Patents

Literature

41results about How to "High slurry concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

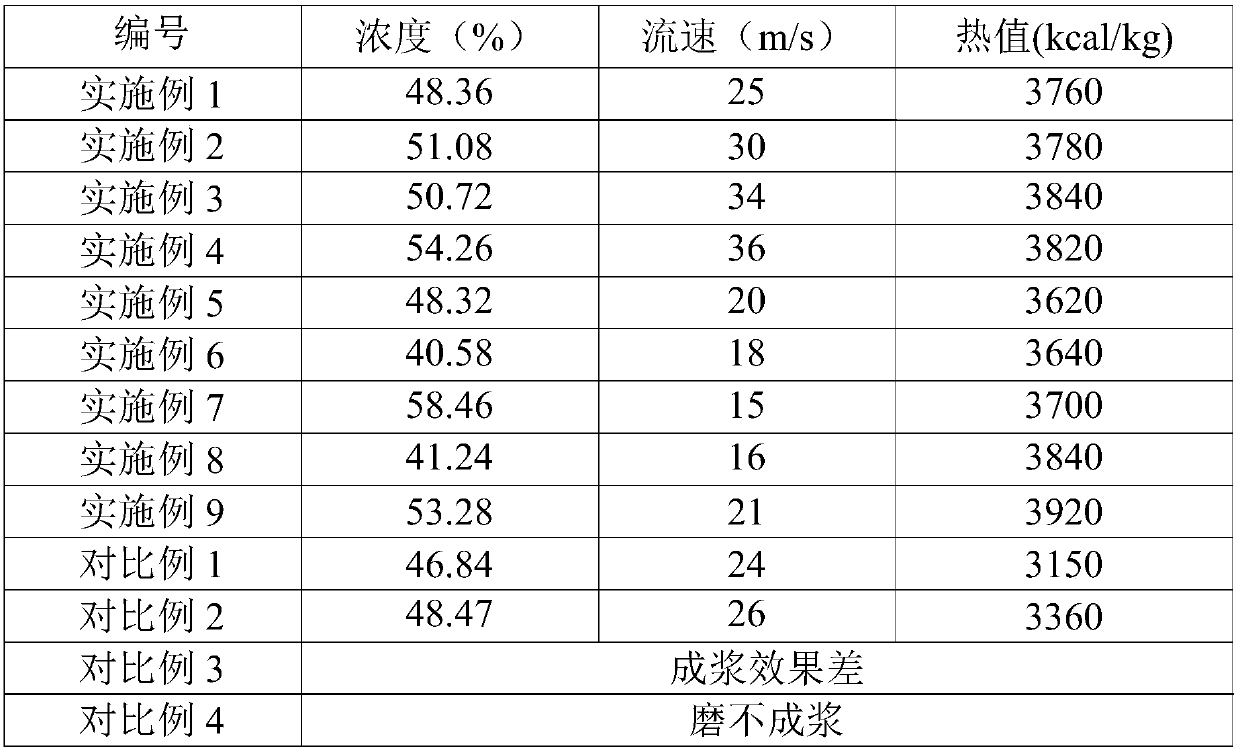

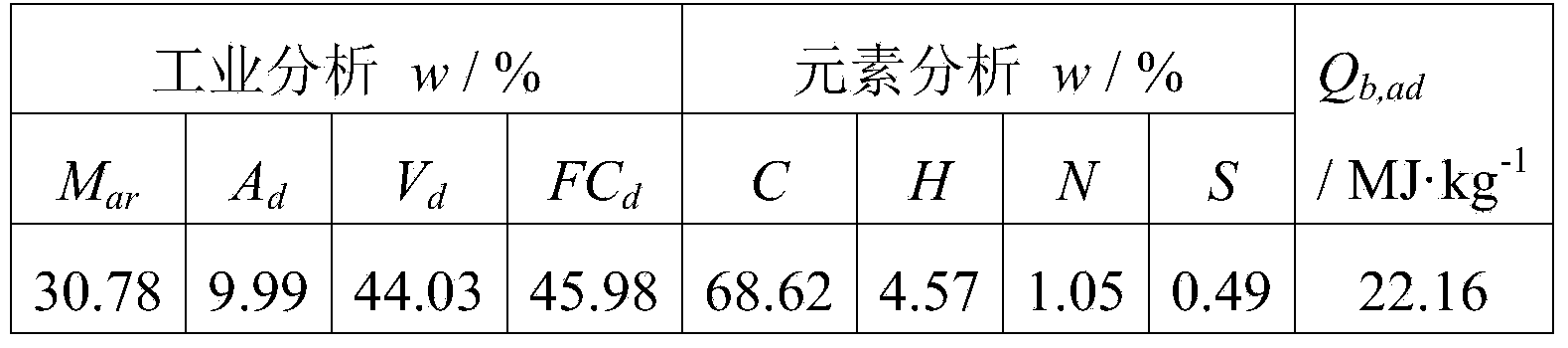

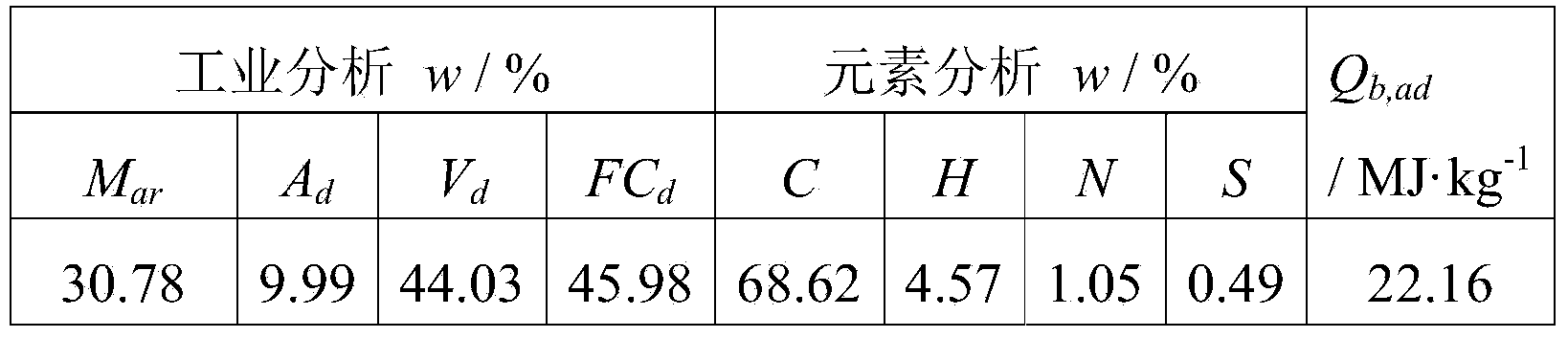

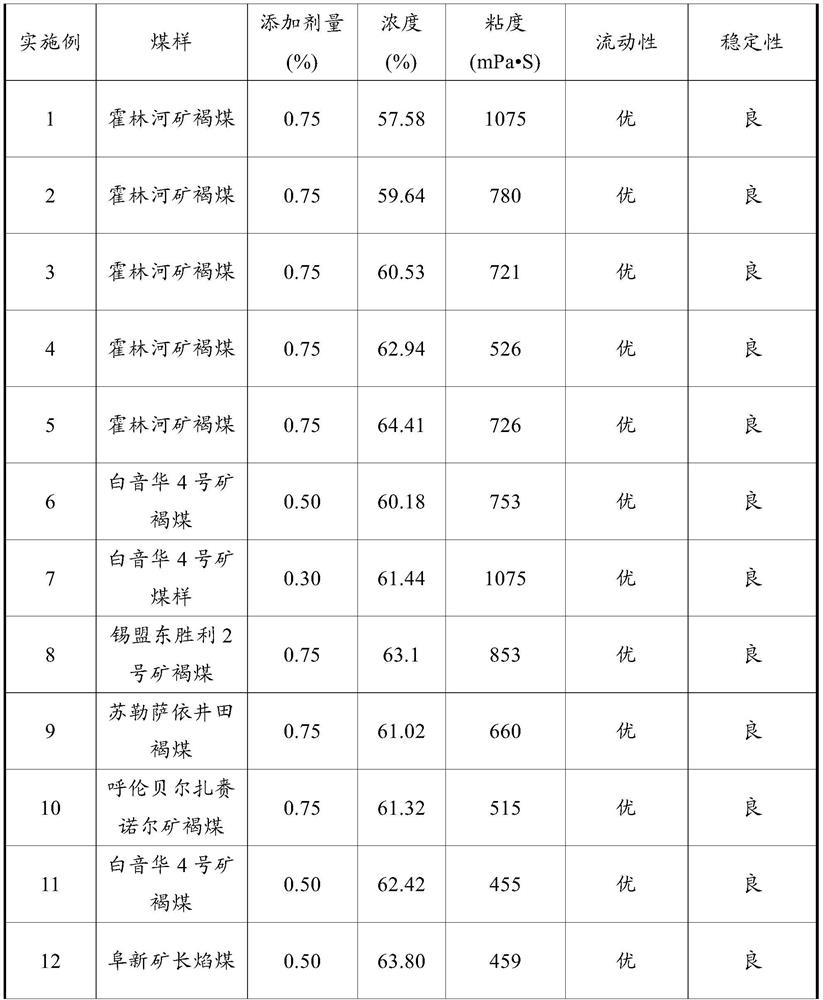

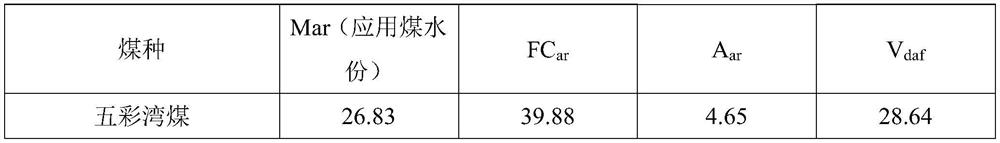

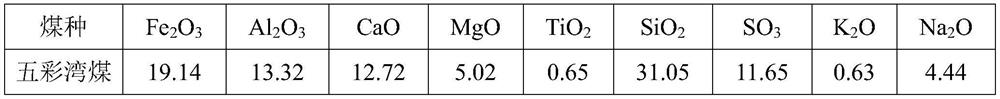

Special composite coal water slurry additive for coal gasification

InactiveCN103509617ALess unit consumptionHigh slurry concentrationLiquid carbonaceous fuelsPowder mixturePhosphate

The invention relates to a special composite coal water slurry additive for coal gasification, which is mixed and prepared from the following components in percentage by weight: 30-75% of lignosulfonate, 10-45% of sulfonate formaldehyde condensate, 5-15% of polyethenoxy ether, 5-25% of phosphate, 0-5% of pH regulator and 0-2% of stabilizer. The components are proportionally prepared into a solid powder mixture or a water solution with arbitrary concentration, and are added into dry-basis coal powder to be uniformly stirred, wherein the additive on dry basis accounts for 0.4-1.0 wt% of the dry-basis coal powder. The finished product coal water slurry prepared from the additive has the advantages of high slurry concentration, low viscosity, favorable rheological property, high stability and wide adaptability to coal types.

