Patents

Literature

603results about How to "Easy to brew" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

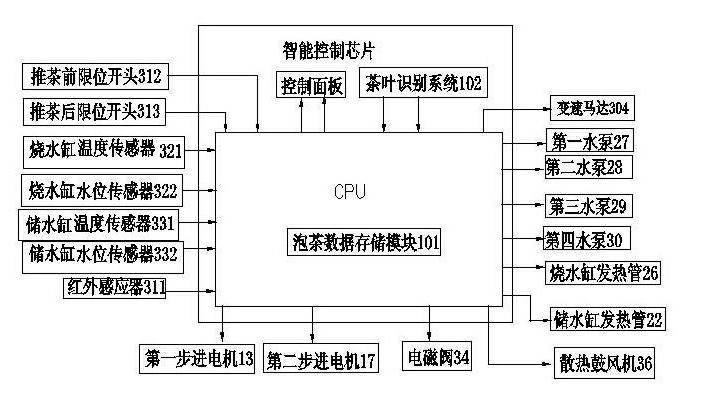

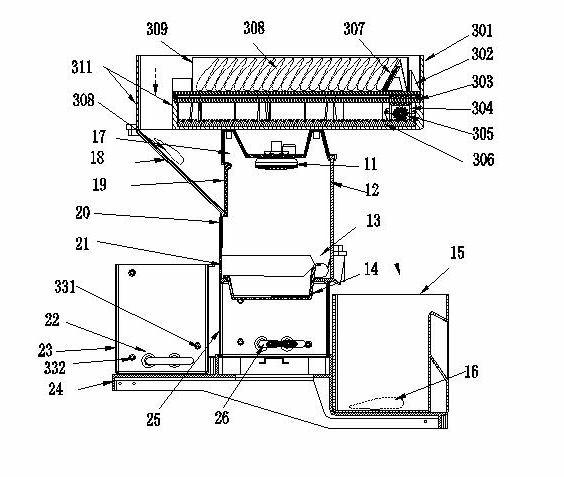

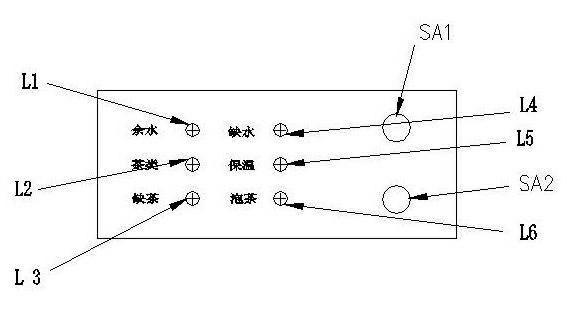

Intelligent automatic tea making device

The invention discloses an intelligent automatic tea making machine device, which is composed of an intelligent control chip, a control panel, a tea pushing mechanism, a tea making mechanism and a tea pouring mechanism arranged under the tea pushing mechanism. The intelligent control chip includes: central processing unit CPU: includes a tea-making data storage module for pre-storing different tea-making water temperature, tea-making water volume, and tea-making time; tea type identification system: used to realize the identification of tea types Identify and feed back the signal to the system central processing unit CPU to select the corresponding brewing method. The present invention is an intelligent full-automatic tea infuser with fast tea production speed, low energy consumption, convenient operation, safety and reliability, capable of intelligently identifying various teas, and intelligently adjusting corresponding tea making processes for different teas. All processes are intelligentized to realize automatic tea bag loading, automatic water boiling, automatic tea making, automatic overturning of brewed tea, and automatic addition of new tea bags. Small size, low energy consumption, suitable for various public places, entertainment places, enterprises and institutions, etc.

Owner:江西龙天茶业有限公司

Processing method of tea making with dendrobium candidum leaves

InactiveCN103238715ATake advantage ofImprove exudation rateTea substituesDendrobium candidumLeaching rate

The invention discloses a processing method of tea making with dendrobium candidum leaves. The method comprises the steps of fresh leaf treatment, high-temperature withering, rolling, fermentation, drying and deodorizing, wherein in the high-temperature withering step, the treated fresh dendrobium candidum leaves are uniformly placed on a withering bed and continuously turned over for 3-5 hours at the constant temperature of 70-90 DEG C to allow the water content of the leaves to reach 60-70%, and the leaves are put away if no crackly fracture sound is heard when the leaves are caught up by hand and pinched forcibly. The method solves the problems that the existing dendrobium candidum leaves are wasted, tea prepared by the dendrobium candidum leaves is inconvenient to drink, and effective components are difficult to utilize; and the method has the advantages of being capable of making full use of a rare resource of dendrobium candidum, effectively increasing the leaching rate of medicinal components of dendrobium candidum, and facilitating brewing.

Owner:福建省晓禾农业科技有限公司

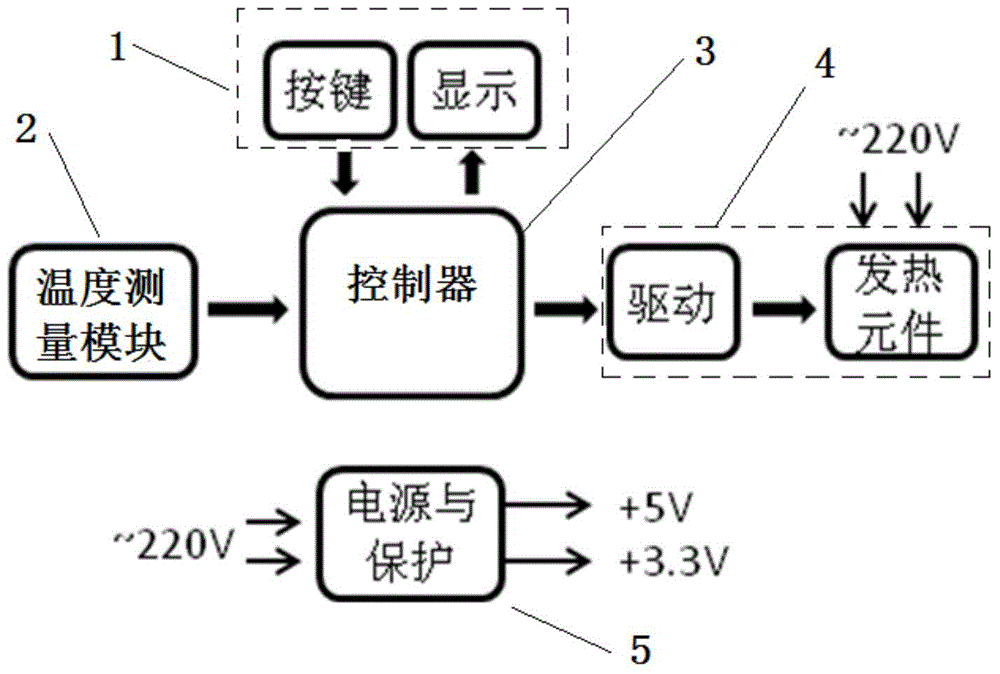

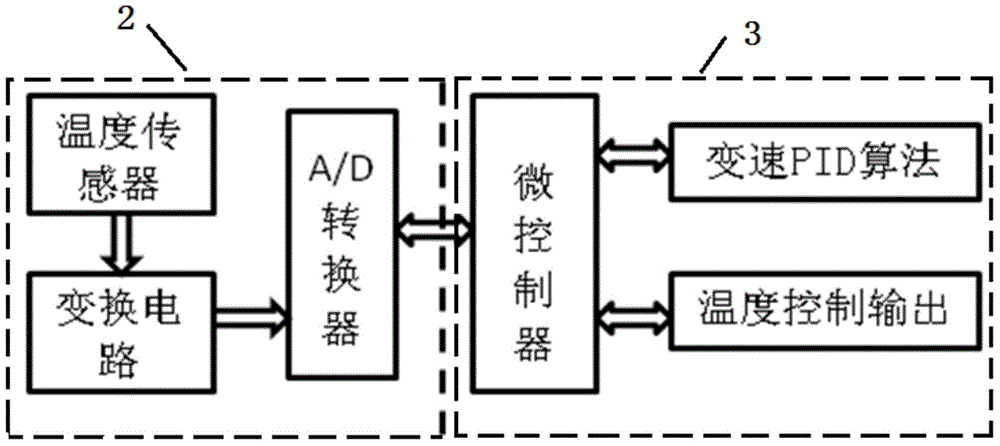

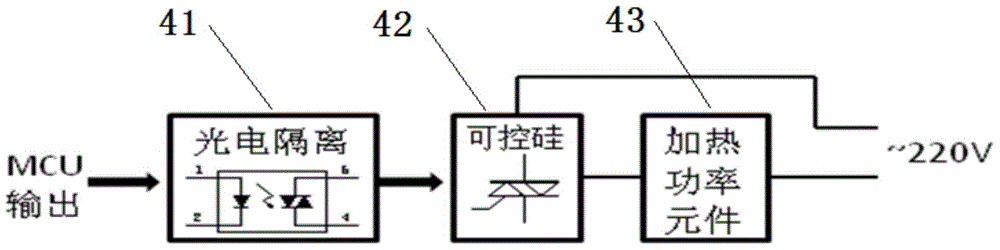

Temperature-adjustable intelligent heater and control method therefor

InactiveCN104825052AAccurate heating timePrevent thermal overshoot problemsWater-boiling vesselsBeverage vesselsEngineeringHeating power

The invention discloses a temperature-adjustable intelligent heater. The temperature-adjustable intelligent heater comprises a man-machine interface module, a temperature measurement module, a control module and an output power control module, wherein the man-machine interface module is used for setting constant temperature and displaying water temperature; the temperature measurement module is used for measuring the water temperature and sending temperature data to the control module; the control module is used for receiving the temperature data of the temperature control module, performing variable parameter PID computation to get heating power PWM data and sending the heating power PWM data to the output power control module; the output power control module is used for heating water and controlling the water temperature. The temperature-adjustable intelligent heater adopts the variable parameter PID computation; according to the heating time of different temperature control heating elements, the water temperature is precisely controlled at any temperature between room temperature and a boiling temperature, and the temperature deviation is controlled within 1.5 DEG C, and the heater is fast in heating and warming and precise in temperature control, so that thermal overshoot during the heating process is effectively prevented.

Owner:江丽 +1

Kiwifruit wine and method for brewing same

ActiveCN102776098ATaste is mellowImprove tasteAlcoholic beverage preparationMicroorganism based processesChemistryFruit drinks

Owner:河南伏牛山生物科技股份有限公司

Processing method of flower fragrance type kung fu black tea

InactiveCN106070796AHigh organic contentShort organic contentPre-extraction tea treatmentClimate change adaptationShootBlack tea

The invention discloses a processing method of flower fragrance type kung fu black tea. The method comprises the steps of fresh leaf picking, sun drying, fine manipulation of green tea leaves, quick-freezing withering, unfreezing, rolling, fermentation, first firing, full firing, fragrance increasing, vacuum packaging and the like. The technology is improved for solving the problems that when Lingyun white tea variety black tea is processed, taste is light in freshness and sweetness, fragrance is light and style and variety are monotonous. The processing method comprises the specific steps that tea shoots with two leaves and a bud or with three leaves and a bud of Lingyun white tea trees are picked as raw materials, and technological parameters of sunlight withering, fine manipulation of green tea leaves, freezing withering, rolling, fermentation, full-fire drying, drying and fragrance increasing are enhanced so as to improve a traditional processing method, so that the product has the quality style characteristics that strips are compact and uniform, color and luster are black and smooth, the soup color is orange red and bright, the fragrance is rich and lasting, the taste is mellow and refreshing and leave bottoms are red, bright and uniform, and the black tea has obvious nectar fragrance besides sweet fragrance, and meets requirements of different consumers.

