Patents

Literature

137 results about "Cryogenic grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyrogenic grinding, also known as freezer milling, freezer grinding, and cryomilling, is the act of cooling or chilling a material and then reducing it into a small particle size. For example, thermoplastics are difficult to grind to small particle sizes at ambient temperatures because they soften, adhere in lumpy masses and clog screens. When chilled by dry ice, liquid carbon dioxide or liquid nitrogen, the thermoplastics can be finely ground to powders suitable for electrostatic spraying and other powder processes. Cryogenic grinding of plant and animal tissue is a technique used by microbiologists. Samples that require extraction of nucleic acids must be kept at −80 °C or lower during the entire extraction process. For samples that are soft or flexible at room temperature, cryogenic grinding may be the only viable technique for processing samples. A number of recent studies report on the processing and behavior of nanostructured materials via cryomilling.

Smooth, flexible powder coatings

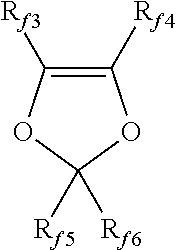

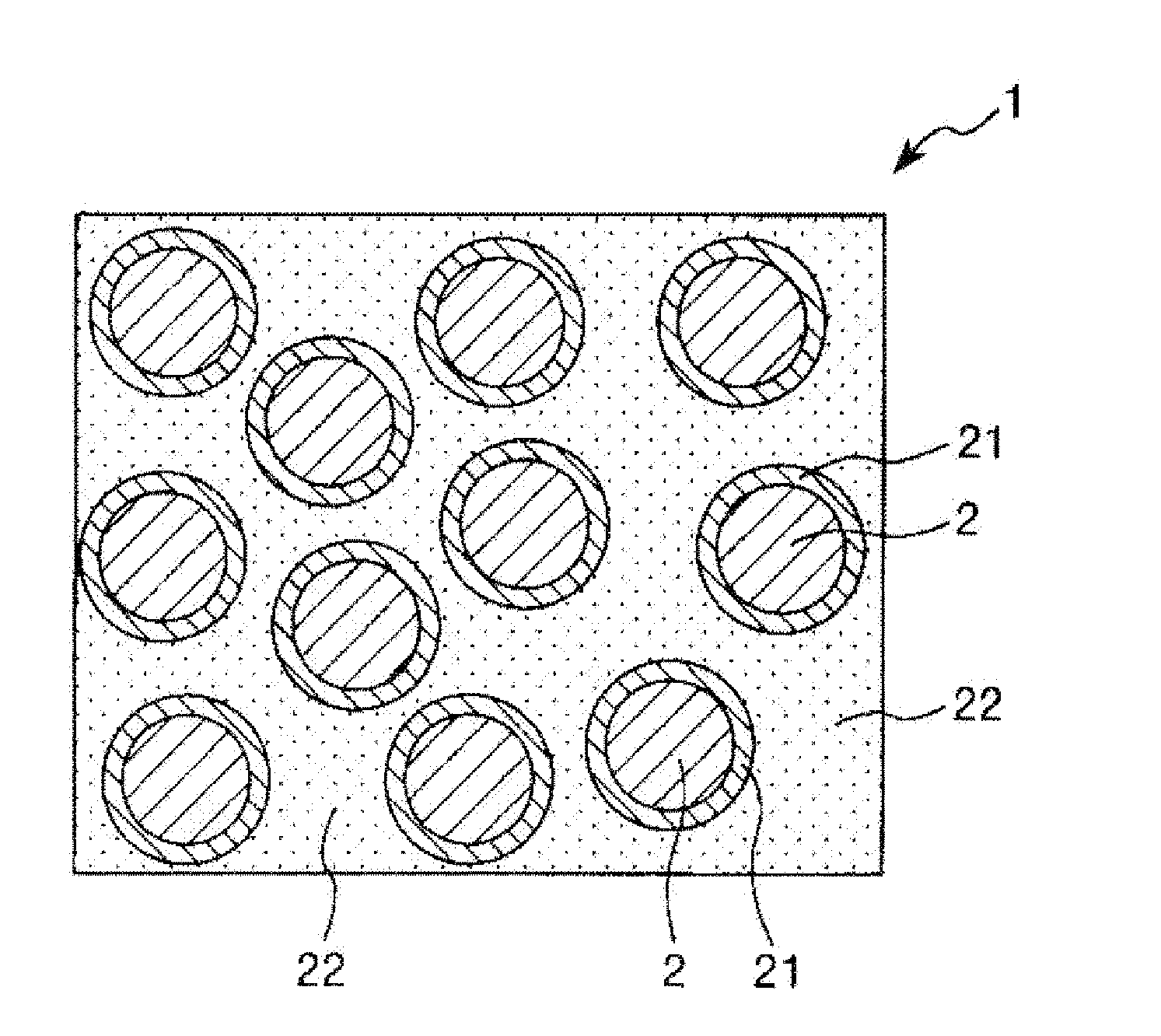

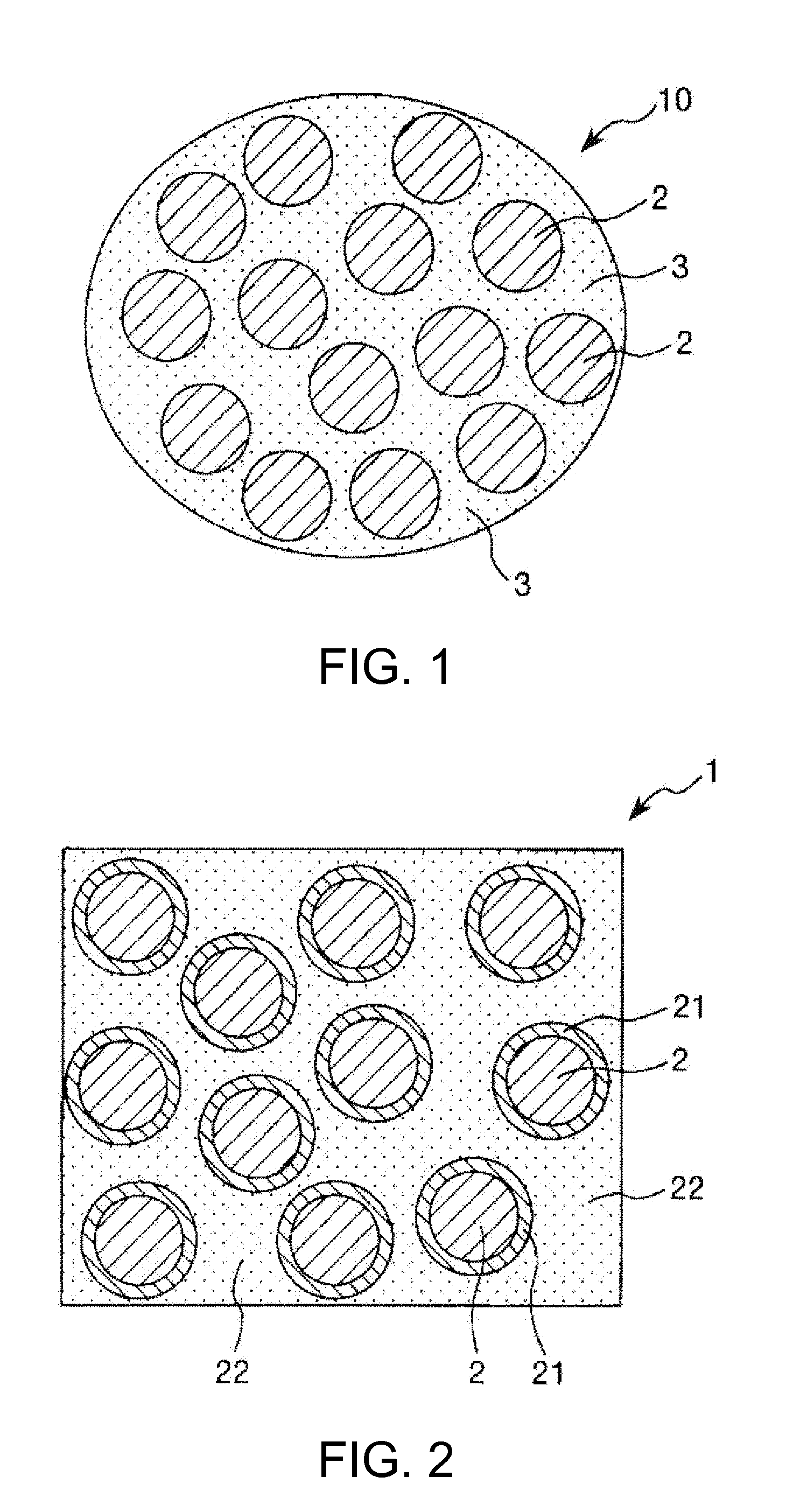

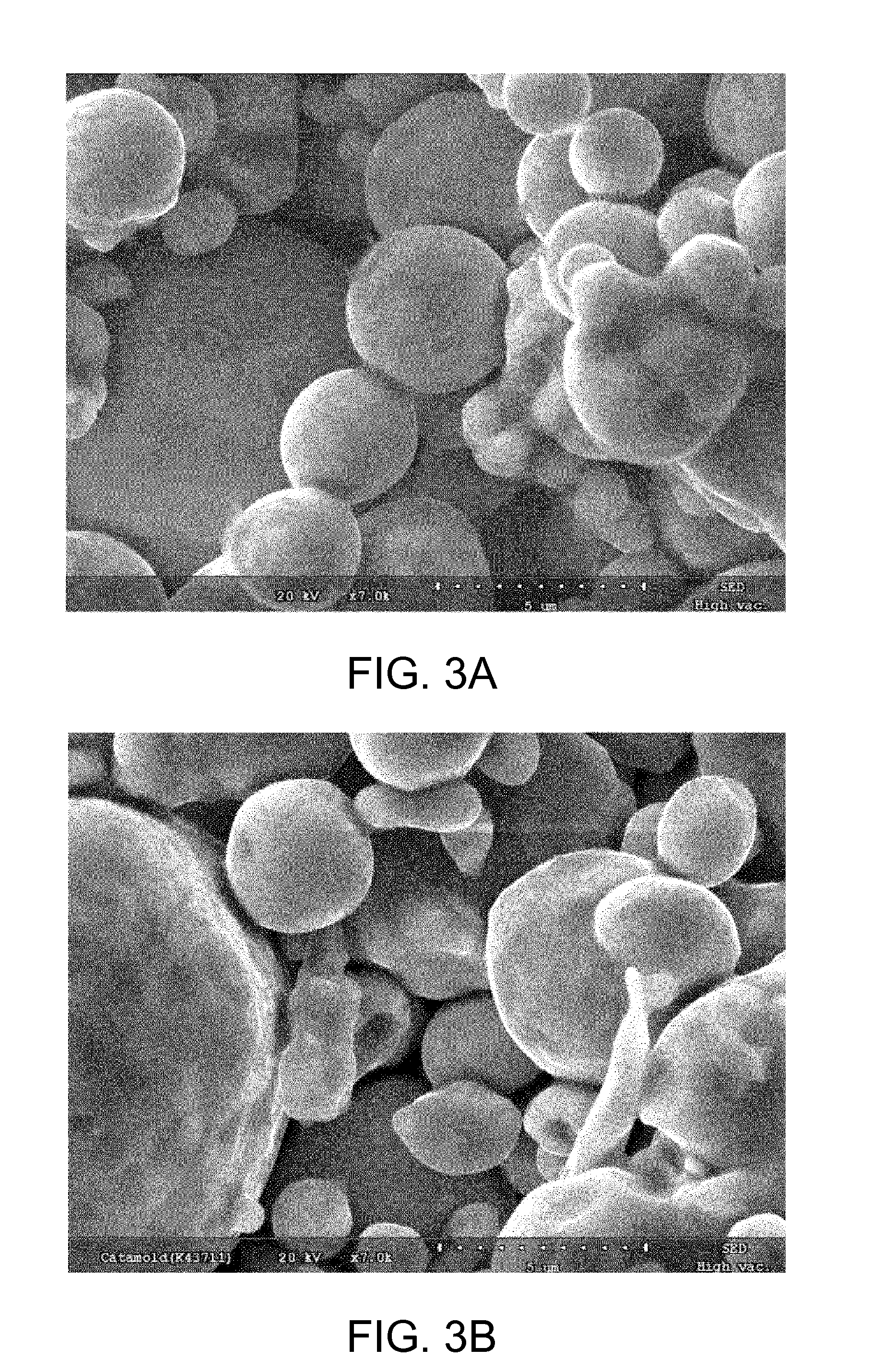

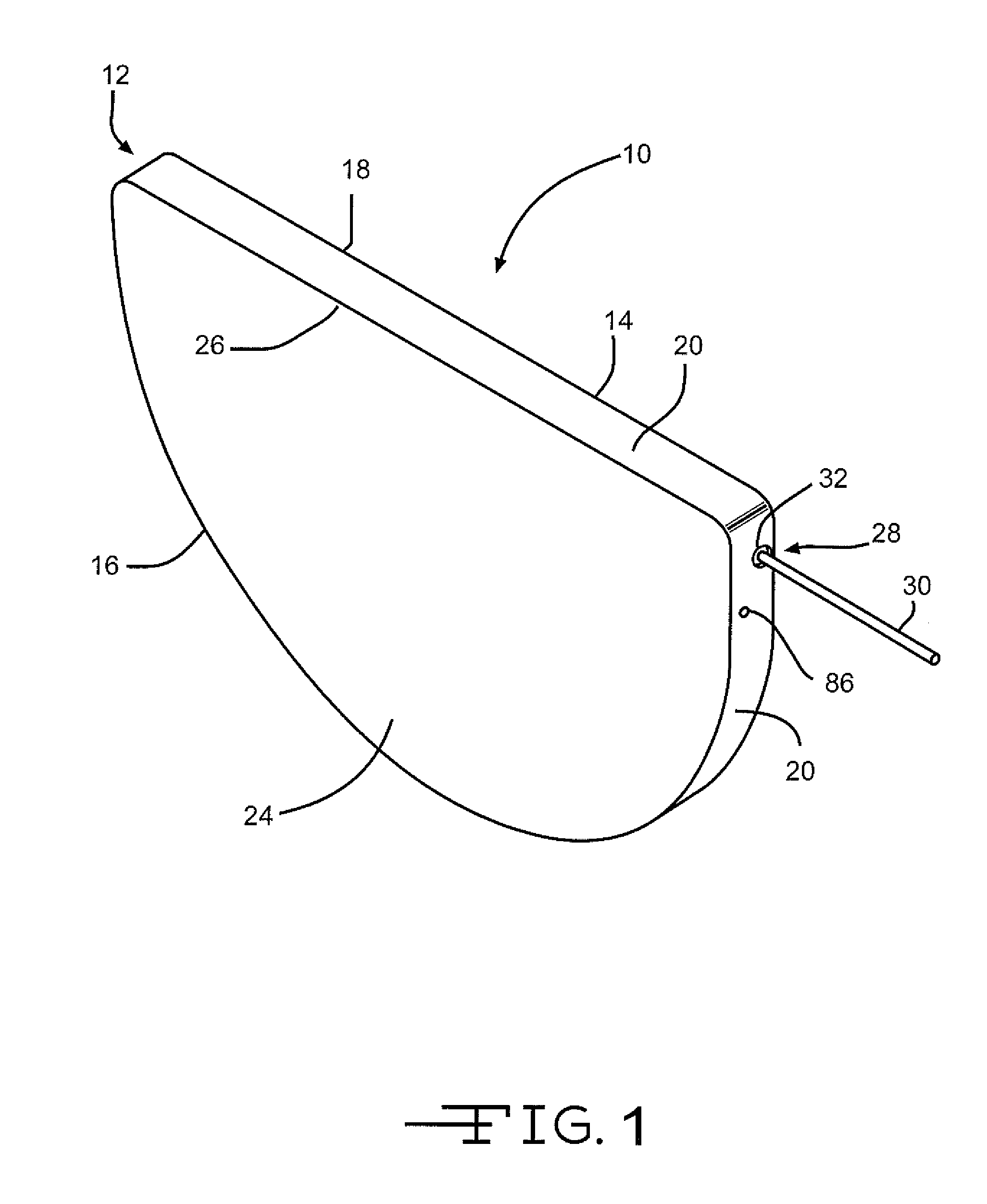

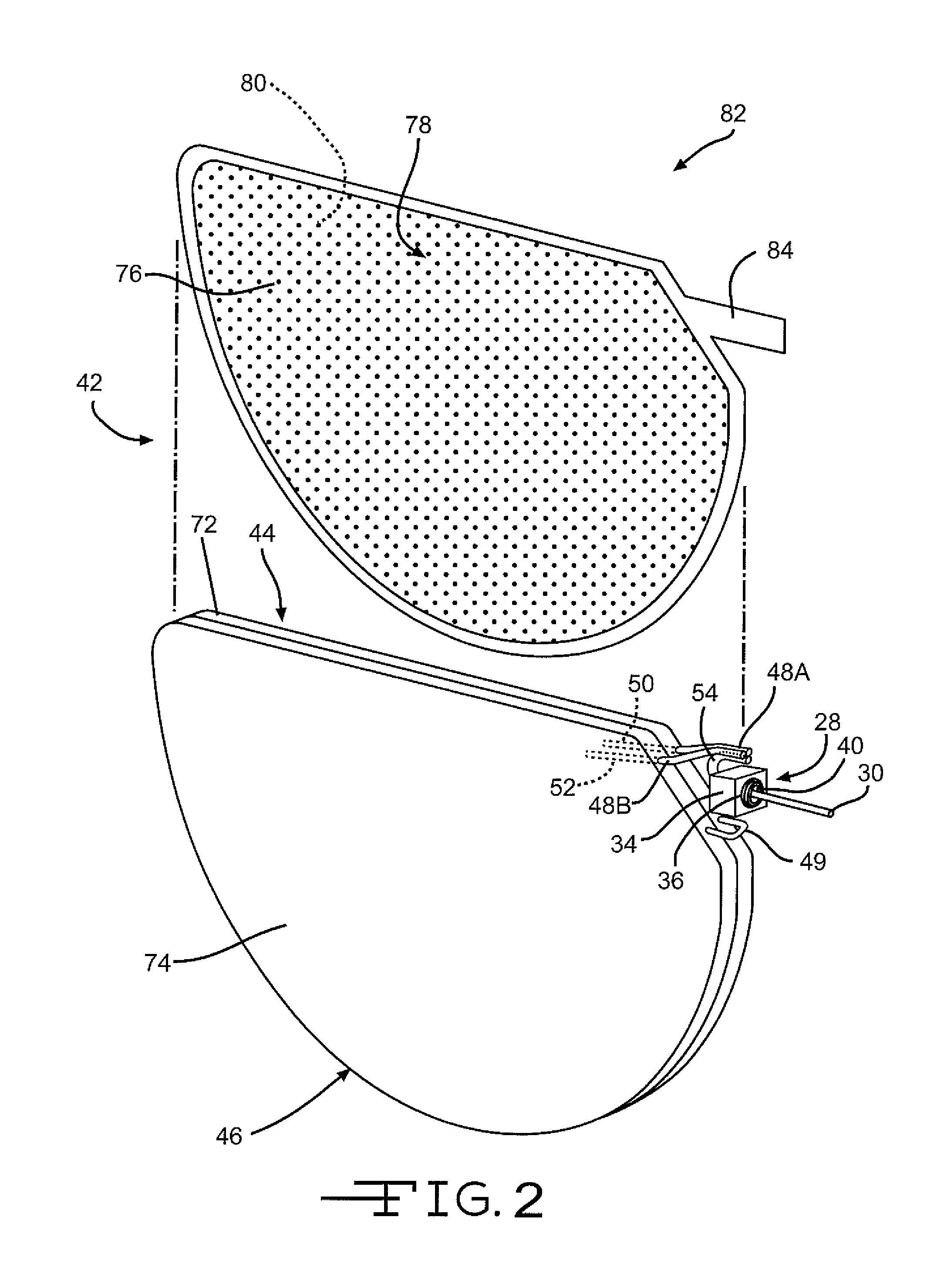

The present invention, a powder composition for making powder coatings comprising one or more than one curable polymer or resin and an agglomerate of a core-shell polymer, wherein the agglomerate of a core-shell polymer has an average particle size of from 5 to 190 microns, preferably from 10 to 127 microns. The powders in accordance with the present invention provide a cured powder coating that is flexible, smooth, and which may be applied in a thickness of only from 0.3 to 8 mils. In a preferred embodiment of making a powder in accordance with the present invention, the agglomerate is cryoground to form a reduced agglomerate prior to adding it into a powder as a post-blend or a powder-forming mixture as a preblend. The preferred core-shell polymer for use in accordance with the present invention comprises an acrylic impact modifier having a poly(methyl methacrylate) shell and a poly(butyl acrylate) core. Further, the preferred curable polymer or resin powder is an epoxy resin, wherein the powder composition is a low temperature curing one component powder composition which cures at from 107 to 149 degrees C.

