of the Chinese medical extract, and the purpose of low-temperature drying of the Chinese medical extract is achieved. Through the method, the defects, occurring to traditional vacuum drying and the like, that thermosensitive components of extract are decomposed due to high temperature, the energy consumption is high, the heat efficiency is low, the extract is dried and burnt, drying is insufficient can be overcome. According to the dried Chinese medical extract obtained through the drying method, the content of effective components is high, the quality of finished products is good, the water content is low, and preparation processing and storage of the finished products are facilitated; fresh scent of medicinal materials is maintained, the color and lustre are natural, the texture is loose and uniform, the extract is easy to crush; and continuous and automatic production can be achieved, and the method has quite high operability and practicability.

Owner:LUNAN PHARMA GROUP CORPORATION

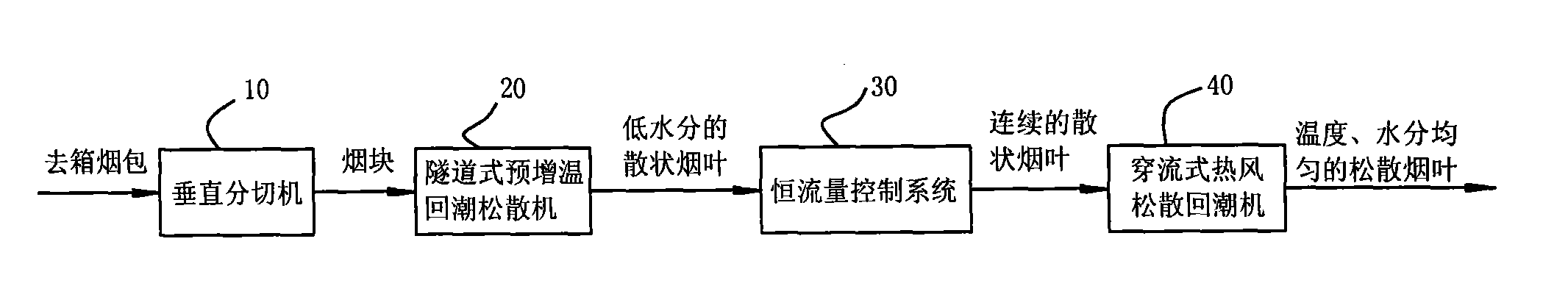

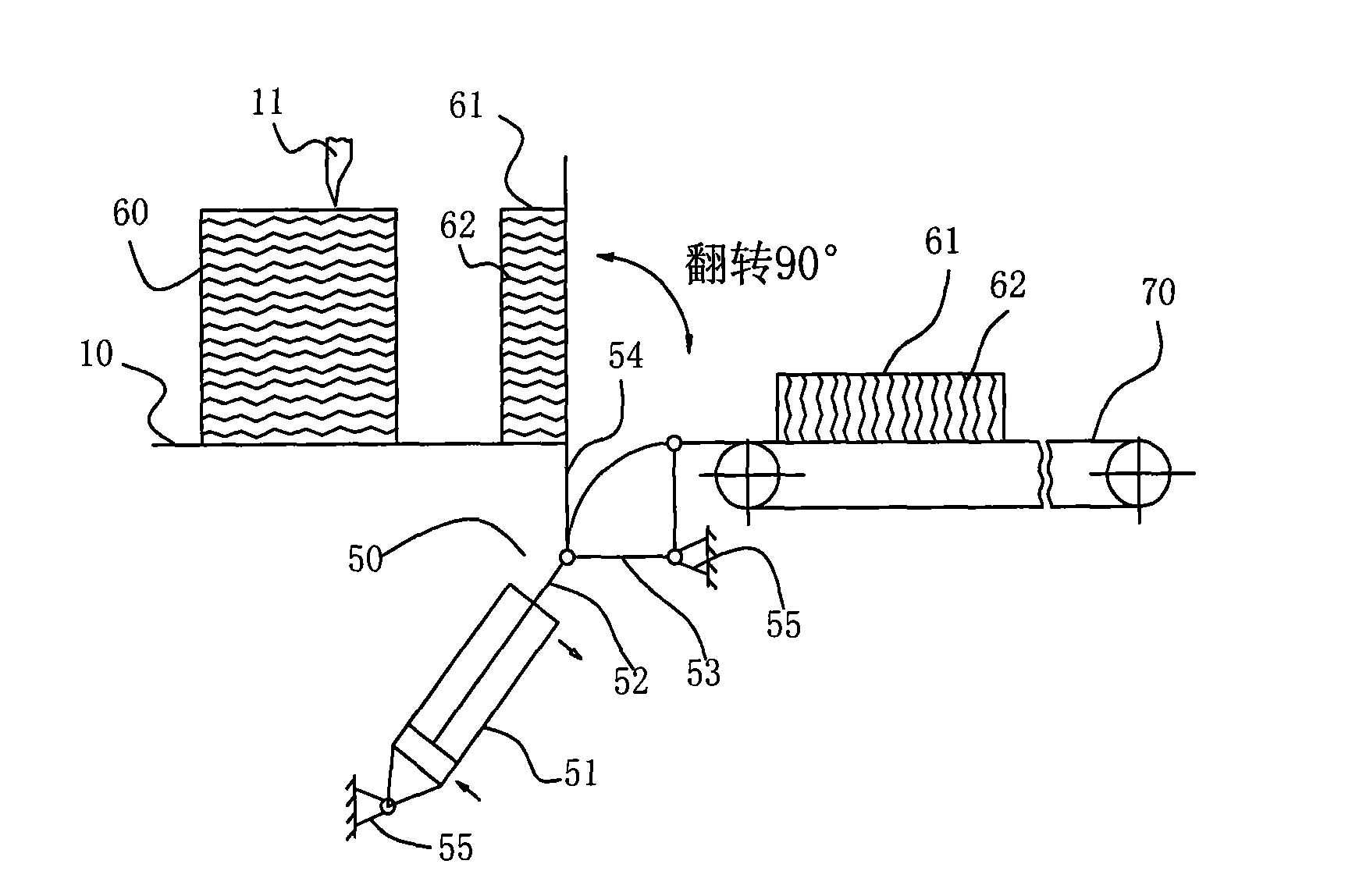

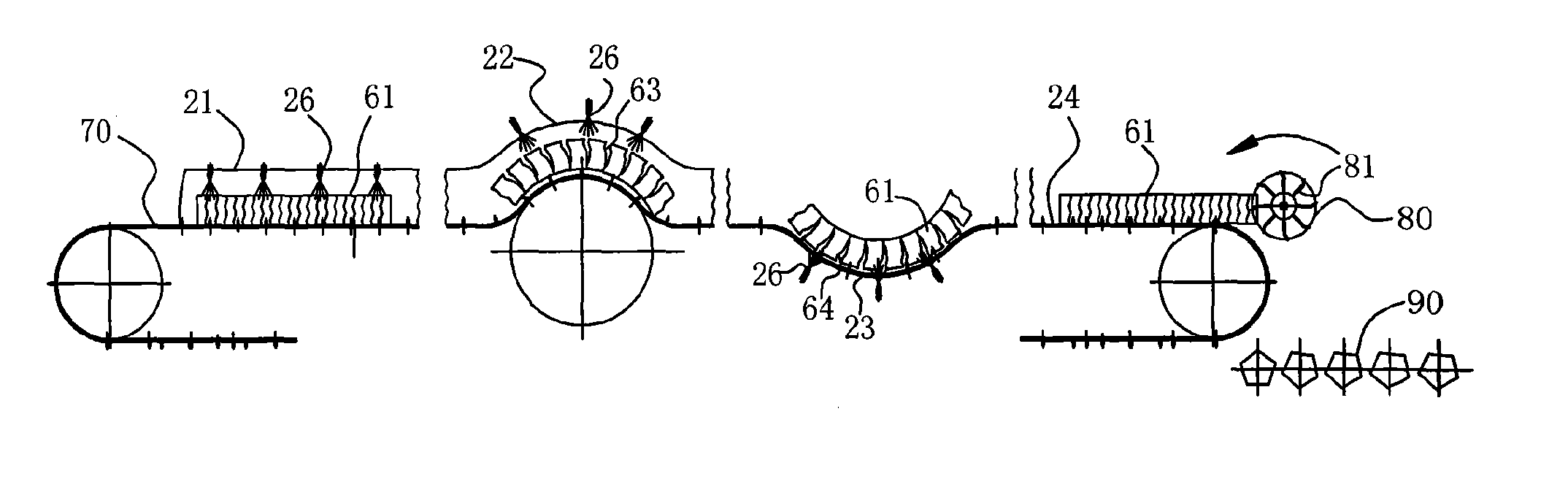

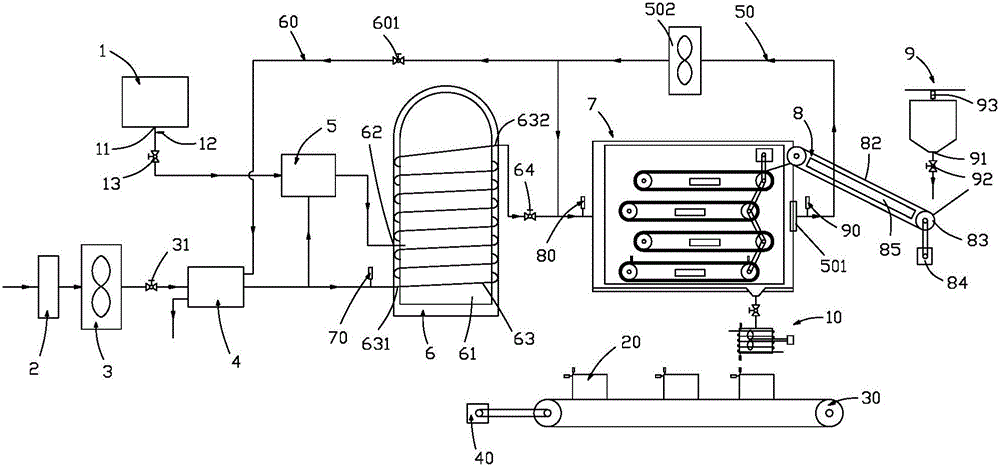

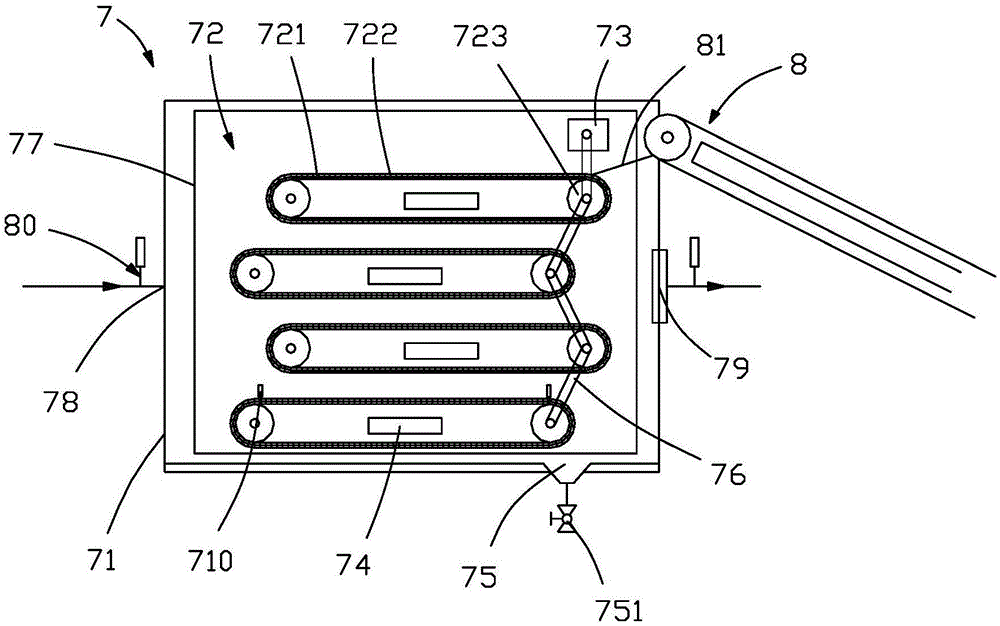

Tobacco piece loosening and conditioning system

ActiveCN101637297AReduce breakage rateAvoid breakingTobacco preparationControl systemPulp and paper industry