Owner:广西隆林三冲茶业有限公司

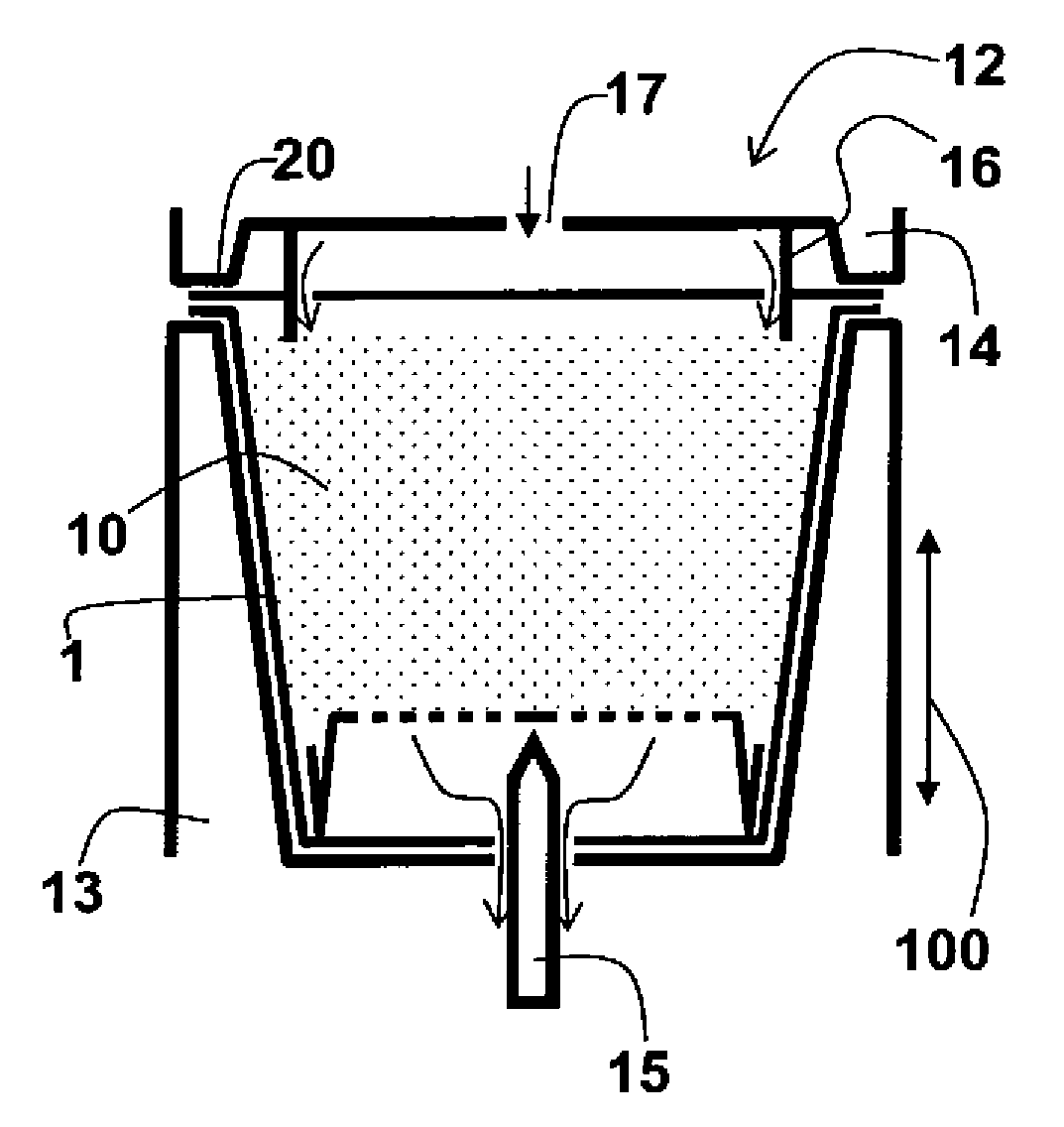

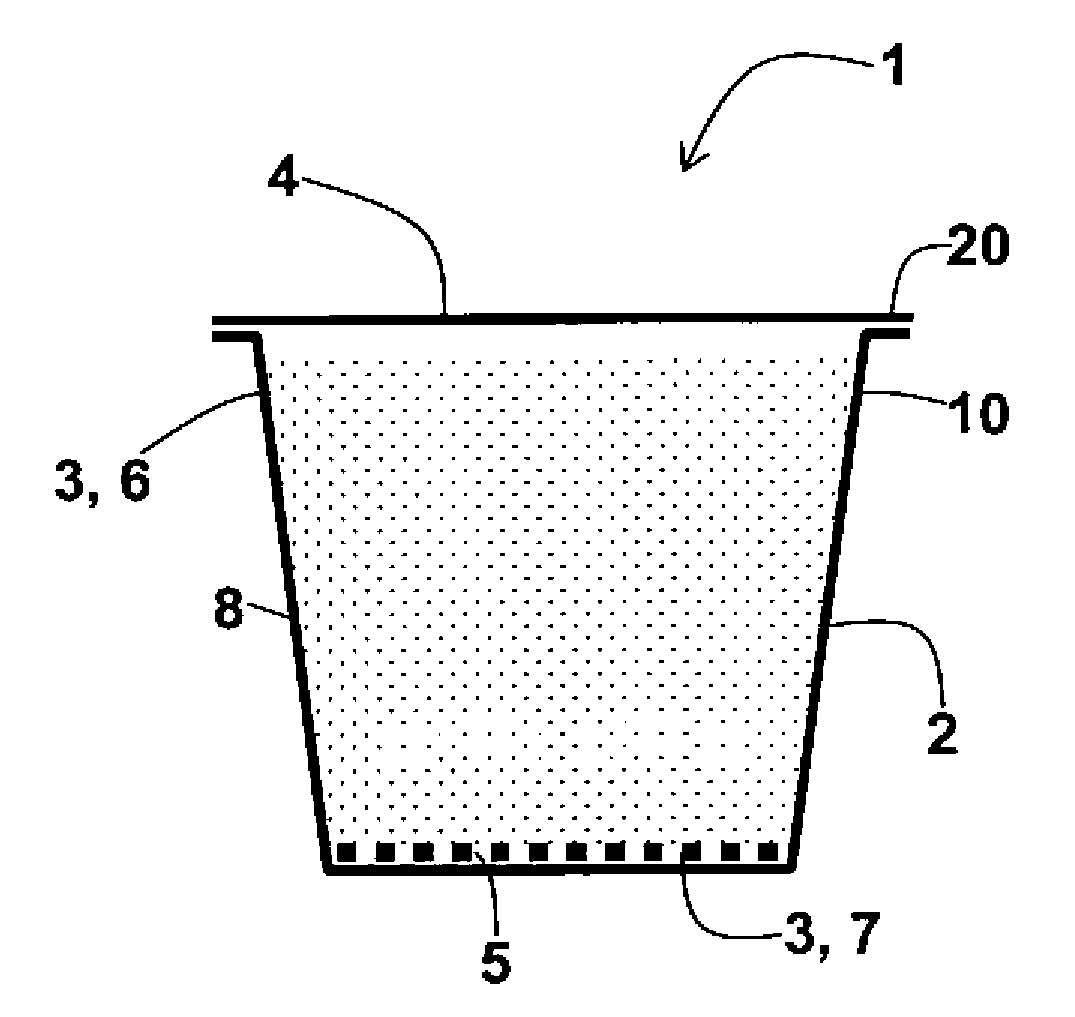

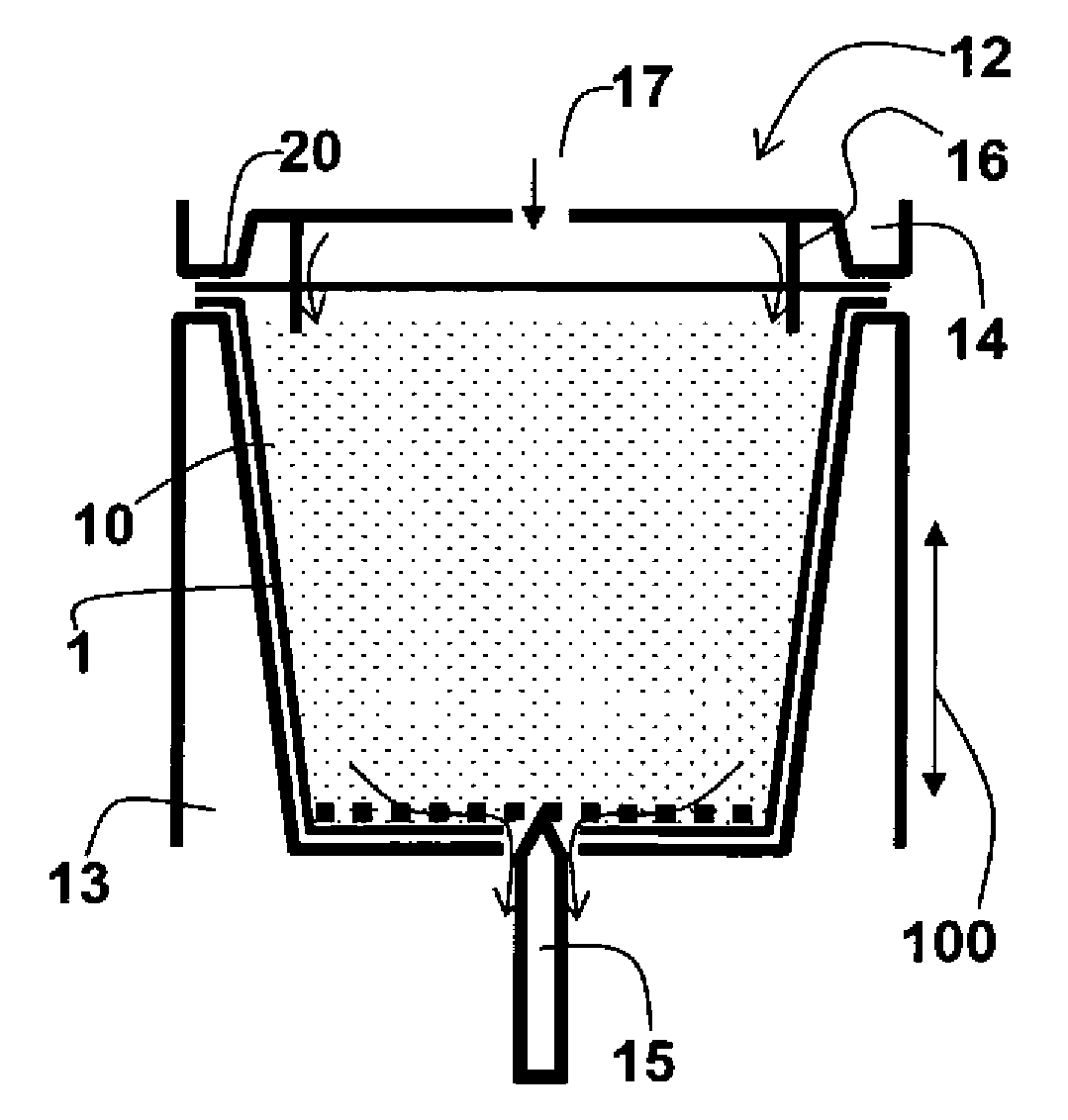

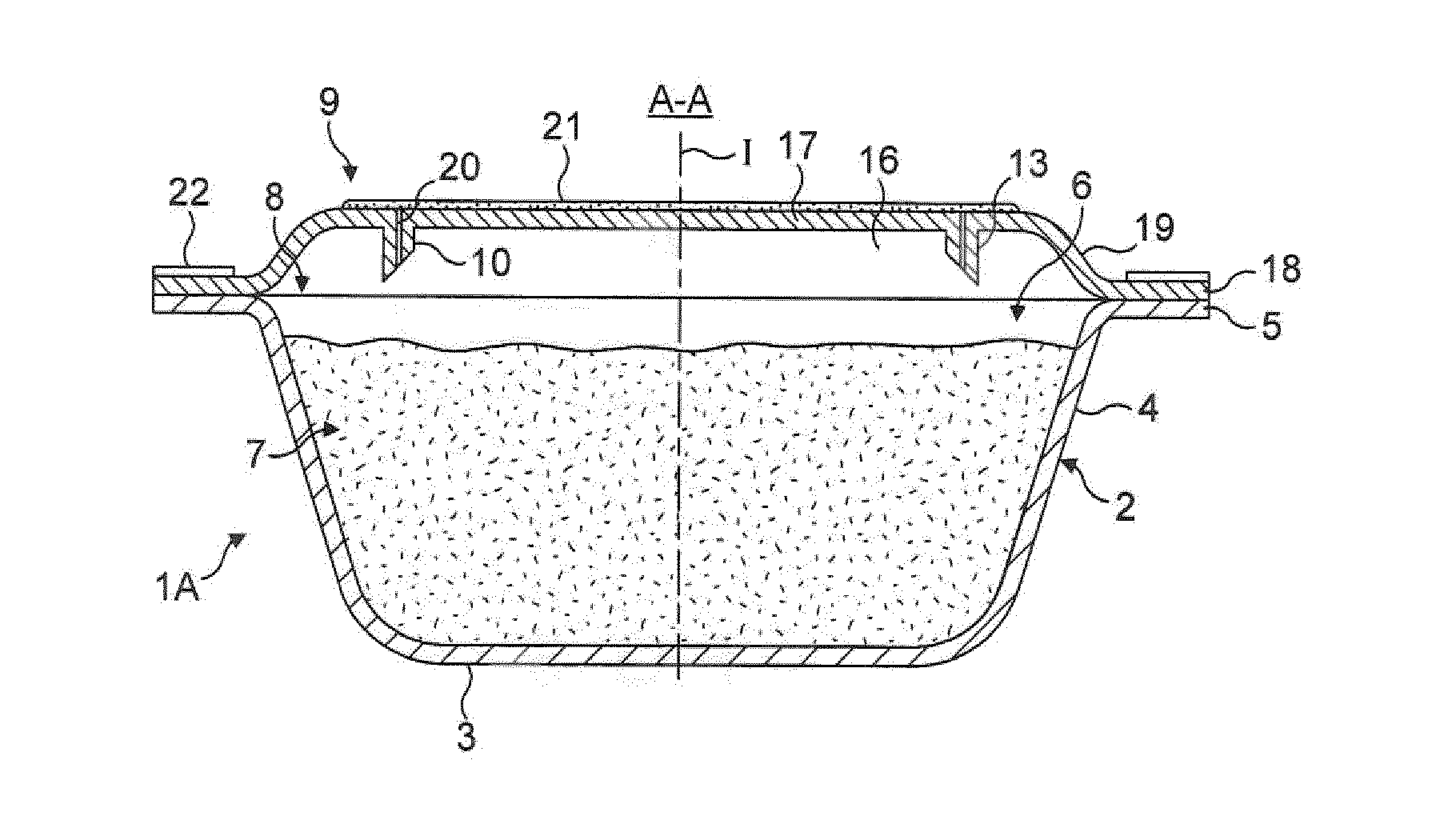

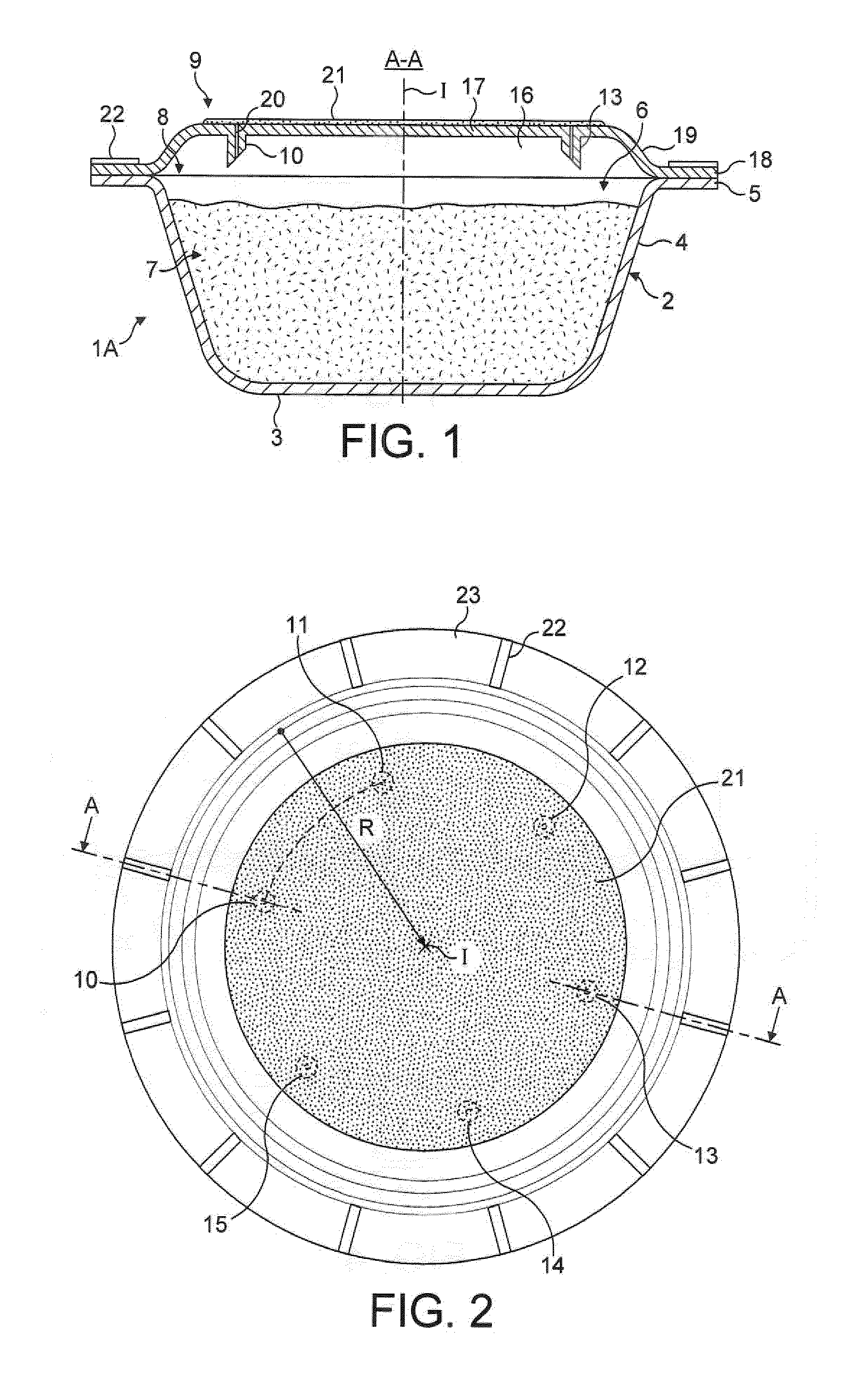

Beverage substance, portion capsule, and method for producing a beverage

ActiveCN103501624AEfficient brewingFaster and cleaner brewingPre-extraction tea treatmentTea extractionParticulatesFood science

Owner:K FEE SYST

Preparation method of instant tea

InactiveCN104543143AEasy to brewGuaranteed demand for drinking teaTea extractionInstant teaSeparation technology

The invention discloses a preparation method of instant tea. The preparation method comprises the following steps: smashing tea, soaking into water at 20-50 DEG C, wherein the weight of water is 10-15 times of that of the tea; treating the water to which the tea is added through 20-40kHz of ultrasonic wave for 25-35 minutes; carrying out coarse filtration on processed solution containing the tea by virtue of a filter, and then carrying out filtering treatment through a film separation technology to obtain purified tea water; and carrying out drying treatment on the obtained purified tea water to obtain the solid instant tea. According to the preparation method, the brewed tea water can be prepared into grain or powder crystal; and the grain or powder crystal only needs to be brewed with warm water or boiled water or purified water when people need to drink the tea, so that people can conveniently brew a cup of tea within a relatively short period of time.

Owner:罗婷元

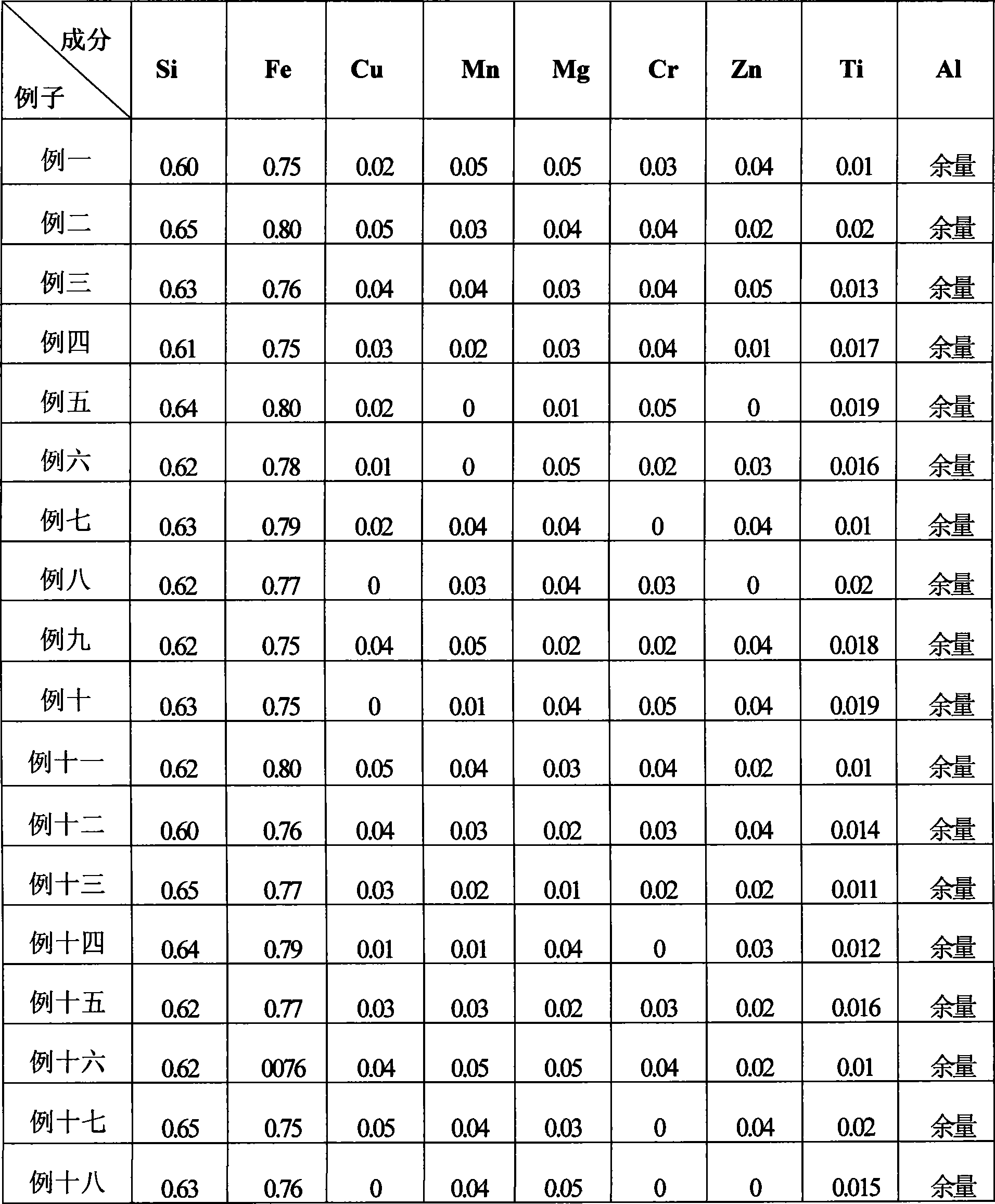

Hot rolling aluminium alloy for bottle cap material and producing method thereof

InactiveCN101386941AImprove performanceReduce consumptionMetal rolling arrangementsManganeseTitanium

