Patents

Literature

122results about How to "Wide particle size range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

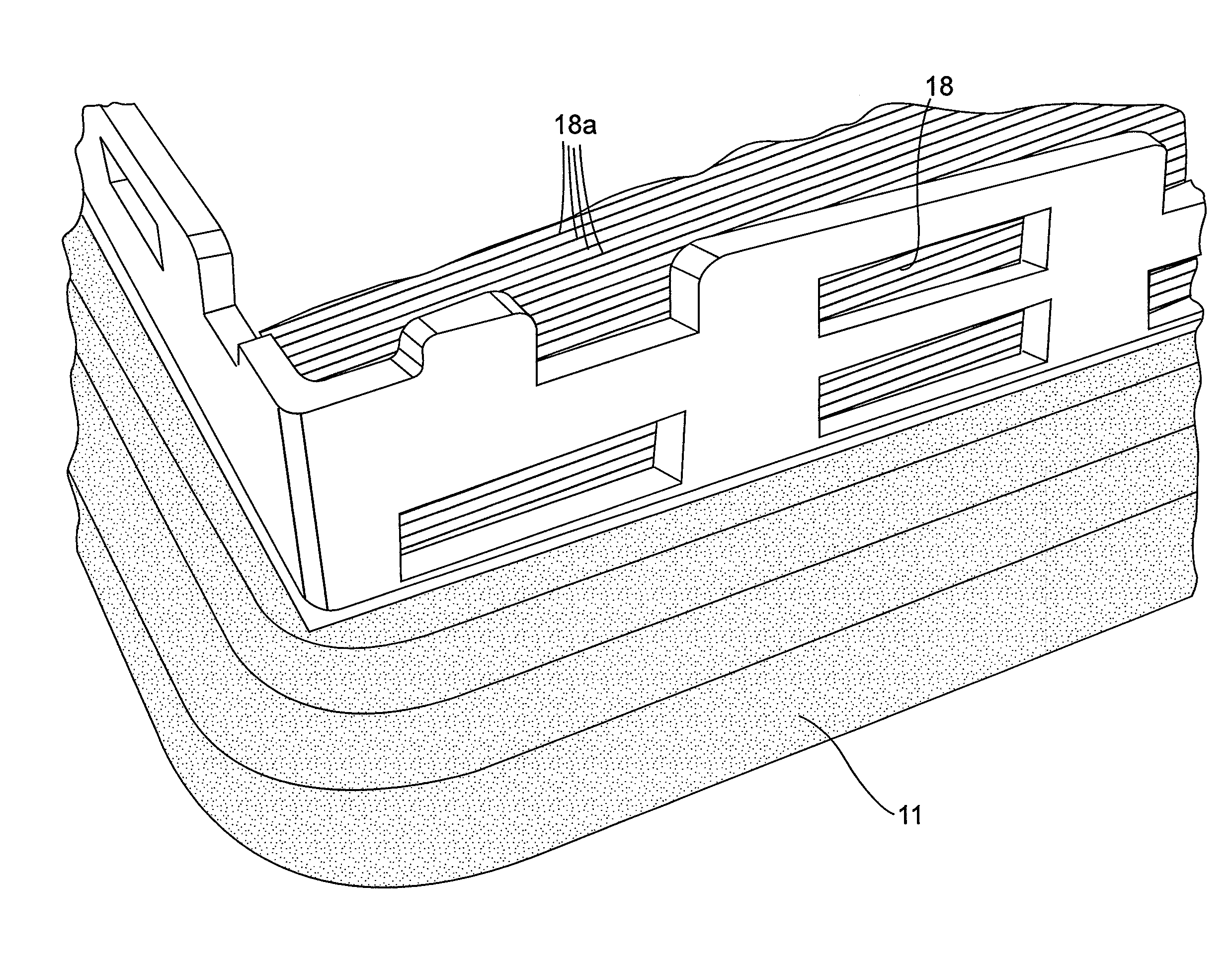

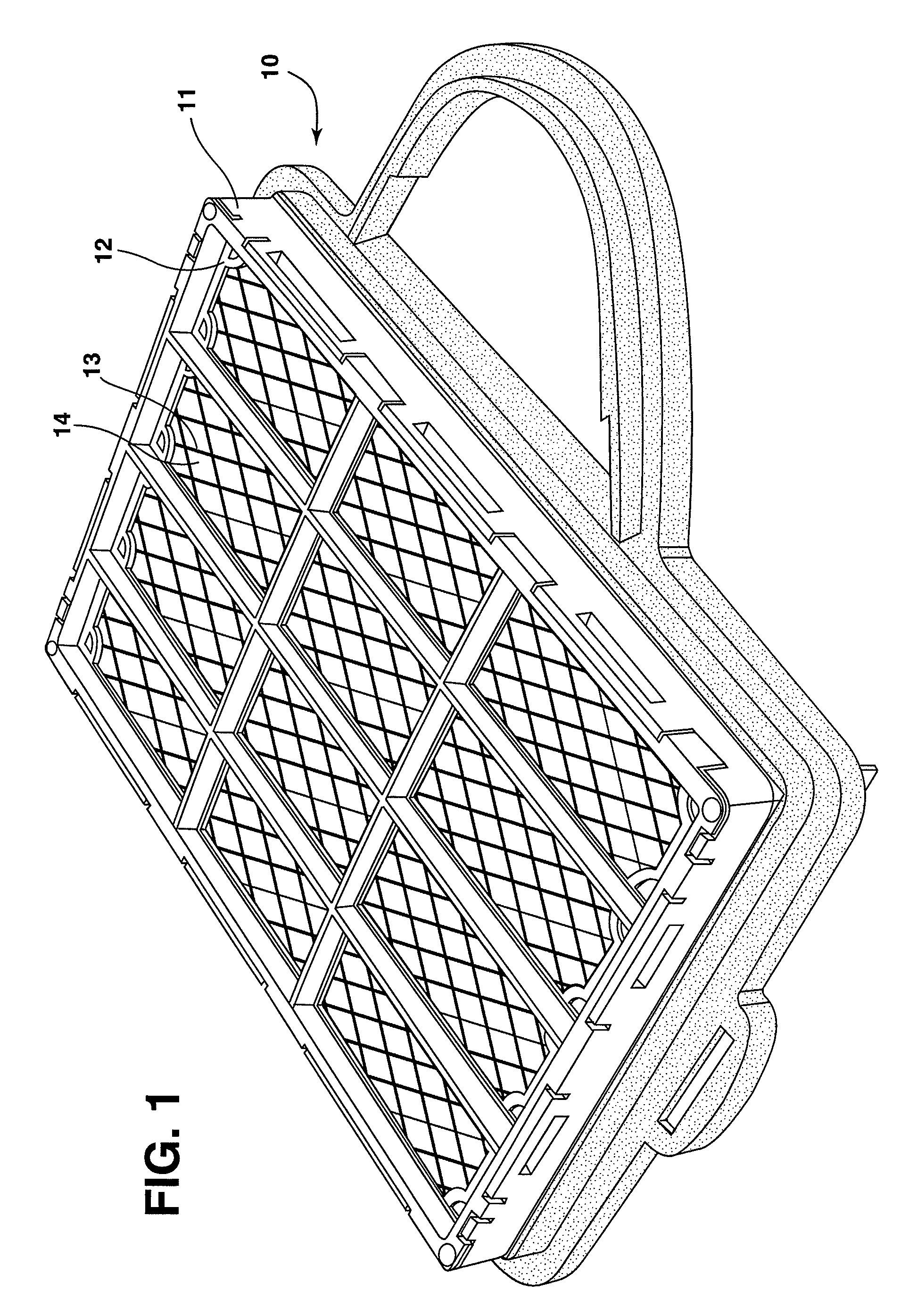

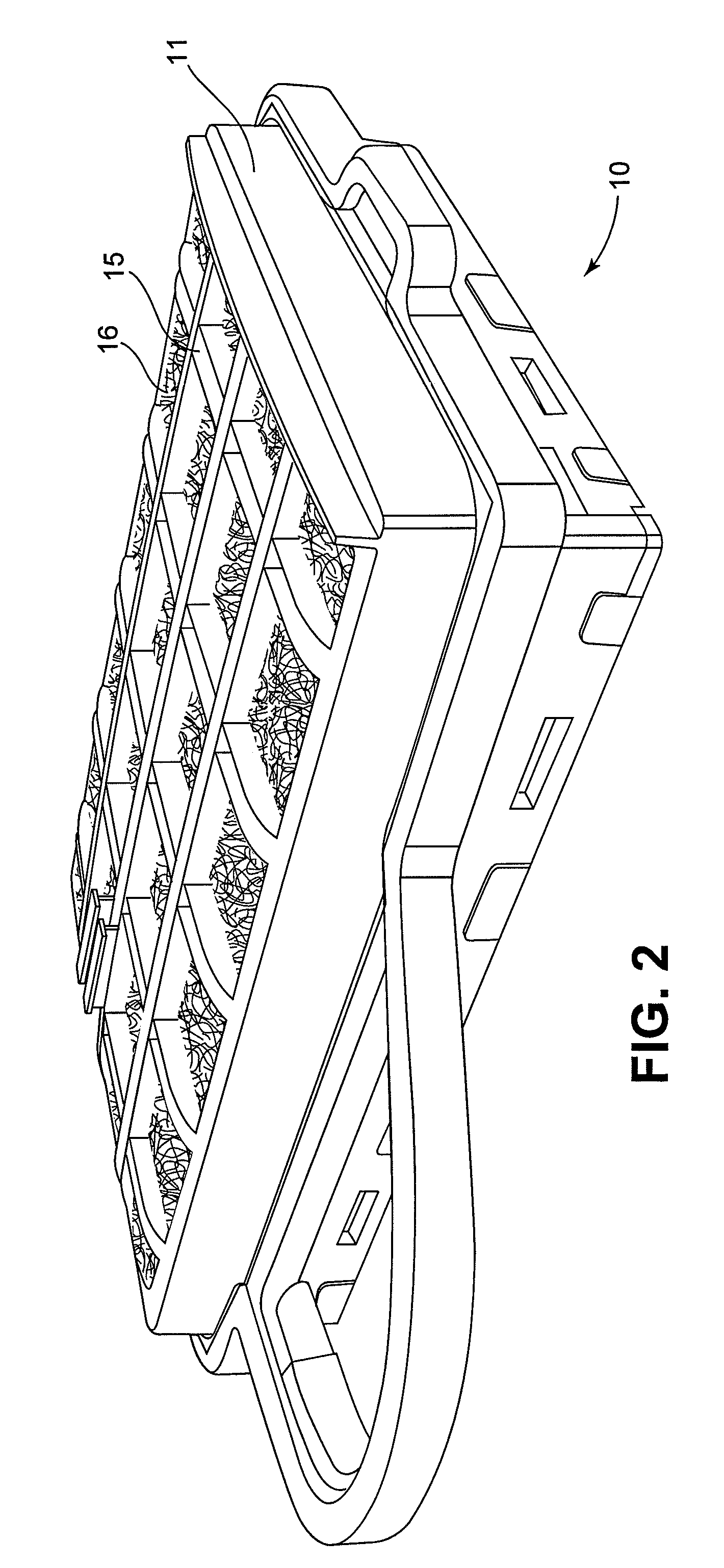

Filter element and method

InactiveUS20090044702A1Life of element can be lengthenedIncrease capacityCombination devicesNon-fibrous pulp additionMultiple formsParticulates

A filter element having multiple formed layers of filtration media is disclosed. The media are layered so as to form a pore size gradient. The filter element is capable of removing both solid and liquid particulates from a moving fluid stream. The filter element has high strength and compressibility. The layers can be supported on a porous or perforate support to provide mechanical stability during filtering operations. The filtration media layers can be formed into various filter element forms such as panels, cartridges, inserts, and the like.