Owner:湖南东盈节能环保科技开发有限公司

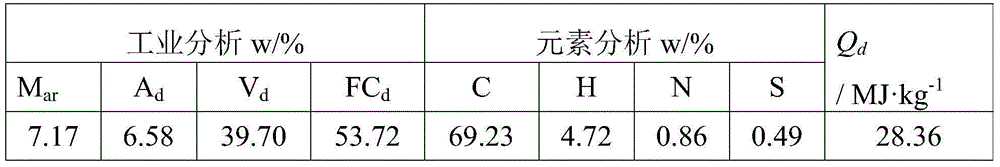

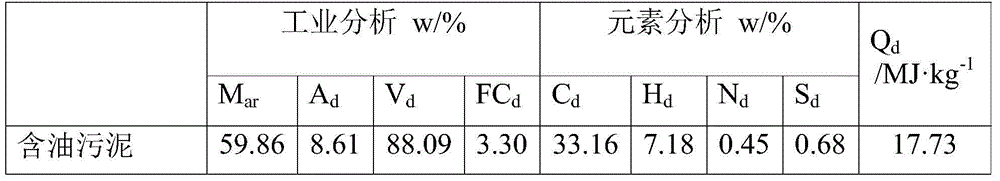

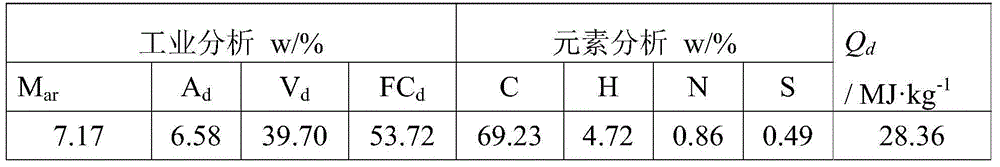

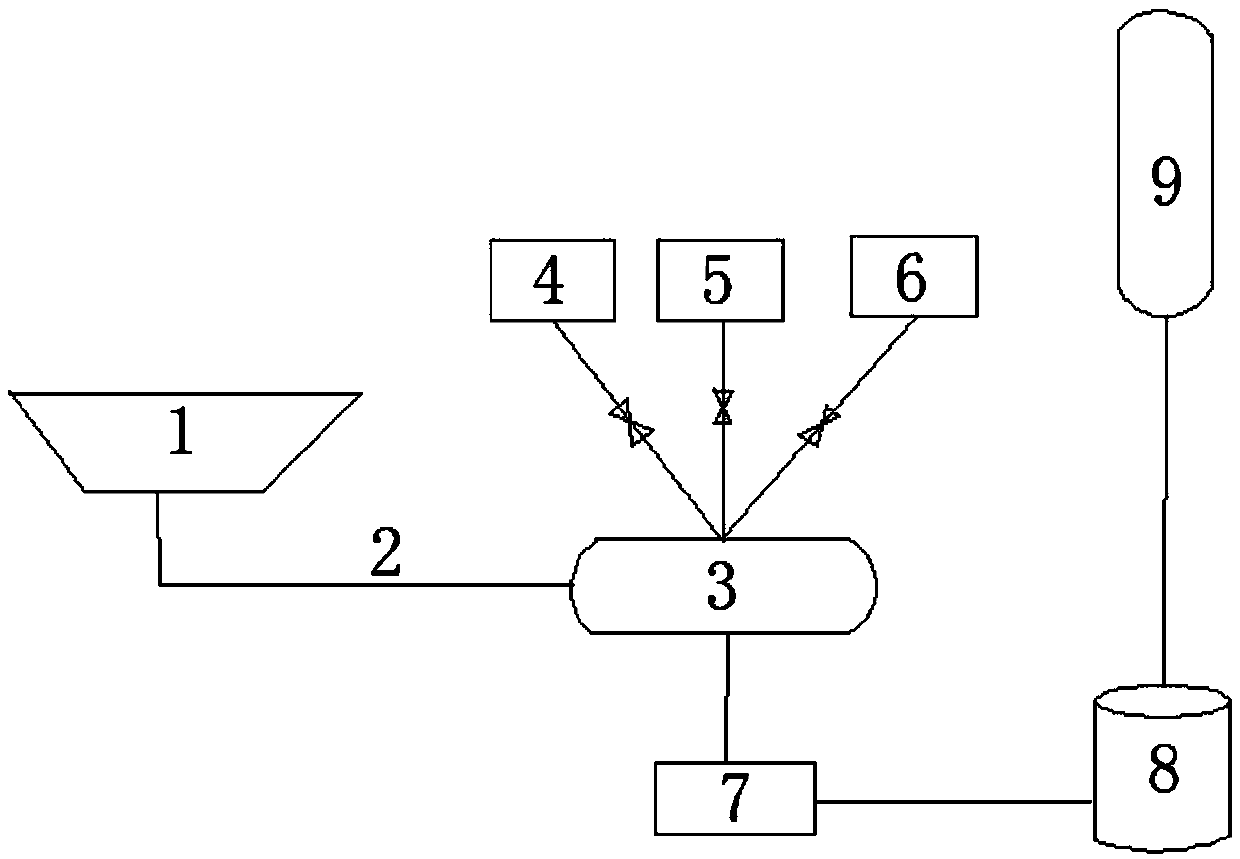

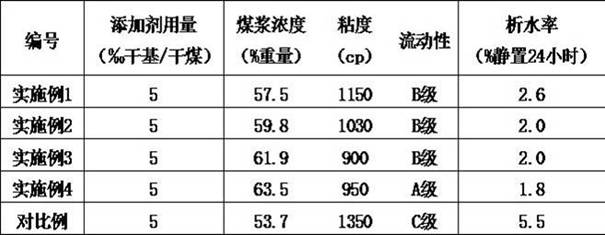

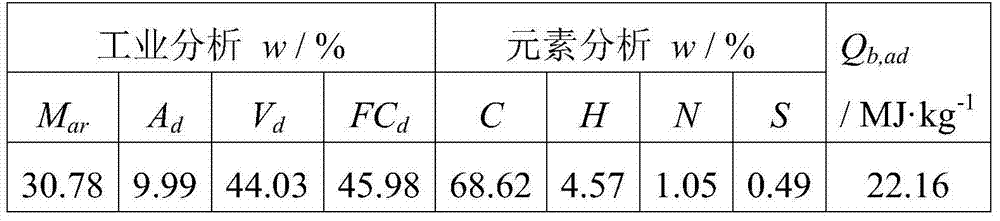

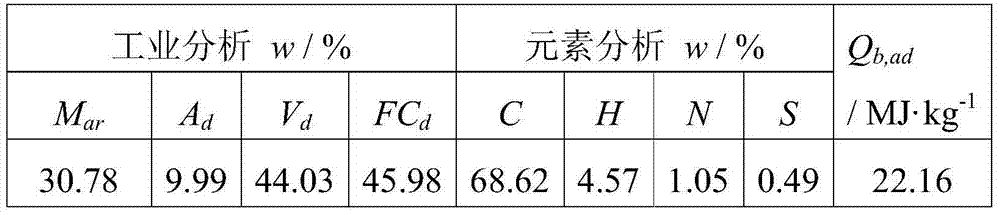

Oil-containing sludge coal slurry and preparation method thereof

ActiveCN103980968AHigh slurry concentrationTake advantage ofLiquid carbonaceous fuelsCombustionSludge

The invention discloses oil-containing sludge coal slurry and a preparation method thereof. The oil-containing sludge coal slurry comprises the following components in percentage by mass: 57-62% of coal powder, 3-14.3% of oil-containing sludge, 0.2-0.7% of a dispersing agent and water, totaling 100%. The method comprises the following steps: uniformly mixing the oil-containing sludge and the coal powder to obtain a mixture A; and uniformly mixing the mixture A, the water and the dispersing agent to obtain the oil-containing sludge coal slurry. The oil-containing sludge coal slurry disclosed by the invention is easily available in raw material, good in fluidity, high in slurry concentration, and quite high in conversion rate when being applied to combustion and gasification.

Owner:EAST CHINA UNIV OF SCI & TECH +1

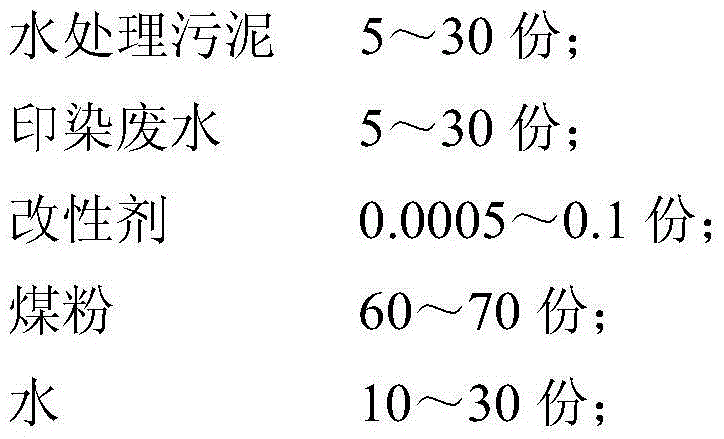

Sludge coal-water slurry and preparation method thereof

The invention discloses sludge coal-water slurry and a preparation method thereof. The sludge coal-water slurry comprises the following components in parts by weight: 5-30 parts of water-treatment sludge, 5-30 parts of printing and dyeing wastewater, 0.0005-0.1 part of modifier, 60-70 parts of coal powder and 10-30 parts of water. The preparation method provided by the invention has the advantages that the slurrying process is simple, and energy and the slurrying cost are saved; the added amount of the water-treatment sludge is high, and the fluidity of the modified sludge is good, so that the sludge is easy to mix with the coal powder uniformly; the slurrying concentration of the sludge coal slurry is higher than 60%, and the fluidity, the stability and the rheological property are relatively good; additives can be saved by more than 40%, water for slurrying can be partially or wholly saved, and a stabilizer can be saved by 100%; and while the heat value of the sludge is fully utilized, an effective technical path is provided for reclamation, reduction and harmlessness of the sludge.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Sludge petroleum charred slurry and preparing process and application thereof

ActiveCN101054541AHigh reactivityImprove utilization efficiencyBiofuelsSolid fuelsHigh concentrationHydrogen

The invention discloses a sludge petroleum coke slurry and its producing method and application. Said sludge petroleum coke slurry contains 100-200 shares of petroleum coke by weight, 5-100 shares of moisture sludge by weight, 5-200 shares of water by weight, 0.01-2 shares of dispersant by weight, 0.01-2 shares of sludge modification reagent by weight. The produced high concentration sludge petroleum coke slurry can be a burning fuel or producing synthetic gas and hydrogen by gasification. It not only fully utilize the caloric caloricity in the sludge and gets over the problems that the present moisture sludge has a high heat treatment energy consumption and the offgas and dregs are harmful and poisonous and has a big industrialization prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Technique for procuring desulfurization type water-solubility instant coal powder

InactiveCN101144042AQuality improvementHigh slurry concentrationLiquid carbonaceous fuelsLump/pulverulent fuel preparationSolubilityFluidized bed

The present invention relates to the liquid coalite slurry dry processing technology, in particular to a desulphurization type dry liquid coalite slurry production process. The process includes the steps that: firstly, rough coal is broken up to below 30 mm through a jaw crusher or a roll crusher, the water content is controlled below 7 percent, and the coal is chosen by a dry coal cleaning way through an air dense medium fluidized bed; secondly, the full or the part of addition agent, desulfurization agent, desulfurization additive is added into the deashing float coal after the dry coal cleaning, and combined through two to eight swing type powder machines or bowl type powder machines, and powder is prepared through a parallel or series combination grade, the qualified powdered coal is collected through the air separation with a pipeline, the partial or full addition agent mixture is added again, namely, the dustless desulfurization type water soluble quick dissolving powdered coal.The appearance of the product can be non-dust emission powdery, or granulated, or massive. The present invention provides a high grade liquid coalite slurry dry formed slurry process which has high quality, desulfurization, and low cost, the liquid coalite slurry is convenient to be transported, when being used, the water content or the other industrial organic waste water is only required to be added into according to the proportion, the slurry is formed through agitating.

Owner:张绍龙

Water coal slurry prepared from hazardous waste coal tar, and preparation method and use method thereof

ActiveCN109536224AReduce usageHigh slurry concentrationLiquid carbonaceous fuelsSelf consumptionCoal tar

The invention discloses water coal slurry prepared from hazardous waste coal tar, and a preparation method and a use method thereof, and relates to the technical field of coal tar reutilization. The water coal slurry is prepared from the following ingredients in parts by weight: 13 to 20 parts of coal powder, 5 to 12 parts of coal tar, 0.2 to 0.8 parts of dispergators, 0.2 to 0.4 part of additivesand 15 to 20 parts of water. The water coal slurry is prepared from the coal tar and coal powder, so that the coal tar can be reasonably treated and used; the self consumption of the coal powder perse is reduced. Through the matched use of a certain amount of coal tar and the coal powder and through the addition of dispergators and additives, the water coal slurry with high slurry concentrationand low viscosity can be prepared; meanwhile, a great amount of solid state carbon and organic ingredients in coal tar can be utilized; the calorific value of the water coal slurry can be well improved, so that the coal tar is changed from waste materials into valuable materials; the popularization and application prospects are wide.