The invention relates to an aluminum alloy for a hot-rolling bottle cap material and a manufacturing method thereof. The compositions of the aluminum alloy are silicon, iron, copper, manganese, magnesium, chromium, zinc, titanium and the balance being aluminum, and the total amount is 100 portions. The manufacturing method comprises the following steps: cast ingots are cast at a temperature of between 715 and 725 DEG C during the manufacturing process; surfaces of the cast ingots are milled; the cast ingots of the aluminum alloy are heated to a temperature of between 540 and 560 DEG C and kept for 6 to 10 hours; the cast ingots are rolled for a plurality of passes and roughly rolled until the thickness of the cast ingots is between 30 and 40 millimeters; the cast ingots undergo four-tandem rolling until the thickness of the cast ingots is 4 millimeters; and when the cast ingots undergo cold rolling and final finish and are rolled from 4 millimeters to between 1.2 and 0.46 millimeters, intermediate annealing is respectively performed for two times, and finally the cast ingots are rolled into the finished product with the thickness between 0.19 and 0.23 millimeter. The earing rate of the aluminum alloy is less than or equal to 2 percent; the strength of the aluminum alloy is between 140 and 160 MPa; the elongtation percentage of the aluminum alloy is more than or equal to 3 percent; and the product has stable performance and is favorable for improving the production efficiency. The aluminum alloy for the bottle cap material is widely used for bottle caps of containers such as various winebottles, beverage bottles, medicine bottles and so on, and can meet the high-quality requirement of bottle cap processing enterprises at home and abroad on the variety.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

