Patents

Literature

86results about How to "Good pulping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing tar and hydrocarbon fuel products from coal

InactiveCN104893748AIncrease varietyImprove utilization efficiencyGaseous fuelsLiquid hydrocarbon mixture recoveryWater dischargeMethanation

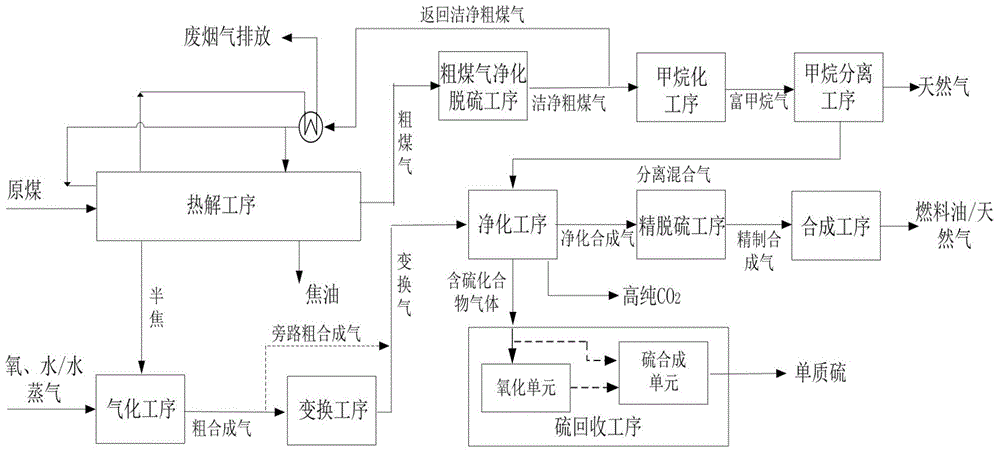

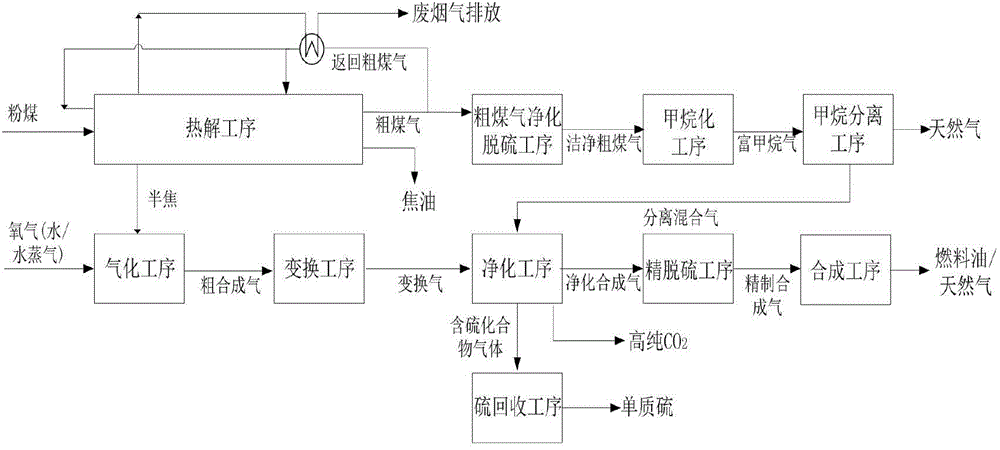

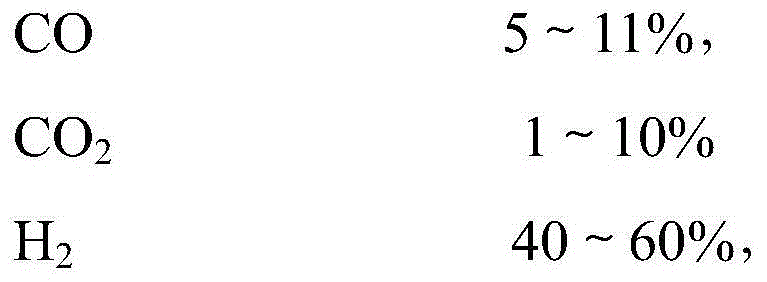

The invention relates to a method for producing tar and hydrocarbon fuel products from coal. The method comprises steps of pyrolysis, raw gas purification and desulfurization, a methanation process, a methane separation process, a gasification process, a conversion process, a purification process, a sulfur recovery process, a fine desulfurization process, a synthesis process and the like. With the adoption of the method, raw coal is firstly subjected to low-temperature pyrolysis and then subjected to gasification conversion, the types of coal chemical products are increased, and the utilization efficiency of the coal raw material is improved; the problem that low-rank coal cannot be gasified and utilized by a wet-process entrained-flow bed is solved, the raw material consumption during gasification is reduced, the waste water discharge is reduced, the greenhouse gas production amount in the process is reduced, and efficient class-based and quality-based utilization of the coal resource is realized.

Owner:XIAN ORIGIN CHEM TECH +1

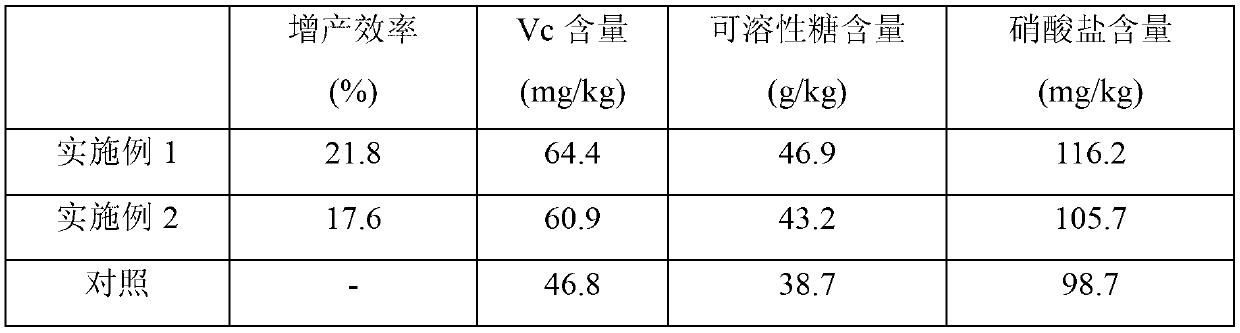

Sunlight greenhouse tomato culture method

The invention discloses a sunlight greenhouse tomato culture method comprising the following steps: breed selection; greenhouse preparation; greenhouse disinfection; soil preparation and furrowing; building a bioreactor; seeds treatment; grafting seedling growing; transplanting and colonization; post-colonization management; proper harvesting. The culture management method can obviously improve greenhouse temperature and reduce disease generation, can prevent lightless condition from affecting overwintering vegetables, so the tomato market time can be reasonable, and a harvest time can last for 8 months; compared with a conventional facility sunlight greenhouse, the annual yield of the tomato using the novel method can be increased to a level above 30%; the novel culture method is simple, easy to apply, and the harvested tomato is good in fruit shape and color, smooth and juicy in pulp, good in tasting mouthfeel, and high in yield.

Owner:张月强

Method for producing tar and hydrocarbon fuel products with coal

ActiveCN104531186AIncrease varietyImprove utilization efficiencyCarburetting airGaseous fuelsMethanationChemical products

The invention relates to a method for producing tar and hydrocarbon fuel products with coal. The method comprises the steps such as pyrolysis, coarse gas purification and desulfuration, methanation reaction, gasification reaction, transformation reaction, purification treatment, sulfur recovery procedure, fine desulfurization treatment and synthesis procedure. According to the method provided by the invention, raw coal is subjected to low-temperature pyrolysis and then subjected to gasification transformation, which not only increases the number of categories of coal chemical products, but also increases the utilization efficiency of raw coal material. The method provided by the invention solves the problem that low-rank coal is hard to gasify and utilize with a wet-process entrained-flow bed, lowers the consumption of raw material in the gasification process, reduces the emission of waste water, lowers the production of greenhouse gas in the process and achieves the purpose of efficient classified and quality-divided utilization of coal resources.

Owner:THE NORTHWEST RES INST OF CHEM IND

North greenhouse cultivation method of papaya

InactiveCN102150592ATroubleshoot common technical issuesRich varietyCultivating equipmentsFruit treePapaya family

The invention relates to a system and a normative north greenhouse cultivation method of the papaya. The method comprises the following steps of: selecting a greenhouse with good thermal insulation property, adjusting the soil acidity, managing the temperature and the humidity in the greenhouse, and the like. The cultivation method is suitable for normatively cultivating the papaya in the north greenhouse, and cultivating the tropic and subtropic fruit trees by utilizing an existing greenhouse condition in the north, so that the types of the crops which are cultivated by north facilities are enriched. The papaya which is planted by the method is beautiful in tree body, beautiful in fruit shape, good in color and luster, mellow in taste, exquisite and succulent in pulp, good in mouthfeel during eating, and high in yield, thereby being suitable for touring and picking in the north greenhouse.

