Normal-temperature grinding production method for fine rubber powder

A production method and technology of rubber powder, which is applied in the field of waste rubber product processing, can solve problems such as difficulties in start-up, production, maintenance, management, difficulty in adapting to industrial production requirements, and unstable quality of rubber particles, and achieve high raw material utilization and structure. Compact and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

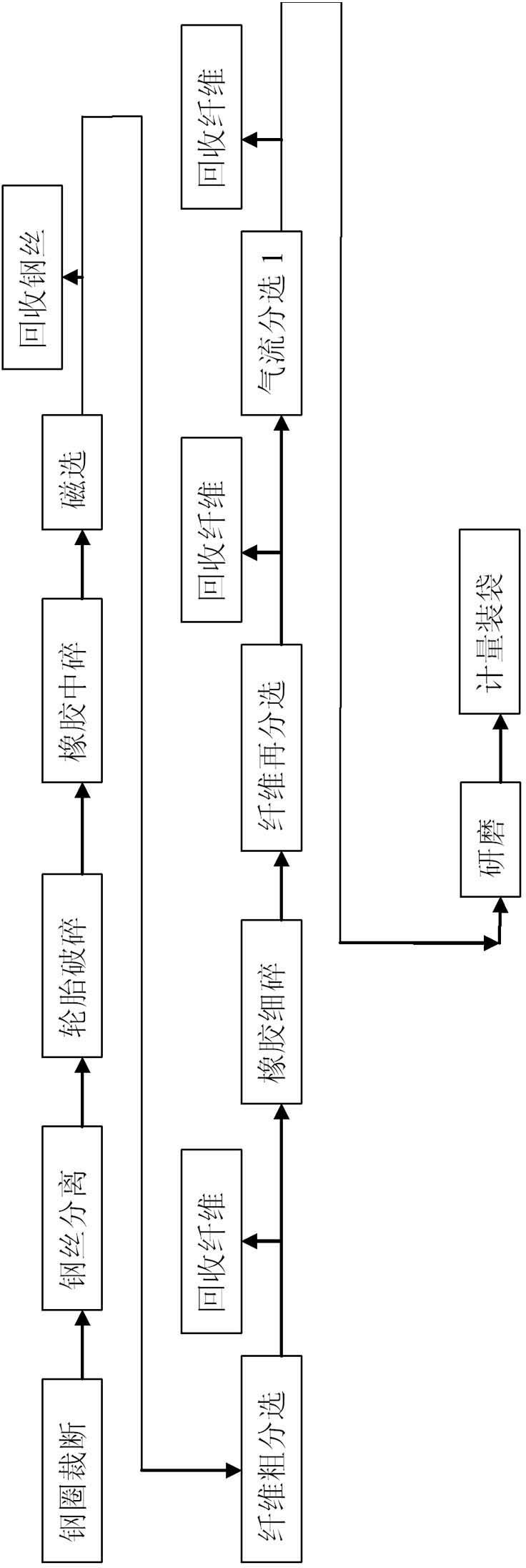

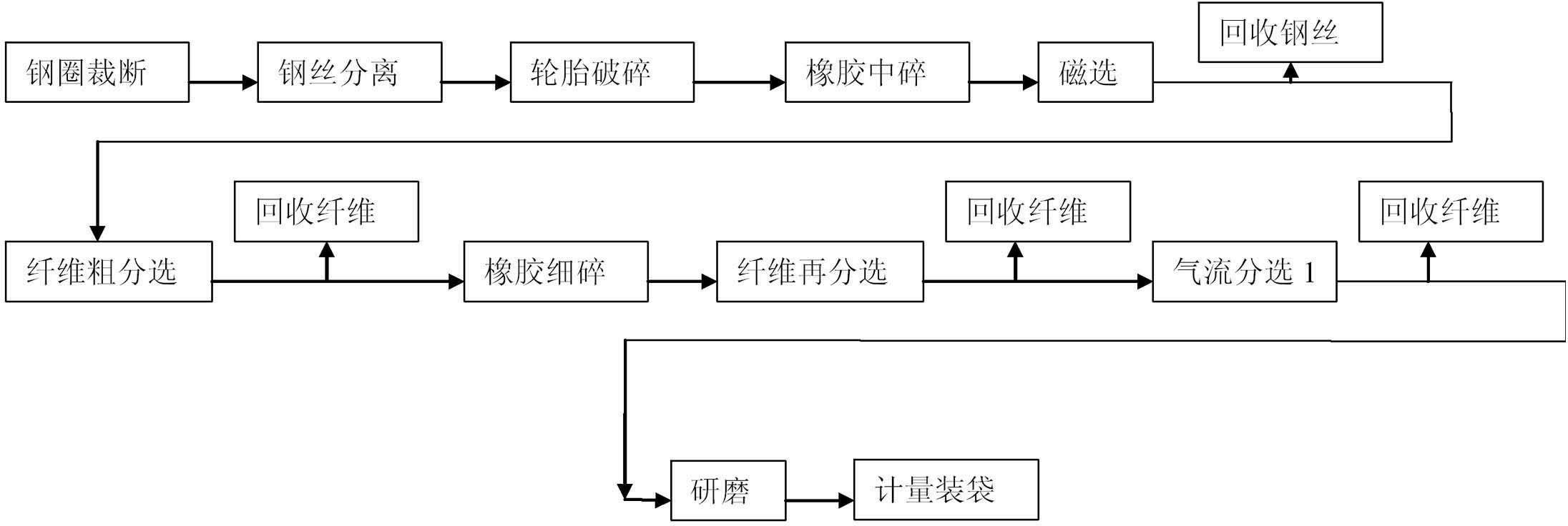

[0029] See accompanying drawing, its production method is:

[0030] 1) Steel ring cutting: Cut the waste tires on the steel ring cutting machine to cut the tire seam bead ring; (A utility model patent has been applied for, and the patent number is ZL200820043072.4)

[0031] 2) Steel wire separation: After the tire with the bead bead cut off is passed through the bead separator, the bead bead is separated from the tire (a utility model patent has been applied for, and the patent number is ZL201120168364.2);

[0032] 3) For tire crushing, the whole tire that has broken away from the bezel wire ring is directly transported to the tire crusher (has obtained the utility model patent right, the patent number is ZL201020298420.X) for the first complete tire crushing. After the whole tire is crushed, the output is about 50mm×50mm block rubber, and the size of the output can be adjusted within a certain range by changing the roller screen of the crusher;

[0033] 4) Crushing in the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com