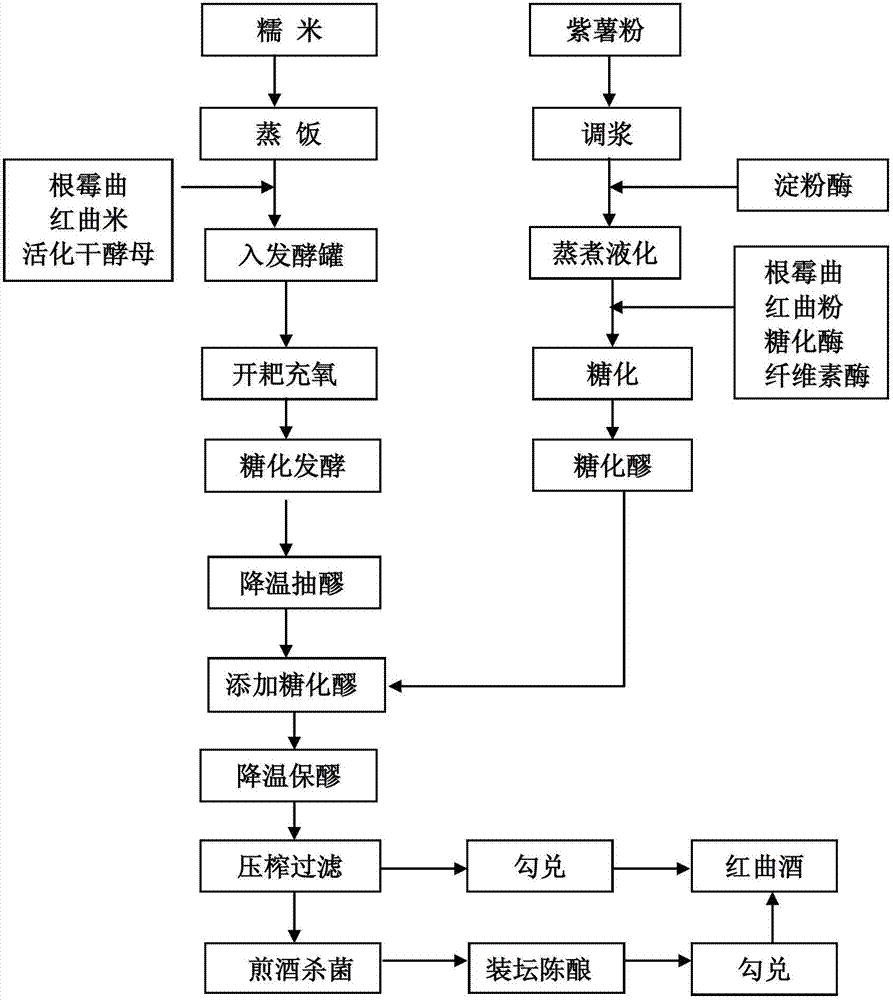

Preparation method of semi-sweat red rice yellow wine

ActiveCN103173318ABright colorReach sugar requirementsAlcoholic beverage preparationMicroorganism based processesChaptalizationProcess engineering

The invention relates to a preparation method of semi-sweat red rice yellow wine. The method is characterized by comprising the following steps of: decocting sticky rice; putting into a tank to ferment; in the process of stirring and cooling and oxygenating, adjusting sugar degree, squeezing and filtering, blending, decocting wine for sterilization and packaging and aging, further adopting a preparation method of cooling and extracting dregs, adjusting sugar degree and cooling and maintaining dregs between the step of stirring and cooling and oxygenating and fermenting and the step of squeezing and filtering. The step of cooling and extracting dregs is realized by quickly cooling the fermenting dreg liquid to 10 DEG C and standing for 1-2 days for extracting fermenting dreg liquid at the bottom. The step of adjusting sugar degree is realized by adding adjusting sugar degree sweet mash to the fermenting tank. The step of cooling and maintaining dregs is realized by cooling the fermenting dreg liquid at 1 DEC G / day and cooling to 0-2 DEG C, maintaining the temperature and continuously culturing for 20-30 days. The preparation process of the method provided by the invention is based on a mechanical production line of red rice yellow wine, and the fermenting process is completed in one tank. Compared with conventional brewing process, the preparation method provided by the invention has the advantages that the fermenting period is shortened, the demand of sugar degree of the semi-sweat red rice yellow wine is met, and meanwhile, the brewing flavor is better.

Owner:FUJIAN NORMAL UNIV

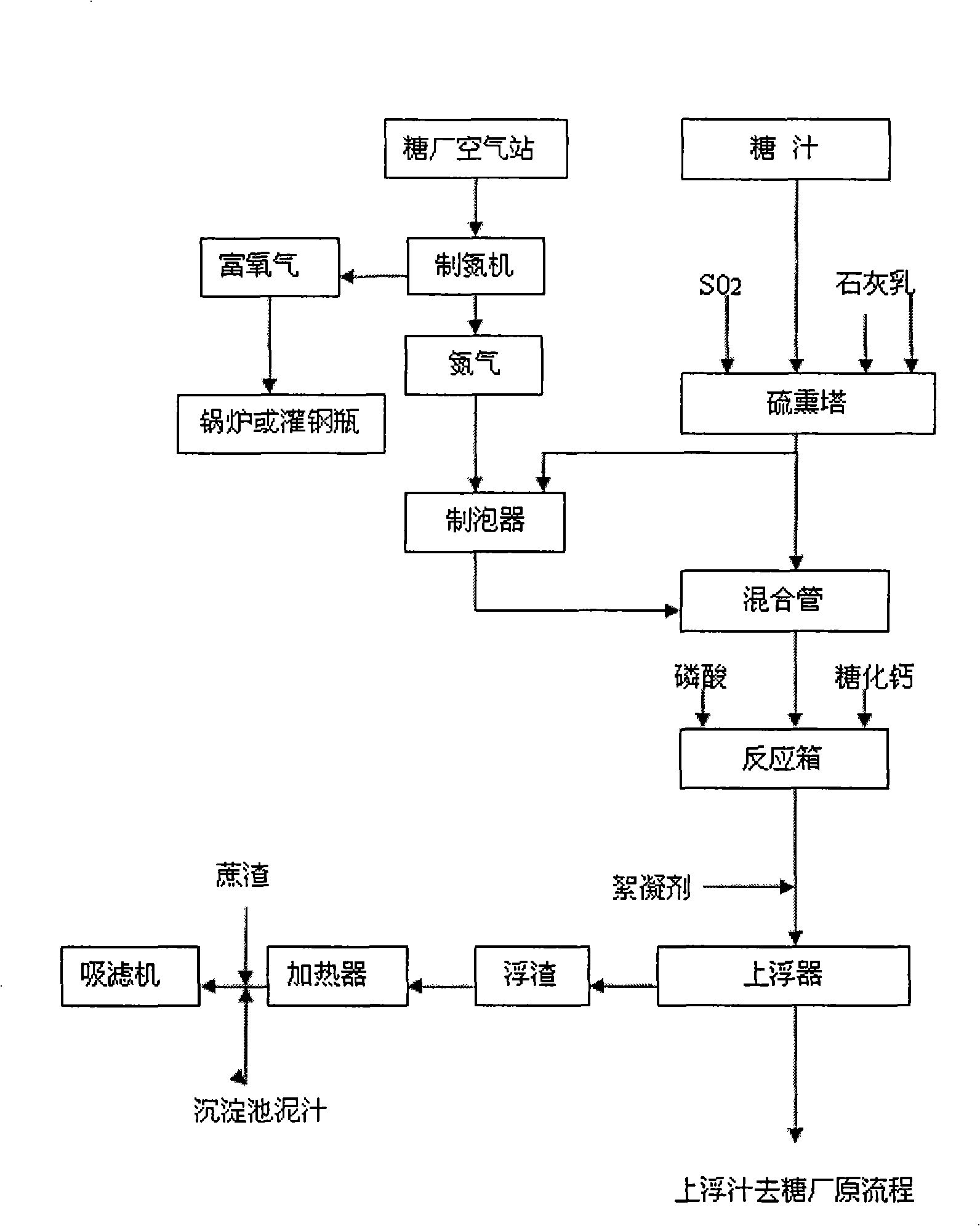

Sugar juice air-float clearing method

InactiveCN101294227AHighlight substantive featuresSignificant progressSugar juice purificationNitrogenNitrogen gas

The invention discloses an air floatation lustration method of sugar juice. Nitrogen is used as foaming air supply instead of air; thin juice (such as mixed juice, diffusion juice, neutral juice, clear juice and filtered juice) and concentrated sugar juice (such as syrup and molasses) in a sugar-refinery are processed through floatation lustration. The lustration method solves the problems that oxygen generated in the air floatation lustration method which takes the air as the foaming air supply has the oxidation encolouration side effects on the phenols in the sugar juice, the intensity of sulfitation is reduced, the sugar juice is fermented under the low temperature, etc., the sugar juice with better quality is obtained, and the product quality of the sugar-refinery is increased.

Owner:GUANGXI NANNING HUAXIN SUGAR IND TECH

Antialcoholic tea and preparation method thereof

InactiveCN101530147ATo promote metabolismAlleviate pathological changesTea substituesFood preparationDaily livingFood grade

The invention provides antialcoholic tea and a preparation method thereof, and relates to a herbal tea preparing process. The preparation method comprises the following steps: mixing raisin tree seed, pueraria flower, kudzuvine root and black tea, sterilizing the mixture by microwaves for 3 minutes, baking the mixture for 8 hours at 85 DEG C; and then crushing the mixture into coarse powder, and filling the coarse powder in bags. The preparation method has simple and reasonable process, and easy operation; and a prepared product has low cost, is easy to store, carry and contributes to tea-making. The invention takes the tea in a food grade, and the formulation ensures mouthfeel and has special effects; tea-making and drinking has no toxic and side effect for a long time, and is convenient and quick; and the tea is suitable for daily life, offices, travels and leisure, particular people who often drink wines, and the people have health care enjoyment from drinking the tea.

Owner:李国柱 +2

Method for processing instant rice flour for infants

The invention provides a method for processing instant rice flour for infants. The method comprises the following steps of: (1) preparing raw rice flour; (2) weighing lactalbumin accounting for 20-30% of the raw rice flour by weight, mixing the lactalbumin with the raw rice flour uniformly, and adding water to soak the mixture for 20-30 minutes to obtain mixed paste liquor; (3) adding food-grade protease accounting for 0.3-0.5% of the raw rice flour by weight, stirring the mixture uniformly, heating the mixture to 50-55 DEG C, preserving heat for 40-60 minutes, and then deactivating the protease; (4) adding trehalose accounting for 1-3% of the raw rice flour by weight and isomaltooligosaccharide accounting for 1-3% of the raw rice flour by weight, stirring the mixture uniformly, and heating to concentrate the mixture; and (5) spray-drying or pneumatically drying the obtained concentrated paste liquor to obtain floury products with moisture content being lower than 8wt%, and packaging the floury products, thus obtaining the instant rice flour. The instant rice flour produced by the method provided by the invention has good brewing property, does not have allergic reactions to the infants, and is suitable for the infants to eat.