Owner:ROHM & HAAS CO

Medlar and red date enzyme and preparation method thereof

InactiveCN104872674AKeep natural colorImprove biostabilityNatural extract food ingredientsFood ingredient functionsRipeningHigh pressure

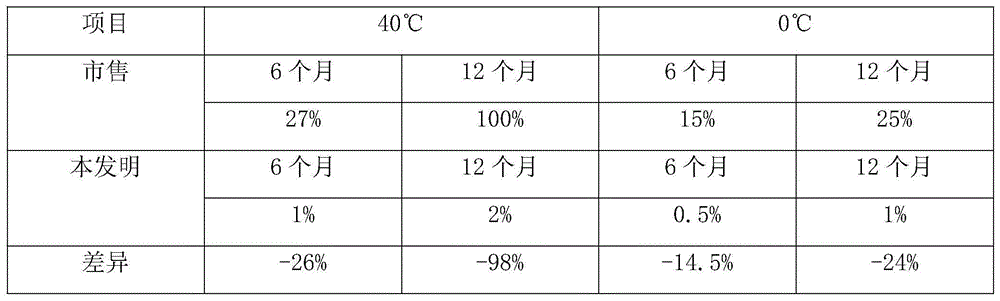

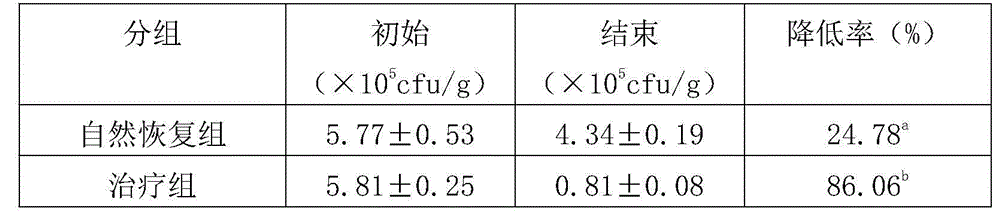

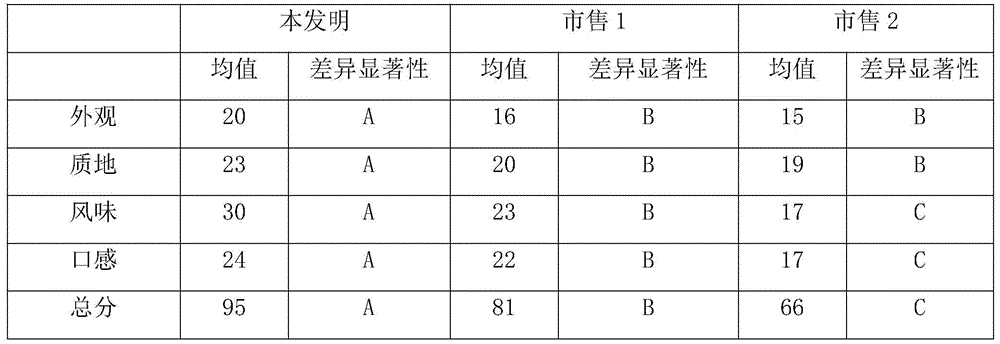

The invention discloses a medlar and red date enzyme and a preparation method thereof, which belong to the technical field of enzyme preparation. Multi-strain composite fungi powder is adopted as a leavening agent; the medlar and the red date are adopted as main raw materials; dietary fiber, pectin hydrolyzate, seasoner extracting liquor, Chinese herbal medicine extracting liquor, enzyme stabilizer and other multifunctional auxiliary raw materials are scientifically compounded and modified; low-temperature processing technology such as ultrasonic cleaning, cryogenic grinding, microwave-assisted high-voltage pulse electric field processing and ultrasonic ripening are mainly adopted in the whole process, so that the natural colors, the flavor, the taste and the content of the active materials of the medlar and the red date are maintained furthest, the biological stability, the non-biological stability and the biological activity of the medlar and red date enzyme are obviously enhanced, the introduction of chemical addition agent is reduced, and the juicing rate of the medlar and the red date as well as the food safety of the enzyme are improved. Finally, the medlar and red date enzyme with high biological activity, strong stability, strong taste, flavor and appetite, long expiration date and edible safety is prepared.

Owner:NINGXIA JINSHANGQI BIOTECH

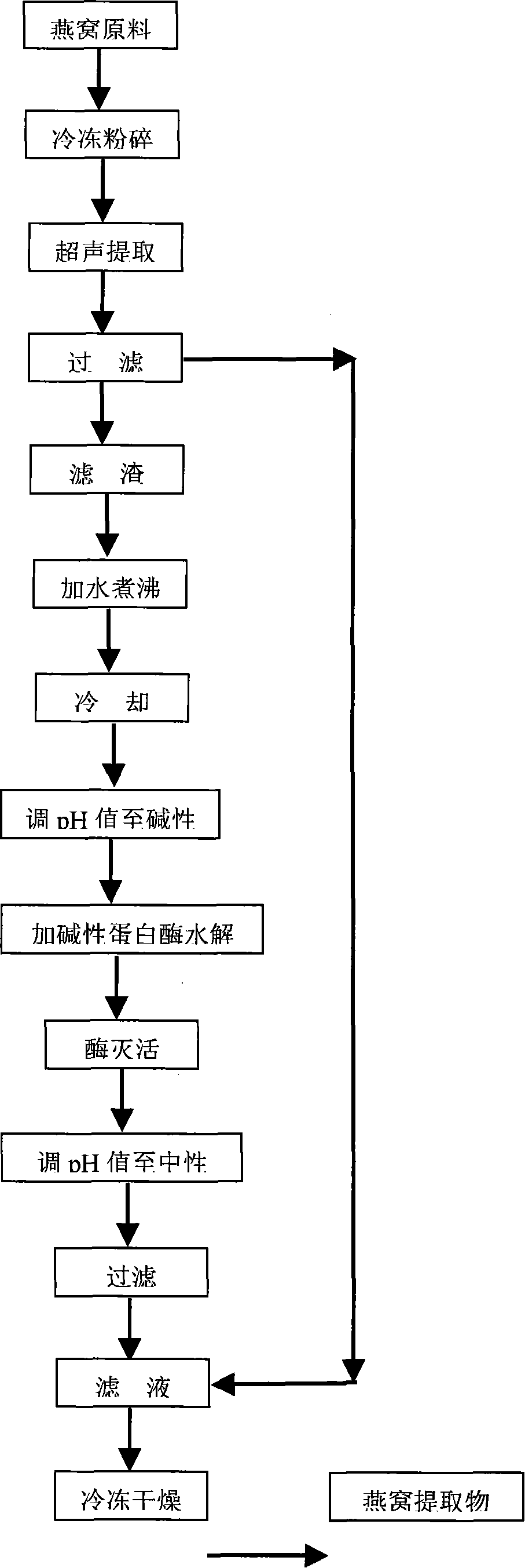

Process for preparing edible bird's nest extraction used for cosmetics

ActiveCN101084873AReasonable molecular weight distributionEasy to operateCosmetic preparationsToilet preparationsWater bathsSolubility

The invention discloses a method for preparing cubilose extract used in cosmetics. Steps are as follows: (1) cryogenic grinding cubilose, sieving, adding water 20 times the weight of the dry cubilose, ultrasonic extracting at room temperature for 1h, filtering, (2) adding water 30 times the weight of the dry cubilose into the filter cake, boiling for 60 minutes under mechanical stirring, (3) cooling to room temperature, regualting pH to 9.8 with Na2CO3 solution, adding alkali protease 1.5% the weight of the dry cubilose, carrying out hydrolysis in water bath at 55deg.C under mechanical stirring, (4) deactivating enzyme at 85deg.C for 20min, (5) cooling to room temperature, regulating pH to neutrality with thin HCl, (6) filtering, combining the filtrate with ultrasonic extract, and freeze drying to obtain powdered cubilose extract. The invention has simple process, good extract water-solubility, high extraction yield, rational product molecular weight distribution, good wetness protection, high product whitening activity, and good product stability; and avoid the influence of boiling to the thermo instable active ingredient in hydrolysis technology. The obtained cubilose extract is suitable for using as cosmetic compounding.

Owner:ZHEJIANG UNIV +1

Method for preparing calcium alginate

The invention provides a method for preparing calcium alginate, comprising the following steps: soaking brown algae, and adding soda ash to digest and extract an alginic acid; washing and dehydrating; granulating; carrying out cryogenic grinding; calcifying; dehydrating; drying and grinding. The flocculent alginic acid is changed into powder in the process of preparing to be convenient for subsequent processing. The prepared calcium alginate has good stability, safety and flowability and is easy to disperse when in use. As the processes of cryogenic grinding and liquid-phase calcifying are adopted, the quality of the product can be improved, the drying can be carried out easily, and the scale production can be achieved. As the alga powder is dispersed into an organic solvent, and a calcifying agent is added to calcify, the purifying can be carried out while calcifying. The final product can be used for producing pharmaceutical products, cosmetic products and other high-end products.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

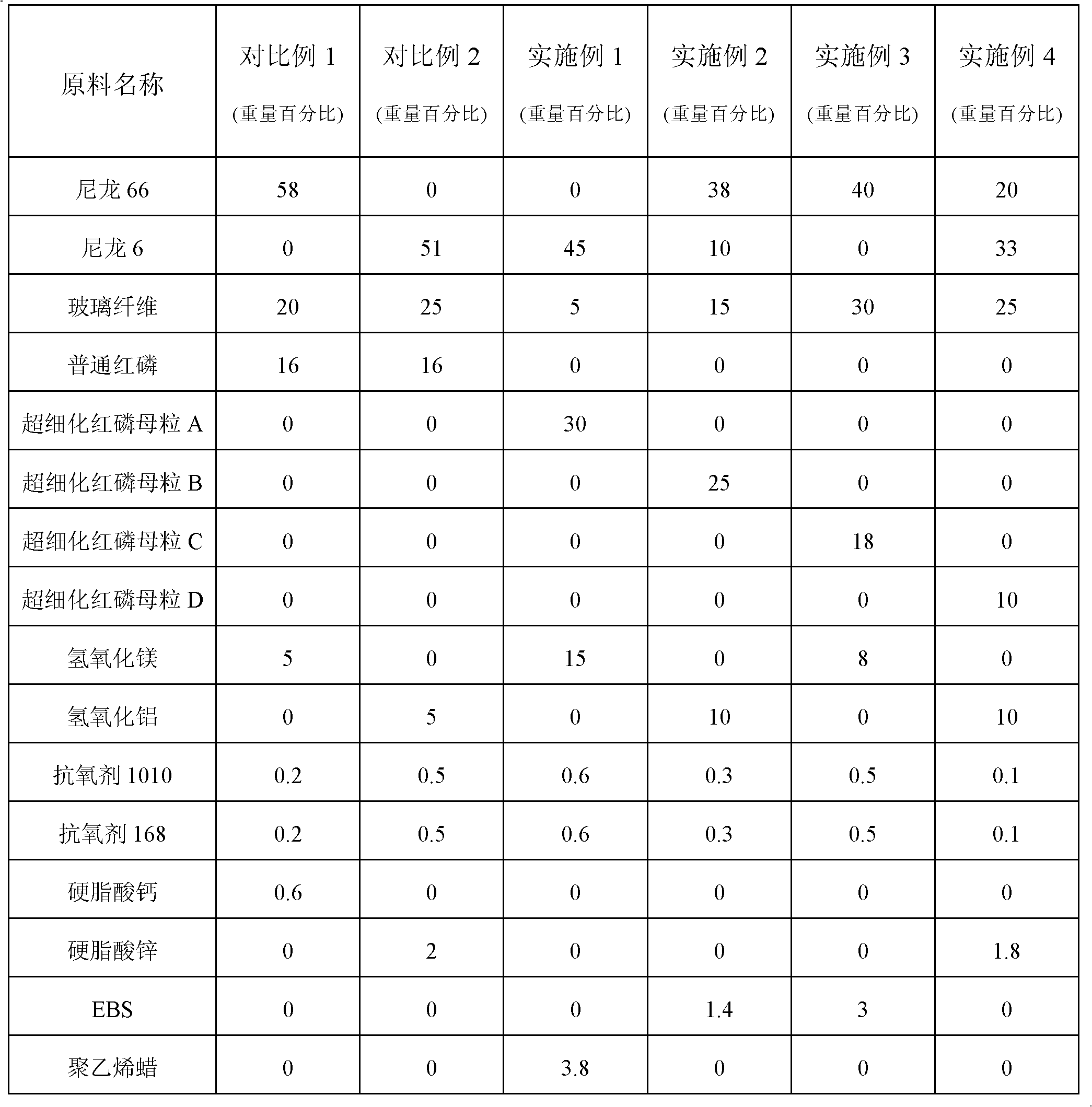

Preparation method of ultrafine low precipitation red phosphorus inflaming retarding glass fiber reinforced nylon

InactiveCN102492295AGuaranteed mechanical propertiesGuaranteed flame retardant performanceFire retardantPrecipitation

The invention relates to a preparation method of an ultrafine low precipitation red phosphorus inflaming retarding glass fiber reinforced nylon. Raw materials comprise the following substances, by weight: 40-60% of nylon, 10-30% of ultrafine red phosphorus masterbatch, 5-15% of synergistic flame retardant, 5-30% of glass fiber and 1-5% of other auxiliaries. The ultrafine red phosphorus masterbatch is prepared by carrying out liquid nitrogen cryogenic grinding on red phosphorus to have a fineness higher than 1250 mesh; and carrying out melt blending on the red phosphorus, high temperature silicone oil and flexibilizer. The ultrafine low precipitation red phosphorus inflaming retarding glass fiber reinforced nylon is prepared by steps of: weighing the raw materials according to weight percentage; mixing well the raw materials in a high speed mixer; carrying out melt blending in a twin-screw extruder and adding the glass fiber simultaneously; and extruding for granulation. Technological conditions of the extruder are as below: a 1-2 zone temperature of the twin-screw extruder being 230-250 DEG C, a 3-4 zone temperature of 250-270 DEG C, a 5-6 zone temperature of 260-280 DEG C, a 7-8 zone temperature of 240-270 DEG C, a handpiece temperature of 230-250 DEG C and a screw revolving speed of 150-350 round / min.

Owner:NANJING HONGRUI PLASTIC PROD

Method for preparing collagen protein powder from fish scales

The invention discloses a method for preparing collagen protein powder from fish scales. The method comprises the following steps of: (1) deordorization, decalcification and washing treatment on the fish scales; (2) cryogenic grinding treatment on the fish scales; (3) steam explosion treatment on the fish scales; (4) enzyme hydrolysis of the fish scales; and (5) preparation of the collagen protein powder from the fish scales. The production method provided by the invention is simple, less in dosage of protease, low in production cost, short in processing cycle, mild in condition, high in utilization rate of equipment and easy to realize industrialized production, and can reach an average extraction rate of above 70%. The collagen protein content in the prepared collagen protein powder reaches above 95%, the in vitro digestibility of the powder reaches above 95%, and the problem of utilization of fish scales in fish processing is well solved, so that the additional value of leftovers in the processing of aquatic products increases, and the comprehensive utilization rate of freshwater fish is improved.