Owner:DONALDSON CO INC

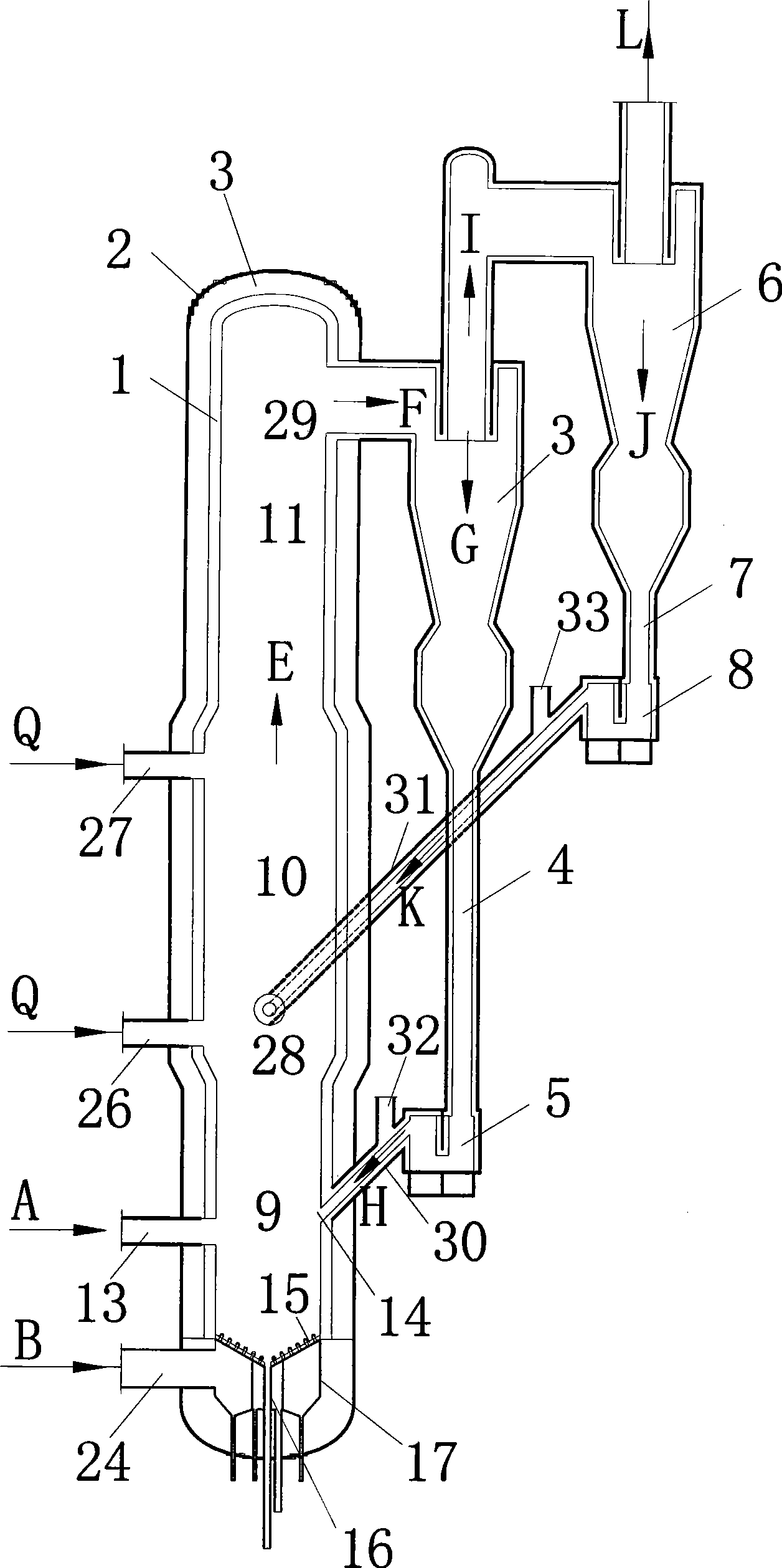

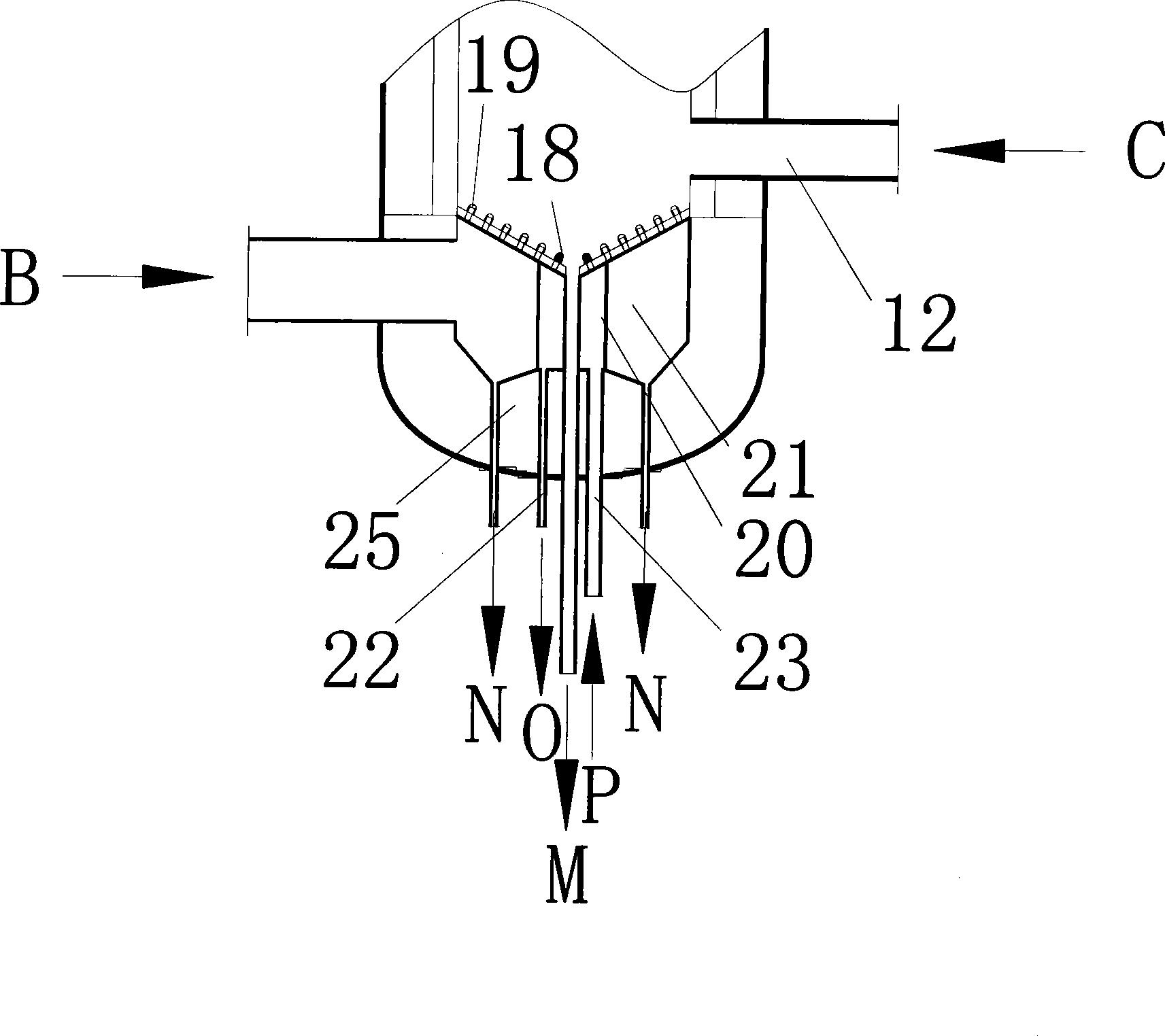

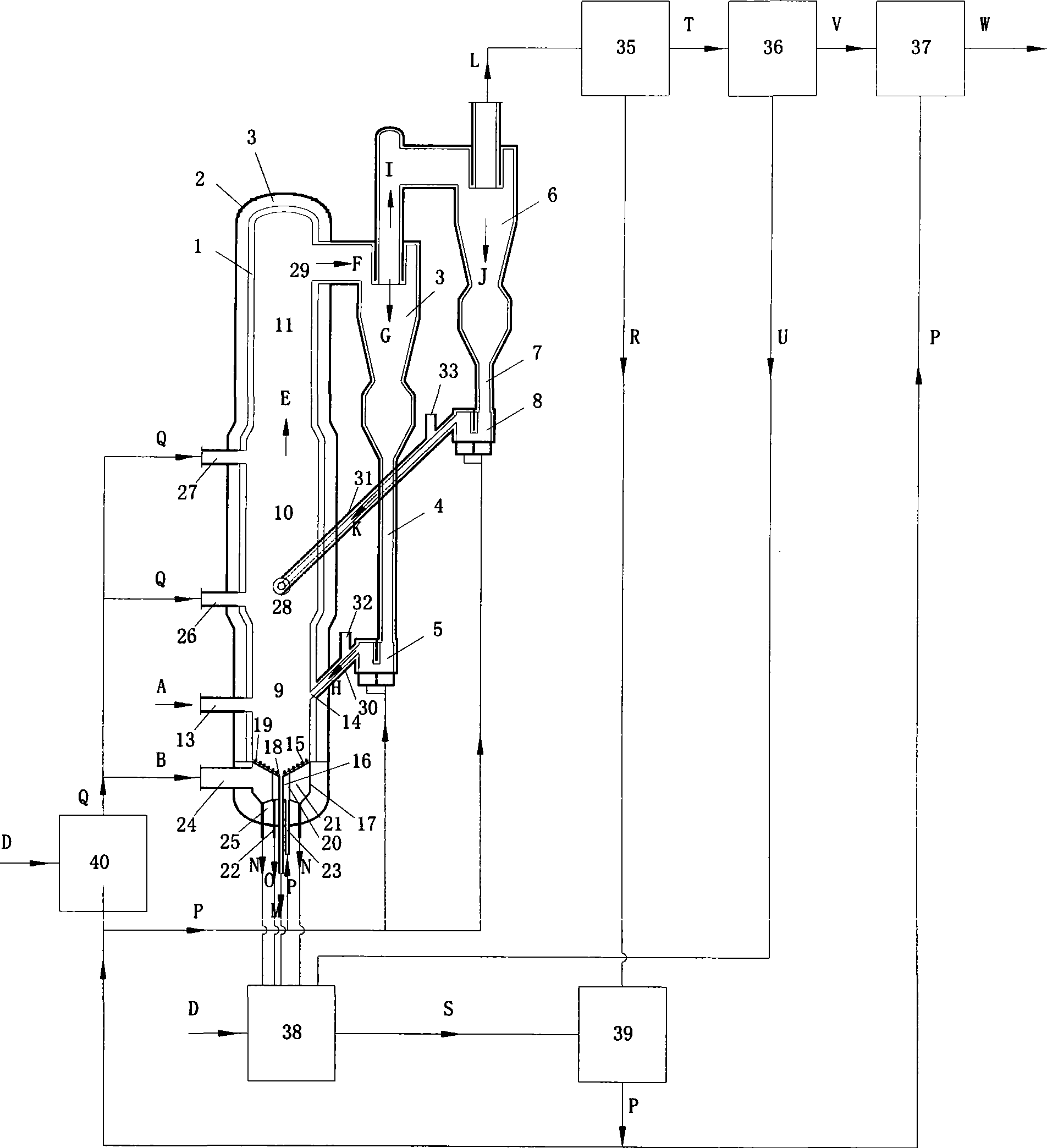

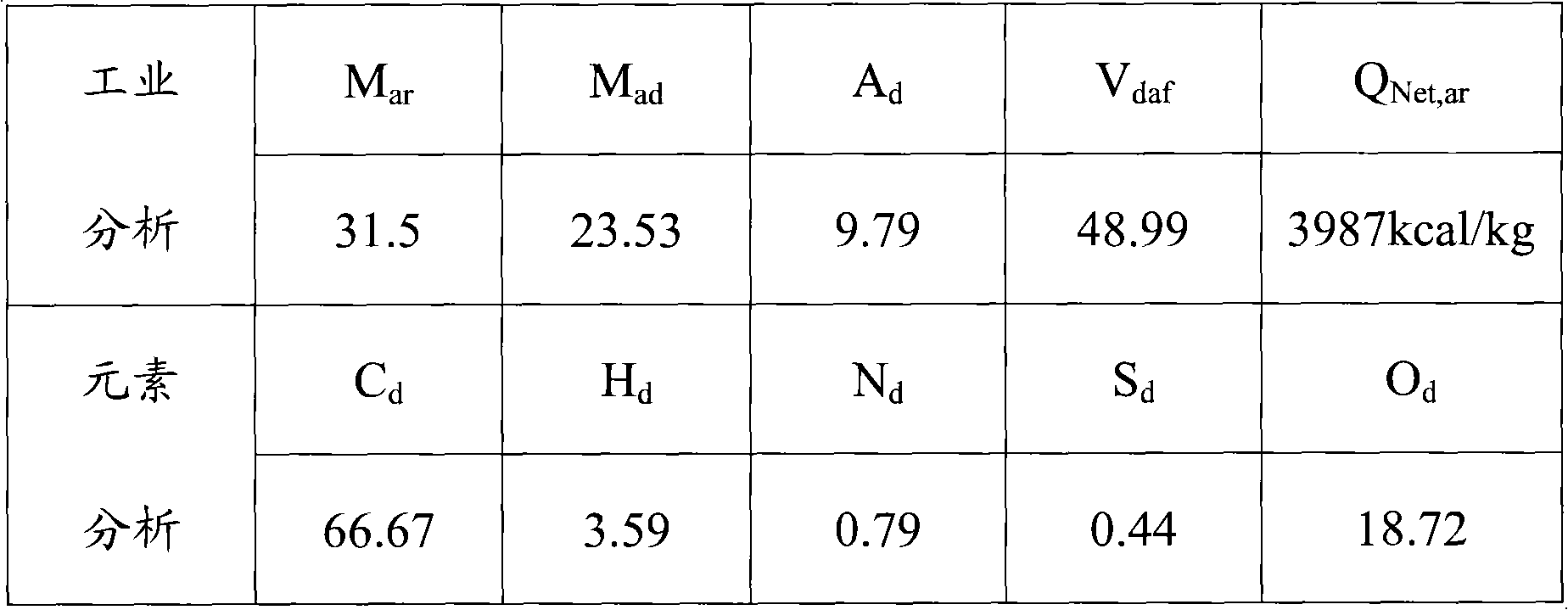

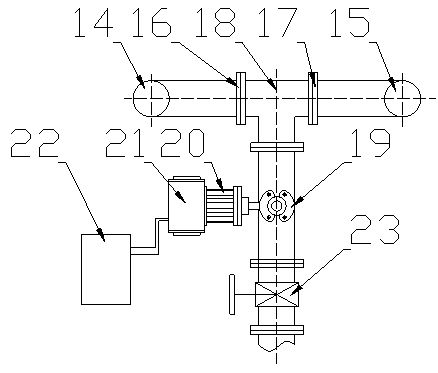

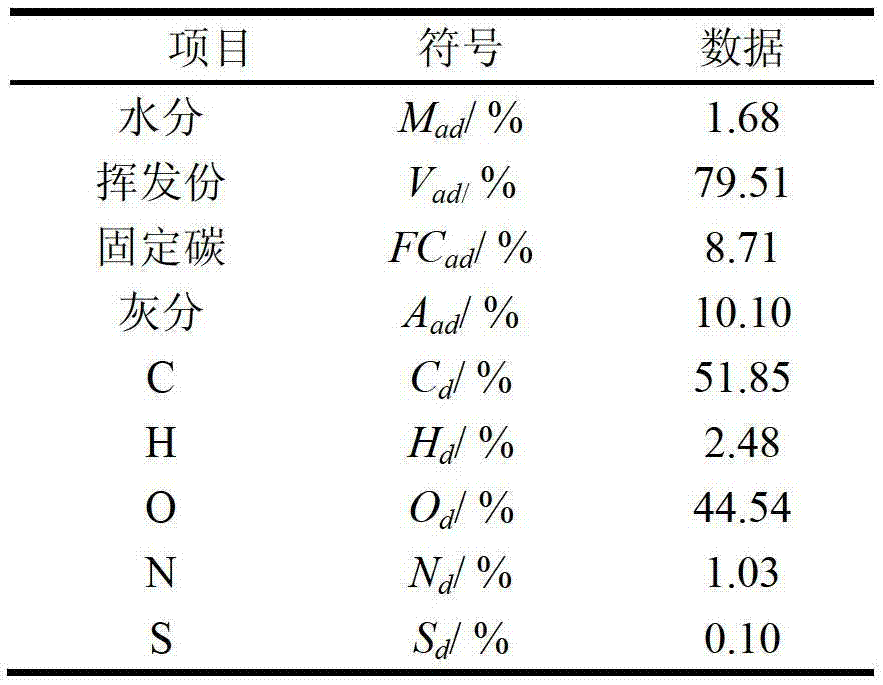

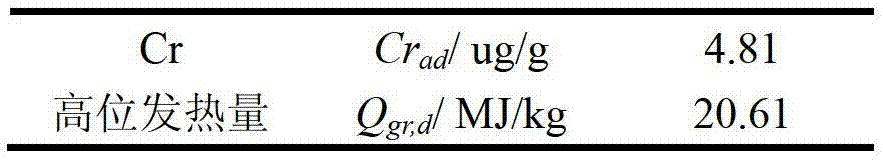

High-density pressurized fluidized bed coal gasification apparatus and method

ActiveCN101372635AGood amplification performance of flow dynamic characteristicsImprove carbon conversionCombined combustion mitigationGranular/pulverulent flues gasificationProcess engineeringTransformation ratio

A high-density pressurized fluid bed coal gasification device and a method relate to a gasification device and a method which are especially suitable for the efficient treatment of the high-sulfur, high-ash and high ash fusion point coal with high reserve volume in China and have the advantages of broad coal type adaptability, high carbon transformation ratio in the gasification process, high heat value of coal gas, low investment and excellent environment-friendly performance. A gasification reactor (1) is arranged in a pressure shell (2) and is divided into a dense-phase turbulent flow fluidizing section (9), a high-density core-annulus flow section (10) and a density rapid flow section (11) from bottom to top, and according to the gasification character of the goal with high sulfur, high ash and high ash fusion point, flow states with different features are adopted for pressurizing and sectionalized gasification from bottom to top and the pressure for gasification is 1.0-2.5MPa.

Owner:SOUTHEAST UNIV

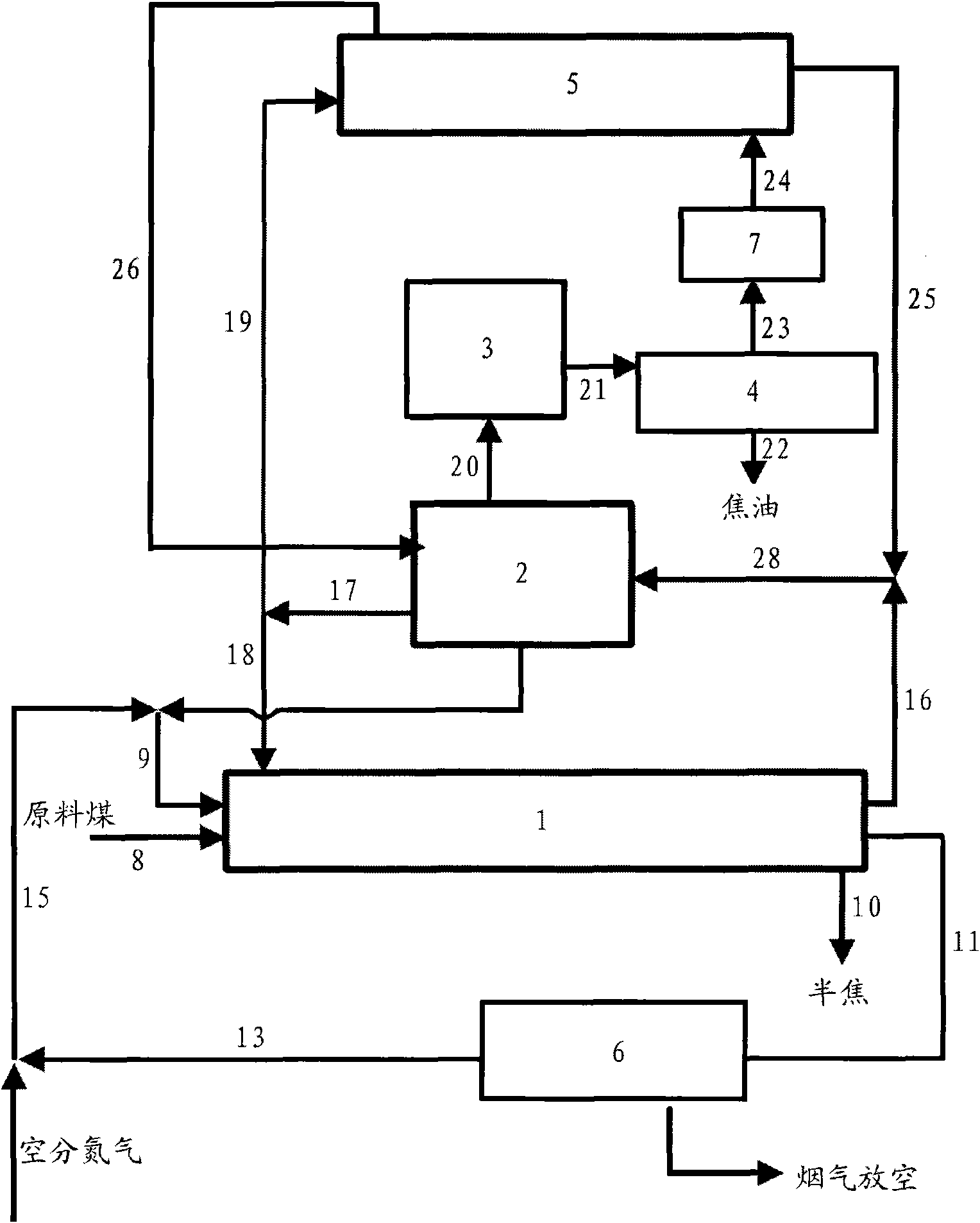

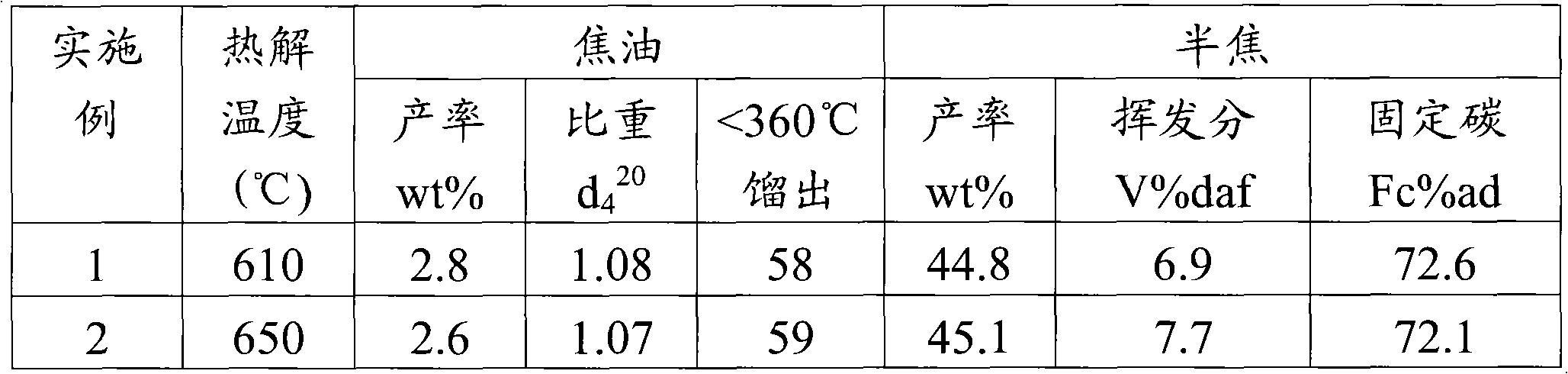

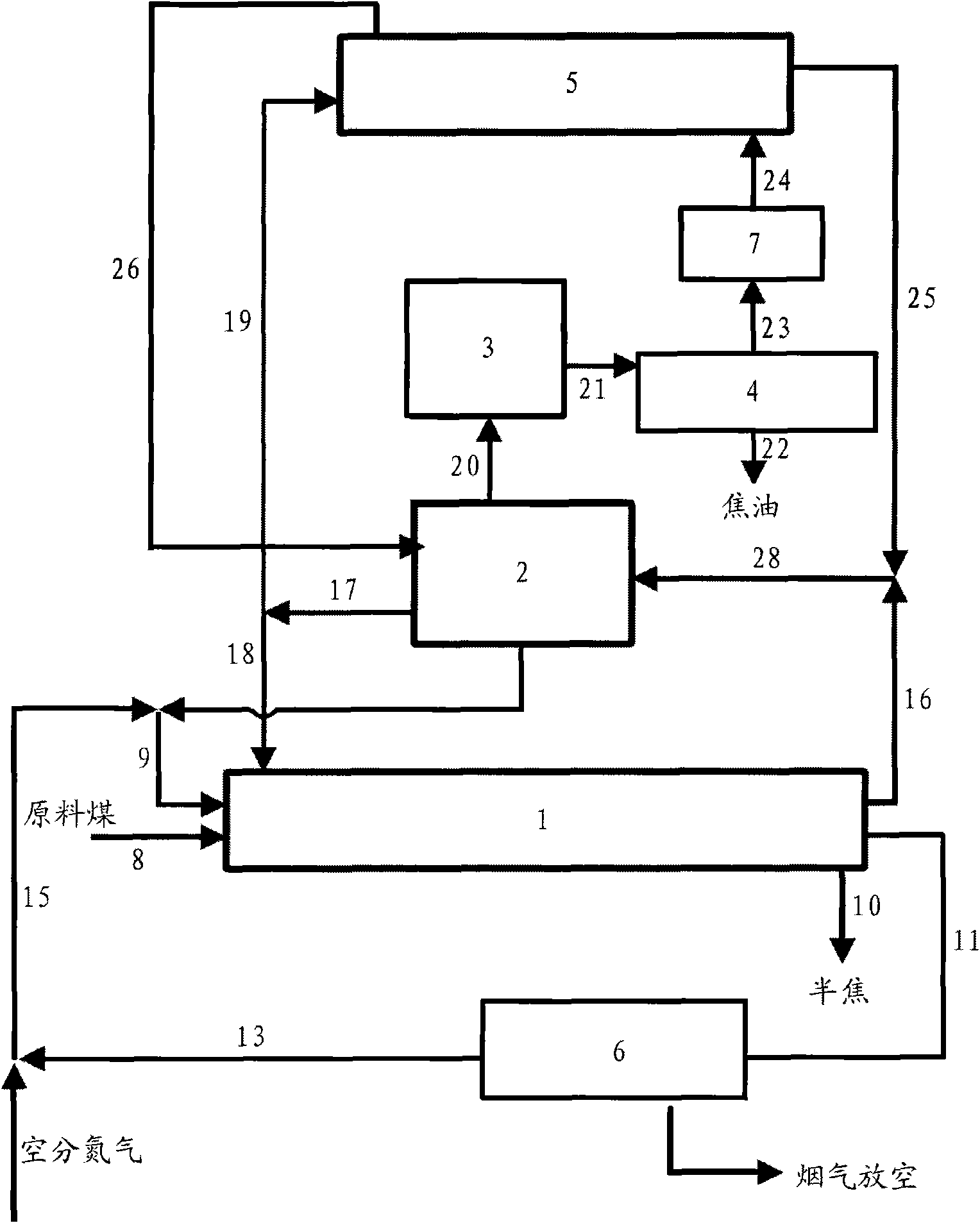

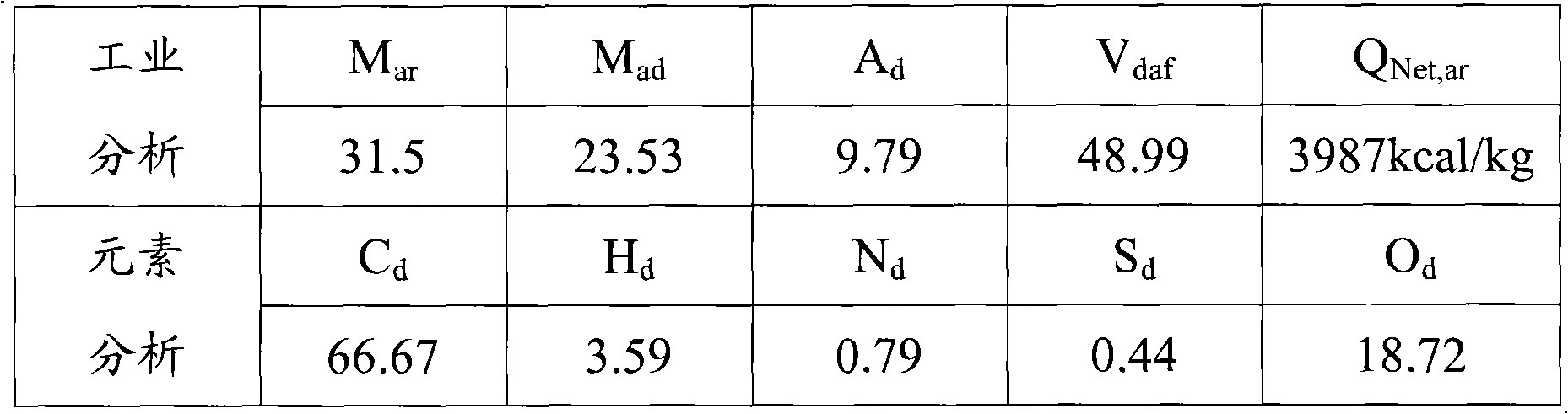

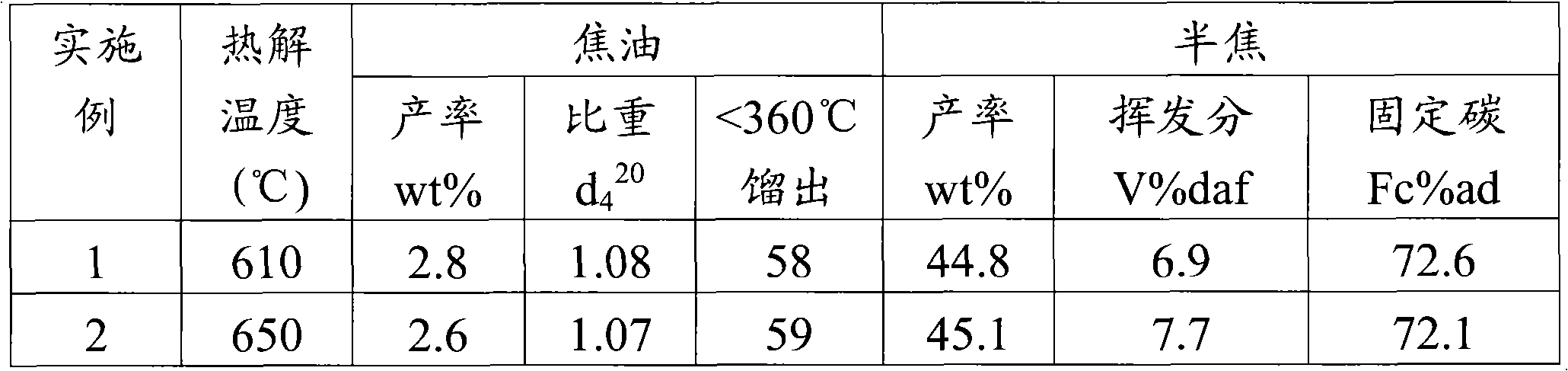

Method for upgrading coal pyrolysis

ActiveCN101608125AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a method for upgrading coal pyrolysis, comprising the following steps: (a) sending raw coal with granularity being less than and equal to 30mm into a rotary drier, so that the raw coal and hot flue gas are connected with each other by the means of parallel flow and directly change heat, and the raw coal exchanges heat indirectly with hot semicoke from a pyrolyzer in the rotary drier, to dry the raw coal; (b) mixing the dried raw coal with the high-temperature semicoke from a heating rotary kiln and sending the mixture into the pyrolyzer, wherein the coal material directly changes heat with the high-temperature semicoke and pyrolyzes to generate hot semicoke, tar steam and coal gas, wherein final pyrolyzing temperature is 500 DEG C-700 DEG C; and (c) sending a part of the hot semicoke generated into the heating rotary kiln for processing by means of heating, and sending the rest part of the hot semicoke into the rotary drier for exchanging heat directly with the raw coal. The method for upgrading coal pyrolysis has flexible operation, wide granularity range of the coal material, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Device for improving quality of coal by pyrolysis

ActiveCN101608126AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a device for improving the quality of the coal by pyrolysis, comprising a rotary drier, a pyrolyzer and a heating rotary kiln. The rotary drier is used for receiving and drying raw coal with granularity being less than and equal to 30mm, and is provided with a sleeve structure to directly change heat between the raw coal and the hot flue gas and indirectly change heat between the raw coal and hot semicoke; the pyrolyzer receives mixture of the dried raw coal and the high-temperature semicoke by a feed line of solid material, directly changes heat between the raw coal and the hot semicoke, pyrolyzes the mixture, and is further provided with a heat clamping sleeve accompanied with high-temperature flue gas; and the heating rotary kiln is used for receiving the hot semicoke from the pyrolyzer and processing the hot semicoke by the means of heating. The device for improving the quality of the coal by pyrolysis has flexible operation, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