The invention discloses a tobacco piece loosening and conditioning system. The system comprises a vertical splitting machine, a tunnel type preheating conditioning loosening machine and a percolationtype hot-air loosening conditioning machine which are arranged in accordance with a pipeline method in turn. A constant flow control system is arranged between the tunnel type preheating conditioningloosening machine and the percolation type hot-air loosening conditioning machine. A turning and slow releasing device is arranged between the vertical splitting machine and the tunnel type preheatingconditioning loosening machine. The tunnel type preheating conditioning loosening machine is equipped with a bending delivery tunnel. The tobacco piece loosening and conditioning system has a combination of the tunnel type preheating conditioning loosening machine and the percolation type hot-air loosening conditioning machine, causes more even heating, improves loosening rate of tobacco flakes and reduces fragment generation ratio. The tobacco piece can be loosened and conditioned under low strength condition, and the raw materials of the tobacco can be subject to maximal flexible looseningto keep original fragrant of the tobacco, and realize coordination of sensor quality and material loosening.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Navel orange peel jam and processing method thereof

InactiveCN102524617AImprove use valueImprove economyFood preparationSaline solutionsNational standard

The invention belongs to the field of deep processing of agricultural products and discloses navel orange peel jam and a processing method thereof. The processing method comprises the following steps of: soaking navel orange peel into water for 1 to 2 days; draining; placing into saline solution and cooking for 10 to 20 minutes; draining; rinsing and draining; crushing into navel orange peel pulp; placing navel orange flesh into water at the temperature of 90 to 95 DEG C; blanching for 2 to 10 minutes; crushing into fruit pulp; mixing the navel orange peel pulp and the fruit pulp; adding citric acid; heating to 90 to 100 DEG C; preserving heat for 5 to 10 minutes; adding white granulated sugar and pectin; and boiling on a soft fire at the temperature of 80 to 90 DEG C for 30 to 40 minutes to obtain the navel orange peel jam. In the navel orange peel jam, the soluble solid matter content is more than or equal to 35 percent, the total sugar content is less than or equal to 65 percent, the total arsenic content is less than or equal to 0.5, the lead is less than or equal to 1.0 and the microbiological index accords with the national standard. In addition, the navel orange peel jam is golden yellow, sour and sweet and delicious, maintains fragrance of the navel orange peel and the mouthfeel of the fruit flesh, is uniform and exquisite and has high flowability.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing high-fragrance tobacco extract

ActiveCN106307606AStrong aroma of tobaccoGood hair permeabilityTobacco preparationTobacco treatmentMacromolecular SubstancesSolvent

The invention discloses a method for preparing a high-fragrance tobacco extract and belongs to the technical field of a tobacco additive. The method comprises the steps of 1, adding propylene glycol into tobacco raw materials, and then standing and baking the raw materials; 2, crushing, adding solvent extraction liquid into crushed materials; 3, filtrating extraction liquid with an ultra-filtration membrane to prepare permeate liquid, and decompressing and distilling the permeate liquid to prepare a condensate; and 4, secondarily separating the condensate by a molecular distillation method, and collecting a light component as the high-fragrance tobacco extract. In the preparing method, tobacco raw materials are in advance treated by baking so that Maillard reaction presents between the tobacco reducing sugar and the nitrogen-containing compound, generate pyrone and furanone substances are prepared and baking fragrance is increased; propylene glycol is added into the tobacco so that bad flavor caused by charred tobacco at high baking temperature can be prevented; macro-molecular substances and high boiling-point non-volatile substances can be effectively removed by the membrane separation-molecular distillation double separation process, and specific aroma components enriched in the tobacco are separated.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Highland barley chip and processing method thereof

The invention provides a highland barley chip food, belonging to the food processing technical field. The chip is obtained by the steps that highland barley grass is subject to impurity removal, killing out, drying and cutting into sections, smashing is carried out by adopting ultramicro equipment, then mixing with beta-glucan powder by certain ratio is carried out, and finally chip preparation, drying, packaging and sterilization are carried out. The highland barley chip food of the invention maintains the original nutrient component and health care function of highland barley and beta-glucan at the utmost extent, is crispy and delicious, has low fat and high fiber and is full of nutriments, is both leisure food and health care food and is a new comer of highland barley food family.

Owner:TIBET TIANMAILI HEALTH PROD CO LTD

Microwave vacuum freeze-drying method for rhizoma gastrodiae

InactiveCN107308350ANutrients are not destroyedAppearance color is not damagedDrying solid materials with heatDrying solid materials without heatFreeze-dryingAdditive ingredient

The invention discloses a microwave vacuum freeze-drying method for rhizoma gastrodiae. The microwave vacuum freeze-drying method comprises the following steps: firstly, cleaning and draining fresh rhizoma gastrodiae; secondly, pre-freezing the rhizoma gastrodiae at the temperature of 10 DEG C below zero to 30 DEG C below zero for 1 hour to 1 year; thirdly, slicing and pricking the rhizoma gastrodiae obtained in the second step; fourthly, putting the pricked rhizoma gastrodiae into a microwave freezing dryer, and freezing at the pressure of 5 to 20 Pa and the temperature of 35 DEG C below zero to 40 DEG C below zero for 1 to 3 hours; introducing nitrogen, controlling the pressure at 20 to 100 Pa, controlling microwave power at 100 to 300 w / kg when the time reaches 0 to 3 hours, controlling the microwave power at 300 to 500 w / kg when the time reaches 3 to 6 hours, controlling the microwave power at 100 to 200 w / kg when the time reaches 6 to 8 hours, and warehousing to obtain freeze-dried rhizoma gastrodiae slices. The method disclosed by the invention has the advantages of short production period and low energy consumption and cost for freeze drying; in addition, effective ingredients, nutritional ingredients, appearance, color and luster of the fresh rhizoma gastrodiae are sufficiently protected from being damaged, original shapes of crude products are maintained, and the rhizoma gastrodiae slices are crisp and tasty in mouthfeel.