Owner:BEIJING AGRI TECH PROMOTION STATION

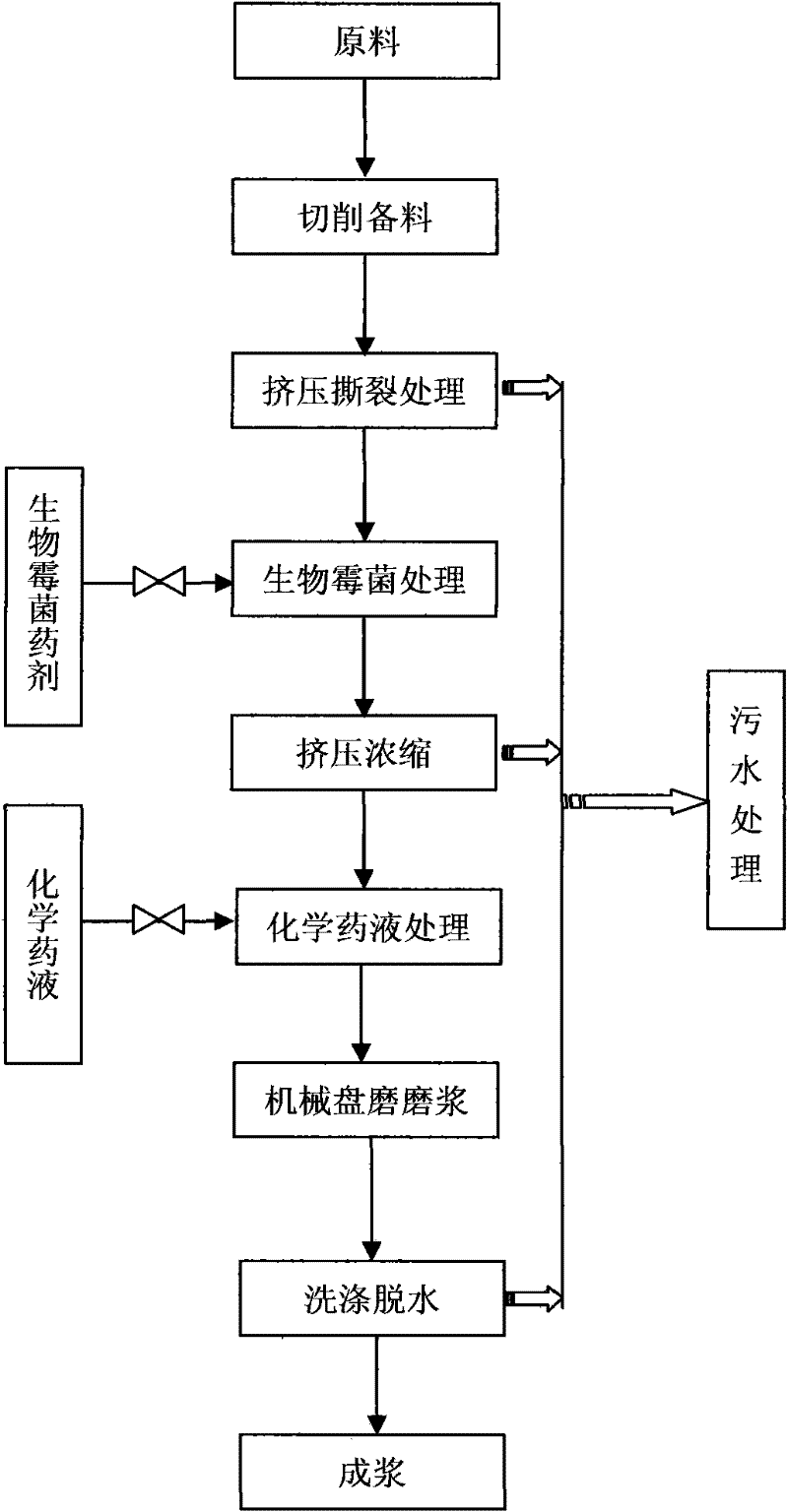

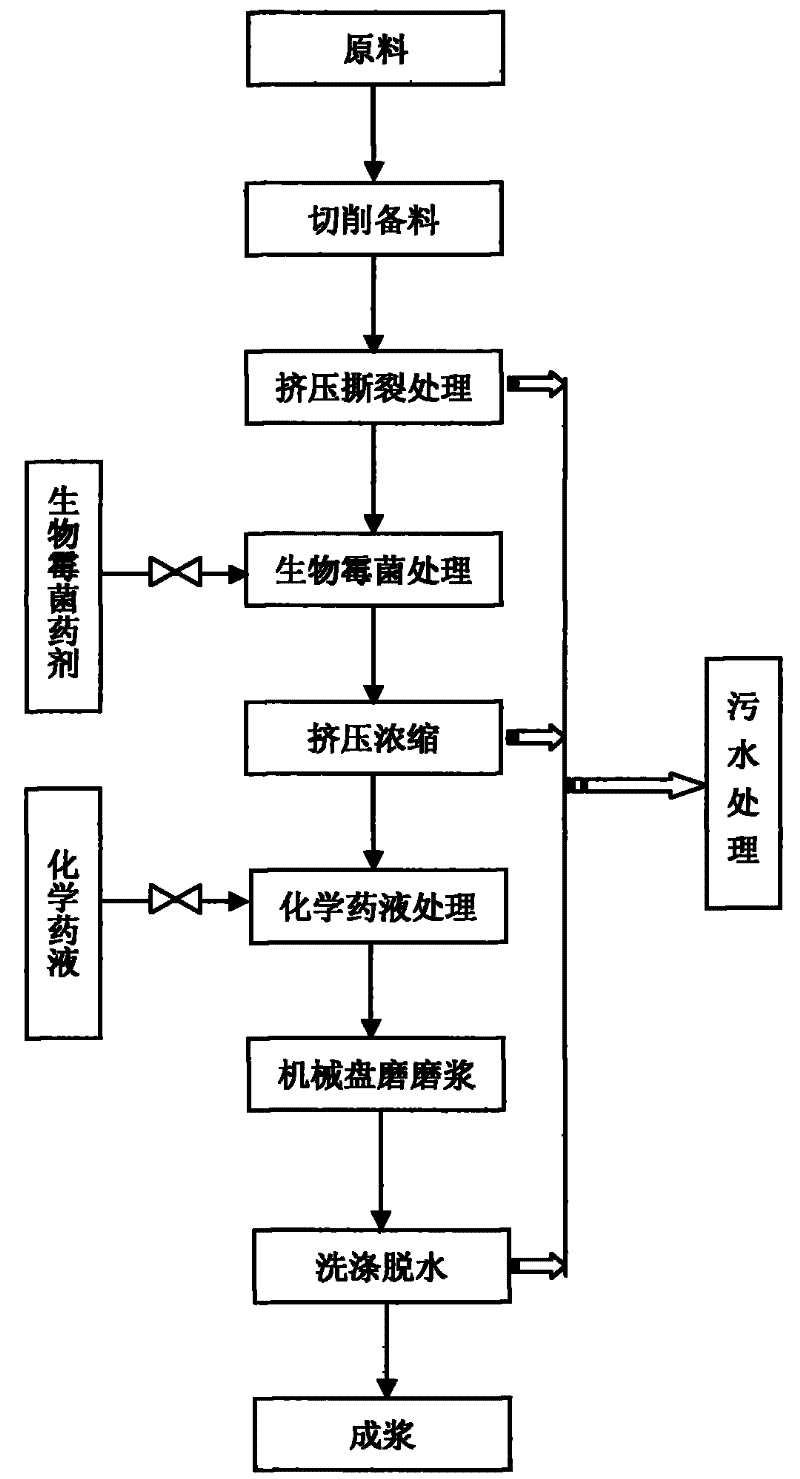

A combined pulping method

InactiveCN102268826AImprove efficiencyReduce pollutionPulping with inorganic basesPulp beating/refining methodsMature technologyPulp industry

A combined pulping method, using bamboo wood as raw material. The present invention relates to a combined pulping method, in particular to a biological, chemical and mechanical combined pulping method, which belongs to the technical field of pulping and papermaking, especially biochemical and mechanical Combined pulping technology. The present invention combines the current advanced biotechnology, mature chemical pulping technology and high-efficiency mechanical pulping technology through organic integration, comprehensively utilizes the advantages of the above technologies, conducts targeted combination, and develops a new pulping method. The method of the invention reduces the pollution of the pulping industry and improves the economic benefits of the pulping industry. The combined pulping method has strong raw material adaptability, good pulping performance, and good pulp is suitable for compounding various papers.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

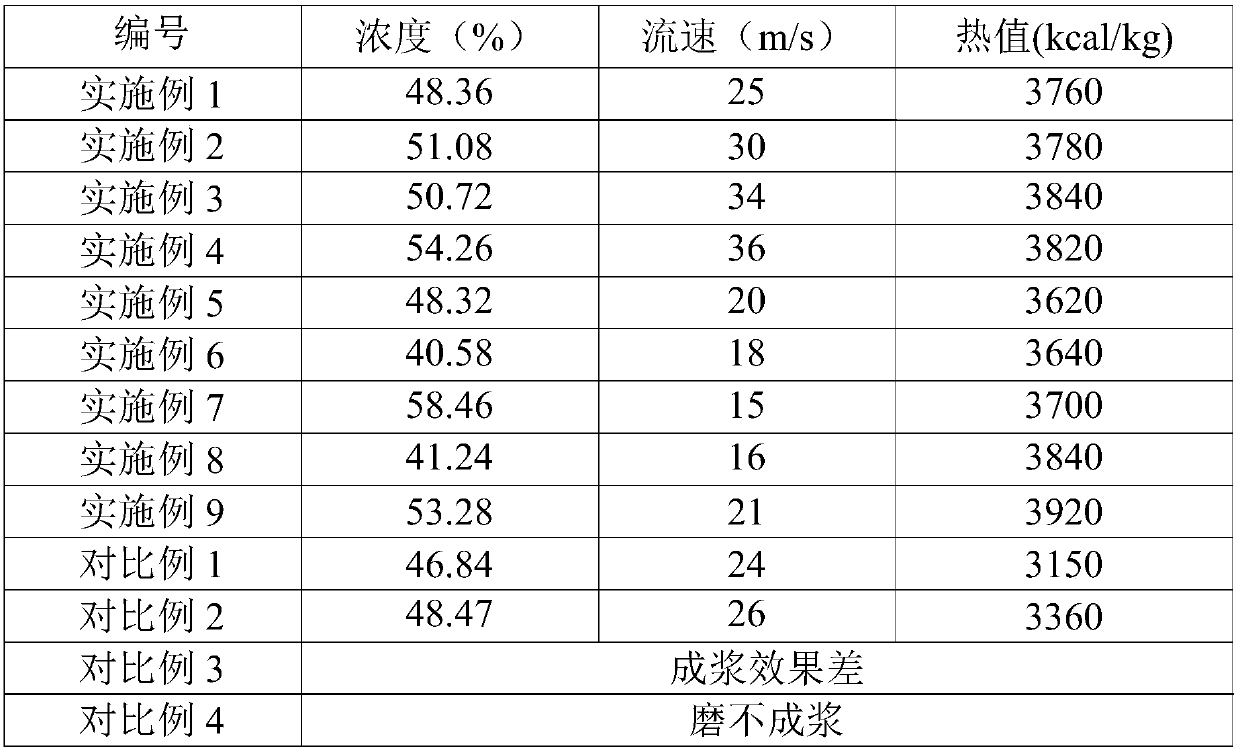

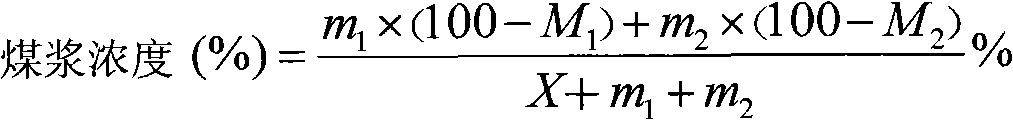

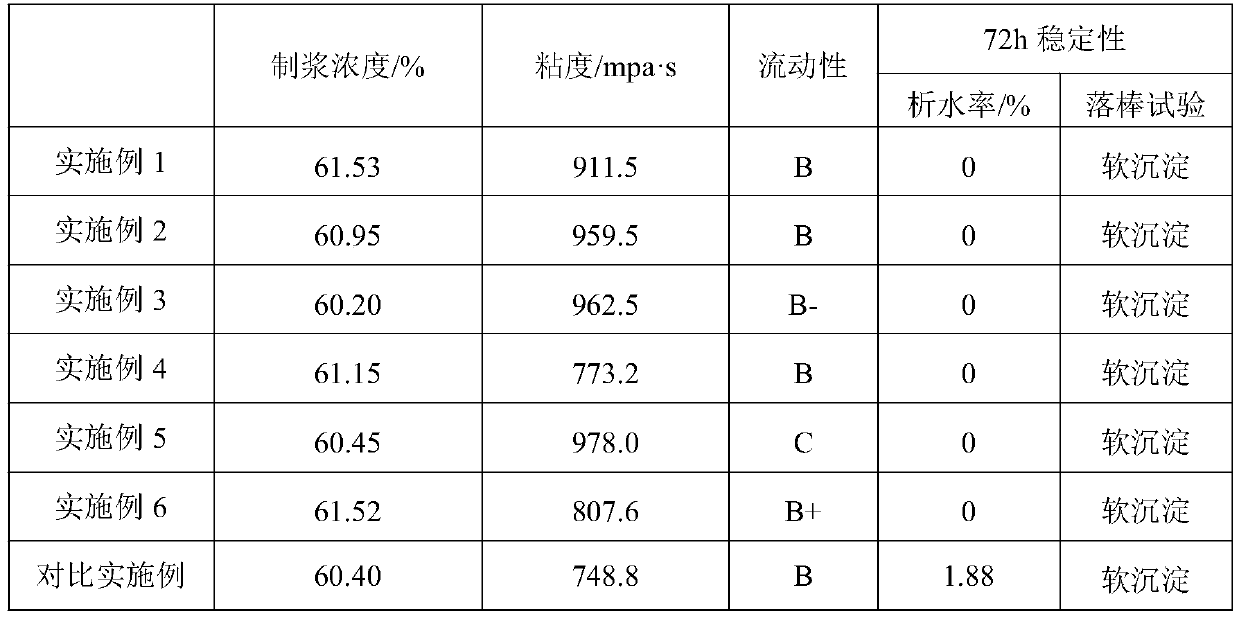

Water coal slurry prepared from hazardous waste coal tar, and preparation method and use method thereof

ActiveCN109536224AReduce usageHigh slurry concentrationLiquid carbonaceous fuelsSelf consumptionCoal tar

The invention discloses water coal slurry prepared from hazardous waste coal tar, and a preparation method and a use method thereof, and relates to the technical field of coal tar reutilization. The water coal slurry is prepared from the following ingredients in parts by weight: 13 to 20 parts of coal powder, 5 to 12 parts of coal tar, 0.2 to 0.8 parts of dispergators, 0.2 to 0.4 part of additivesand 15 to 20 parts of water. The water coal slurry is prepared from the coal tar and coal powder, so that the coal tar can be reasonably treated and used; the self consumption of the coal powder perse is reduced. Through the matched use of a certain amount of coal tar and the coal powder and through the addition of dispergators and additives, the water coal slurry with high slurry concentrationand low viscosity can be prepared; meanwhile, a great amount of solid state carbon and organic ingredients in coal tar can be utilized; the calorific value of the water coal slurry can be well improved, so that the coal tar is changed from waste materials into valuable materials; the popularization and application prospects are wide.