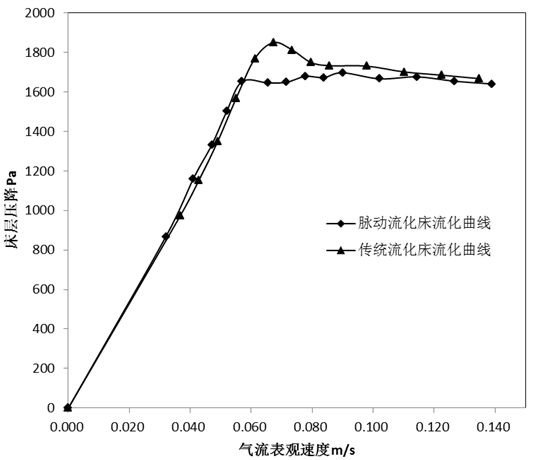

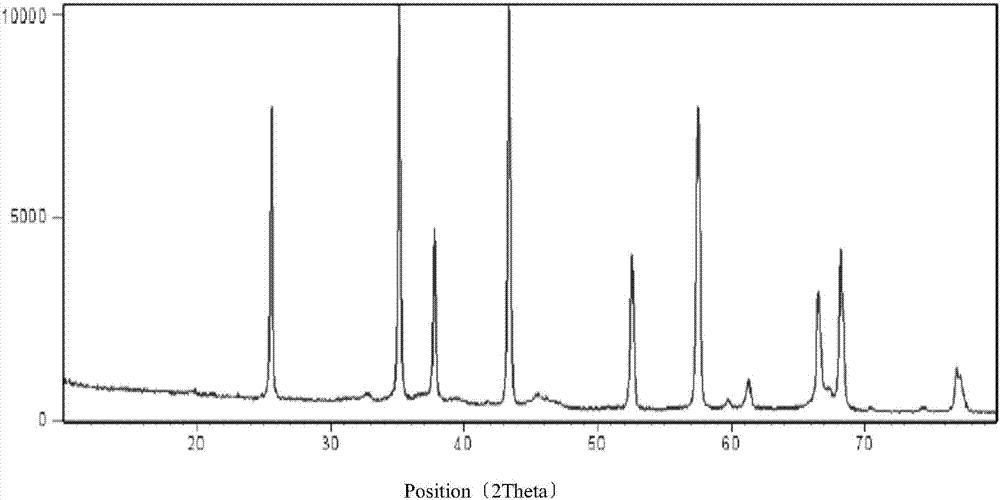

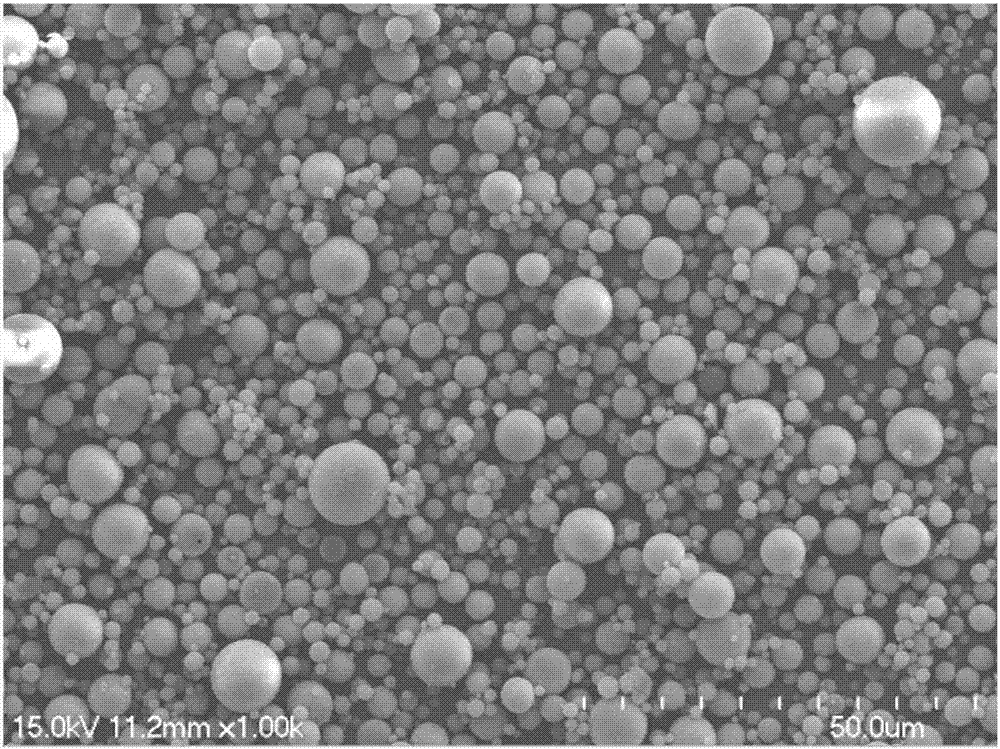

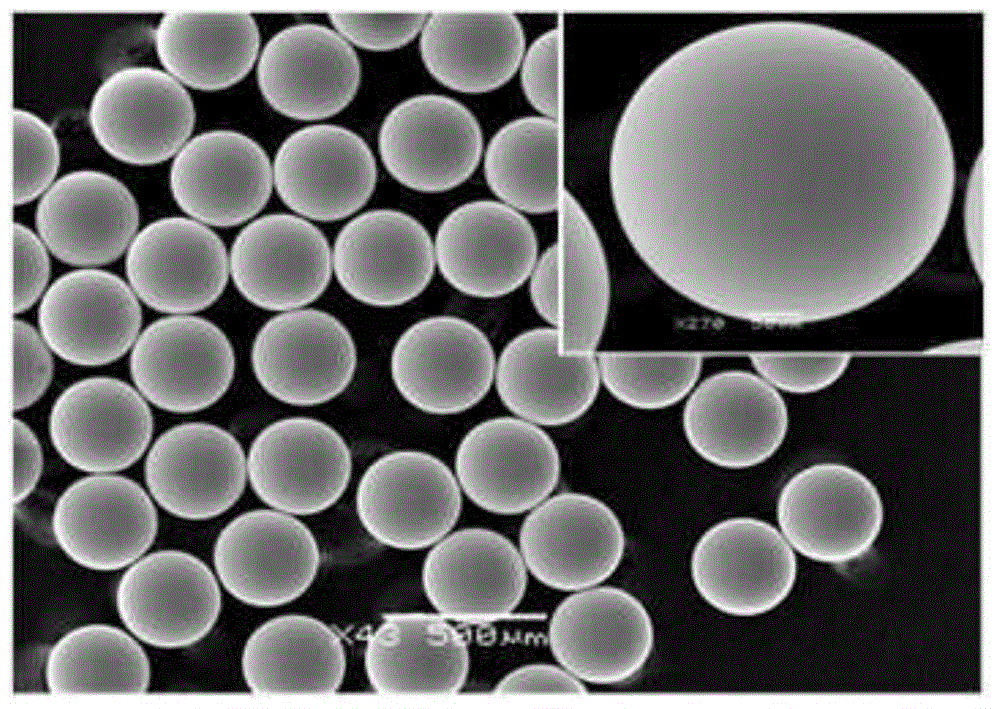

Plasma preparation method of spherical titanium powder for 3D printing

InactiveCN105562700AHigh sphericityUniform particle size distributionAdditive manufacturing apparatusTransportation and packagingPrillSpherical shaped

The invention discloses a plasma preparation method of spherical titanium powder for 3D printing. Titanium powder in an irregular shape is selected as the raw material; argon carries titanium powder particles to be sprayed into a plasma torch through a feeding gun; the titanium powder particles are rapidly heated and fused, and the fused particles form liquid drops with a high degree of sphericity under the action of surface tension; and crushing gas is introduced to crush the fused liquid drops again, the fused liquid drops are rapidly cooled and solidified to form spherical titanium powder particles under the two different progressively increasing temperature gradients, powder is separated from plasma gas due to the efficient filtering gas, and the spherical powder is collected through a powder collection device. The titanium powder prepared by the method is controllable in component, particle size and degree of sphericity; the prepared spherical titanium powder is high in degree of sphericity, good in mobility, uniform in size distribution, little in impurity, high in compactness, high in quality and used for 3D printing; the preparation process is rapid and easy, and one-time molding is achieved.

Owner:LONGYAN ZIJIN INNOVATION RES INST

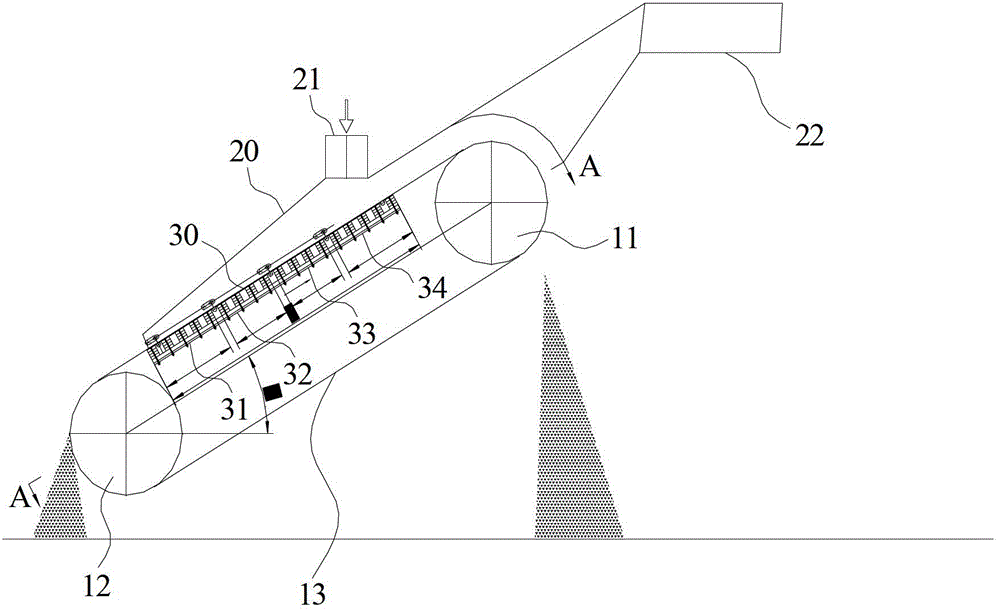

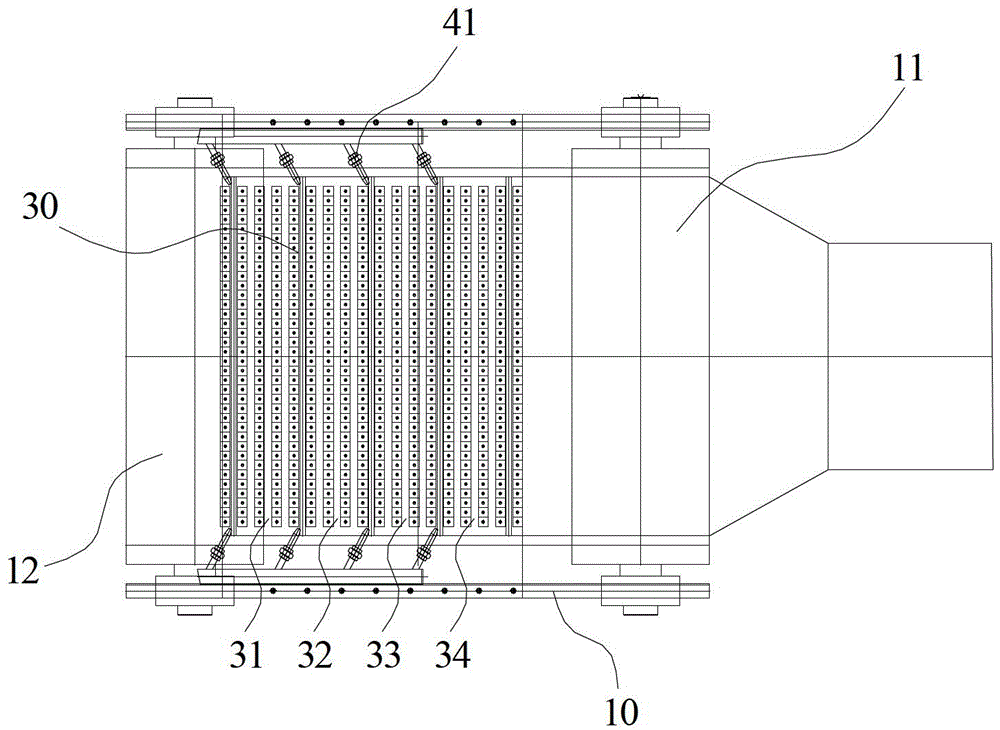

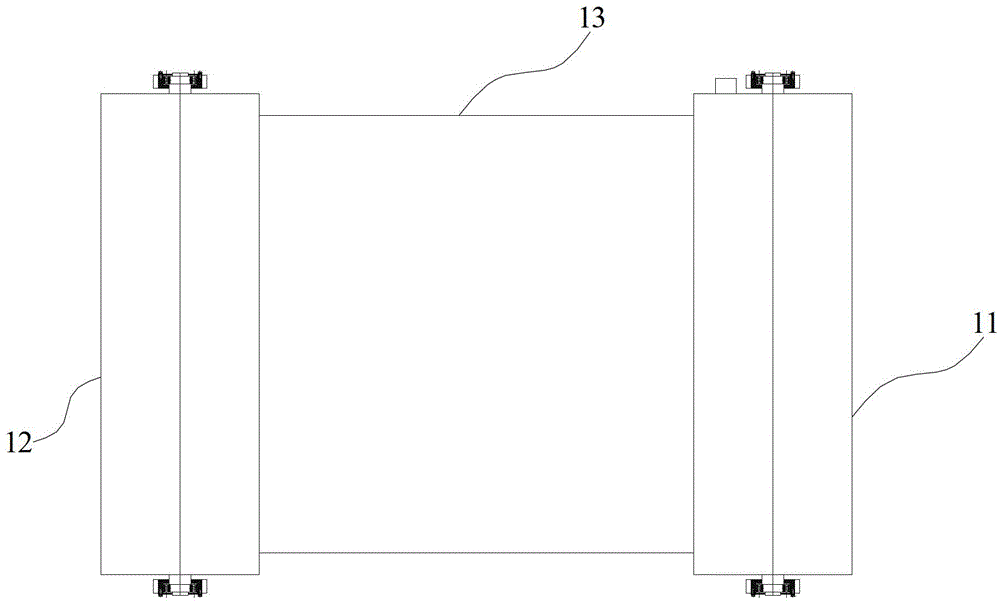

Gravity-magnetic composite dry separator and method utilizing same for mineral separation

InactiveCN103331208AIncrease productivityWide particle size rangeMagnetic separationMagnetic field gradientEngineering

The invention discloses a gravity-magnetic composite dry separator, which comprises an upper roller, a lower roller, a belt, a magnetic system, a guiding cover and a high-pressure gas injection atomization device, wherein the belt is arranged between the upper roller and the lower roller and is driven by the upper roller and the lower roller; the magnetic system is arranged between the upper roller and the lower roller and comprises a plurality of magnetic field areas of which the magnetic field intensity is gradually decreased from bottom to top, and thus the surface of the belt forms a magnetic field gradient; a material conveying space is formed between the guiding cover and the belt; the high-pressure gas injection atomization device is used for atomizing materials entering the guiding cover. The invention also discloses a method utilizing the gravity-magnetic composite dry separator for mineral separation.

Owner:陕西三沅重工发展股份有限公司

Micro-nano blocking lubricant for drilling fluid and preparation method thereof

ActiveCN108239522AHigh fat contentImprove temperature resistanceDrilling compositionMicro nanoSolid particle

The invention relates to a micro-nano blocking lubricant for a drilling fluid and a preparation method thereof and belongs to the field of oil and gas field drilling and oilfield chemical auxiliary agents. The micro-nano blocking lubricant for the drilling fluid is prepared from the following components in parts by weight: 100-200 parts of a nano emulsion and 100 parts of composite graphite micropowder. The micro-nano blocking lubricant for the drilling fluid also contains a dispersant. The nanoemulsion is prepared from components including paraffin, white oil, a composite emulsifier, a co-emulsifier and water by a phase inversion emulsification method. The micro-nano blocking lubricant for the drilling fluid can resistant the temperature of 150 DEG C, does not have adverse effects to viscosity of the drilling fluid, can reduce the filter loss of the drilling fluid remarkably, improve the quality of mud cakes remarkably, reduce the frictional resistance of a drilling tool and improve the mechanical drilling speed, and can bridge and block micro-cracks of shale quickly by means of a small size effect to prevent solid particles and a filtrate from invading the stratum to achieve a good blocking effect, so that the micro-nano blocking lubricant for the drilling fluid is particularly suitable for blocking fine throats which are 0.05-50[mu]m.

Owner:CHINA PETROLEUM & CHEM CORP +1

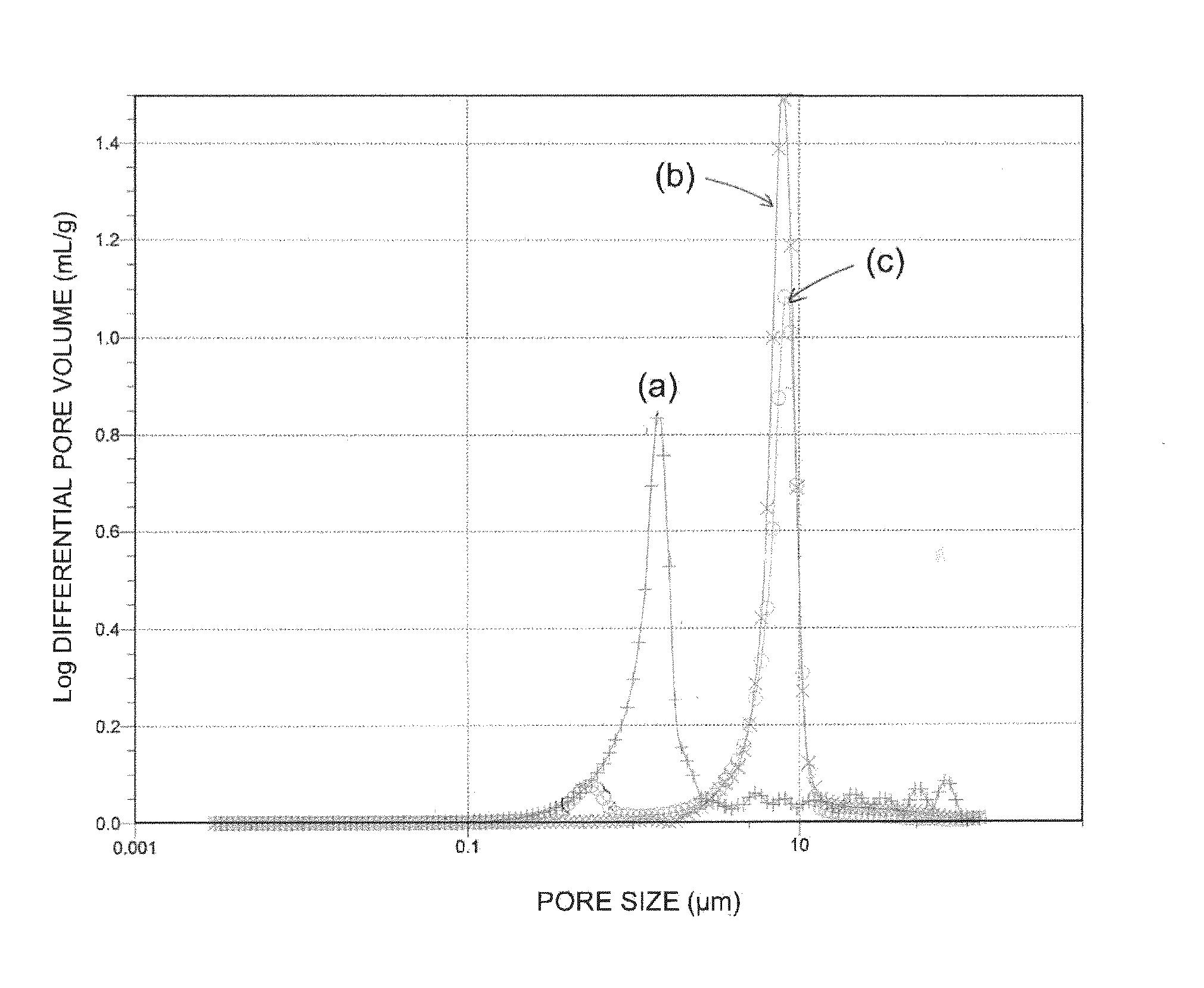

Thermal spray powder

ActiveUS20160244868A1Less poreImprove corrosion resistanceMolten spray coatingElectric discharge tubesThermal sprayingMetallurgy

Provided is a compact thermal spray powder suitable for forming a ceramic thermal spray coating which is compact and excels in durability. The thermal spray powder disclosed herein includes ceramic particles formed of a ceramic material with a melting point equal to or lower than 2000° C. The thermal spray powder is configured such that the peak top of a main peak is in a range of 10 μm or less in a log differential pore volume distribution obtained by a mercury porosimetry, and when the peak top of a second peak is at a fine pore size less than that of the peak top of the main peak, the ratio (H2 / H1) of the height H2 of the second peak to the height H1 of the main peak is 0.05 or less.

Owner:FUJIMI INCORPORATED

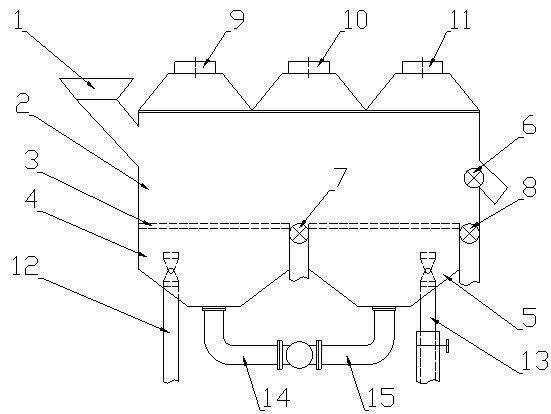

Gas-solid fluidized bed sorting machine based on pulse airflow

InactiveCN102652940AImprove uniformity and stabilitySimple structureGas current separationFluidized bedEngineering

The invention discloses a gas-solid fluidized bed sorting machine based on pulse airflow. The gas-solid fluidized bed sorting machine mainly comprises a sorting groove, an air distributing plate, a dedusting cover and a support, wherein the tail end of the sorting groove is provided with a light product material discharge wheel; the tail end of a rear air distributing chamber is provided with a rear heavy product material discharge wheel; the tail end of a front air distributing chamber is provided with a front heavy product material discharge wheel; the bottom parts of the rear air distributing chamber and the front air distributing chamber are respectively provided with a rear air tube and a front air tube; the rear air tube and the front air tube are connected with an air inlet tube through a three-way connector; and the air inlet tube is provided with a pulse airflow generator and an airflow quantity regulating valve in sequence. According to the invention, the pulse airflow is introduced into a gas-liquid fluidized bed, materials are conveyed forward relying on the oblique angle of the sorting groove and the effect of the pulse airflow; floating materials and sediment materials are respectively discharged through the light product material discharge wheel and the heavy product material discharge wheels, and the medium circulating quantity is reduced effectively; and the height of a front support leg can be adjusted, the front support leg can be used for regulating the oblique angle of the sorting groove, the regulation of coal conveying speed and sorting time can be realized.

Owner:CHINA UNIV OF MINING & TECH

Artificial colour sand and preparation method thereof

The invention discloses artificial colour sand and belongs to the field of building coating. The artificial colour sand comprises stone sand and base slurry, wherein stone sand comprises at least one of silica sand, basalt and calcite, the grain size of the stone sand is 30-120 meshes, the base slurry is prepared from the following raw materials in parts by weight: 40-50 parts of fluorocarbon resin, 25-35 parts of base solvent, 0.5-0.9 part of dispersing agent, 0.1-0.3 part of wetting agent, 10-20 parts of colour powder, 18.8-20 parts of cosolvent, 0.1-0.5 part of accelerant, 5-10 parts of coupling agent and 0.5-0.8 part of thickening agent, and the weight ratio of stone sand to base slurry in the artificial colour sand is 19:1. The invention also provides a preparation method of the artificial colour sand. The artificial colour sand is uniform in colour, good in weather resistance, economical and environment-friendly, the problem that natural colour sand is scare is solved, and requirements of building decoration are met.

