Boiler power generation system utilizing rubbish gasification and incineration synthesis gas

A technology for boiler power generation and synthesis gas, which is used in steam boilers, steam generation, and liquid degassing. The effect of improving heat exchange efficiency and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

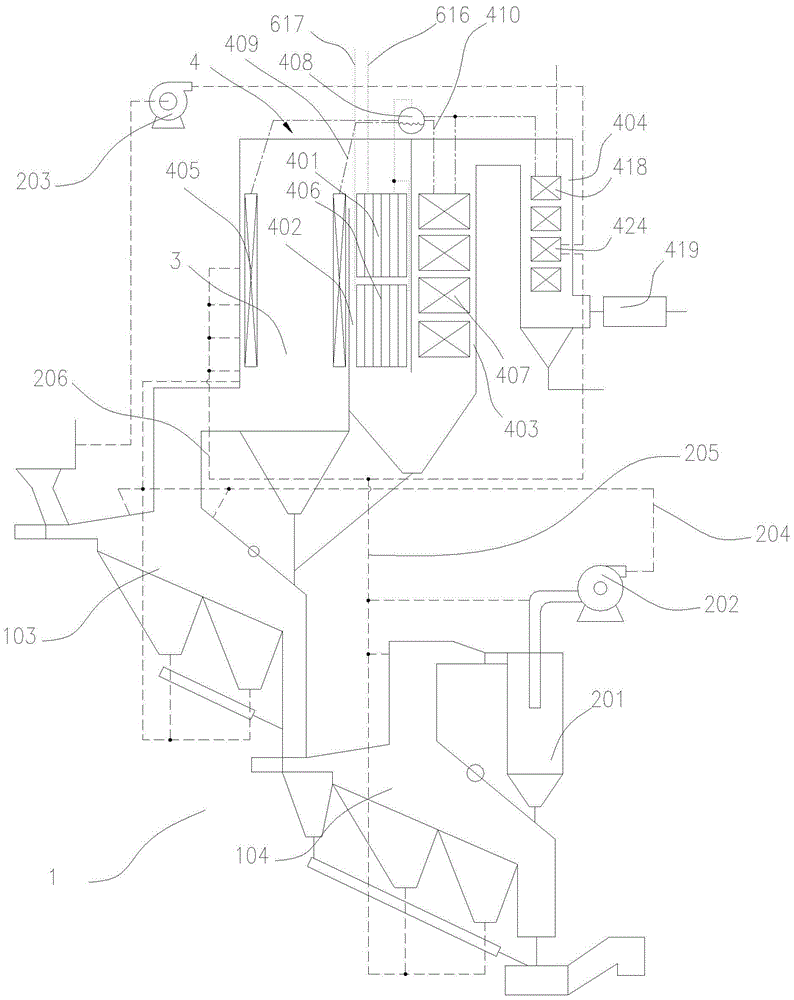

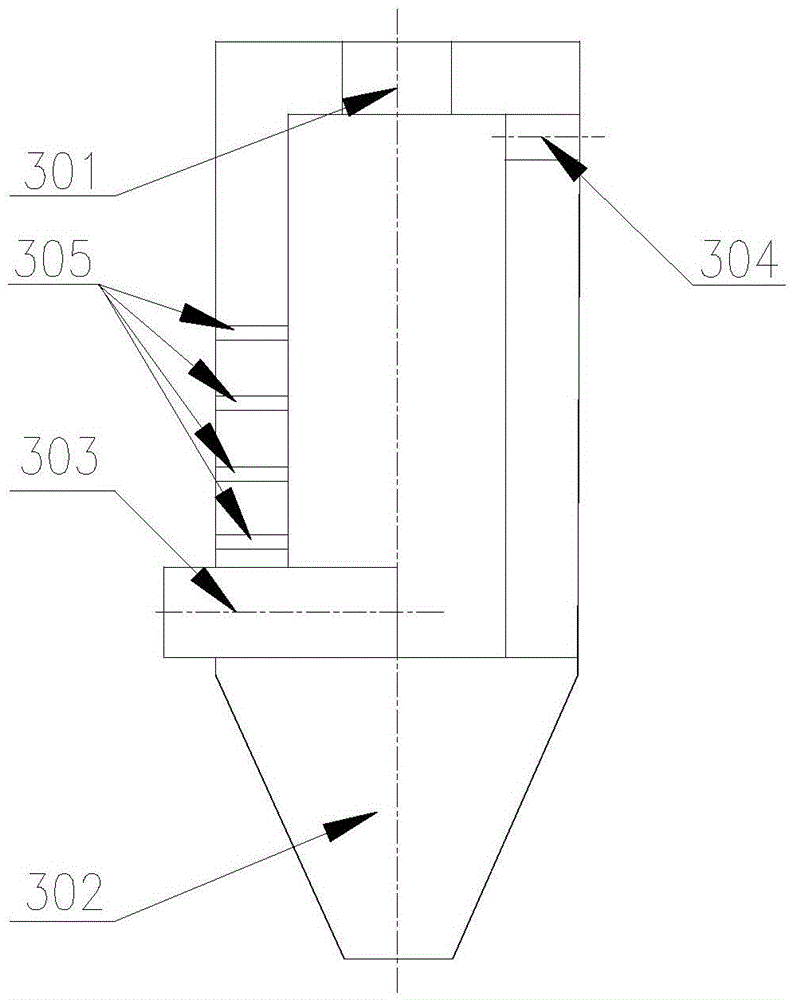

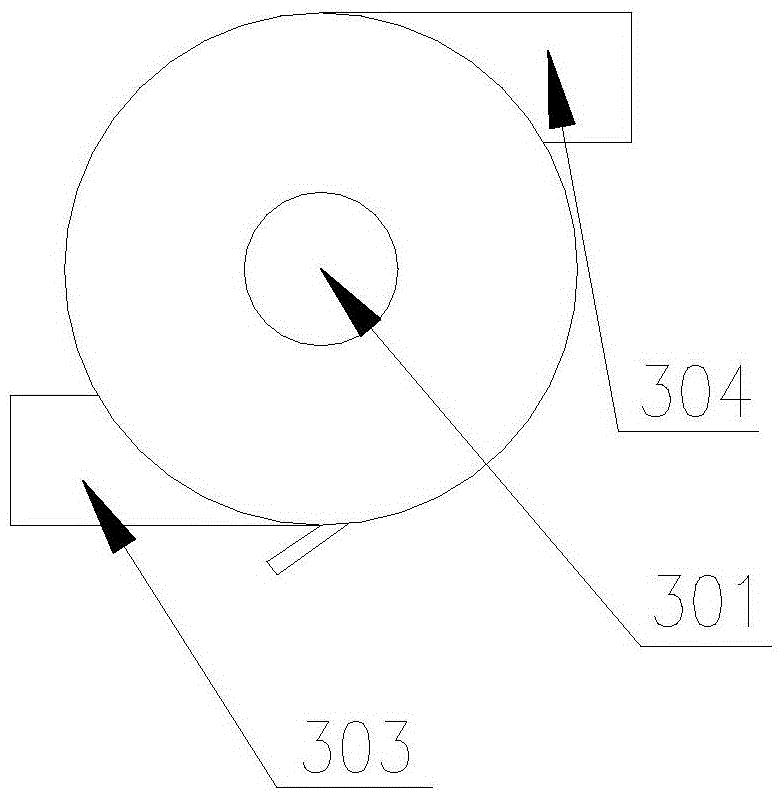

[0045] see Figure 1 to Figure 7 , which is a preferred embodiment of a boiler power generation system using waste gasification and incineration of syngas.

[0046] see Figure 4 The power generation system includes a steam turbine and a generator 613 power-connected with the steam turbine. The steam turbine includes a high-pressure cylinder 601, a medium-pressure cylinder 602, and a low-pressure cylinder 603. A first-stage water vapor is arranged between the high-pressure cylinder 601 and the medium-pressure cylinder 602. Separator 604, first-stage high-pressure steam heater 605, the input end of the first-stage water-steam separator 604 is connected to the output end of the high-pressure cylinder 601 through a pipeline, and the steam output end of the first-stage water-steam separator 604 is connected to the first-stage water-steam separator 604. The heating input end of the first-stage high-pressure steam heater 605 is connected through a pipeline, and the heating output e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com