Owner:江西省安亲健康食品有限公司

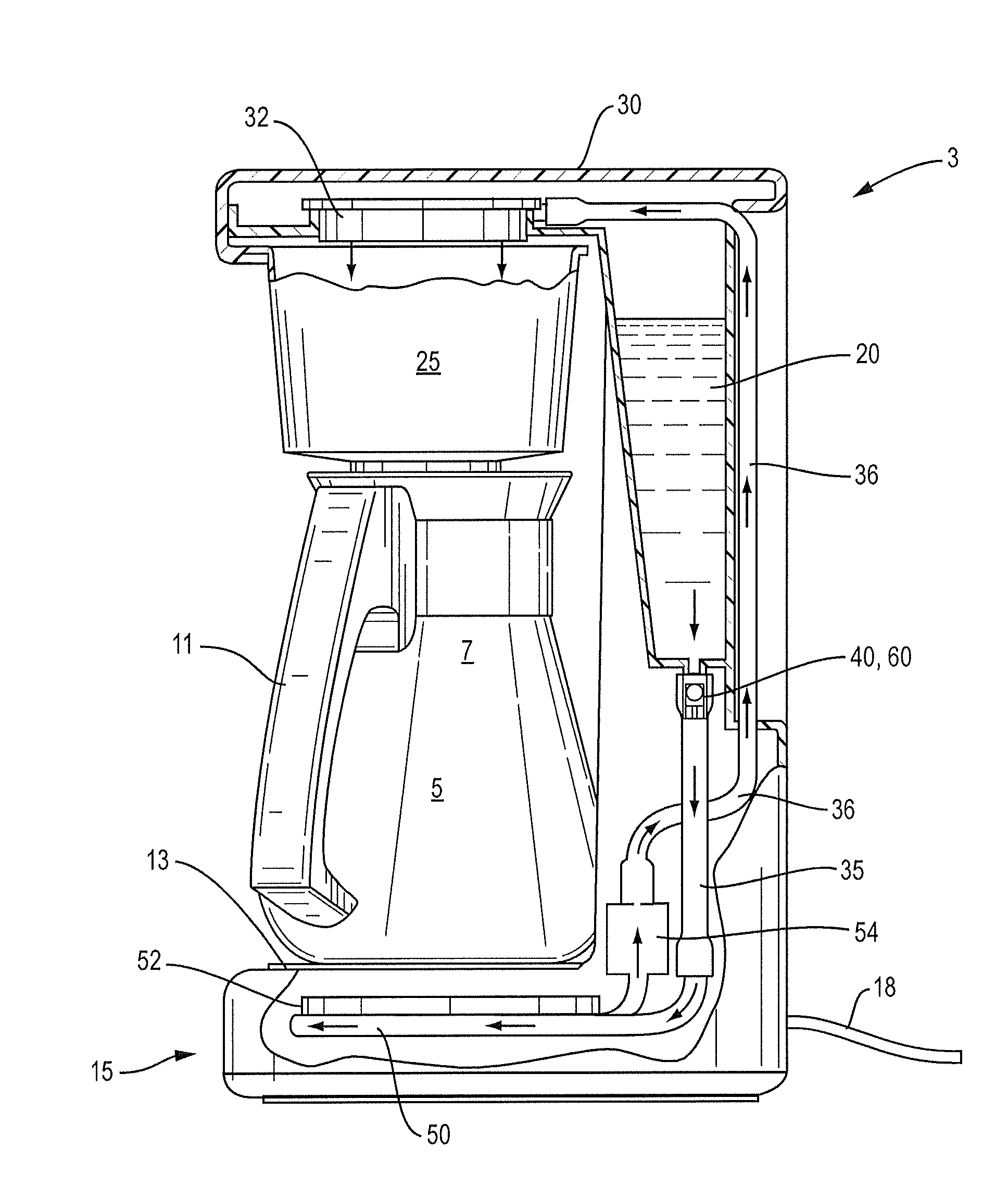

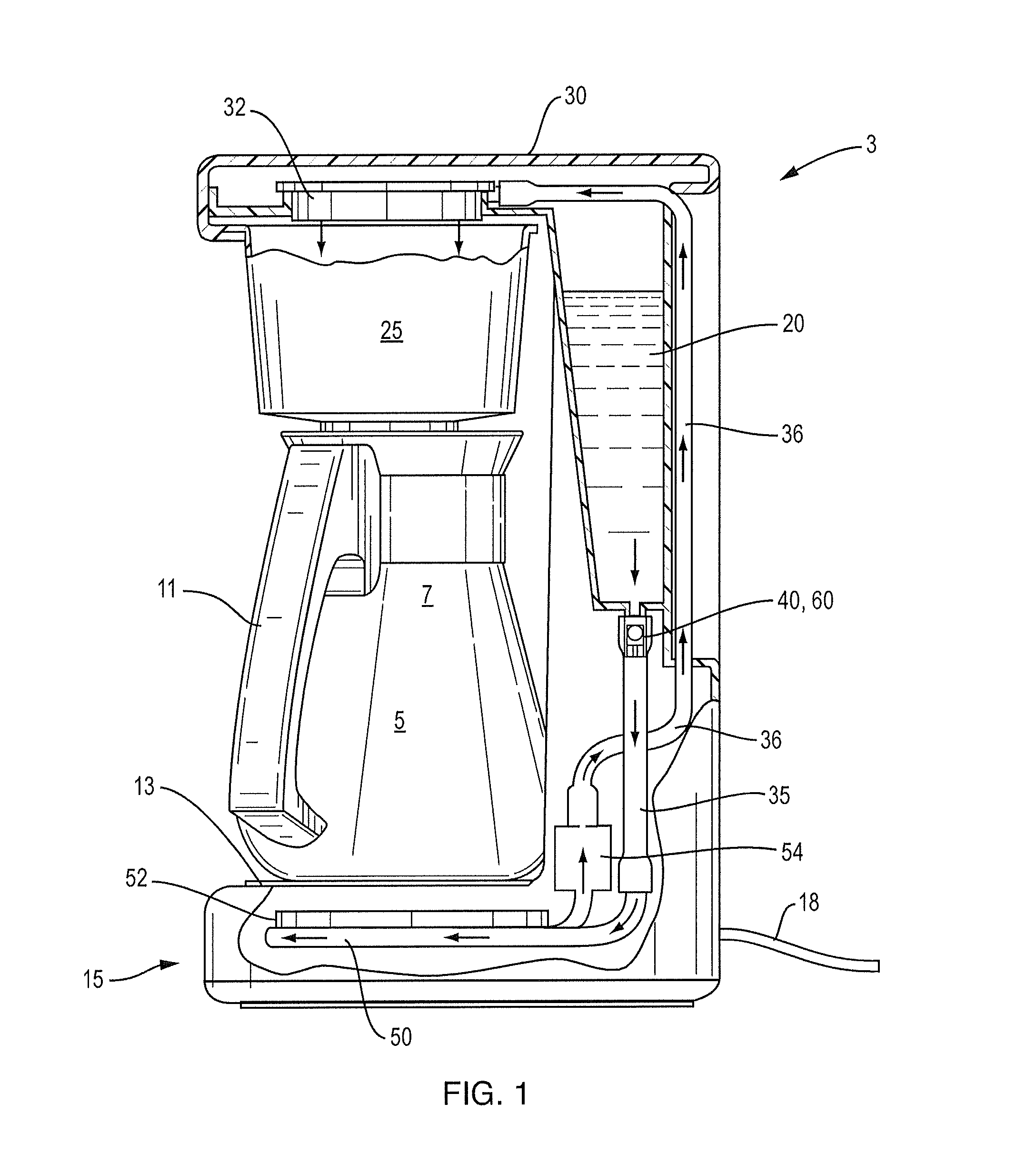

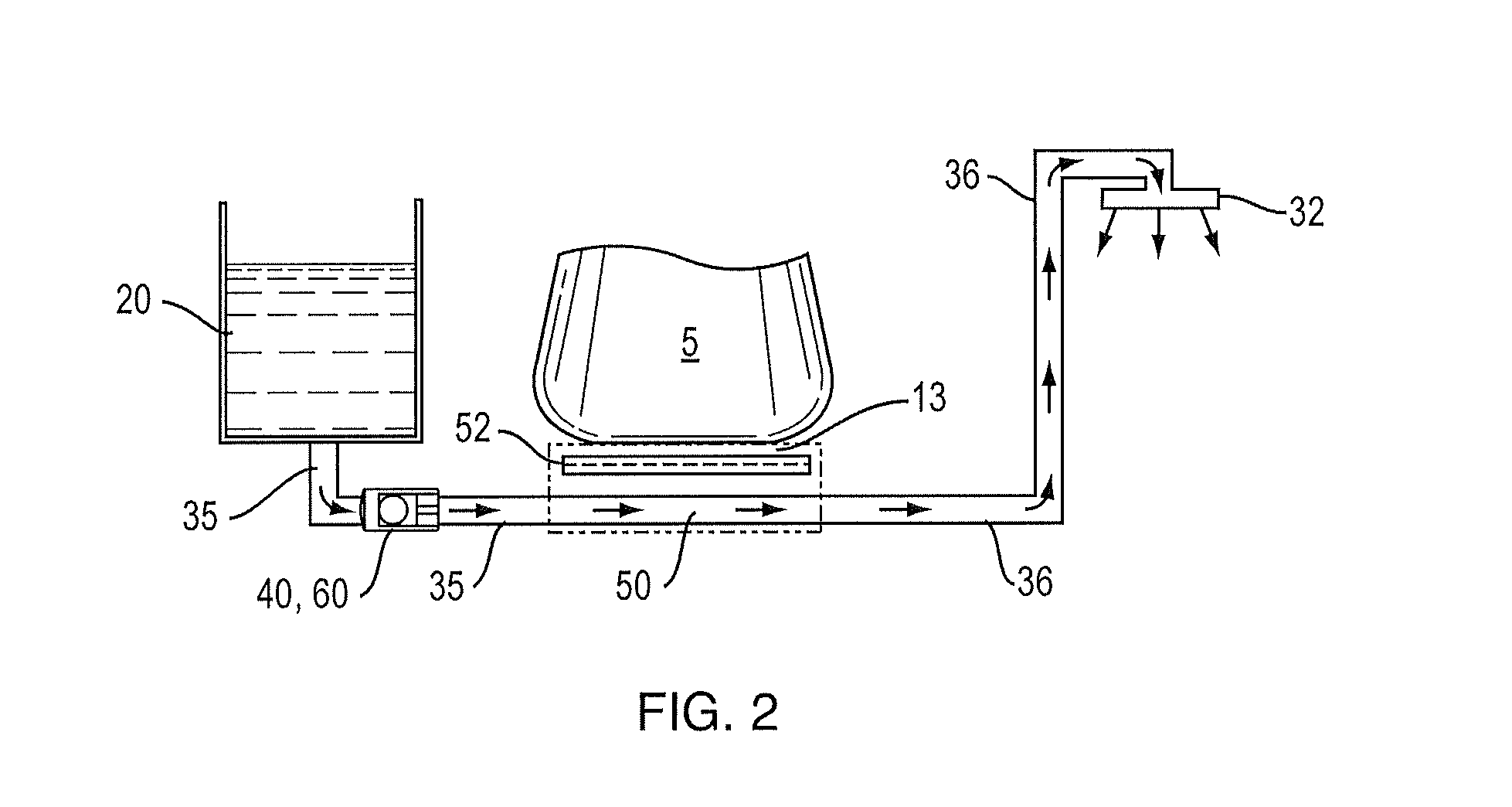

Stop valve for coffee maker

InactiveUS20150282662A1Variation in levelVariation in temperatureCheck valvesBeverage vesselsFresh waterEngineering