Owner:浙江曼得丽涂料有限公司

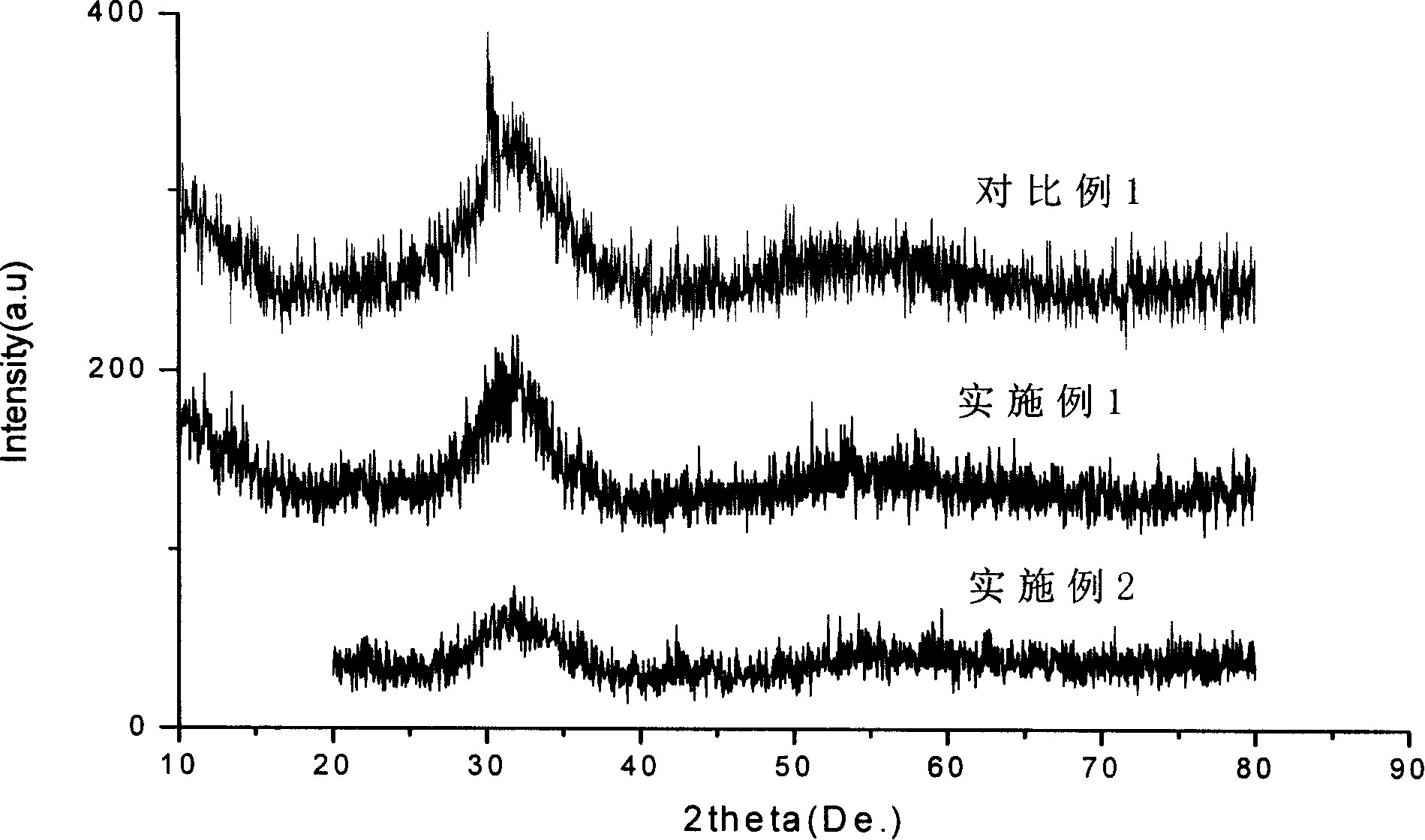

Amorphous powdered alloy and method for producing the same

The invention provides a non-crystal alloy powder, which comprises compounds which contain at least one or a plurality of the non-crystal alloy powder as Zr group, Cu group, Ti group, Ni group and Re group which contain rare-earth elements. Average particle diameters of powder are 50 micrometers-2000 micrometers. The invention also provides a process for preparing the non-crystal alloy powder, which comprises firstly, smelting the non-crystal alloy raw materials as Zr group, Cu group, Ti group, Ni group and Re group under protecting environment or a vacuum condition, and secondly, spraying melted metal into mist under the protecting environment and producing the non-crystal alloy powder with flash cold-settings, wherein the rare-earth elements are added in the first step to be smelted with the non-crystal alloy raw materials. The non-crystal alloy powder which is obtained through the invention has wide grain-size range, and the powder which is prepared can be used for addition agent of antifriction materials. The process for preparation has low requirements for preparing environment and pureness of raw materials, and is applied to productions with commercial scales.

Owner:BYD CO LTD

Refractory iron ore fines grading combined processing method

ActiveCN103949404AWide particle size rangeImprove resource utilizationMagnetic separationIronstoneResource utilization

The invention aims to provide a refractory iron ore fines grading combined processing method which is simple, high-efficiency, low in grading cost and high in comprehensive metal recovery rate. A mechanical vibration screen and a spiral classifier are combined for size grading, a method of combining strong magnetic separation and magnetic roasting-low intensity magnetic separation is adopted for processing refractory iron ore with the particle size of 0-15mm, the difficult problems of difficulty in grading particle sizes of a fine-grained iron-containing material and rotary kiln accretion are solved, the particle size range for magnetic roasting of the refractory iron ore is widened, and the resource utilization rate of the refractory iron ore is improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

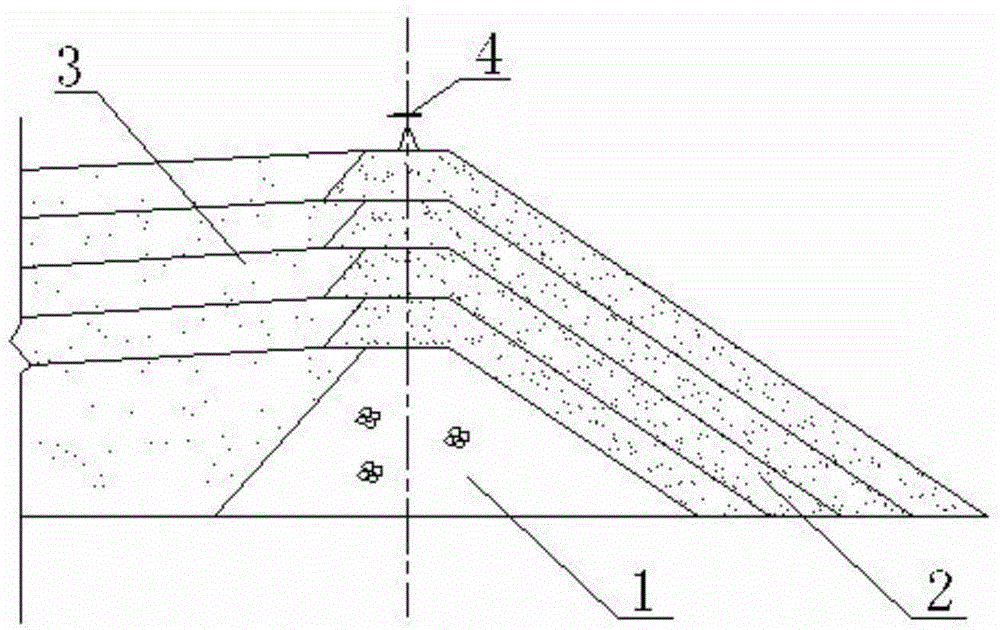

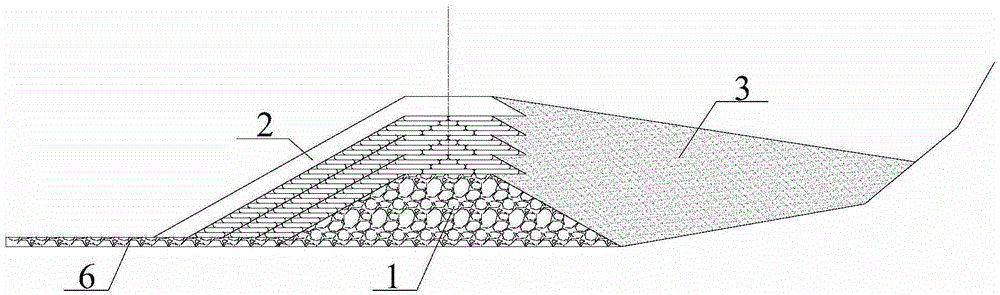

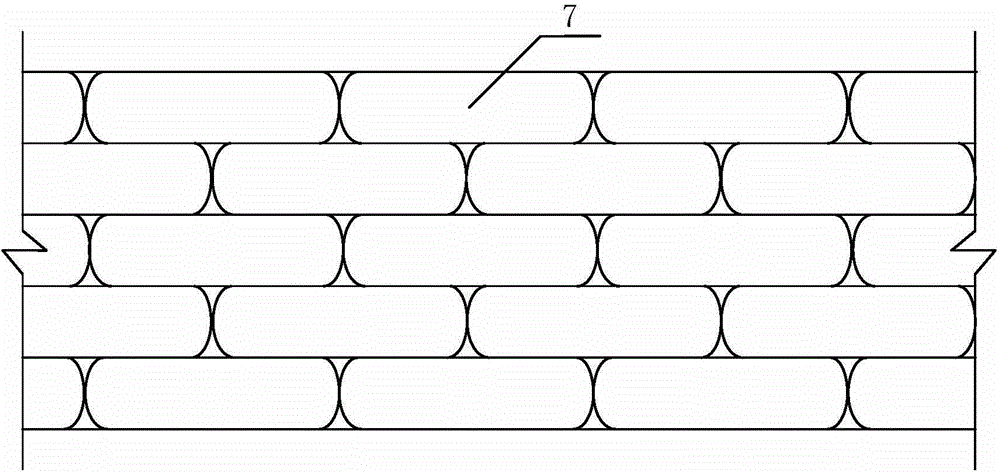

Median type tailing damming method utilizing mold bags

ActiveCN104912087ADrain fastAccelerated consolidationEmbankmentsSoil preservationPrillEnergy consumption

The invention discloses a median type tailing damming method utilizing mold bags. The median type tailing damming method has the advantages that the grouted mold bags 7 are piled up to build a downstream dam body 2, the downstream dam body 2 is kept clean and smooth by the sand consolidation effect of the mold bags 7, and the environmental problems such as dust flying, gullying and coarse sand loss are solved well; tailing pulp with the content of tailing particles, smaller than 0.05mm in size, not larger than 40% (by weight) is taken as mold bag filling pulp for the mold bags 7, so that the particle size range of tailing sand available for damming is widened, sand quantity available for the median type tailing damming method is increased, water drainage of the mold bags 7 can be accelerated, solidification can be speeded up, and grouting efficiency of the mold bags 7 is improved; in addition, the action of gravity is fully utilized for grouting, and the mold bags 7 can be grouted by multiple branch ore drawing pipes 92 at the same time, so that cost and energy consumption are reduced, and damming efficiency is improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

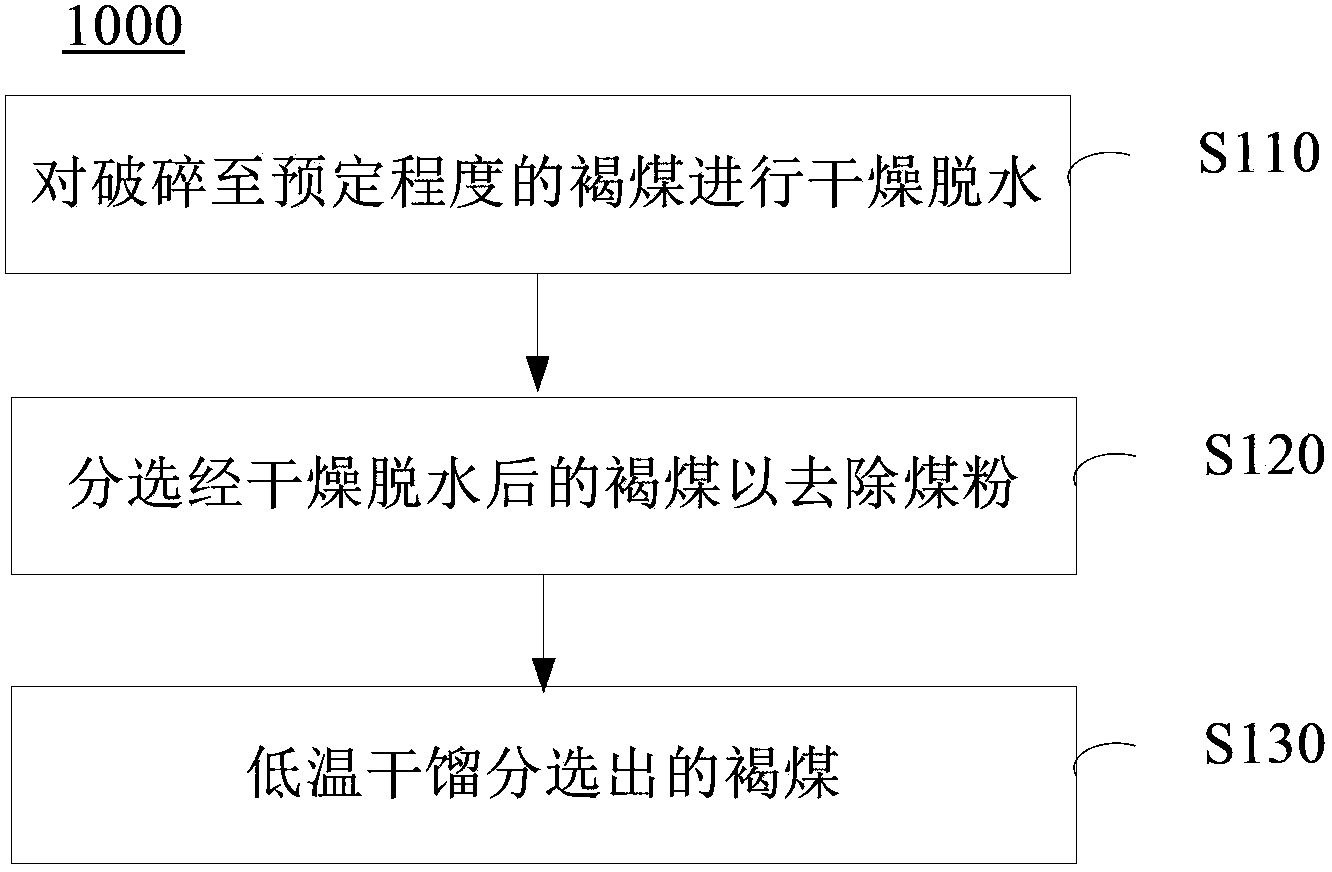

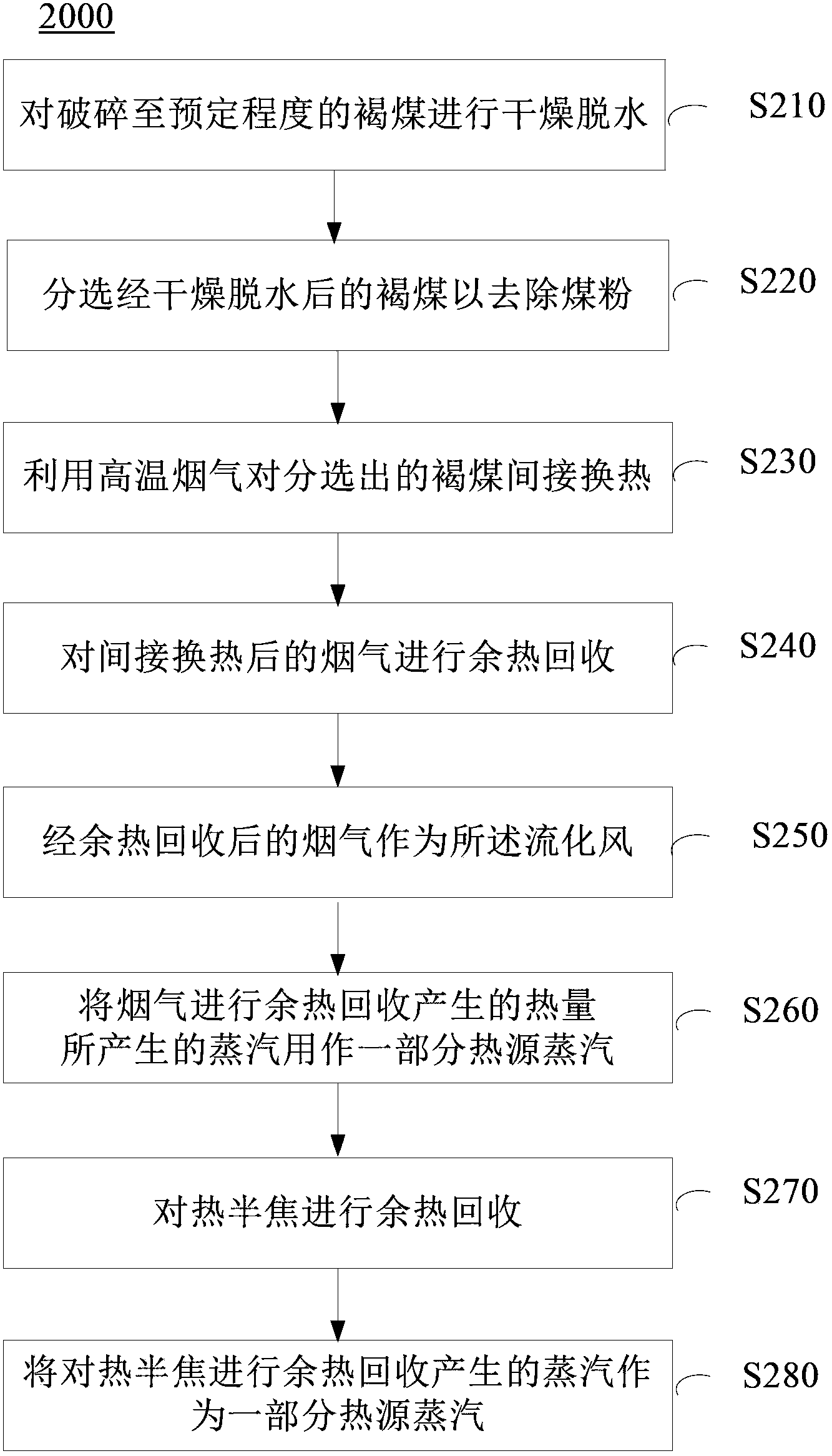

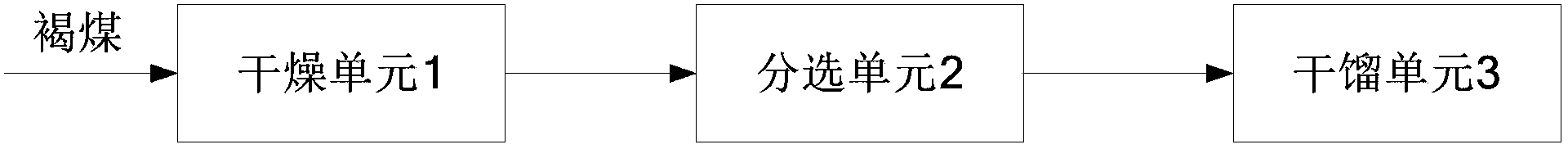

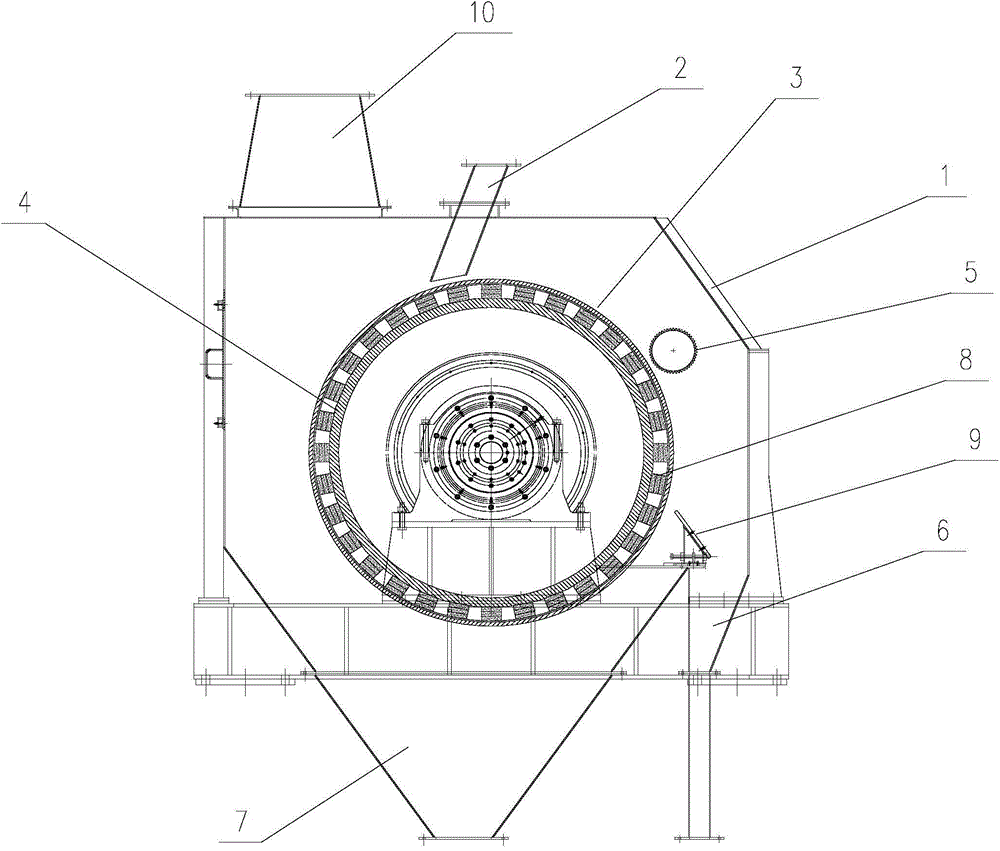

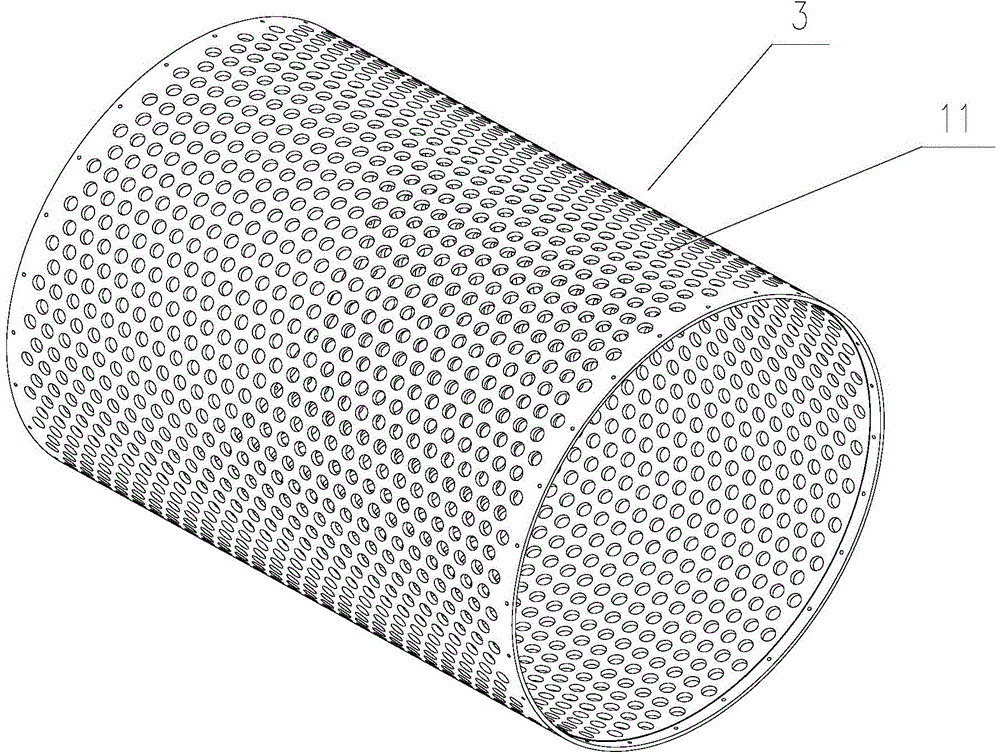

Method and system for improving quality of low-rank coal

ActiveCN103421525AFlexible combinationImprove qualitySpecial form destructive distillationSpontaneous combustionGranularity

The application discloses a method and system for improving the quality of low-rank coal. The method comprises the following steps: drying to remove water in lignite which is crushed into a preset degree; sorting the dried lignite to remove pulverized coal; conducting destructive distillation on the sorted lignite at a low temperature. According to the application, the adjustability of the whole process is enhanced, and the energy distribution of the system is optimized, so that the adverse impact of pulverized lignite on low-temperature destructive distillation is reduced to the maximum extent, the quality of tar is improved, and the granularity range of quality-improving feed coal is broadened; as severe screening of the feed coal is not required, equipment investment is reduced, and potential accidents of dust pollution and spontaneous combustion are reduced.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP +1

Dry magnetic separator with introduced wind power and mineral magnetic separation method

The invention discloses a dry magnetic separator with introduced wind power and a mineral magnetic separation method. The dry magnetic separator comprises an outer shell, a feeding device, a ventilation roller barrel, an unloading roller, a concentrate hopper and a tailings hopper, wherein ventilation roller barrel is arranged in the outer shell in a horizontal rotation manner; a low-frequency alternating magnetic field is arranged at the surface of the ventilation roller barrel; a plurality of through holes are uniformly formed in the surface of the ventilation roller barrel; ventilation materials are embedded into the through holes; the ventilation roller barrel is provided with a closed inner cavity; pressure air is introduced into the inner cavity; the feeding device corresponding to the ventilation roller barrel is arranged at the top of the outer shell; the unloading roller is arranged at the right side of the ventilation roller barrel; the concentrate hopper is correspondingly arranged below the unloading roller; the tailings hopper is correspondingly arranged below the ventilation roller barrel. According to the device and the method, the wind power is introduced into the separation and sorting processes of magnetic materials, so that the wind power, gravity and centrifugal force together directly take part in completion with magnetic force, and further the recovery rate of magnetic mineral can be obviously increased, and the concentrate grade is obviously promoted.

