Patents

Literature

64results about How to "Reduce fly ash content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

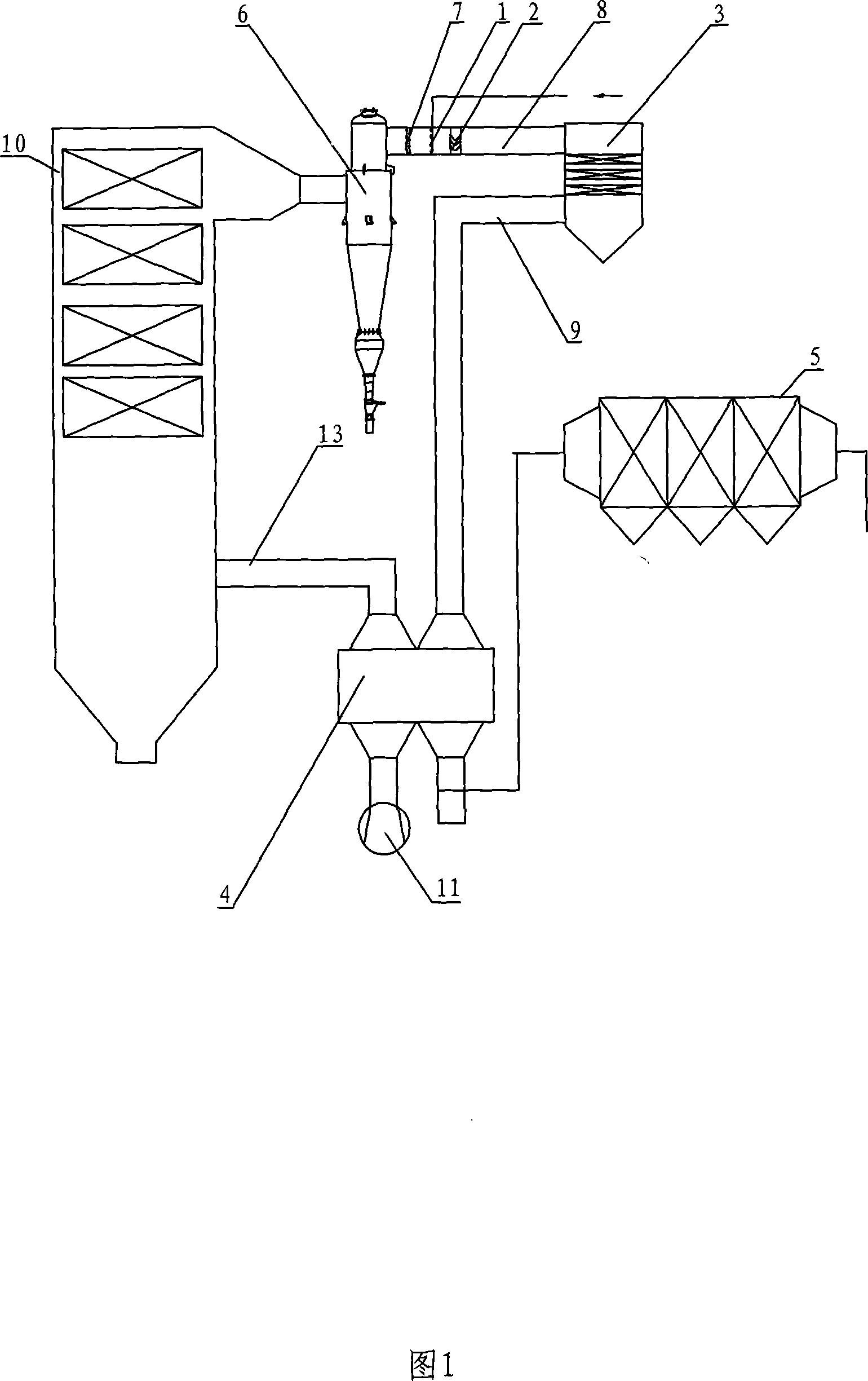

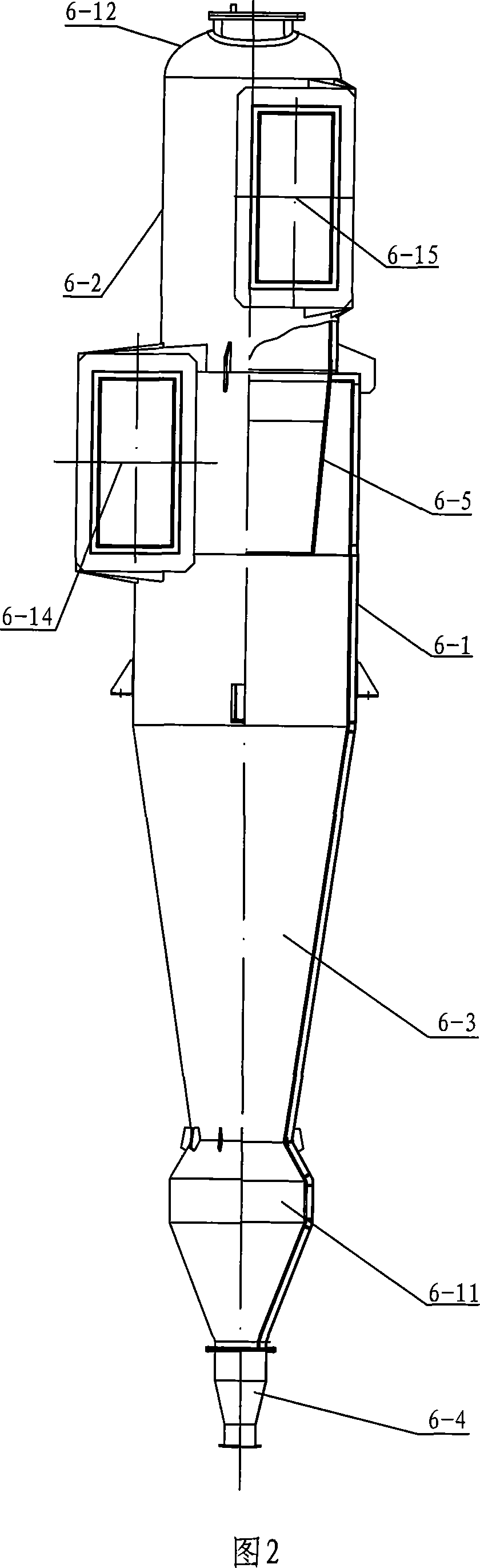

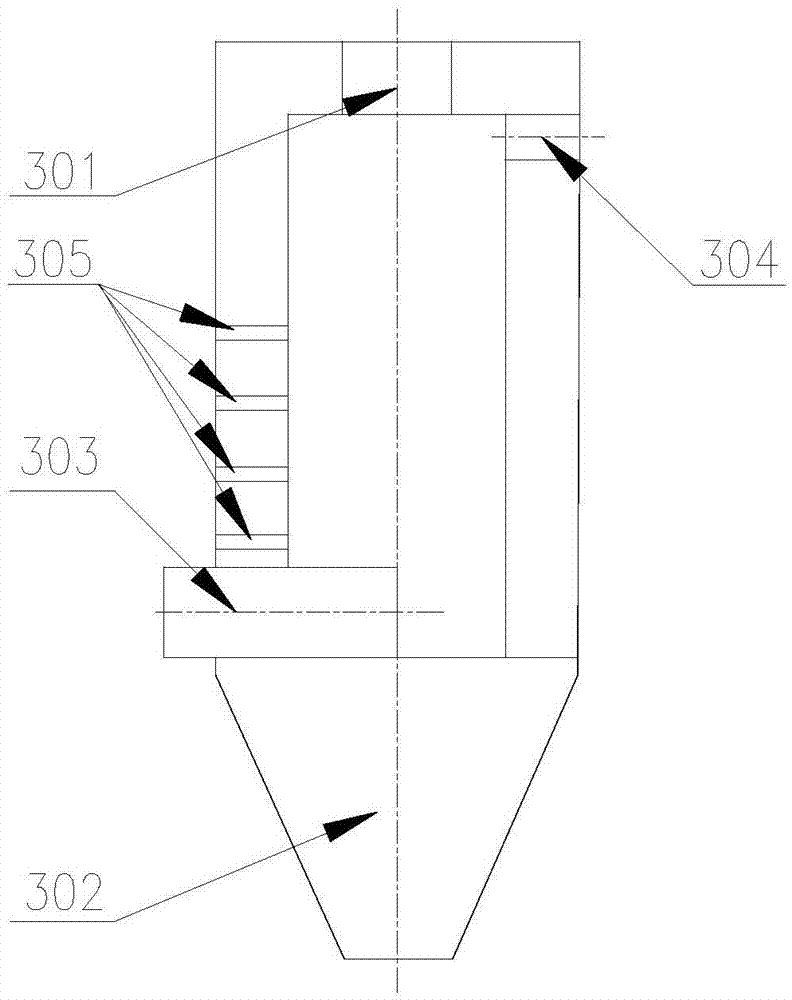

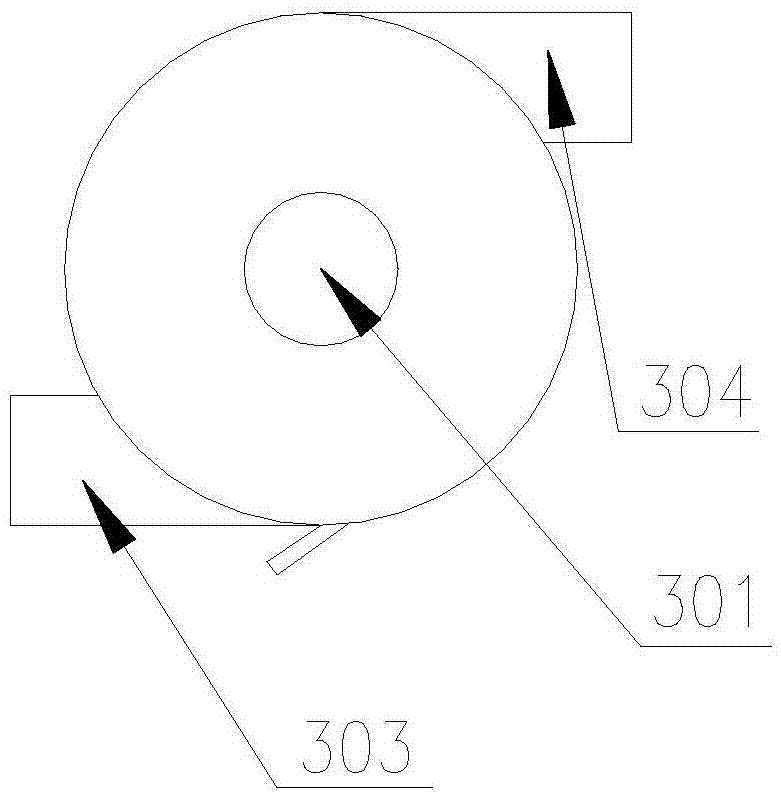

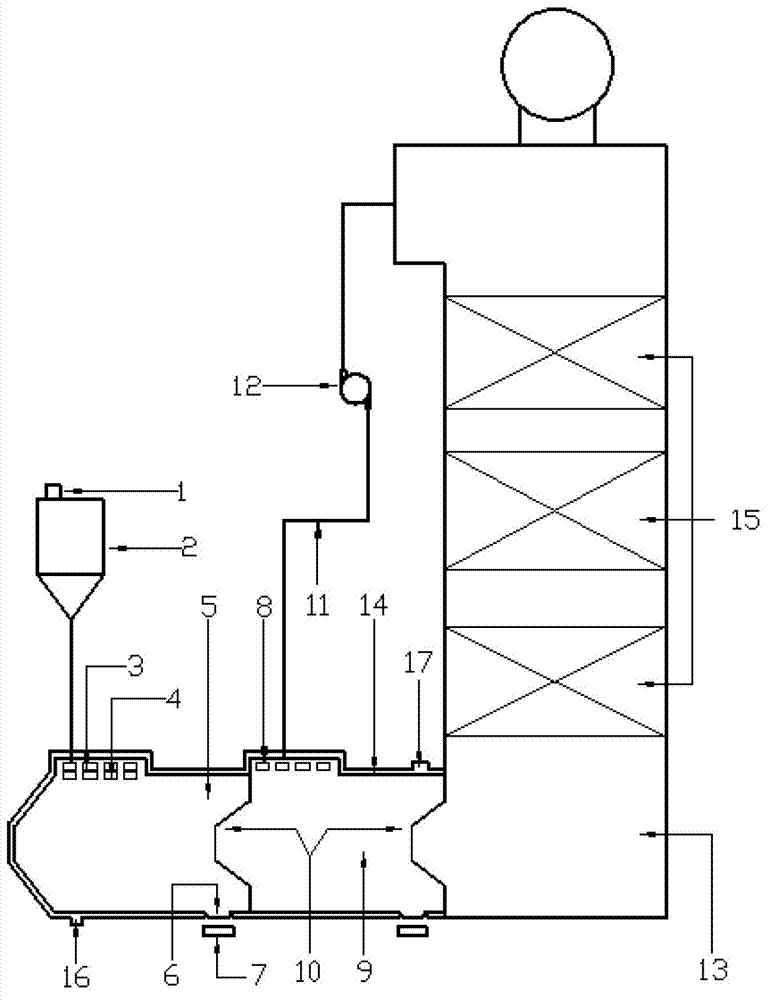

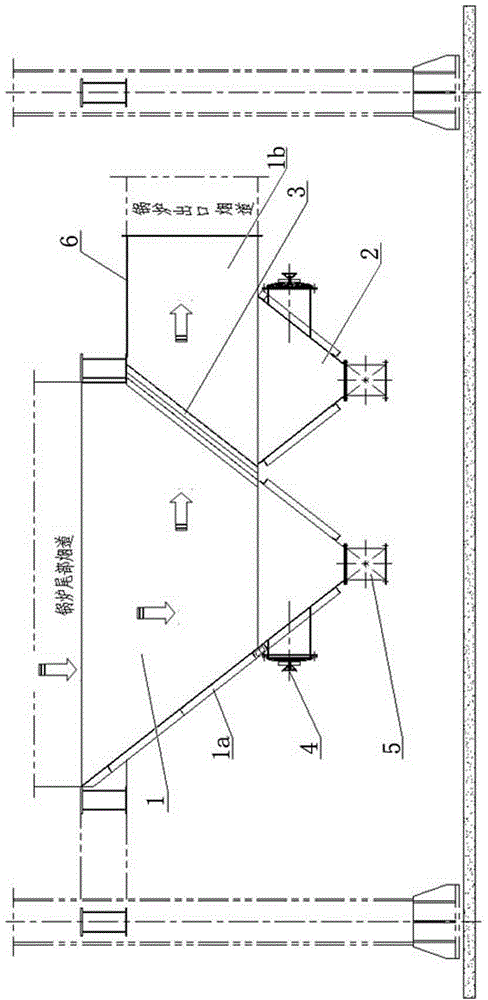

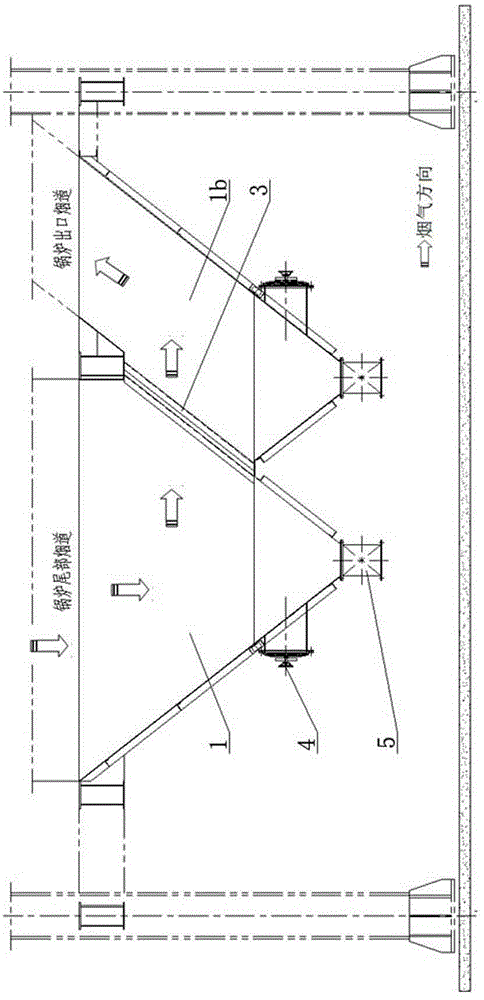

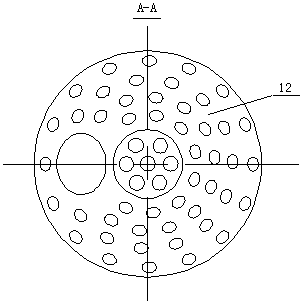

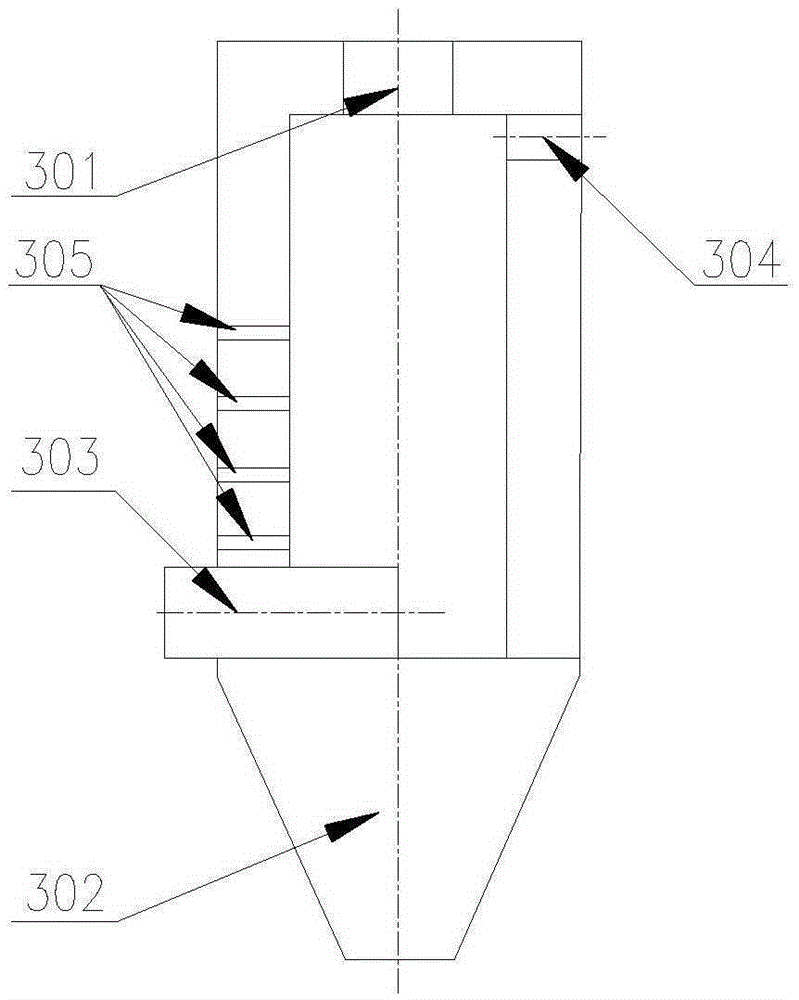

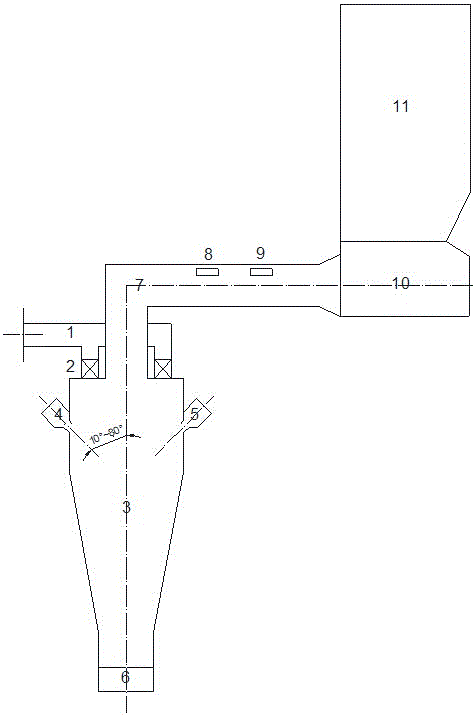

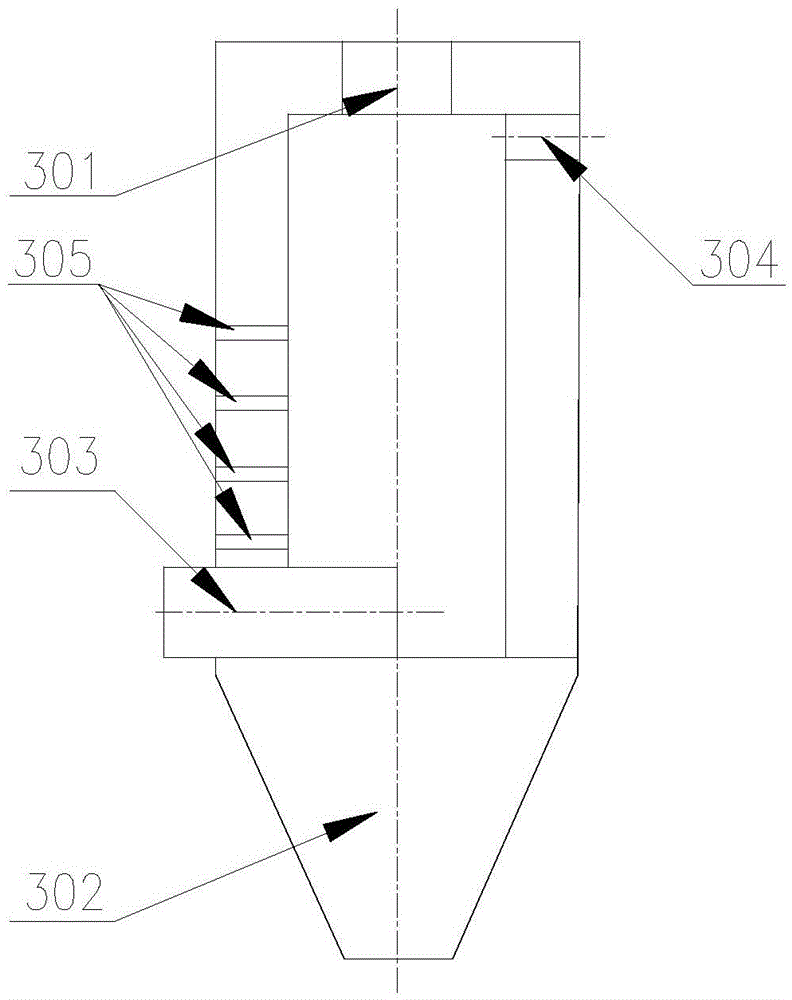

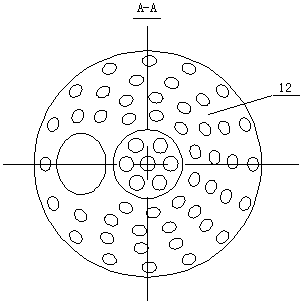

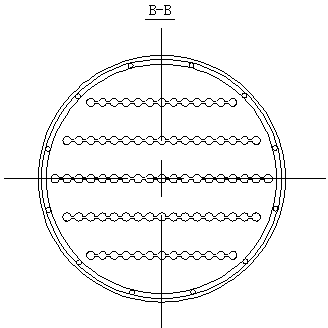

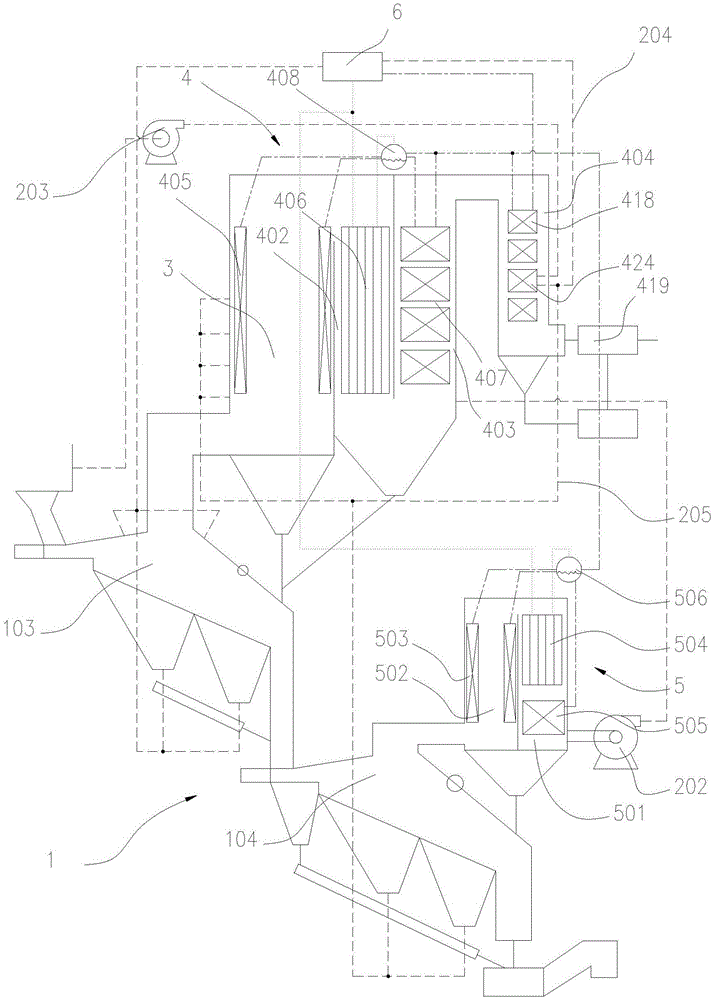

Flue gas denitrating technique with preposed whirlwind beforehand dust removal SCR