Owner:广东汇昇环保科技有限公司

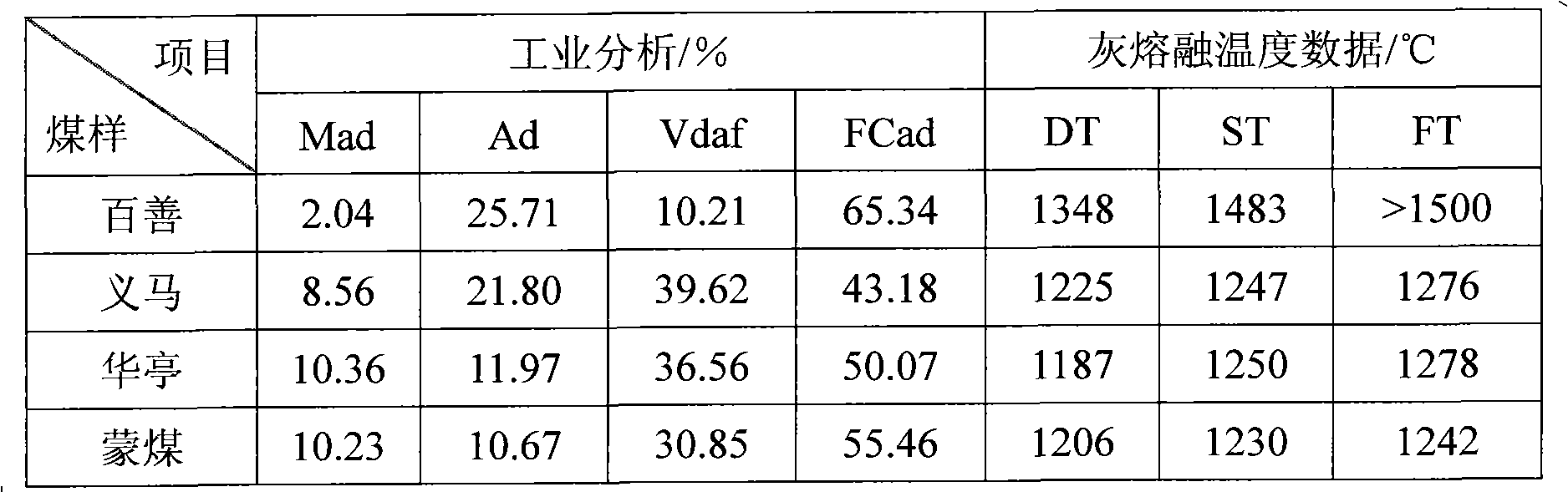

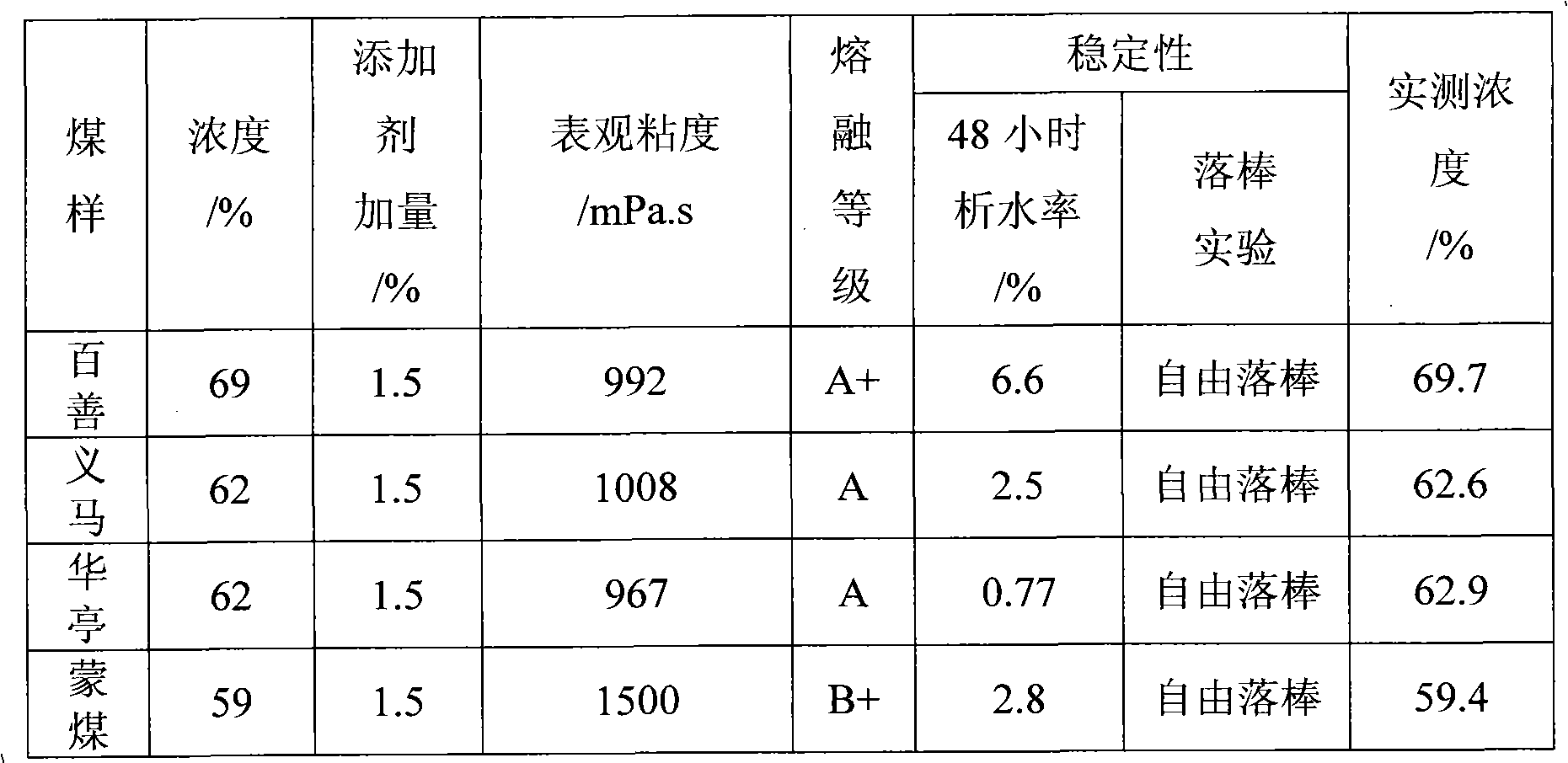

Coal blending method suitable for coal for pressurizing gasification of Texaco water coal slurry

InactiveCN101845330AOvercome the disadvantages of difficulty in pulpingLower melting temperatureLiquid carbonaceous fuelsGranular/pulverulent flues gasificationSocial benefitsPulverized fuel ash

The invention relates to a coal blending method suitable for coal for the pressurizing gasification of Texaco water coal slurry, which comprises the following step of blending coal by using coal with the high-ash fusion temperature of more than 1,500 DEG C and coal which is difficult to form slurry and has the low-ash fusion temperature of less than 1,300 DEG C as raw materials, wherein the blending proportion of the coal with the high-ash fusion temperature is between 10 and 60 percent, and the blending proportion of the coal which is difficult to form the slurry and has the low-ash fusion temperature is between 40 and 90 percent, and the raw materials are blended uniformly to form the coal for the gasification of Texaco water coal slurry. The method has an obvious practical significance for the effective utilization of the coal with the high-ash fusion temperature and the coal which is difficult to form the slurry and the stable, high-efficiency and economic operation of the gasification of the water coal slurry, and has the important social benefits for the diversification of the pressurizing gasification raw materials of the water coal slurry and the reasonable utilization of coal resources. The method is suitable for meeting the requirements on coal consumption of both a water coal slurry pressurizing gasification liquid slag-tap furnace and a pulverized coal pressurizing gasification liquid slag-tap furnace.

