Method for preparing spherical chromium powder by gas atomization

A gas atomization, chromium powder technology, applied in the field of powder metallurgy, can solve the problems of high cost, difficult to control gas content, inability to prepare fine powder, etc., achieve the effect of high density, improve grinding efficiency, and shorten production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

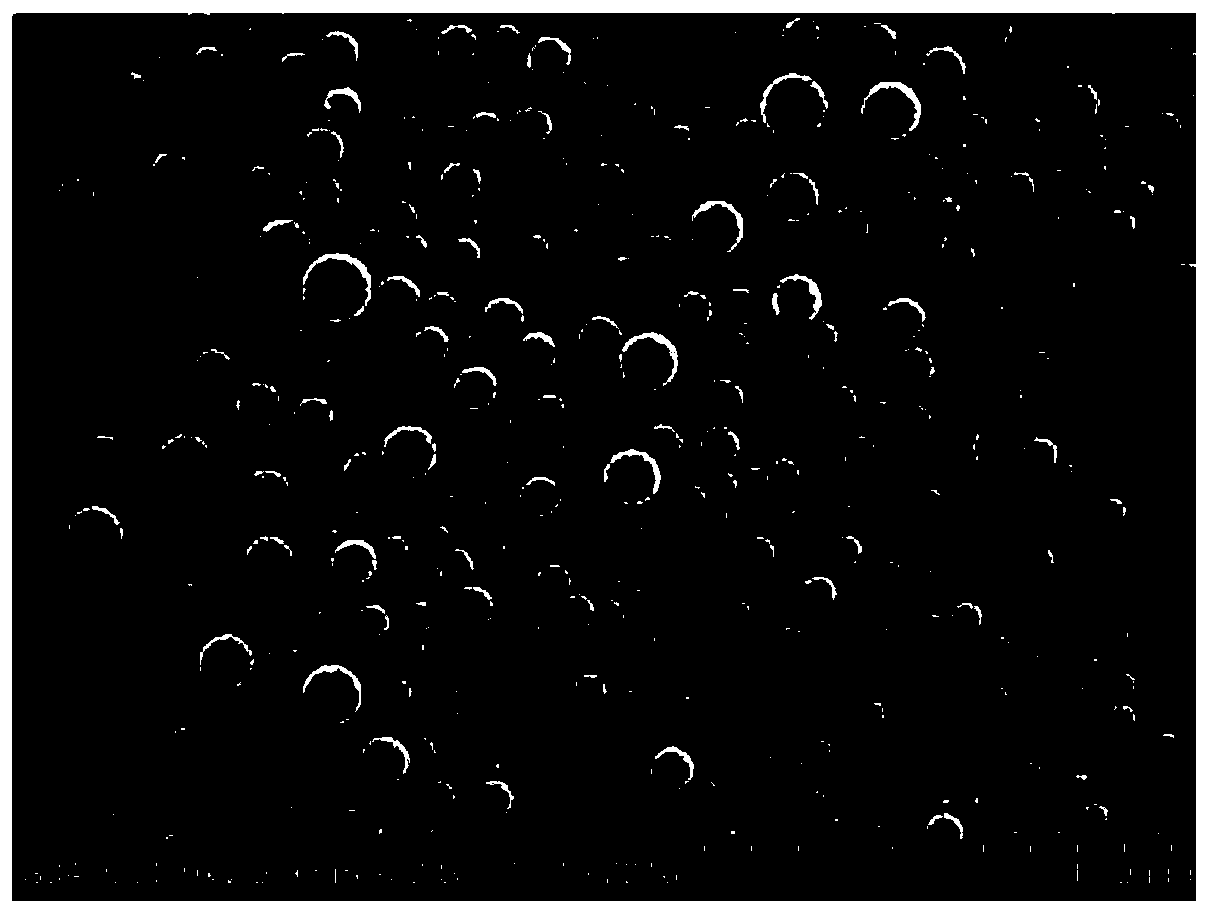

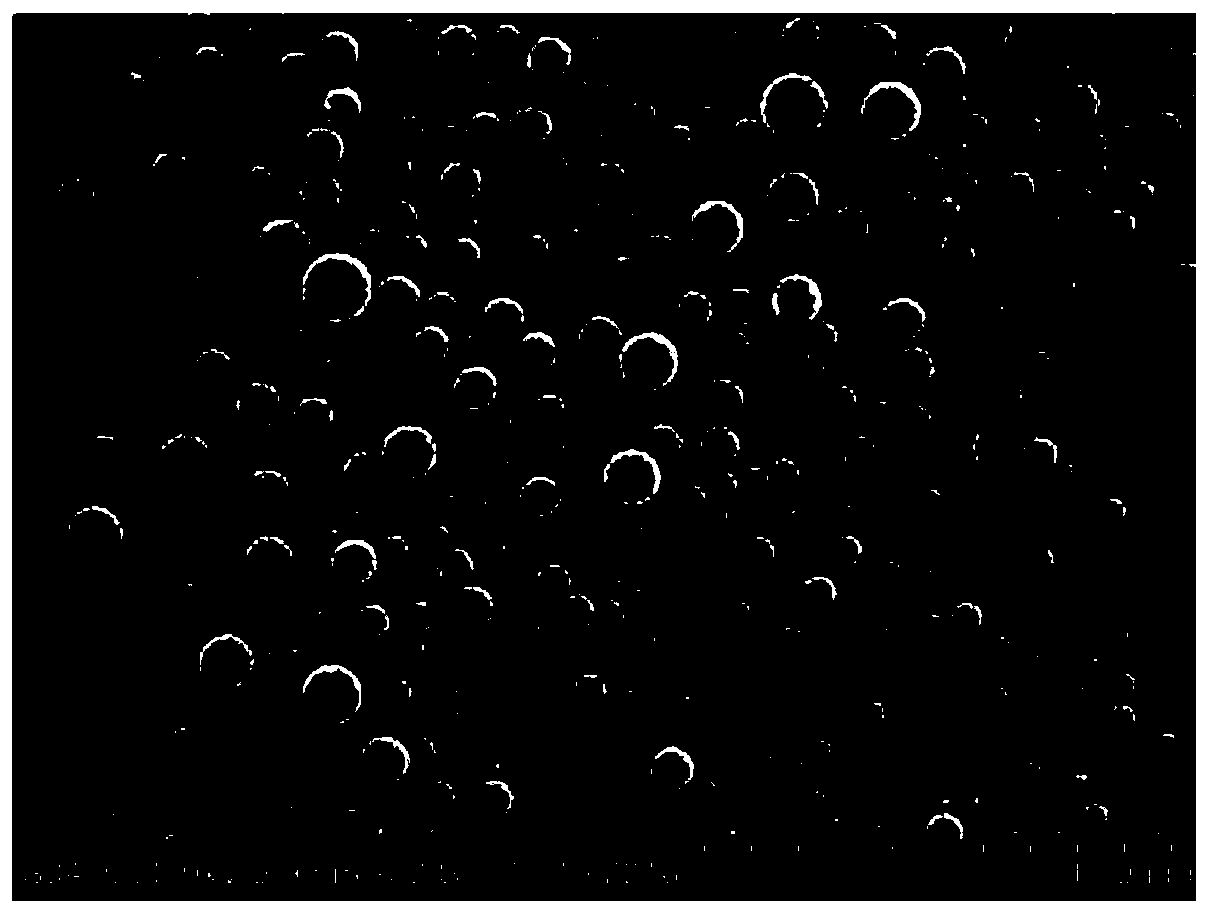

Image

Examples

Embodiment 1

[0022] First remove the surface skin, oxide film and nitrogen film of the chromium block, and use a hydraulic coarse crusher to mechanically crush the chromium block at a water-cooled temperature of -50°C to break it into particles; vibrate the particles at -50°C Grind to make chromium powder, put the chromium powder into the rubber sleeve and vibrate, reverse pier and then press, the pressure is 150MPa, the pressure holding time is 5min, press into chromium rods, put the pressed chromium rods into Sintering is carried out in a vacuum sintering furnace, the maximum sintering temperature is controlled at 1000°C, the holding time is 30 minutes, and the vacuum degree is <100pa. The sintered chromium rods are loaded into EIGA for powder making, and the heating power is 10Kw; the prepared spherical chromium powder has a particle size distribution of 35-45 μm.

Embodiment 2