Owner:广东汇昇环保科技有限公司

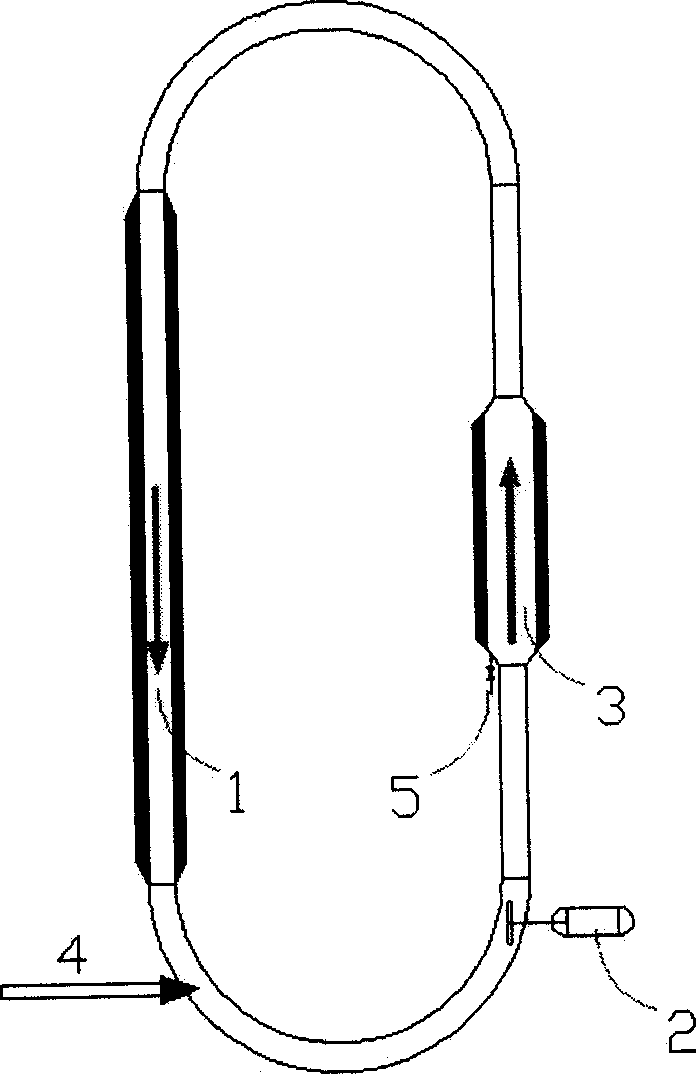

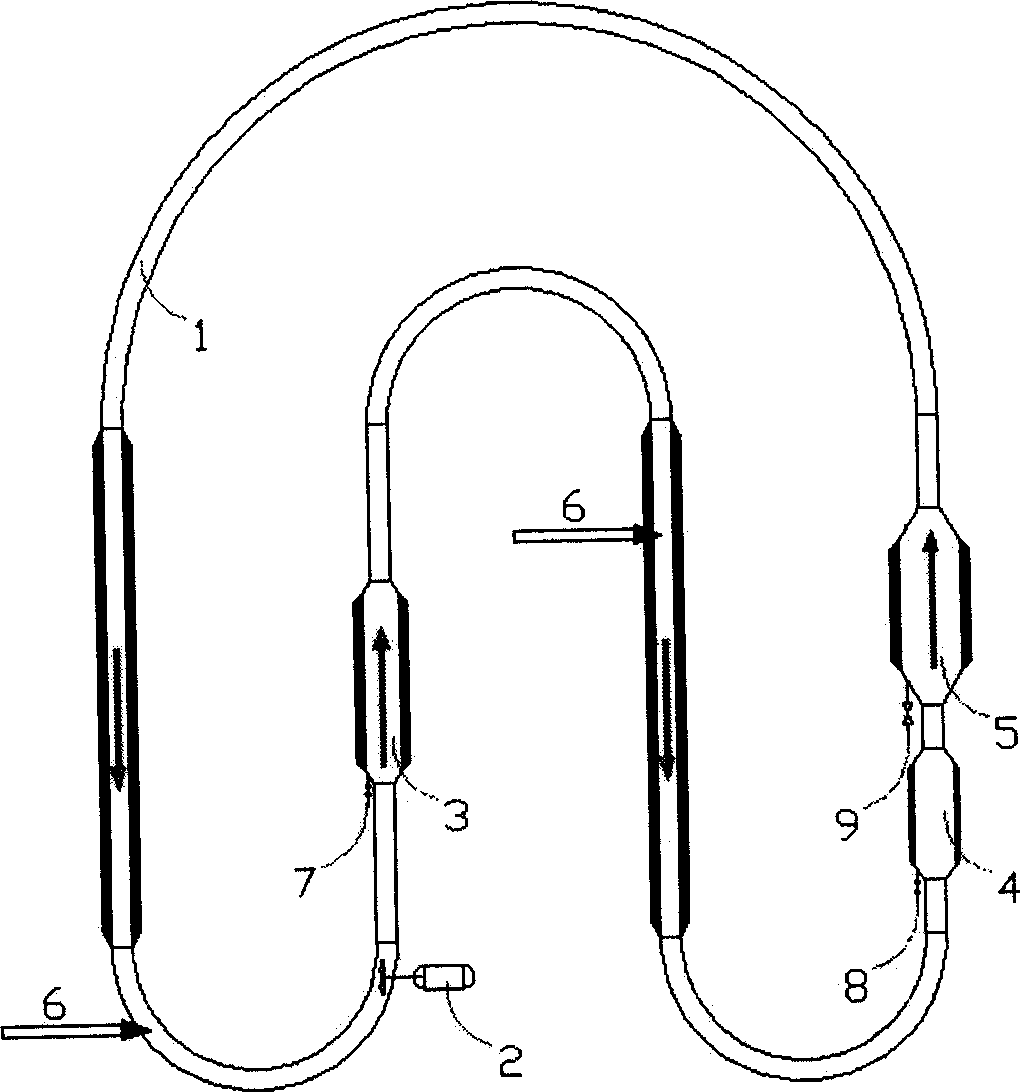

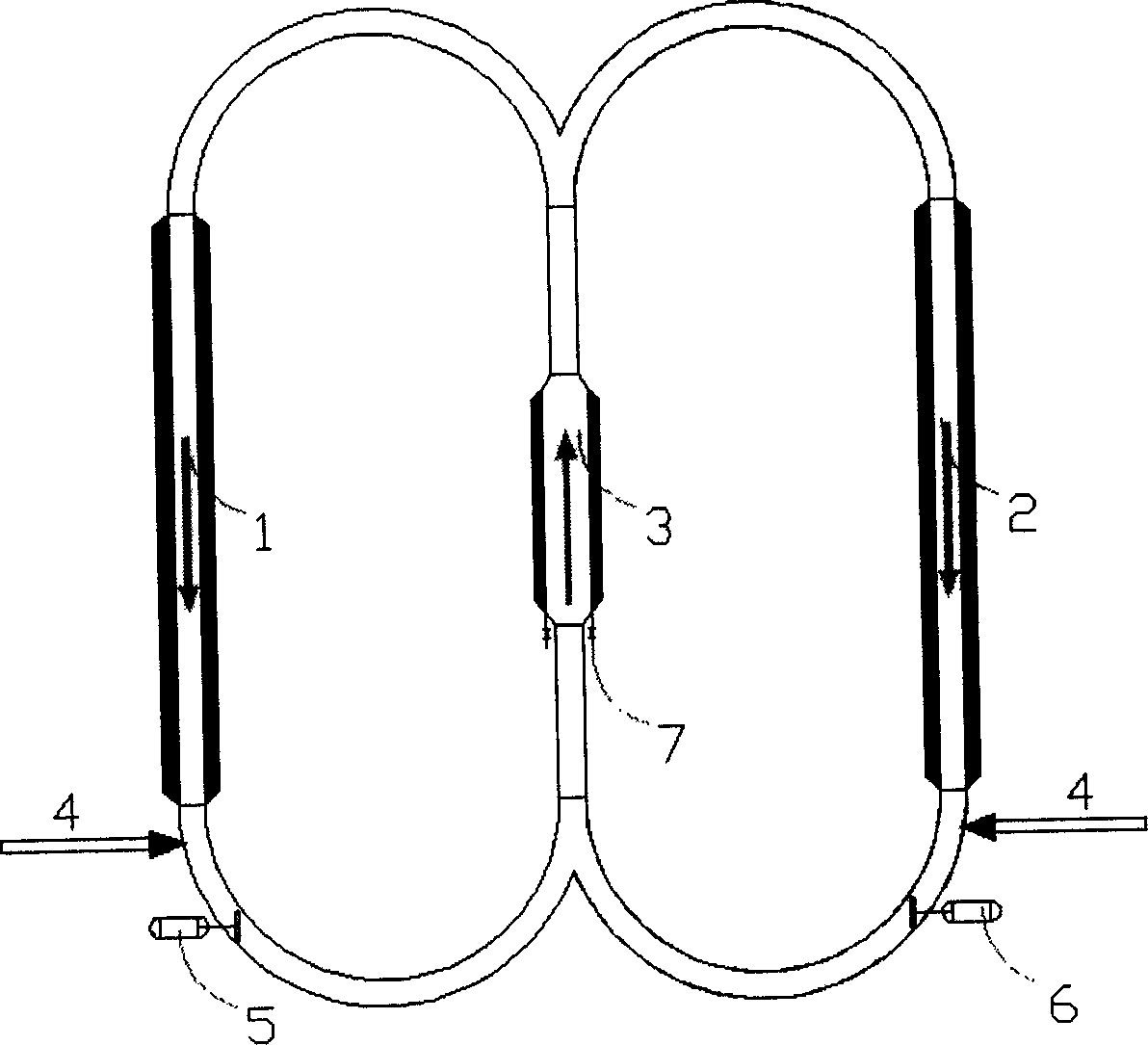

Olefin polymerizing reactor

An olefine polymerization reactor consists of circular reaction pipeline, axial flow pump or centrifugal pump, feeder unit, discharger, heat exchanger, at least one enlarging section with discharger is arranged at ascending straight pipe, the internal diameter of enlarging section is at least as 2 times as that of enlarging section. It has higher circulation sizing concentration, more space-time recovery rate, less consumption, single granular diameter distribution and better quality. It can be used for polyvinyl and polypropylene production.

Owner:CHINA PETROLEUM & CHEM CORP +1

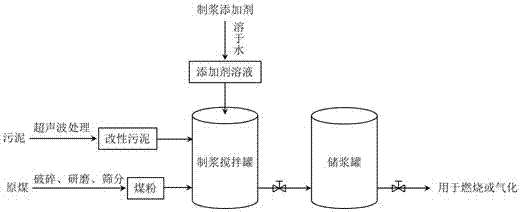

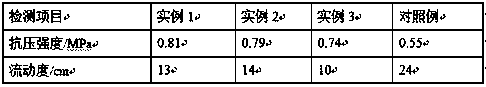

Method for improving slurry-forming ability of sludge and coal-water slurry by cracking sludge flocculation through ultrasonic waves

InactiveCN107164003ASmall granularityReduce slurry viscositySludge treatmentLiquid carbonaceous fuelsCoal waterFlocculation

The invention discloses a method for improving slurry-forming ability of sludge and coal-water slurry by cracking sludge flocculation through ultrasonic waves. The ultrasonic waves are used for modifying sludge, microbial cell walls in a sludge floc structure and the sludge are broken by high-temperature high-pressure environments and shearing action generated by ultrasonic cavitation action, sludge particle granularity is reduced, part of interstitial water is released, the modified sludge is mixed with coal, slurry-forming additives, water and the like to prepare the sludge and coal-water slurry, or finished coal-water slurry is doped into the modified sludge and uniformly stirred to prepare the sludge and coal-water slurry. Compared with the prior art, the method has the advantages that the slurry-forming viscosity of the sludge and coal-water slurry can be obviously reduced, slurry-forming concentration is increased, the sludge and coal-water slurry with excellent slurry-forming ability is obtained, treatment time is short, operation is convenient, and the method is applicable to large-scale popularization and application.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

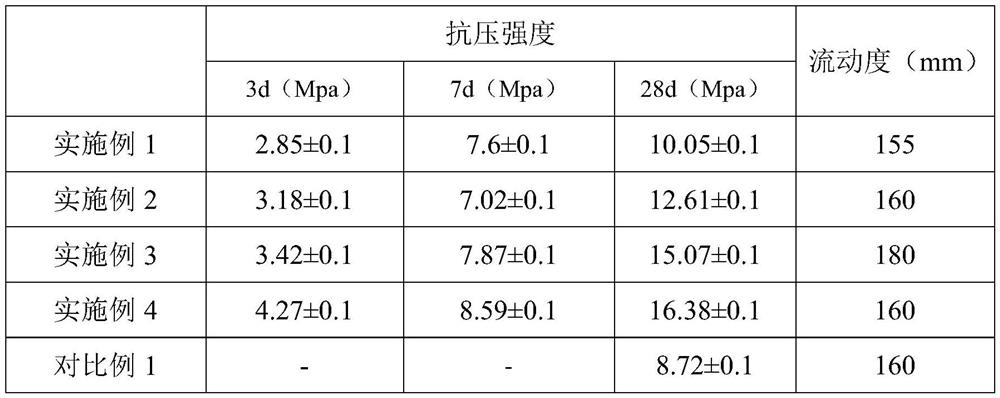

Preparation method of tailings paste filling material

The invention relates to a preparation method of a tailings paste filling material and belongs to the technical field of filling materials. The tailings paste filling material is prepared by adding limestone powder; the limestone powder which has good filling effect enables the paste structure to be compacted, so that pore size distribution is improved, and compressive strength of concrete is improved; the limestone power features low water adsorption; compared with fly ash, mineral residue and other active mineral mixtures, the limestone powder can evidently improve pumpability of concrete under same mixing amount. The mineral residue powder is added to prepare the tailings paste filling material; the mineral residue powder is an industrial byproduct made by treating a melt formed at 1350-1450 DEG C during mineral extraction, and is a high-quality concrete admixture; the mineral residue powder has high potential activity, helps improve late strength of a mix, has high activity, and can partly replace cement, reduce hydration heat, inhibit alkali-aggregate reaction and improve durability of concrete.