Owner:宜昌湘宜水产品有限公司

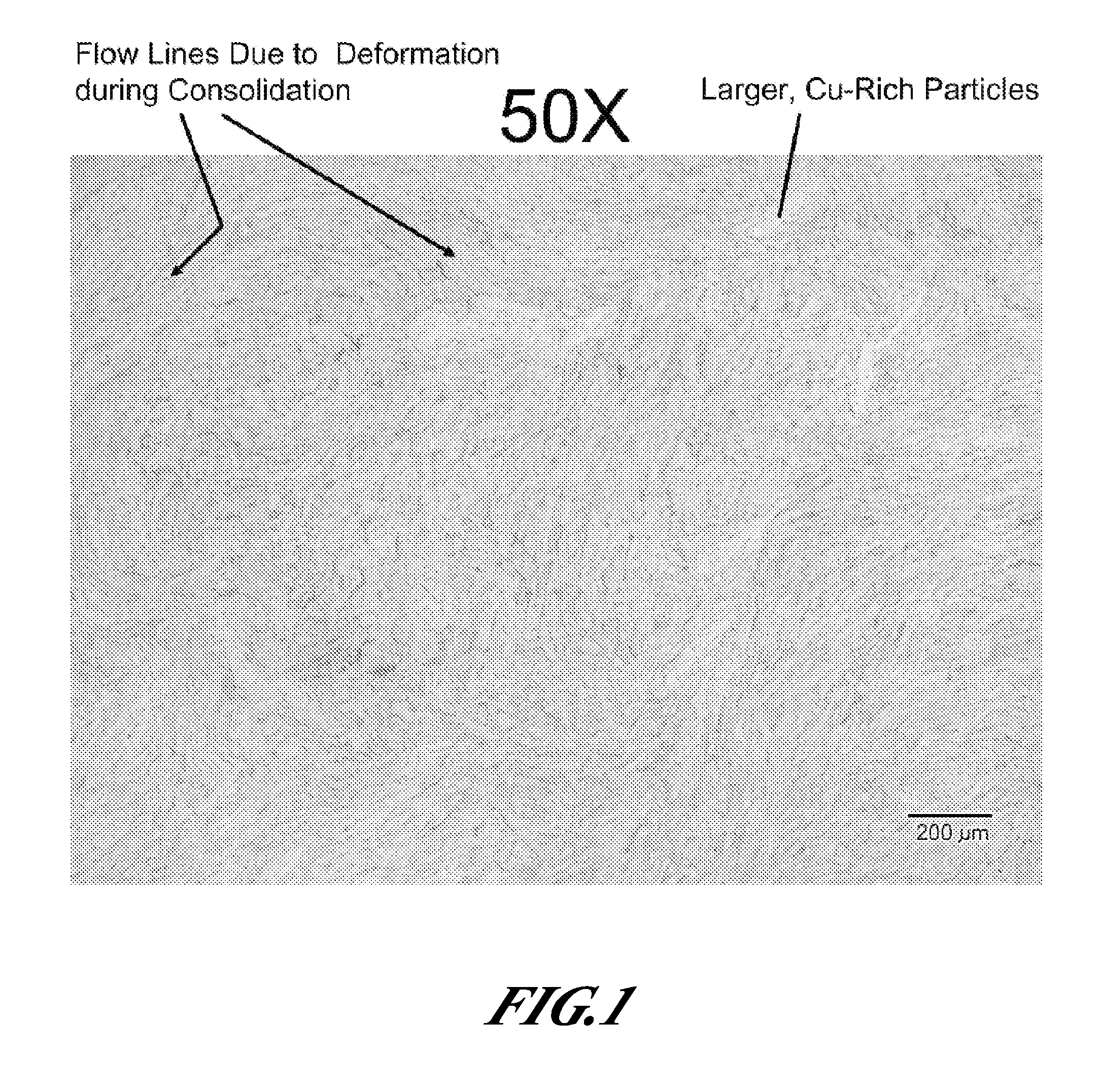

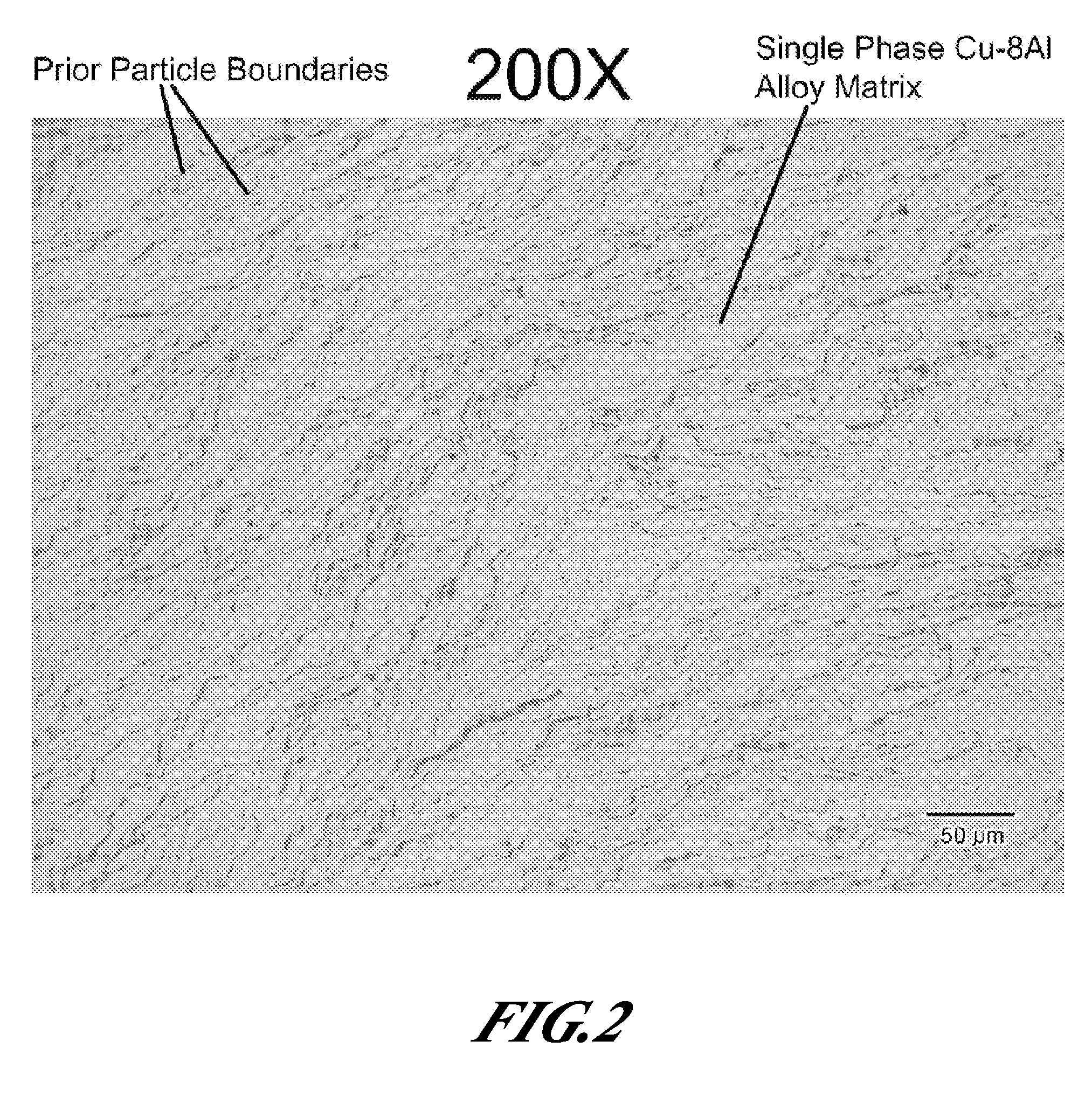

Nanophase cryogenic-milled copper alloys and process

InactiveUS20100278679A1Desirable physical propertyHigh strengthTransportation and packagingMetal-working apparatusHigh intensityNanometre

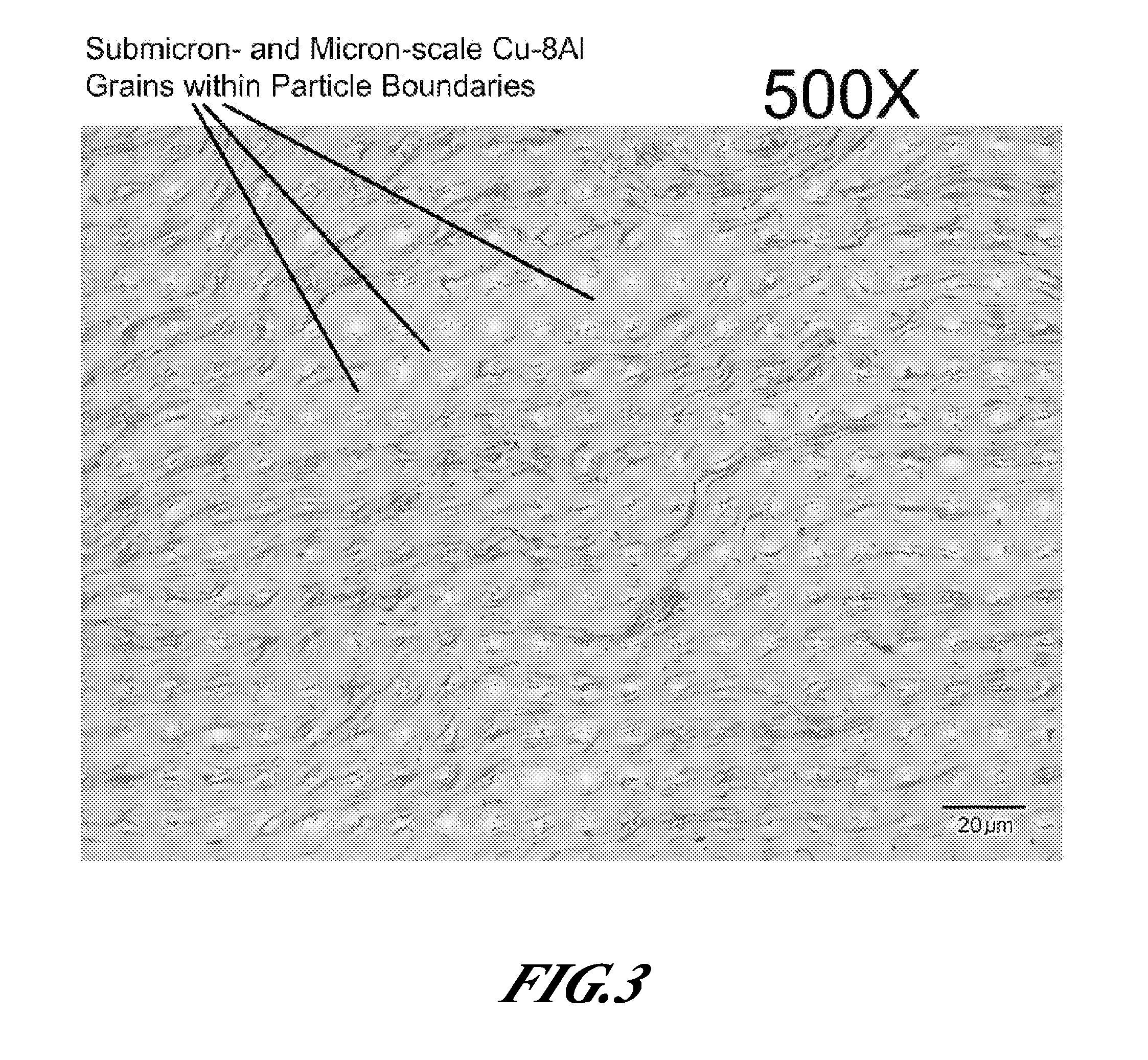

There is provided cryogenic milled nanophase copper alloys and methods of making the alloys. The alloys are fine grained having grains in the size range from about 2 to about 100 nanometers, and greater. The nanophase alloys possess desirable physical properties stemming from the fine grain size, such as potentially high strength. Some embodiments of the cryogenic milled copper alloys may also be tailored for ductility, toughness, fracture resistance, corrosion resistance, fatigue resistance and other physical properties by balancing the alloy composition. In addition, embodiments of the alloys generally do not require extensive or expensive post-cryogenic milling processing.

Owner:THE BOEING CO

Thermite compositions, articles and low temperature impact milling processes for forming the same

ActiveUS20100193093A1Easy to controlLoomsExplosive working-up apparatusChemical compositionLayer thickness

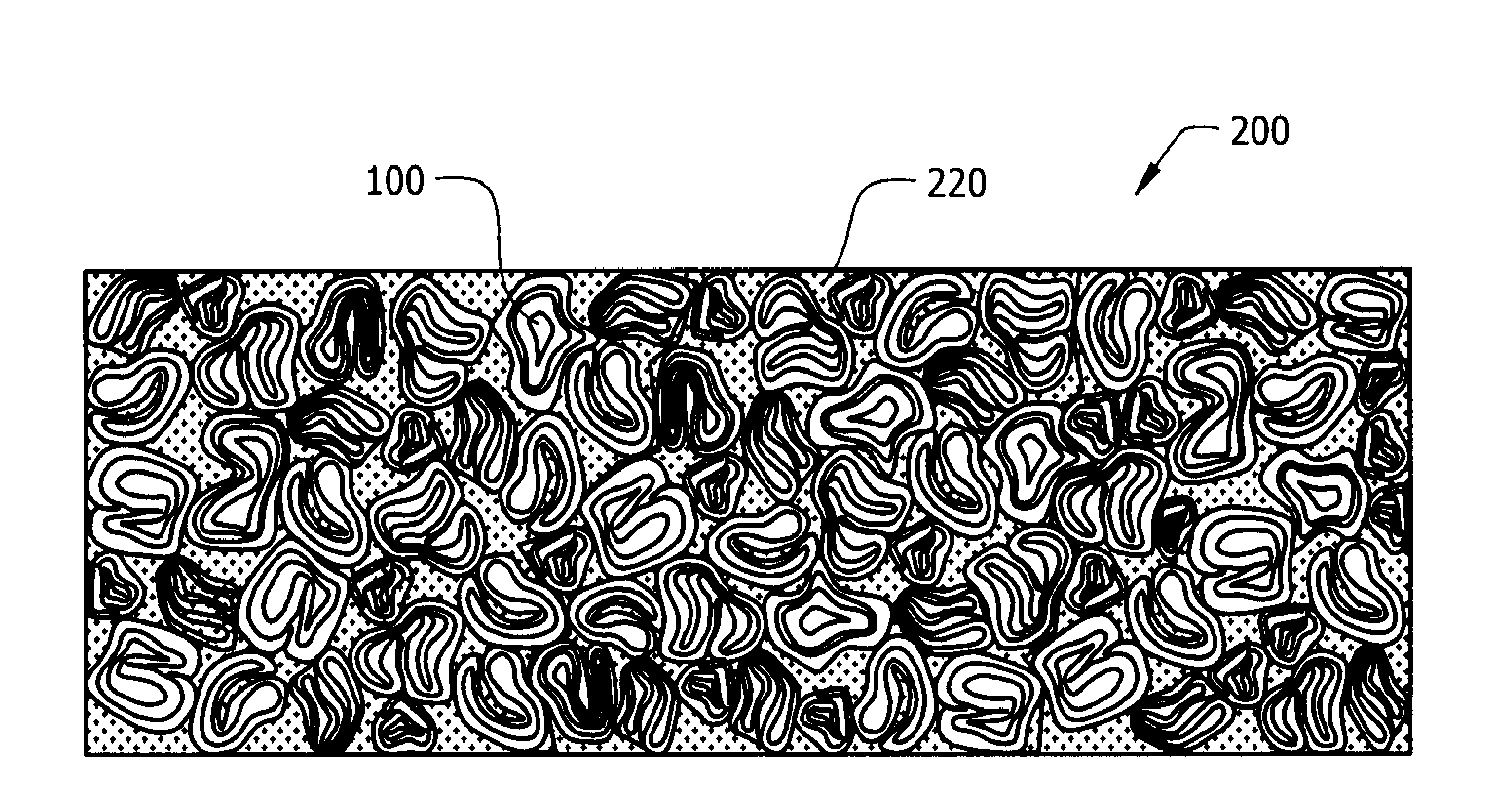

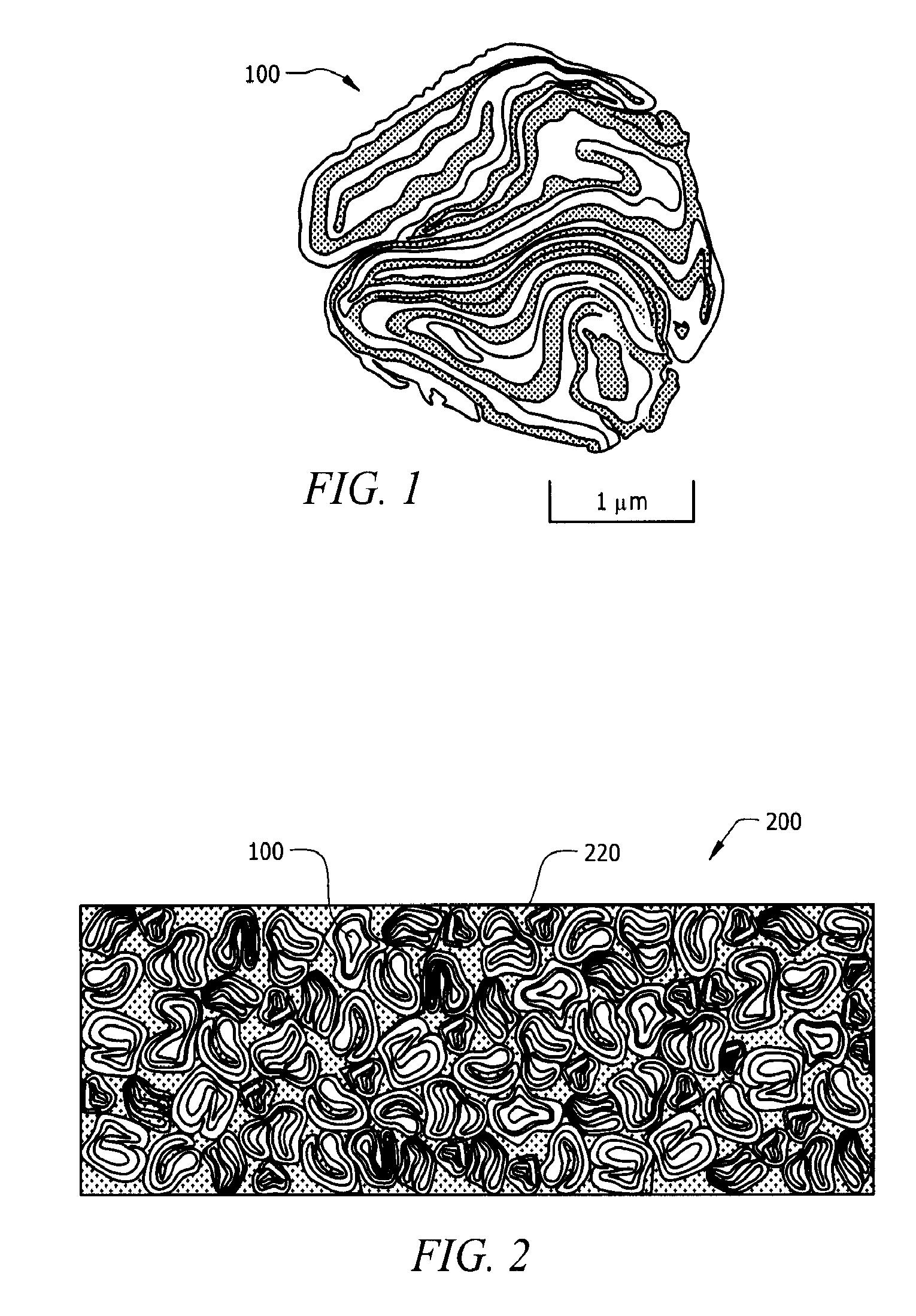

A process for the preparation of composite thermite particles, and thermite particles and consolidated objects formed from a plurality of pressed composite particles. The process includes providing one or more metal oxides and one or more complementary metals capable of reducing the metal oxide, and milling the metal oxide and the metal at a temperature below −50° C., such as cryomilling, to form a convoluted lamellar structure. The average layer thickness is generally between 10 nm and 1 μm. The molar proportions of the metal oxide and metal are generally within 30% of being stoichiometric for a thermite reaction.