[0024] First remove the surface skin, oxide film and nitrogen film of the chromium block, and use a hydraulic coarse crusher to mechanically crush the chromium block at water-cooled temperature to break it into particles; vibrate the particles at 10°C to make Chromium powder, put the chromium powder into the rubber sleeve and vibrate, reverse pier and then press, the pressure is 300MPa, the pressure holding time is 20min, press into chromium rods, put the pressed chromium rods into the vacuum sintering furnace For sintering, the maximum sintering temperature is controlled at 1200°C, the holding time is 480min, and the vacuum degree is <100pa. The sintered chromium rods are loaded into EIGA for powder making, and the heating power is 40Kw; the prepared spherical chromium powder has a particle size distribution of 15-25μm.

Embodiment 3

[0026] First remove the surface skin, oxide film and nitrogen film of the chromium block, and use a hydraulic coarse crusher to mechanically crush the chromium block at water-cooled temperature to break it into particles; vibrate the particles at -20°C to make To form chromium powder, put the chromium powder into the rubber sleeve and vibrate, reverse pier and then press, the pressure is 225MPa, the pressure holding time is 12.5min, press into chromium rods, put the pressed chromium rods into vacuum sintering Sintering is carried out in the furnace, the maximum sintering temperature is controlled at 1100°C, the holding time is 240min, and the vacuum degree is <100pa. The sintered chromium rods are loaded into EIGA for powder making, and the heating power is 25Kw; the prepared spherical chromium powder has a particle size distribution of 25- 35 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com