Owner:雷江容

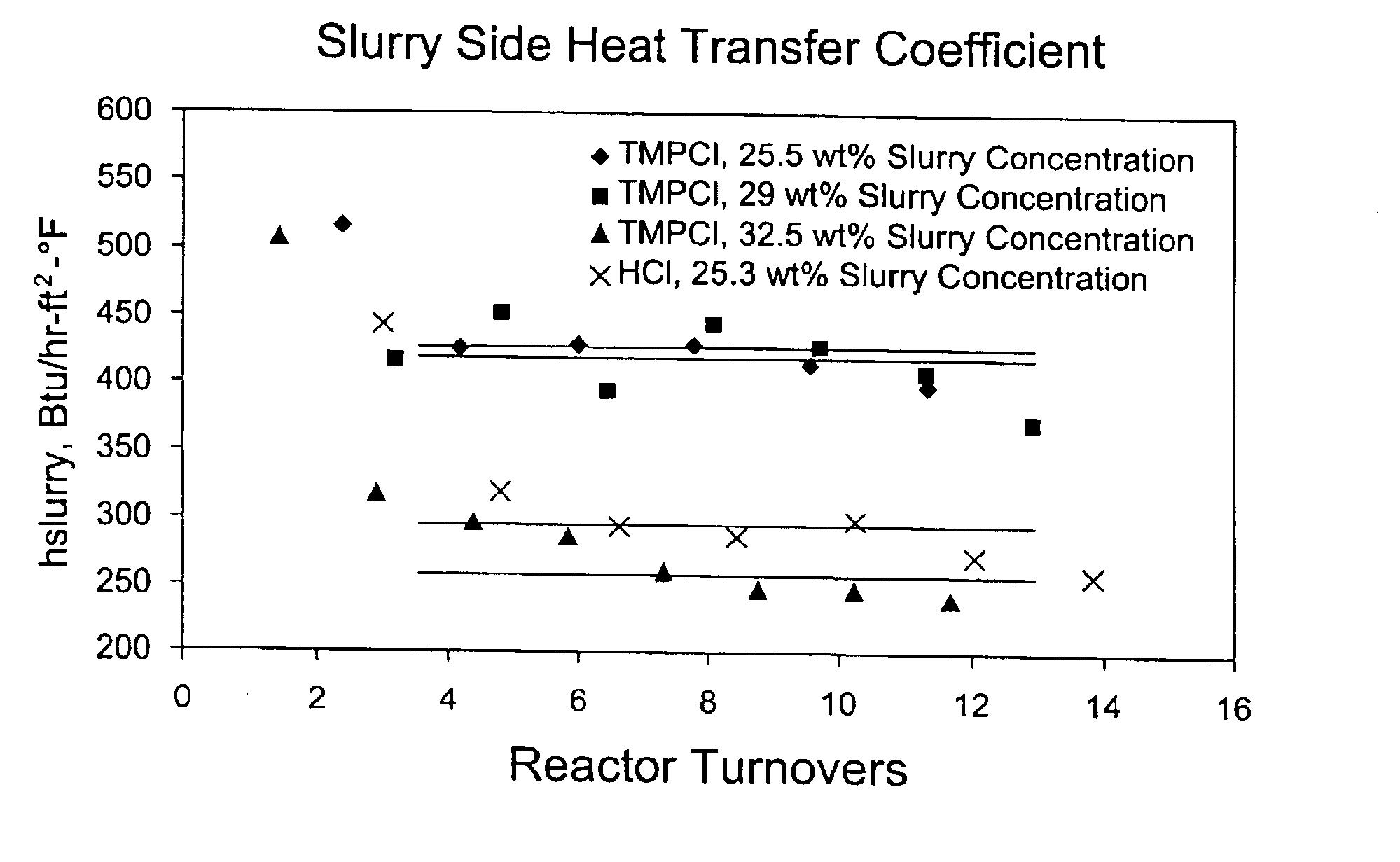

Process for polymerizing cationically polymerizable monomers

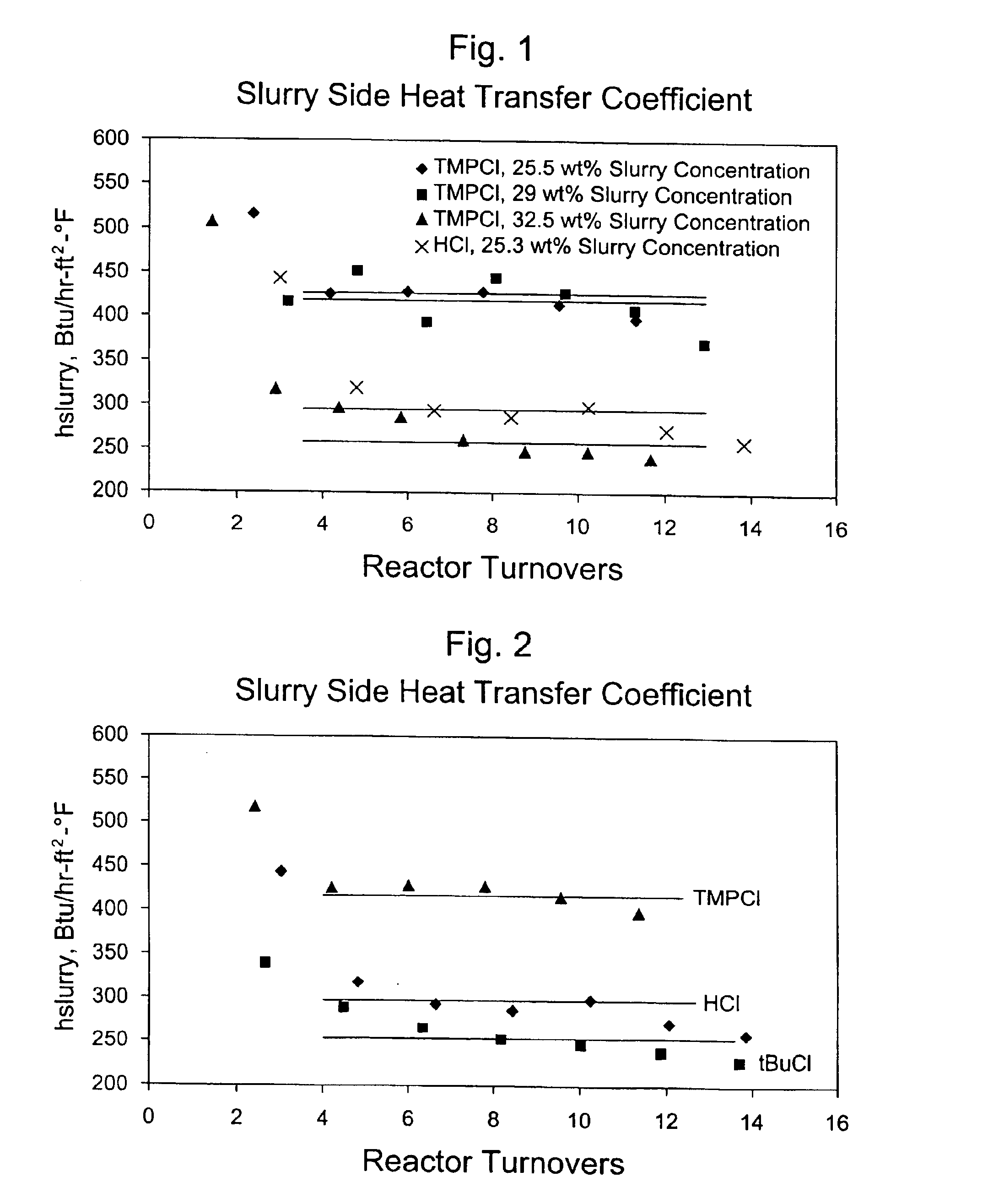

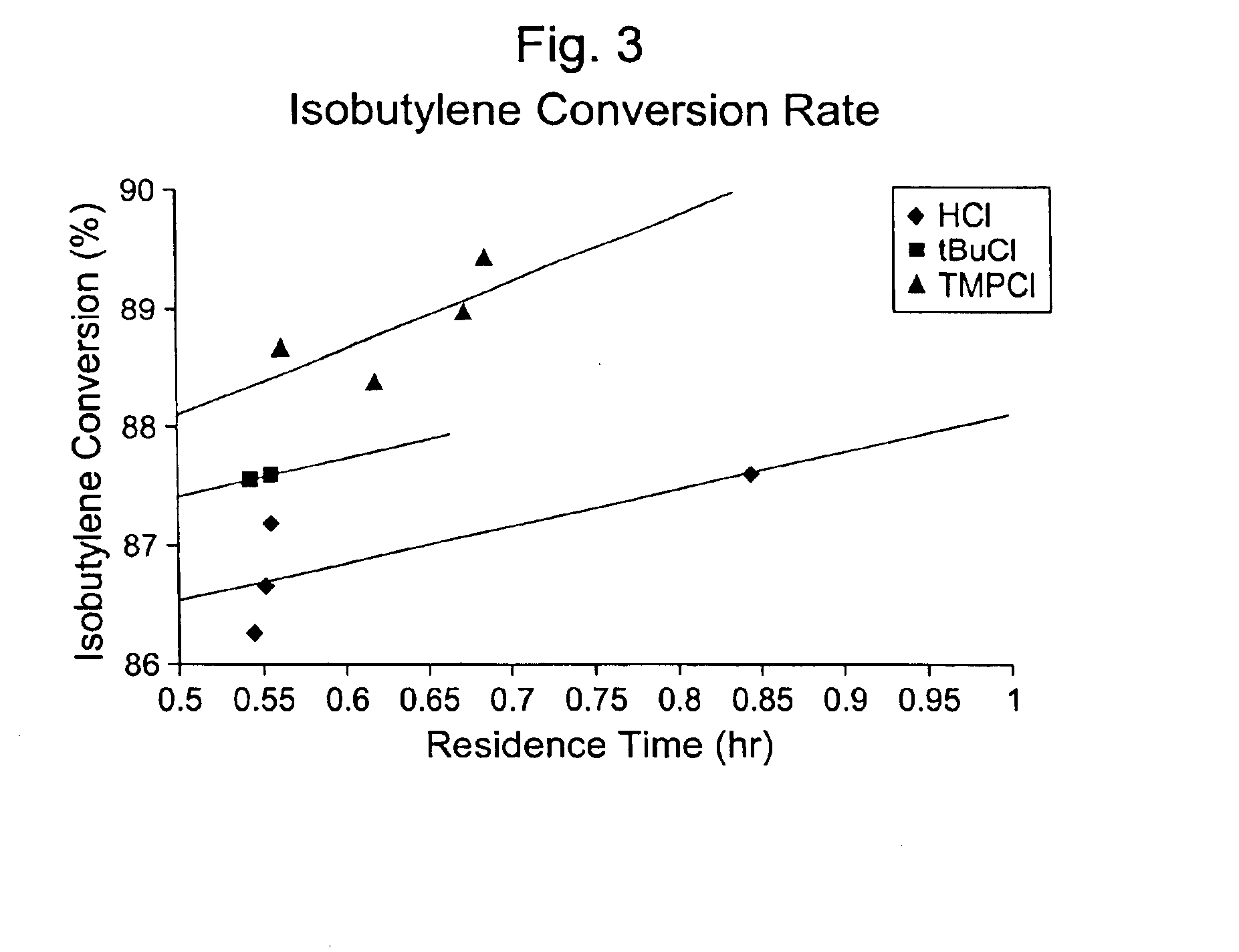

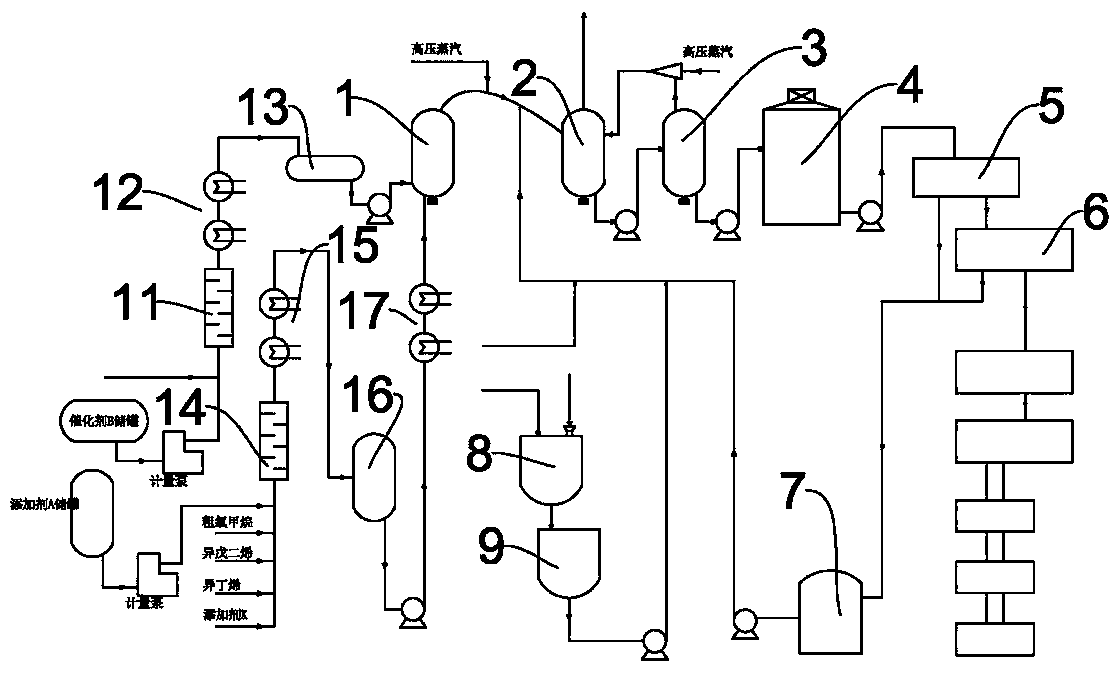

InactiveUS6939933B2Improve heat transfer performanceDecrease in heat transfer coefficientProcess systemsDiluent

The invention relates to a new catalyst system that improves the heat transfer capability of a butyl reactor slurry process system in the production of random copolymers of one or more isoolefin monomers and one or more conjugated diene monomers in continuous slurry polymerization processes. The process is carried out in an anhydrous polymerization system containing a mixture of the monomers in a polar diluent along with a Lewis acid and a C5 or greater initiator having a tertiary halide.

Owner:EXXONMOBIL CHEM PAT INC

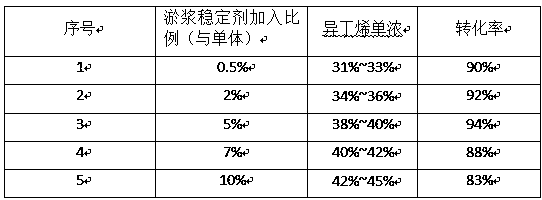

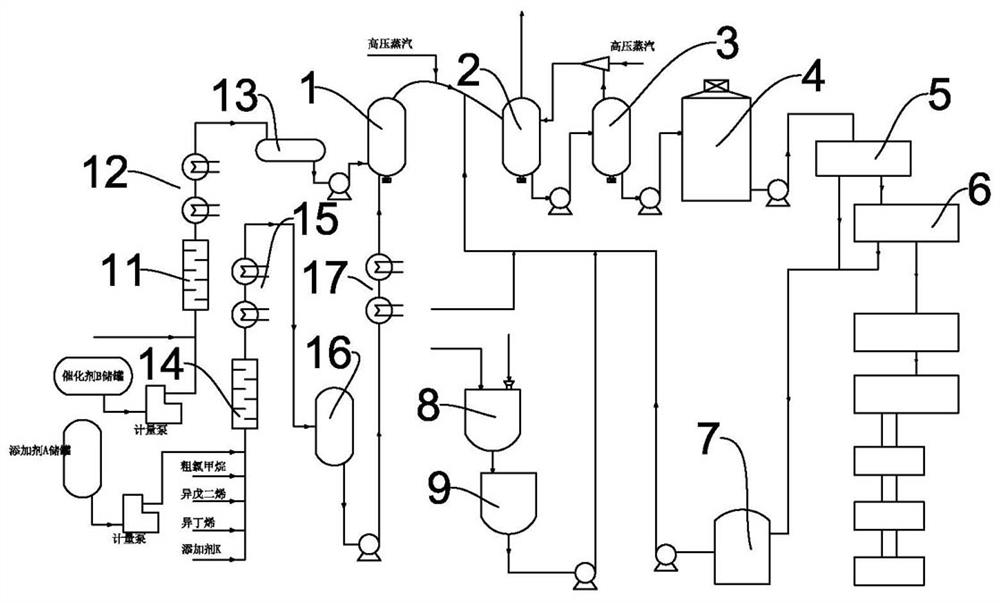

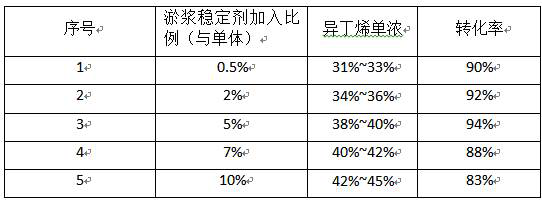

Butyl rubber production method and device

ActiveCN111234077AHigh slurry concentrationIncrease productivityProcess control/regulationIsopreneIsobutylene

The invention relates to a high-single-concentration and high-conversion-rate production method of butyl rubber, and belongs to the technical field of rubber production. The method comprises the following steps: a, feeding a catalyst and a solvent into a polymerization reaction kettle from a first passage; b, feeding an isoprene monomer, an isobutene monomer and a slurry stabilizer into the polymerization reaction kettle from asecond passage; c, polymerizing in the polymerization reaction kettle to generate a butyl rubber suspension; d, enabling the butyl rubber suspension to flow into a degassing kettle from the polymerization reaction kettle, and introducing steam and hot water into the butyl rubber suspension at the same time; e, carrying out degassing kettle treatment; f, carrying outsteam stripping kettle treatment; and g, carrying out vibration dehydration screen treatment, and carrying out subsequent treatment to obtain butyl rubber. A polymerization stabilizer and a matched process are adopted, so that chloromethane slurry containing butyl rubber particles is generated in the production process, and the content of the butyl rubber particles in the slurry reaches 40 wt% orabove; the content obviously exceeds 30wt% in the prior art; therefore, the method provided by the invention has the characteristics of high slurry concentration and stability.

Owner:ZHEJIANG CENWAY MATERIALS CO LTD

Coal water slurry dispersant and its preparation method and use

ActiveCN105018160AHigh slurry concentrationReduce manufacturing costLiquid carbonaceous fuelsCoal waterLiquid glucose