Owner:CHENGDU LEEJUN TECH CO LTD

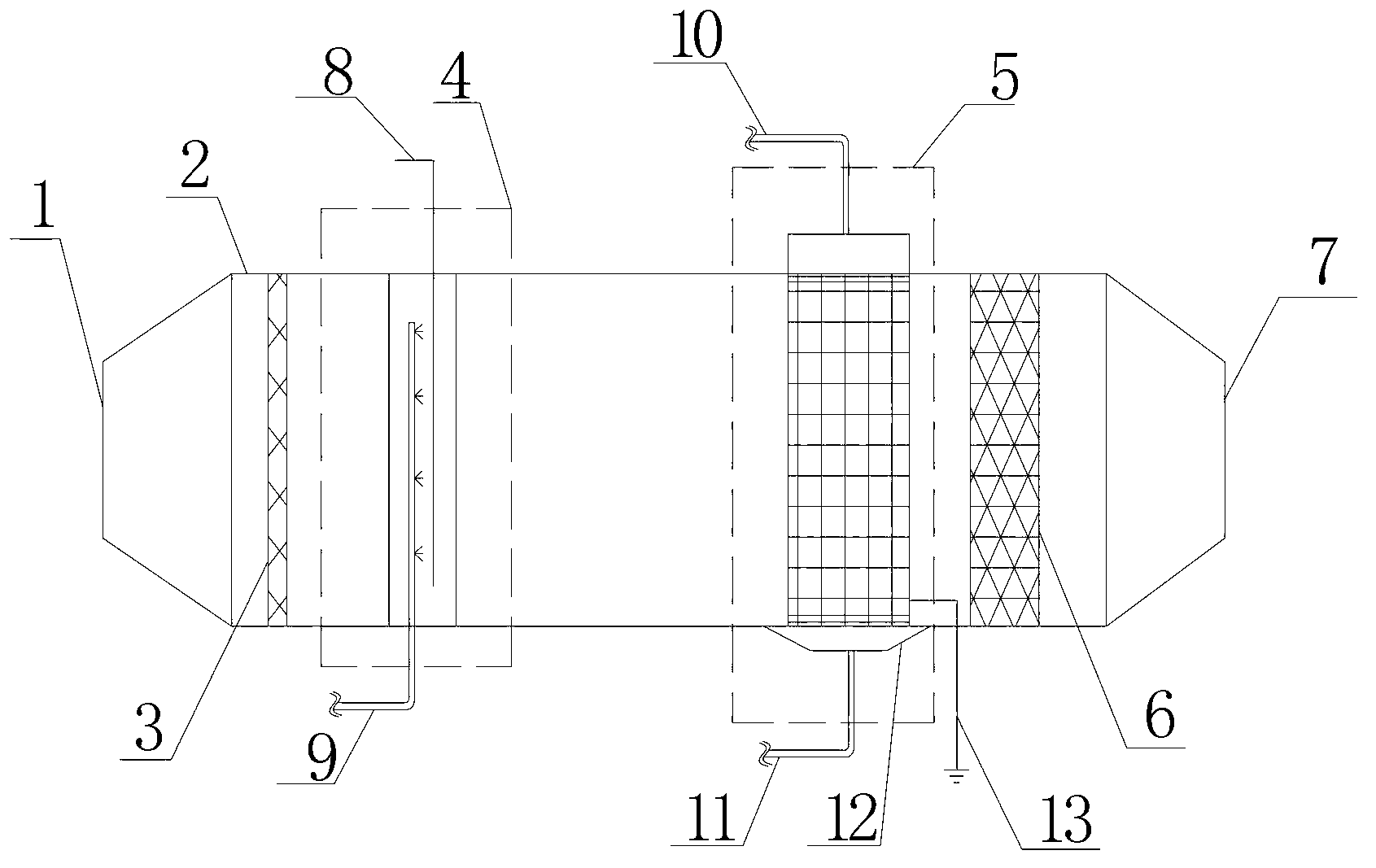

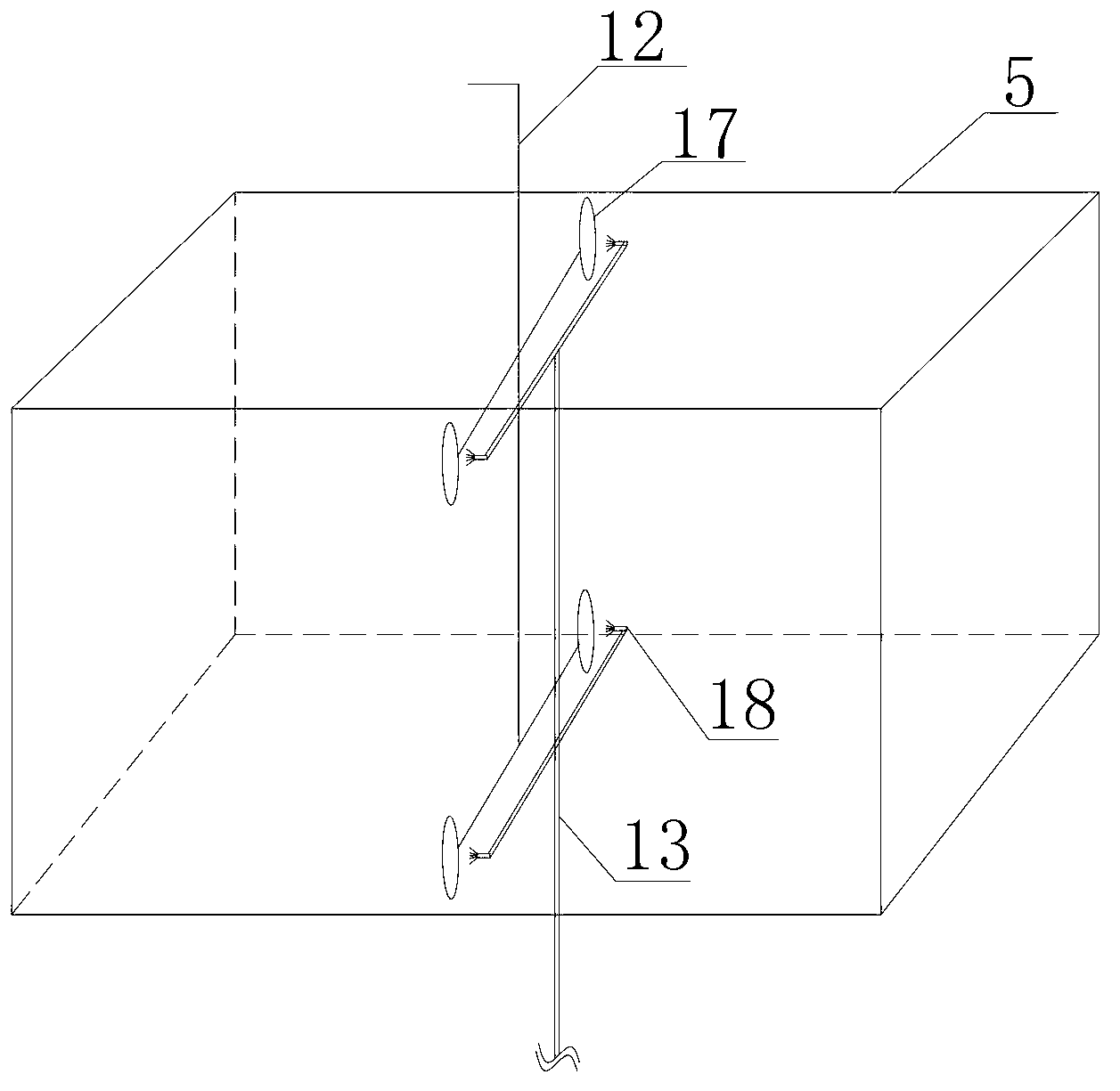

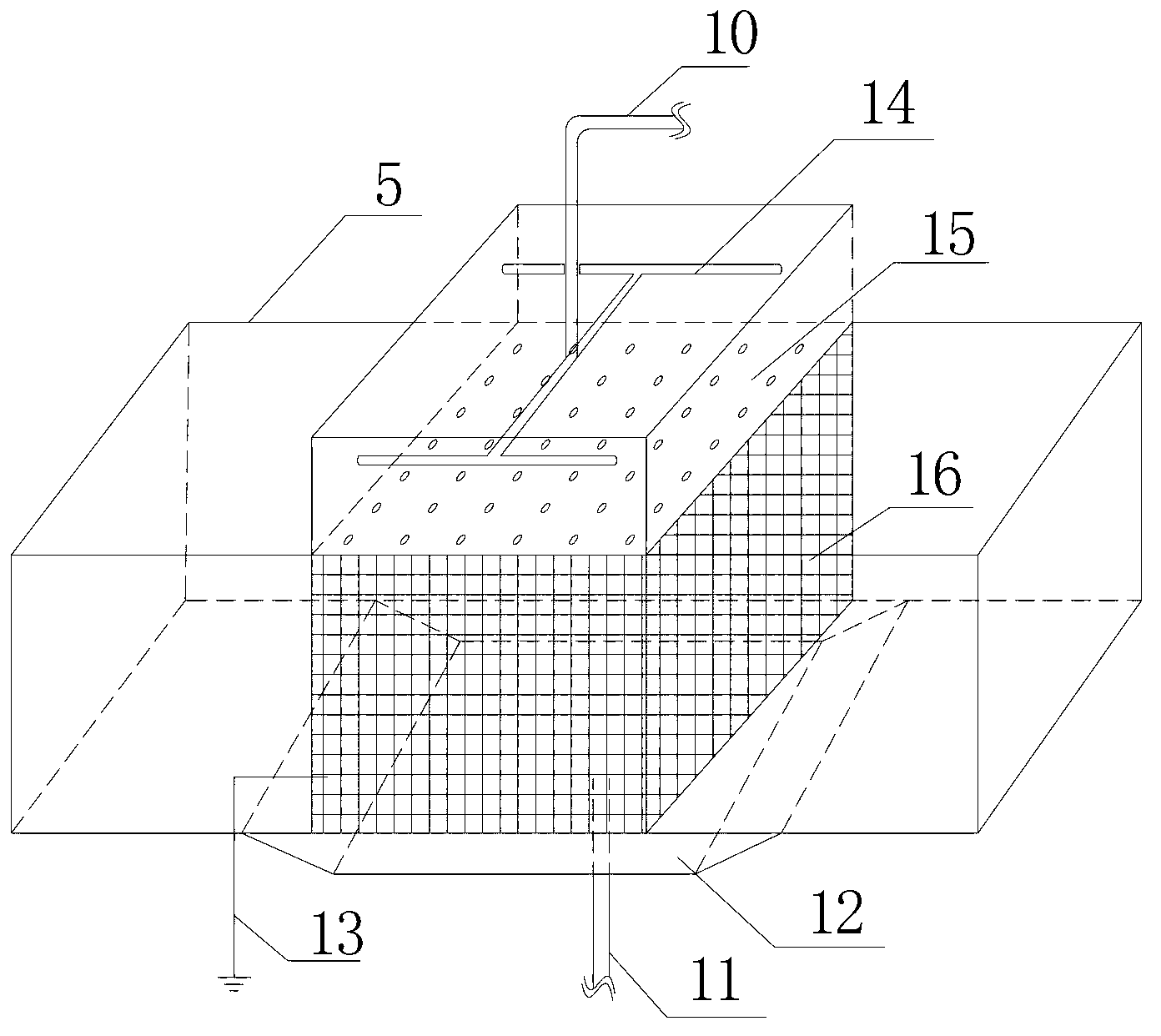

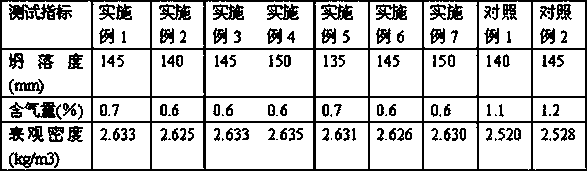

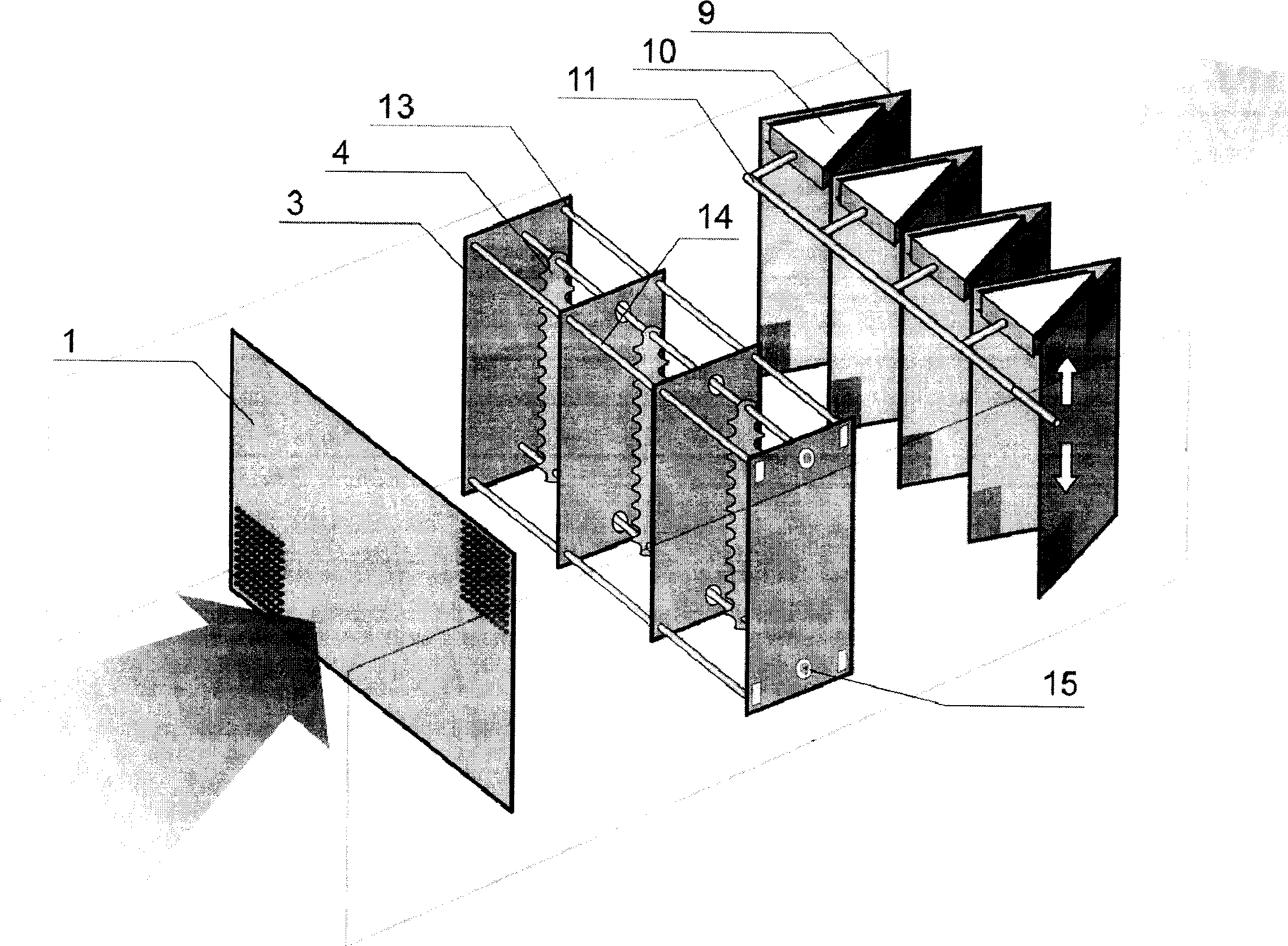

Electrostatic spraying and dust-removing system

InactiveCN102698557AImprove filtration efficiencyMeet dust removal requirementsCombination devicesHigh pressureDistributor

The invention relates to an electrostatic spraying and dust-removing system. One end of a shell is an inlet of a dust-removing system while the other end of the shell is an outlet of the dust-removing system; an air flow distributor, an electrostatic spraying device, a filtering dust-collecting and washing device and a water separator are arranged in the shell orderly from the inlet to the outlet; at least one atomizing nozzle is connected to a water supply pipe in the electrostatic spraying device, a high pressure static ring is arranged in front of each atomizing nozzle; the high pressure static ring is connected with a high pressure static generator at the outer part of the system through a lead; a filler is arranged in the filtering dust-collecting and washing device, and the upper part of the filler is provided with a water pouring distributor; the water pouring distributor is connected with a system external water supply pipe through a water pipe; and the bottom part of the filler is provided with a water collecting disk, and the water collecting disk is provided with a water draining pipe. The system can satisfy the dust removing requirement of grains in different sizes in air, and has a relatively good effect to filter the powder dust with the grain diameter being more than 0.1 micro meters.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

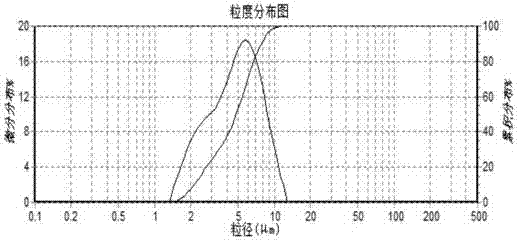

Preparation method for spherical aluminum oxide powder

InactiveCN107117635AEvenly distributedGood shape rateAluminium oxide/hydroxide preparationWater basedEmulsion polymerization

The invention discloses a preparation method for nano-scale and micro-scale spherical aluminum oxide powder. According to the invention, the manner of combining a sol-gel technology with an emulsion method is utilized to prepare the spherical aluminum oxide; a water-based aluminum sol is used as a main raw material; an organic reagent is used as a dispersion medium; the spherical aluminum oxide is compounded in the manner of water-in-oil emulsion polymerization; the interfacial tension between an oil phase and a water phase is utilized to manufacture a tiny spherical droplet; and the formation of a water-phase sol particle and the gel is limited in the tiny droplet. The raw material components of the spherical aluminum oxide according to the technology are convenient for design; the particle size of the powder is within the scope of 0.5-100mu m and is adjustable; the spheroidization rate is high; the liquidity is excellent; and the dispersion is easy.

Owner:SUZHOU NANODISPERSIONS

Dense-medium shallow-groove separating and waste-rock exhausting system used under coal mine

InactiveCN101670310AReduce ineffective lift trafficIncrease production capacityWet separationProduction rateSlag

The invention relates to a dense-medium shallow-groove separating and waste-rock exhausting system used under coal mine. A raw-coal belt conveyer is arranged on the feeding end side of a roller screen; a fine-cold belt conveyer arranged below the roller screen; a lump-coal belt conveyer is arranged between the discharging end of materials on the roller screen and a feeding end of a dense-medium shallow-groove separator; the dense-medium shallow-groove separator is connected with a clean-coal medium-removing scraping plate conveyor through an overflow groove; a waste-rock medium-removing scraping plate conveyor is arranged below the dense-medium shallow-groove separator; the clean-coal medium-removing scraping plate conveyor is connected with a clean-coal belt conveyer; the clean-coal beltconveyer is connected with the fine-cold belt conveyer which is arranged below the roller screen; the waste-rock medium-removing scraping plate conveyor is connected with a first waste-rock belt conveyer; the first waste-rock belt conveyer is connected with a second waste-rock belt conveyer; a qualified-medium barrel is connected with the dense-medium shallow-groove separator; and a diluted-mediumbarrel is connected with a slag slurry pump and a magnetic separator. The invention can greatly reduce the ineffective conveying volume of the waste rock in the mine, improve the producion rate, lower the operating cost and avoid causing pollution to the environment.