Owner:ZHEJIANG JIANFENG HEALTH TECH

Technology for preparing bamboo shoot dietary fiber by microbial fermentation method

The invention relates to a technology for preparing a dietary fiber by a microbial fermentation method. The technology comprises the steps of taking waste scraps generated in a processing procedure of a bamboo shoot as a raw material, and performing fermentation seed liquid preparation, raw material treatment, raw material fermentation substrate preparation, inoculation, fermentation, vacuum freeze drying and the like to form a finish product of the bamboo shoot dietary fiber. The final product is natural in color, delicate in taste and fragrant in smell, a soluble dietary fiber content, water-holding power and swelling power are increased to various extents, and the technology can be put into industrial production. The technology is simple in operating condition and reliable in method, realizes comprehensive utilization of bamboo shoot resources, and increases a production added value of the bamboo shoot.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Instant green tea powder

InactiveCN104186796AEasy to get ingredientsKeep the fragrancePre-extraction tea treatmentAdditive ingredientSemen

The invention discloses instant green tea powder. In parts by weight, the instant green tea powder comprises 40-50 parts green tea, 10-15 parts of chrysanthemum, 10-15 parts of broadleaf holly leaf, 5-8 parts of scaphium scaphigerum, 5-8 parts of radix angelicae, 5-8 parts of astragalus membranaceus, 5-8 parts of semen cassiae, 5-8 parts of medlar, 5-8 parts of coptis chinensis, 5-8 parts of red dates, 5-8 parts of lotus leaves, 5-8 parts of mulberry leaves, 5-8 parts of sweet potato leaves and 5-8 parts of summer purslane. The instant green tea powder can be instantly dissolved in cold and hot water, is crystal-clear, transparent and rich in nutrients, and has the functions of reducing fat to lose weight and removing liver-fire to improve eyesight.

Owner:CHANGSHU CITY YUSHAN GREEN TEA

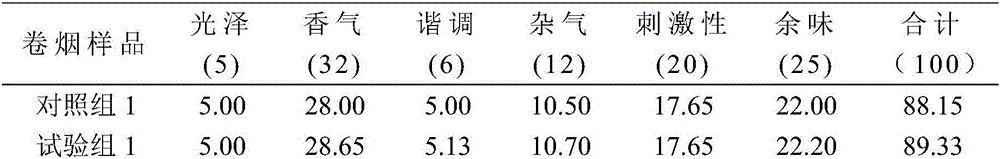

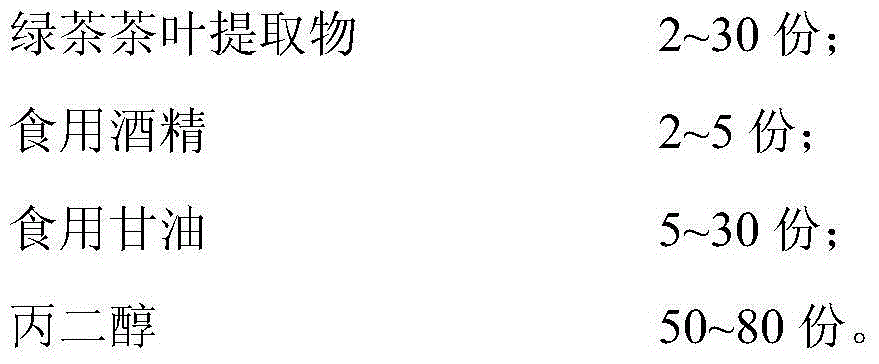

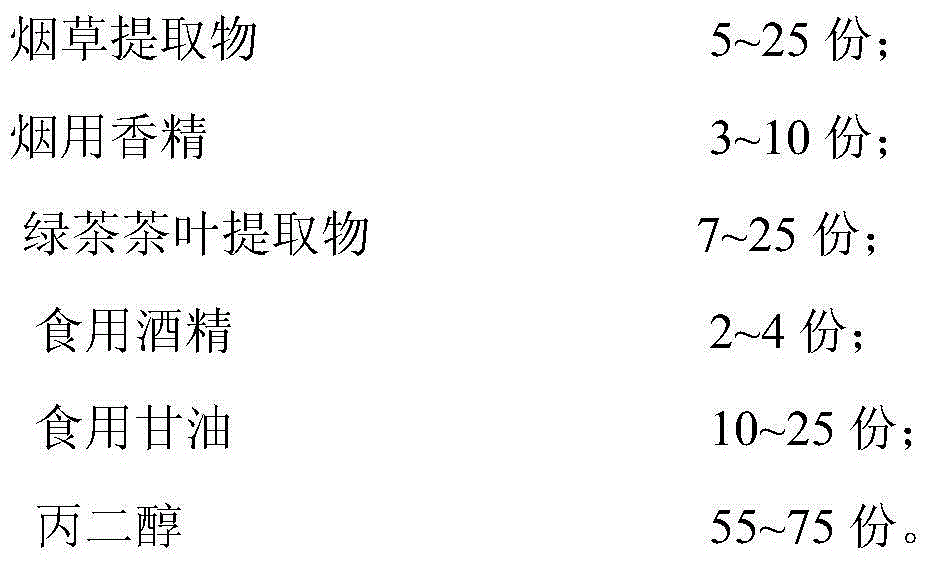

Electronic cigarette smoke solution prepared through green tea leaf extract

The invention relates to an electronic cigarette smoke solution prepared through a green tea leaf extract. The electronic cigarette smoke solution is prepared from the following raw materials and components in parts by weight: 2 to 30 parts of tobacco extract, 1 to 13 parts of tobacco flavor, 2 to 30 parts of green tea extract, 2 to 5 parts of edible ethyl alcohol, 5 to 30 parts of edible glycerinum, and 50 to 80 parts of propylene glycol. According to the electronic cigarette smoke solution, the green tea extract is prepared by supercritical fluid extraction and then is mixed with the tobacco extract, and then proper tobacco flavor and perfume and an atomizing agent are added, so as to prepare the electronic cigarette smoke solution with rich fragrance and comfortable taste.

Owner:CHINA TOBACCO GUIZHOU IND

E-cigarette nicotine liquid and preparation method thereof

ActiveCN106617265ASimple preparation processSimple and fast operationTobacco treatmentAdditive ingredientLiquid smoke

The invention discloses E-cigarette nicotine liquid and a preparation method thereof and belongs to the technical field of E-cigarette nicotine liquids. The E-cigarette nicotine liquid is made from high-nicotine tobacco extract, tobacco flavor and the like, wherein the tobacco extract has rich tobacco characteristic fragrant ingredients (such as megastigmatrienone, beta-damascone, pyrones, and furanones) and nicotine, can provide tobacco aroma and curing aroma and meet the physiological needs of consumers, and provides better satisfaction. The high-nicotine tobacco extract has very low contents of high-boiling-point ingredients and macromolecular substances (such as proteins, pectin, and polysaccharides), is free of burnt smell and low in sweetness, and can supplement aroma and cover peculiar odors, lower stimulus and improve taste strength. By being used with tobacco flavors, the E-cigarette nicotine liquid has enhanced curing aroma and tobacco aroma, and has strong aroma and good volatility. The preparation process of the E-cigarette nicotine liquid is simple, is simple and easy to perform, and is applicable to large-scale industrial production and application.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Tea and its preparation method

InactiveCN1830284AEasy to brewHeat-clearing and detoxifyingMetabolism disorderDigestive systemVeinLower blood pressure

A tea for antipyresis, detoxication, lowering blood pressure, decreasing blood fat, losing weight, etc is prepared from lotus leaf through washing, removing veins, disinfecting in high-temp water, cutting for shaping, kneading, backing, drying and kneading.