Owner:LOCKHEED MARTIN CORP +1

Angelica keiskei compound teabag and preparation method thereof

InactiveCN104222441AImprove diastolic propertiesEnhance cell viabilityTea substituesFlavorUltra high pressure

The invention discloses an angelica keiskei compound teabag and a preparation method thereof. The teabag is composed, by weight, of 28-32 parts of angelica keiskei, 12-16 parts of hippophae rhamnosides leaves, 3-5 parts of perilla leaves, 14-18 parts of white orchid, 6-8 parts of loquat flower and 17-21 parts of walnut flower. The preparation method includes the steps of cleaning all raw materials, removing impurities, performing ultralow temperature cryogenic grinding and vacuum freeze drying, mixing according to the formula ratio, and performing ultra-high pressure sterilization and sealed packaging to obtain a finished product. The angelica keiskei compound teabag prepared through the preparation method greatly maintains nutritional values and functional components of angelica keiskei and other plant materials, has health effects of immunity enhancing, blood pressure reducing, fat removing, heat clearing, detoxification, lung moistening to arrest cough and the like, and is clear in tea soup, heavy in tea aroma, mellow in flavor and harmonious in taste after brewing. The raw materials of the teabag are natural, non-toxic, wide in sources and low in costs. The teabag is easy to product, high in quality, easy to brew and suitable for daily drinking.

Owner:SHAANXI DATONG YONGSHOU ECOLOGICAL DEV

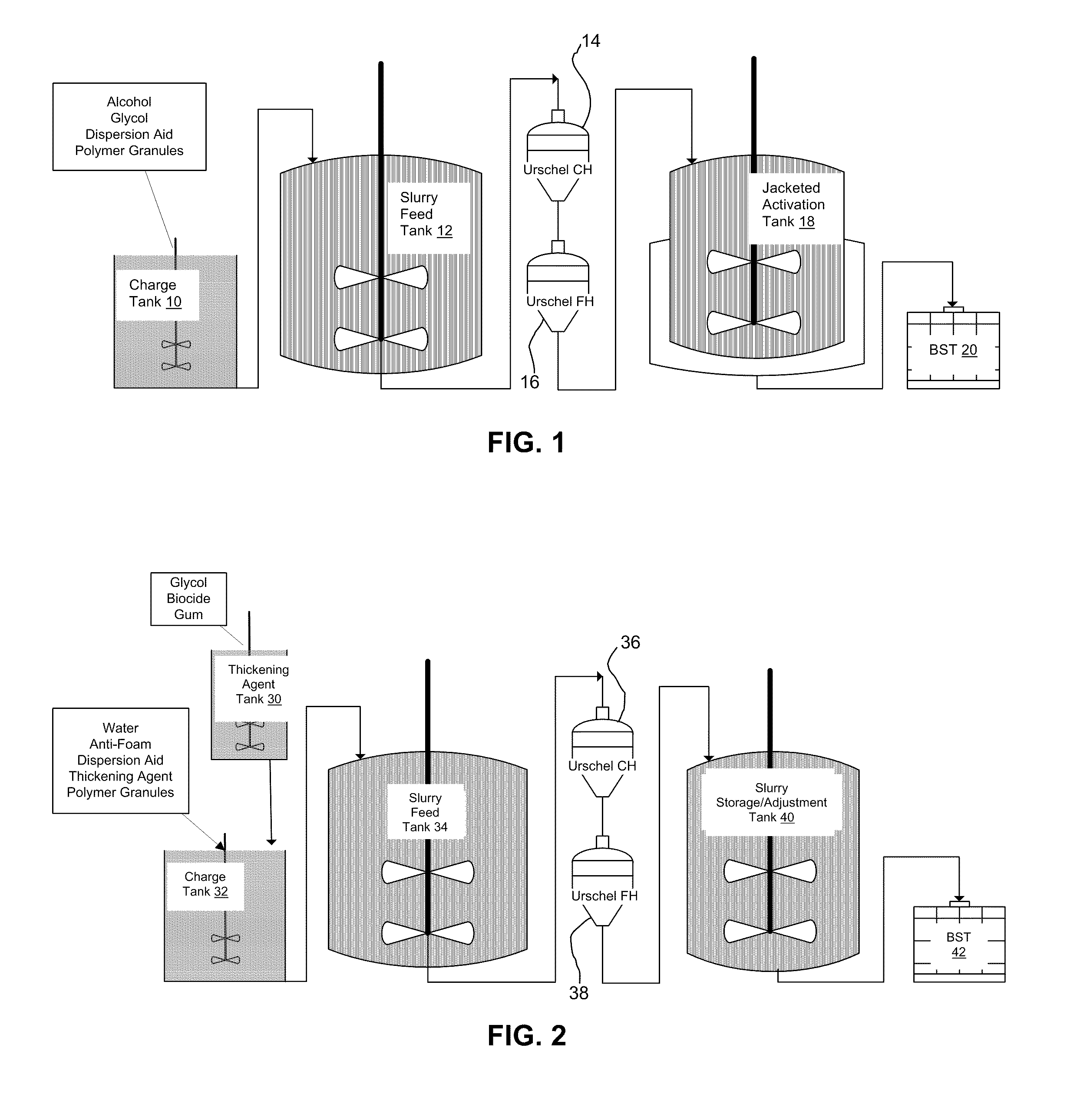

Polyolefin Drag Reducing Agents Produced by Multiple Non-Cryogenic Grinding Stages

InactiveUS20110319520A1Small sizeImprove efficiencyOther chemical processesPipeline systemsPolyolefinModal particle

Fine particulate polymer drag reducing agents (DRAs) in bi-modal or multi-modal particle size distributions may be produced simply and efficiently without cryogenic temperatures. The grinding or pulverizing of polymer, e.g. non-porous poly(alpha-olefin) suitable for reducing drag in hydrocarbons may be achieved by the use of at least one liquid grinding aid and at least two grinding processors in series. The blades of the stators of the grinders are of different configuration so that granulated polymer fed to the first processor having relatively larger gaps between blades is ground to an intermediate size which is fed to the second processor having relatively smaller gaps between blades which grinds the polymer to a second, smaller size. A non-limiting example of a suitable liquid grinding aid includes a blend of propylene glycol, water and hexanol. Particulate DRA may be produced at a size of 300 microns or less in only two passes.

Owner:BAKER HUGHES INC

Auricularia auricula polysaccharide extracting method

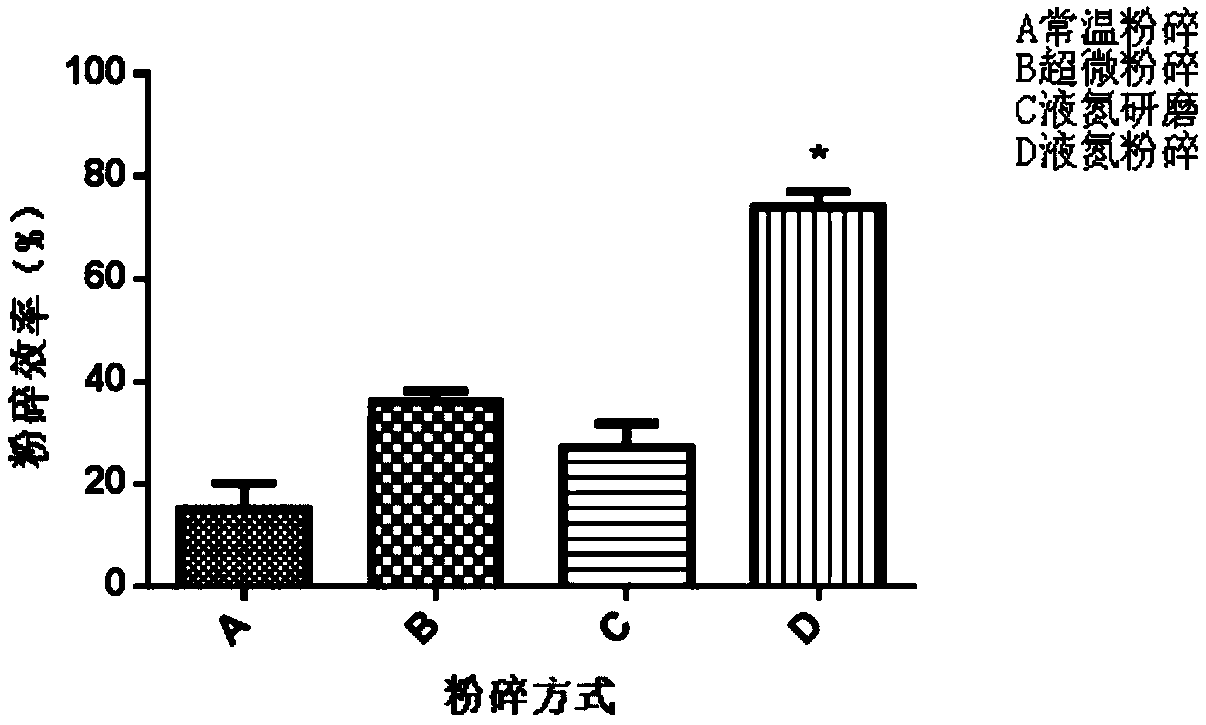

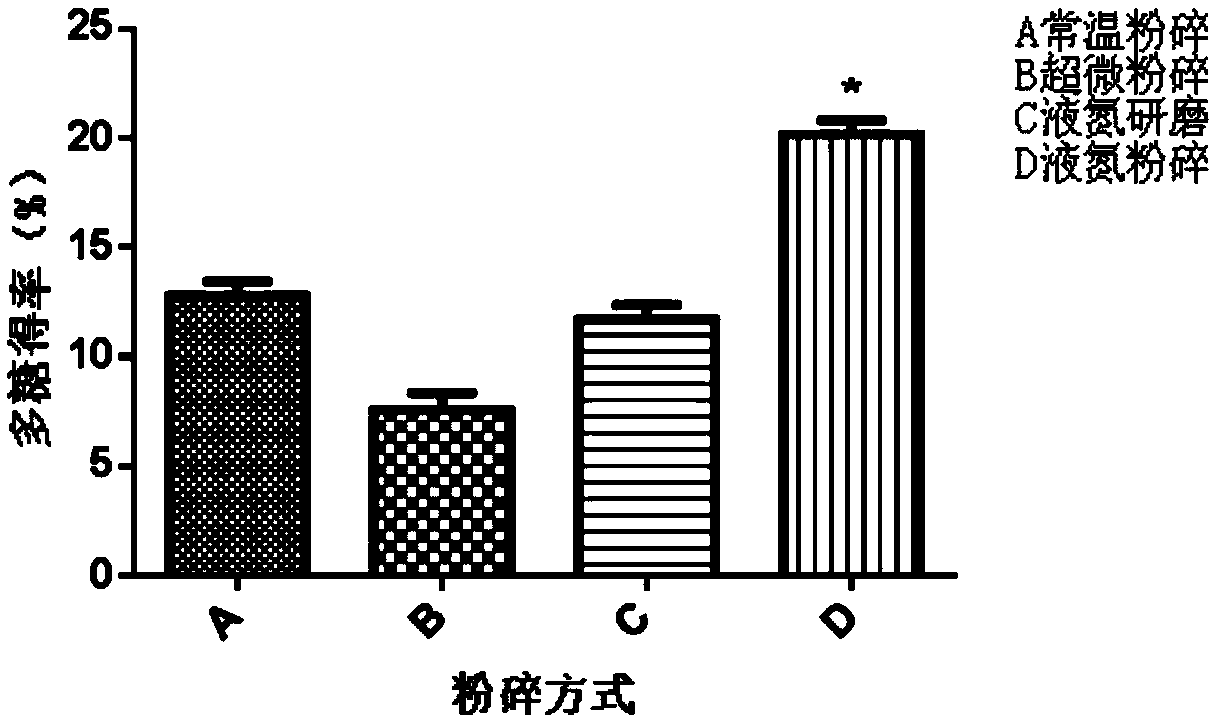

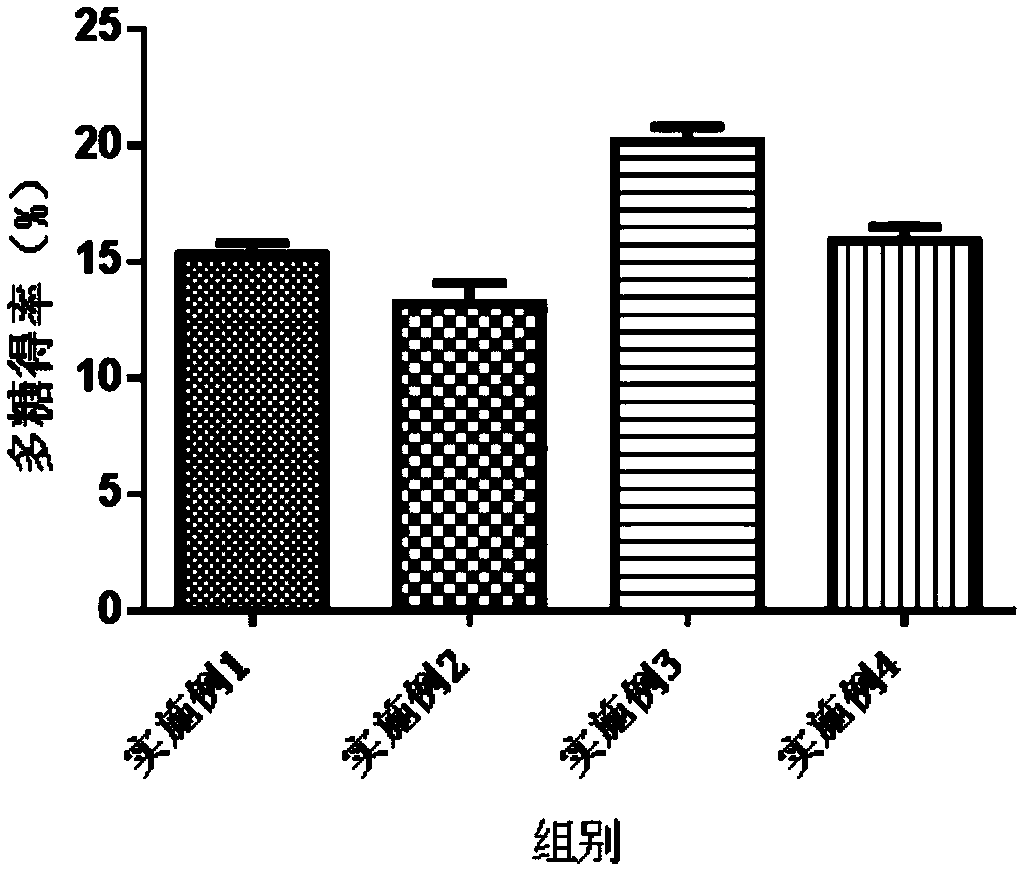

The invention discloses an auricularia auricula polysaccharide extracting method, and belongs to the technical field of auricularia auricula deep processing. According to the method, auricularia auricula is dried until the water content reaches 1-15%, and the auricularia auricula is placed into a grinding machine for cryogenic grinding, wherein cryogenic grinding means that firstly, liquid nitrogen is introduced into the grinding machine, and then grinding is conducted to obtain auricularia auricula powder; water is added into the auricularia auricula powder for ultrasonic extraction, after extraction is completed, centrifugation is conducted to take supernate, the above steps are repeated for sediment after centrifugation, and an auricularia auricula polysaccharide extracting solution isobtained by mixing two-time supernate. According to the method, the cryogenic grinding mode is adopted for conducting cell wall breaking treatment on the auricularia auricula, meanwhile, auricularia auricula polysaccharide extraction is conducted supplemented by an ultrasonic technology, by implementing the method, the auricularia auricula grinding particle size can be improved to 125 mu m, the grinding rate is up to 74%, and the polysaccharide extraction efficiency is improved to 20%; by means of liquid nitrogen grinding treatment, dissolution of components with low molecular mass is promoted, the antioxidation effect is good, and accordingly the method is suitable for extracting polysaccharides in the auricularia auricula.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Efficient bone powder preparing system and using method

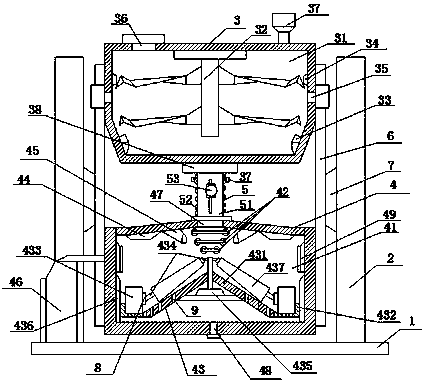

PendingCN107552202AIncrease productivityImprove product qualityGrain treatmentsProcess specificationUltrasonic vibration