The invention discloses a preposing cyclone pre-dedusting SCR flue gas denitration technique. The flue gas extracted from a boiler economizer (12) primarily passes through a high temperature resistant cyclone separator (6), then passes through a flue gas current equalizer (7) and a static mixer (2) to unify the flow direction of the flue gas evenly; meanwhile, the flue gas after being mixed evenly with ammonia is preprocessed before reacting with a catalyst of an SCR reactor (3); finally, the flue gas is output after the temperature is reduced through an air preheater (4) and the flue gas is dedusted through an electrical precipitator (5). The invention reduces the volume of the catalyst and the SCR reactor, reduces the requirements of the support, eliminates an SCR bypass and greatly reduces engineering cost of the SCR; meanwhile, the invention also prolongs the service life of the catalyst and the cleaning period of the air preheater without installing a soot blower or prolonging the period of sootblowing.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

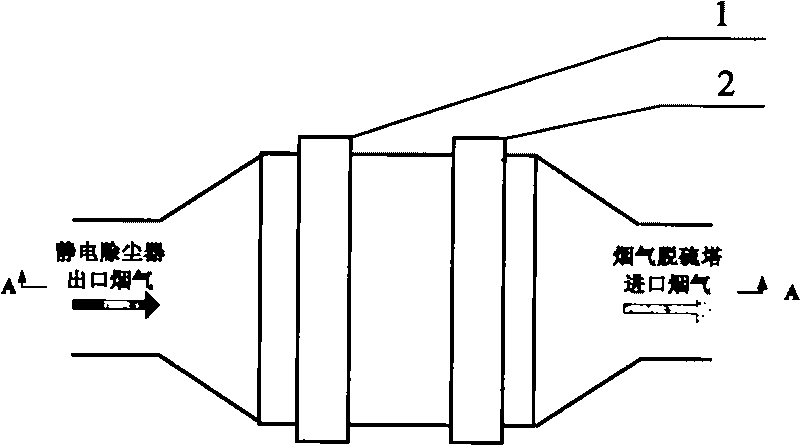

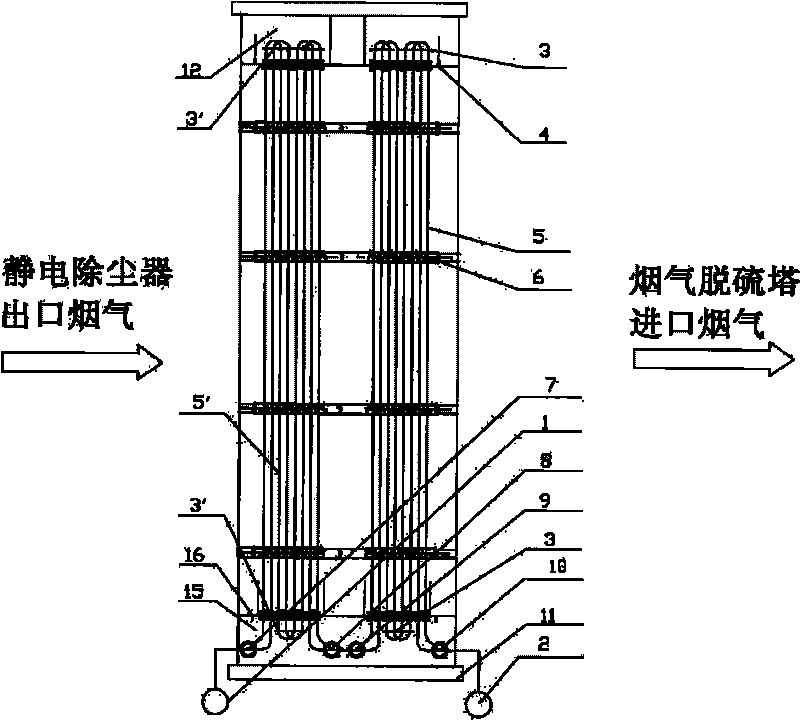

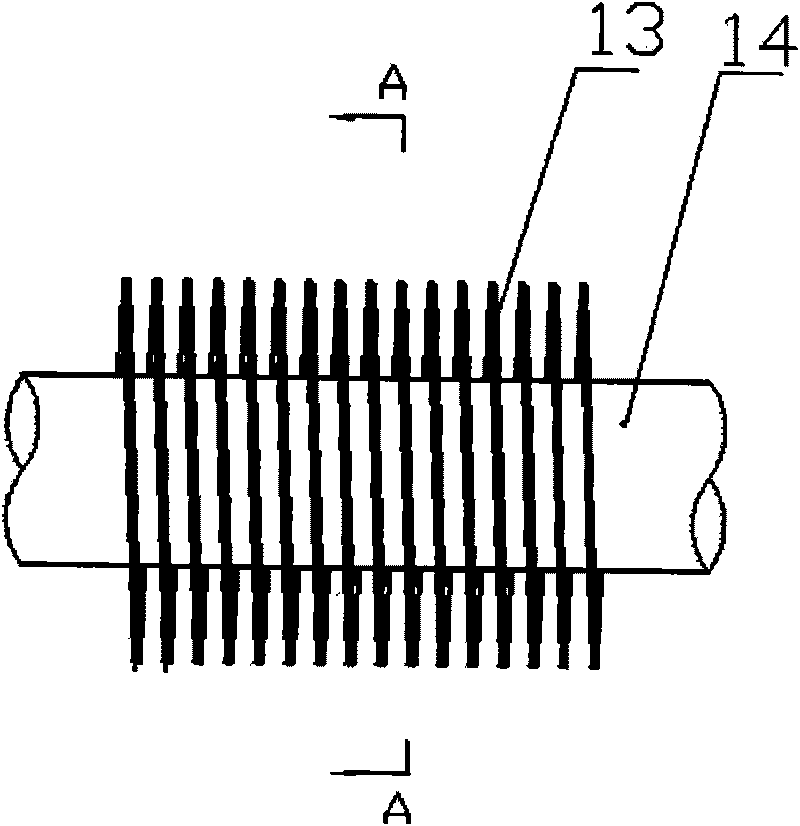

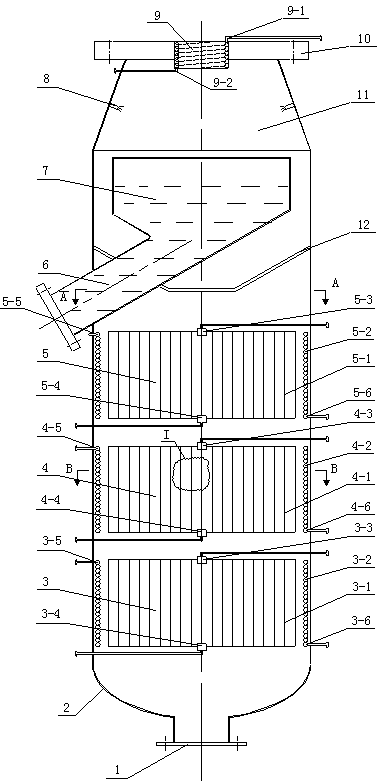

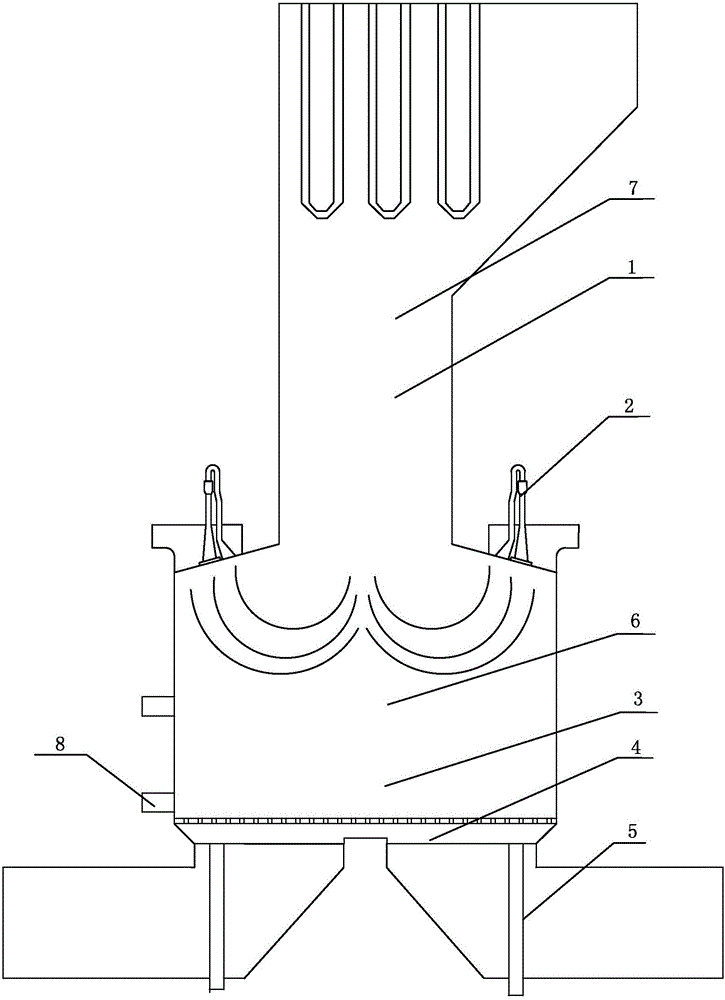

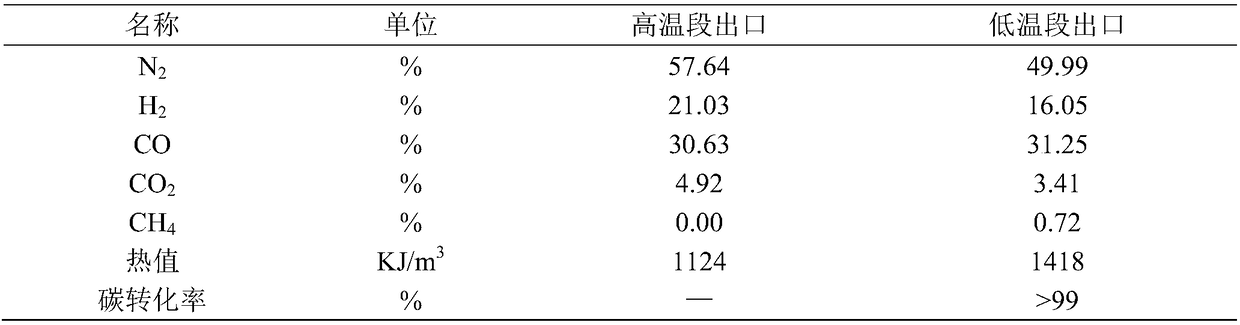

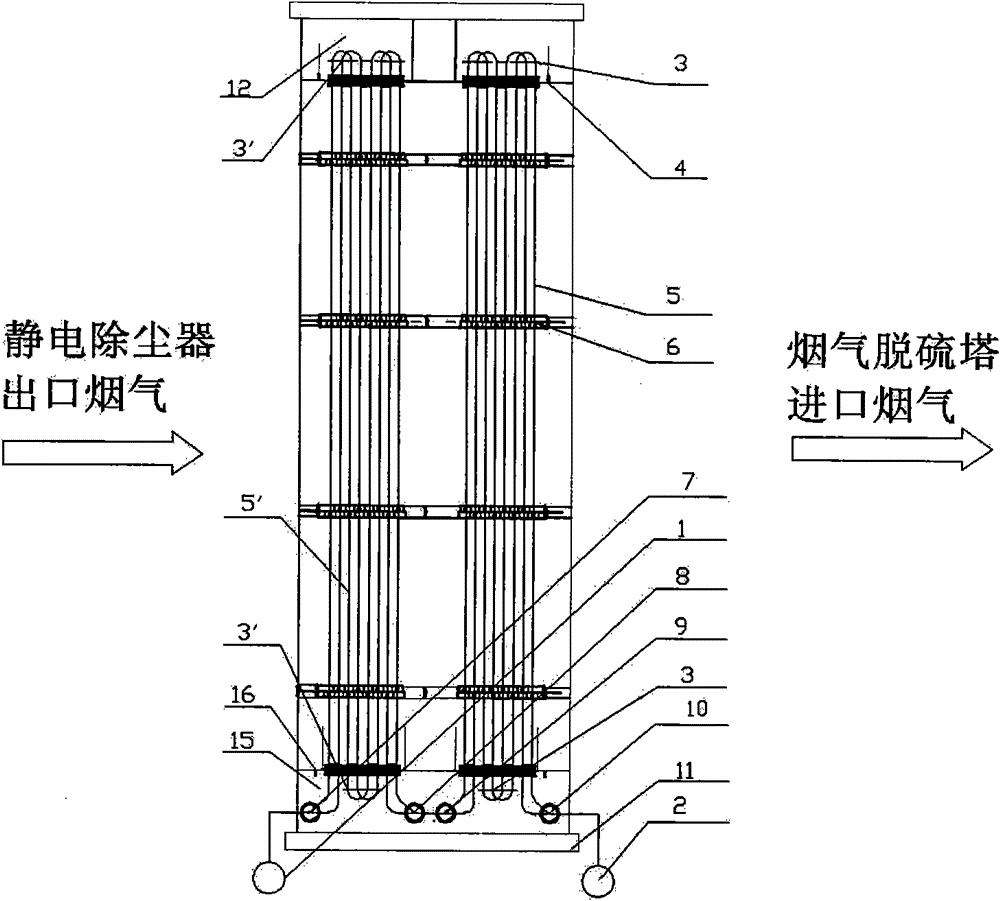

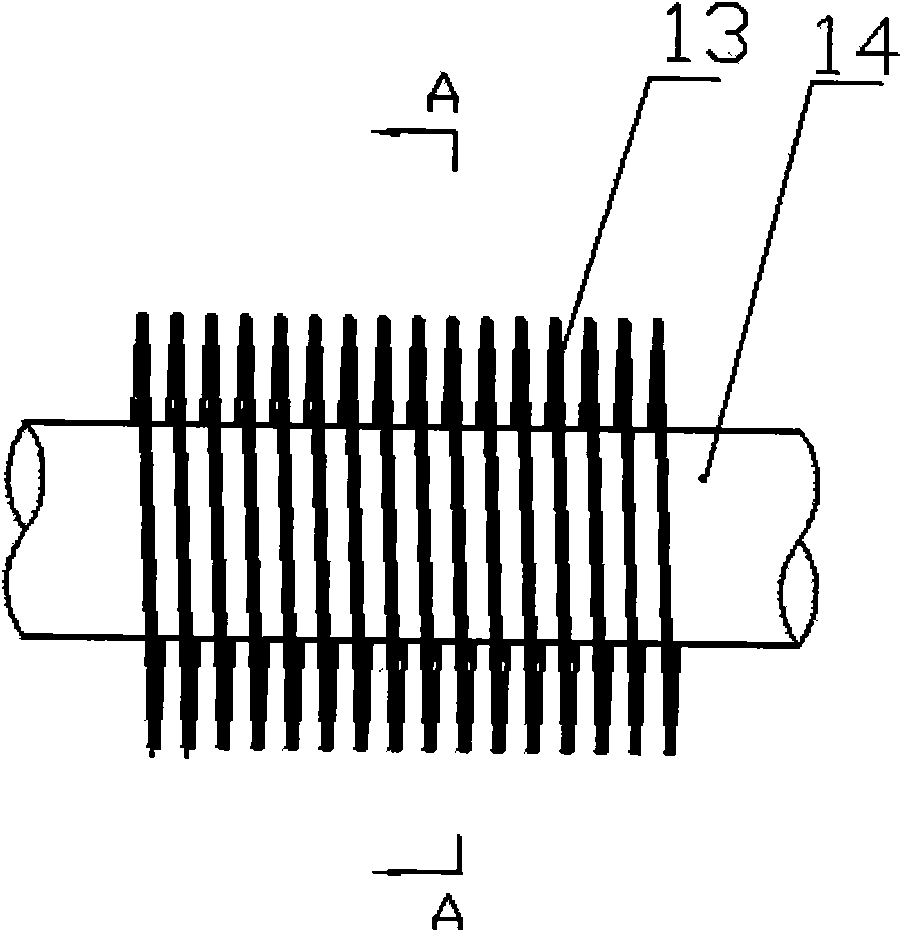

Embedded deep cooler for boiler flue gas

The invention discloses an embedded deep cooler for boiler flue gas, which comprises a shell 11; the side close to an inlet flue in the shell 11 is a high temperature section, and the side close to an outlet flue is a low temperature section; and flue clapboards 14 and 16 divide an inner cavity of the shell 11 into an upper flue compartment 12, a middle flue and a lower flue compartment 15. The embedded deep cooler performs deep cooling on boiler flue gas, effectively recovers afterheat of the boiler flue gas, reduces the temperature of flue gas at an inlet of a desulfurizing tower, reduces water consumption of the desulfurizing tower, improves the boiler efficiency and desulfurization efficiency, and achieves the aims of saving energy, improving efficiency and saving water resource.

Owner:XI AN JIAOTONG UNIV +1

Boiler system utilizing garbage incineration synthesis gas

ActiveCN105444145ABurn fullyIncrease temperatureSteam engine plantsIncinerator apparatusSyngasCombustion chamber

The invention discloses a boiler system utilizing garbage incineration synthesis gas, which has small heat conversion efficiency loss and higher heat recovery efficiency. The boiler system comprises a boiler body, wherein the boiler body is provided with a cyclone combustion chamber, a furnace chamber a and a furnace chamber b, which communicate with one another; a water wall is arranged in the cyclone combustion chamber; a superheater is arranged in the furnace chamber a; an evaporator is arranged is the furnace chamber b; a steam drum is arranged at the top end of the boiler body; a steam-water inlet is formed in the steam drum; the steam drum is connected with a water inlet of the water wall through a first downcomer to output water; the steam drum is connected with a water inlet of the evaporator through a second downcomer to output water; a steam outlet of the water wall and a steam outlet of the evaporator are connected with a steam inlet of the steam drum to reflux high-temperature steam; a saturated steam outlet of the steam drum is connected with a steam inlet of the superheater through a pipeline to input high-temperature steam to the superheater; and a steam outlet of the superheater outputs superheated steam.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

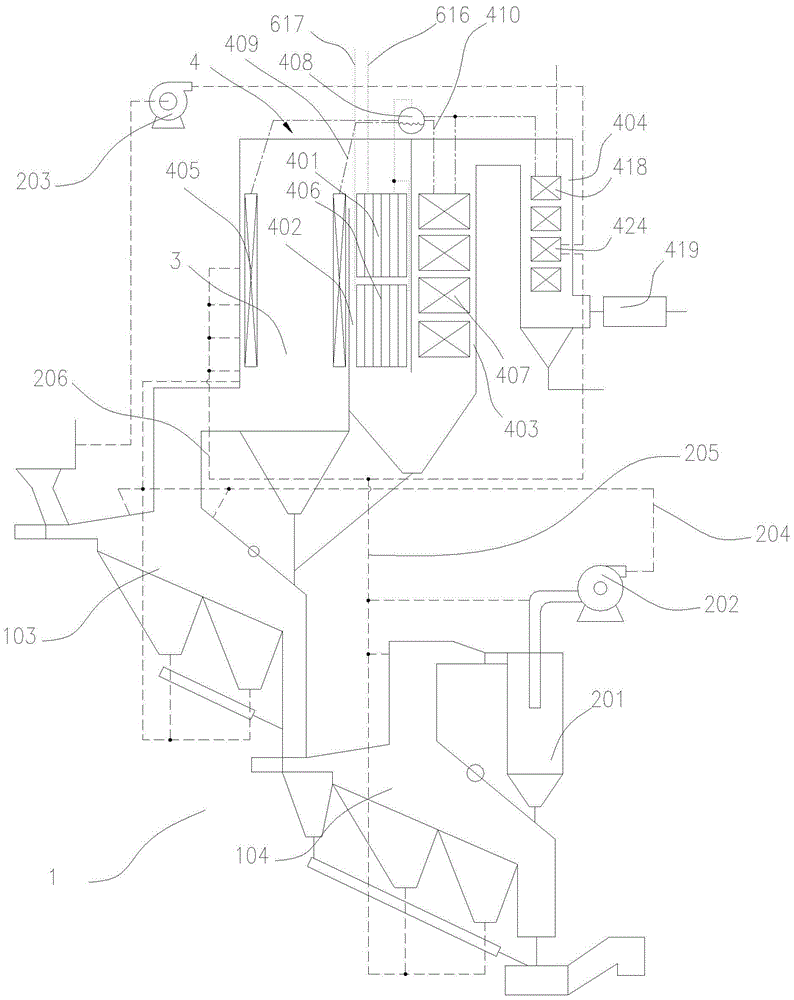

Garbage gasified fuel gas and steam turbine combined power generation system adopting multi-stage heat exchange mode

ActiveCN106224036AEmission reductionImprove recycling efficiencyGas turbine plantsSolid fuel combustionCombustion chamberGas compressor

The invention discloses a garbage gasification fuel gas and steam turbine combined power generation system adopting a multi-stage heat exchange mode. The garbage gasified fuel gas and steam turbine combined power generation system comprises a garbage gasification system, a boiler system and a power generation system; the power generation system comprises a mixer, an air compressor, a synthesized smoke gas compressor, a synthesized smoke gas combustion chamber, a turbine a, a turbine b, a steam turbine, a power generator a, a power generator b and a waste heat boiler. A heating channel of a synthesized gas steam-gas heat exchanger, a heating channel of an air steam-gas heat exchanger and a heating channel of a steam-water heat exchanger are connected between a gas outlet of the turbine a and a water feeding hole of a water feeding input system. A heated channel of a gas-water heat exchanger is connected between a low-pressure air compressor and a high-pressure air compressor. According to the garbage gasification fuel gas and steam turbine combined power generation system adopting the multi-stage heat exchange mode disclosed by the invention, large-scale garbage continuous gasification treatment is realized, garbage treatment capacity is greater, heat recycling efficiency is high, and emission of pollutants can be effectively reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Leather waste vaporizing combustion and heat recovery system, and operation method thereof

The invention discloses a leather waste vaporizing combustion and heat recovery system, and an operation method thereof. The operation method comprises the steps that leather waste is subjected to high-temperature cyclone vaporizing in a section of the vaporizing combustion and heat recovery system; after gas is separated from liquid ash, the gas enters a second section and is supplemented with excessive air, so that the gas is combusted completely; flue gas generated after the gas is combusted completely enters waste heat recovery equipment, so that waste heat is recovered; and finally, the flue gas is discharged after purification and dust removal. The system is simple in structure and high in combustion intensity, can reduce pollutants effectively, and achieves clean recycling of the leather waste.

