Preparation method of metal chromium powder special for high-performance CuCr electrical contact

A technology of metal chromium powder and electrical contacts, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of high oxygen content of CuCr contacts, too fine particle size of chromium powder, increased oxygen content of chromium powder, etc., to achieve moist Good wettability, low oxygen content, good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

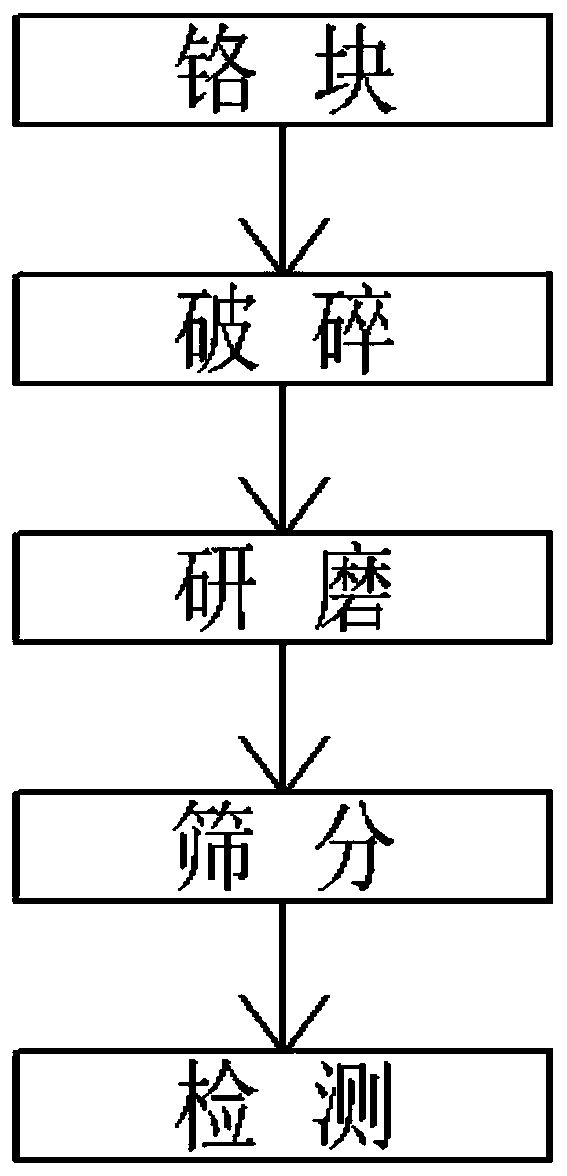

[0020] Embodiment 1: a kind of preparation method of high-performance CuCr electric contact special metal chromium powder, comprises the following steps:

[0021] (1) Broken, put the chromium block into the crusher, and the chromium block is broken into granular form; the granular chromium block is screened with a 10mm aperture screen, and the chromium particles under the sieve are selected, and the chromium particle size is 10mm; use this particle size range Chromium particles are mainly for the convenience of the next grinding process;

[0022] (2) Grinding, vacuumize the low-temperature grinding and pulverizing equipment, and keep the vacuum at -0.08Mpa to prevent the chromium particles from being oxidized. Add the chromium particles to the low-temperature grinding and pulverizing equipment, and then pass in the cooling medium, which is cryogenic liquid Nitrogen, the temperature is controlled at -30°C to obtain metal chromium powder;

[0023] (3) sieve, metal chromium powd...

Embodiment 2

[0025] Embodiment 2: a kind of preparation method of metal chromium powder special for high-performance CuCr electric contact, comprises the following steps:

[0026] (1) Broken, put the chromium block into the crusher, and the chromium block is broken into granular form; the granular chromium block is screened with a 10mm aperture sieve, and the chromium particles under the sieve are selected, and the chromium particle size is 9mm; use this particle size range Chromium particles are mainly for the convenience of the next grinding process;

[0027] (2) Grinding, vacuumize the low-temperature grinding and pulverizing equipment, and keep the vacuum at -0.10Mpa to prevent the chromium particles from being oxidized. Lower the temperature of the cooling medium to reach the embrittlement temperature of the corresponding chromium particles, and then pass in the cooling medium, the cooling medium is low-temperature liquid nitrogen, the temperature is controlled at -45°C, and the crush...

Embodiment 3

[0030] Embodiment 3: a kind of preparation method of metal chromium powder special for high-performance CuCr electric contact, comprises the following steps:

[0031] (1) Broken, put the chromium block into the crusher, and the chromium block is broken into granular form; the granular chromium block is screened with a 10mm aperture screen, and the chromium particles under the sieve are selected, and the chromium particle size is 9mm; use this particle size range Chromium particles are mainly for the convenience of the next grinding process;

[0032] (2) Grinding, vacuumize the low-temperature grinding and pulverizing equipment, and keep the vacuum at -0.11Mpa to prevent the chromium particles from being oxidized. Lower the temperature of the cooling medium to reach the embrittlement temperature of the corresponding chromium particles, and then pass in the cooling medium, the cooling medium is low-temperature liquid nitrogen, the temperature is controlled at -75°C, and the crus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com