Owner:郑州中技联创环境技术有限公司

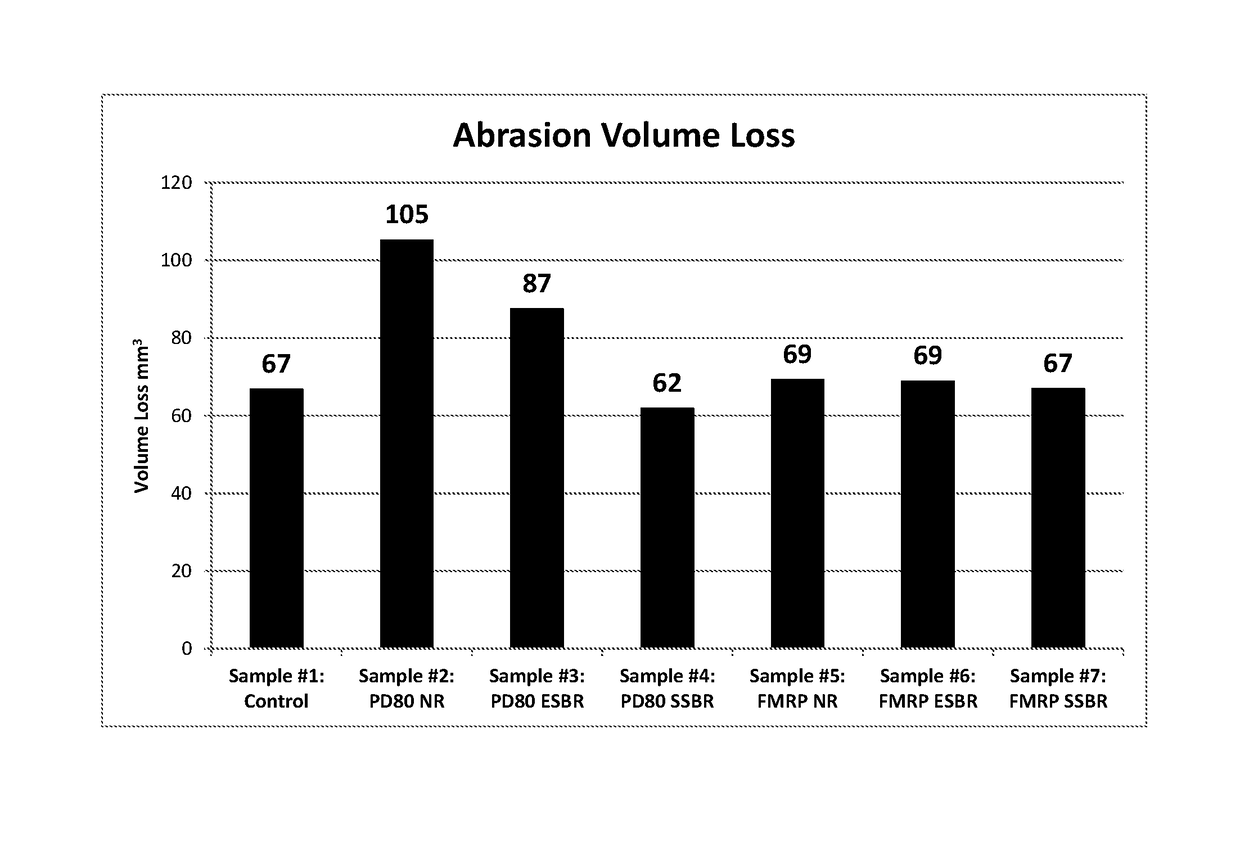

Recycled micronized rubber formulation having improved abrasion resistance

ActiveUS9815974B2Without significantly compromising the abrasion resistance of the rubber formulationSeverely abrasion resistanceProductsConveyorsEngineeringSynthetic rubber

This invention is based upon the discovery that micronized solution styrene-butadiene rubber from postconsumer sources can be included in rubber formulations without severely compromising abrasion resistance. The micronized solution styrene-butadiene rubber utilized in the rubber formulations of this invention can be made by cryogenic grinding postconsumer rubber products using conventional procedures. For instance, it can be made by cryogenically grinding a tire tread containing a high level of solution styrene-butadiene rubber. The micronized solution styrene-butadiene rubber can then be blending into desired virgin rubbers and cured without significantly compromising the abrasion resistance of the rubber formulation. The rubber formulation of this invention is comprised of a natural or synthetic rubber and from 1 weight percent to 30 weight percent of a micronized rubber composition containing at least 10 weight percent solution styrene-butadiene rubber and having a particle size of 40 mesh to 200 mesh.

Owner:LEHIGH TECH INC

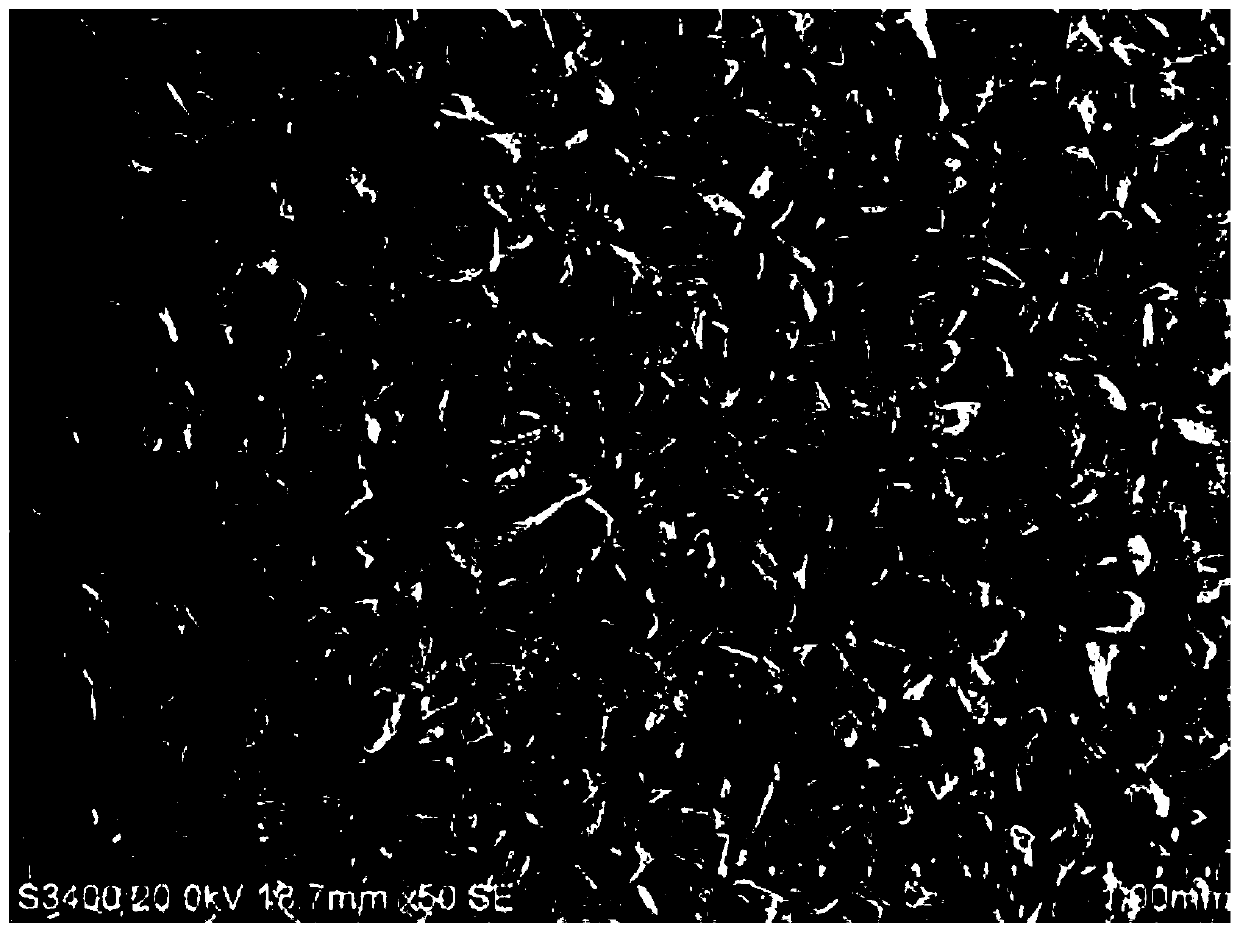

Method for preparing spherical chromium powder by gas atomization

PendingCN110014158AControl gas contentHigh purityAdditive manufacturing apparatusTemperature controlHeating power

The invention discloses a method for preparing spherical chromium powder by gas atomization, and belongs to the technical field of powder metallurgy. The method comprises the following specific stepsthat 1) preparing chromium powder; 2) pressing; 3) sintering; and 4) carrying out gas atomization EIGA. In the step 1), low-temperature grinding and crushing are carried out on a chromium block to prepare powder, the temperature is controlled between 50 DEG C-100 DEG C; in the step 2) after the chromium powder is put into a rubber sleeve for vibrating and reverse pier material, the chromium powderis pressed, wherein the pressure is 150 MPa-300 MPa, and the pressure maintaining time is 5 min-15 min; in the step 3), the pressed chromium rod is put into a vacuum sintering furnace for sintering,the sintering temperature is controlled to be 1000 DEG C-1200 DEG C, the heat preservation time is 30-480 min, and the vacuum degree is 100 pa; and in the step 4), the sintered chromium rod is injected into an EIGA (rotary electrode induction smelting vacuum air atomization) to prepare powder, wherein the heating power is 10-40 Kw. The spherical chromium powder prepared by the method is high in purity, low in gas content, good in sphericity and wide in particle size range distribution.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

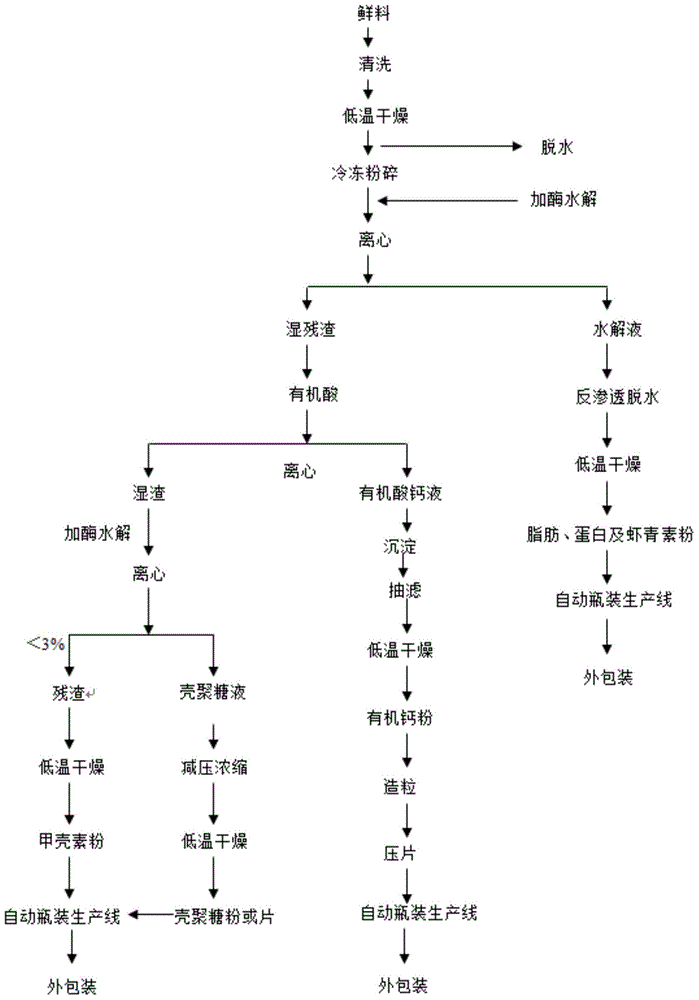

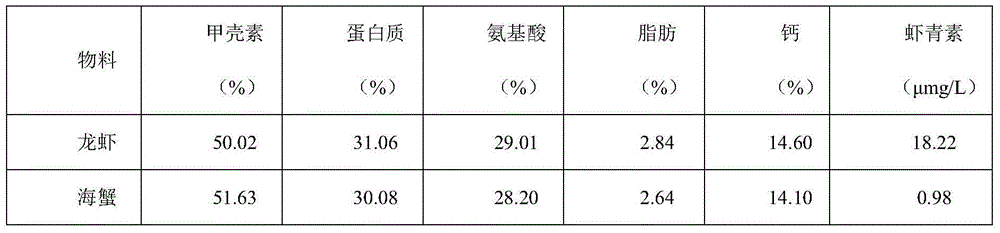

Comprehensive aquatic product processing leftover utilization method

InactiveCN104938604ANo breedingOdorlessShrimp/lobster processingFish processingAstaxanthinReverse osmosis

The invention discloses a comprehensive aquatic product processing leftover utilization method which comprises the following steps: with processing leftovers of crustacean including fish, shrimp, crab and the like as the raw materials, cleaning, low-temperature drying, cryogenic grinding, complex enzymatic degradation, organic acid extraction, high-speed centrifugal separation, reverse osmosis dehydration, molecule embedding, high-pressure homogenizing, vacuum low-temperature cryogenic drying, pelletizing, tabletting, automatic bottled packaging production line processing and outer packing are carried out, and all high value-added bio-active substances including astaxanthin, protein, organic calcium, chitin and the derivative of the chitin namely chitosan in the aquatic product processing leftovers are extracted, so that resources are comprehensively and effectively utilized without waste discharge. According to the invention, the moderate bio-enzyme degradation technique is adopted, the whole process is carried out under the low-temperature condition, strong acid, strong base and toxic solvents are not used, the technological process is short, the industrial chain is long, and the products are high in bioactivity, various in variety, excellent in quality, safe to eat, wide in application fields, large in potential market, and high in comprehensive economic benefit.

Owner:台建祥 +3

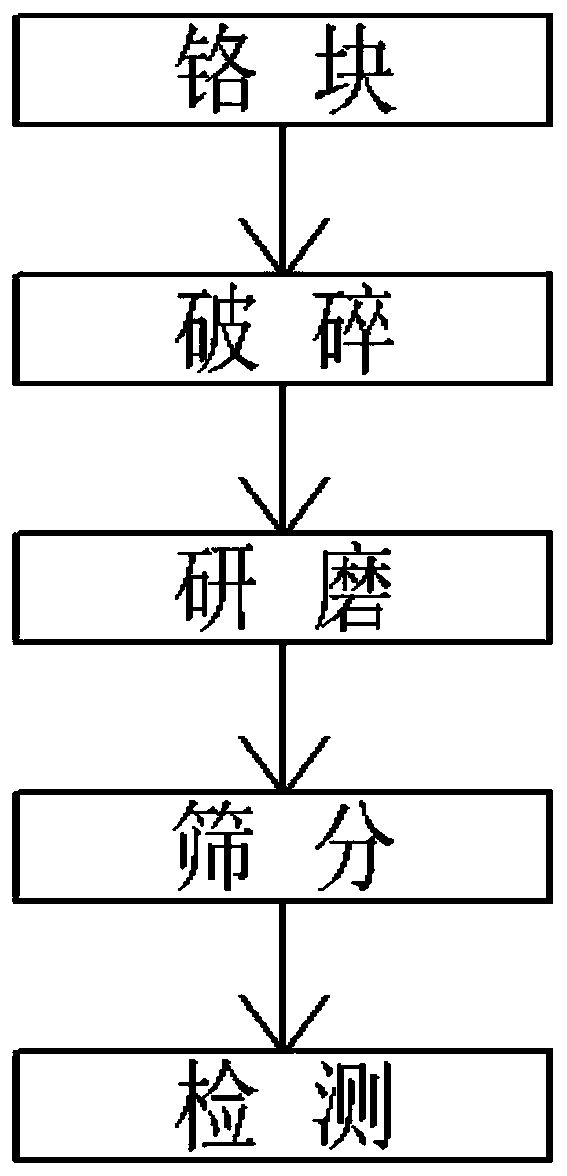

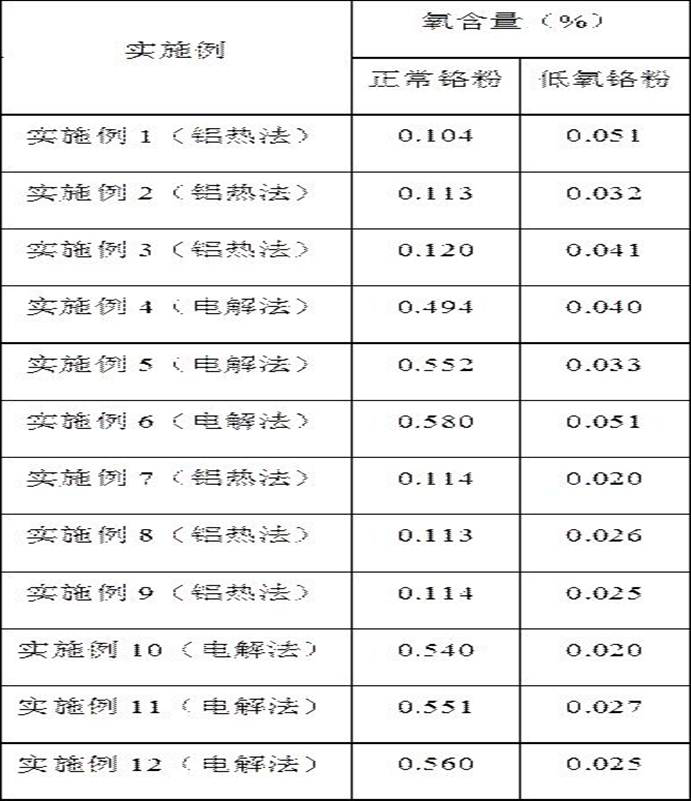

Preparation method of metal chromium powder special for high-performance CuCr electrical contact

ActiveCN110202159AImprove wettabilityGuaranteed oxygen contentTransportation and packagingMetal-working apparatusNitrogenCrusher

The invention discloses a preparation method of metal chromium powder special for a high-performance CuCr electrical contact. The preparation method comprises the steps of crushing, specifically, a chromium block is placed into a crusher and crushed into granules; screening the granulated chromium block by using a 10-mm aperture screen, and selecting undersize chromium particles; grinding, specifically, the chromium particles are added into low-temperature grinding powder manufacturing equipment, and a cooling medium is introduced to obtain the metal chromium powder; screening again, specifically, the metal chromium powder is respectively screened by using a 200-mesh screen, a 240-mesh screen and a 320-mesh screen; and detecting, specifically, oxygen content in the metal chromium powder isanalyzed by using a nitrogen-oxygen analyzer and is required to be no greater than 600 ppm. According to the preparation method of the metal chromium powder, the oxygen content in the chromium powdercan be effectively controlled; and the chromium powder is not prone to segregation after being mixed with Cu powder, has good formability, and has good wettability of Cr and Cu after sintered.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

