Double-boiler power generating system capable of incinerating syngas through garbage gasification

A technology for power generation system and synthesis gas, which is applied to steam generation methods using heat carrier, incinerators, steam boilers, etc. The effect of high rate and less waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

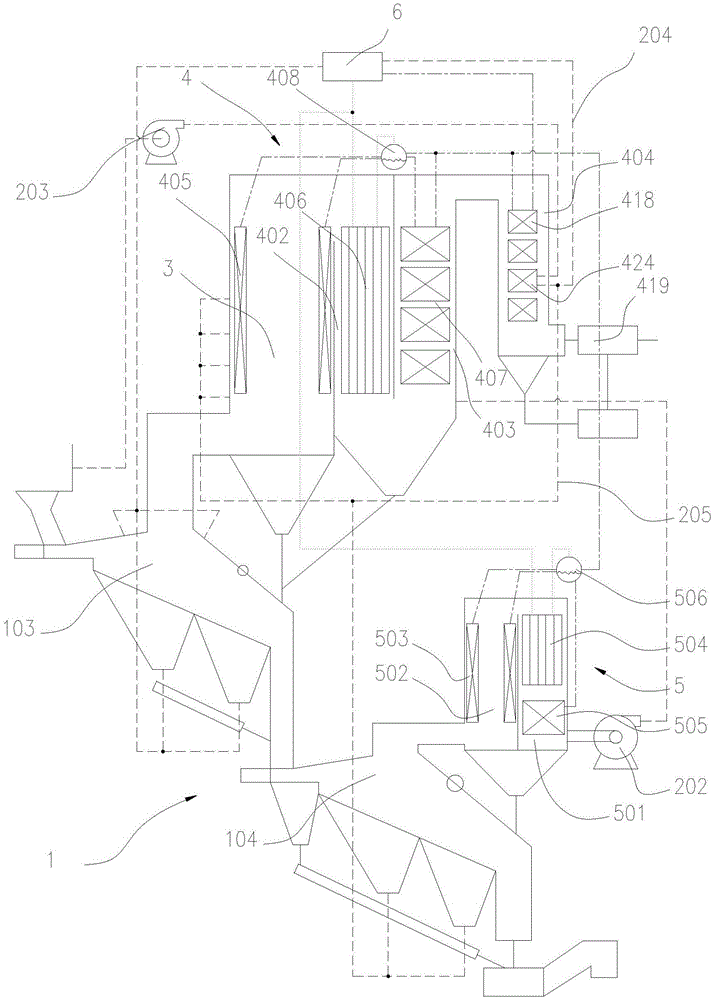

[0044] see Figure 1 to Figure 6 , which is a preferred embodiment of a double boiler power generation system using waste gasification and incineration of syngas, including a gasification incinerator, a boiler system, and a circulating air supply system.