Owner:严介龙

Method for extracting flavone from bamboo leaves

InactiveCN102068630ABig cost lossHigh cost lossCosmetic preparationsToilet preparationsPolymer scienceSpray dried

The invention discloses a method for extracting flavone from bamboo leaves. The method comprises the following steps of: A, placing the bamboo leaves into a kettle, stewing the bamboo leaves by heating the kettle, turning off a heating device, cooling, and leaching dissolving-out substances from the bamboo leaves; B, allowing solution in the reaction kettle to pass through a filtering plate at the bottom of the reaction kettle to remove dregs and then pass through a filter with multifilament filter cloth to enter a settling tank; C, standing filtrate after filtering until the filtrate is clear and transparent; D, performing acid and alkali treatment on a macroporous resin NKA-9 polar resin, washing the resin with deionized water until the resin does not comprise ethanol, and placing the resin into a column; E, placing the clear and transparent filtrate into the column with the resin and stopping when the weight ratio of the resin to the filtrate is reached; F, washing with the deionized water until effluent liquid of the column is colorless, eluting the column with edible ethanol, and recovering the ethanol; and G, performing spray drying on the recovered solution without the ethanol in a spray tower to obtain total flavone. The method is practicable, easy and convenient to operate and low in cost. By the method, the flavone can be efficiently separated from the bamboo leaves and the effect is good. The flavone content is over 30 to 50 percent.

Owner:武汉神农天香生物科技有限公司

Lotus leaf tea and its preparing process

The invention relates to a lotus leaf tea and relative production. Wherein, it uses lotus leaf as material, which keeps the characters of lotus leaf in process. And the production comprises that selecting, cutting, aging with steam, removing water with hot wind, and baking. And it adds 1-3% dried glutinous rice flour to support shaping.

Owner:重庆荷香食品开发有限公司

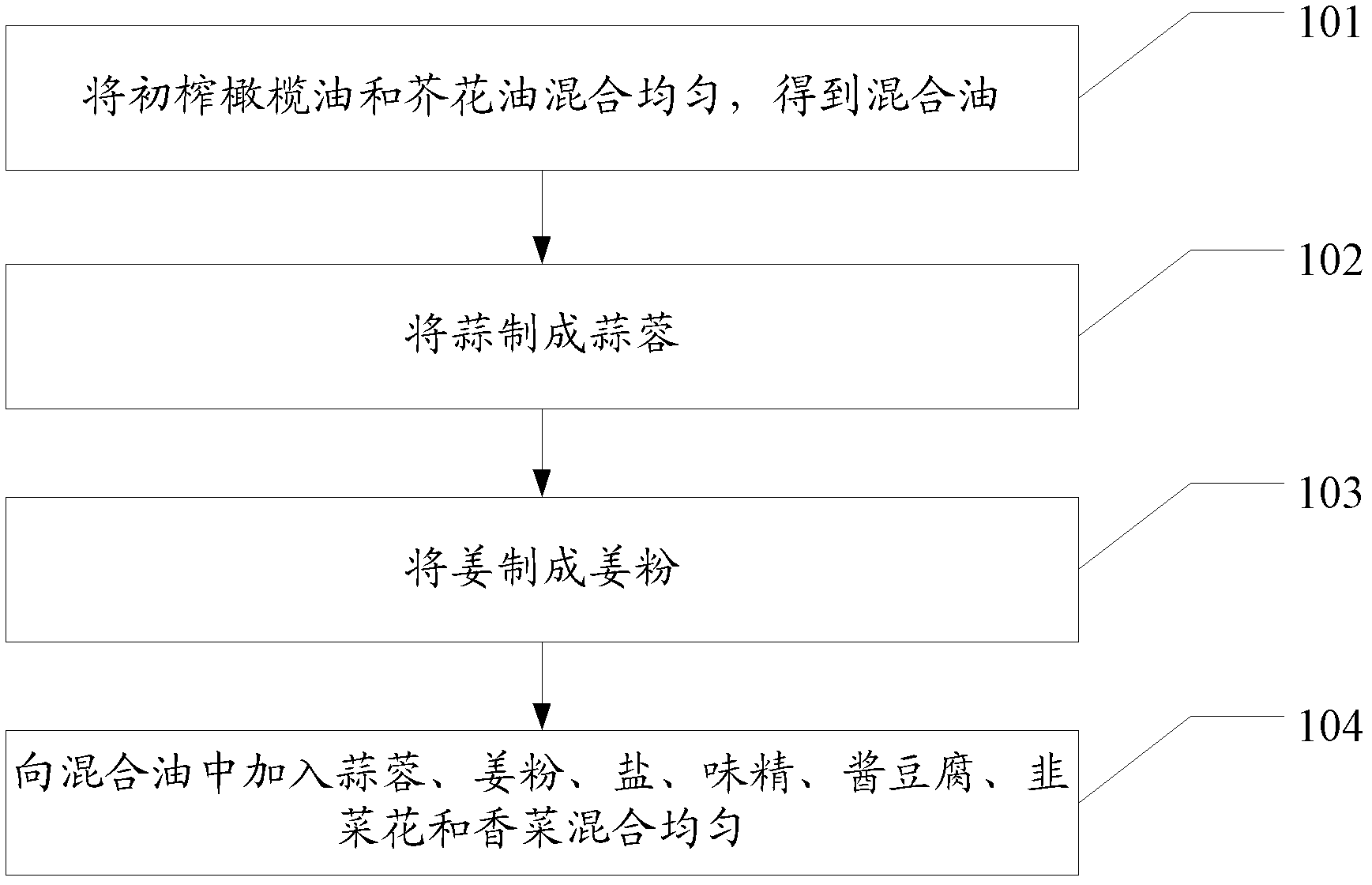

Olive oil hotpot dipping sauce and preparation method thereof

ActiveCN102551018AHigh nutritional valueIncrease fragranceFood preparationChemistryMonosodium glutamate