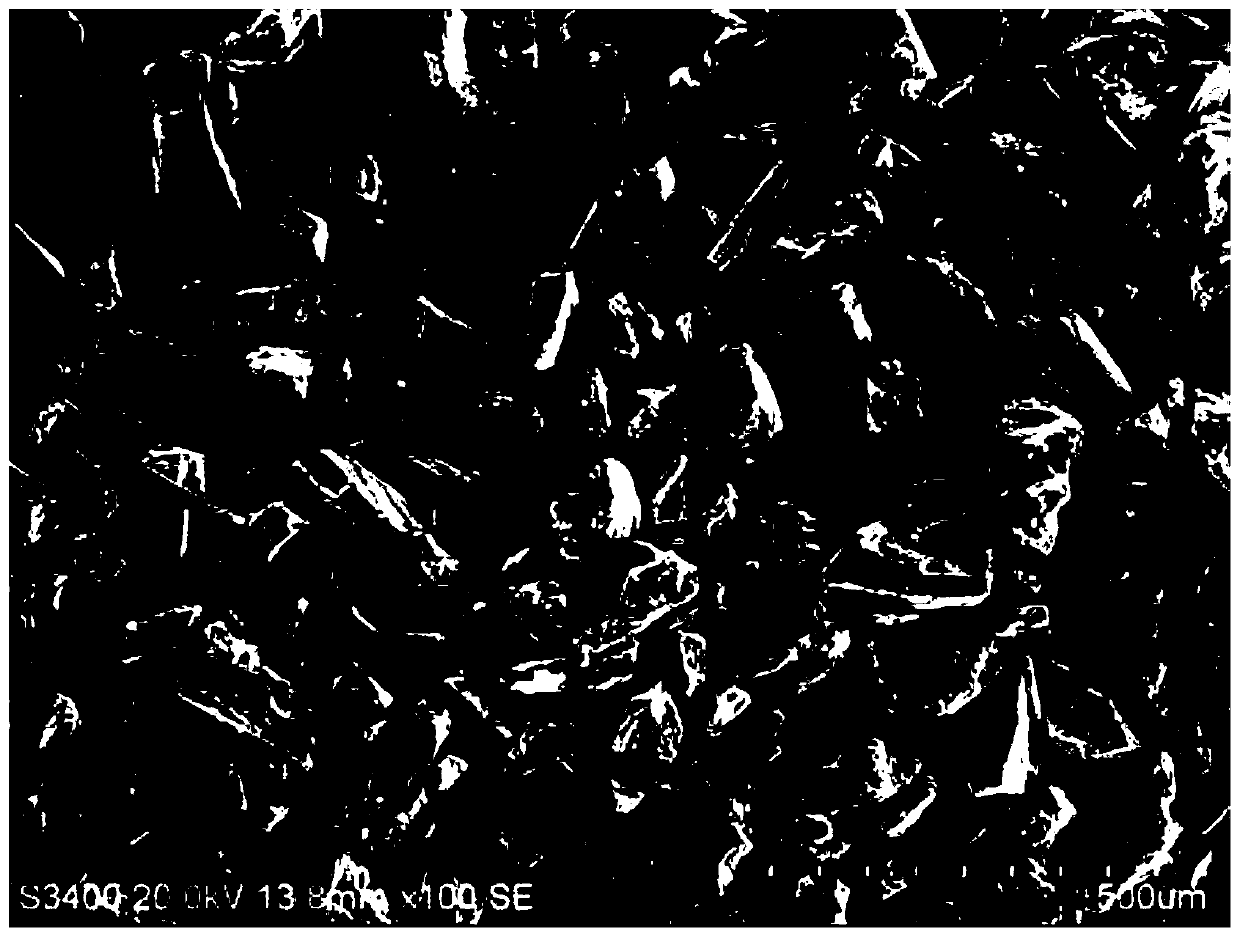

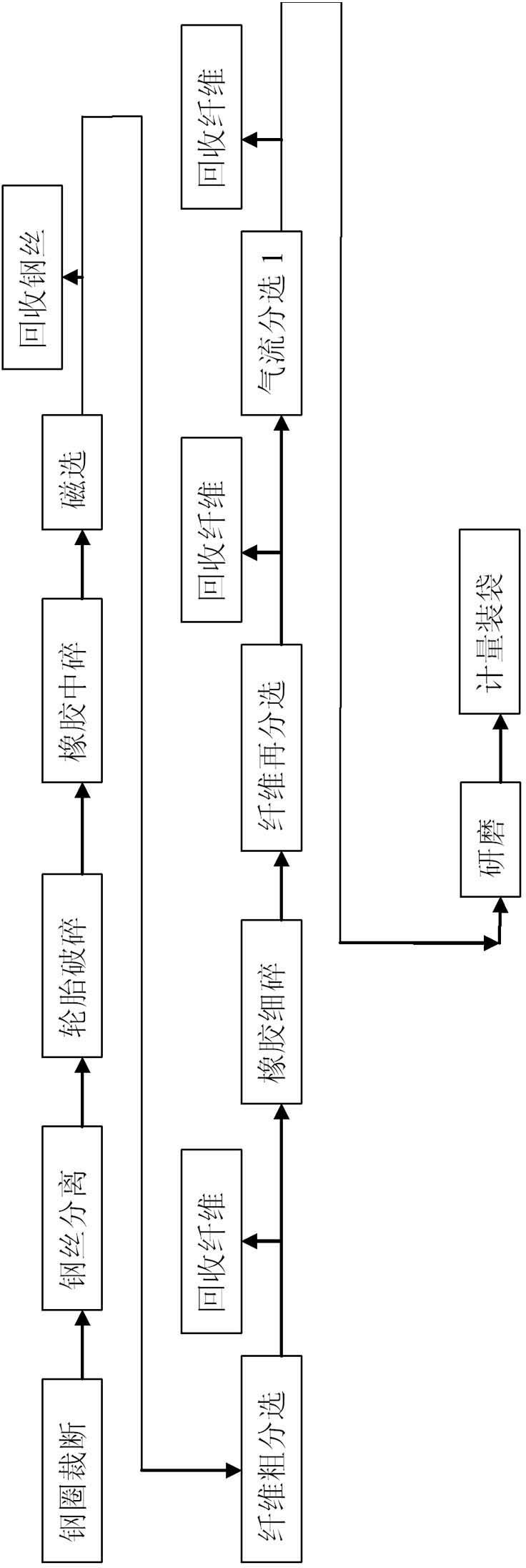

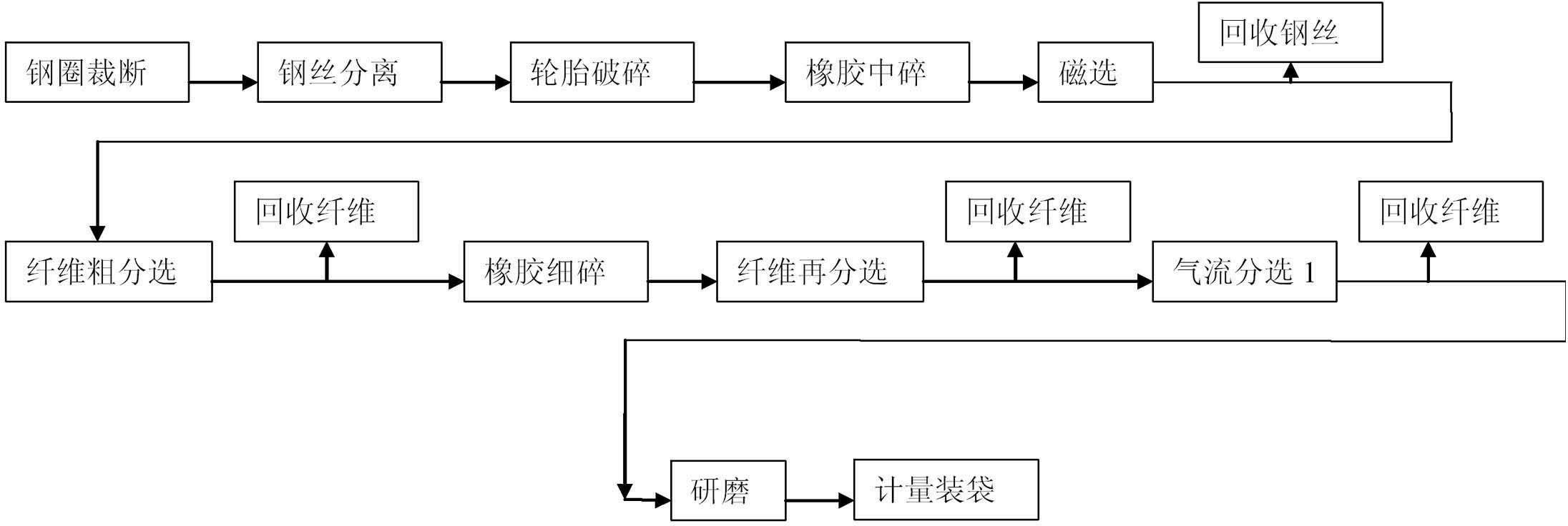

Normal-temperature grinding production method for fine rubber powder

InactiveCN102248615ACompact structureEasy to install and maintainPlastic recyclingMechanical material recoveryLow noiseFiber

The invention discloses a normal-temperature grinding production method for fine rubber powder. The method comprises the following process steps of: cutting a steel ring; separating a steel wire; crushing a tire; grinding in rubber; performing magnetic separation; coarsely separating fibers; finely grinding the rubber; separating the fibers again; grinding; and performing airflow separation treatment. The industrial method is the precedent of batch production of the fine rubber powder, and equipment investment in the whole production line is a half that of the conventional normal-temperature grinding method, and is approximately one eighth that of a low-temperature cryogenic grinding production line. The industrial production line has a compact structure, equipment is convenient to mount and maintain and has long service life, high rubber discharging rate, low power consumption and low noise, and various technical indexes are superior to those of more advanced air turbine expansion refrigeration rubber powder production technologies at present compared with those of rubber powder which is produced by a low-temperature cryogenic grinding method.

Owner:东莞市运通环保科技有限公司

Method for preparing superfine konjac powder by using supersonic airflow pulverization technology

A method for preparing ultra-fine konjac powder using supersonic airflow crushing technology, using a certain concentration of ethanol solution to swell konjac fine powder, using airflow crushing technology: compressed air is frozen, filtered, and dried, and the nozzle forms a sonic speed of 1~3 The supersonic airflow at twice the speed is injected into the crushing chamber, making the materials fluidized, and the accelerated materials meet at the intersection point of the jets of several nozzles, resulting in violent collision, friction, and shearing to achieve ultra-fine crushing of particles. It can obtain konjac flour with a particle size of 200~600 mesh or even finer, which can save energy by 30-40%. The equipment has a compact structure and a small footprint. Low-temperature medium-free pulverization, especially suitable for pulverization of low melting point, heat-sensitive, sugar-containing and volatile materials.

Owner:SOUTHWEST UNIVERSITY

Milling process

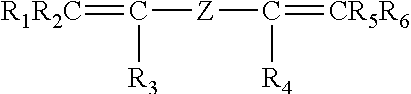

The invention pertains to a process for cryogenic milling mixtures of (per)fluoroelastomers and semicrystalline thermoplastic VDF polymers, and to free-flowing micronized pellets obtainable therefrom, said micronized pellets advantageously yielding, after extrusion and compounding, excellent mechanical properties, even improved over those of base fluoroelastomer matrix.

Owner:SOLVAY SOLEXIS

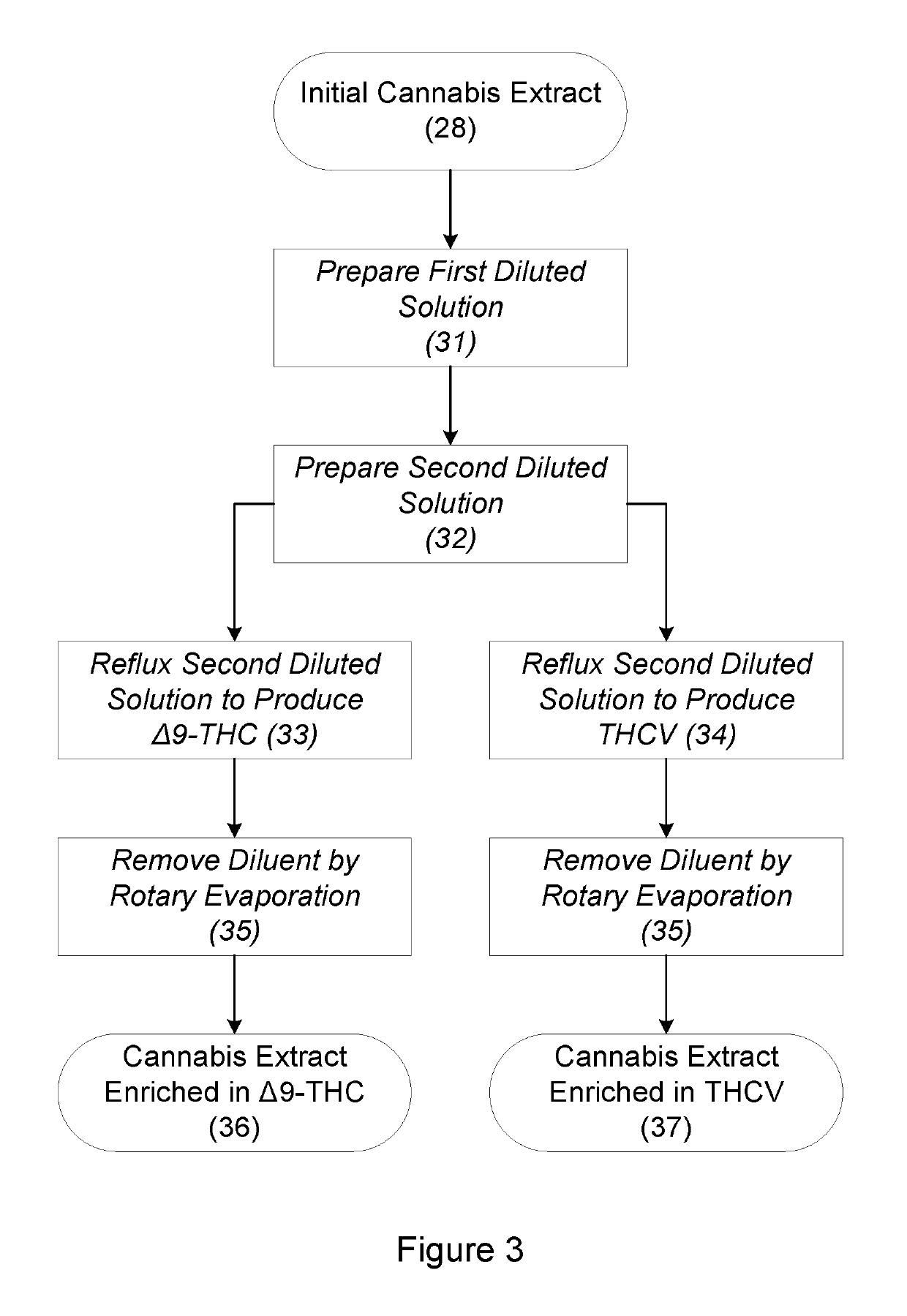

Producing cannabis extracts via selective decarboxylation

ActiveUS10471113B1Promote conversionOrganic active ingredientsSolid solvent extractionCannabisChemical treatment