Owner:LEVINE HARVEY +1

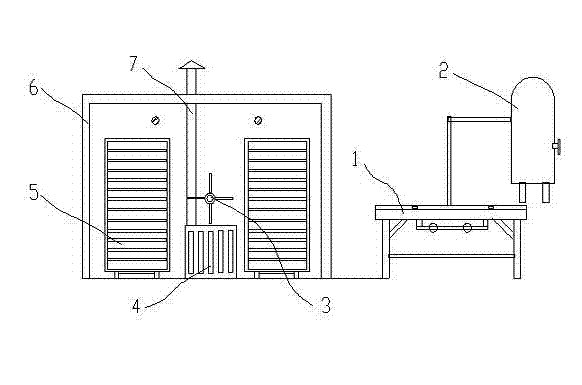

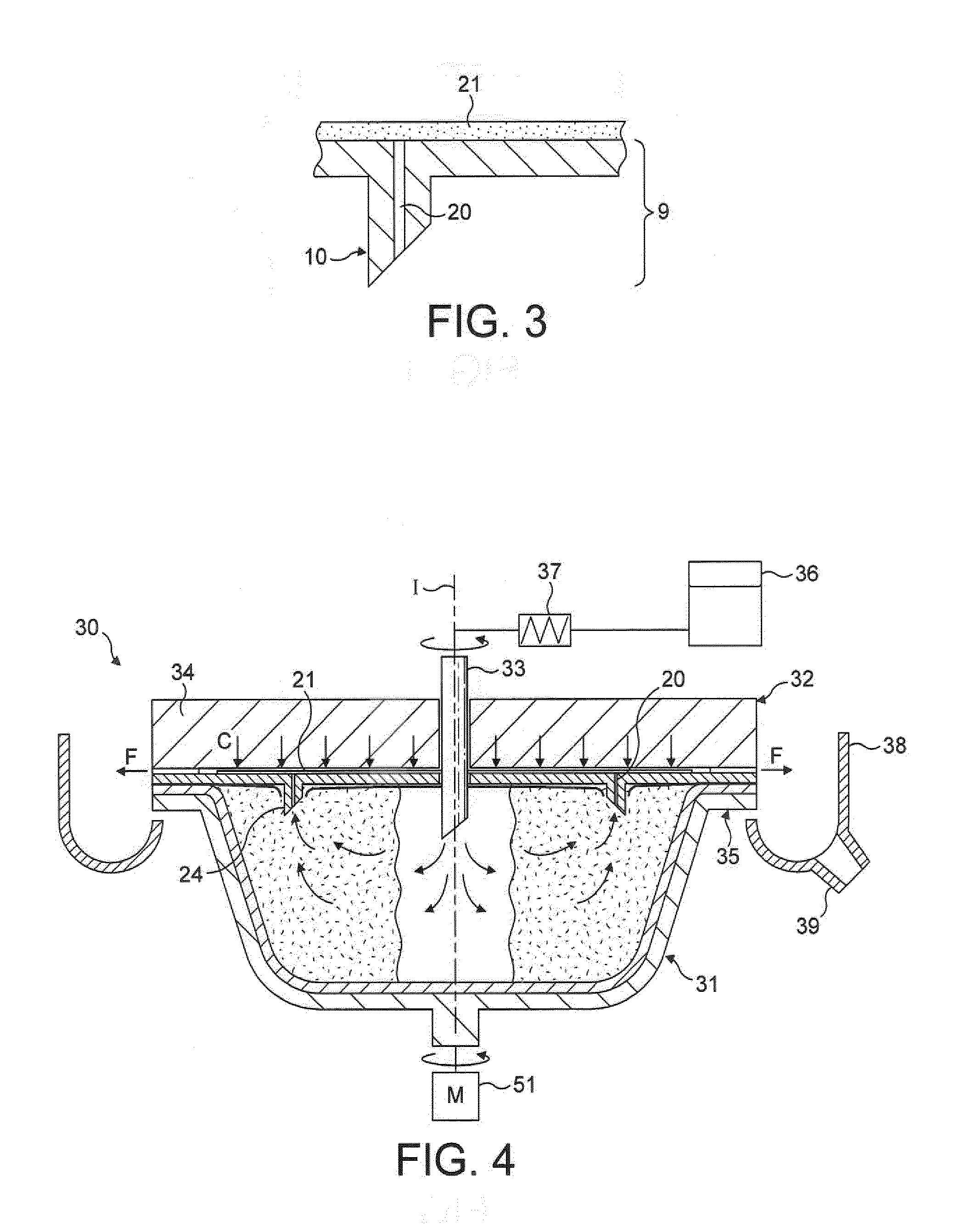

Processing technology and device of white chrysanthemum

The invention relates to the technical field of tea product processing, in particular to production technology and a device of white chrysanthemum tea, aiming to solve the problem of chrysanthemum preservation and the problem that how the fragrant dry chrysanthemum tea with original taste is made. The environmentally-friendly chrysanthemum tea product with pure taste is obtained by steaming and smoking the white chrysanthemum with pure steam, sealing the chrysanthemum in a baking chamber to be baked with dry fire and adopting a pure wooden steam box and smokeless baking equipment.

Owner:淳安县枫树岭中药材专业合作社

Capsule and method for the preparation of a beverage by centrifugation

ActiveUS20130243911A1Easy to brewAvoid liquid short cutsReady-for-oven doughsBeverage vesselsEngineeringBiomedical engineering

Owner:SOC DES PROD NESTLE SA

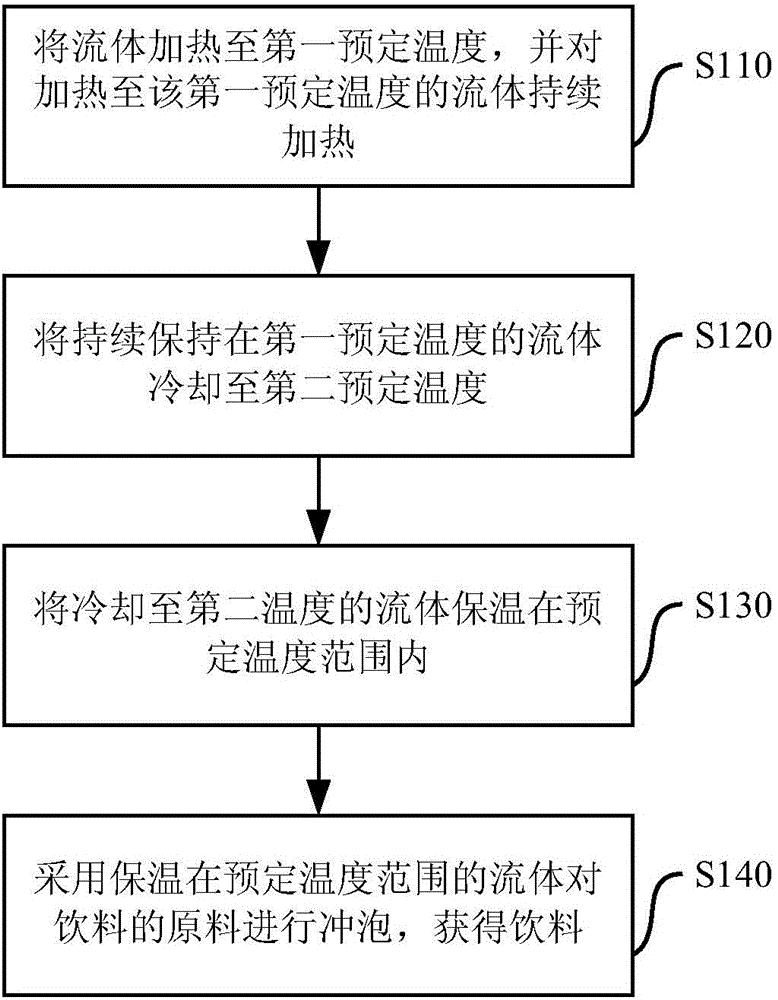

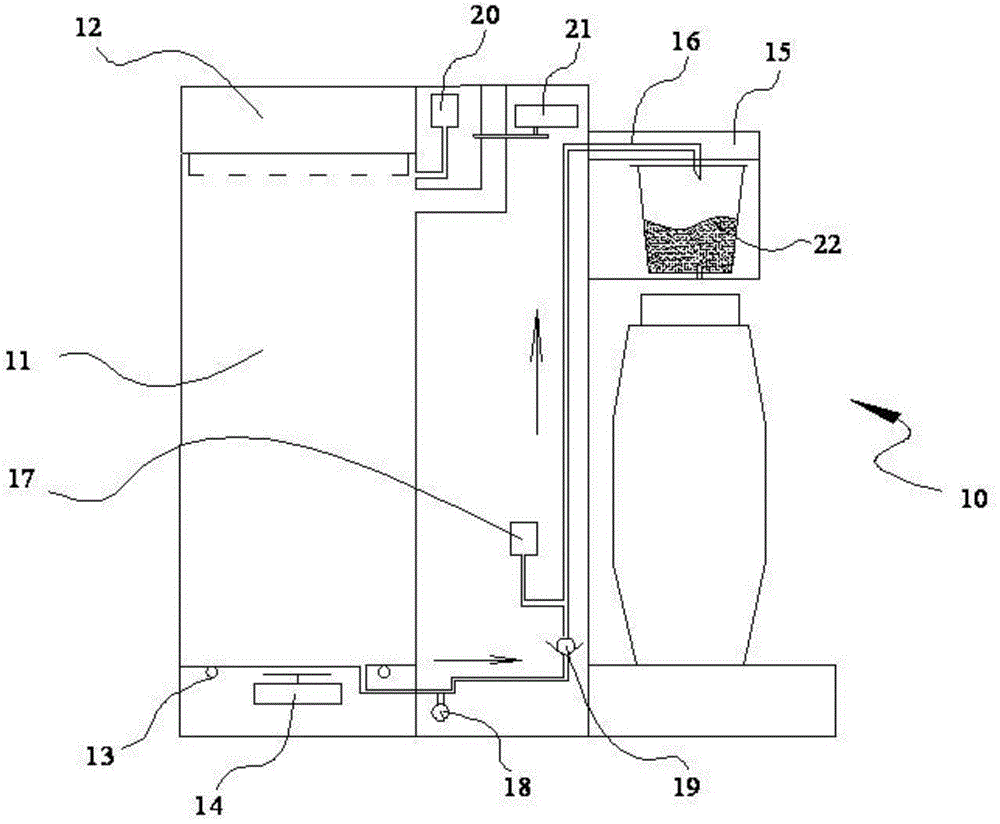

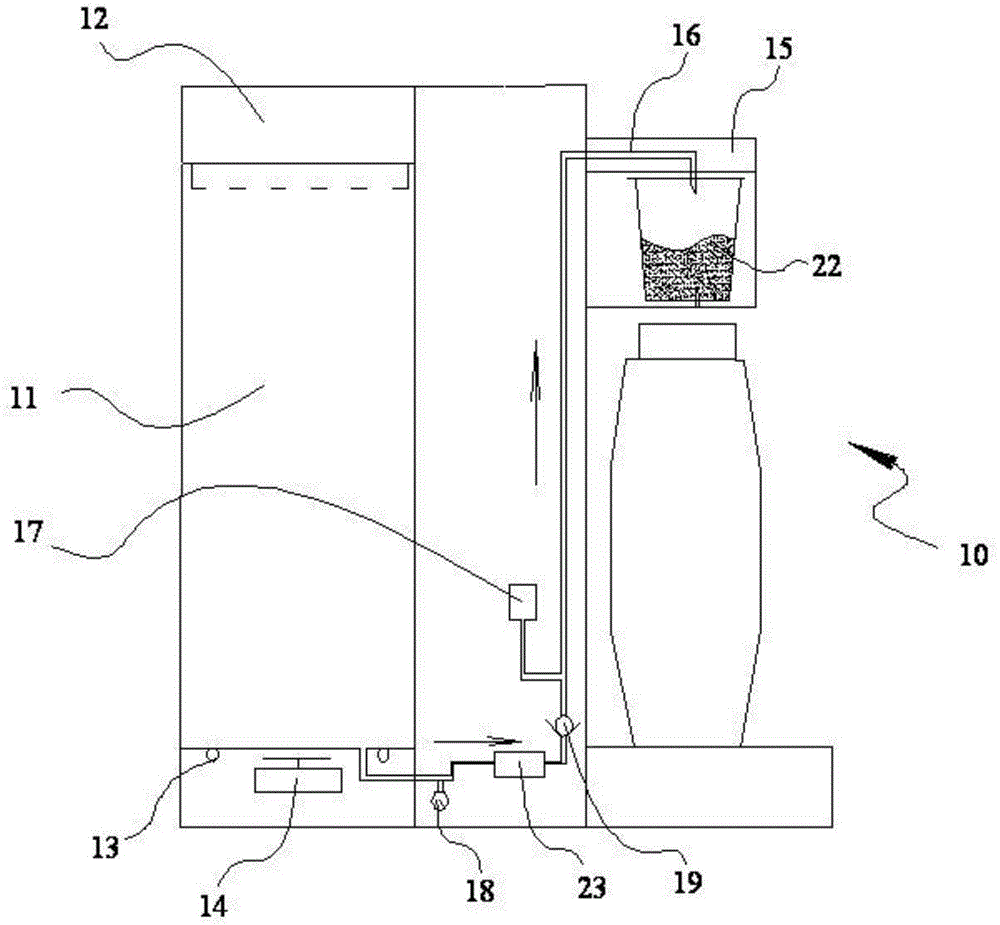

Method and device for brewing beverage

The invention discloses a method and a device for brewing a beverage. The method for brewing the beverage comprises the following steps: heating fluid to a first predetermined temperature; cooling the fluid at the first predetermined temperature to a second predetermined temperature, wherein the second predetermined temperature is lower than the first predetermined temperature; and brewing the raw material of the beverage by using the cooled fluid so as to obtain the beverage. Through the method for brewing the beverage, a user can brew the beverage by using the fluid at the proper temperature; the beverage brewed by the fluid at the proper temperature is better in taste and low in loss of nutritional ingredients.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Tartary buckwheat tea and preparation technology thereof

InactiveCN102934710AExact health benefitsThe composition of the formula is reasonablePre-extraction tea treatmentBiotechnologyGreen teas

The invention discloses a tartary buckwheat tea and a preparation technology thereof. The tartary buckwheat tea is composed of 500 parts to 800 parts of tartary buckwheat cortex powder, 50 parts to 100 parts of tartary buckwheat extractives and 50 parts to 80 parts of green tea powder. The preparation technology of the tartary buckwheat tea includes steps of powder mixing, molding, drying and fragrance improving, the tartary buckwheat cortex powder, the tartary buckwheat extractives and the green tea powder are mixed uniformly until the color is uniform, and the mixture is stood for 20 minutes; uniformly mixed green tea is taken, 25% to 30% of water is added, the mixture is mixed uniformly by a pressurization molding machine and subjected to 30 meshes to be granulated; molded tartary buckwheat granules are placed in a plate and then in a hot air drying box, the granules are dried at a temperature ranging from 50 DEG C to 55 DEG C until the water content is less than 8%, then the dried granules are placed in a far infrared oven to be baked at a temperature ranging from 200 DEG C to 220 DEG C for 2 to 3 minutes and then cooled naturally; and the cooled tartary buckwheat tea is placed in a roller drying oven to be baked at a temperature ranging from 110 DEG C to 145 DEG C until the water content is no more than 5%.