The invention relates to the field of catering and in particular relates to an olive oil hotpot dipping sauce and a preparation method thereof. The olive oil hotpot dipping sauce can retain faint scent of olive oil and has no astringent taste. The olive oil hotpot dipping sauce comprises virgin olive oil and canola oil and further comprises the following one or more materials in parts by weight selected from the group consisting of table salt, monosodium glutamate, fermented beancurd, chives flowers, garlic and ginger. The preparation method of the olive oil hotpot dipping sauce comprises the following steps: thoroughly mixing virgin olive oil and canola oil to obtain an oil mixture, and adding the following one or more materials in parts by weight selected from the group consisting of table salt, monosodium glutamate, fermented beancurd, chives flowers, garlic and ginger to the oil mixture.

Owner:朱星全

Electronic cigarette smoke solution prepared through black tea leaf extract

The invention relates to an electronic cigarette smoke solution prepared through black tea leaf extract. The electronic cigarette smoke solution is prepared from the following components in parts by mass: 1 to 25 parts of black tea leaf extract, 2 to 25 parts of tobacco extract, 0.5 to 15 parts of tobacco flavor, 50 to 80 parts of propylene glycol, 5 to 30 parts of glycerinum, and 2 to 5 parts of edible alcohol. According to the electronic cigarette smoke solution prepared through the black tea leaf extract, the special black tea leaf extract is mixed with the special tobacco extract, so that the electronic cigarette smoke solution is rich in fragrance, coordinated in perfume, and high in sense of satisfaction; the disadvantages of insufficient fragrance and taste of the electronic cigarette smoke solution can be improved to some extent; meanwhile, the tea essential oil contains a plurality of effective ingredients which bring a healthcare effect to some extent.

Owner:CHINA TOBACCO GUIZHOU IND

Full-automatic tea leaf drying device

ActiveCN106288727ASolve pollutionAvoid moisture returnTea dryingDrying gas arrangementsMechanical equipmentEngineering

The invention provides a full-automatic tea leaf drying device, and belongs to the field of tea leaf processing mechanical equipment. The full-automatic tea leaf drying device comprises a fuel storage bin, a first draught fan, a boiler, a drying box, a feeding device and a leaf storage bin. The fuel storage bin and the first draught fan are connected with the boiler, and the boiler is then connected with the drying box. The leaf storage bin is sequentially connected with the feeding device and the drying box. A heat exchange pipe is arranged on the inner wall of the boiler and provided with a heat exchange pipe opening end and a heat exchange pipe outlet end which are connected with the first draught fan and the drying box correspondingly. The drying box is provided with a hot air inlet end and a hot air outlet end which are connected with each other through a hot air circulation pipe. The hot air circulation pipe is provided with a second draught fan and a hot air extension pipe which is provided with a first electromagnetic valve in a penetrating manner. The full-automatic tea leaf drying device can achieve automatic feeding, drying, discharging and cooling of the tea leaf drying process and can accurately control the drying degree of tea leaves and improve the tea leaf drying quality and drying efficiency, and the device is easy and convenient to operate.

Owner:江西浮梁贡茶叶有限公司

Technique for processing air-drying pork under hyperthermia

InactiveCN1689413AMaintain nutrientsKeep the fragranceMeat/fish preservationWater contentEngineering

The low temperature air dried port producing process includes sorting material, making port strip, air drying, disinfecting, vacuum packing and other steps. Streaky pork is cut into pork strips of 4-10 cm width and 2-5 cm thickness, and the pork strips are hang in naturally low temperature air drying room or industrial low temperature air drying room to dehumidified with cold wind at temperature lower than 8 deg.c to water content of 8-10 %. Compared with other pork treating process, the process of the present invention is simple, has no addition of color, seasoning, preservative, etc. and no secondary pollution.

Owner:曾建设

Vegetable juice and method for producing the same

InactiveCN101467736AMaintain nutrientsKeep the fragranceFood preparationFruit juiceAdditive ingredient

The invention provides a vegetable juice and a manufacture method thereof, which relates to the formulation of a health food and manufacture method thereof and is characterized in that the vegetable juice is processed and prepared by using vegetable, sugar and water as raw materials according to a certain proportioning ratio. The manufacture method is as follows: the vegetable is prepared into beverage and then sterilized after material selection, washing, leaching, juice squeezing, mother solution prefiltration, fine filtering and sugar adding. The vegetable juice has the beneficial effects as follows: the vegetable juice is purely natural green food, holds the original nutrient contents, active ingredients and natural fragrance of fresh vegetables, and does not contains any chemical additive and preservative. The juice has simple process of preparation technology and low cost. The oral liquid is not only applied to living pace of modern people but also capable of having better absorption for human body.

Owner:TIANJIN ZHONGYING HEALTH FOOD

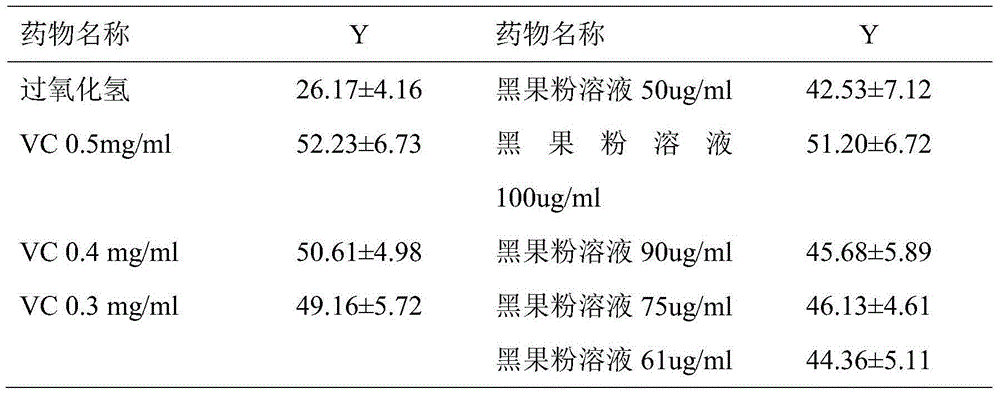

Silverweed cinquefoil root-VC composite effervescent tablet and preparation method thereof