Owner:WENZHOU SPECIAL EQUIP INSPECTION CENT +1

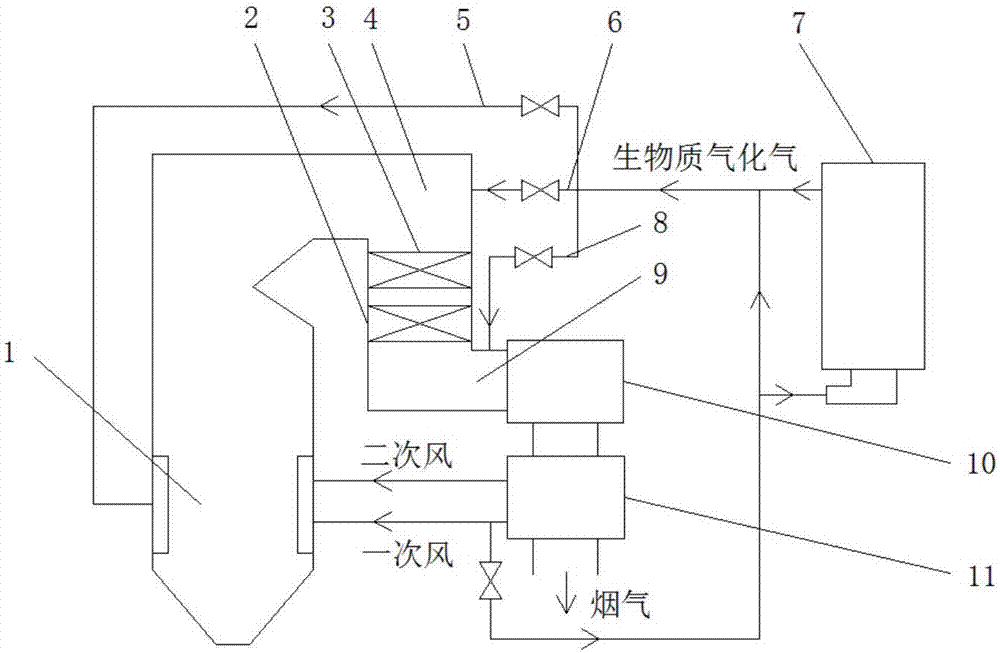

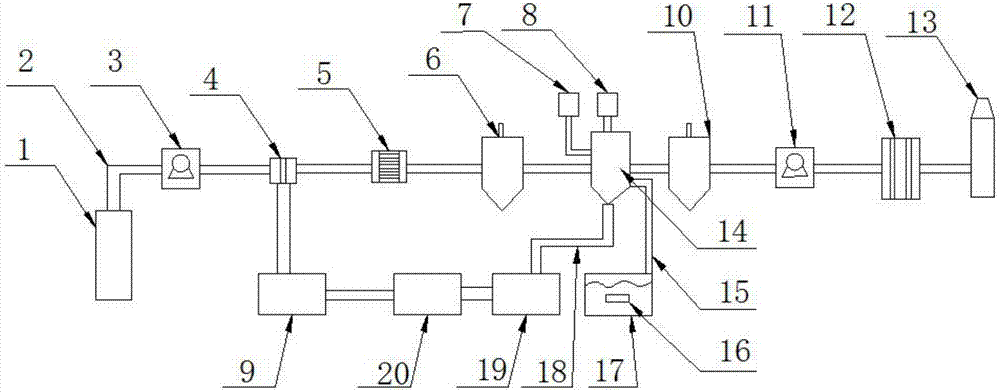

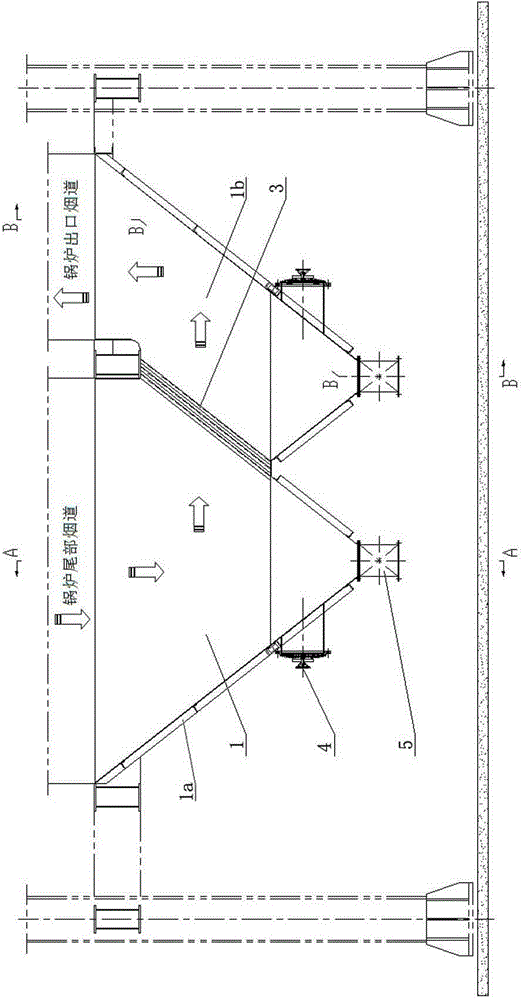

Power station boiler system and method for increasing tail fume temperature of power station boiler by integrating supplemental combustion for biomass gasification

InactiveCN107255269AIncrease smoke temperatureSafe and stable operationGas treatmentDispersed particle separationPower stationCombustion

The invention discloses a power station boiler system and a method for increasing the tail fume temperature of a power station boiler by integrating supplemental combustion for biomass gasification. According to the method, one or more fixed bed biomass gasifiers are additionally arranged, the gasifiers maintain the rated loads to continuously and stably operate, and hot primary air of the boiler is used as a gasification agent to promote the gasification efficiency of the gasifiers and increase the heat value of gasified gas; when the boiler operates with the low load, the biomass gasified gas is delivered into a flue behind a coal economizer or a steering fume chamber in front of the coal economizer, and the fume temperature at an outlet of the coal economizer is increased through supplemental combustion of the biomass gasified gas, so that a selective catalytic reduction fume denitration system operates safely and stably; supplemental-combustion gas is reduced correspondingly along with increasing of the loads, and the reduced gasification gas for supplemental combustion is delivered into the upper portion of a hearth so as to be combusted, and when the boiler operates with the full load, all the biomass gasified gas is delivered into the upper portion of the hearth so as to be combusted; and supplemental-combustion temperature increasing of the tail fume of the power station boiler is finally achieved through biomass resources, and meanwhile, the biomass resources can be further efficiently used for power generation.

Owner:GUODIAN SCI & TECH RES INST

Boiler waste gas treatment device

The invention discloses a boiler waste gas treatment device, which comprises a boiler exhaust port. The boiler exhaust port is connected to a No. 1 induced draft fan through an exhaust pipe. The pipe is connected to the heat exchanger, the heat exchanger is connected to the cooling tower through the exhaust pipe, the cooling tower is connected to the desulfurization tower through the exhaust pipe, the desulfurization tower is connected to the demister through the exhaust pipe, and the desulfurization tower is connected to the water tank through the water pipe Connect the slurry pump through the slag discharge pipeline, the slurry pump is connected to the belt filter through the slag discharge pipeline, the belt filter is connected to the waste residue collection box through the slag discharge pipeline, the demister is connected to the No. 2 induced draft fan through the exhaust duct, and the No. 2 induced draft fan The activated carbon filter box is connected through the exhaust pipe, and the activated carbon filter box is connected to the chimney through the exhaust pipe. The boiler exhaust gas treatment device can effectively treat the atmosphere, have sustainable circular reaction, low reaction cost, and effectively protect the environment.

Owner:赵魁

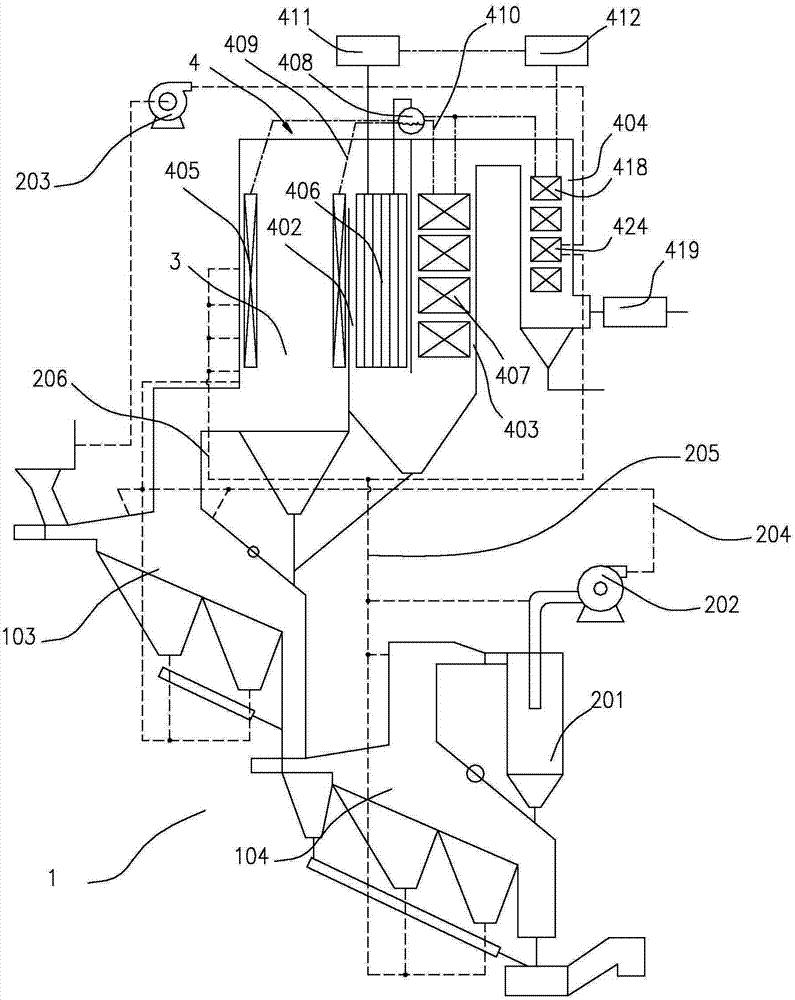

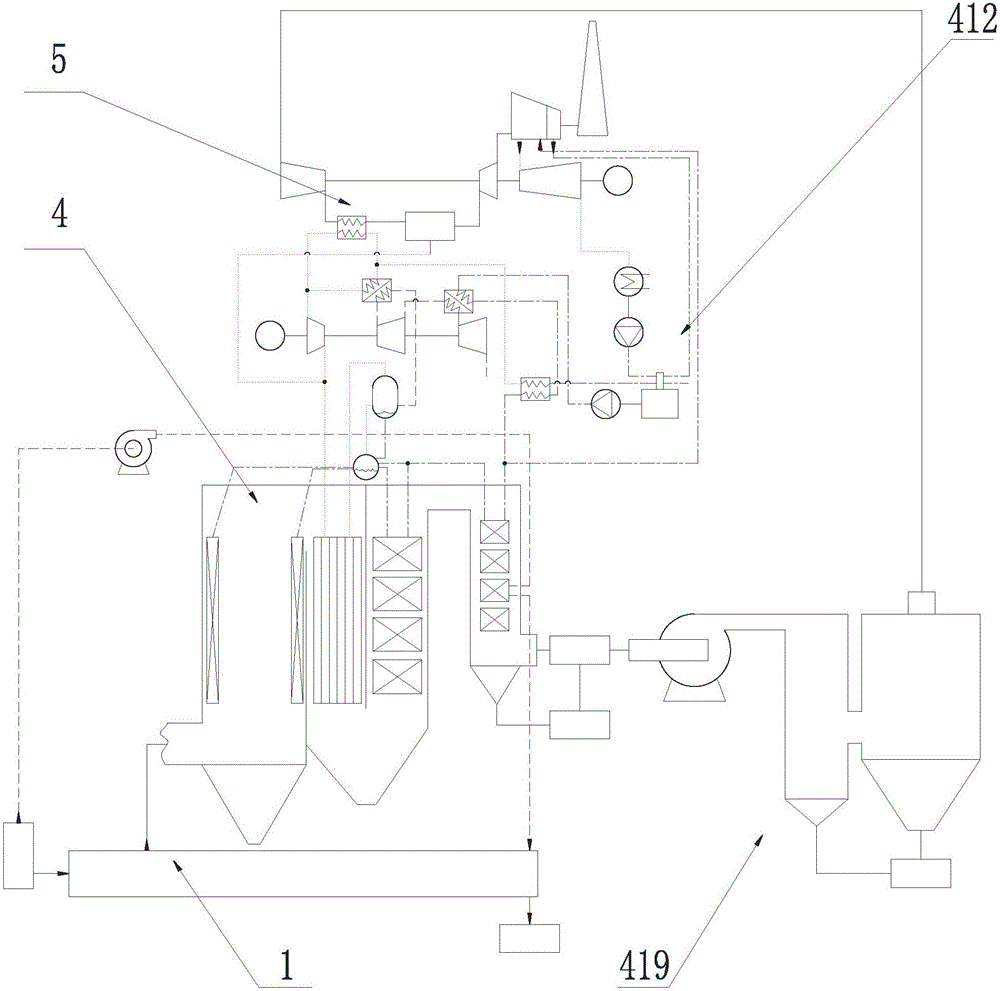

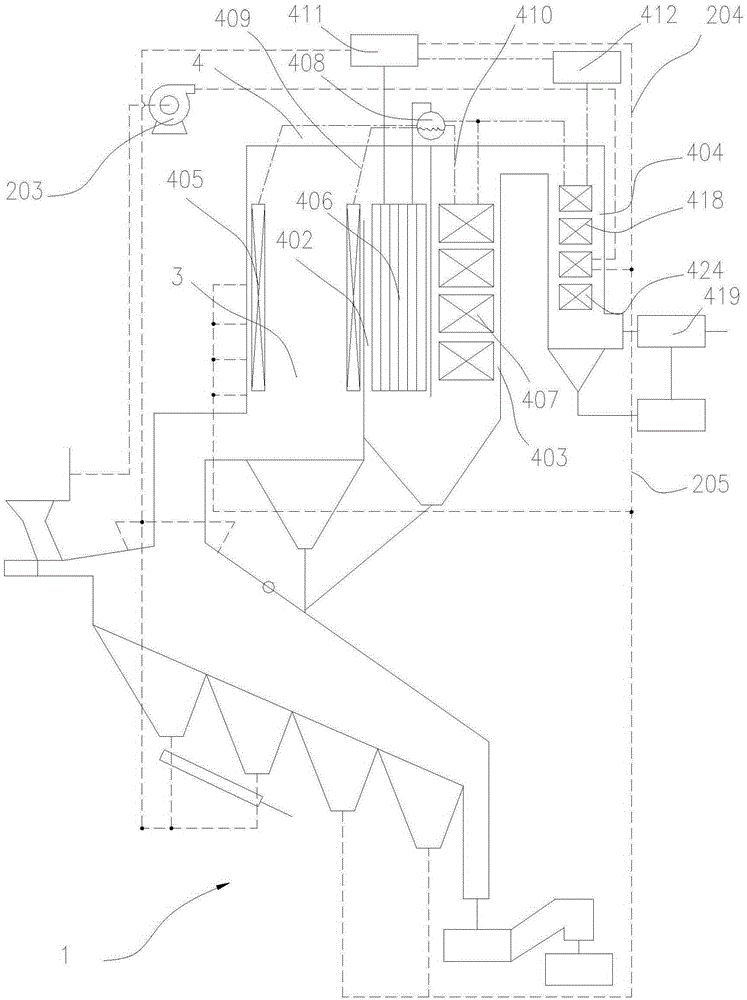

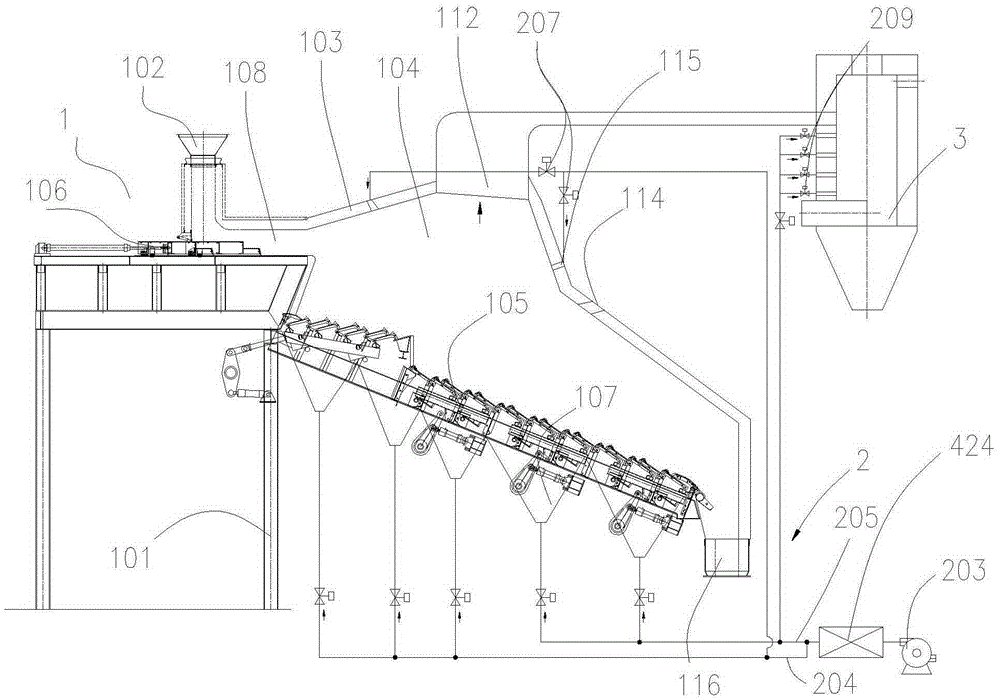

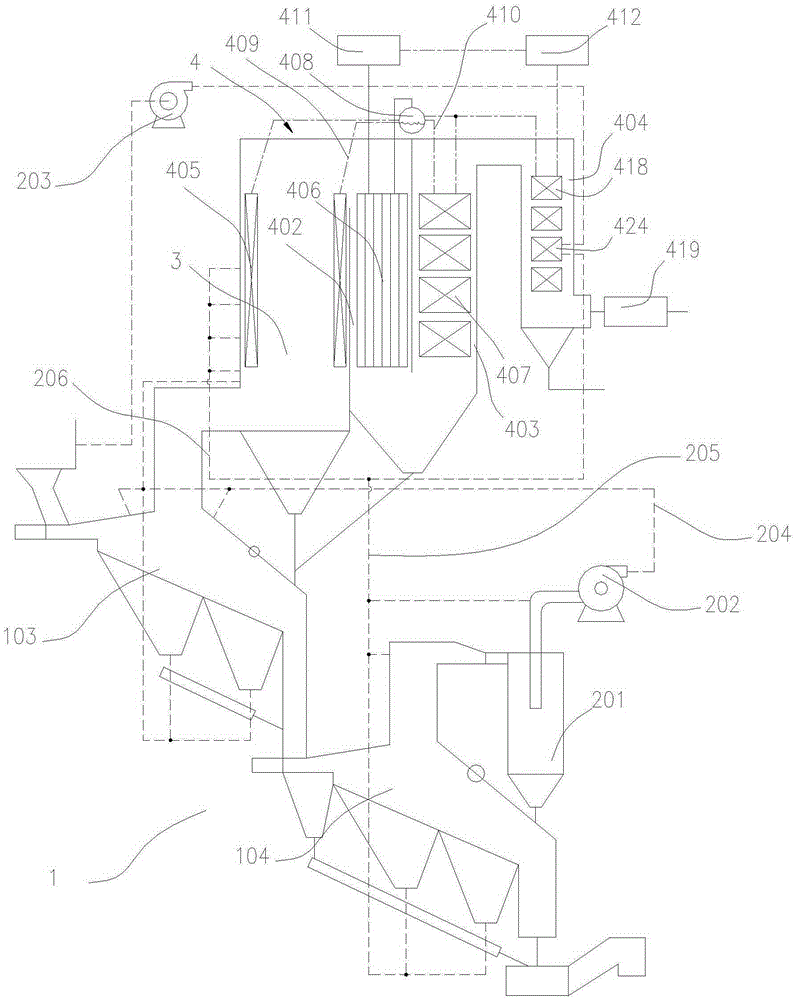

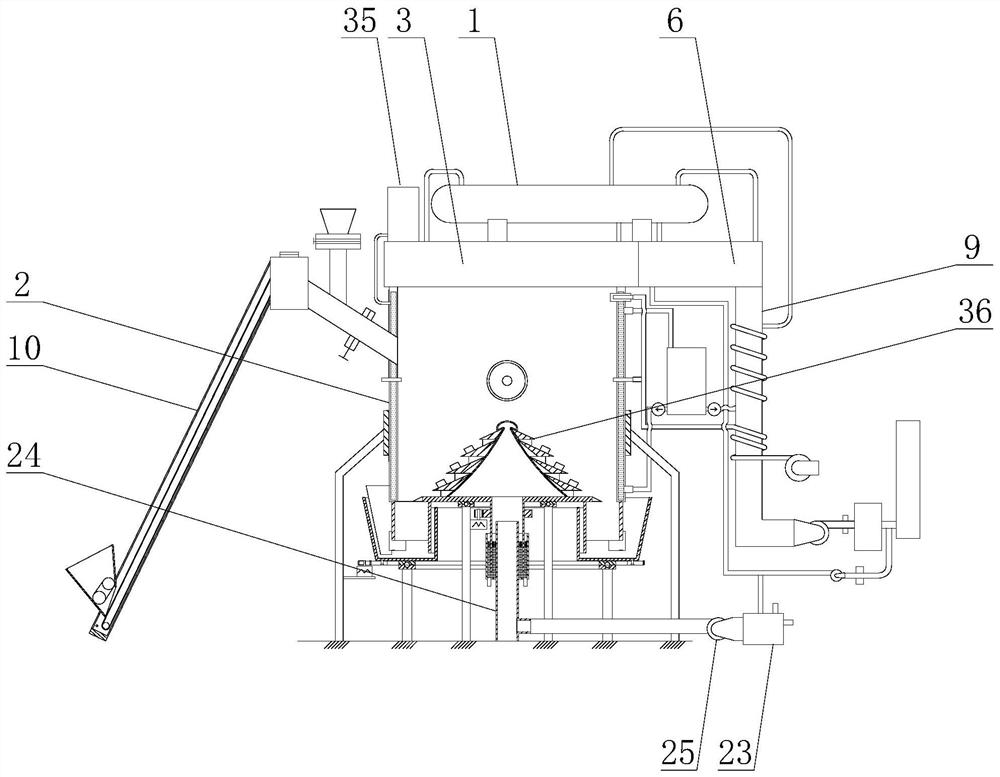

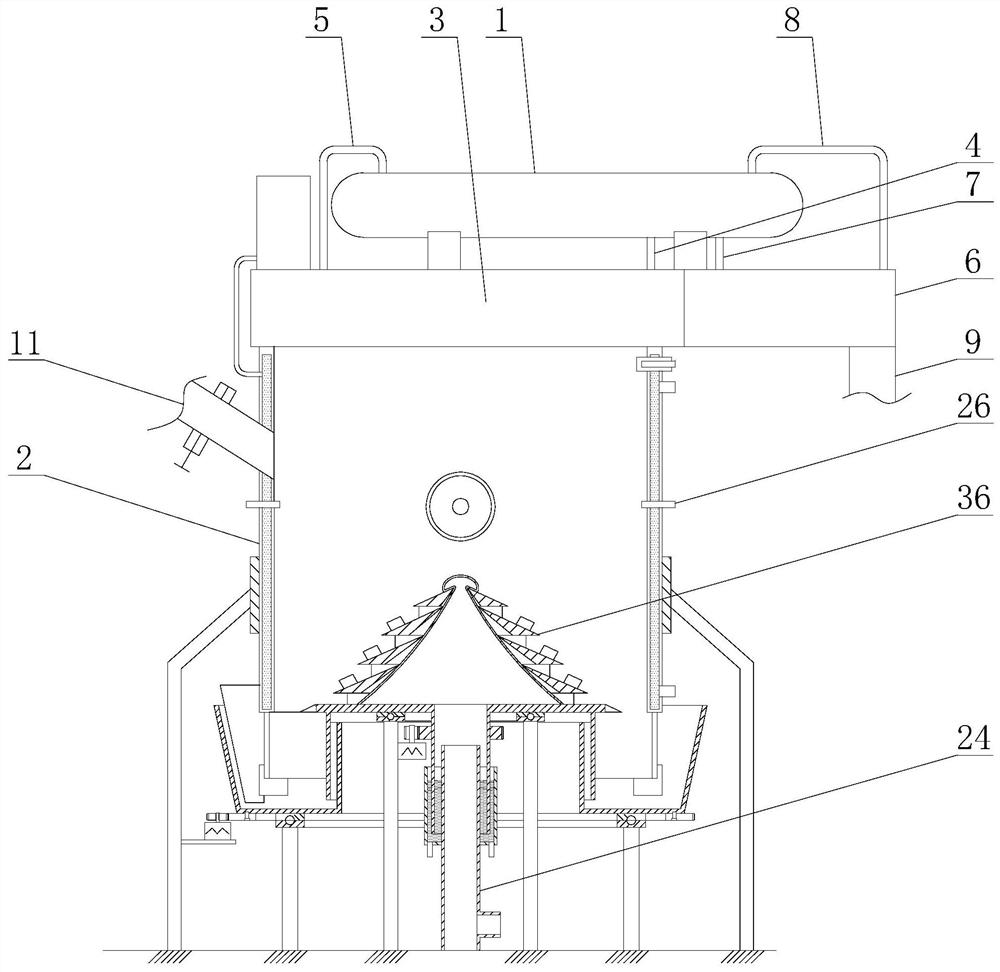

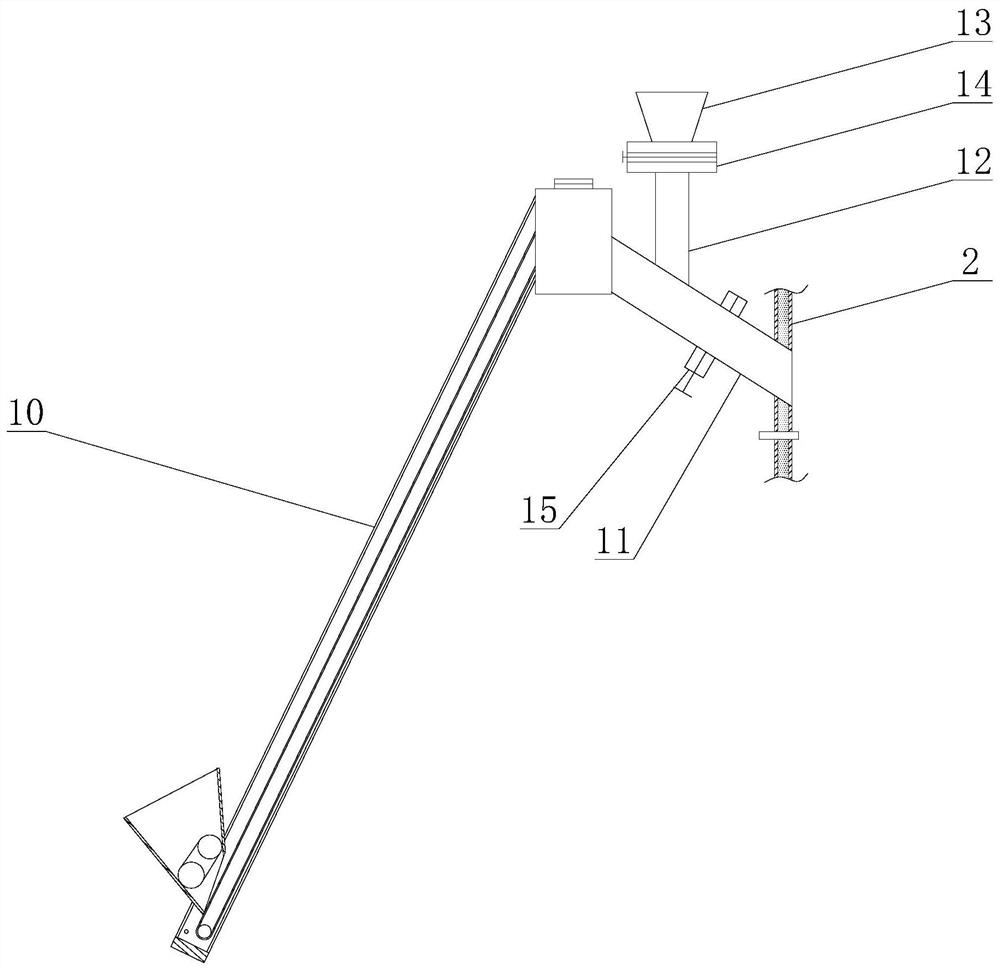

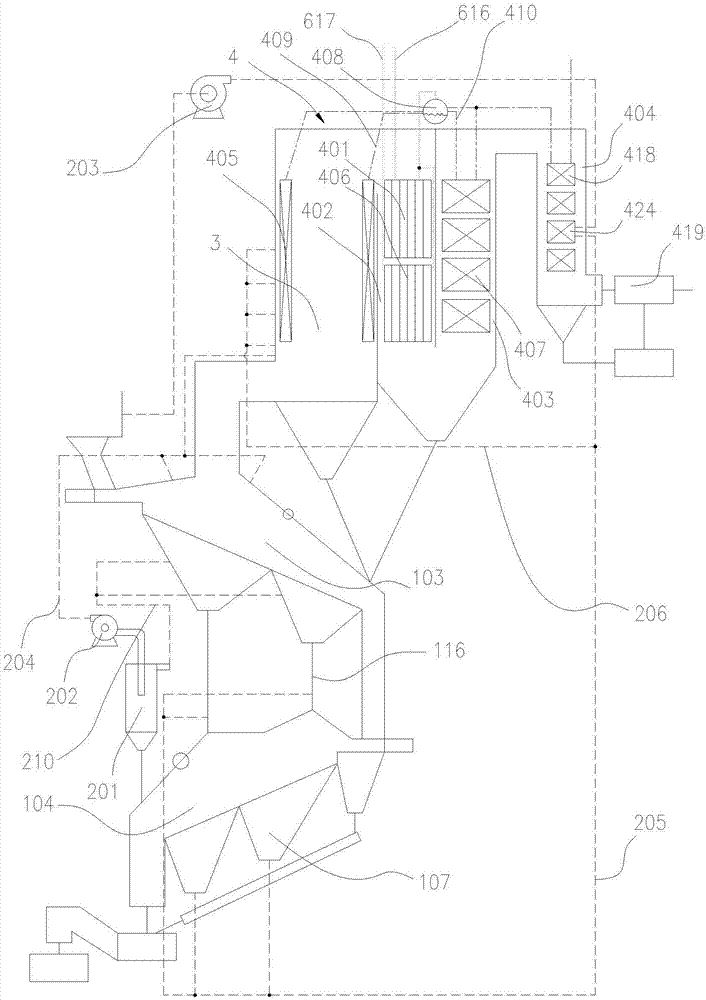

Mechanical grate type waste gasifying incinerator and boiler power generation system thereof