Owner:ANHUI HUAIHUA

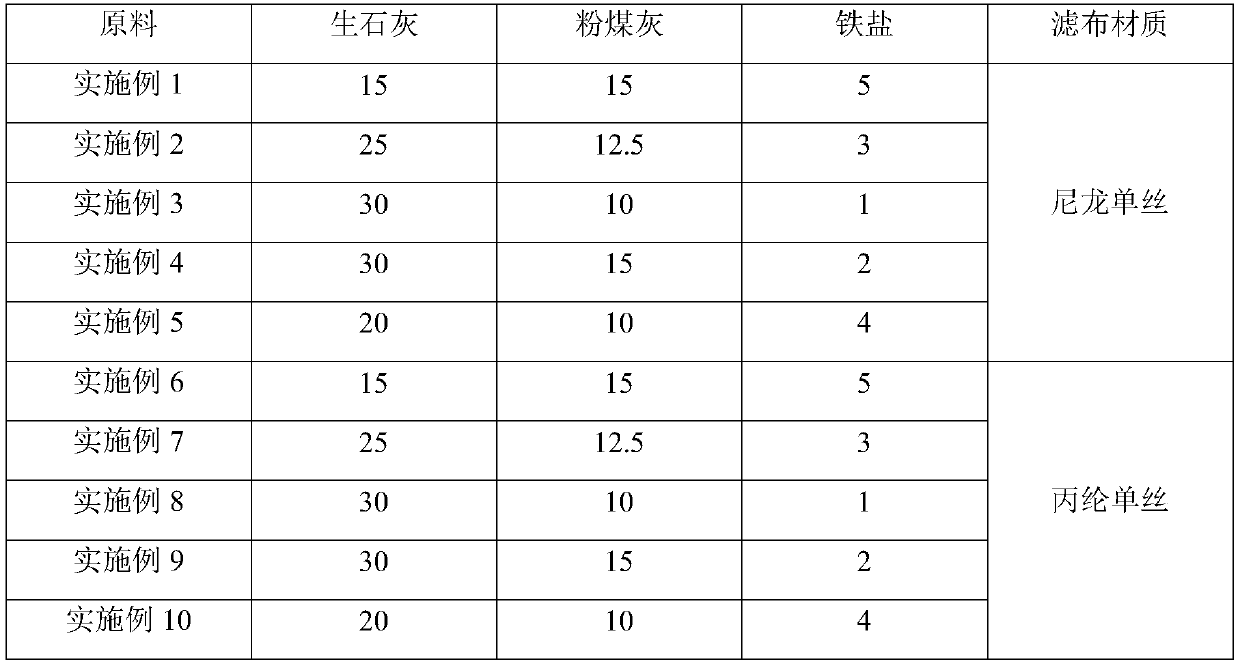

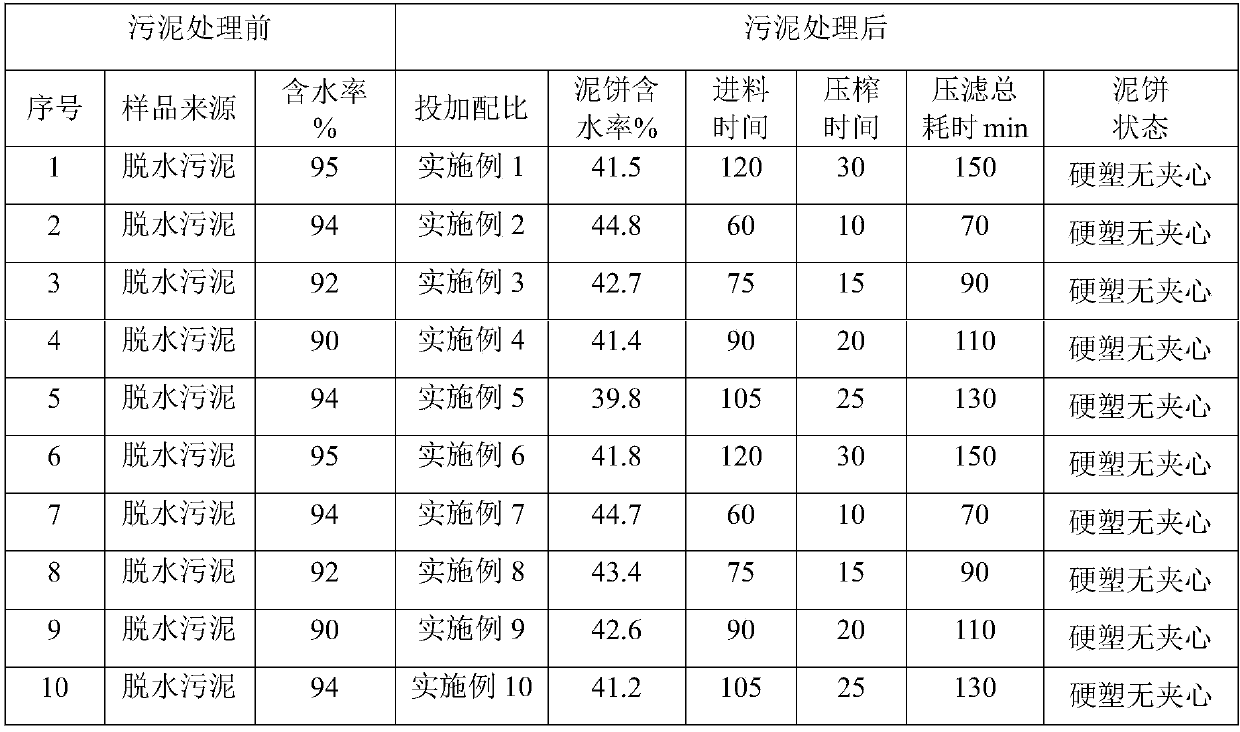

Deep city sludge dehydration curing method

InactiveCN110395878AWide variety of sourcesEasy to useSpecific water treatment objectivesFixation/solidifcation sludge treatmentIron saltsDry weight

The invention relates to a deep city sludge dehydration curing method which needs a curing conditioning agent and comprises the following steps: 1) adding water into municipal sludge, and performing uniform stirring and mixing so as to obtain sludge slurry; wherein the mass percentage of the water is 8-10% of the dry weight of the sludge; 2) adding quick lime and coal ash into the sludge slurry prepared in the step 1), performing stirring, adding an iron salt, and performing stirring so as to obtain paste slurry; and 3) performing press filtering on the paste slurry prepared in the step 2) byusing a plate frame filter press till the water content is 50% or less, so as to obtain mud cakes of which the water content is 50% or less. The method not only is low in cost, good in sludge dehydration effect, capable of forming hard plastic mud cakes after dehydration and good in curing effect, but also takes effects of sterilization and deodorization on sludge.

Owner:ROAD ENVIRONMENT TECH

Method for breeding a kind of fast growing poplar

InactiveCN1415185AStay Cold and Drought ResistantGrow fastPlant phenotype modificationForestryHigh resistanceBud

A method for breeding fast-growing poplar tree includes the first bud grafting between the twigs of southern-type poplar and northern-type poplar, the second bud grafting between same poplars, mutual grafting between their survival saplings, direct cuttaging, and grafting with the new saplings. Its advantages are high growth speed, high trunk, high wood quality, and high resistance to cold and drought.

Owner:赵建永

Re-pulping method for high wet strength waste paper containing PAE resin

InactiveCN102677514ALow costEasy to operatePaper recyclingWaste paper working-upFiberChemical solution

The invention provides a re-pulping method for high wet strength waste paper containing PAE resin. The method is based on the action principle of damaging the wet strength of paper by an oxidation process, and an oxidizing agent having an obvious action on the wet strength of PAE resin-contained high wet strength paper is used for chemical damage and mechanical defibering treatment of paper in a system with a certain water phase concentration under the conditions of a proper dosage of reagent and temperature; the PAE resin-contained high wet strength waste paper is soaked in chemical solution containing the oxidizing agent for a while and then subjected to crushing and defibering treatment by a fiber pulping defibering machine, so the paper scraps are subjected to defibering to form fiber pulp which can be used for paper making or other purposes. The method has the advantages of low cost, good pulp-forming effect and the like, and is easy to operate.

Owner:SHAANXI UNIV OF SCI & TECH

Method of seed selection for a kind of fast growing poplar

A method for selectively breeding fast-growing poplar includes the first bud grafting between wild white poplar and northern-type poplar, the second bud grafting between same poplars, mutually grafting between their survival saplings, direct cuttaging, and grafting with the new saplings. Its advantages are high growth speed, high trank, high wood quality, and high resistance to cold and drought.

Owner:和建强

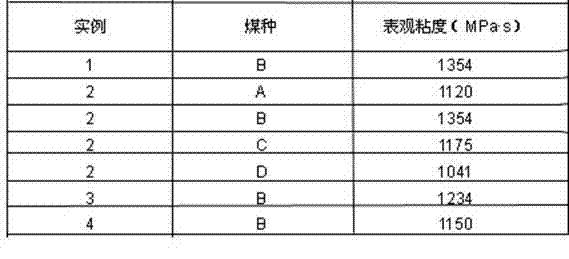

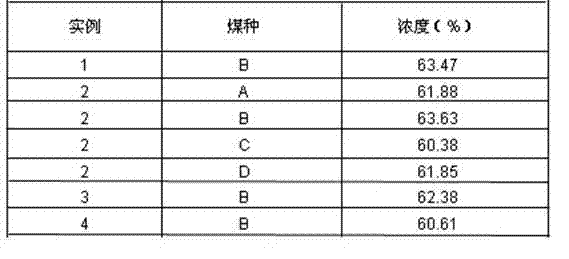

Coal water slurry additive

ActiveCN102329669AImprove adaptabilityReduce dosageLiquid carbonaceous fuelsFuel additivesCoal waterCoal slurry

The invention relates to a coal water slurry additive. Two types of dispersant, penetrant and emulsifier are compounded according to a certain proportion, and thereby the additive with high universality and good slurriability is produced. The additive can be applied in coal water slurry produced with a variety of coals for gasification, and under 0.5 to 2.5 per thousand of addition, coal water slurry reaches or even excels the GB / T18855-2002 standard.

Owner:SHANGHAI HUAYI ENERGY CHEM

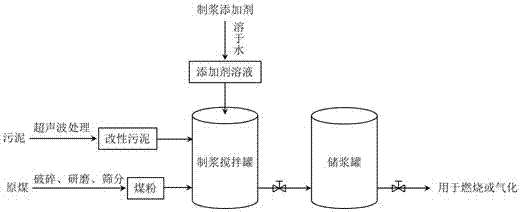

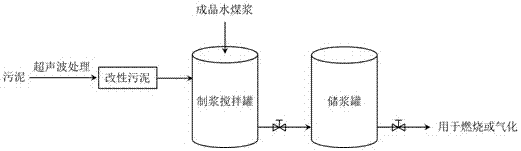

Method for improving slurry-forming ability of sludge and coal-water slurry by cracking sludge flocculation through ultrasonic waves

InactiveCN107164003ASmall granularityReduce slurry viscositySludge treatmentLiquid carbonaceous fuelsCoal waterFlocculation

The invention discloses a method for improving slurry-forming ability of sludge and coal-water slurry by cracking sludge flocculation through ultrasonic waves. The ultrasonic waves are used for modifying sludge, microbial cell walls in a sludge floc structure and the sludge are broken by high-temperature high-pressure environments and shearing action generated by ultrasonic cavitation action, sludge particle granularity is reduced, part of interstitial water is released, the modified sludge is mixed with coal, slurry-forming additives, water and the like to prepare the sludge and coal-water slurry, or finished coal-water slurry is doped into the modified sludge and uniformly stirred to prepare the sludge and coal-water slurry. Compared with the prior art, the method has the advantages that the slurry-forming viscosity of the sludge and coal-water slurry can be obviously reduced, slurry-forming concentration is increased, the sludge and coal-water slurry with excellent slurry-forming ability is obtained, treatment time is short, operation is convenient, and the method is applicable to large-scale popularization and application.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

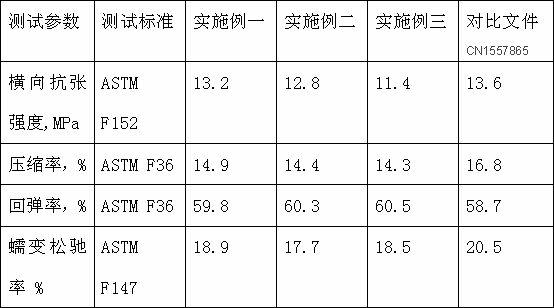

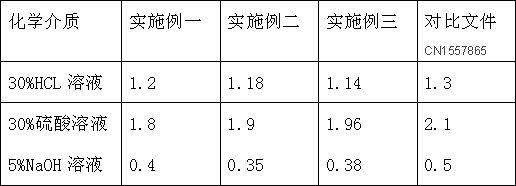

New type of pump seal gasket for environment-friendly vehicles

The invention discloses a novel pump sealing gasket for an environmental-friendly vehicle, which is formed by mixing and preparing the following raw materials in percentage by weight: 5-8 percent of acrylon pulp, 25-40 percent of silicate fiber, 5-10 percent of nylon fiber, 15-35 percent of silicate packing, 8-12 percent of chloroprene rubber, 5-10 percent of natural rubber and 0.5-2.5 percent ofcuring system. Preferably, the novel pump sealing gasket is prepared by mixing the following raw materials in percentage by weight: 7 percent of acrylon pulp, 35 percent of silicate fiber, 7 percent of nylon fiber, 27 percent of silicate packing, 12.5 percent of chloroprene rubber, 9 percent of natural rubber and 2.5 percent of curing system. The novel pump sealing gasket for the environmental-friendly vehicle is formed by mixing the raw materials, carrying out sizing molding at one step and continuously rolling and vulcanizing by a plurality of rolls.

Owner:南阳天一密封股份有限公司

Tomato cultivation method

InactiveCN106717917AEasy to shapeGood pulpingCalcareous fertilisersAlkali orthophosphate fertiliserDiseaseEconomic benefits

The invention discloses a tomato cultivation method, comprising the specific steps of selecting and preparing a land, selecting and soaking seeds, sowing the seeds in proper time, managing a field, performing field planting, preventing and treating disease and pest damage, and harvesting in proper time; compared with the prior art, the tomato cultivation method of the invention is scientific and advanced, is highly operable and is simple and handy; through reasonable fertilization and field management, planting cycle is shortened effectively, planting density is increased, yield is increased, and economic benefit is increased accordingly; tomato cultivated via the tomato cultivation method has good color and fine, juicy pulp and has good taste.

