Water coal slurry prepared from hazardous waste coal tar, and preparation method and use method thereof

A technology of coal water slurry and coal tar, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of low calorific value utilization rate and environmental pollution, so as to increase the calorific value, broaden the prospect of popularization and application, and prevent clustering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

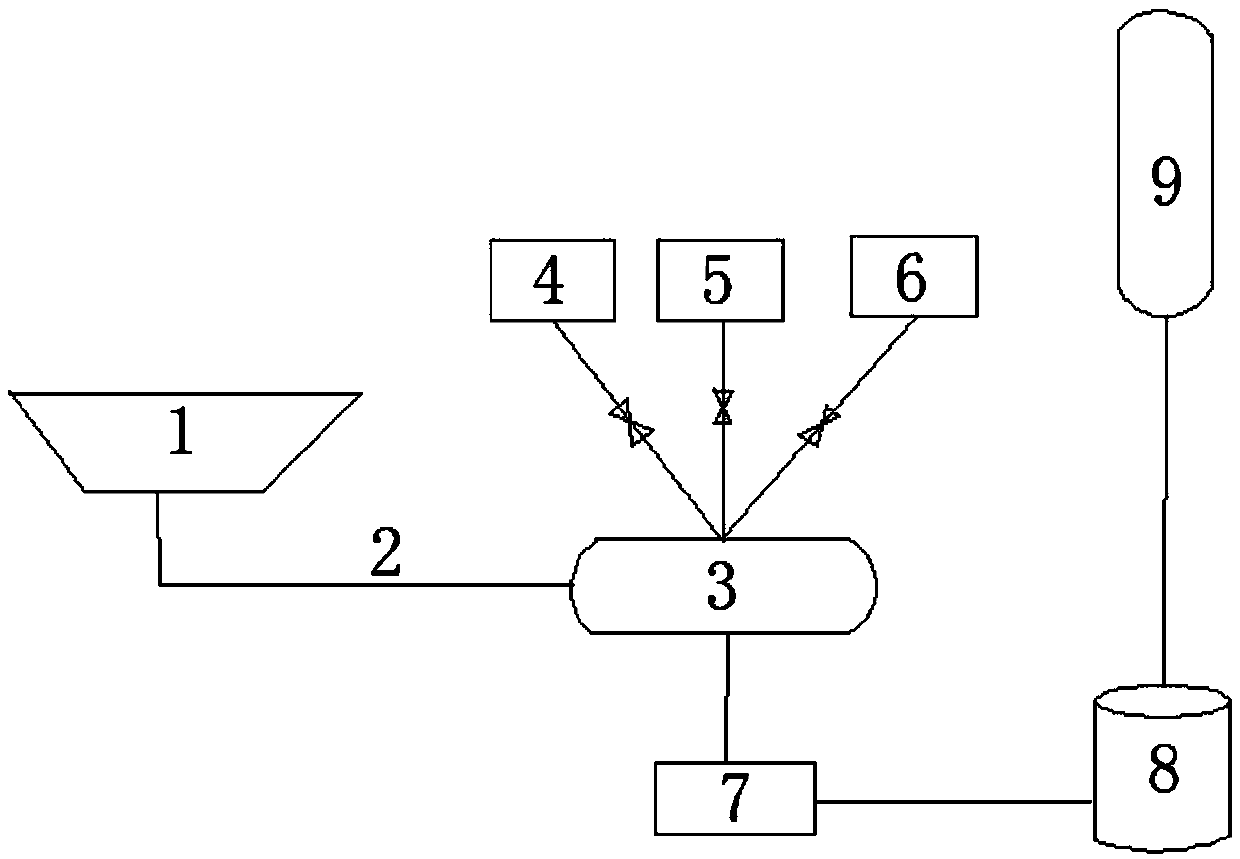

Method used

Image

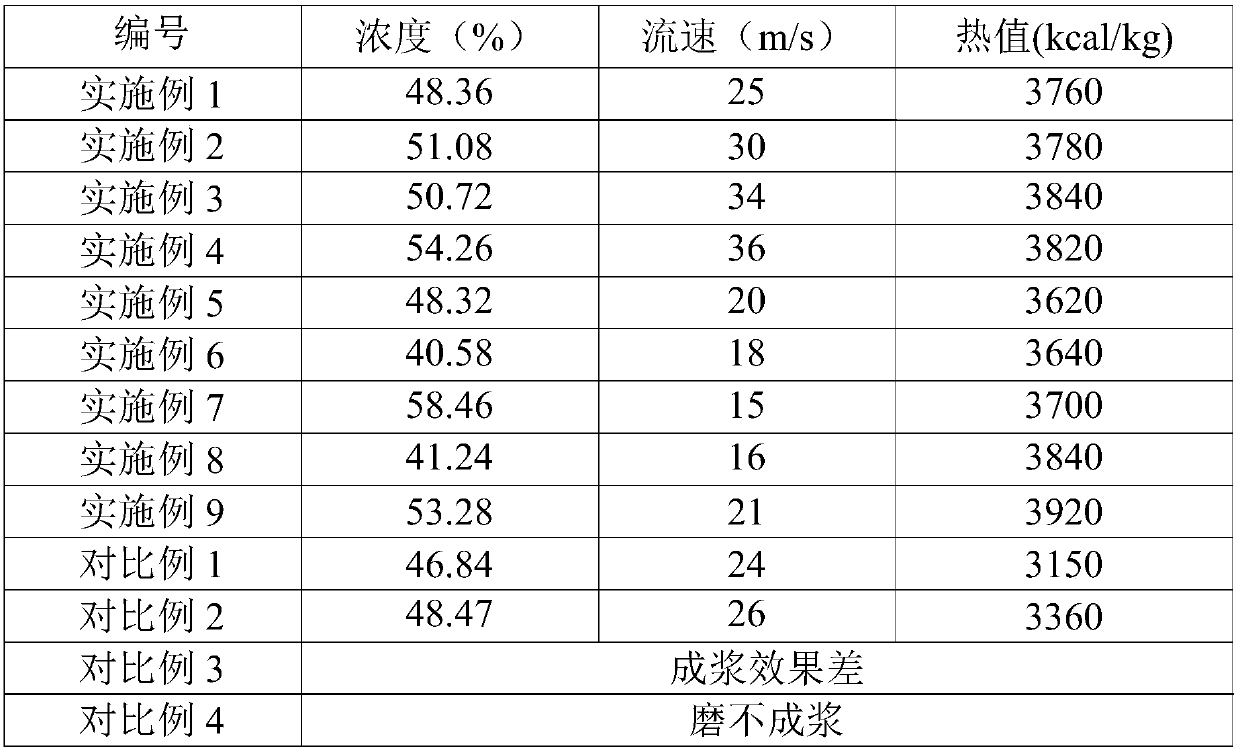

Examples

preparation example Construction

[0076] According to a second aspect of the present invention, a kind of preparation method of coal-water slurry is provided, comprising the following steps:

[0077] Coal powder, coal tar residue, debonding agent, additives and water are mixed and ground to remove coarse grains and impurities, and stored or transported to obtain coal water slurry.

[0078] The process of the invention is simple, easy to implement, and environmentally friendly. In the existing process, coal tar residue is added in the pre-order to reduce the amount of coal powder used to save energy. After grinding, the solid particle size in the slurry is small, and the slurry Uniform distribution, good stability and fluidity.

[0079] In one embodiment, the grinding is ball milling, and the ball milling process parameters include: the rotation speed of the cylinder is 8-12r / min, and the ball milling time is 3.5-4.5h.

[0080] The rotation speed of the cylinder is, for example, 8r / min, 9r / min, 10r / min, 11r / mi...

Embodiment 1

[0096] A coal water slurry comprises the following raw materials in parts by weight: 13 parts of coal powder, 12 parts of coal tar residue, 0.2 part of debonding agent, 0.2 part of dispersant, 0.2 part of stabilizer and 18 parts of water.