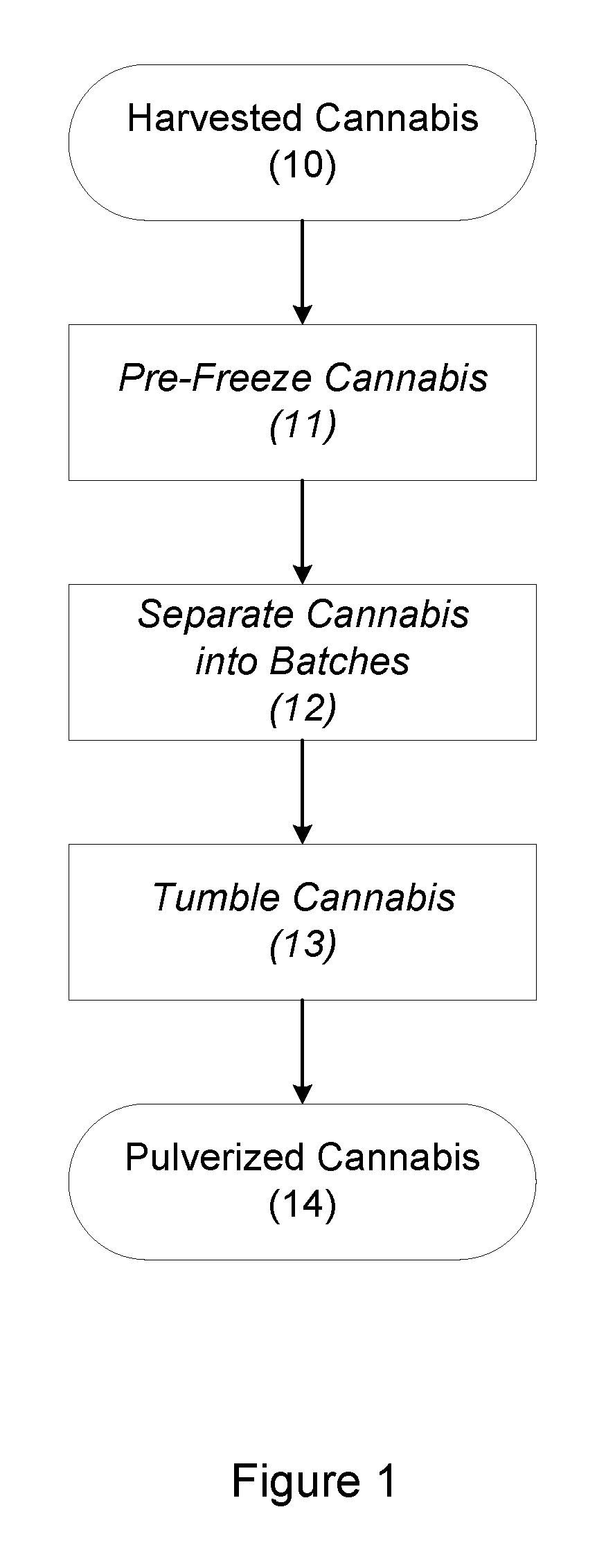

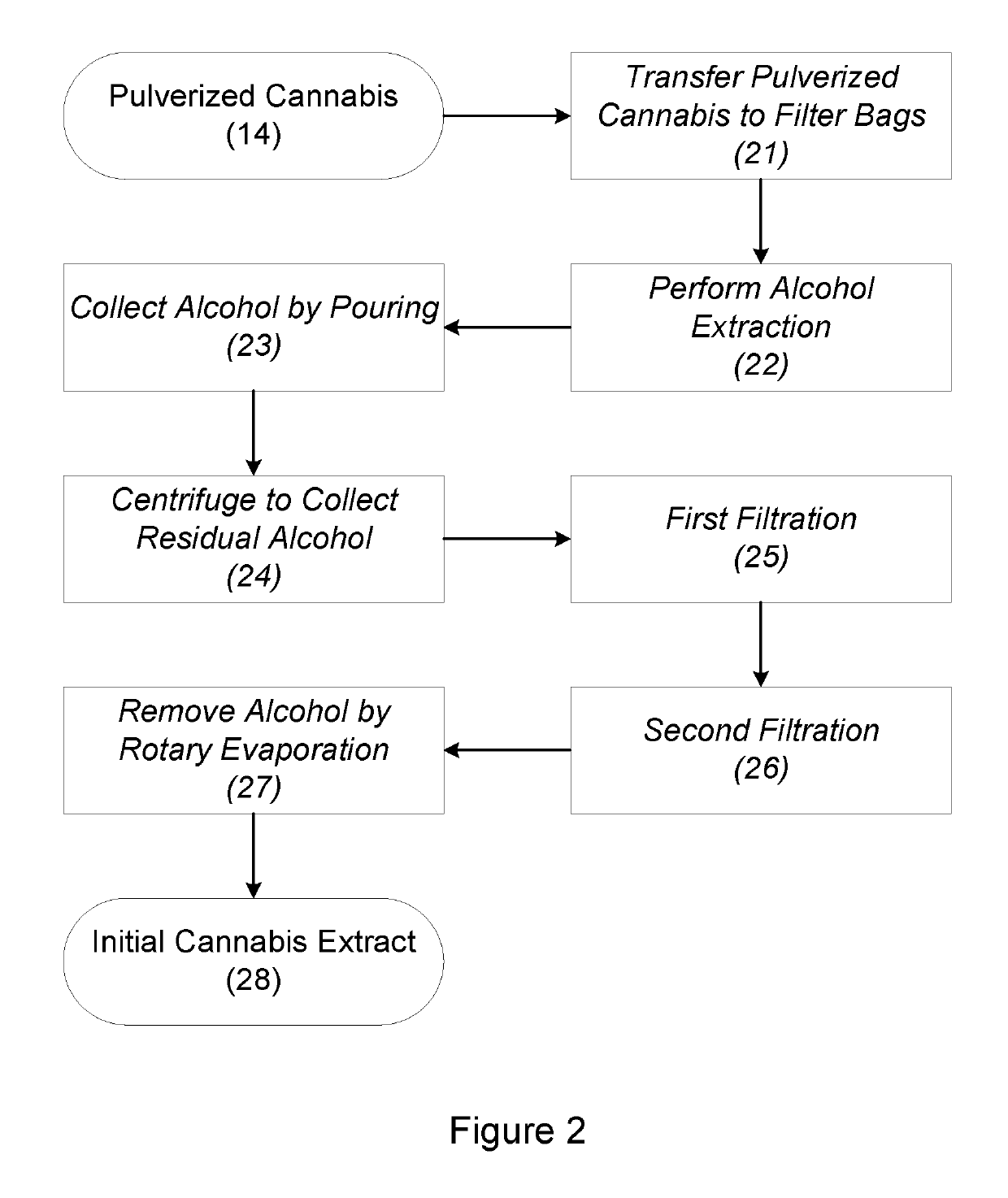

The present invention is a process for producing various types of cannabis extract from harvested cannabis. A quantity of harvested cannabis, which typically includes the inflorescence, floral leaves, and small stems of a flowering cannabis plants, is pre-frozen. The harvested cannabis is first subjected to cryogenic grinding to produce pulverized cannabis. The pulverized cannabis is then subjected to alcohol extraction to produce an initial cannabis extract, which can be subjected to one of several forms of further processing according to the desired chemical profile of the final product. The initial cannabis extract may then be subjected to chemical processing that promote the conversion of THCA to Δ9 THC; the conversion of THCVA to THCV; the conversion of THCA to cannabinol (“CBN”); or the conversion of THCA to Δ8-THC.

Owner:JENNYS ROSE LLC

Powder metallurgy composite lubricant and preparation method thereof

Provided is a powder metallurgy composite lubricant and a preparation method thereof. The lubricant is composed of 20-80 parts of octadecanamide and 10-60 parts of zinc stearate. The process includes: firstly adding the octadecanamide and the zinc stearate with certain proportion into a high-temperature sealing furnace, heating the mixture to the temperature of 142.8-143.6 DEG C until the raw materials are melted into liquid, then evenly mixing through stirring, grinding and smashing at low temperature to enable the particle degree to be -325 meshes, smashing the particles into powder, filtering to obtain finished products.

Owner:曾锐

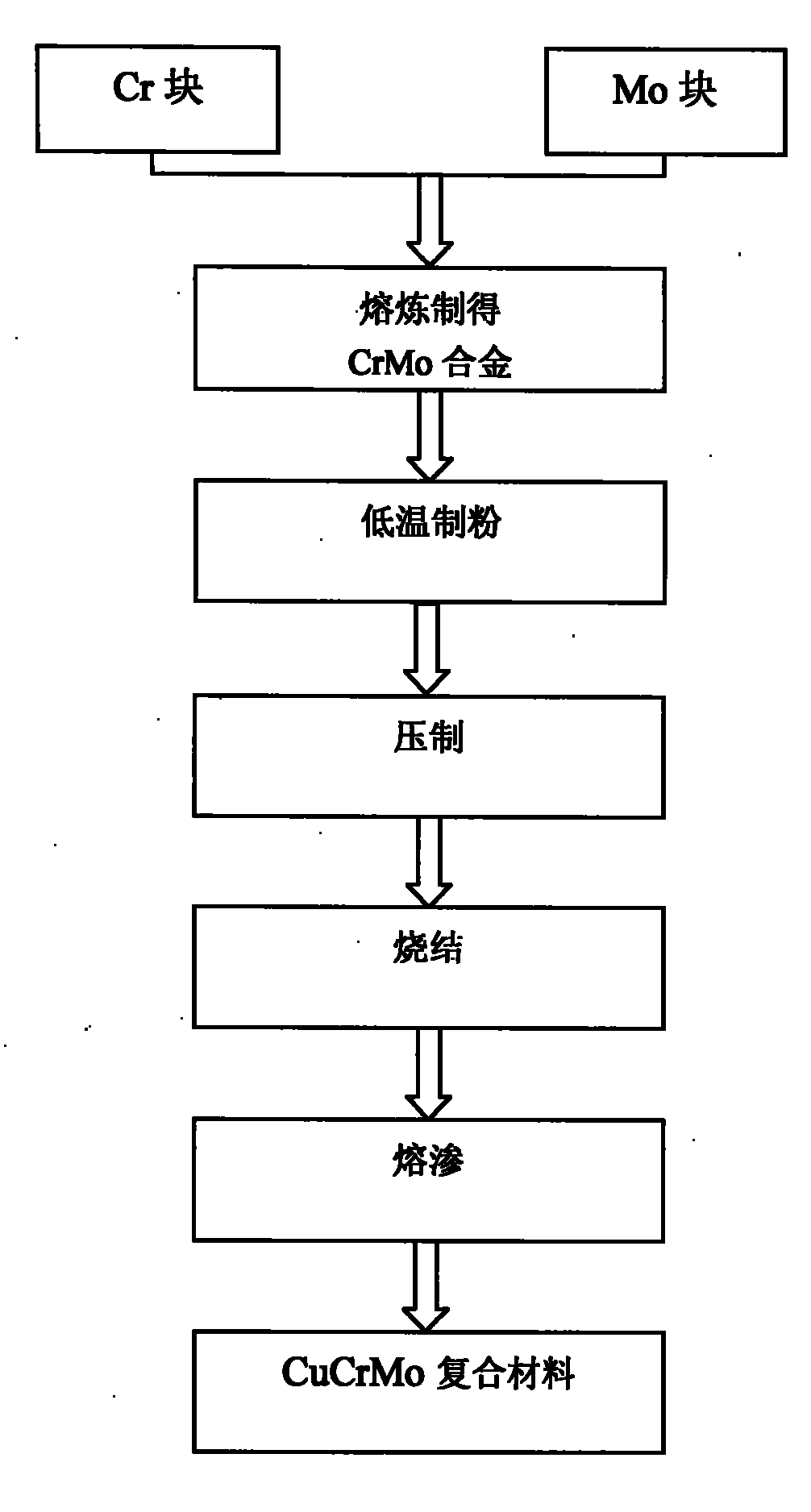

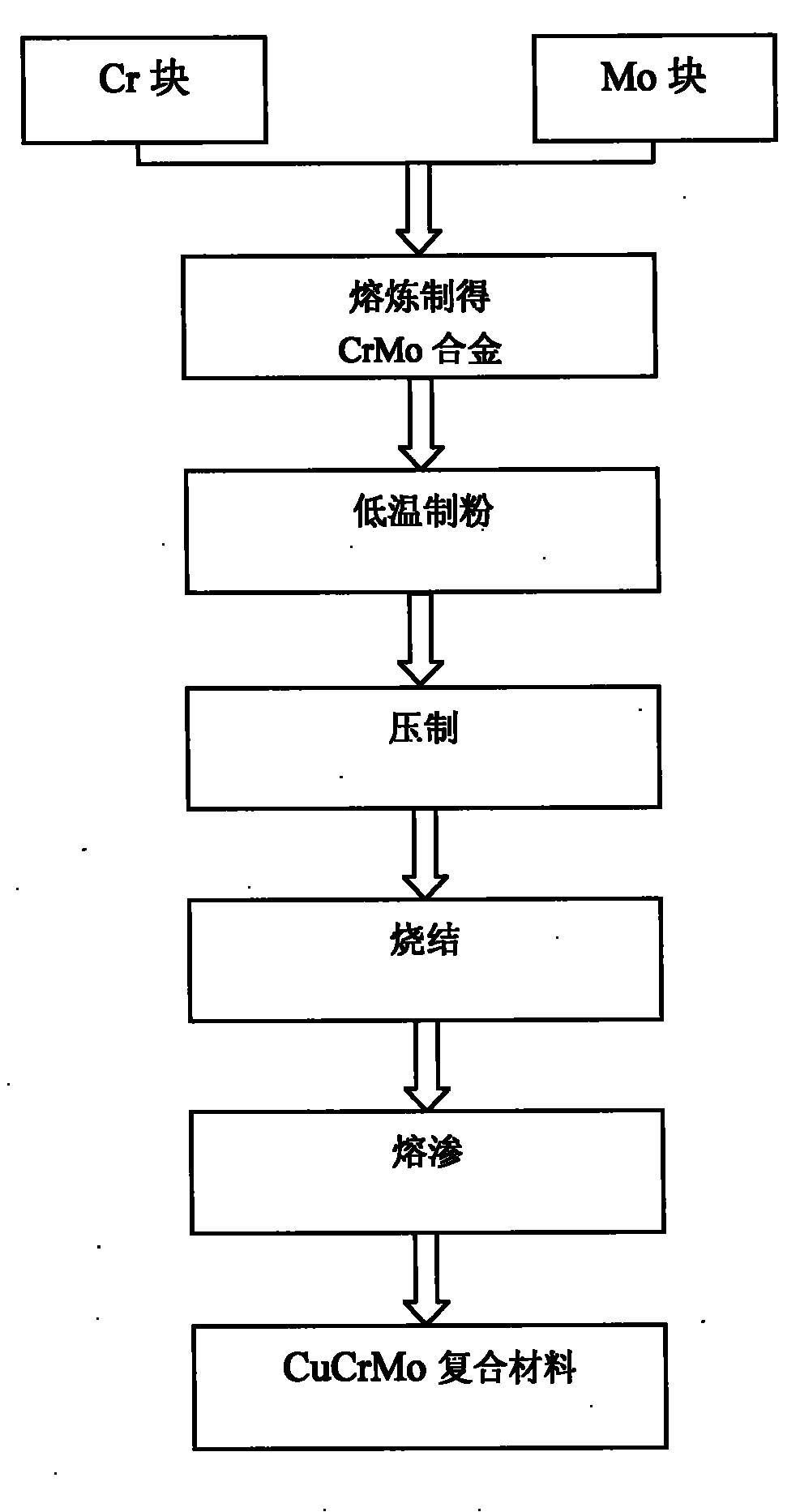

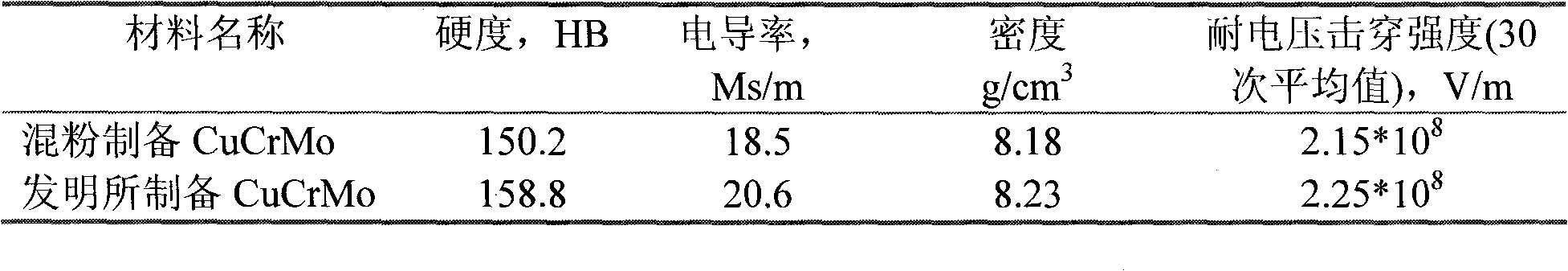

Method for preparing CuCrMo contact material by adopting CrMo alloy powder

The invention discloses a method for preparing a CuCrMo contact material by adopting CrMo alloy powder. In the method, Cr blocks and Mo blocks are firstly prepared into intermediate alloy, and then through low-temperature grinding and pulverizing, CrMo alloy powder is prepared to replace Cr and Mo mixed powder to prepare a CuCrMo electrical contact, wherein the CuCrMo electrical contact comprises the following components in percentage by weight: 10 percent of Mo, 40 percent of Cr and the balance of Cu. The electrical contact is obtained through the following method of: smelting the Cr blocks and the Mo blocks in a vacuum furnace; preparing the CrMo alloy powder through low-temperature pulverizing; preparing a CrMo skeleton through press molding and sintering; and then infiltrating Cu to prepare a CuCrMo composite material. The preparation method has simple process and low cost; and compared with a CuCrMo composite material prepared by direct powder mixing, the prepared CuCrMo composite material has more excellent properties.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Nylon composite material used for selective laser sintering and preparation method of nylon composite material

InactiveCN107974077AIncrease contentEvenly distributedAdditive manufacturing apparatusAdditive manufacturing with solidsSelective laser sinteringPolymer science

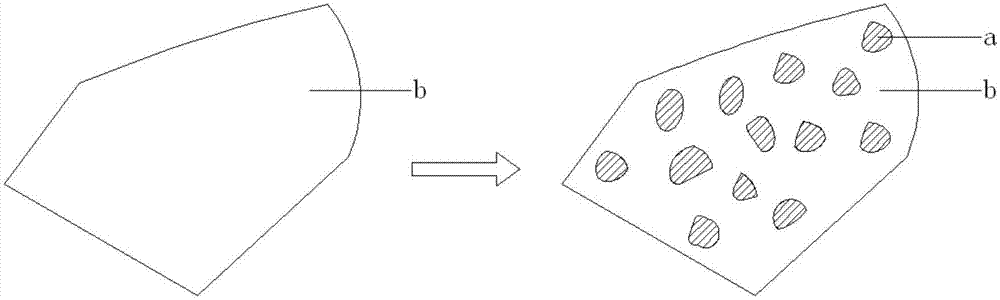

The present invention provides a nylon composite material used for selective laser sintering. The nylon composite material is prepared from the following components in percentages by mass: 10%-30% ofa nylon raw material, 66%-88% of tungsten powder, 1%-2% of a coupling agent, and 1%-2%of a molecular weight modifier. According the method provided by the present invention, the nylon raw material, the tungsten powder, the coupling agent and the molecular weight modifier are added into a polymerization kettle, and a nylon composite material is prepared in the polymerization kettle under the stirring condition; and then the powder particle size is controlled by adjusting a cryogenic grinding process, after drying is performed, other auxiliary agents are added, and therefore the high-tungsten-content nylon composite material is obtained. When the material provided by the invention is used to the selective laser sintering process, a workpiece with a complex shape, low costs and a high densitycan be prepared, and the workpiece has better radiation resistance.