Owner:王迪业

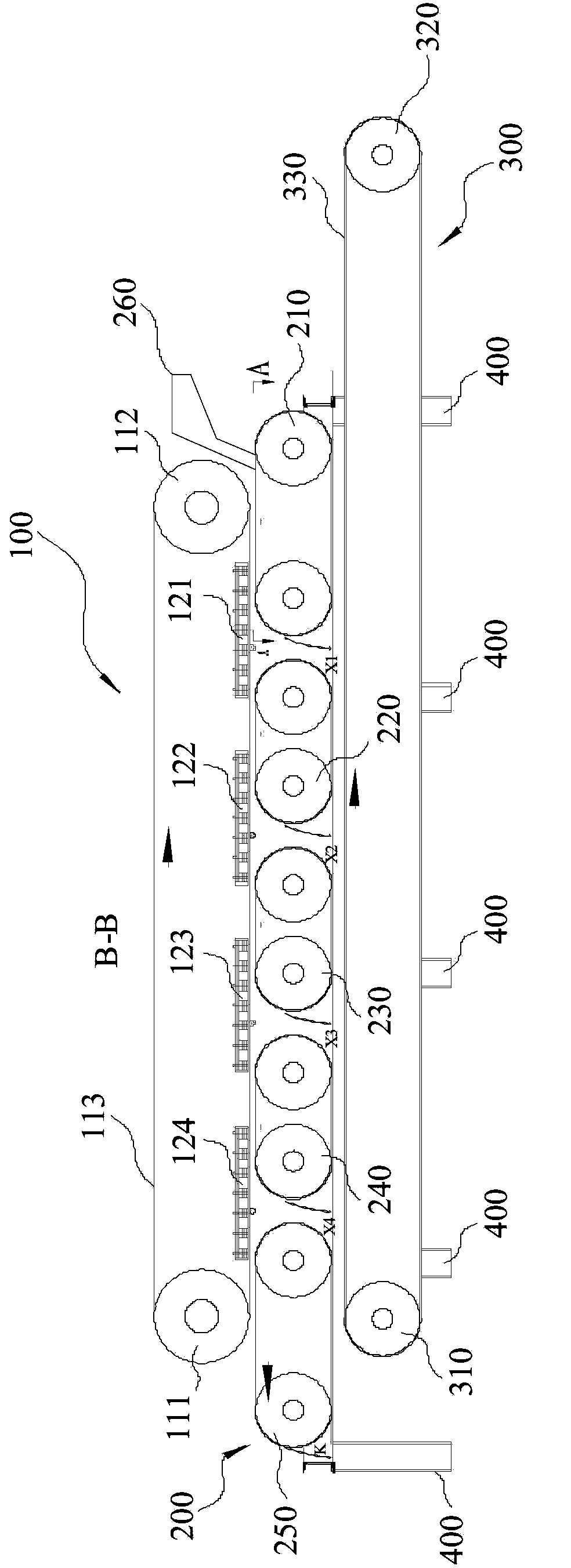

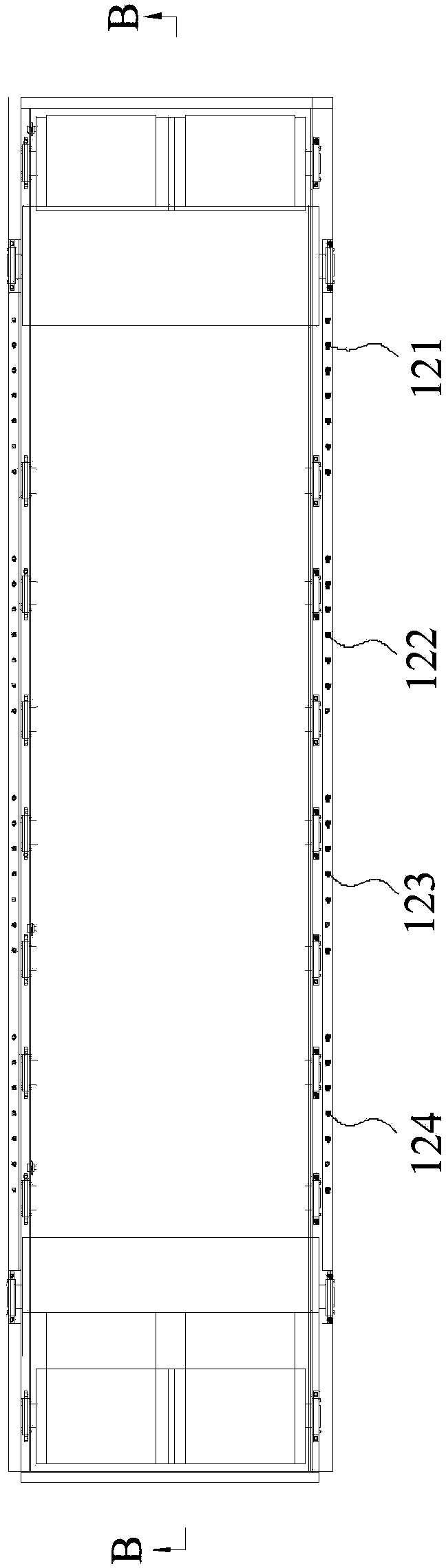

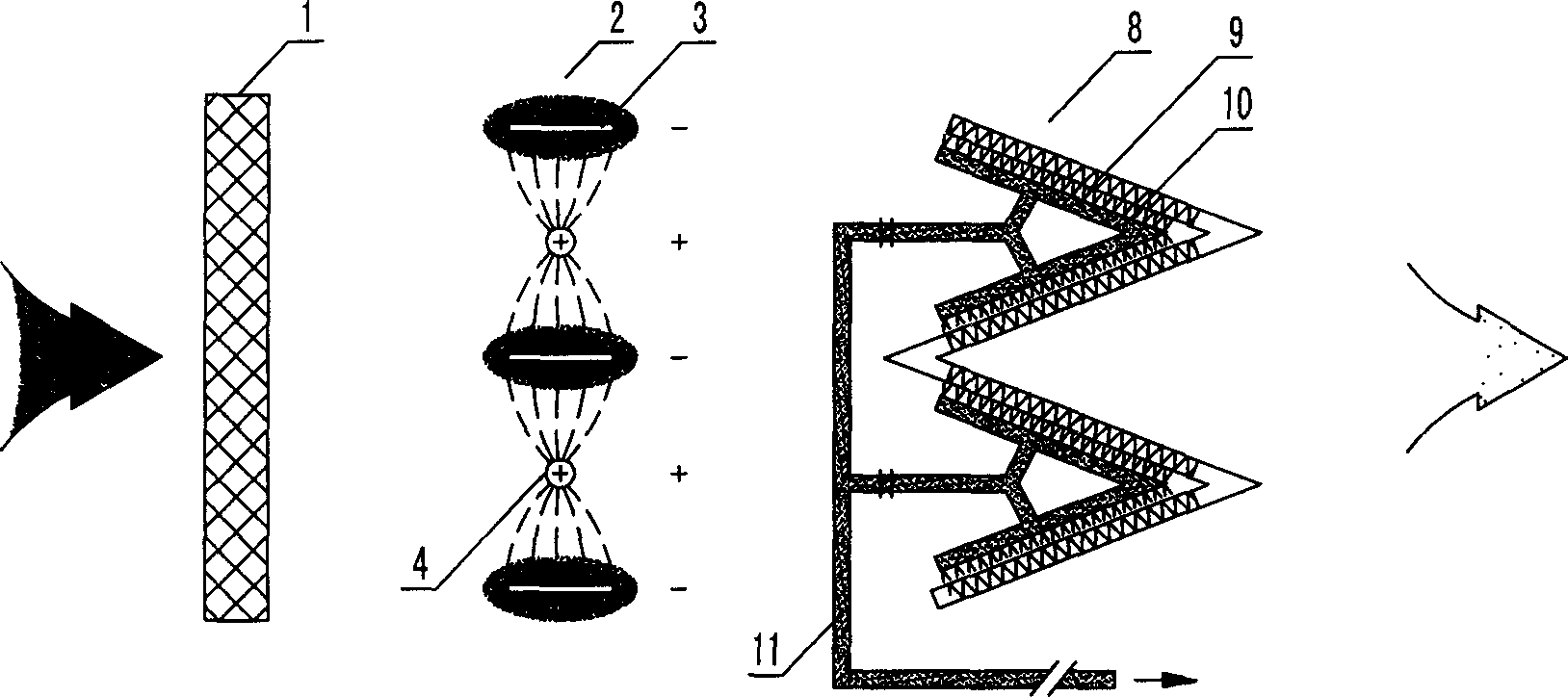

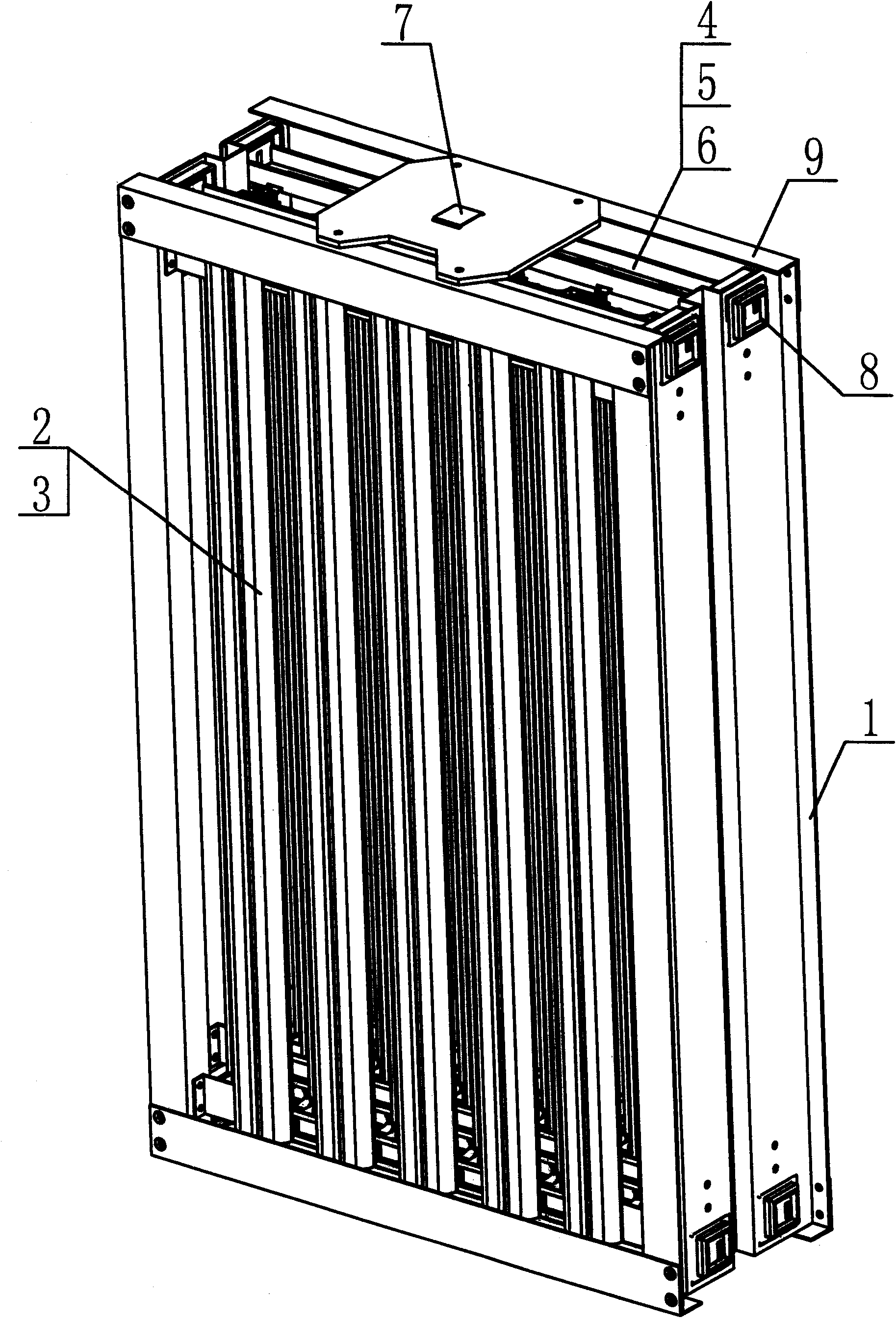

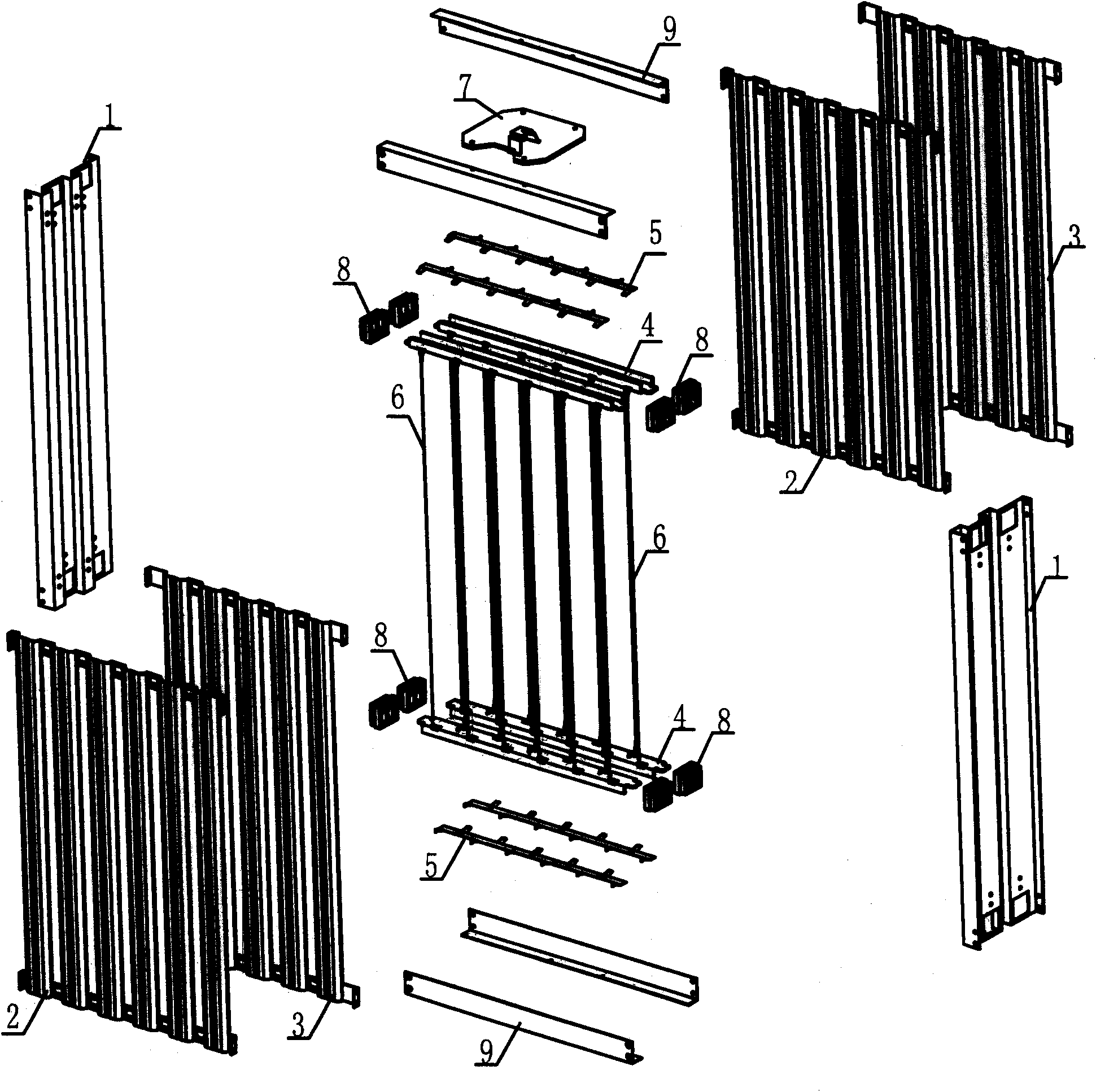

Belt-type multi-stage multi-gradient magnetic separator and method for mineral separation by using belt-type multi-stage multi-gradient magnetic separator

The invention discloses a belt-type multi-stage multi-gradient magnetic separator which comprises a magnetic separating device, a multi-stage material conveying device and a tailing conveying device, wherein the magnetic separating device comprises a belt-type conveyer and a magnetic system arranged inside the belt-type conveyer; the multi-stage material conveying device comprises a plurality of belt-type conveyers which are arranged on one same horizontal height and are arranged at intervals; the tailing conveying device is used for receiving and conveying tailings from the multi-stage material conveying device; the magnetic system comprises a plurality of magnetic field areas of which the magnetic field strength is gradually weakened along the material conveying direction; non-magnetic areas are arranged between every two adjacent magnetic field areas; the magnetic field areas cover the gaps between adjacent belt-type conveyers of the multi-stage material conveying device. The invention further discloses a method for mineral separation by using the belt-type multi-stage multi-gradient magnetic separator.