The invention provides a coal water slurry dispersant and its preparation method and use. The coal water slurry dispersant is prepared by mixing reaction of aldehyde and lignosulfonate prepared from liquid glucose, wherein in the reaction, reaction pH is controlled in a range of 9-11 and the aldehyde comprises one or more of formaldehyde, acetaldehyde and propionaldehyde. The coal water slurry dispersant is used in coal water slurry so that the coal water slurry has high slurry concentration, has a small use amount, a low preparation cost and a wide raw material sources, and is conducive to industrial production.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Coal slurry and preparation method thereof

ActiveCN103642550AHigh slurry concentrationHigh solid contentLiquid carbonaceous fuelsSolventChemistry

The invention discloses coal slurry and a preparation method thereof. The coal slurry comprises the following components: 100-300 parts by weight of coal, 50-200 parts by weight of water, 0.01-3 parts by weight of dispersant and 0.01-3 parts by weight of nonpolar solvent, wherein the mass ratio of the nonpolar solvent to the coal is less than or equal to 1%. The preparation method comprises the following steps: evenly mixing the nonpolar solvent with the coal to obtain a material A; and then evenly mixing the material A with water and the dispersant to obtain the coal slurry. The coal slurry prepared by the preparation method disclosed by the invention is high in slurrying concentration, high in solid content and low in viscosity; the coal slurry can be burnt or gasified as a fuel; the coal slurry is advantageous for pumping, storage and transportation, and easy to atomize, burn and gasify.

Owner:EAST CHINA UNIV OF SCI & TECH +1

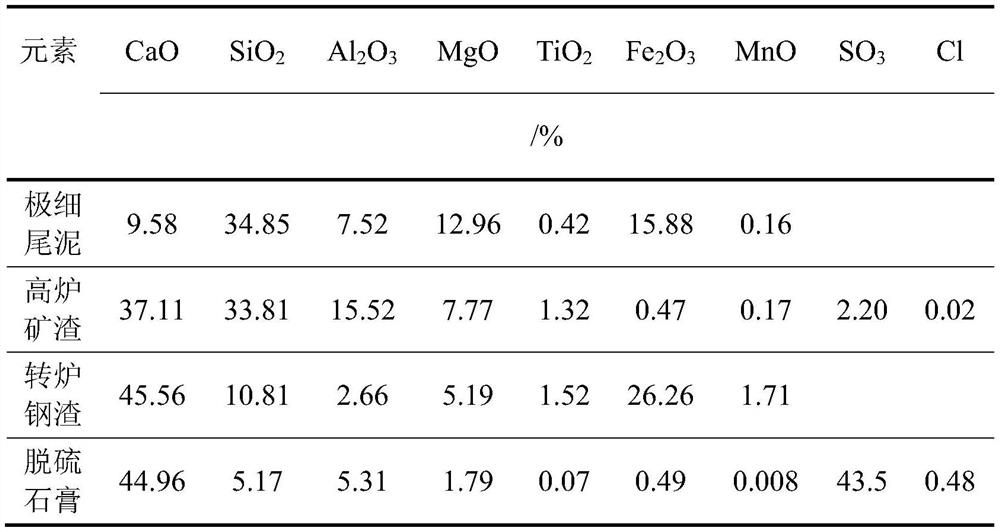

Paste filling material containing ultrafine tail mud as well as preparation method and application thereof

The invention relates to a paste filling material containing ultrafine tail mud as well as a preparation method and application of the paste filling material. The filling material is prepared from the following raw materials: a cementing material, aggregate and water, wherein the cementing material comprises the following components in parts by weight: 40-80 parts of converter steel slag, 5-30 parts of desulfurized gypsum and 0-20 parts of desulfurized ash; the aggregate comprises superfine tail mud; the mass ratio of the cementing material to the aggregate is 1: 4-6; the slurry concentration is 55-70%. According to the filling material, a large amount of superfine tail mud is utilized, good compressive strength (larger than or equal to 10 MPa) capable of being industrially applied is achieved without adding a water reducing agent, it is guaranteed that the filling material has good practical value, and the problem that the roof contact rate of a stope is not high is solved. The method is beneficial to solving the problems of reduction, harmlessness and recycling of industrial solid waste, solving the problem of tailing stockpiling, and promoting cooperative utilization of solid waste and hazardous waste and environmental protection; meanwhile, cyclic utilization of water resources is achieved through pre-plant return water, and therefore waste of the water resources is reduced.