ActiveCN103977100AFull of nutritionGood effectPharmaceutical delivery mechanismAntinoxious agentsEffervescent tabletVitamin C

The invention relates to a silverweed cinquefoil root-VC composite effervescent tablet and a preparation method thereof. The silverweed cinquefoil root-VC composite effervescent tablet is prepared by the following steps: mixing silverweed cinquefoil root powder and VC powder, adding additives, and tabletting to finally prepare the silverweed cinquefoil root-VC composite effervescent tablet. Through the silverweed cinquefoil root, the effervescent tablet is rich in nutrition, significant in function and special in faint scent; through deastringency treatment, original astringent taste of the silverweed cinquefoil root is removed and taste of the silverweed cinquefoil root is improved; meanwhile, the preparation method overcomes shortcomings of original extracting and concentrating treatment in which most nutrient ingredients such as vitamin and amino acid in the silverweed cinquefoil root are damaged and the special faint scent is lost. The effervescent tablet, which is made from raw powder of the silverweed cinquefoil root and the vitamin C is added to the tablet, comprehensively improves taking taste; moreover, the special faint scent is reserved, anti-fatigue and antioxidant functions are improved, and shelf life is prolonged.

Owner:SHAANXI UNIV OF SCI & TECH

Health care cocktail composition and preparation method thereof

ActiveCN105886278AFully extract and utilizeAvoid high temperature damageAlcoholic beverage preparationEffervescent tabletFood material

The invention provides a health care cocktail composition and a preparation method thereof; the invention includes a wine blending method and an application of health care. The finished product (the cocktail composition) is prepared from such fruit food materials as blueberries, lycium chinenses mill, lycium ruthenicum murr, dark plums, mulberries, black currants, lemons and the like. The cocktail, which has brilliant color, is blended from blending base liquor, blending fruit powder and a blending effervescent tablet. The cocktail has functions of resisting fatigue, resisting oxidation, resisting aging, protecting vision, resisting radiation and the like; and meanwhile, various nutrient elements, such as vitamins, amino acids, fructose, fruit peptide and the like, are supplemented. The finished product, which is free from artificial colorants and additives, is green and natural, and various combinations of the food materials can take effects on resisting oxidation and fatigue; and the finished product is a cocktail which simultaneously integrates fashion elements and a health care effect. The health care cocktail composition is widely applicable to bars, restaurants and home health care drinks.

Owner:韩玲玲

Watermelon beer brewing process

InactiveCN105820894AEliminate high sugar contentEliminate adverse effectsBeer brewingSaccharomyces cerevisiaeAdverse effect

The invention discloses a watermelon beer brewing process .Improvement is performed based on a common beer brewing process, freshly squeezed watermelon juice, common boiled malt juice for brewing and hops are prepared into fermentation raw material liquid, and healthy watermelon beer having a fresh and cool taste is made through fermentation of brewer's yeast after sterilization .The watermelon beer brewing process utilizes carbohydrates in watermelons in a fermentation mode, eliminates the higher adverse effect of the carbohydrates of the watermelons from the perspective of health, retains a fresh scent of the watermelons from the perspective of flavor, not only enriches the types of beer, also reduces the waste of the watermelons in summer and improves the added value of the watermelons.