Owner:陕西三沅重工发展股份有限公司

Cermet composite material and coating preparation method thereof

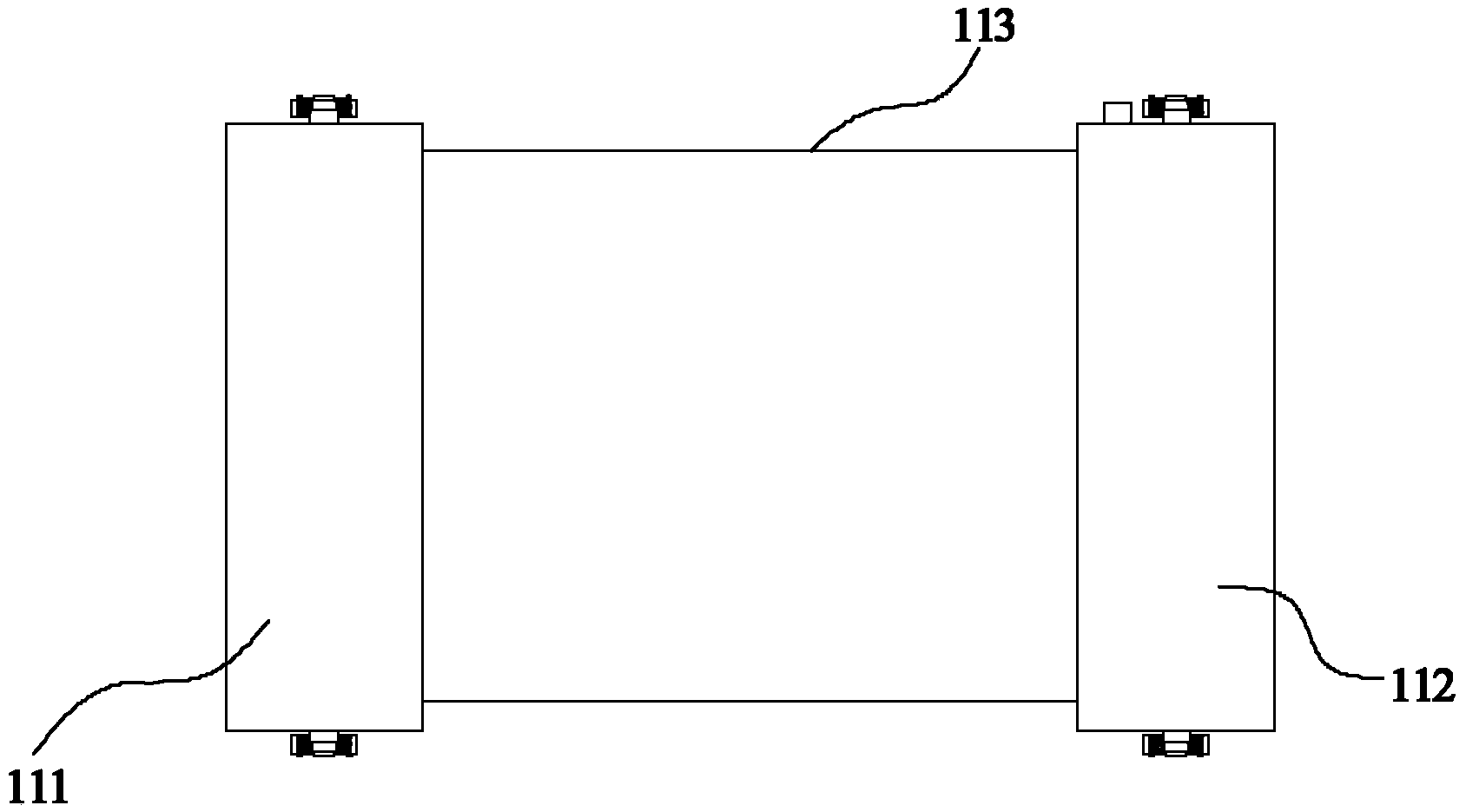

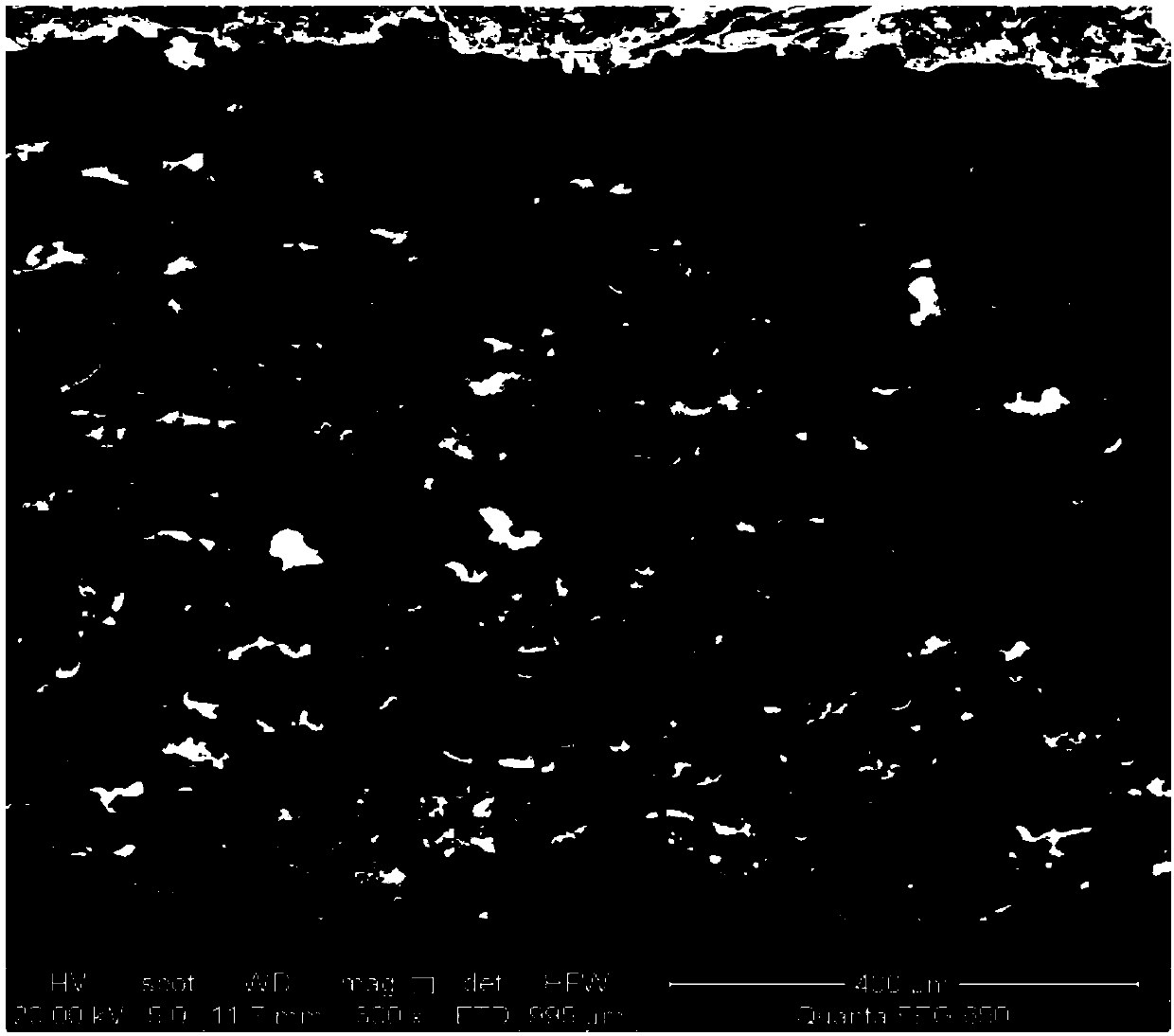

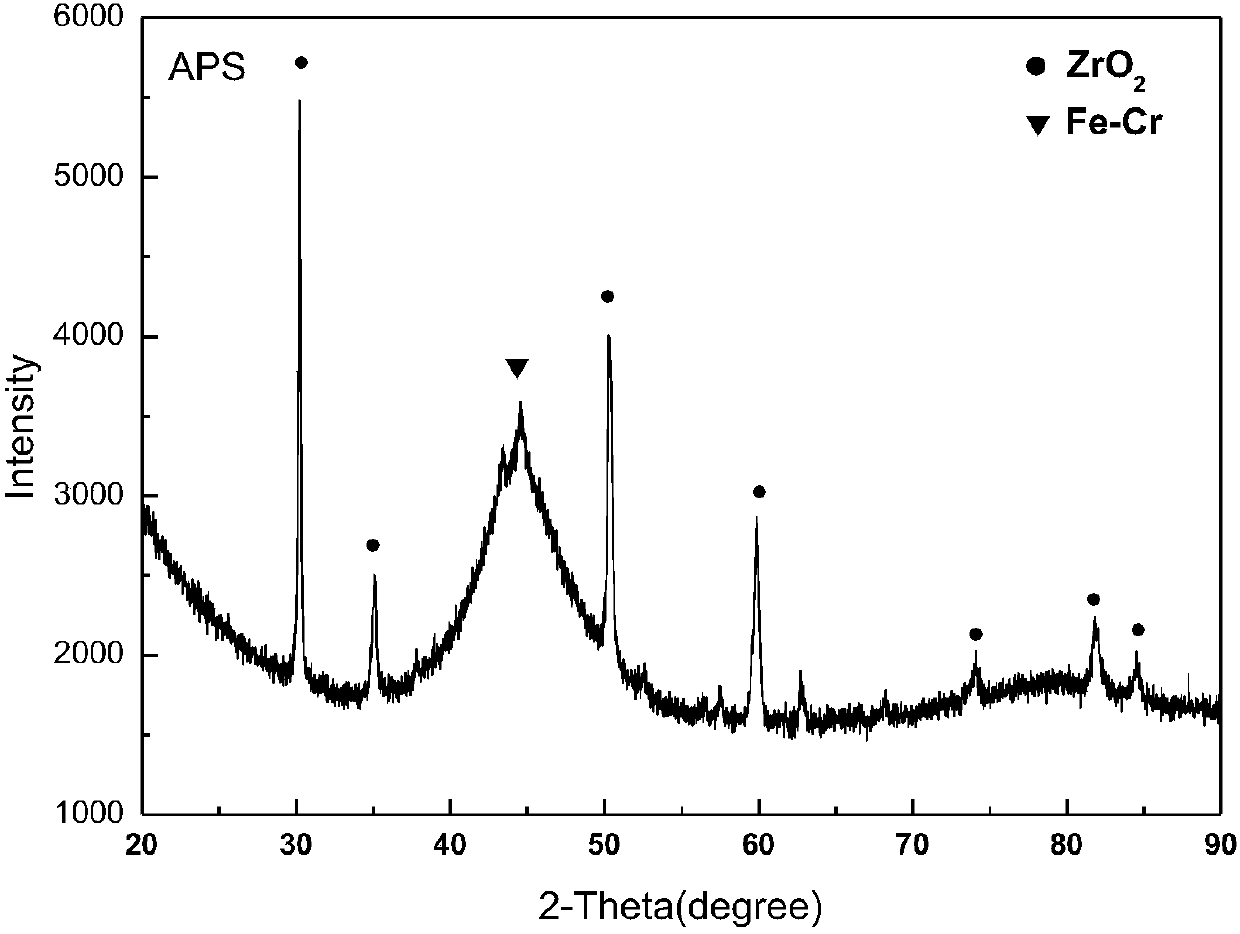

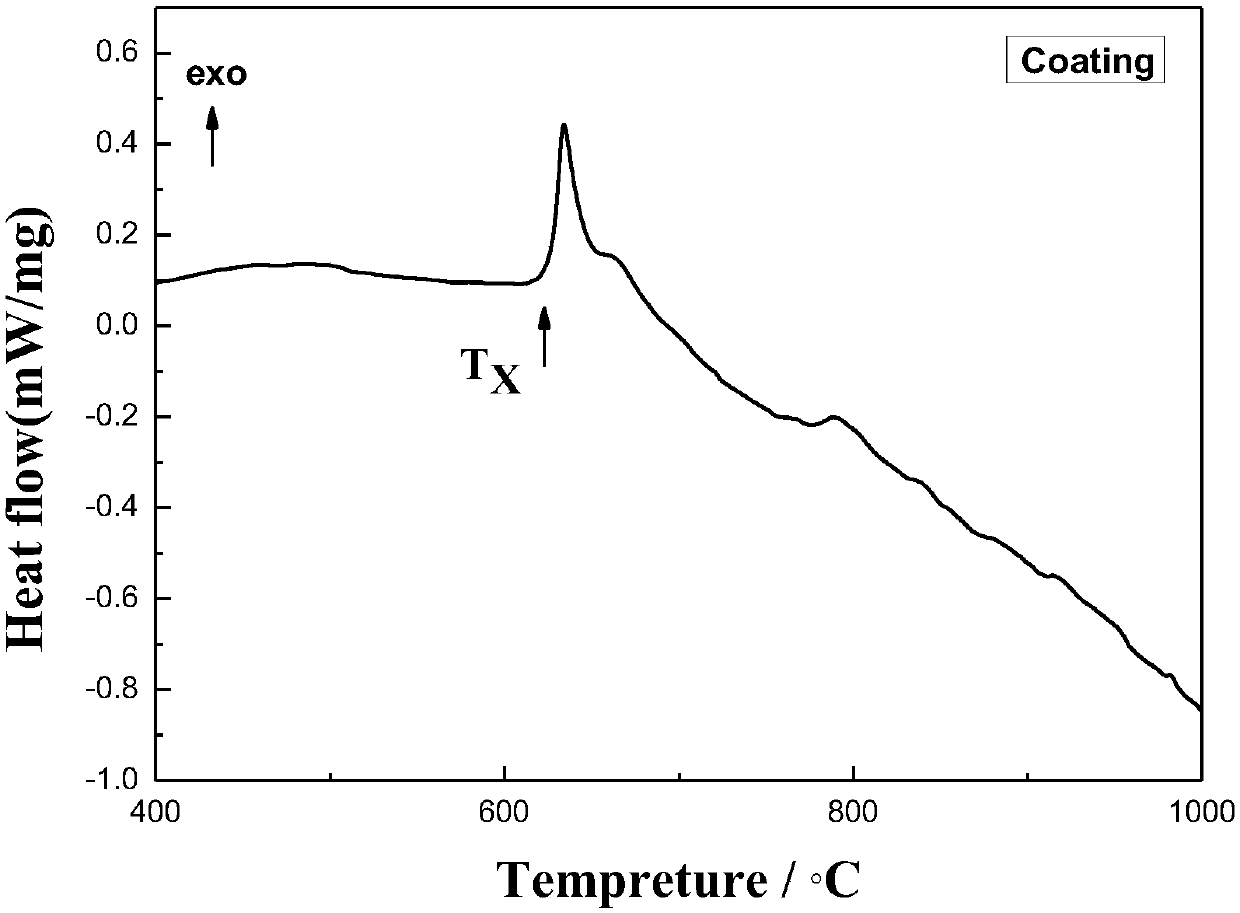

InactiveCN107653430AGood matching of thermal expansionGood bonding strengthMolten spray coatingSurface engineeringNitrogen gas

The invention provides a cermet composite material and a coating preparation method thereof, belongs to the field of thermal spraying in composite materials and surface engineering, and particularly relates to a preparation method for metal-based composite powder with low thermal conductivity and a coating thereof by atmospheric plasma spraying. The method comprises the following steps that iron-based amorphous powder prepared by the high pressure nitrogen gas atomization method is mixed with zirconia powder prepared by the agglomeration sintering method according to a certain mass ratio, andfinally the composite powder with a better sphericity and a particle size of 25-75 [mu]m is obtained. The iron-based-ceramic composite coating is prepared by adopting the atmospheric plasma spraying mode, and the composite coating prepared has relatively low thermal conductivity, and can be used for insulation protection for hot end parts of a diesel engine.

Owner:BEIJING UNIV OF TECH

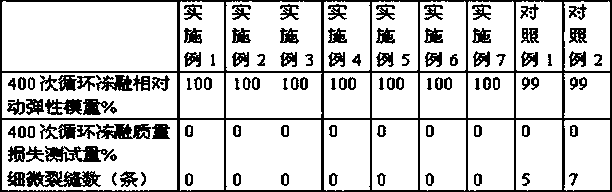

Non-steam autoclaved PHC tubular pile concrete

Owner:浙江沪嘉住宅工业股份有限公司

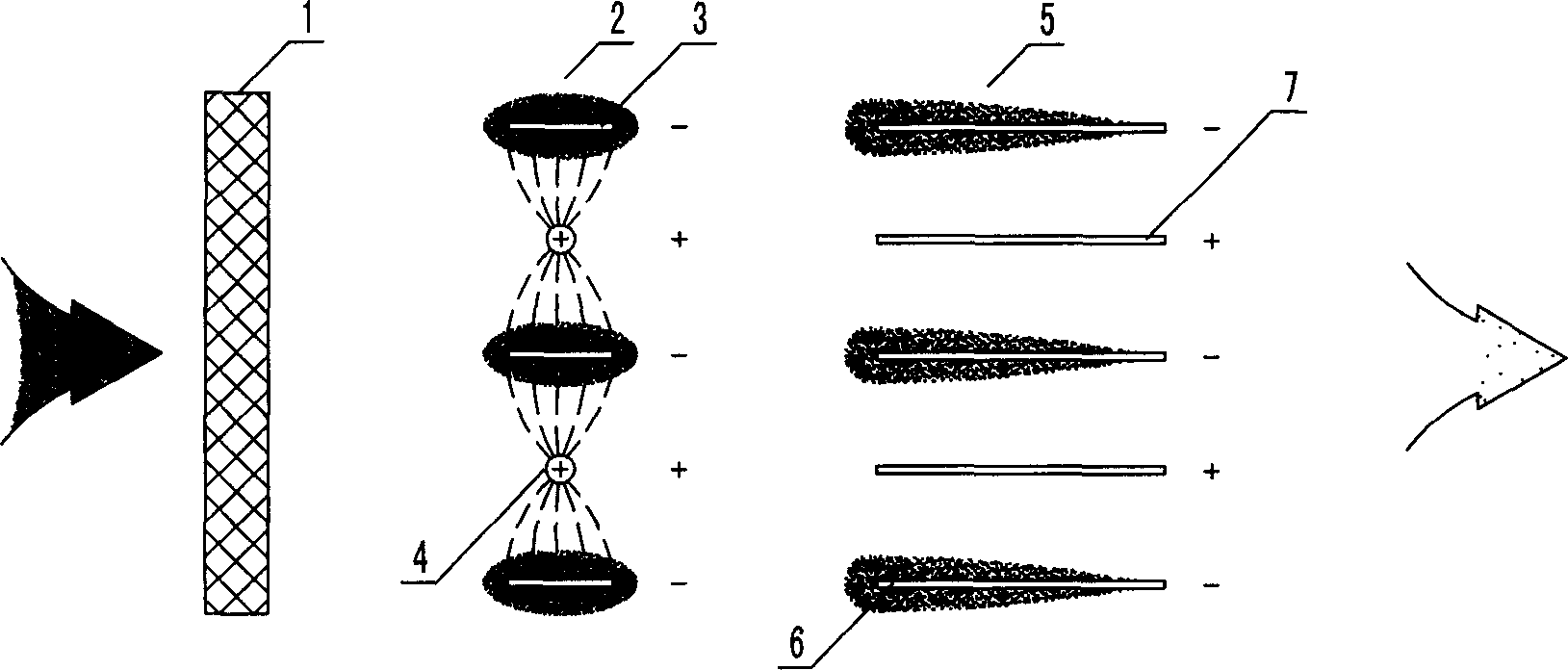

Self-purging type high performance electronic air puifier

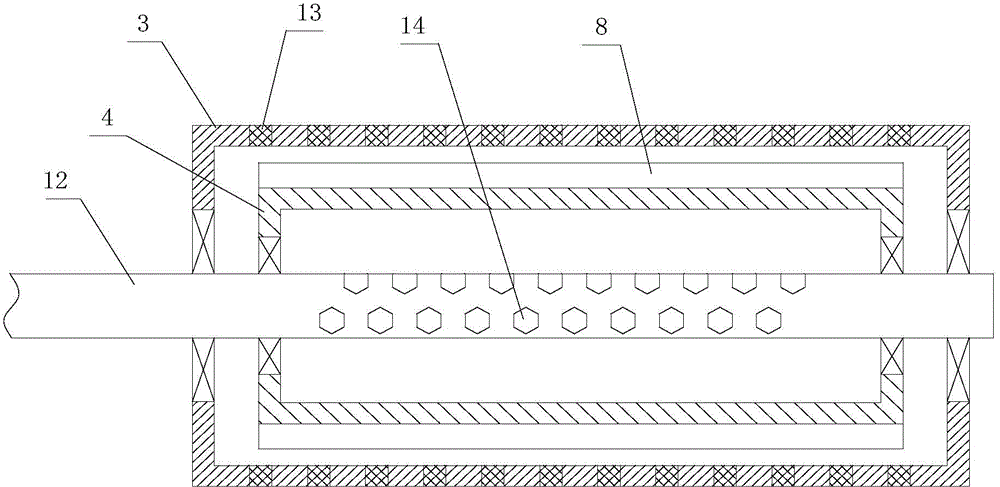

ActiveCN1872422AImprove air filtration efficiencyWide particle size rangeElectrode constructionsElectrodes cleaningFriction lossMetal mesh

A self-cleaning type efficient electronic air cleaner combining the electrostatic dusting principle with the traditional dusting principle is composed of a flow homogenizing plate for primary filtering, an ionizing region, a dust gathering region with the electrode plates made of the folded metallic mesh and the automatic dust sucking modules in the included angle of each folded metallic mesh, and an automatic dust discharging unit.

Owner:BEIJING KANGFU TECH

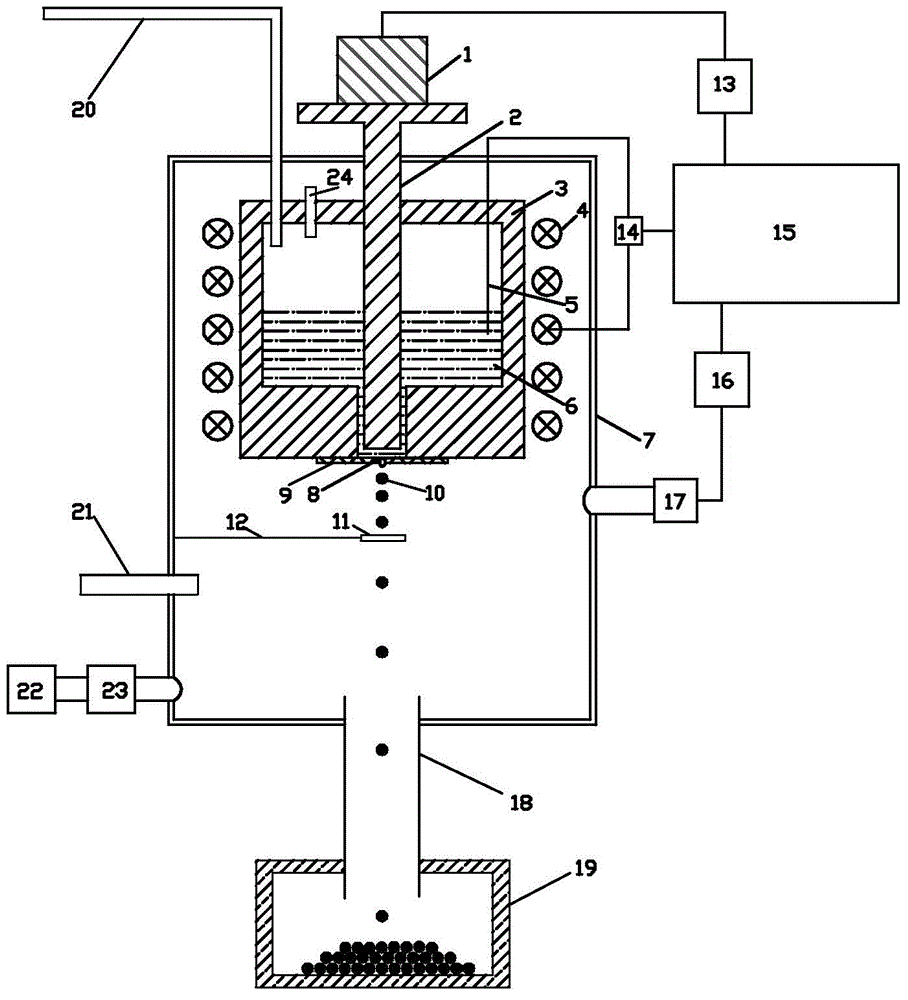

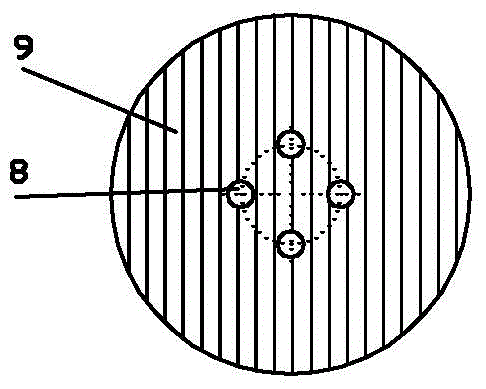

Method and device for manufacturing metallic glass particles

ActiveCN104096845AConsistent thermal stateAvoid uncontrollable factors such as heterogeneous nucleationElectricityDifferential pressure

The invention discloses a method and a device for manufacturing metallic glass particles, and belongs to the field of technologies for manufacturing metallic glass. The method includes generating stable differential pressures of 0-50KPa for metal melts in molten states under a vacuum condition; generating certain pulse signals for a piezoelectric ceramic to act on the metal melts; ejecting tiny liquid droplets from a hole in the bottom of a crucible; quickly cooling and solidifying the tiny liquid droplets without containers to form the spherical metallic glass particles. The device comprises a vacuum chamber. A particle collecting device is mounted at the bottom of the vacuum chamber, a liquid droplet ejecting system is mounted on the top of the vacuum chamber and is positioned right above the particle collecting device, and an image acquiring system is connected onto the vacuum chamber of a vacuum system. The method and the device have the advantages that the metallic glass particles are manufactured by a pulse hole ejecting process, the tiny liquid droplets are quickly solidified without the containers, accordingly, the particles with uniform and consistent particle sizes and high sphericity can be obtained, the particle sizes can be controlled, the manufacturing efficiency is high, and problems of low cooling speed, uneven particle size distribution, inconsistent thermal history and the like of an existing technology for manufacturing metallic glass particles can be solved.

Owner:GAOYOU INST CO LTD DALIAN UNIV OF TECH

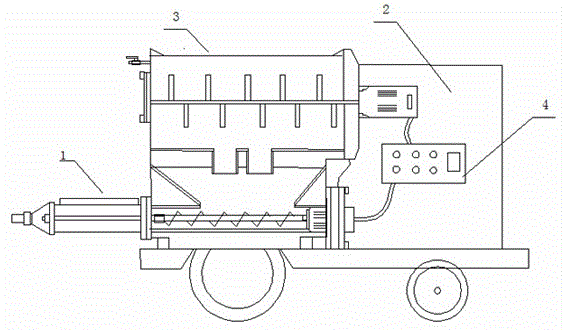

Grouter with stirring device and control method of grouter

InactiveCN105089272ASolve the requestNovel structureUnderground chambersFoundation engineeringControl systemIntellectual property

The invention discloses a grouter with a stirring device and a control method of the grouter. The grouter comprises a single-screw pump and a stirring mechanism which are fixed to a machine frame. A hopper is arranged below the stirring mechanism. The lower portion of the hopper is connected with the single-screw pump. The invention further discloses a control system based on the grouter with the stirring mechanism and an integral control method based on the control system of the grouter. The grouter has the advantages that by means of the Europe and America advanced worm pressurization technology, through the combination of current domestic construction situations, through many years of study and research, by gathering the advantages of similar products, the novel high-pressure thick-paste large-flow anchoring grouting pump with proprietary intellectual property rights is put forward, the strict requirements for the water-cement ratio of mortar and grouting pressure in engineering are met, mortar within a water-cement ratio design range can be easily grouted, and design pressure is reached; meanwhile, the pump can be provided with an ejector, and spray protection construction can be conducted on wall surfaces of a roadway.

Owner:张荣斌

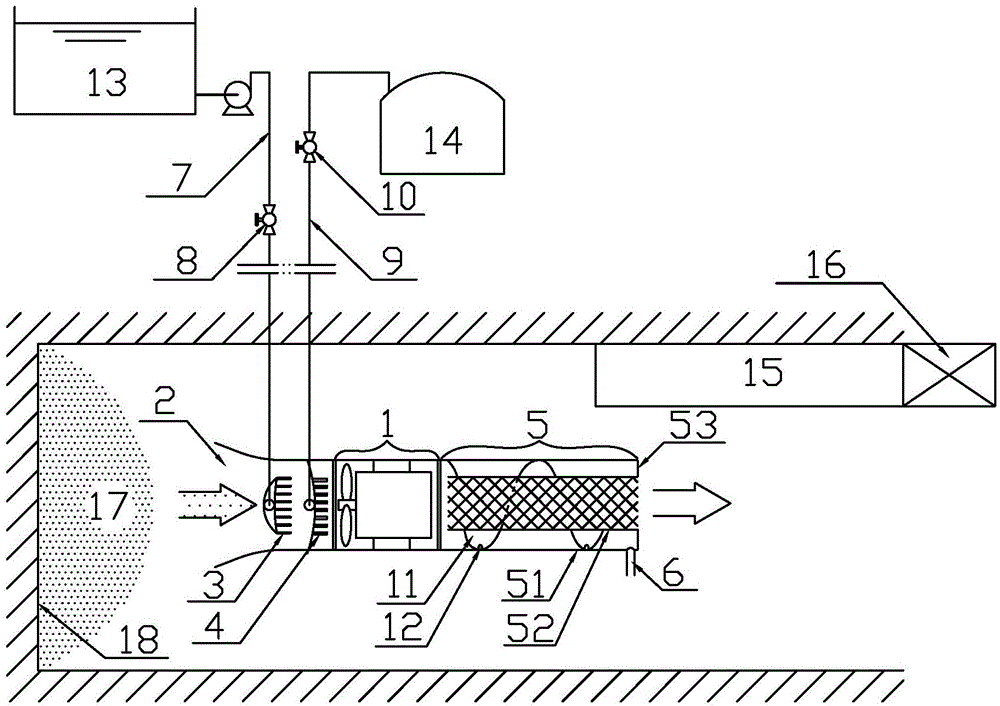

Method for improving underground coal mine negative pressure suction dust removal technology

The invention relates to a method for improving an underground coal mine negative pressure suction dust removal technology. According to the method, a horn opening, high-pressure water jet pumps and high-pressure gas jet pumps are additionally arranged in front of an air inlet of an axial flow fan, and a water film dust removal barrel is additionally arranged at an air outlet of the axial flow fan; water, dust and fog are fully mixed through the high-pressure water jet pumps, the high-pressure gas jet pumps and the axial flow fan, and then the water, dust and fog are separated out by the water film dust removal barrel. The method for improving the underground coal mine negative pressure suction dust removal technology has the advantages of being small in investment, fast to take effect, obvious in dust removal effect and suitable for coal mine driving face dust removal.