Owner:太原市素有苦荞食品有限公司

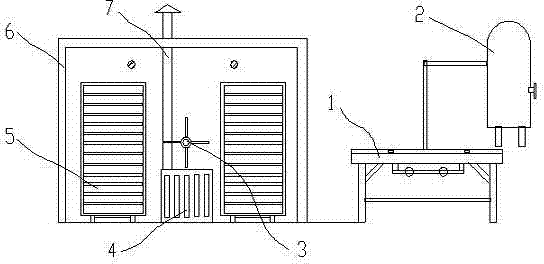

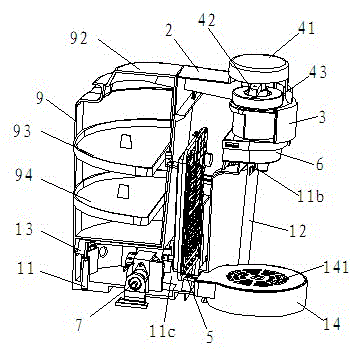

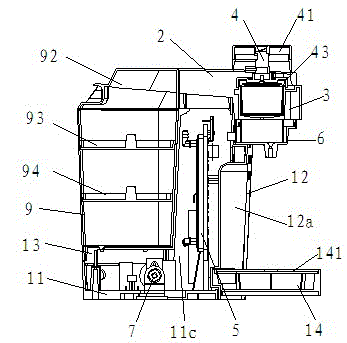

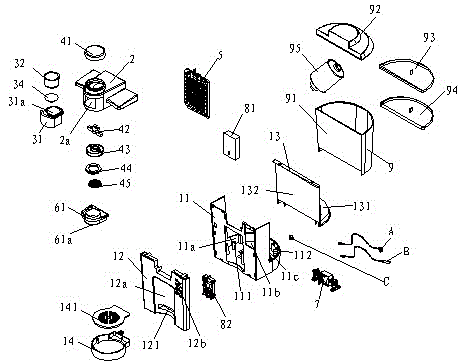

Instant multifunctional tea making machine

ActiveCN102940449AAvoid hidden dangersFlexible and easy to installBeverage vesselsPublic placeWater storage tank

The invention discloses an instant multifunctional tea making machine, which comprises a rack body with a water storage tank. An upper cover is installed on the rack body. A tea making container assembly is installed in the tea making chamber of the upper cover in a slideable pushing and pulling way. A water nozzle part which is communicated with the tea making container assembly is installed at the lower opening of the tea making chamber. An upper sling filter screen assembly which spirally locks the tea making container is installed at the upper opening of the tea making chamber. A quick heating plate which is used for providing tea making water for the tea making container assembly and a micro water pump which is used for quantitatively providing water for the quick heating plate are installed in the rack body. The quick heating plate and the micro water pump are controlled by an intelligent control module. The intelligent control module is connected with a key board. The key board can be used for manually inputting command signals. The intelligent control module can control the micro water pump and the quick heating plate to make a cup of tea with needed temperature each time in a programmed way according to the command signals. The instant multifunctional tea making machine has the advantages of high safety and reliability, stable operation and convenience in operation, and is suitable for families, offices, vehicles and various public places.

Owner:蚌埠航宇知识产权服务有限公司

Angelica keiskei compound teabag and preparation method thereof

InactiveCN104222441AImprove diastolic propertiesEnhance cell viabilityTea substituesFlavorUltra high pressure

The invention discloses an angelica keiskei compound teabag and a preparation method thereof. The teabag is composed, by weight, of 28-32 parts of angelica keiskei, 12-16 parts of hippophae rhamnosides leaves, 3-5 parts of perilla leaves, 14-18 parts of white orchid, 6-8 parts of loquat flower and 17-21 parts of walnut flower. The preparation method includes the steps of cleaning all raw materials, removing impurities, performing ultralow temperature cryogenic grinding and vacuum freeze drying, mixing according to the formula ratio, and performing ultra-high pressure sterilization and sealed packaging to obtain a finished product. The angelica keiskei compound teabag prepared through the preparation method greatly maintains nutritional values and functional components of angelica keiskei and other plant materials, has health effects of immunity enhancing, blood pressure reducing, fat removing, heat clearing, detoxification, lung moistening to arrest cough and the like, and is clear in tea soup, heavy in tea aroma, mellow in flavor and harmonious in taste after brewing. The raw materials of the teabag are natural, non-toxic, wide in sources and low in costs. The teabag is easy to product, high in quality, easy to brew and suitable for daily drinking.

Owner:SHAANXI DATONG YONGSHOU ECOLOGICAL DEV

Tea and its preparation method

InactiveCN1830284AEasy to brewHeat-clearing and detoxifyingMetabolism disorderDigestive systemVeinLower blood pressure

A tea for antipyresis, detoxication, lowering blood pressure, decreasing blood fat, losing weight, etc is prepared from lotus leaf through washing, removing veins, disinfecting in high-temp water, cutting for shaping, kneading, backing, drying and kneading.

Owner:严介龙

Blueberry green tea bag

The invention discloses a blueberry green tea bag. The blueberry green tea bag comprises a brewing bag and blueberry green tea sealed in the brewing bag, the blueberry green tea is prepared by fresh blueberry leaves, and the processing procedures include fresh leaf picking, water-removing, a first rolling, stir-frying, a second rolling, drying and the like. The blueberry green tea bag has the advantages that the blueberry green tea bag is free of caffeine, the brewing is convenient, the leaching speed of soluble matters in tea-leaf is fast, the leaching is thorough, brewed tea water tastes fresh and fragrant, the color of the tea water is pleasant, the tea is rich in tea polyphenol and anthocyanin, and the blueberry green tea bag has heath care effects of anticancer, preventing cardiovascular and cerebrovascular diseases, restraining free radicals, antianaphylaxis, improving human body comprehensive immunity, and the like.

Owner:开原景隆现代农业综合开发有限公司

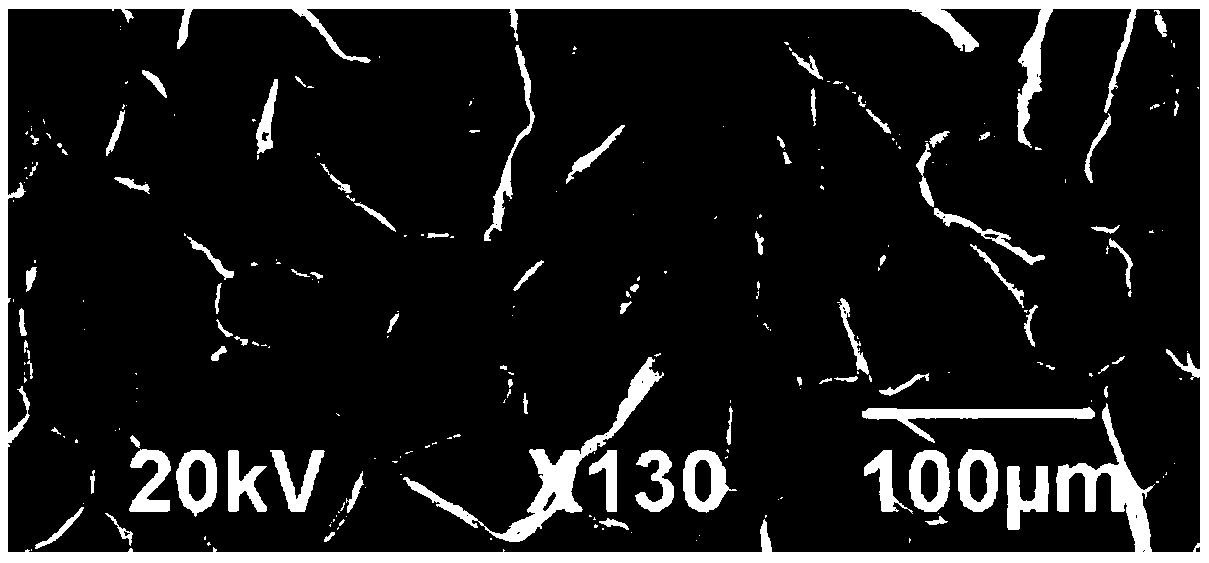

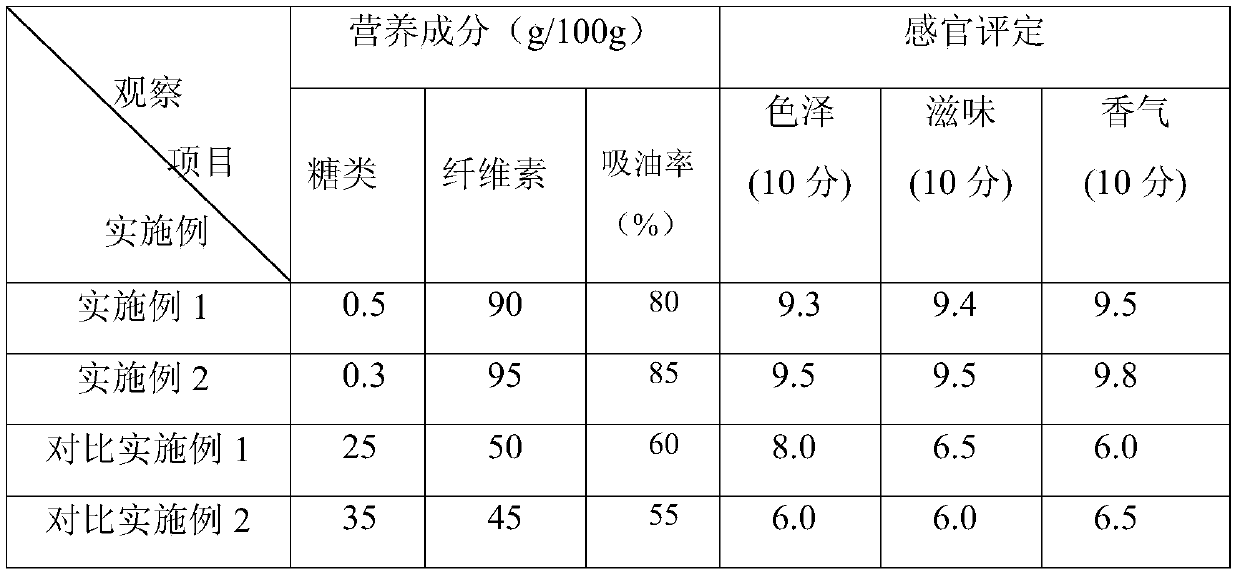

Porous coarse cereal flour including dietary fibers

ActiveCN105495314AProtect healthAchieve lipid-lowering effectFood ingredient functionsFood ultrasonic treatmentNutritive valuesDietary fibre

The invention relates to porous coarse cereal flour including dietary fibers. Mung bean shell, corn husks and sorghum husks are taken to be thoroughly washed and aired; a glycollic acid solution is used for soaking, and the mixture is put into an ultrasonic cleaner to be cleaned; drying is carried out, and the mixture is smashed into powder; fresh pumpkin peel residues, sweet potato peel residues, kudzu vine skin residues, Chinese yam peel residues and lotus root peel residues are cleaned, smashed, blanched with boiling water and cooled, the temperature is kept at 30 DEG C to 35 DEG C, amylase is added for enzymolysis, and enzyme deactivation is carried out; saccharomycetes and lactic acid bacterium inoculation is carried out, and the humidity of the aerobiotic and anaerobic fermentation environment is 85%; cleaning, filtering, precipitation and drying are carried out, and then the mixture is smashed into powder; coarse cereal husk powder, coarse cereal residue powder and Konjac powder are taken, a flavoring agent is added, and the porous coarse cereal flour including the dietary fibers is obtained. Ethyl alcohol is used for ultrasonically eluting the coarse cereal husks, amylase, saccharomycetes and saccharomycetes are added to the husk residues for mixed fermentation, the nutritive value of coarse cereals is improved, and a high healthcare function is achieved. Meanwhile, all the portions of the coarse cereals are reasonably utilized, the best use of the coarse cereals is achieved, cost is reduced to a certain degree, and economic benefits are increased.