ActiveCN105509060AImprove qualityEasy to remove dustSteam engine plantsIncinerator apparatusCombustion chamberEngineering

The invention discloses a mechanical grate type waste gasifying incinerator which is smaller in heat conversion efficiency loss and is higher heat recovery efficiency, and a boiler power generation system thereof. The mechanical grate type waste gasifying incinerator comprises a gasifying incinerator, a boiler system, an air supply system and a power generation system, wherein the gasifying incinerator comprises a gasifier and an incinerator, the gasifier and the incinerator can be sealed or communicated, and an upper end of the gasifier and the incinerator are respectively provided with a smoke outlet; the boiler system comprises a boiler body, the boiler body is provided with a cyclone combustion chamber, a furnace chamber a and a furnace chamber b which are communicated with one another, a water-cooled wall is arranged in the cyclone combustion chamber, superheaters are arranged in the furnace chamber a, an evaporator is arranged in the furnace chamber b, and a top end of the boiler body is provided with a steam drum; the power generation system comprises a steam turbine, a power generator and a steam input pipe, an output end of the steam turbine is sequentially connected with a condenser, a water pump, a low-pressure steam water heater, a deaerator, a booster pump and a high-pressure steam water heater, and first-stage and second-stage water-steam separators and first-stage and second-stage high-pressure steam-steam heaters are arranged between air cylinders of the steam turbine.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

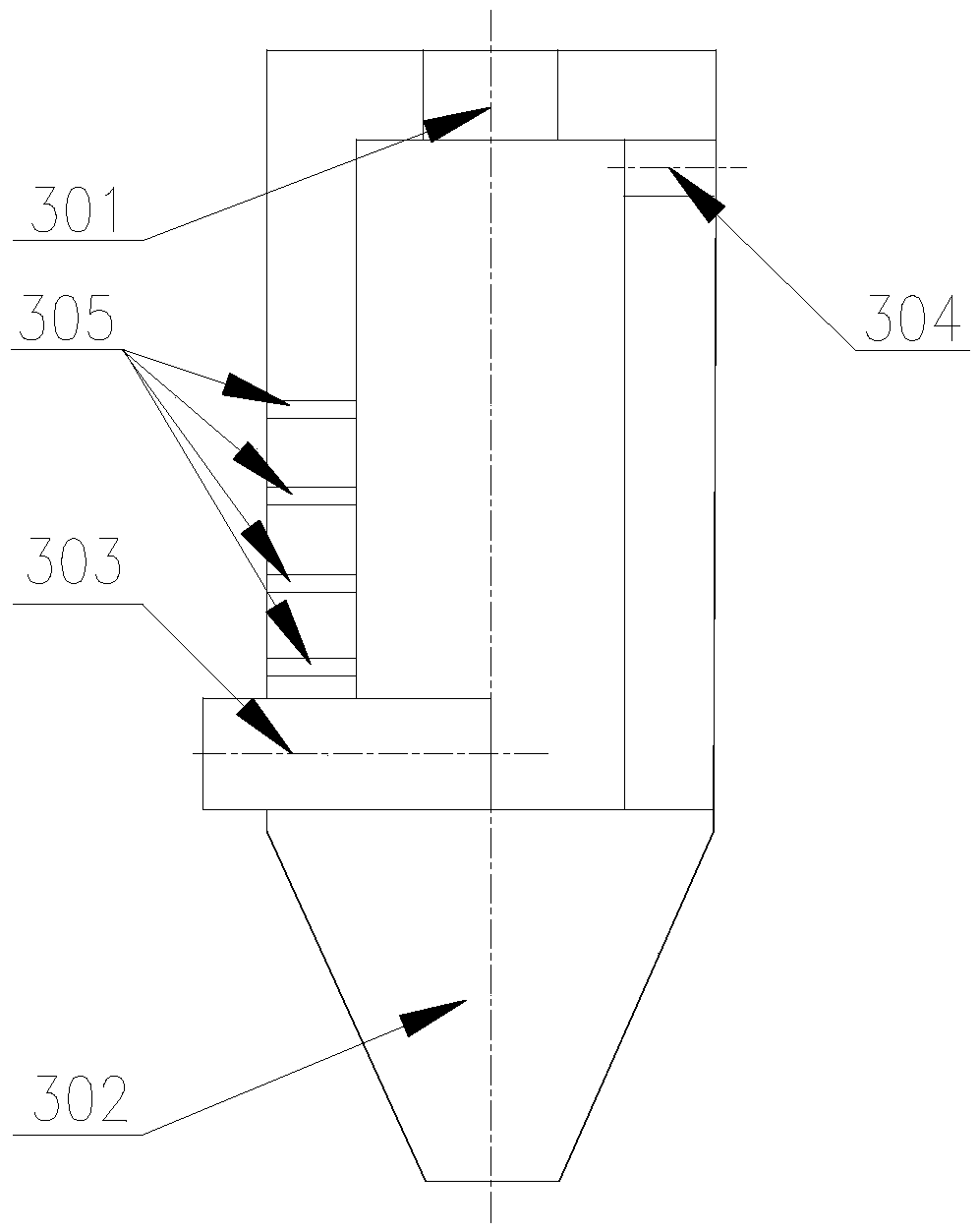

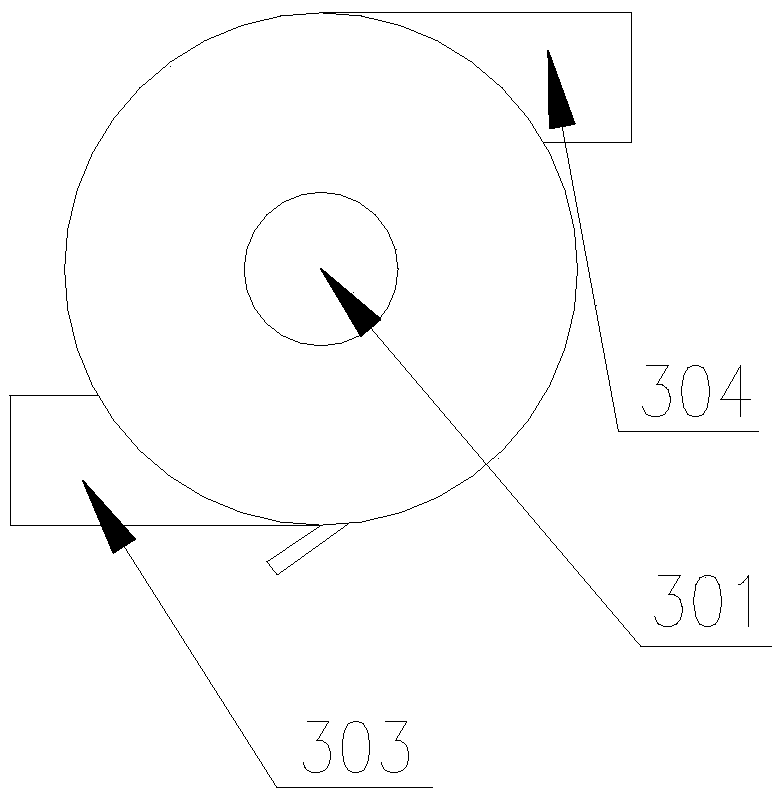

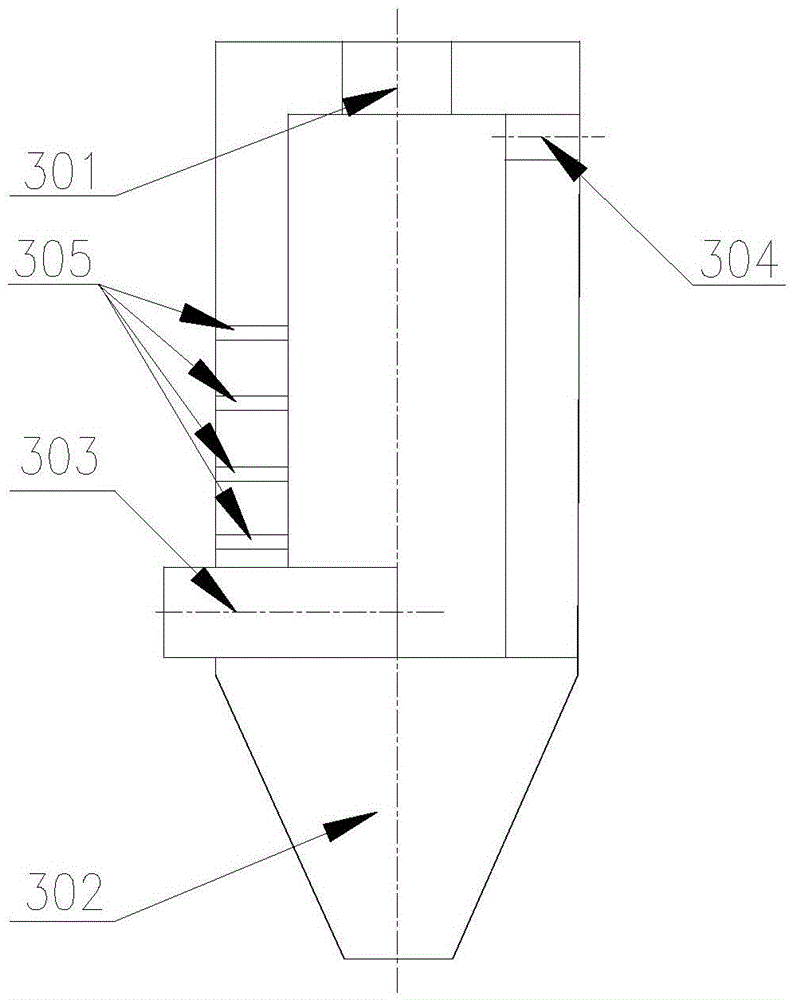

Irregular ash falling device

The invention belongs to the technical field of boiler parts, and specifically relates to an irregular ash falling device. The device comprises a front ash bucket, a rear ash bucket, an access door and a rotary ash discharging valve; the front ash bucket is connected with a smoke channel at the tail part of a boiler; the rear ash bucket which is communicated with the front ash bucket is connected with a smoke channel at an outlet of the boiler; a trough type separator is obliquely arranged at a part in which the front ash bucket is connected with the rear ash bucket. With the adoption of the device, lots of ash in the smoke can be effectively separated, thus the phenomenon of ash-doped smoke returning of the ash buckets can be avoided; the effect of removing ash is obvious, the smoke purifying cost is decreased, and the irregular ash falling device is applicable to the arrangement of ash buckets of boilers of different types.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

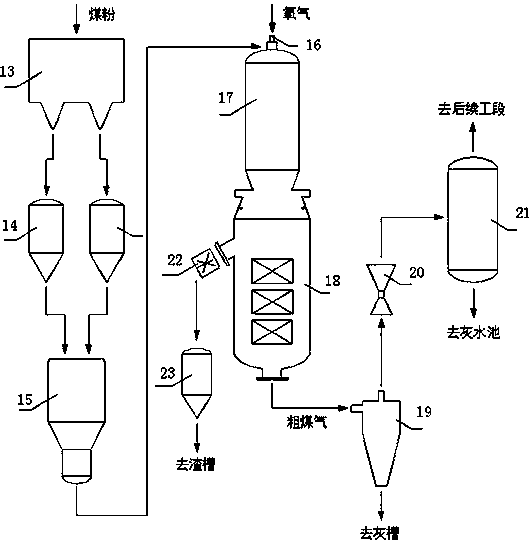

Dry pulverized coal gasification device

InactiveCN104263415AImprove energy utilizationReduce intermediate heat lossGasifier mechanical detailsEnergy inputSlagProcess engineering

The invention relates to a dry pulverized coal gasification device. The device comprises a pulverized coal silo, pulverized coal lock hoppers, a pulverized coal distributing tank, a gasifier gasification chamber, a coal gasification waste heat recovery device, a cyclone separator, a Venturi scrubber and a scrubbing tower, wherein the pulverized coal silo is used for storing ground and dried pulverized coal; the pulverized coal lock hoppers supplement materials in good time according to the material level of the pulverized coal distributing tank, are installed below the pulverized coal silo and are used for receiving pulverized coal; the pulverized coal distributing tank conveys pulverized coal to the gasifier gasification chamber via a carrier gas; the coal gasification waste heat recovery device is connected at the bottom of the gasifier gasification chamber; the cyclone separator is connected on the coal gasification waste heat recovery device via a pipeline; the Venturi scrubber is connected on the cyclone separator via a pipeline; the scrubbing tower is connected on the Venturi scrubber via a pipeline. Combining a quenching chamber with a convective waste heat boiler into a whole, the device has the advantages that the device fully recovers high-temperature raw coal gases and slag sensible heat, removes fly ash, reduces the investment and improves the heat efficiency.

Owner:中国东方电气集团有限公司

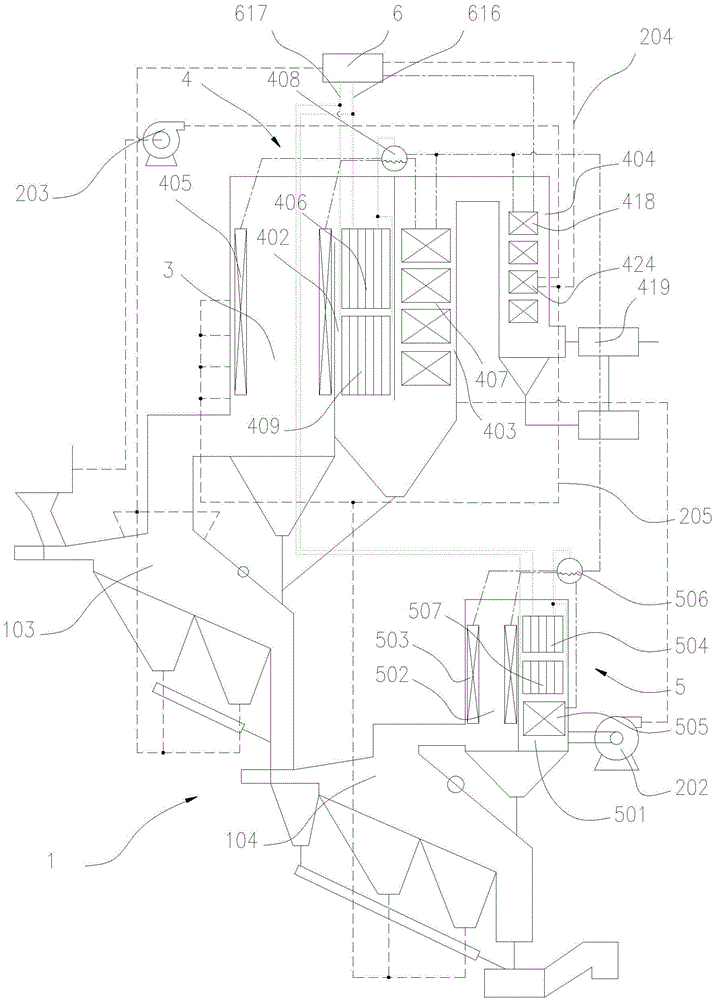

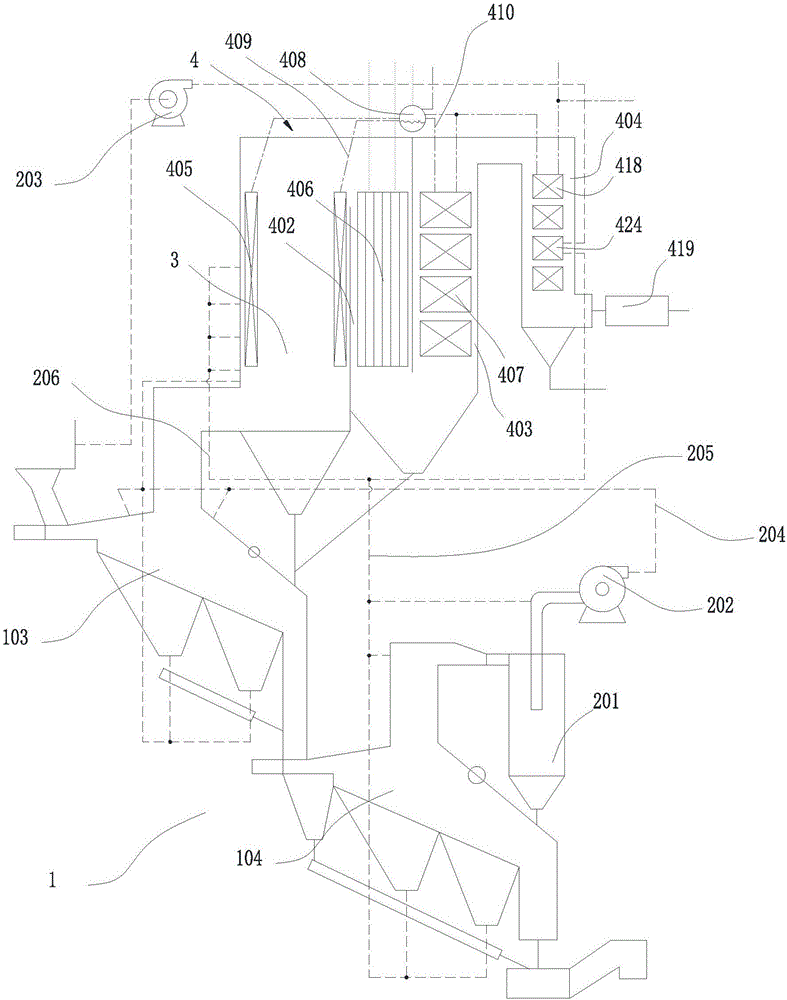

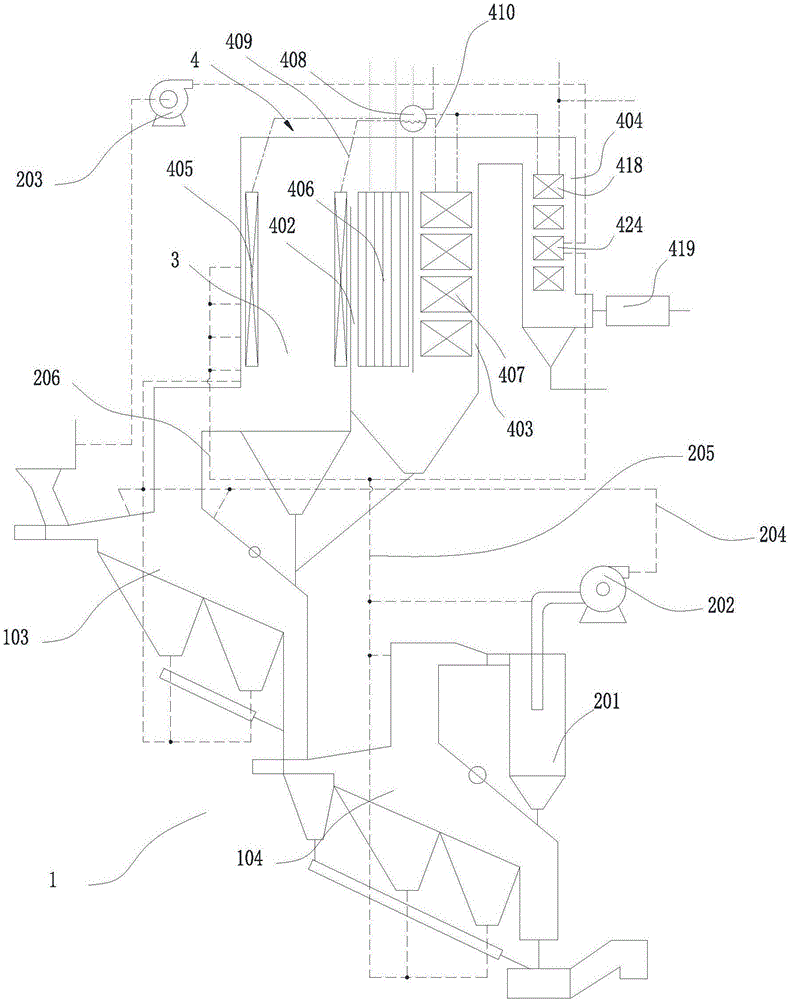

Mechanical grate-type garbage single-furnace gasifying incineration and boiler system

The invention discloses a mechanical grate-type garbage single-furnace gasifying incineration and boiler system which is smaller in transformation heat efficiency loss and higher in heat recovery rate. The system comprises a gasifying incineration furnace, a boiler system and an air supply system, wherein the gasifying incineration furnace comprises a material feeding cabin and a furnace body; a material stacking sealing section is arranged between the material feeding cabin and the furnace body; the upper end of the furnace body is upwards convex and is provided with a first smoke outlet; the boiler system comprises a boiler body; the boiler body comprises a cyclone combustor, a furnace chamber a and a furnace chamber b which are communicated with one another; a water-cooling wall is arranged in the cyclone combustor; a superheater is arranged in the furnace chamber a; an evaporator is arranged in the furnace chamber b; the smoke inlet of the cyclone combustor is connected with the first smoke outlet; the top end of the boiler body is provided with a steam pocket; a steam-water inlet is formed in the steam pocket; the steam pocket is connected with water-cooling wall and the water inlet of the evaporator for outputting water; the water-cooling wall and the steam outlet of the evaporator are connected with the steam inlet of the steam pocket for steam backflow; and the saturated steam outlet of the steam pocket is used for outputting superheated steam through the superheater.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

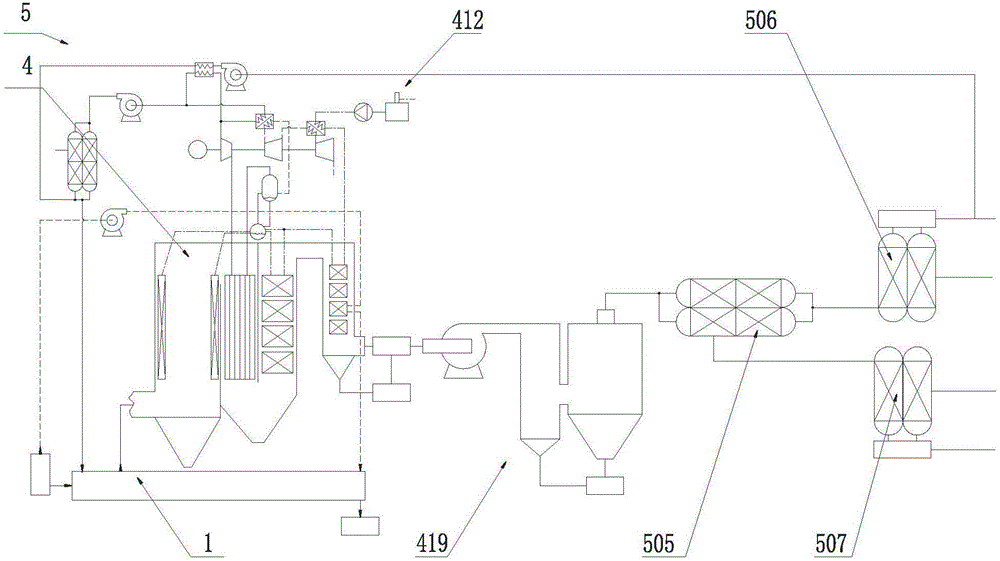

Mechanical fire grate type rubbish gasification incinerator and dual-boiler energy-saving power generation system thereof

ActiveCN105588131AImprove qualityEasy to remove dustMachines/enginesSteam generation plantsCycloneCombustion chamber

