Biomass pyrolysis and gasification incinerator with differential rotating bed

A technology of pyrolysis gasification and rotating bed, which is applied in the field of energy science, can solve the problems of severe ash in the heating area of the combustion chamber, low gasification efficiency, and high content of fly ash in flue gas, so as to improve energy conversion efficiency and heat energy utilization efficiency , The effect of low fly ash content in flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

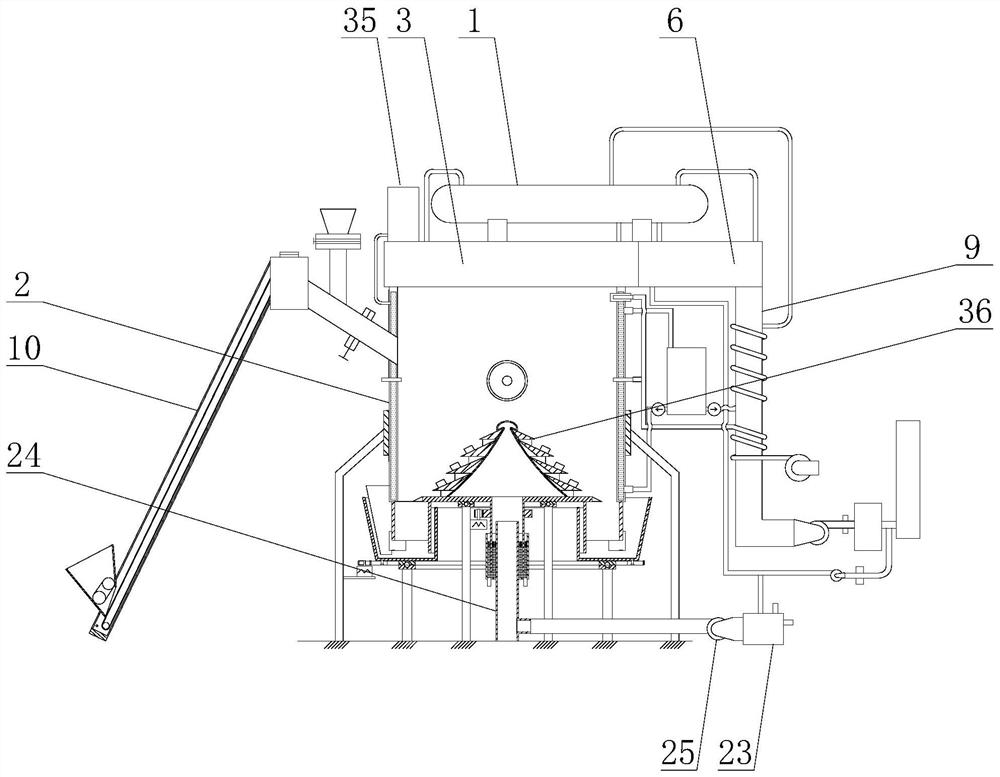

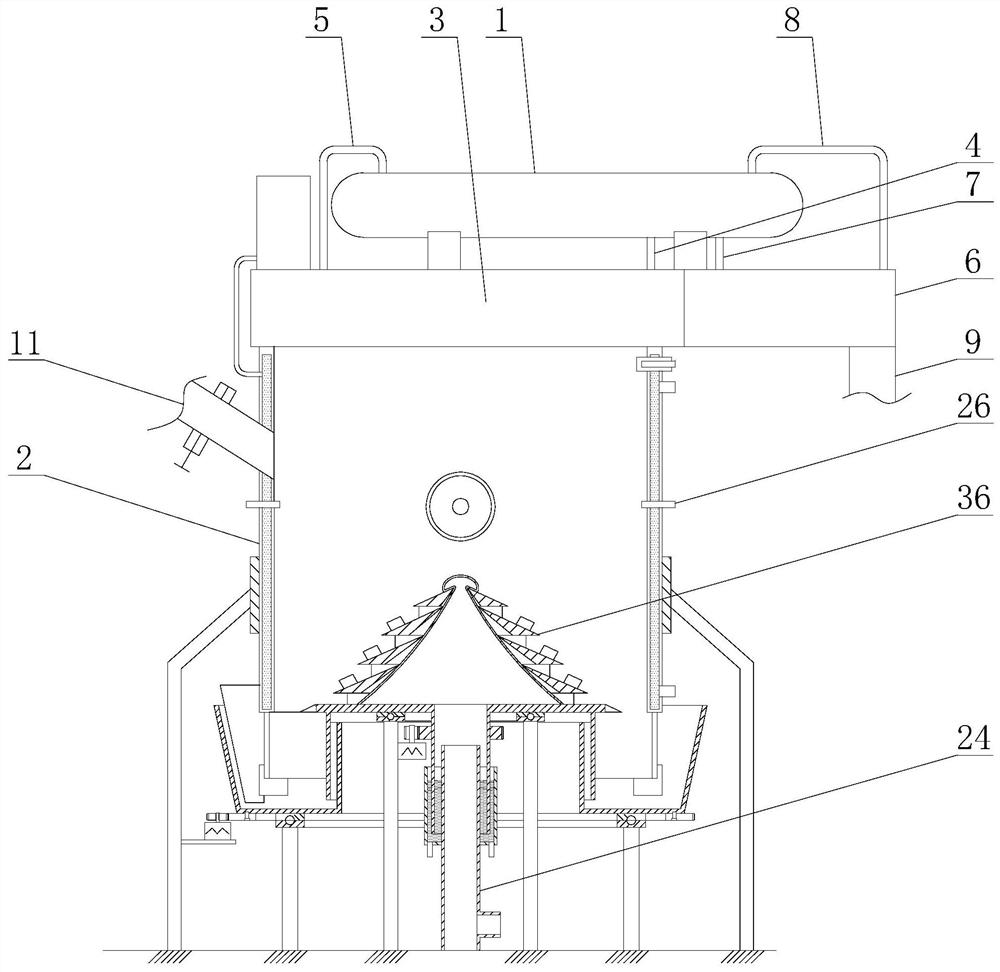

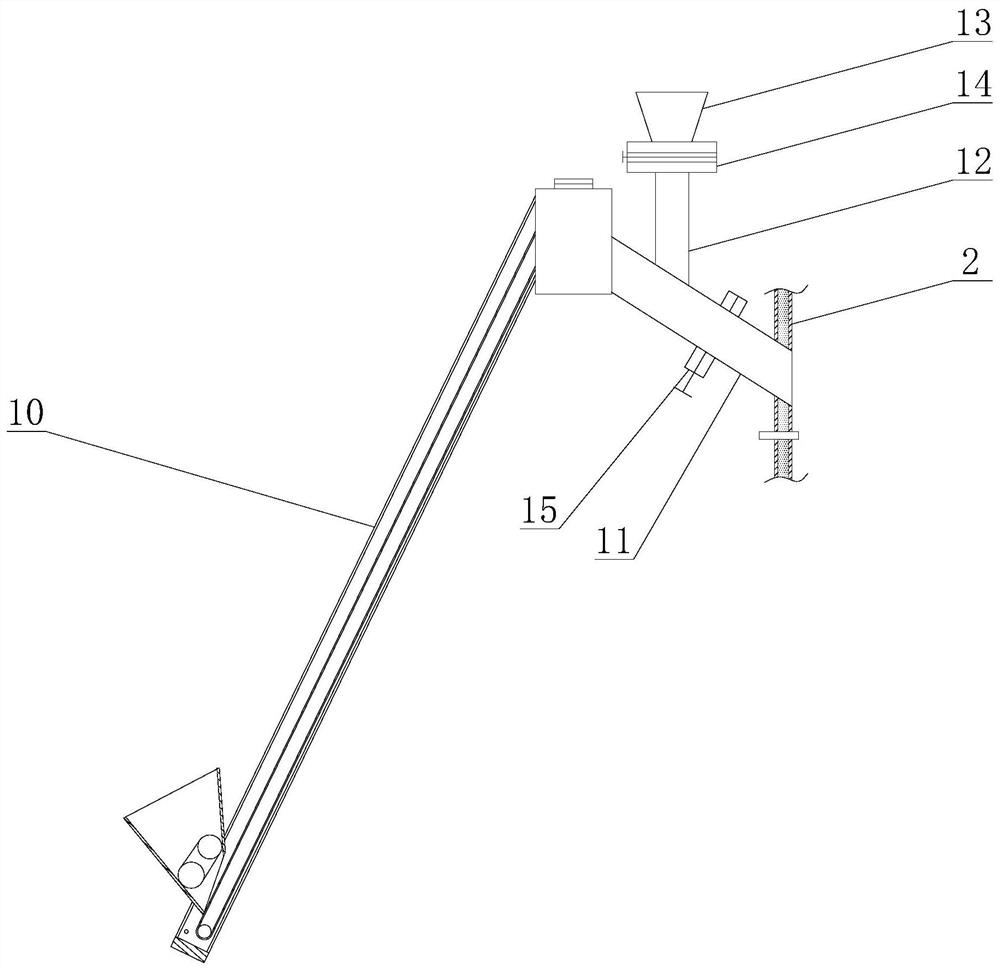

[0024] Example: as attached Figure 1-4 As shown, the present invention is a differential rotating bed biomass pyrolysis gasification incinerator, including a drum 1, a furnace body 2 with an open top, and the drum 1 is used for water storage. The top of the furnace body 2 is provided with a radiation heat exchanger 3 covering the top of the furnace body 2, and the radiation heat exchanger 3 covers the upper side of the furnace body 2, and the radiation heat exchanger 3 is used for direct heat exchange. The drum 1 is installed on the top of the radiation heat exchanger 3 , and a bracket is welded on the bottom of the drum 1 . The drum 1 is provided with a first water inlet pipe 4 and a first air outlet pipe 5 communicating with the radiation heat exchanger 3. The water in the drum 1 enters the radiation heat exchanger 3 through the first water inlet pipe 4 and is exchanged by radiation. After being heated by the heater 3, it becomes gas, which flows back into the drum 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com