[0097] Among them, the oil content in coal tar residue is 44.6%;

[0098] The degumming agent is composed of the following components in weight percentage: 29% sodium hydroxide, 20% sodium carbonate, 5% sodium phosphate, 16% liquid sodium silicate, 20% sodium tripolyphosphate and 10% polyacrylamide;

[0099] The dispersant is sodium lignosulfonate, and the stabilizer is carboxymethyl cellulose.

[0100] The preparation method of coal water slurry comprises the following steps:

[0101] The coal powder, coal tar residue, debonding agent, additives and water are weighed or measured in proportion and sent to the ball mill for ball milling, and ball milled at a cylinder speed of 8r / min for 3.5h to make coal water slurry, which is vibrated Sie...

Embodiment 2

[0103] A coal water slurry comprises the following raw materials in parts by weight: 20 parts of coal powder, 5 parts of coal tar residue, 0.8 part of debonding agent, 0.1 part of dispersant, 0.1 part of stabilizer and 20 parts of water.

[0104] Among them, the oil content in coal tar residue is 44.6%;

[0105] The degumming agent is composed of the following components in weight percentage: 30% sodium hydroxide, 13% sodium carbonate, 15% sodium phosphate, 12% liquid sodium silicate, 20% sodium tripolyphosphate and 10% polyacrylamide;

[0106] The dispersant is sodium humate, and the stabilizer is sodium carboxymethyl cellulose.

[0107] The preparation method of coal water slurry comprises the following steps:

[0108] The coal powder, coal tar residue, debonding agent, additives and water are weighed or measured in proportion and sent to the ball mill for ball milling, and ball milled at a cylinder speed of 12r / min for 4 hours to make coal water slurry, which is passed thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com