Owner:兖矿能源集团股份有限公司

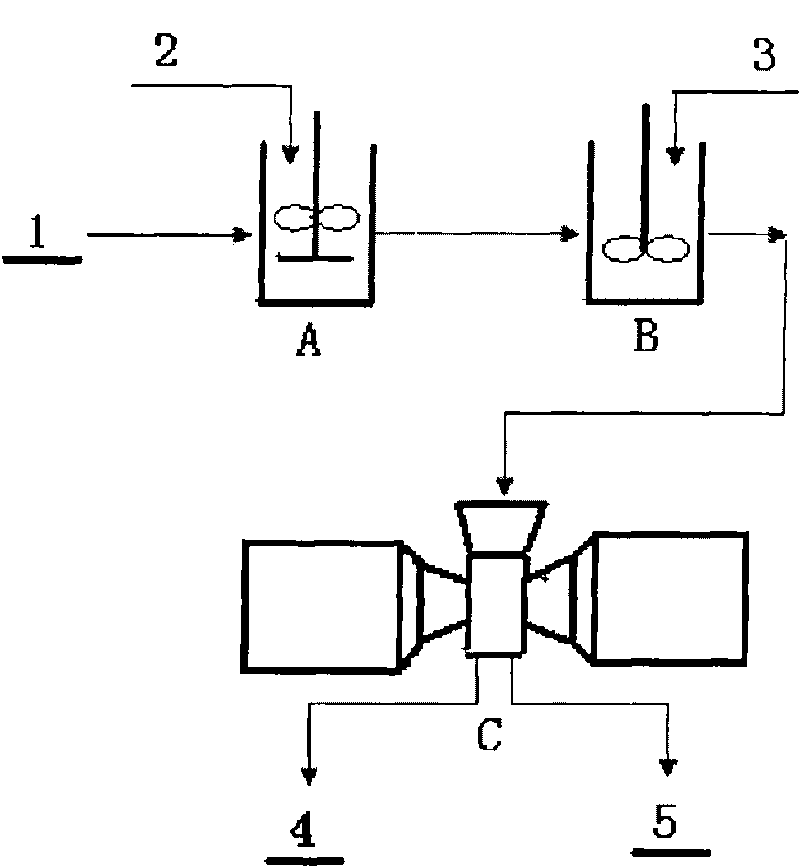

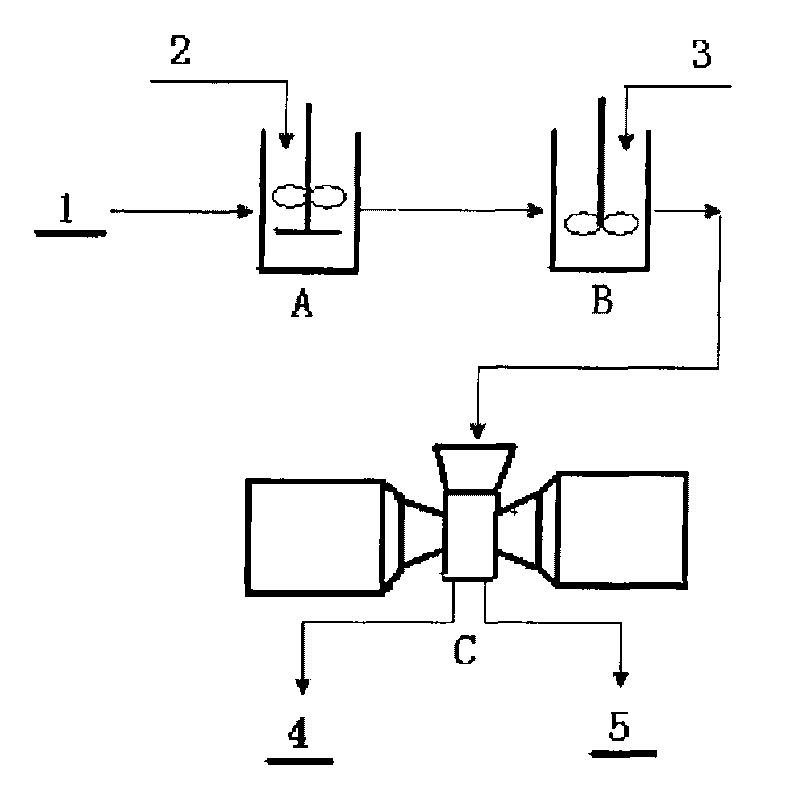

Magnetic separation and deinking method for waste paper

InactiveCN101736635AImprove deinking efficiencyReduce fiber lossPaper recyclingWaste paper working-upChemistrySodium silicate

The invention relates to a magnetic separation and deinking method for waste paper, comprising the following steps: (1) adding waste paper and magnetic seeds in a pulper, adding water, sodium silicate and NaOH for repulping, wherein the repulping conditions are as follows: the magnetic seed dosage is 0.05-0.2wt%, the dosage of sodium silicate is 2-10wt%, NaOH is used to regulate the pH value to be 7-10, and the pulp concentration is 10-15wt%; (2) adding water for diluting after water paper repulping until the pulp concentration to be 0.5-4wt%, adding flocculant which accounts for 0.01-0.1wt% of dry paper into the pulp after repulping for magnetic seed flocculation, enabling the deciduous ink particles to be adhered with magnetic seeds, wherein the pH value is 7.0-11.0, the time is 10-30min, and the stirring speed is 200-1000rpm; and (3) separating the flocculated ink particles from the pulp by a deinking device for size after magnetic seed flocculation. The method in the invention can obviously improve pulp whitness and fiber yield of water paper, and can be used for producing deinking pulp with high whiteness and high deinking rate and small amount of paper fiber loss.

Owner:有研资源环境技术研究院(北京)有限公司

Air cleaning single region electronic dust-collecting unit

The invention relates to an air cleaning electronic dust-removing device which comprises a single region electronic dust-collecting unit that consists of corona electrodes and w-shaped dust-collecting plates and integrates dust particle charge and collection function. The dust-collecting unit is formed by a plurality of corona electrodes and w-shaped dust-collecting plates which are multi-distributed on a vertical surface of the airflow direction. The air cleaning electronic dust-removing device is characterized in that the w-shaped dust-collecting plates are multi-distributed on the vertical surface of the airflow direction against the wind, thereby improving the speed of the charge dust particles moving towards the dust-collecting plates, prolonging the movement track of the dust particles in a dust-collecting region, and realizing the miniaturization of the dust-collecting unit under the conditions of same input air and efficiency. The air cleaning electronic dust-removing device is also characterized in that high dust-collecting efficiency is always kept under high airflow speed, thereby being suitable to be arranged in environment with high airflow speed. Moreover, the air cleaning electronic dust-removing device is characterized by having convenient manufacture and less operation and maintenance cost. The air cleaning electronic dust-removing device has the advantages of high processing wind speed, good dust-collecting effect, large dust-collecting amount, low power consumption, and less operation and maintenance cost, can be used for cleaning air with dust diameter not less than 0.3 micrometer and wind speed reaching up to 4m / s under the matching of a rated electric field and can achieve the one-time cleaning efficiency of 90 percent.

Owner:深圳市电精科技有限公司

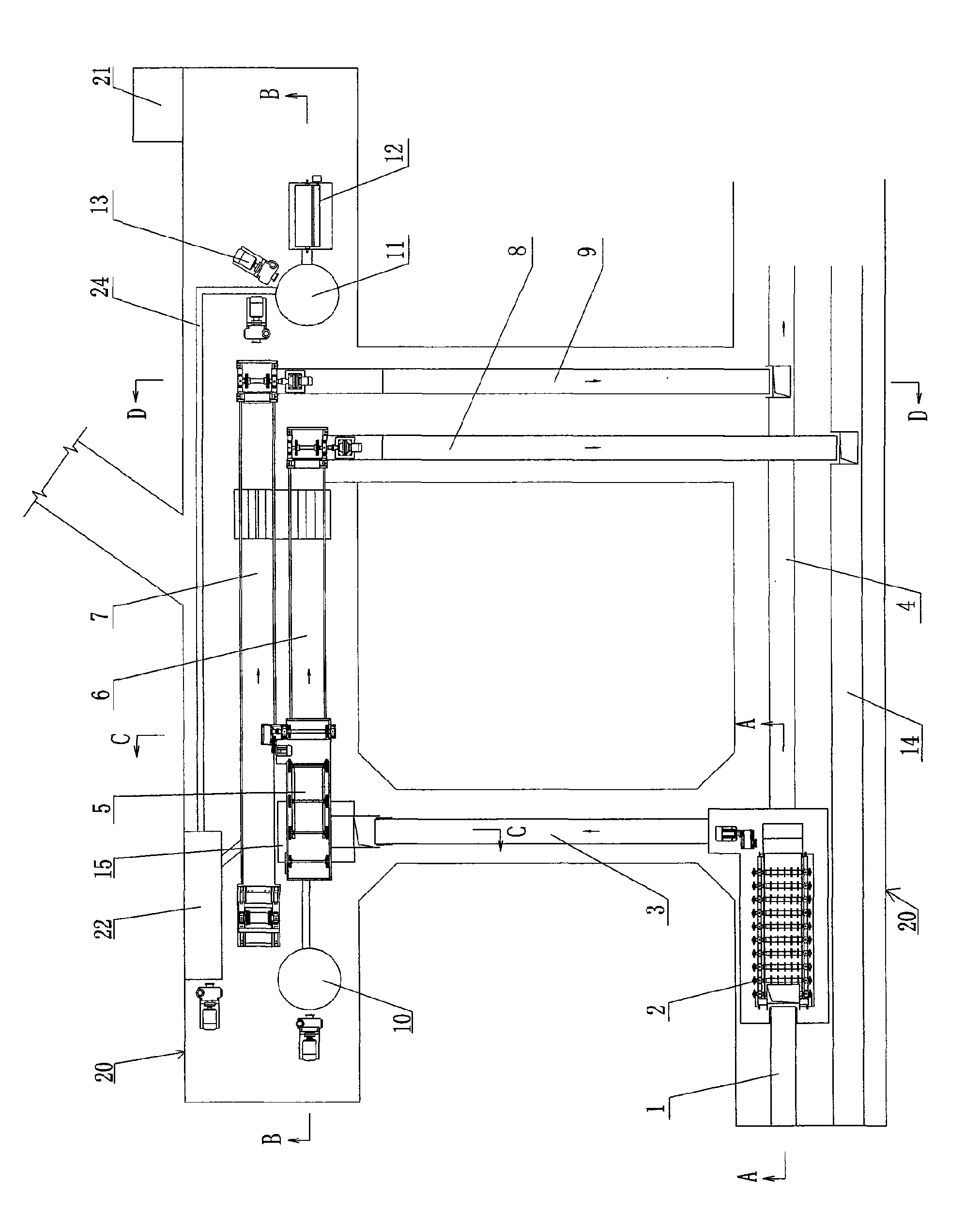

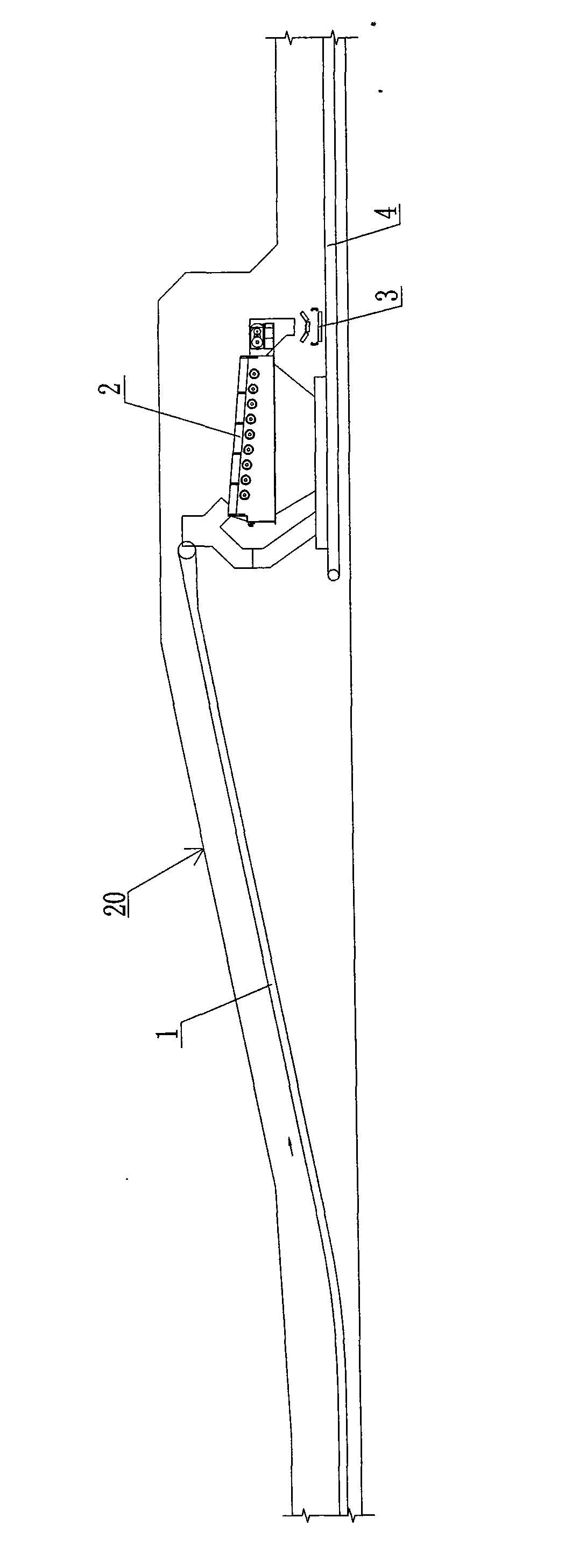

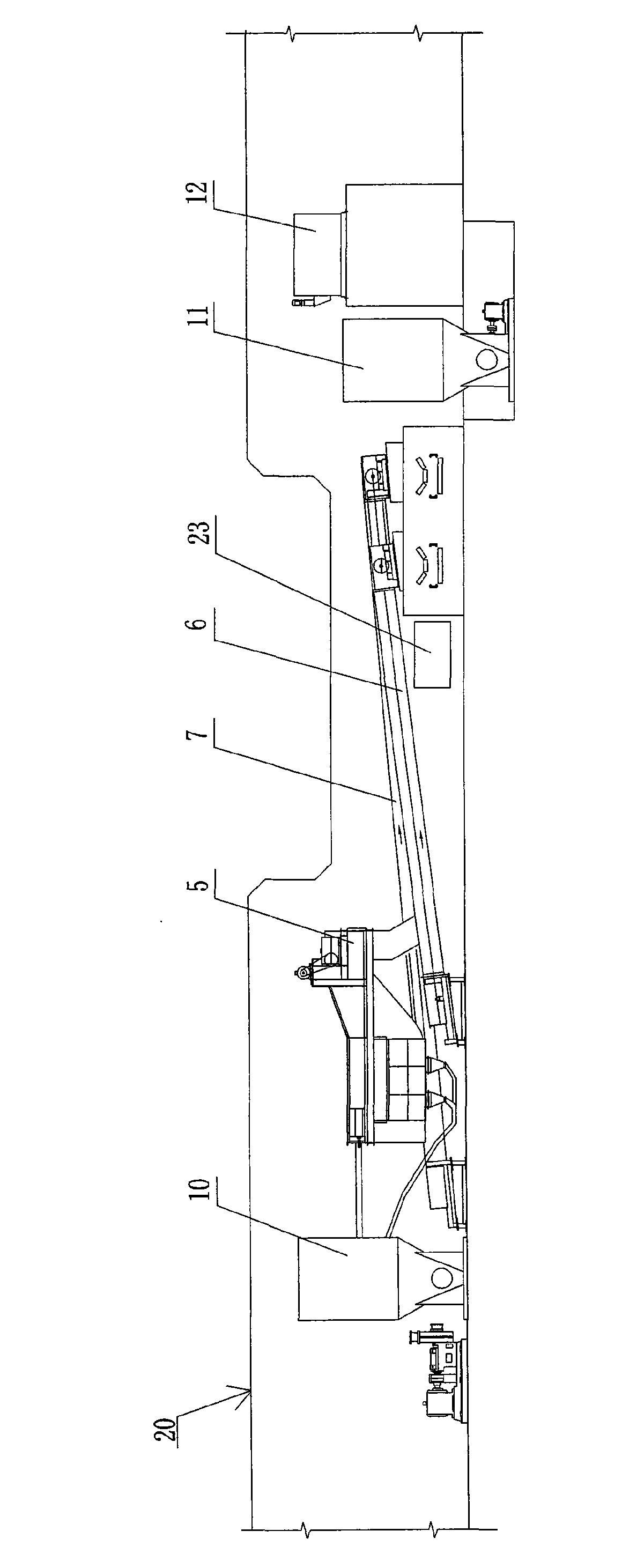

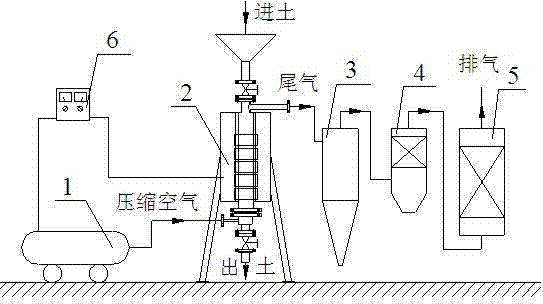

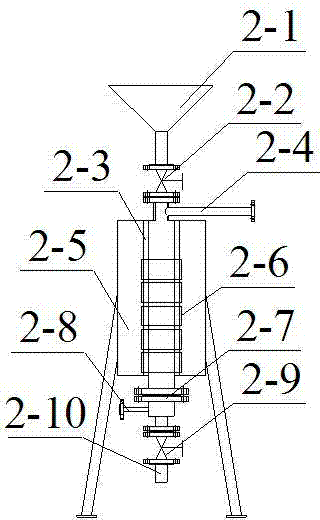

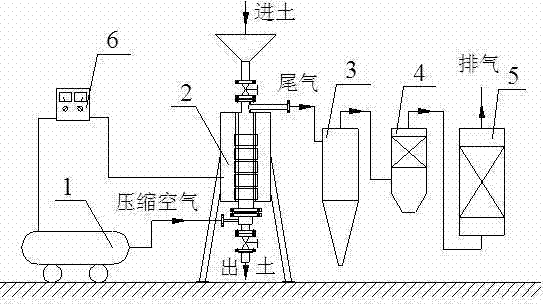

System for repairing organic contaminated soil by soil ventilation-vertical desorption furnace

ActiveCN102069088BEfficient repairSimple processContaminated soil reclamationEngineeringAir compressor

The invention provides a system for repairing the organic contaminated soil by a soil ventilation-vertical desorption furnace, comprising a thermal desorption system, a tail gas treatment system and a control system, wherein the thermal desorption system consists of an air compressor 1 and a vertical desorption furnace 2; the tail gas treatment process consists of a cyclone dust collector 3, a dehumidifier 4 and an adsorption tower 5; and the control system 6 can realize the effective control of the soil heating temperature. The system can be used for repairing the organic contaminated soil in which the main contaminants are volatile / semivolatile.

Owner:NANJING AGRICULTURAL UNIVERSITY

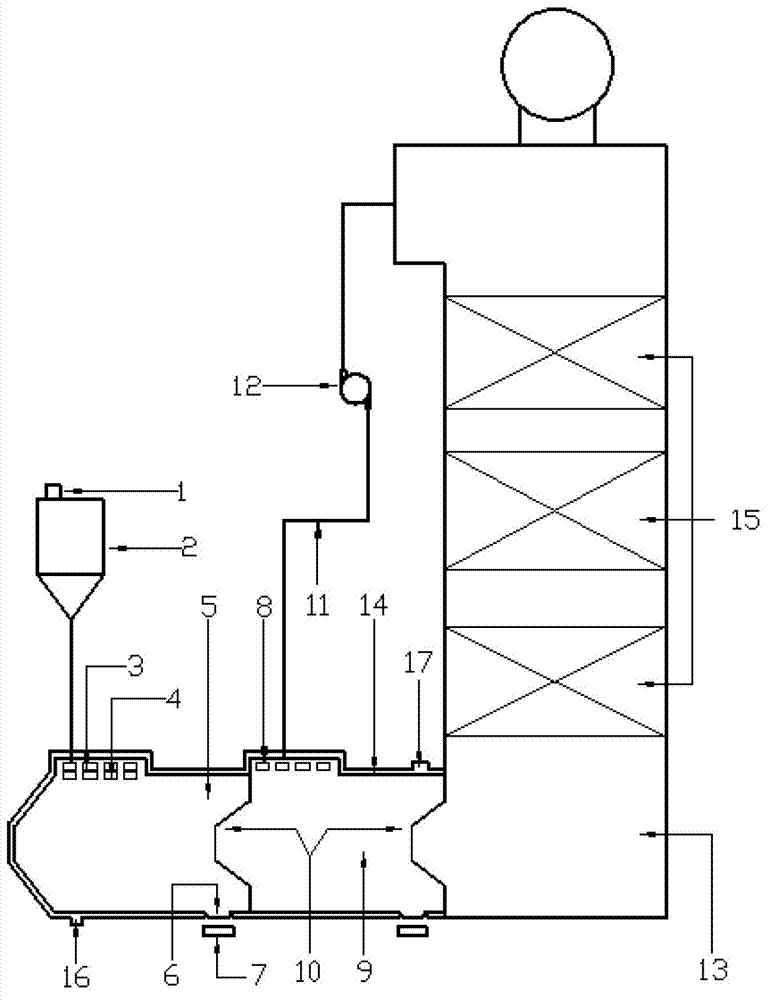

Leather waste vaporizing combustion and heat recovery system, and operation method thereof

The invention discloses a leather waste vaporizing combustion and heat recovery system, and an operation method thereof. The operation method comprises the steps that leather waste is subjected to high-temperature cyclone vaporizing in a section of the vaporizing combustion and heat recovery system; after gas is separated from liquid ash, the gas enters a second section and is supplemented with excessive air, so that the gas is combusted completely; flue gas generated after the gas is combusted completely enters waste heat recovery equipment, so that waste heat is recovered; and finally, the flue gas is discharged after purification and dust removal. The system is simple in structure and high in combustion intensity, can reduce pollutants effectively, and achieves clean recycling of the leather waste.

Owner:WENZHOU SPECIAL EQUIP INSPECTION CENT +1

Production method of high-quality superfine light calcium carbonate

InactiveCN107416884AConducive to reasonable recyclingGood dispersionCalcium/strontium/barium carbonatesCalcium hydroxideRoom temperature

The invention discloses a production method of high-quality ultrafine light calcium carbonate, belonging to the technical field of calcium carbonate production. A production method of high-quality ultrafine light calcium carbonate is characterized in that it comprises the following steps: (1) using limestone as raw material, putting it into a reaction furnace for heating and calcining to obtain calcium oxide, and sealing it for later use after cooling; Calcium is added to impurity-free water, stirred for 2-4h, and calcium hydroxide slurry is obtained after cooling down; (3) Carbon dioxide gas is introduced into the calcium hydroxide slurry at room temperature for carbonization, and carbonized to the pH of the calcium hydroxide slurry It is 6.5-7.5, obtains calcium carbonate slurry, stops carbonization; (4) puts the calcium carbonate slurry that step (3) obtains into storage tank and leaves standstill 10-12h, makes its pH value stabilize. The object of the present invention is to provide a production method of high-quality ultrafine light calcium carbonate, which is simple in operation, stable in quality, and capable of efficiently preparing high-quality ultrafine light calcium carbonate.

Owner:广西华洋矿源材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com