Preparation method of ultrafine low precipitation red phosphorus inflaming retarding glass fiber reinforced nylon

An ultra-fine, red phosphorus technology, applied in the field of polymer materials, can solve problems such as the influence of particle size precipitation of red phosphorus powder that is not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

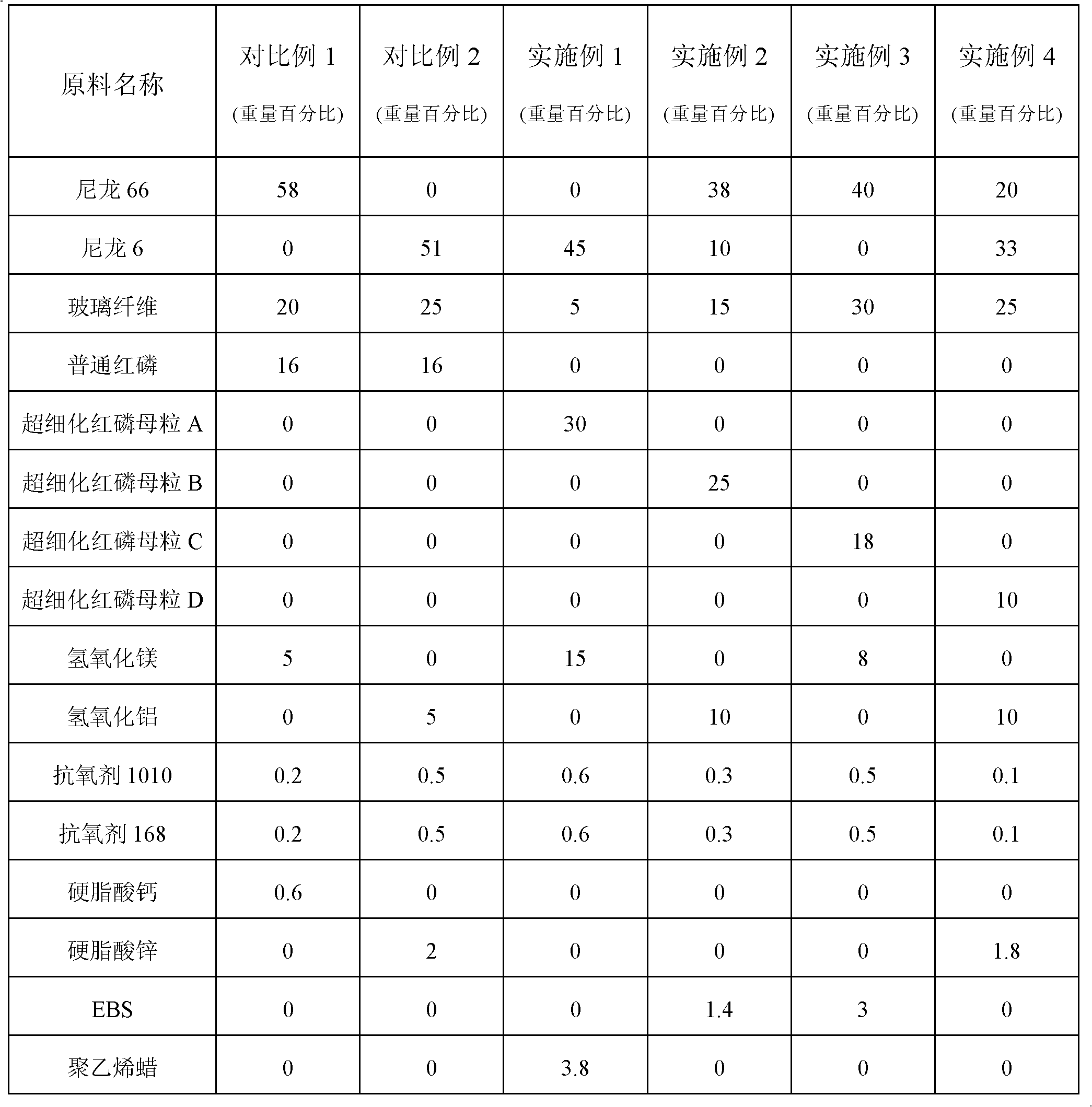

[0029] Specific implementation plan

[0030] The following examples are used to further explain the present invention, but the present invention is not limited to these examples.

[0031] 1. Preparation of ultra-fine red phosphorus masterbatch

[0032] The red phosphorus with a particle size above 1250 meshes crushed by liquid nitrogen is mixed with 1% high temperature silicone oil, and then it is extruded and granulated with maleic anhydride grafted SBS in an extruder. The content of toughening agent in the masterbatch is 70%. It is superfine red phosphorus masterbatch A.

[0033] The red phosphorus crushed by liquid nitrogen with a particle size of 1250 mesh or more is mixed with 3% high-temperature silicone oil, and then is extruded and granulated with maleic anhydride grafted SEBS in an extruder. The content of toughening agent in the masterbatch is 50%. It is superfine red phosphorus masterbatch B.

[0034] The red phosphorus whose particle size is above 1250 meshes crushed by li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com