The invention discloses a mechanical fire grate type rubbish gasification incinerator which is smaller in heat efficiency conversion loss and higher in heat recovery rate and a dual-boiler energy-saving power generation system of the mechanical fire grate type rubbish gasification incinerator. The mechanical fire grate type rubbish gasification incinerator comprises a gasification incinerator body, a boiler system, a circulation air supply system and a power generation system; the gasification incinerator body comprises a gasification boiler and a burning ash boiler which can be sealed or communicated; the boiler system comprises boiler bodies a and b, the boiler body a is provided with a cyclone burning chamber and boiler chambers a and b, the boiler body b is provided with a boiler chamber d and a cyclone dust removal chamber, water cooling walls are arranged in the cyclone burning chamber and the cyclone dust removal chamber, a superheater unit is arranged in the boiler chamber a, and an evaporator is arranged in the boiler chamber b; and a superheater unit and an evaporator are arranged in the boiler chamber d, steam pockets are arranged at the top ends of the two boiler bodies, a smoke inlet of the cyclone burning chamber is connected with a smoke outlet of the gasification incinerator body, and a smoke inlet of the cyclone dust removal chamber is connected with a smoke outlet of the burning ash boiler. The power generation system comprises a steam input pipe, a steam turbine and a power generator, and the steam input pipe is connected with the superheater units a and b and the steam turbine.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

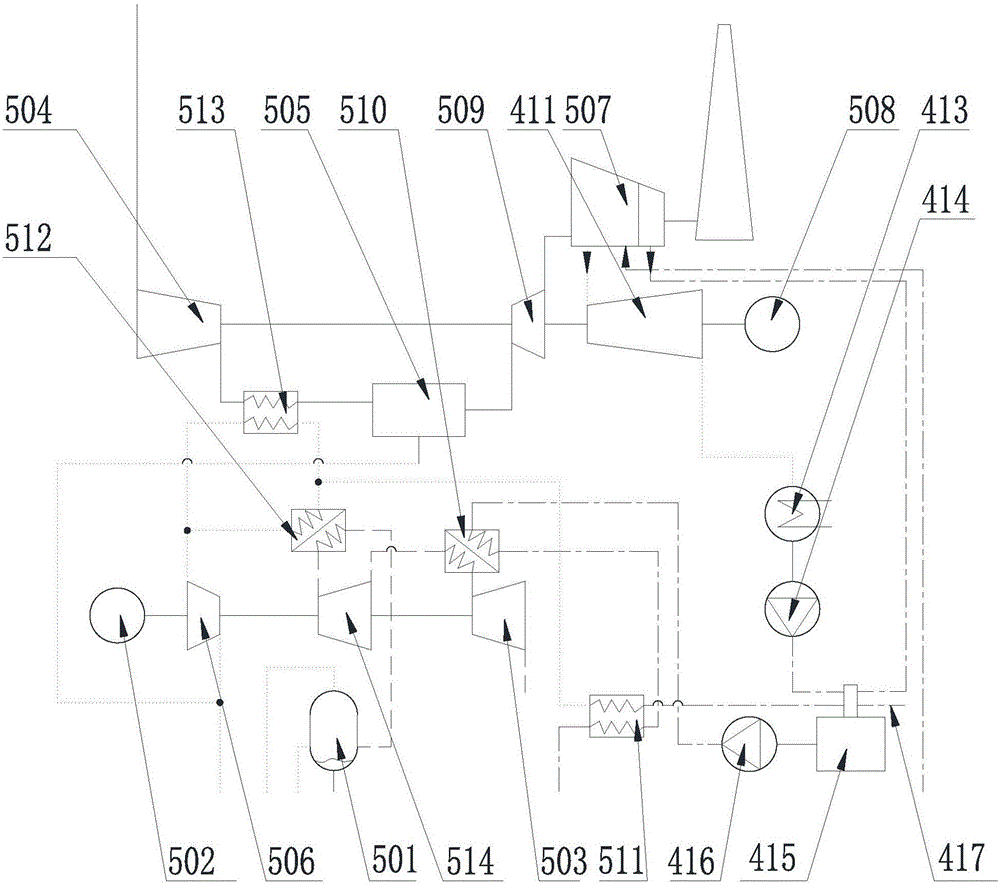

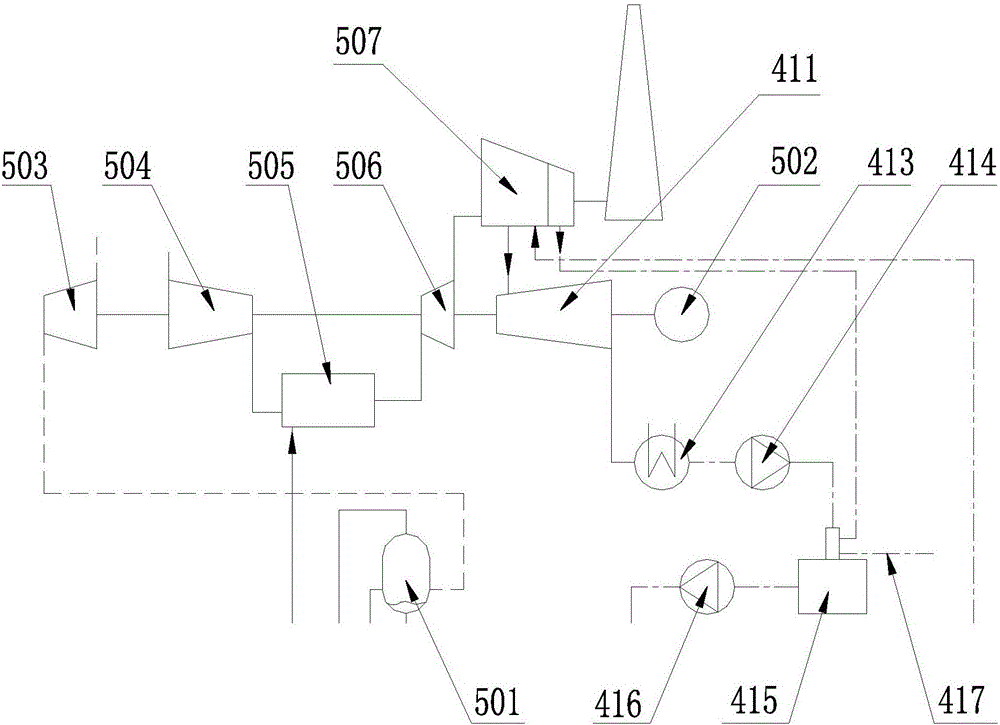

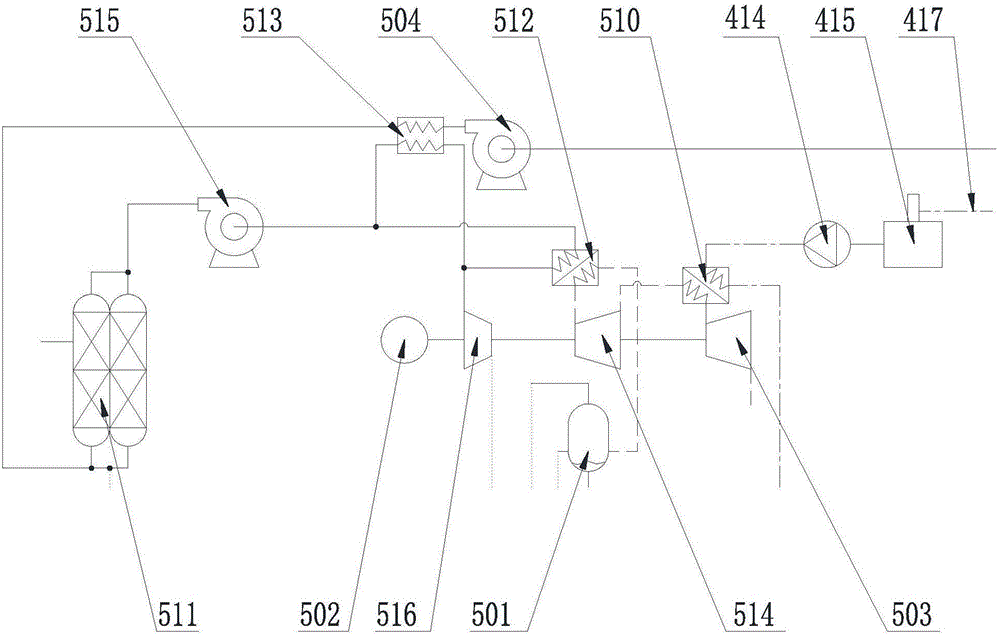

Gas turbine-steam turbine coaxial combined power generation system based on waste gasification

ActiveCN106287642AImprove qualityEasy to remove dustSteam generation plantsSteam engine plantsCombustion chamberGas compressor

The invention discloses a gas turbine-steam turbine coaxial combined power generation system based on waste gasification. The gas turbine-steam turbine coaxial combined power generation system comprises a waste gasification incineration system, a boiler system and a power generation system, wherein the power generation system comprises a mixer, an air compressor, a synthetic flue gas compressor, a synthetic flue gas combustion chamber, a turbine, a steam turbine, a power generator, a waste heat boiler and a water supply input system; the inlet of the mixer is connected with the saturated steam outlet of a steam manifold and the air outlet of the air compressor; the water outlet of the mixer is connected with the water inlet of the steam manifold; the steam outlet of the mixer is connected with the steam inlet of a super-heater; the gas inlet of the flue gas compressor is connected with the waste gas discharge outlet of the boiler system; the steam outlet of the super-heater and the gas outlet of the flue gas compressor are connected with the synthetic flue gas combustion chamber, the turbine and the waste heat boiler in sequence; the steam outlet of the waste heat boiler is connected with the steam inlet of the steam turbine; the turbine, the steam turbine and the power generator are in power connections. By adopting the gas turbine-steam turbine coaxial combined power generation system, large-scale continuous waste gasification treatment can be performed, high heat recovery efficiency is achieved, and pollutant discharge is reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Boiler power generation system utilizing rubbish gasification and incineration synthesis gas

ActiveCN105464727AIncrease profitLarge amount of garbage disposalLiquid degasificationSteam engine plantsSyngasEngineering

The invention discloses a boiler power generation system utilizing rubbish gasification and incineration synthesis gas. The boiler power generation system is small in heat conversion efficiency loss and higher in heat recovery efficiency. The boiler power generation system comprises a steam turbine, a generator, a high-pressure steam input pipe and a medium-pressure steam input pipe. The steam turbine comprises a high-pressure steam cylinder, a medium-pressure steam cylinder and a low-pressure steam cylinder. A first-stage water-steam separator and a first-stage high-pressure steam-steam heater are connected between the high-pressure steam cylinder and the medium-pressure steam cylinder. A second-stage water-steam separator and a second-stage high-pressure steam-steam heater are connected between the medium-pressure steam cylinder and the low-pressure steam cylinder. The steam output end of the low-pressure steam cylinder is connected with a condenser, a water pump, a low-pressure steam-water heater, a deaerator, a booster water pump and a high-pressure steam-water heater in sequence through a pipeline. The high-pressure steam input pipe is connected with the high-pressure steam cylinder and is connected with the deaerator through the heating end of the first-stage high-pressure steam-steam heater, the heating end of the high-pressure steam-water heater, the heating end of the second-stage high-pressure steam-steam heater and the heating end of the low-pressure steam-water heater.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

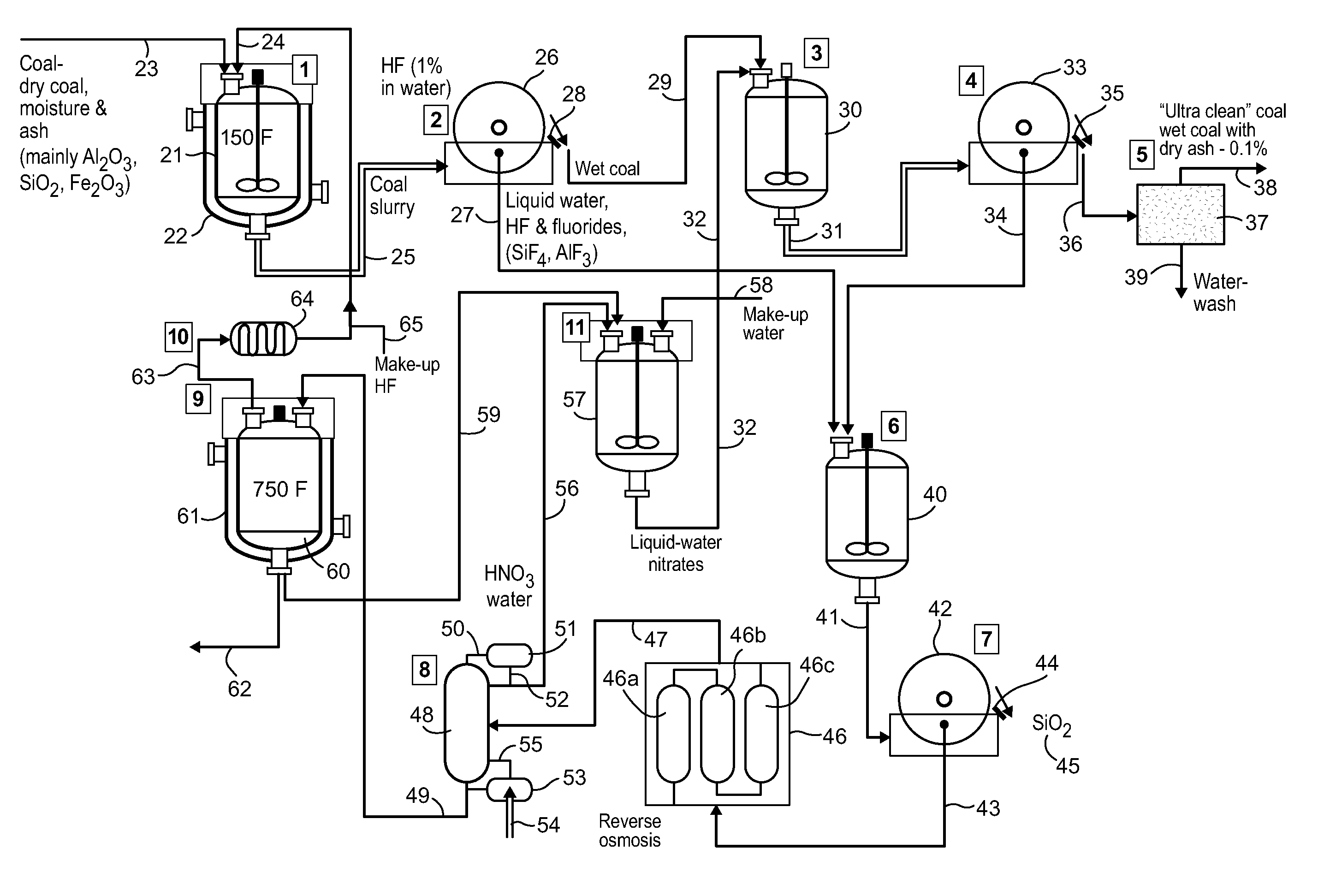

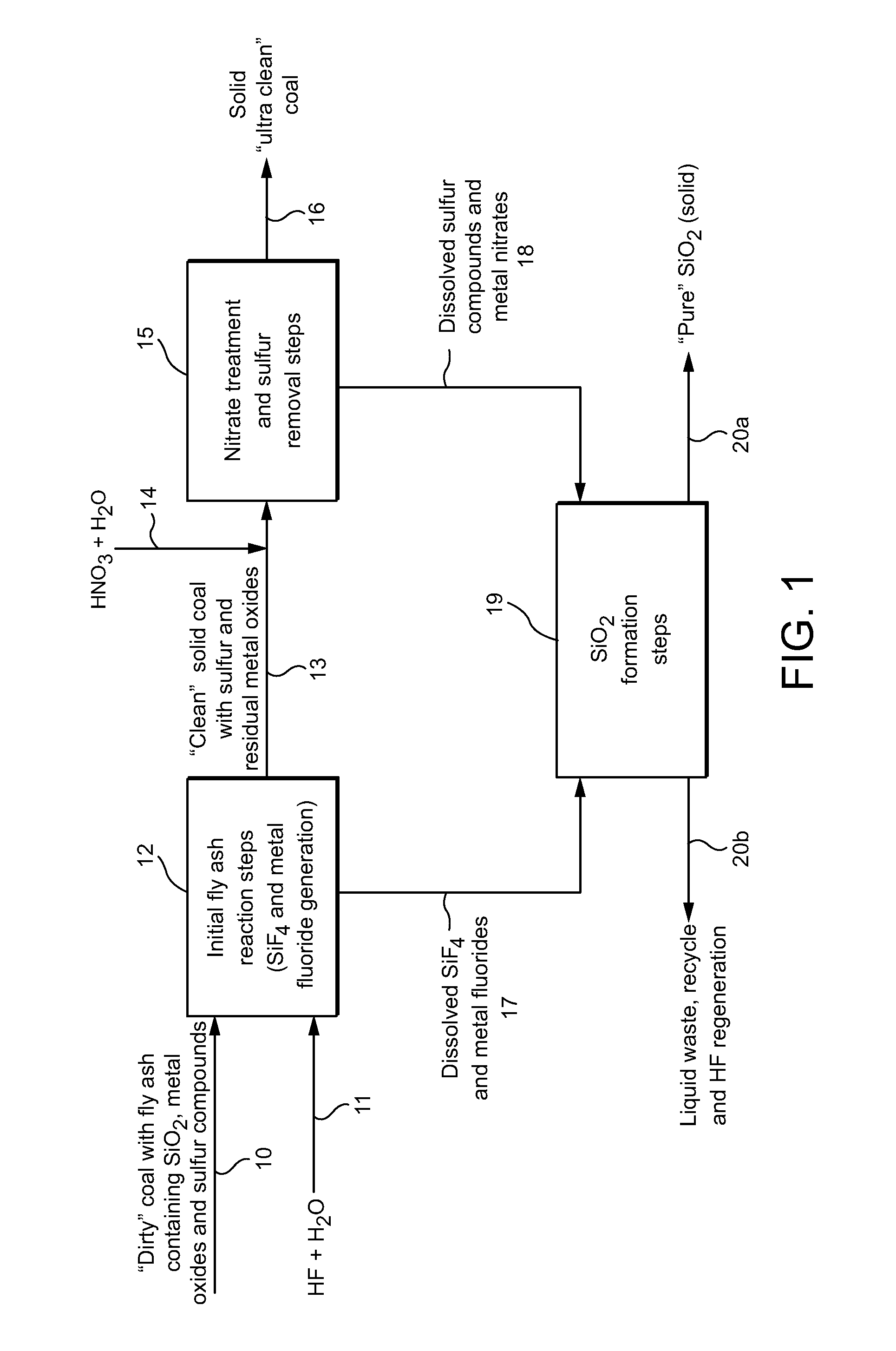

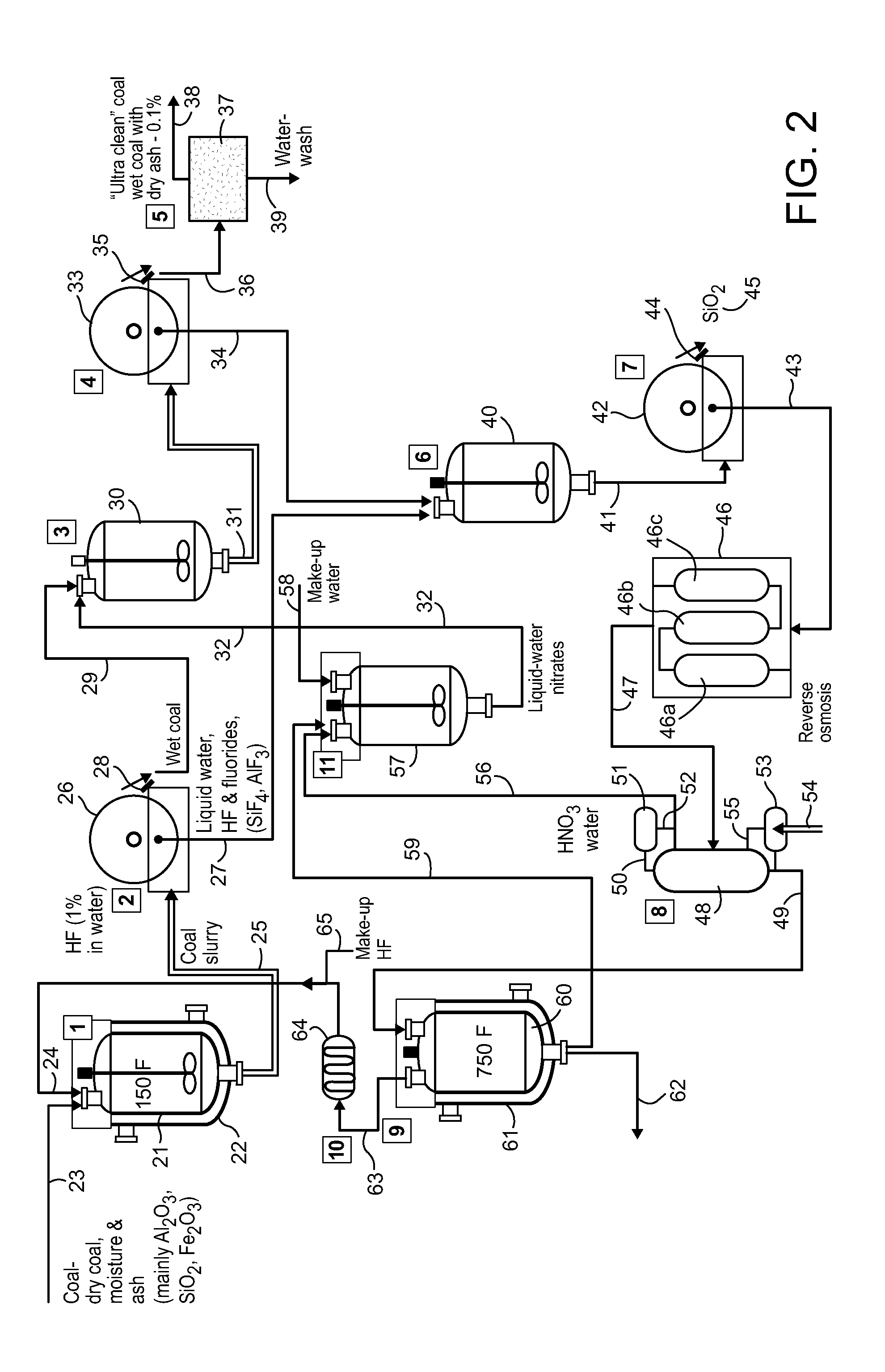

Process for obtaining treated coal and silica from coal containing fly ash

A process for treating mixtures of solid coal and fly ash containing metallic oxides, silicon dioxide and sulfur compounds in order to produce treated coal and substantially pure silicon dioxide comprising (1) reacting a mixture of the coal and fly ash with hydrogen fluoride in water to produce a liquid stream comprising silicon fluoride and metal fluorides and a solids stream comprising unreacted coal and sulfur compounds; (2) reacting the sulfur compounds with metallic nitrates dissolved in water to form an aqueous solution of nitrate, metallic and sulfur ions; (3) separating the aqueous solution of nitrate, sulfur and metallic ions from the solid coal; (4) washing the previously treated solid coal with water; (5) reacting the silicon fluorides and metal fluorides with metallic nitrates in an aqueous mixture to form solid silicon dioxide; and separating the solid silicon dioxide from the aqueous mixture.