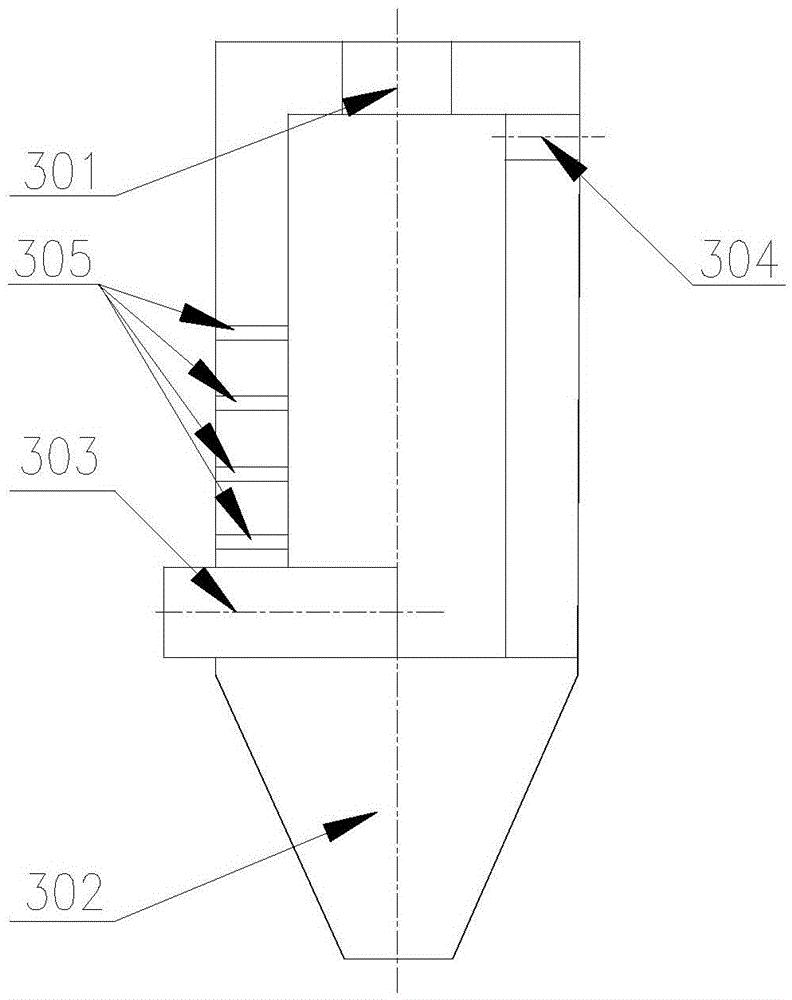

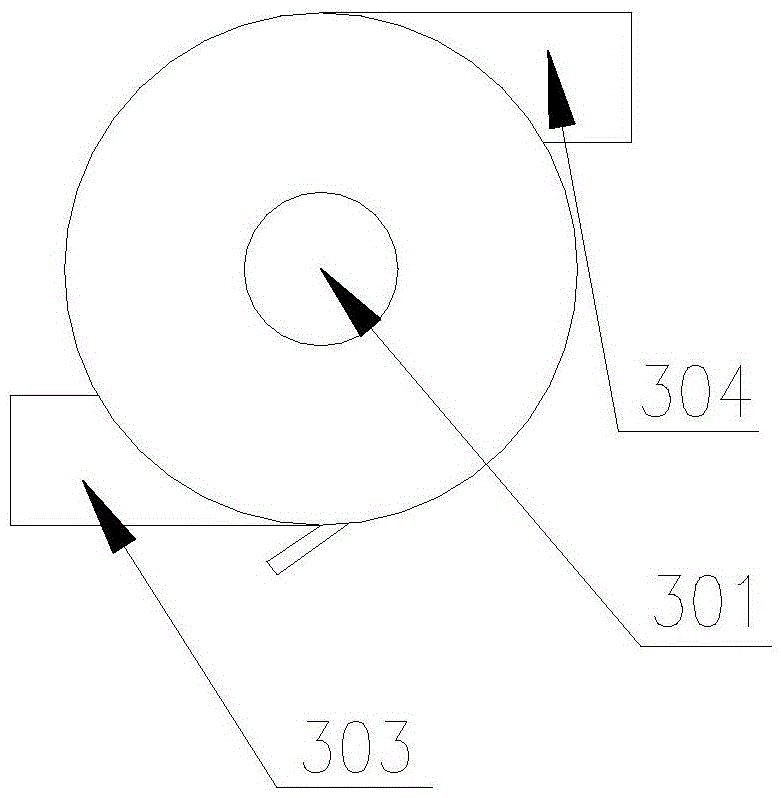

[0045] see Image 6 , is a mechanical grate type garbage gasification incinerator, including a furnace frame 101, and a feed bin 102, a gasification furnace 103, and an ember furnace 104 that are sequentially arranged on the furnace frame 101 along the feeding direction, and the ember furnace 104 The rear is the slag outlet 116 of the embering furnace 104. The slag outlet 117 is provided on the embering furnace 104. The slag outlet 116 of the embering furnace 104 is located directly below the slag outlet 117 of the embering furnace. The structural sealing effect is good, which can effectively reduce the emission of pollutants. The gasification furnace 103 mainly gasifies the charcoal part of the garbage, and discharges com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com