Owner:合肥安农源生物工程技术有限公司

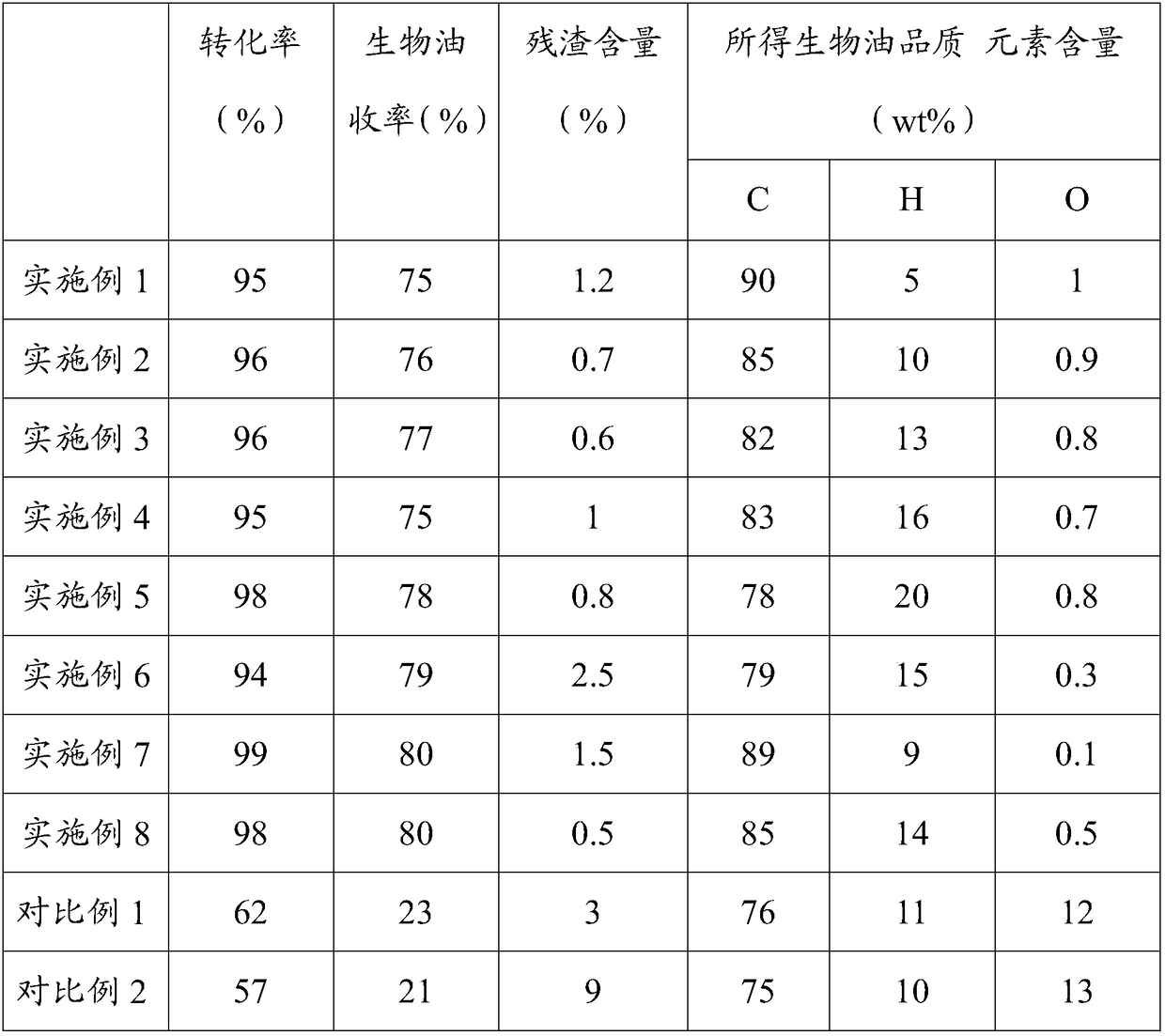

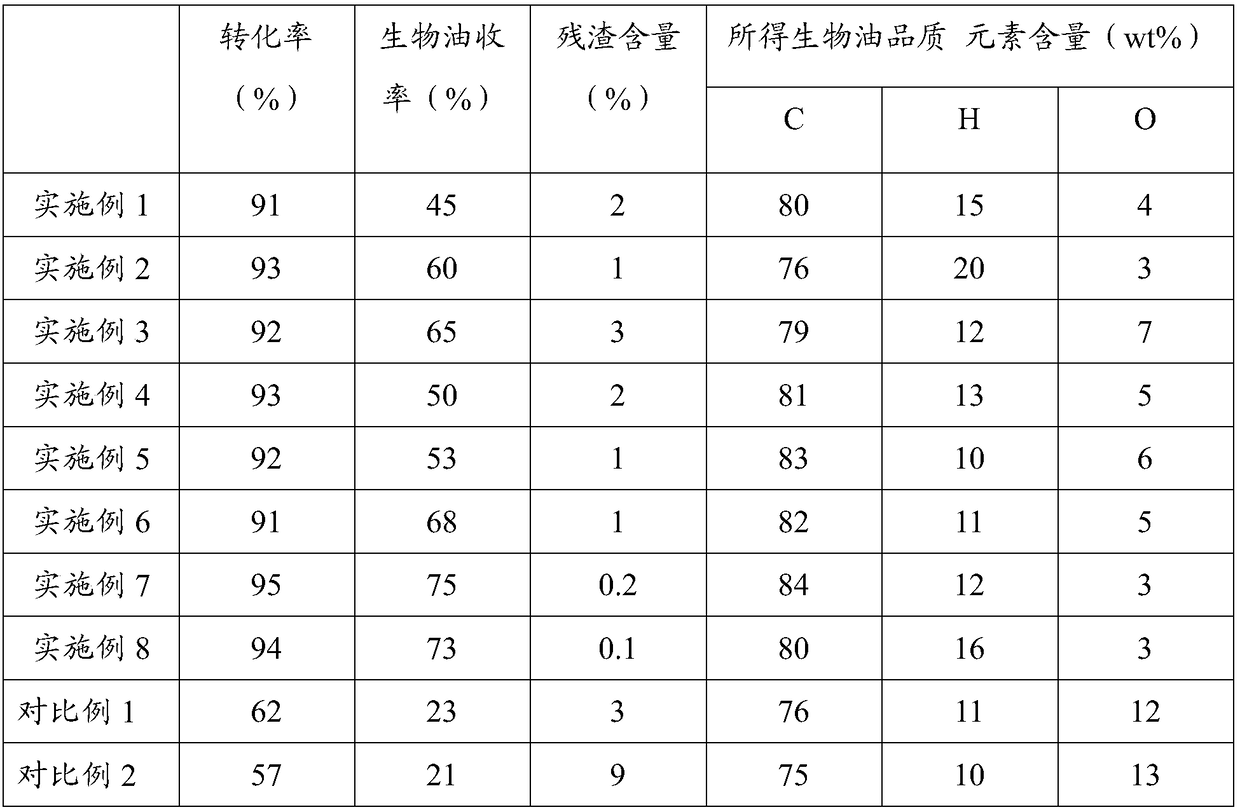

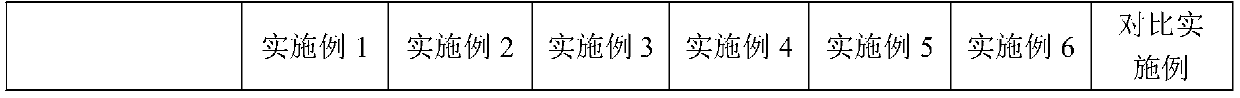

Multi-grade liquefying technology of coal and biomass

ActiveCN108285808ARealize mixing and liquefactionIncrease contactBiofuelsLiquid hydrocarbon mixture productionSolventBiomass

The invention relates to the technical field of clean energy, and specifically provides a multi-grade liquefying technology of coal and biomass. The technology is characterized in that the coal and the biomass raw materials are processed by crushing, compressing and crushing again, then the sizing is prepared, so that biomass diesel oil which is high in solid content and can be stably conveyed through a pump can be obtained; high-viscosity waste oil which cannot be used as a coal and biomass liquefying solvent in the prior art can be utilized. According to the technology, coal and biomass canbe liquefied under high pressure and high temperature in the existence of proper volume of water; the liquefying product is sequentially subjected to primary cracking, hydrogenation reaction and deepcracking and hydrogenation reaction under the effects of resisting hydrogen and a first catalyst and a second catalyst, so that the coal and the biomass can be converted into biomass oil, and the biomass oil can be refined; the conversion rate of the biomass and the coal is up to 95-99%; the yield of the biomass oil is up to 70-80%; and moreover, the residue content is less than 2.5%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Special fertilizer for loquat and preparation method thereof

InactiveCN104446900ARich in nutrientsEasy to prepareAmmonium salt fertilisersFertilizer mixturesChemistryDisease

The invention discloses a special fertilizer for loquat and a preparation method thereof. The fertilizer comprises the following formula components in parts by mass: 26-28 parts of water lettuce green manure, 21-23 parts of urea, 16-18 parts of a calcium-magnesium-phosphate fertilizer, 13-15 parts of potassium nitrate, 11-13 parts of cottonseed cake fertilizer, 7-9 parts of yeast fertilizer, 5-7 parts of forchlorfenuron, 6-8 parts of composted pig manure, 4-6 parts of organic chelated iron, 3-5 parts of ammonium molybdate, 1-3 parts of manganese chloride, 4-6 parts of ammonium humate, 2-4 parts of agricultural rare earth and 50-60 parts of water. The fertilizer is rich in nutrients, the preparation method is simple; by application of the fertilizer, the tenacity of the loquat peel is promoted to be strong, the flesh is fine and juicy and has sweet flavor; and since the formula contains agricultural rare earth, the stress resistance and disease resistance of loquat are increased and the quality of the loquat fruit is significantly improved.

Owner:张爱丽

Chaenomeles speciosa cultivation method

InactiveCN105265139AThe cultivation method is simpleEasy to implementCultivating equipmentsHorticultureFertilizerThinning

The invention discloses a Chaenomeles speciosa cultivation method. The method comprises the following steps: soil improvement, seedling field planting, fertilizer and water management, flower and fruit thinning, tree disease control and mature fruit picking. The fertilizer and water management step comprises sub steps of fertilization in the case of seedling field planting, fertilization in the case of budding, fertilization in the case of blooming, fertilization in the case of fruit bearing, and fertilization in the case of swelling fruit until maturity. The cultivation method is simple and easy to operate and execute; and the cultivated Chaenomeles speciosa has a beautiful appearance, good color, mellow taste, delicate and juicy fruit, good taste in the case of eating, and high yield.

Owner:LIUYANG YONGLE PLANTATION SPECIALIZED COOP

Method for bleaching natural color pulp

InactiveCN101871177AQuality improvementThe bleaching process is compact and simplePulp bleachingPulping with inorganic basesSocial benefitsEconomic benefits

The invention discloses a method for bleaching natural color pulp. The method adopts the bleaching flows of oxygen delignification (O), alkali extraction (E), ozone bleaching (Z) and hydrogen peroxide bleaching (P), wherein the oxygen delignification can be divided into single section or two sections; the alkali extraction process can adopt the reinforcing treatment of hydrogen peroxide or oxygen and hydrogen peroxide; and the hydrogen peroxide bleaching section comprises normal-pressure hydrogen peroxide bleaching and oxygen reinforced hydrogen peroxide bleaching. The bleaching flow uses the chemicals such as oxygen, hydrogen peroxide, ozone, alkali and the like, and does not use any chlorine-containing bleaching agent. The bleaching flow of the invention is efficient and simple, and is suitable for the natural color pulp of various materials of between 5 and 40 kappa valences. The obtained bleached pulp can be used for making various paper. The waste water produced by the method has no AOX, and can be directly recycled to a washing or digesting section of the natural color pulp. The method improves the product quality and production efficiency, reduces the energy consumption, has strong environment friendliness, obviously reduces the production cost, and has remarkable economic benefit and social benefit.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Special full-value nutrition liquid and organic substrate integral cultivating mode for eggplants

InactiveCN103210823AAppropriate and sufficient nutrient supplyAvoid harmCultivating equipmentsSoilless cultivationDiseaseFeces