Owner:GENERAL ELECTRIC CO

Wet air turbine power generation system based on recycling of garbage gasifying synthesis gas

ActiveCN106224035AImprove recycling efficiencyPyrolysis is beneficialChemical industrySteam useProcess engineeringAir compressor

The invention discloses a wet air turbine power generation system based on recycling of garbage gasifying synthesis gas. The wet air turbine power generation system based on recycling of the garbage gasifying synthesis gas comprises a garbage gasifying system, a boiler system and a power generation system, wherein the power generation system comprises a mixer, a low-pressure air compressor, a high-pressure air compressor, a turbine, a generator, an air steam-gas heat exchanger, a CO2 steam-gas heat exchanger, a CO2 fan, a recycling fan, a mixing separator, a CO2 separator and a water supply feeding system of the boiler system; the CO2 separator is connected to space between a waste gas discharge opening of the boiler system and a gas inlet of the CO2 fan; and a gas outlet of the turbine is in parallel connection with heating channels of the CO2 steam-gas heat exchanger and the air steam-gas heat exchanger, and is then connected with the recycling fan and the mixing separator. By the wet air turbine power generation system based on recycling of garbage gasifying synthesis gas, a large amount of garbage is continuously gasified and incinerated, the treatment amount of the garbage is high, recycling efficiency of heat is high, regenerated chemical raw materials and synthesized natural gas can be extracted, and near zero emission of pollutants and CO2 can be realized effectively.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Double-layered mechanical grate type garbage gasifying incinerator and boiler system

ActiveCN105444182AImprove insulation effectPrevent leakageIncinerator apparatusCombined combustion mitigationCombustion chamberFlue gas

The invention discloses a double-layered mechanical grate type garbage gasifying incinerator and boiler system which comprises a double-layered garbage gasifying incinerator, a boiler system and a circulating air supply system, wherein the double-layered garbage gasifying incinerator comprises a feed hopper, a gasifier and a burn-out furnace; the burn-out furnace is located under the gasifier; the feeding direction of the burn-out furnace is opposite to that of the gasifier; flue gas outlets are formed in the upper end of the gasifier and the upper end of the burn-out furnace; the boiler system comprises a boiler body; the boiler body is provided with a cyclone combustion chamber, a furnace chamber a and a furnace chamber b, which communicate with one another; a water wall is arranged in the cyclone combustion chamber; a superheater is arranged in the furnace chamber a; an evaporator is arranged is the furnace chamber b; a steam drum is arranged at the top end of the boiler body; a steam-water inlet is formed in the steam drum; the steam drum is connected with a water inlet of the water wall and a water inlet of the evaporator to output water; a steam outlet of the water wall and a steam outlet of the evaporator are connected with a steam inlet of the steam drum to reflux steam; and a saturated steam outlet of the steam drum outputs superheated steam through the superheater.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

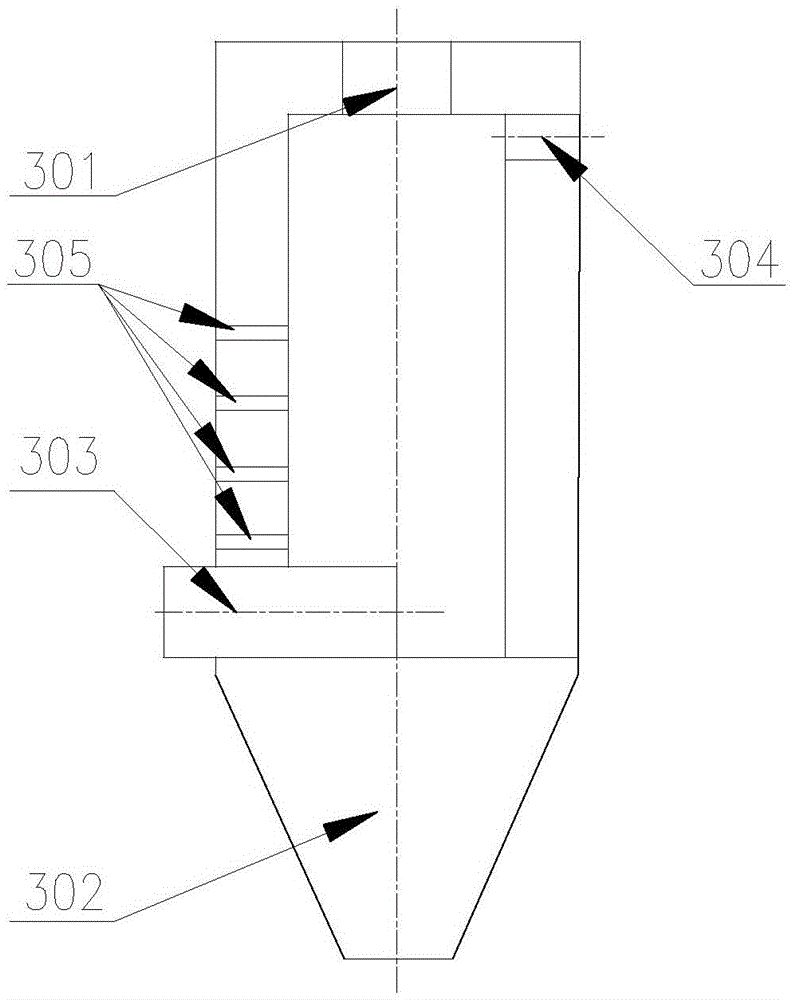

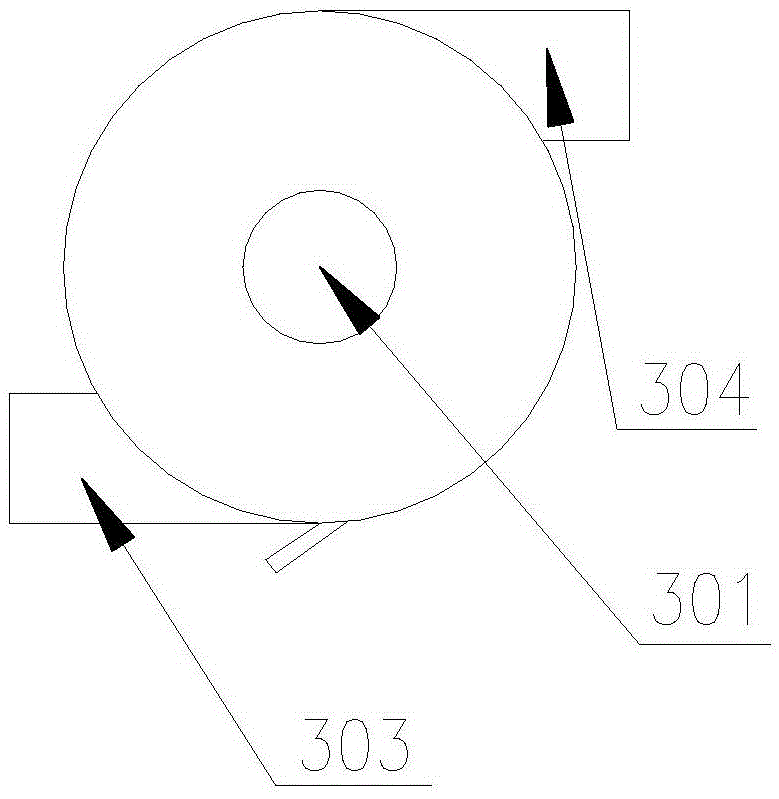

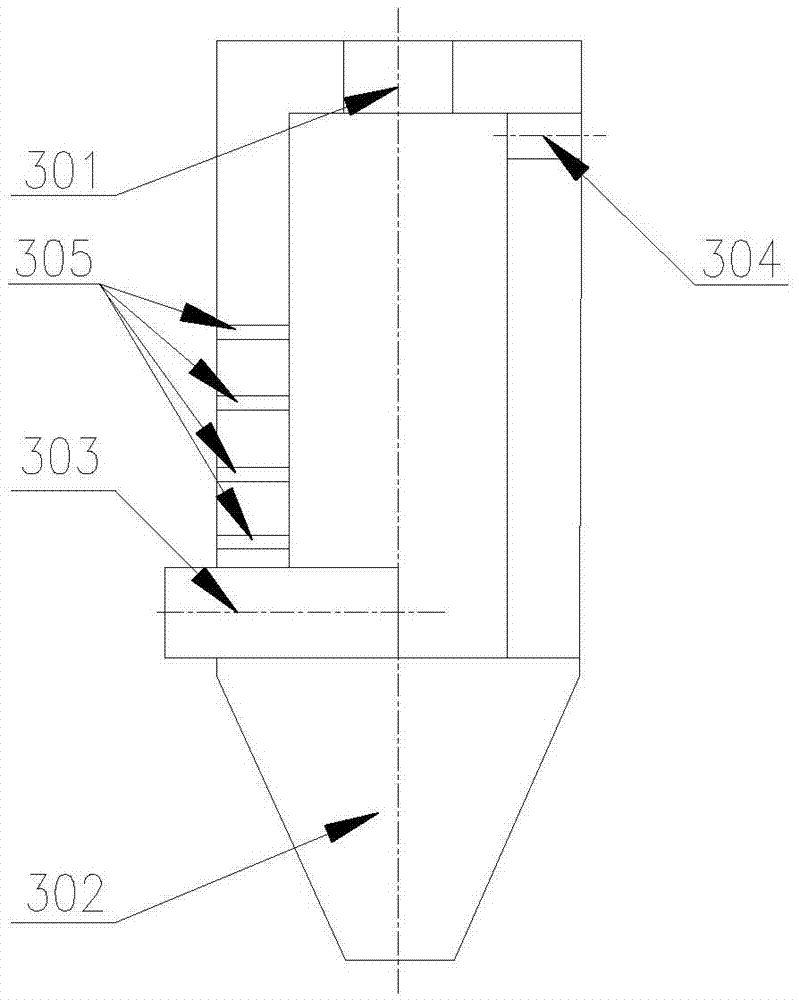

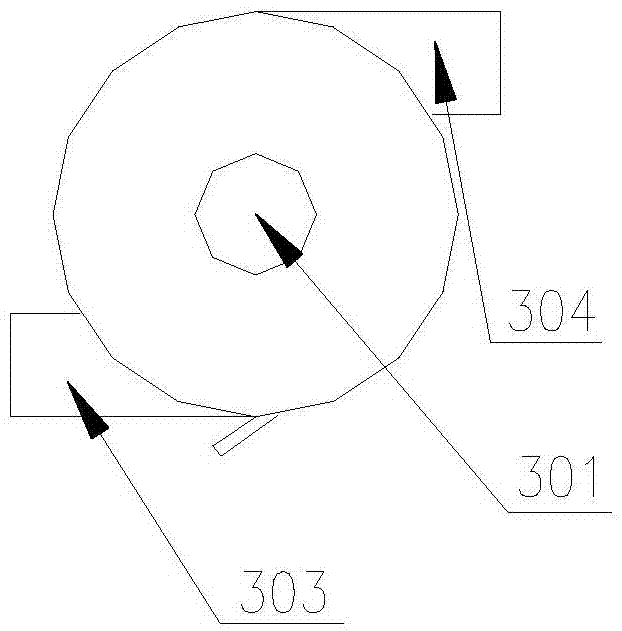

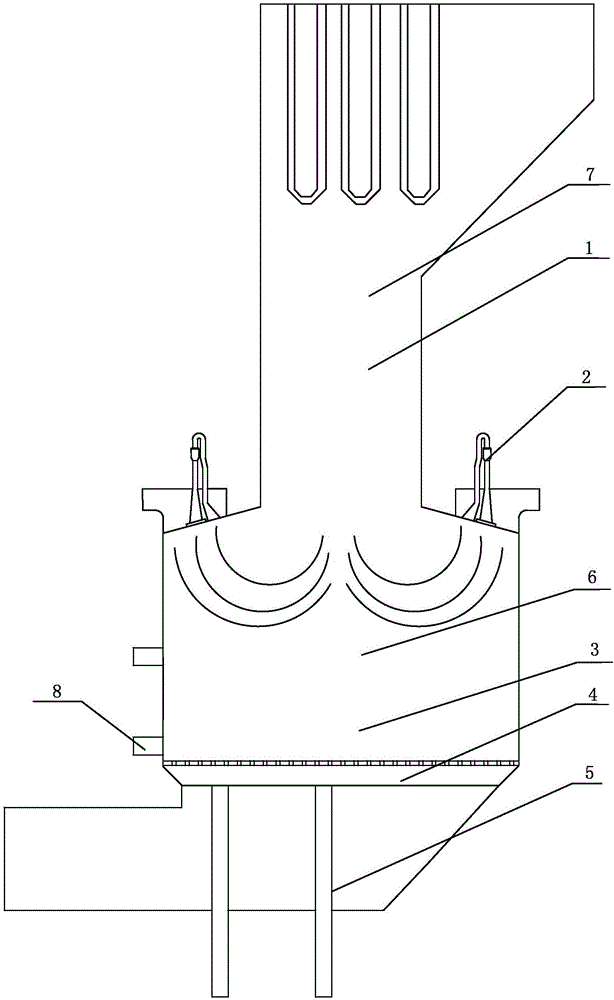

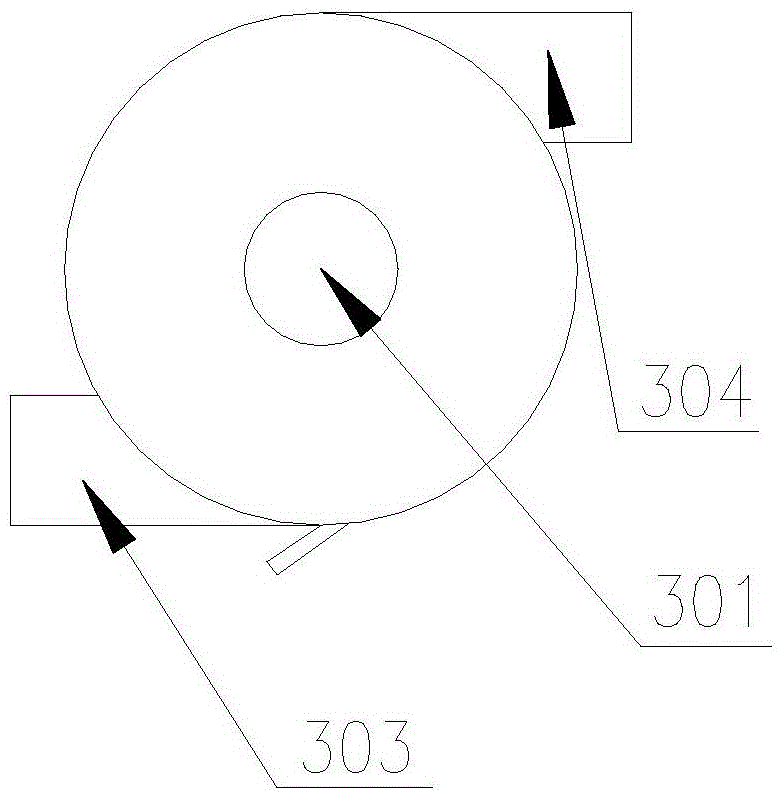

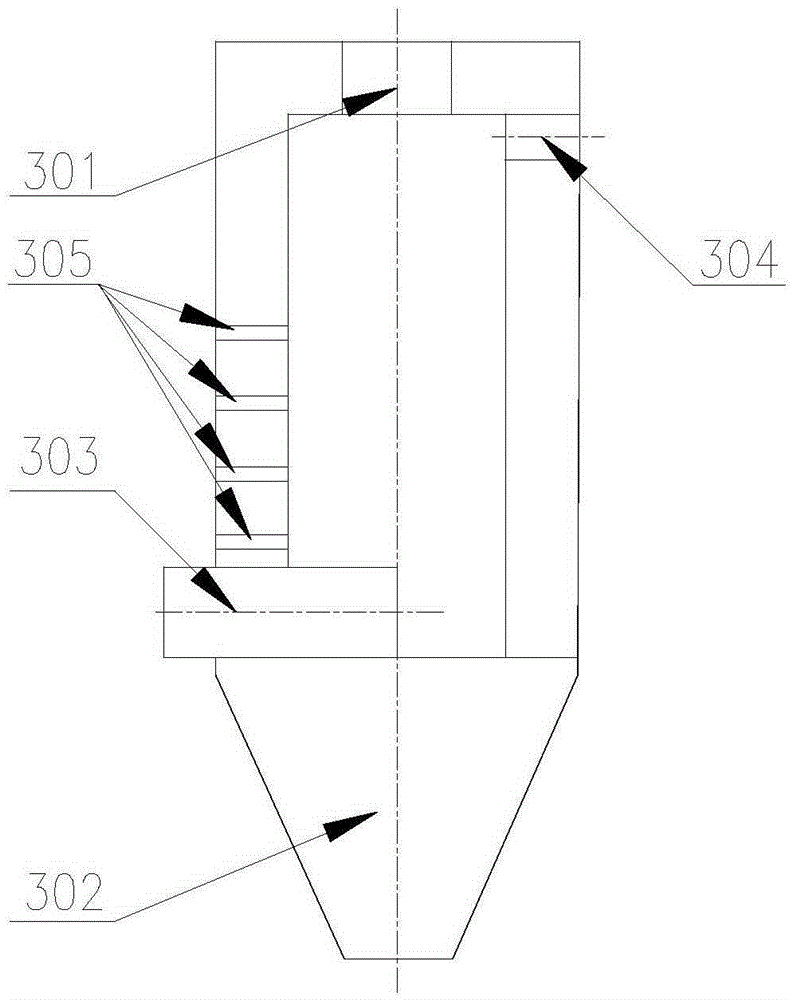

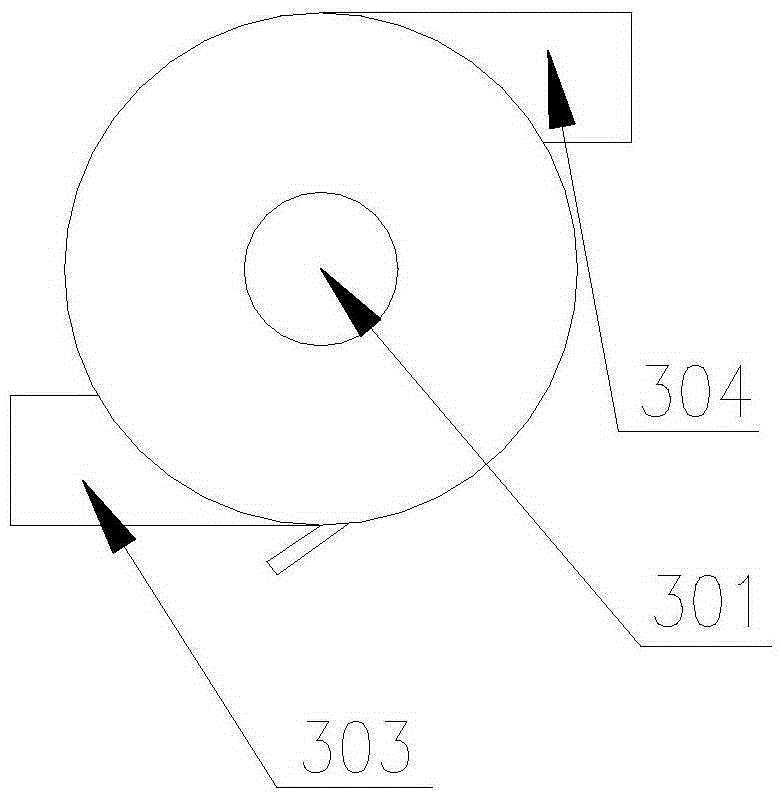

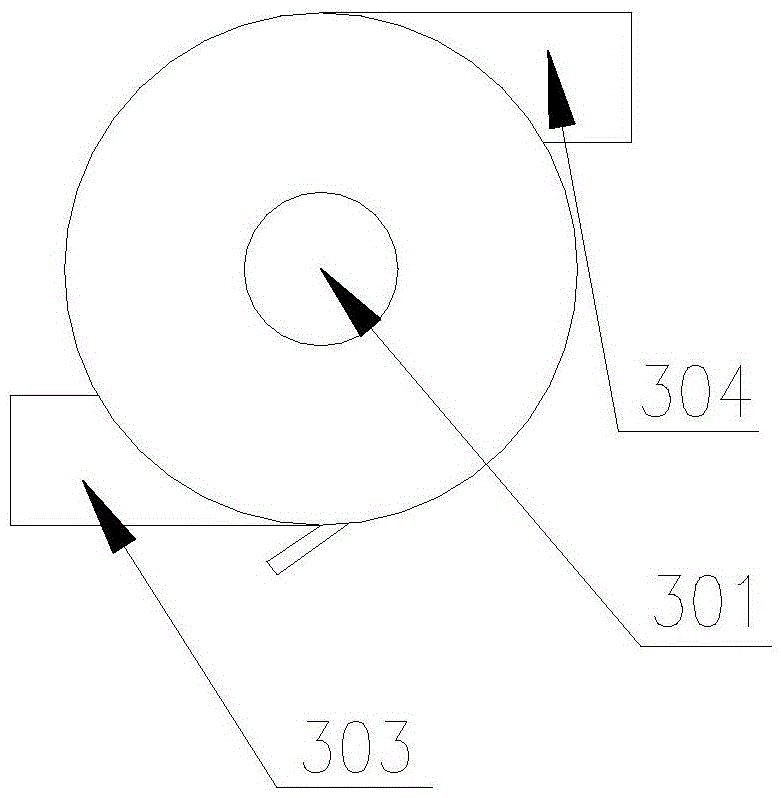

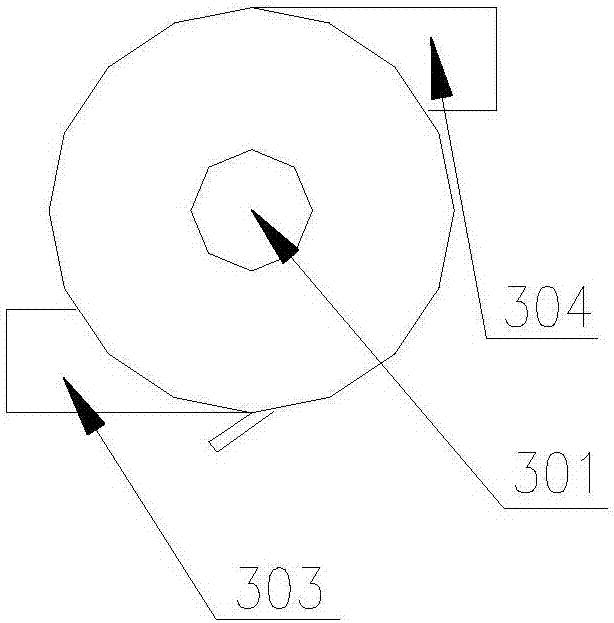

Small-sized cyclone-melting pulverized coal furnace

ActiveCN106642082AReduce fly ash contentPromote environmental protectionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustion chamber

The invention relates to a small-sized cyclone-melting pulverized coal furnace, belonging to the field of pulverized coal combustion equipment. The small-sized cyclone-melting pulverized coal furnace comprises a blade type cyclone combustor, a vortex-melting combustion chamber, a high-temperature flue gas outlet pipe, a burn-out chamber and a heat exchange hearth, wherein the blade type cyclone combustor, as a mixed inlet of primary air and pulverized coal, comprises a shell and swirl blades and is connected with the top end of the vortex-melting combustion chamber; a tangential down-sloping high-temperature air inlet (with an adjustable inclination angle) is formed in each of the left and right sides of the upper part of the vortex-melting combustion chamber, and a slag outlet is formed in the lower part of the vortex-melting combustion chamber; and the high-temperature flue gas outlet pipe is led out from a middle position of the top of the vortex-melting combustion chamber, two tangential air inlets are formed in a horizontal section of the high-temperature flue gas outlet pipe, the end part of the high-temperature flue gas outlet pipe is finally connected with the burn-out chamber in a certain expanding angle, the heat exchange hearth is arranged at the upper part of the burn-out chamber, heated surfaces are distributed in the heat exchange hearth, and the heat exchange of high-temperature flue gas is realized in the heat exchange hearth. According to the small-sized cyclone-melting pulverized coal furnace, the problems of poor coal type adaptability, low hearth temperature, instability in combustion and high fly ash carbon content of current popular small pulverized coal furnaces are improved.

Owner:HARBIN INST OF TECH

W-shaped flame direct-current burner pulverized coal composite furnace with fluidized bed

InactiveCN106051744AImprove combustion efficiencyReduce fly ash contentCombustion using gaseous and pulverulent fuelFluidized bed combustionCombustion chamberSlag

The invention discloses a W-shaped flame direct-current burner pulverized coal composite furnace with a fluidized bed, relates to a pulverized coal composite furnace, and aims to solve the problems of higher content of fly ash in a W-shaped pulverized coal furnace, high emission content of nitric oxides and sulfur dioxide and single fuel in the prior art. The W-shaped flame direct-current burner pulverized coal composite furnace comprises a furnace body, at least one fluidized bed, a slag discharge pipe and multiple direct-current burner primary wind pipes; the fluidized bed is mounted at the bottom end of the furnace body, and is provided with a wind distribution plate; the multiple direct-current burner primary wind pipes are mounted on a furnace arch of the furnace body; an area near the top end of the furnace body in the furnace body is an upper hearth; an area near the upper side of the fluidized bed in the furnace body is a dense-phase area combustion chamber; an area between the upper hearth and the dense-phase area combustion chamber is a pulverized coal furnace combustion chamber; and the top end of the slag discharge pipe is fixedly connected with the fluidized bed, and is communicated with the dense-phase area combustion chamber. The W-shaped flame direct-current burner pulverized coal composite furnace is applied to the field of boiler combustion.