Owner:HUBEI UNIV OF TECH

Preparation method and product of tuan-shaped black tea (tuan is a Chinese character)

InactiveCN103493910AEasy to drinkImprove pressure resistancePre-extraction tea treatmentChinese charactersBlack tea

The invention discloses a preparation method of tuan-shaped black tea (tuan is a Chinese character). The method takes bulk tea of finished black tea as raw tea and comprises the following specific steps: (1) humidifying and softening the raw tea and carrying out mould pressing on the softened raw tea to form tuan-shaped raw tea; (2) drying the tuan-shaped raw tea into the tea with the predetermined water content through using vacuum dehumidification, optical wave heating and / or microwave heating and cooling means to obtain the required tuan-shaped black tea. The method provides a feasible technical way for preparing different types of the bulk tea of the black tea into the tuan-shaped black tea; the tuan-shaped black tea brings a brand-new black tea drinking way to people and can be conveniently drunk by the people.

Owner:林志宾

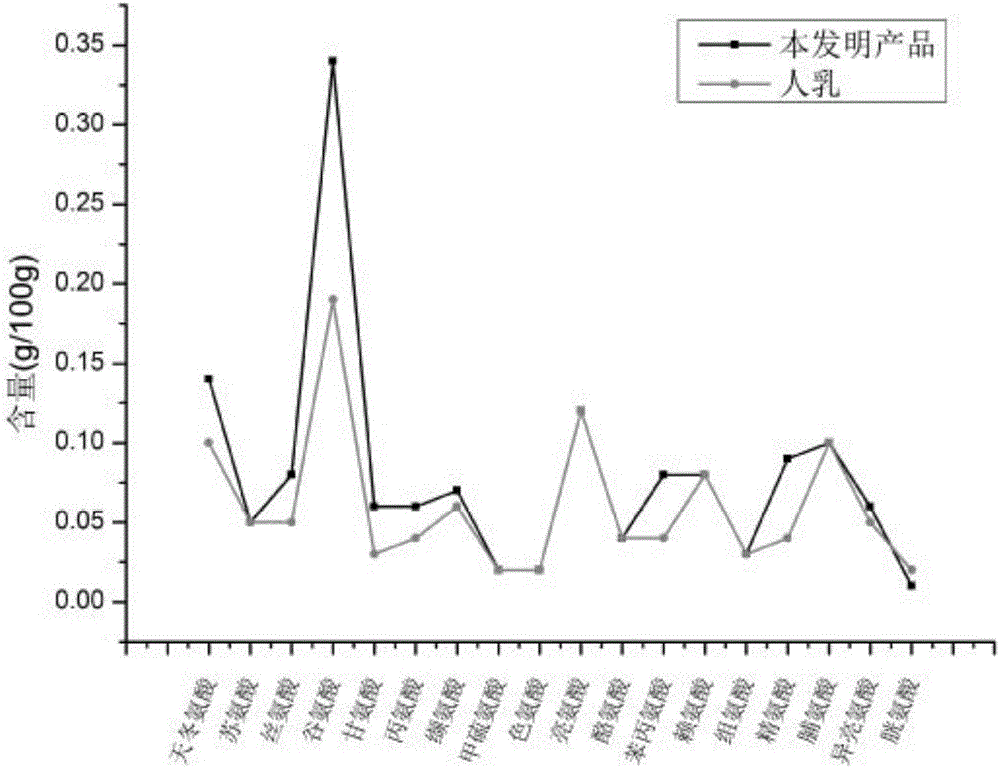

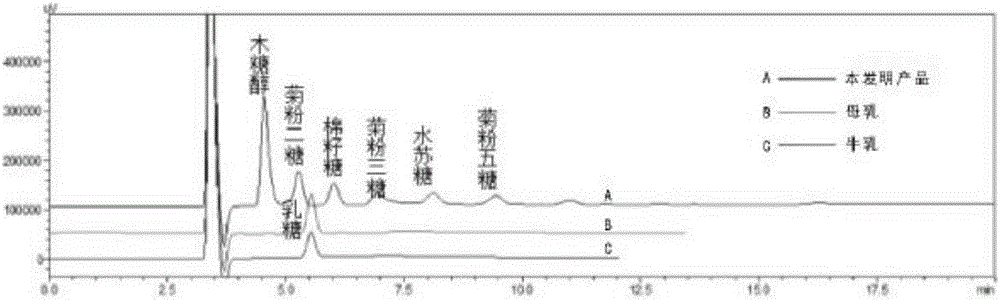

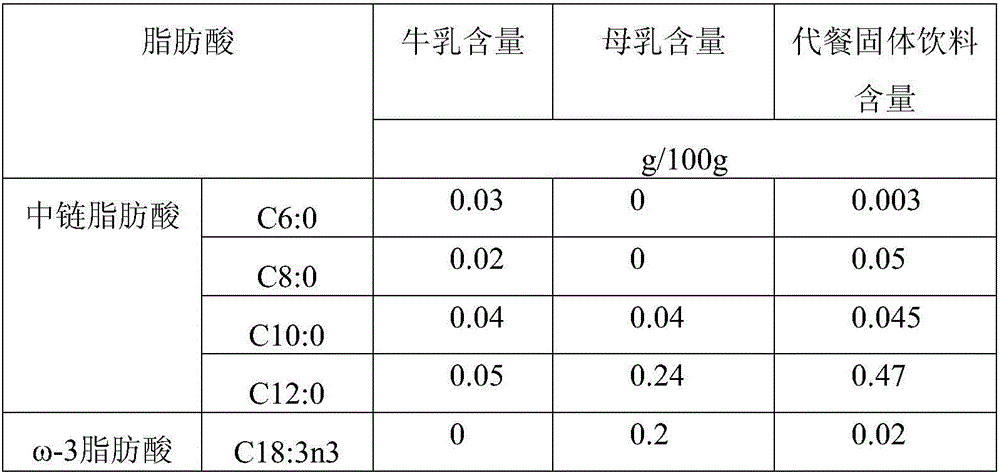

Meal replacement solid drink and preparation method thereof

ActiveCN106360233ARich in nutrientsImprove liquidityLipidic food ingredientsFood dryingAdditive ingredientMoisture absorption

The present invention relates to meal replacement solid drink. The meal replacement solid drink comprises the following components in mass percentages: 20-40% of cereal flour, 10-50% of coconut oil powder, 5-50% of soybean protein isolate, 5-20% of xylitol, 1-20% of wheat oligopeptides, 1-10% of inulin and 1-20% of lotus root starch. The present invention also relates to a preparation method of the meal replacement solid drink. The meal replacement solid drink is comprehensive in nutrients, rich in 18 reasonably matched amino acids, a pure-plant, high-protein and low-fat healthy food, and helps to improve the immunity of the body. In addition, the meal replacement solid drink is simple in preparation technology, wherein the xylitol is treated separately from the other components so as to avoid moisture absorption during the processing, thereby the stability of the product is increased, and the various ingredients are sieved using 30-mesh sieves, so that the prepared meal replacement solid drink has relatively good stability and is more easy to brew.

Owner:NINGBO YUFANGTANG BIOTECH

Olive tea and preparation method thereof

The invention discloses an olive tea which comprises the following components in parts by weight: 40-70 parts of olive leaves, 30-50 parts of honeysuckles, 20-40 parts of chrysanthemums and 10-30 parts of honey. The invention also discloses a preparation method for the olive tea. The preparation method is simple in operation step; no special equipment is required; the operation is easily performed; the production cost is low; the prepared olive tea has excellent brewing property; after being brewed, the olive tea has beautiful color, special flavor and good taste; the olive tea is suitable for most people; and the olive tea has the effects of decreasing cholesterol, decreasing blood sugar, resisting aging, and the like.

Owner:四川文理学院

Preparation method of ashitaba tea

The invention discloses a preparation method of ashitaba tea. The preparation method comprises the following steps: processing tender shoots of ashitaba by steaming blanching; hydrating; fermenting with lactic acid bacteria; drying at low temperature; rolling; and drying. With the adoption of the preparation method, the grass smell of ashitaba is fundamentally removed, the bad taste like astringency and piquance can be avoided; and when brewing, the ashitaba tea soup is clear and transparent, faint scent, tastes pure and mild, and has a good drinking effect. The method is simple in process, low in preparation cost, out of environmental pollution, and beneficial for industrial production, and brings a new method for effectively utilizing ashitaba.

Owner:徐州绿之野生物食品有限公司

Health-care tea for nourishing yin and nourishing blood and its processing method

InactiveCN102293292ANourishing yin and nourishing bloodBeautyTea substituesAging resistanceActive component

The invention discloses health tea with functions of yin nourishing and blood nourishing, and a processing method thereof. The health tea is prepared through the following steps: carrying out the extraction with ultrasonic frequency for common jujube, medlar, ass-hide gelatin, tuckahoe and other components in the ethanol; condensing the extracting solution to obtain extract; drying and crushing the residues of the drugs to obtain the residue powder of the drugs; mixing the residue powder of the drugs and the extract, then carrying out pelletizing to obtain the health tea. According to the present invention, the health tea has effects of yin nourishing and blood nourishing, face and skin beautifying, fatigue resistance, aging resistance, improvement of immune function, and the like; with adopting the ultrasonic extraction, the dissolving-out amount of the active components in unit time in the extracted material can be improved; especially that, the residue powder of the drugs and the extract are firstly separated, then are subjected to mixing and drying, such that the resulting health tea is easy to be brewed, the loss of the active components is small, the health tea is easy to beabsorbed by the user so as to substantially improve the effects.

Owner:USU SHENGWEI BIOENG CO LTD

Processing method for green tea from macadamia ternifolia leaves

The invention discloses a processing method for green tea from macadamia ternifolia leaves. The processing method comprises the following technological steps: fresh leaf picking, sun-withering and burn-withering treatment, primary kneading, rocking-withering, blending, withering, fixation, secondary kneading, primary drying, shaping, drying and the like. According to the processing method, fresh sugarcane leaves and the fresh macadamia ternifolia leaves are used as raw materials, the sun-withering and rocking-withering techniques of oolong tea are combined onto the traditional green tea processing techniques, the bitterness degree of the taste is reduced, and the flowery flavor of the oolong tea is improved; meanwhile, the large leaves are tightly wound to be screwed by utilization of a shaping machine, so that the dried tea is relatively compact and aesthetic in appearance and easy to package, and in addition, is mellow in taste and rich in flowery flavor.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Lipid-lowering tea and production method thereof

InactiveCN101390547AInhibition of denaturationReduce formationPre-extraction tea treatmentMetabolism disorderFatty liverLow density lipoprotein cholesterol

A lipid-lowering tea and a production method relate to the production process of bagged tea. The invention mainly comprises raw hawthorns, cassia seeds, lotus leaves and black tea. The invention can obviously inhibit the increase of total cholesterol (TC), low-density lipoprotein cholesterol (LDL-C), triglycerides (TG) and atherosclerosis index (CAI) of serum, improve the high-density lipoprotein cholesterol (HDL-C) and anti-atherogenic index (AI), prevent fatty liver degeneration, slow and inhibit the formation of atherosclerotic plaque. The tea is of food class, which ensures the taste and has the specific effect; long-term tea drinking causes no toxic side effects; besides, the lipid-lowering tea is convenient and can be used in daily life, working, tourism and leisure time, and the user can enjoy health-care in tea drinking.

Owner:李国柱 +2

Golden camellia dark tea and processing technology thereof

ActiveCN106720556AReduce moisture lossPromote conversionPre-extraction tea treatmentChemistryFermented tea

The invention discloses golden camellia dark tea and a processing technology thereof. The golden camellia dark tea is prepared from, by weight, 30-80% of fresh leaves of golden camellia tea and 20-70% of loose tea of finished dark tea products. The processing technology comprises the steps of preparation, fixation, rolling, mixture storage, moisture regaining, fermentation, drying, aroma increasing and filling. The golden camellia dark tea is organic integration of ingredients, beneficial to the human body, in the golden camellia tea and the dark tea, compared with the golden camellia tea and the dark tea, the golden camellia dark tea is higher in health care efficacy, the cold nature of golden camellia tea leaves is eliminated, the taste is improved, and consumer groups are expanded.

Owner:广西国茗金花茶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com