Paddy field harrow with cutting toothed plates

A knife-tooth, paddy field technology, applied in rake, application, agriculture, etc., to achieve the effect of uniform load, fast effect and reasonable spacing distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

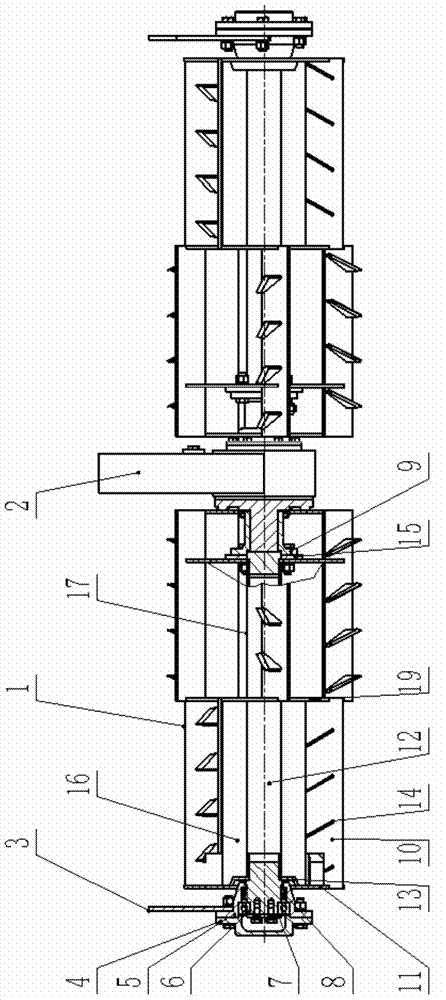

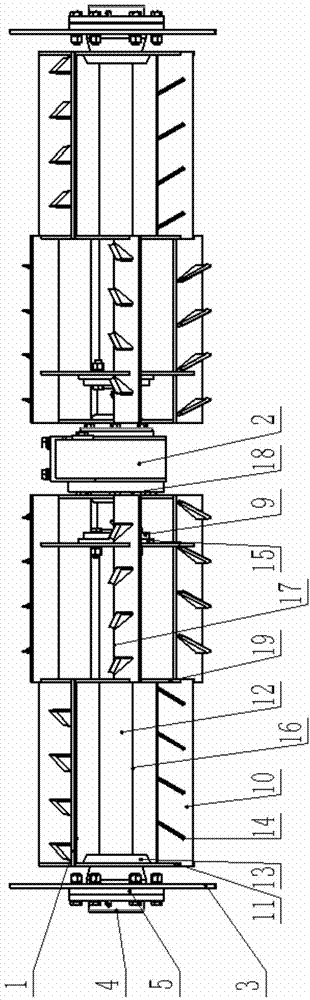

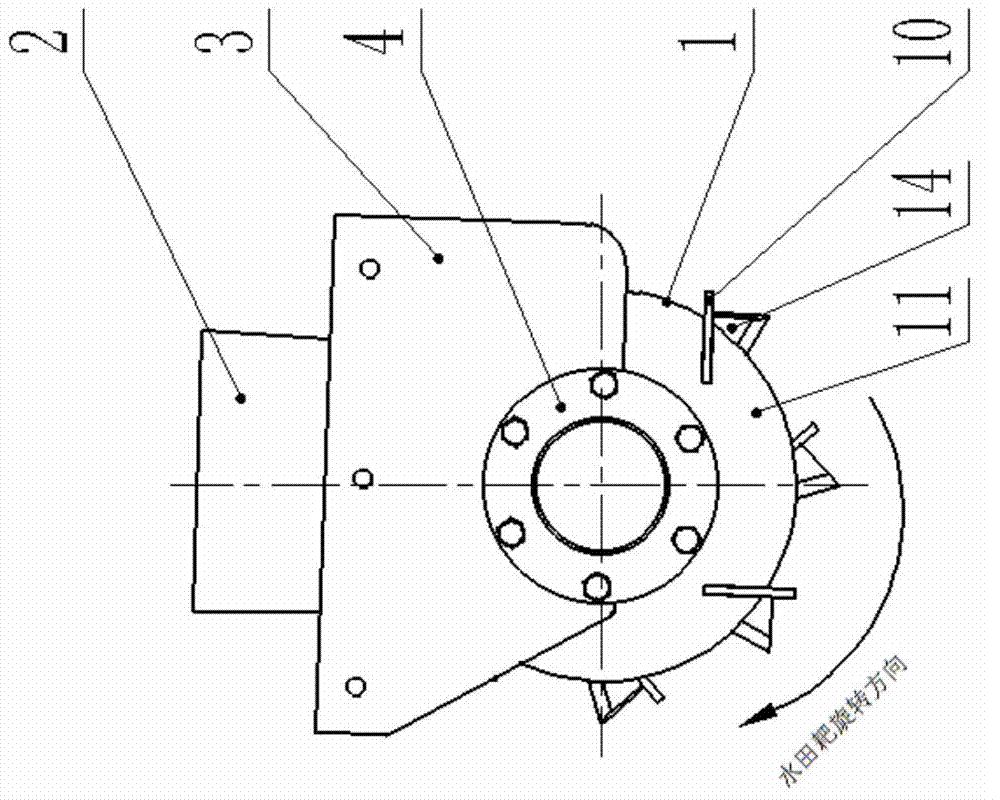

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] As shown in the accompanying drawings, the paddy field harrow of the present invention includes two groups of rolling harrows 1, a power transmission box 2 and two suspension plates 3 of the main frame. Two groups of roller rakes 1 are symmetrically arranged on both sides of the power transmission box 2, each group of roller rakes 1 is composed of a support side circular plate 11, a support shaft 12, a knife tooth plate 10, and a cutter 14, and the support shaft of each group of roller rakes 1 One end of 12 is fixedly connected with the output shaft of the power transmission box 2 through the spline sleeve 9, the other end of the support shaft 12 is installed on the bearing seat 5, the bearing seat 5 is installed on the suspension plate 3 of the main frame, and the two ends of the support shaft 12 are installed There is a support side circular plate 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com