Owner:HARBIN INST OF TECH

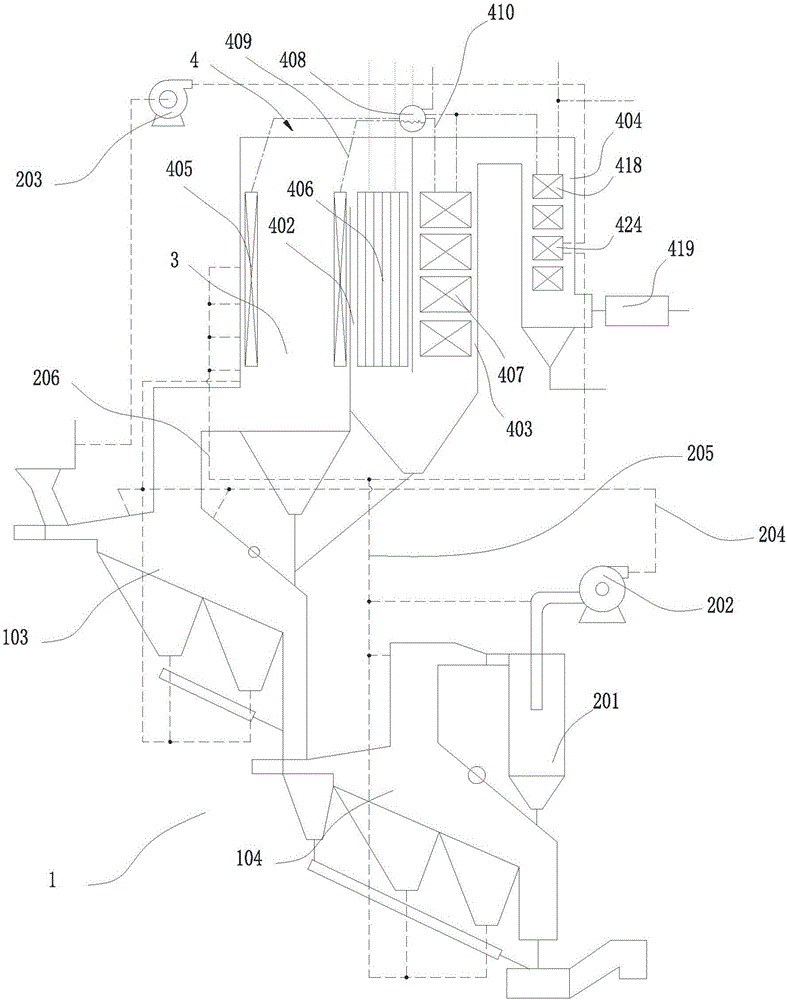

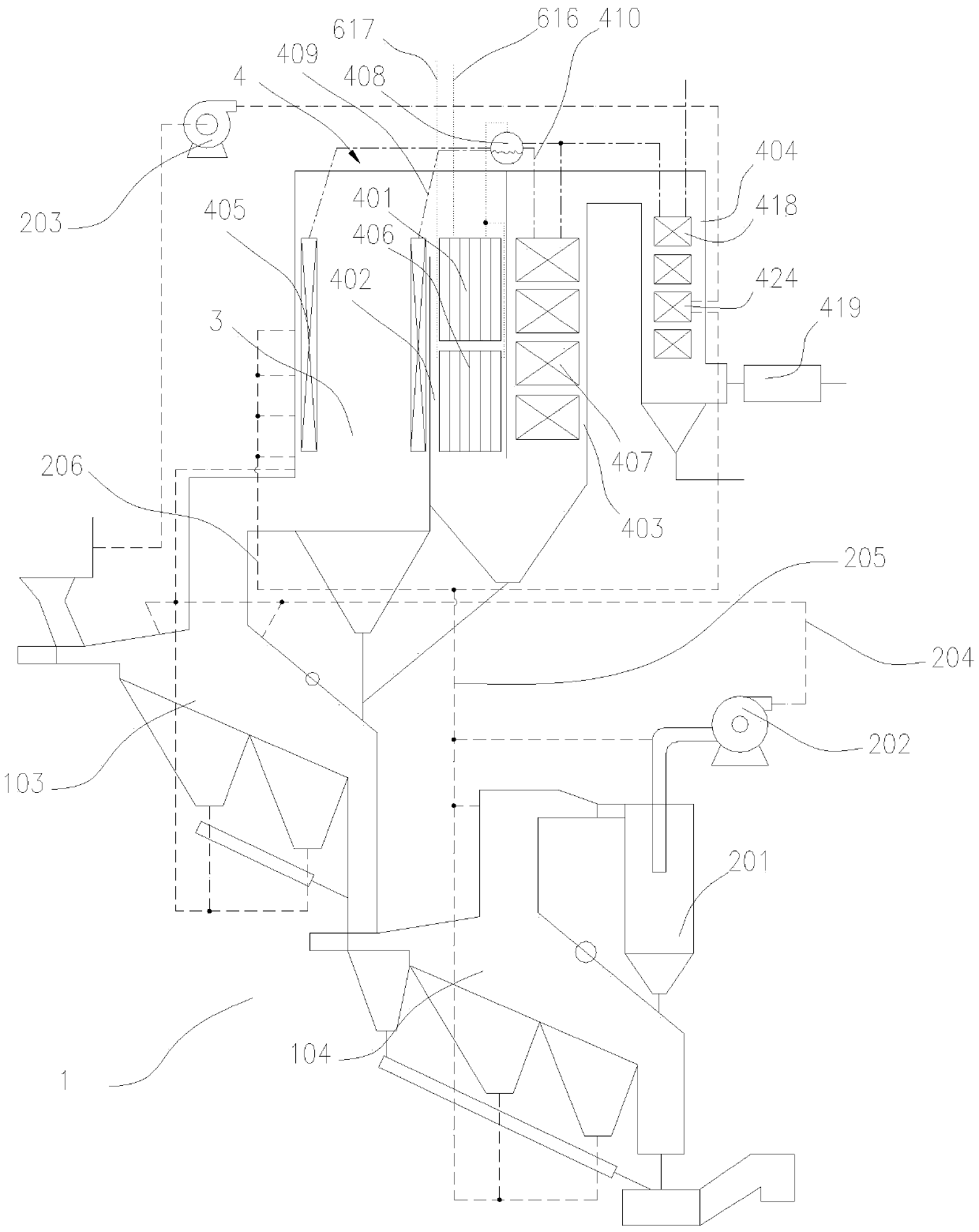

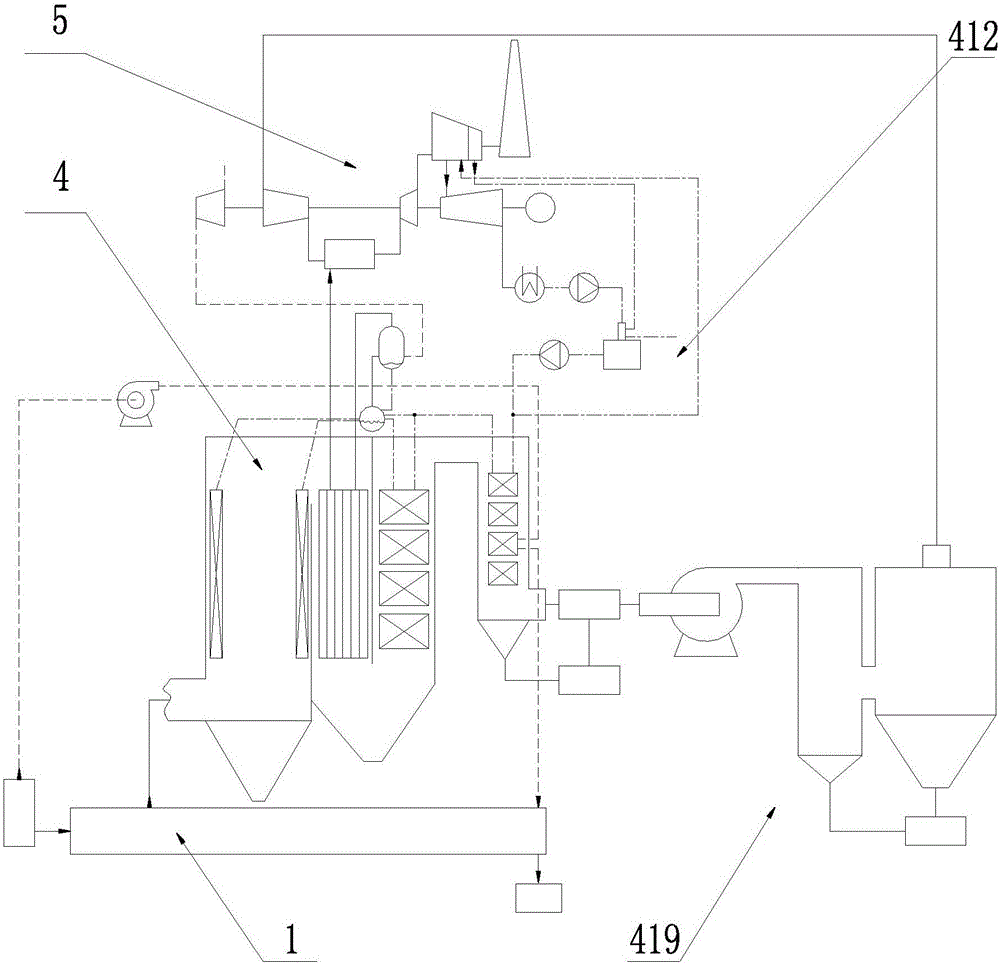

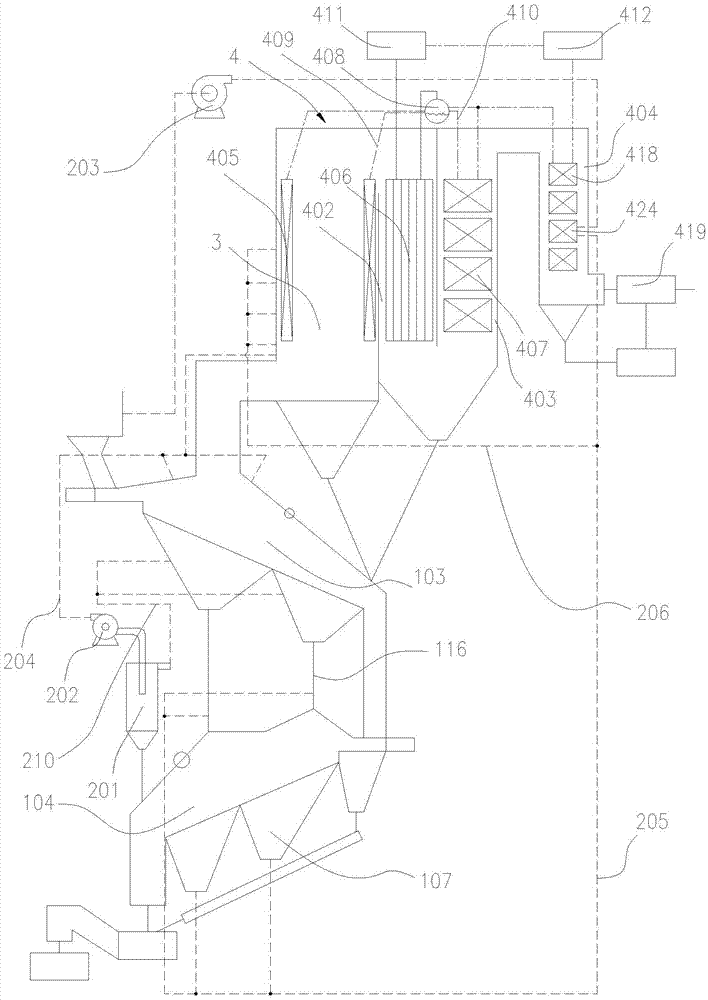

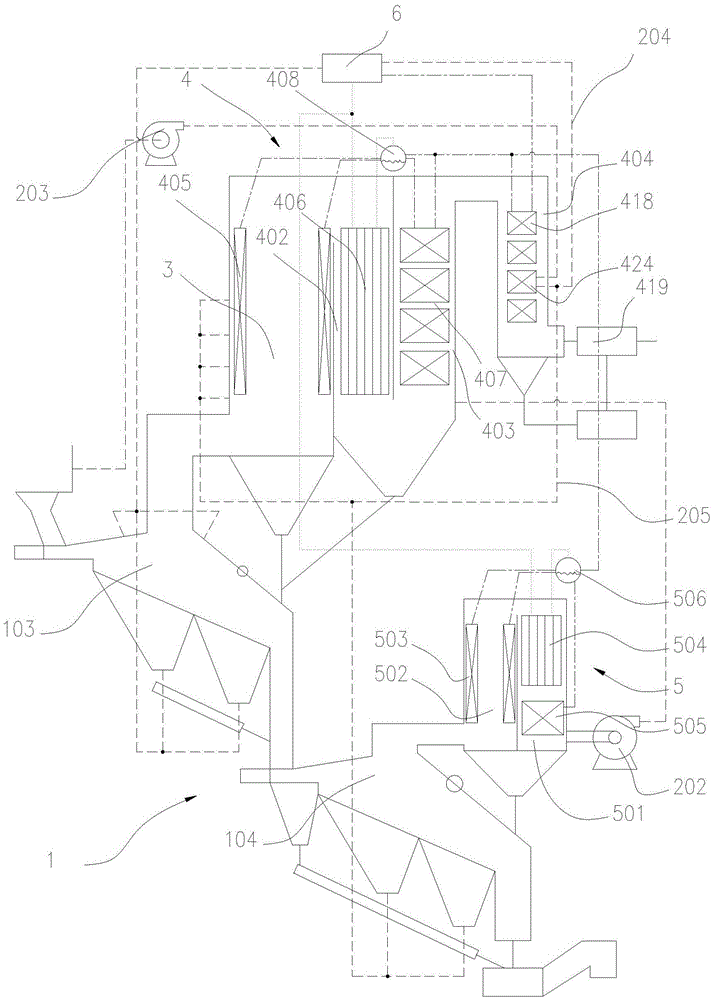

Mechanical grate type garbage gasification and incineration furnace and double-boiler power generation system

ActiveCN105627320AImprove qualityEasy to remove dustSteam engine plantsIncinerator apparatusCycloneCombustion chamber

The invention discloses a mechanical grate type garbage gasification and incineration furnace and double-boiler power generation system with relatively small heat conversion efficiency loss and higher heat recovery efficiency. The system comprises a gasification and incineration furnace, a boiler system, a circulating air supply system and a power generation system, wherein the gasification and incineration furnace comprises a gasifier and an incinerator, which can be sealed or communicated; the boiler system comprises boiler bodies a and b; the boiler body a comprises a cyclone combustion chamber and furnace chambers a and b; the boiler body b comprises a furnace chamber d and a cyclone dust chamber; water cooling walls are arranged in the cyclone combustion chamber and the cyclone dust chamber; a superheater is arranged in the furnace chamber a; an evaporator is arranged in the furnace chamber b; a superheater and an evaporator are arranged in the furnace chamber d; steam pockets are arranged at the top ends of the two boiler bodies; a smoke inlet of the cyclone combustion chamber is connected with a smoke outlet of the gasifier; a smoke inlet of the cyclone dust chamber is connected with a smoke outlet of the incinerator; the power generation system comprises a steam inlet pipe, a steam turbine and a power generator; and the steam inlet pipe is connected with the superheaters a and b and the steam turbine.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Mechanical grate type waste gasification incinerator and boiler system thereof

ActiveCN105423307AImprove qualityEasy to remove dustSteam superheatersIncinerator apparatusCombustion chamberSlag

The invention discloses a mechanical grate type waste gasification incinerator with less conversion thermal efficiency loss and higher thermal recovery efficiency and a boiler system of the waste gasification incinerator. The mechanical grate type waste gasification incinerator comprises a gasification incinerator, the boiler system and a circulating air supply system, wherein the gasification incinerator comprises a feeding bin, a gasifier and a burnout furnace, a stockpiling sealing section is arranged between the feeding bin and the gasifier, a transition slag blanking section is arranged between the gasifier and the burnout furnace, and flue gas outlets are formed in the upper ends of the gasifier and the burnout furnace respectively. The boiler system comprises a boiler body, the boiler body is provided with a cyclone combustion chamber, a furnace chamber a and a furnace chamber b which are mutually communicated, a water cooling wall is arranged in the cyclone combustion chamber, a superheater is arranged in the furnace chamber a, an evaporator is arranged in the furnace chamber b, a steam drum is arranged at the top end of the boiler body, a steam-water inlet is formed in the steam drum, the steam drum is connected with water inlets of the water cooling wall and the evaporator and used for outputting water, steam outlets of the water cooling wall and the evaporator are connected with a steam inlet of the steam drum for backflow of steam, and a saturated steam outlet of the steam drum outputs superheated steam through the superheater.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Biomass pyrolysis and gasification incinerator with differential rotating bed

PendingCN112197269APromote gasificationFully vaporizedIncinerator apparatusProcess engineeringConvection heat

The invention discloses a biomass pyrolysis and gasification incinerator with a differential rotating bed, and mainly relates to the technical field of energy science. The incinerator comprises a boiler barrel and a boiler body with an opening in the top, wherein a radiation heat exchanger covering the top end of the boiler body is arranged at the top of the boiler body, the boiler barrel is installed at the top of the radiation heat exchanger, a first flue communicating with the boiler body is arranged in the radiation heat exchanger, a convection heat exchanger is arranged on one side of theradiation heat exchanger, a second flue communicating with the first flue is arranged in the convection heat exchanger, an exhaust pipe communicating with the second flue is arranged at the end, awayfrom the radiation heat exchanger, of the convection heat exchanger, and a tower-shaped rotary air distribution disc and an air distribution disc driving device are arranged at the bottom in the furnace body. According to the incinerator, disturbing between a fire grate and a material layer can be increased, meanwhile, through proper air distribution, materials can be fully gasified, the heat exchange efficiency and the energy conversion efficiency can be improved, the service life is prolonged, the gasification strength is improved, the heat energy utilization rate can be increased, and theheat load requirements of users can be met.

Owner:山东信科环境科学研究院有限公司

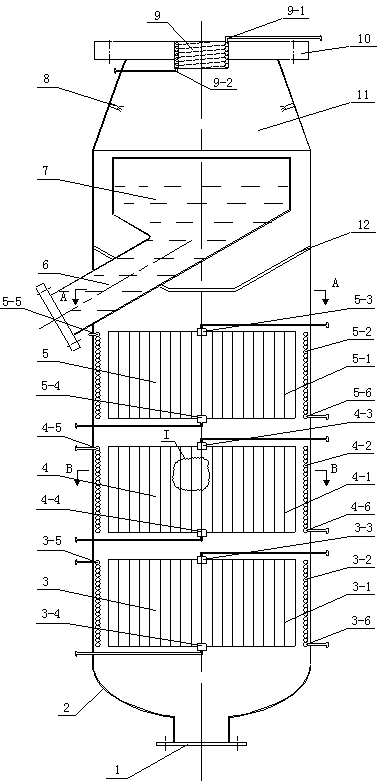

Integrated coal gasification waste heat recovery device

InactiveCN104263414AIncrease wasteAvoid wastingEnergy inputGranular/pulverulent flues gasificationSlagWastewater

The invention relates to an integrated coal gasification waste heat recovery device. The device comprises a tank, wherein a feeding hole, a quenching chamber, a slag pool, a convective waste heat boiler and a gas outlet are formed from top to bottom of the tank in sequence; the coal gas flows downwards from the feeding hole of the tank and is quenched in the quenching chamber; the temperature of the quenched coal gas is 800-900 DEG C; the wastewater enters the slag pool while the coal gas continuously flows downwards into the convective waste heat boiler to be cooled; the temperature of the cooled coal gas is 200-300 DEG C; the cooled coal gas is exhausted from the gas outlet. Combining the quenching chamber with the convective waste heat boiler into a whole, the device has the advantages that the device fully recovers high-temperature raw coal gases and slag sensible heat, removes fly ash, reduces the investment and improves the heat efficiency.

Owner:中国东方电气集团有限公司

Double-boiler power generating system capable of incinerating syngas through garbage gasification

ActiveCN105627324AGuaranteed qualityReduce lossSteam generation plantsIndirect carbon-dioxide mitigationSyngasDeaerator

The invention discloses a double-boiler power generating system capable of incinerating syngas through garbage gasification, and the double-boiler power generating system is small in heat conversion efficiency loss and higher in heat recovery efficiency. The double-boiler power generating system comprises a steam input pipe, a steam turbine and a power generator. The steam input pipe is connected with the steam input end of the steam turbine. The steam output end of the steam turbine is sequentially connected with a condenser, a water pump, a low-pressure steam water heater, a deaerator, a booster water pump and a high-pressure steam water heater. The heated input end of the low-pressure steam water heater is connected with the water pump, and the heated output end of the low-pressure steam water heater is connected with the deaerator. The heated input end of the high-pressure steam water heater is connected with the booster water pump, and the heated output end of the high-pressure steam water heater is used for outputting water which is used for boilers. The steam turbine is provided with a first steam fetching pipe and a second steam fetching pipe which are used for fetching steam from the steam output end of the steam turbine. The output end of the first steam fetching pipe is connected with the heating input end of the high-pressure steam water heater. The output end of the second steam fetching pipe is connected with the heating input end of the low-pressure steam water heater.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