The invention relates to a special full-value nutrition liquid and organic substrate integral cultivating mode for eggplants. Organic wastes, such as crop straws, waste slag after edible fungi cultivating, and feces of livestock, are used as raw material, and are subjected to harmless treatment to form an eggplant cultivating substrate. Water-soluble fertilizer is prepared into full-value nutrition liquid according to the fertilizer requiring rule of the eggplant, and the water and the nutrients are supplied to the root area of the eggplant in a water and fertilizer integral way. The cultivating mode for planting the eggplant has the advantages that safety is realized, the water and the labor are saved, the cost is low, the management is easy, the raw material of the substrate can be easily obtained, the utilization rate of the fertilizer is high, soil-borne diseases are avoided, and the like. The produced eggplant has the advantages that the yield is high, the fruit is fine, the taste is good, the nutrition ingredients are rich, the content of pesticide residues is low, the color is bright, the commodity rate is high, and the like. The cultivating mode disclosed by the invention is used for producing high-quality eggplant in the areas where the normal agricultural production cannot be carried out, such as heavy-salt alkaline lands, mountain lean lands and abandoned industrial and mining lands.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

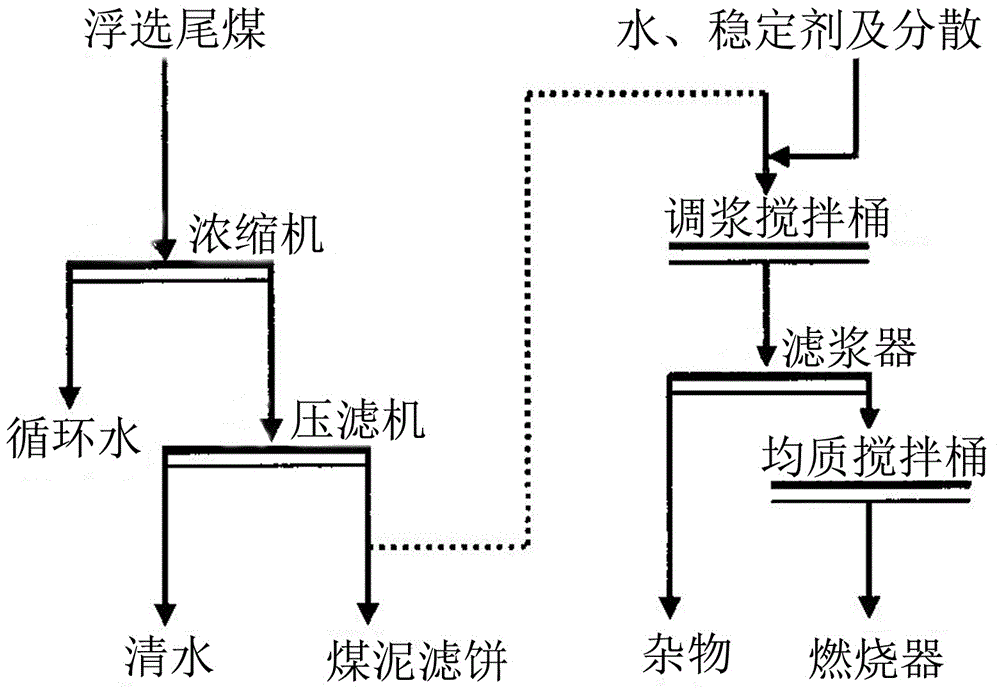

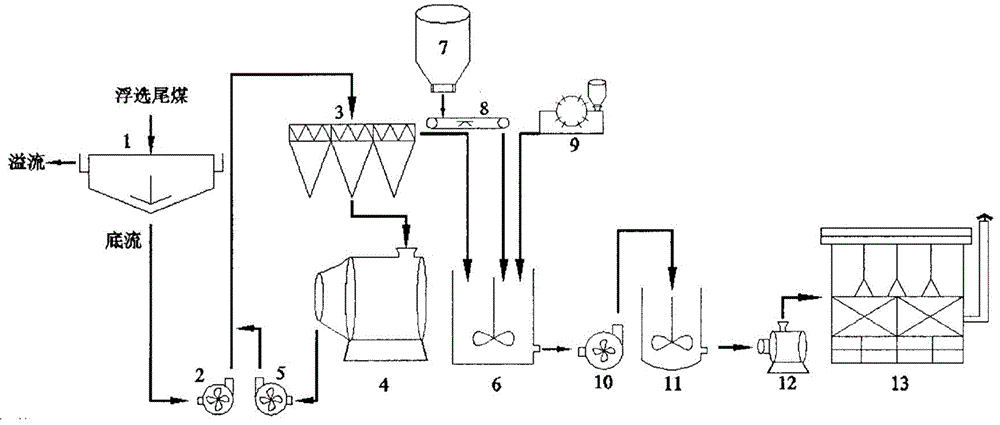

Process for directly preparing coal water slurry from underflow of concentrator of coal preparation plant

ActiveCN106635208AImprove uniformityImprove stabilityLiquid carbonaceous fuelsCoal waterCoal preparation plant

The invention discloses a process for directly preparing coal water slurry from underflow of a concentrator of a coal preparation plant. The process comprises three working procedures of preparing raw materials, blending the coal water slurry and conveying a finished product; floatation tailings are concentrated by the concentrator; the underflow of the concentrator is not subjected to pressure filtration dehydration treatment and is directly fed into a hydrocyclone group for classifying; qualified fine materials are fed into a coal slurry mixing tank; a certain proportion of fine pulverized coal and a proper amount of dispersant and stabilizer are proportioned in the coal slurry mixing tank according to the feeding amount of the materials and the requirement on the quality of the coal water slurry; the substances are sufficiently and uniformly mixed and stirred to prepare a slime coal water slurry product with good flowability and stability and can be provided for a nearby industrial kiln for burning. According to the process disclosed by the invention, the pressure filtration working procedures in the treatment process of the floatation tailings can be reduced, the treatment process of the tailings is simplified, and the operation cost of the coal preparation plant is reduced; in addition, the dispersion difficulty caused by agglomeration of filter cakes in the process of preparing the coal water slurry from the coal slime subjected to pressure filtration can be reduced, the wear of the equipment is reduced, and further the production cost of the slime coal water slurry is reduced.

Owner:HENAN POLYTECHNIC UNIV

Cultivation method of papayas in sunlight greenhouse

InactiveCN104472299ASimple fruit shapeBeautiful fruit shapeCultivating equipmentsGreenhouse cultivationPest control

The invention provides a cultivation method of papayas in a sunlight greenhouse. The cultivation method comprises the following steps: (1) soil improvement; (2) greenhouse field planting; (3) fertilizer and water management: a. a germination acceleration and fertilization phase; b. a flower forcing phase; c. a fruit strengthening fertilization phase; (4) flower thinning and fruit thinning; (5) prevention and treatment of plant diseases and insect pests. By the aid of the scientific and reasonable sunlight greenhouse cultivation method of the papayas, the requirements of supplying the papayas in northern, and high and cold regions for a long period can be met; the cultivation method is simple and easy to operate and implement; the planted papayas have good fruit shapes, good color and luster, mellow taste, fine and smooth, and juicy pulp, good eating mouth feel and high yield.

Owner:宋鸟生

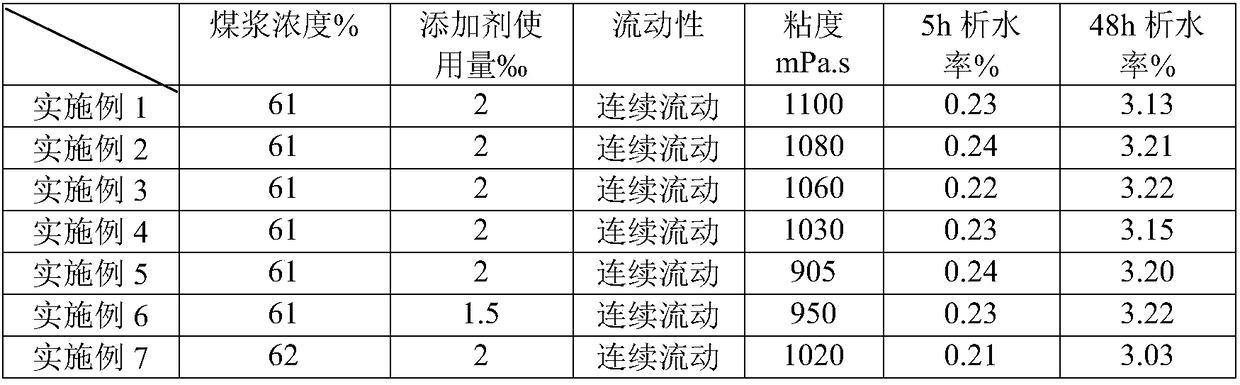

TA (tannic acid) modifying additive and application to coal-water slurry preparation