Owner:HUNAN FARSOON HIGH TECH CO LTD

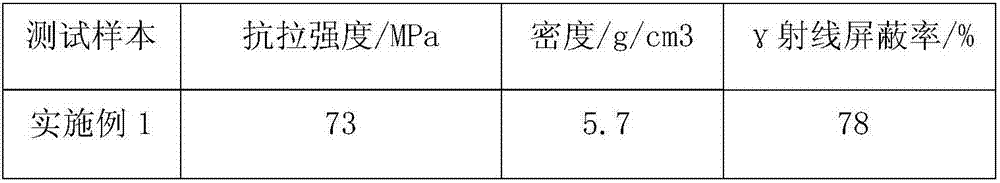

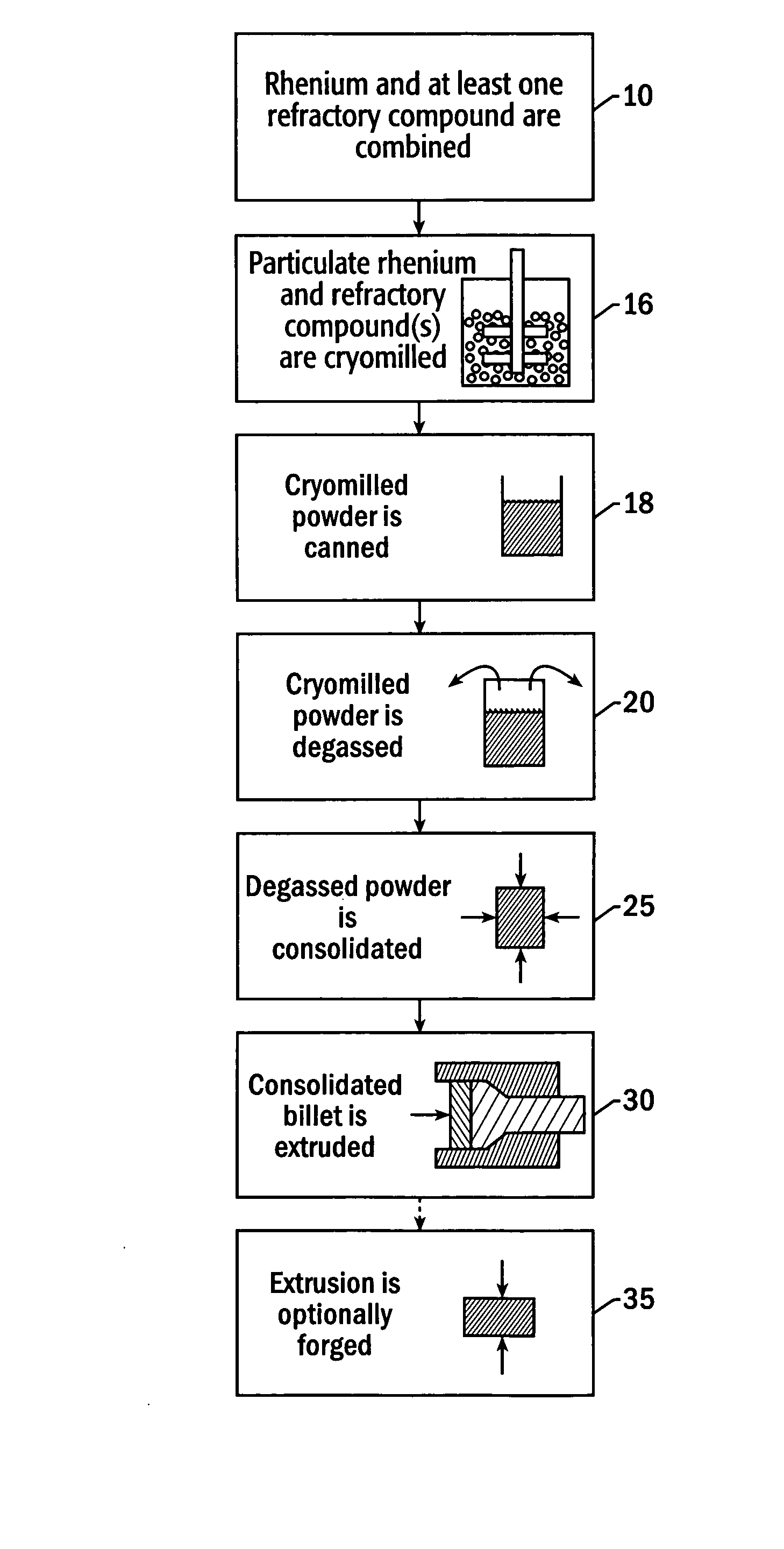

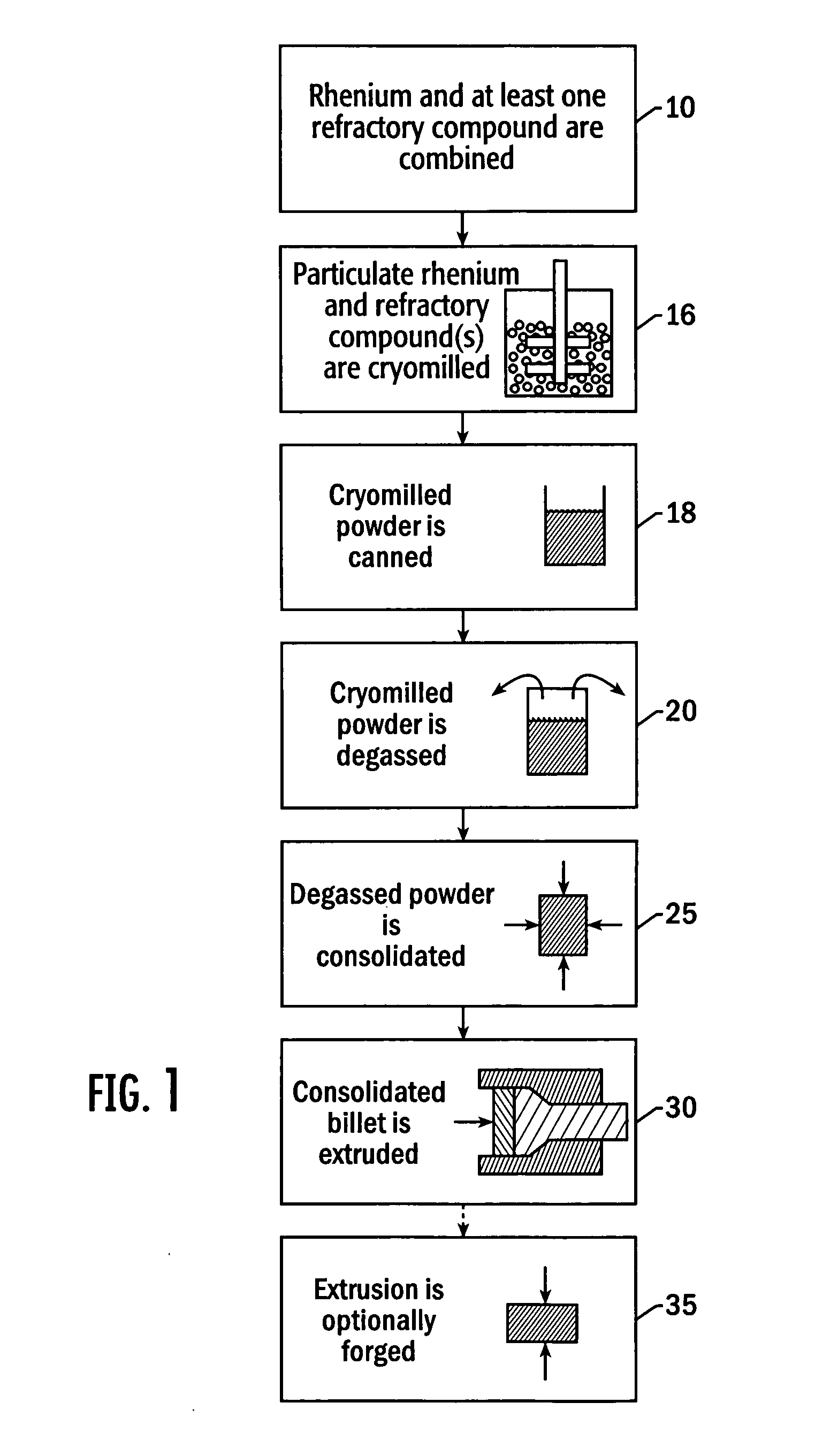

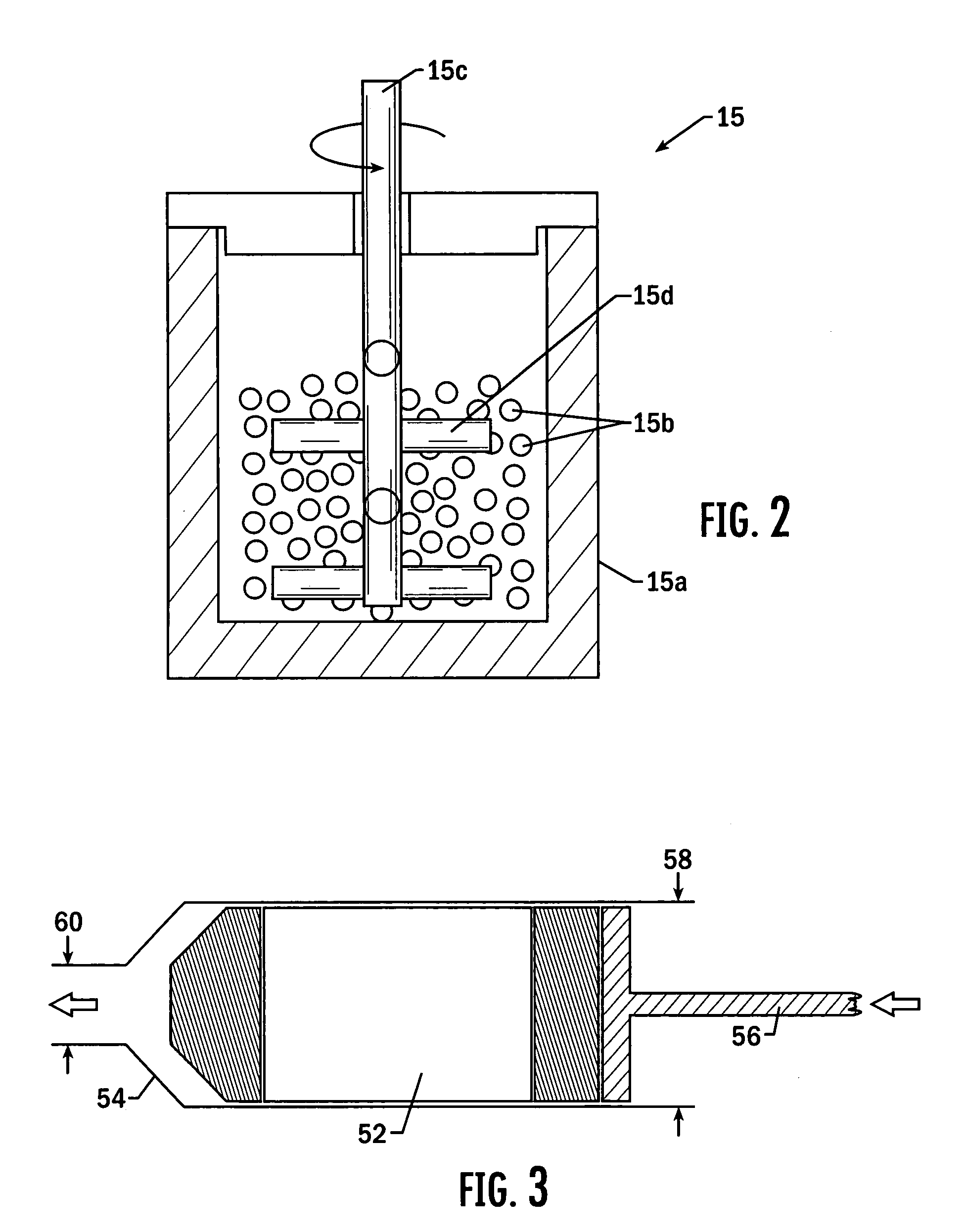

Rhenium composite alloys and a method of preparing same

ActiveUS20080003452A1Improve mechanical propertiesMinimizing its growthThin material handlingCryogenicsRheniumParticulates

A rhenium alloy is provided having from about 50 atomic % to 99 atomic % rhenium and a refractory compound particulates that are present in the alloy in an amount up to about 10 atomic %. The refractory compound comprises a nano-scale dispersion that is incorporated into the conventional rhenium structure. The nano-scale dispersion acts as grain boundary pins that result in a relatively fine grained, equiaxed structure that improves the mechanical properties of the alloy and helps to minimize the growth of large grains during operations at high temperatures. As a result, the amount of the rhenium used in high temperature applications may be reduced without sacrificing its high temperature and mechanical properties. Cryomilling in the presence of nitrogen may be used to prepare the rhenium alloy having a stable fine grain structure at high temperatures.

Owner:THE BOEING CO

High-barrier composite plastic allowing direct blow molding and preparation method

The invention belongs to the technical field of preparation of high-barrier composite plastic and provides high-barrier composite plastic allowing direct blow molding and a preparation method. According to the method, surface-modified graphene oxide is firstly prepared and mixed with an ethylene-vinyl alcohol copolymer, an ethylene-vinyl acetate copolymer and silicon dioxide aerogel in a certain ratio, high-density polyethylene grafted maleic anhydride is added, and low-temperature grinding and homogenization are performed; a product, high-density polyethylene and an antioxidant are subjected to extrusion palletization, and the high-barrier composite plastic allowing direct blow molding is obtained. Silicon dioxide aerogel has a porous network structure and is interwoven and compounded with a polymer and graphene, an interweaving body structure capable of obstructing oil, gas and water is formed in the whole system, a directly blow-molded film has high barrier property, and defects of complicated conventional barrier film multi-layer composite process and high cost are overcome.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

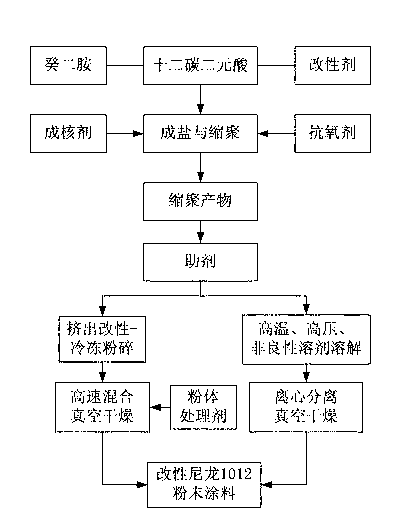

Modified nylon 1012 powder coating and preparation method thereof

InactiveCN102888182ALow melting pointSimple preparation processPowdery paintsPolyamide coatingsDiaminePowder coating

The invention discloses a modified nylon 1012 powder coating and a preparation method thereof. The nylon powder coating is prepared by uniformly mixing decamethylene diamine, dodecanedioic acid and a modifying agent, carrying out polycondensation and carrying out extrusion modification-cryogenic grinding or solvent grinding, wherein the mass percents of the decamethylene diamine, the dodecanedioic acid and the modifying agent are respectively 25-40%, 35-54% and 6-40%. The modified nylon 1012 powder coating and the preparation method have the following beneficial effects that the modified nylon 1012 powder coating can overcome such defects of the ordinary nylon 1012 powder as high melting point, poor powder flowability and difficult construction and has the characteristics of good powder flowability and convenience in thermal spraying construction; the preparation method is simple and is easy to implement; the product yield is high; the grain size of the powder is easy to control; and the modified nylon 1012 powder coating can realize large scale production and is convenient to popularize and apply.

Owner:NANJING RATE BIOCHEM

Epoxy resin conductive adhesive for electronic packaging

InactiveCN107686713AIncrease chance of contactImprove conductivityEpoxy resin adhesivesElectrically-conducting adhesivesEpoxyAdhesive

The invention discloses epoxy resin conductive adhesive for electronic packaging, and belongs to the technical field of adhesive. The epoxy resin conductive adhesive for electronic packaging is prepared from the following steps: stirring and mixing graphene oxide and water in an amount which is 10 to 20 times of the weight of the graphene oxide, cryogenic grinding, dissolving, filtering and dryingto obtain pretreated graphene oxide; and performing heating, stirring and refluxing reaction on 5 to 6 parts of graphene oxide, 8 to 10 parts of polyamine curing agent and 15 to 20 parts of diluent,adding 50 to 60 parts of epoxy resin, 5 to 6 parts of modified nano-copper powder, 5 to 6 parts of modified silver nanowire and 1 to 2 parts of coupling agent, stirring and mixing to obtain the epoxyresin conductive adhesive for electronic packaging. The epoxy resin conductive adhesive for electronic packaging, which is provided by the technical scheme of the invention, has excellent electrical conductivity and shearing strength.

Owner:常州市沃兰特电子有限公司

Method for preparing high-purity low-oxygen chromium metal powder

ActiveCN111922351AReduce oxygen contentLow costTransportation and packagingMetal-working apparatusDeoxygenationCryogenic grinding

The invention discloses a method for preparing high-purity low-oxygen chromium metal powder, and belongs to the technical field of metal material processing. The method comprises the following steps that S1, chromium powder raw materials are prepared, wherein chromium metal is powdered through a low-temperature grinding and smashing method, and the chromium powder raw materials are obtained; S2, powder mixing is carried out, wherein after the chromium powder raw materials in the step S1 are screened, then graphite powder is added, and mixed materials are obtained; S3, pressing is carried out,wherein the mixed materials in the step S2 are pressed into a chromium blank through compression molding forming, then the chromium blank is placed in a low-temperature plasma device for deoxygenationpretreatment; S4, sintering is carried out, wherein the chromium blank obtained after deoxygenation pretreatment is carried out in the step S3 is placed in a vacuum sintering furnace to be sintered,degassed and deoxidized, and a chromium block is obtained; and S5, finished chromium powder is prepared, wherein the chromium block in the step S4 is powdered through the low-temperature grinding andsmashing method, and the high-purity low-oxygen chromium metal powder is obtained. In conclusion, the chromium metal powder prepared through the method has the advantages of being low in oxygen content, low in cost, capable of achieving volume production and the like.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

Method for producing composition for injection molding and composition for injection molding

ActiveUS20130136926A1Low melting pointGood moldabilitySynthetic resin layered productsMetal-working apparatusMetallic materialsInjection molding machine

A method for producing a composition for injection molding which contains an inorganic powder composed of at least one of a metal material and a ceramic material and a binder containing a polyacetal-based resin and a glycidyl group-containing polymer. The method includes: cryogenically grinding a first resin containing the polyacetal-based resin as a main component; cryogenically grinding a second resin containing the glycidyl group-containing polymer as a main component; mixing a powder obtained by grinding the first resin, a powder obtained by grinding the second resin, and the inorganic powder, thereby obtaining a mixed powder; and kneading the mixed powder.

Owner:SEIKO EPSON CORP

Cryogenic grinding of tantalum for use in capacitor manufacture

InactiveUS20160336115A1Easy millingExemption stepsLiquid electrolytic capacitorsCapacitor electrodesElectrolysisEngineering

An electrolytic capacitor comprising an anode comprised of cryogenically milled anode material is described. The cryogenic milling process prepares the active anode material for anode fabrication. The capacitor further comprises a casing of first and second casing members secured to each other to provide an enclosure. A feedthrough electrically insulated from the casing and from the casing and extending there from through a glass-to-metal seal, at least one anode electrically connected within the casing, a cathode, and an electrolyte. The cathode is of a cathode active material deposited on planar faces of the first and second casing members.

Owner:WILSON GREATBATCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com