Owner:上海宝钢新型建材科技有限公司 +3

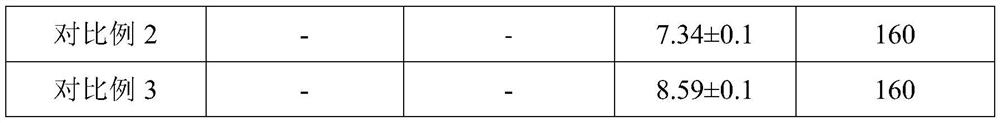

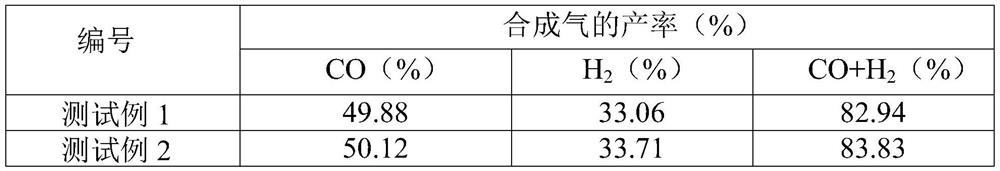

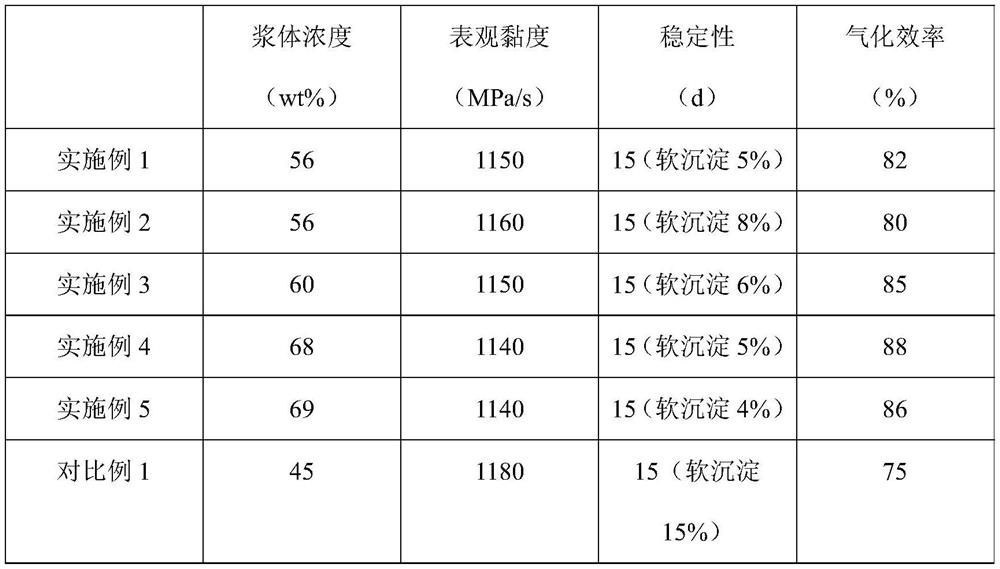

Coal water slurry, preparation method thereof and preparation method of synthesis gas

ActiveCN112852513AUniform particle size distributionHigh slurry concentrationLiquid carbonaceous fuelsBulk chemical productionCoal waterSyngas

The invention relates to the technical field of coal water slurry, and discloses coal water slurry and a preparation method thereof and a preparation method of synthesis gas, and the method comprises the following steps: adjusting the pH value of MTP process wastewater to be greater than 8, and then mixing the MTP process wastewater with a chemical additive and water to obtain slurry; and mixing the slurry with coal and the waste MTP catalyst, and grinding the mixture to obtain the coal water slurry. According to the invention, the coal water slurry prepared by taking the MTP process wastewater, the chemical additive, the water, the coal and the waste MTP catalyst as raw materials has the characteristics of uniform particle size distribution, high slurry concentration, small apparent viscosity and good fluidity; when the coal water slurry is used for preparing the synthesis gas, the utilization rate of the coal water slurry and the yield of the synthesis gas can be effectively improved.

Owner:CHINA ENERGY GRP NINGXIA COAL IND CO LTD

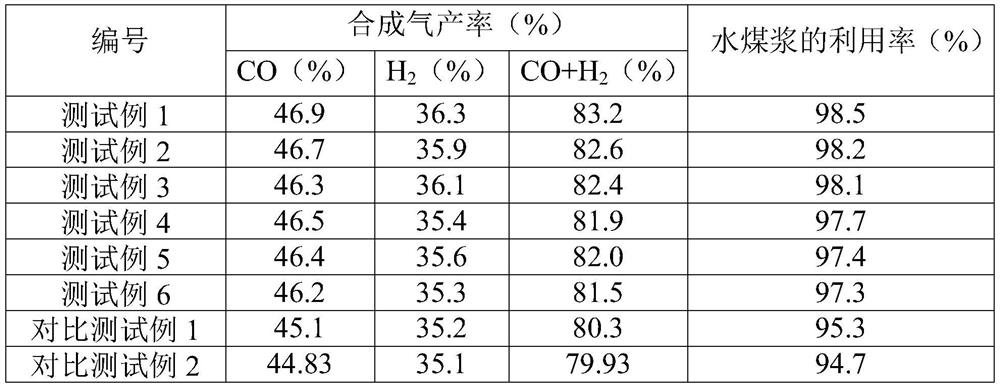

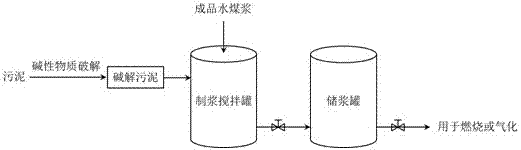

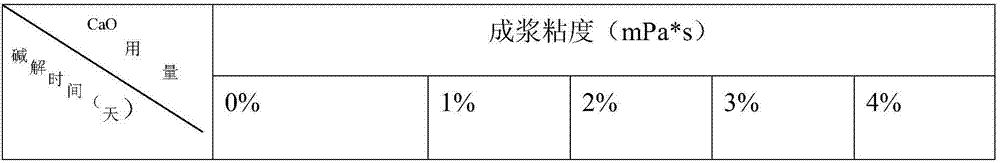

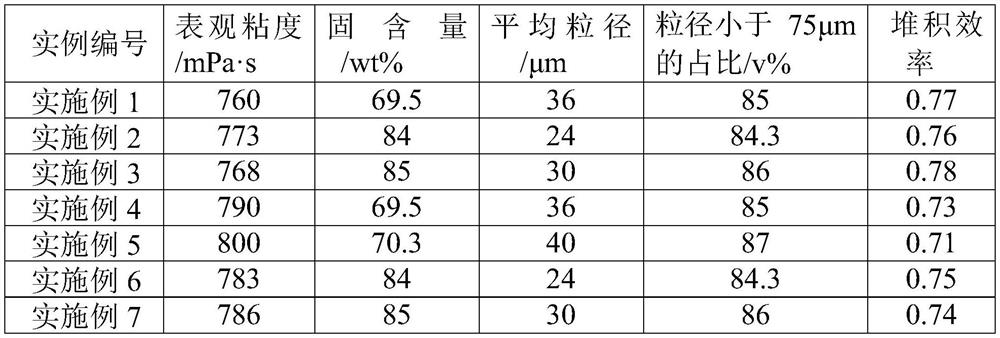

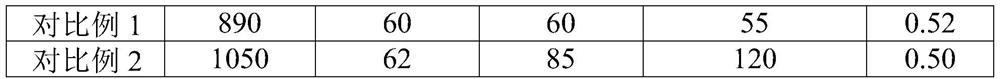

Method for using sludge floccules decomposed by alkaline substances to promote slurry forming of sludge and coal-water slurry

InactiveCN107164004ALow costEasy to operateSludge treatmentLiquid carbonaceous fuelsCoal waterSludge

The invention discloses a method for using sludge floccules decomposed by alkaline substances to promote slurry forming of sludge and coal-water slurry. The method comprises the following steps: (1) firstly, adding the alkaline substances to sludge, and fully stirring for a certain time to obtain alkali-decomposed sludge; (2) crushing, grinding and sieving raw coal sequentially to obtain pulverized coal having a particle size of smaller than 150 microns; and (3) fully dissolving a slurry preparing additive in water to obtain an additive solution, adding the alkali-decomposed sludge in the step (1) and the pulverized coal in the step (2) to the additive solution, and fully stirring by a slurry preparing and stirring device to obtain uniform sludge and coal-water slurry; or, directly doping the alkali-decomposed sludge in the step (1) into a finished product of coal-water slurry, and fully stirring to obtain the uniform sludge and coal-water slurry. Compared with the prior art, the method provided by the invention has advantages of low cost and convenient operation, and can effectively reduce slurry forming viscosity of the sludge and coal-water slurry, improve a slurry forming concentration, acquire the sludge and coal-water slurry with excellent slurry forming performance, and being suitable for large-scale promotion and application.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Coal water slurry, preparation method thereof and preparation method of synthesis gas

ActiveCN112812866AUniform particle size distributionHigh slurry concentrationLiquid carbonaceous fuelsCoal waterSyngas

The invention relates to the field of coal water slurry, and discloses a coal water slurry, a preparation method thereof and a preparation method of synthesis gas, the method comprises the following steps of: (1) mixing coal, water, an additive and wax residue to obtain a slurry, then grinding and screening the slurry to obtain primary slurry, and dividing the primary slurry into a coal water slurry A, a coal water slurry B and a coal water slurry C; (2) performing primary grinding on the coal water slurry A to obtain a slurry A, and performing secondary grinding on the coal water slurry B to obtain a slurry B; and mixing the slurry A and the slurry B with the coal water slurry C obtained in the step (1) to obtain the final coal water slurry. The coal water slurry provided by the invention has the characteristics of uniform particle size distribution, high slurry concentration, small apparent viscosity, high stacking efficiency, good fluidity and good stability; when the coal water slurry is used for preparing the synthesis gas, the yield of the synthesis gas and hydrogen can be higher.

Owner:CHINA ENERGY GRP NINGXIA COAL IND CO LTD

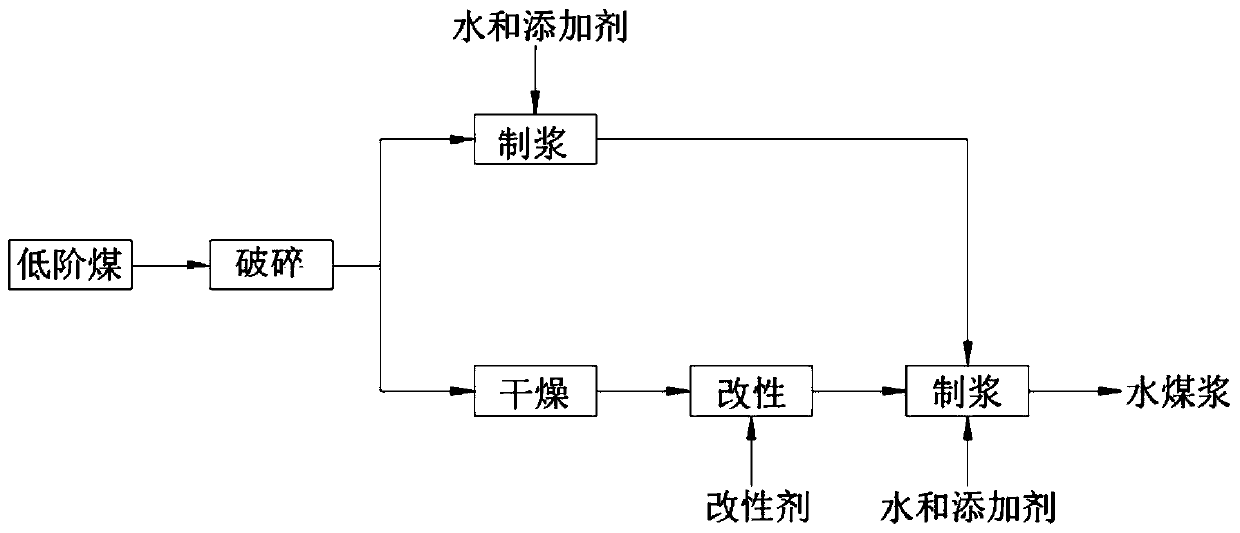

Method for preparing coal water slurry by modifying low-rank coal

InactiveCN110699132AReduce porosityHigh slurry concentrationLiquid carbonaceous fuelsCoal waterProcess engineering

The invention provides a method for preparing coal water slurry by modifying low-rank coal. The method comprises a step of mixing and pulping low-rank coal slurry and modified low-rank coal to obtainthe coal water slurry. The method specifically comprises the following steps: (1) crushing the low-rank coal, dividing the crushed low-rank coal into a first raw material and a second raw material, performing wet pulping on the first raw material to obtain the low-rank coal slurry, and sequentially drying and modifying the second raw material to obtain the modified low-rank coal; and (II) performing wet pulping on the low-rank coal slurry and the modified low-rank coal to obtain the coal water slurry. Through physical and chemical modification modes, the content of oxygen-containing functionalgroups on the surface of the low-rank coal is reduced, reabsorption of the low-rank coal is inhibited, and the porosity of the low-rank coal is reduced, so the highest slurry concentration of the low-rank coal is improved.