Owner:NANTONG SCI & TECH VOCATIONAL COLLEGE

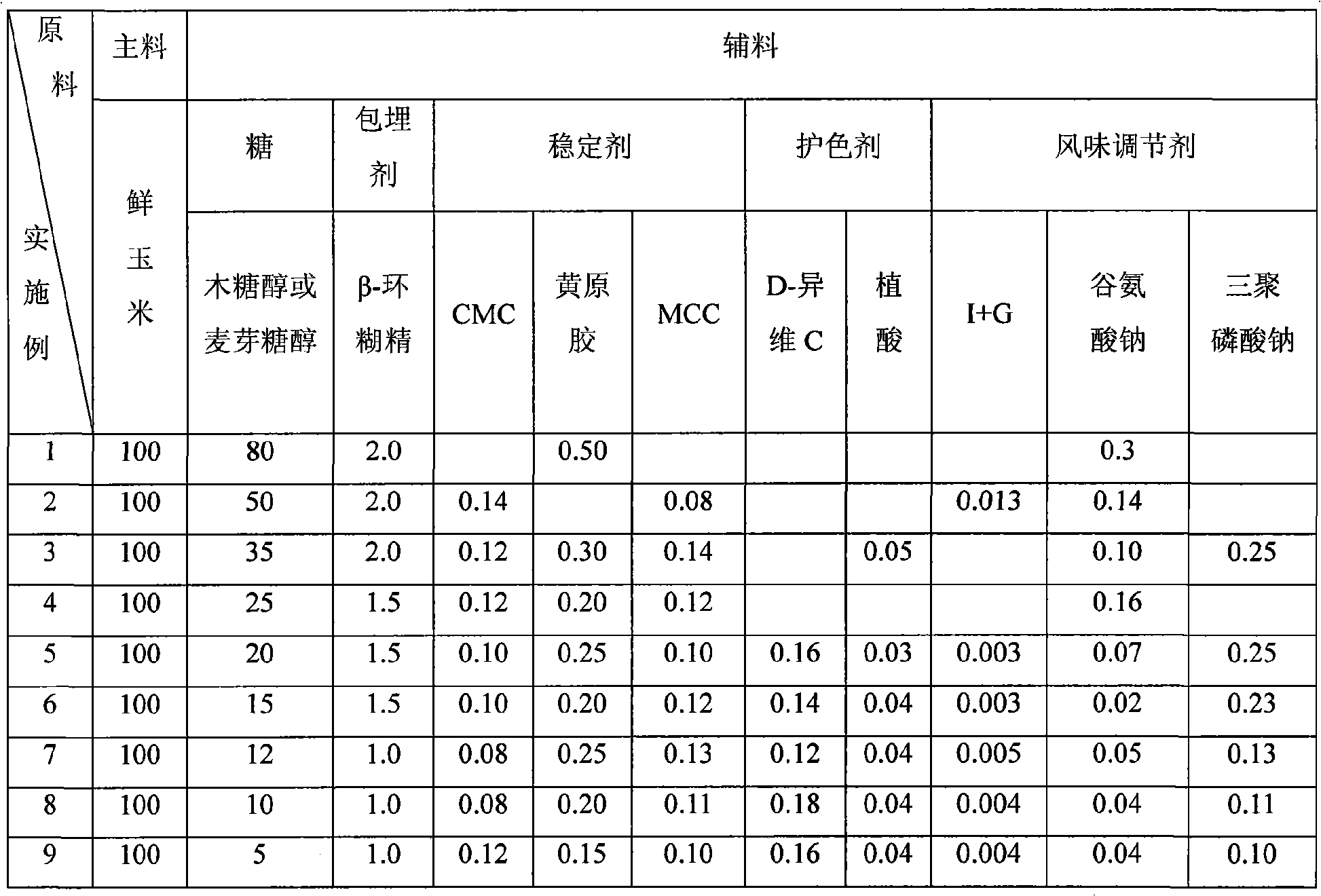

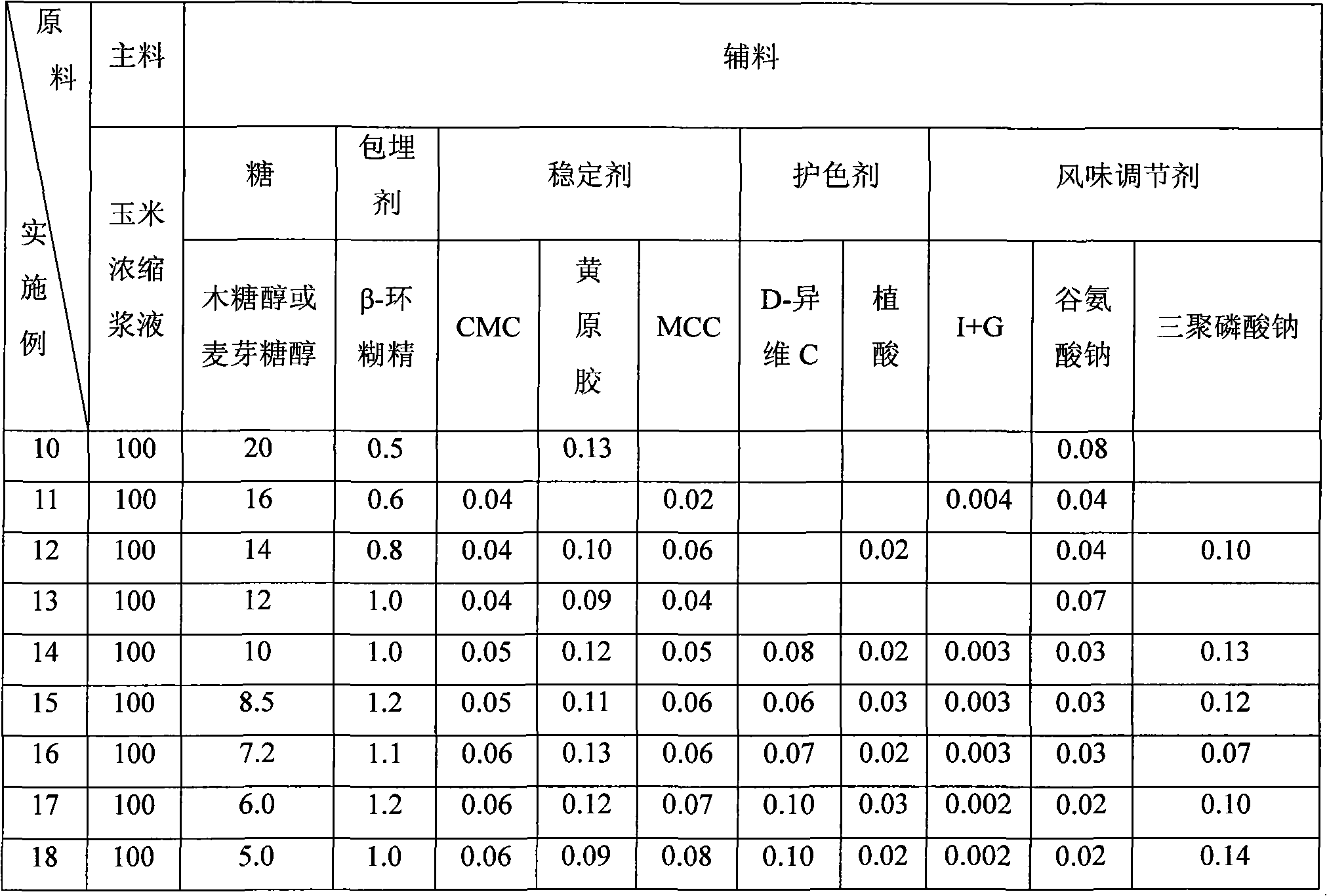

Method for preparing corn beverage

The invention relates to the preparation method of corn beverage, which is characterized in that: beta-cyclodextrin is added into corn serosity to mix and blend for 5 to 25 min at the temperature of 50 to 70 DEG C, then mixing blending solution is homogenized for twice at the temperature of 55 to 65 DEG C, finally the solution is vacuum degassed and sterilized at high temperature so as to prepare the corn beverage. Since the beta-cyclodextrin is a molecule embedding medium, embedding treatment is carried out to the flavor, coloring matter and essence of the product by the beta-cyclodextrin embedding medium, which can fully maintain the original fragrance, flavor and color and luster of the corn. The beta-cyclodextrin has the effect of having a stabilizer, which facilitates the system of the product to be stable.

Owner:ZHEJIANG LIZIYUAN FOOD CO LTD

Coconut ice-cream and preparation method thereof

InactiveCN101390560ARich varietyHas a sweet tasteFrozen sweetsFood preparationFiltrationPepsin digestion

The invention discloses a coconut ice cream, which is composed of 100 weight portions of ice cream and 5-30 weight portions of coconut granules; the ice cream is made of ice cream powder, coconut powder and water through even mixing and preparation, wherein, the ratio of sum of the ice cream powder and coconut powder to water is 1:2.8, while the ratio of ice cream powder to coconut powder is 7-8:1; and the coconut powder is made of coconut flesh through pepsin digestion, filtration and drying. The coconut ice cream contains the unique nutrients of coconut pulp and adopts the coconut powder through enzymatic treatment to enhance the utilization rate of nutrients in the coconut; moreover, the coconut granules enable the ice cream to have fruit taste and maintain the fragrance of coconut flesh.

Owner:熊旭华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com