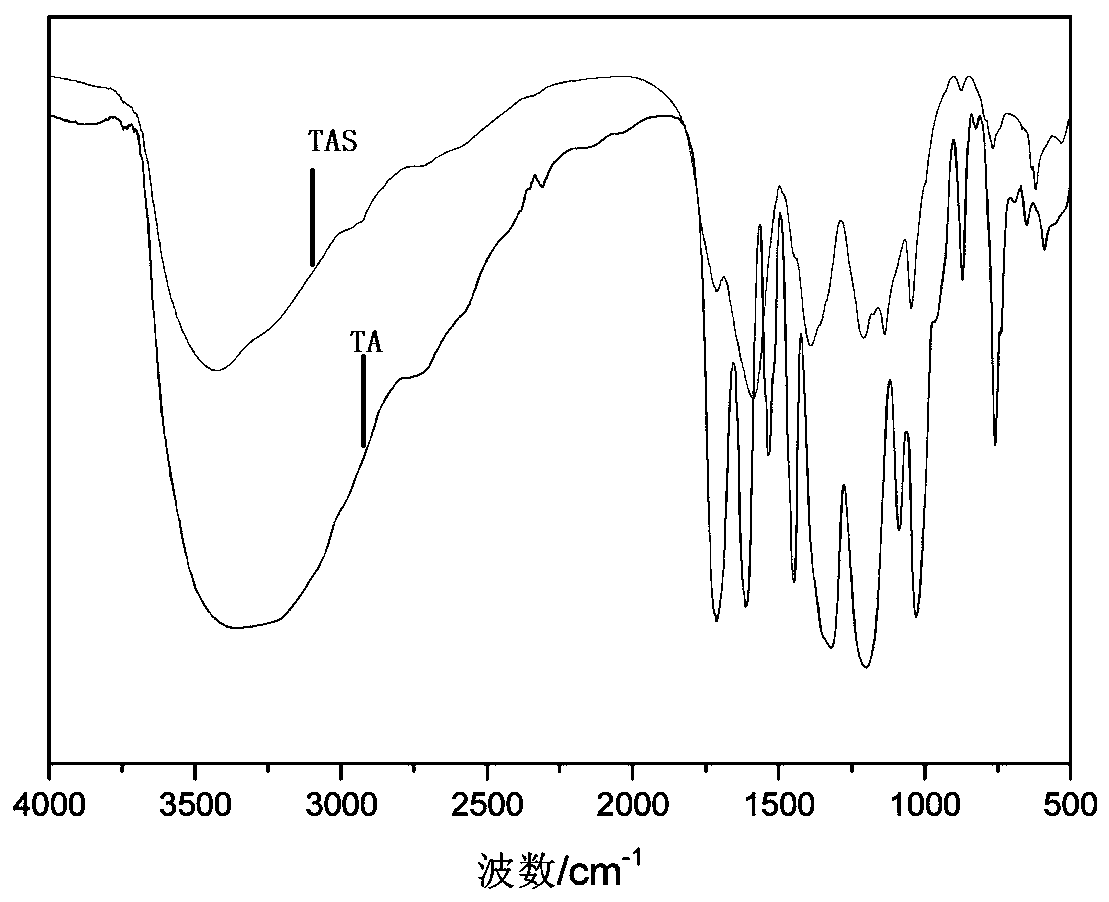

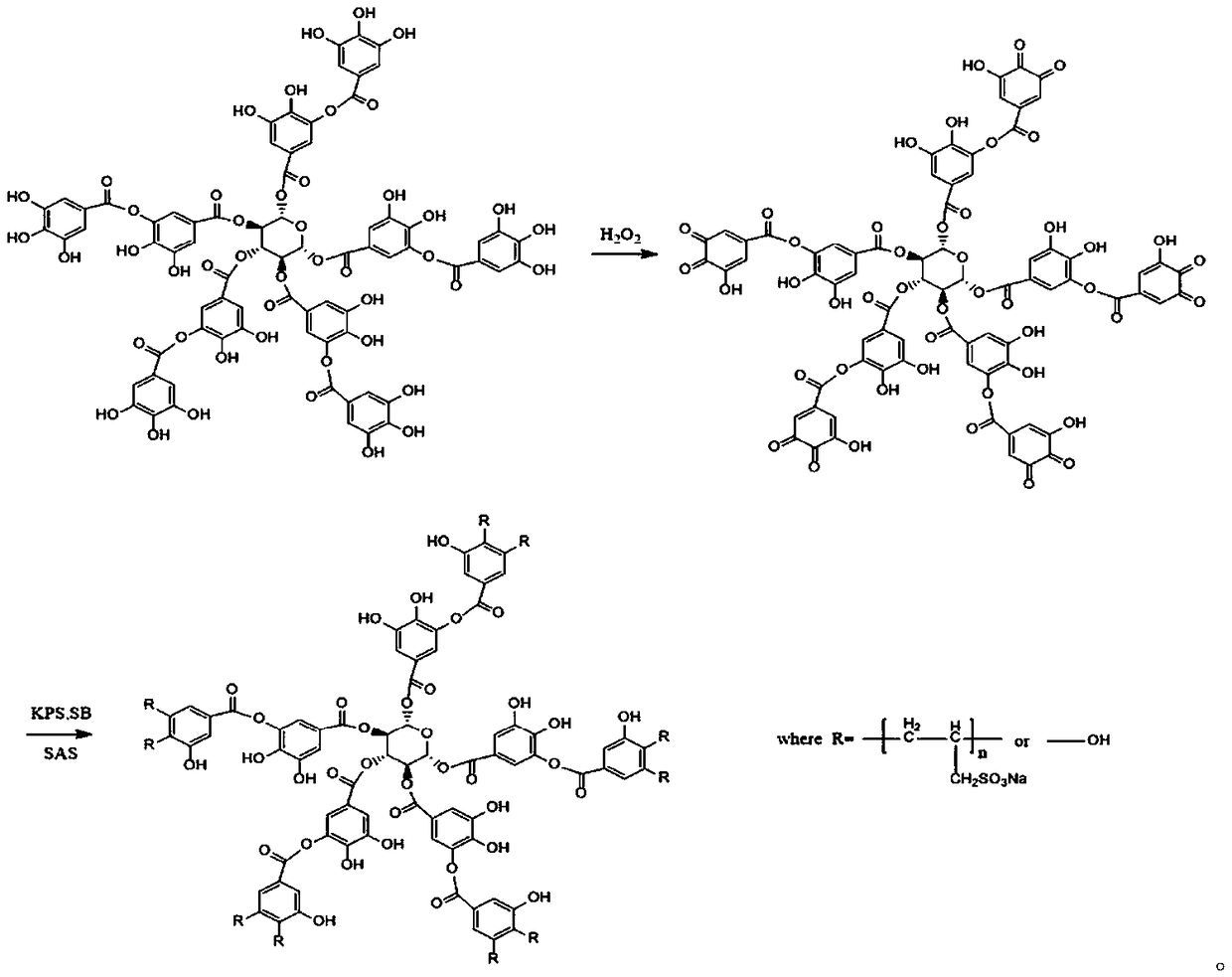

ActiveCN109096428AImprove stabilityDispersedLiquid carbonaceous fuelsPotassium persulfatePhysical chemistry

The invention provides a coal-water slurry modifying additive in the field of coal chemical. Cheap TA (tannic acid) is taken as a raw material, water is taken as a solvent, TA is oxidized by H2O2 firstly, then a certain amount of SAS (sodium allylsulfonate), KPS (potassium persulfate) and SB (sodium bisulfite) are added for graft copolymerization, and a novel TA dispersing agent is obtained. Comparison between infrared spectra of TAS (modified TA) and TA discovers that graft copolymerization of TAS succeeds. TA as the main raw material is naturally macromolecular, widely sourced and cheap, a synthesis process is simple, and the prepared coal-water slurry has better dispersity, viscosity, flowability and stability and has considerable market potential.

Owner:HUBEI UNIV +1

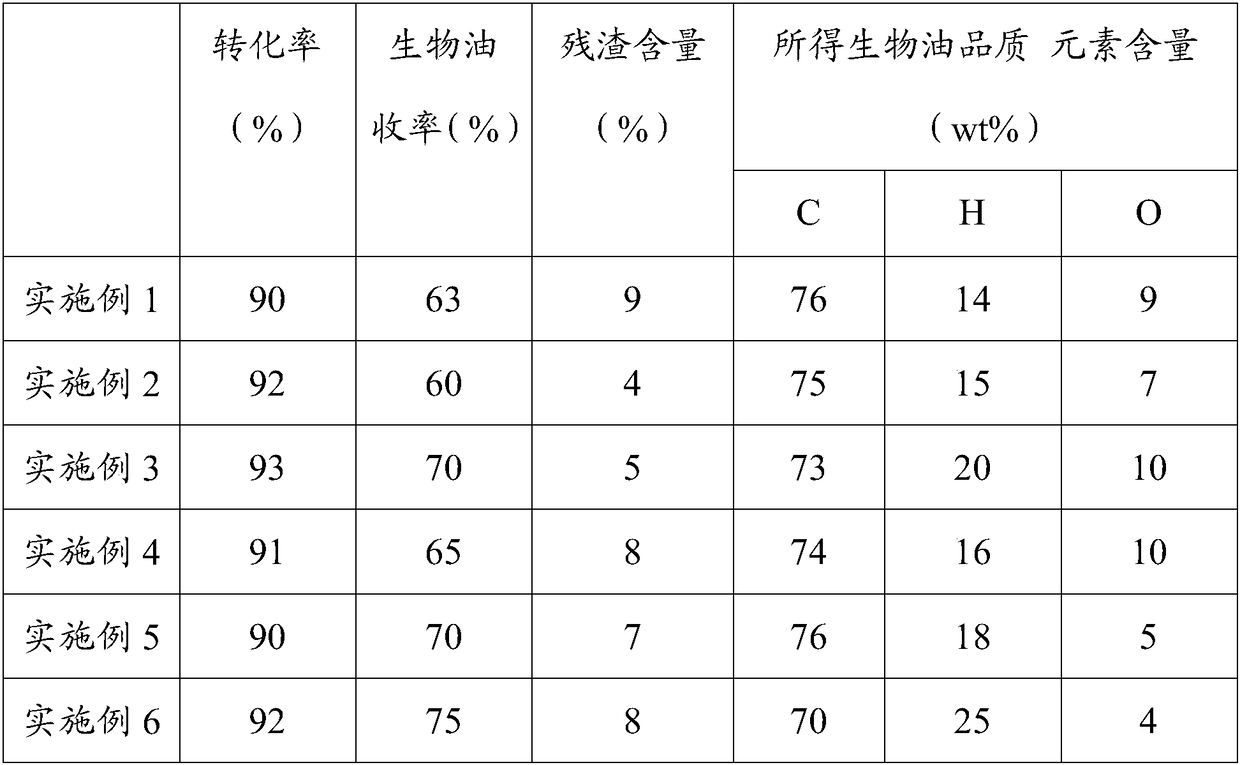

Co-hydrolysis hydrogenation process for coal and biomass

ActiveCN108277038AHigh densityIncreased accessible areaLiquid hydrocarbon mixture productionHydrocarbon oils treatmentHydrogenation reactionReaction temperature

The invention relates to the technical field of clean energy, in particular to a blending process of coal and biomass. The invention provides a co-hydrolysis hydrogenation process for coal and biomass, the coal and biomass raw materials are subjected to crushing, compression and re-crushing, then the slurry is prepared, and the biomass water coal slurry which is high in solid content and capable of being stably conveyed by a pump is successfully obtained. Hydrogen is introduced into the biomass water coal slurry, the reaction pressure is controlled to be 15-25 MPa, the reaction temperature iscontrolled to be 300-420 DEG C, and finally the biological oil is prepared. The process disclosed by the invention is characterized in that the coal and the biomass are subjected to high-pressure high-temperature hydrolysis under a subcritical or a supercritical state of water, furthermore subjected to cracking and hydrogenation reaction, so that the conversion of the coal and the biomass into thebiological oil is realized. In the process disclosed by the invention, the conversion rate of the coal and the biomass can reach 85-95%, the yield of the biological oil can reach 60-80%, and the residue amount is less than 5%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Special sealing plate material for automobile engine and gearbox

InactiveCN101696727AImprove creep resistanceReduce stress relaxation rateEngine sealsAcrylonitrileStress relaxation

The invention discloses a special sealing plate material for an automobile engine and a gearbox, comprising the following raw materials by weight percent: 5-8% of aramid pulp, 20-25% of plant fiber, 23-28% of mineral fiber, 5-10% of nylon fiber, 15-35% of silicate filler, 8-12% of butadiene-acrylonitrile rubber, 10-15% of natural rubber, 1-3% of coupling agent and 0.5-2.5% of vulcanizing system. Compared with the prior art, the invention improves the creep resistance of sealing products, reduces the stress relaxation rate, improves ageing-resistant performance and compactness, changes the proportion of horizontal and longitudinal arrangements of the fiber, and reduces the difference of the longitudinal direction and the horizontal direction so as to improve the tightness.

Owner:南阳天一密封股份有限公司

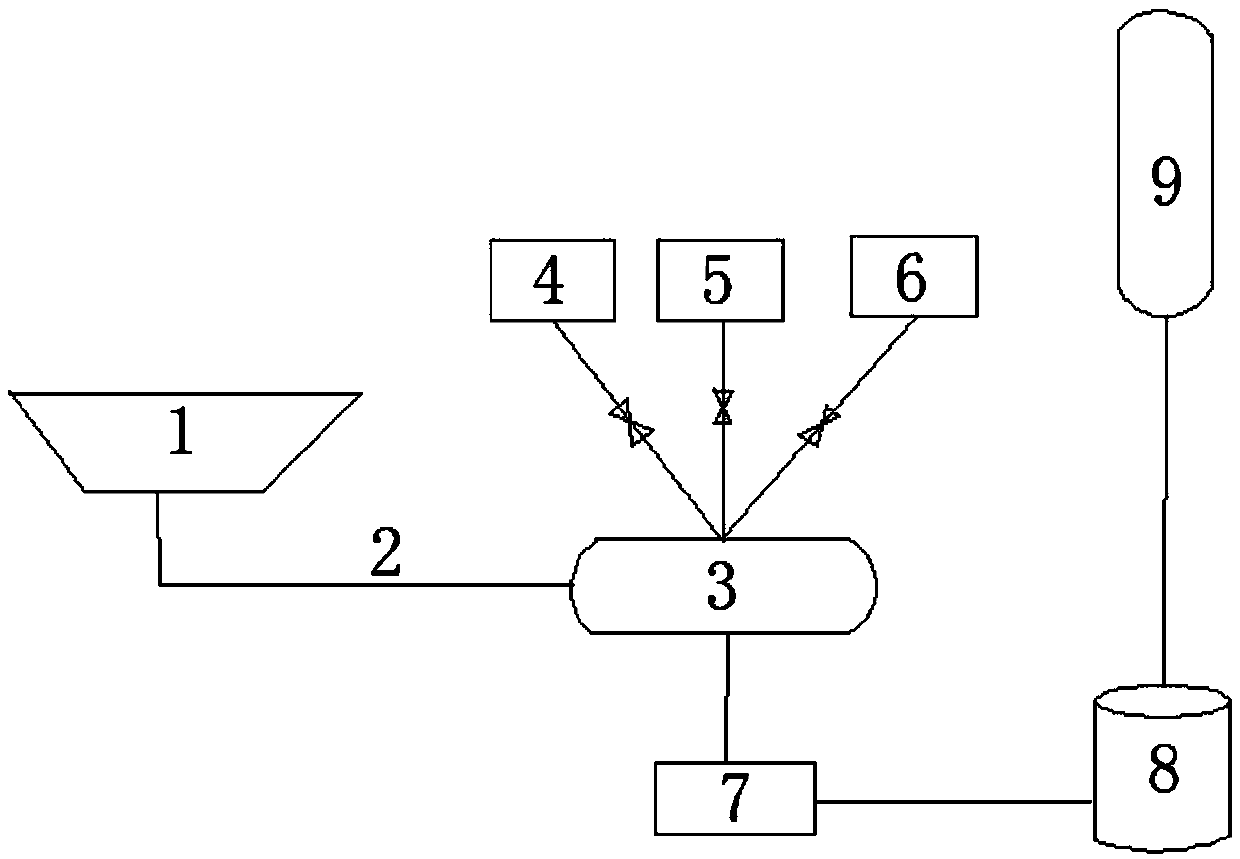

Method for preparing coal water slurry

InactiveCN104560245AIncrease concentrationImprove finenessLiquid carbonaceous fuelsCoal waterProcess engineering