Owner:CCTEG CLEAN ENERGY CO LTD

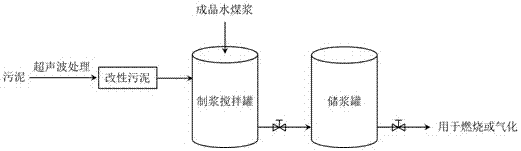

Sludge coal-water slurry and preparation method thereof

The invention discloses sludge coal-water slurry and a preparation method thereof. The sludge coal-water slurry comprises the following components in parts by weight: 5-30 parts of water-treatment sludge, 5-30 parts of printing and dyeing wastewater, 0.0005-0.1 part of modifier, 60-70 parts of coal powder and 10-30 parts of water. The preparation method provided by the invention has the advantages that the slurrying process is simple, and energy and the slurrying cost are saved; the added amount of the water-treatment sludge is high, and the fluidity of the modified sludge is good, so that the sludge is easy to mix with the coal powder uniformly; the slurrying concentration of the sludge coal slurry is higher than 60%, and the fluidity, the stability and the rheological property are relatively good; additives can be saved by more than 40%, water for slurrying can be partially or wholly saved, and a stabilizer can be saved by 100%; and while the heat value of the sludge is fully utilized, an effective technical path is provided for reclamation, reduction and harmlessness of the sludge.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Sludge petroleum charred slurry and preparing process and application thereof

ActiveCN101054541BHigh reactivityImprove utilization efficiencyBiofuelsSolid fuelsHigh concentrationHydrogen

The invention discloses a sludge petroleum coke slurry and its producing method and application. Said sludge petroleum coke slurry contains 100-200 shares of petroleum coke by weight, 5-100 shares of moisture sludge by weight, 5-200 shares of water by weight, 0.01-2 shares of dispersant by weight, 0.01-2 shares of sludge modification reagent by weight. The produced high concentration sludge petroleum coke slurry can be a burning fuel or producing synthetic gas and hydrogen by gasification. It not only fully utilize the caloric caloricity in the sludge and gets over the problems that the present moisture sludge has a high heat treatment energy consumption and the offgas and dregs are harmful and poisonous and has a big industrialization prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Treatment method of methanol rectification wastewater in coal chemical industry

InactiveCN105482860ALow costRealize resource utilizationWaste based fuelGasification processes detailsActivated sludgeAlcohol

The invention relates to the field of sewage treatment, in particular to a treatment method of methanol rectification wastewater in the coal chemical industry. The treatment method comprises steps as follows: coal is primarily broken, coal with the particle size of 150-50 meshes is crude coal powder, and coal with the particle size smaller than 50 meshes is fine coal powder; 59-63 parts of the coal powder, 31-37.5 parts of slurrying water, 5-9 parts of activated sludge and 0.4-0.8 parts of a dispersing agent are weighed in parts by weight, and the mass ratio of the crude coal powder to the fine coal powder is 3:7; the slurrying water, the activated sludge and the dispersing agent are stirred and uniformly mixed, and the molecular structure of the dispersing agent is sufficiently spread; the coal powder is gradually poured into the mixture obtained in the step 2, the stirring rotation speed is increased, and after all the coal powder is added, the mixture continues to be stirred for 20-25 min, and methanol rectification wastewater, sludge and coal slurry is obtained. Organic matters, such as alcohols, a little oil and the like, in the methanol rectification wastewater can generate heat in the gasification process, the organic matters in the wastewater can be sufficiently used, resource utilization of the methanol rectification wastewater is realized, and the treatment problem of the methanol rectification wastewater is fundamentally solved.

Owner:中国寰球工程有限公司辽宁分公司

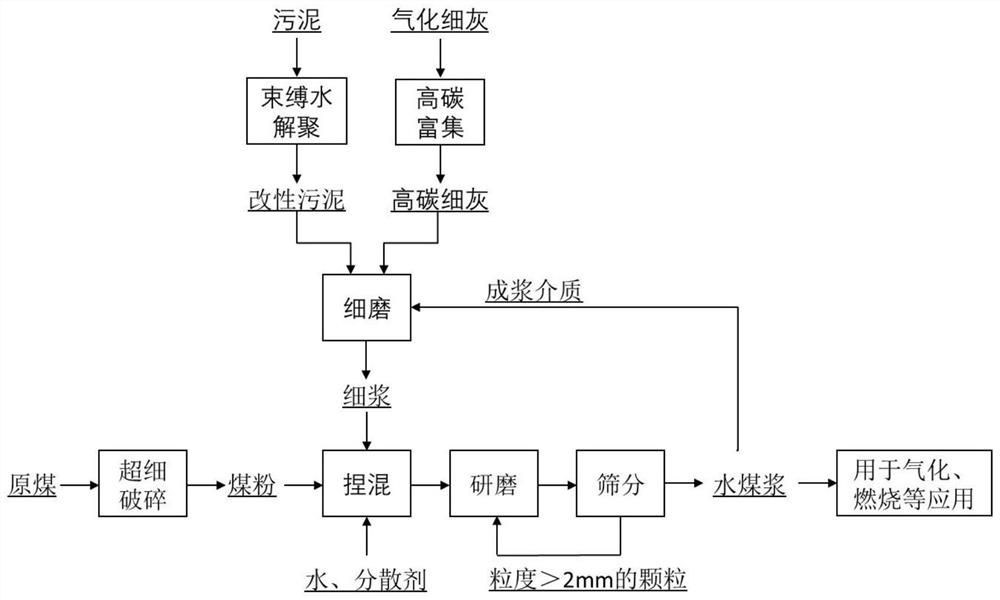

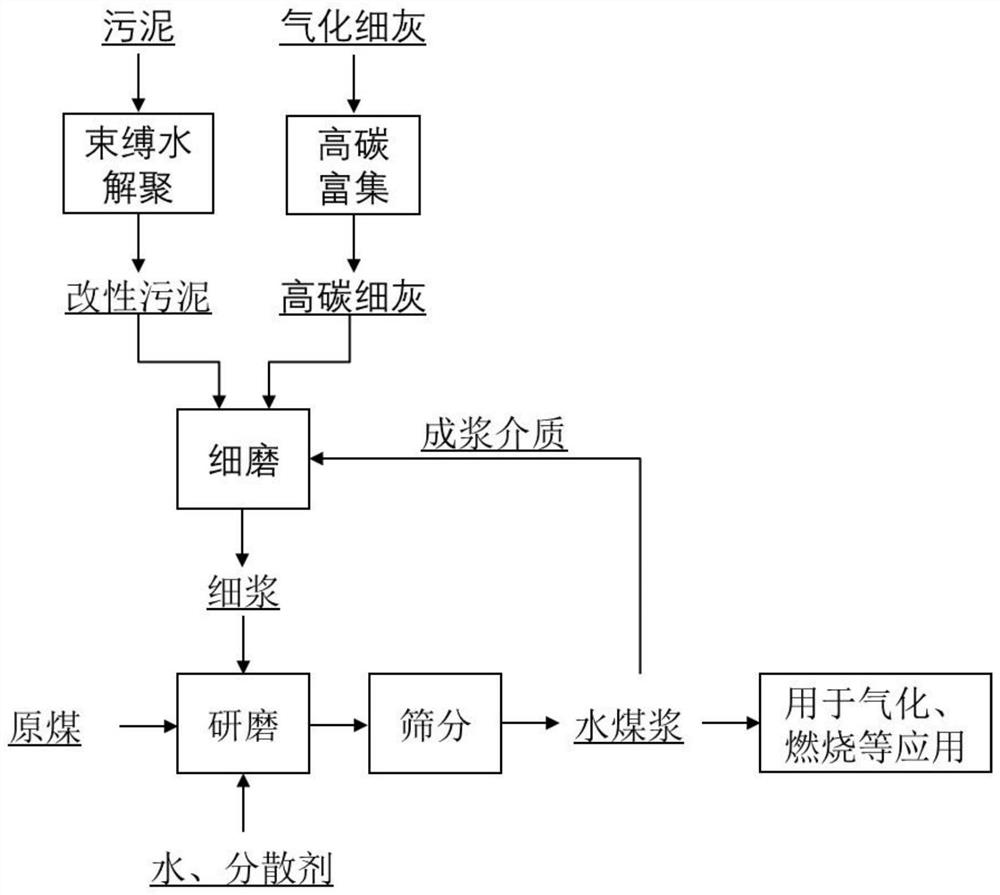

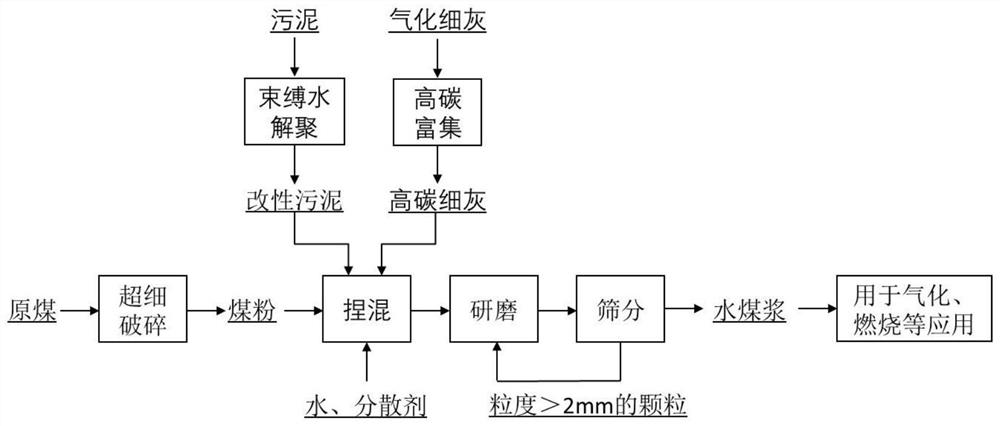

Method for preparing coal water slurry from sludge and gasified fine ash

PendingCN114381308AHigh slurry concentrationIncrease concentrationLiquid carbonaceous fuelsWaste based fuelCoal waterSludge

The invention provides a method for preparing coal water slurry from sludge and gasified fine ash, which comprises the following steps: depolymerizing the sludge through bound hydrolysis to obtain modified sludge, enriching the gasified fine ash through high carbon to obtain high-carbon fine ash, and finely grinding the modified sludge and the high-carbon fine ash to obtain fine slurry; the coal water slurry is obtained by sequentially performing kneading mixing, shaping grinding and first screening on pulverized coal obtained after raw coal is subjected to superfine crushing, water, a dispersing agent and fine slurry, or sequentially performing grinding and second screening on the raw coal, the water, the dispersing agent and the fine slurry. According to the method disclosed by the invention, the gasified fine ash and the sludge are blended with the coal to synergistically prepare slurry and gasify, so that the problems that the sludge and the gasified fine ash are high in water content and difficult to treat, and the sludge and the gasified fine ash are low in slurry preparation concentration and small in treatment capacity after being blended are mainly solved, and the gasified fine ash and the sludge are subjected to reduction, harmlessness, resource, quality and high-value utilization; the method has obvious practicability and advancement and is suitable for large-scale popularization and application.