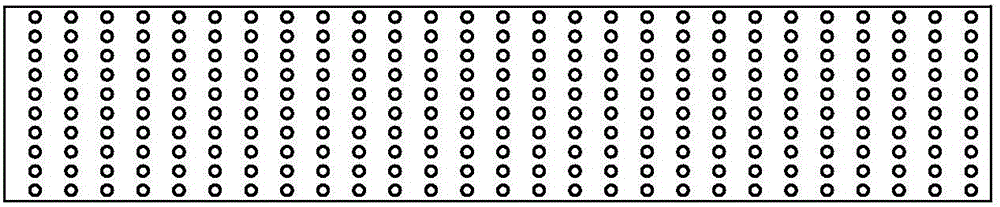

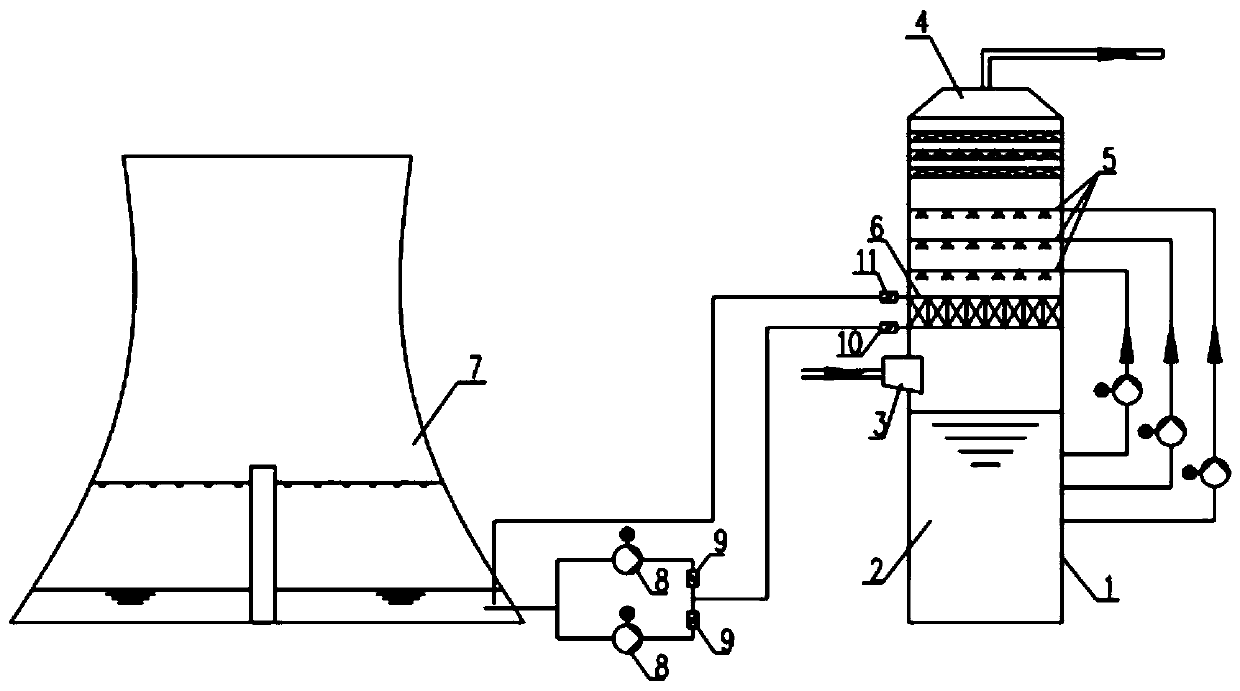

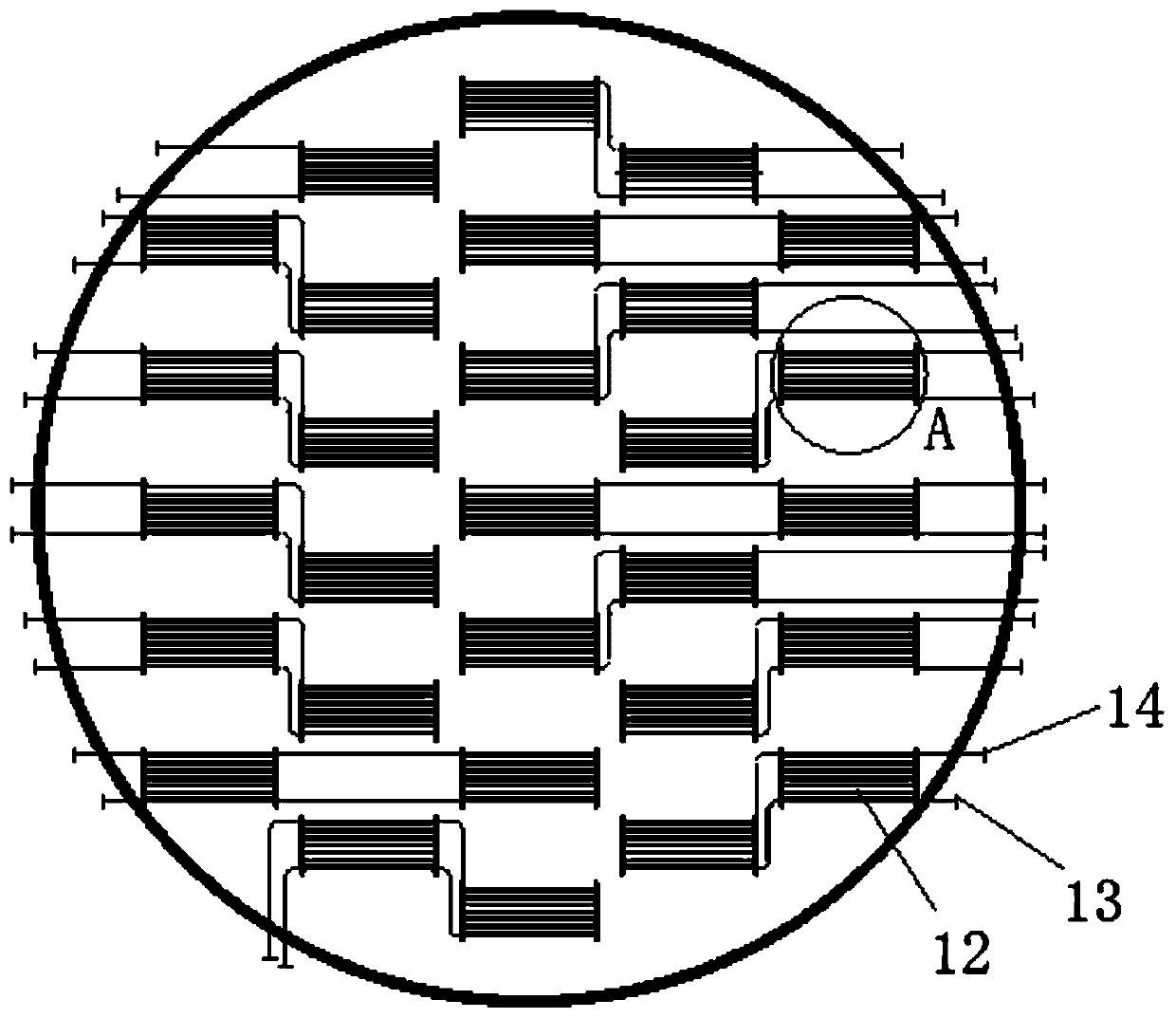

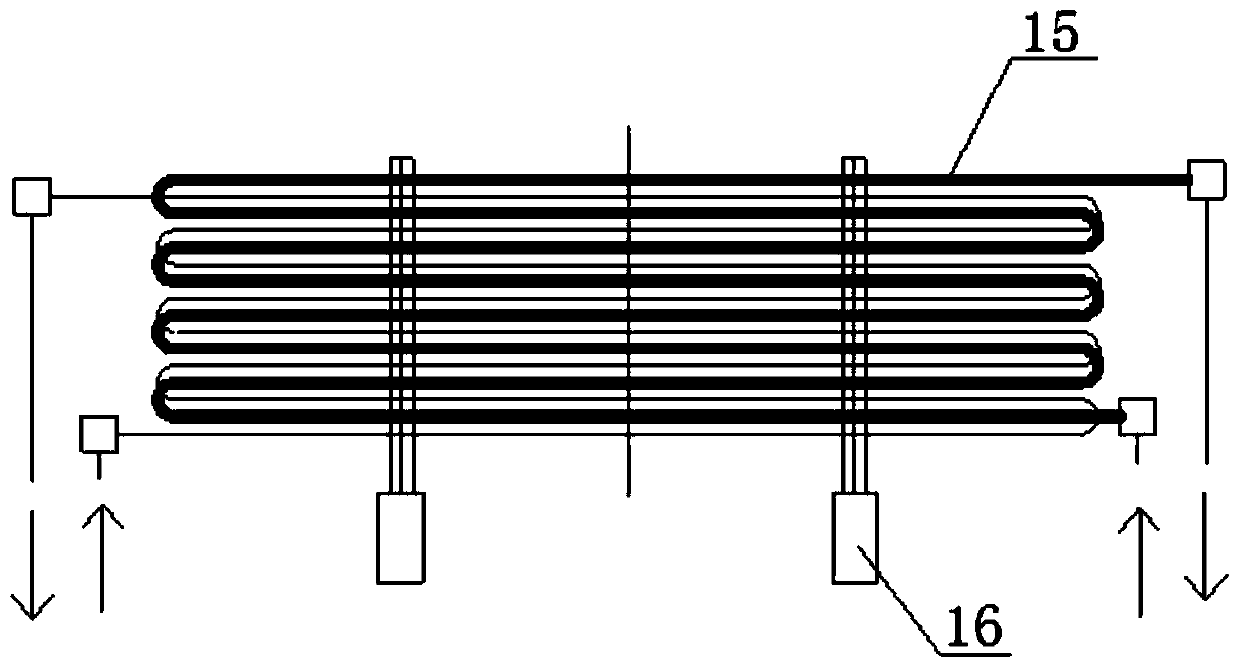

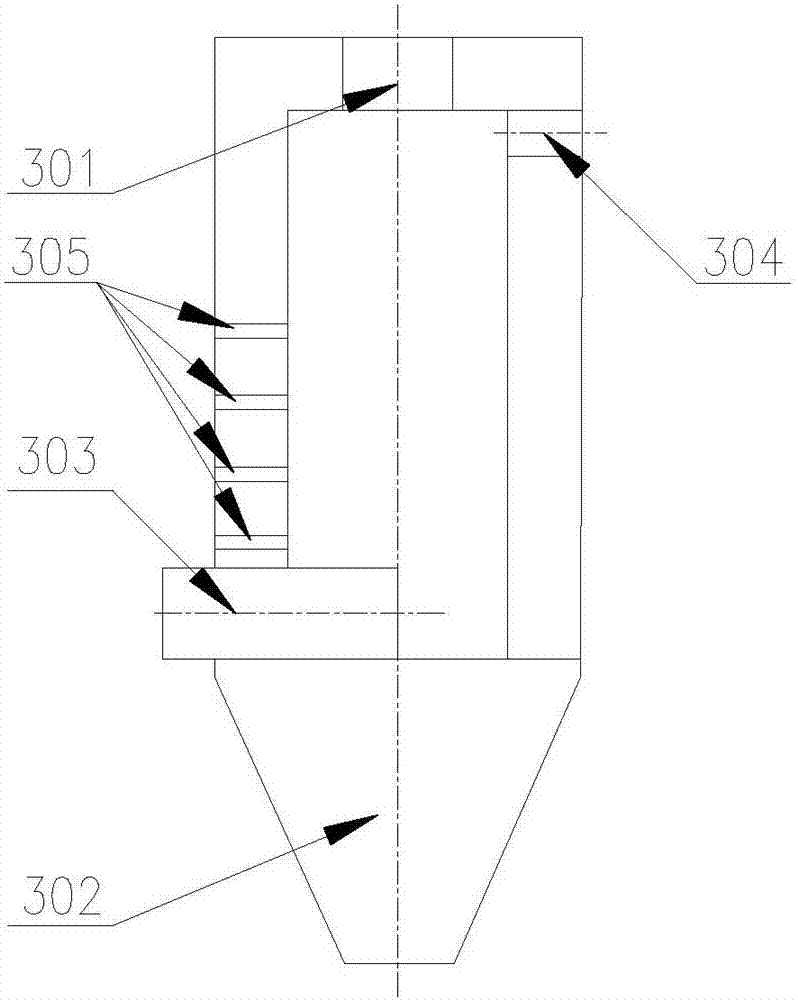

Condensing type white smoke removing system and method for flue gas slurry

InactiveCN109806697APlay the role of distributing airRapid primary coolingUsing liquid separation agentCombustion technology mitigationFlue gasEngineering

The invention discloses a condensing type white smoke removing system and method for flue gas slurry. The white smoke removing system comprises a desulfurization tower and a water cooling tower, wherein the desulfurization tower is sequentially provided with a slurry tank, a flue gas inlet, a heat exchange layer, a spraying layer, a demister and a flue gas outlet from bottom to top; the slurry tank is connected with the spraying layer through a pipeline; the pipeline is provided with a first water pump; the heat exchange layer comprises a plurality of heat exchangers; the plurality of heat exchangers are uniformly distributed on the cross section of the desulfurization tower; heat exchange pipes on each heat exchanger are arrayed in a matrix; the heat exchange pipes on adjacent layers in the vertical direction are distributed in a staggered manner; the heat exchange pipes are parallel to the cross section of the desulfurization tower; a water cooling tank is arranged at the bottom of the water cooling tower; a water inlet and a water outlet of each heat exchanger are connected with the water cooling tank through a pipeline and each pipeline is provided with a second pump. Accordingto the condensing type white smoke removing system, the modularized heat exchangers are arranged between an inlet flue of the desulfurization tower and the spraying layer on the bottommost layer anda space in the tower is sufficiently utilized; white smoke of flue gas is alleviated and even removed and the water consumption in a desulfurization process is reduced.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

Solid waste treatment furnace and solid waste treatment method

PendingCN113028423ASmooth slag dischargeReduce fly ash contentCasings/liningsIncinerator apparatusCombustion chamberNitrogen oxides

The invention discloses a solid waste treatment furnace and a solid waste treatment method. A furnace body of the treatment furnace comprises a melting chamber, a necking section and a combustion chamber, more than three first nozzles are arranged on the straight cylinder section of the melting chamber, the included angle alpha between the axis of each first nozzle and the radial direction of the furnace body is 0 degree-15 degrees, and the distance h1 between the intersection point of the axis of each first nozzle and the inner wall surface of the straight cylinder section of the melting chamber and the bottom surface of the straight cylinder section of the melting chamber is 0.1 m-2.0 m; the ratio x1 of the length to the inner diameter of the straight cylinder section of the melting chamber is 0.5-8; the treatment furnace is further provided with a granulating device, a first cooling device, a second nozzle and a second cooling device. According to the solid waste treatment furnace, smooth slag discharging of a slag discharging opening can be achieved, slag blocking is avoided, the fly ash content of flue gas discharged out of the furnace body is reduced, solidified particle slag good in shape and uniform in particle size can be formed, the amount of fly ash adhering to the water cooling wall of the combustion chamber can be reduced, the generation amount of nitric oxide can be reduced, and the flue gas discharged out of the furnace body does not contain dioxin.

Owner:EAST CHINA UNIV OF SCI & TECH

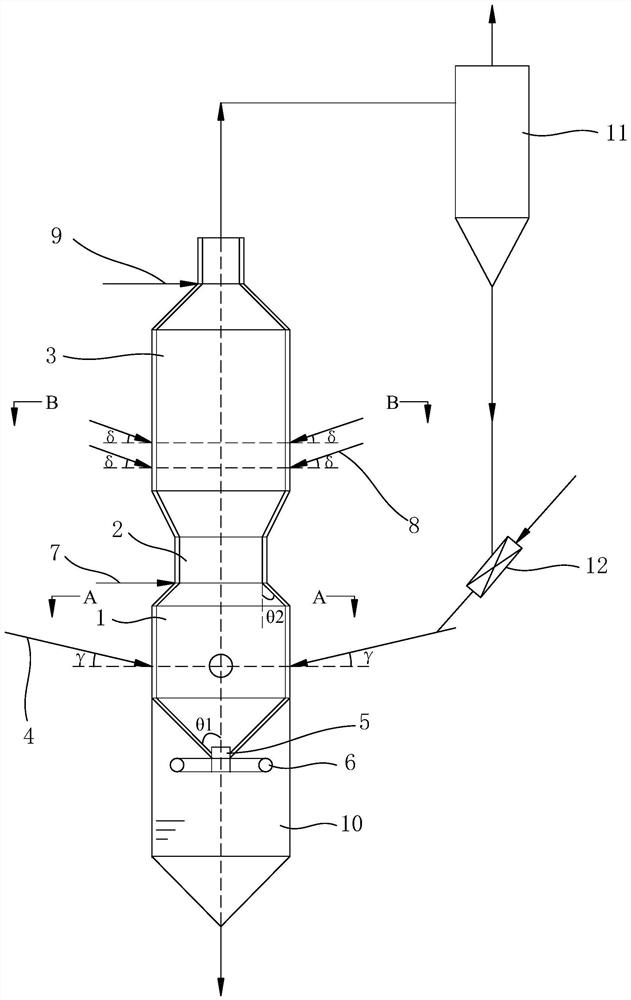

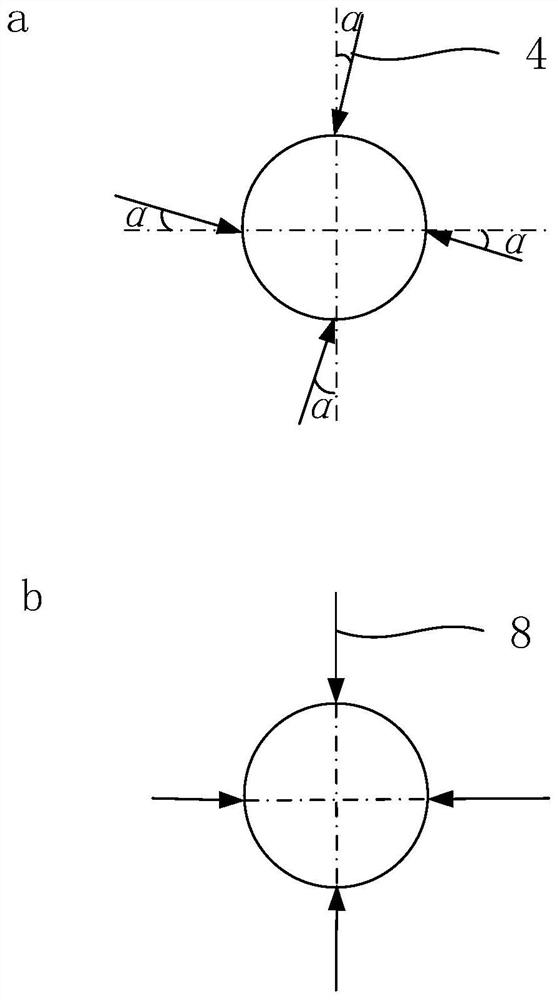

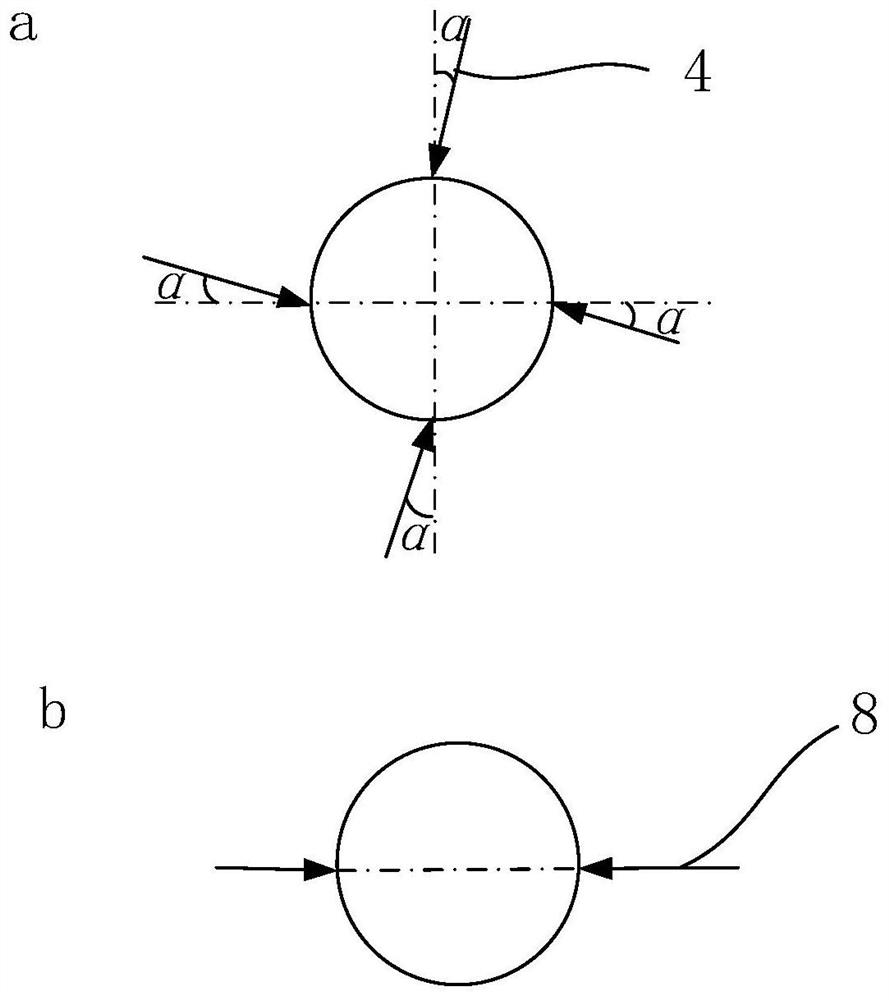

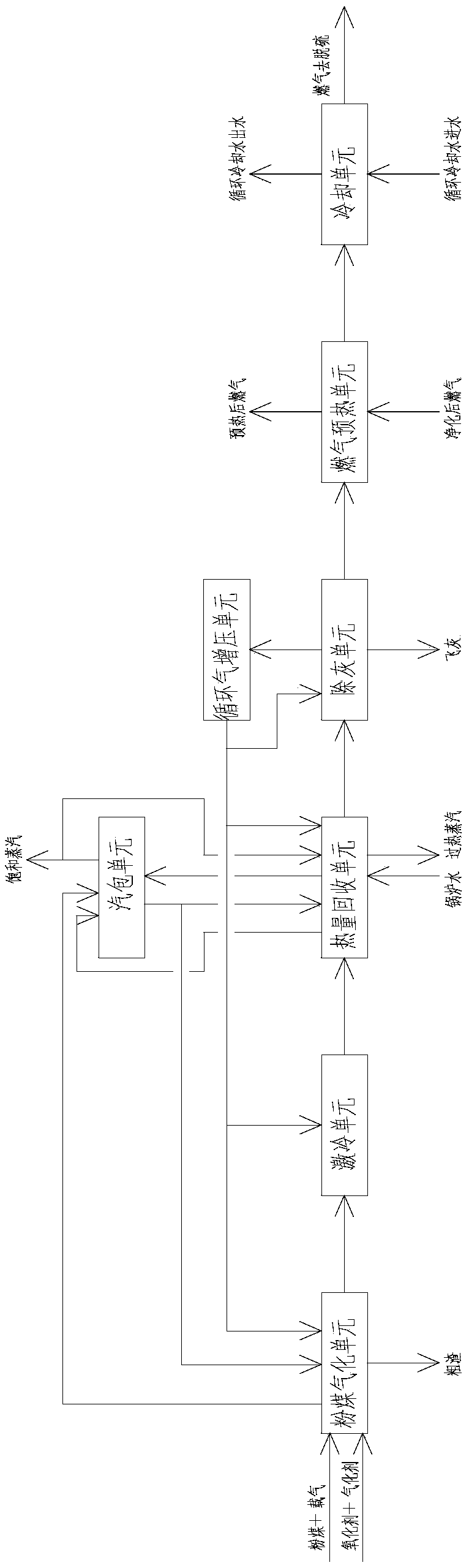

Process method for preparing fuel gas from coal

InactiveCN108977230AConcentration adjustableHigh gasification temperatureGranular/pulverulent flues gasificationEnvironmental resistanceWastewater

The invention relates to a process method for preparing fuel gas from coal. A device for preparing fuel gas from coal used in the method comprises a powdered coal gasification unit, a quenching unit,a heat recovery unit, an ash removing unit, a circulation gas pressurization unit, a steam bag unit, a fuel gas preheating unit and a cooling unit. The process method for preparing fuel gas from coalhas the advantages of high gasification temperature and high coal type applicability; the local cheap coal types can be used as raw materials for greatly reducing the gas preparation cost; the environmental-friendly performance is good; no organic waste water is generated; the fly ash content in the coal gas is low; the fuel gas pressure is from normal pressure to 0.5MPa; the heat value is 900 to2500 kcalNm<3>; the method meets the requirement of low-heat-value fuel gas need in industries of aluminum oxide, ceramics, glass and the like.

Owner:EAST CHINA UNIV OF SCI & TECH +1

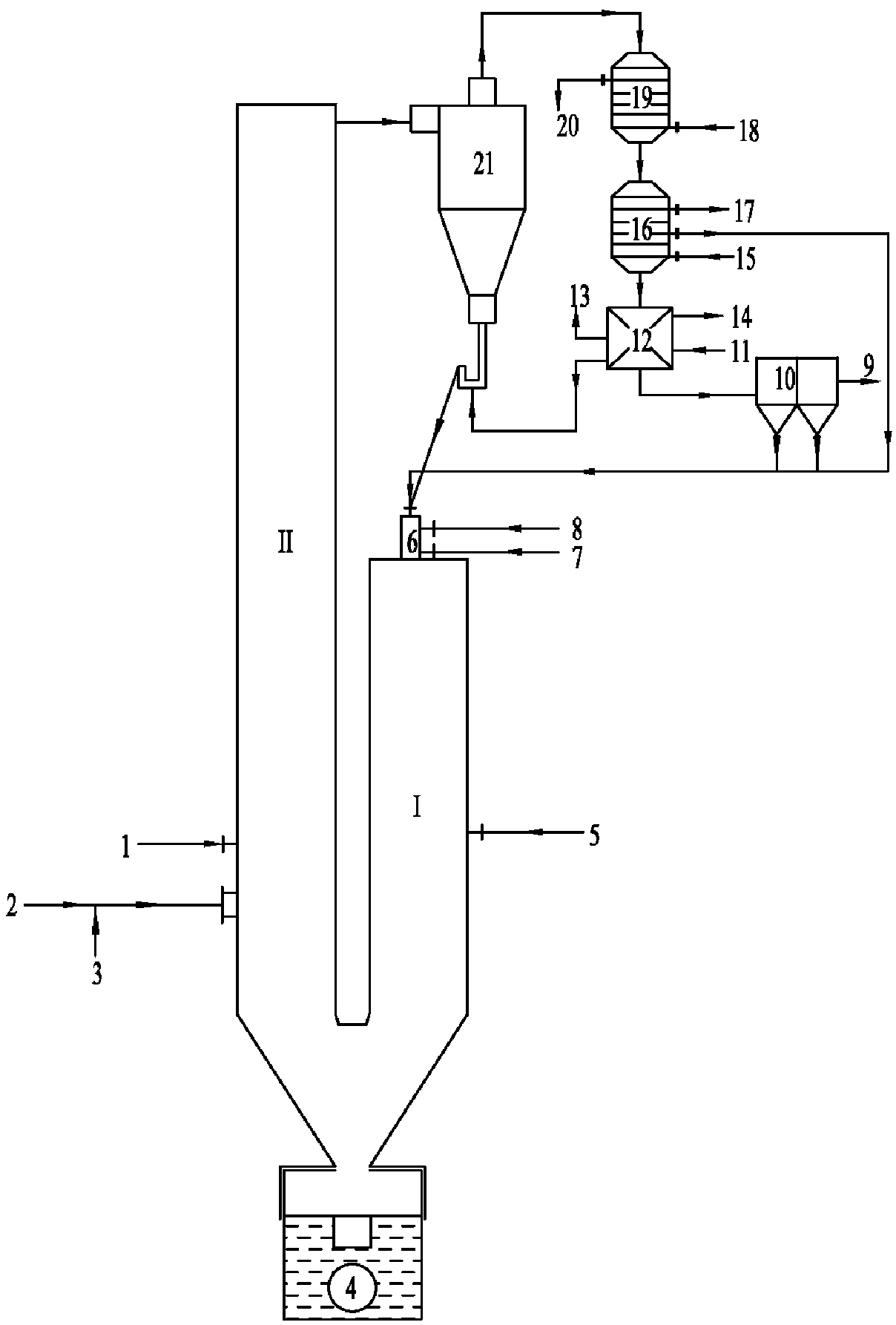

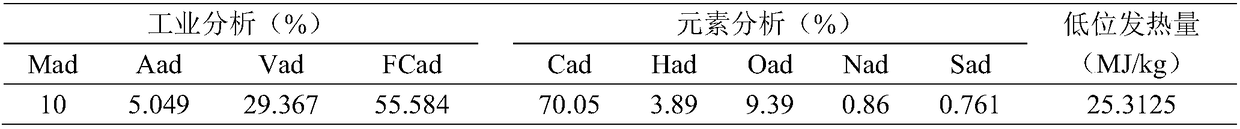

Coal gasification process and device for liquid slagging and high-temperature coke loopback

ActiveCN108998098AReduce fly ash contentReduce carbon contentGasification processes detailsGranular/pulverulent flues gasificationGas pipelineProcess engineering

The invention discloses a coal gasification process and device for liquid slagging and high-temperature coke loopback. The device comprises a U-shaped gas generator and a high-temperature separator, wherein the U-shaped gas generator comprises a high-temperature section and a low-temperature section which are of a U shape; the high-temperature section and the low-temperature section share a ash bucket; an outlet of the U-shaped gas generator is formed in the top of the low-temperature section and connected with an inlet of the high-temperature separator; a coal powder inlet, an air inlet and afirst vapor inlet are formed in the top of the high-temperature section; the coal powder inlet is connected with each of a coal powder source and a high-temperature coke outlet of the high-temperature separator; a second vapor inlet is formed in the middle part of the high-temperature section; a coal powder feeding port and a third vapor inlet are formed in the bottom of the low-temperature section; the third vapor inlet is located above the coal powder feeding port; the coal powder feeding port is connected with a coal powder pipeline; and the coal powder pipeline is provided with a gas pipeline. Through the adoption of the device, a carbon conversion rate can be provided and the efficient utilization of coal can be realized.

Owner:SHANDONG UNIV

Embedded deep cooler for boiler flue gas

The invention discloses an embedded deep cooler for boiler flue gas, which comprises a shell 11; the side close to an inlet flue in the shell 11 is a high temperature section, and the side close to an outlet flue is a low temperature section; and flue clapboards 14 and 16 divide an inner cavity of the shell 11 into an upper flue compartment 12, a middle flue and a lower flue compartment 15. The embedded deep cooler performs deep cooling on boiler flue gas, effectively recovers afterheat of the boiler flue gas, reduces the temperature of flue gas at an inlet of a desulfurizing tower, reduces water consumption of the desulfurizing tower, improves the boiler efficiency and desulfurization efficiency, and achieves the aims of saving energy, improving efficiency and saving water resource.

Owner:XI AN JIAOTONG UNIV +1

Double-layer mechanical grate type garbage gasification incinerator and its boiler power generation system

ActiveCN105465789BImprove insulation effectPrevent leakageSteam engine plantsIncinerator apparatusCombustion chamberFlue gas

The invention discloses a double-layer mechanical grate type garbage gasification incinerator and its boiler power generation system, including a double-layer garbage gasification incinerator, a boiler system, a circulating air supply system, a power generation system, and a double-layer garbage gasification incinerator The ember furnace is located directly below the gasification furnace, and the gasification furnace and the upper end of the ember furnace are provided with flue gas outlets. The boiler system includes a boiler body, and the boiler body has a cyclone combustion chamber, furnace chamber a, furnace chamber b, and cyclone A water-cooled wall is set in the combustion chamber, a superheater is set in the furnace room a, an evaporator is set in the furnace room b, a steam drum is set on the top of the boiler body, and the superheater outputs superheated steam; the power generation system includes a steam turbine, a generator, a steam input pipe, and a steam turbine The output end is sequentially connected to the condenser, water pump, low-pressure steam-water heater, deaerator, booster water pump, and high-pressure steam-water heater. The first and second-stage water-steam separators and the first and second-stage high-pressure Steam heater.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com