The invention discloses a method for preparing coal water slurry. The method comprises the following steps: A. conveying raw coal into a hopper by using a lifter at first, then conveying the raw coal in the hopper into a high-speed centrifugal jet mill by using a quantitative feeding machine for crushing, and crushing the raw coal to coal powder with fineness of 200-300 meshes; B. conveying the coal powder obtained in the step A by crushing into a dust collector by using a pipeline and a centrifugal fan in an air draft manner, and collecting the coal powder; and C. conveying the obtained coal powder into a slurrying stirring tank by using a feeding machine and a screw conveyor, adding water and additives, stirring for 2-3 hours, and filtering to obtain a finished product of coal water slurry. The fineness of the coal water slurry product prepared by the preparation method disclosed by the invention is larger than 200 meshes, the 200-mesh sieving rate is 100%, and the 300-mesh sieving rate is 60%.

Owner:广西梧州日成林产化工股份有限公司

Cation asphalt emulsion-coated modified low-rank coal and method for preparing coal-water slurry employing same

ActiveCN106929115APrevent relapseGood pulpingSolid fuelsLiquid carbonaceous fuelsCoal waterHigh concentration

The invention discloses a method for coating and modifying low-rank coal with a cation asphalt emulsion. The method comprises the steps of removing internal water of the low-rank coal under the microwave action until the mass of pulverized coal is constant, and then carrying out hole sealing and surface coating modification on the pulverized coal by adopting cation emulsified asphalt as a surface modifier, wherein the obtained modified low-rank coal can be used for preparing coal-water slurry. The method has the advantages of being small in modifier dosage, uniform in covering and significant in effect, the modified pulverized coal is low inrehydration rate, the hydrophobicity is increased, the preparation of high-concentration coal-water slurry by using a commercial dispersing agent is facilitated, and the rheological property and the stability of a slurry body of the coal-water slurry can be improved.

Owner:SHAANXI UNIV OF SCI & TECH

Coal and biomass co-liquefaction technology

ActiveCN108192652ARealize mixing and liquefactionIncrease contactHydrocarbon oil crackingLiquid hydrocarbon mixture productionKeroseneReaction temperature

The invention relates to the technical field of clean energy, in particular to a coal and biomass co-liquefaction technology. According to the coal and biomass co-liquefaction technology, coal and biomass materials are subjected to crushing, compression and re-crushing treatment, and then slurry is prepared, so that biomass coal oil slurry, with high solid content, capable of being stably conveyedthrough a pump, is obtained, and high-viscosity waste oil which can not serve as a coal and biomass liquefaction solvent in the prior art can be utilized. By leading hydrogen into the biomass coal oil slurry and controlling the reaction pressure to be 15 to 25MPa and the reaction temperature to be 380 to 480 DEG C, biomass oil is formed finally. The technology ensures that coal and biomass are liquefied in high pressure and high temperature environment, and cracking and hydrogenation reaction are further produced, so that the conversion of coal and biomass to biomass oil is realized. In the technology, the conversion ratio of coal and biomass can reach 90 to 95 percent, the yield of biomass oil can reach 40 to 75 percent, and the amount of residue is not greater than 3 percent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for preparing coal water slurry from butanediol (BDO) wastewater

InactiveCN109810738AGood slurryability and combustibilityGood pulpingLiquid carbonaceous fuelsCoal waterCoal slurry

The invention discloses a method for preparing coal water slurry from butanediol (BDO) wastewater. The coal water slurry is prepared from the raw materials in parts by weight: 60-70 parts of pulverized coal, 0.1-0.3 part of a dispersant, 20-50 parts of tap water or deionized water and 3-7 parts of the BDO wastewater. The preparation method includes the steps that the quantitative tap water or deionized water and the quantitative dispersant are weighed separately and then poured into a container, after full stirring and uniform mixing, the BDO wastewater is added and stirred to be dissolved, the pulverized coal is quickly added while stirring, and the coal water slurry is obtained after a period of time of stirring. The prepared coal water slurry has good slurry ability and combustion performance, and the BDO wastewater can replace the effect of the dispersant in the coal water slurry.

Owner:ANHUI UNIV OF SCI & TECH

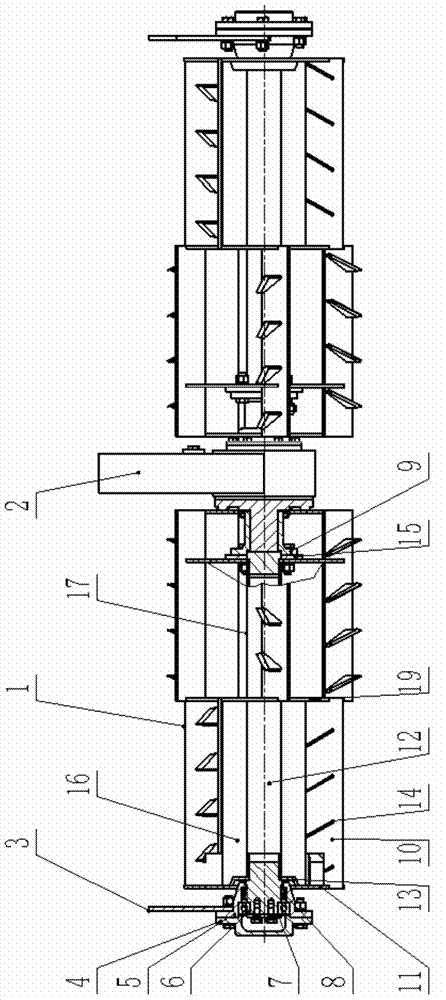

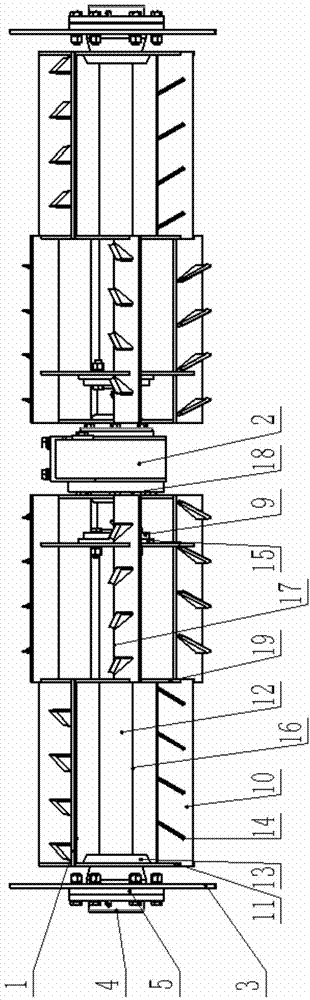

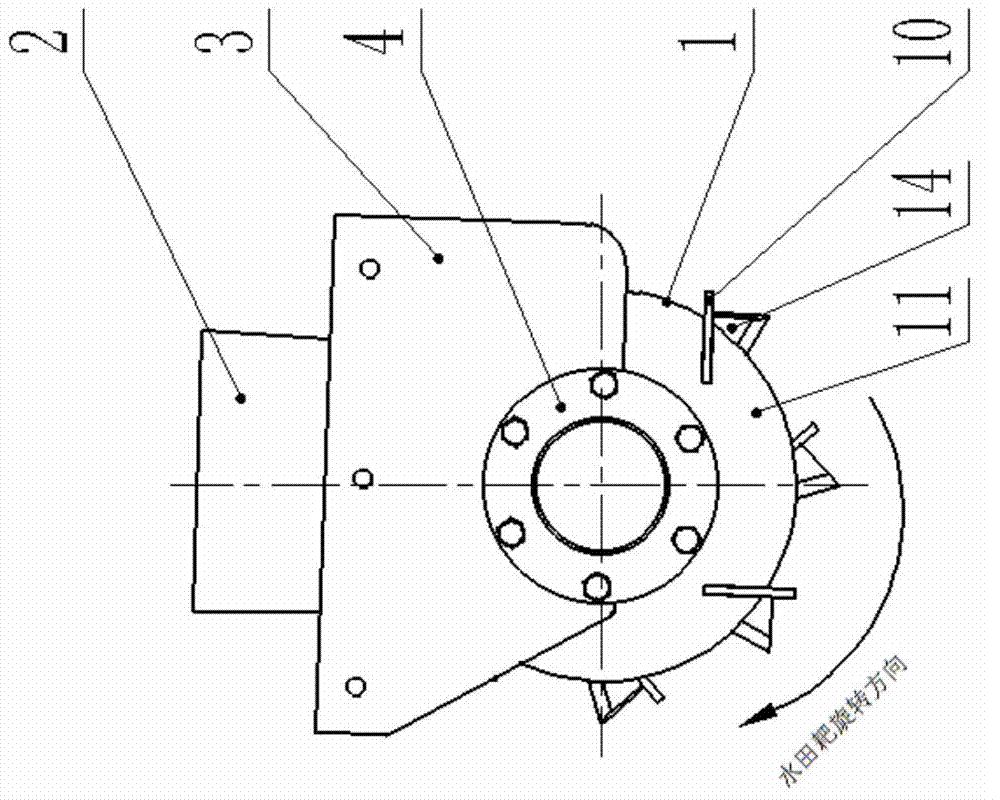

Paddy field harrow with cutting toothed plates

The invention discloses a paddy field harrow with cutting toothed plates. The paddy field harrow comprises two groups of rolling harrows, a power transmission box and main framework suspension plates. The two groups of rolling harrows are symmetrically arranged on two sides of the power transmission box, each group of rolling harrows comprises support-side circular plates, a support shaft, the corresponding cutting toothed plates and cutters, one end of the support shaft of each group of rolling harrows is connected with an output shaft of the power transmission box, the other end of the support shaft of each group of rolling harrows is mounted on a bearing block, the bearing blocks are mounted on the main framework suspension plates, the corresponding support-side circular plates are mounted at two ends of each support shaft, the corresponding cutting toothed plates which are uniformly arranged are arranged between the support-side circular plates of each group of rolling harrows in a fixedly connected manner, and the cutters are transversely uniformly distributed on the cutting toothed plates. The paddy field harrow has the advantages that the paddy field harrow can be divided into a front-rake paddy field harrow and a rear-rake paddy field harrow according to difference of relative welded positions and directions of cutting edges of the cutters on the cutting toothed plates, and the front-rake paddy field harrow and the rear-rake paddy field harrow can be selectively utilized according to difference of paddy field operation environments; the paddy field harrow is simple in structure, excellent soil crushing, pulping and green manure returning effects can be realized, agricultural requirements can be met by operation effects to a great extent, and accordingly the paddy field harrow has certain economical efficiency and practicality.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com