Owner:CCTEG CLEAN ENERGY CO LTD

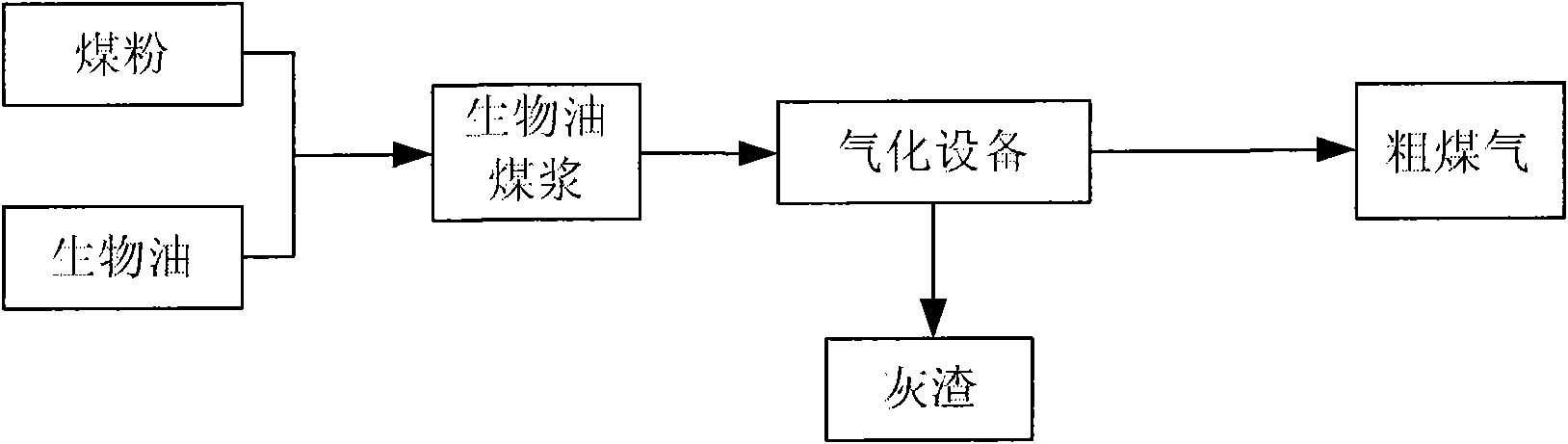

Biological oil-coal slurry and method for preparing gas from same

ActiveCN102080004BHigh calorific valueSave investment costLiquid carbonaceous fuelsCombined combustion mitigationCombustionProduct gas

The invention discloses biological oil-coal slurry. The biological oil-coal slurry is prepared by stirring or grinding and mixing pulverized coal and biological oil according to a certain proportion, wherein the pulverized coal accounts for 20-80 parts by weight, and the biological oil accounts for 20-80 parts by weight. The invention also discloses a method for preparing gas, which comprises the following steps of: (1) mixing pulverized coal with biological oil according to a certain proportion, wherein the pulverized coal accounts for 20-80 parts by weight, and the biological oil accounts for 20-80 parts by weight, adding additive, and stirring to obtain biological oil-coal slurry; (2) atomizing the prepared biological oil-coal slurry by a delivery pump through a delivery pipeline and an atomizing nozzle, charging into a gasification furnace, carrying out pyrolysis, gasification and combustion reaction on the atomized biological oil-coal slurry and the charged gasification agent in the gasification furnace; and (3) obtaining the reacted gas which is rough gas and discharging residues formed in reaction at the bottom of the gasification furnace in a liquid stata. The invention can realize the common gasification of the biological oil and coal.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

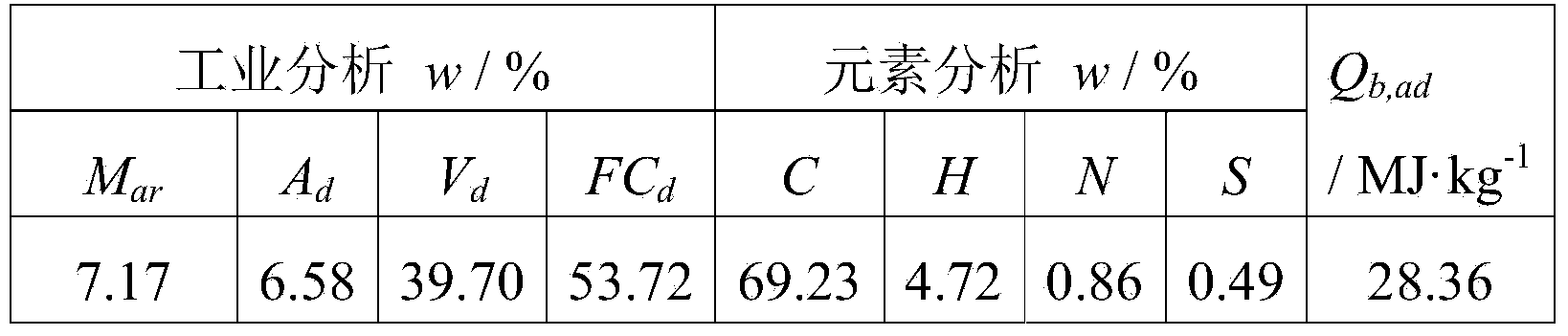

Method for preparing coal-water slurry by treating and modifying lignite or long-flame coal

ActiveCN109943372BModerate investmentEnergy saving and consumption reductionLiquid carbonaceous fuelsCoal waterBrown coal

The invention relates to a method for processing and modifying lignite or long-flame coal to prepare coal-water slurry. The method comprises the following steps: (1) providing lignite or long-flame coal with a particle size less than or equal to 10mm and a water content of 12-20% (2) process and modify the lignite or long-flame coal provided in step (1) under normal pressure and inert gas protection to obtain modified coal, the temperature of the treatment is 250-375 ° C, and the residence time is 45 ~ 90 minutes; and (3) cooling the modified coal obtained in step (2) to below 80°C under the protection of an inert gas, taking out the cooled modified coal and grinding until the particle size is less than or equal to 0.2mm, adding water to prepare CWS. The method provided by the invention has the advantages of moderate investment, energy saving and consumption reduction in operation, and high slurry concentration, and is especially suitable for making lignite or long-flame coal into high-concentration coal-water slurry.

Owner:辽宁大唐国际阜新煤制天然气有限责任公司

Coal water slurry dispersant and its preparation method and application

ActiveCN105018160BHigh slurry concentrationReduce manufacturing costLiquid carbonaceous fuelsCoal waterHigh concentration

The invention provides a coal water slurry and its preparation method and application. The coal water slurry dispersant provided by the invention is obtained by mixing lignosulfonate and aldehyde prepared from sugar solution; and during the reaction, by controlling the reaction The pH value is 9 to 11; the aldehyde is one or more of formaldehyde, acetaldehyde and propionaldehyde; the prepared coal water slurry dispersant is applied to the coal water slurry to make the resulting coal water slurry into a slurry The concentration is high, the dosage of the dispersant is small, the preparation cost of the dispersant is low, and the source is wide, which is beneficial to industrial production.

Owner:JINAN SHENGQUAN GRP SHARE HLDG CO LTD

Method for preparing high-alkali coal water slurry from coking wastewater

ActiveCN114196452AMeet the requirementsImprove gasification efficiencyLiquid carbonaceous fuelsFuel additivesCoal waterProcess engineering

The invention discloses a method for preparing high-alkali coal water slurry from coking wastewater. The method comprises the following steps: mixing and stirring high-alkali coal powder, coking wastewater and three additives to prepare the coal water slurry; the additives comprise a stabilizer, a formaldehyde aqueous solution, a dispersant, an emulsifier and the like. Compared with the prior art, the method has the advantages that low-cost treatment of coking wastewater and viscose wastewater can be realized while the coal water slurry is prepared from the high-alkali coal, the gasification efficiency of the obtained coal water slurry is remarkably improved, and meanwhile, the obtained coal water slurry has relatively ideal slurry concentration, stability and flowability; and the process requirements of the gasification furnace can be better met.

Owner:新疆中泰创新技术研究院有限责任公司

Production method and device of butyl rubber

ActiveCN111234077BHigh slurry concentrationIncrease productivityProcess control/regulationPolymer sciencePtru catalyst

The invention relates to a production method of high single concentration and high conversion rate of butyl rubber, which belongs to the technical field of rubber production. The method comprises the following steps: a, catalyst and solvent, enter the polymerization reactor from the first passage; b, isoprene monomer, isobutylene monomer and slurry stabilizer, enter the polymerization reactor from the second passage; c, Polymerize in the polymerization reactor to form a butyl rubber suspension; d, make the butyl rubber glue flow into the degassing kettle from the polymerization reactor, and at the same time pass steam and hot water into the suspension; e, degassing still treatment; f, stripping still treatment; g, vibrating dehydration screen treatment, and then through subsequent treatment to obtain butyl rubber. The present invention has adopted polymerization stabilizer and supporting technology, makes the present invention produce the chloromethane slurry containing butyl rubber colloid in production process, and the butyl rubber colloid content in the slurry reaches more than 40wt%; Obviously exceeds 30wt% in the prior art; so that the method of the present invention has the characteristics of high slurry concentration and stability.

Owner:ZHEJIANG CENWAY MATERIALS CO LTD

A kind of environment-friendly coal-water slurry additive for low-rank coal pulping and preparation method thereof

The invention discloses a preparation method of an environment-friendly water-coal-slurry additive for low-rank coal slurrying. The method comprises the following steps that 1, a reaction device is heated to 90 DEG C in advance, 1.2-1.5 parts of crude naphthalene is added, a mixture is heated to 130 DEG C, and is stirred evenly, and 1.3-1.6 parts of concentrated sulfuric acid is added dropwise; 2,0.4-0.6 part of water is added, the acidity is adjusted to be 28-30%, and a temperature is controlled at 110-120 DEG C; 3, 0.12-0.15 part of styrene sulfonic acid and 0.12-0.15 part of acrylic esterare added, and 0.8-1 part of formaldehyde is added dropwise; 4, alkali is added for neutralization until a PH value is 10-11, water is added for cooling a mixture to room temperature, and a methylenenaphthalene sulfonate-styrene sulfonate-acrylic ester high-molecular polymer condensation material with a concentration of 40wt% is obtained for later use; 5, lignosulfonate is added into a mixing device for stirring, and then the methylene naphthalene sulfonate-styrene sulfonate-acrylic ester high-molecular polymer condensation material is added into the mixing device. By means of the preparationmethod of the environment-friendly water-coal-slurry additive for low-rank coal slurrying, the defects in the prior art can be overcome, and the preparation method of the environment-friendly water-coal-slurry additive for low-rank coal slurrying has good adaptability to low-rank coal water-coal-slurry preparation.

Owner:南京楠达环保科技有限公司

Preparation method of coal water slurry additive

InactiveCN111662756ARaw materials are easy to getLow priceLiquid carbonaceous fuelsMicrosphereCyclodextrin

The invention discloses a preparation method of a coal water slurry additive. The method comprises the following steps: uniformly mixing 5-10 parts of carboxyl modified ionic triazole nano-microspheres, 5-10 parts of sodium sulfobutyl beta-cyclodextrin, 10-15 parts of modified sorbitan trioleate, 1-3 parts of lauryl alcohol polyether sulfate and 30-40 parts of water, adding sodium hydroxide to adjust the pH value to 7-8, and sieving with a 200-300-mesh sieve to obtain the coal water slurry additive. The coal water slurry additive prepared by the preparation method disclosed by the invention islow in production cost and stable in performance, and is high in slurry concentration, low in viscosity, good in flowability and stability, low in dosage and wide in adaptability when being used forpreparing coal water slurry.

Owner:朱建余

A kind of coal slurry and preparation method thereof

ActiveCN103642550BHigh slurry concentrationHigh solid contentLiquid carbonaceous fuelsSolventSolid content

The invention discloses coal slurry and a preparation method thereof. The coal slurry comprises the following components: 100-300 parts by weight of coal, 50-200 parts by weight of water, 0.01-3 parts by weight of dispersant and 0.01-3 parts by weight of nonpolar solvent, wherein the mass ratio of the nonpolar solvent to the coal is less than or equal to 1%. The preparation method comprises the following steps: evenly mixing the nonpolar solvent with the coal to obtain a material A; and then evenly mixing the material A with water and the dispersant to obtain the coal slurry. The coal slurry prepared by the preparation method disclosed by the invention is high in slurrying concentration, high in solid content and low in viscosity; the coal slurry can be burnt or gasified as a fuel; the coal slurry is advantageous for pumping, storage and transportation, and easy to atomize, burn and gasify.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com