Electronic cigarette smoke solution prepared through black tea leaf extract

A technology of tea extract and electronic cigarette liquid, applied in the field of electronic cigarettes, can solve problems such as poor taste and insufficient aroma, and achieve the effects of rich aroma, solving insufficient aroma and taste, and eliminating edema

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

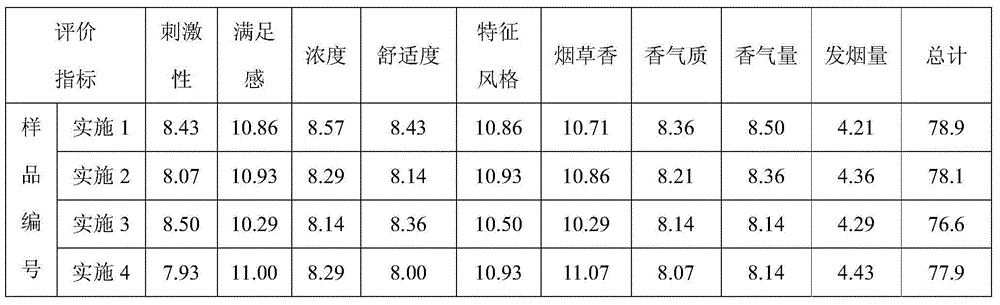

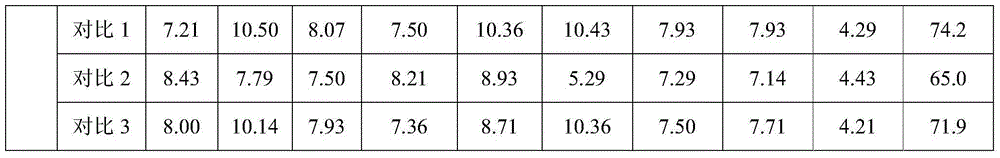

Examples

Embodiment 1

[0051] Preparation of tobacco extract: take intermediate flue-cured tobacco leaf samples, dry them in an oven at 40° C. for 3 hours, cool to room temperature, and crush them to 40-100 meshes. Weigh 100g of tobacco powder into a 1L Erlenmeyer flask, add 300mL of deionized water, conduct ultrasonic extraction at 50±5°C for 4 hours, then let it settle for 4 hours, filter it with a sand core funnel to obtain the filtrate, and depressurize at 70±10°C Concentrate to 3mL by rotary evaporation to obtain tobacco extract.

[0052] Supercritical preparation method of black tea leaf extract: Weigh 100g of Wuyi Mountain Lapsang Souchong, grind it into 20-30 mesh powder by a pulverizer, put it into a 1L extraction kettle, control the extraction pressure to 25MPa, and the extraction temperature to 50°C , regulating supercritical CO 2 The flow rate is 25L / h, and the extraction time is 3h. After extraction, the supercritical fluid dissolved with the extract is decompressed through the thrott...

Embodiment 2

[0057] Preparation of tobacco extract: take a Burley tobacco leaf sample, dry it in an oven at 40° C. for 3 hours, cool it to room temperature, and crush it to 40-100 mesh. Weigh 100g of tobacco powder into a 1L Erlenmeyer flask, add 300mL of deionized water, ultrasonically extract at 50±5°C for 4 hours, then let it settle for 4 hours, filter with a sand core funnel to obtain the filtrate, and decompress at 70±10°C Concentrate to 3mL by rotary evaporation to obtain tobacco extract.

[0058] The supercritical preparation method of black tea leaf extract: Weigh 100g of Keemun Kungfu tea, grind it into 45-55 mesh powder through a pulverizer, put it into a 1L extraction kettle, control the extraction pressure to 40MPa, and the extraction temperature to 35°C. Supercritical CO 2 The flow rate is 35L / h, and the extraction time is 5h. After extraction, the supercritical fluid dissolved with the extract is decompressed through the throttle valve, and enters the separation kettle to b...

Embodiment 3

[0063] Tobacco extract preparation: take the shredded shredded tobacco sample of sun-dried red tobacco and extract it. The extraction method is the same as that in Example 1.

[0064] The supercritical preparation method of black tea leaf extract: weigh 100g of Huhong Gongfu tea, grind it into 10-20 mesh powder through a pulverizer, put it into a 1L extraction kettle, control the extraction pressure to 50MPa, and the extraction temperature to 55°C. Critical CO 2 The flow rate is 20L / h, and the extraction time is 7h. After extraction, the supercritical fluid dissolved with the extract is decompressed through the throttle valve, and enters the separation kettle to become a gas, and the extract is precipitated in the separation kettle, and collected in the receiving bottle to obtain the black tea leaf extract.

[0065] Tobacco flavor (percentage by weight): 15% β-Damascenone, 30% macrostigmatrienone, 5% 2,3,5-trimethylpyrazine, 8% ethyl vanillin, 4% palmitic acid , 9% dihydroac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com